Full-automatic intelligent feeding, centering, rotary-cutting and stacking veneer processing production line

A fully automatic, production line technology, applied in the stacking of objects, comprehensive factory control, wood processing equipment, etc., can solve the problems of increasing waste boards, reducing qualified products, and low efficiency of veneer rotary cutting, so as to shorten rotary cutting Time, accurate centering, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

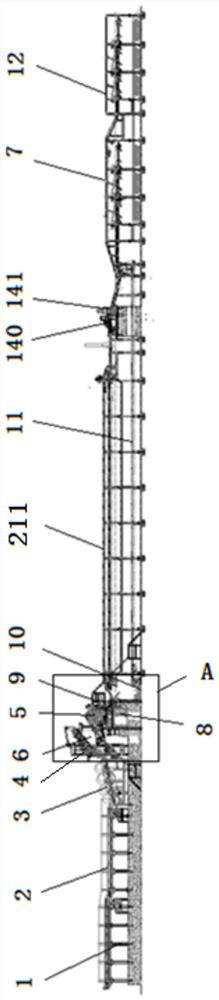

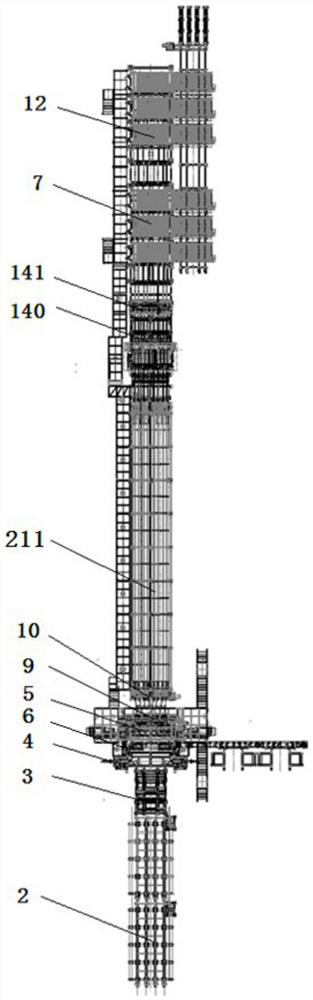

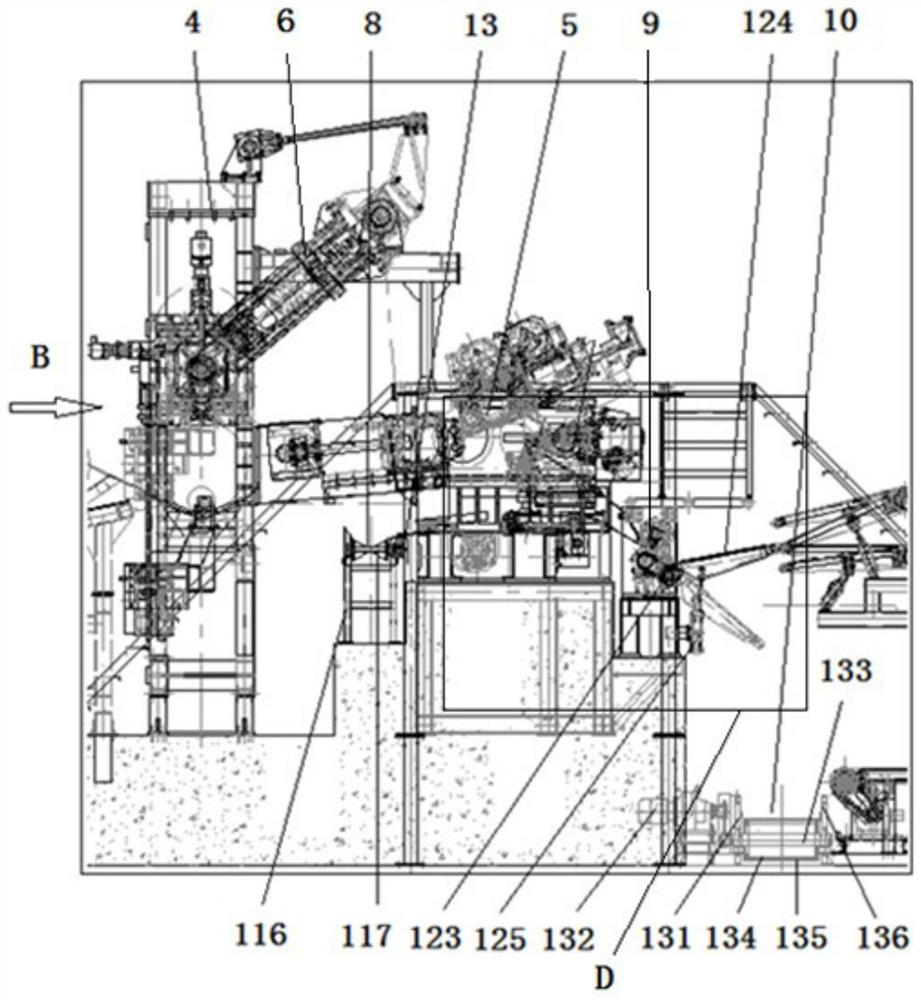

[0093] As shown in the accompanying drawings, a fully automatic intelligent feeding centering rotary cutting and stacking veneer processing production line is provided with a frame 1 and a control device, the control device adopts a PLC controller, and the frame 1 is sequentially equipped with Connected log horizontal conveying device 2, stepped stepping log loading device 3, log automatic centering device 4, log automatic rotary cutting device 5, veneer transport device 211, veneer automatic shearing device and veneer automatic stacking Device 7, the log automatic centering device 4 and the log automatic rotary cutting device 5 are provided with a log automatic transfer device 6, the log horizontal conveying device 2, the stepped stepping wood device 3, and the log automatic centering device 4 , log automatic rotary cutting device 5, veneer transport device 211,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap