Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Production line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A production line is a set of sequential operations established in a factory where components are assembled to make a finished article or where materials are put through a refining process to produce an end-product that is suitable for onward consumption...

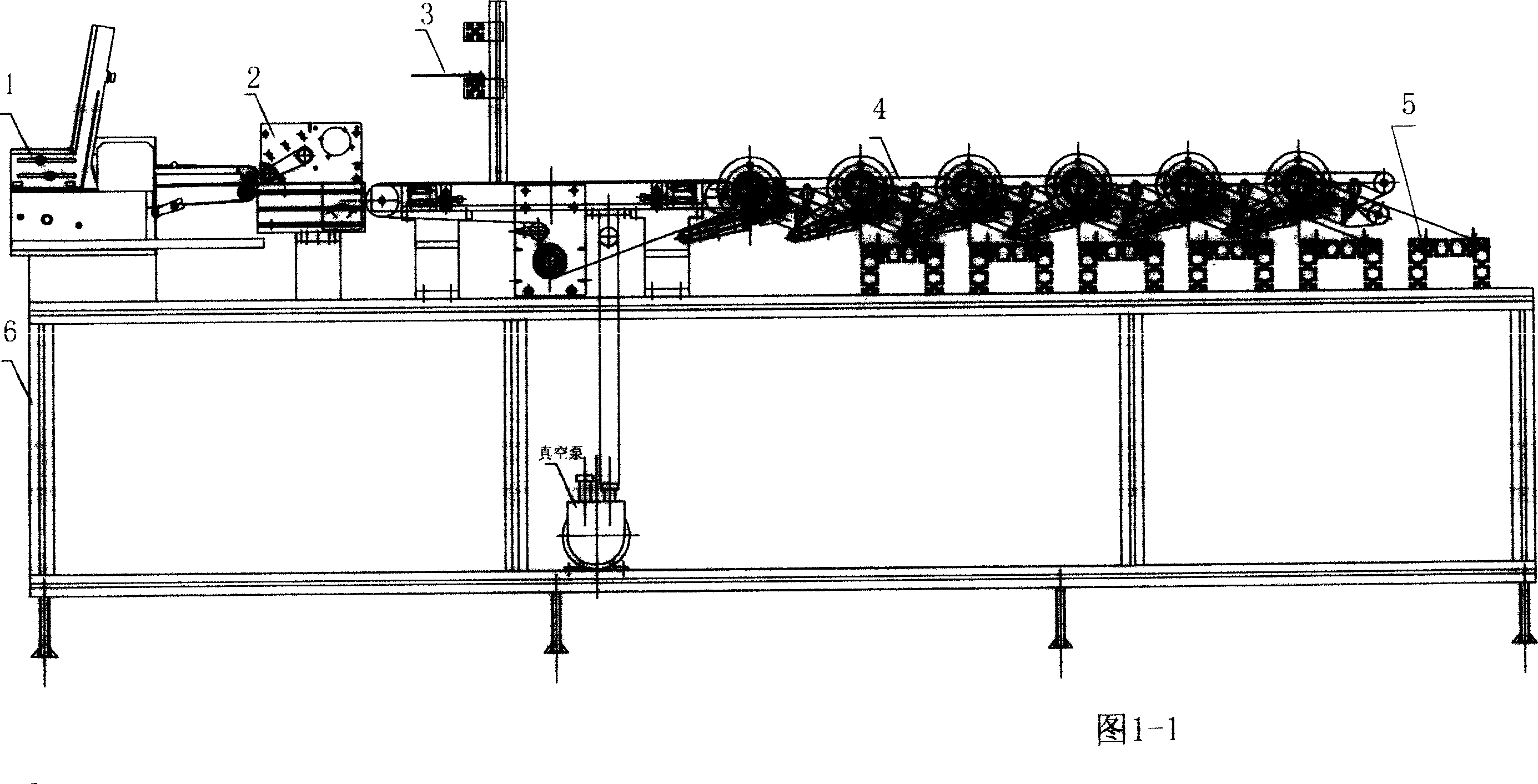

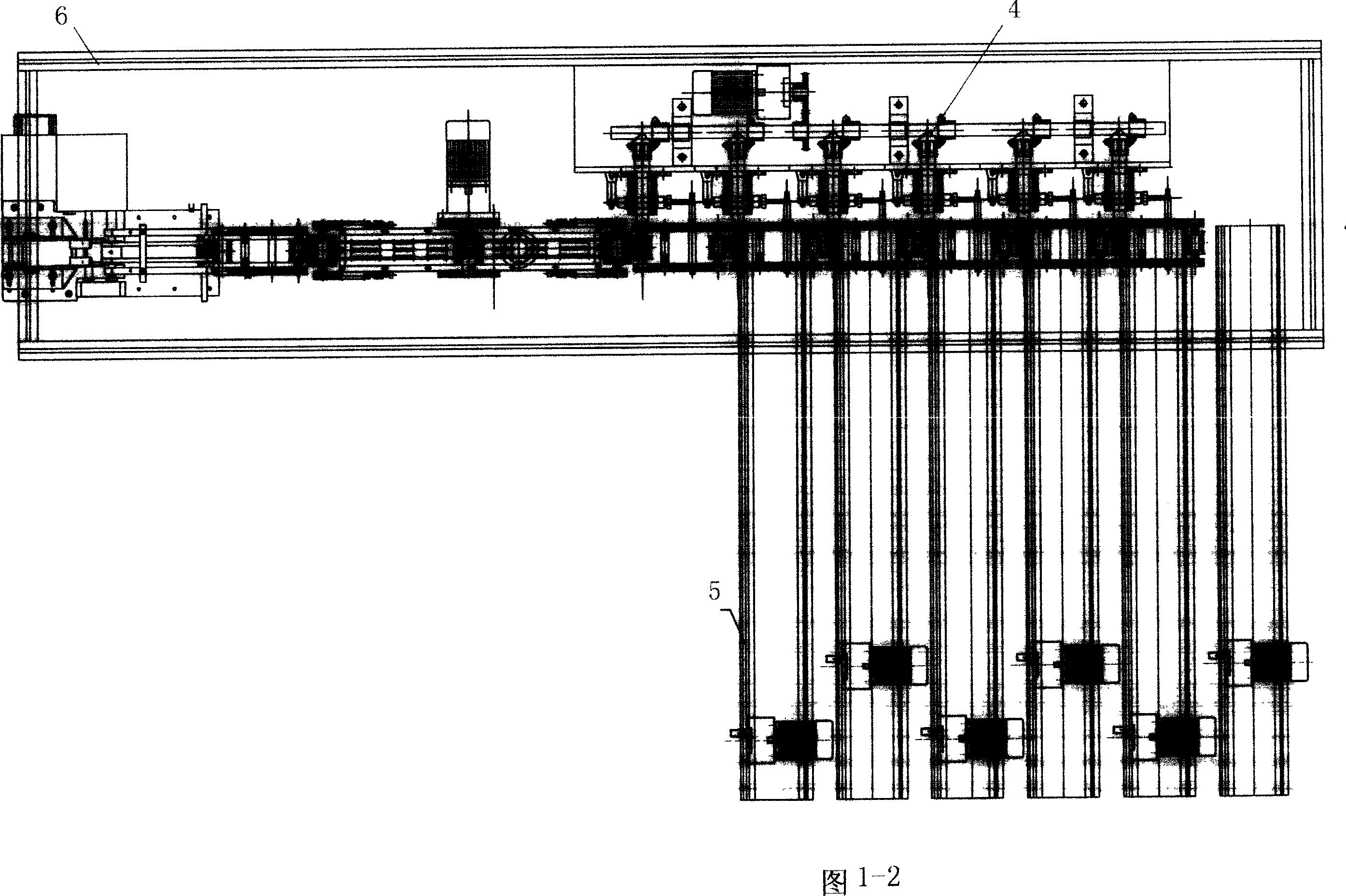

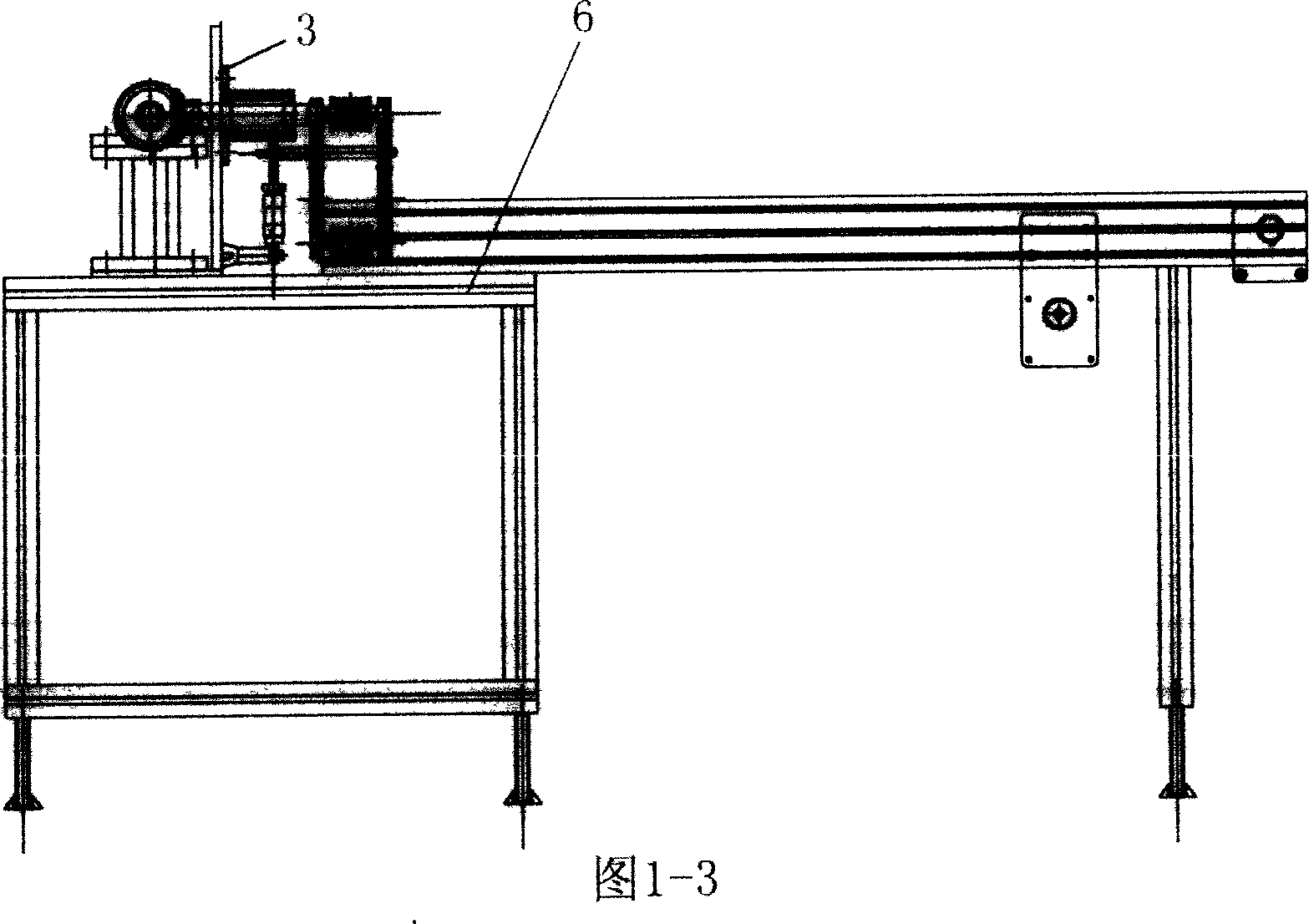

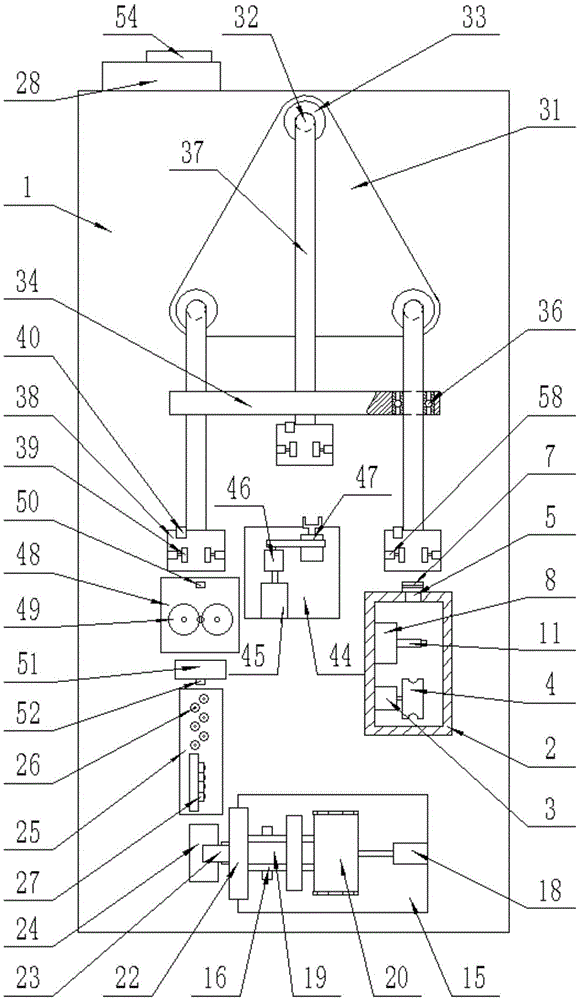

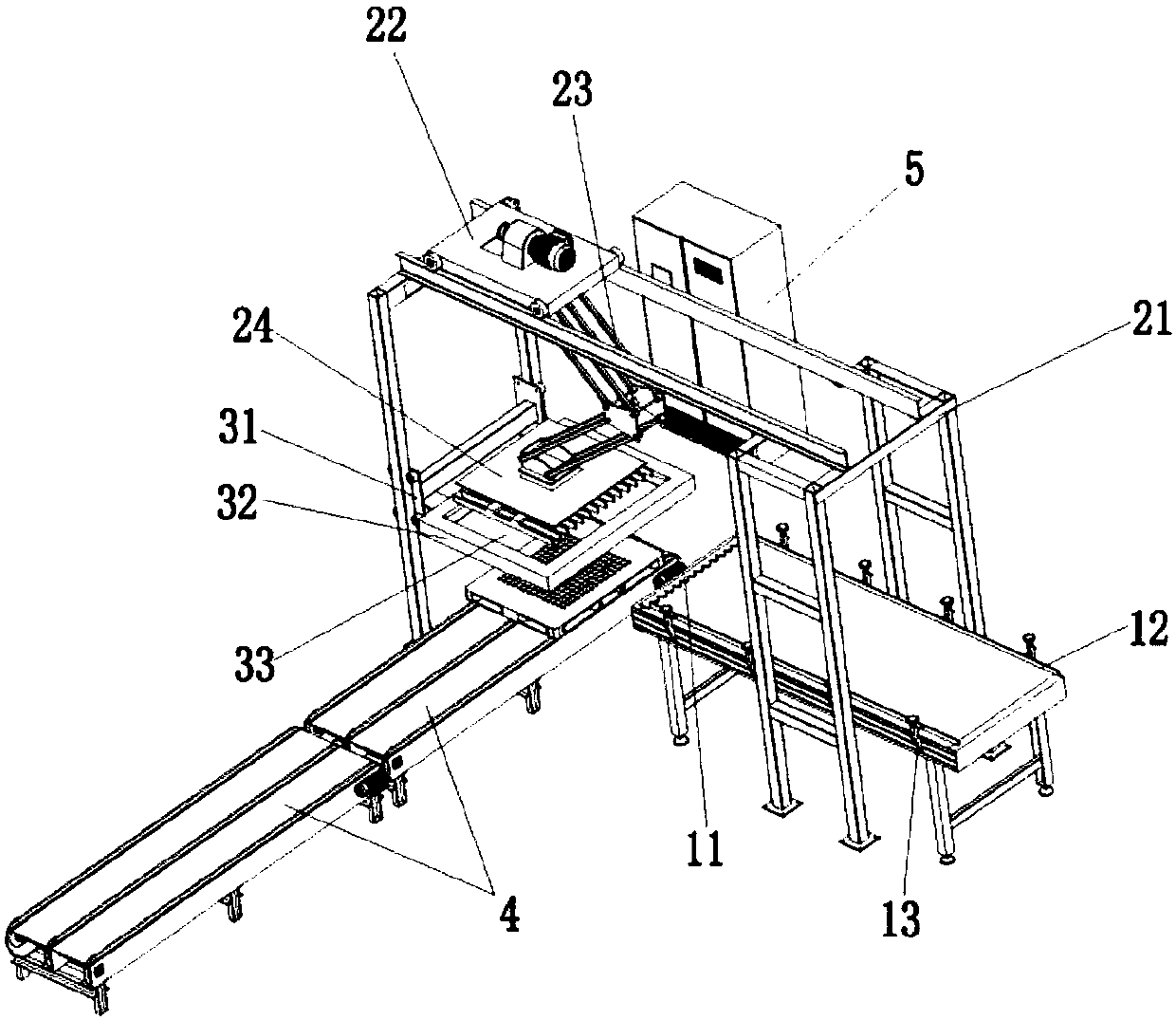

Extensible inspection production equipment for smart cards

Owner:GUANGZHOU SANTUO IDENTIFICATION TECH CO LTD

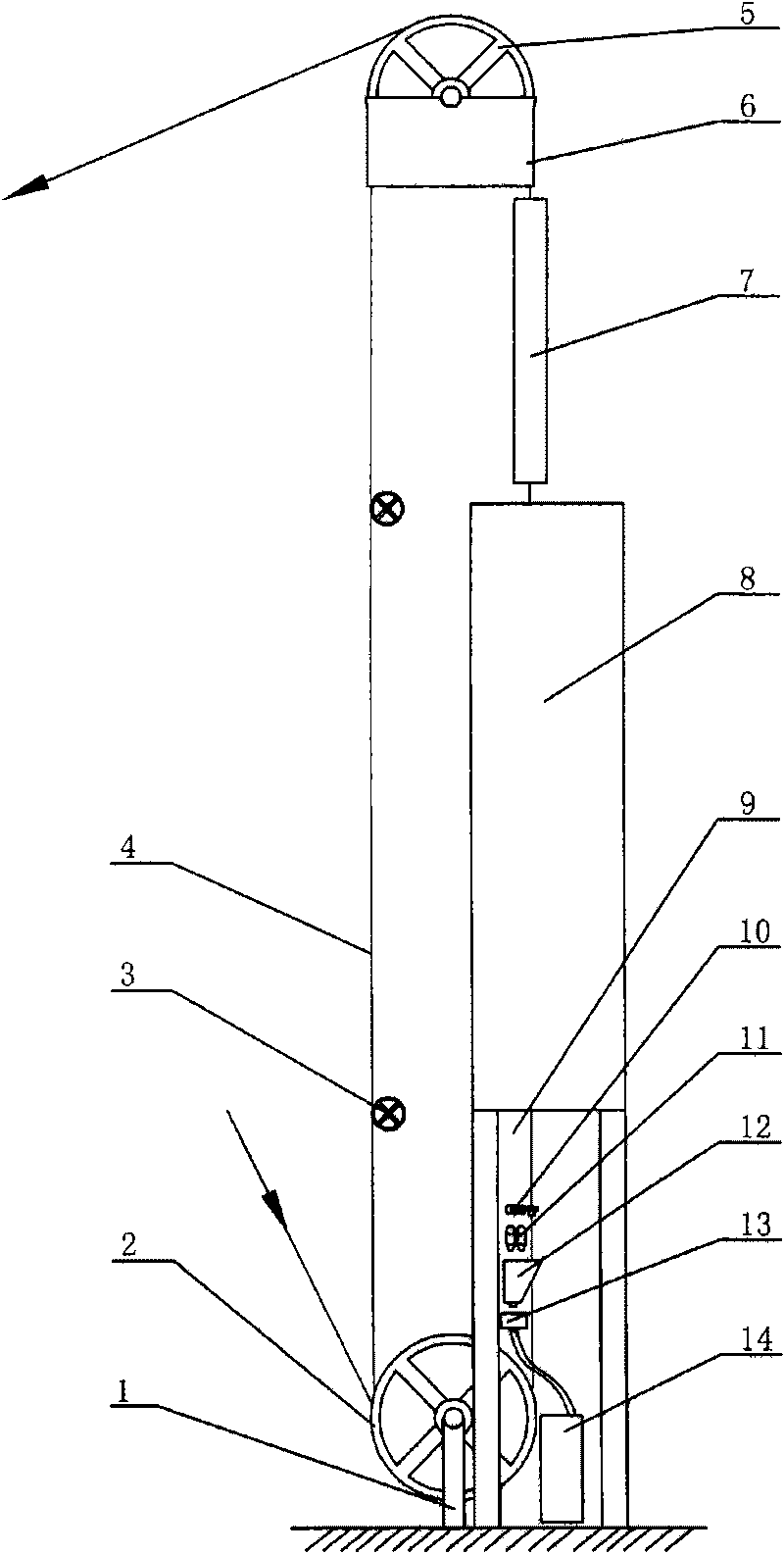

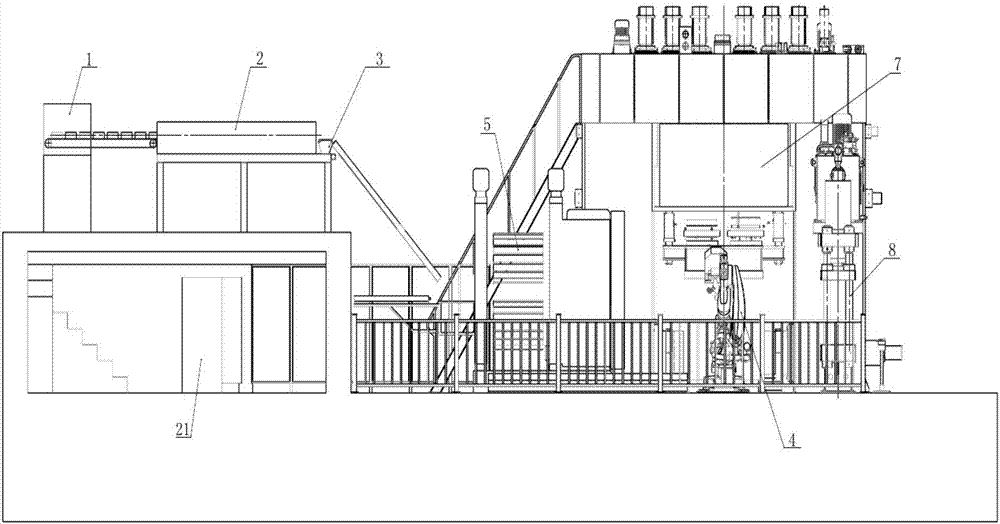

Swing type clamping one-way fuse tube electric wire welding production line

InactiveCN105618637AControllable distanceIncrease productivityLine/current collector detailsProduction lineElectric wire

Owner:徐海慧

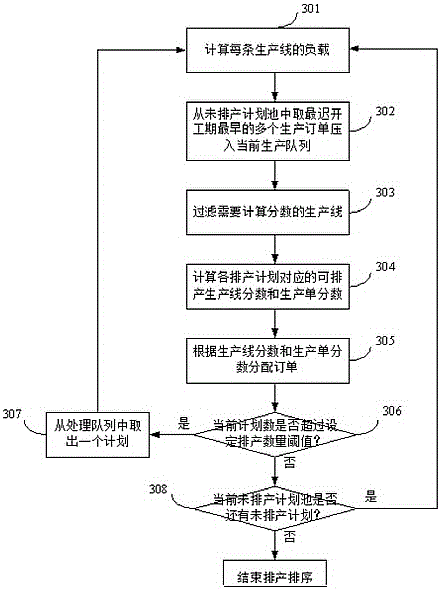

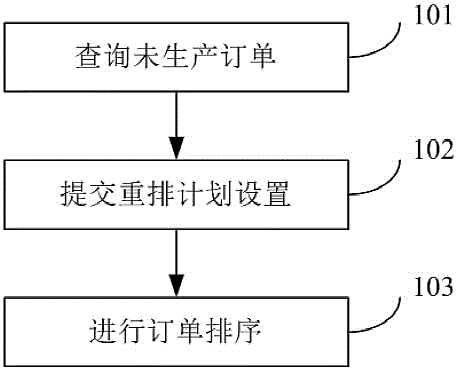

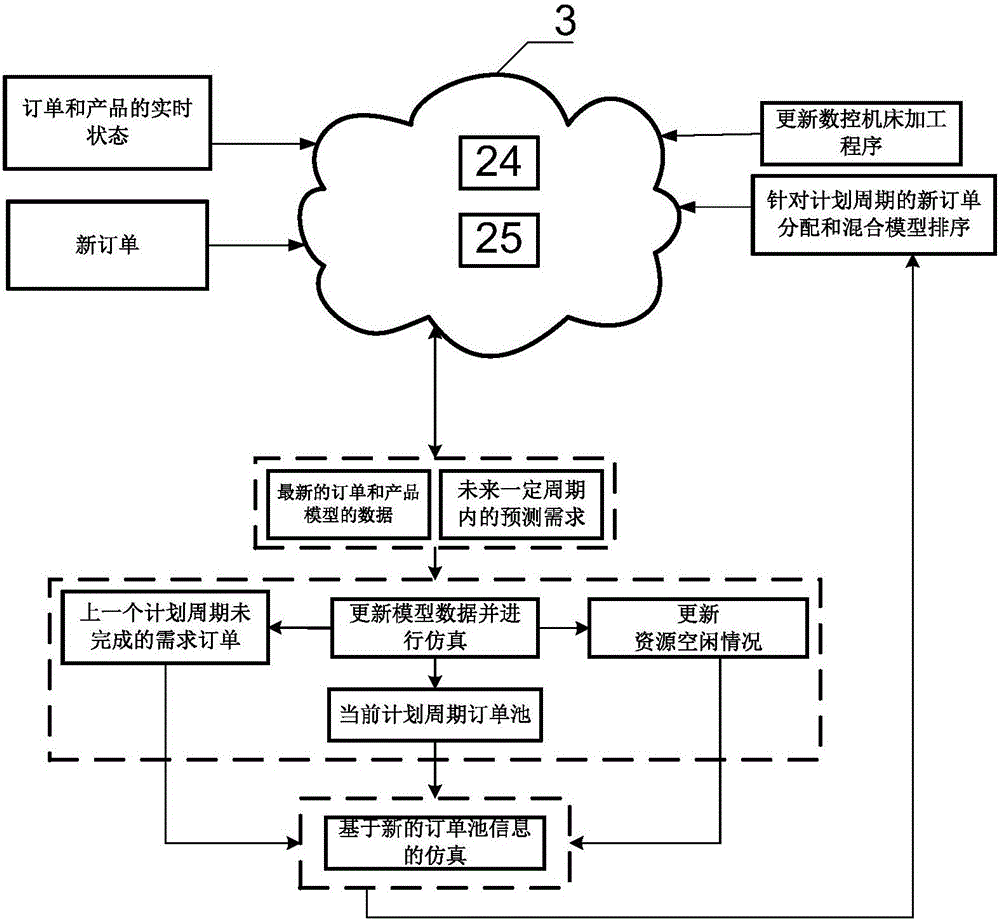

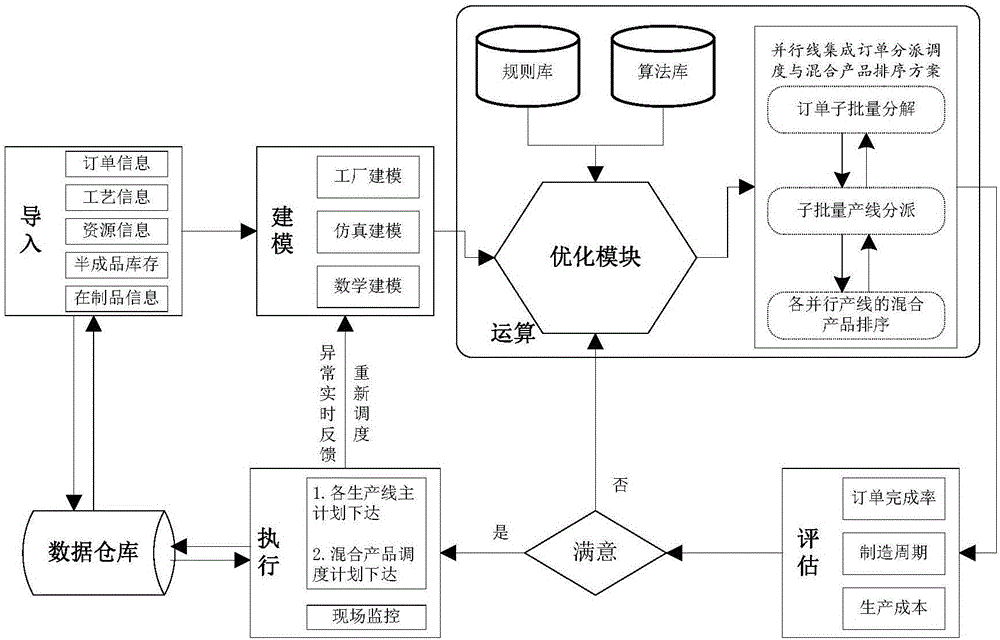

Production order production scheduling management method and production scheduling optimizer system

PendingCN106408112ARealize scientific managementImprove management efficiencyForecastingResourcesProduction lineOrder scheduling

Owner:广州亿澳斯软件股份有限公司

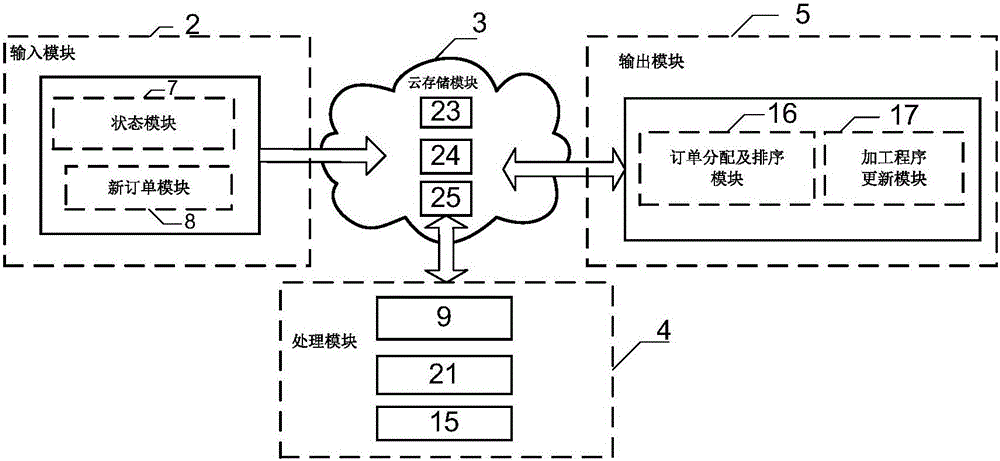

Order distribution scheduling and mixed product ordering system and method

ActiveCN106444643ASimple module structureEasy to installProgramme controlComputer controlNumerical controlProduction line

Owner:HUAZHONG UNIV OF SCI & TECH

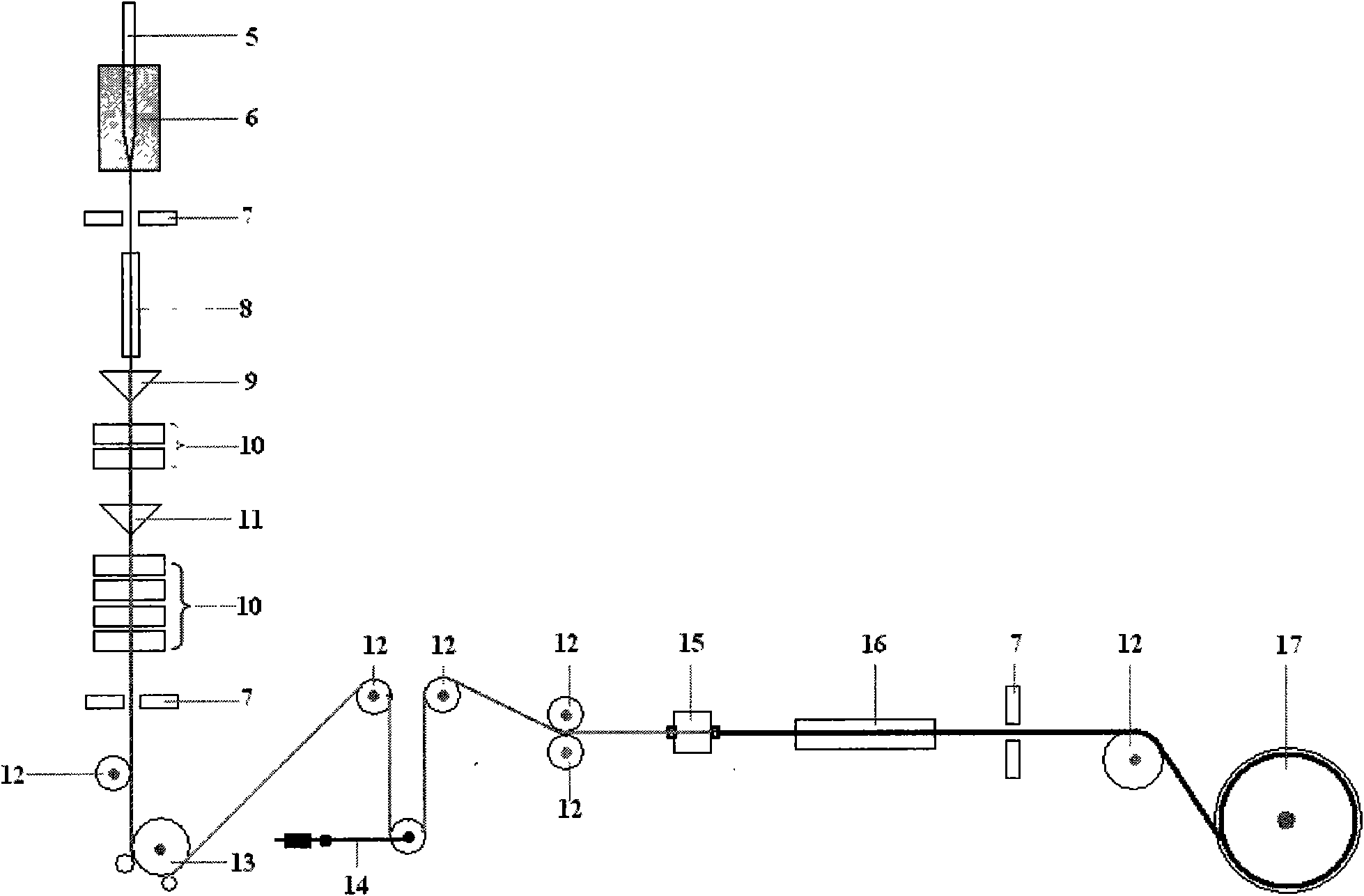

Product line for painting copper sheet wire

InactiveCN101707095AEasy to unloadEasy to spillInsulating conductors/cablesProduction lineFixed frame

Owner:常州市正和电磁线有限公司

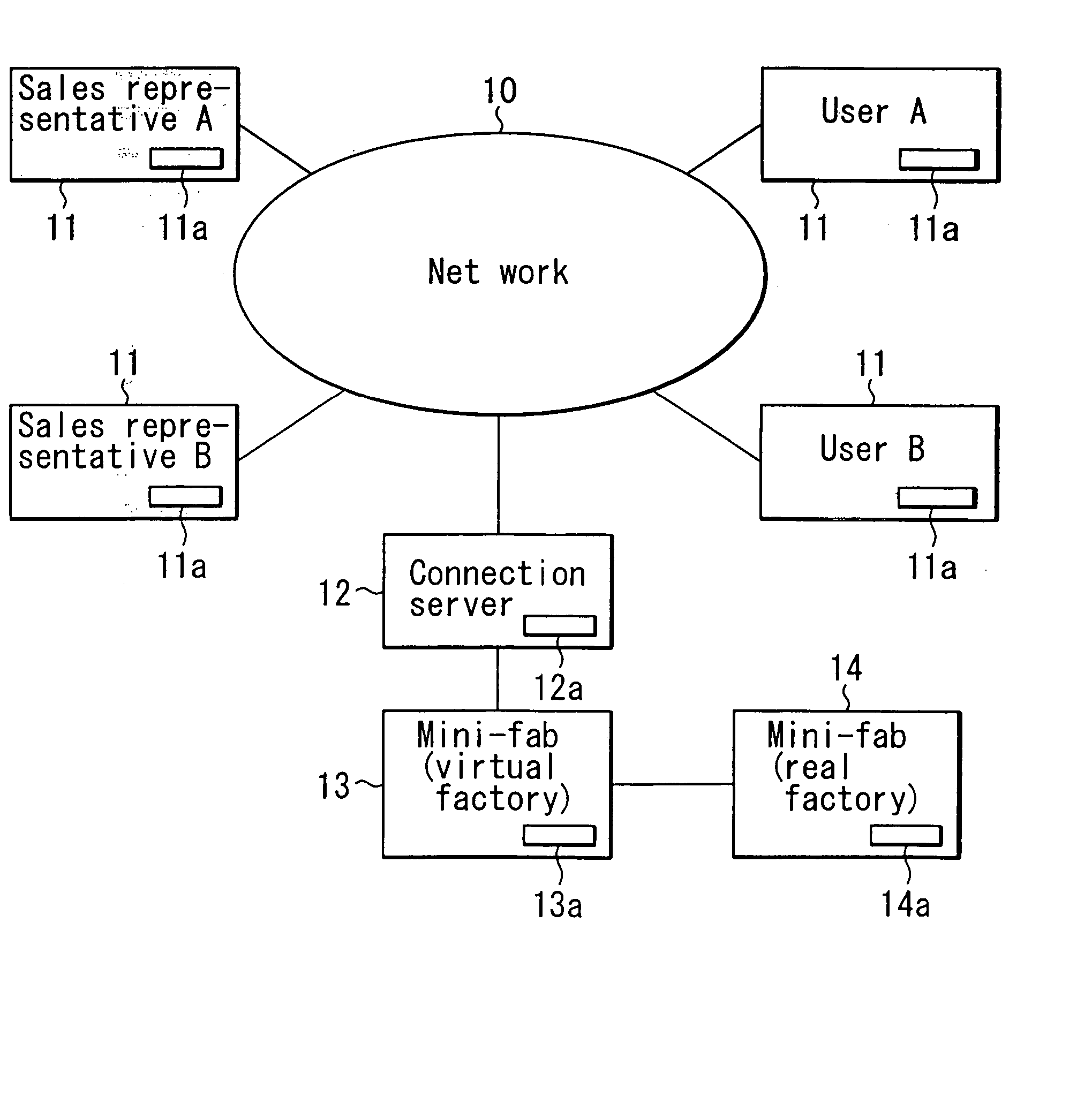

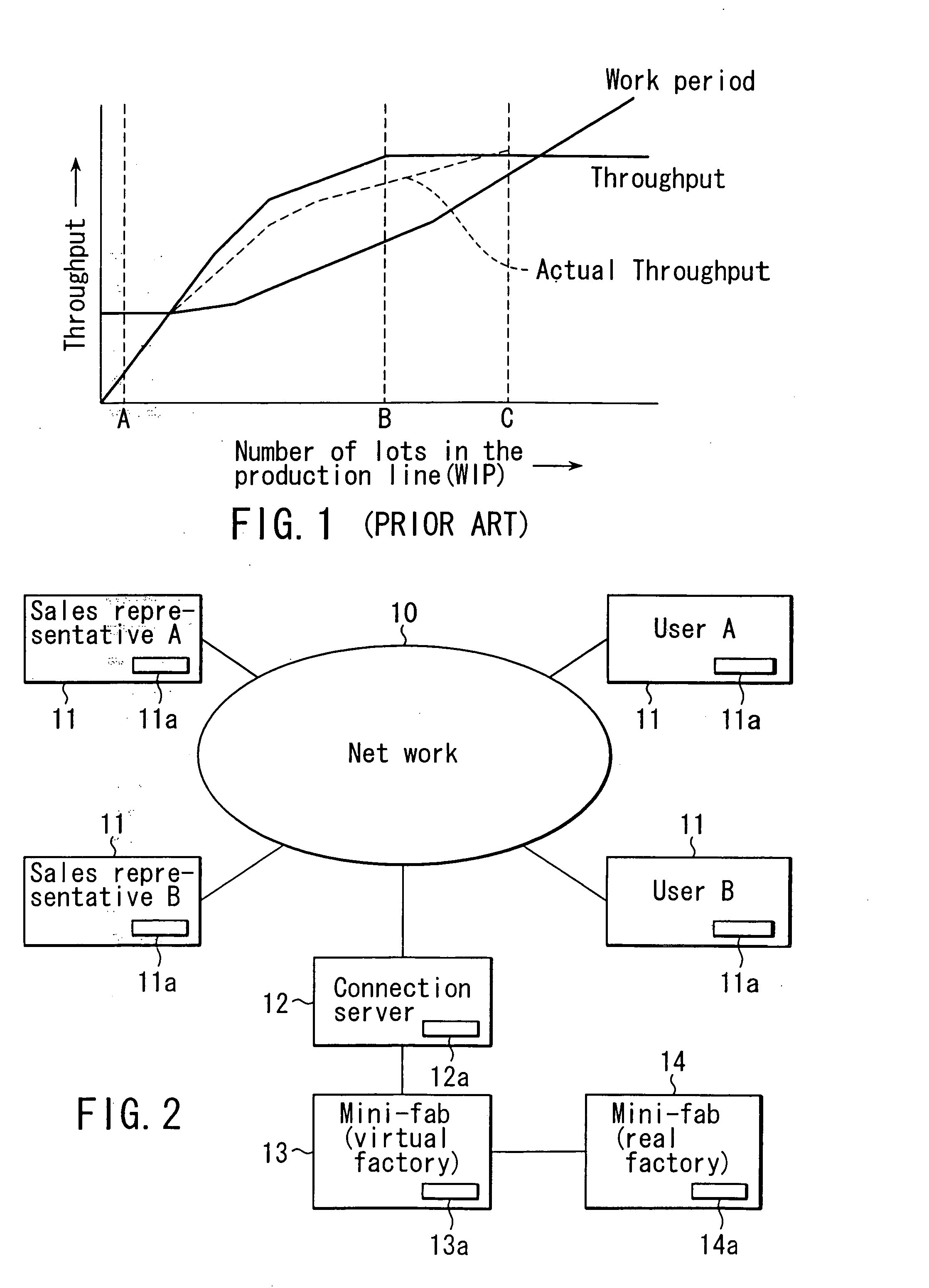

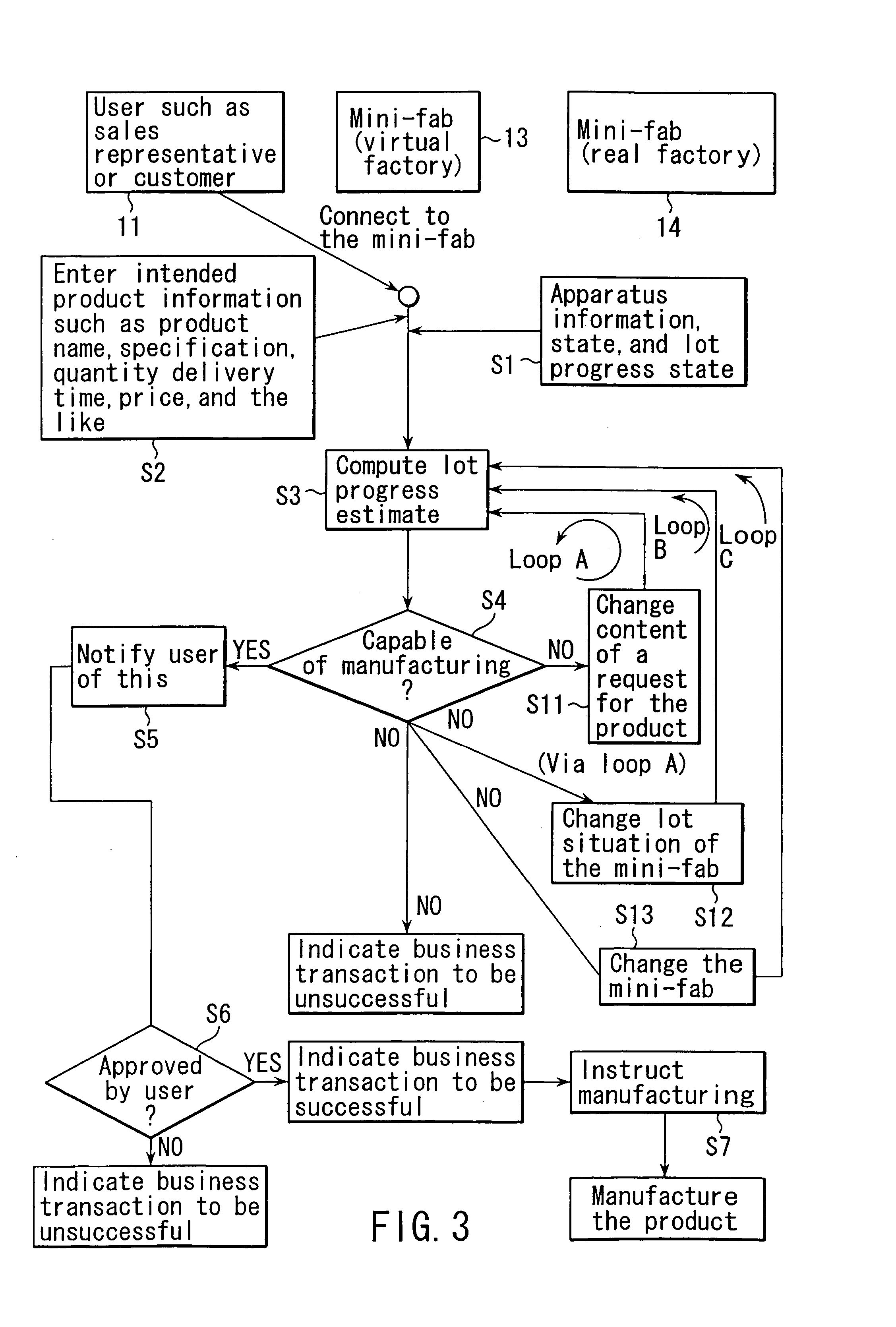

Electronic commerce method for semiconductor products, electronic commerce thereof, production system, production method, production equipment design system, production equipment design method, and production equipment manufacturing method

InactiveUS20050010492A1Increase business opportunitiesBuying/selling/leasing transactionsResourcesProduction lineE-commerce

Owner:MITSUTAKE KUNIHIRO +1

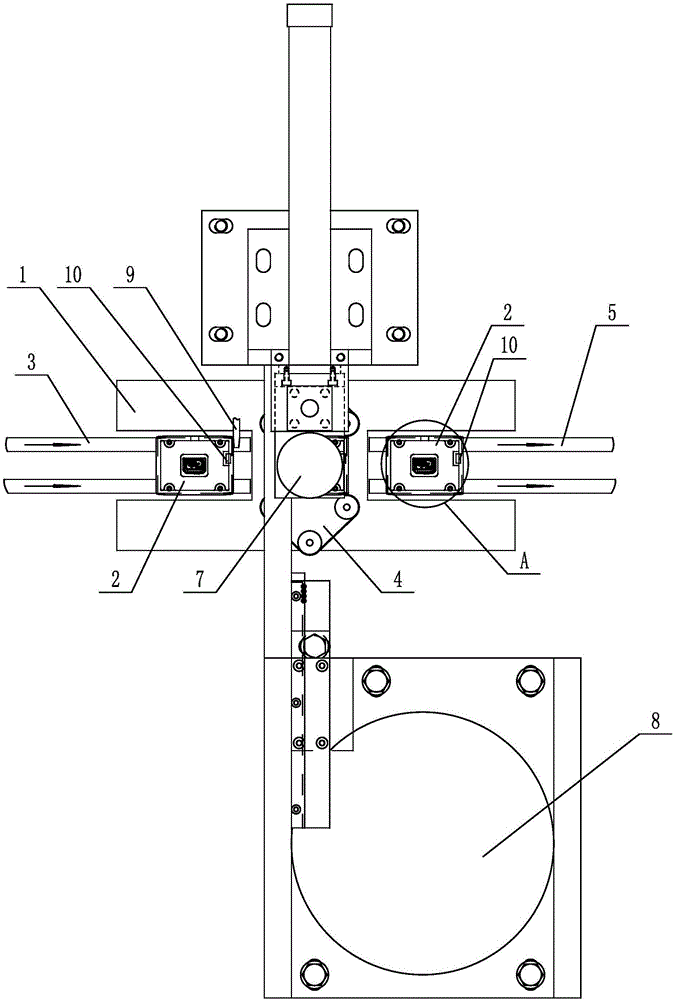

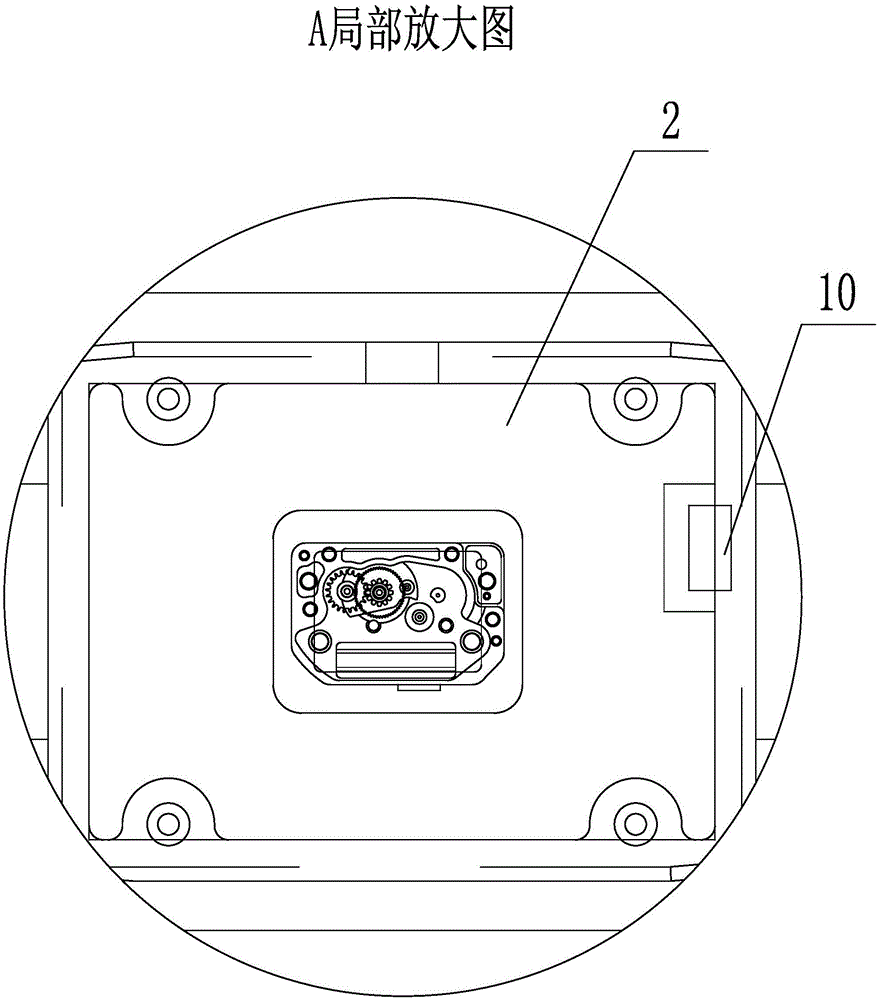

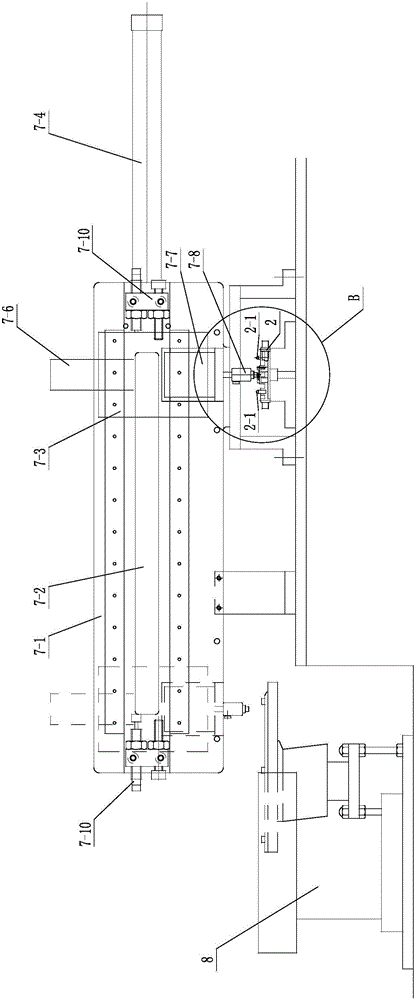

Watch movement gear automatic assembly production line

ActiveCN105710645AFully automatedIncrease productivityAssembly machinesProduction lineManufacturing cost reduction

Owner:FUJIAN GUOYI SHANGRUN INVESTMENT CO LTD

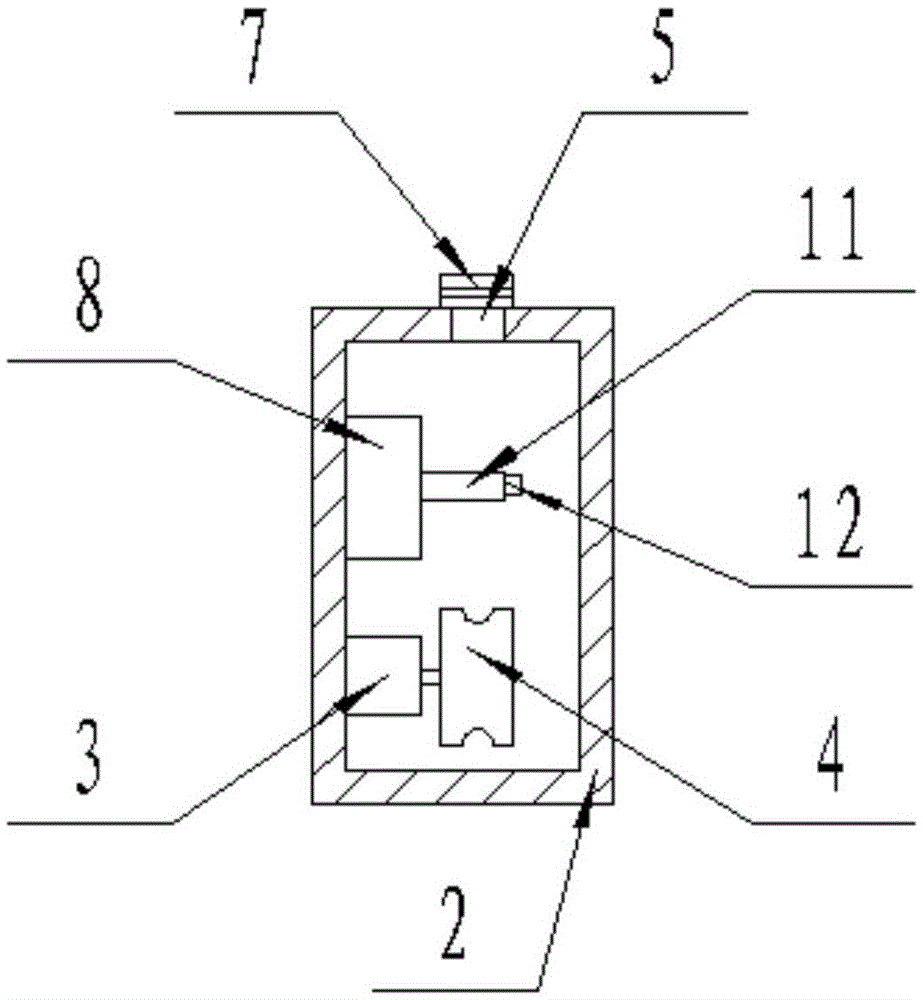

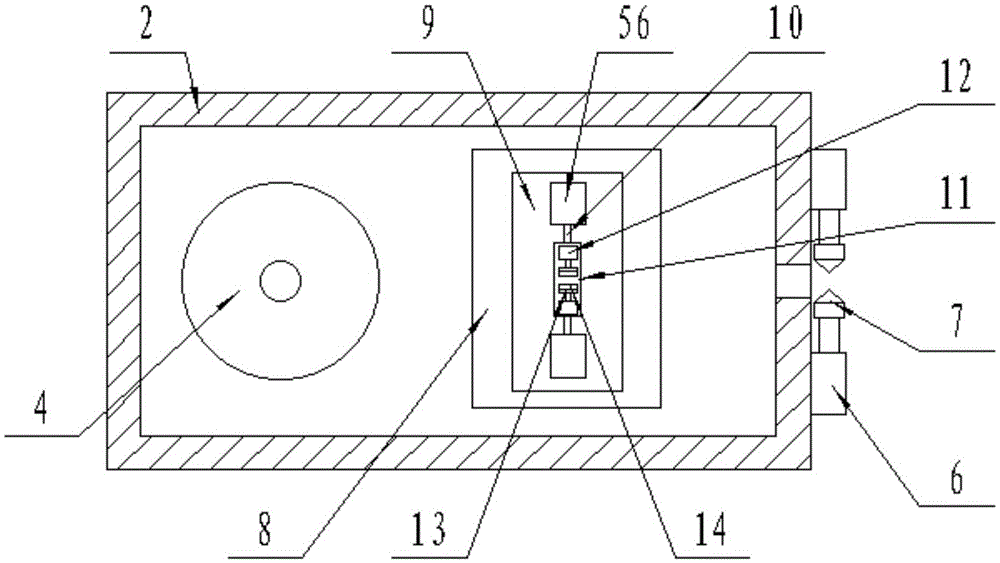

Forming device with turning mechanism

Owner:QUANZHOU S L MACHINERY MFG

Valve body closed type multidirectional precision forging production line

ActiveCN106955955AIncrease profitReduce wasteValve arrangementsForging/hammering/pressing machinesProduction lineAutomatic control

Owner:HUZHOU MACHINE TOOL WORKS

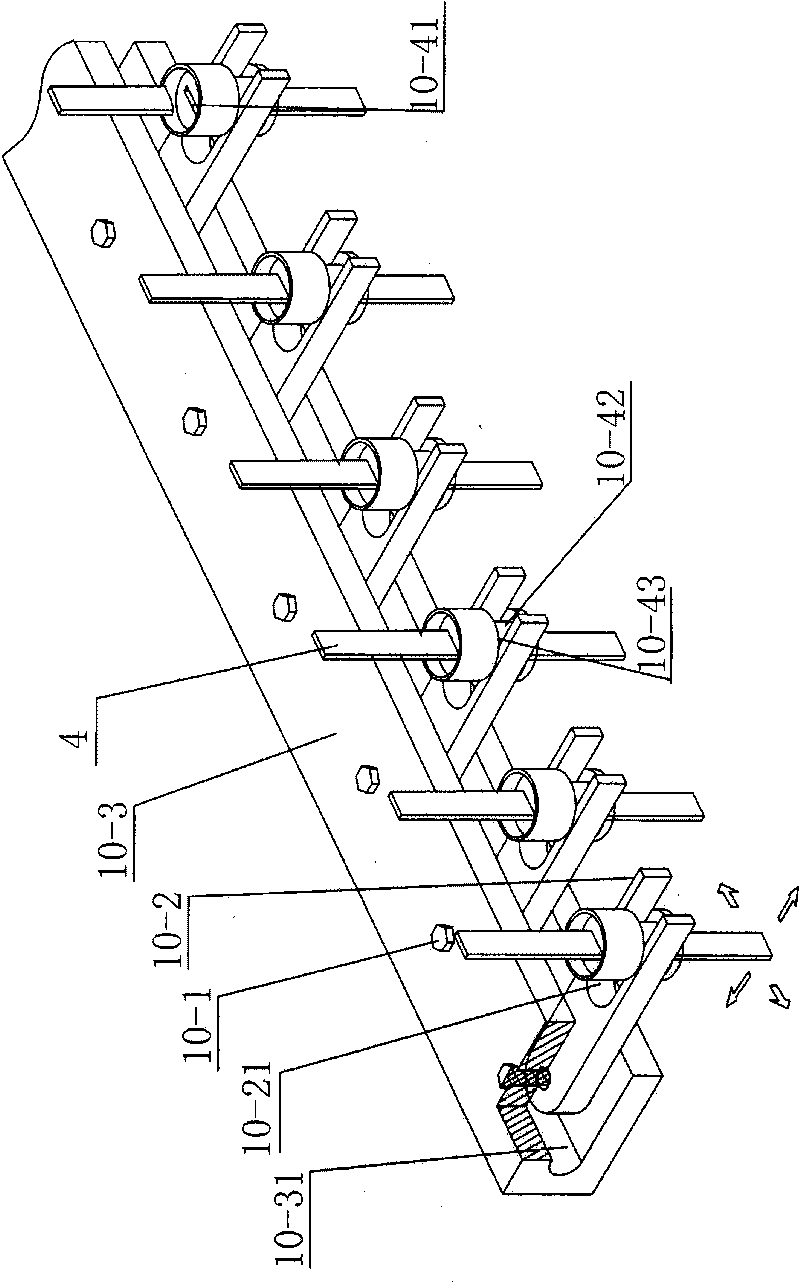

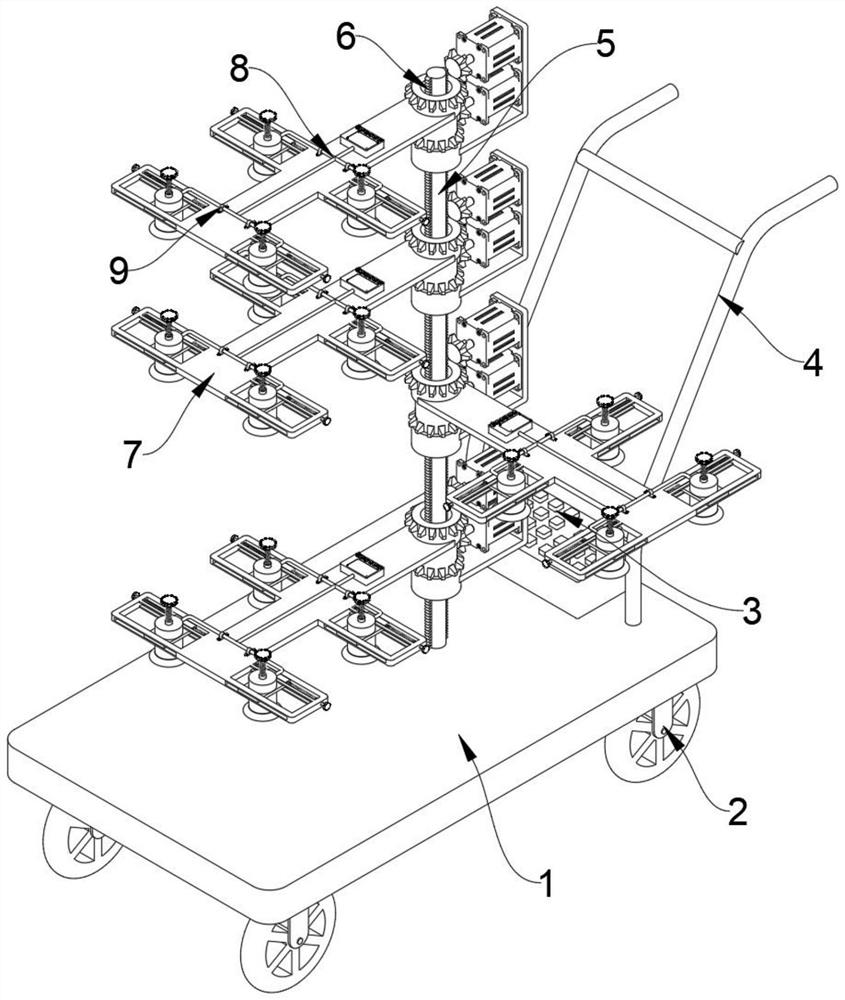

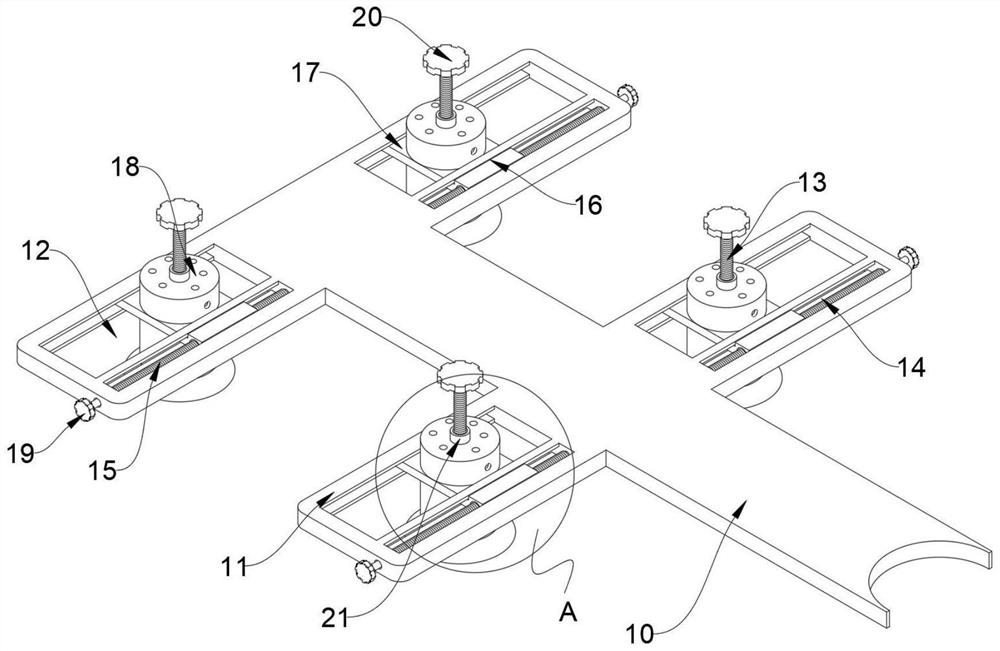

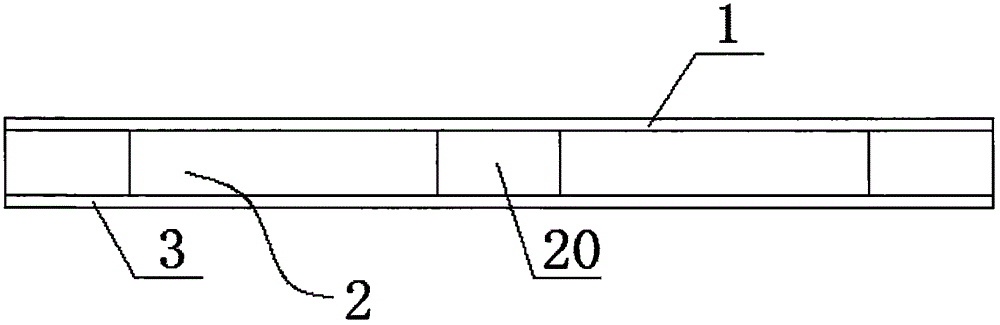

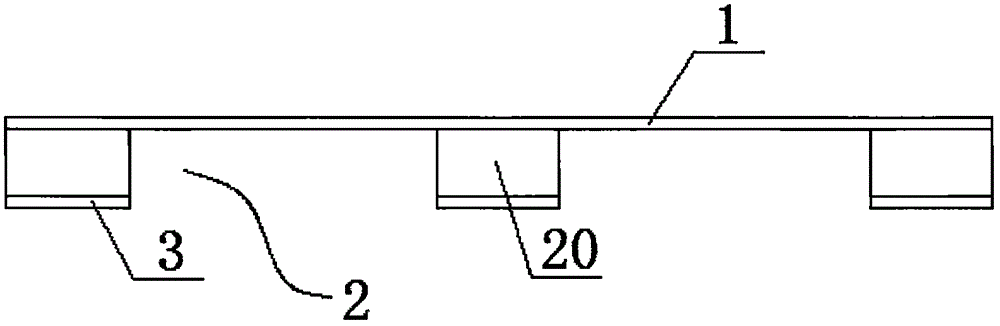

Conveyer belt production line centering mechanism capable of realizing convenient adjustment

ActiveCN106626152AAffect qualityImprove alignment efficiencyBeltsDomestic articlesProduction lineLocking mechanism

The invention discloses a conveyer belt production line centering mechanism capable of realizing convenient adjustment. The conveyer belt production line centering mechanism comprises an upper guide rail, a lower guide rail and a clamping device, wherein the lower guide rail is provided with a first slide block and a second slide block; the lower side of the clamping device is in slip connection with the first slide block; the upper side of the clamping device is in slip connection with the upper guide rail; an electrically controlled locking mechanism is arranged between the clamping device and the first slide block; the first and second slide blocks are respectively provided with first and second synchronization cylinders; piston rods of the first and second synchronization cylinders are respectively provided with first and second references; the working cavity of the first synchronization cylinder communicates with the working cavity of the second synchronization cylinder; an intermediate point between the first reference and the second reference is positioned on the centered flat plane of a vulcanizer; and a synchronization moving mechanism is connected between the first slide block and the second slide block, so that the first slide block and the second slide block synchronously move. The conveyer belt production line centering mechanism can obviously improve the centering efficiency, ensure the centering precision and prevent the quality of a conveyer belt from being influenced due to a centering error.

Owner:ZHEJIANG SANWEI RUBBER ITEM CO LTD

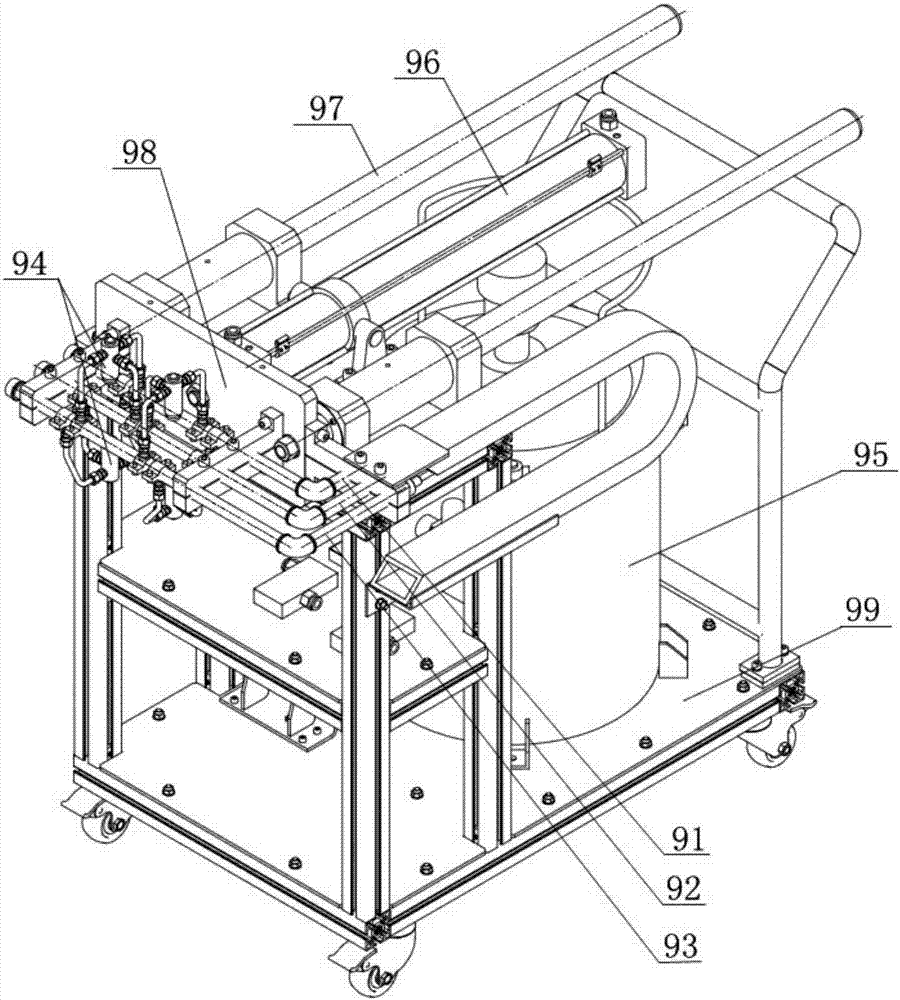

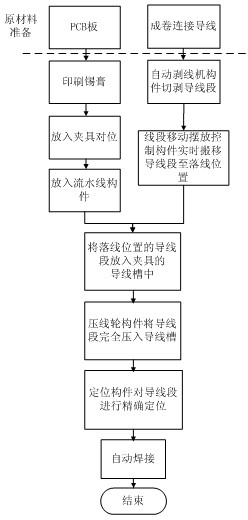

Automatic welding method and system for LED module connecting lead

InactiveCN102570237AFacilitate automatic weldingImprove qualityLine/current collector detailsProduction lineEngineering

Owner:黎明

Production line for fireproof heat-insulating wall plates, and method for on-site processing of fireproof heat-insulating wall plates by utilizing production line

InactiveCN102699994AImprove foaming qualityImprove insulation effectCeramic shaping plantsProduction lineEngineering

The invention relates to a production line for fireproof heat-insulating wall plates, and a method for on-site processing of the fireproof heat-insulating wall plates by utilizing the production line, and solves the problems that the conventional multi-layer fireproof heat-insulating wall plate processing equipment has a large occupied area, high investment and failure in on-site processing. Therefore, the production line comprises a stirrer, a pouring vehicle, and two lines of pouring molds, wherein the stirrer comprises an agitation tank; a stirring paddle driven by an external motor is arranged in the agitation tank; the agitation tank is provided with a liquid feeding device, a solid feeding device and a baiting valve, and is fixed on four support legs; the pouring vehicle comprises a vehicle body and a wagon box; the wagon box is fixed on the vehicle body; wheels are arranged below the vehicle body; the opening of the wagon box faces upwards; an emptying gate is arranged at the rear part of the wagon box; and a scraping plate is arranged on a fixing bracket behind the emptying gate. The invention further relates to a corresponding processing method. The production line has the advantages of low investment and small occupied area, ensures on-site processing, saves transportation cost, and is an ideal upgrading product for the conventional fireproof heat-insulating wall plate production line.

Owner:SHANDONG XINFA ENVIRONMENTAL PROTECTION TECH CO LTD

Powerless pile separation device

ActiveCN109160273AGuaranteed uptimeSimple structureConveyorsDe-stacking articlesProduction lineEngineering

The invention discloses a powerless pile separation device. The powerless pile separation device comprises a machine body, a pile separation module, a conveying module and a connecting rod module, wherein the machine body is provided with a first slide way and a second slide way arranged at intervals; the first slide way and the second slide way are used for conveying goods containers; the pile separation module is connected with the machine body, is arranged above the first slide way, and is used for separating the goods containers on the first slide way; the conveying module is arranged between the first slide way and the second slide way, and is used for conveying the goods containers to the second slide way after separation by the pile separation module; the connecting rod module is rotationally arranged on the machine body; one end of the connecting rod module is connected with the pile separation module, and the other end of the connecting rod module is connected with the conveying module; the connecting rod module is provided with a handle; and when the handle pulls the connecting rod module to move, the connecting rod module drives the pile separation module to separate thegoods containers on the first slide way, and the connecting rod modules drives the conveying module to convey the goods containers, separated on the first slide way, to the second slide way. The powerless pile separation device is simple and small in structure and convenient for operation and application to a small production line.

Owner:GAC TOYOTA MOTOR

Oil cylinder assembly production line

ActiveCN103659247AHigh degree of automationSave human effortOther manufacturing equipments/toolsMetal working apparatusProduction lineIndustrial engineering

Owner:无锡金峰园弹簧制造有限公司

Composite sheet material production technology and production equipment

ActiveCN107160812ASimple structureIncrease productivityLamination ancillary operationsLaminationProduction lineCorona treatment

The invention discloses a composite sheet material production technology and a production equipment. The production equipment comprises a core material unreeling device, a core material conveying processing device, a gluing device, a combination device, a fine rolling combination device, and a subsequent production line which are connected successively; the core material conveying processing device comprises a first conveying device, a second conveying device, a corona processing device, a third conveying device, and a first machine frame; the first conveying device, the second conveying device, and the third conveying device are arranged on the first machine frame successively; and the corona processing device is arranged on the second conveying device. The composite sheet material production technology and the production equipment possess following advantages: structure is simple, process is novel, and the composite sheet material production technology is safe and reliable.

Owner:沈惠华

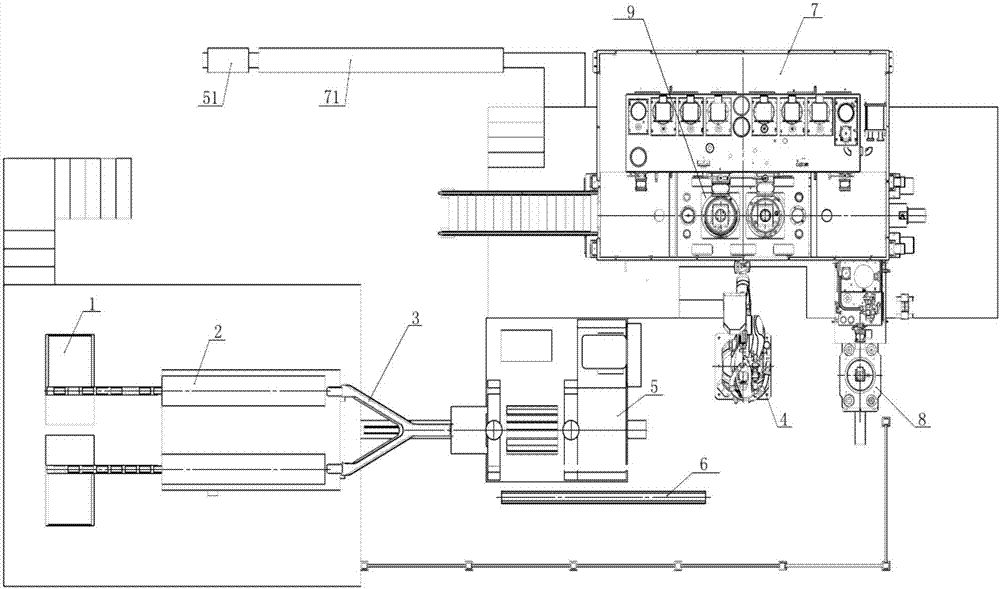

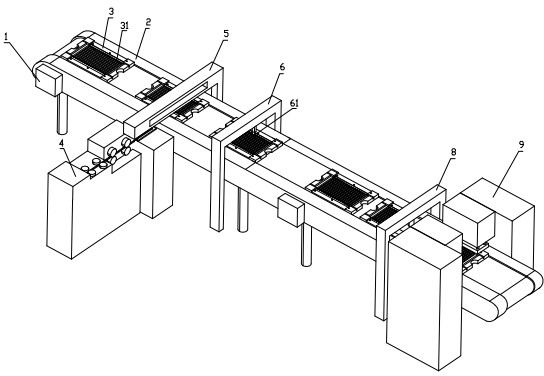

Automatic production line of laminated board and automatic production method of laminated board

ActiveCN109928209ARealize automated productionNo manual operationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineFixed frame

The invention provides an automatic production line of a laminated board and an automatic production method of the laminated board. The automatic production line comprises a double-head spot welding machine, a feeding mechanical arm, a discharging device and a conveying line; the discharging device comprises a machine frame, an overturning mechanism, a clamping mechanism, a clamping and positioning mechanism, a lifting discharging mechanism and a pushing mechanism, wherein the machine frame is arranged on the front side of a positioning mold, and the overturning mechanism is erected between the machine frame and the positioning mold; the overturning mechanism comprises a bearing seat, a swinging shaft, two overturning arms, a swinging driving part and a fixing frame, wherein the bearing seat and the swinging driving part are oppositely arranged, one end of the swing shaft is rotationally arranged on the bearing block, and the other end of the swing shaft is arranged on the swing driving part, the fixing frame is fixedly connected to the swing shaft, one ends of the two overturning arms are arranged on the fixing frame in a spaced mode through the clamping mechanism, the clamping and positioning mechanism is arranged at the extending end of each overturning arm, and the lifting discharging mechanism is arranged on the machine frame and is positioned between the two overturning arms. According to the automatic production line, the automatic production of the laminated board can be realized, and the working efficiency is improved.

Owner:HONORFAITH FURNITURE

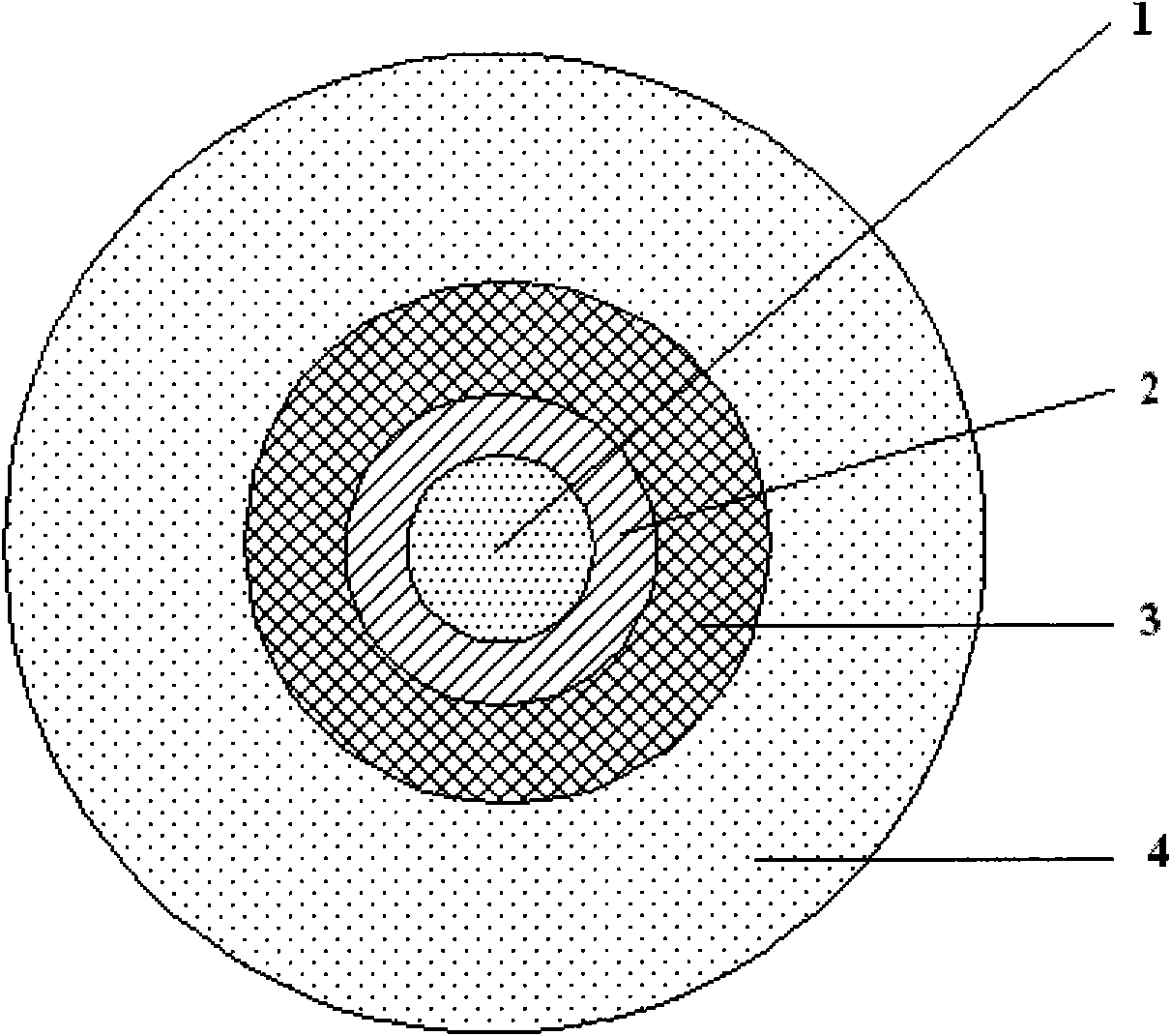

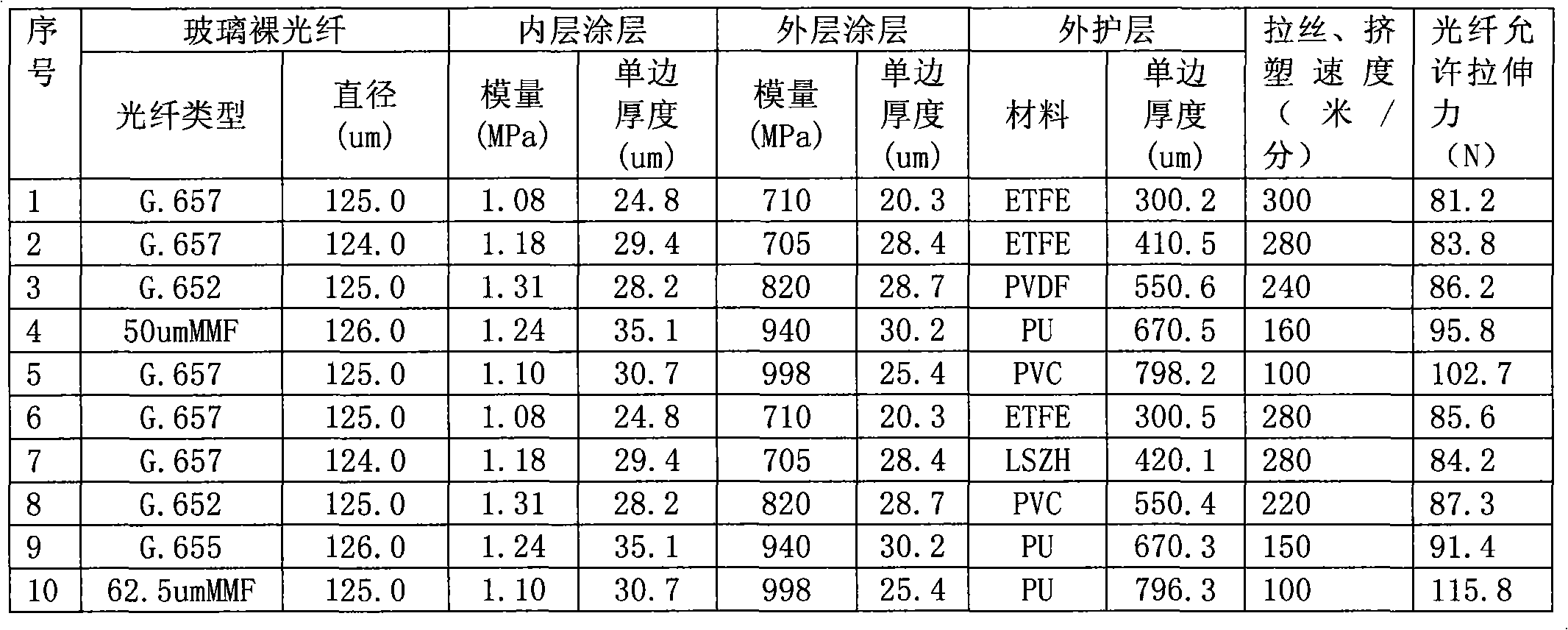

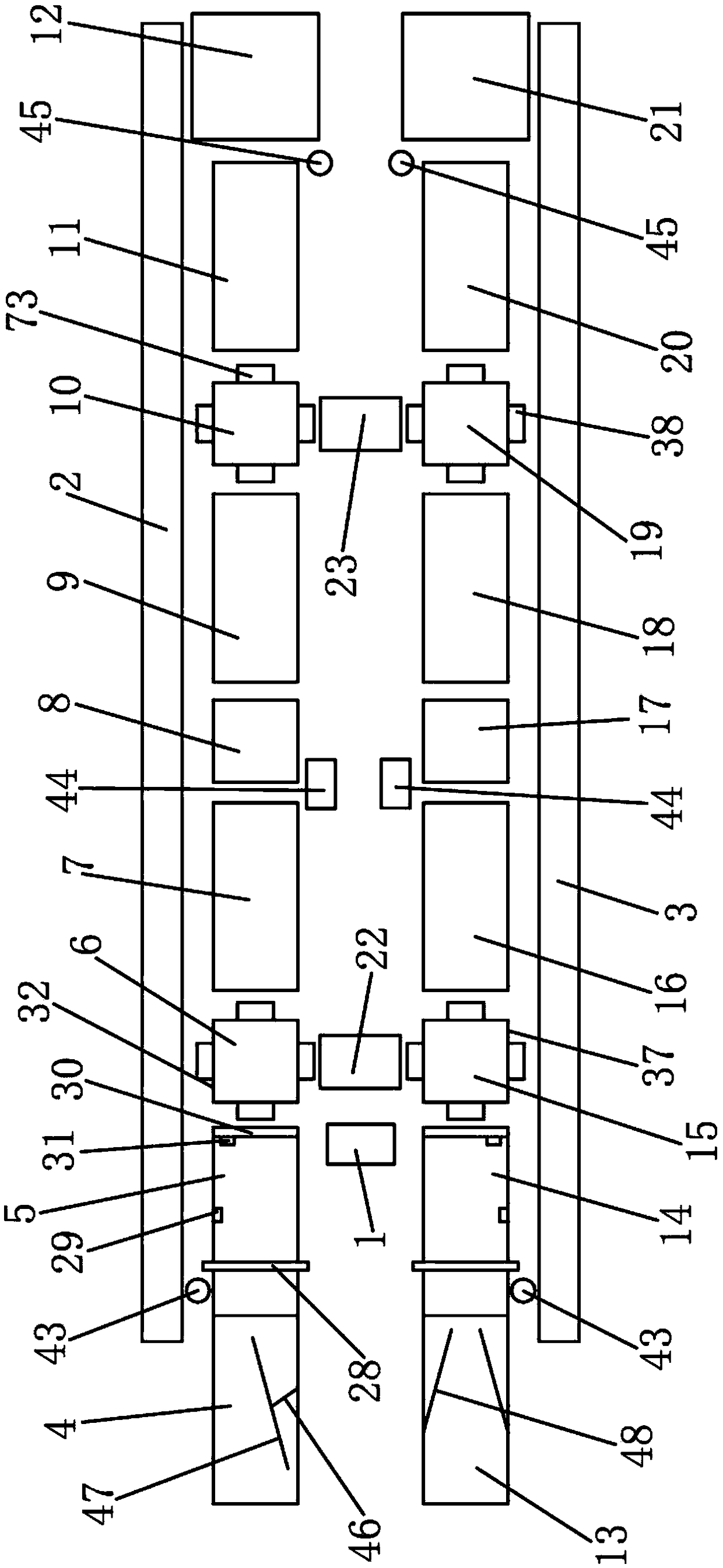

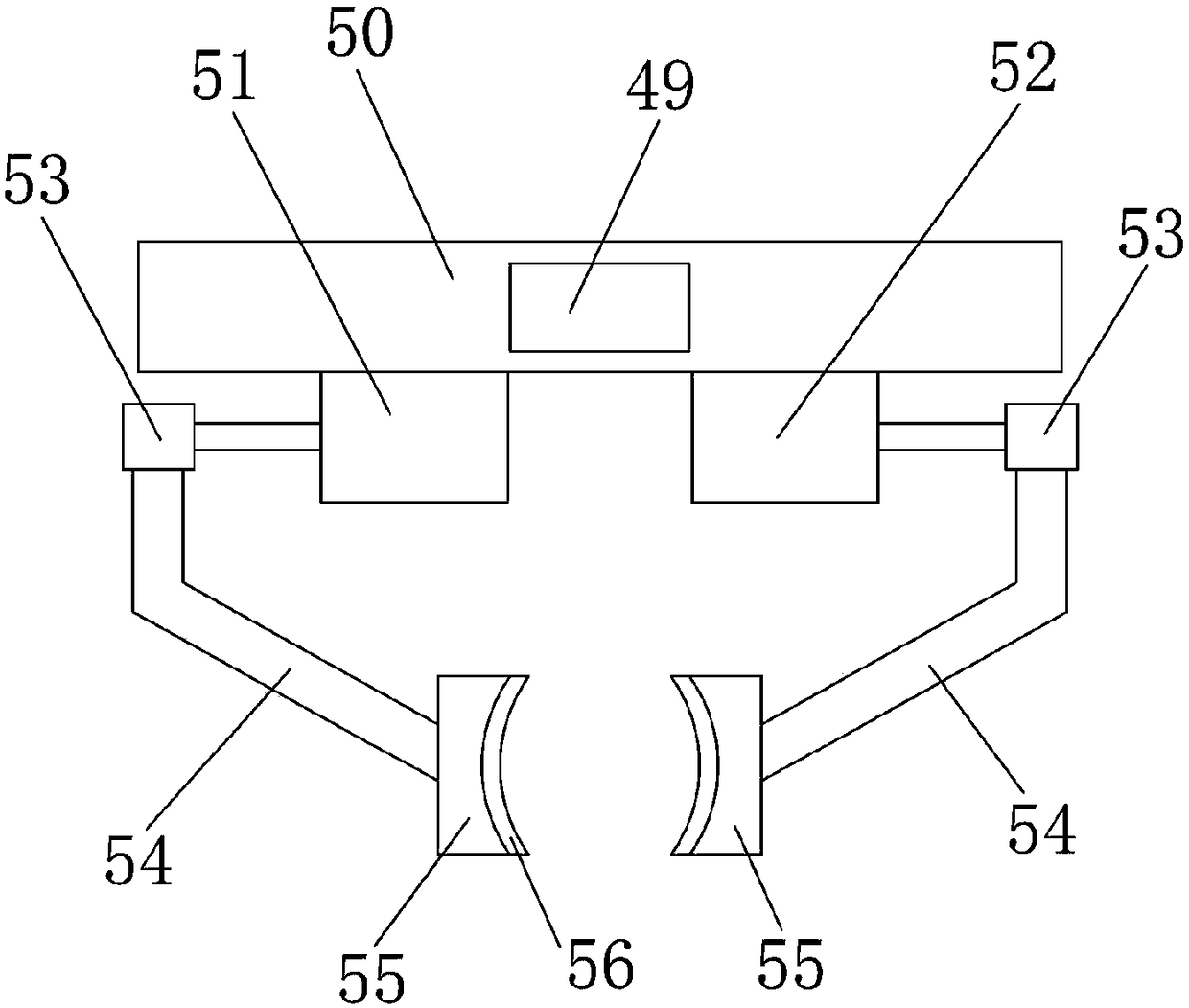

Indoor-laying optical fiber and manufacture method thereof

ActiveCN101614842AQuality improvementIncrease internal stressGlass making apparatusCladded optical fibreProduction lineProtection layer

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

Tray stacking production line

InactiveCN107585583AHigh degree of automationSave human effortStacking articlesDe-stacking articlesProduction lineMechanical engineering

The invention relates to the field of a tray production devices, in particular to a tray stacking production line. The tray stacking production line comprises a first conveying belt, a tray taking andputting device, stacking and aligning devices, a second conveying belt and a control device. The first conveying belt is used for conveying trays and comprises tray grabbing positions. The second conveying belt comprises tray stacking positions, trays are stacked at the tray stacking positions to form tray stacks, and the second conveying belt is used for conveying the tray stacks. The tray taking and putting device is used for taking up the trays from the tray stacking positions of the first conveying belt and putting the trays at the tray stacking positions of the second conveying belt. Thestacking and aligning devices are located above the tray stacking positions and guide the tray stacks. The control device is used for controlling the first conveying belt, the tray taking and puttingdevice, the stacking and aligning devices and the second conveying belt. The tray stacking production line can complete tray stacking work without participation of excessive workers, save labor, canensure the stacking quality and guarantee the production safety.

Owner:广东精泽企业服务有限公司

Automatic lamination, detection and boxing production line of stator and rotor

PendingCN108526375AReduce in quantityReduce labor intensityManufacturing stator/rotor bodiesSortingProduction lineMechanical equipment

Owner:浙江钜丰科技有限公司

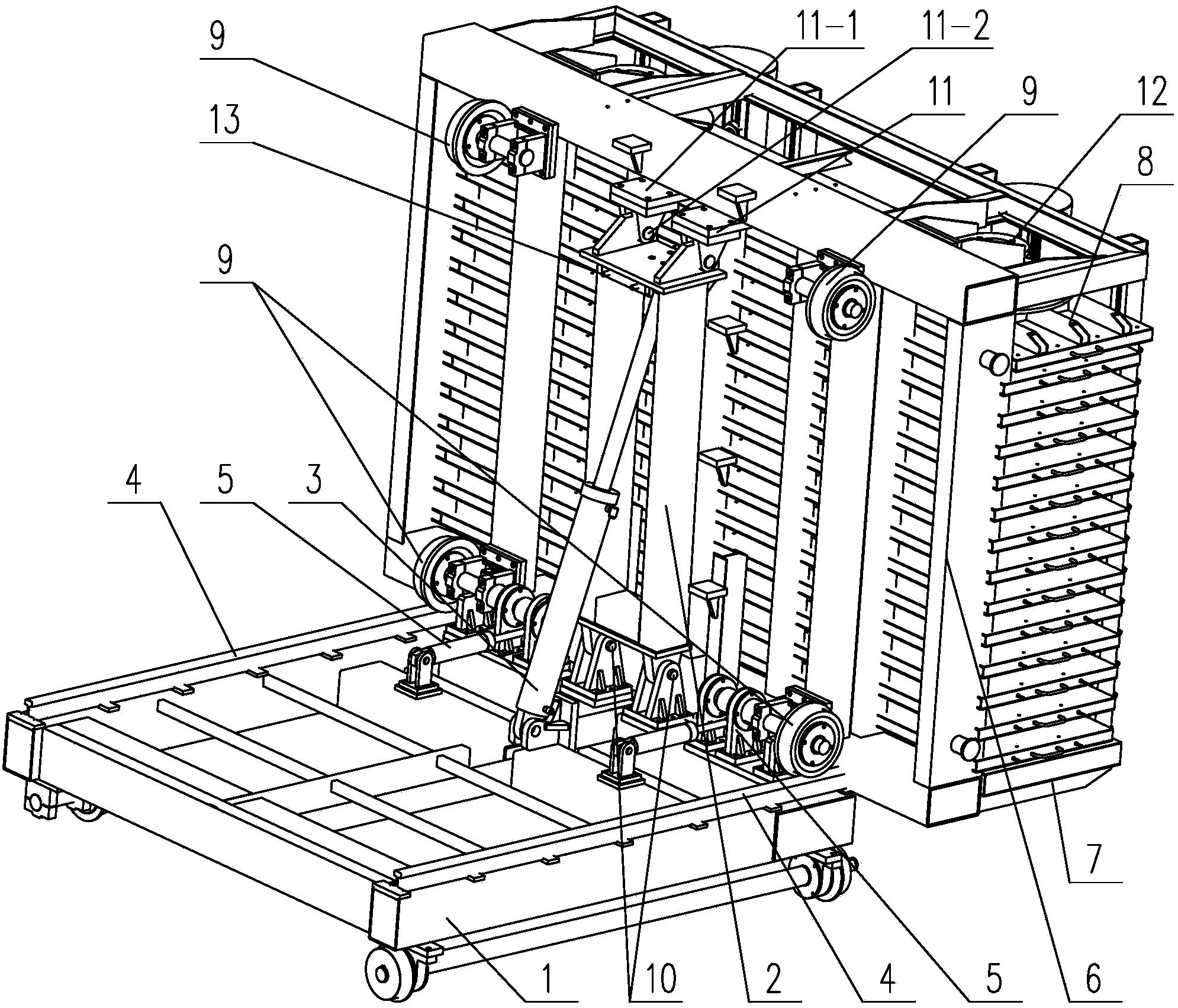

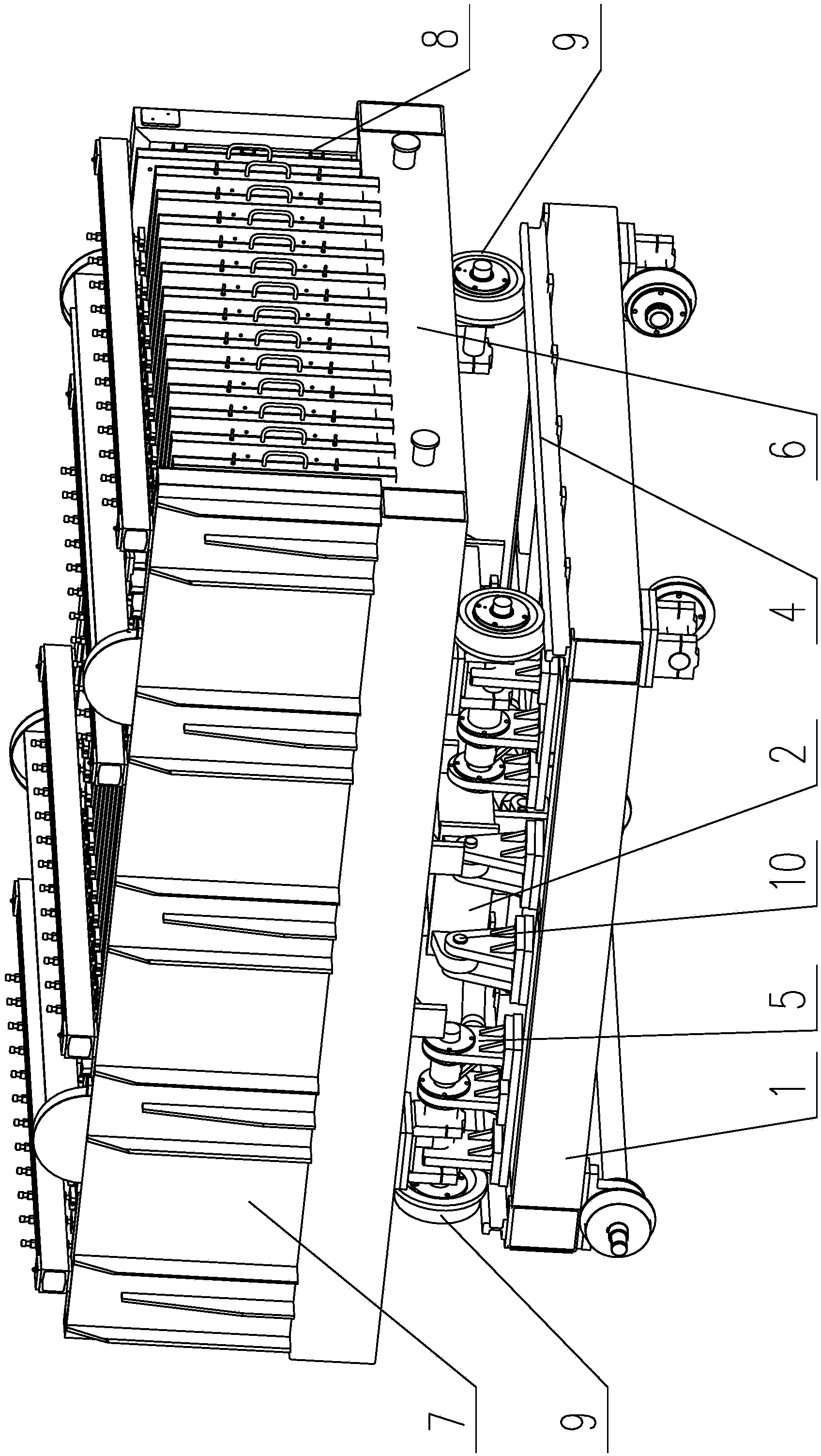

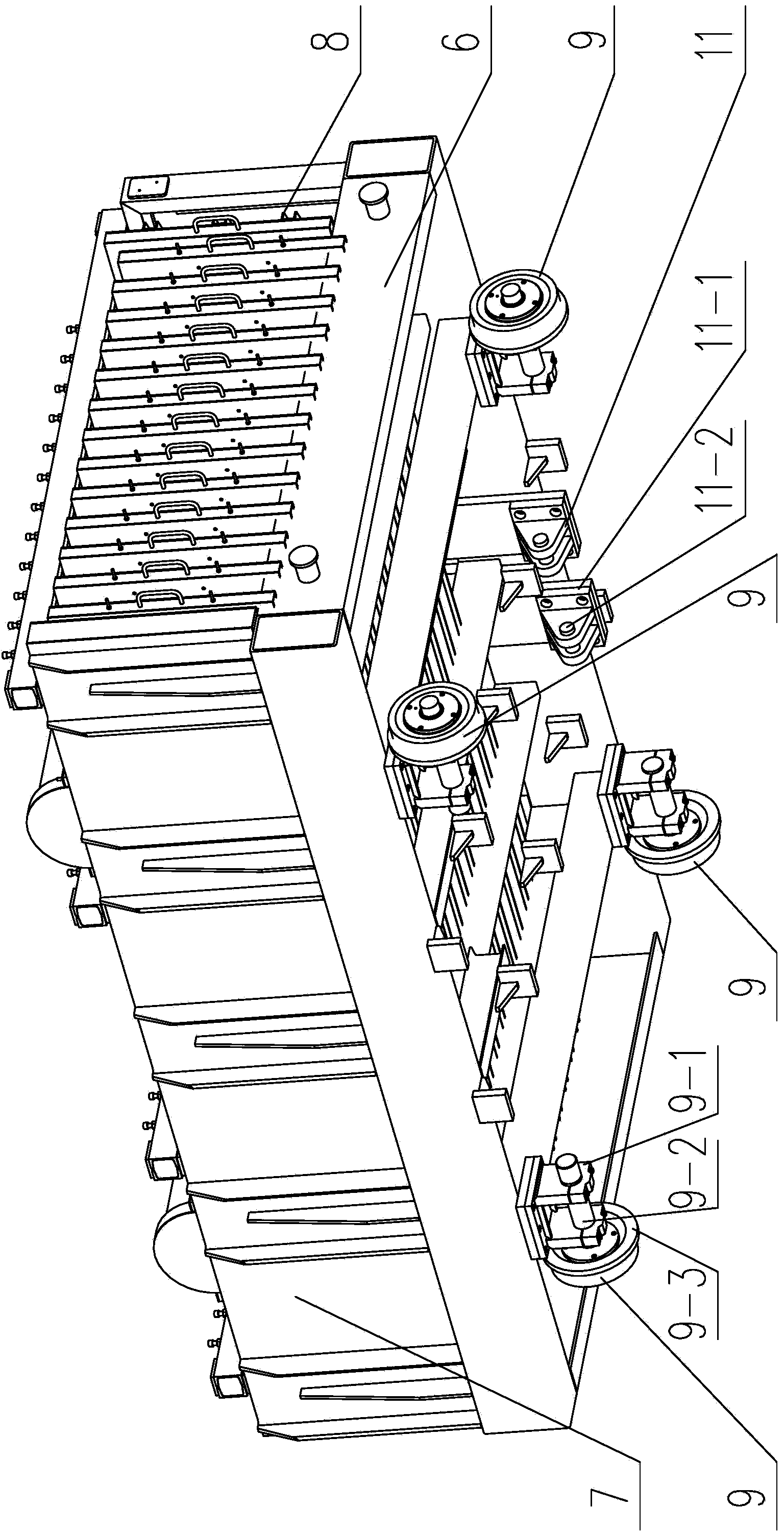

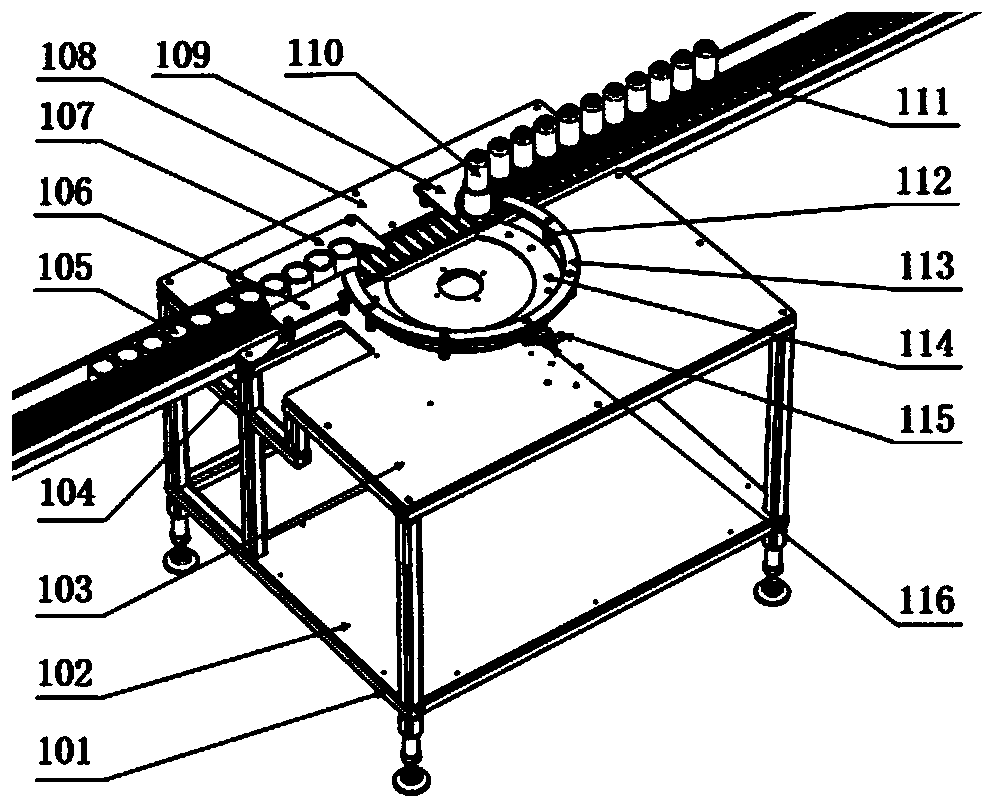

Ceramic forming mold automatic exchange machine

InactiveCN108724449APositioning synchronizationPrecise positioningConveyorsAuxillary shaping apparatusProduction lineCeramic molding

The invention relates to the field of ceramic forming production equipment, in particular to a ceramic forming mold automatic exchange machine. The ceramic forming mold automatic exchange machine is characterized by comprising a longitudinal moving mechanism, an exchange mechanism and a clamping mechanism; the longitudinal moving mechanism comprises a mold clamping rack, a longitudinal slide railfixedly arranged on the mold clamping rack, a longitudinal moving rack slidably arranged on the longitudinal slide rail and a longitudinal driving unit driving the longitudinal moving rack to move; the exchange mechanism comprises an exchange servo motor fixedly arranged on the longitudinal moving rack and a rotary frame driven by the exchange servo motor to rotate. According to the ceramic forming mold automatic exchange machine provided by the invention, rising, dropping, position exchange and clamping of plaster molds can be implemented through the longitudinal moving mechanism, the exchange mechanism and the clamping mechanism; unformed plaster molds on a production line and formed plaster mold on an automatic forming machine can be exchanged; the automation degree is high, manual carrying of molds is omitted; the production efficiency is improved; and the labor cost is lowered.

Owner:FUJIAN DEHUA BOLONG CERAMICS CO LTD

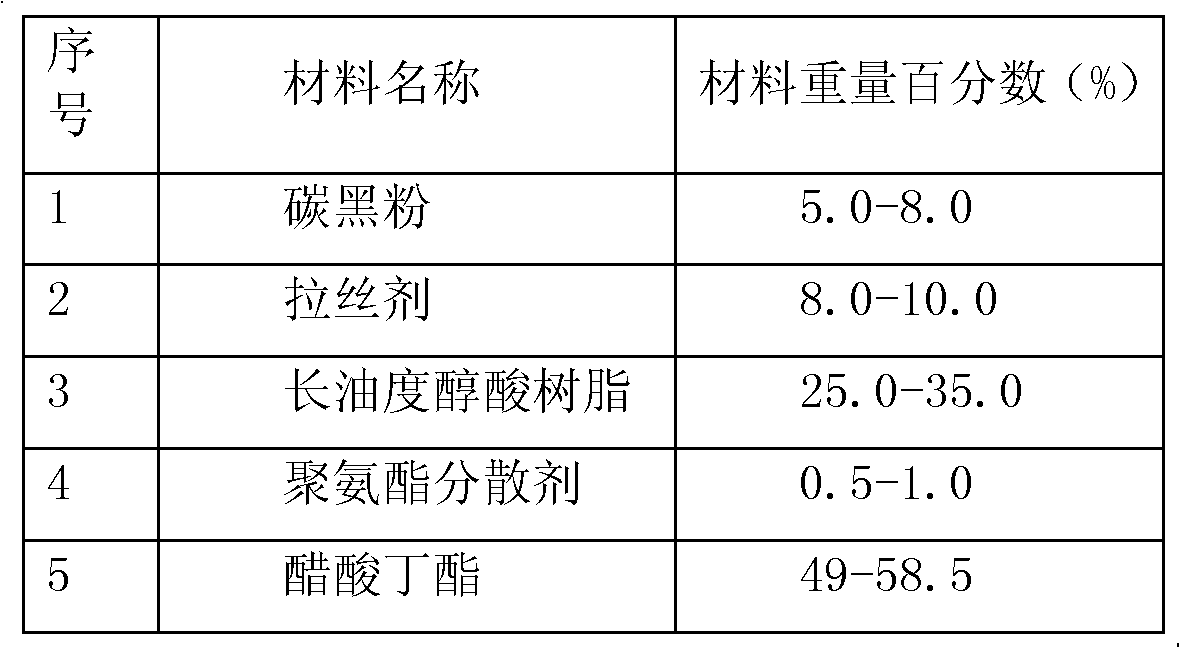

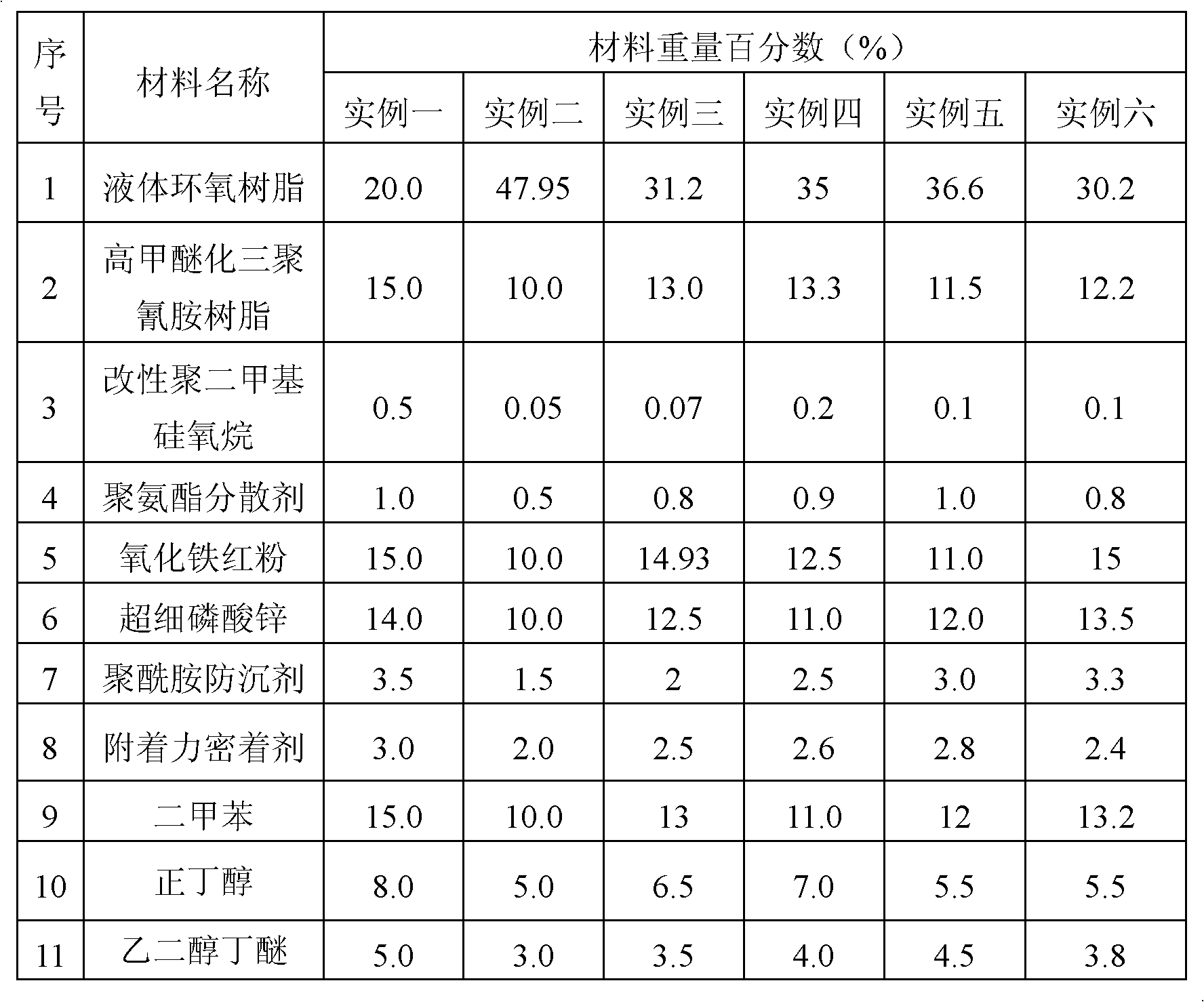

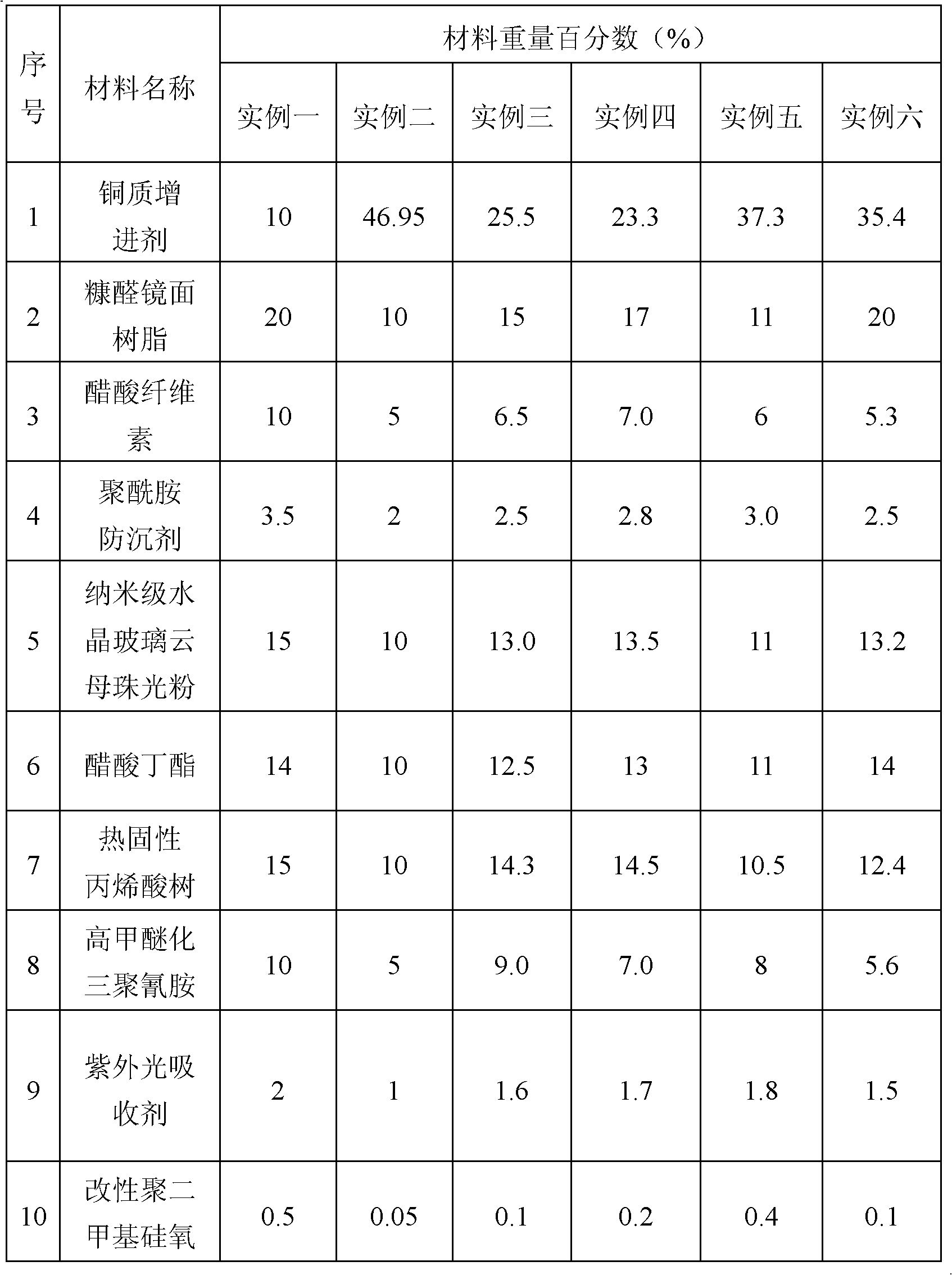

True copper metallic combination paint as well as preparation method and construction process thereof

InactiveCN102533056AImprove anti-corrosion performanceExcellent anti-rustPretreated surfacesAnti-corrosive paintsEpoxyProduction line

Owner:江苏佳尔利装饰材料有限公司 +1

Press fitting device for aerosol tank and universal base

PendingCN109732321ASimultaneous pressingDoes not affect the beatMetal working apparatusProduction lineButt joint

Owner:YANGZHOU MEIDA FILLING MACHINERY

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

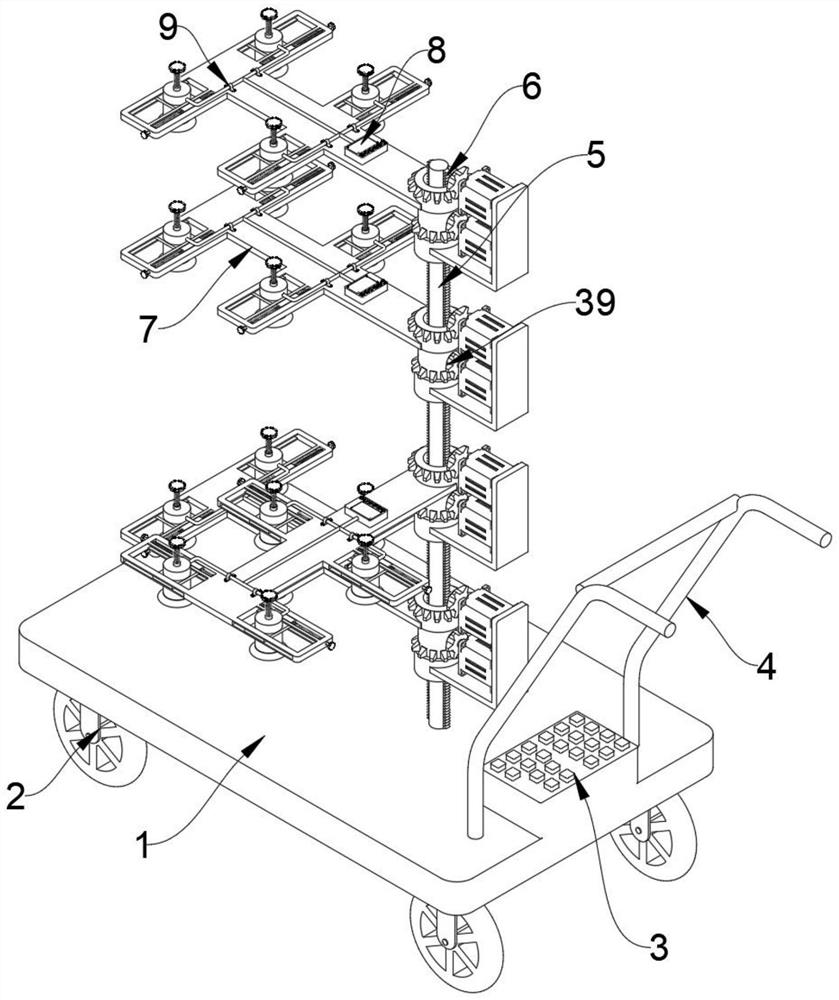

Feeding device for liquid crystal screen production line

ActiveCN111908127AEasy to fixGreat suctionCharge manipulationConveyor partsProduction lineSuction force

Owner:四川京龙光电科技有限公司

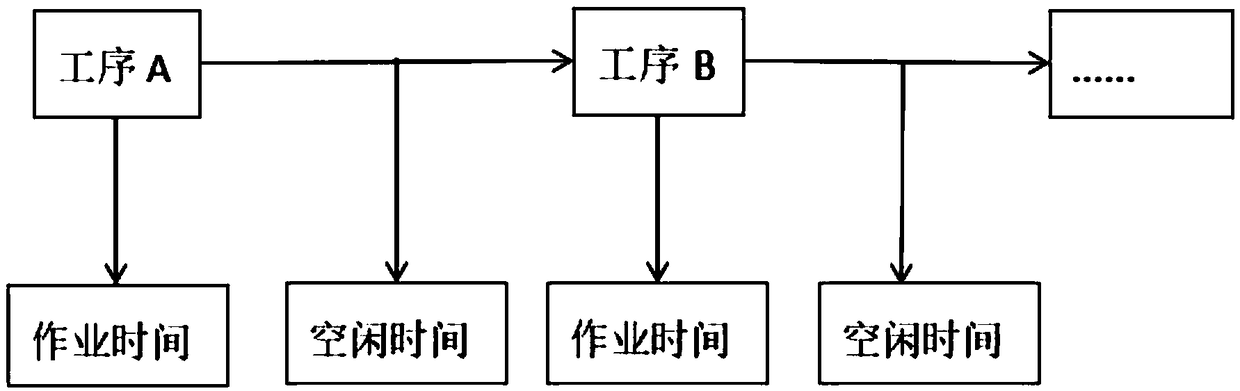

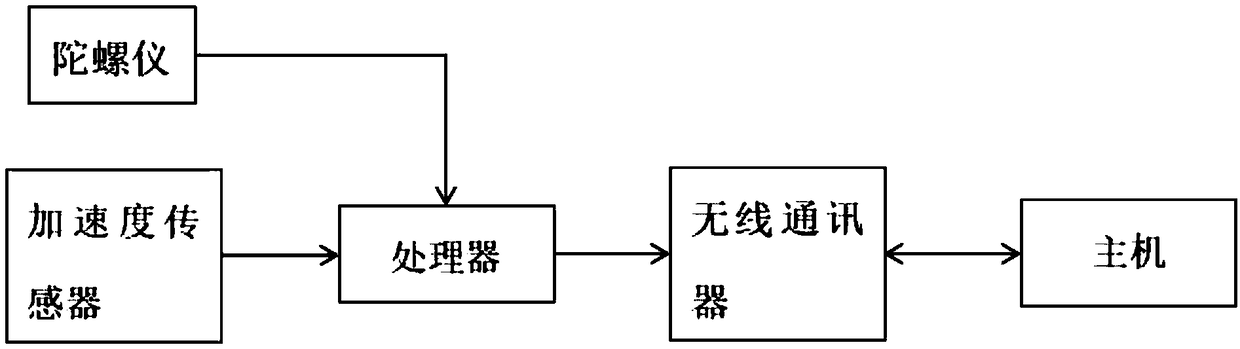

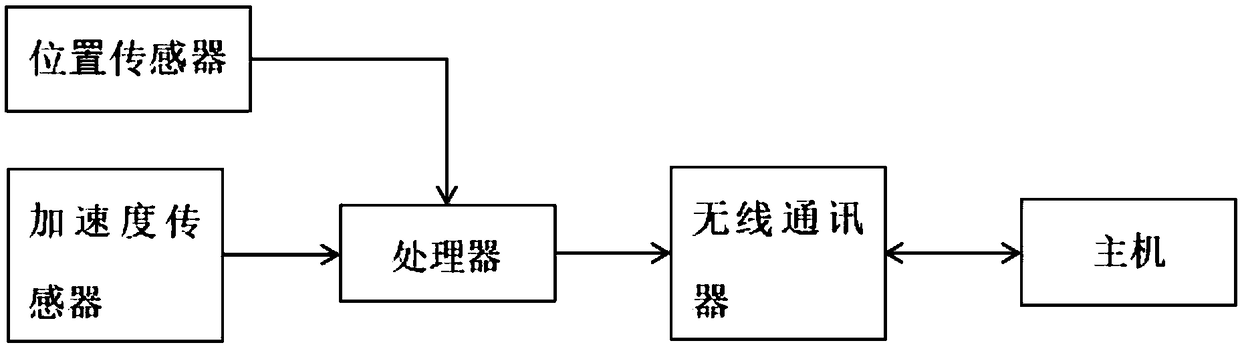

Production line operation management and control method

InactiveCN109213107AAccurately record work timeAccurately record idle timeTotal factory controlProgramme total factory controlProduction lineIdle time

Owner:XIAMEN INTRETECH

PCB non-metallic material steel-plastic compound plate tray, preparing production line and preparing method

InactiveCN106005678AHigh tensile strengthImprove bending abilityPackage recyclingDomestic articlesProduction lineShrinkage rate

Owner:王传华

Simulation teaching system for simulating classified storage

InactiveCN111681487ASolve problems such as packet loss and delayCosmonautic condition simulationsProgramme control in sequence/logic controllersProduction lineControl signal

The invention discloses a simulation teaching system for simulating classified storage. The system comprises a classified storage simulation module and a programmable control module, the programmablecontrol module is a programmable controller and a computer provided with PLC programming software and is mainly used for transmitting PLC control signals to the classified storage simulation module end, the classified storage simulation module is connected with a PLC in the programmable control module through a communication line, and the classified storage simulation module is a developed software client, mainly simulates a classified storage assembly line and provides an experimental environment for a user to operate and control a workpiece. According to the invention, students can be helpedto understand the professional knowledge of process control automation and the working principle and application method of the PLC, real operation practice equipment (automatic production line) doesnot need to be invested, and the purpose of teaching can be achieved in a virtual simulation mode.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Pentahedral box automatic box gluing method and automatic box gluing equipment

ActiveCN108381995ARealize automatic glue box functionAutomatic box-gluing function is easyPaper-makingBox making operationsProduction lineEngineering

The invention discloses a pentahedral box automatic box gluing method and automatic box gluing equipment and belongs to the technical field of package printing. According to the technical scheme of the invention, by adding one independent downward bending step in the automatic box gluing method and designing one downward bending mechanism corresponding to the downward bending step in the corresponding automatic box gluing equipment, the downward bending mechanism can continuously finish all bending movements of a box gluing surface of a pentahedral box with an upward bending mechanism on an ordinary tetrahedral box gluing and folding production line together, so that machine automatic box gluing of the pentahedral box is realized. Compared with the original manual operation method, by adopting the technical scheme of the invention, the production efficiency is greatly improved; and as the downward bending mechanism can be disassembled and move, the automatic box gluing equipment can bemounted on all the existing box gluing and folding equipment and has very high compatibility and applicability.

Owner:SUZHOU GENERAL PRINTING HOUSE

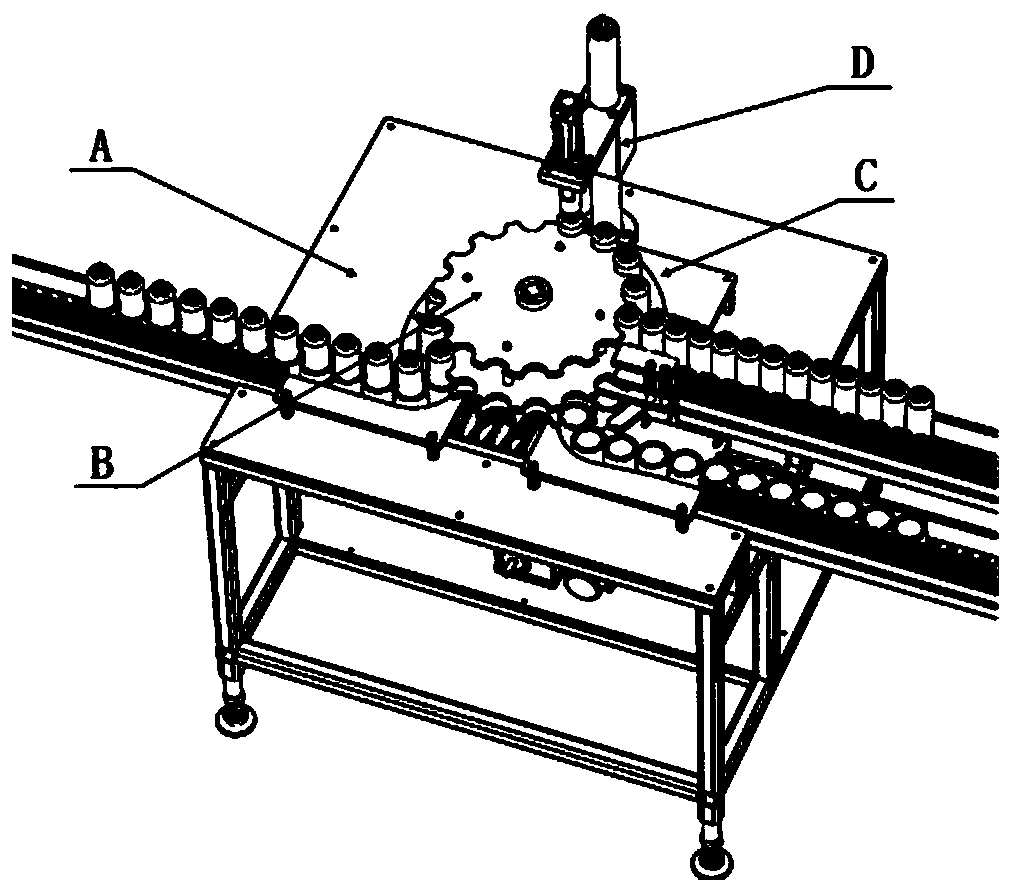

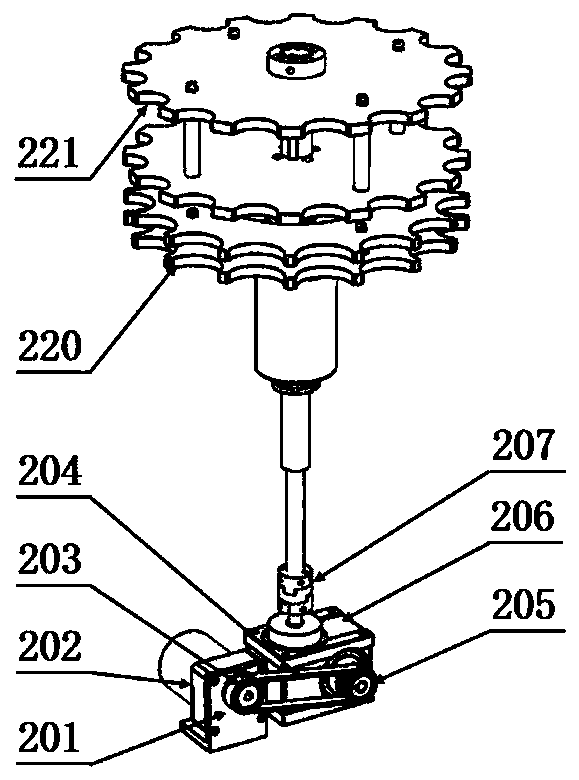

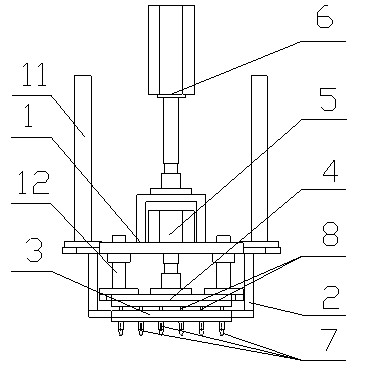

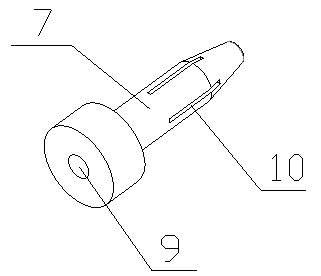

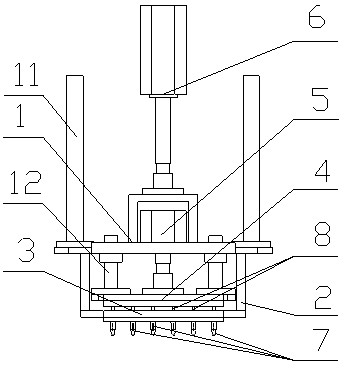

Method and device for automatically grabbing detonators

ActiveCN102557848ARealize automatic removalIncrease productivityDetonatorsEngineeringProduction line

The invention discloses a method and device for automatically grabbing detonators. A device for grabbing the detonator is arranged on a middle blocking production line or an opening closing production line of the detonator; a group of expansion heads are arranged at the bottom of the device; the opening of the detonator is expanded and clamped by the expansion heads through the lifting of a cylinder control device and the deformation of the expansion heads to realize the purpose that the detonator is automatically taken out from a detonator filling mould. In the invention, the expansion heads controlled by machinery are adopted, and the opening of the detonator is expanded and clamped after the expansion heads are deformed, so that the detonator is automatically taken out from the detonator filling mould. A plurality of expansion heads are arranged at the same device, thus a plurality of detonators can be taken out by one device at one time, thereby greatly improving the production efficiency. The method provided by the invention is simple; and the adopted device is easy to manufacture, and has a good using effect.

Owner:GUIZHOU JIULIAN IND EXPLOSIVE MATERIALS DEV

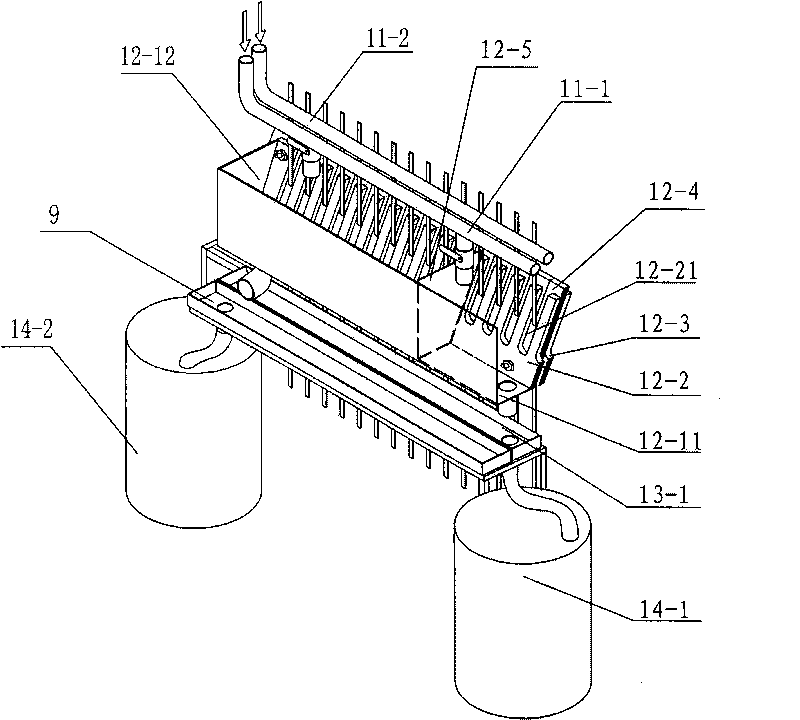

Bolt electroplating production line passivation sealing system and method

InactiveCN109609947AIncrease productivityImprove product qualityMetallic material coating processesProduction lineHydrogen

The invention discloses a bolt electroplating production line passivation sealing system and method. The system is used for processing bolts subjected to dehydrogenation, and comprises a transfer device, a cooling device and a processing device; the processing device comprises a first transit apparatus and a function passivation apparatus; and the function passivation apparatus comprises a white liquid trough, a black liquid trough and a dehydrator which are arranged in sequence, and accordingly, coloring sealing is conducted on the bolts. The transfer device, the cooling device and the processing device are arranged, automatic transmitting is conducted between the procedures, controlling is achieved through a central controller, and the production efficiency and the product quality are improved.

Owner:ZHEJIANG MINGTAI STANDARD PARTS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap