Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

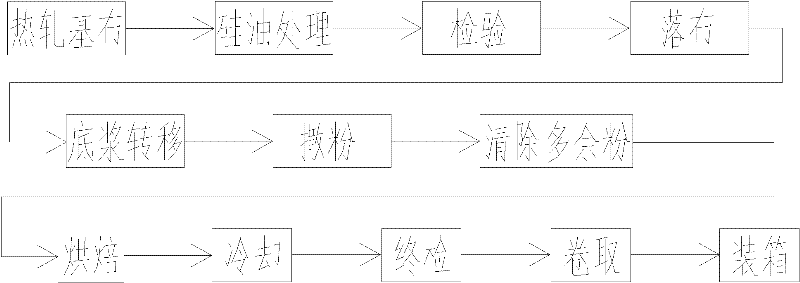

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costPolyureas/polyurethane adhesivesFibre typesInterliningPolyester

Owner:温州鸿马科技有限公司

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

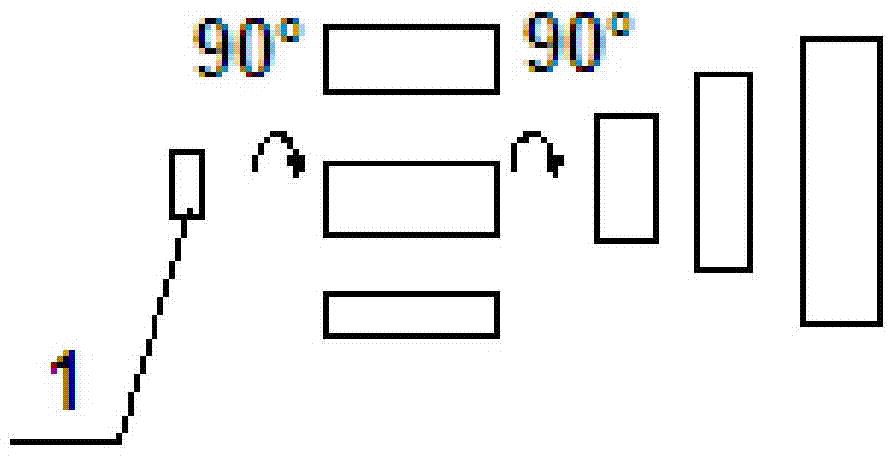

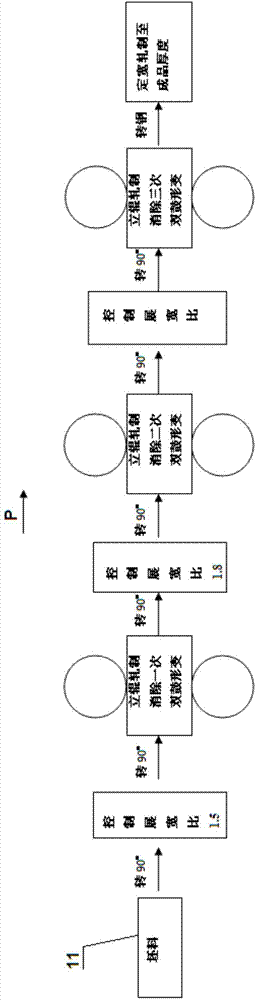

Method for improving double bulges at edge part of broadened intermediate slab in thick plate rolling process

InactiveCN104772332AEliminate double drum deformationImprove plane shapeMetal rolling arrangementsProfile control deviceThick plateSheet steel

Owner:BAOSHAN IRON & STEEL CO LTD

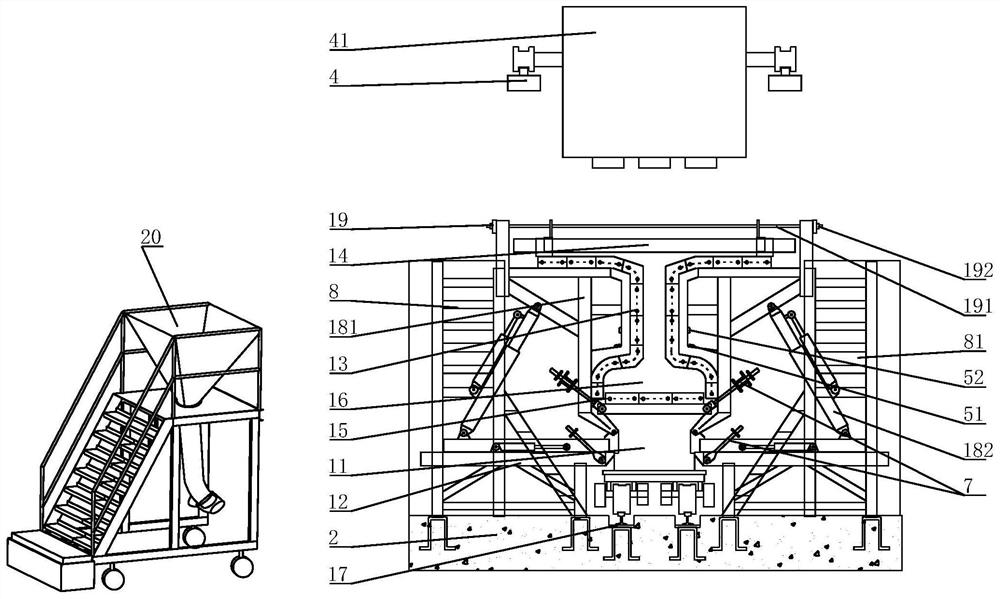

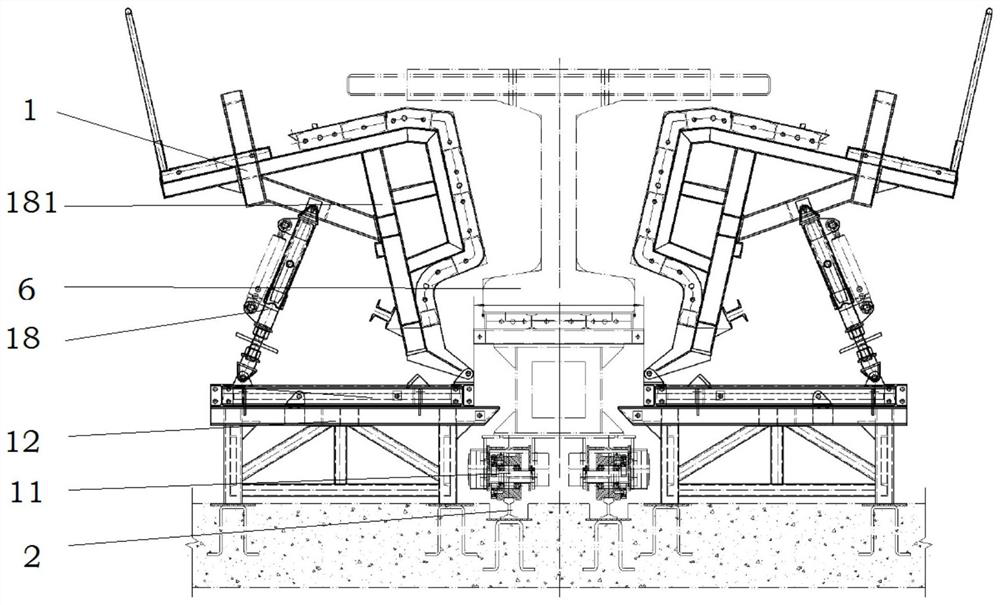

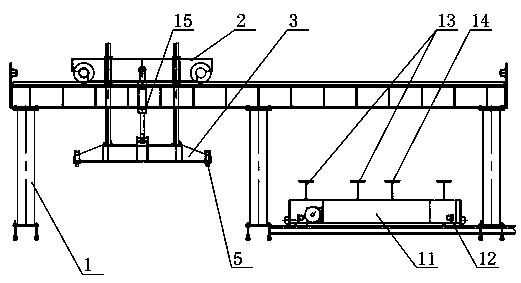

Pouring system and method for automatic prefabricated T beam

PendingCN111702948AStable structureIncrease productivityDischarging arrangementFeeding arrangmentsT-beamButt joint

Owner:安徽省路港工程有限责任公司

Garment production quality tracing system

Owner:HIGH ROCK RECREATION PROD CO LTD

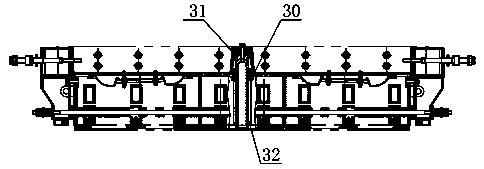

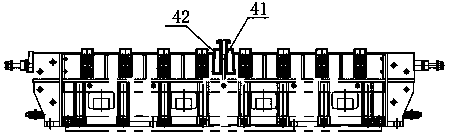

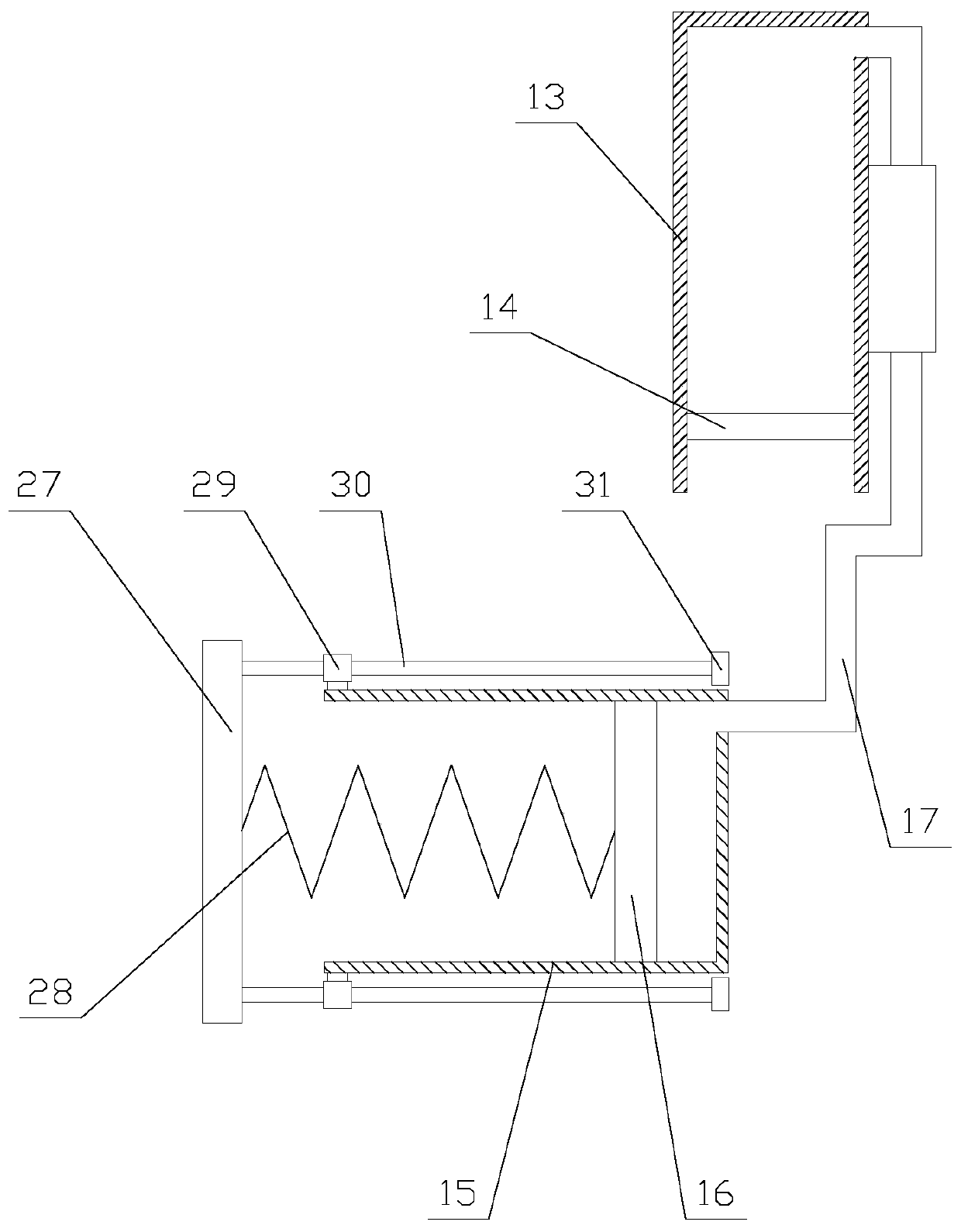

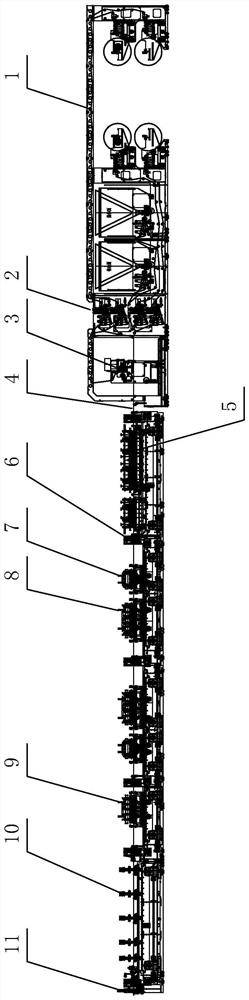

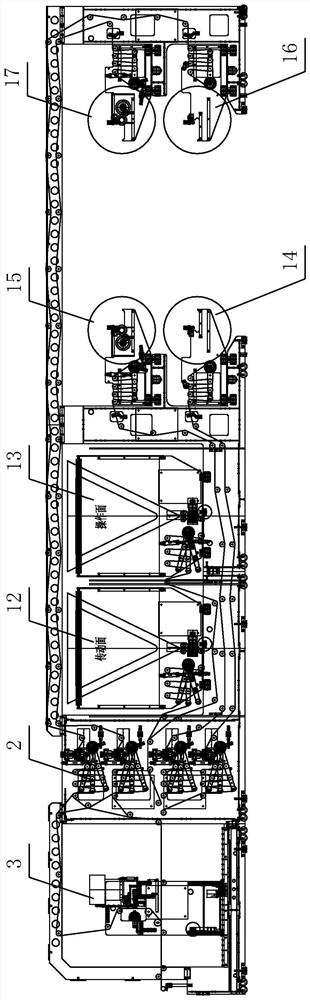

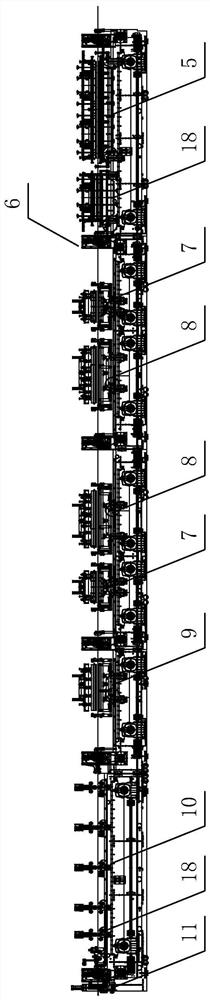

Track plate stripper machine

PendingCN109278175AAvoid bumpingGuarantee product qualityDischarging arrangementInverted-T shapeProduction quality

Owner:SHANDONG LINQU SLEEPER

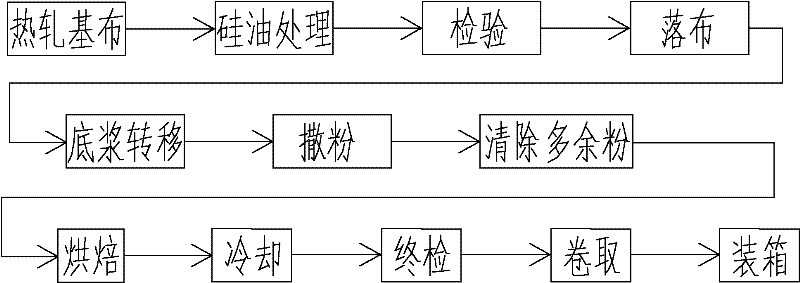

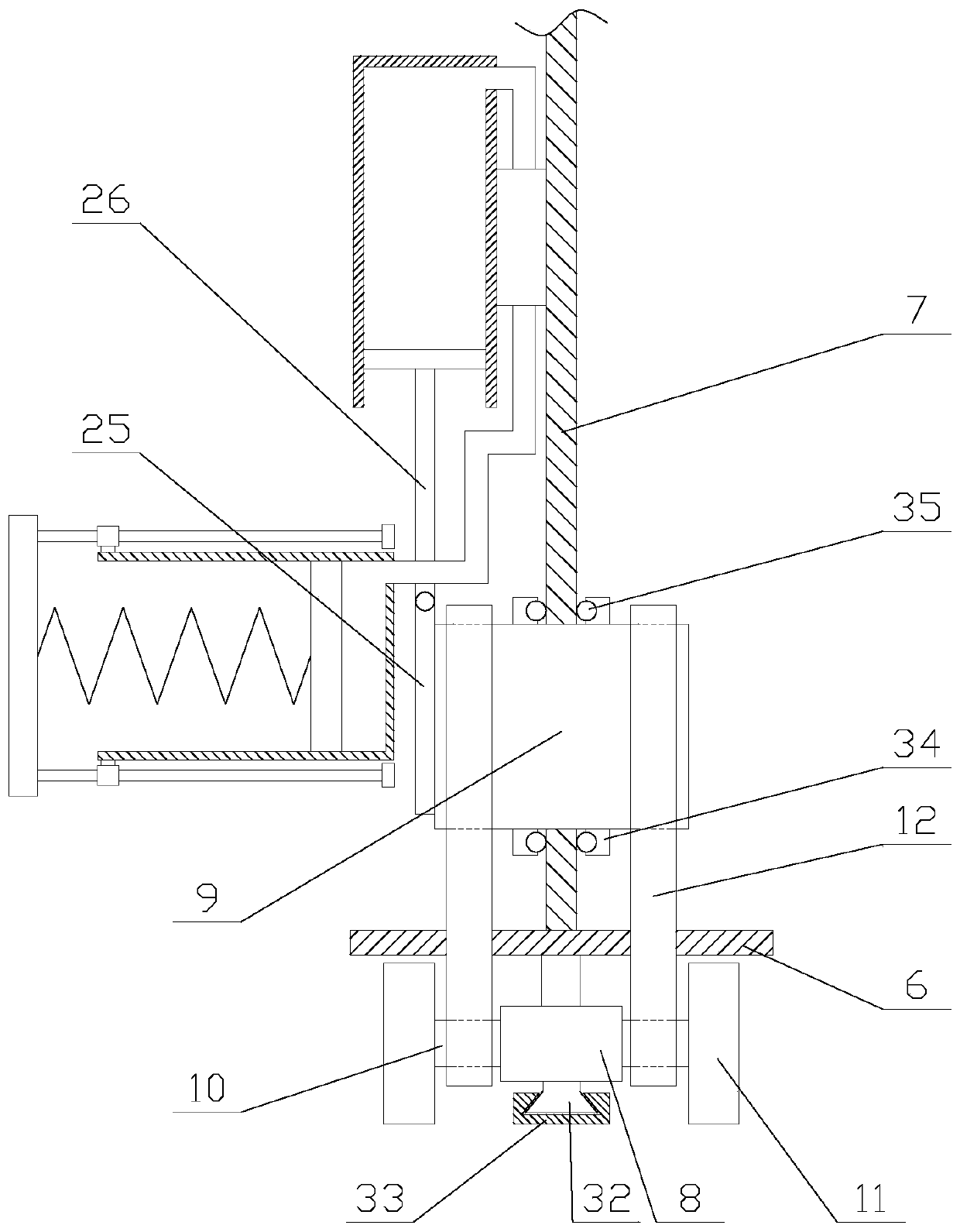

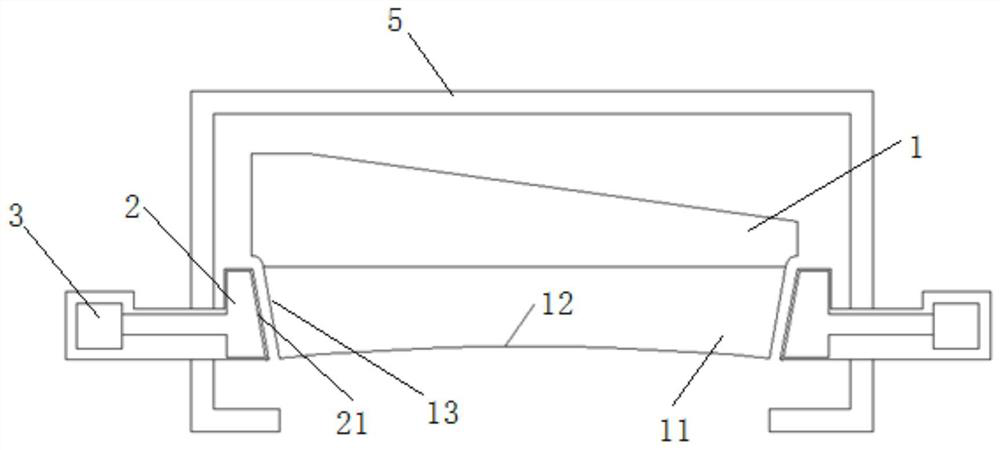

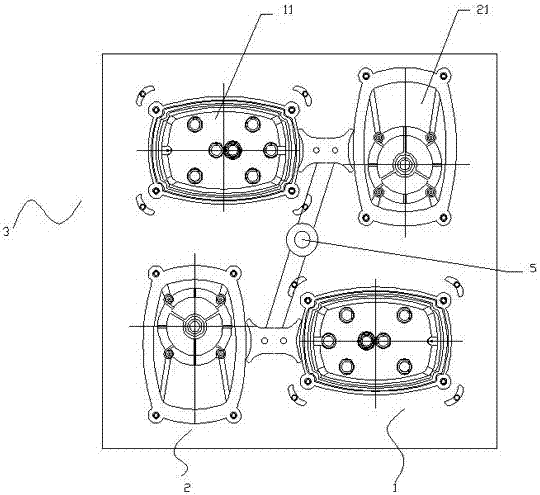

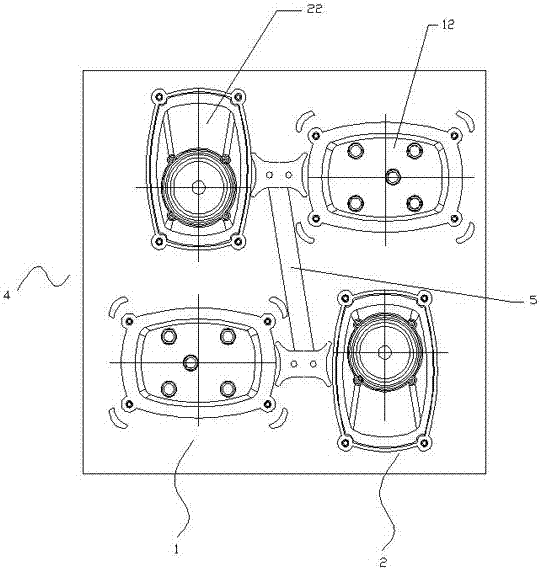

Installation device of printing mesh for solar cell

The invention provides an installation device of a printing mesh for a solar cell. The installation device is used for the connection of a printing mesh (7) and a mesh frame (9) and comprises an operation platform (1) and a location supporting piece (2) which is arranged on a platform surface of the operation platform (1) and is in contact with the edge of the printing mesh (7), wherein the printing mesh (7) is arranged on the location supporting piece (2), and a gap is arranged between the inner side of the edge of the printing mesh (7) and the location supporting piece (2). According to the installation device of the printing mesh for the solar cell, provided by the invention, the printing mesh (7) is prevented from being polluted as the printing mesh (7) is in contact with other objects during a combination and installation process and is prevented from being damaged during an operation process, the production quality of the solar cell of a solar cell assembly is ensured, the operation difficulty of installation and connection of the printing mesh (7) and the mesh frame (8) is reduced simultaneously, and the working efficiency is greatly increased.

Owner:YINGLI ENERGY CHINA

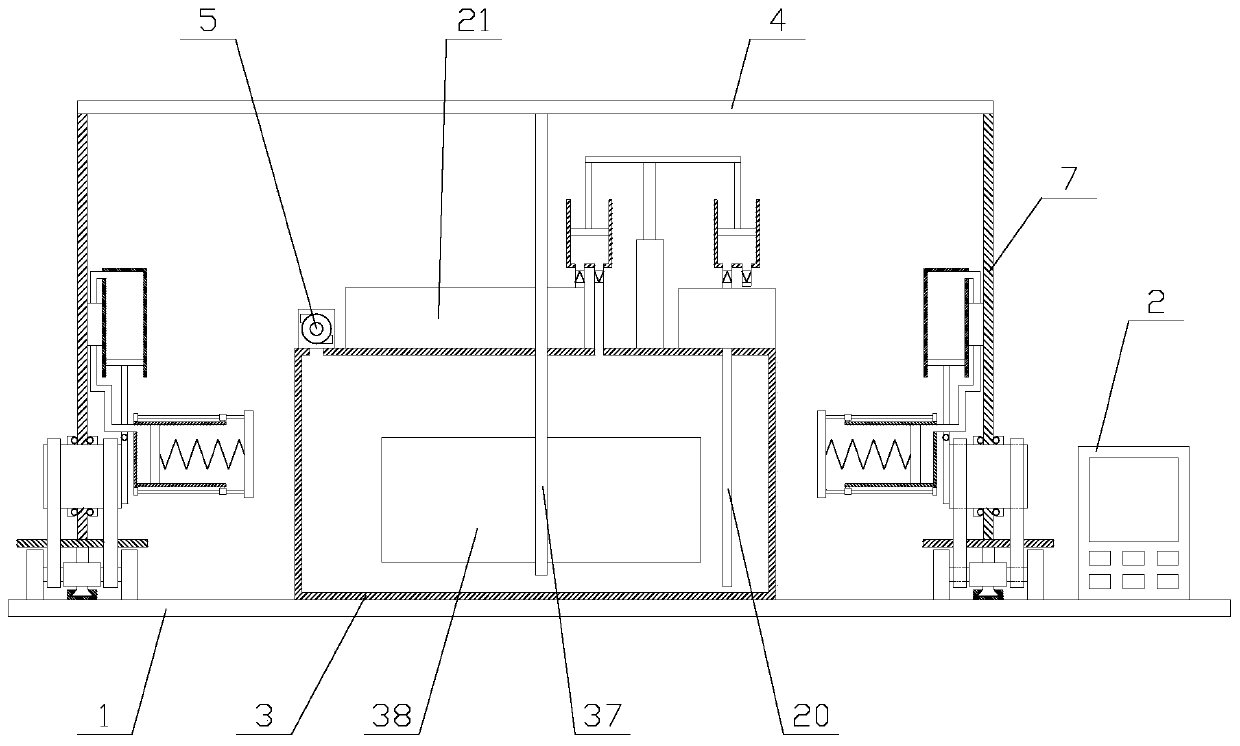

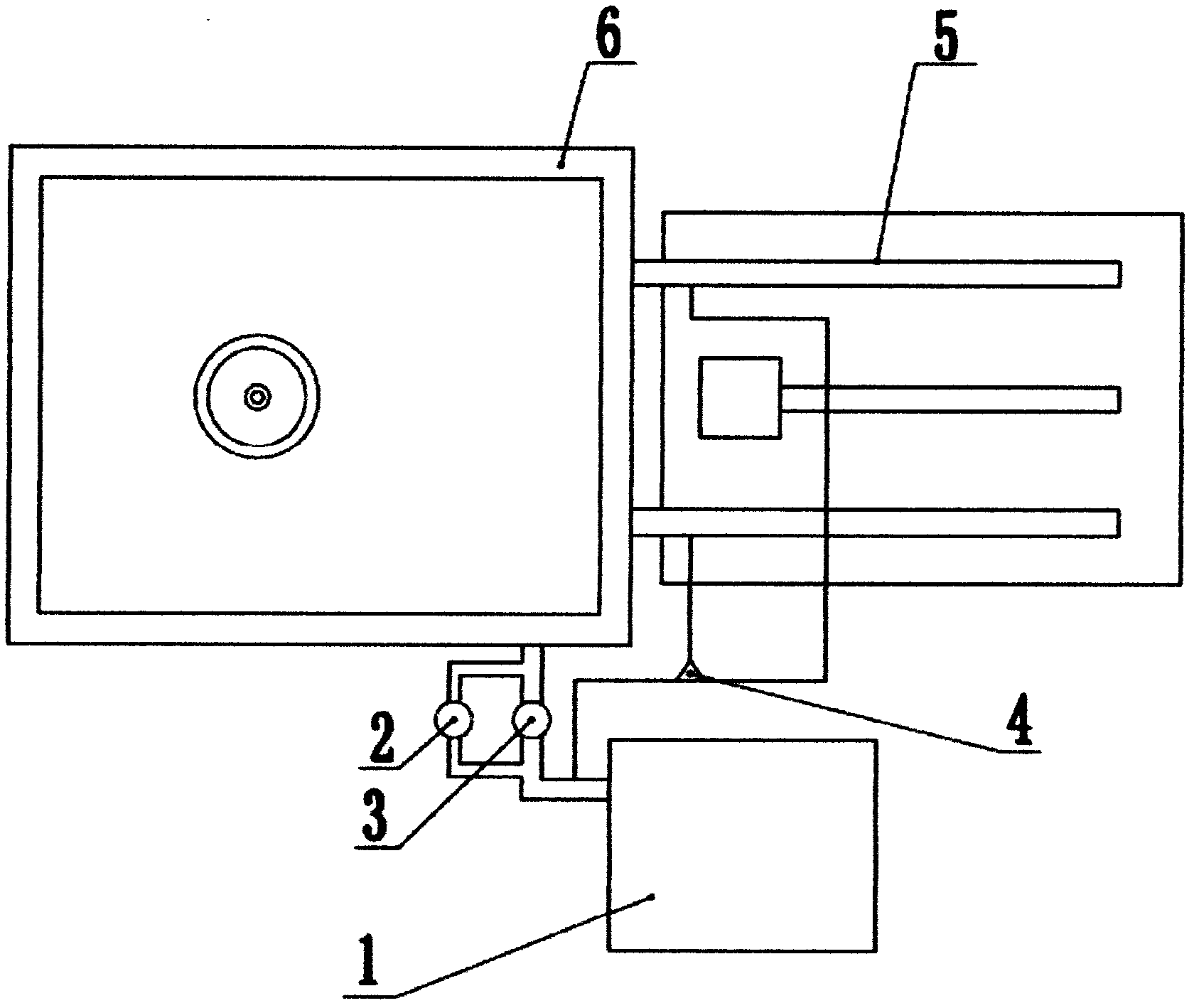

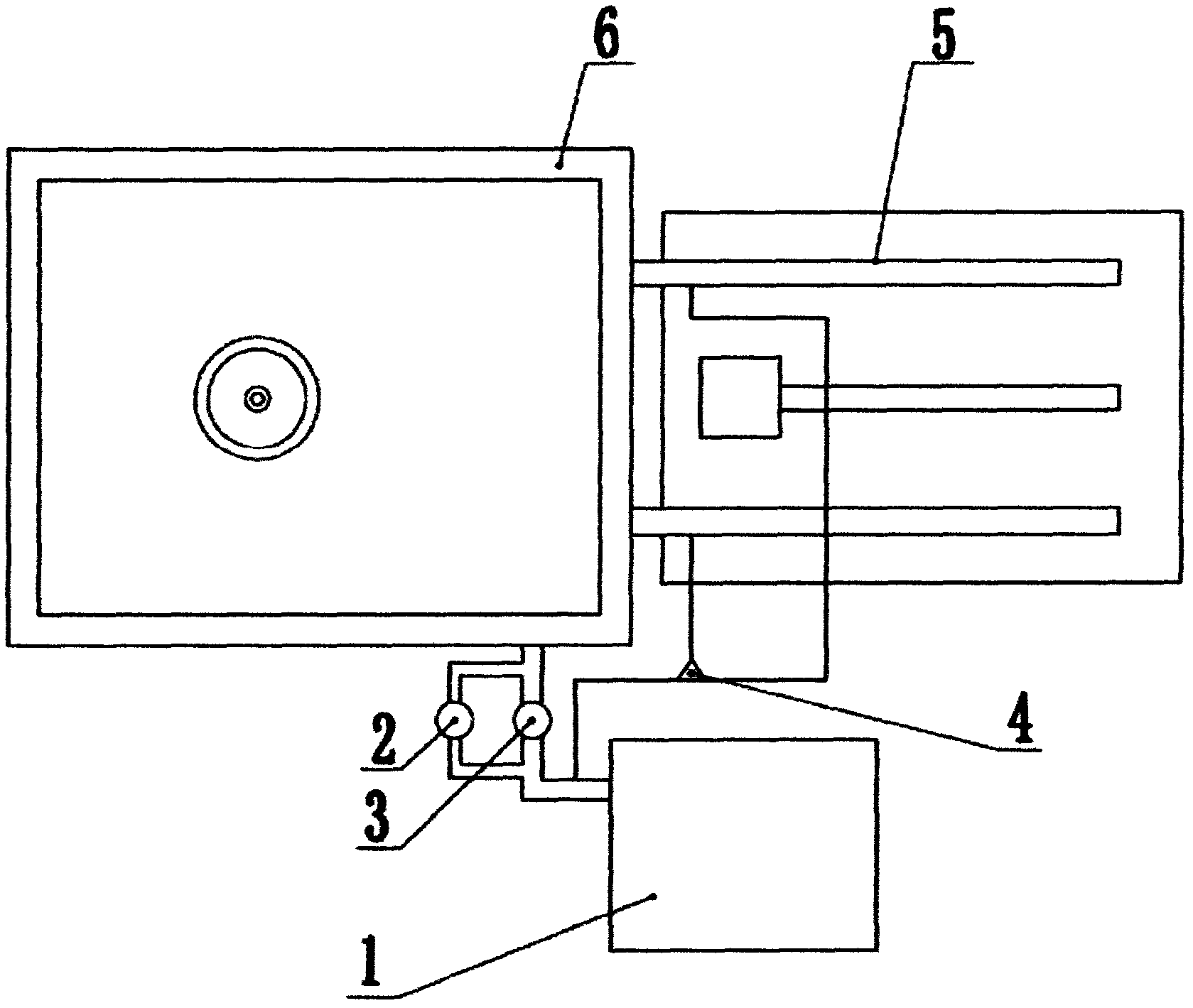

Bearing ring cleaning device for bearing production

ActiveCN113145561AImprove product qualityAvoid compromising cleaning qualityCleaning using toolsCleaning using liquidsElectric machineMegasonic cleaning

The invention discloses a bearing ring cleaning device for bearing production. The bearing ring cleaning device comprises an ultrasonic cleaning pool used for containing cleaning fluid, a cleaning device mounted in the ultrasonic cleaning pool, a driving device mounted at the bottom of the ultrasonic cleaning pool, and a brush device mounted at the side, close to the cleaning device, of the ultrasonic cleaning pool. The cleaning device can be controlled to move by controlling a driving motor so as to drive bearing rings to move, and meanwhile, a cleaning motor can be controlled to control movement, inner ring cleaning and outer ring cleaning of the bearing rings, so that operation is easy; and meanwhile, the bearing rings with special outer surface shapes can be thoroughly cleaned, dirt is prevented from falling into gaps again to affect the cleaning quality, and the bearing production quality is improved.

Owner:NINGBO PARAGON BEARING +1

Die-casting equipment for 5G automobile parts

Owner:广西润启互联网科技有限公司

Leak-proof protection system

InactiveCN102560639ASealed double insuranceGuarantee product qualityPolycrystalline material growthSingle crystal growth detailsEngineeringProtection system

Owner:ZHEJIANG HONGYE NEW ENERGY

Glass substrate production furnace and overflow brick

ActiveCN113233740AQuality assuranceQuality impactGlass furnace apparatusGlass forming apparatusBrickMetallurgy

Owner:河南旭阳光电科技有限公司 +2

Cutting device for pearl wool foaming machine

PendingCN112677394AIncrease productivityImprove product qualityMetal working apparatusIndustrial engineeringProduction quality

The invention is applicable to the technical field of pearl wool production, and provides a cutting device for a pearl wool foaming machine. The cutting device comprises a base, wherein an air inlet piece is fixedly arranged at one end of the base, a die outlet head is fixedly arranged at one end of the air inlet piece, a screw is rotationally arranged at one end of the die outlet head, a heating ring is fixedly arranged at one end of the base, a cutting seat is fixedly arranged at one end of the base, a cutting hot melting plate is arranged in the cutting seat in a sliding mode, and the cutting hot melting plate is electrically connected with an external power supply. The cutting device has the advantages that the structure is simple and reasonable, two cutting openings are formed, so that the production speed is increased, the production efficiency is improved, hot melting is carried out immediately after cutting, and the production quality of products is guaranteed.

Owner:CHONGQING XINSHITENG PACKAGING PROD CO LTD

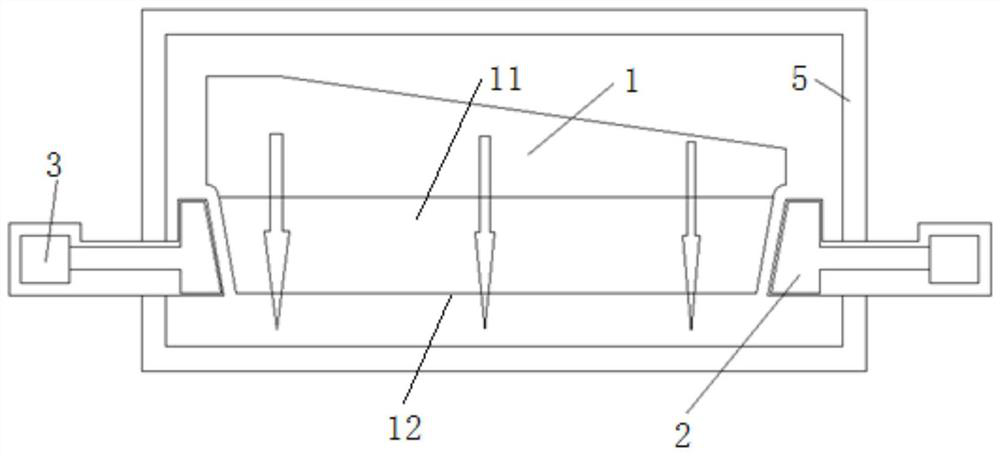

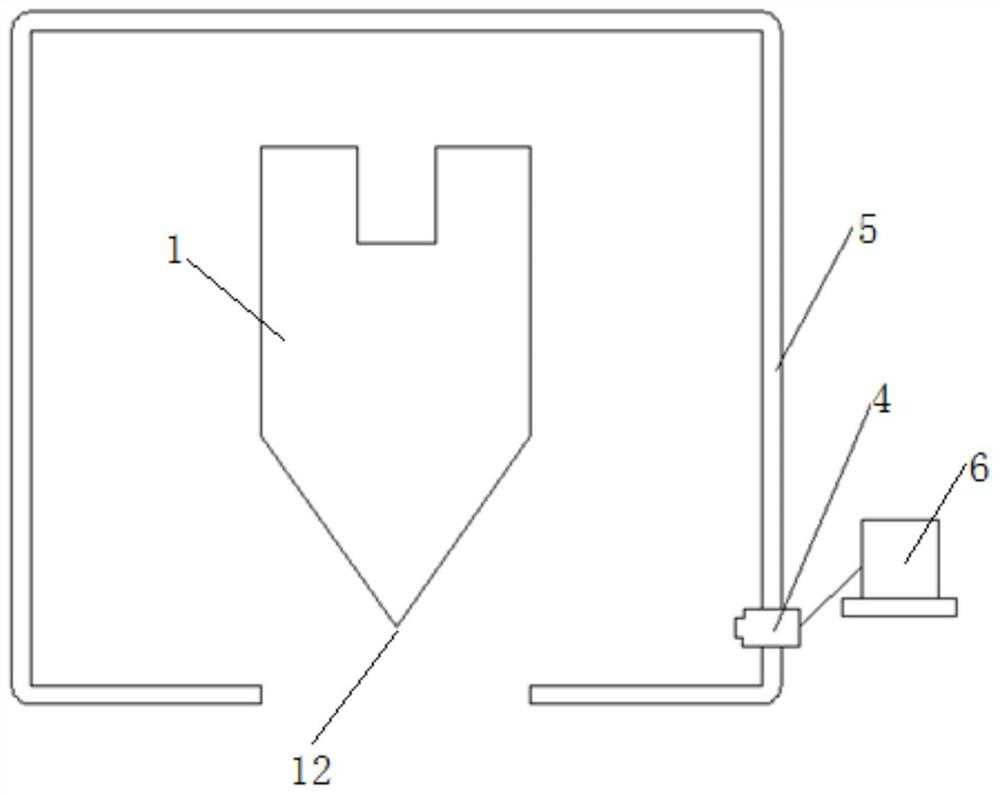

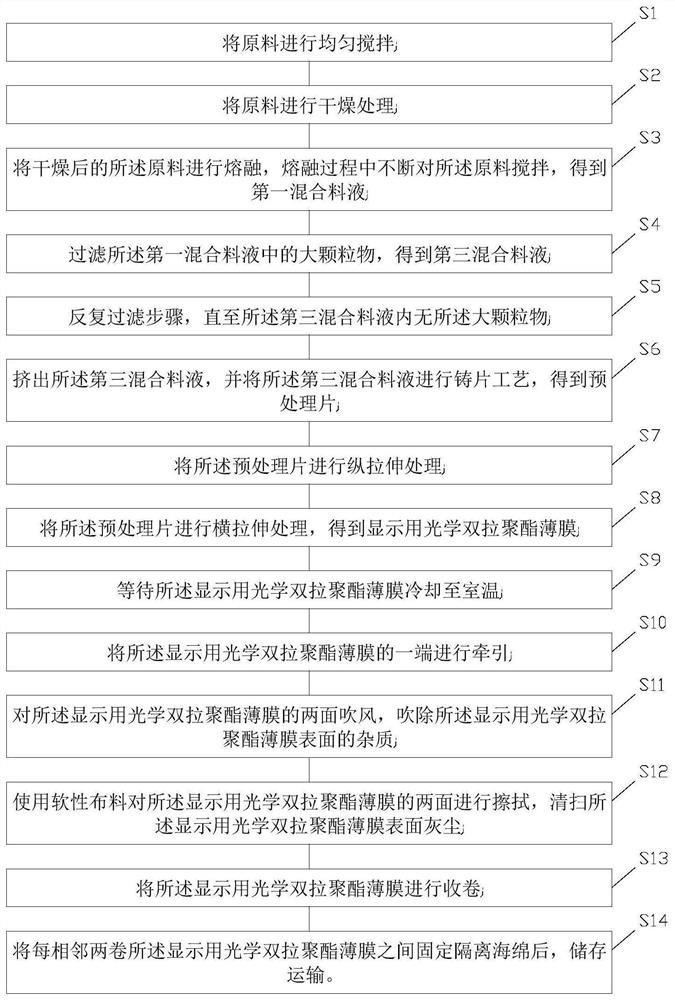

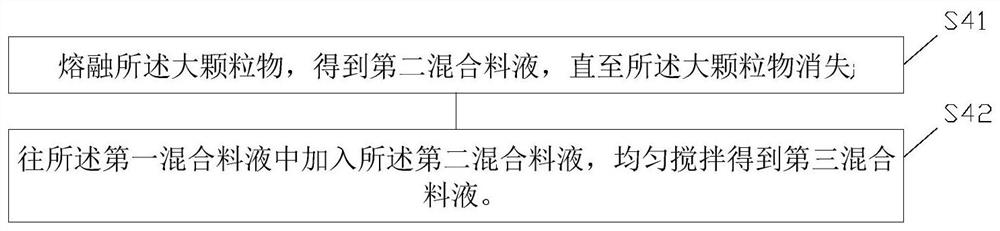

Preparation method of optical double-drawing polyester film for display

Owner:NANJING LANPUCHENG NEW MATERIALS

Multi-sealing fork edge bag making machine and bag making process

PendingCN114670497AImprove product qualityThe production quality cannot be guaranteed, and the production efficiency is improvedBag making operationsPaper-makingProcess engineeringBottle neck

Owner:浙江名立机械科技有限公司

Die-casting forming die for motor conjunction box

ActiveCN107171518AIncrease profitEvenly distributedManufacturing dynamo-electric machinesSupports/enclosures/casingsDie castingEngineering

Owner:JIANGSU HUACAN TELECOMM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap