Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Fully automated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

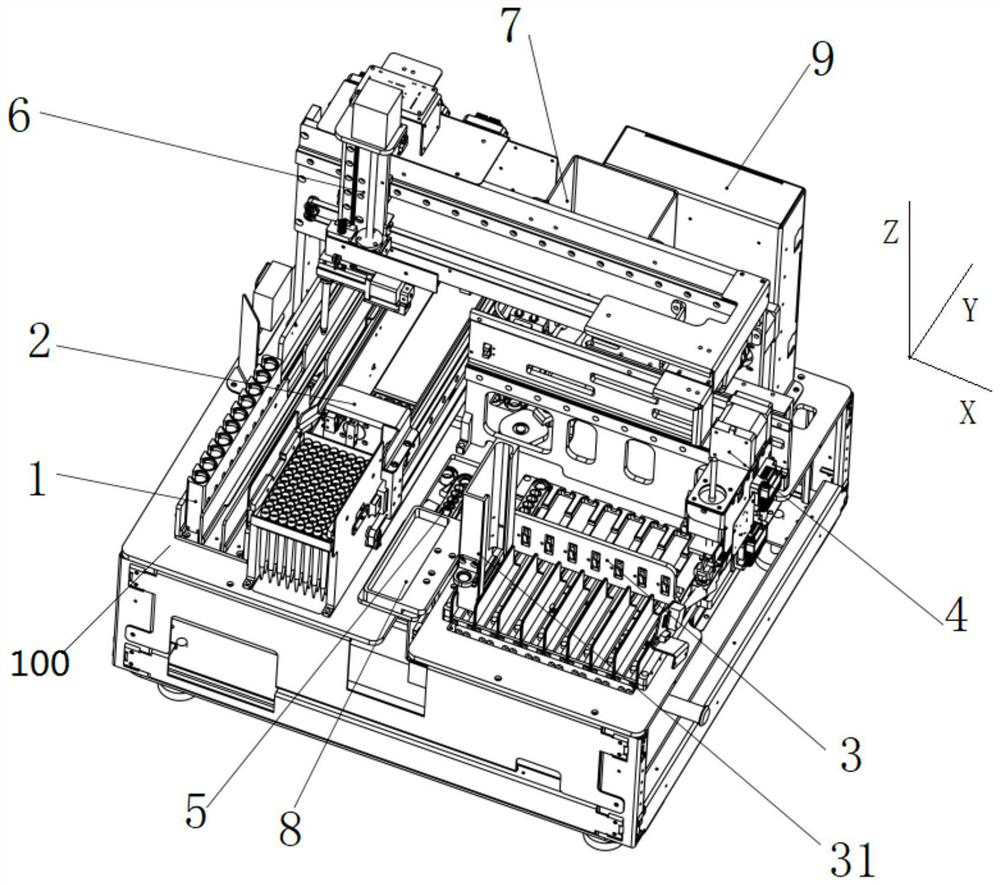

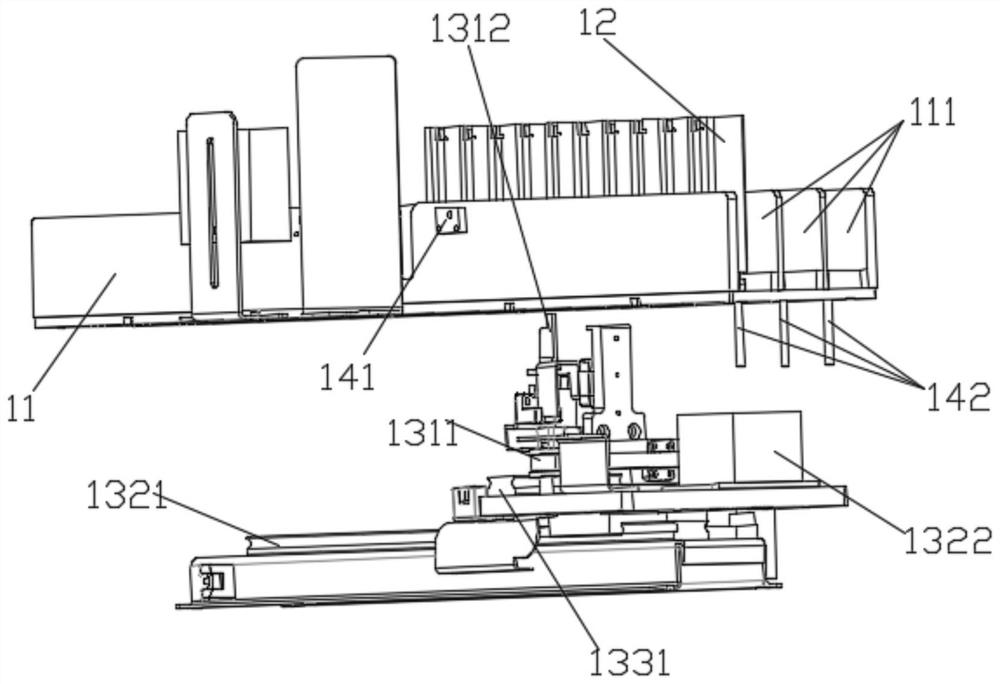

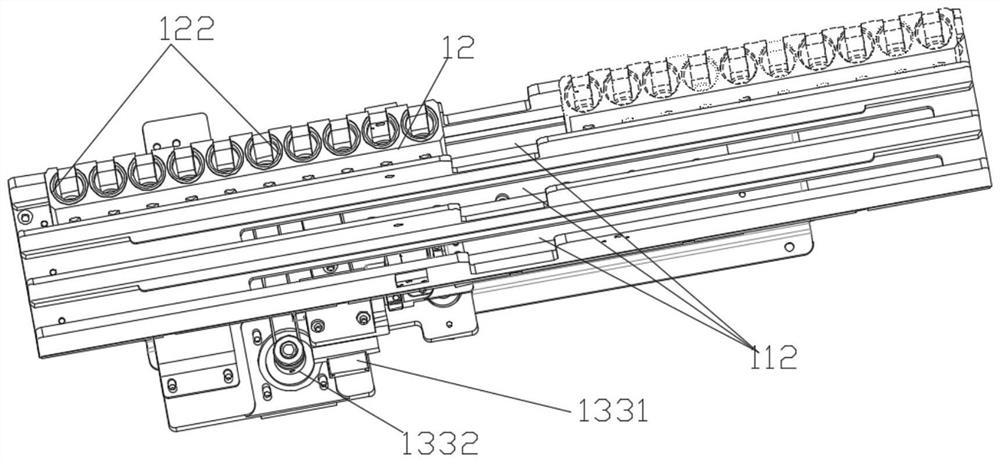

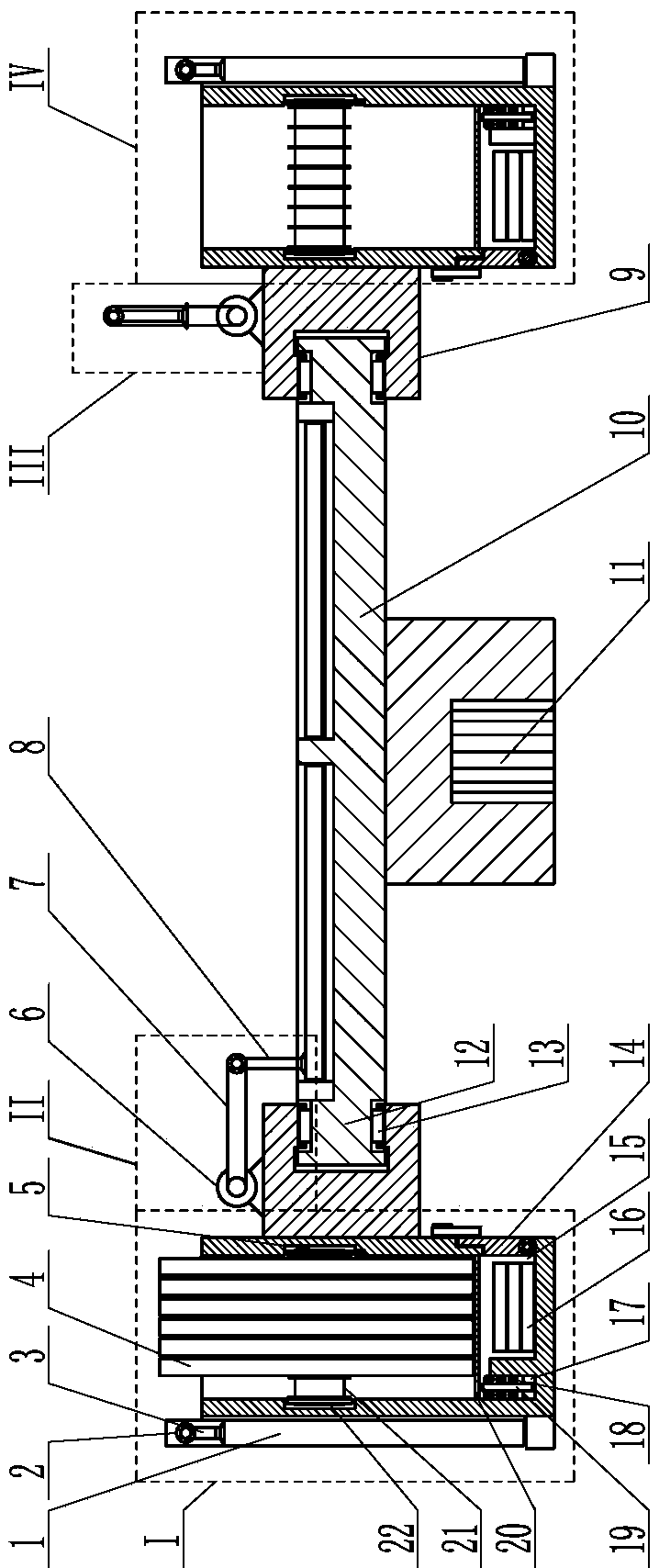

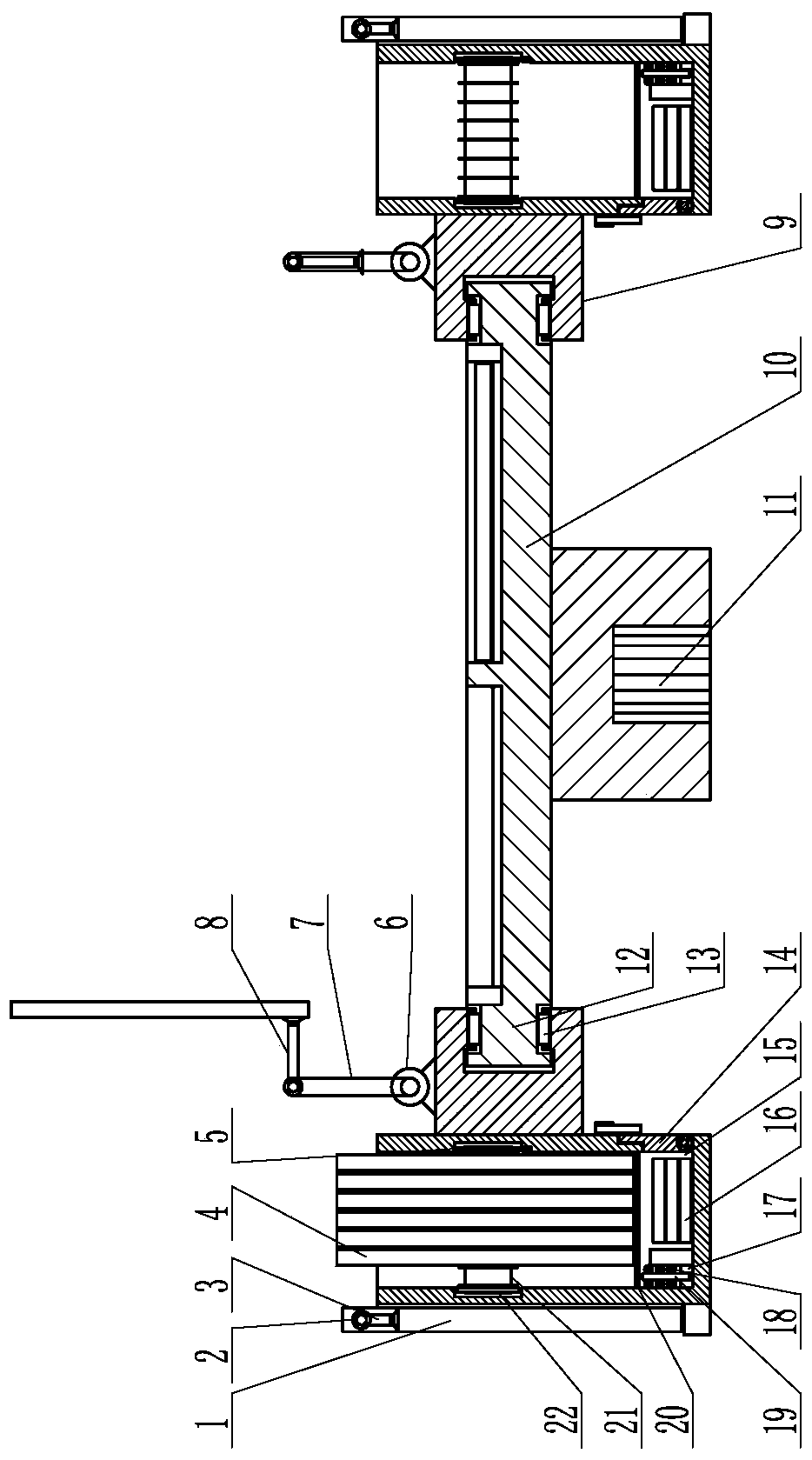

Full-automatic homogeneous chemiluminescence instant detection analyzer

PendingCN114544603ASimplify the point-of-care detection processHigh degree of automationChemiluminescene/bioluminescenceReagent stripEngineering

Owner:成都爱兴生物科技有限公司

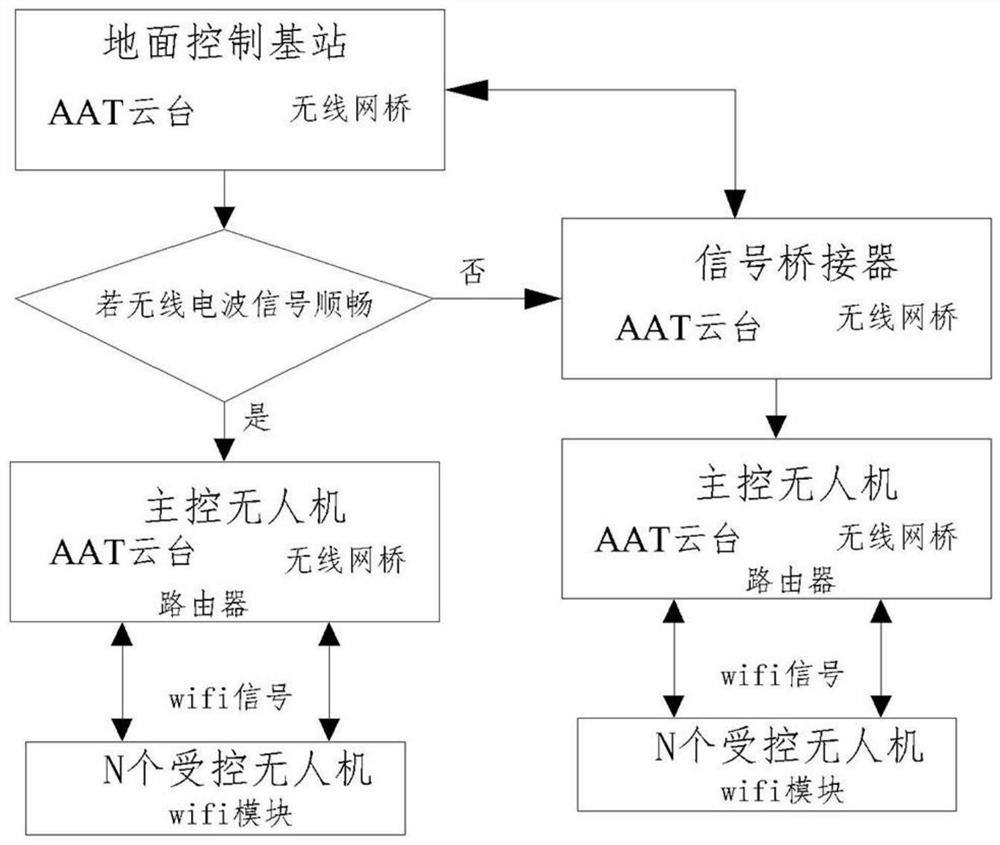

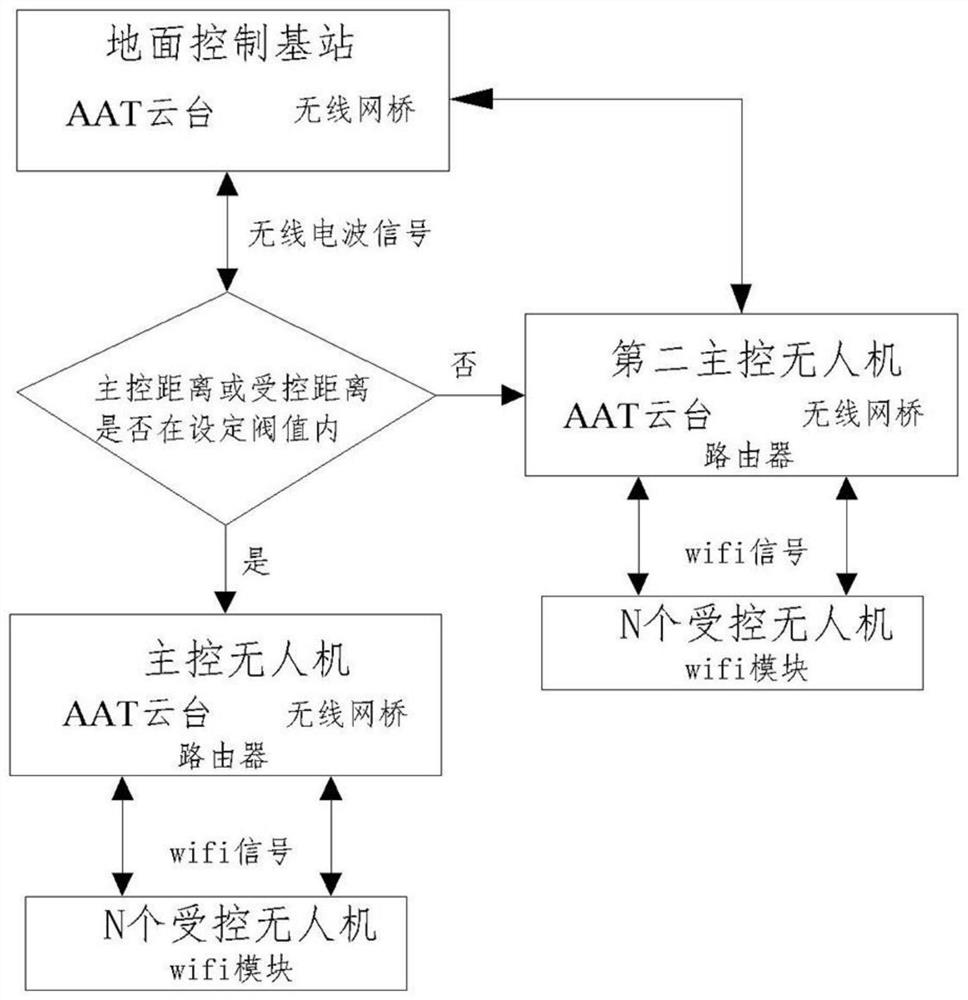

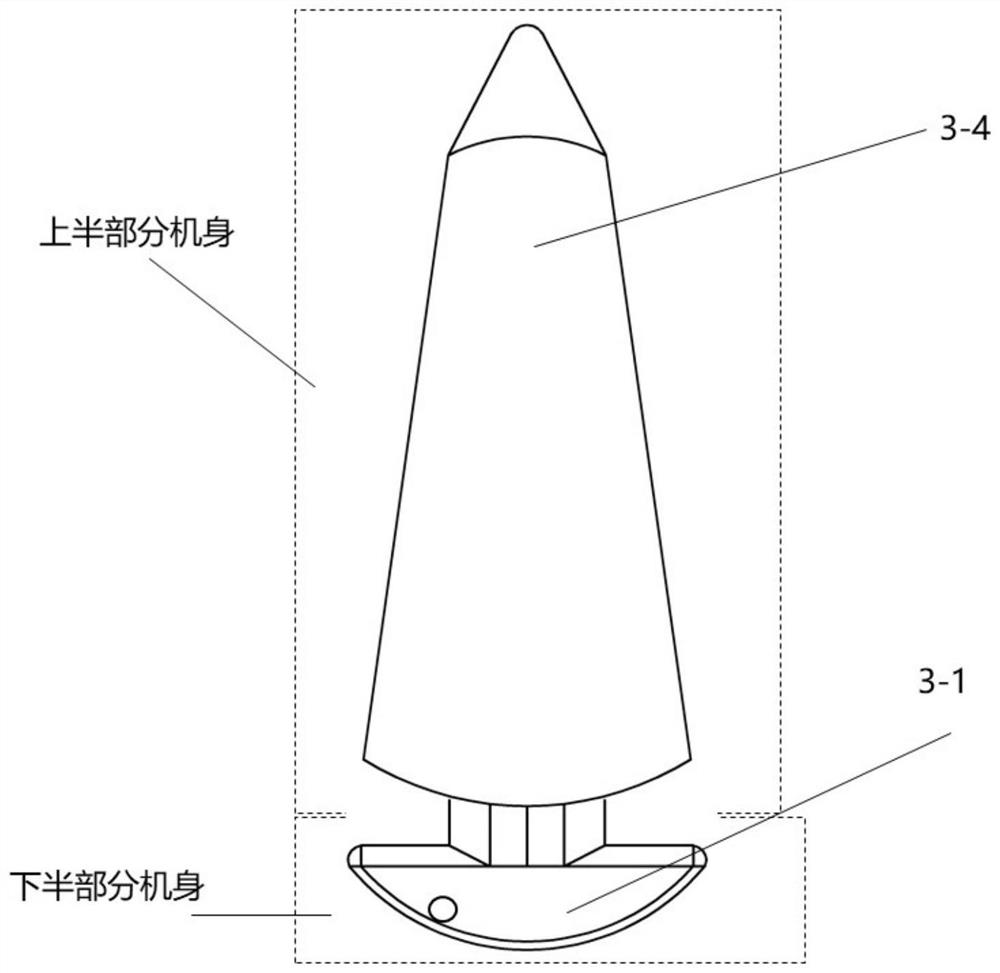

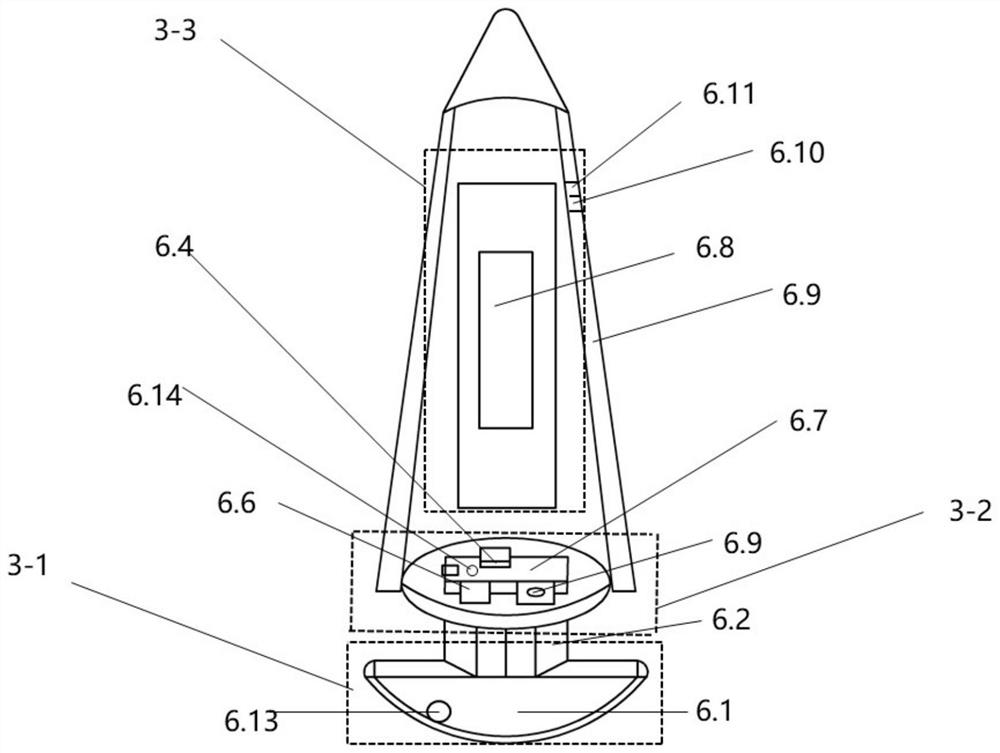

Light-load long-distance cruising unmanned aerial vehicle group system

PendingCN111796604AImprove battery lifeStrong battery lifePosition/course control in three dimensionsUncrewed vehicleWireless network

Owner:四川汉航科技有限公司

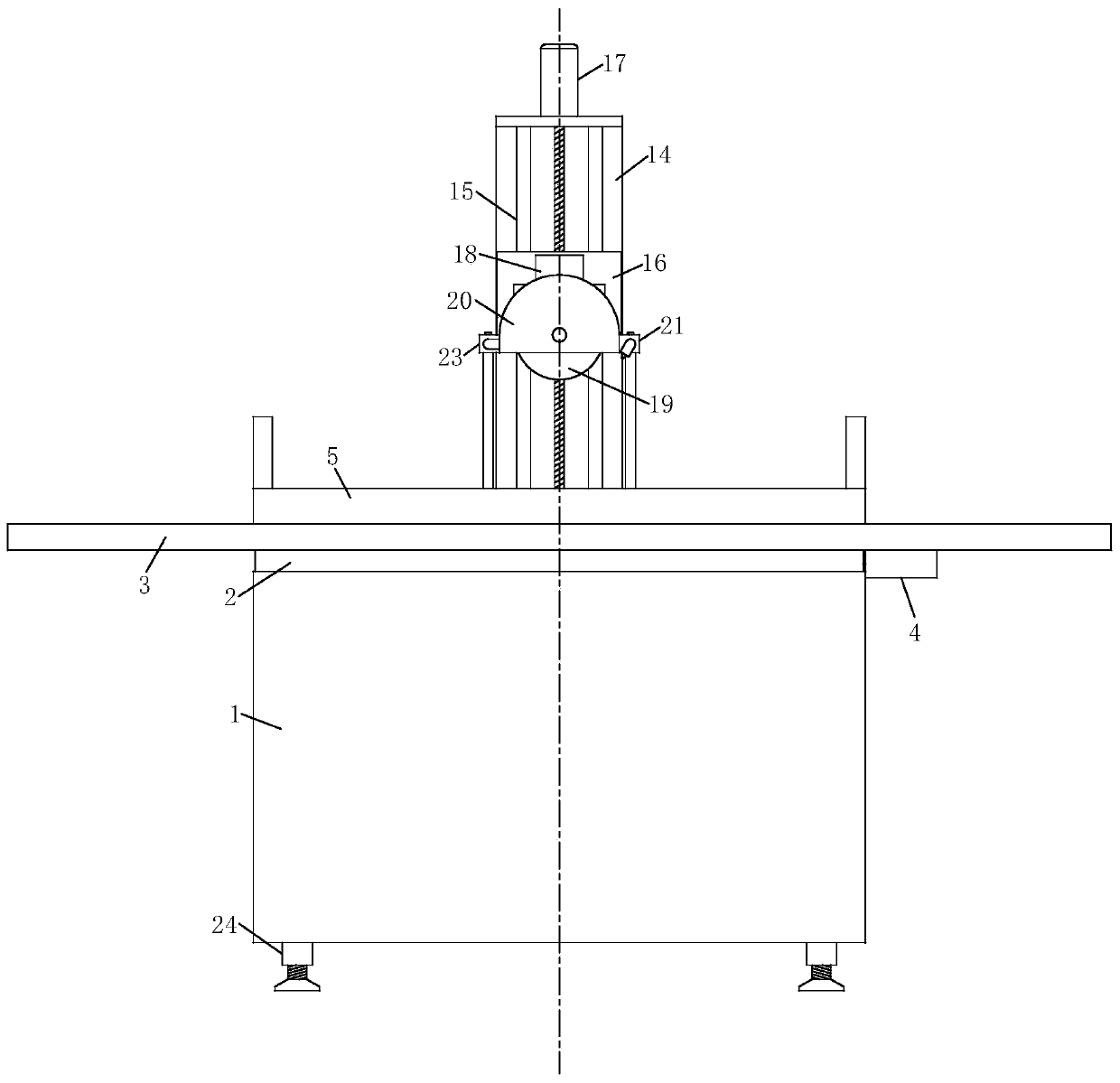

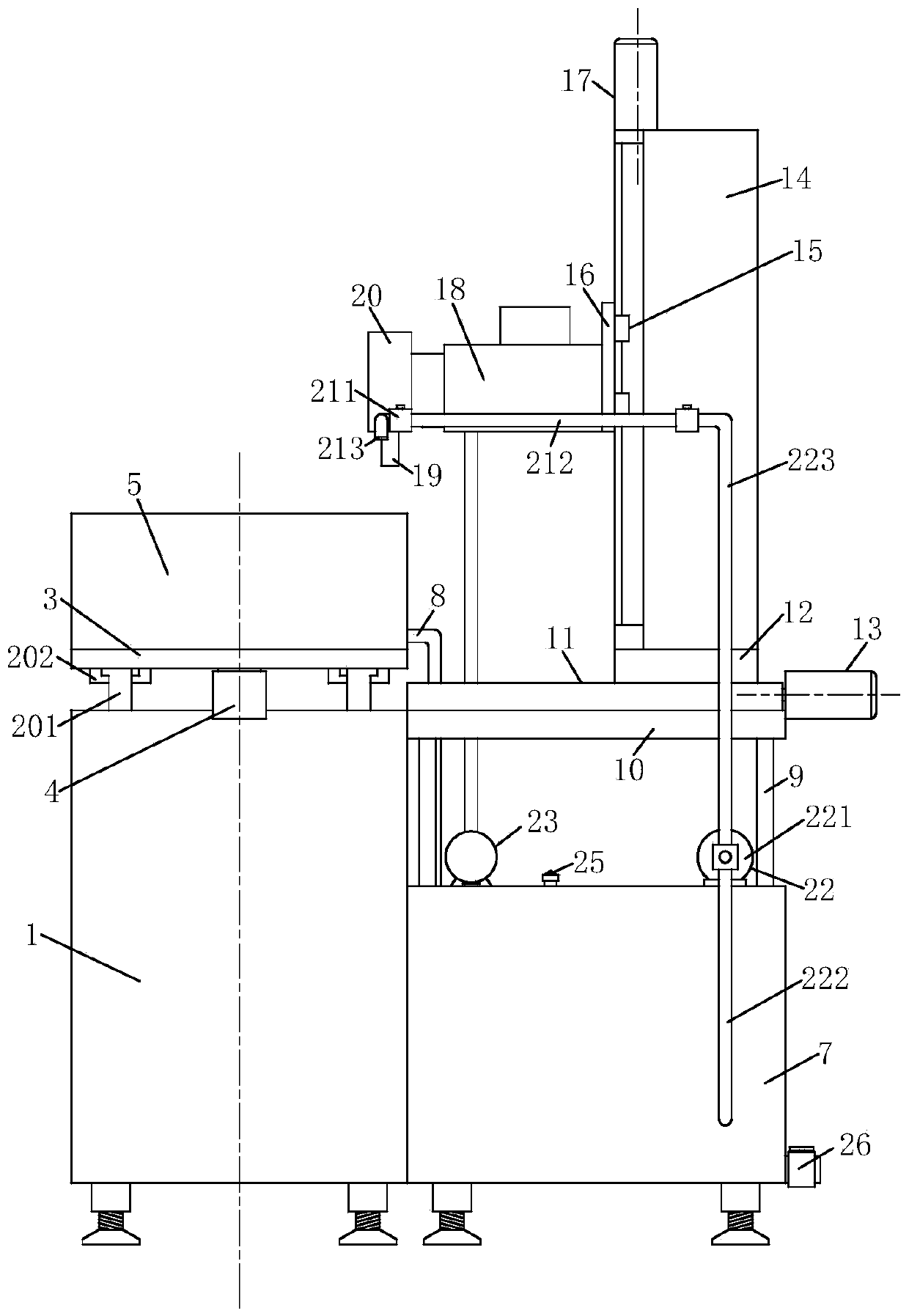

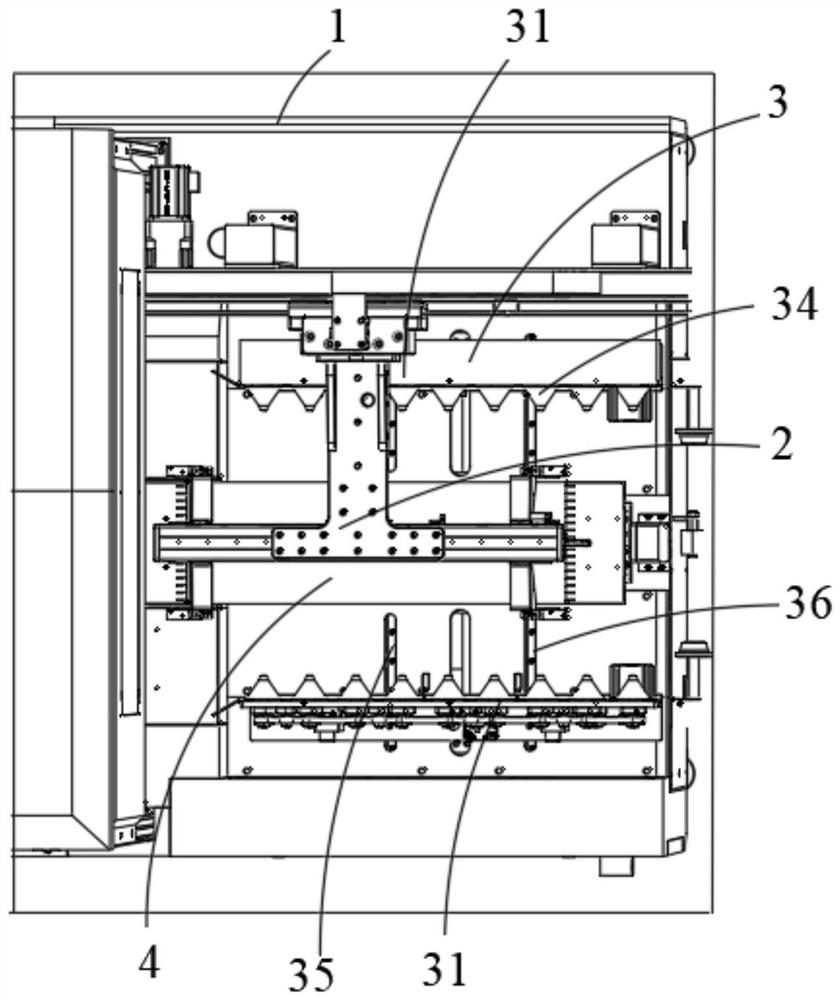

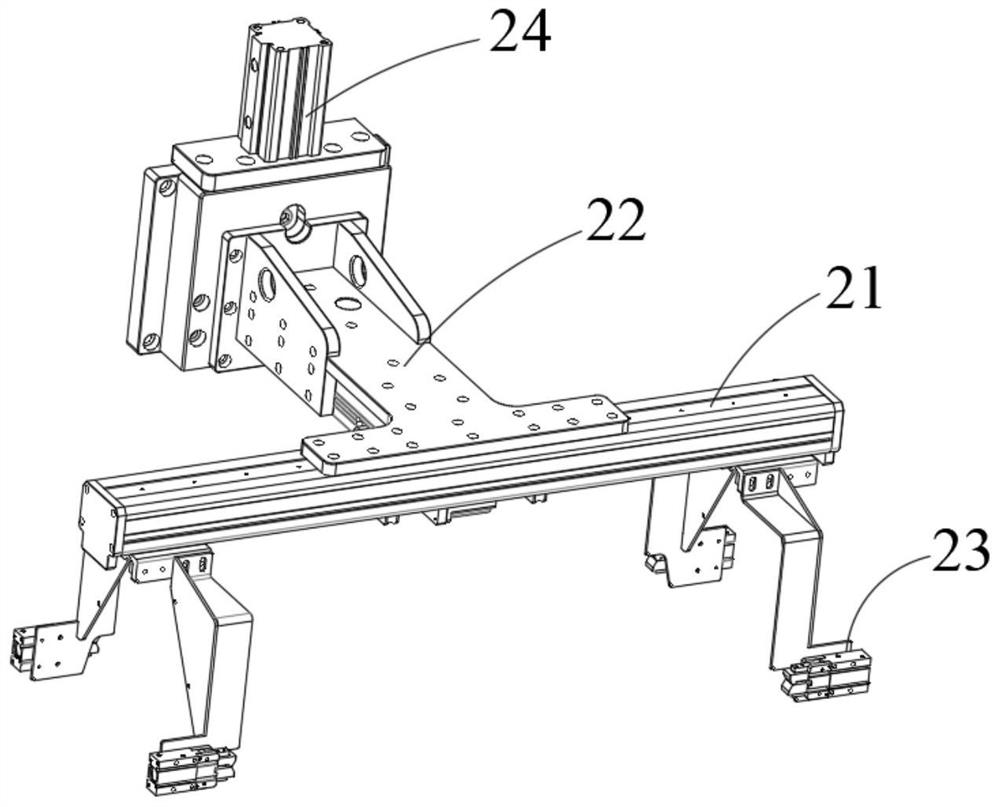

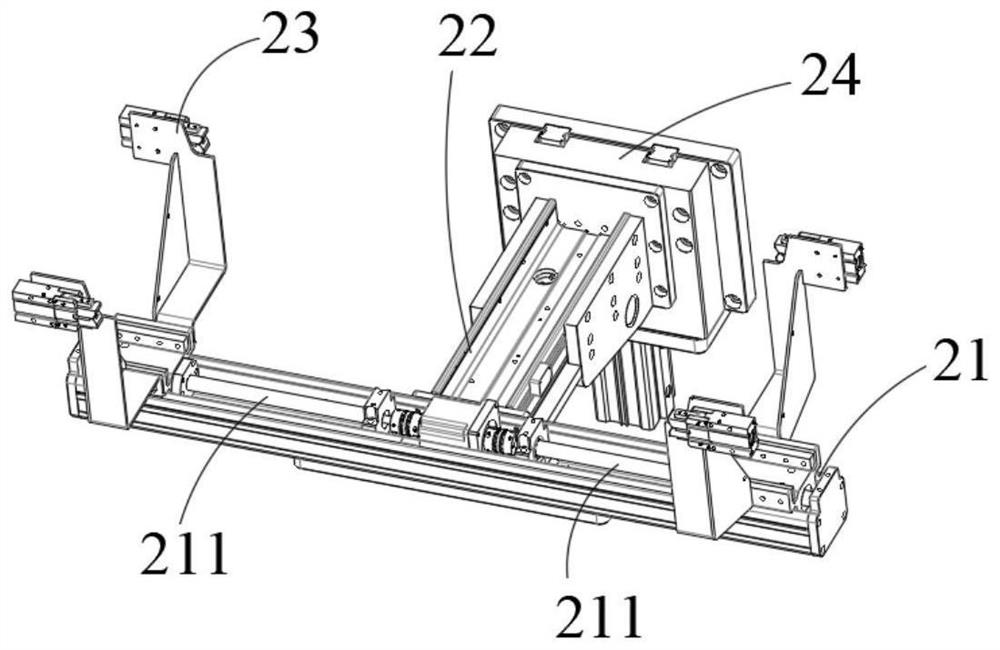

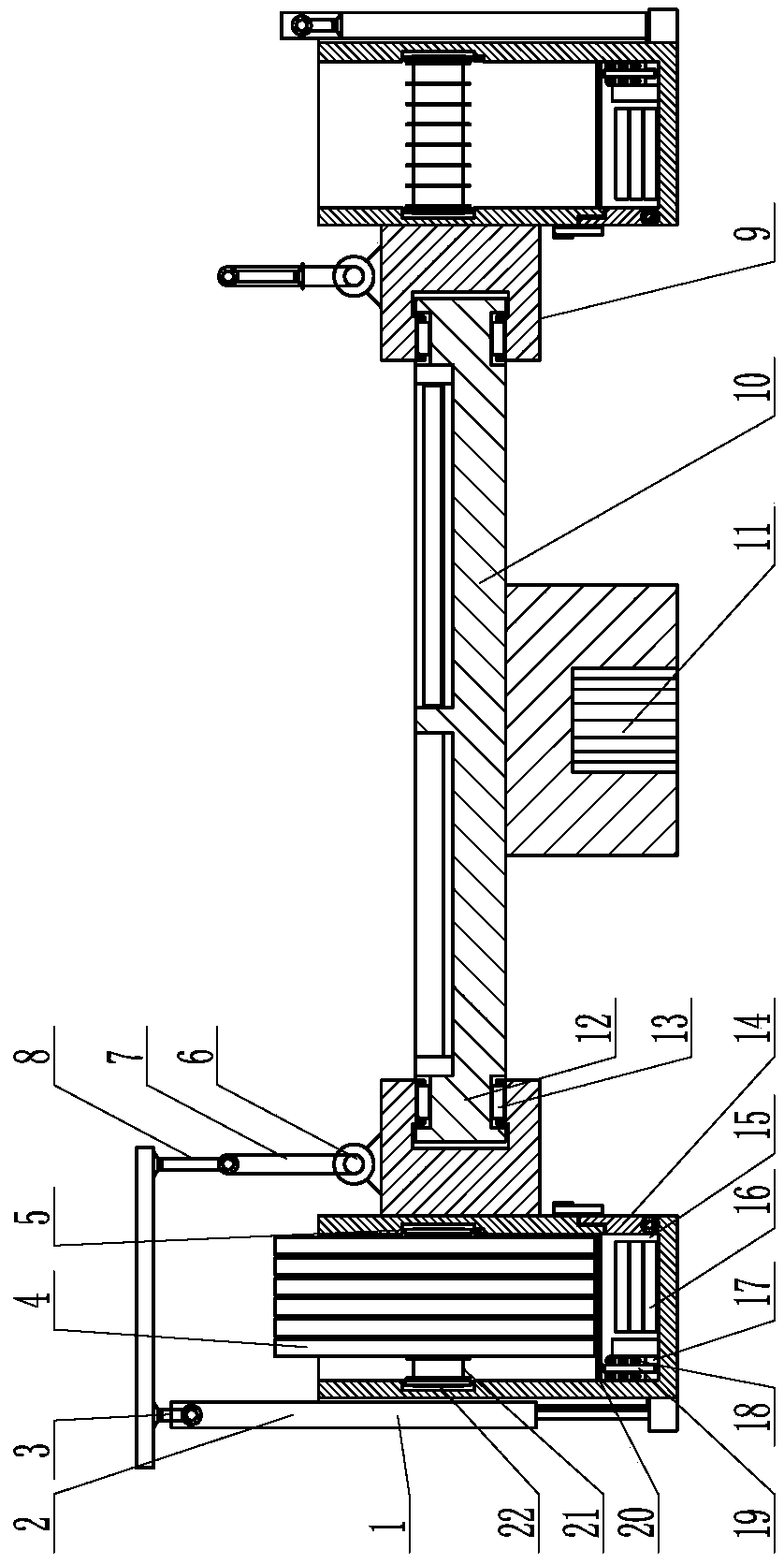

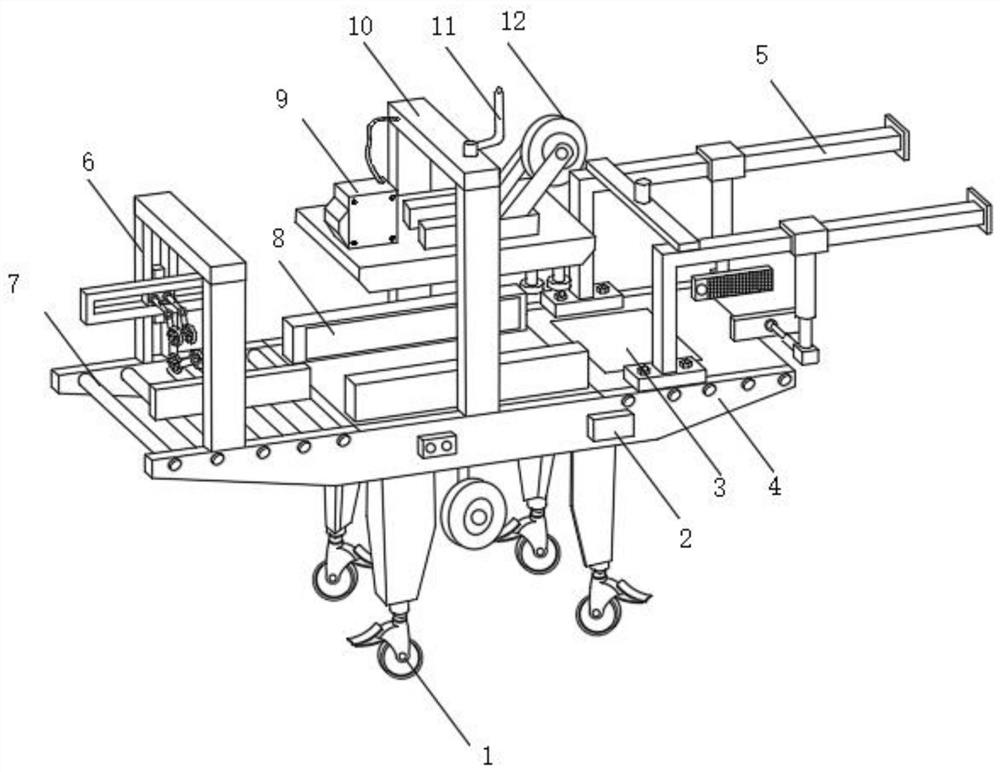

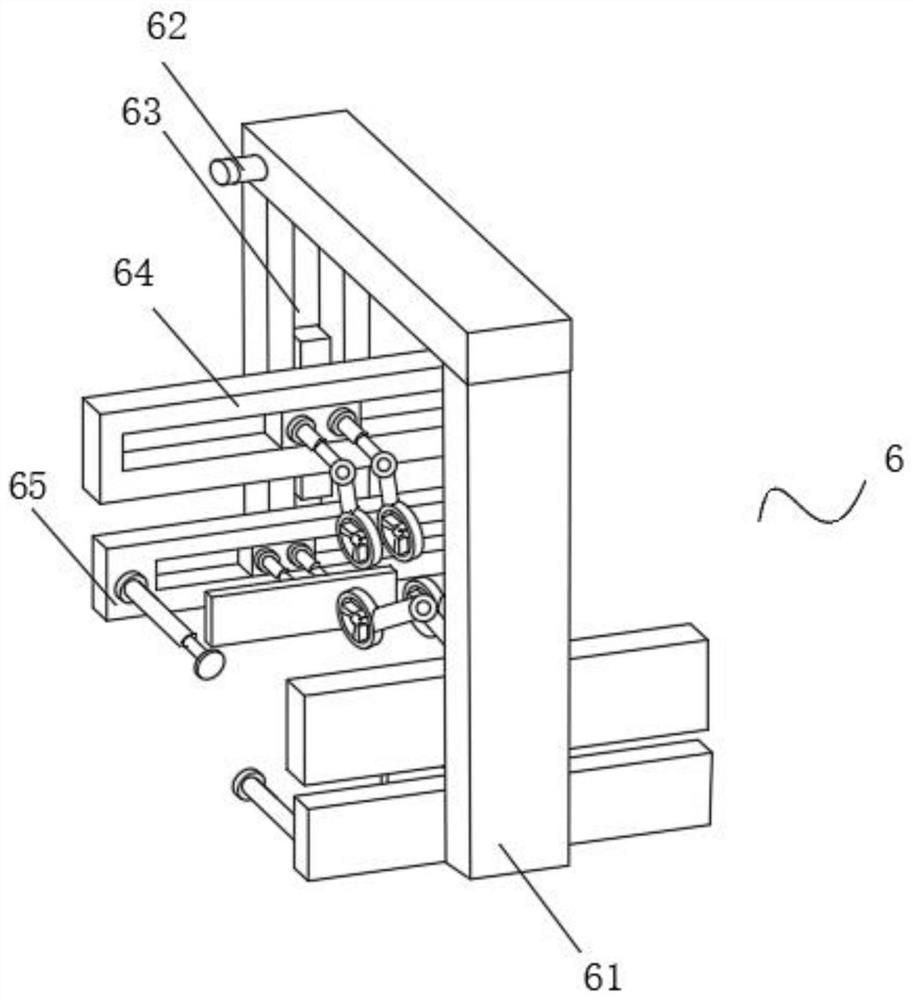

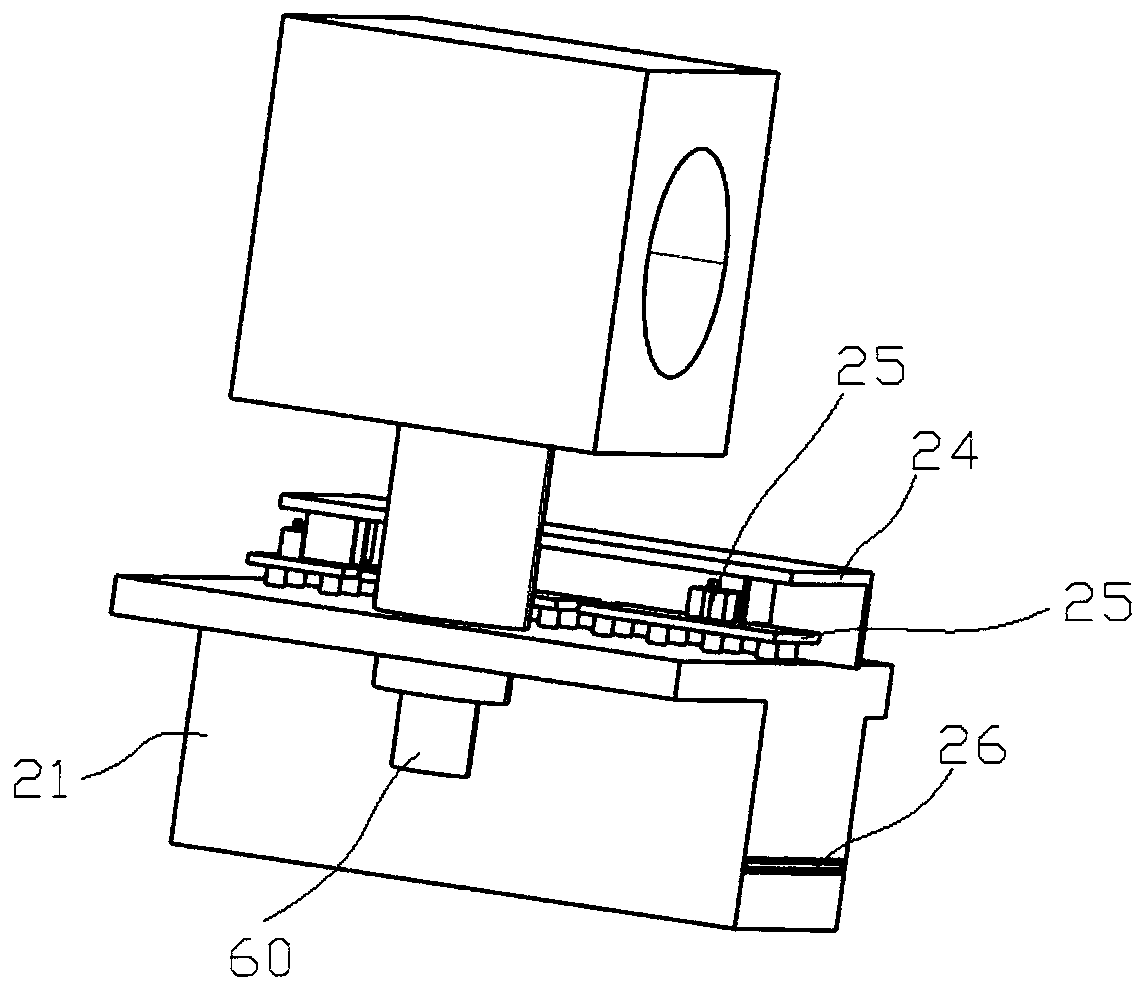

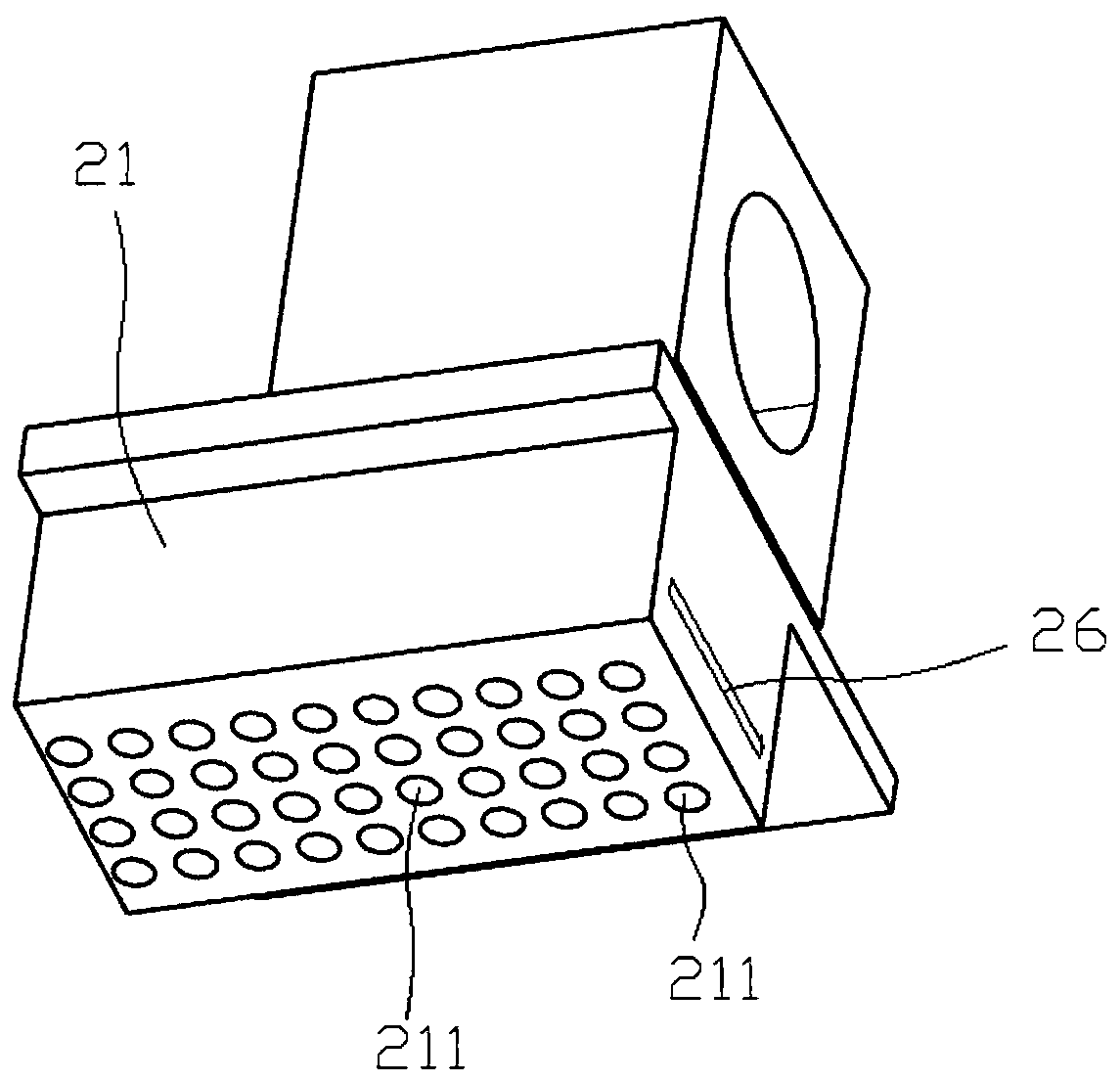

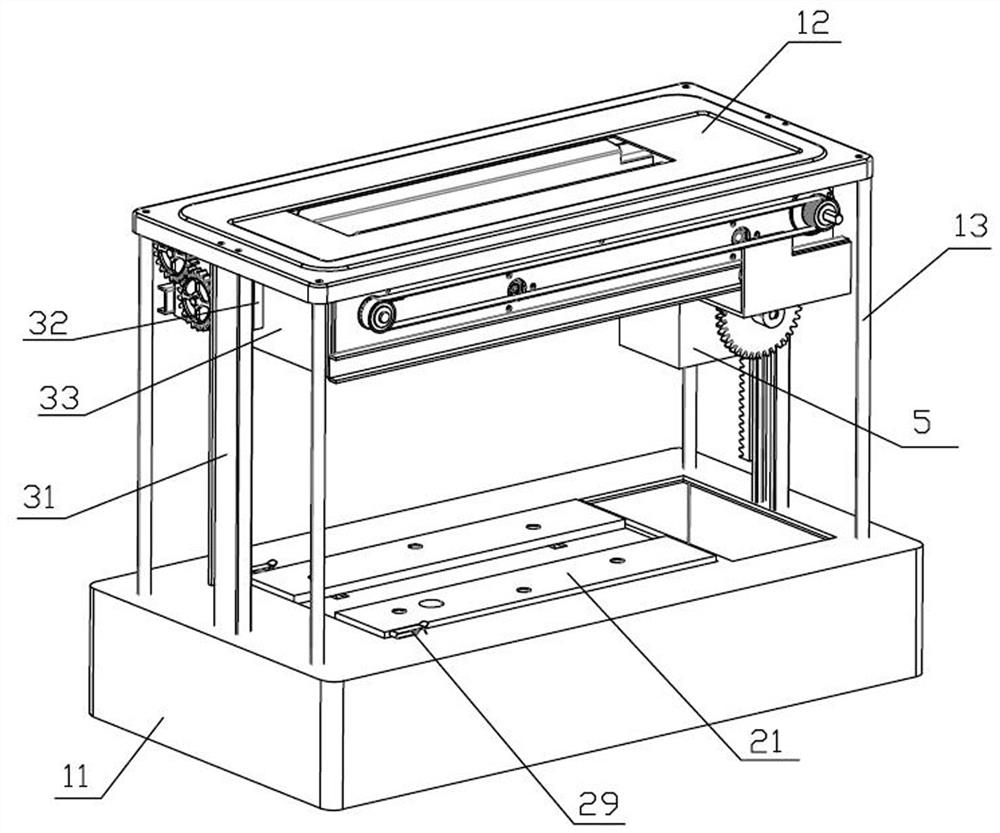

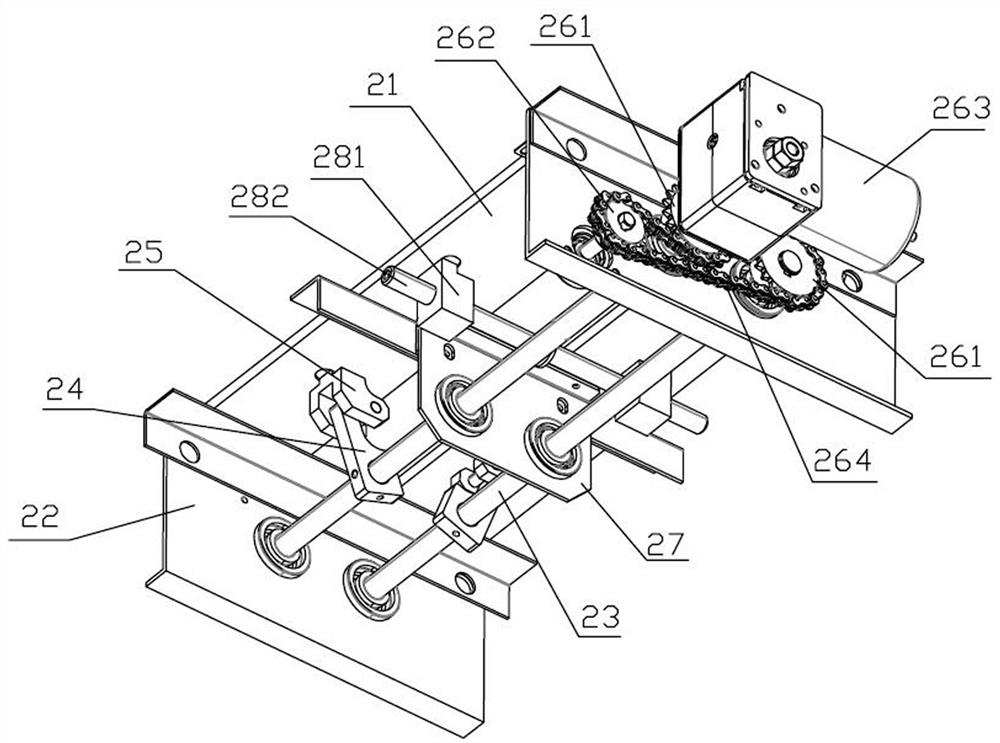

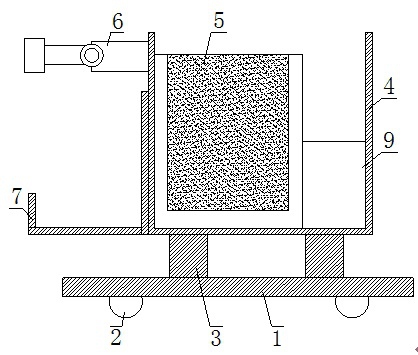

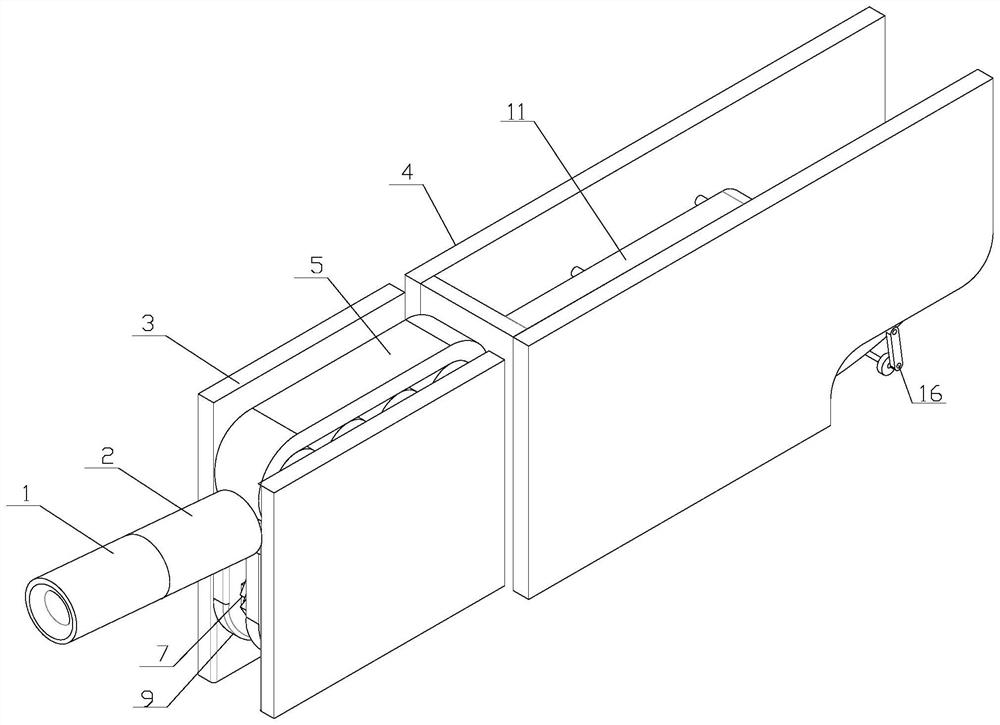

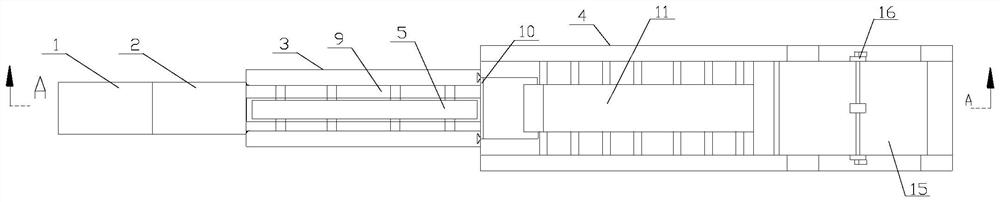

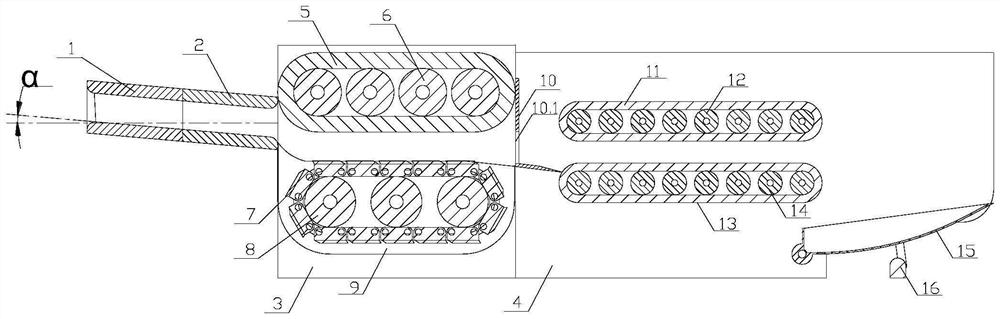

Full-automatic flat grinder

ActiveCN110640564AAchieve recyclingWork environment hygieneGrinding drivesGrinding work supportsEngineeringCooling fluid

Owner:江苏锋宝冶金设备有限公司

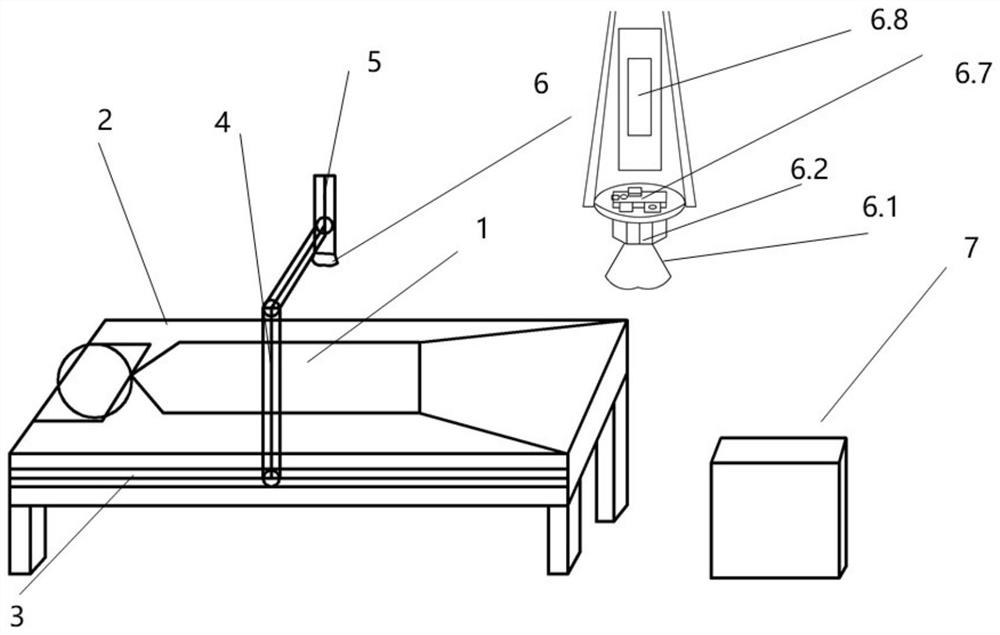

Intelligent therapy health management instrument with Chi needle system based on scraping therapy measurement

PendingCN113576857AReduce power consumptionReduce volumeAcupunctureDevices for locating reflex pointsApparatus instrumentsBody function

Owner:北京明医堂互联网医疗科技有限公司

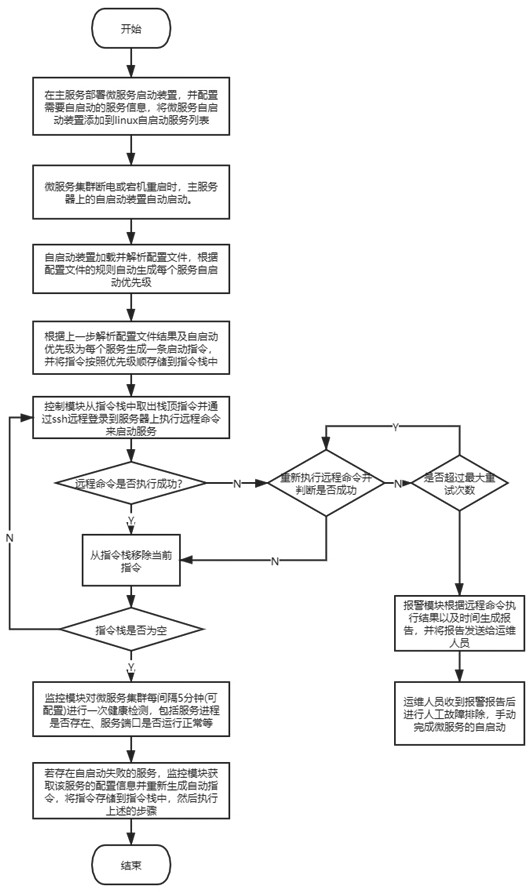

Micro-service cluster self-starting device and method

ActiveCN112769922AGuaranteed success rateReduce operation and maintenance costsProgram initiation/switchingResource allocationService setServer

Owner:NANJING SHICHAZHE INFORMATION TECH CO LTD

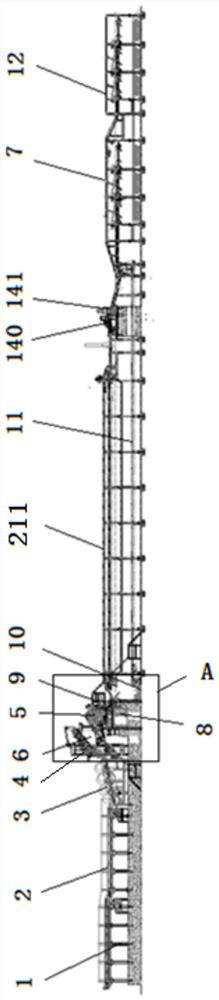

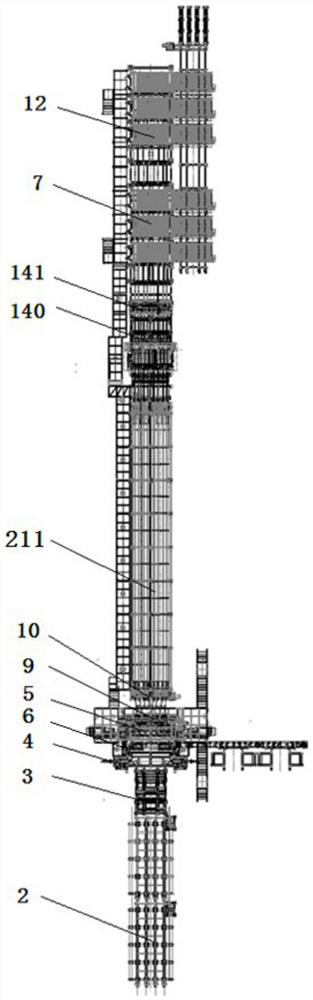

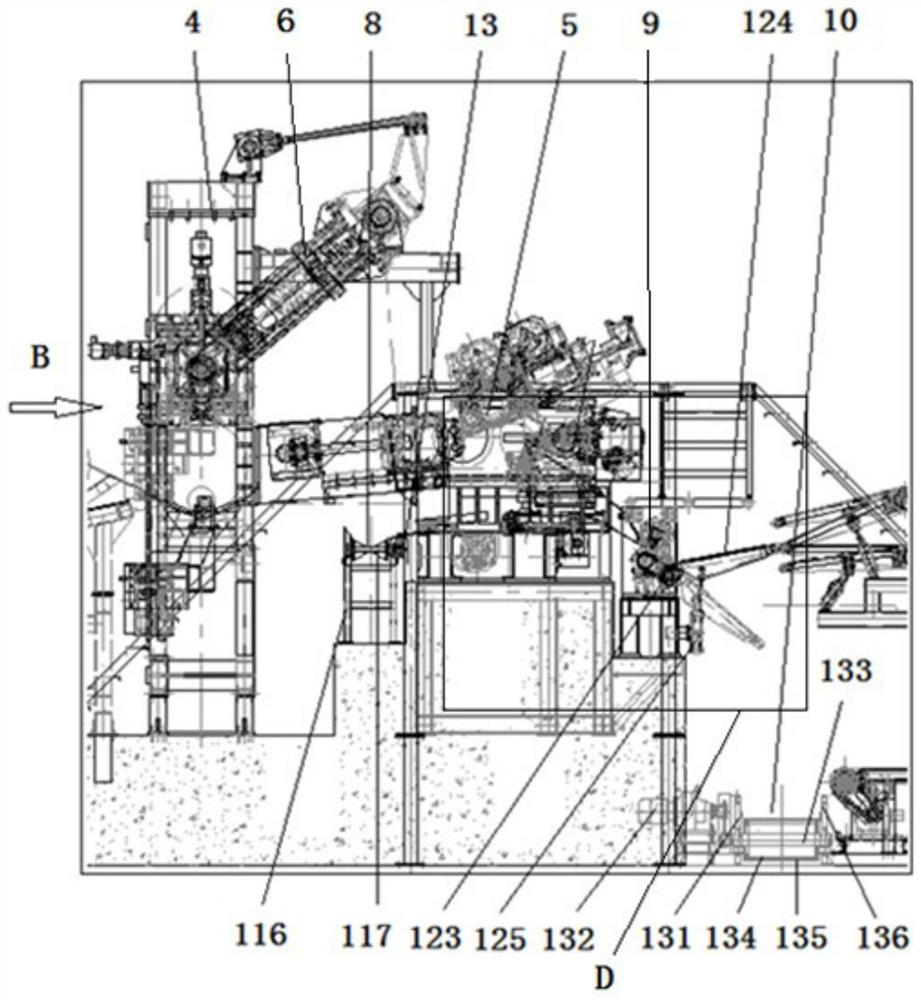

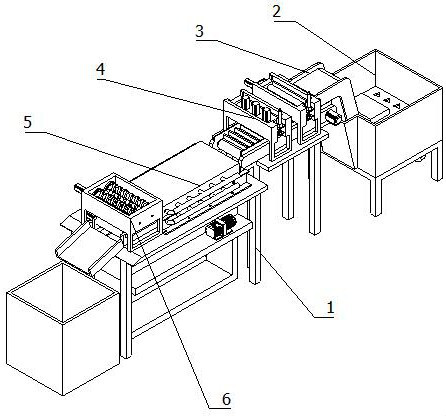

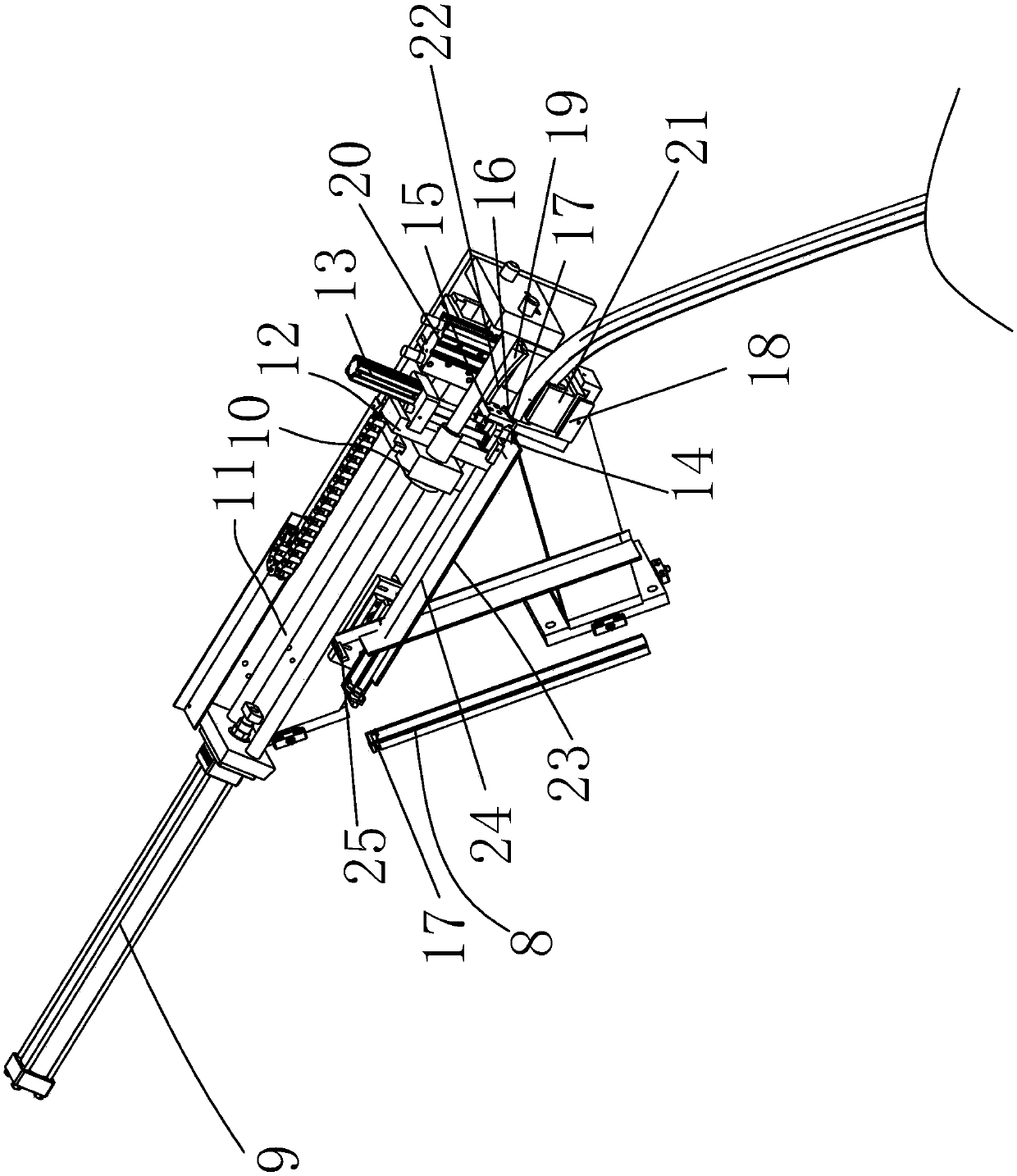

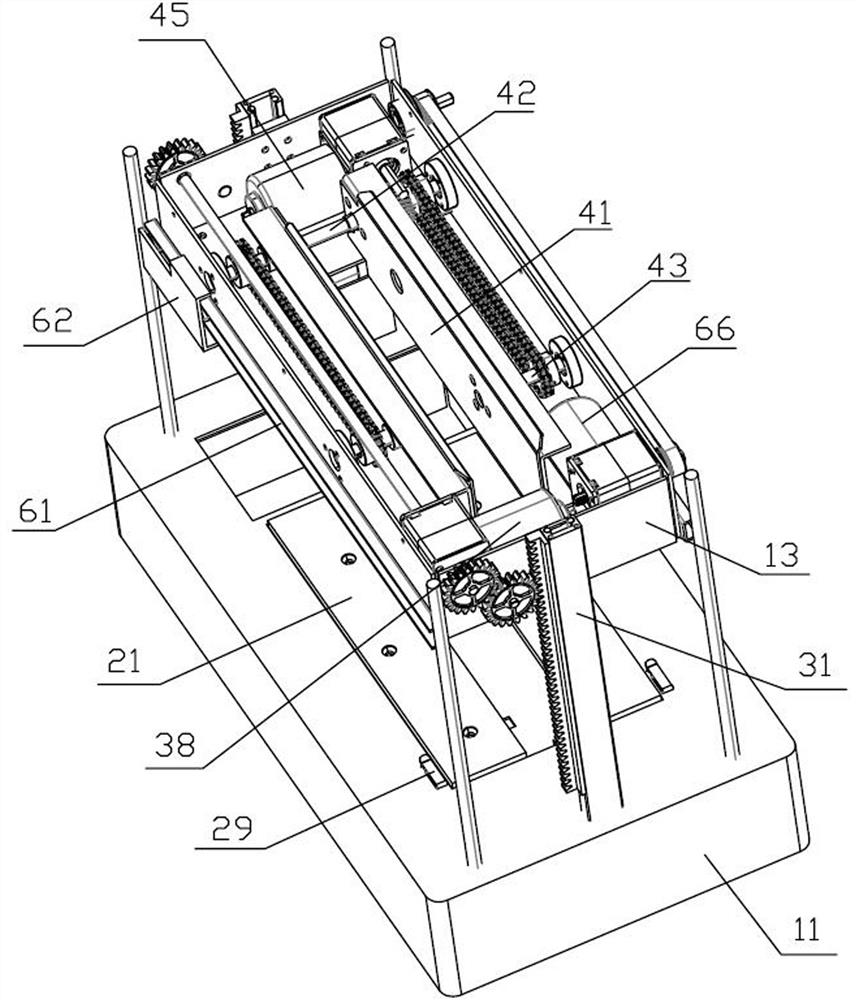

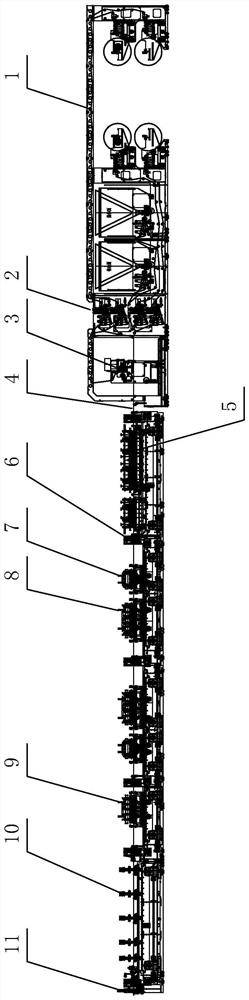

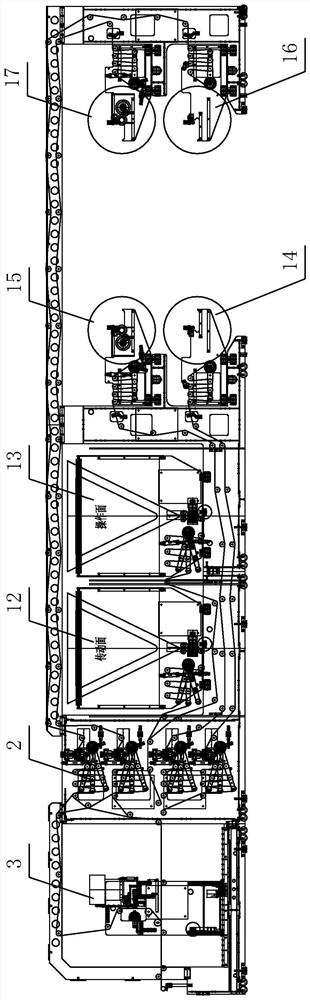

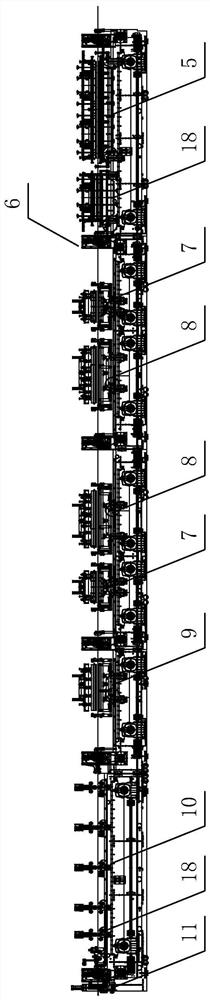

Full-automatic intelligent feeding, centering, rotary-cutting and stacking veneer processing production line

ActiveCN113771175AImprove work efficiencyQuality improvementConveyorsProfiling/shaping machinesStructural engineeringManufacturing line

Owner:SHANDONG BAISHENGYUAN GRP

Information Broadcasting System

InactiveUS20100063991A1Customization processMultiple digital computer combinationsTransmissionPagerInformation device

Owner:ONEIL WILLIAM A

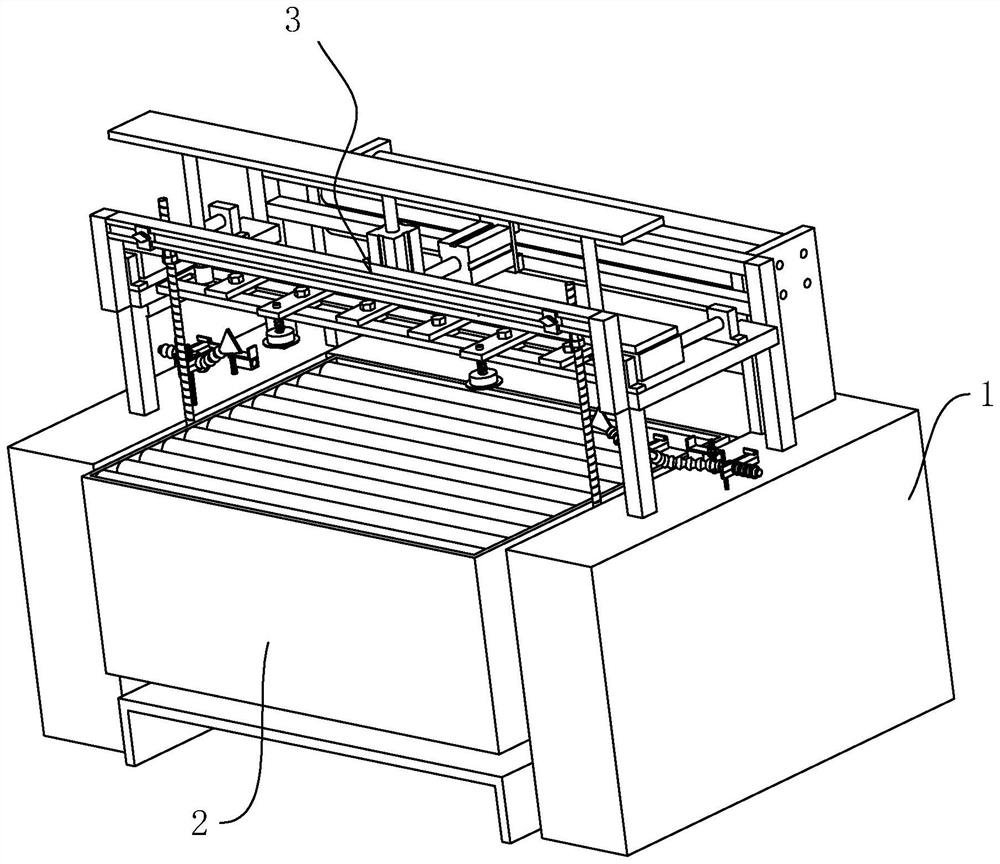

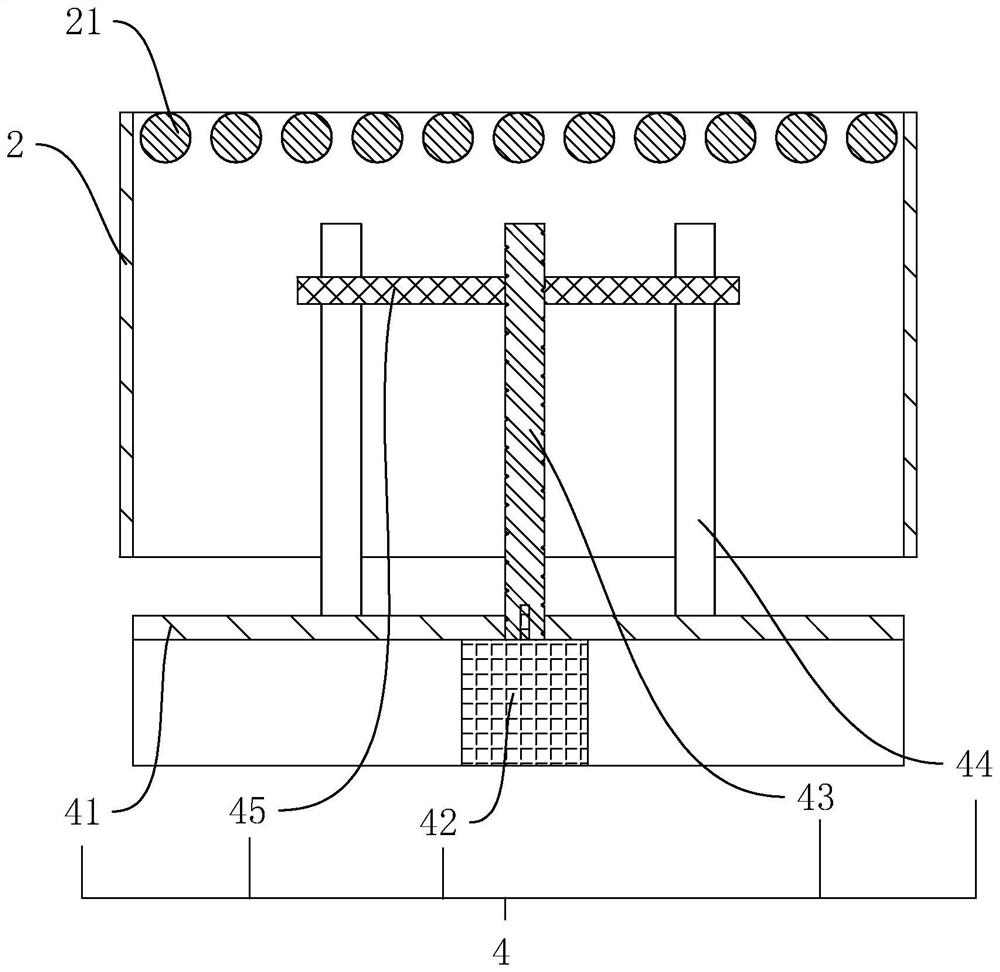

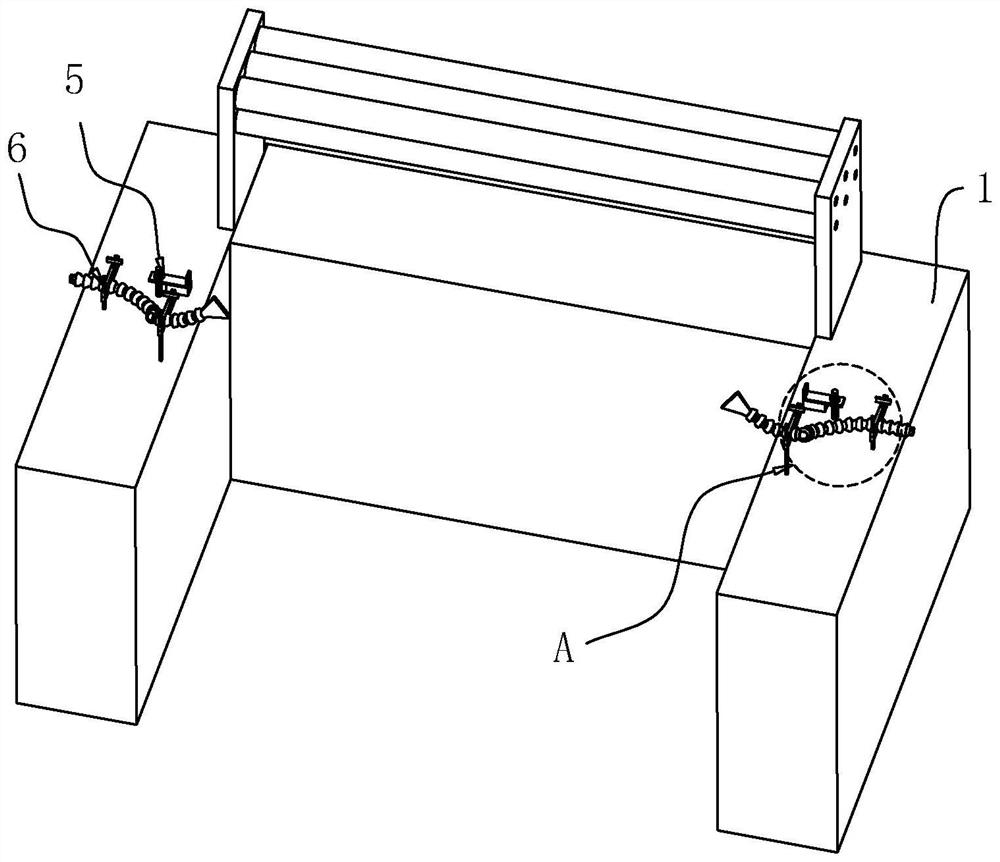

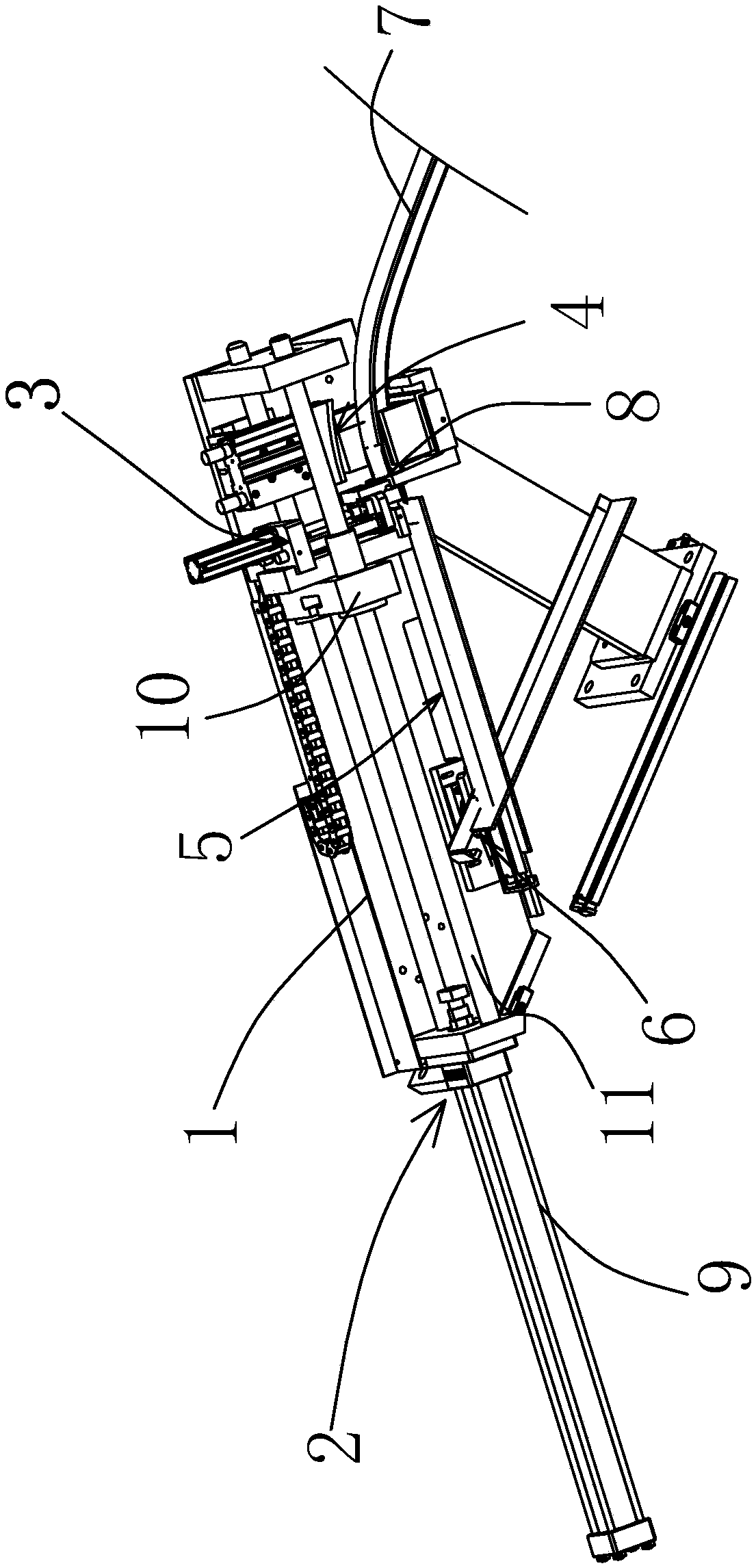

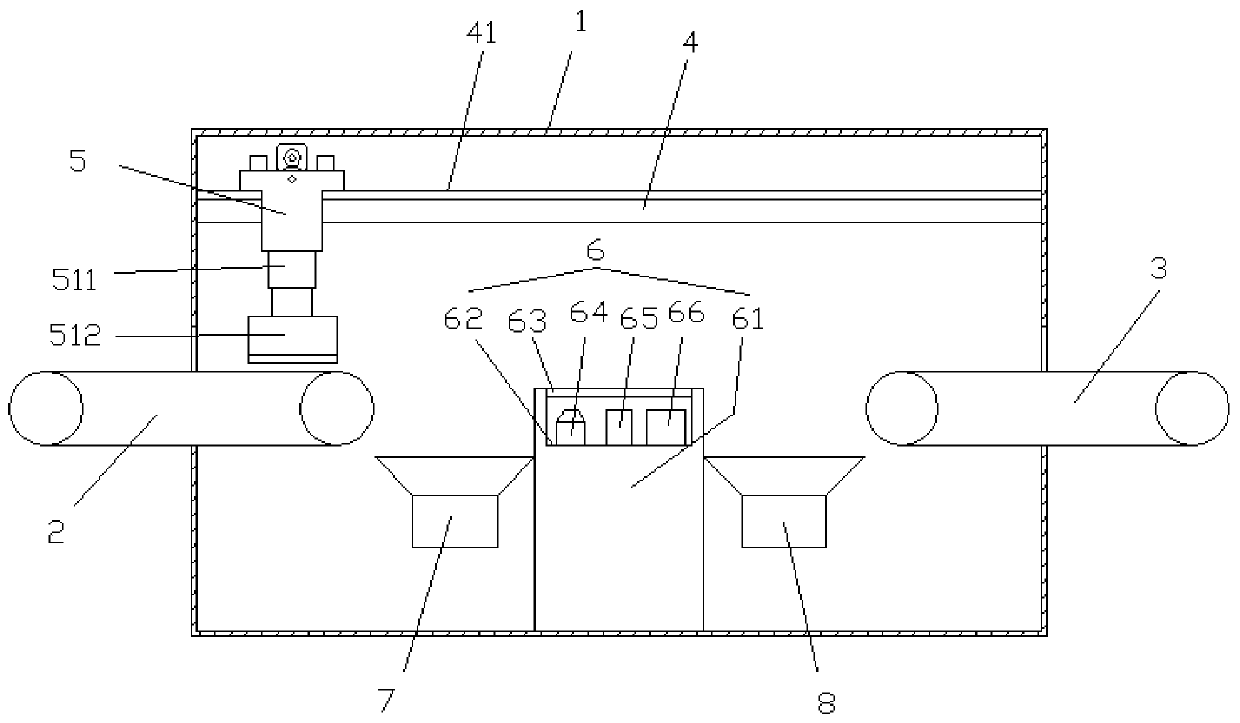

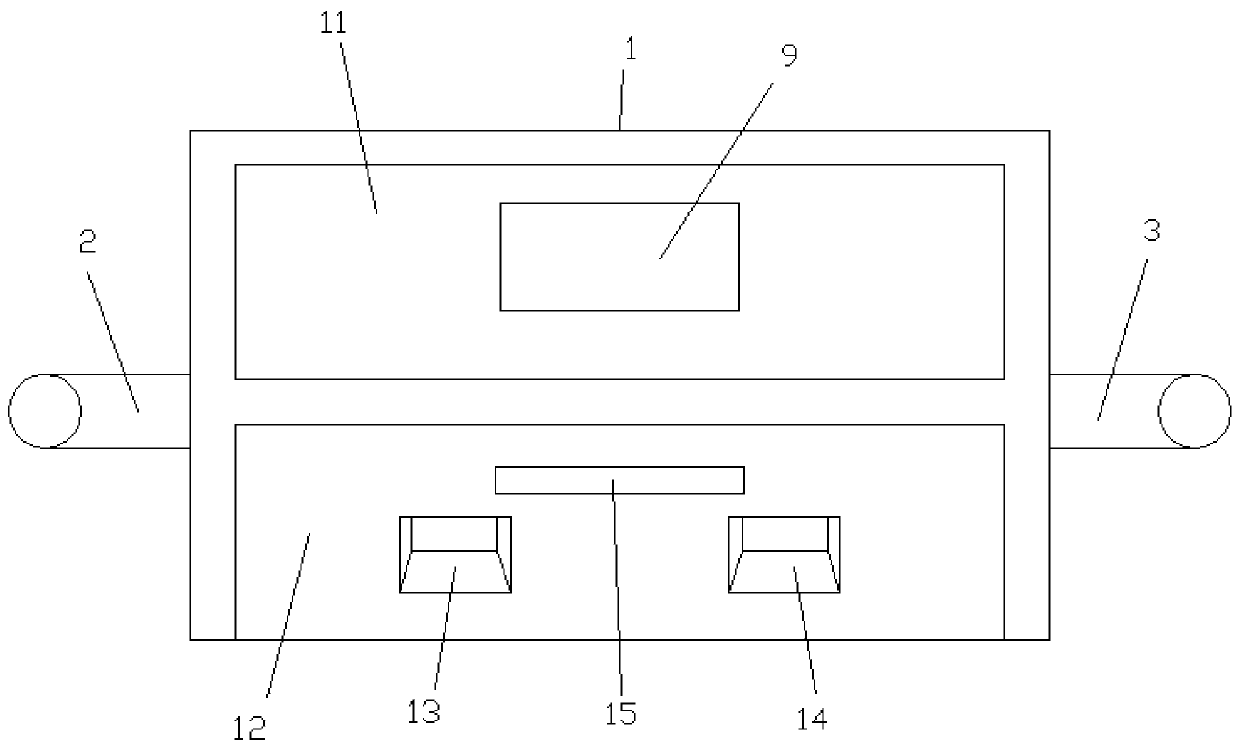

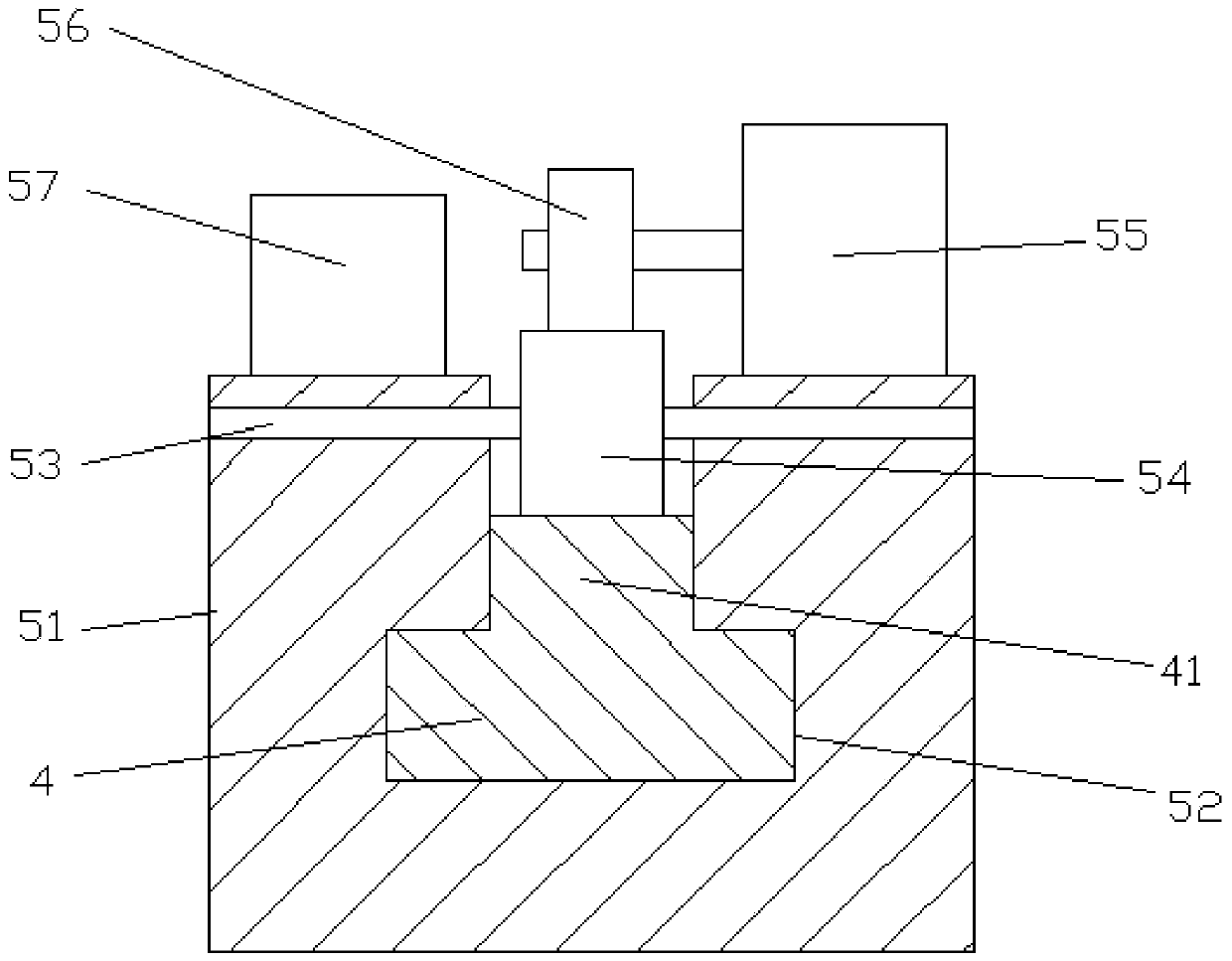

Automatic printing production device for thin plates

ActiveCN112848664AAddressing transfer adaptability issuesRealize fully automatic integrated processing processScreen printersOther printing apparatusPrinting pressMachining process

Owner:广东金玛印刷机械有限公司

Automatic packaging device for fast food

InactiveCN113120288AAchieve a single separationPrecise positioningPackaging foodstuffsRice dishesAssembly line

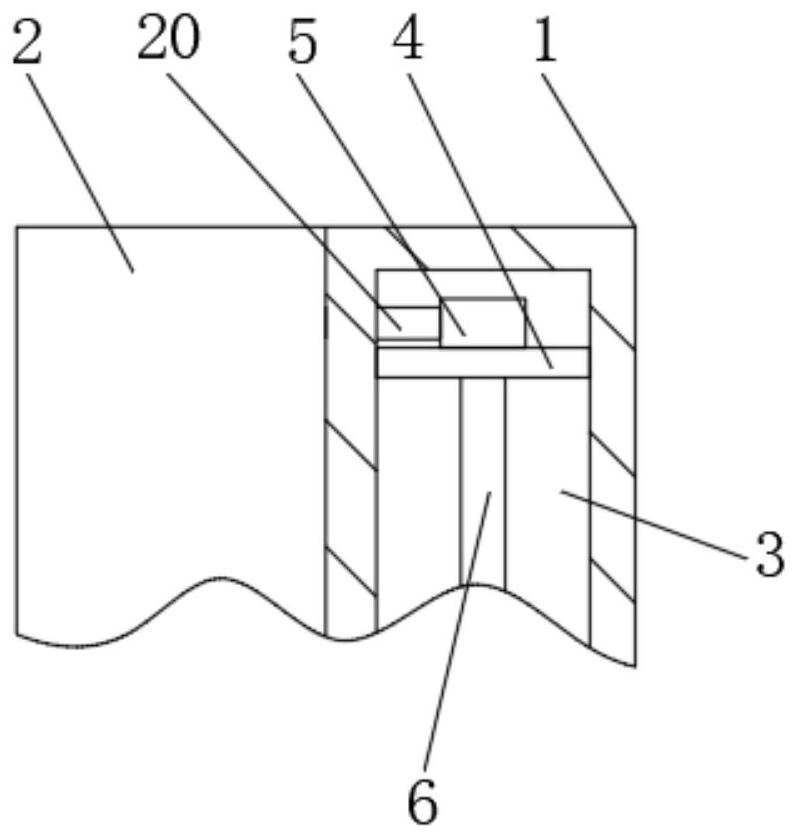

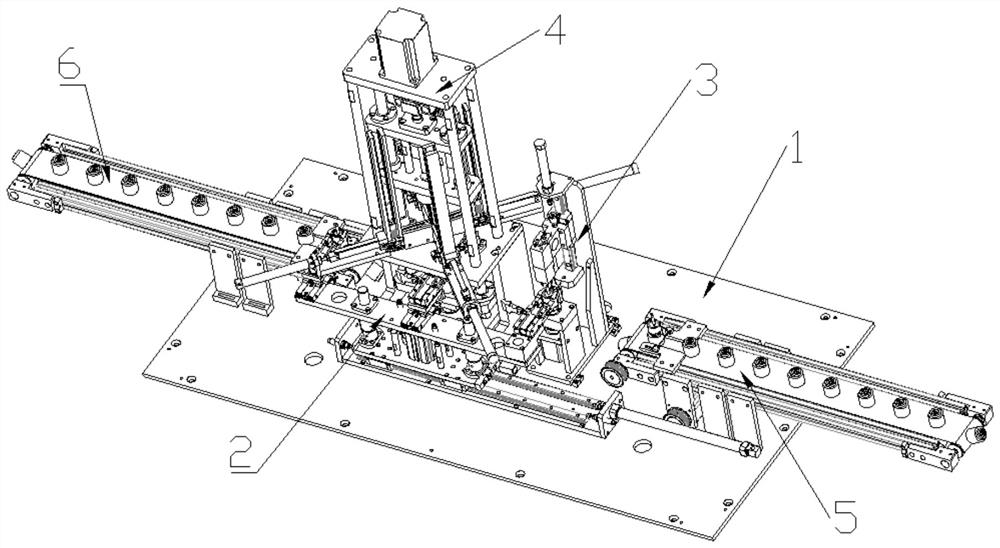

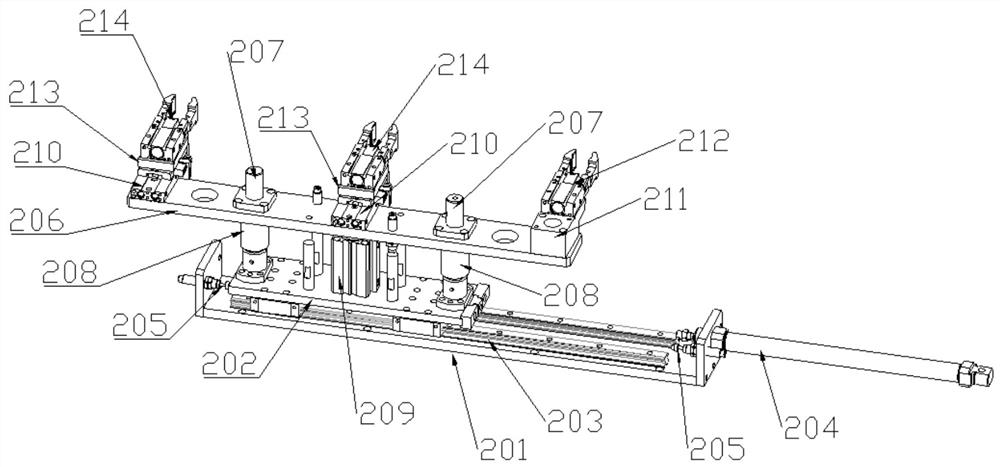

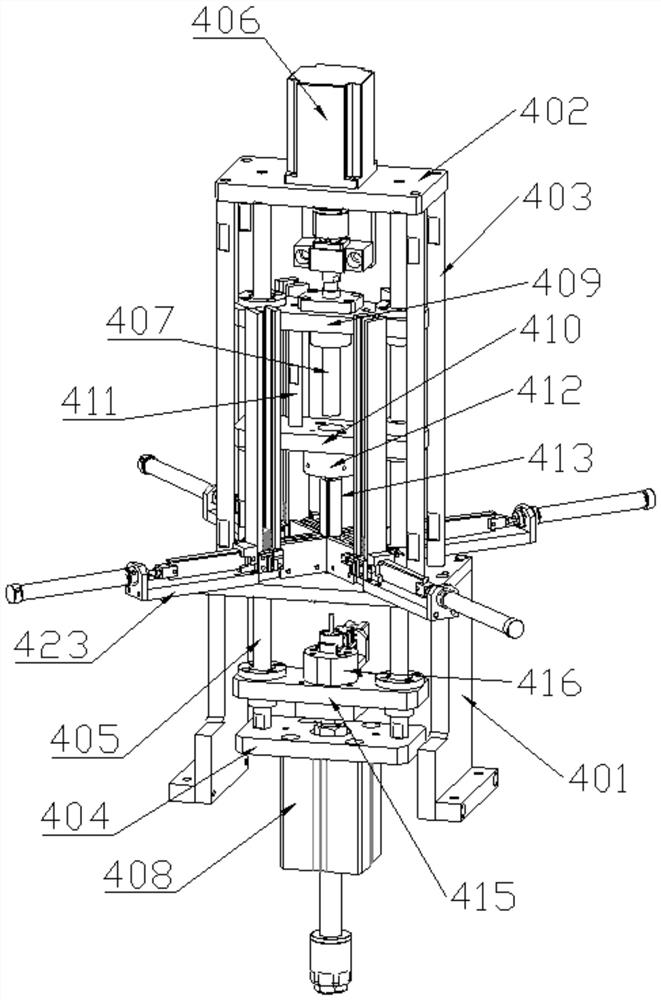

The invention relates to an automatic packaging device for fast food, in particular to a packing device for automatically subpackaging rice and dishes in box-packed fast food. The device is characterized in that assembly line type working equipment is arranged, the equipment automatically grabs a fast food box for operation, and the fast food box operates under the fixation of a clamping jaw of an arranged fast food box clamping conveyor, when the fast food box passes through an automatic food distribution machine area where rice and dishes are placed, a food distribution machine places the rice and the dishes into the fast food box according to the quantity according to set requirements, the fast food box continues to operate backwards after placement is completed, automatic cover sealing is achieved when the fast food box passes through a cover adding area, and finally the fast food box is conveyed out of a packaging area through a fast food box conveyor to complete the automatic fast food packaging function. The automatic packaging device is easy to operate, the rice and the dishes can be quantitatively and rapidly subpackaged, soup separation can be achieved when the dishes are subpackaged, the quality and taste of the dishes are ensured, full-automatic processing is achieved in the working process of the device, and the device is convenient, rapid and sanitary and is an intelligent automatic fast food packaging device meeting the current social requirements.

Owner:JINLING INST OF TECH

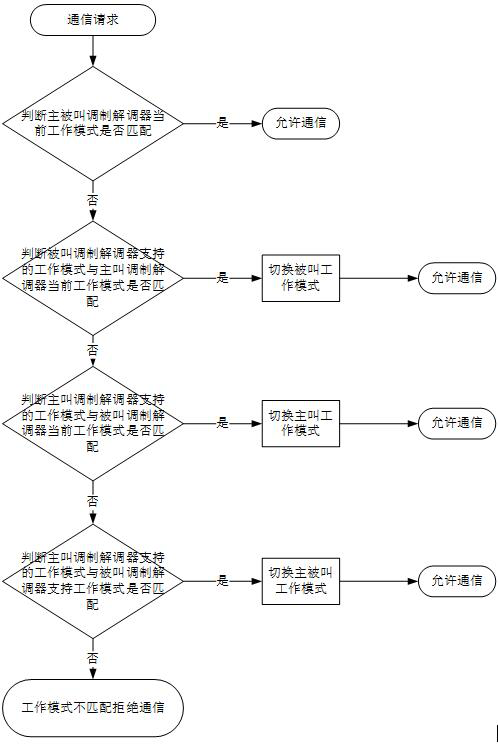

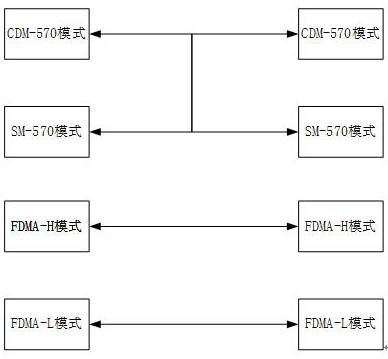

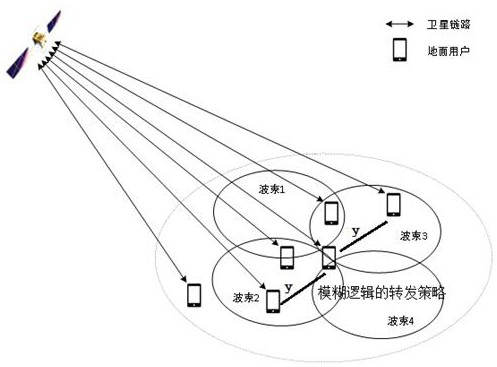

Method and system for automatically matching working mode of modem

ActiveCN113114347AImprove reliabilitySolve the inefficiency of long-running data communicationRadio transmissionTelecommunicationsModem device

Owner:KEYIDEA SATCOM INFORMATION TECH (NANJING) CO LTD

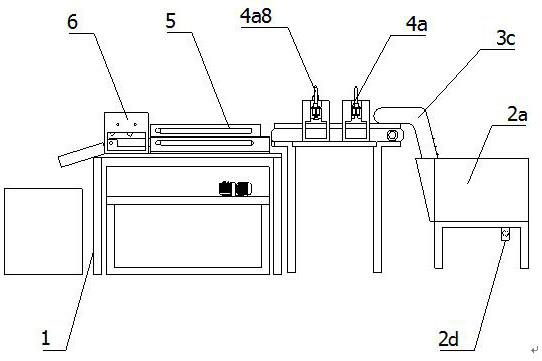

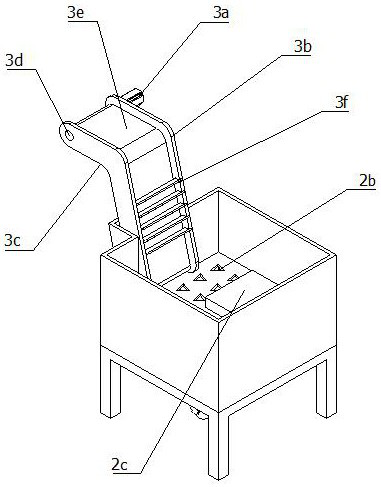

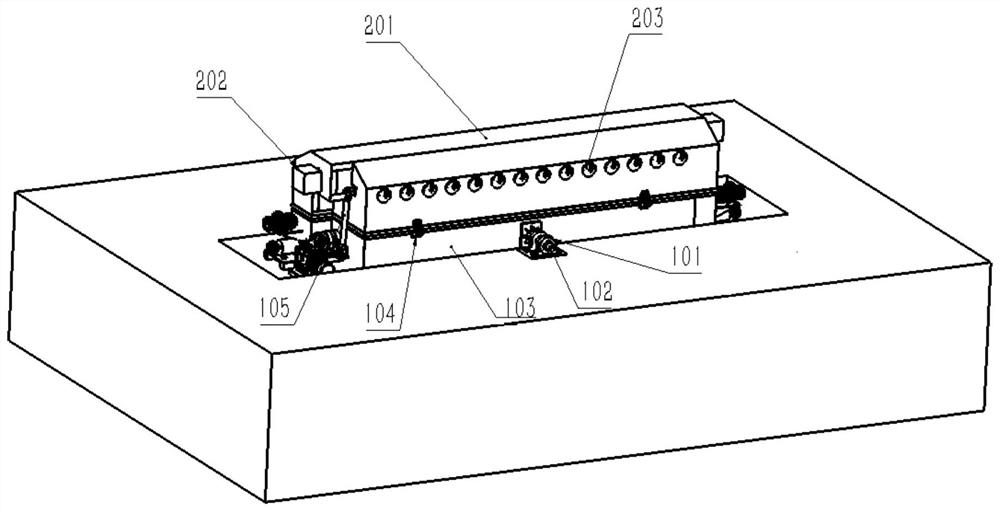

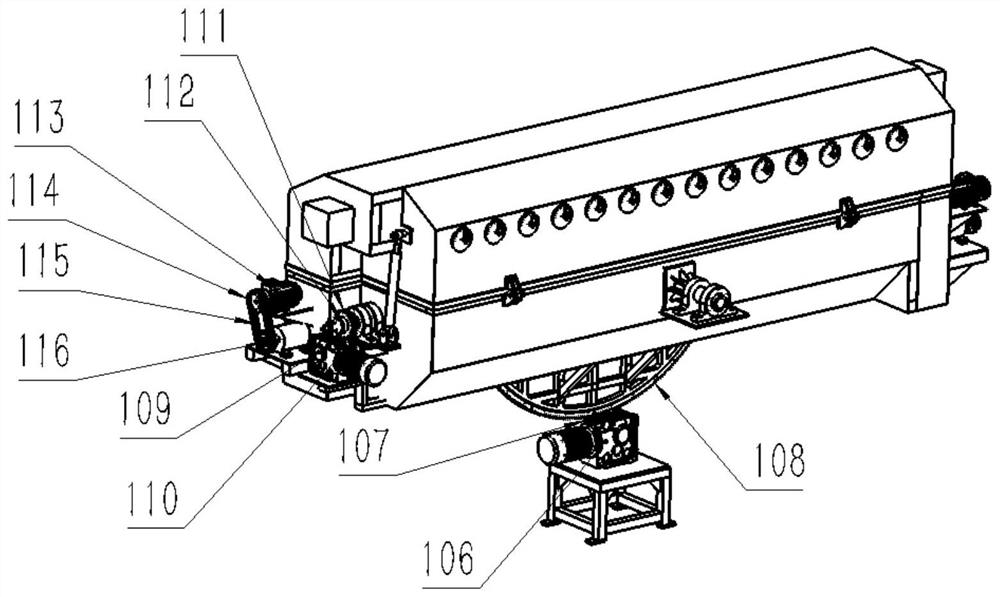

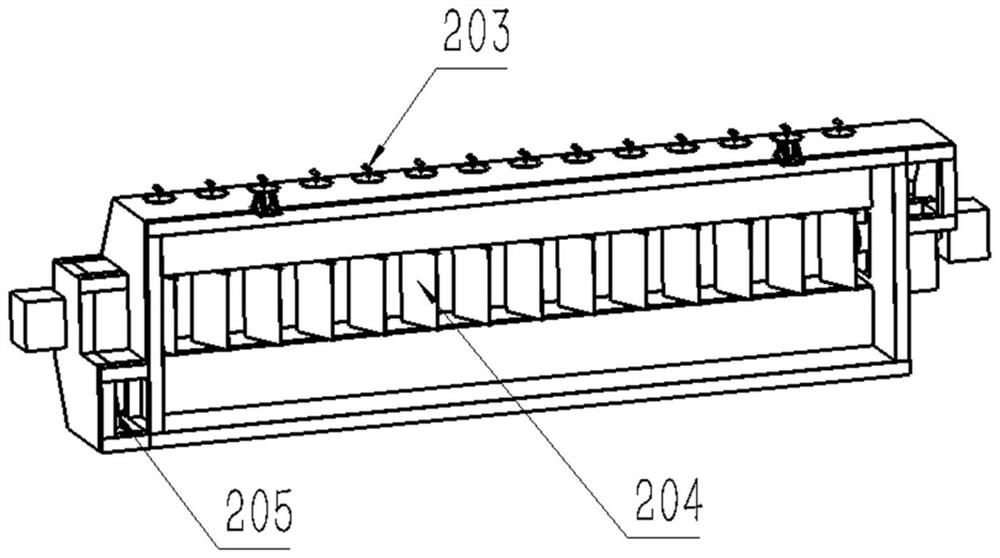

Full-automatic Chinese pastry production line

ActiveCN112960418AOpening and closing effectThere will be no mutual interferenceLoading/unloadingMechanical conveyorsFood safetyProcess engineering

The invention discloses a full-automatic Chinese pastry production line, and relates to the technical field of automatic production. The full-automatic Chinese pastry production line comprises a loading system, a rack car conveying system, a curing system, an unloading system and a car returning system, and the loading system is used for stacking pastry trays loaded with raw pastry and conveyed by an input mechanism on a rack car; after loading is completed, the rack car is conveyed to the curing system through the rack car conveying system to be subjected to fermentation, steaming and cooling, the rack car output by the curing system is conveyed to the unloading system, and the unloading system unloads the pastry trays on the rack car to an output mechanism; and the unloaded empty frame vehicle is conveyed to the loading system by the car returning system for loading. The full-automatic Chinese pastry production line is high in automation degree, does not need manual intervention in the production process, can effectively ensure food safety, can perform whole vehicle steaming processing on the rack vehicle, and is beneficial for improving the yield and the work efficiency.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

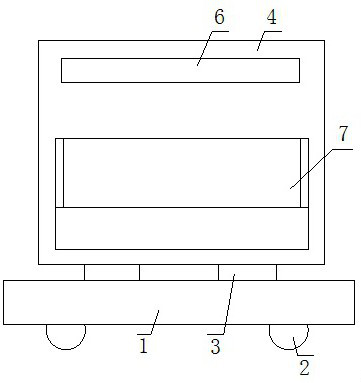

Full-automatic biochemical analyzer with multi-phase sample feeding system

InactiveCN110702934AImplement automatic storageAchieve transferMaterial analysisProcess engineeringBiology

Owner:陈文强

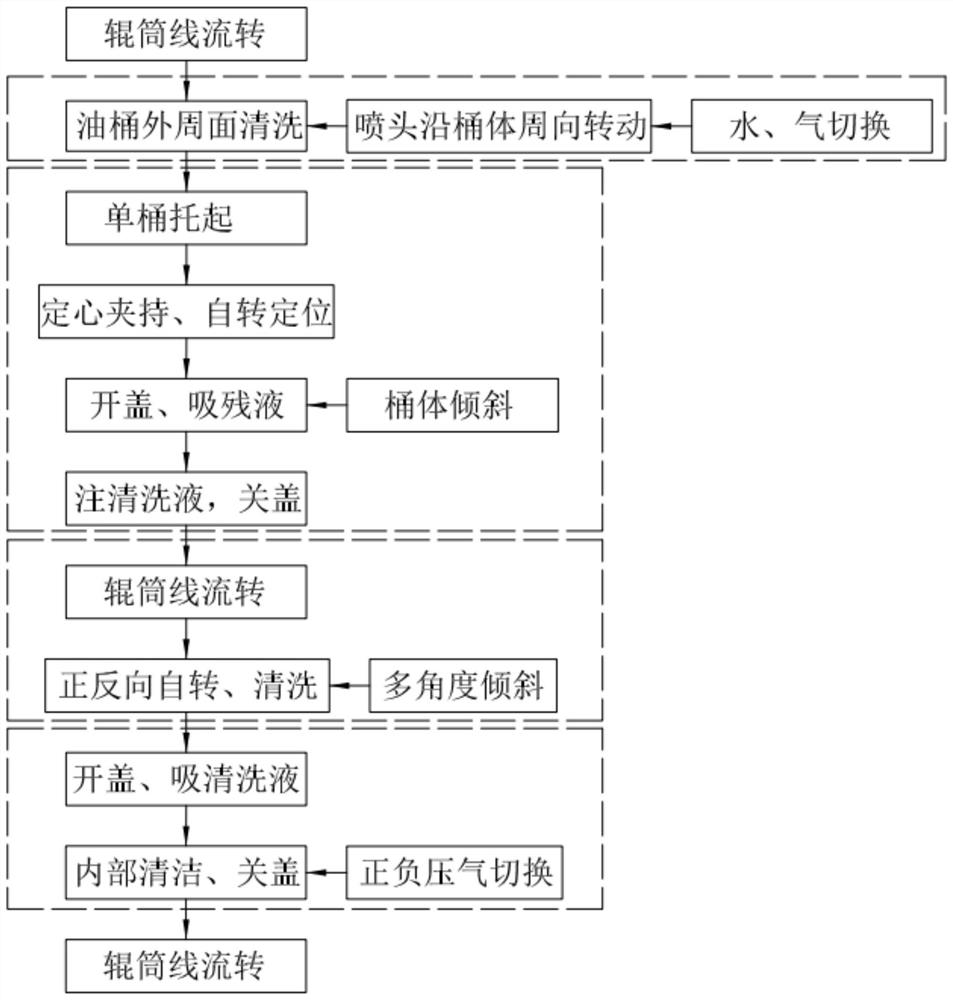

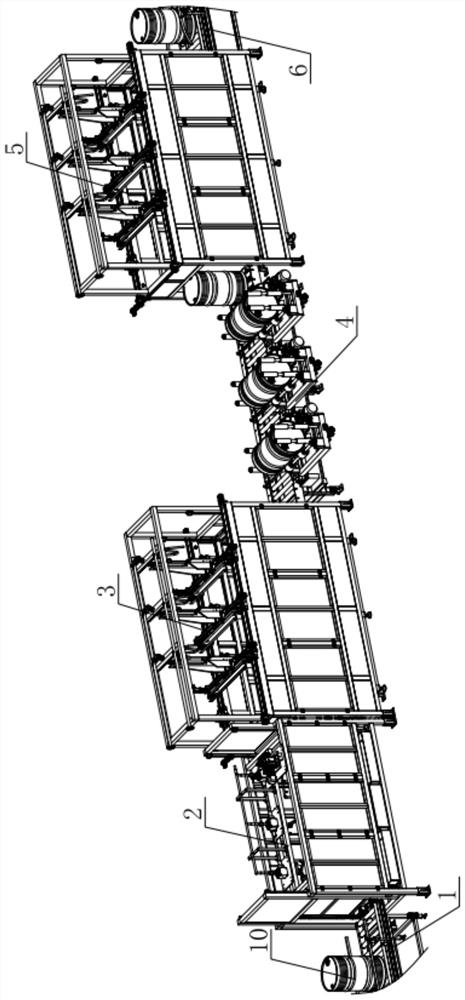

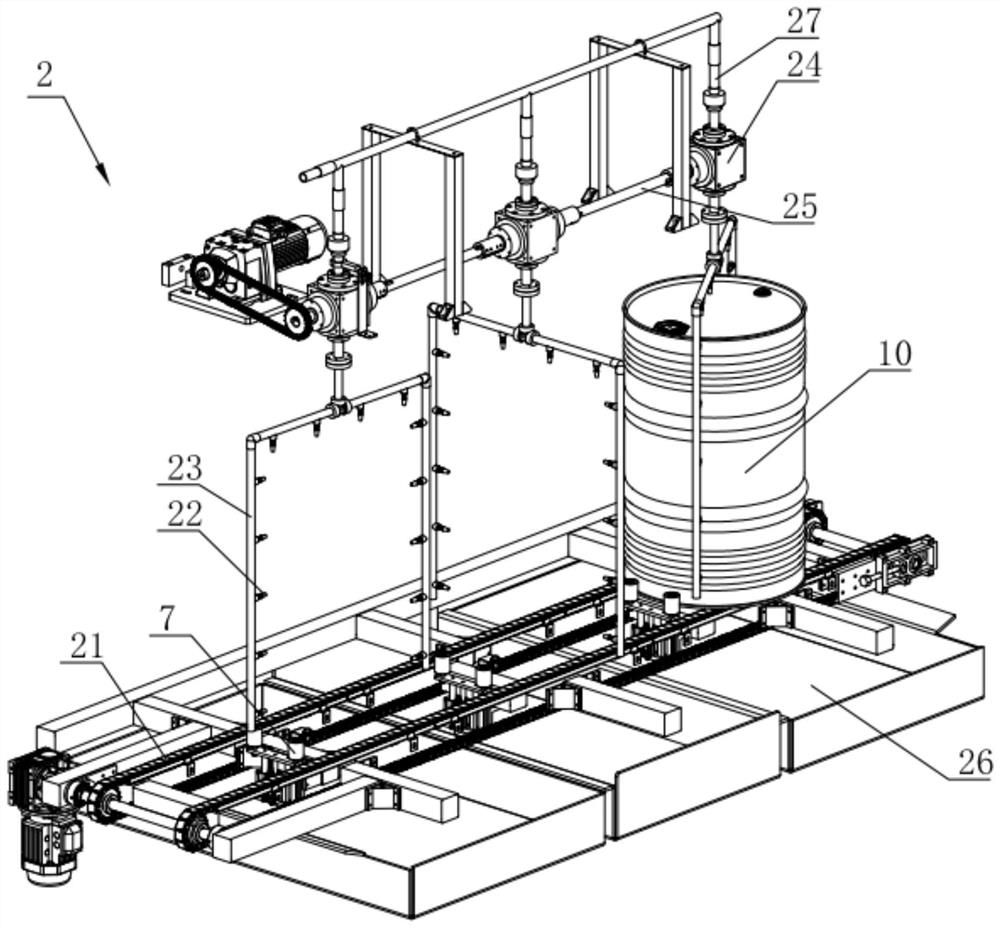

Cleaning method of full-automatic cleaning device for oil drum

ActiveCN114042715AAchieve cleanliness inside and outHelp reuseHollow article cleaningProcess engineeringCleaning methods

Owner:WUXI IDO SCI & TECH CO LTD

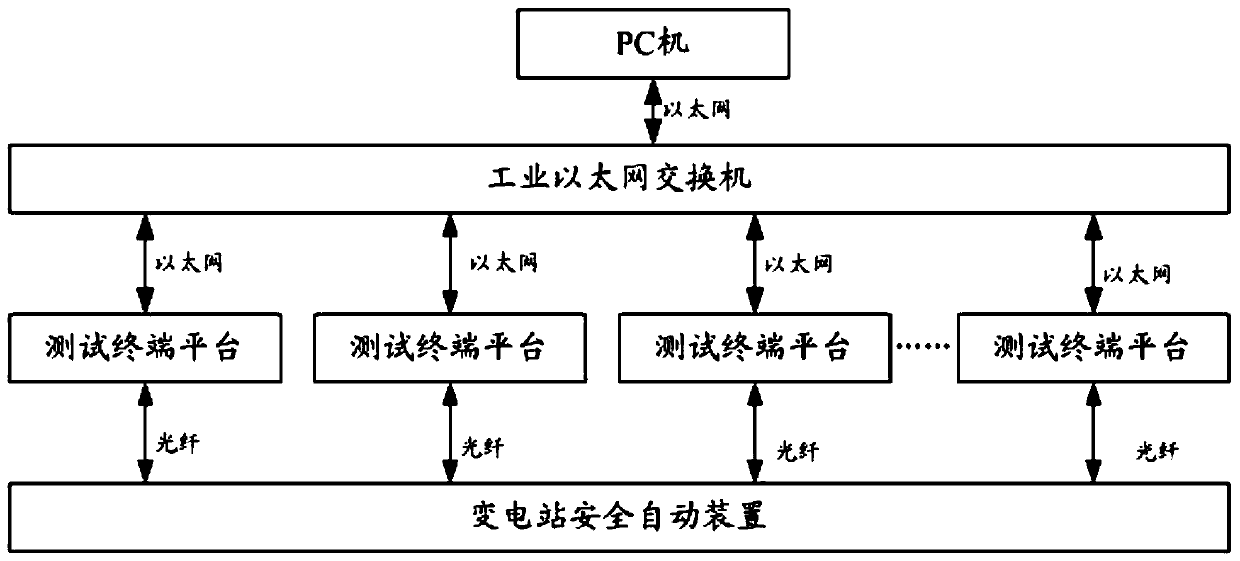

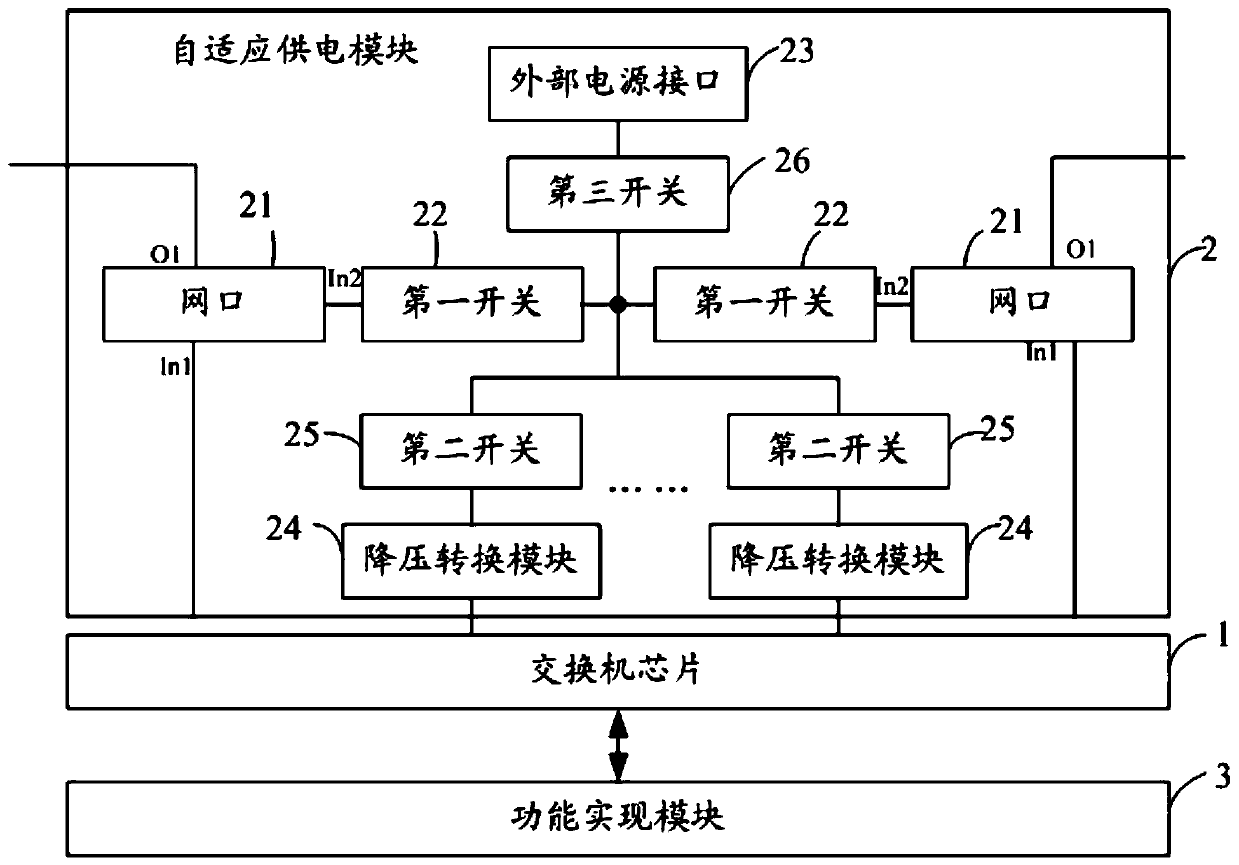

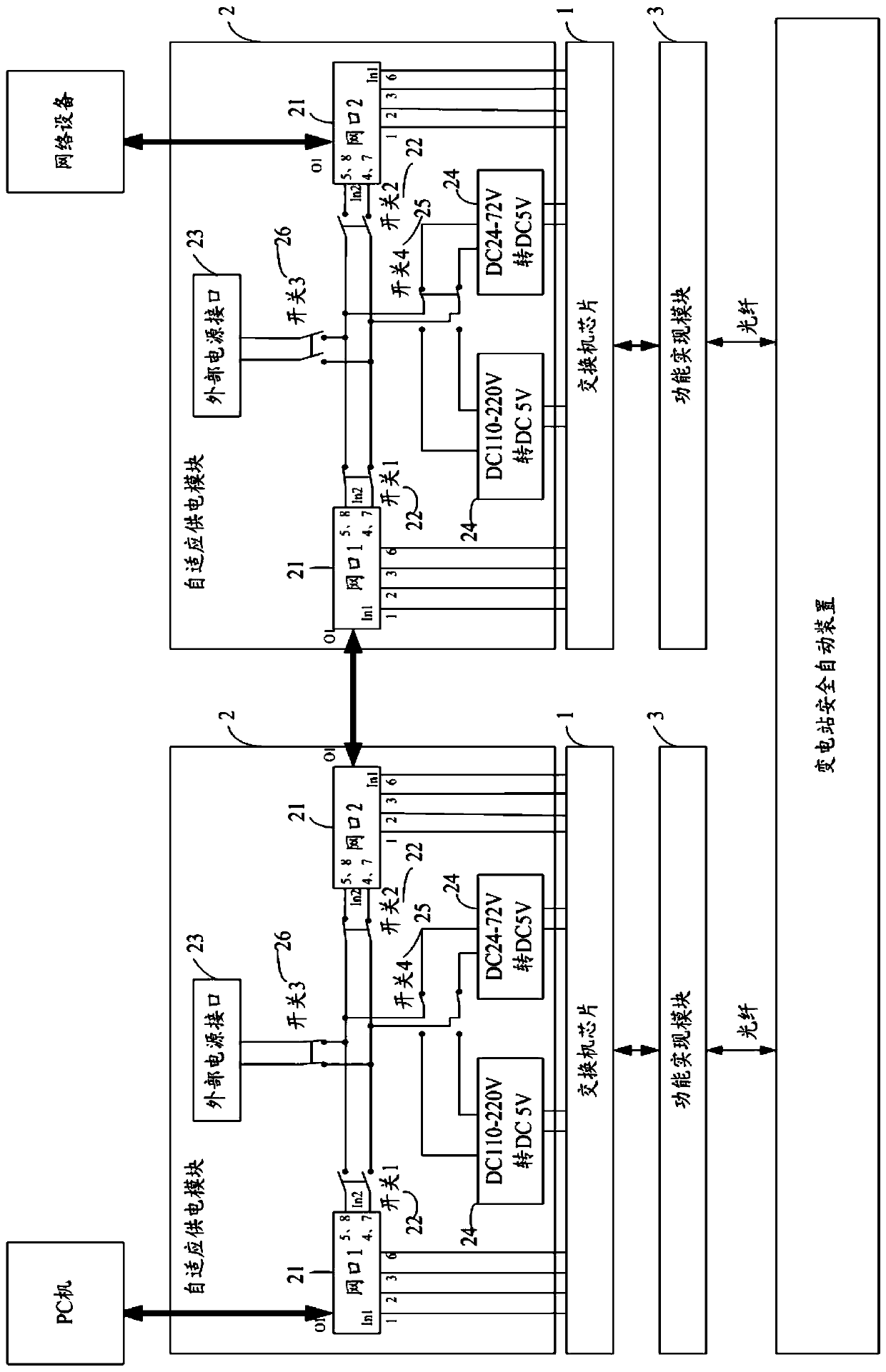

Test terminal platform and test system of transformer substation safety automatic device

ActiveCN110658408AGet rid of dependenceLower access costsElectrical testingElectric testing/monitoringControl engineeringSelf adaptive

Owner:SHENZHEN POWER SUPPLY BUREAU

A read-write test method for memory chip flash by bypassing a customized system-on-chip chip

The invention provides a read-write test method for memory chip flash by bypassing a customized system-on-chip chip. Comprising the following steps: sending multiple groups of specific binary sequence codes to a data line TDI of a JTAG port through a parallel port of a computer; with the help of an oscilloscope, calculating the instruction length, the data length and the highest transmission speed of the JTAG interface through code streams observed on a data line TDO of the JTAG interface; then, converting an operation instruction corresponding to the specification and model of the flash chip needing to be subjected to read-write test into a corresponding binary sequence code according to characteristic parameters of a JTAG interface, and finally loading the binary sequence code to a parallel port card of a computer, so that the parallel port card can automatically match the level of the JTAG interface and shift the sequence code into the pin of the system-on-chip according to the sequence; meanwhile, isolating the internal control logic circuit of the system-on-chip automatically; finally, sending the binary sequence code accurately to the control bus of the flash chip, and realizing the full-automatic read-write test of the flash storage chip.

Owner:GUANGZHOU HANGXIN ELECTRONIC CO LTD

Full-automatic carton double-cut attaching packaging machine

PendingCN112278356ARealize mobile alignmentReduce coefficient of frictionWrapper twisting/gatheringCartonElectric machinery

Owner:高永航

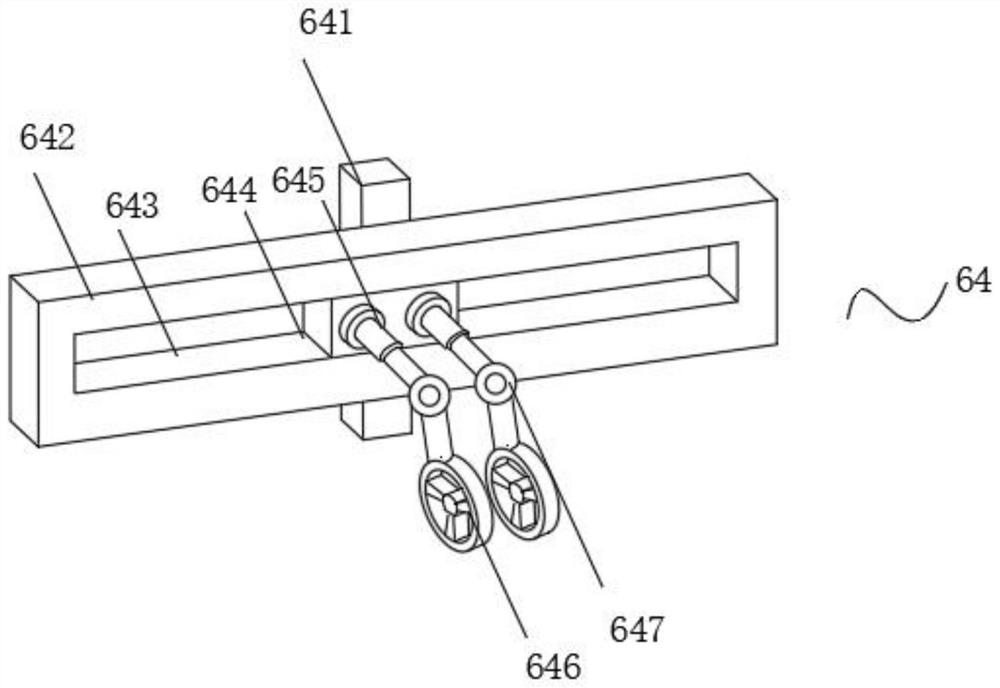

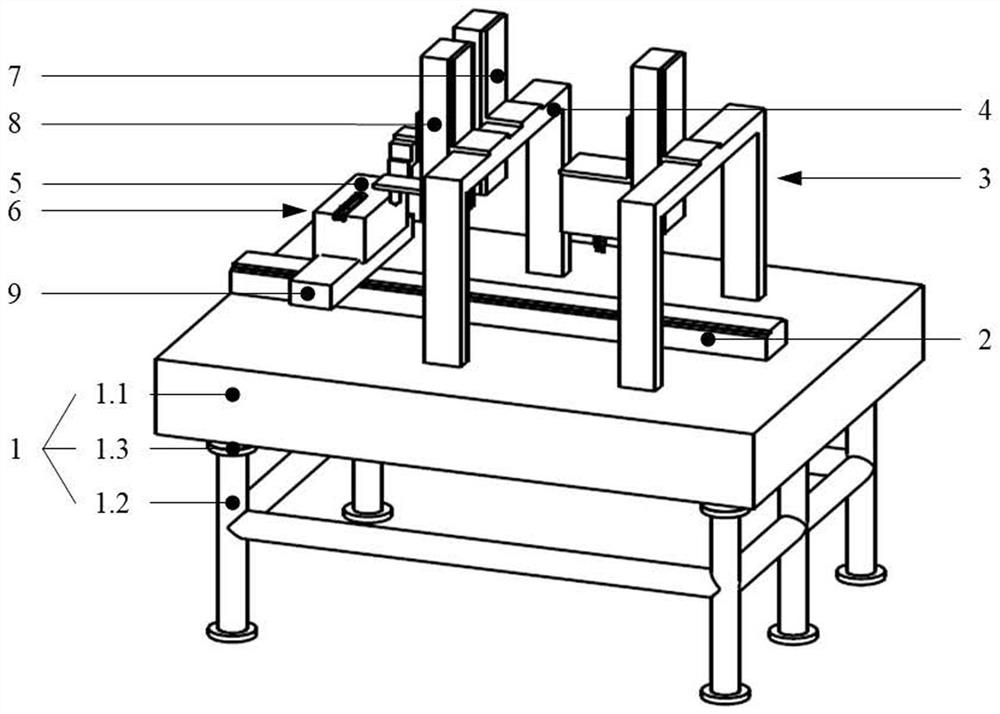

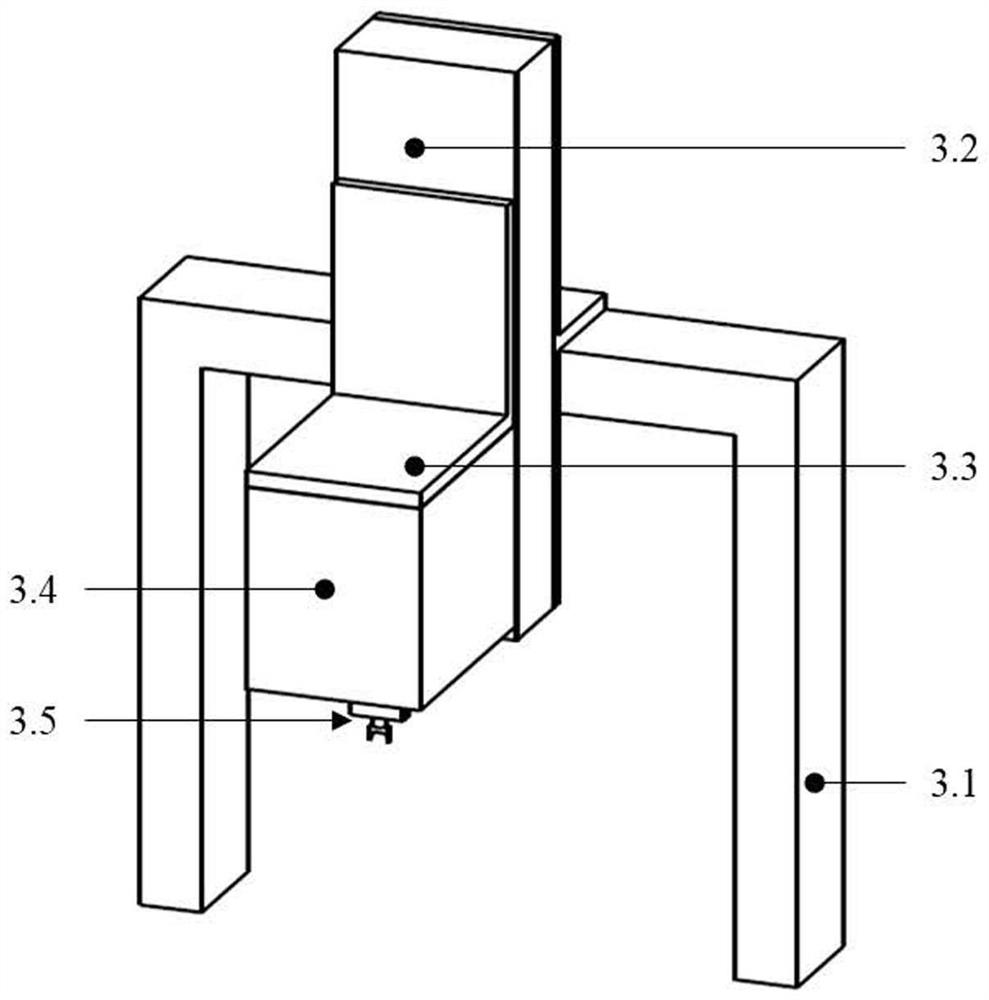

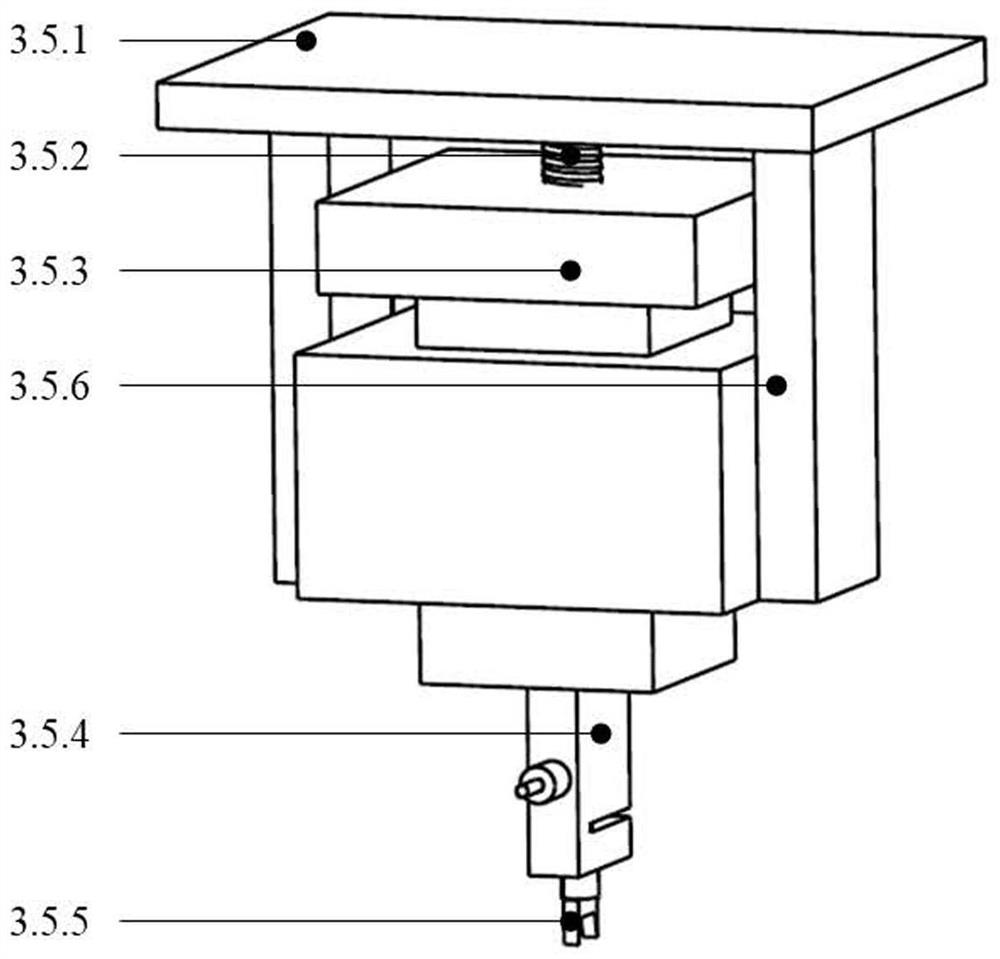

Two-dimensional stroke extension self-sealing irradiation relaxation full-automatic detection device and method

PendingCN114674676ARealize fully automatic detectionSolve the problem of fully automated detectionMaterial strength using steady bending forcesReciprocating motionEngineering

Owner:HARBIN INST OF TECH

Full-automatic feeding device of plate grinding machine

PendingCN114523349AImprove work efficiencyGrinding carriagesGrinding drivesMechanical engineeringPrinted circuit board

Owner:佛山市普能达电子有限公司

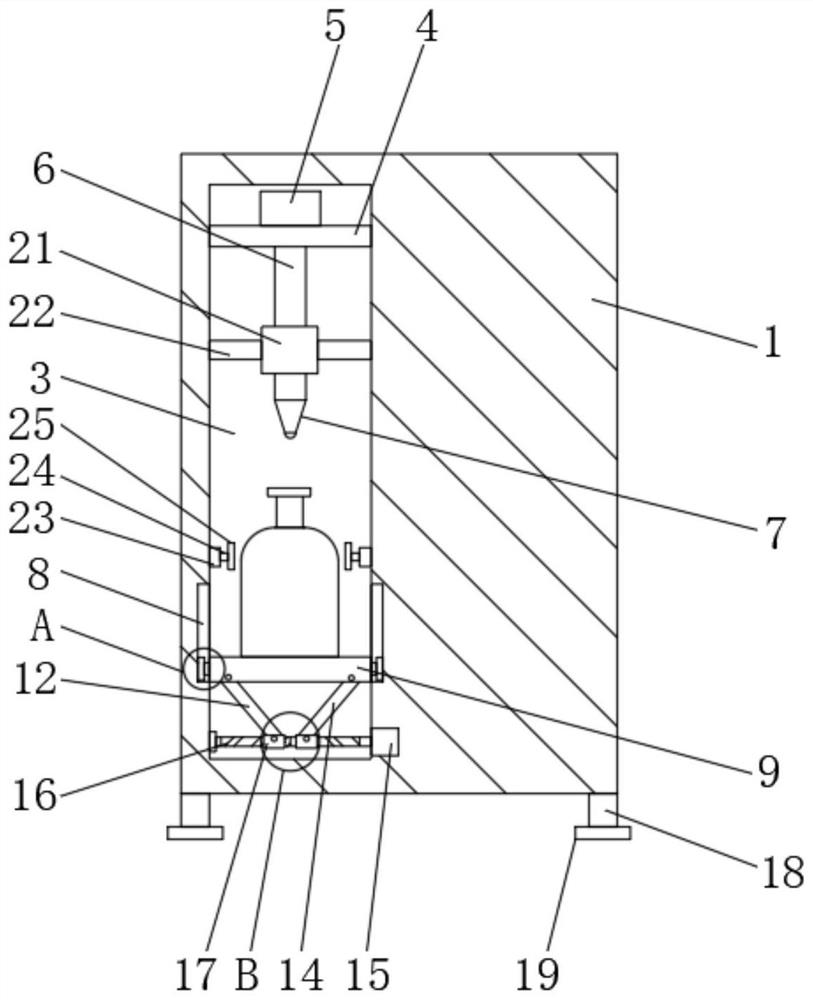

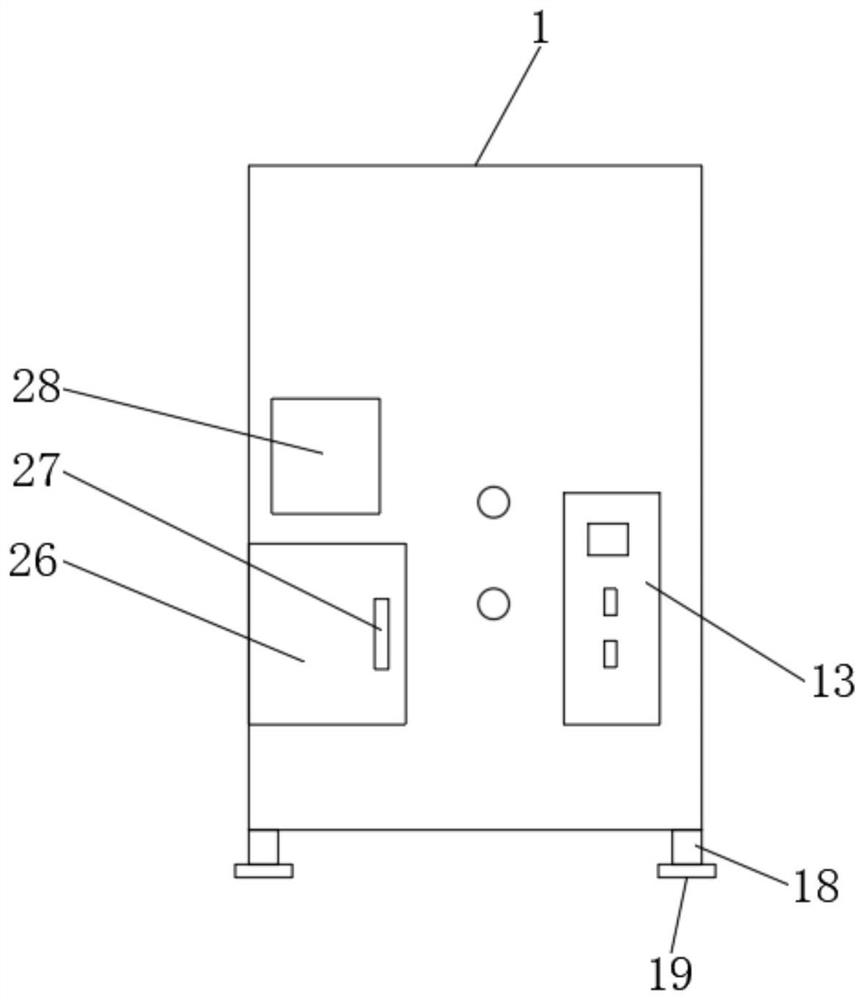

Automatic intelligent testing device for ship instrument

The invention discloses an automatic intelligent testing device for a ship instrument in the technical field of intelligent testing devices, and the automatic intelligent testing device is composed of a machine body, a partition plate, an infrared scanner, a fixed fence, a bidirectional screw rod, a long rod, a clamping block A, a clamping block B, a transmission mechanism and an anti-skid mechanism. The partition plate is fixedly mounted on the inner wall of the machine body. An infrared scanner is fixedly installed on the top face of the inner wall of the machine body, a fixing fence is installed at the position, close to the center, of the top face of the partition plate, and the inner wall of the machine body is rotationally connected with a two-way lead screw. According to the instrument testing device, full-automatic testing operation can be performed on an instrument to be tested through the pressure sensor A and the pressure sensor B, the instrument can be automatically pushed onto the partition plate only by placing the instrument on the supporting plate, and then the clamping block A and the clamping block B can automatically fix the position of the instrument. Meanwhile, the instrument is accurately detected through the infrared scanner, actual use is facilitated, and innovativeness is high.

Owner:JIANGSU UNIV OF SCI & TECH

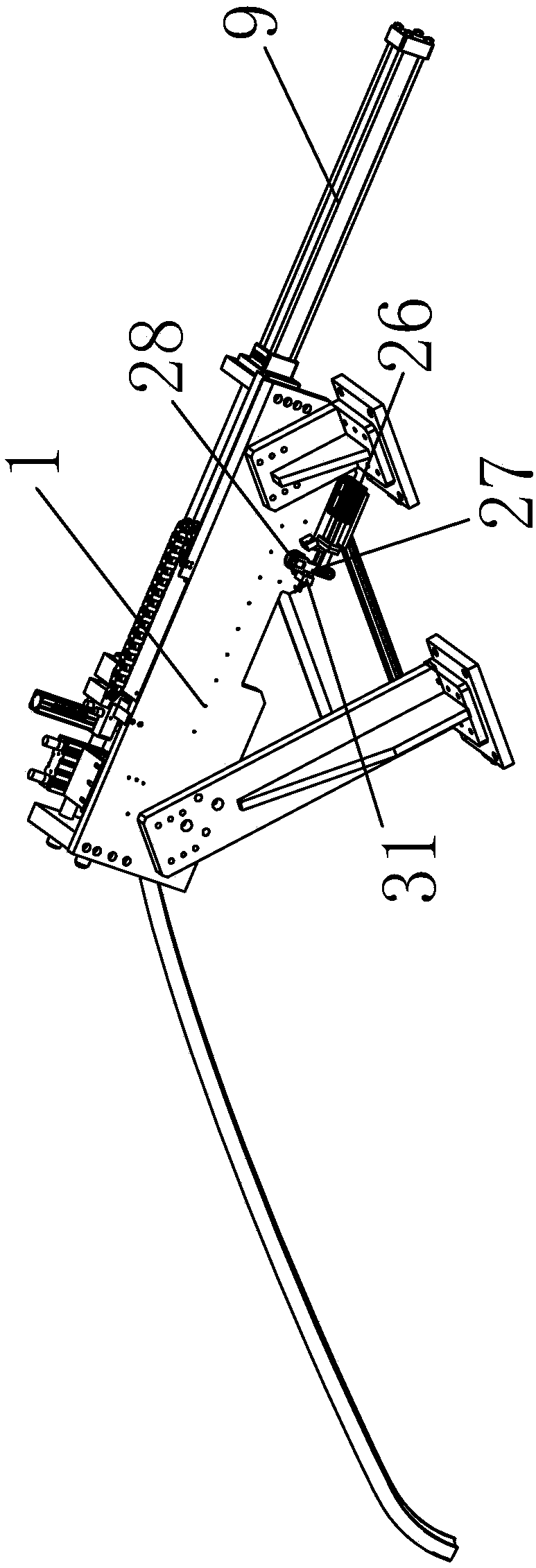

Bended core rod overturning and pulling-out mechanism

Owner:宁波蓝圣智能科技有限公司

Non-contact full-automatic water vending machine

InactiveCN111899424AAvoid contactAvoid pollutionApparatus for dispensing fluids/granular materialsWater storage tankProcess engineering

Owner:四川大绵和净水科技有限公司

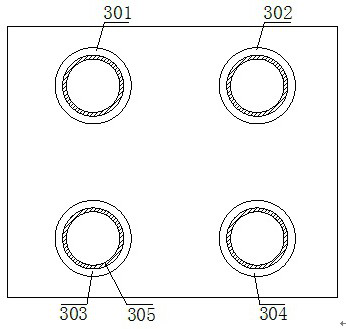

Automatic magnetic feeding device for brushless rotor

PendingCN113824278AFully automatedIncrease productivityManufacturing stator/rotor bodiesMetal working apparatusBrushless motorsMechanical equipment

Owner:深圳市攀鑫智能科技有限公司

Full-automatic capsule aluminum plastic plate detecting equipment

PendingCN110882938AObserve workEasy for daily maintenanceSortingStructural engineeringTransfer mechanism

Owner:ZHEJIANG YALIDA CAPSULES

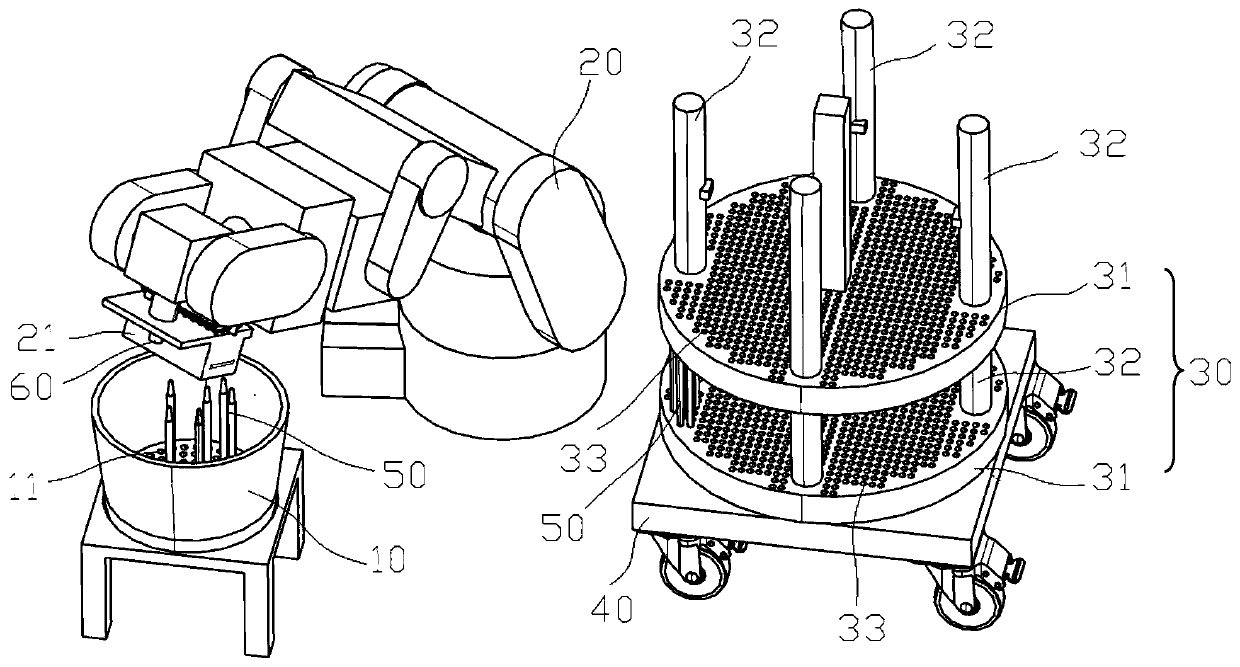

Copper pipe transferring and positioning device

ActiveCN111300410ARealize fully automated transferIncrease productivityProgramme-controlled manipulatorRobot handEngineering

Owner:JIANGSU UNIV OF TECH

Full-automatic wireless glue binding machine

PendingCN114290835AEasy to operate manuallyGuarantee the quality of bindingBookbinding adhesiveStructural engineeringMechanical engineering

Owner:ZHEJIANG ZHIYUAN OFFICE EQUIP MFG

Automatic painting device uniform in painting

InactiveCN112112397AEasy to moveEasy to useBuilding constructionsMechanical engineeringIndustrial engineering

Owner:新沂市新源公共服务有限公司

Full-automatic Chinese chestnut opening and hulling machine

Owner:SHANXI UNIV

Multi-sealing fork edge bag making machine and bag making process

PendingCN114670497AImprove product qualityThe production quality cannot be guaranteed, and the production efficiency is improvedBag making operationsPaper-makingProcess engineeringBottle neck

Owner:浙江名立机械科技有限公司

Full-automatic rotational molding equipment for camouflage canoeing

Owner:常州营创滚塑设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap