Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169results about "Computer control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

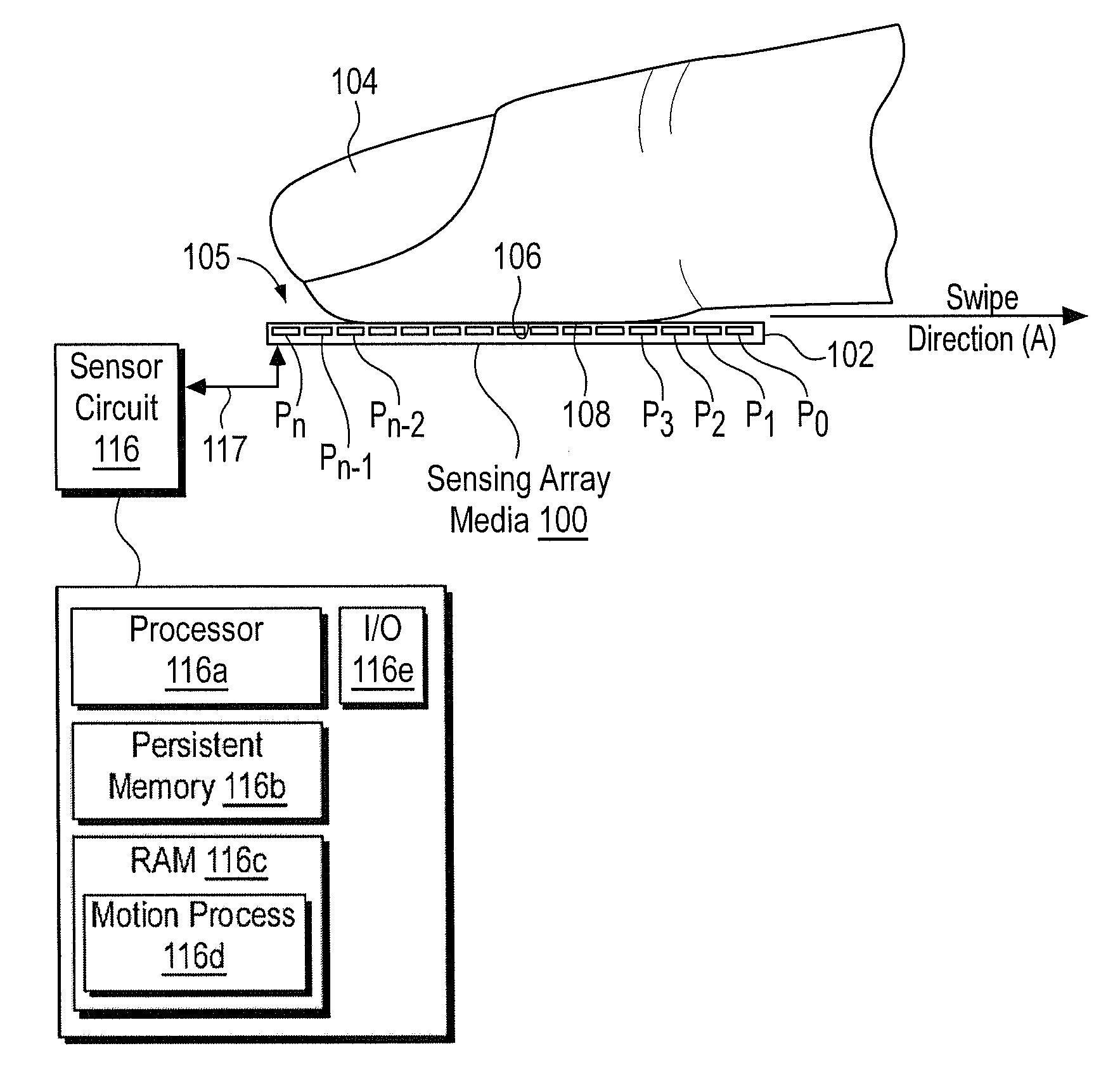

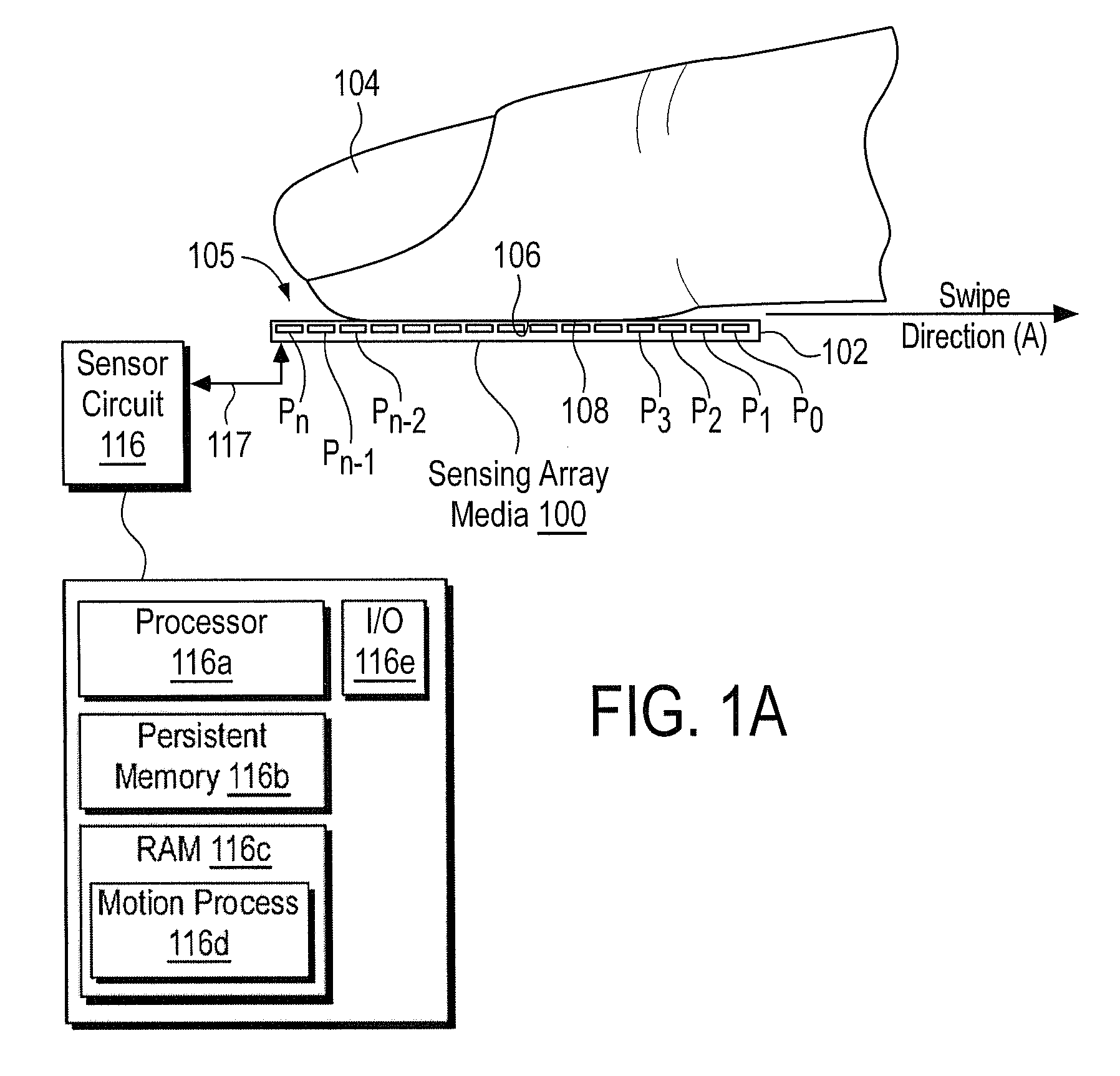

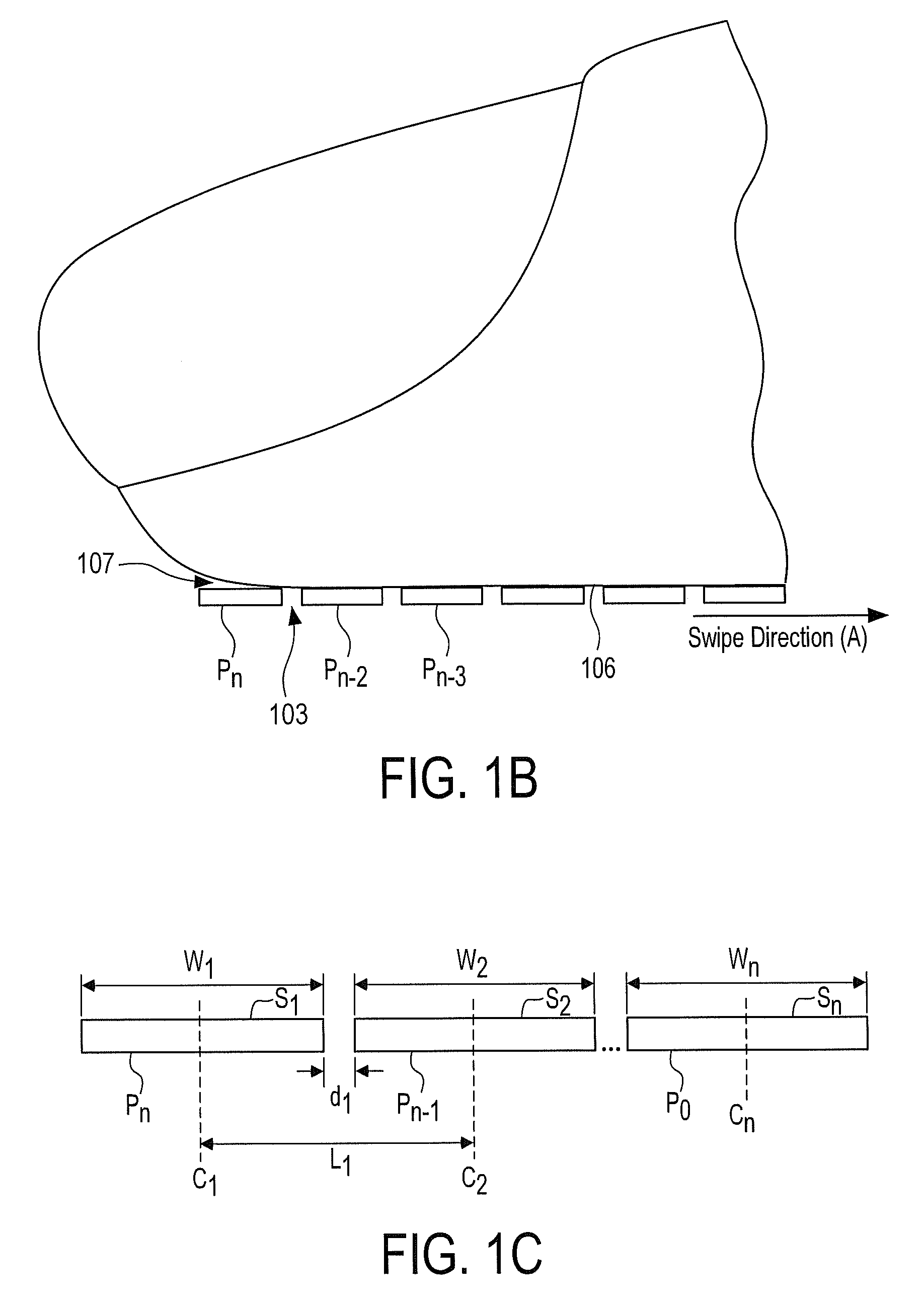

Method and Apparatus for Fingerprint Image Reconstruction

Owner:SYNAPTICS INC

Variable air volume system including BTU control function

InactiveUS6879881B1Improving environmental comfortIncrease volumeMechanical apparatusLighting and heating apparatusVariable air volumeAir volume

A method, as well as a controller, for controlling room temperature with a variable air volume system having a plurality of zones wherein the thermal transfer rate with respect to each of such zones is maintained at a substantially constant value notwithstanding changes in the temperature of the supply air thereby providing improved efficiency and environmental comfort.

Owner:SIEMENS IND INC

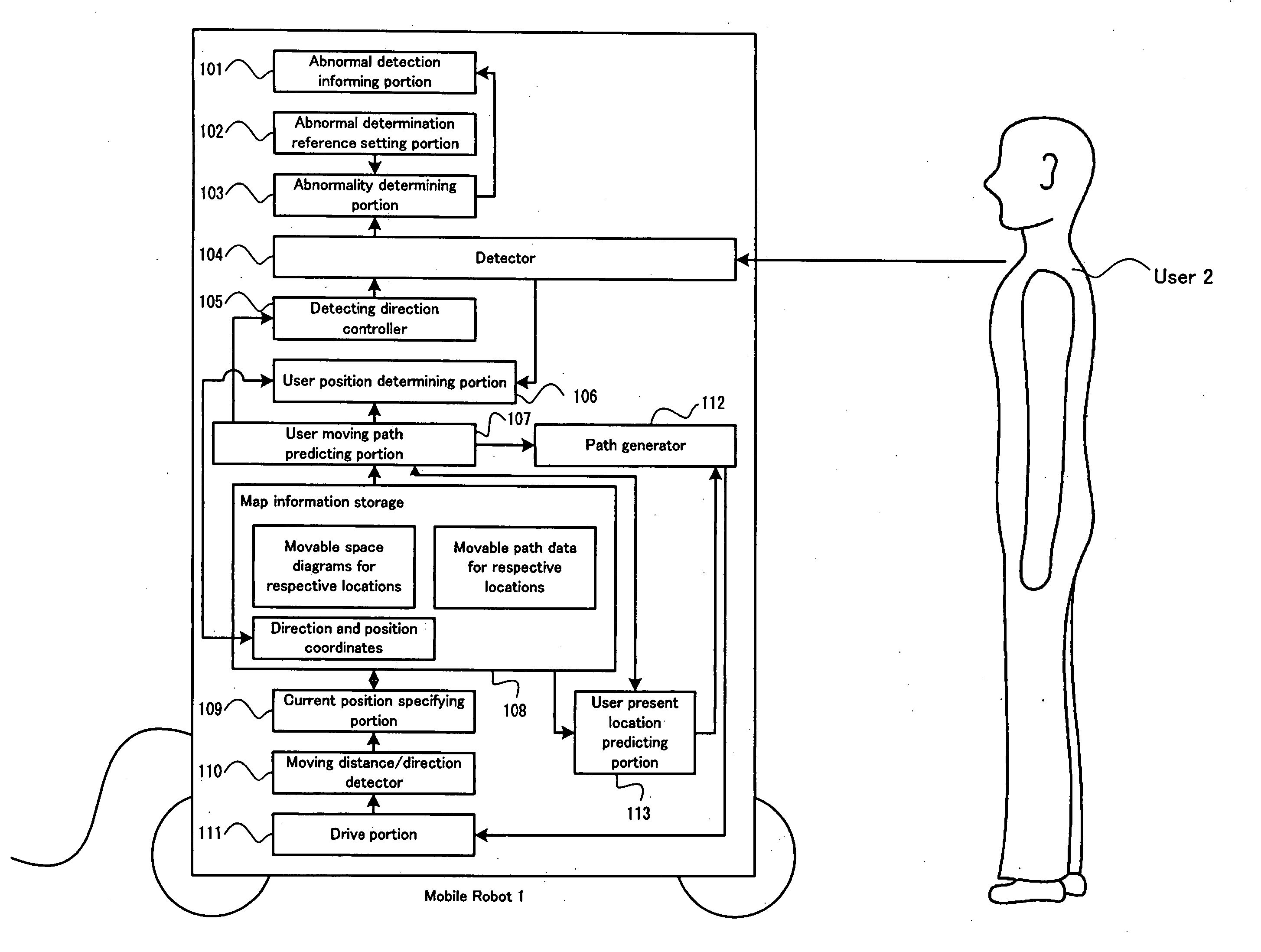

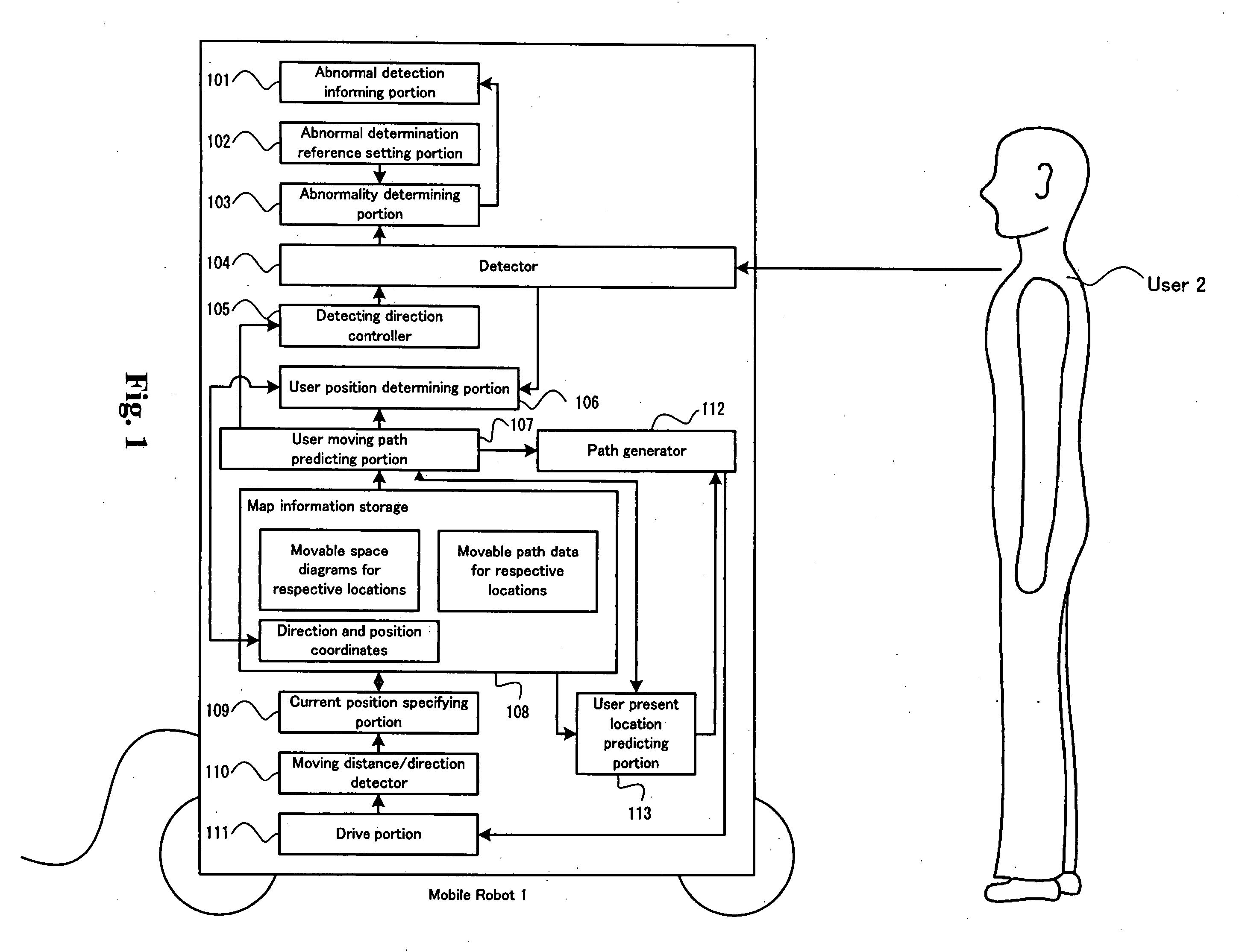

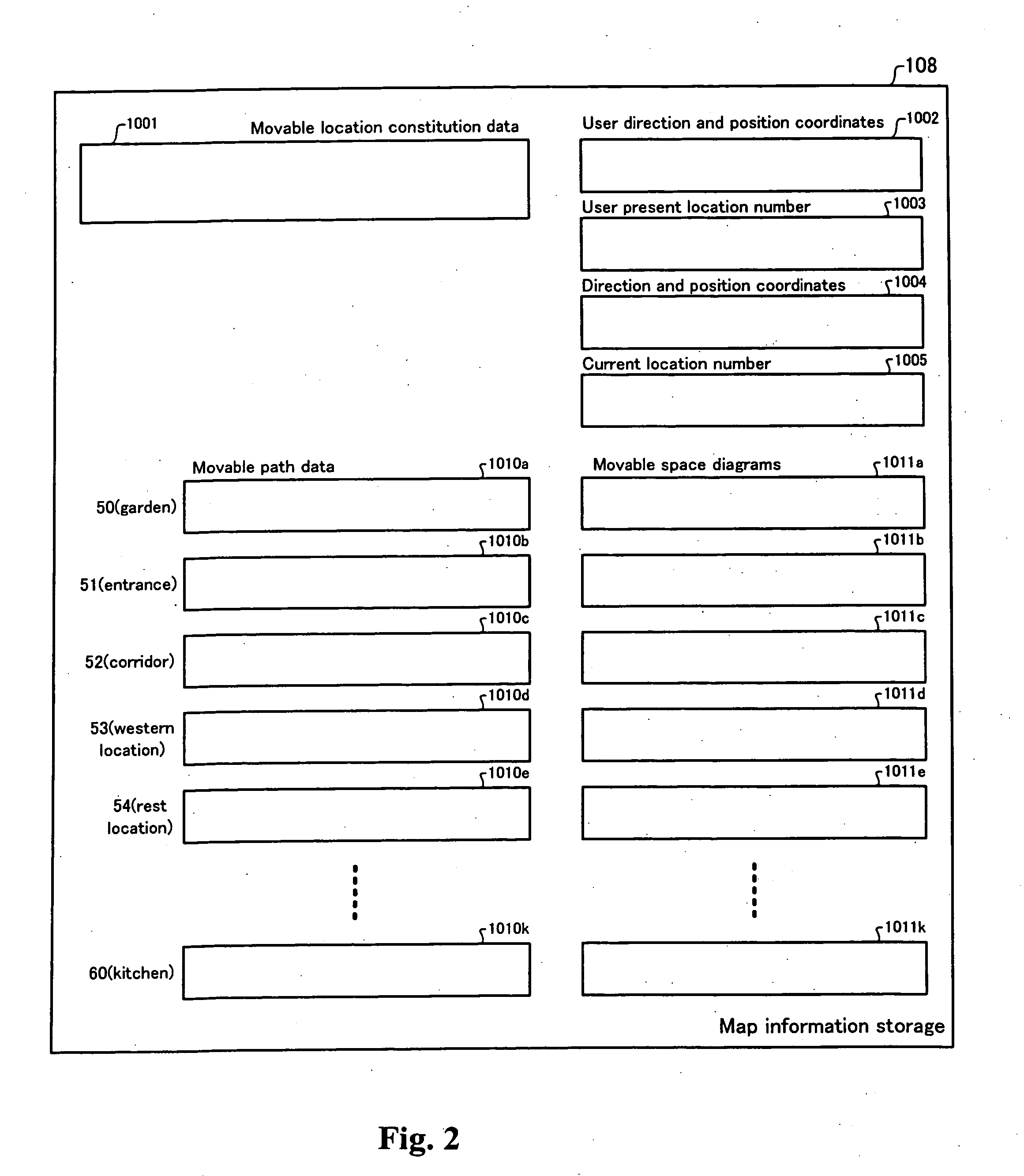

Mobile robot for monitoring a subject

Owner:KK TOSHIBA

Stackable thermostat

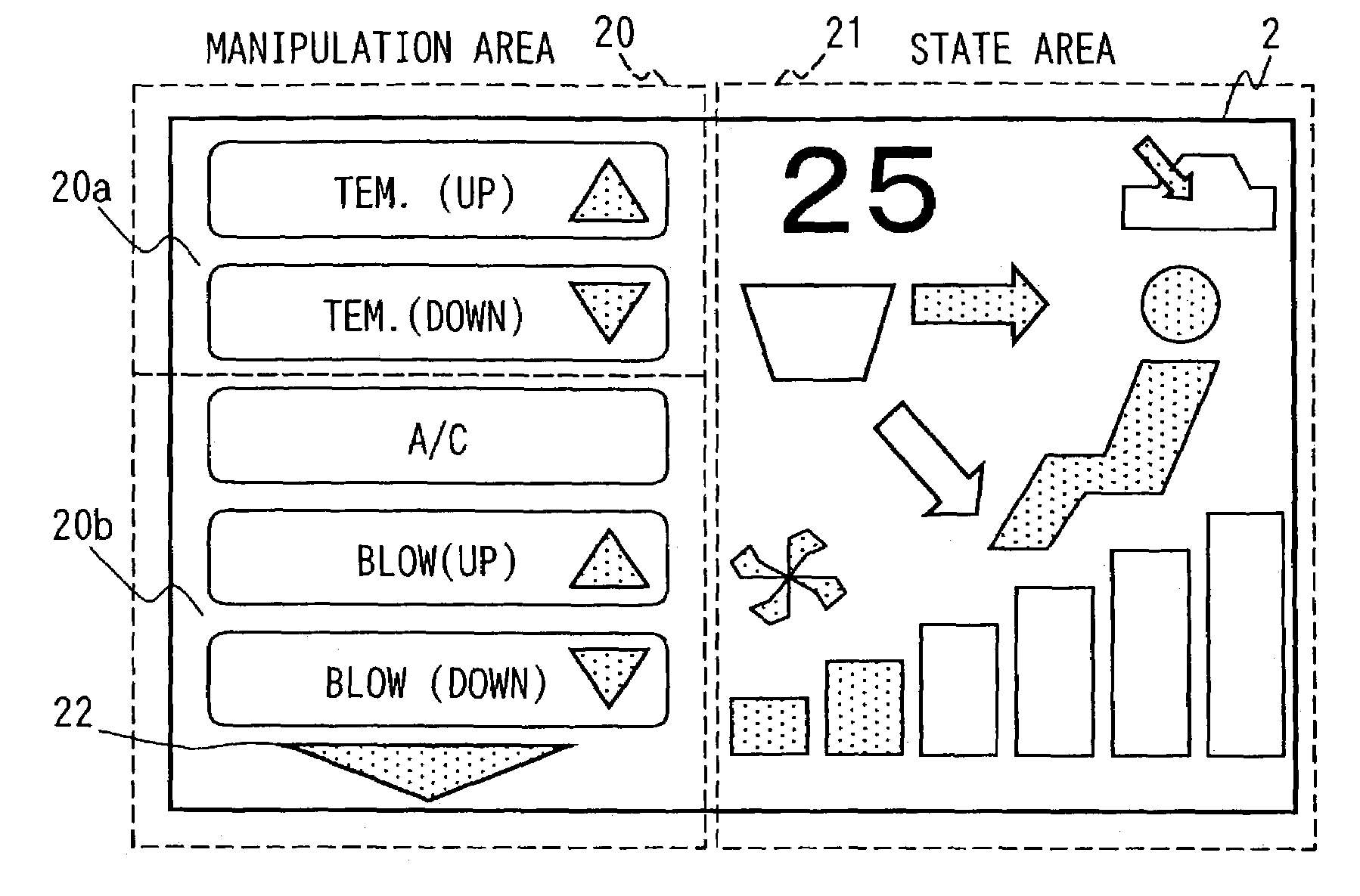

ActiveUS20080147242A1Mechanical apparatusLighting and heating apparatusCommunication interfaceDisplay device

The invention relates to a thermostat including a user interface module. The user interface module has a display, a plurality of user interface buttons, and a first power and communications interface. The thermostat also includes an I / O module, the I / O module electrically coupled to a HVAC plant and the I / O module having a plurality of switches to control the HVAC plant, and a second power and communications interface. The user interface module and the I / O module are communicatively coupled and exchange power via the power and communications interfaces and the thermostat can be mounted and operated in one of two user selectable installations: a stacked configuration comprising a thermostat having the user interface module directly mounted to the I / O module, or a remote configuration comprising a thermostat having the user interface module remotely mounted from the I / O module.

Owner:CARRIER CORP

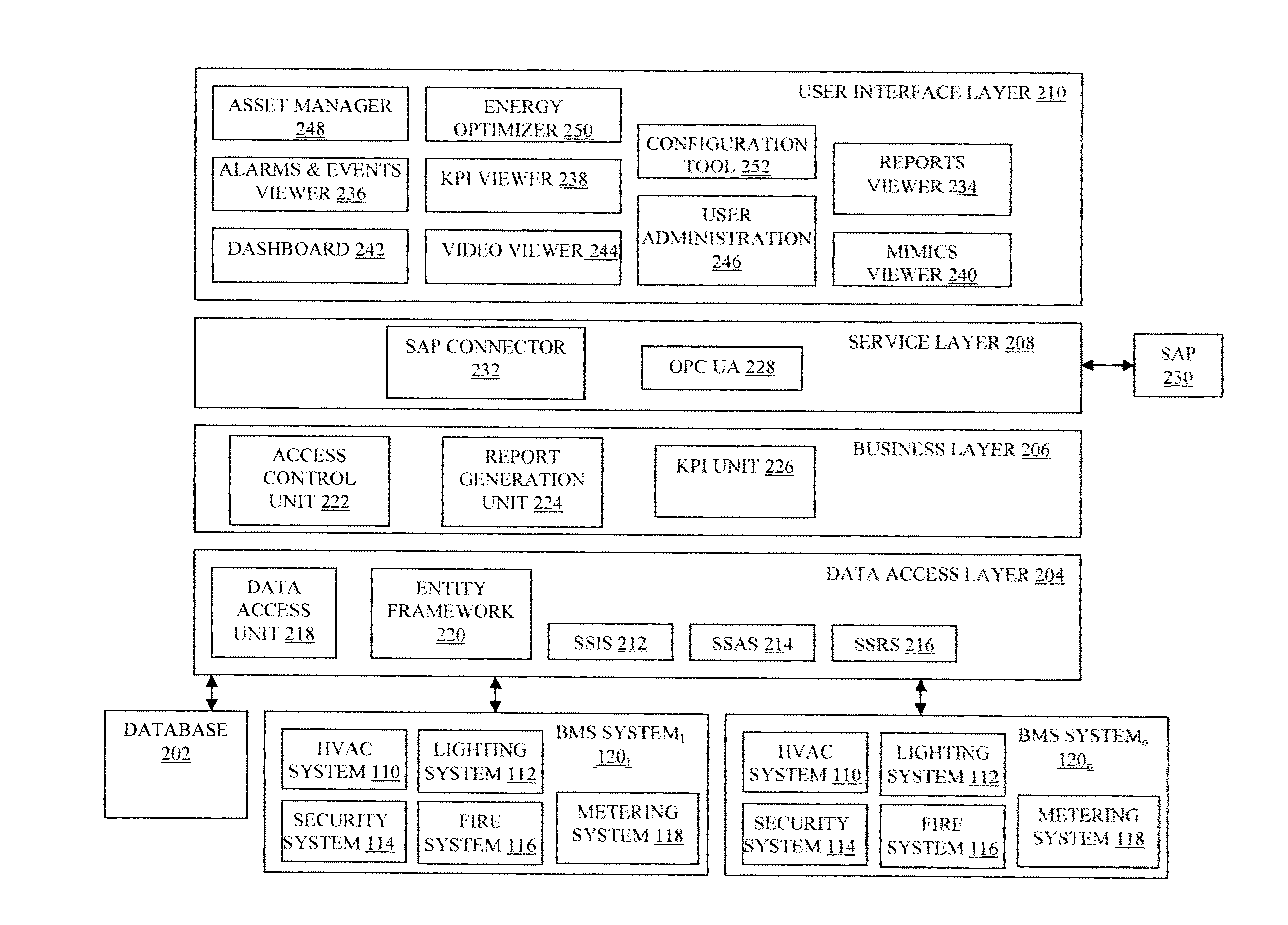

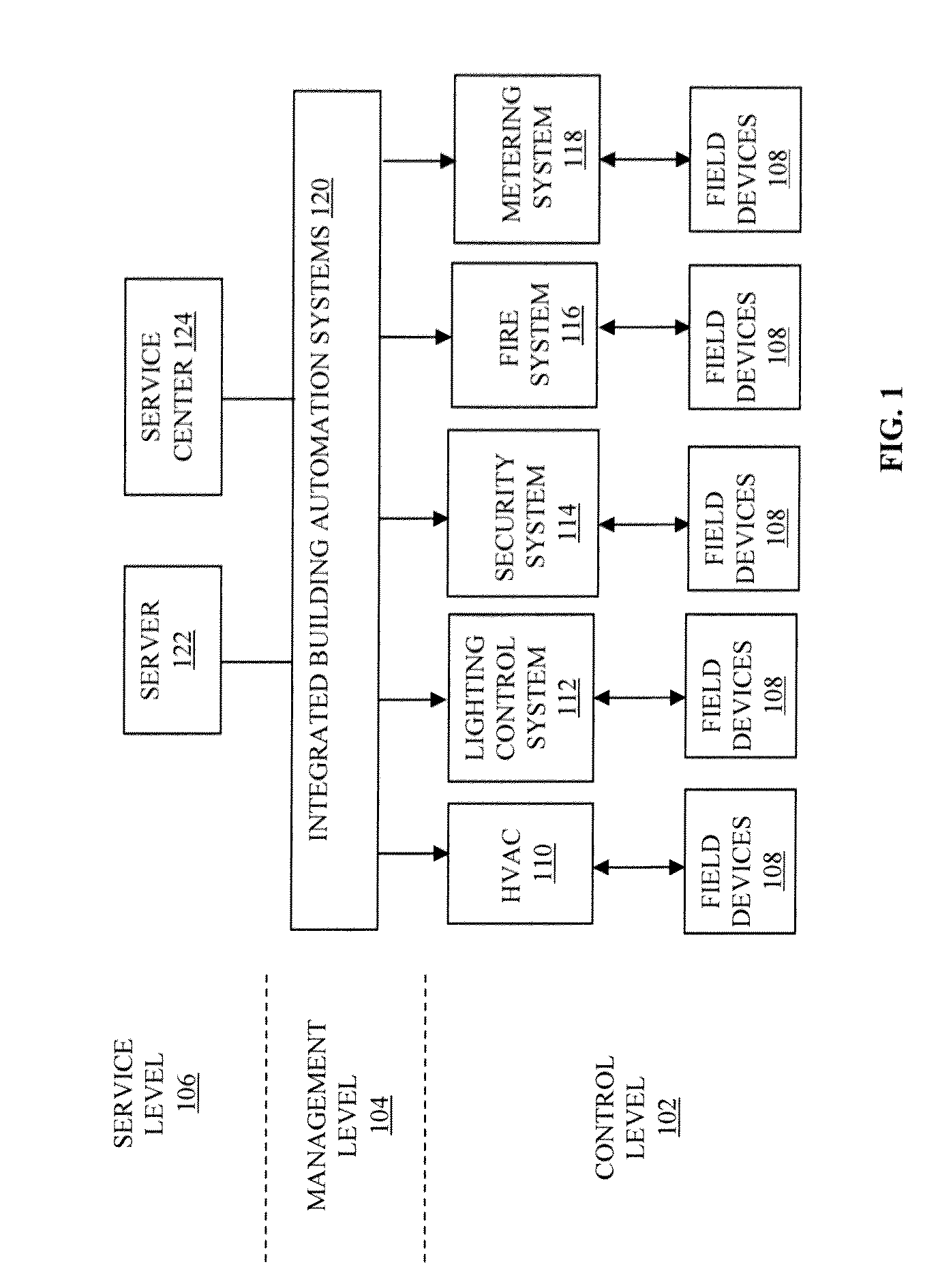

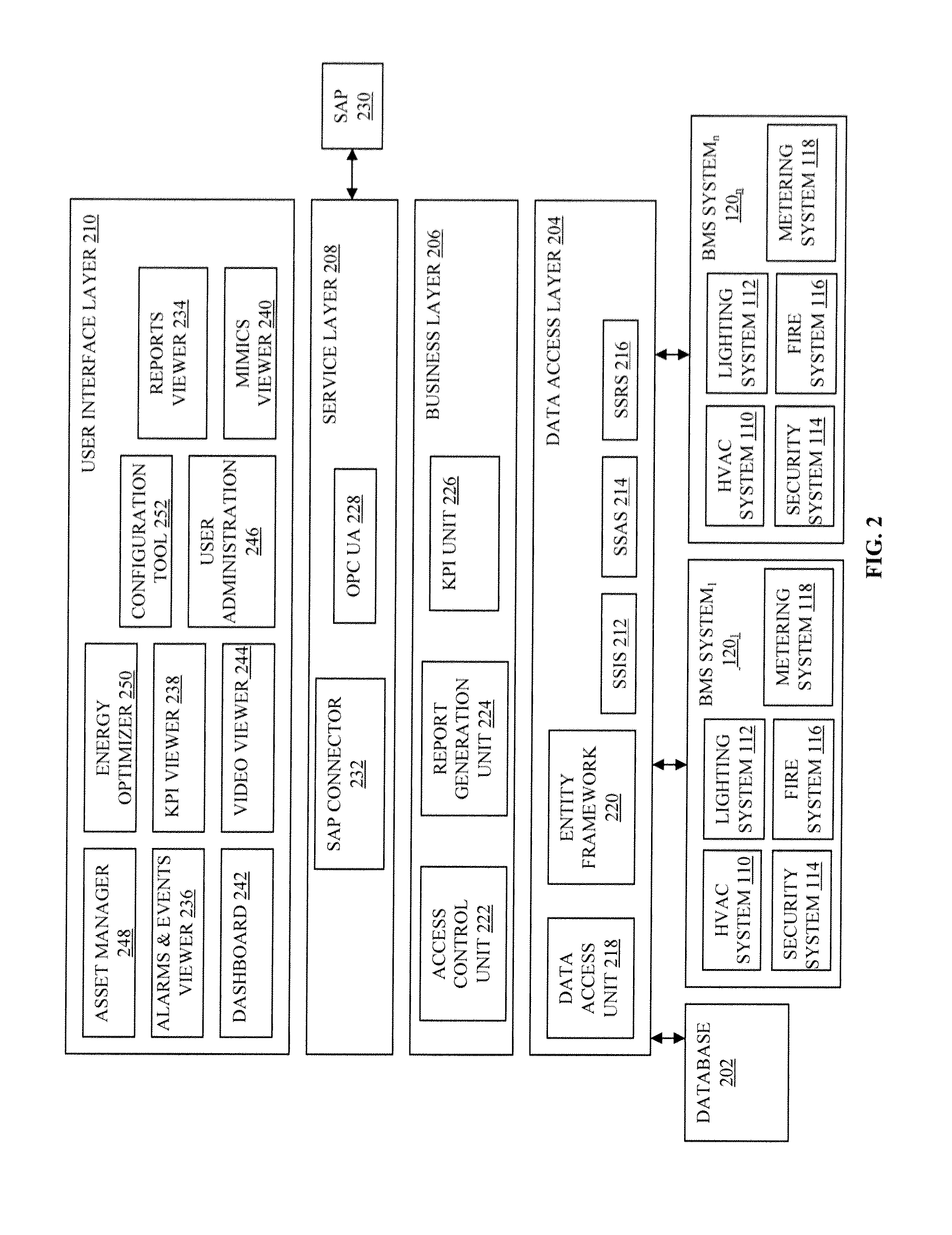

Architecture and method for centrally controlling a plurality of building automation systems

Owner:INFOSYS TECH LTD (IN)

Electricity suppressing type electricity and heat optimizing control device, optimizing method, and optimizing program

ActiveUS20140188295A1Electrical degradationLevel controlBatteries circuit arrangementsTime scheduleProcess engineering

An optimized operating schedule is obtained while avoiding a complexity of formulation and optimization in response to an incentive type demand response. A device includes an energy predictor 10 setting a predicted value of energy of a control-target device 2 within a predetermined future period, a schedule optimizer 11 optimizing the operating schedule of the control-target device 2 within the predetermined period in accordance with a predetermined evaluation barometer, an incentive acceptance determiner 12 determining a time with a possibility that an incentive is receivable, an electricity suppressing schedule optimizer 13 optimizing, for a time with a possibility that the incentive is receivable, the operating schedule of the control-target device 2 based on a unit price of electricity fee having a unit price for calculating the incentive taken into consideration, and an adopted schedule selector 14 selecting either one of the operating schedules.

Owner:KK TOSHIBA

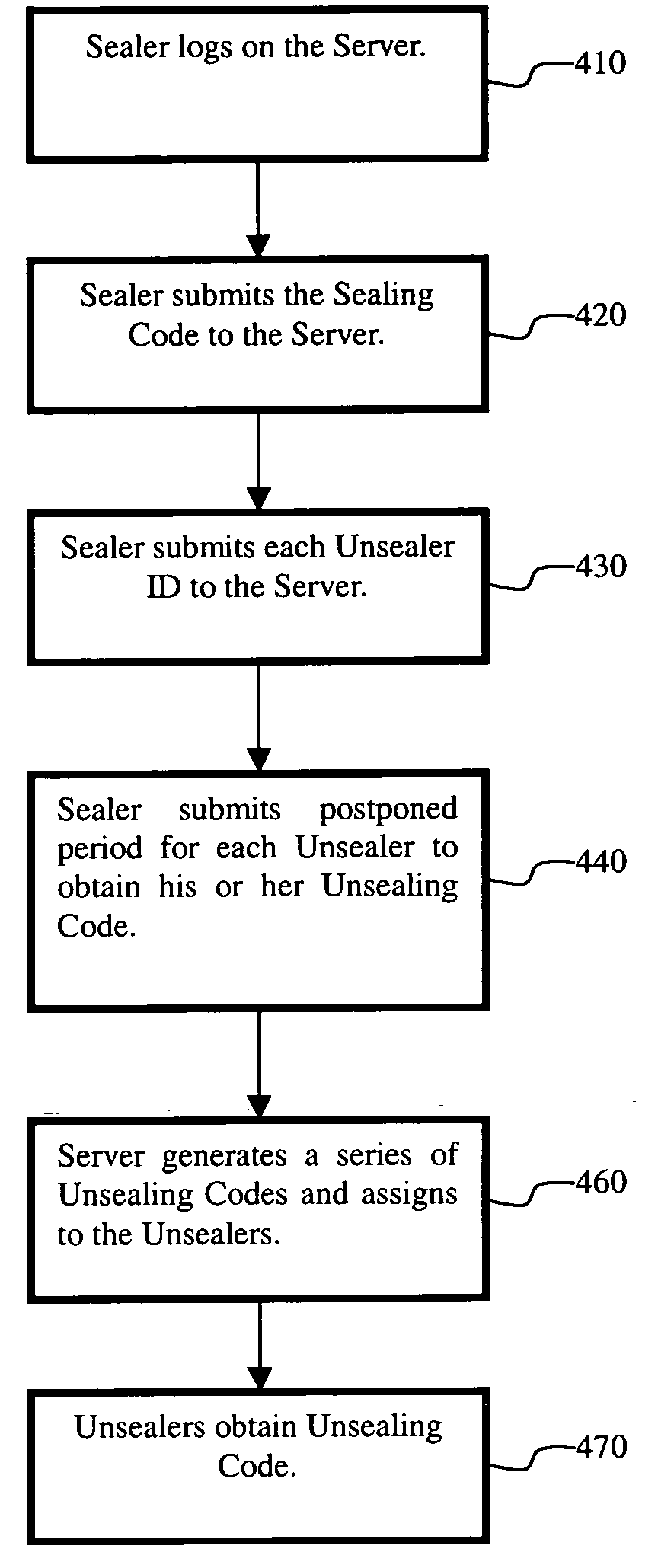

Cargo theft prevention method and system

InactiveUS20050219037A1StampsKey distribution for secure communicationComputer hardwareCommunications system

Owner:HUANG TAO

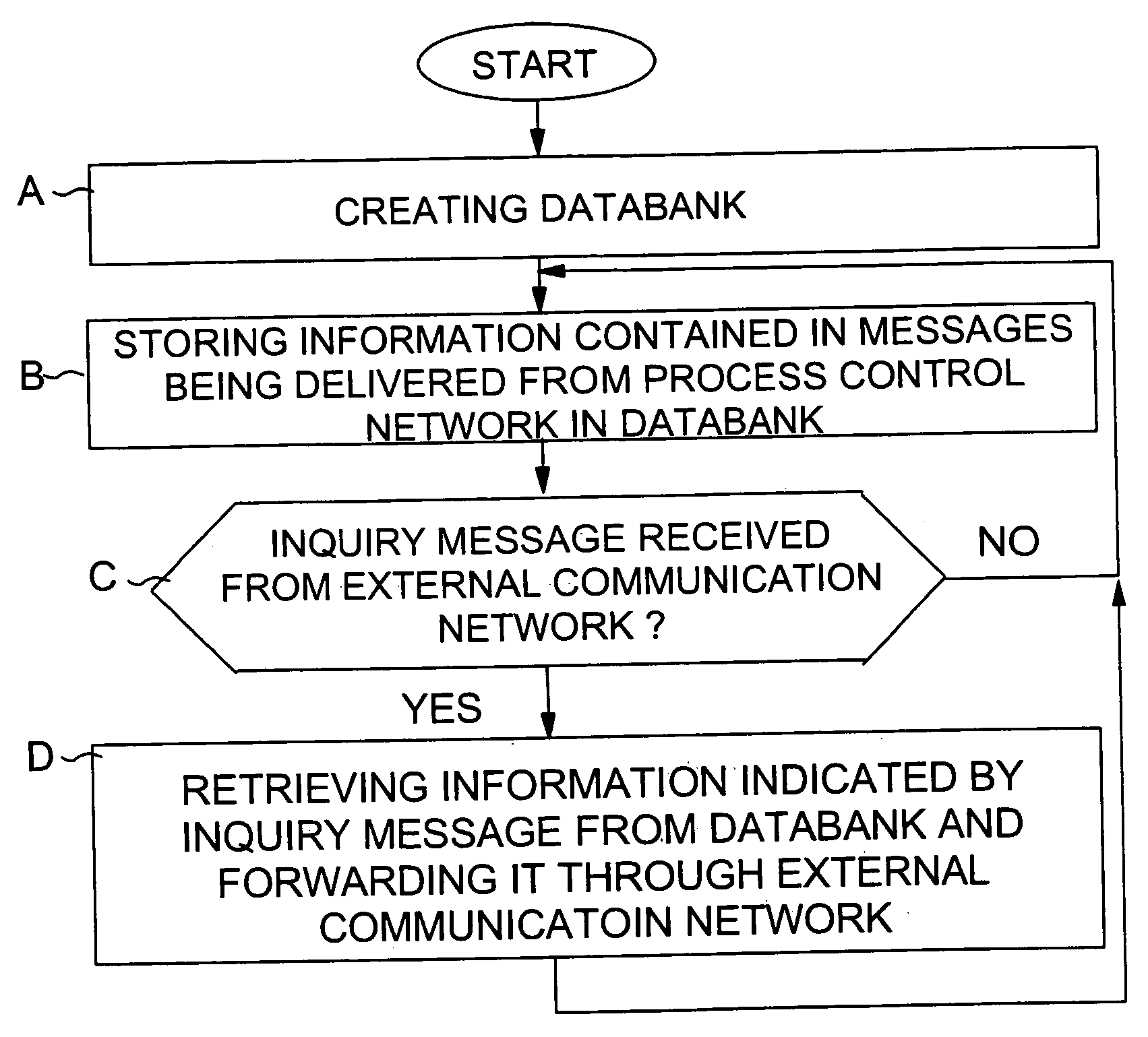

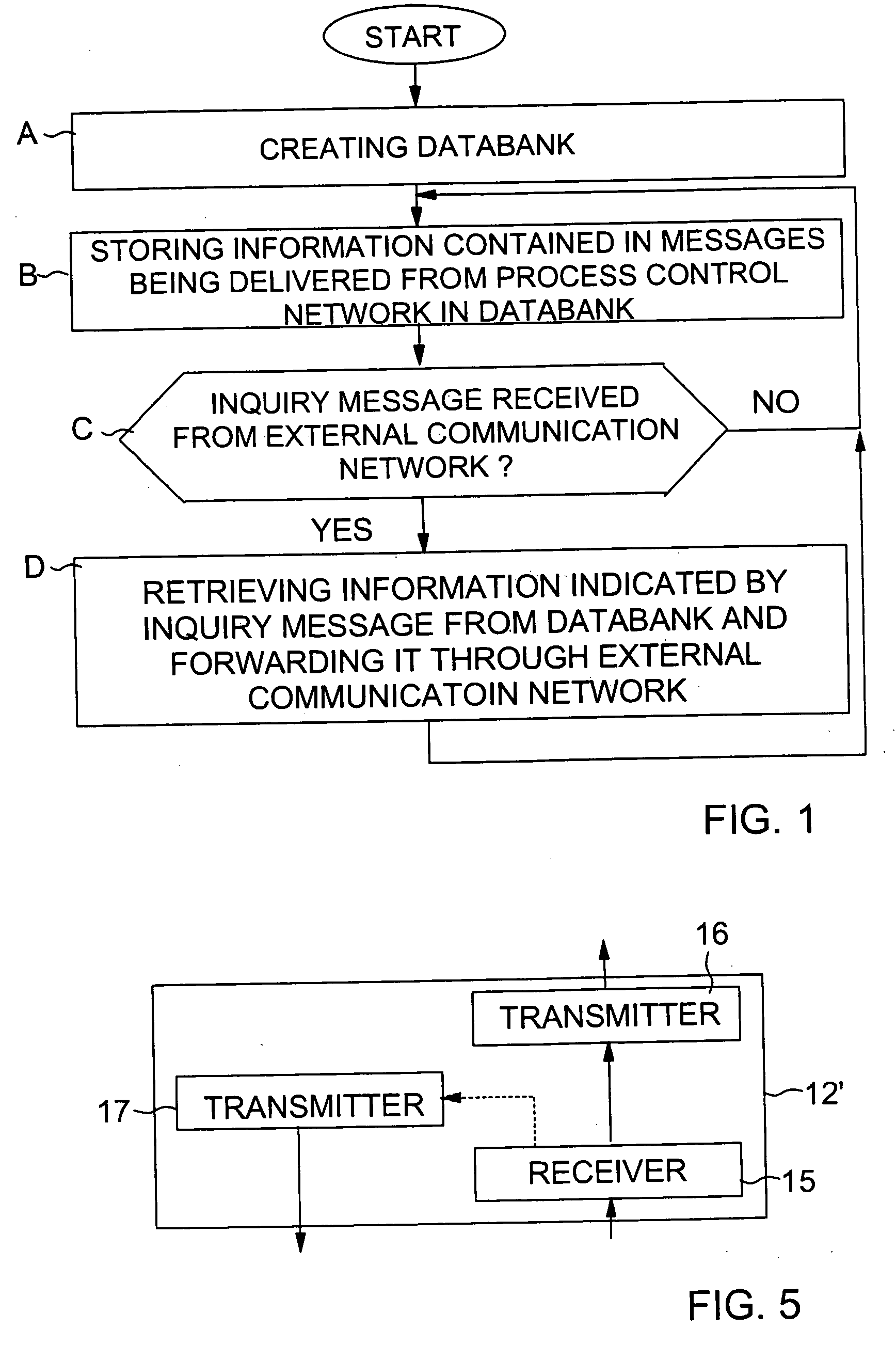

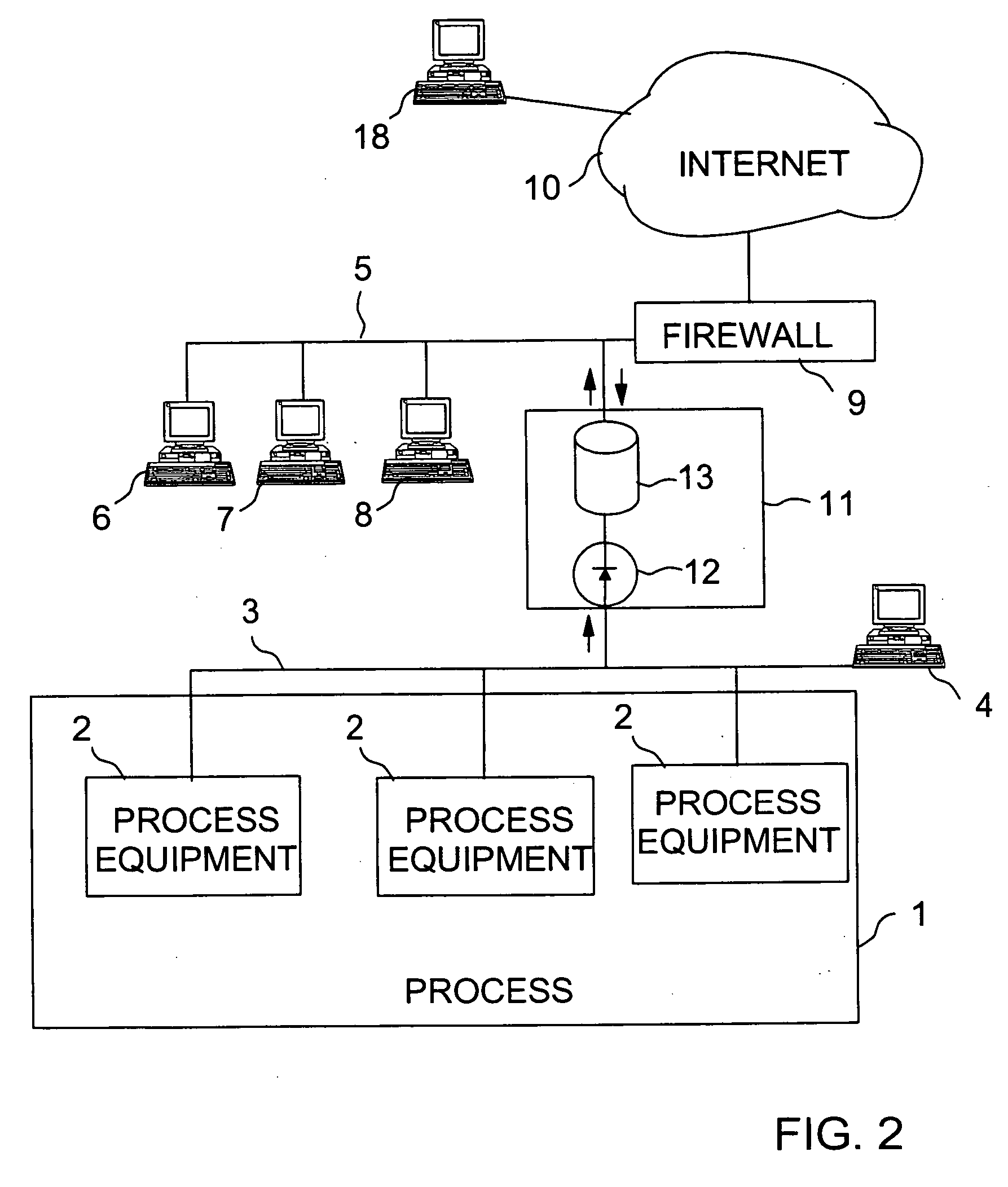

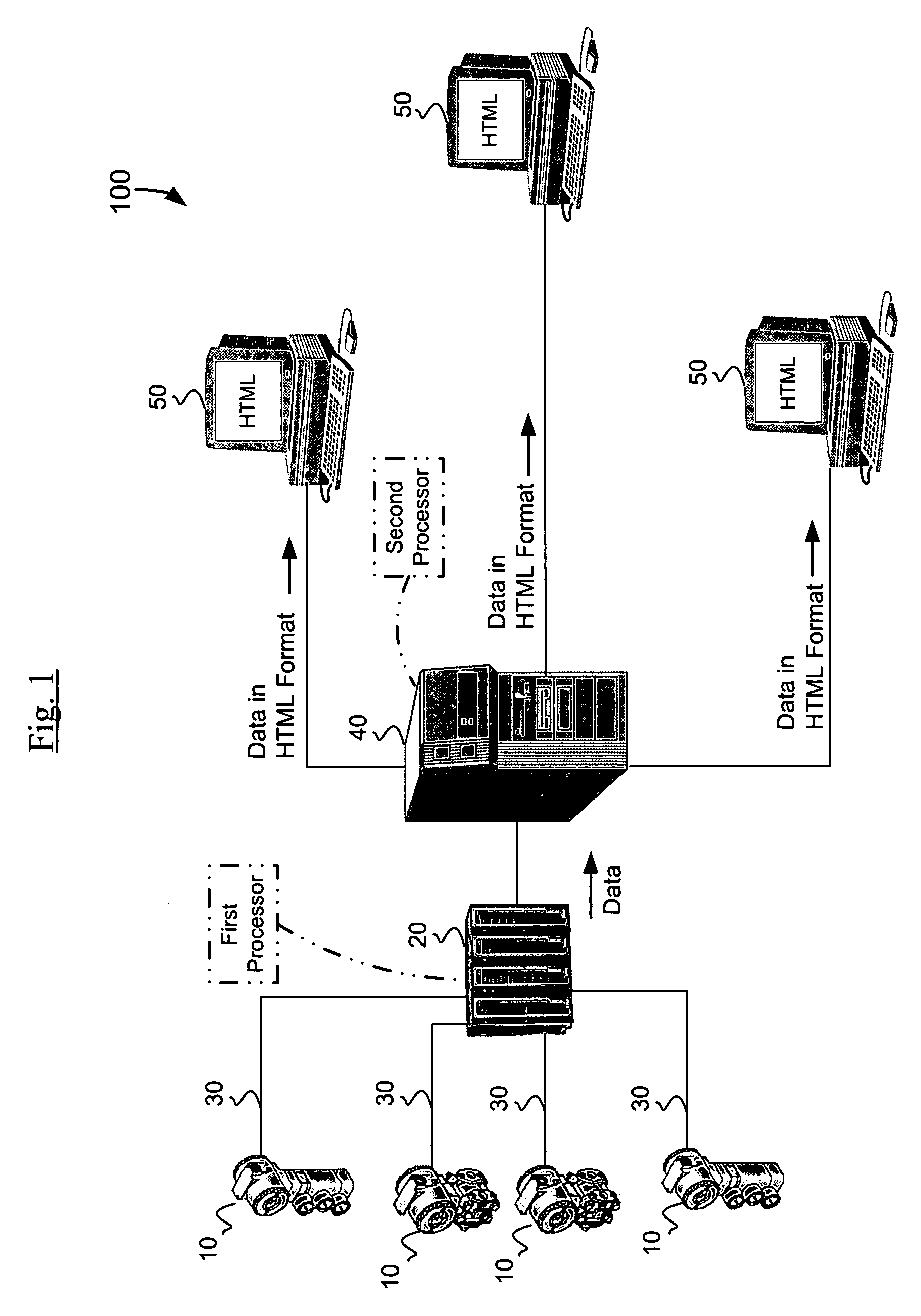

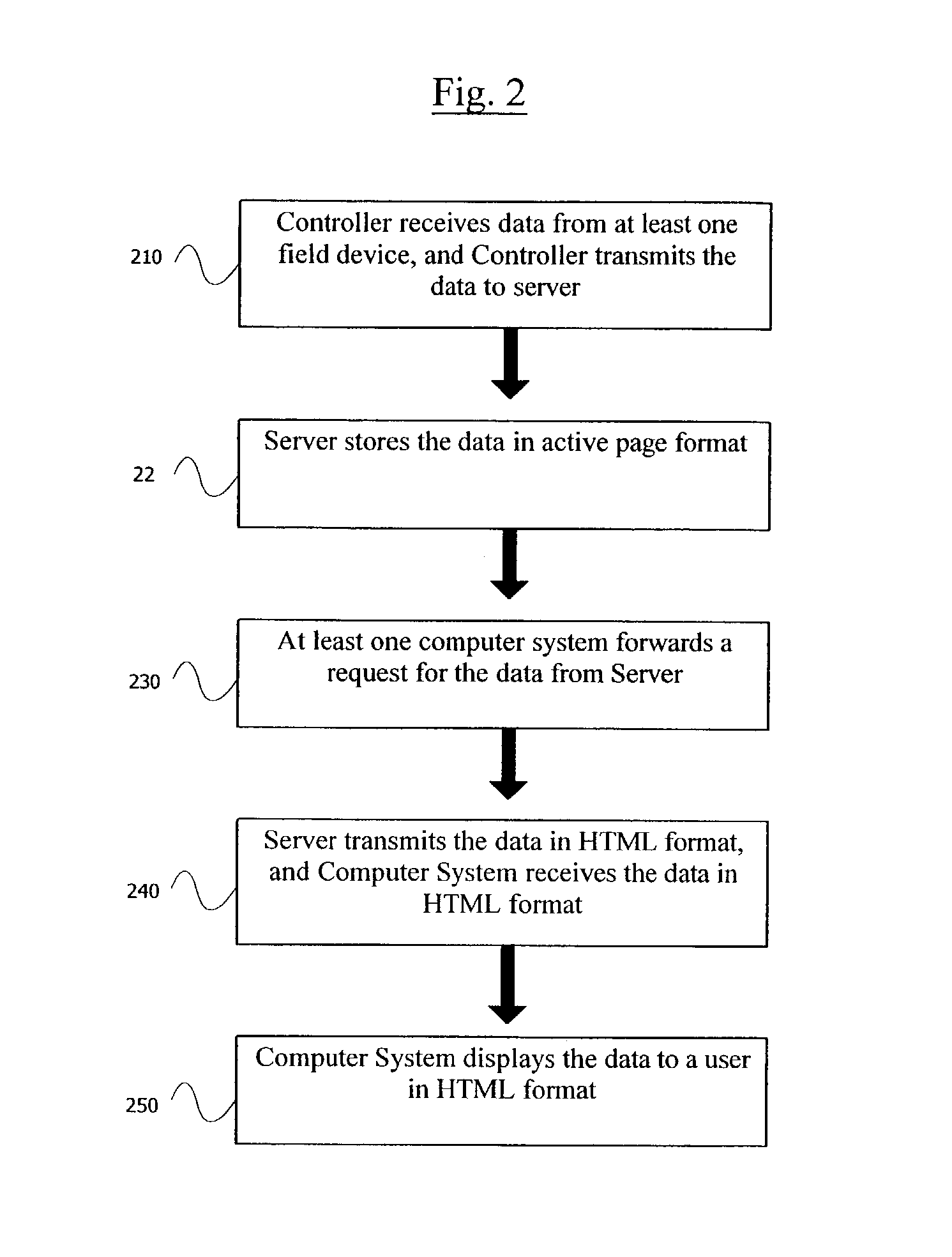

System, communication network and method for transmitting information

InactiveUS20050165939A1Control safetyProgramme controlComputer controlProcess control networkProcess equipment

Owner:METSO AUTOMATION OY

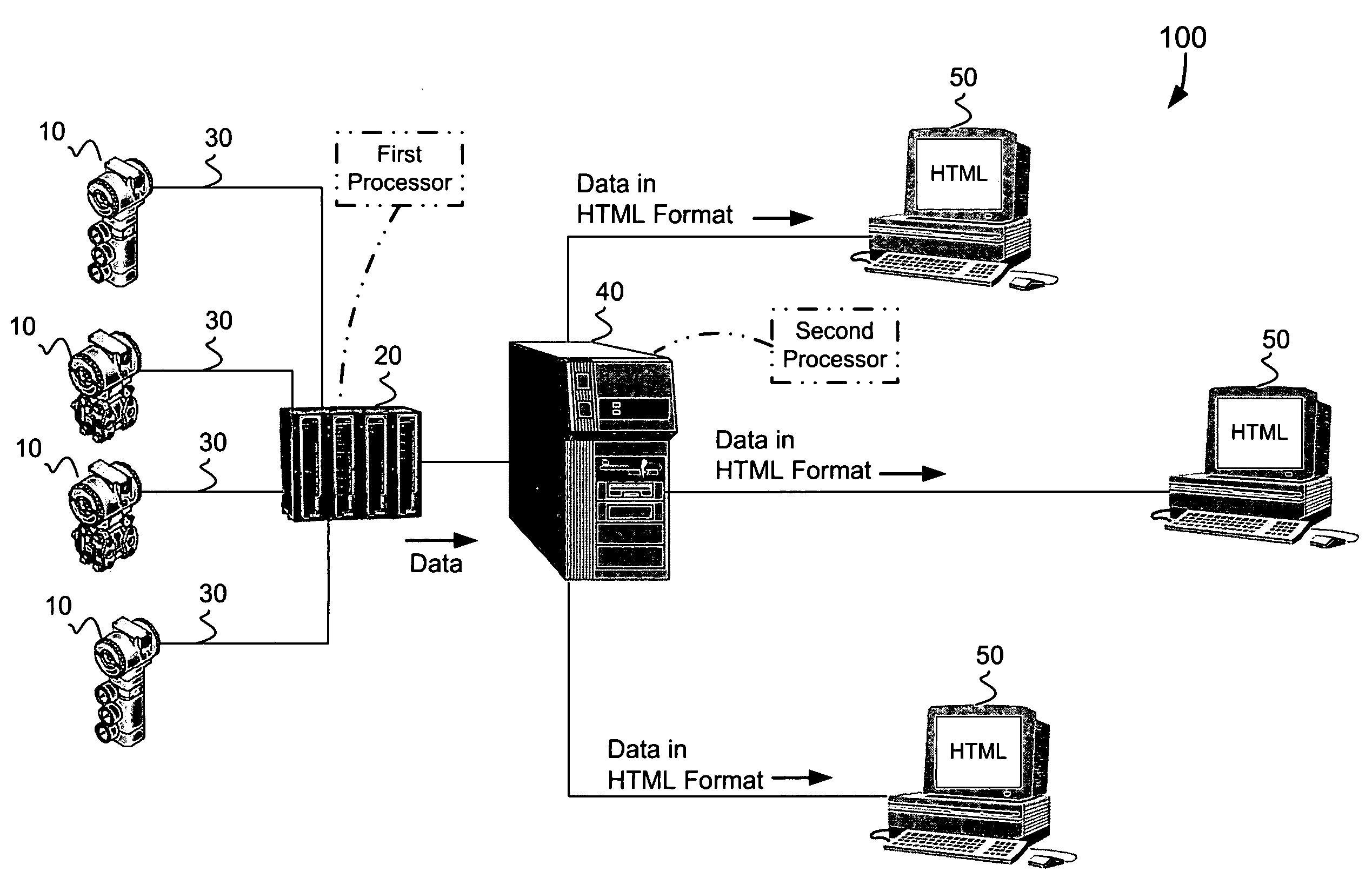

System and method for providing information in a particular format

InactiveUS7092767B2Computer controlSimulator controlNetwork Communication ProtocolsComputerized system

Owner:SMAR RES CORP

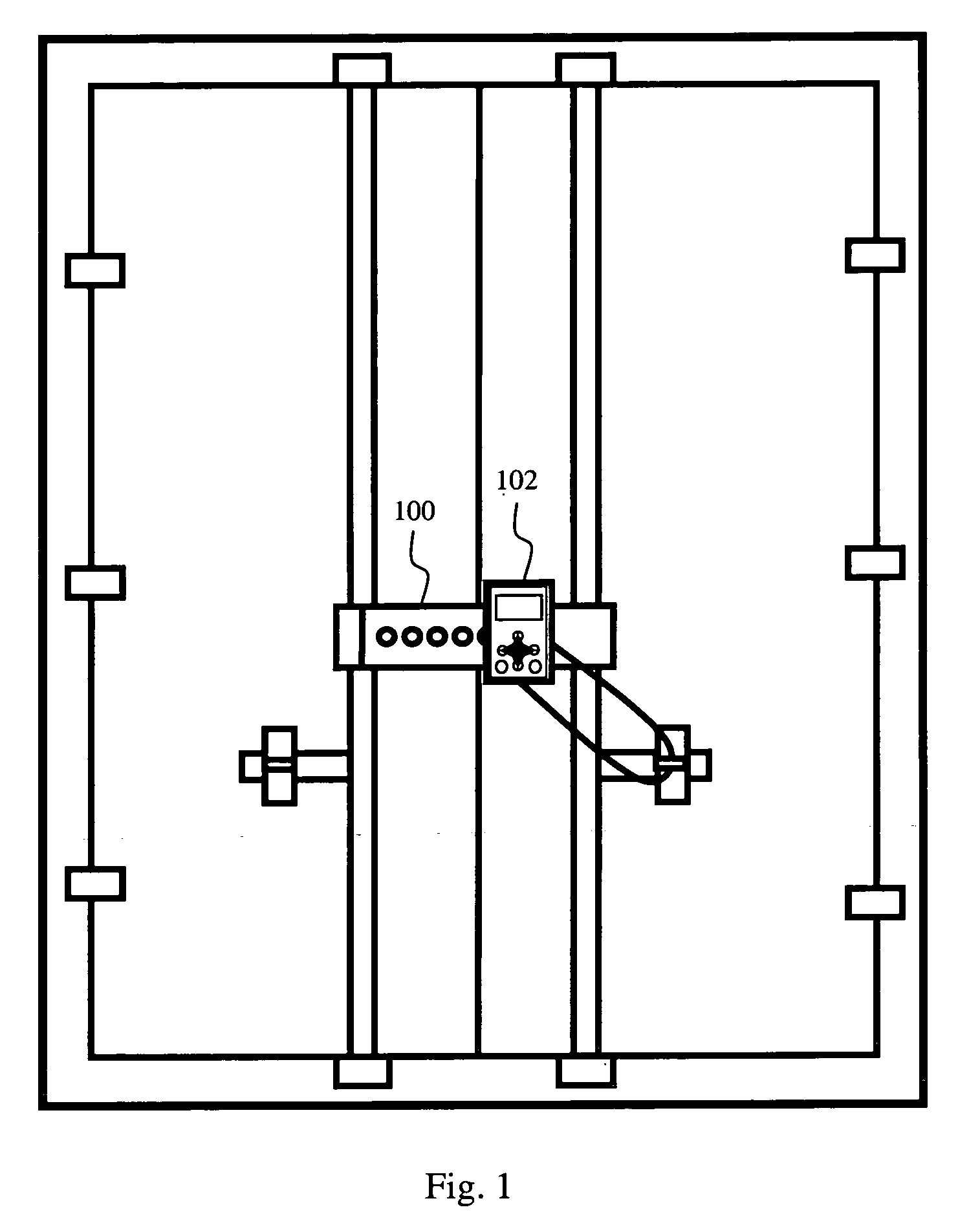

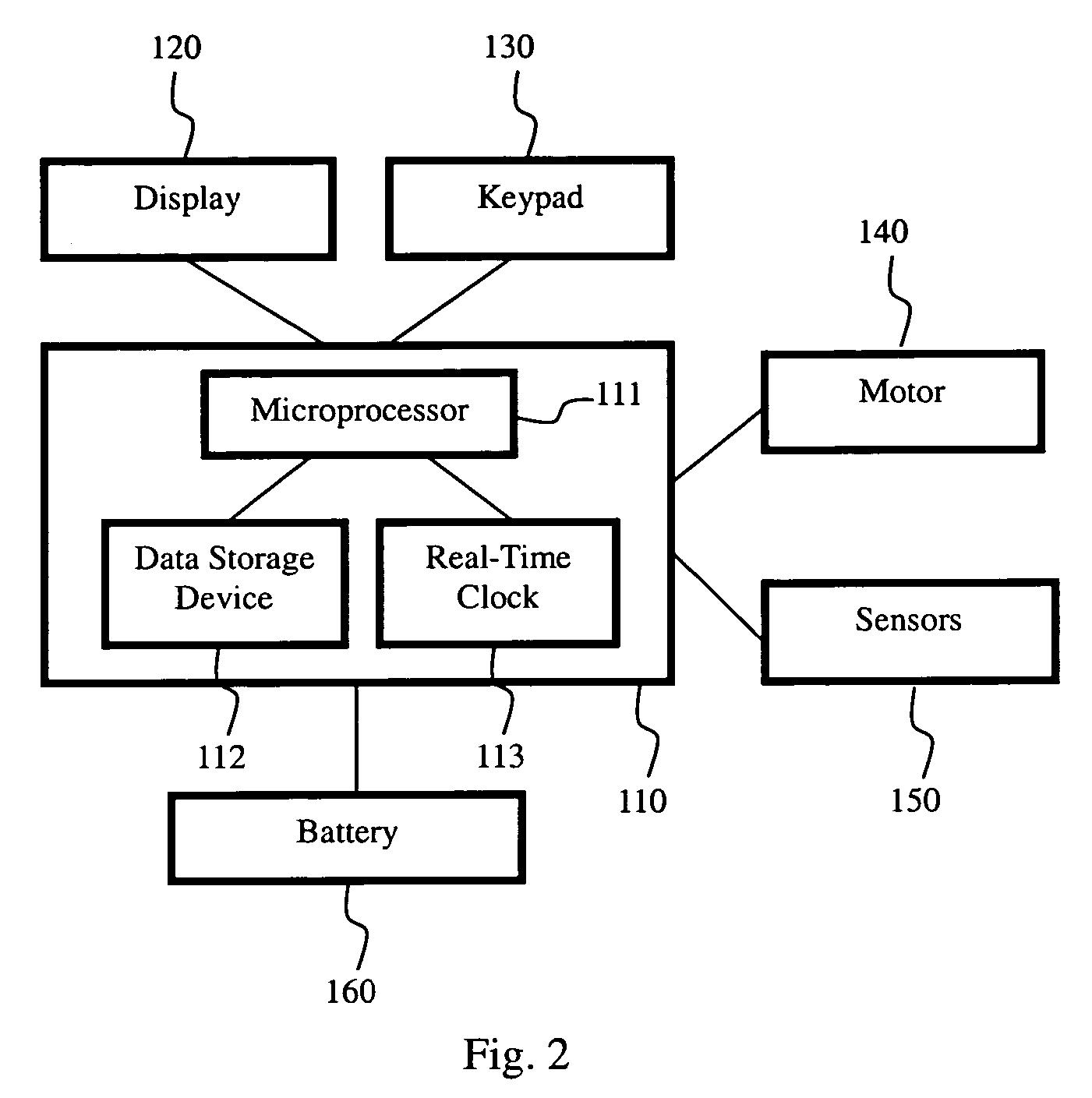

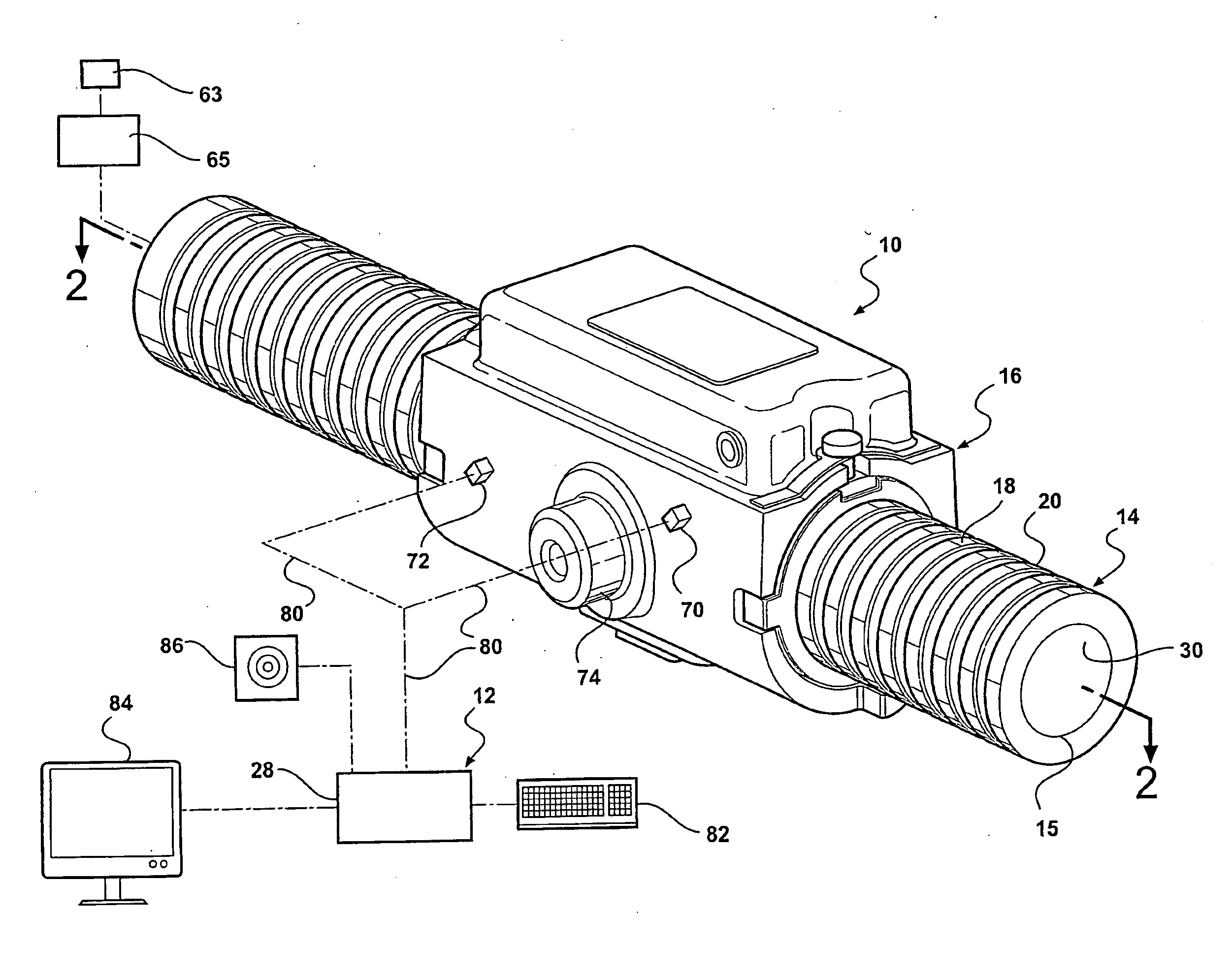

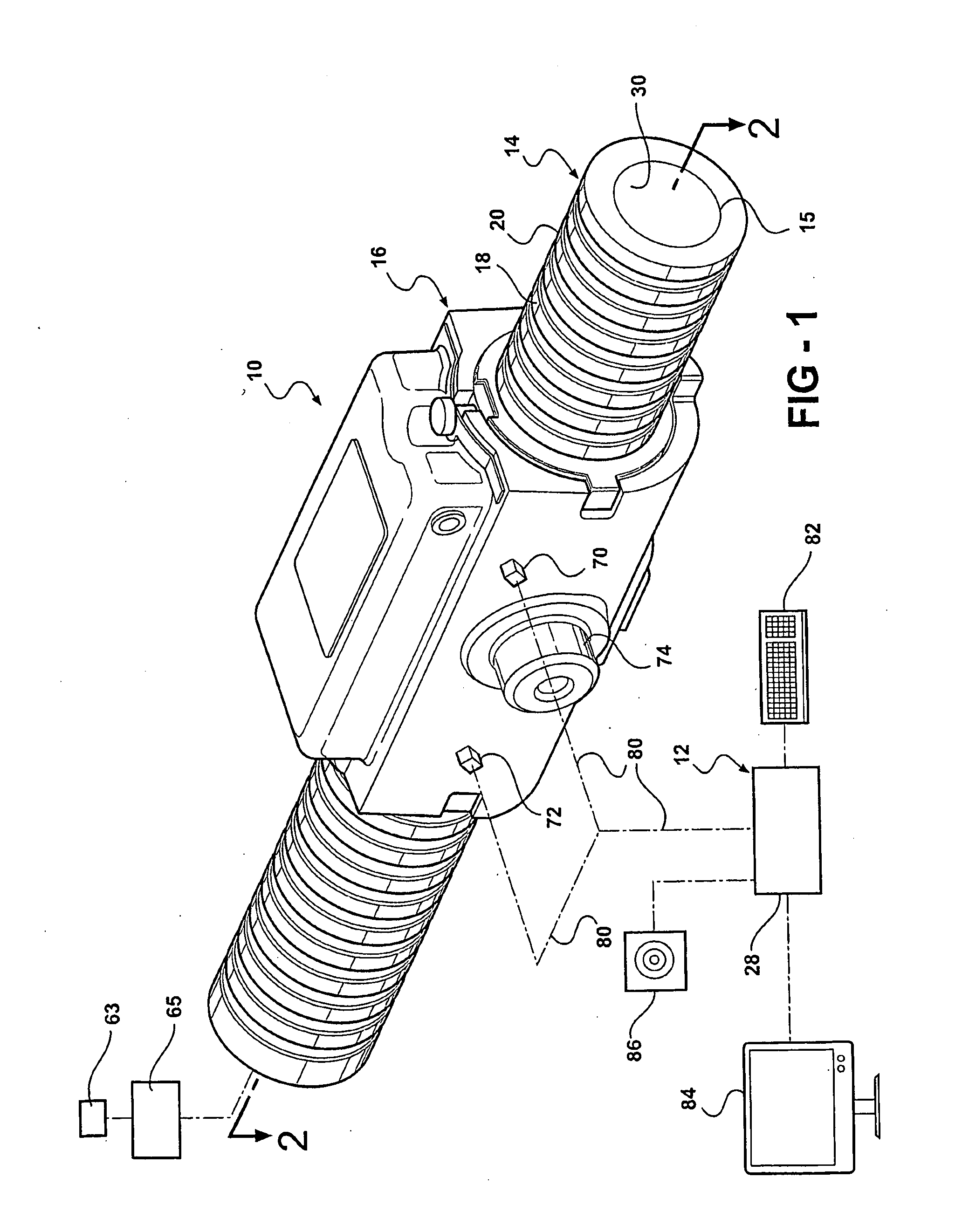

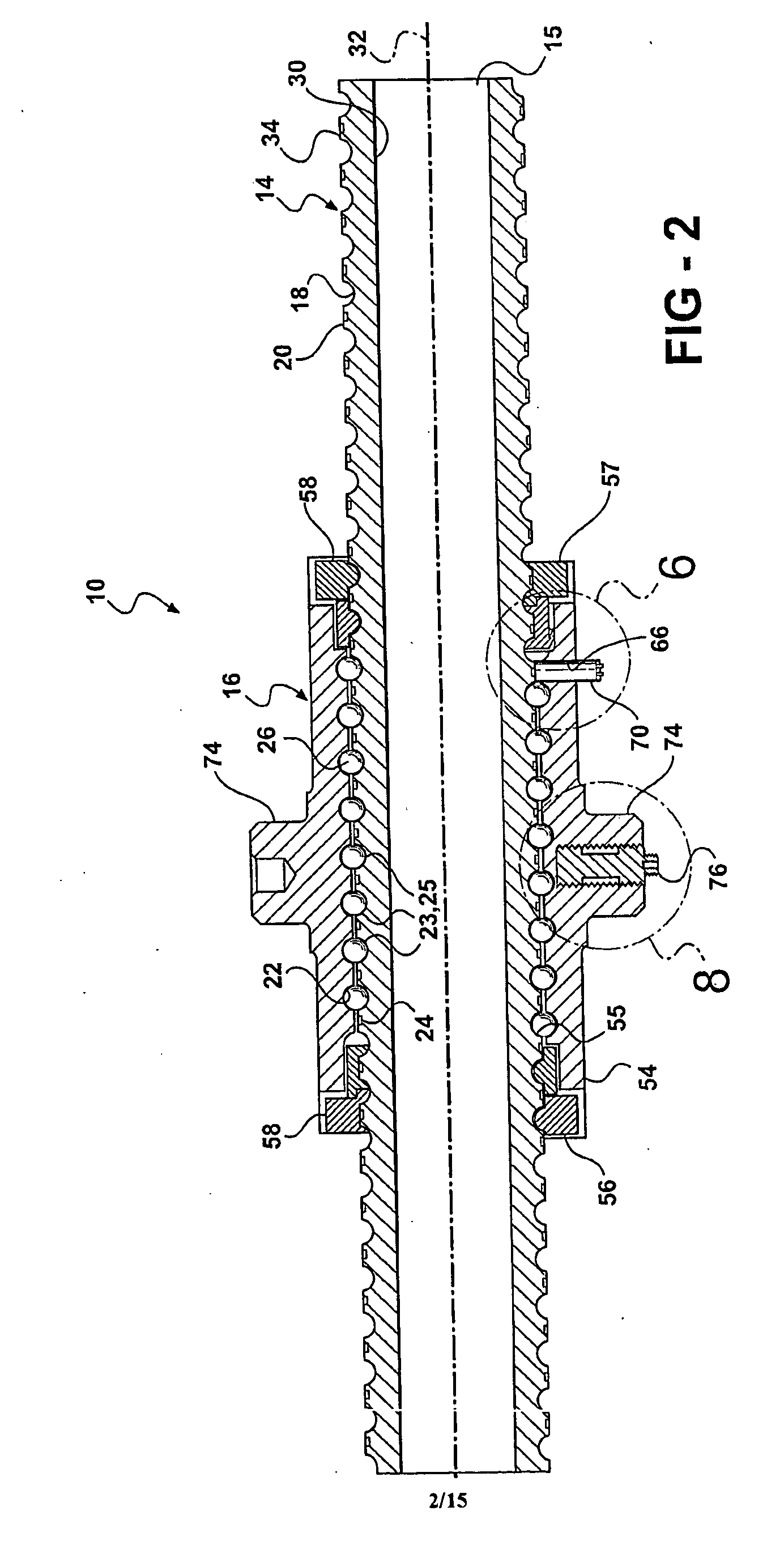

Linear Motion Assembly With Monitoring System and Method of Monitoring

Owner:LINEAR MOTION L L C

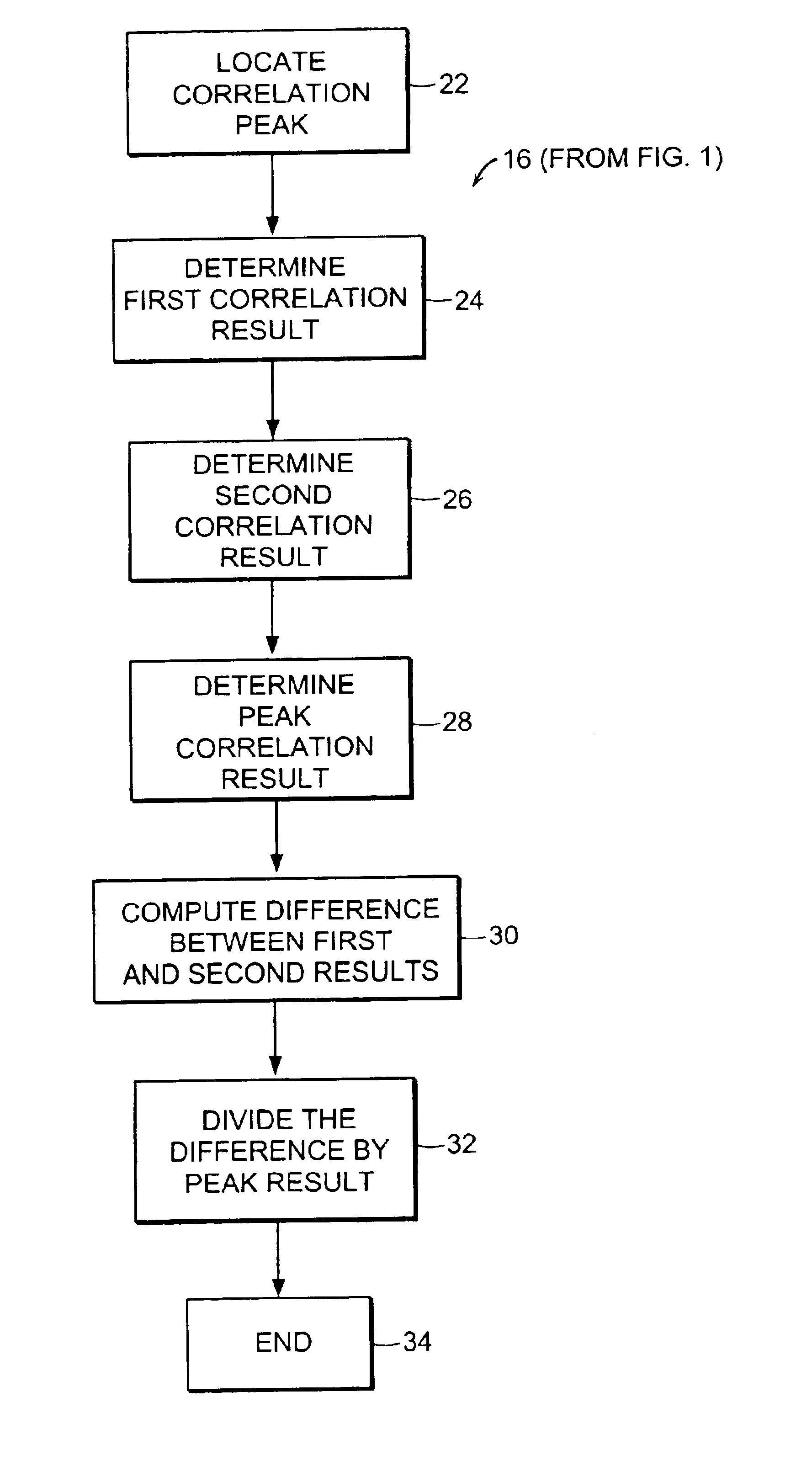

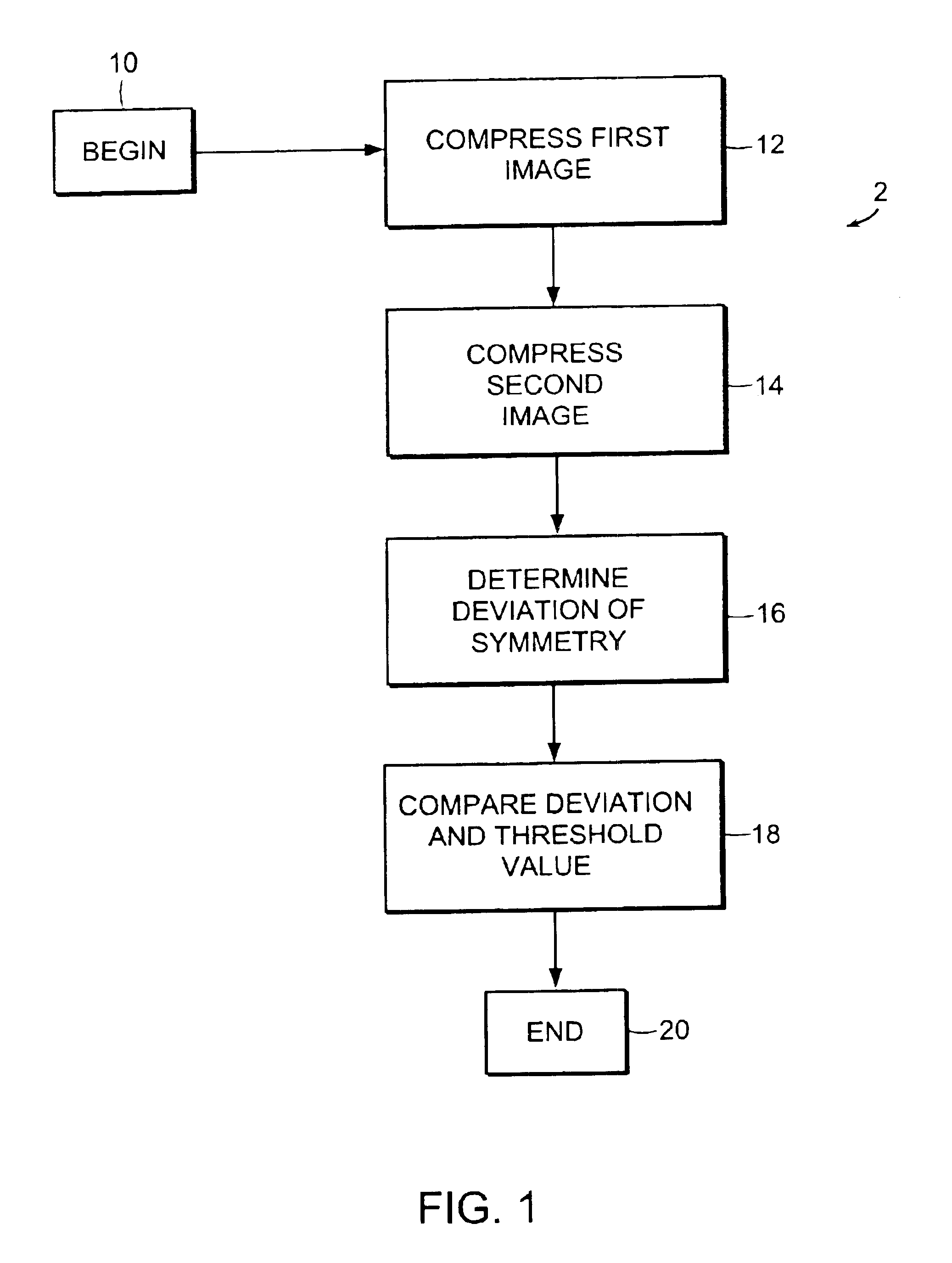

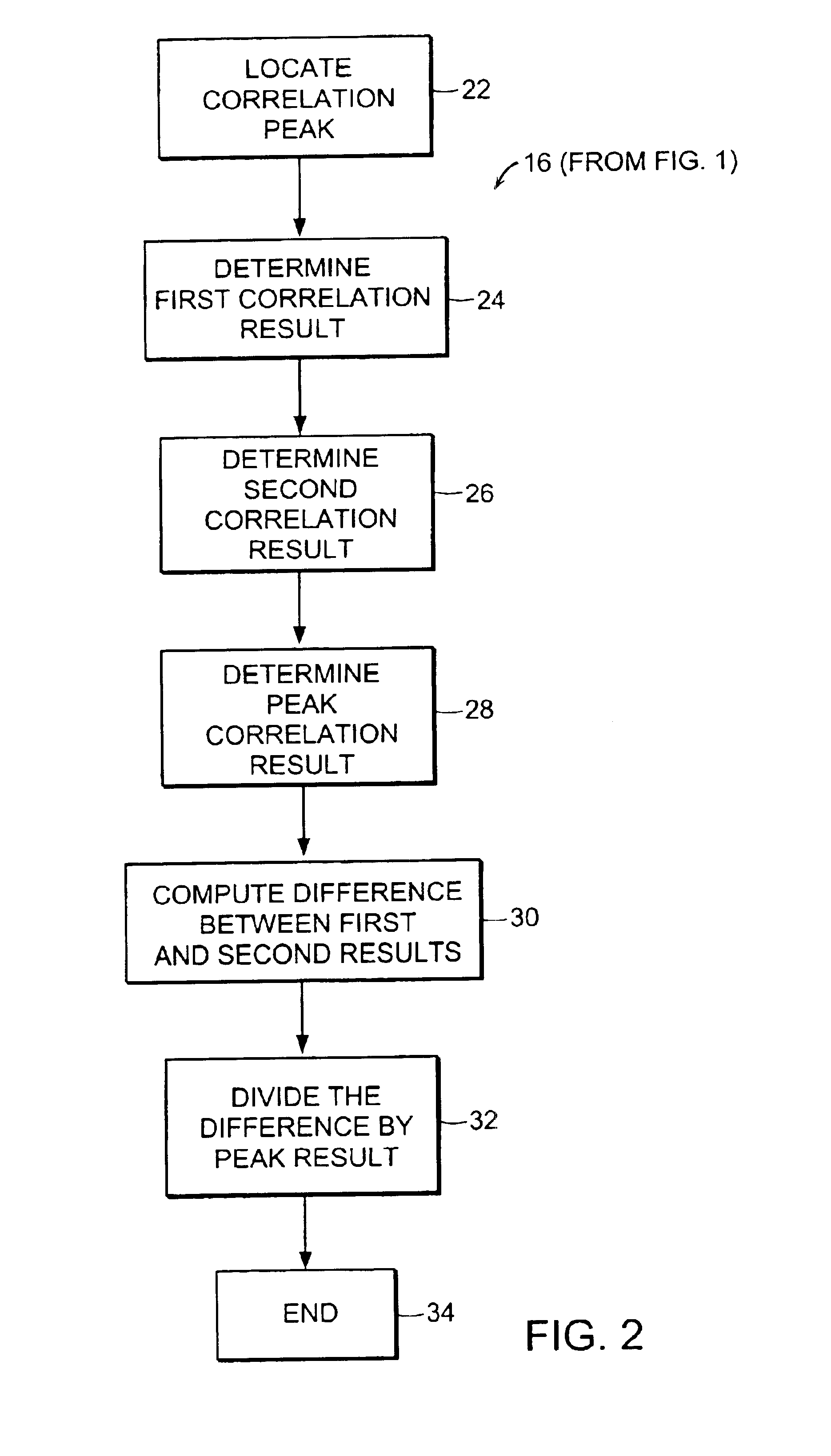

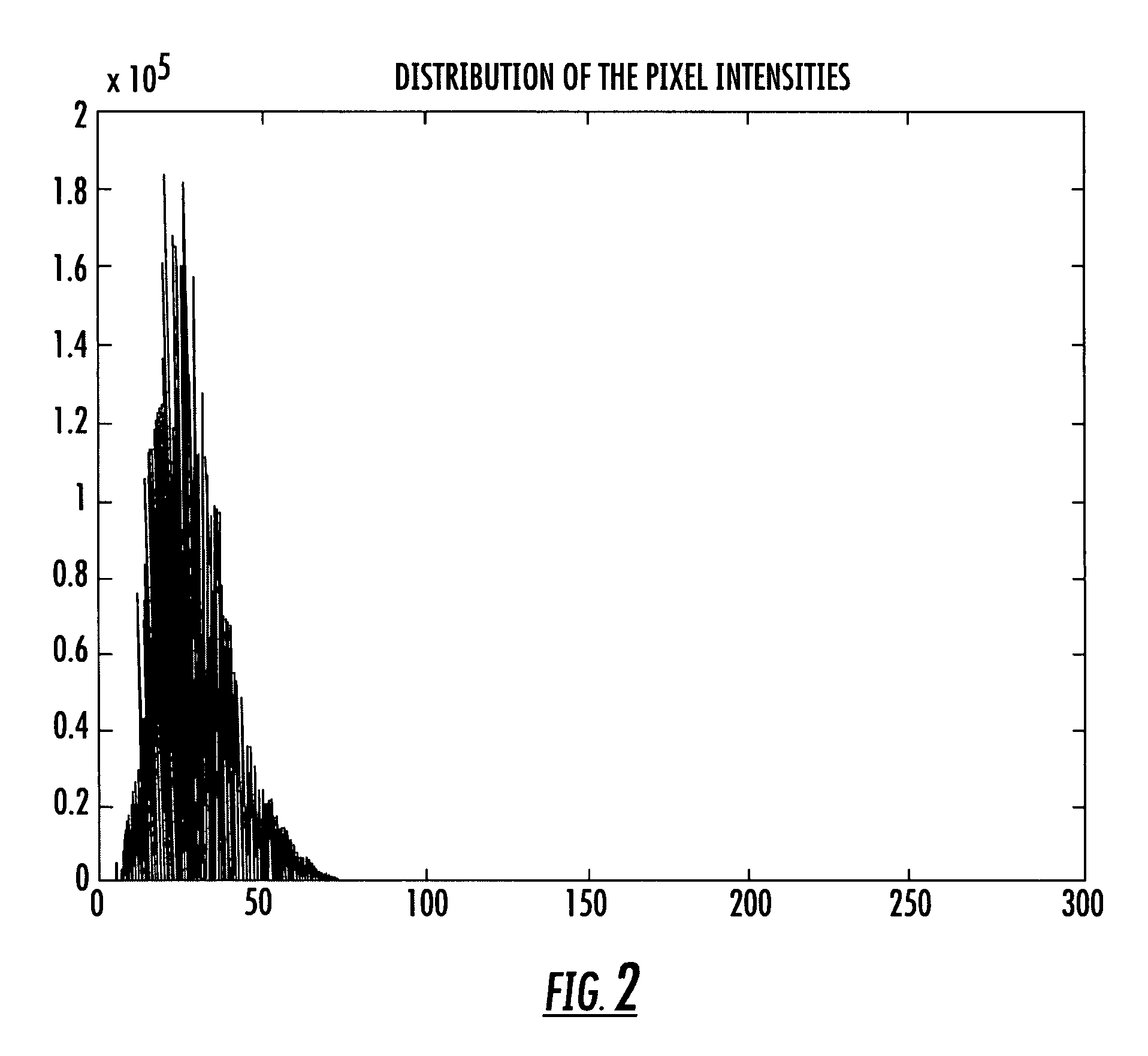

Method of correlation of images in biometric applications

InactiveUS6961449B2Reduce background noiseElectric signal transmission systemsImage analysisPattern recognitionPalm print

Owner:UNIVERSITY OF MASSACHUSETTS LOWELL

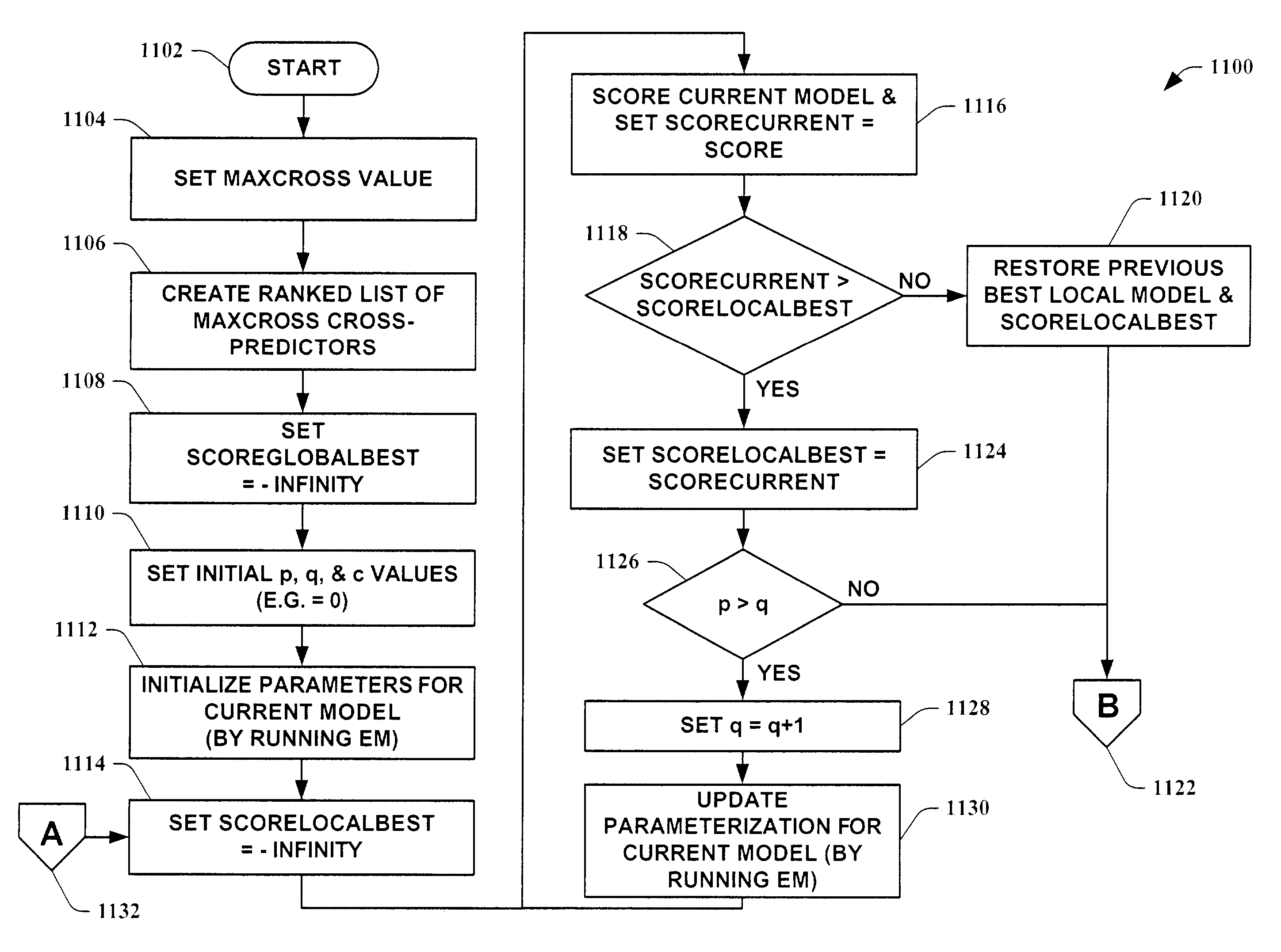

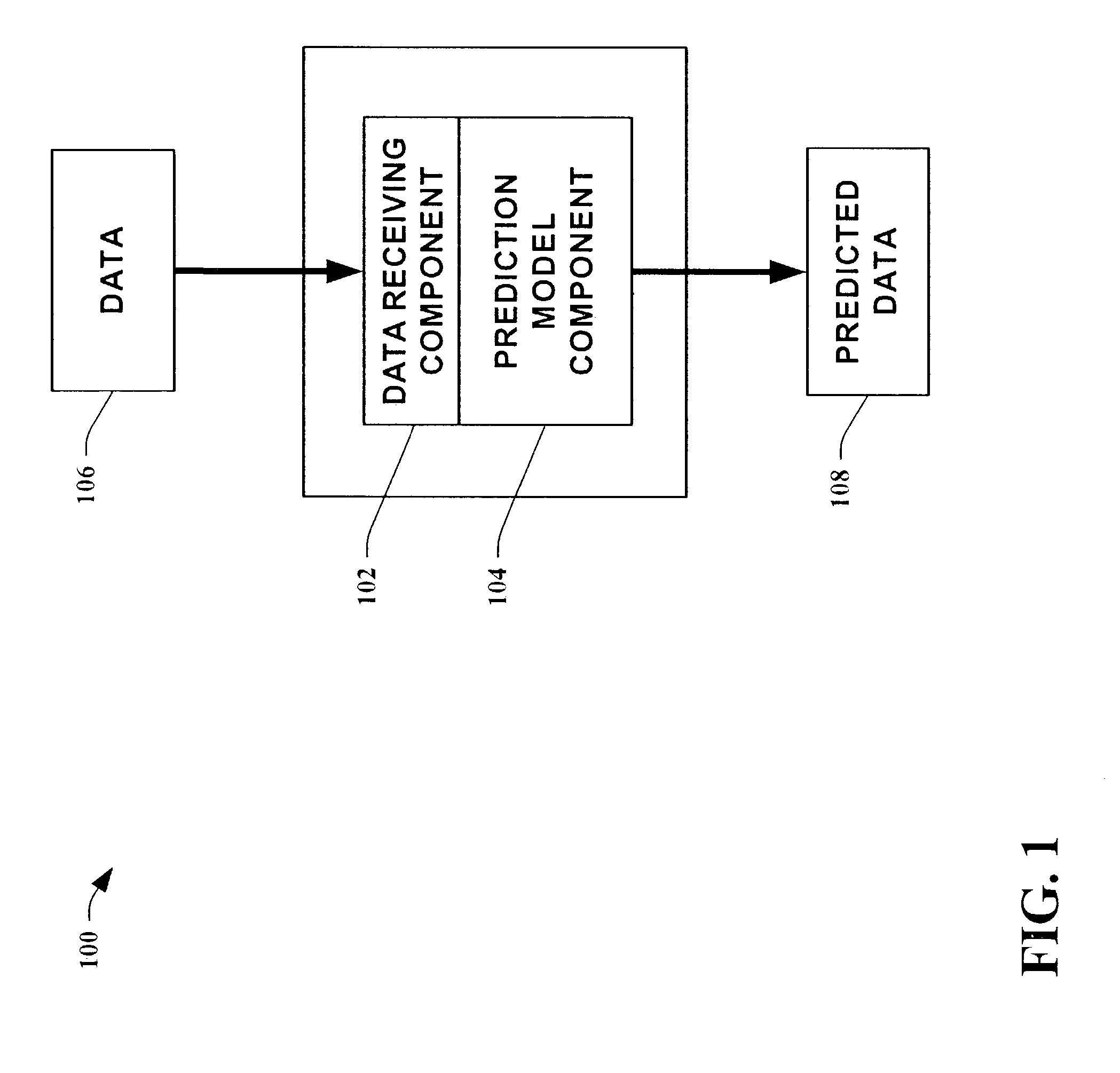

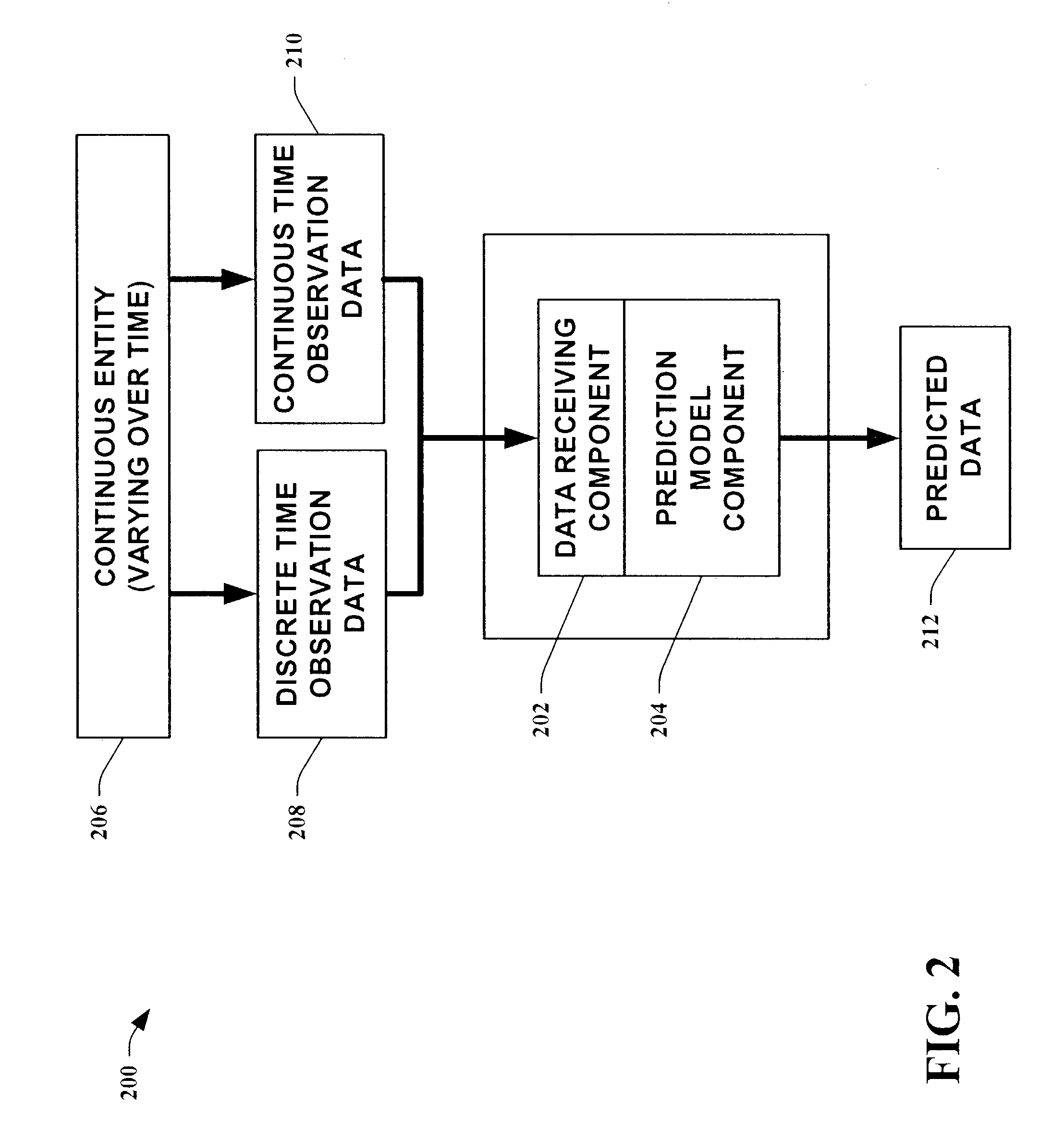

Systems and methods for new time series model probabilistic ARMA

InactiveUS7580813B2Easy to learnComputer controlElectric testing/monitoringObservation dataDecision graph

Owner:MICROSOFT TECH LICENSING LLC

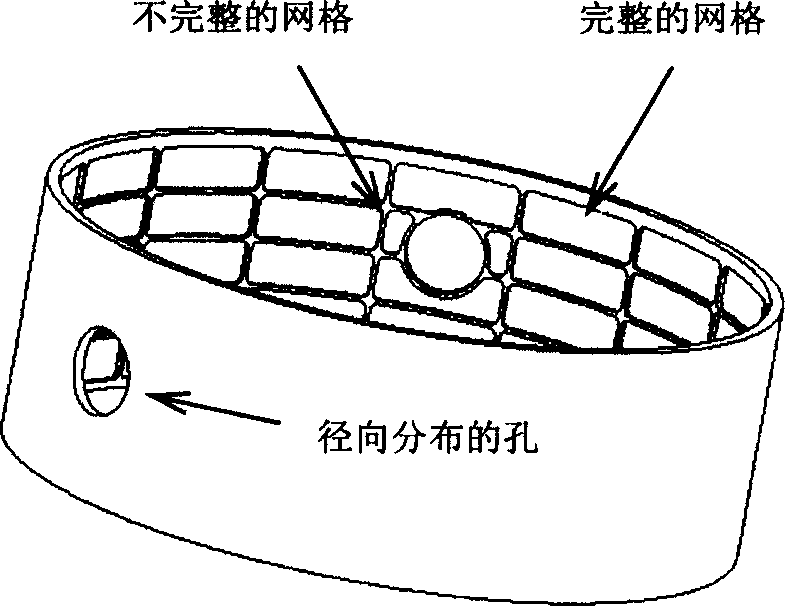

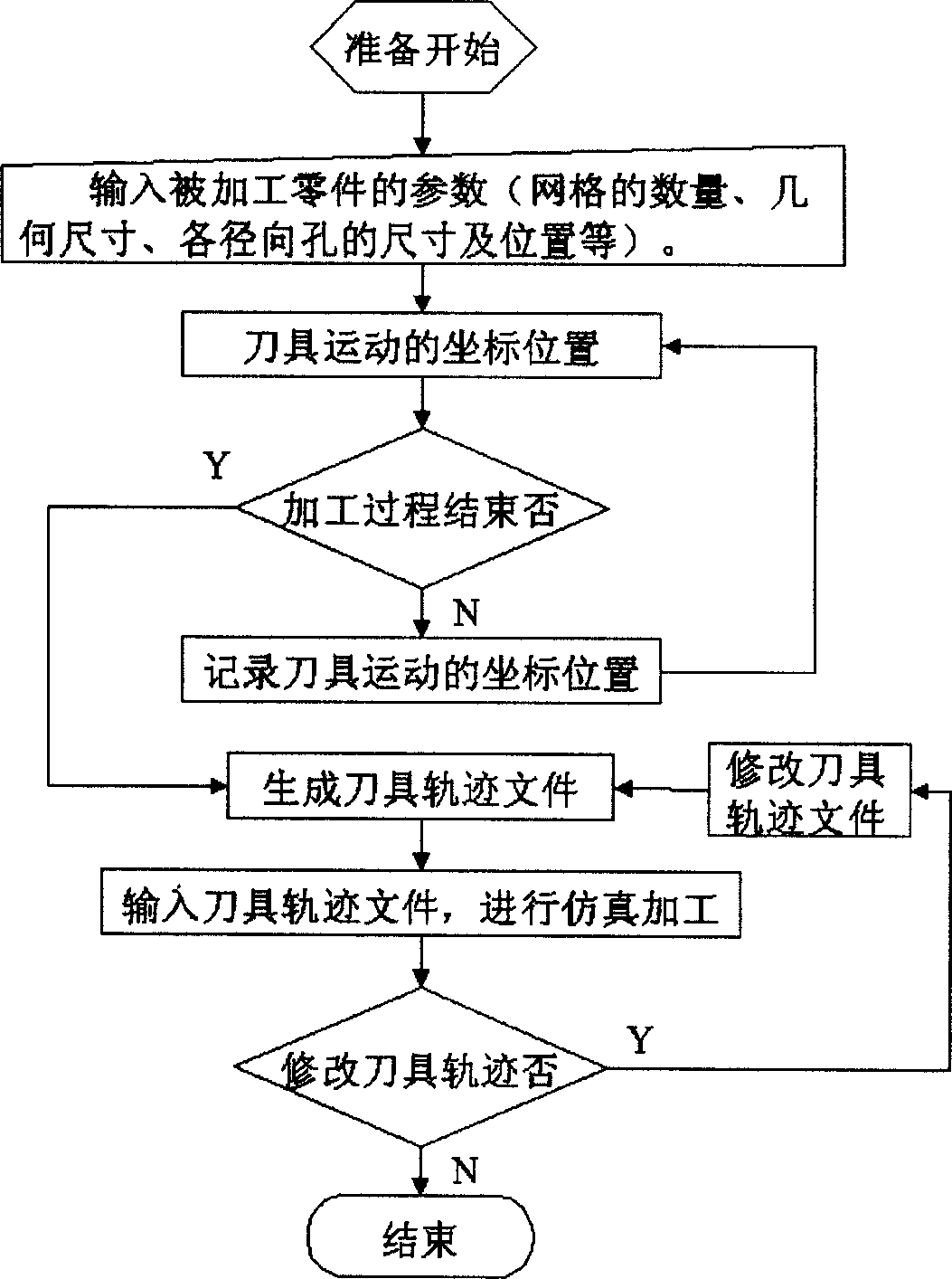

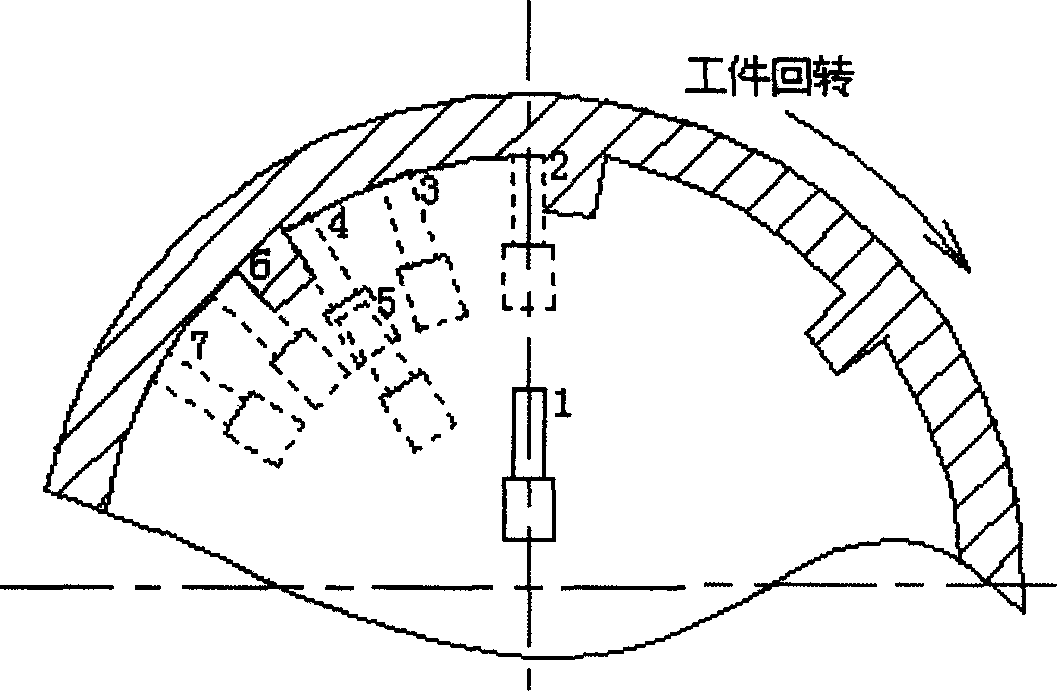

Fast automatic processing method utilized in lathe and milling machine for large thin wall part with cylindrical grids

InactiveCN1562542AMeet the technical requirements of high-speed turning and millingSimple processing technologyProgramme controlComputer controlMachining processAutomatic processing

Owner:沈阳工业学院

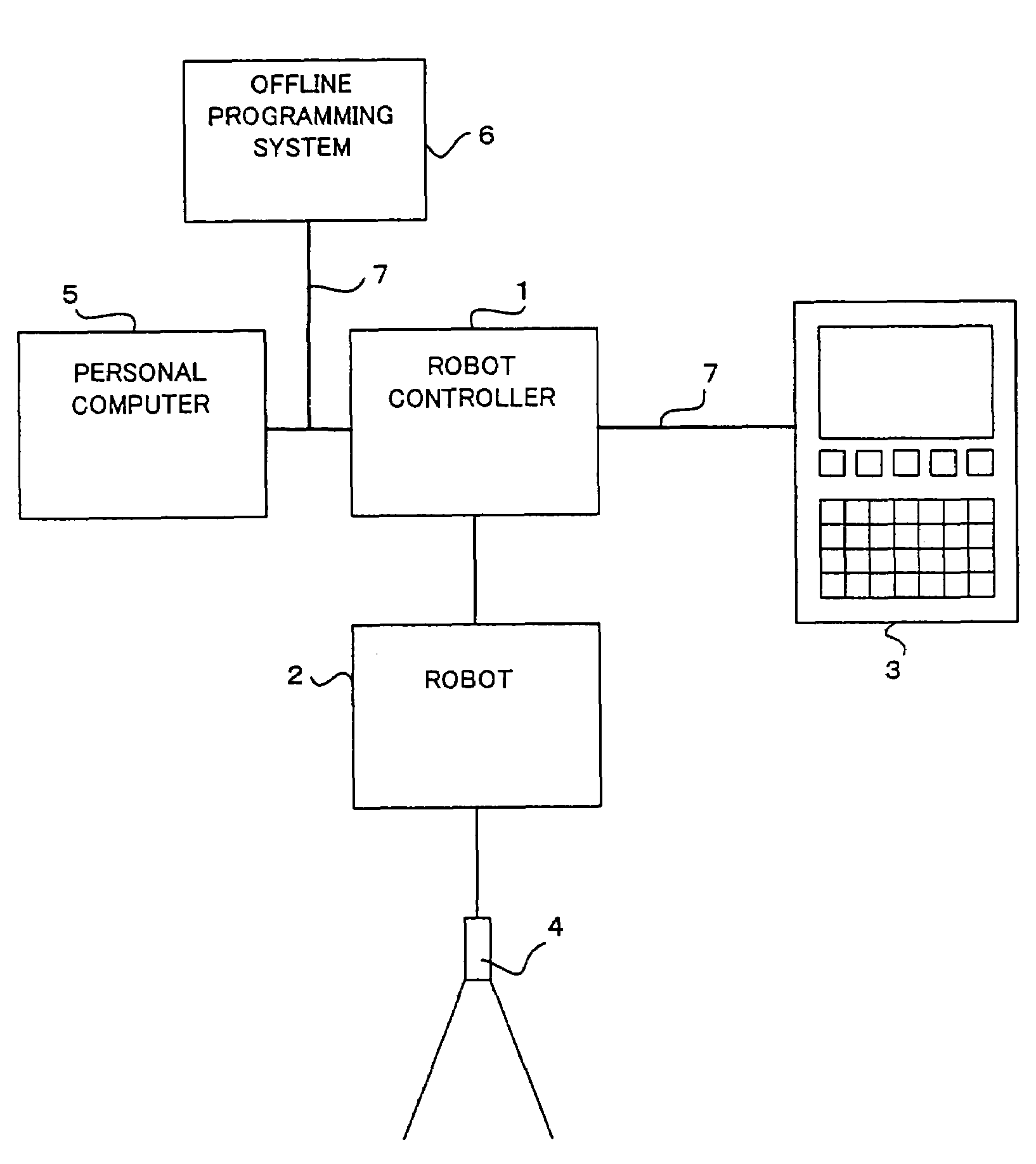

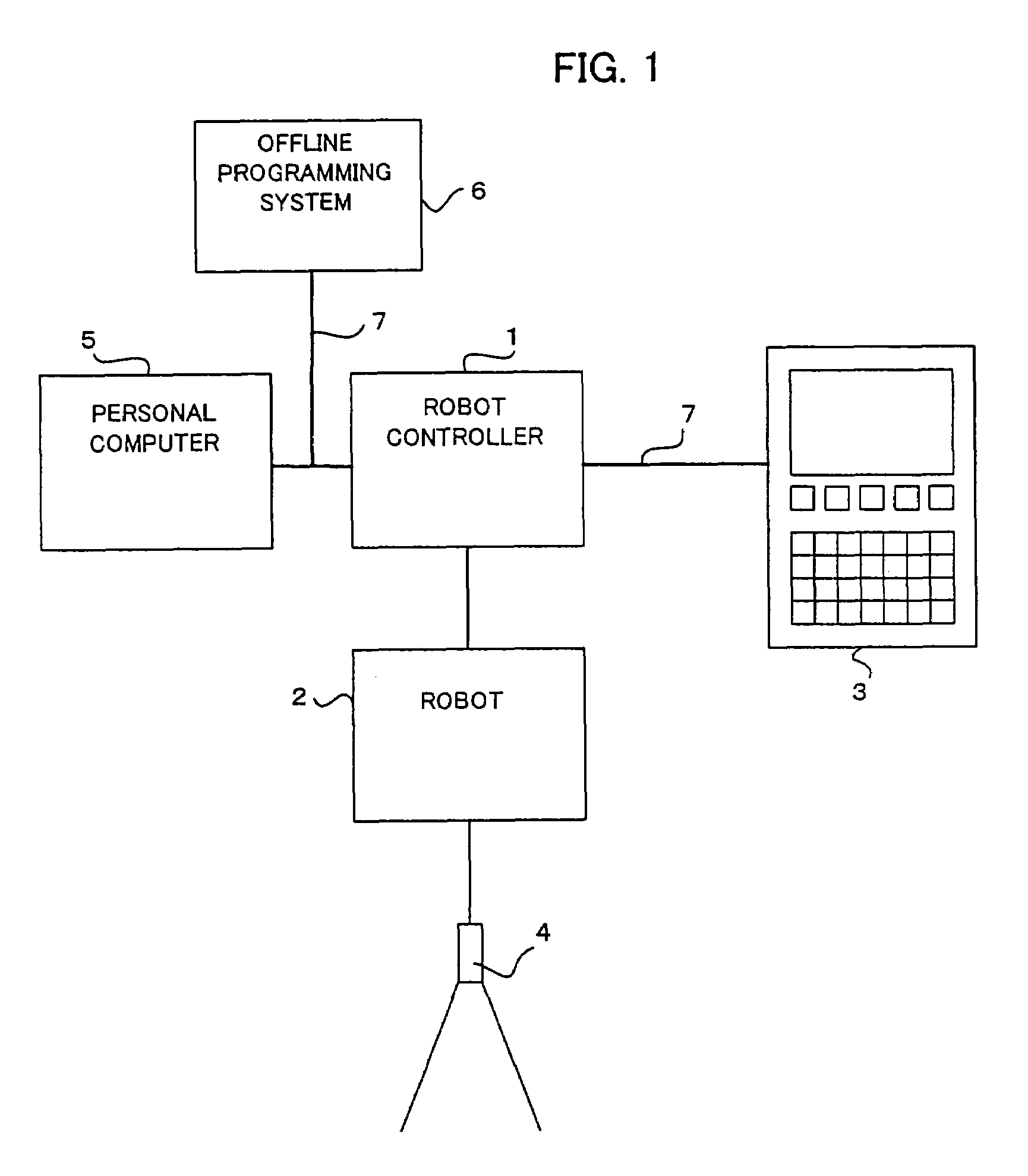

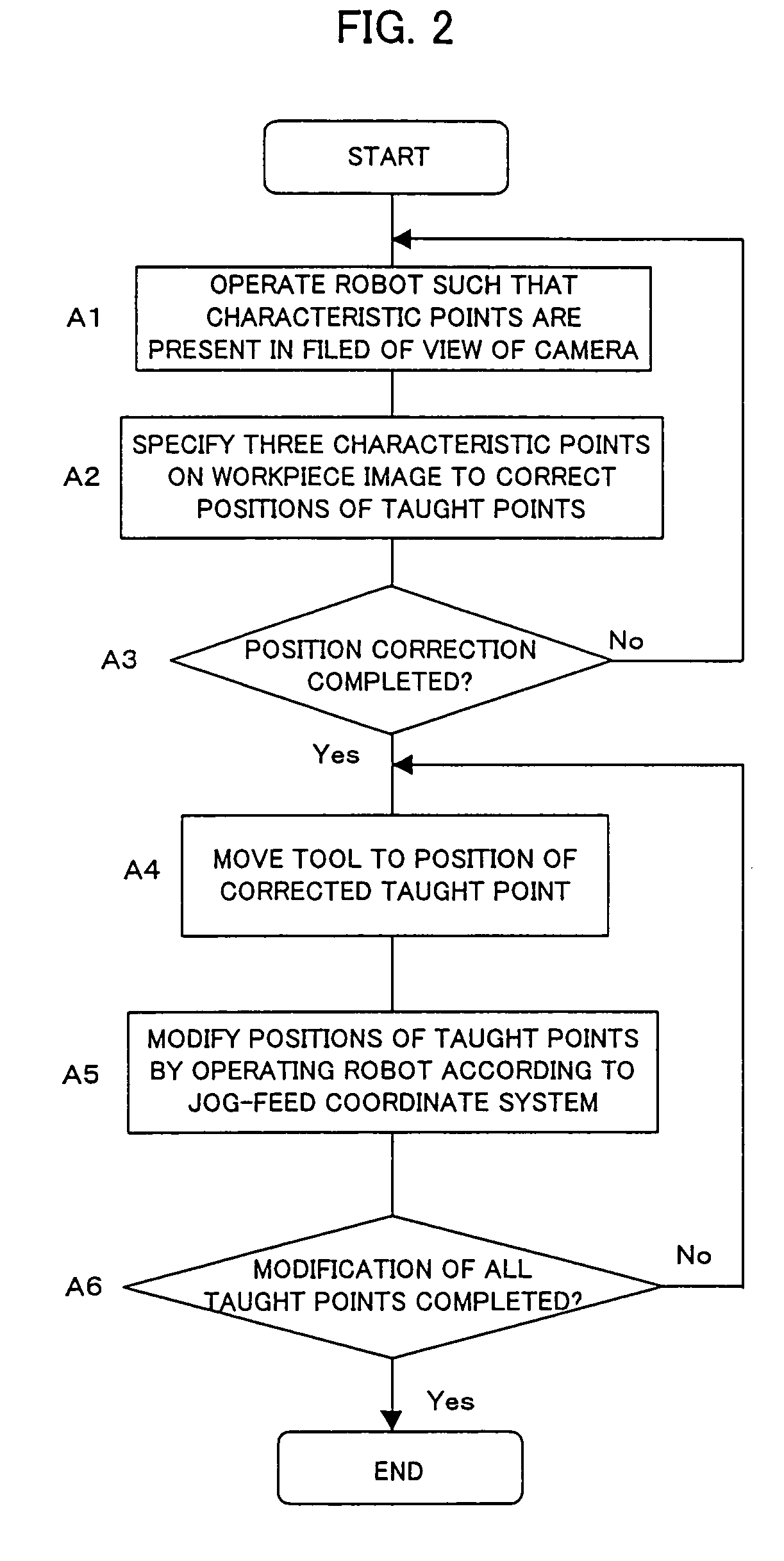

Taught position modification device

InactiveUS7376488B2Easy to modifyShort timeProgramme-controlled manipulatorComputer controlComputer graphics (images)Vision sensor

Owner:FANUC LTD

Eye guard with voice indication

InactiveUS20080082179A1Less interferenceIncrease power consumptionComputer controlElectric controllersElectricityDisplay device

An eye guard with voice indication is provided, and it includes an eye guard body, a filter, a display device and a voice output device. The display device is mounted inside the eye guard body to display a circumstance value or operating condition information. Furthermore, the voice output device is electrically connected with the display device and includes a main controller, a power supply, a sound output controller, a sensor circuit and a drive circuit. The sensor circuit has at least one sensor exposed on an external surface of the eye guard body and defined in a supposed centerline of the filter to detect the surrounding circumstance. Thus, the circumstance value and the operation condition information are noticed in the form of voice and vision simultaneously for the operators.

Owner:YANG YEA CHYI

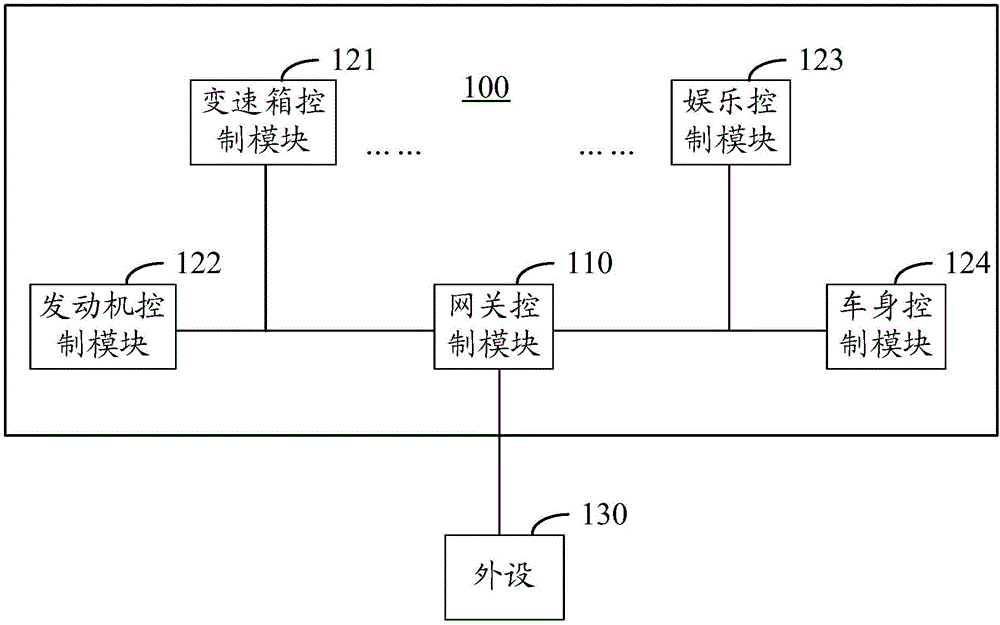

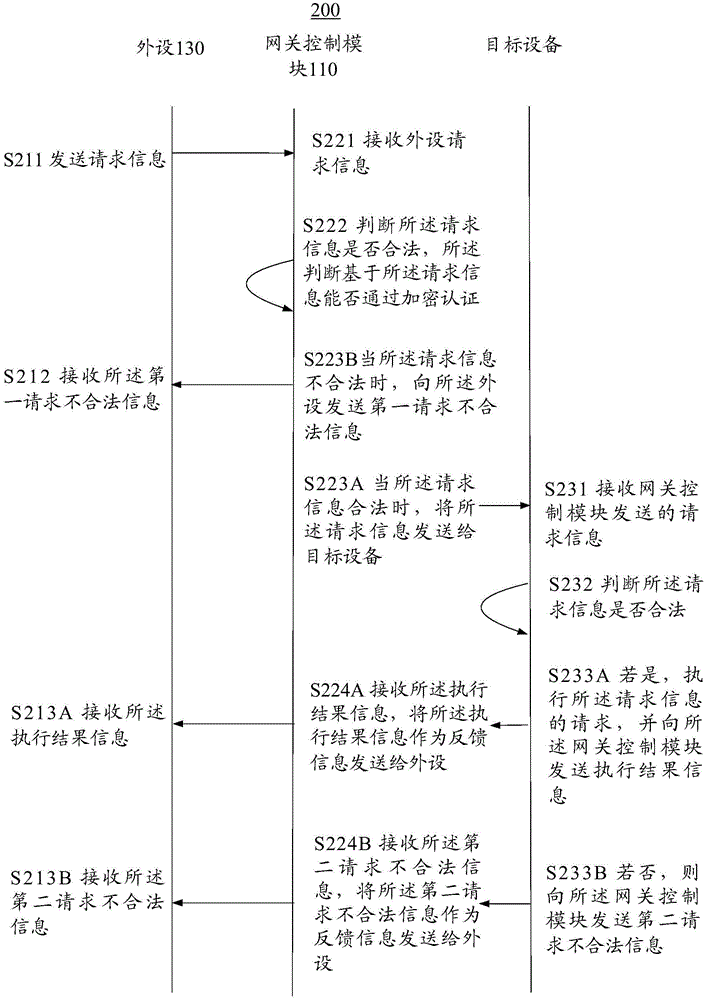

System and method for carrying out information interaction between complete vehicle network and peripheral

Owner:SAIC MOTOR

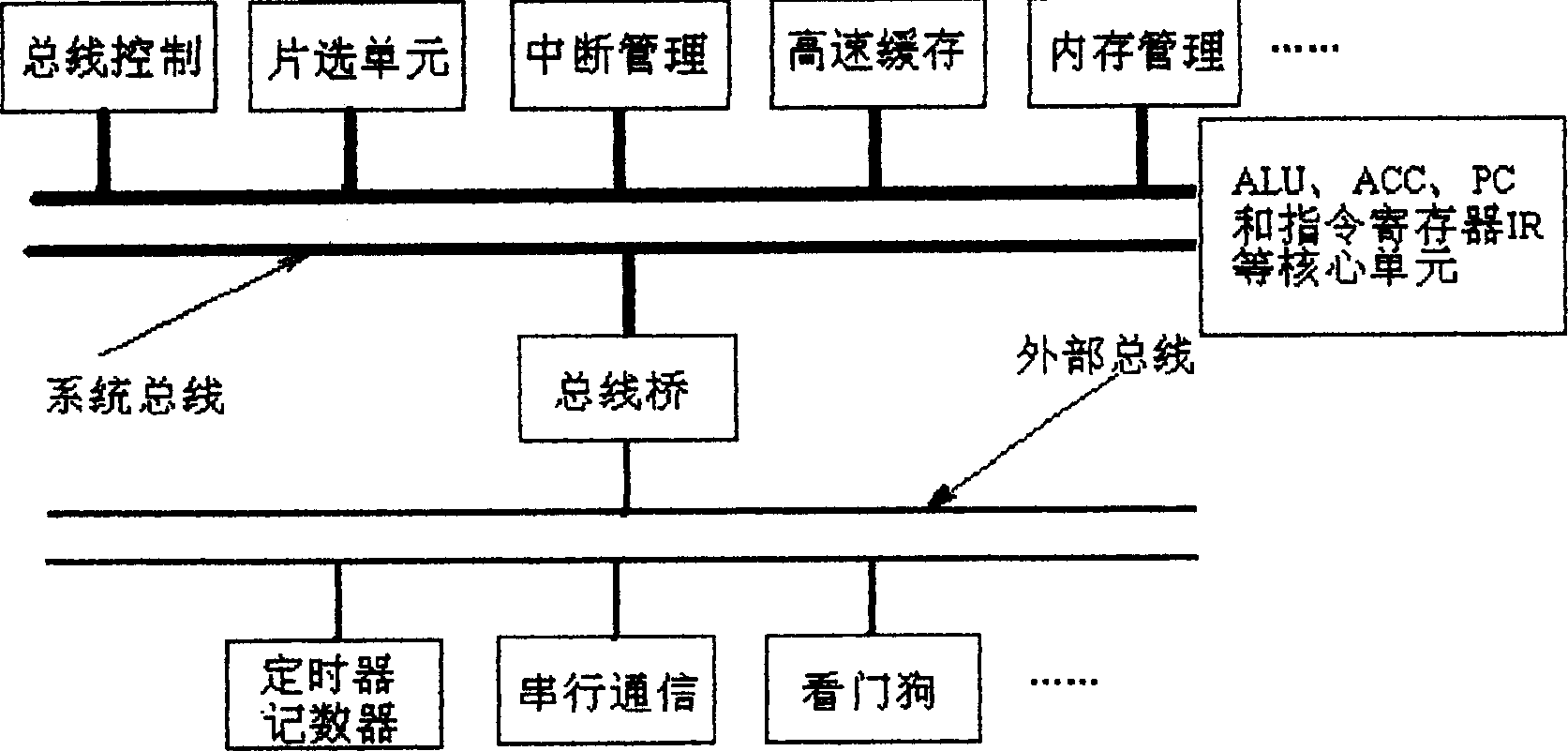

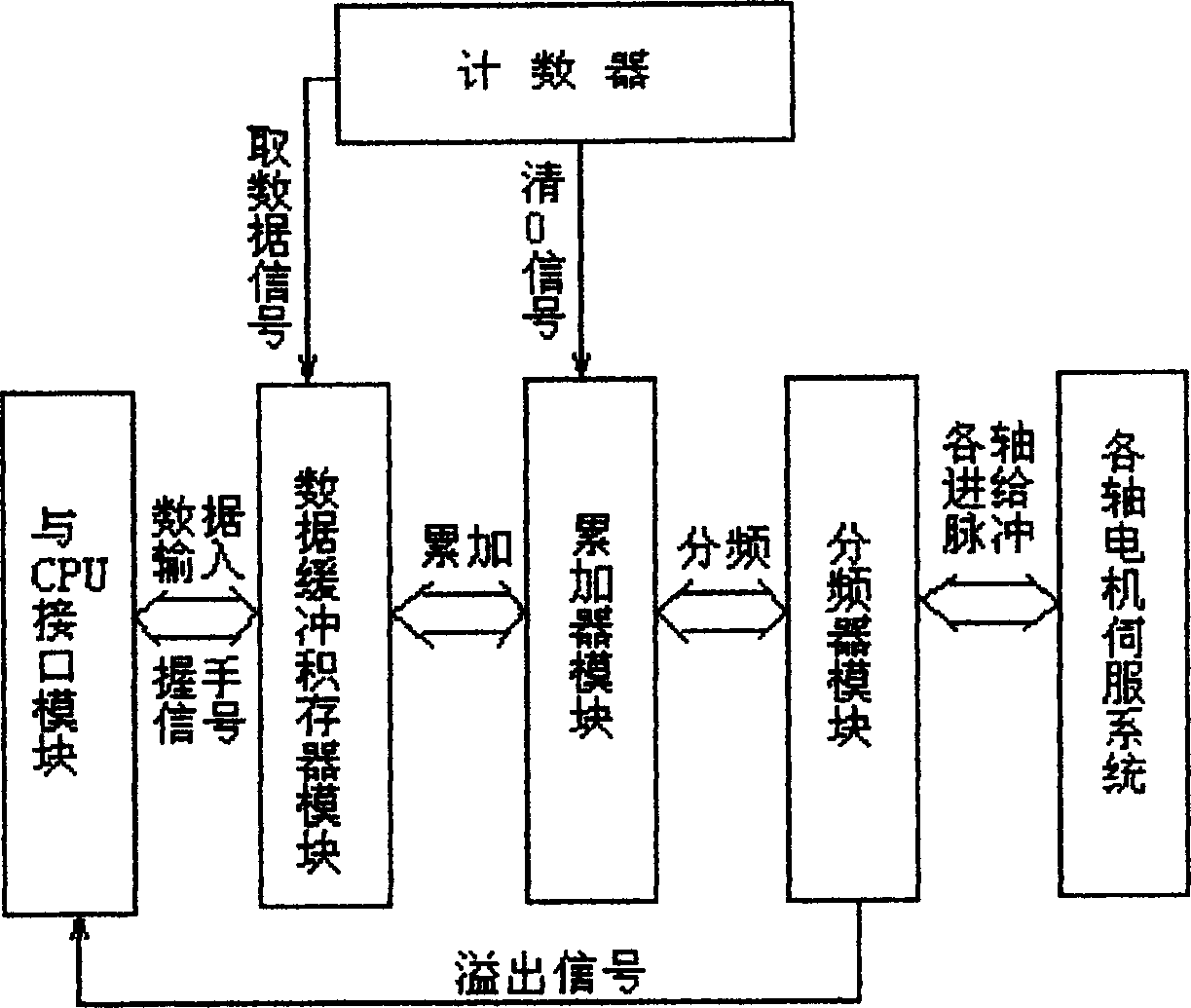

Embedded type motion control method based on plate system and its device

InactiveCN1752874AChoose flexibleFlexible configurationComputer controlNumerical controlMicrocontrollerModularity

Owner:WUHAN UNIV OF TECH

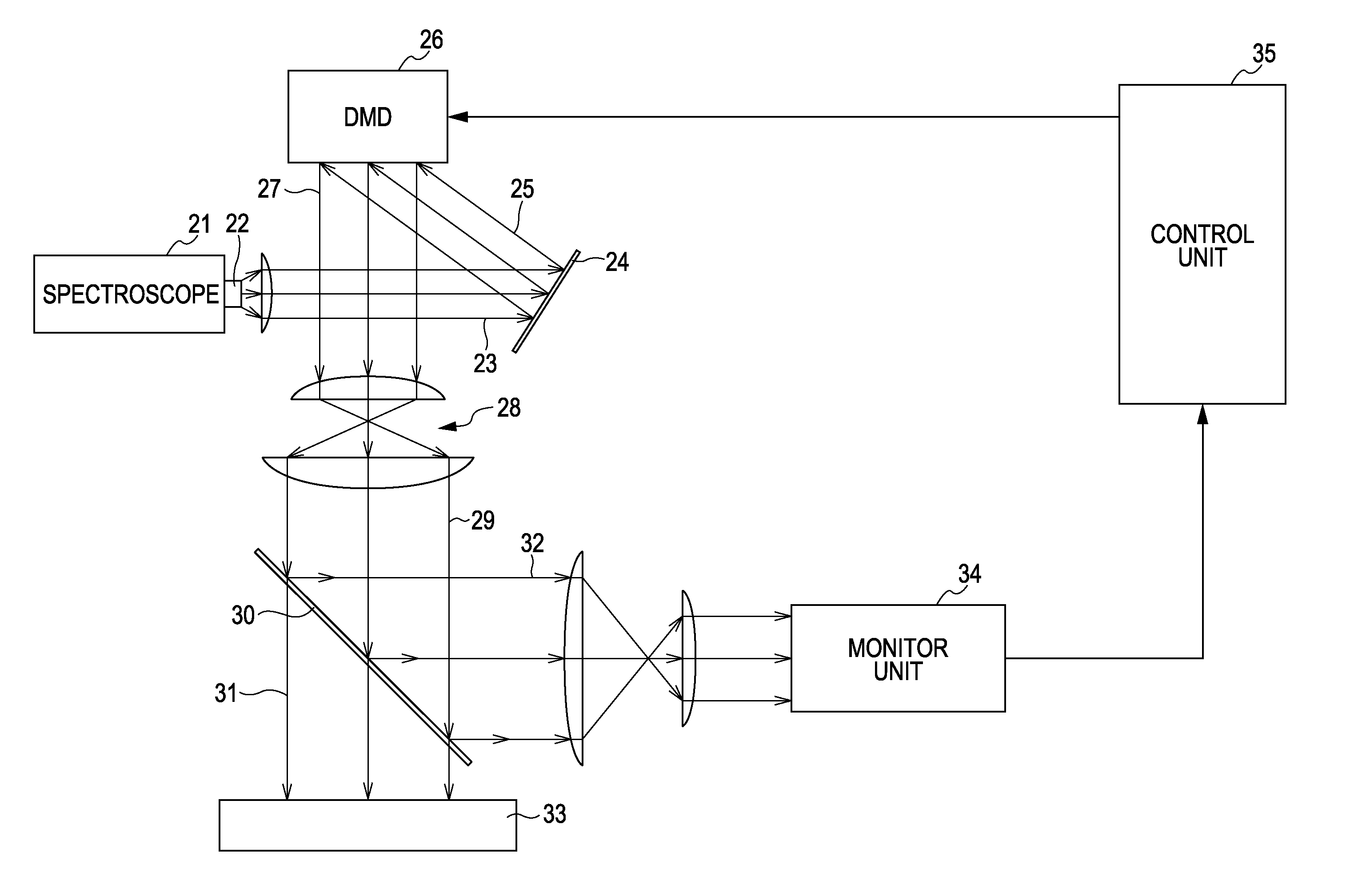

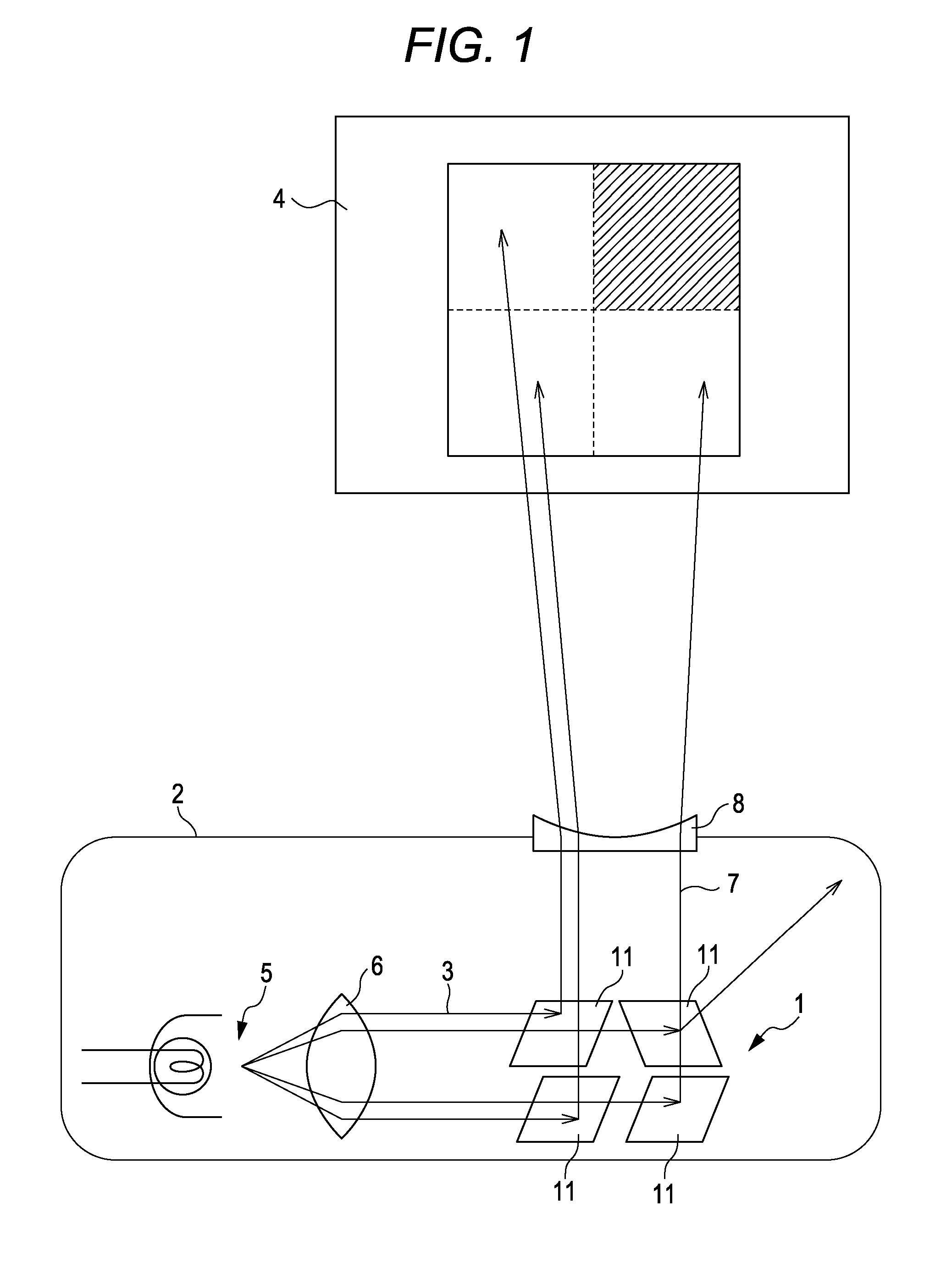

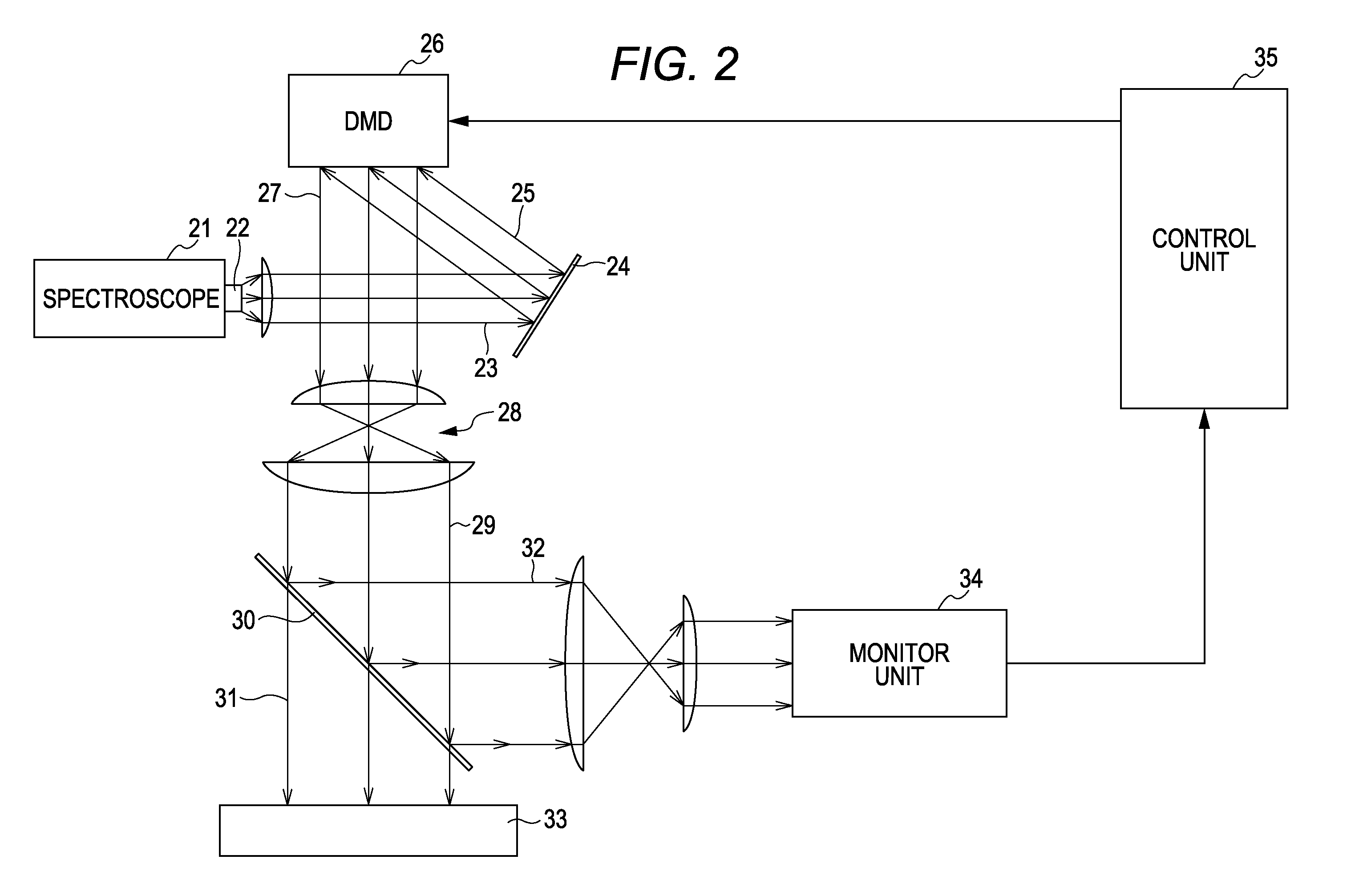

Illumination apparatus and method for obtaining illuminance with high uniformity

InactiveUS20100274392A1Improve uniformityMaintain consistencySampled-variable control systemsComputer controlLight equipmentIlluminance

Owner:NAT INST OF ADVANCED IND SCI & TECH

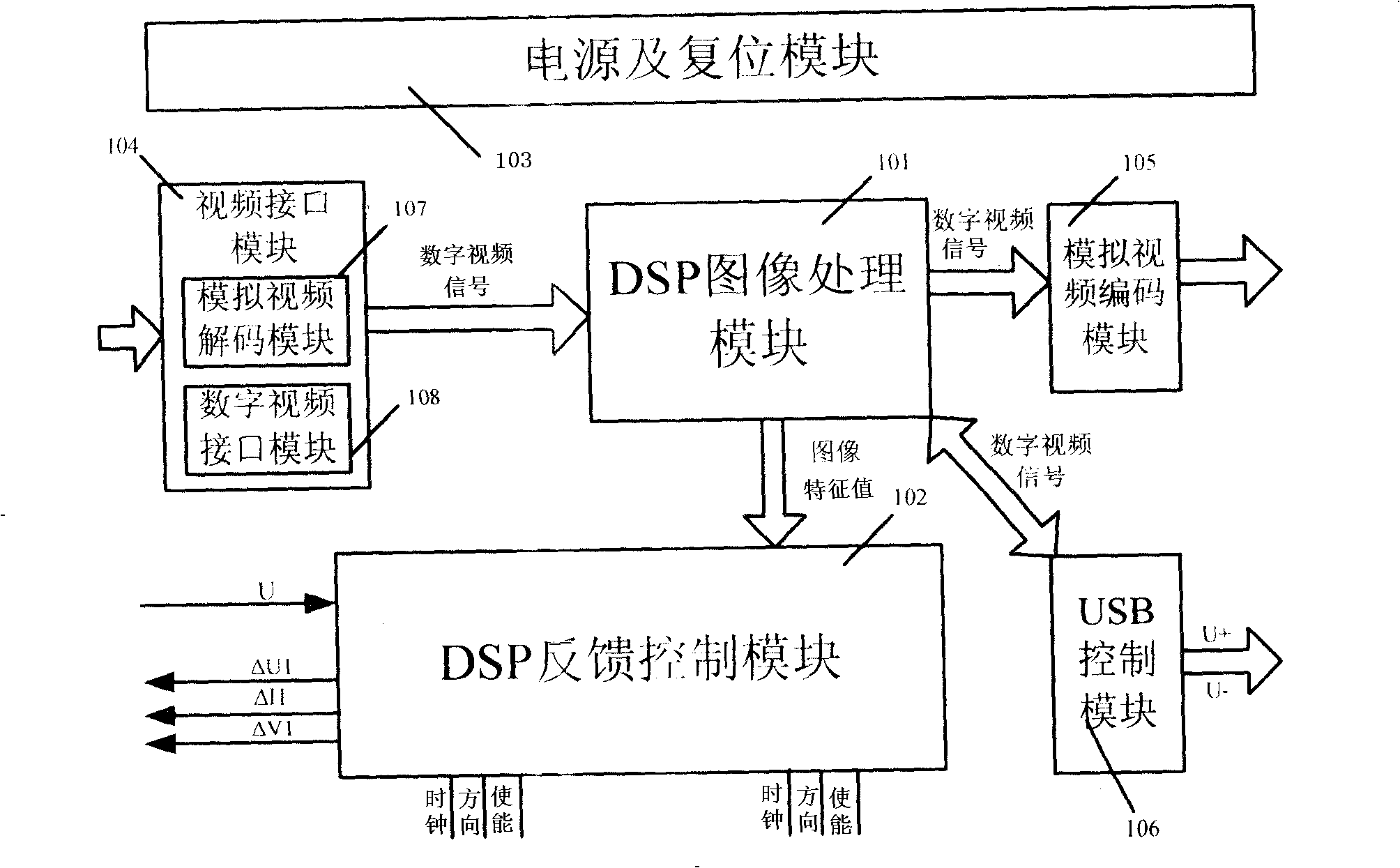

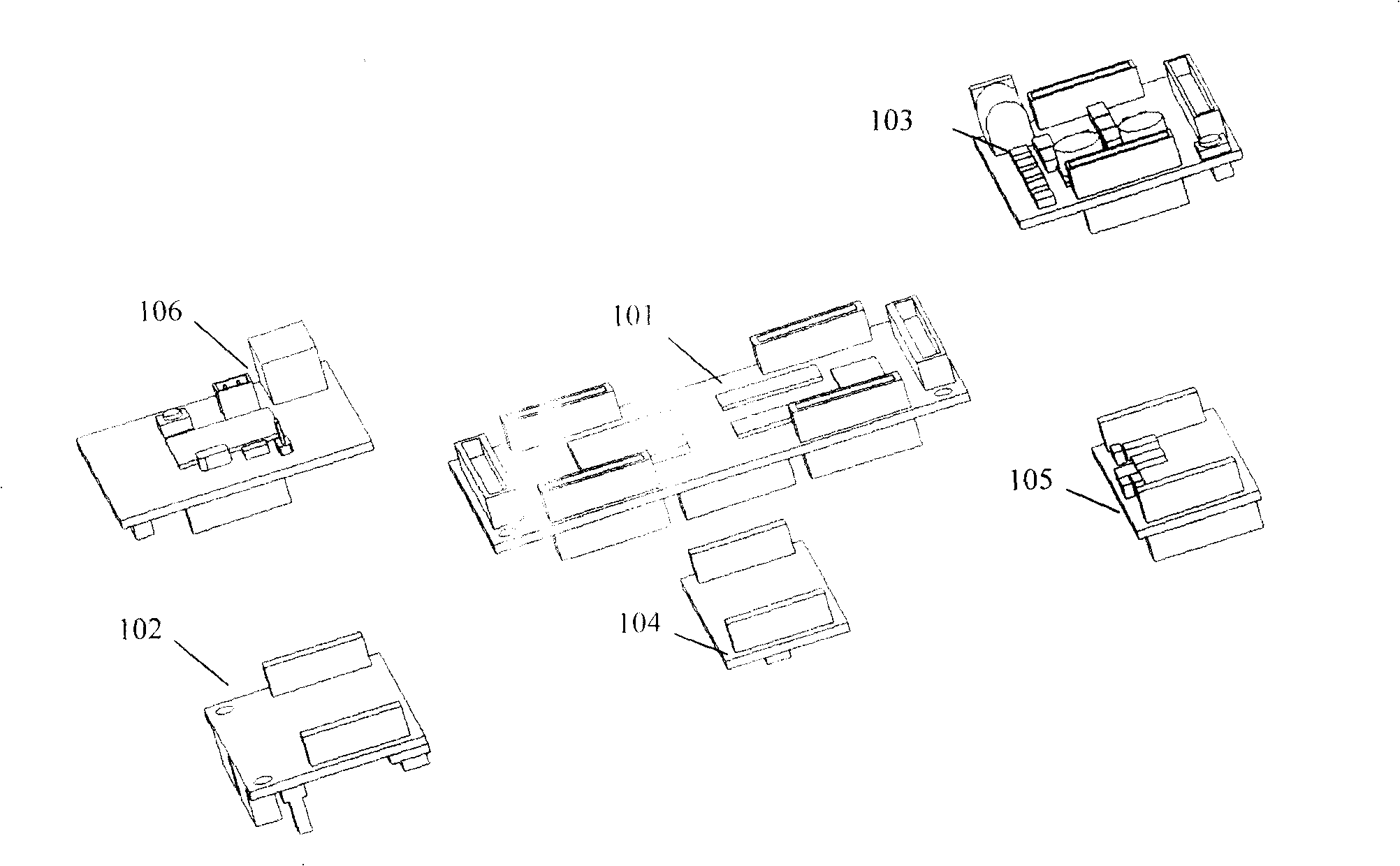

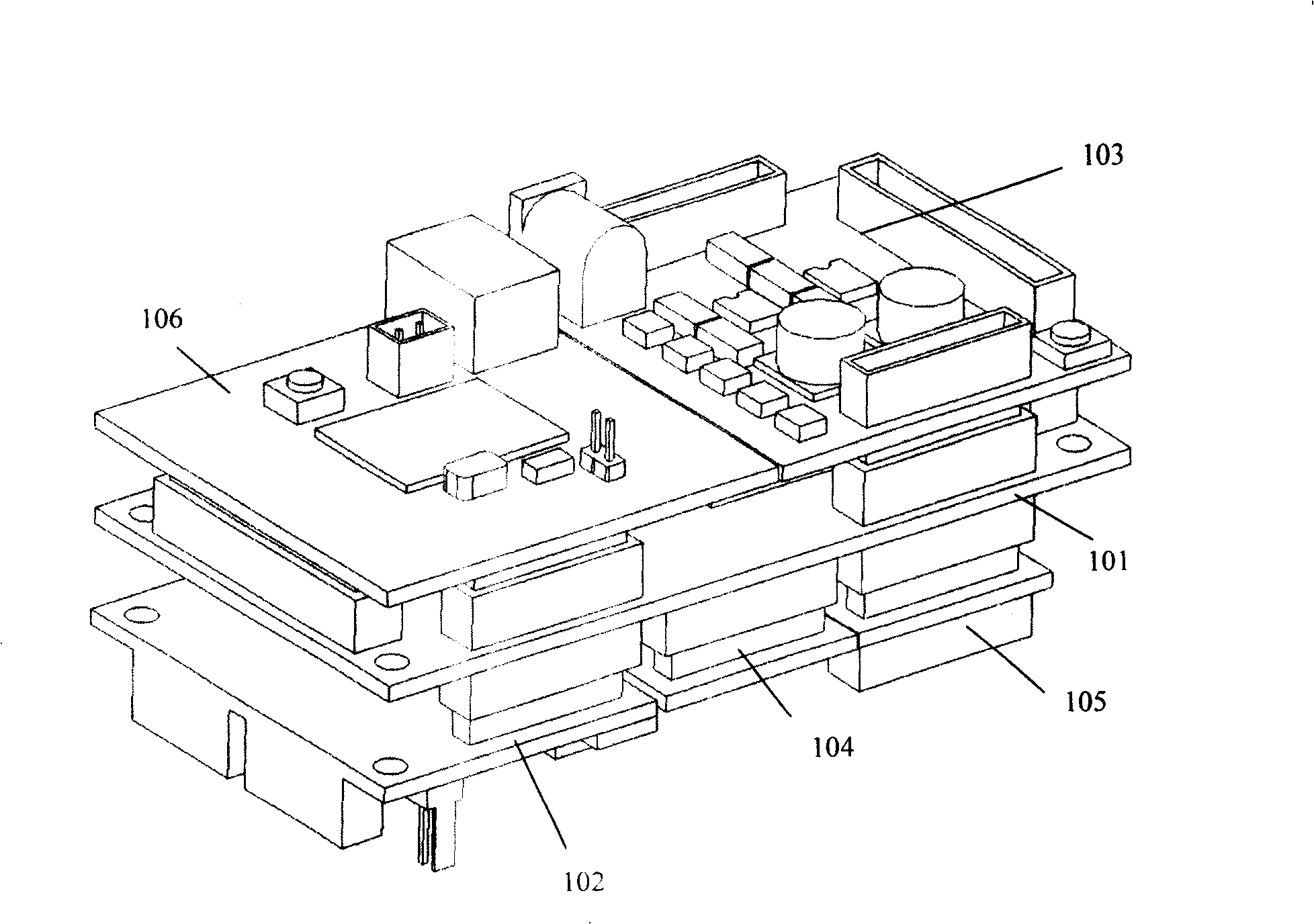

Double DSP built-in control system for visual feedback during soldering process

Owner:TSINGHUA UNIV +1

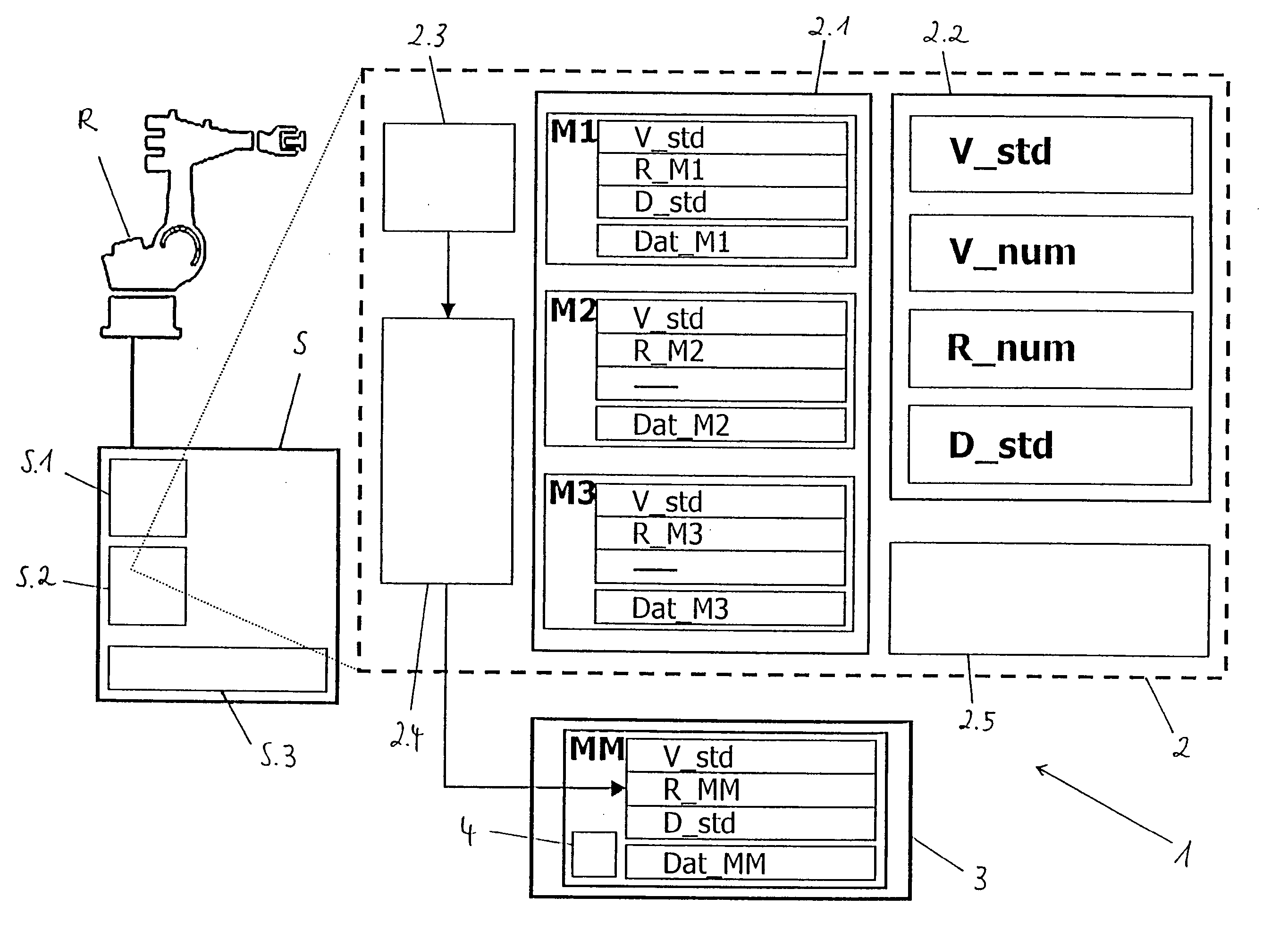

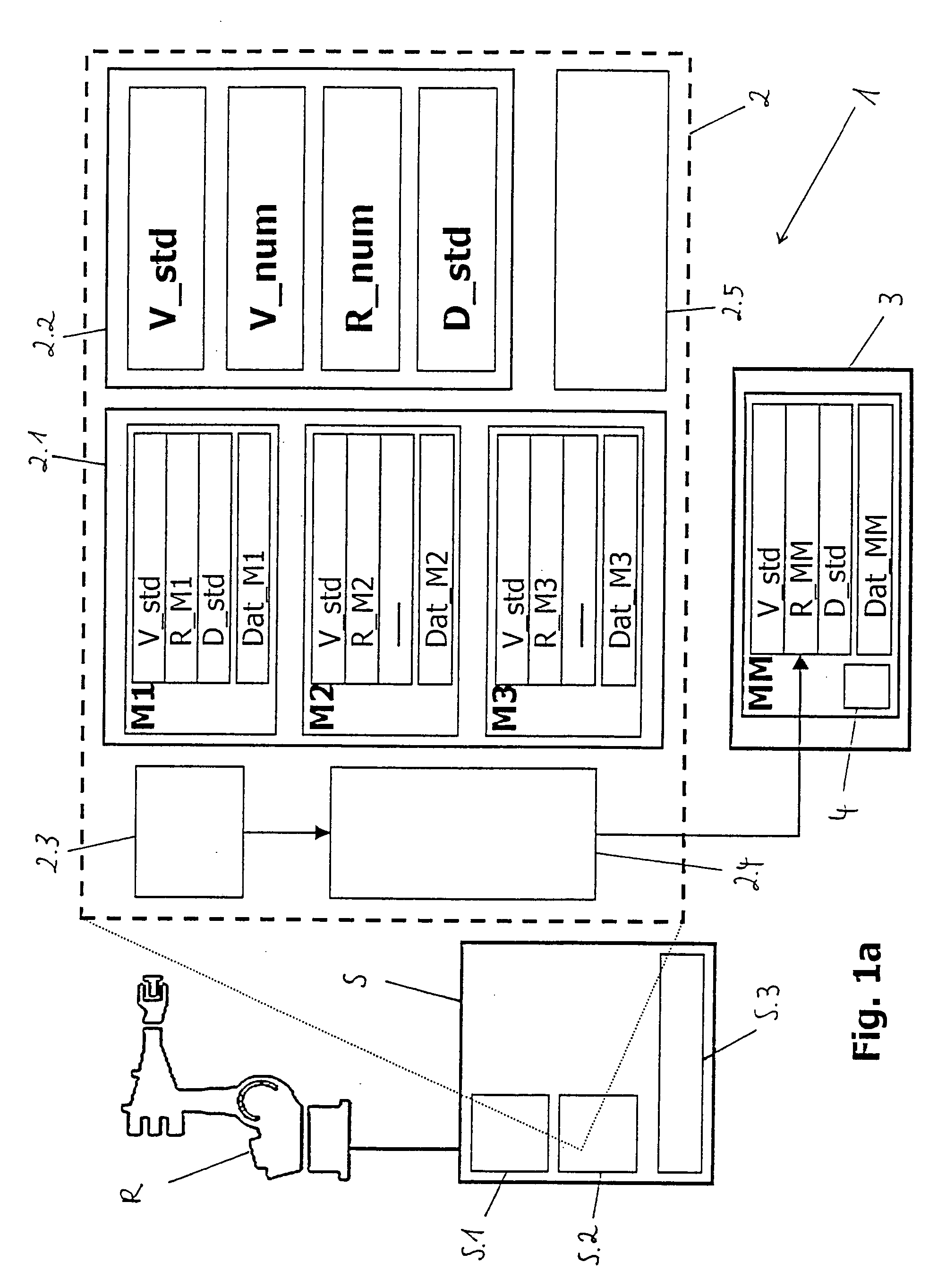

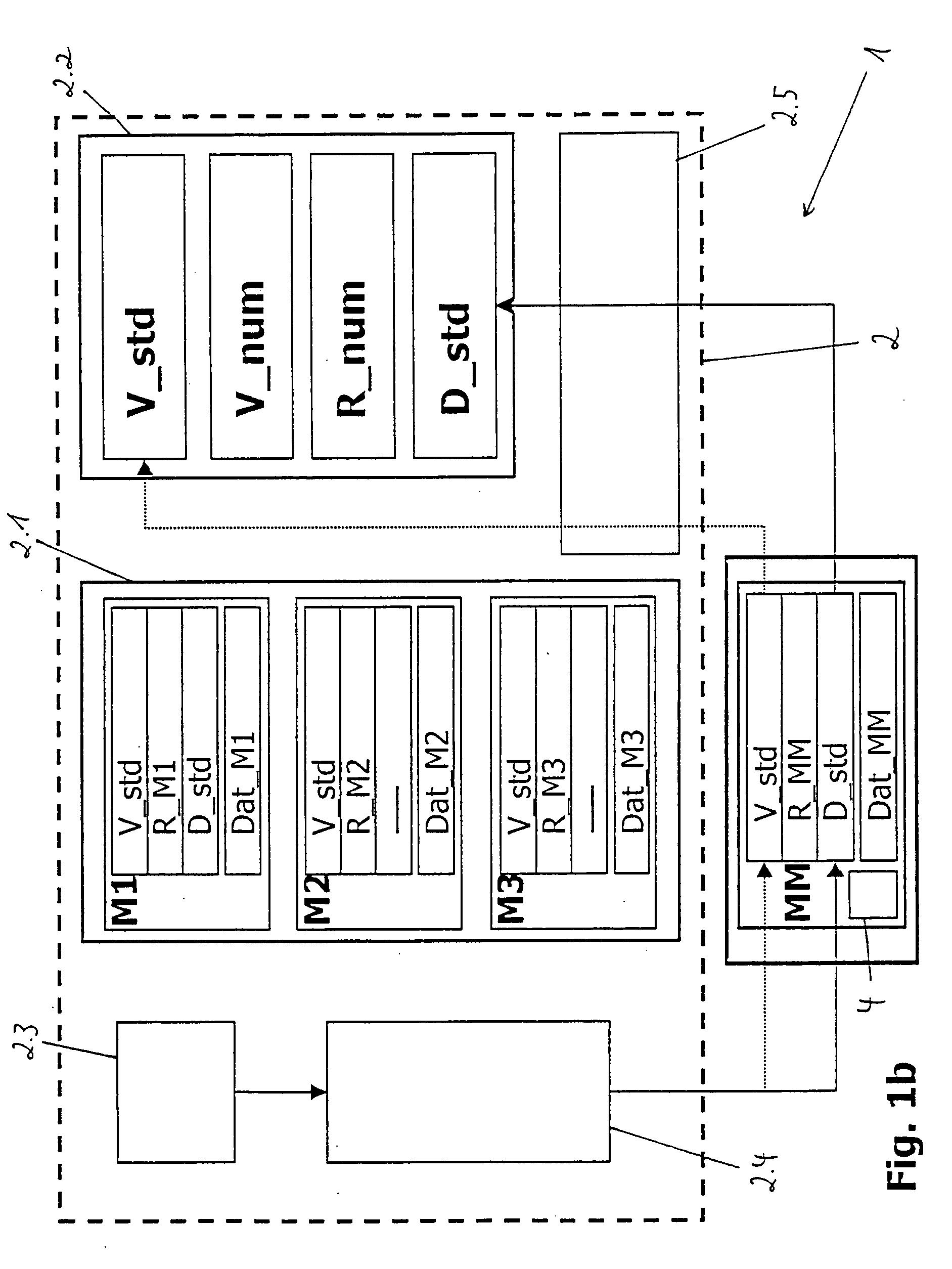

Process and device for controlling the robotal device

InactiveUS20060004489A1Avoid problemsImprove compatibilityProgramme-controlled manipulatorComputer controlThird partyKinematics

Owner:KUKA ROBOTER

Credit card verification system and method

InactiveUS6912312B1Accurate comparisonElectric signal transmission systemsImage analysisCredit cardCommunication unit

The invention provides a credit card verification system, including a credit card company data storage and communication unit (4) for recording and storing data concerning authorized credit card holders, including an electronically reproducible image of each credit card holder, means (6) for introducing the image into the company data storage unit, and at least one remotely positioned credit card reader (10) and image display meants (12) communicating with the company data storage unit, for selectively retrieving data from the storage unit to be displayed on the image display means, to be viewed and approved by the person providing sales services. The invention also provides a method for verifying the identity of a credit card holder effecting a tansaction and a method enabling credit companies to monitor and verify credit card holder identity when a payment transaction is performed at a sales terminal.

Owner:CALLAHAN CELLULAR L L C

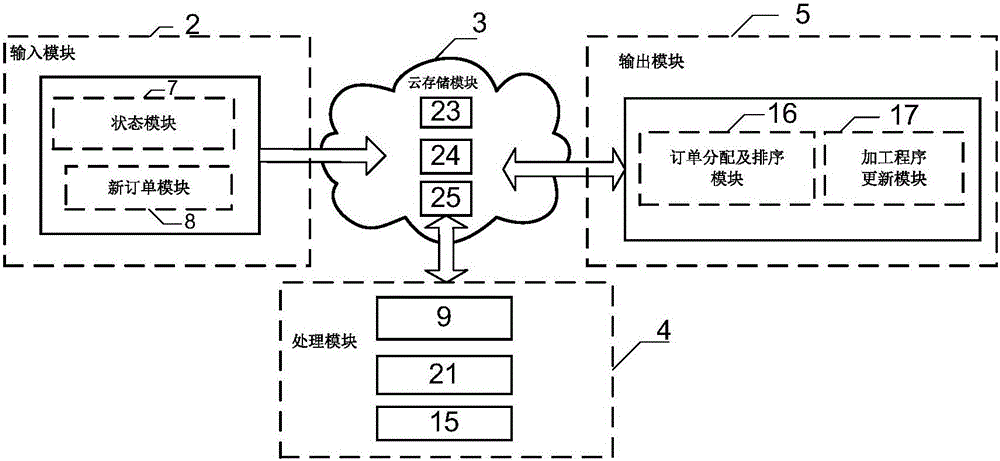

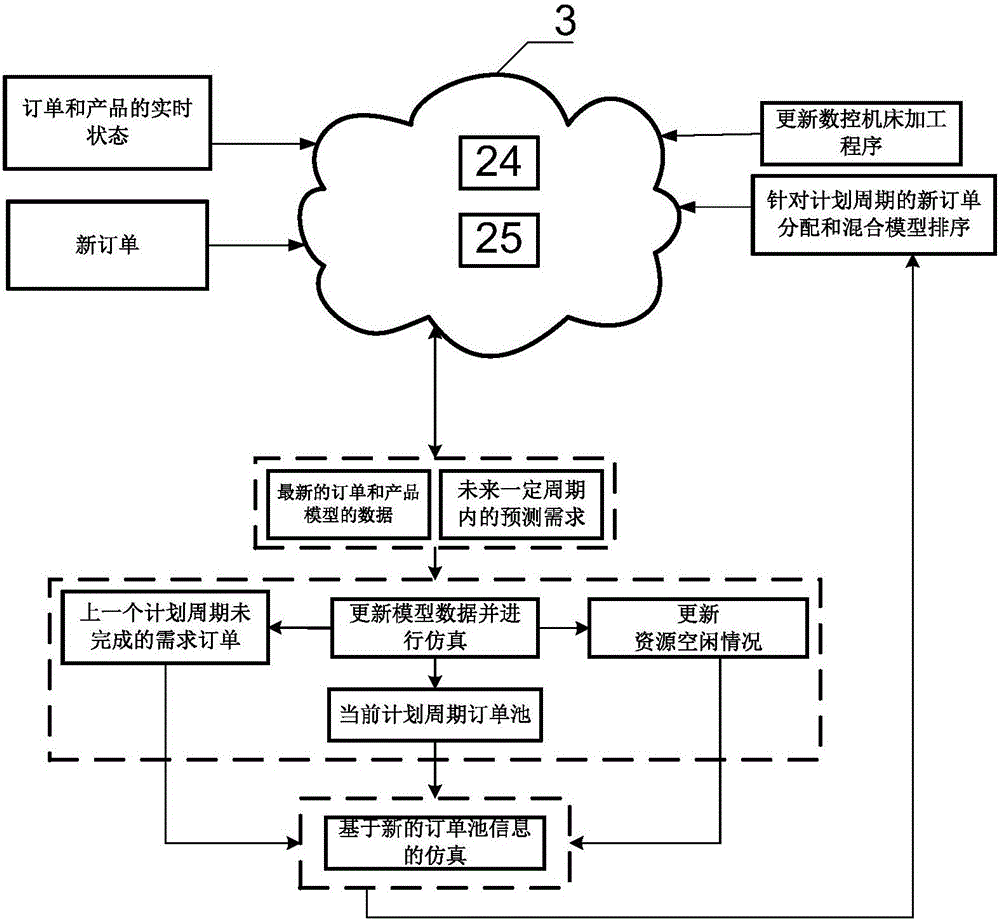

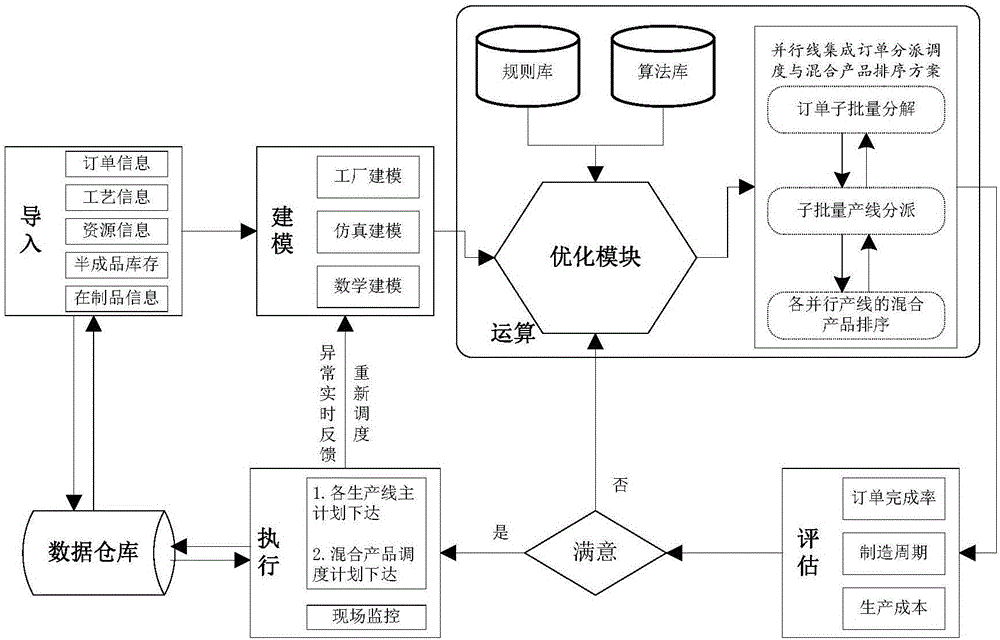

Order distribution scheduling and mixed product ordering system and method

ActiveCN106444643ASimple module structureEasy to installProgramme controlComputer controlNumerical controlProduction line

Owner:HUAZHONG UNIV OF SCI & TECH

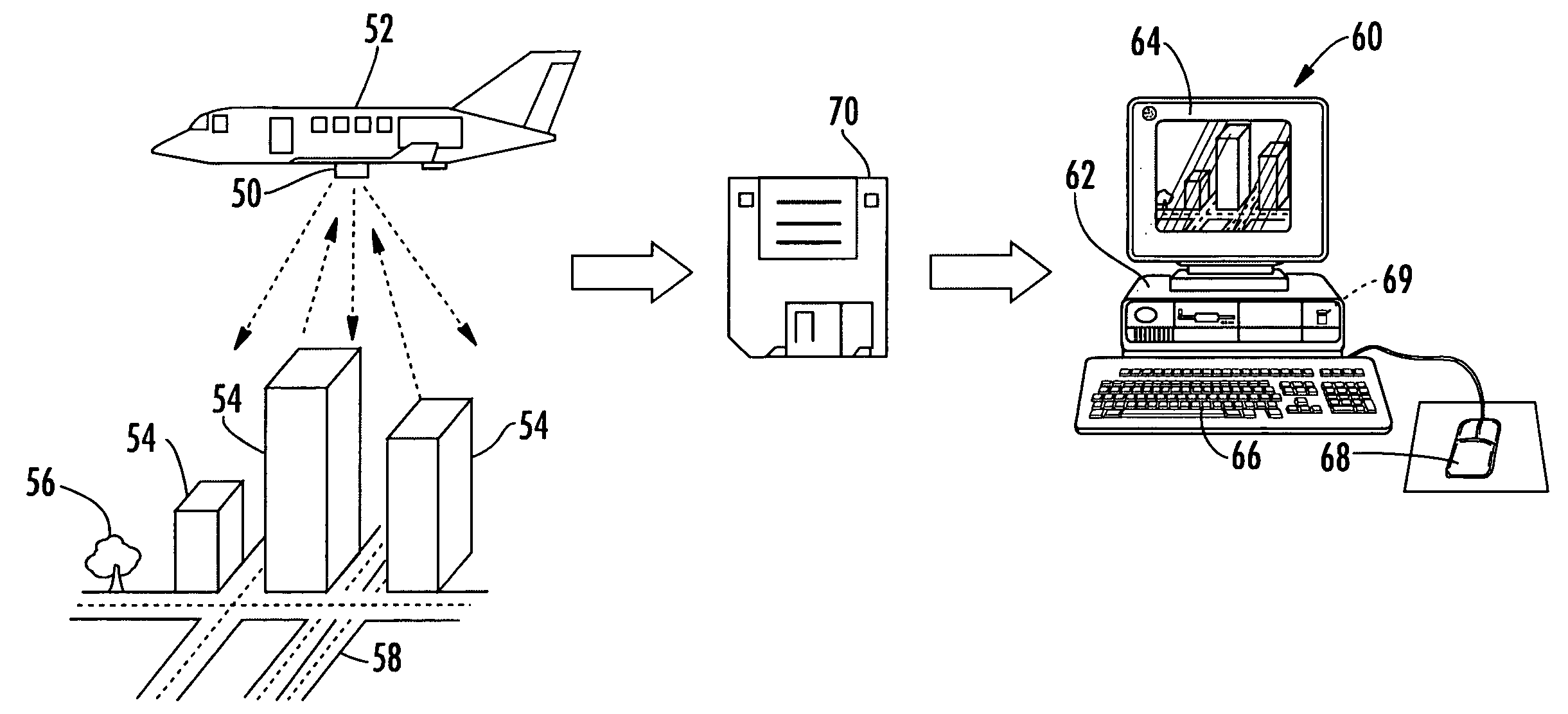

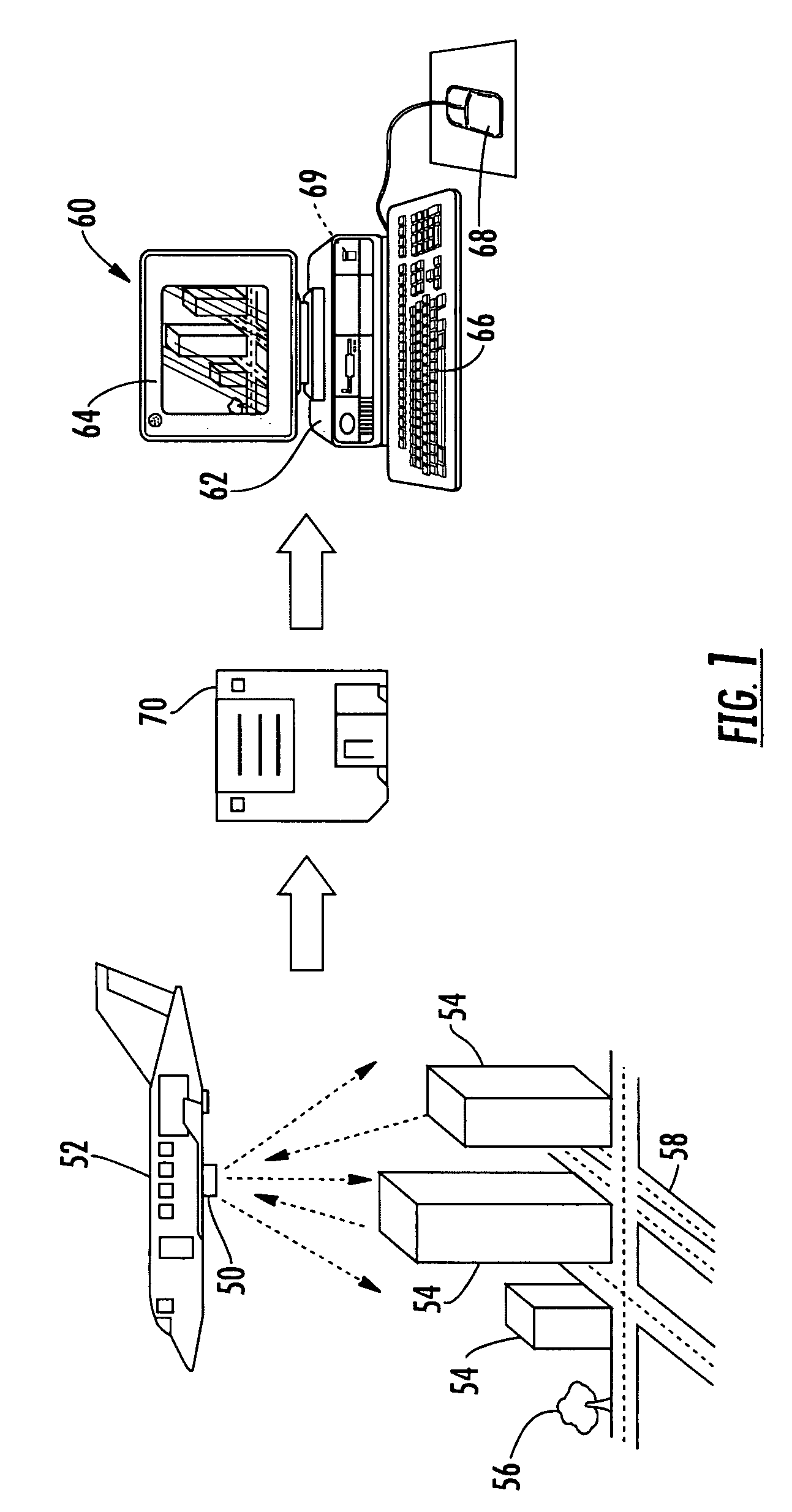

Method and apparatus for processing SAR images based on an anisotropic diffusion filtering algorithm

InactiveUS20080231502A1Improves subsidence measurementImprove boundary qualityImage enhancementImage analysisRadarSynthetic aperture radar

Owner:HARRIS CORP

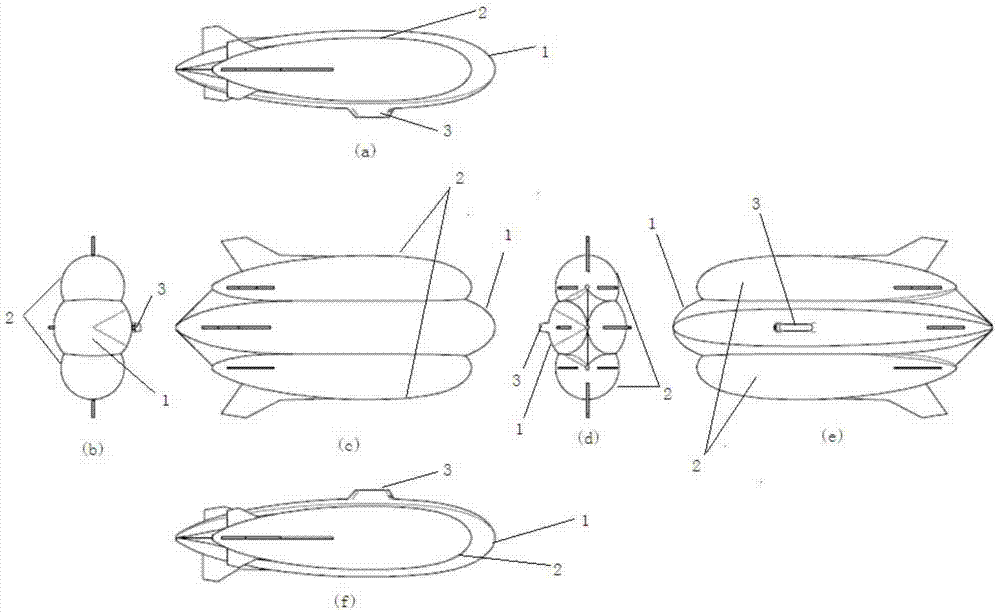

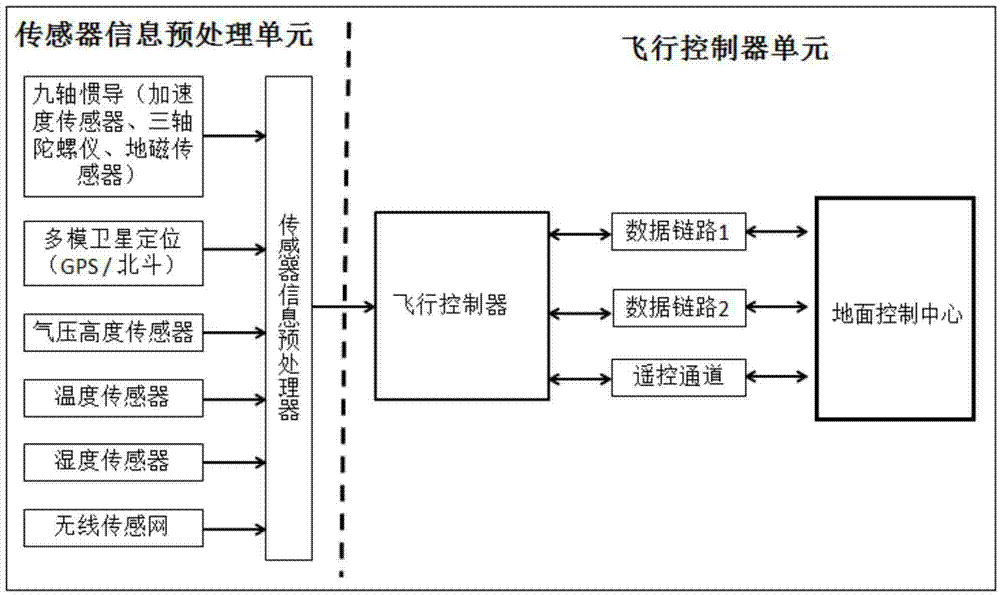

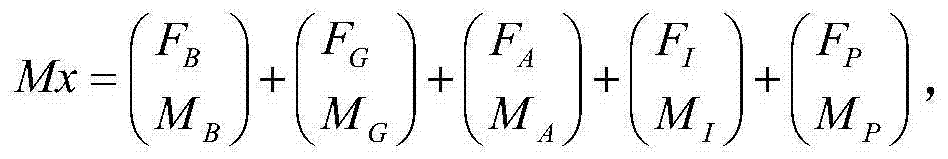

Unmanned autonomous airship and method for building flight control system of unmanned autonomous airship

Owner:PEKING UNIV

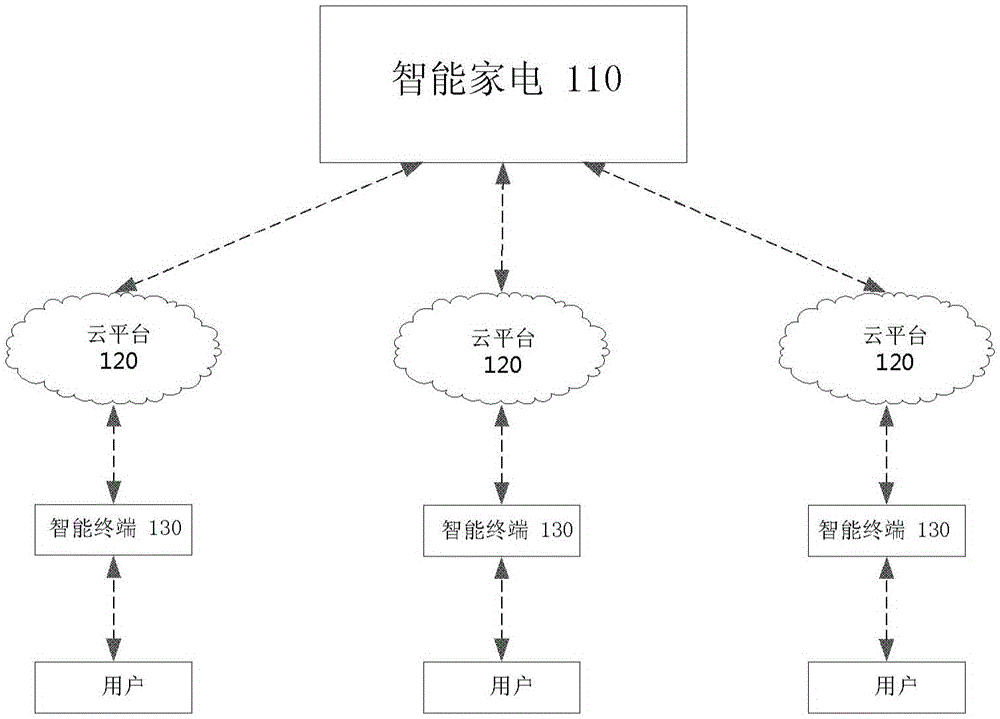

Smart home appliance, smart home appliance system and method thereof

InactiveCN105159102AComputer controlProgramme total factory controlCloud service providerSmart appliance

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Wearable intelligent card used for swimmer state monitoring

Owner:ZHEJIANG WEISS WIRELESS NETWORK TECH CO LTD

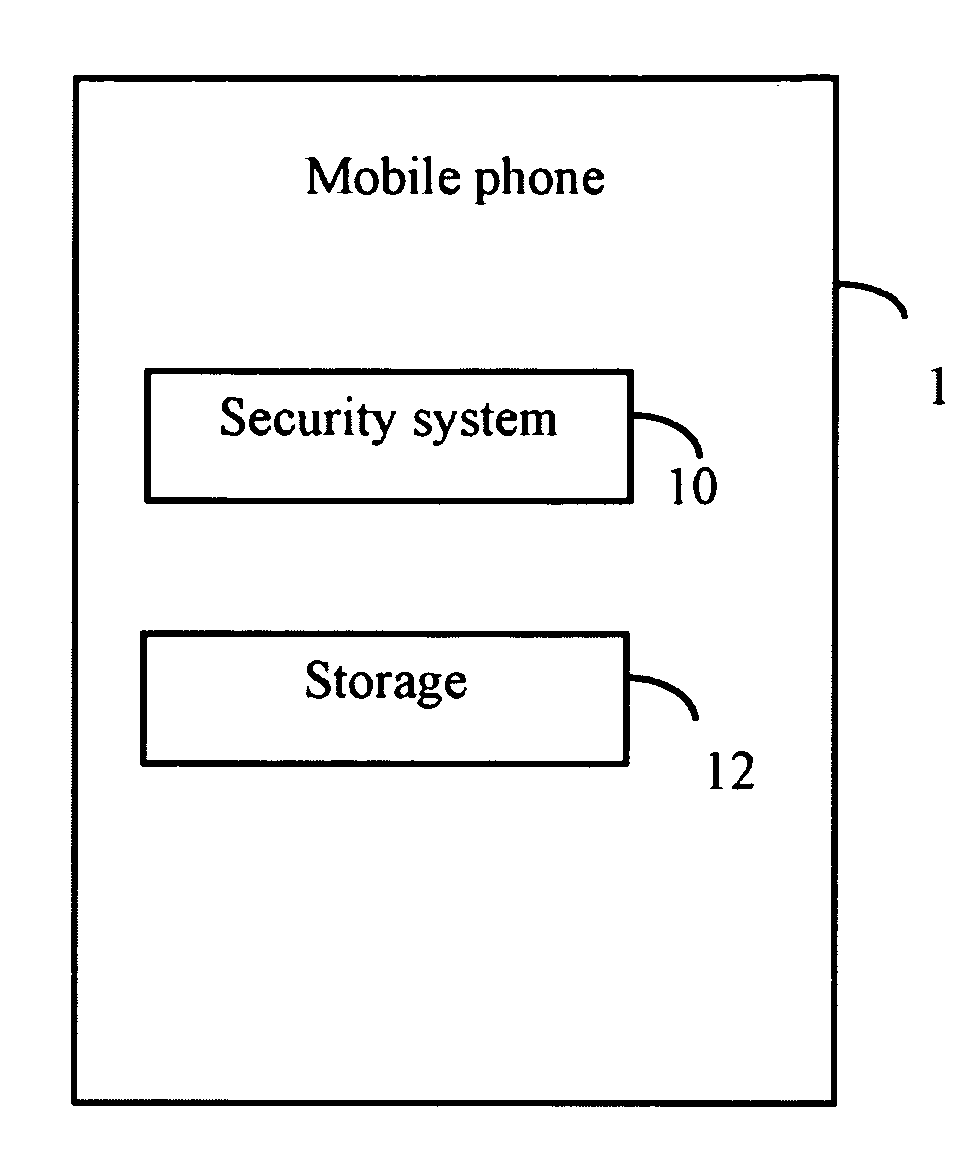

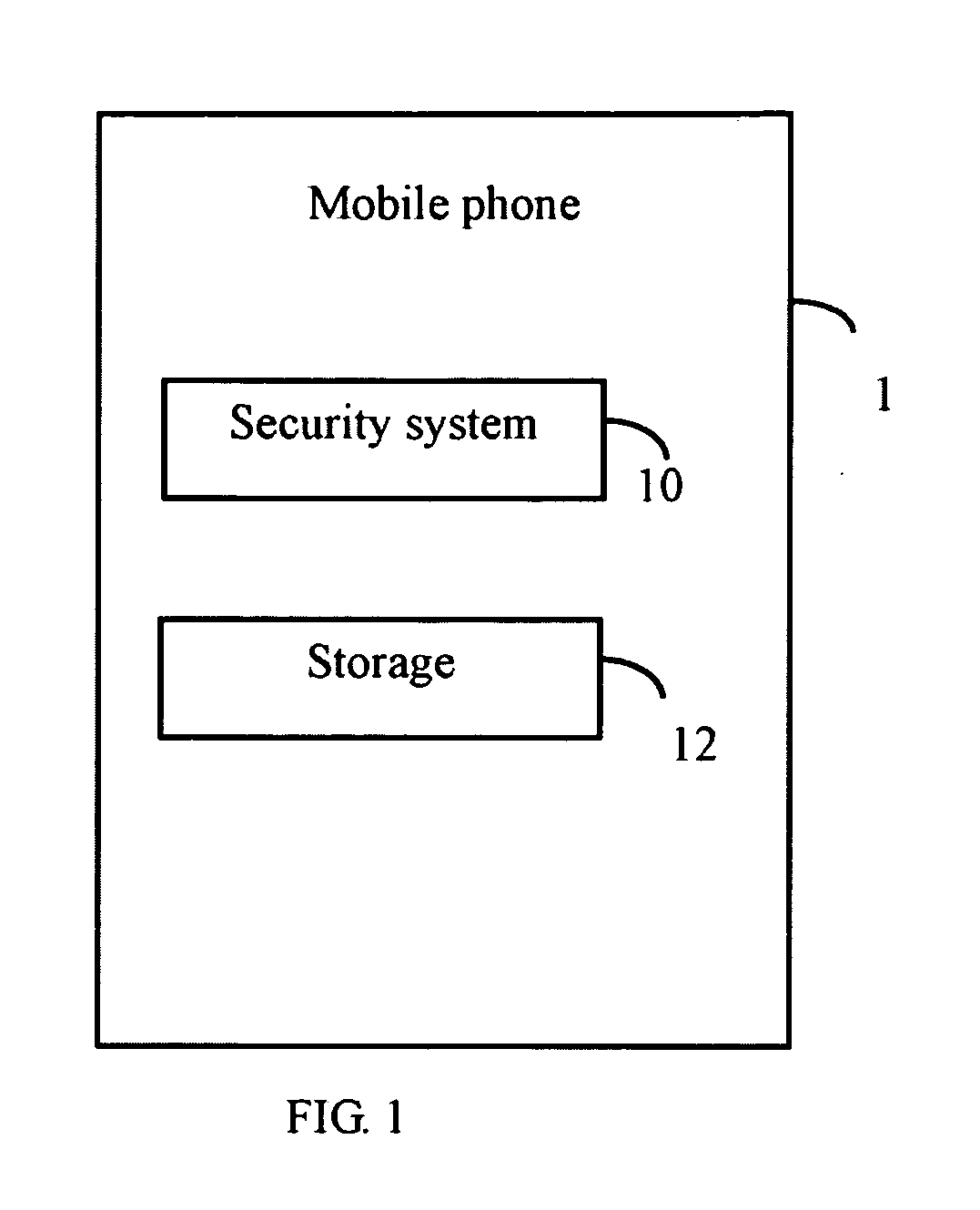

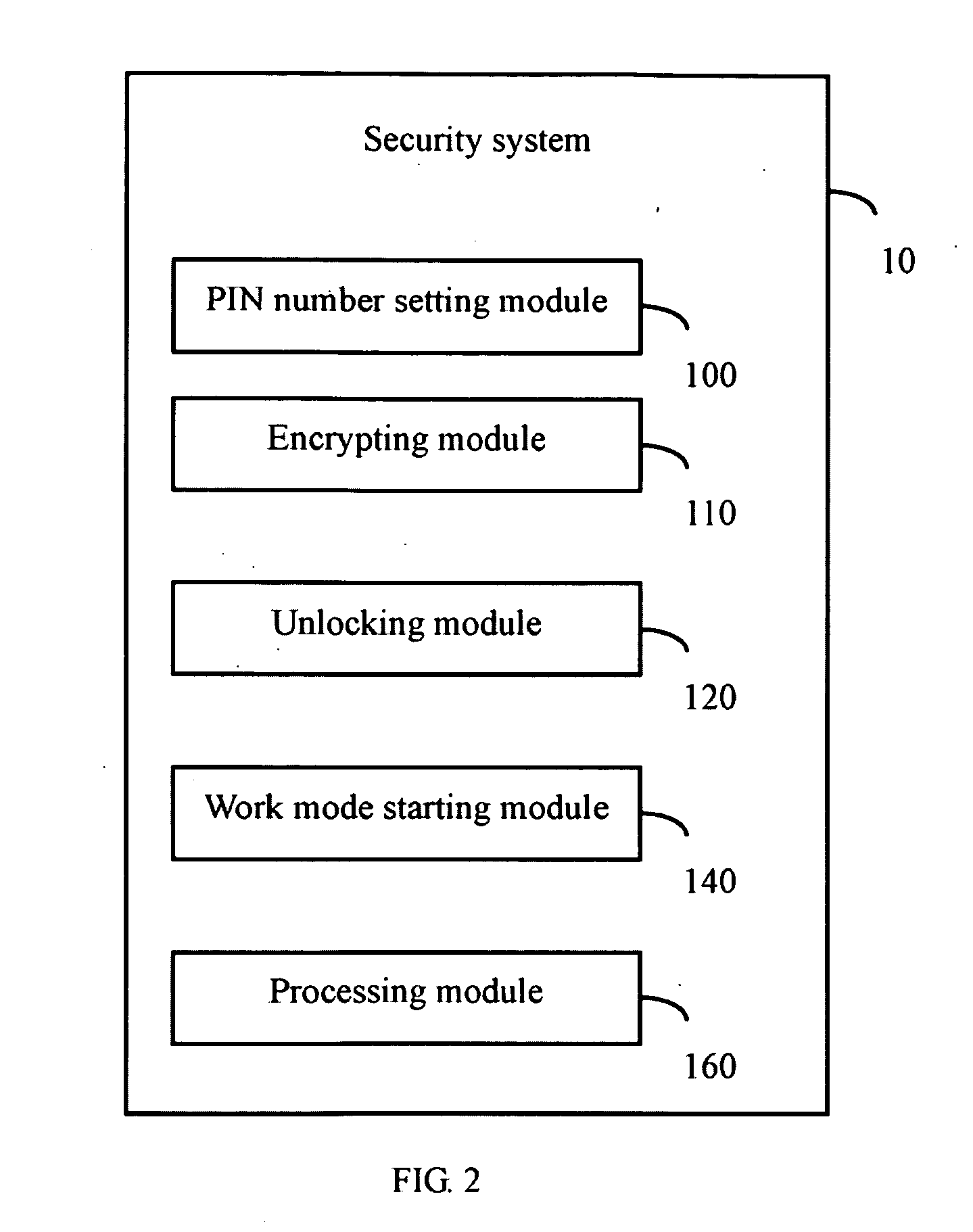

Security system and method for a mobile phone

InactiveUS20090098856A1Satisfies needElectric signal transmission systemsUnauthorised/fraudulent call preventionPower userMobile phone

Owner:CHI MEI COMM SYST INC

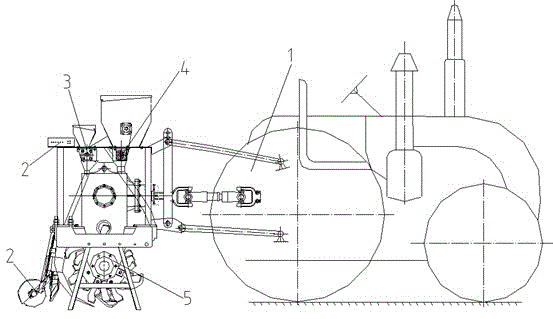

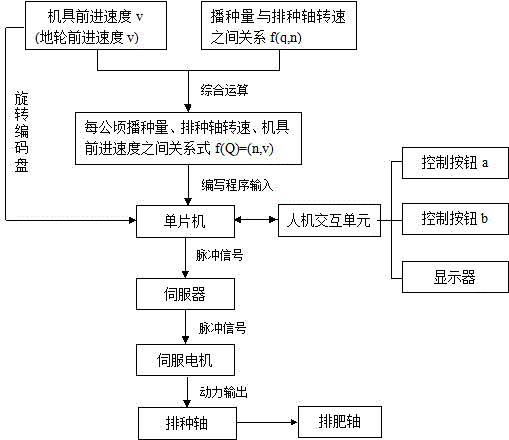

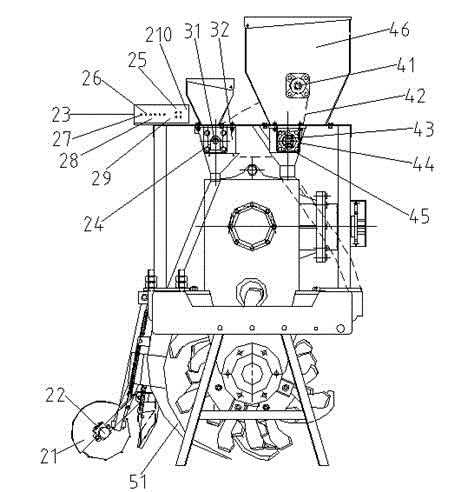

Automatic control system for variable seeding and fertilization and multifunctional planter

ActiveCN104885607AEasy to adjustReasonable structureProgramme controlSpadesMicrocontrollerAutomatic control

Owner:HUNAN AGRICULTURAL UNIV

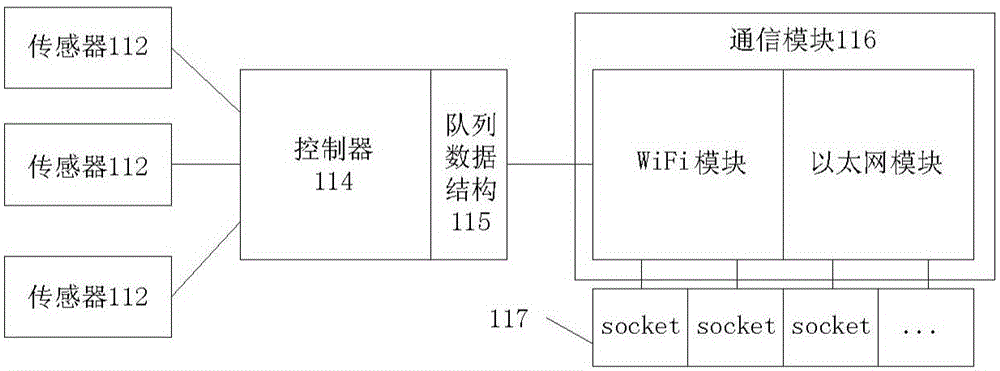

Wireless network based remote monitoring system for sewing equipment

InactiveCN106790566AConvenient production trackingConducive to R&D and improvementProgramme controlComputer controlWireless mesh networkRemote control

The invention provides a wireless network based remote monitoring system for sewing equipment and solves the technical problems that a remote monitoring analysis function and a remote control function are absent and the like in the prior art. The remote monitoring system comprises a service platform and at least one monitoring terminal arranged on sewing equipment, wherein the monitoring terminals and the sewing equipment are in one-to-one correspondence, the service platform and the monitoring terminals are connected through a wireless network and can realize mutual data exchange, and the service platform performs analysis processing on received equipment data and / or can send platform data including setting data and / or control data to the corresponding monitoring terminals, so that remote setting and / or remote control of the corresponding sewing equipment can be realized. The remote monitoring system has the advantages that follow-up research, development and improvement of the equipment and optimization of factory production flow are facilitated, equipment operation is stable, service cost and illegal use risks of the equipment are reduced, equipment management is facilitated and the like.

Owner:JACK SEWING MASCH CO LTD

Popular searches

Digital data processing details Alarms Input/output processes for data processing Efficient regulation technologies Space heating and ventilation details Space heating and ventilation safety systems Space heating and ventilation control systems Adaptive control Air conditioning systems Programme control in sequence/logic controllers

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap