Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by the chemical bonds type as follows: (i) salt-like, (ii) covalent compounds, (iii) interstitial compounds, and (iv) "intermediate" transition metal carbides. Examples include calcium carbide (CaC₂), silicon carbide (SiC), tungsten carbide (WC; often called, simply, carbide when referring to machine tooling), and cementite (Fe₃C), each used in key industrial applications. The naming of ionic carbides is not systematic.

Manufacture method of slip sheet of air conditioner compressor

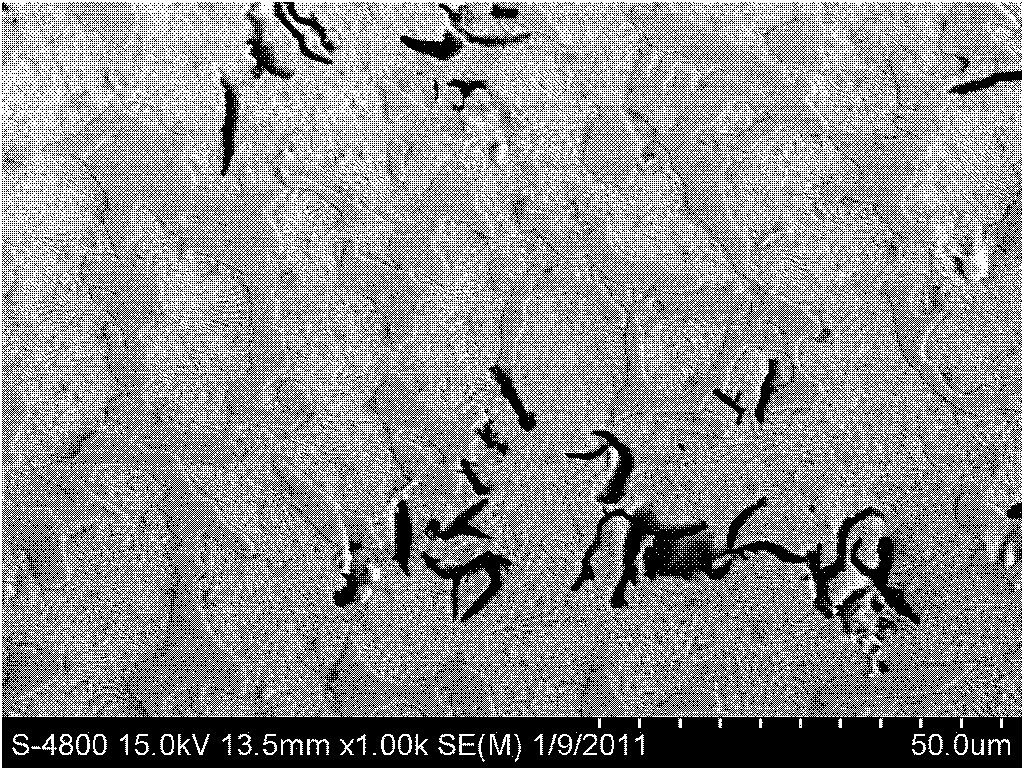

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

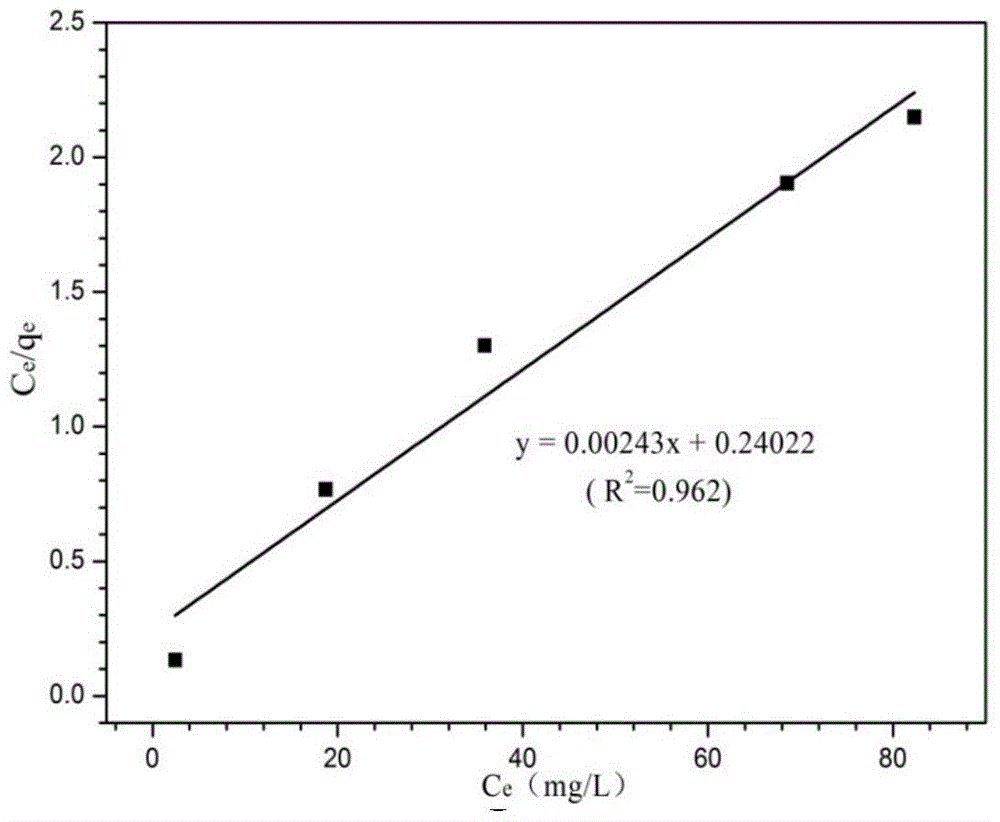

Application of two-dimensional transitional metal carbide nanosheet as radionuclide adsorbent

InactiveCN105304154AImprove adsorption capacityOther chemical processesRadioactive decontaminationFuel reprocessingNuclear power

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

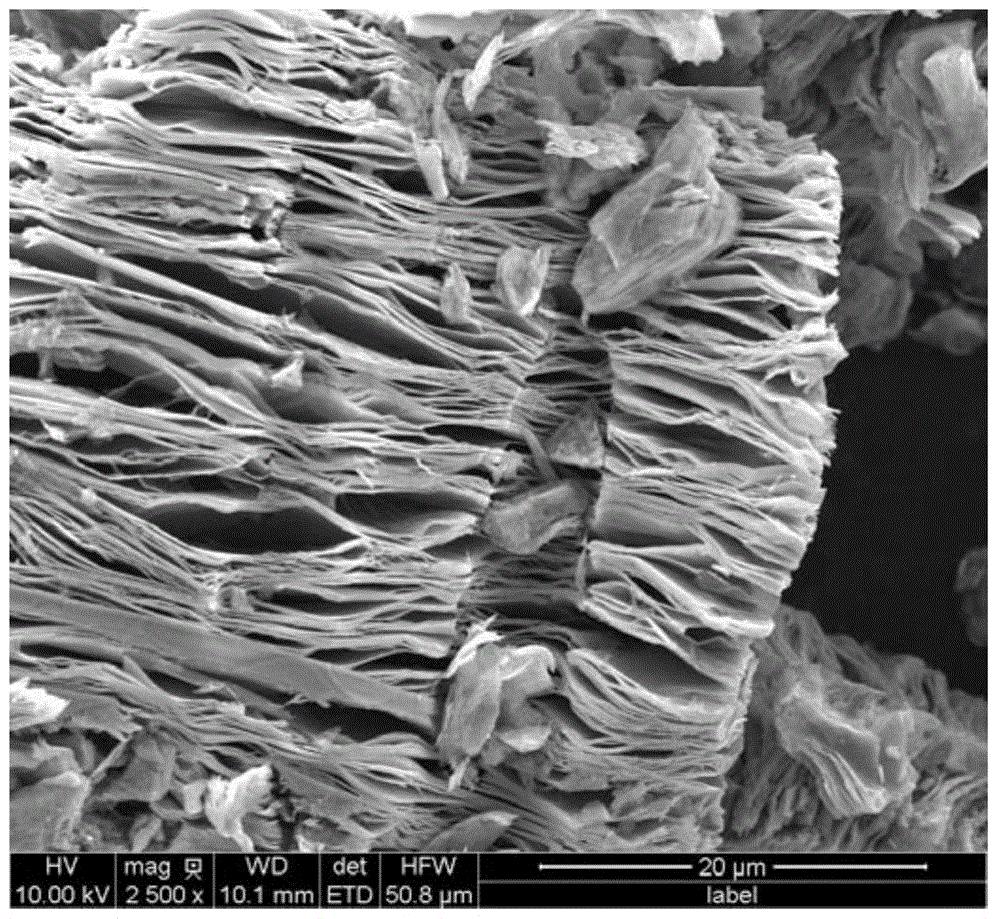

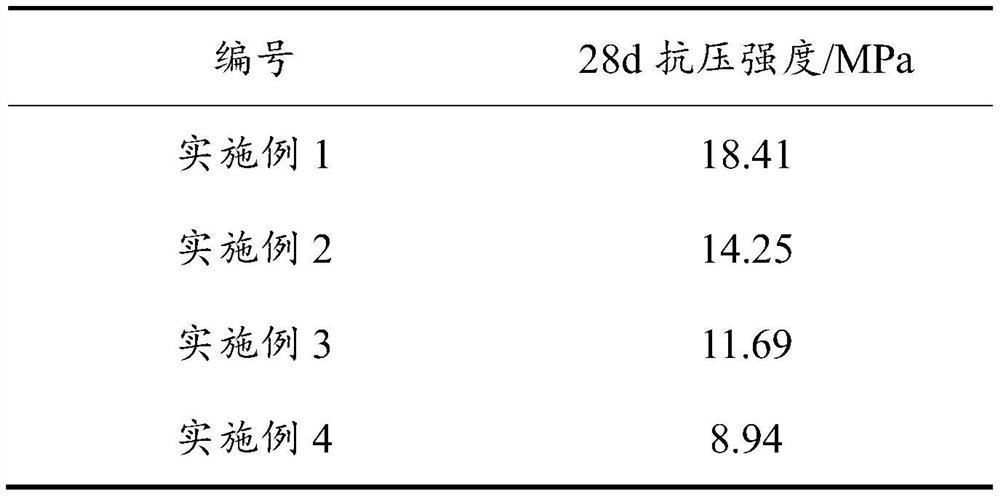

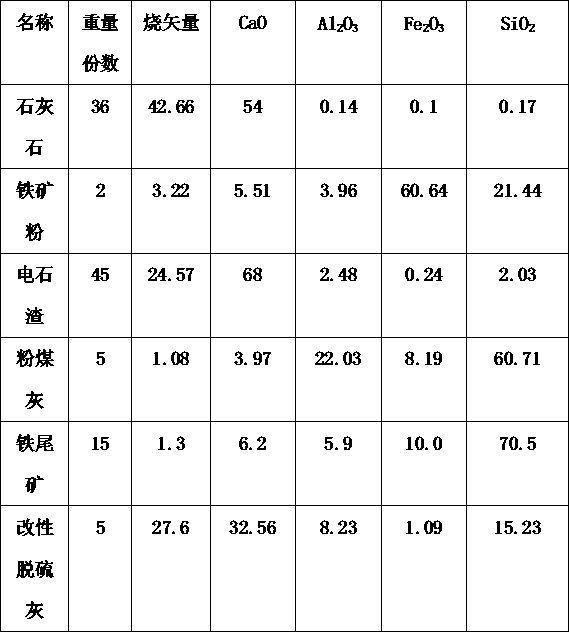

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

High-volume industrial solid waste composite Portland cement and preparation method thereof

Owner:张延年

Separable pick-shaped cutter

InactiveCN104989400AHigh reuse rateImprove wear resistanceSlitting machinesCutting machinesNiobiumCarbide

A separable pick-shaped cutter comprises a cutting pick body and a cutting pick head, wherein the cutting pick body and the cutting pick head are detachable, the cutting pick head is inserted into the top of the cutting pick body and is in shaft and steel ball fit with the cutting pick body, and steel balls under the action of bolts and compression springs are evenly arranged around the top of the cutting pick body; anti-abrasion layers are arranged on the surface of the cutting pick body and the surface of the cutting pick head, and the anti-abrasion layers are made of metal carbides compounded from chrome, vanadium and niobium metal powder and nonmetal boron and carbon compounds. According to the separable pick-shaped cutter, the cutter can rotate in the stress direction of a conical spiral surface, the cutting pick head can rotate alone under the condition that generated cutting resistance is small, and eccentric wear of a carbide bit is effectively prevented; furthermore, due to the fact that the cutting pick body and the cutting pick head are two separated parts, the cutting pick head can be replaced, the reusing rate of the cutting pick body can be increased, and resources can be saved; due to the fact that the anti-abrasion layers are arranged on the surface of the cutting pick body and the surface of the cutting pick head to effectively protect the cutting pick body and the cutting pick head, the anti-abrasion performance of the cutting pick body and the cutting pick head is improved.

Owner:ANQING HUAQI MACHINERY ACCESSORIES CO LTD

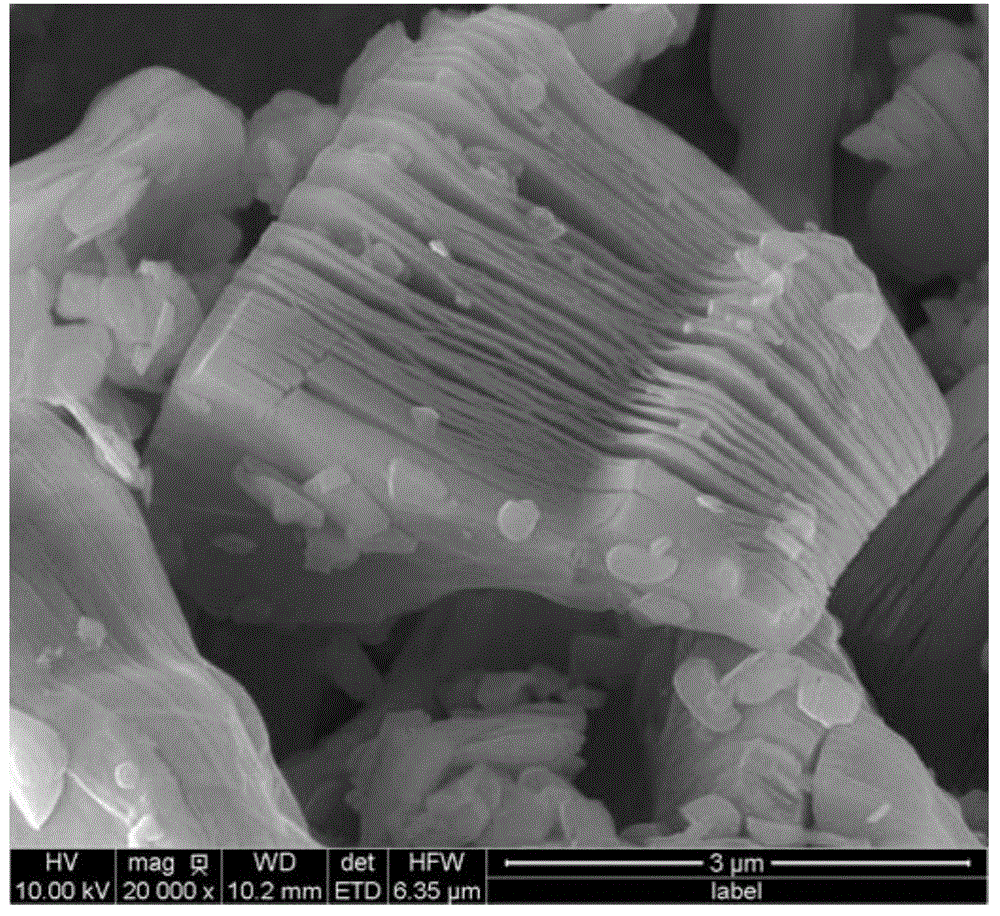

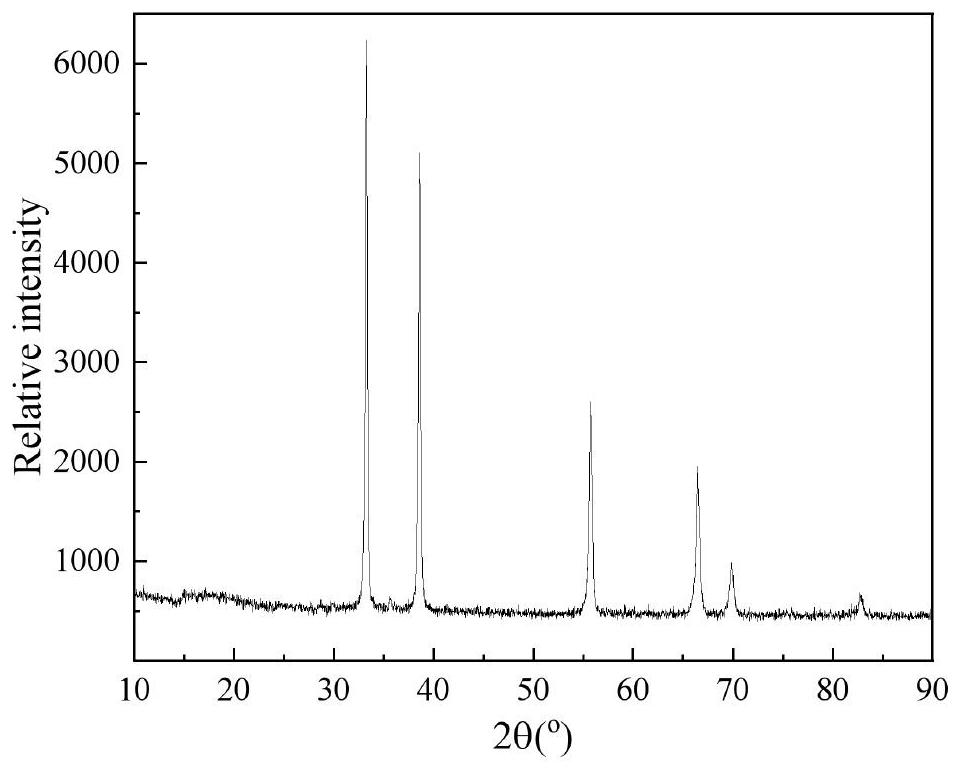

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

Guide guide-wheel for high-speed rolling

ActiveCN108504961AImprove corrosion resistanceImprove wear resistanceGuiding/positioning/aligning arrangementsFurnace typesChemical compositionCarbide

Owner:HEFEI ORIENT METALLURGICAL EQUIP

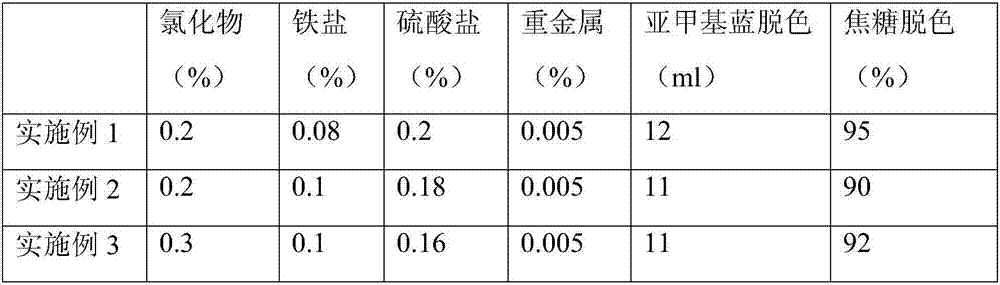

Preparation method of medicinal active carbon

InactiveCN106976873AFast decolorizationImprove adsorption capacityCarbon compoundsEcological environmentCarbonization

Owner:句容市盛达环保净化材料有限公司

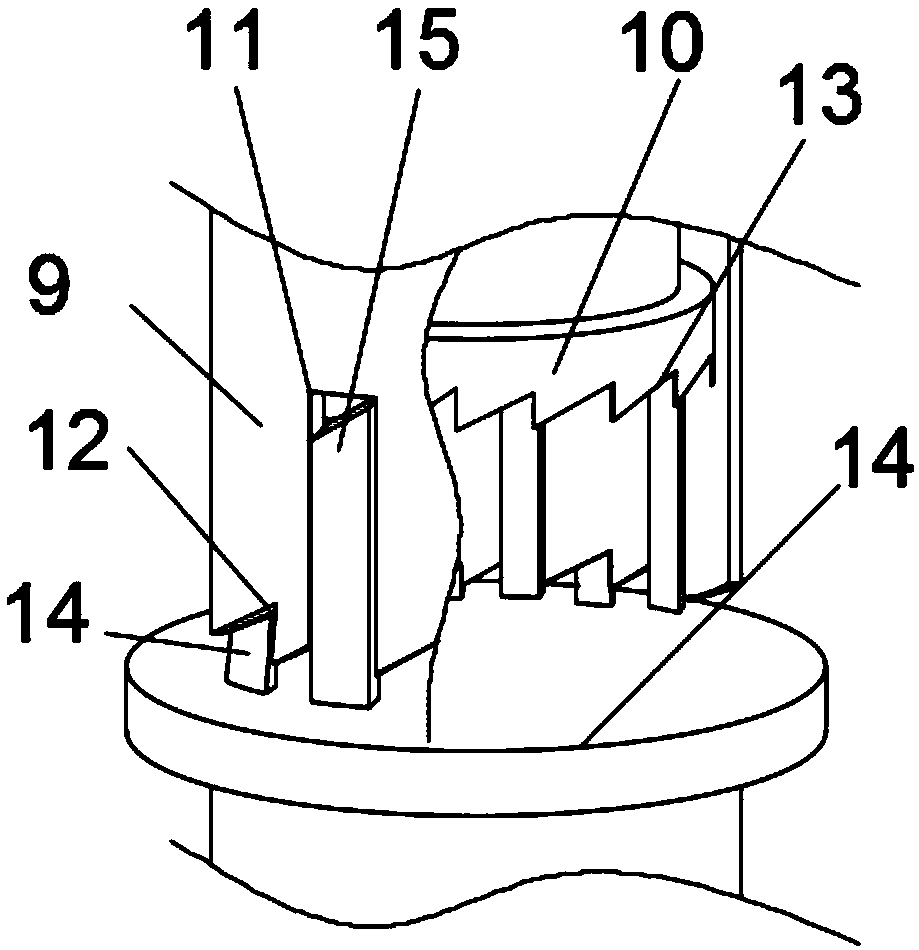

Microwave reactor vessel

ActiveUS10245574B1Chemical/physical/physico-chemical stationary reactorsCarbideNitride

A microwave reactor constructed to produce a homogeneous heat distribution across the body of the microwave reactor subsequent exposure to microwave irradiation. The microwave reactor includes a body having an exterior wall transparent to microwave irradiation. A microwave sensitized element layer is adjacent the exterior wall and is comprised of a carbide mixture wherein the carbide mixture includes a carbide mixed with either a metal oxide, a ferrite or a nitride. The carbide mixture is in granular form wherein the carbide has a larger particle size than the other component. The microwave sensitized element layer further includes a metal layer that extends the length thereof. The metal layer is positioned in various arrangements within or adjacent to the carbide mixture. The body further includes an inner layer adjacent to the microwave sensitized layer opposite the exterior wall. The inner layer is transparent to microwave irradiation.

Owner:SHORE GJERGJI JOSIF

Preparation method of high bonding type salt storage asphalt pavement material

The invention relates to a preparation method of a high bonding type salt storage asphalt pavement material and belongs to the technical field of building materials. According to the technical scheme,heavy saline-alkali soil is adopted as a raw material, and subjected to high-temperature calcining and wire drawing in fusion; by a high-concentration saline-alkali material in the saline-alkali soil, wires are drawn and fibers are collected, and by full bonding with resin particles, the bonding property between the material and resin is effectively improved; by excellent bonding property betweenmixed resin and asphalt, the bonding strength of the material is further improved; in the technical scheme, the saline-alkali soil is adopted as a modifying raw material, organic matters carbonized by high temperature are mostly decomposed, a small part of the organic matters form porous carbide and are loaded to the surface of a fiber material, and by excellent structural property of the surfaceof the carbide, the bonding strength between the material and the resin is improved, so that the bonding property and the mechanical strength of the compound asphalt material are further improved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Bearing steel pipe inspection quality control method for cold rolling and expanding bearing

ActiveCN113088639AQuality improvementExtended service lifeFurnace typesTesting metalsBrinellingCarbide

The invention discloses a bearing steel pipe inspection quality control method for a cold rolling and expanding bearing. In the production process of a bearing steel pipe, pipe blank factory inspection, spheroidizing annealing state capillary pipe inspection and stress relief annealing state finished pipe inspection are sequentially carried out; stress relief annealing state finished pipe inspection includes hardness inspection, microscopic structure inspection, carbide non-uniformity inspection and decarburized layer inspection; during hardness inspection, the Brinell hardness is 179-190 HBW, and the grade is 2-3 according to the fifth grade diagram evaluation in the appendix A of GB / T 18254-2016 during microscopic structure inspection. The bearing steel pipe is subjected to quality control through the method, the surface of the bearing produced through cold rolling and expansion is free of cracks, the structure uniformity is high, thus the quality of the bearing is improved, and the service life of the bearing is prolonged.

Owner:JIANGXI HONGRUIMA STEEL PIPE

A novel electrode material for a supercapacitor and a supercapacitor

InactiveCN109192534AHigh specific capacityFacilitated DiffusionHybrid capacitor electrodesMultiple hybrid/EDL capacitorsPolypyrroleFast charging

Owner:广东粤迪厚创科技发展有限公司 +1

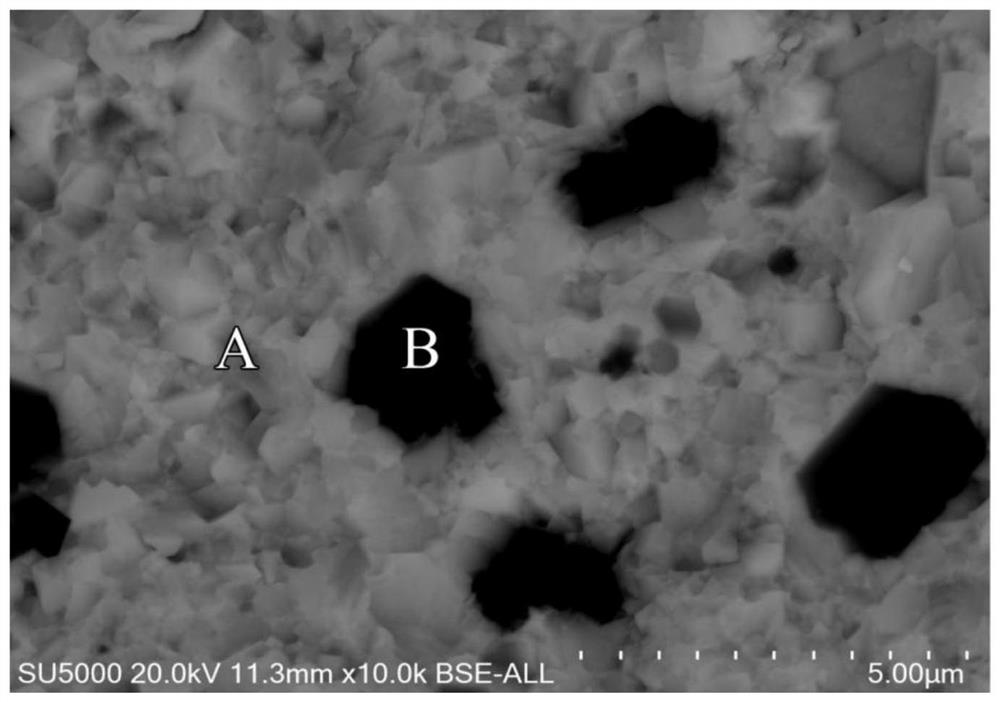

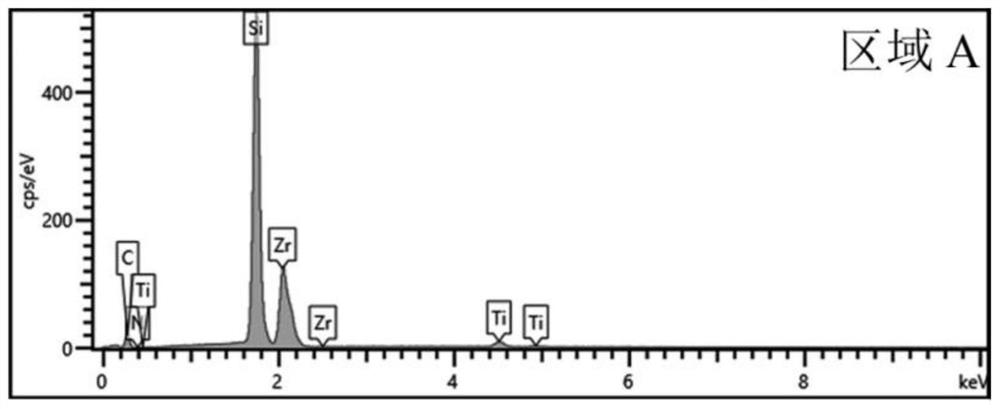

Method for preparing carbonitride-silicide solid solution composite ceramic at low temperature by reaction hot pressing sintering technology

PendingCN113999013AFacilitated DiffusionPromote interactionComposite ceramicCarbide

Owner:HARBIN UNIV OF SCI & TECH

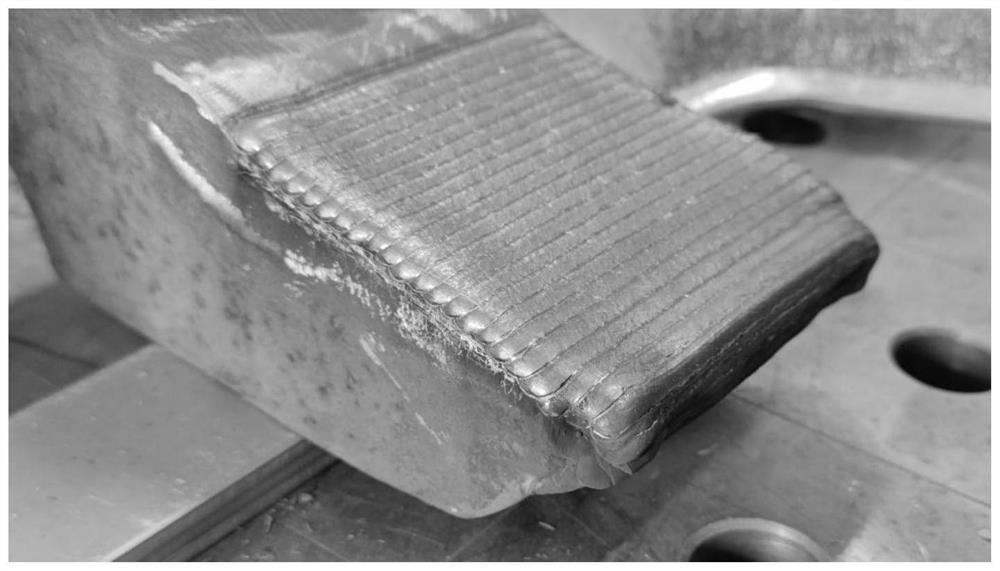

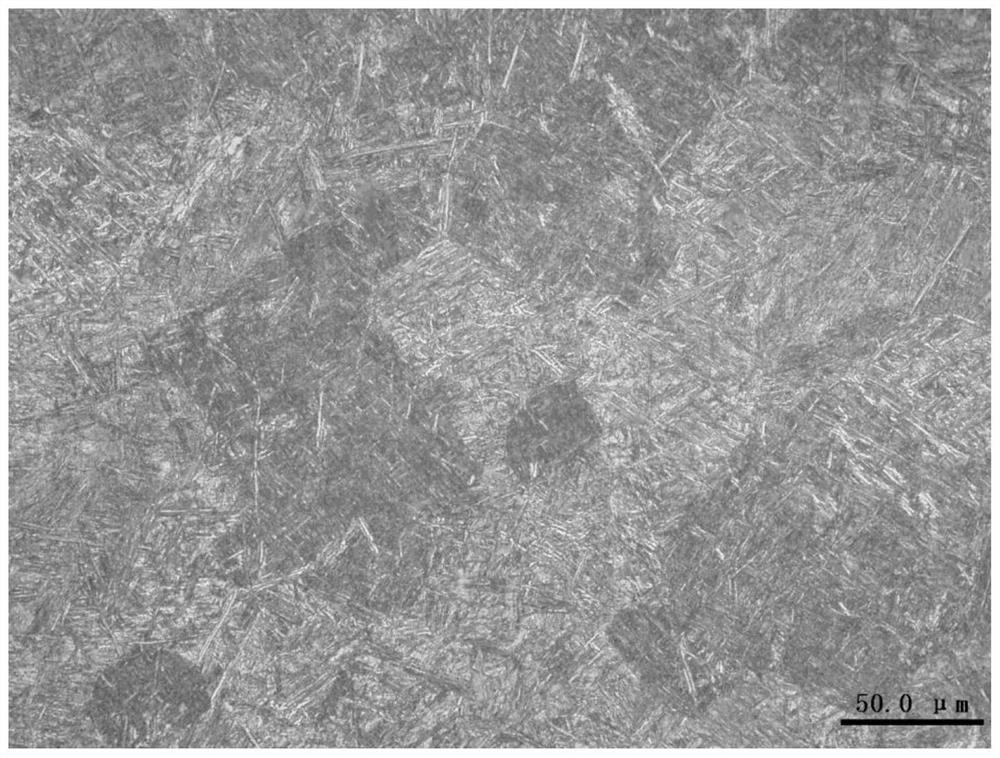

Welding wire for surfacing of composite carbide reinforced scraper and preparation method of welding wire

PendingCN114571127AImprove wear resistanceTo achieve reinforcementWelding/cutting media/materialsProcess efficiency improvementCarbideGraphite

Owner:XIAN UNIV OF TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap