Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "A part of quality management focused on fulfilling quality requirements".

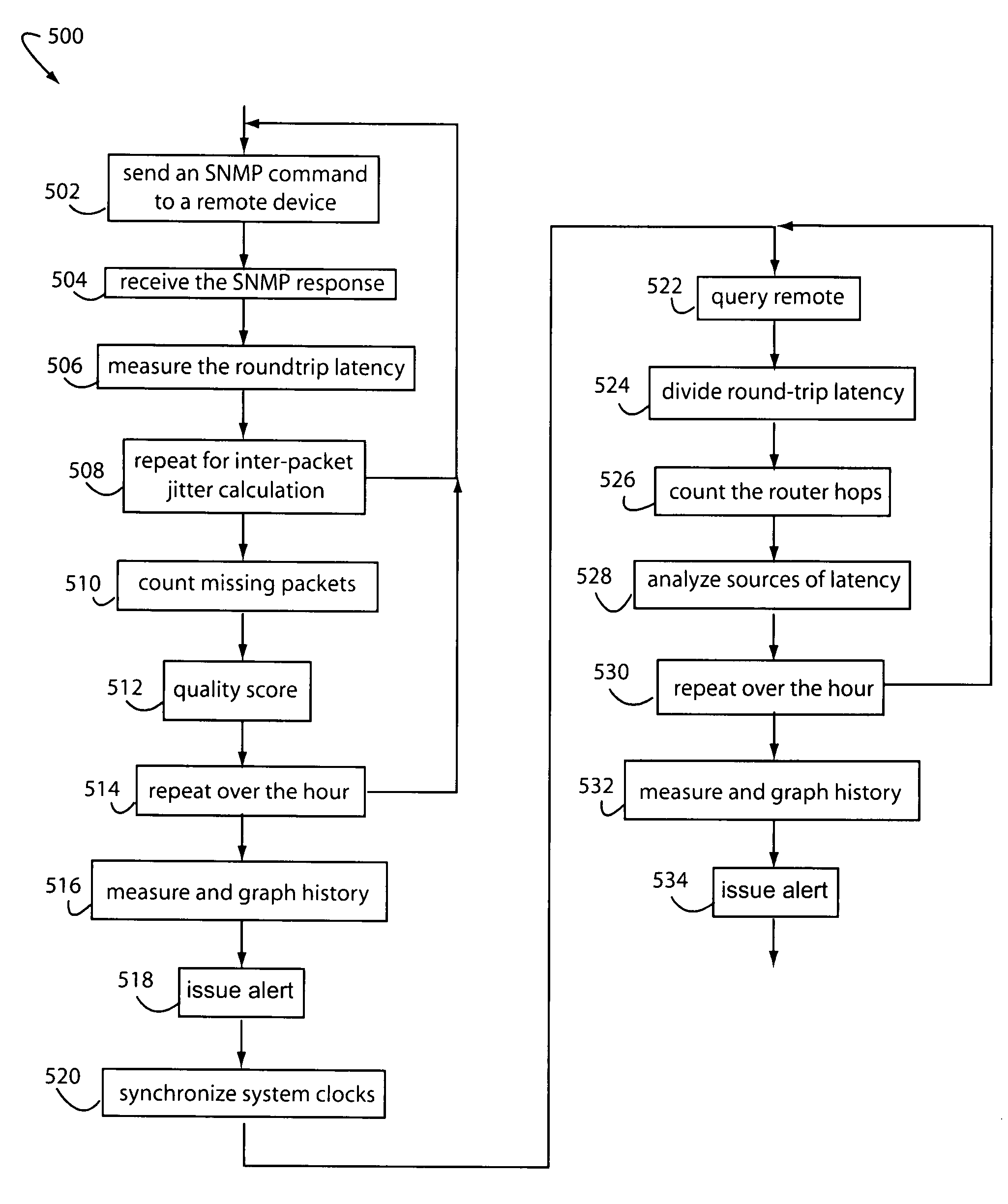

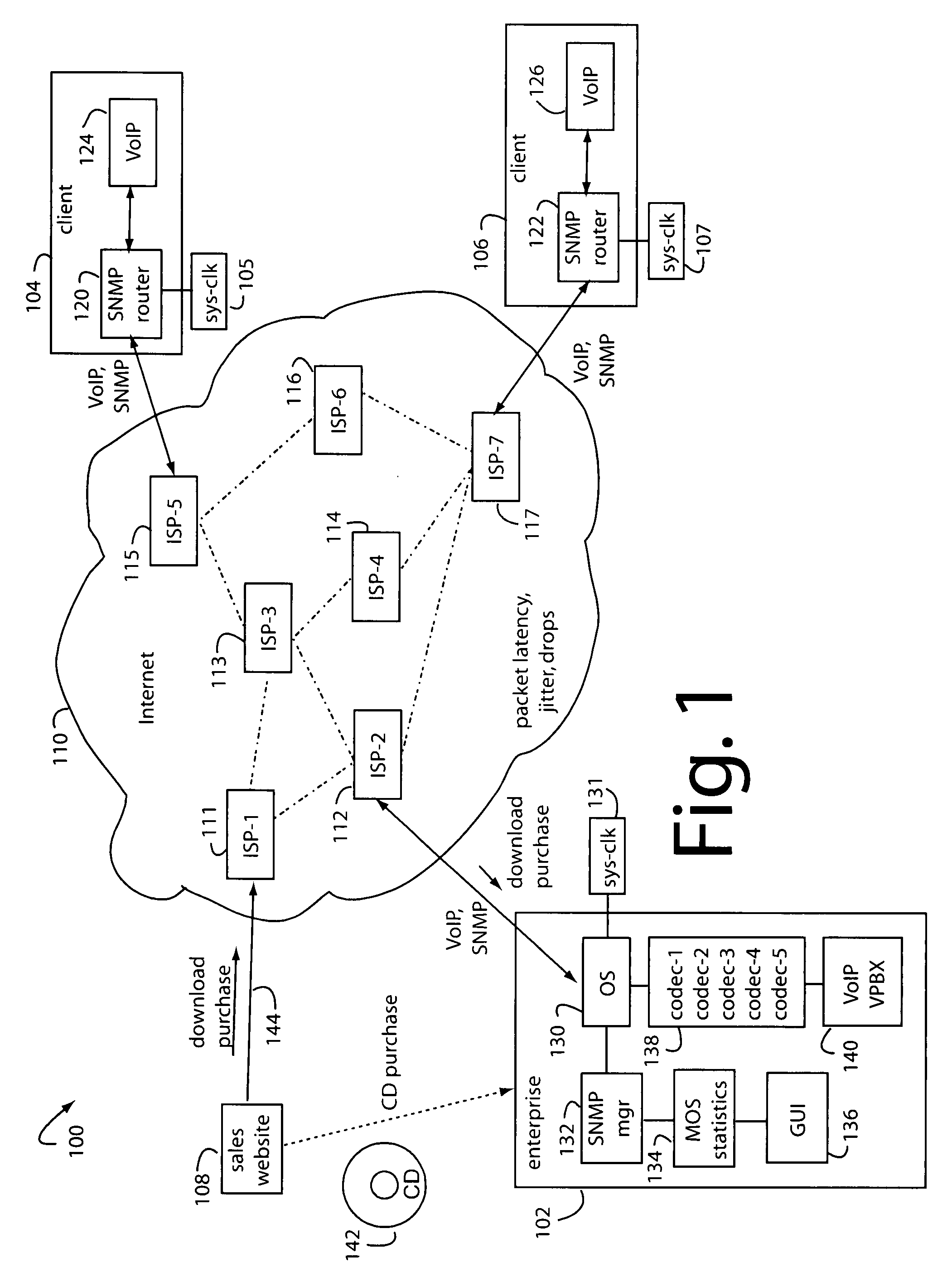

Real-time services network quality control

Owner:TITUS TIMOTHY G

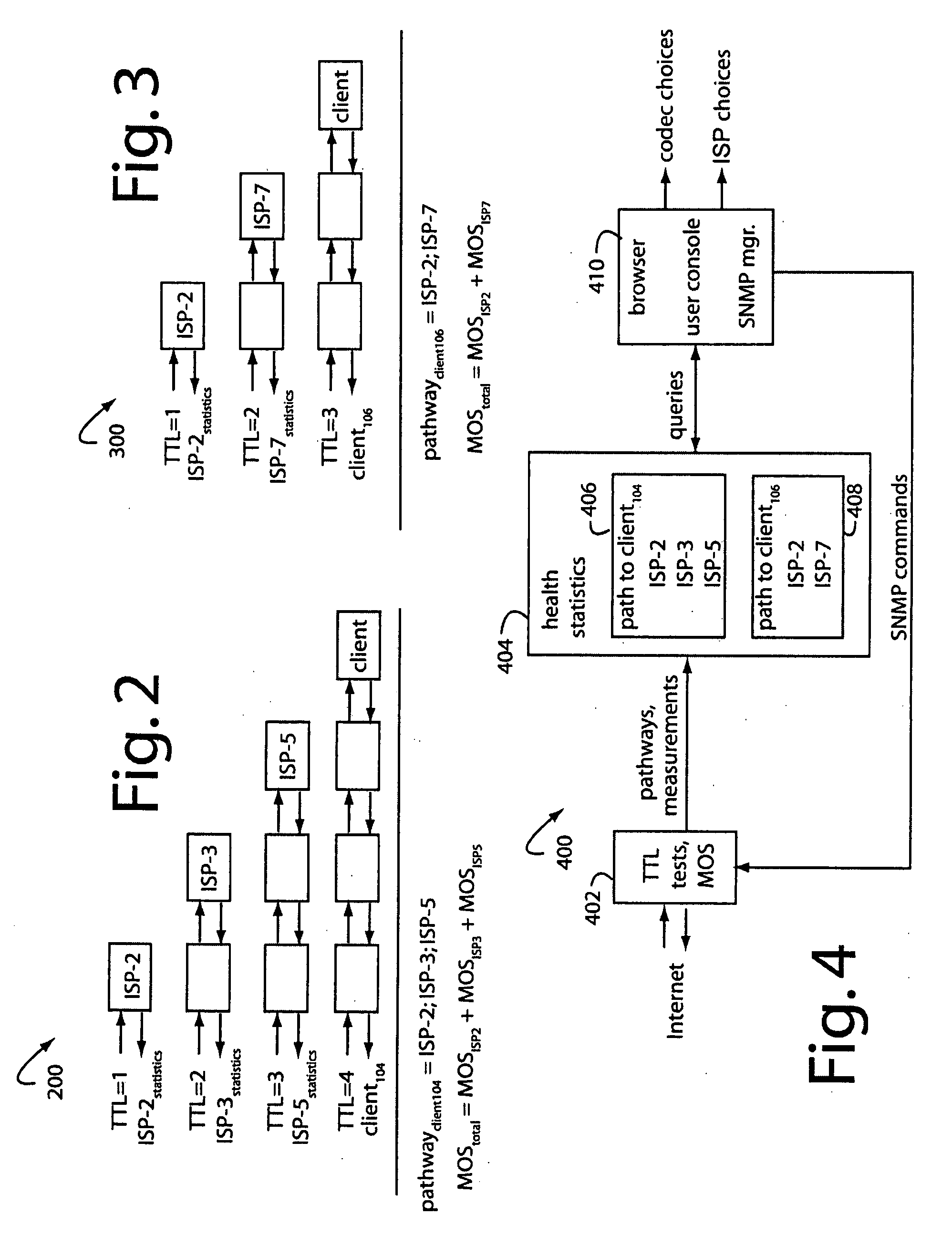

Double DSP built-in control system for visual feedback during soldering process

Owner:TSINGHUA UNIV +1

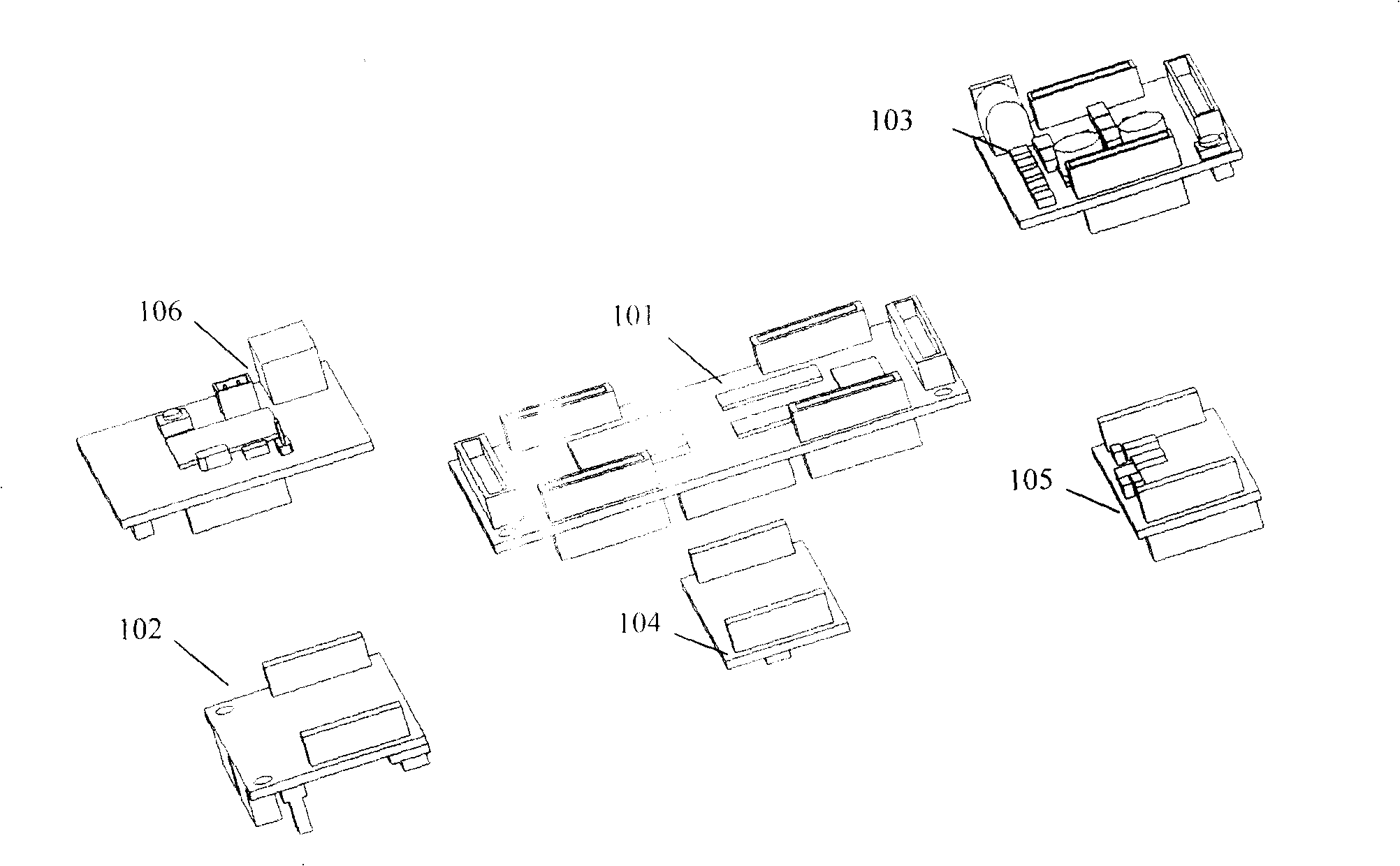

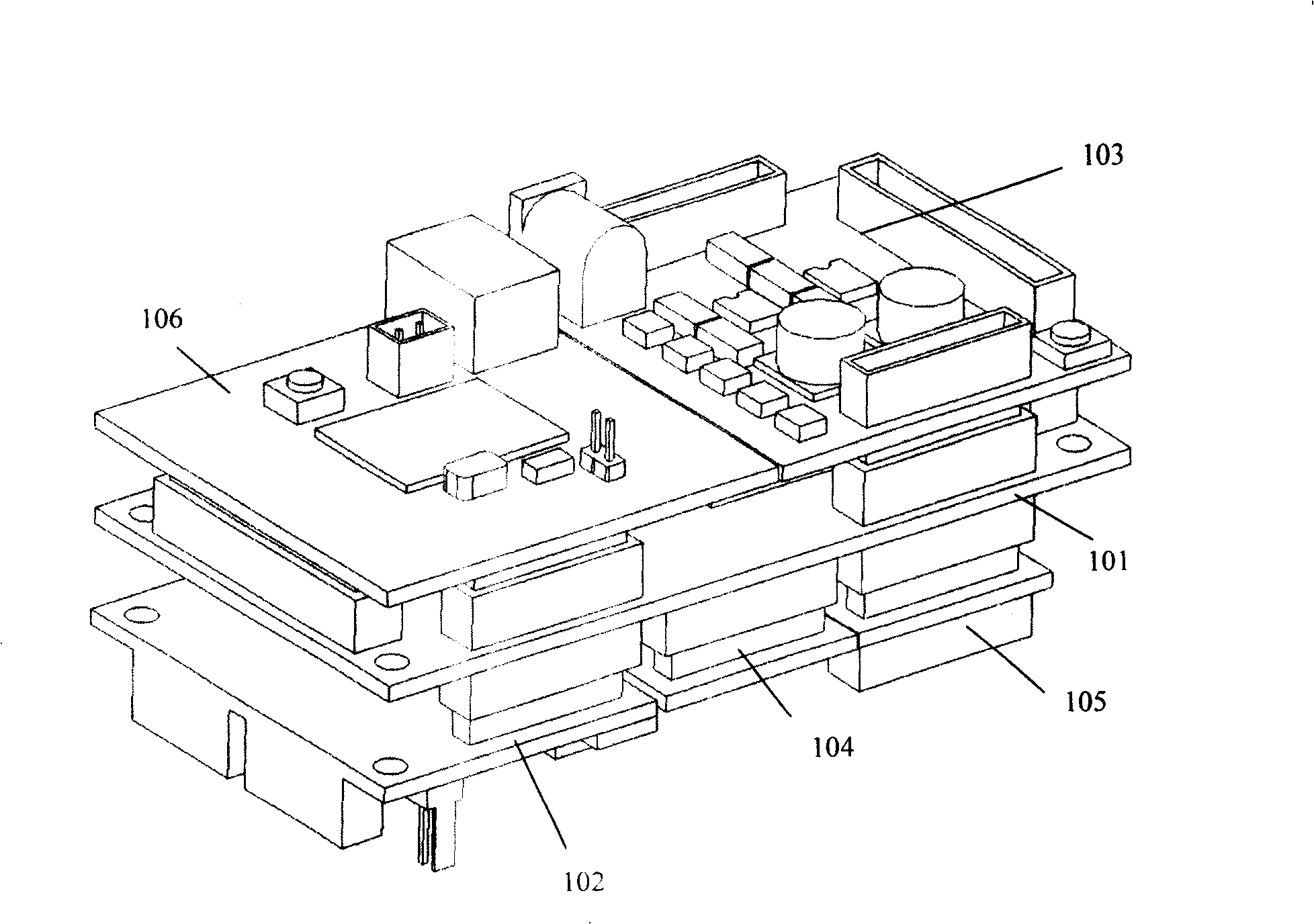

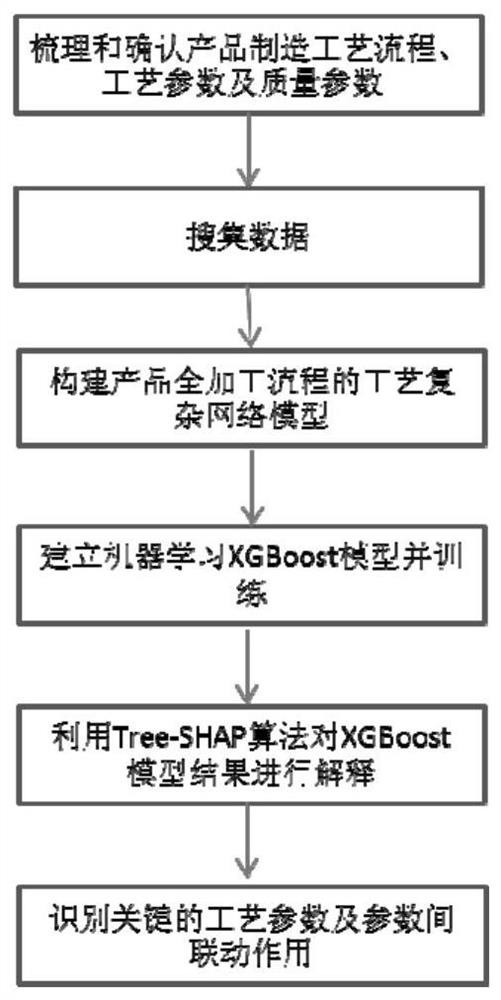

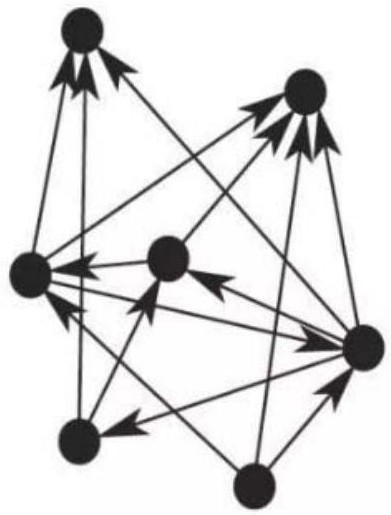

Product quality control method based on process network model and machine learning algorithm

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

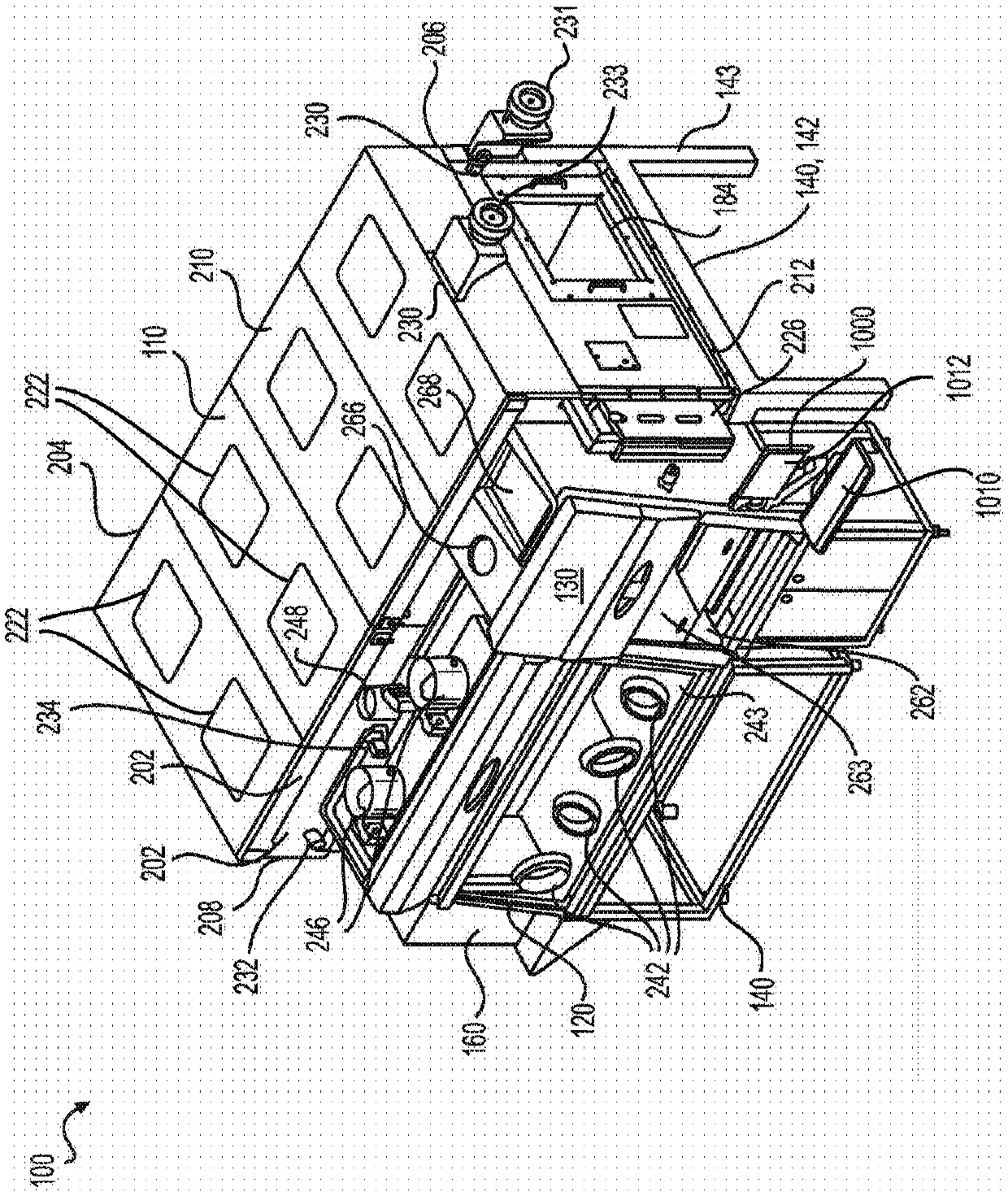

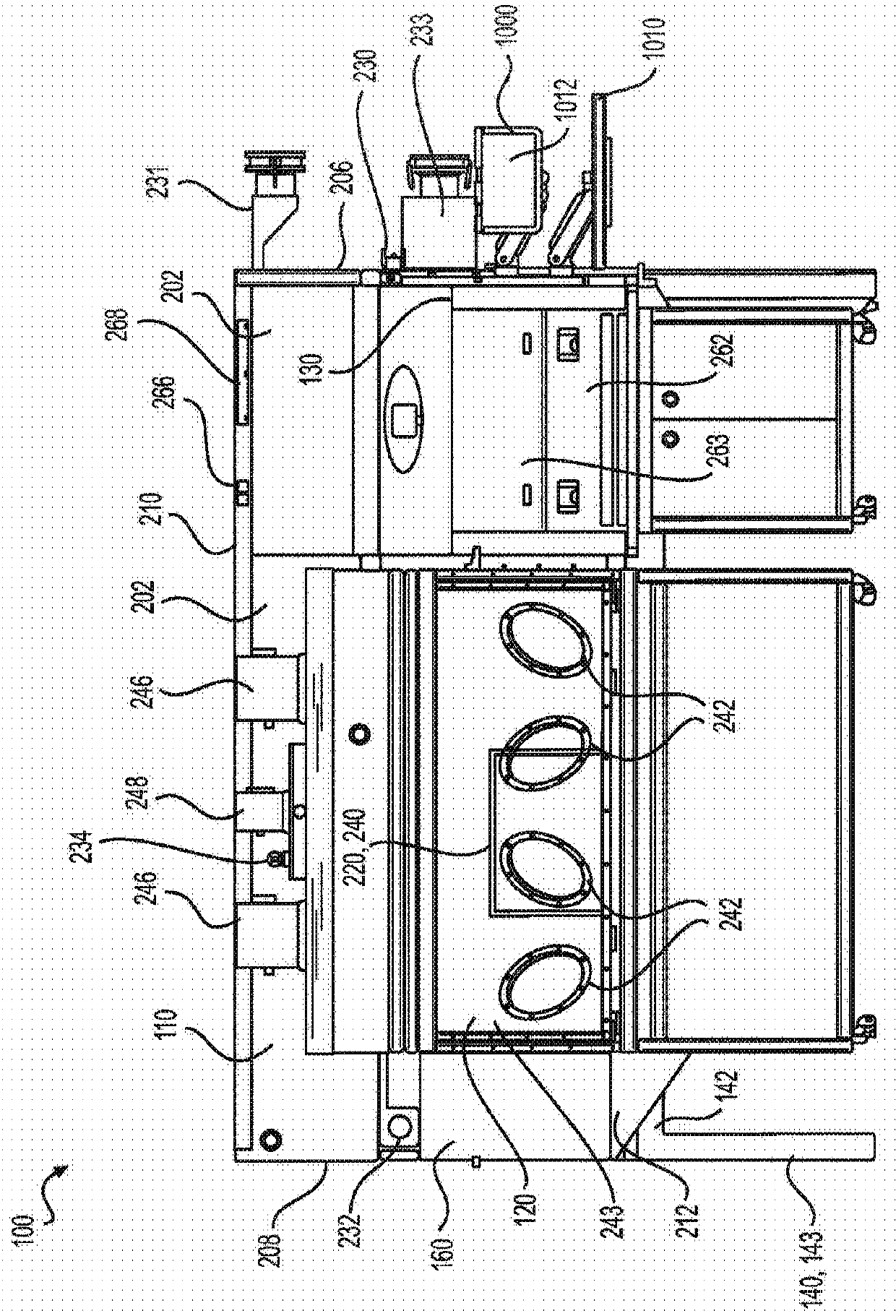

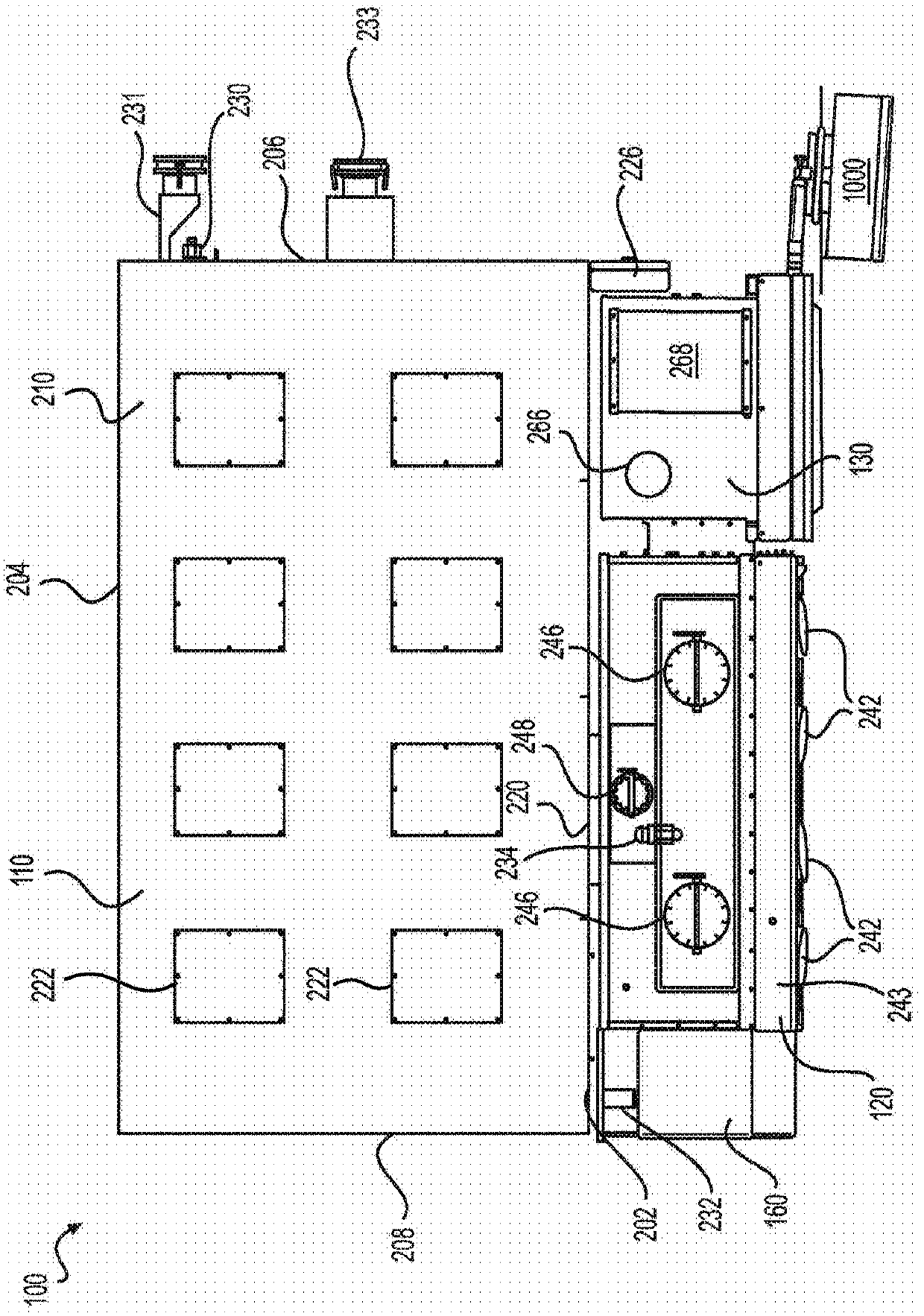

Automated cell processing systems and methods

PendingCN109661582AAir-pressure/air-lock chambersDust-free enclosuresAutomatic processingQuality control

Owner:GENESIS TECH LTD

Frosted cover plastic product injection molding process

InactiveCN109016423AImprove quality and efficiencyImprove injection molding efficiencyHot runnerQuality control

The invention discloses a frosted cover plastic product injection molding process which comprises at least the following process steps: a storage procedure; an extrusion procedure; mold opening; moldassembly; injection; and pressure maintaining, wherein a hot running of a mold used for injection molding comprises the following temperature sections: a first section of 277-280 DEG C, a second section of 277-280 DEG C, a third section of 270-275 DEG C, a fourth section of 285-290 DEG C, a fifth section of 273-278 DEG C, and a sixth section of 270-275 DEG C. Through the precise control of processparameters of all the sections in the frosted cover plastic product injection molding process disclosed by the invention, not only can the injection molding fluid quality control be achieved, but also the injection molding product quality and the injection molding efficiency can be improved, and the scrap rate can be lowered.

Owner:ZHEJIANG FEITENG MOLDING CO LTD

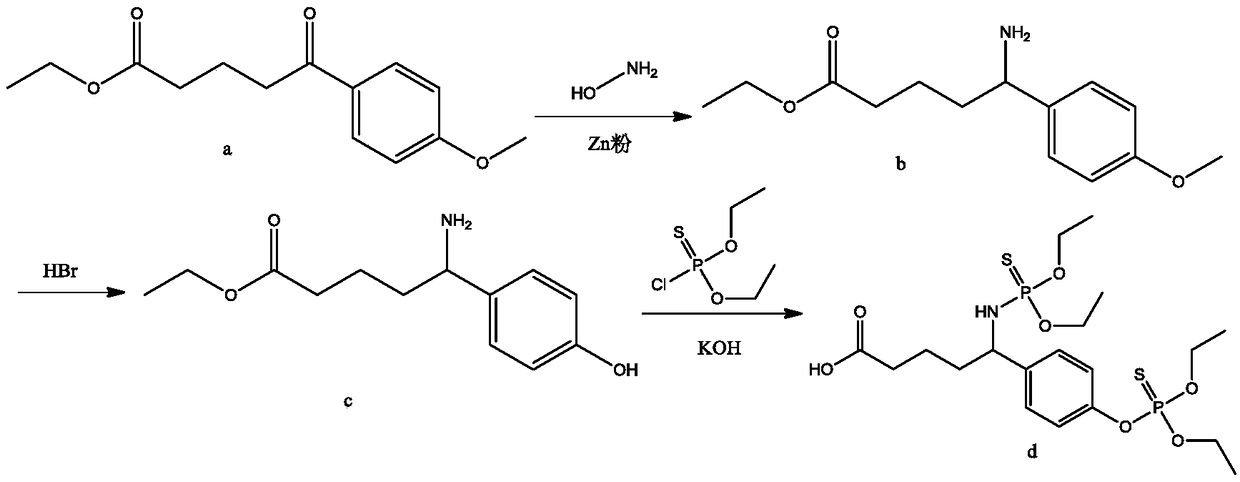

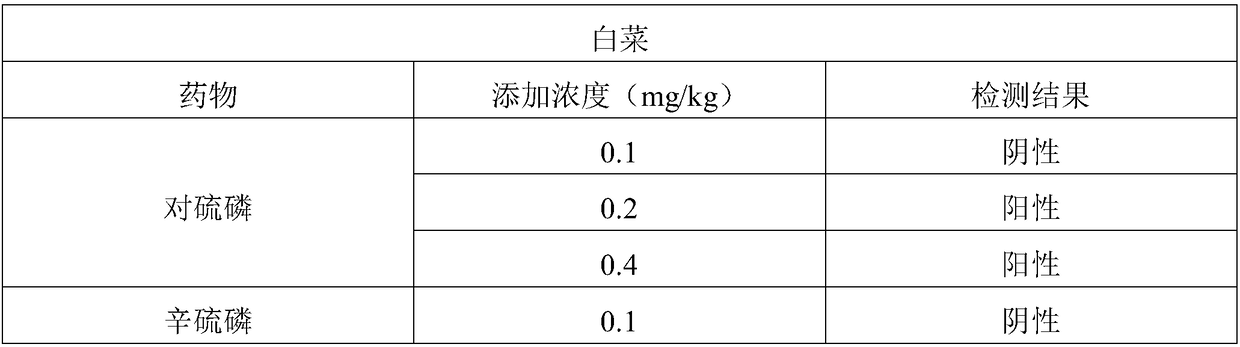

Test strip for detecting organophosphorus pesticide and application thereof

Owner:BEIJING KWINBON BIOTECH

Liquid composite protective agent for long-term culture preservation, and preparation method and application method thereof

InactiveCN106544275AKeep aliveImprove protectionMicroorganism preservationInfusion powderFreeze-drying

Owner:明德松

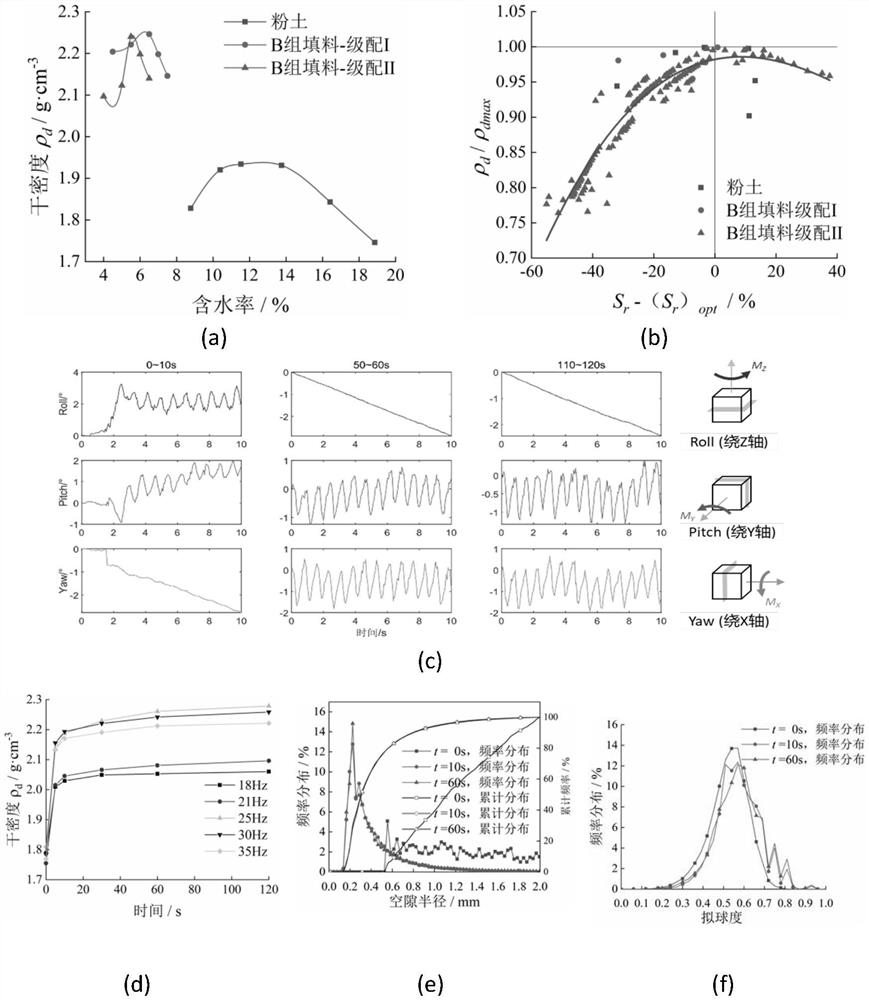

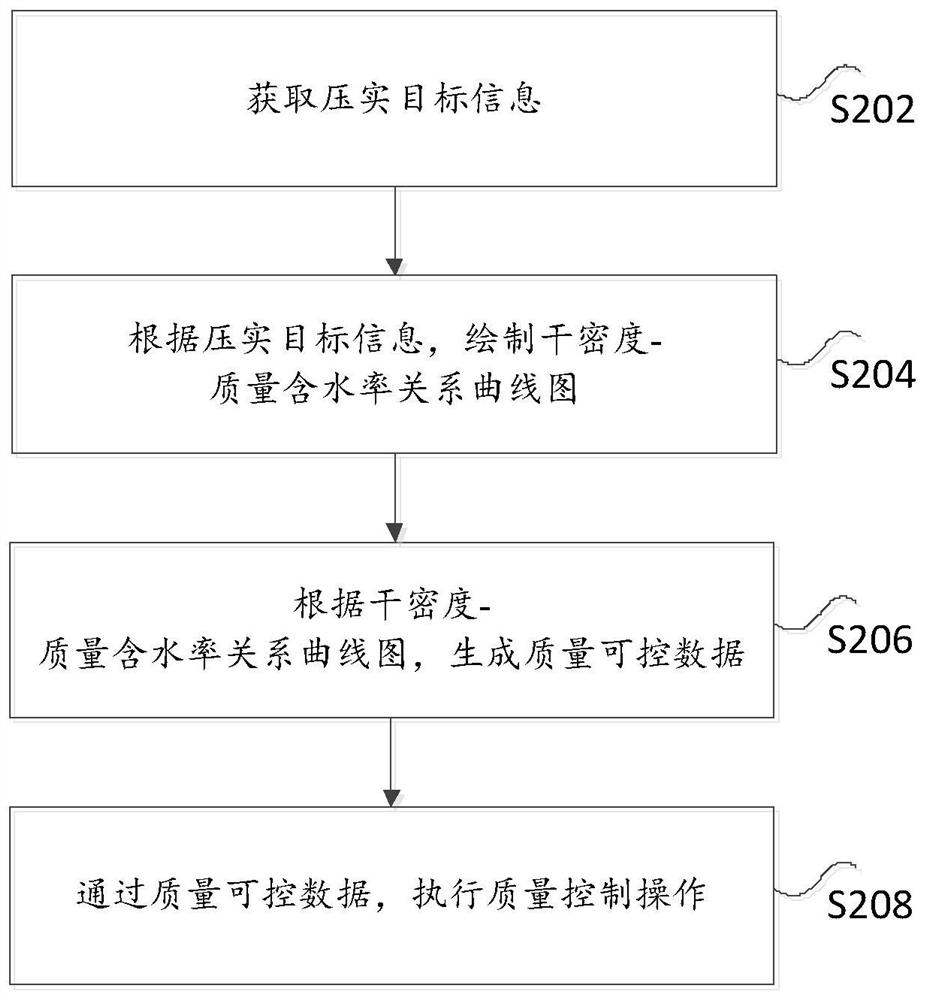

Roadbed filler compaction quality control method and system

ActiveCN113215894AAccurate evaluationPrecise regulationGeometric CADRoadwaysSoil scienceQuality control

Owner:CENT SOUTH UNIV

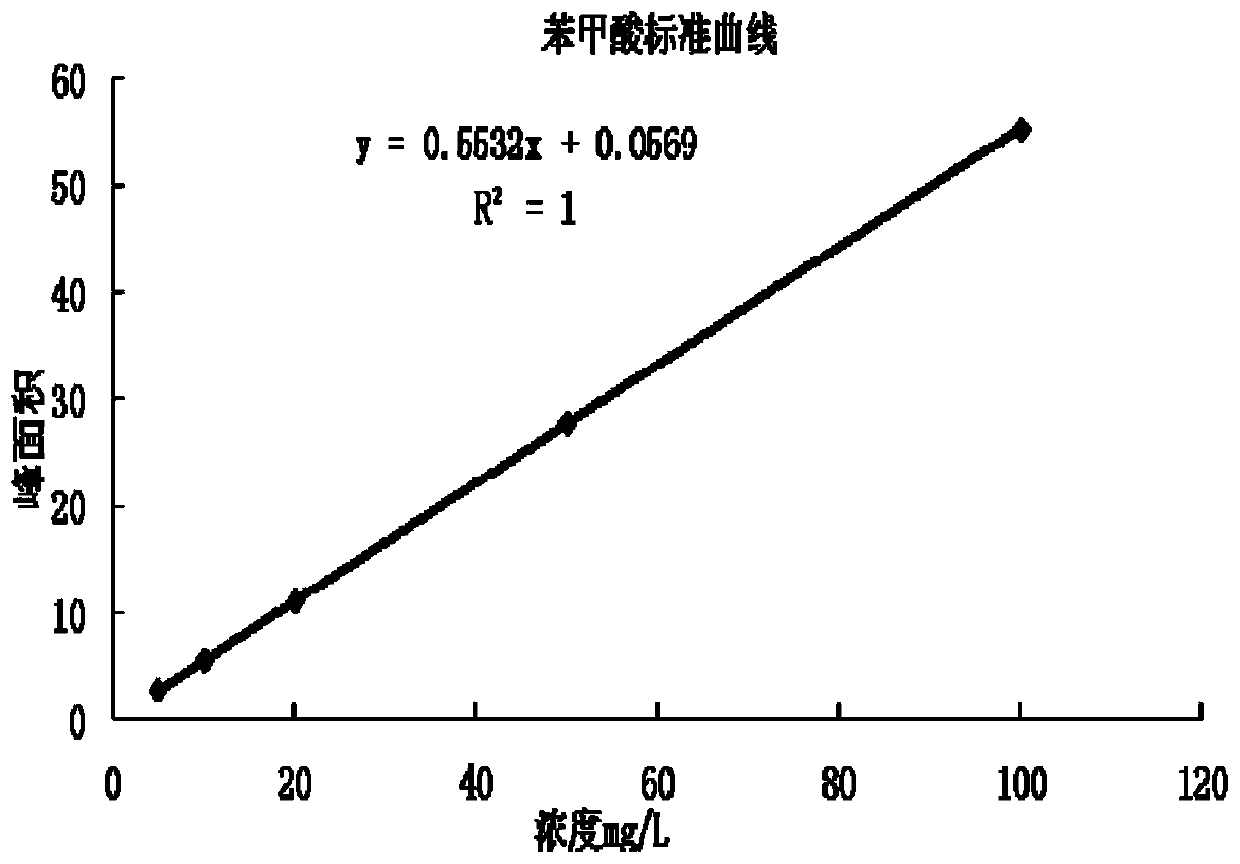

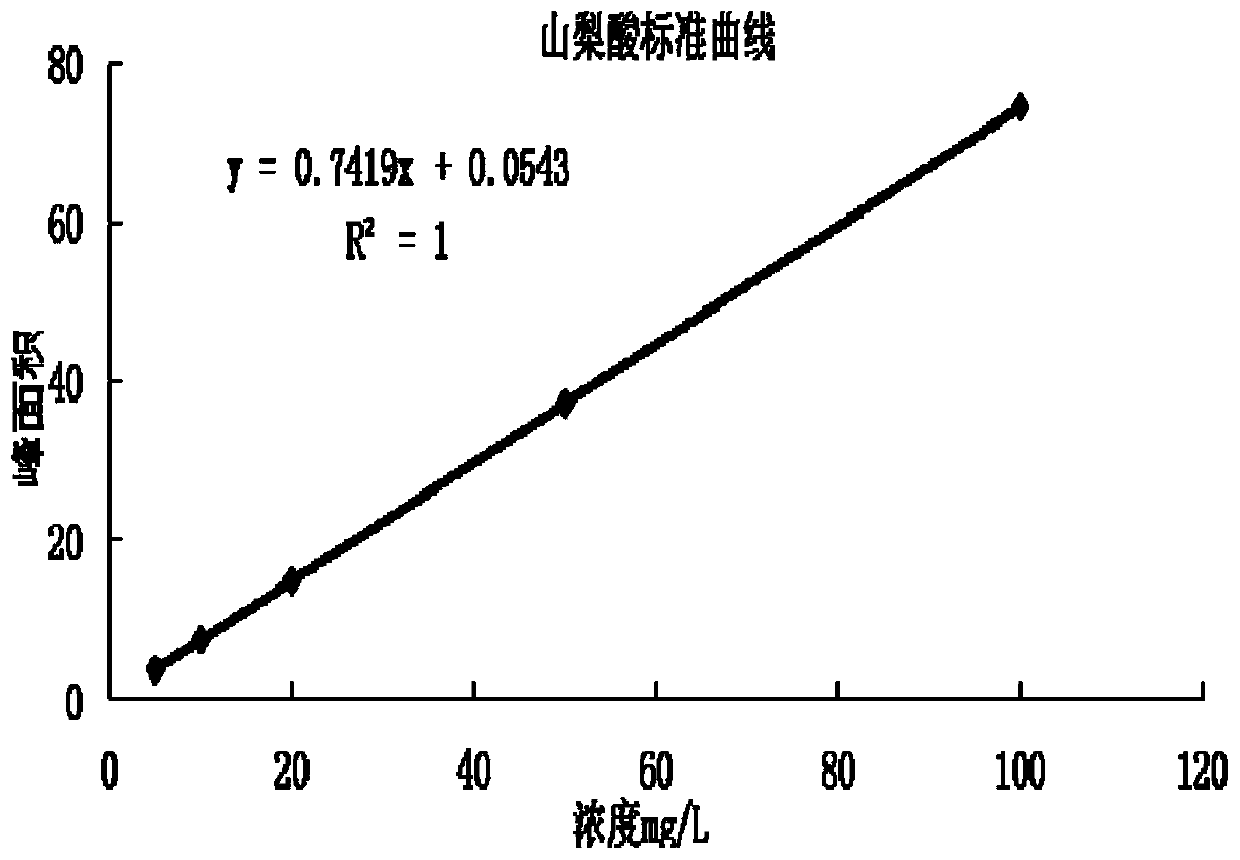

High performance liquid chromatographic analysis method of benzoic acid and sorbic acid in toothpaste

InactiveCN109828061ARapid Quantitative AnalysisAccurate quantitative analysisComponent separationBenzoic acidToothpaste Product

Owner:JIANGSU SUPERVISION & INSPECTION INST FOR PROD QUALITY

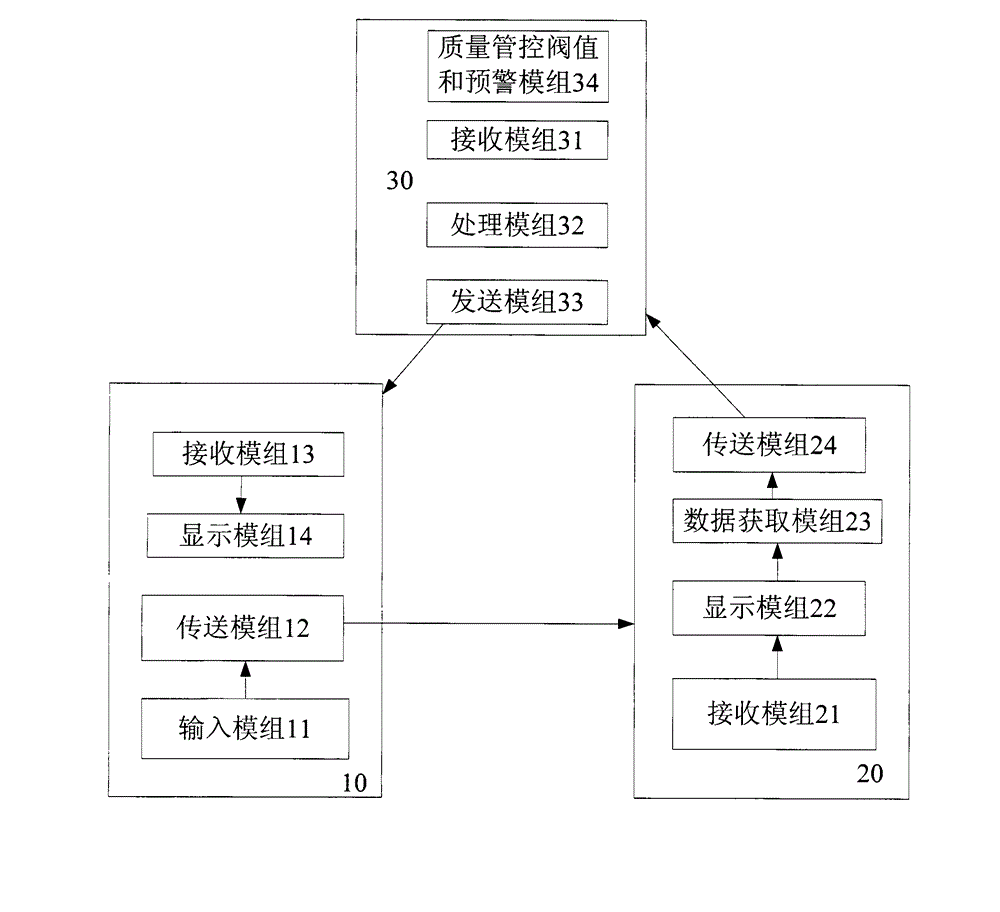

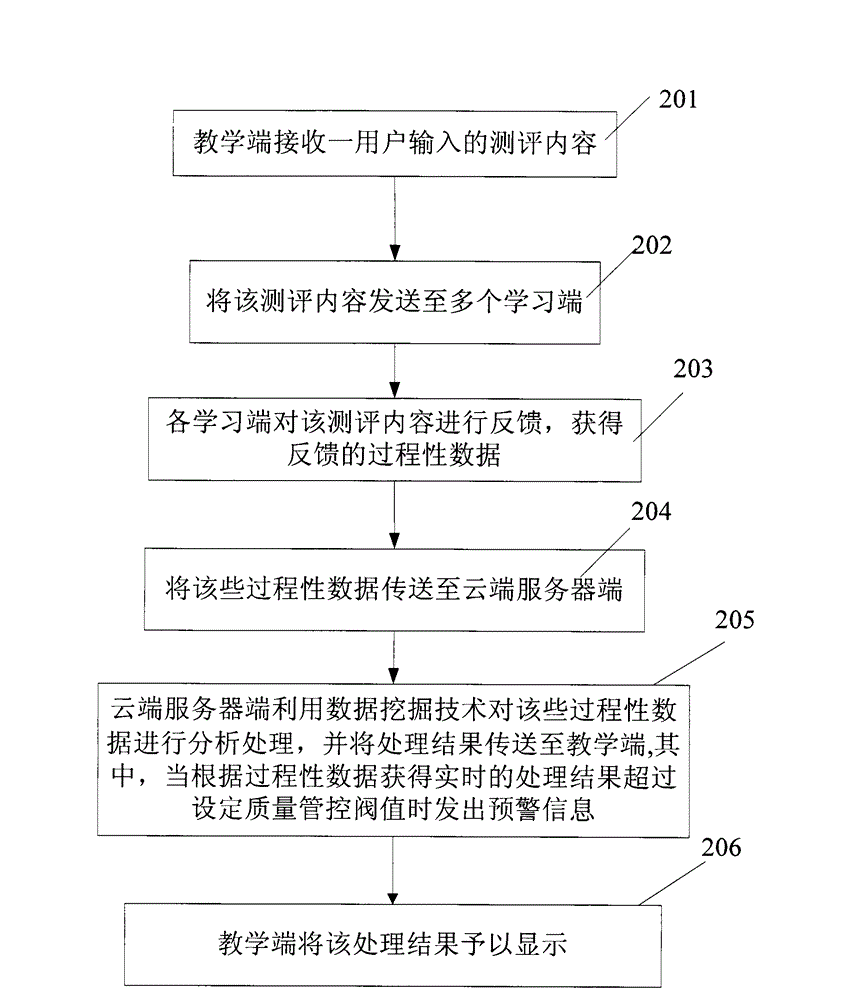

Entire process quality control threshold value and early warning system and method

Owner:KUNSHAN WANFENG GARMENT

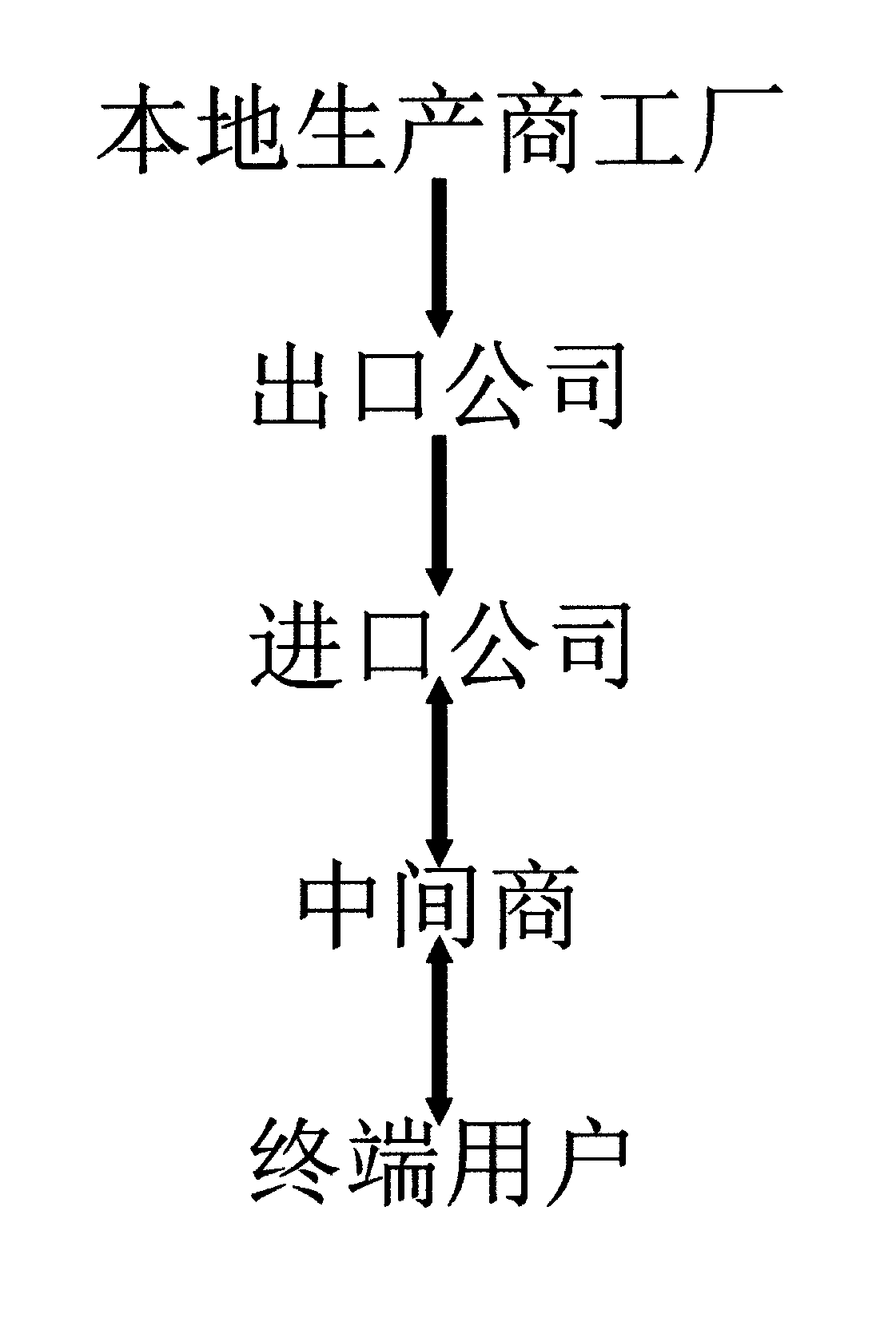

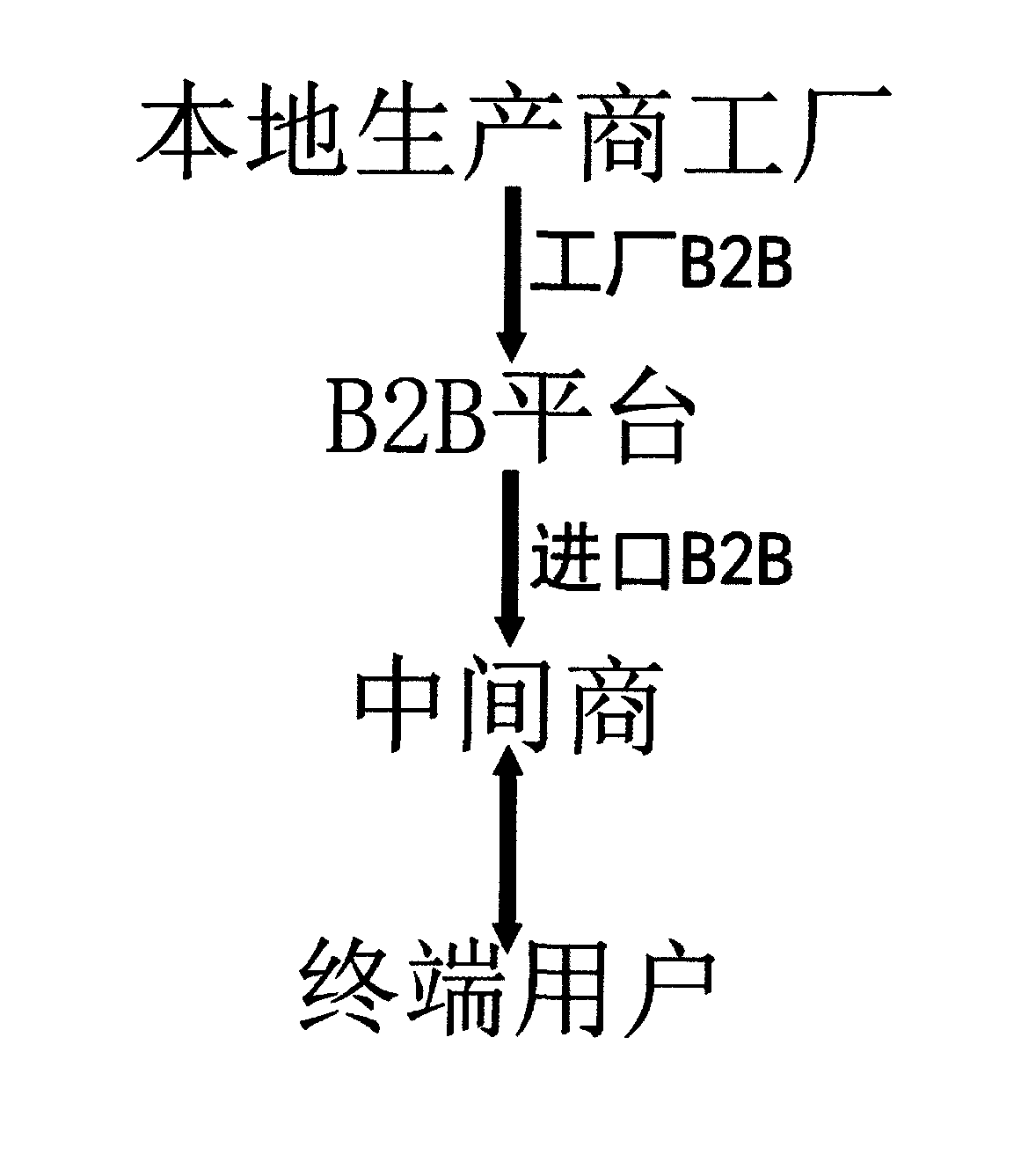

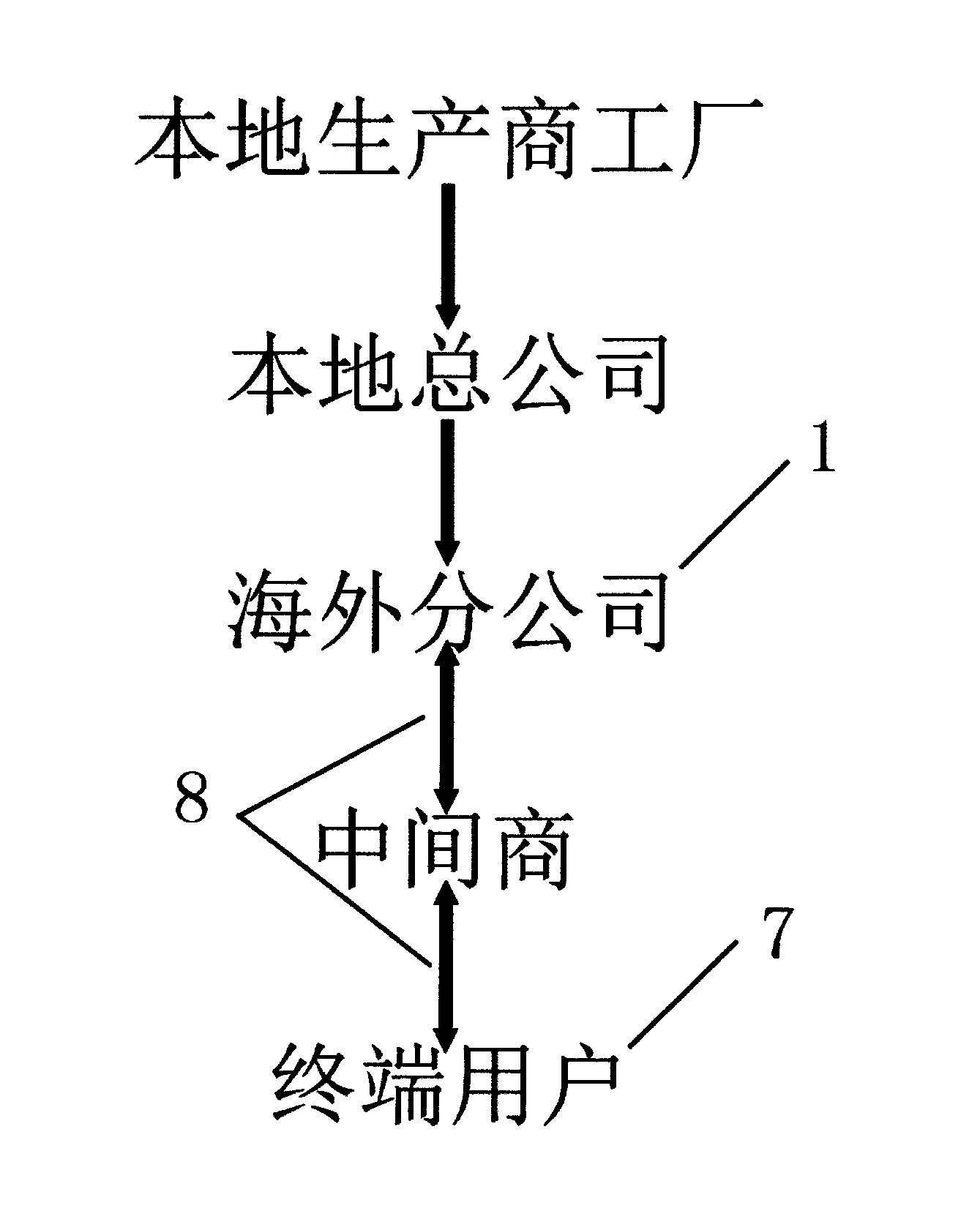

Transnational supply chain distribution and sales management and quality control method thereof

InactiveCN103824142AReduce intermediate linksShorten the timeResourcesLogisticsThird partyLogistics management

Owner:梁铭波

Method for separating and determining calcipotriene starting raw material A and related impurities

Owner:CHONGQING HUABANGSHENGKAI PHARM

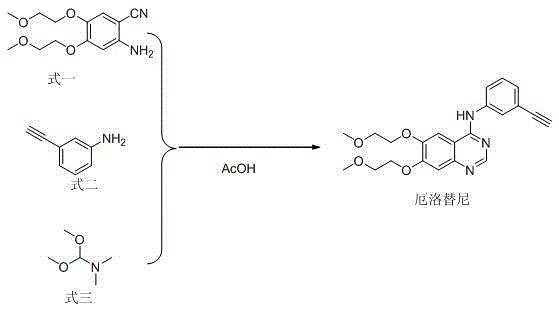

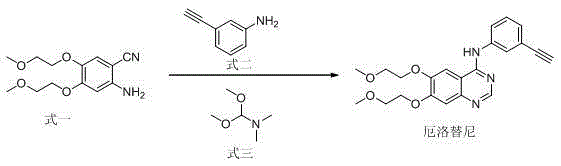

Method for preparing erlotinib

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD

Quality control management platform and method for cyber knife of stereotactic radiotherapy equipment

PendingCN113838564AImprove quality control efficiencyQuality Control Management SupportResourcesMedical equipmentStereotactic radiotherapyQuality control

The invention relates to a quality control management platform and method for a cyber knife of stereotactic radiotherapy equipment, and the platform comprises seven main modules: a quality control user management module, a newly added quality control record module, a quality control record checking module, a user customized quality control module, a quality control project management module, a quality control equipment management module and a manufacturer quality control support module. According to the quality control management method, seven modules in the quality control management platform are used for managing and using the quality control project of CyberKnife. According to the stereotactic radiotherapy equipment CyberKnife disclosed by the invention, a clinical user can achieve the quality control management electronization, automatic CyberKnife quality control result analysis and report generation, automatic CyberKnife quality control project early warning, and customization of a CyberKnife quality control activity and a CyberKnife quality control report; therefore, the quality control efficiency of a clinical CyberKnife physicist is improved, and the quality control management of a plurality of CyberKnife devices is supported.

Owner:CNNC ACCURAY (TIANJIN) MEDICAL TECH CO LTD

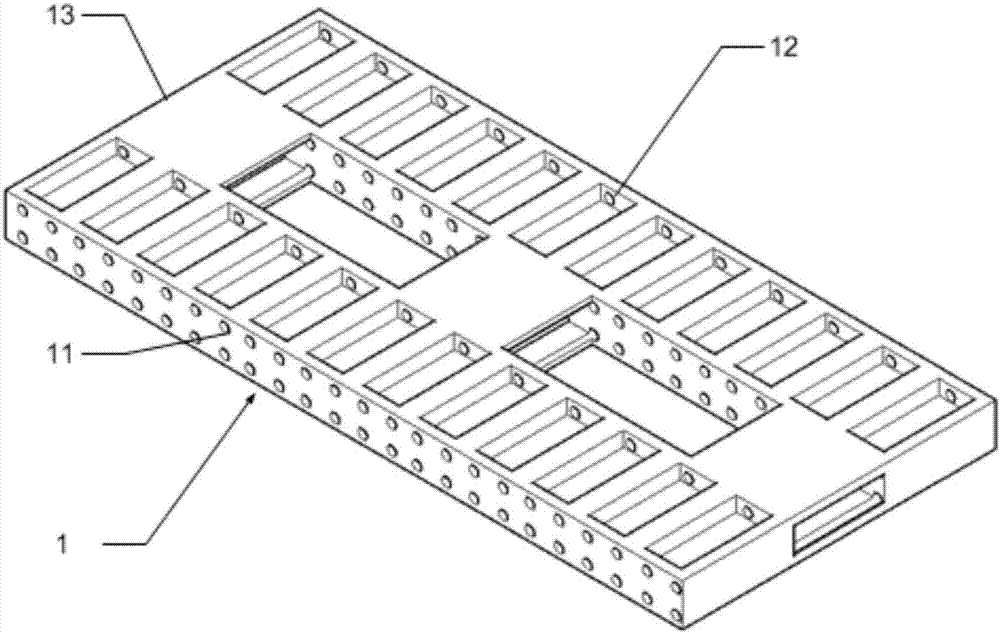

Steel support pressurizing member and construction method thereof

Owner:CHINA MCC20 GRP CORP

Bearing steel pipe inspection quality control method for cold rolling and expanding bearing

ActiveCN113088639AQuality improvementExtended service lifeFurnace typesTesting metalsBrinellingCarbide

The invention discloses a bearing steel pipe inspection quality control method for a cold rolling and expanding bearing. In the production process of a bearing steel pipe, pipe blank factory inspection, spheroidizing annealing state capillary pipe inspection and stress relief annealing state finished pipe inspection are sequentially carried out; stress relief annealing state finished pipe inspection includes hardness inspection, microscopic structure inspection, carbide non-uniformity inspection and decarburized layer inspection; during hardness inspection, the Brinell hardness is 179-190 HBW, and the grade is 2-3 according to the fifth grade diagram evaluation in the appendix A of GB / T 18254-2016 during microscopic structure inspection. The bearing steel pipe is subjected to quality control through the method, the surface of the bearing produced through cold rolling and expansion is free of cracks, the structure uniformity is high, thus the quality of the bearing is improved, and the service life of the bearing is prolonged.

Owner:JIANGXI HONGRUIMA STEEL PIPE

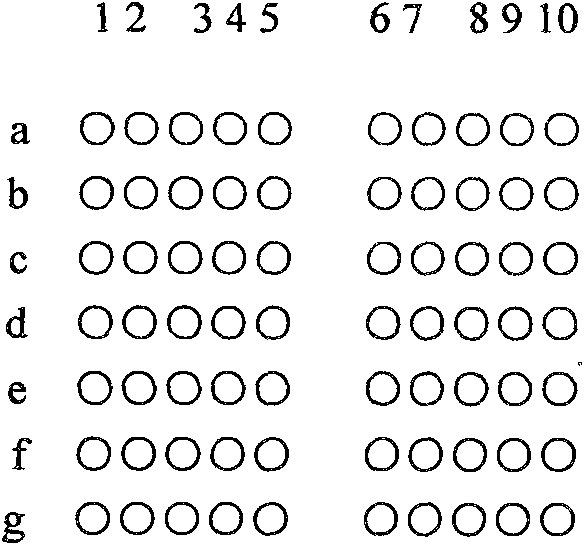

Gene chip for detecting transgenic plant and products containing screened gene NOS and application thereof

InactiveCN101824473AStrong specificityHigh sensitivityMicrobiological testing/measurementFluorescence/phosphorescencePositive controlSpecific detection

Owner:山东鲁保科技开发有限公司

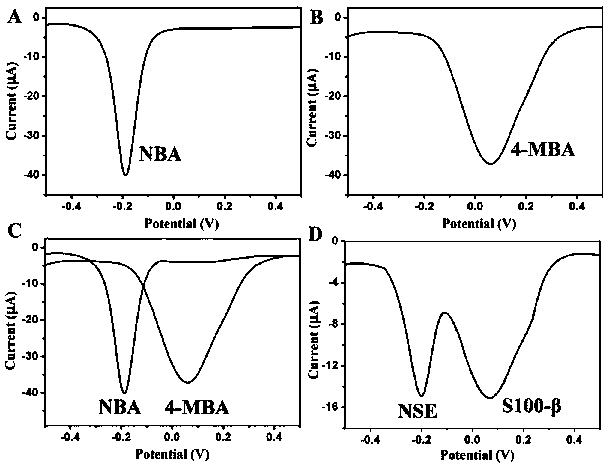

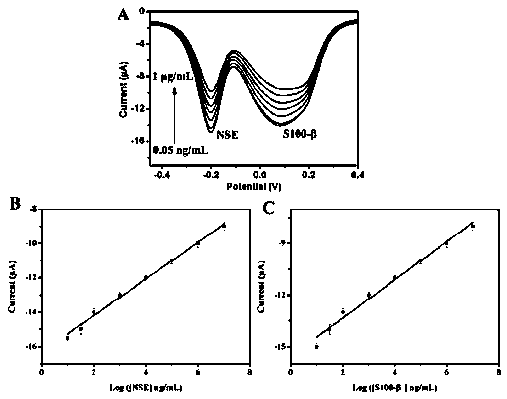

Early stroke electrochemical quantitative detection test strip with hollow gold and silver nanospheres

ActiveCN110470707AImprove accuracyReduce testing costsBiological testingMaterial electrochemical variablesNitrocelluloseQuality control

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap