Multi-sealing fork edge bag making machine and bag making process

A bag making machine and edge film technology, which is applied in bag making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of unguaranteed product quality, poor product consistency, slow production efficiency, etc., and achieve consistent processing Good performance, high adaptability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

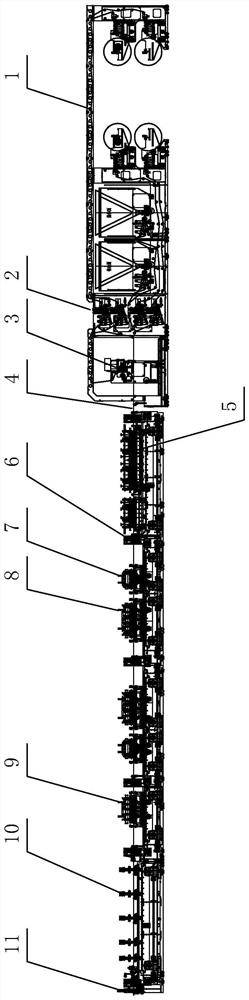

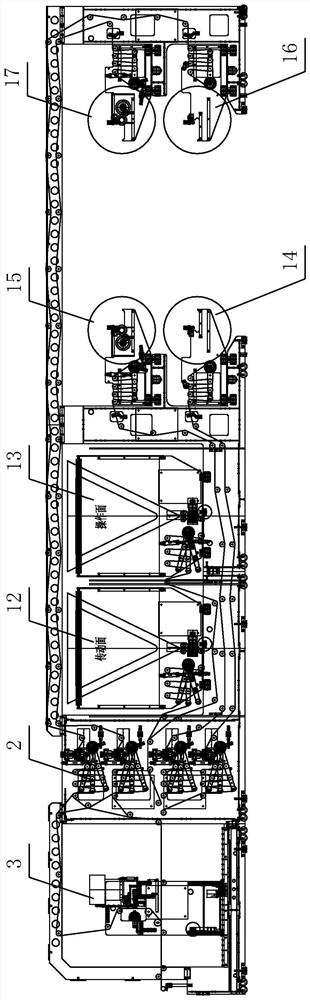

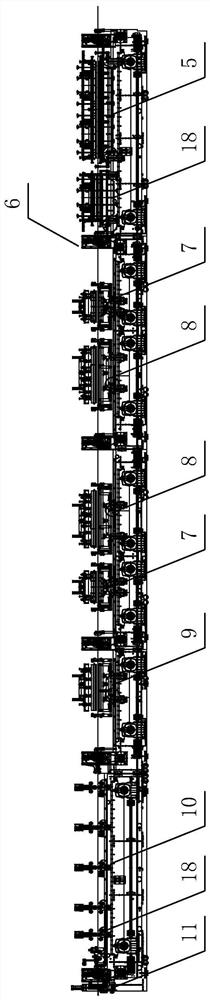

[0049] like Figure 1-12 As shown, a multi-sealing fork edge bag making machine includes:

[0050] The feeding device 1 includes a plurality of raw material supply roll rack mechanisms;

[0051] The adjusting device 2 includes a plurality of adjusting arm mechanisms for receiving the raw materials of the feeding device 1 and adjusting the tension of the raw materials;

[0052] The material distribution device includes a plurality of material distribution guide rollers for receiving the raw materials on the adjustment device 2, and transferring the raw materials in groups to form the upper film conveying route and the lower film conveying route; The device forms the raw material into the upper film conveying route and the lower film conveying route, the upper film 25 is conveyed separately by the upper film conveying route, and the fork film and the lower film 22 are stacked together and conveyed by the lower film conveying route; step, then the upper film 25, the fork film and

specific Embodiment 2

[0074] In the present embodiment, replace steps G-H in specific embodiment 1 with step I:

[0075] Step 1: V-shaped heat sealing, the upper film 25, the left fork film 20, the right fork film 21, and the lower film are sealed with a V-shaped heat-sealing knife 38 extending from the left side of the raw material to the right side of the raw material. 22 is ironed, and a V-shaped sealing seat 43 is formed at the symmetrical position of the upper neck opening 45 of the bag body.

[0076] Other steps are the same as in specific embodiment 1, and produce as Figure 13 The product of this product is characterized in that the bottom of the product is a V-shaped sealing seat 43, which is a structure with a closed lower end, which is mainly used for ton bags of particle products.

[0077] The present invention is not only limited to the production of big bags, but can be extended to various packaging bags produced by heat-sealing mode.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap