Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic Processing. Automatic processing is sort of like muscle memory. When you start to do something that you have done many times, and you can complete it successfully without giving it any thought, that's automatic processing.

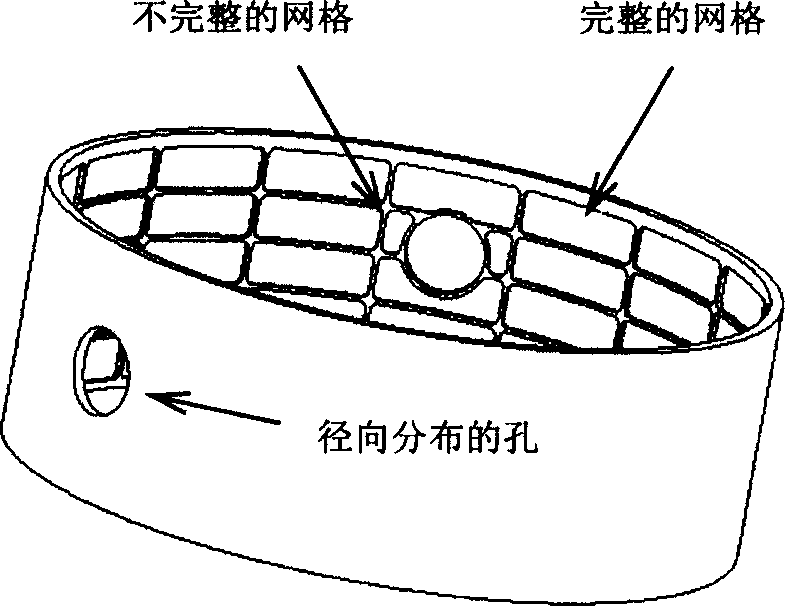

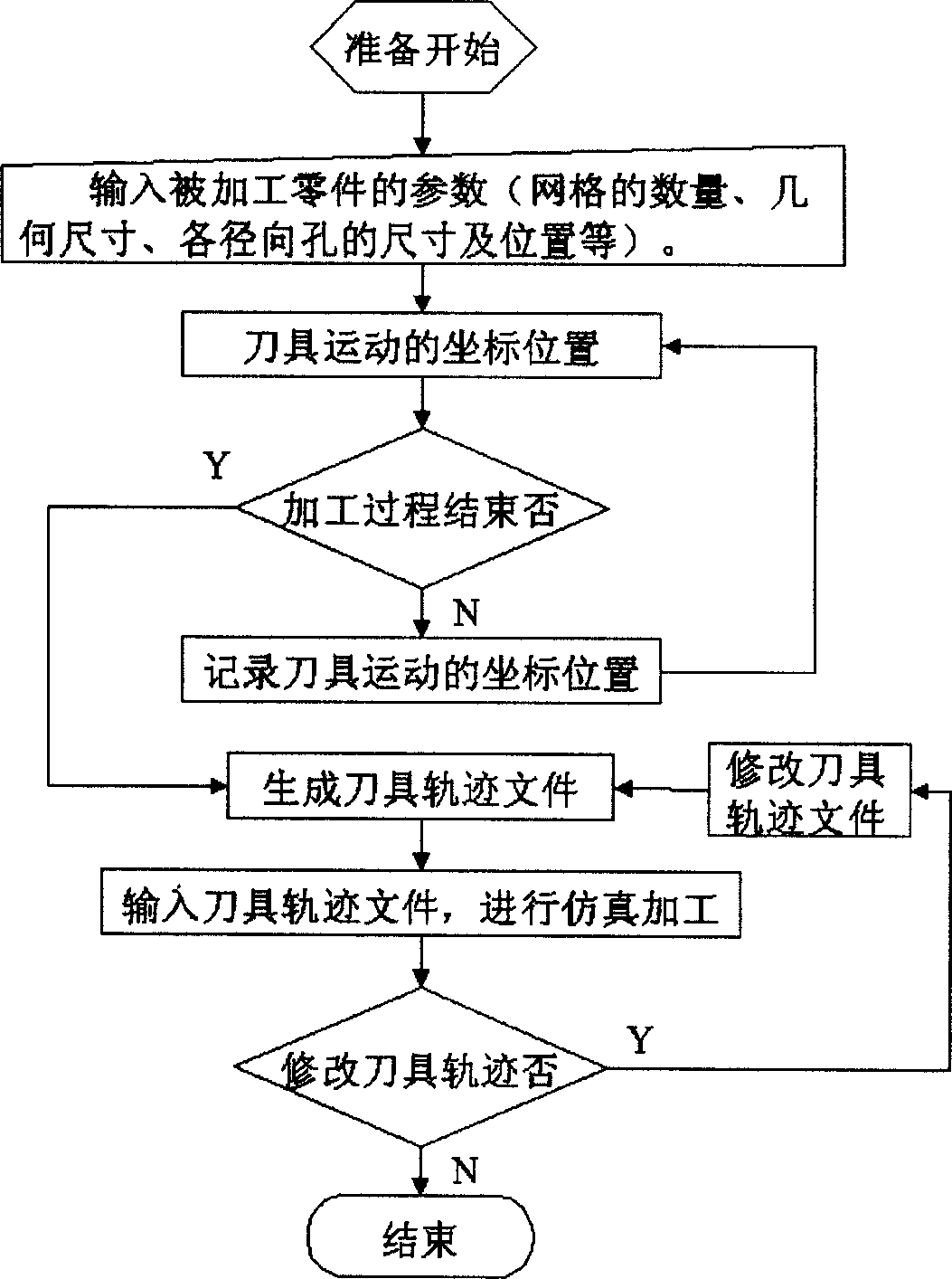

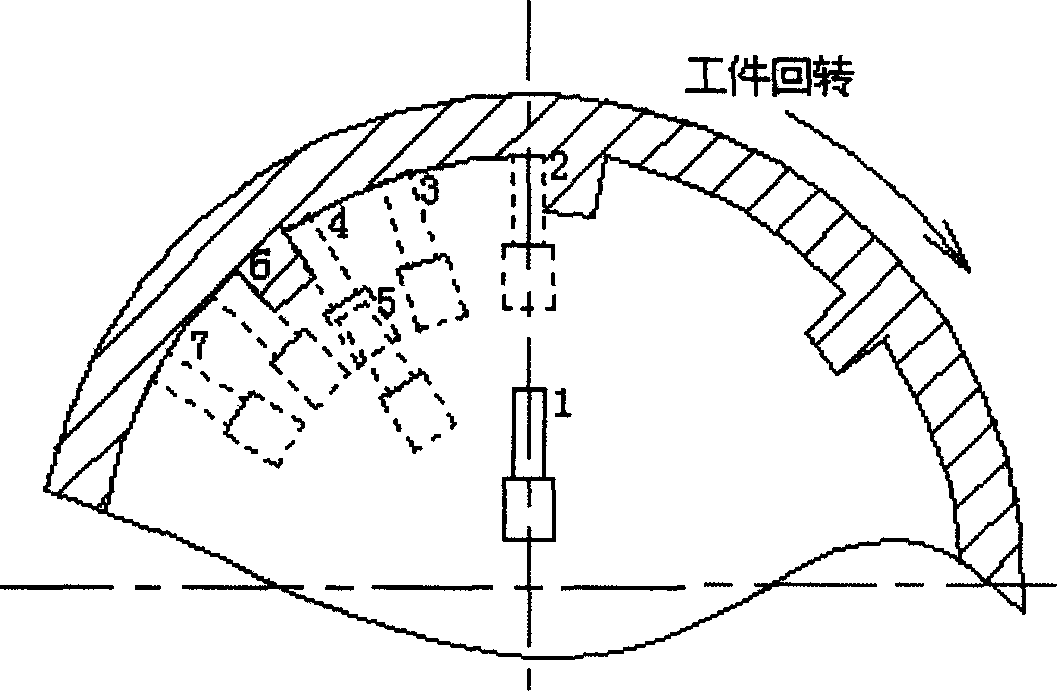

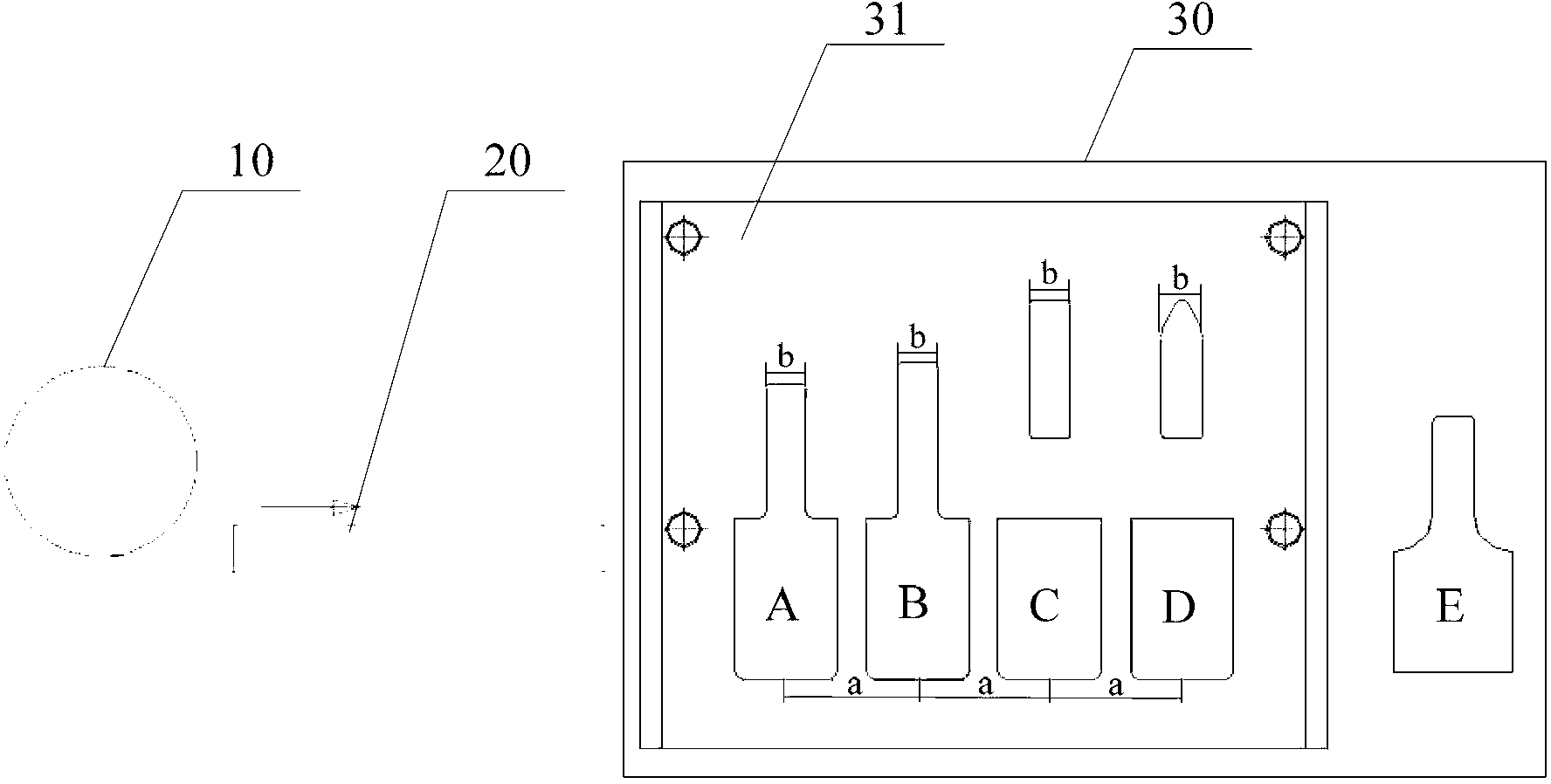

Fast automatic processing method utilized in lathe and milling machine for large thin wall part with cylindrical grids

InactiveCN1562542AMeet the technical requirements of high-speed turning and millingSimple processing technologyProgramme controlComputer controlMachining processAutomatic processing

Owner:沈阳工业学院

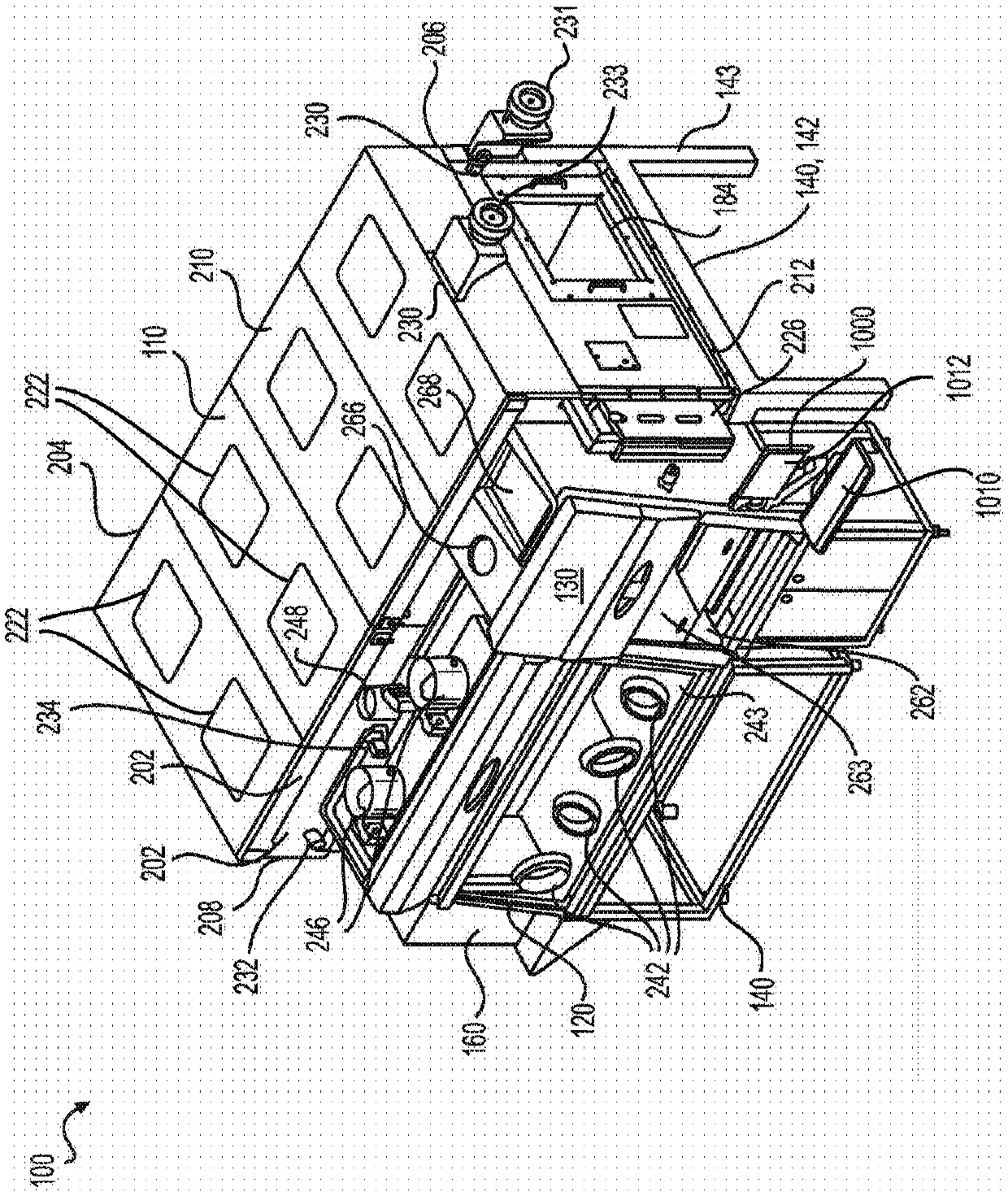

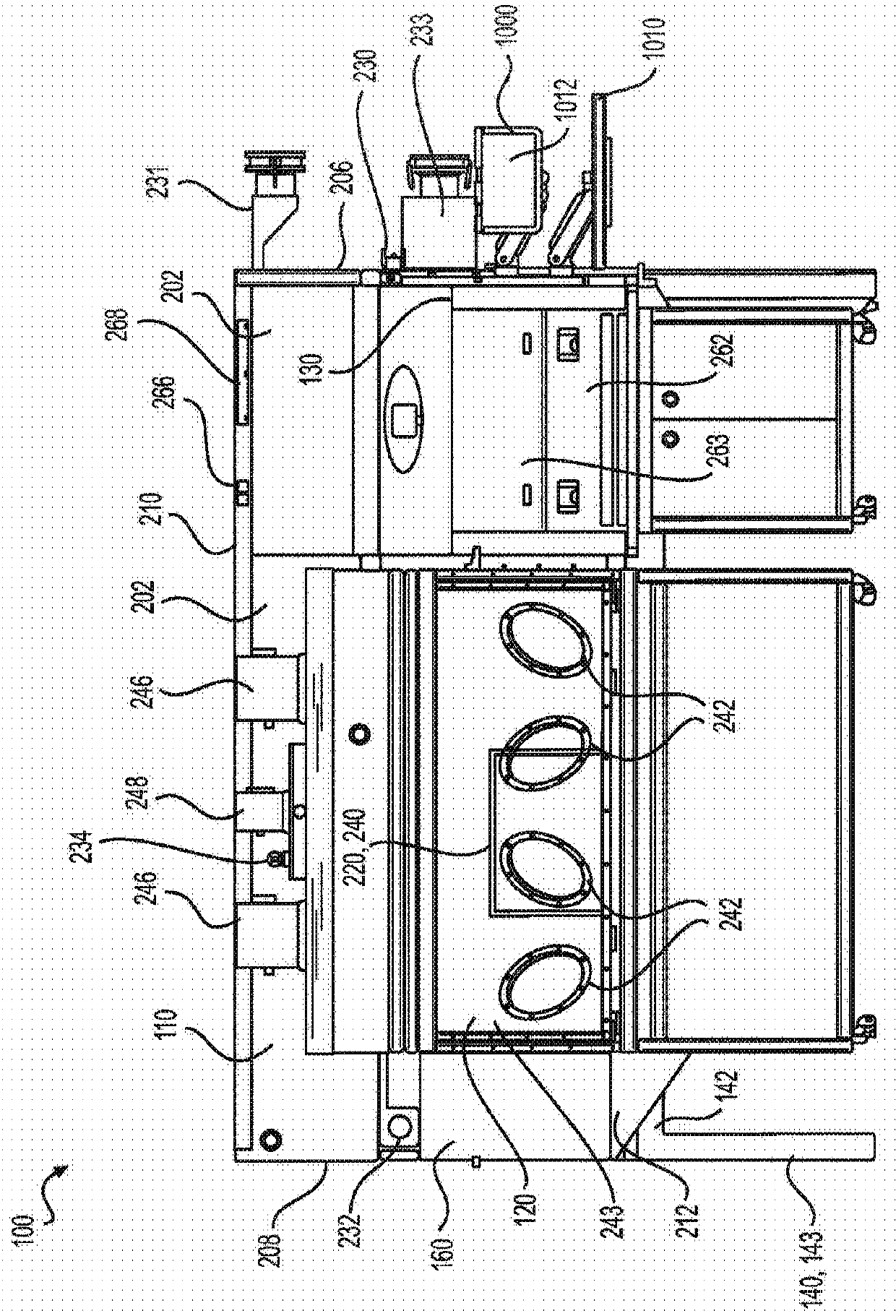

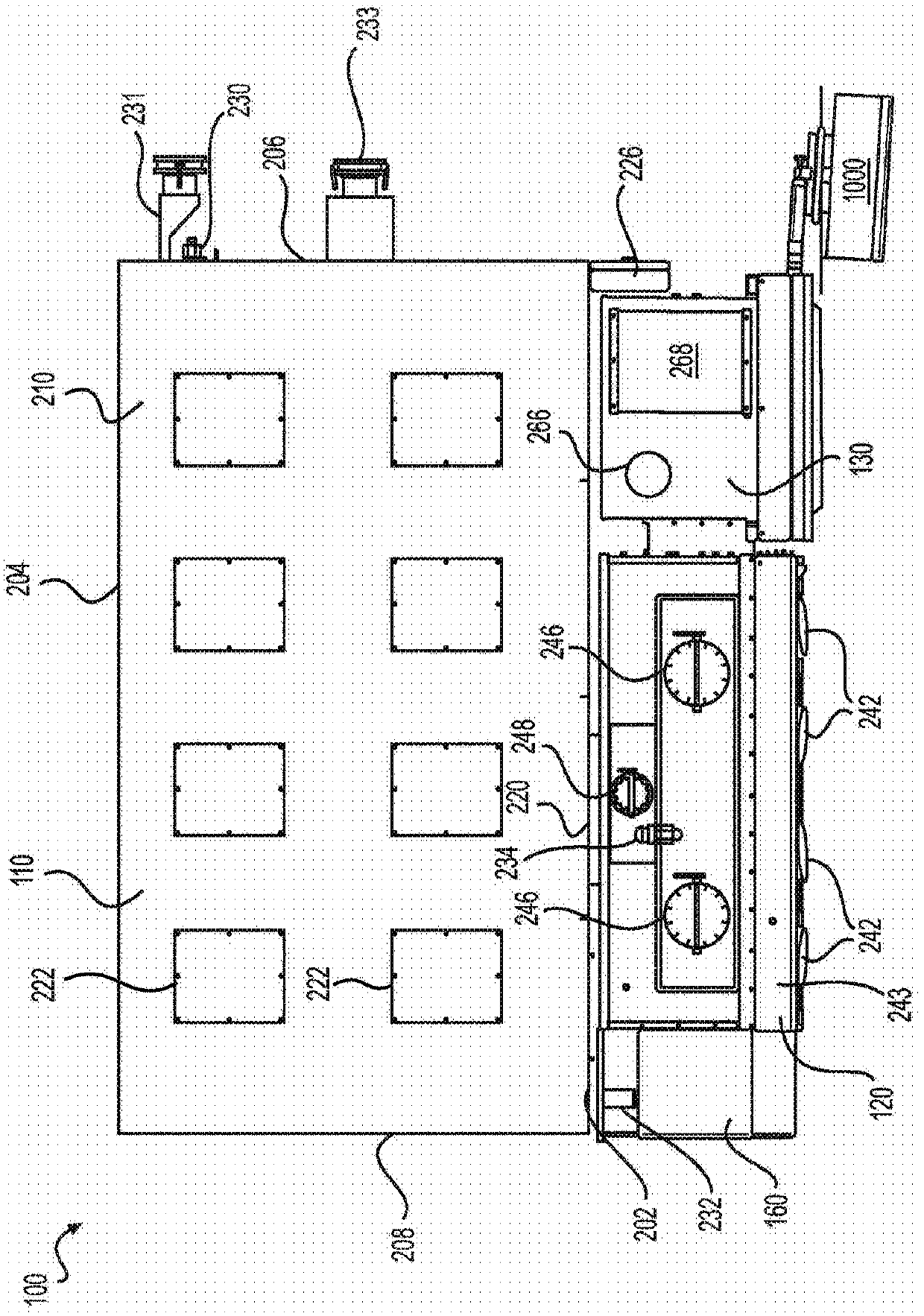

Automated cell processing systems and methods

PendingCN109661582AAir-pressure/air-lock chambersDust-free enclosuresAutomatic processingQuality control

Owner:GENESIS TECH LTD

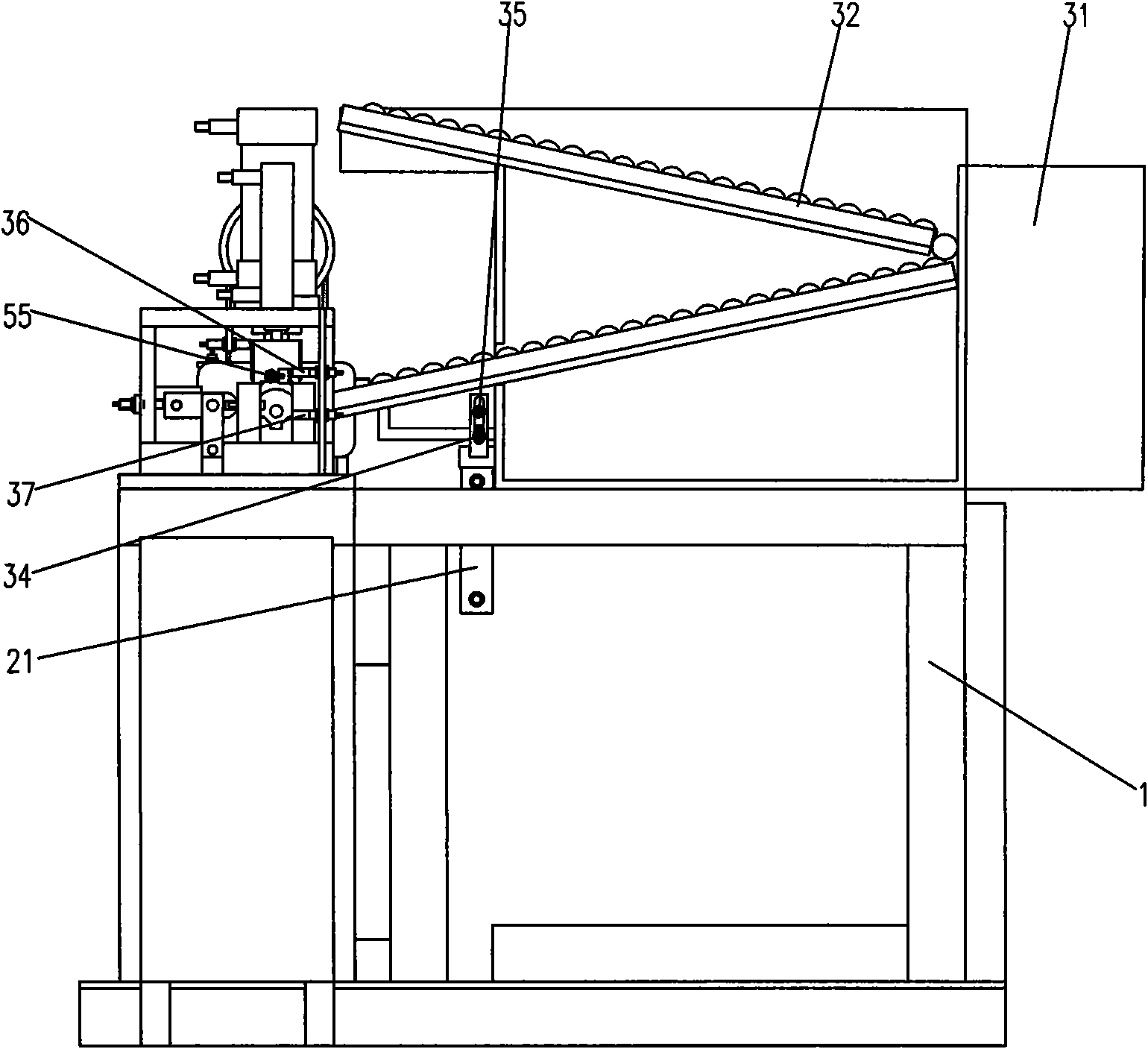

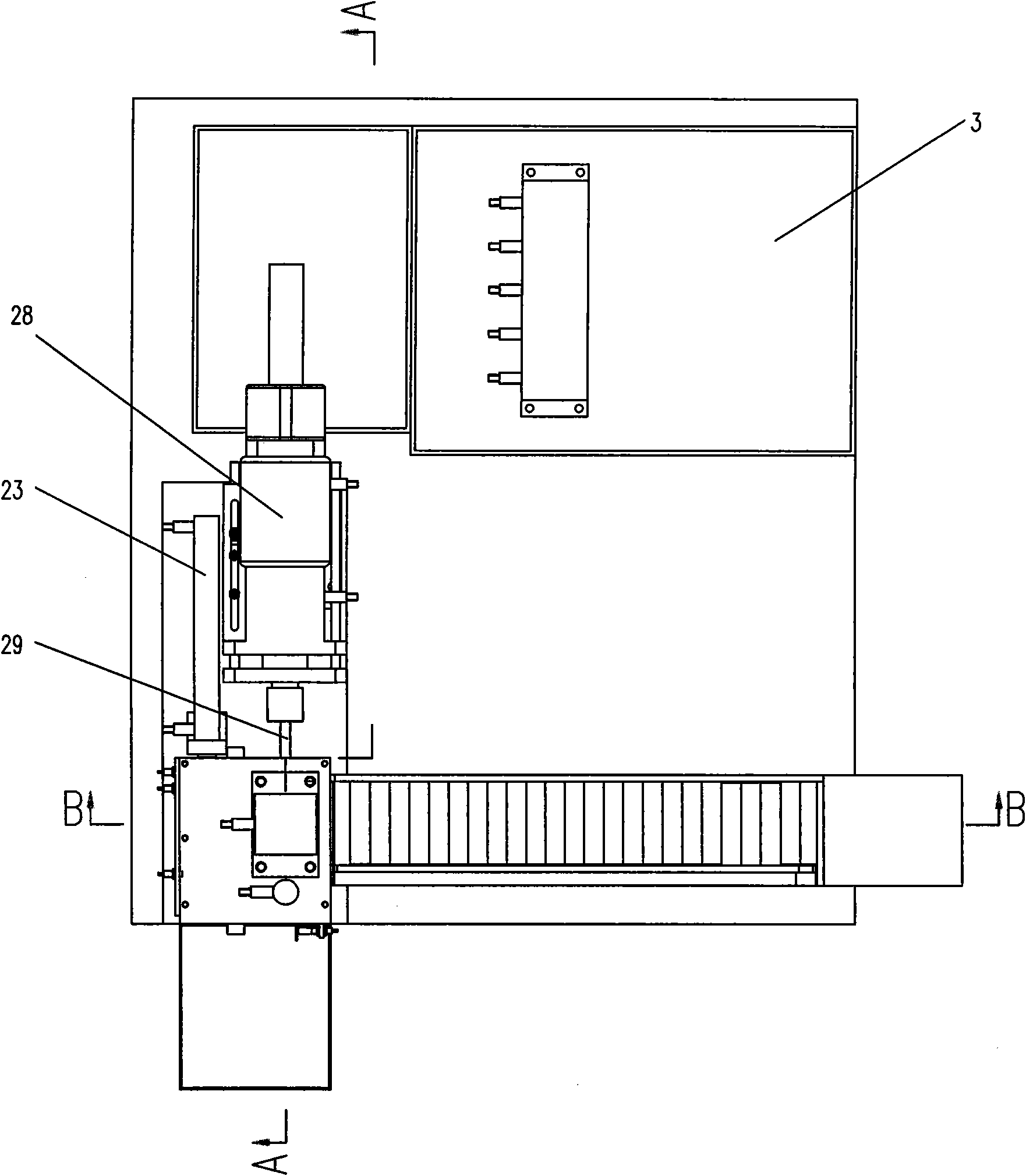

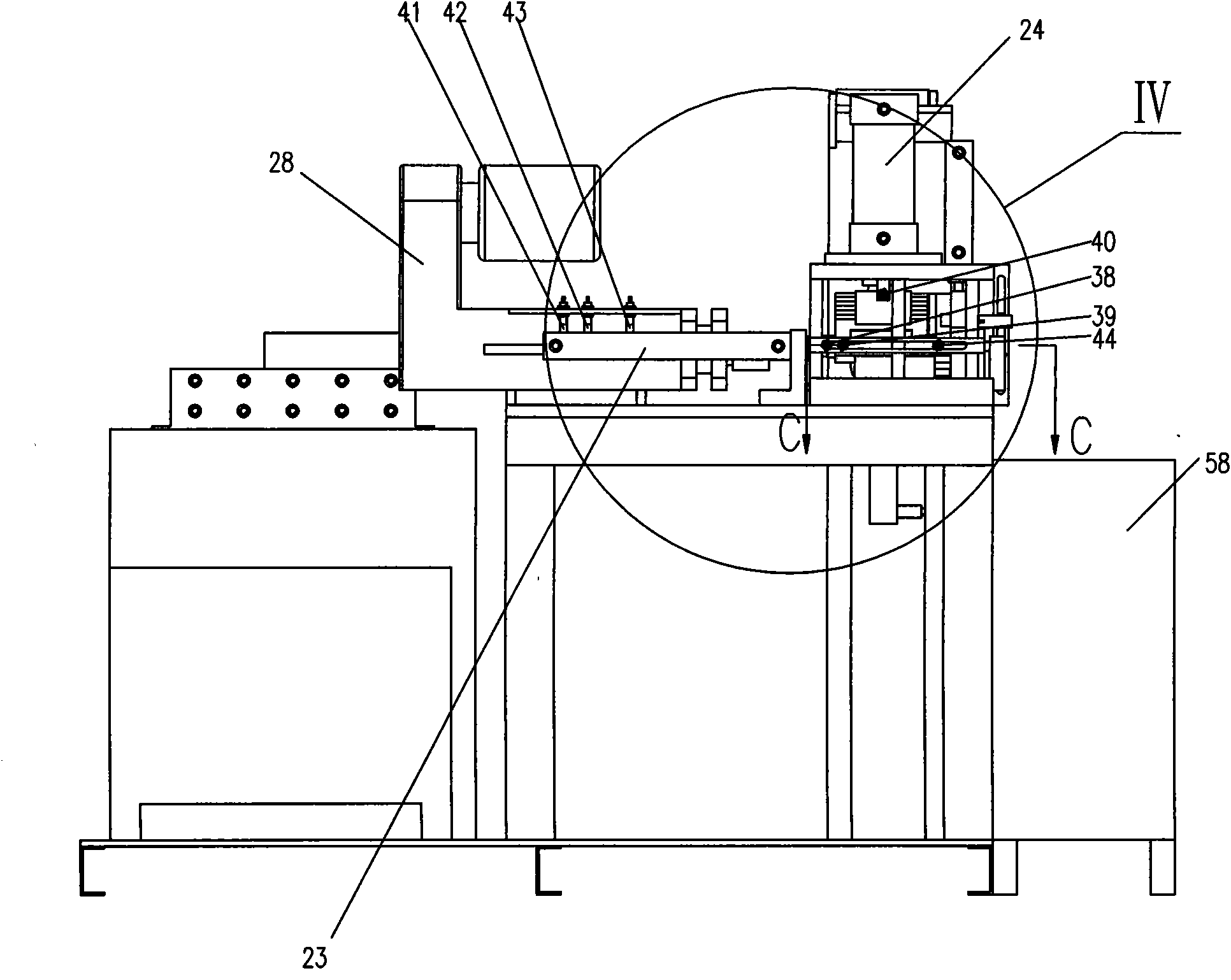

Automatic processing equipment for axle hole

InactiveCN102091798AReduce labor intensityImprove ergonomicsBoring/drilling componentsBoring/drilling machinesAutomatic test equipmentFuel tank

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

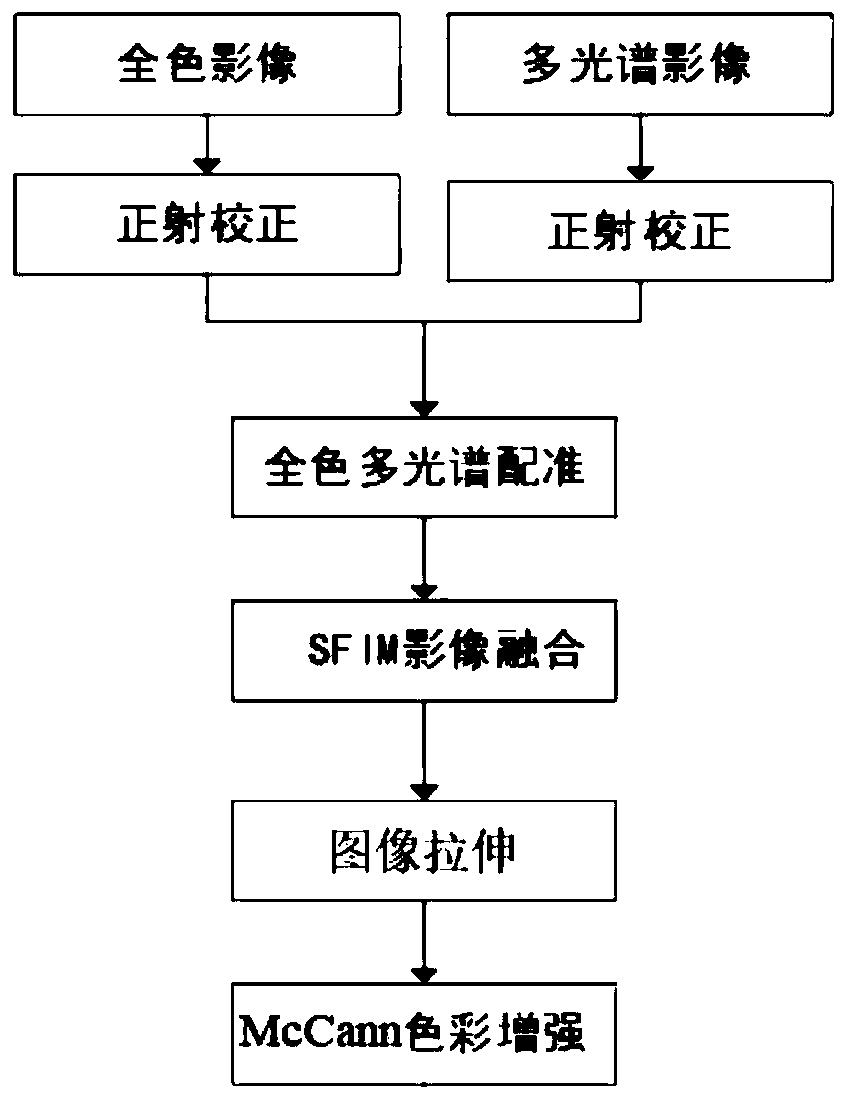

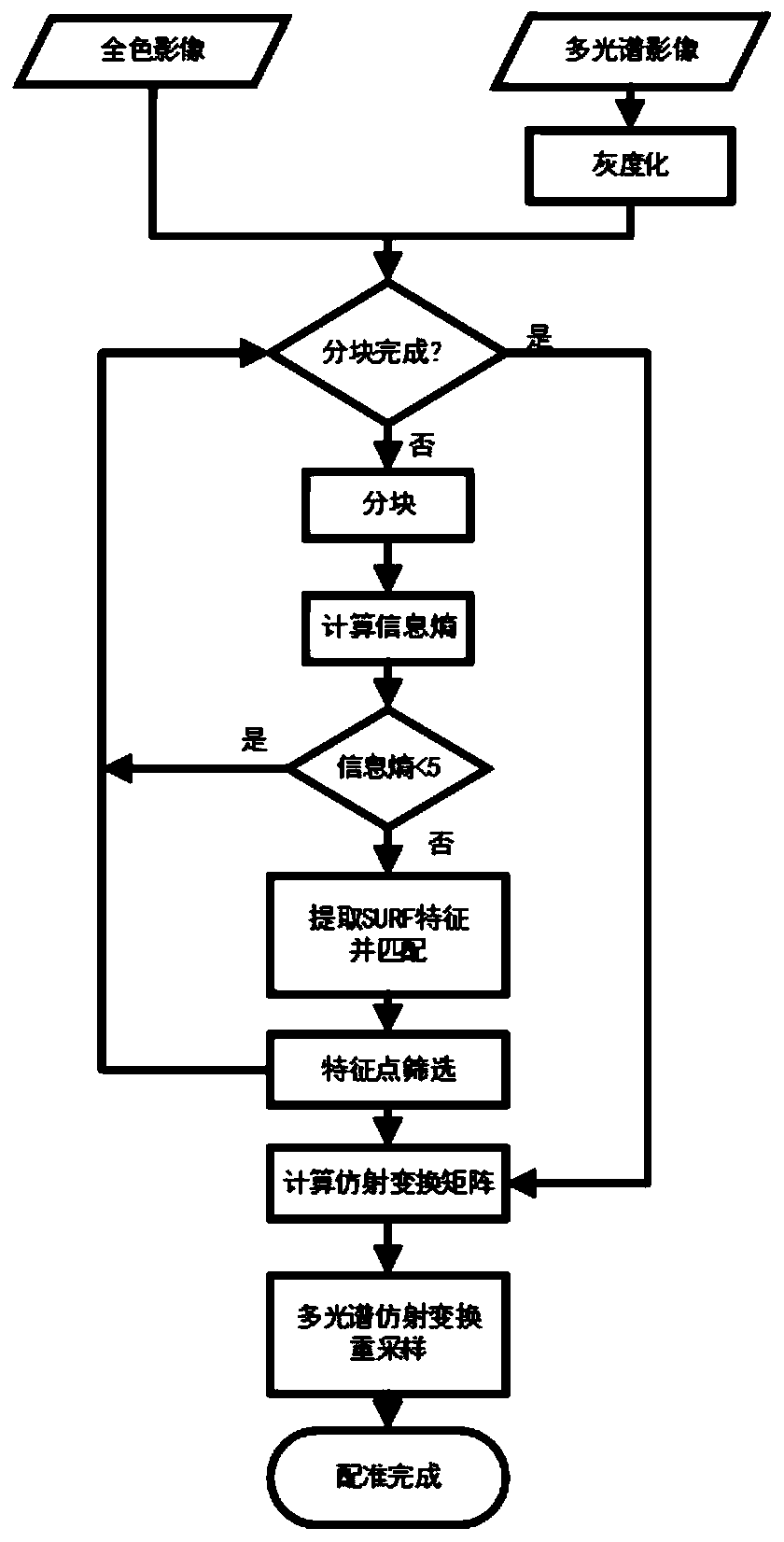

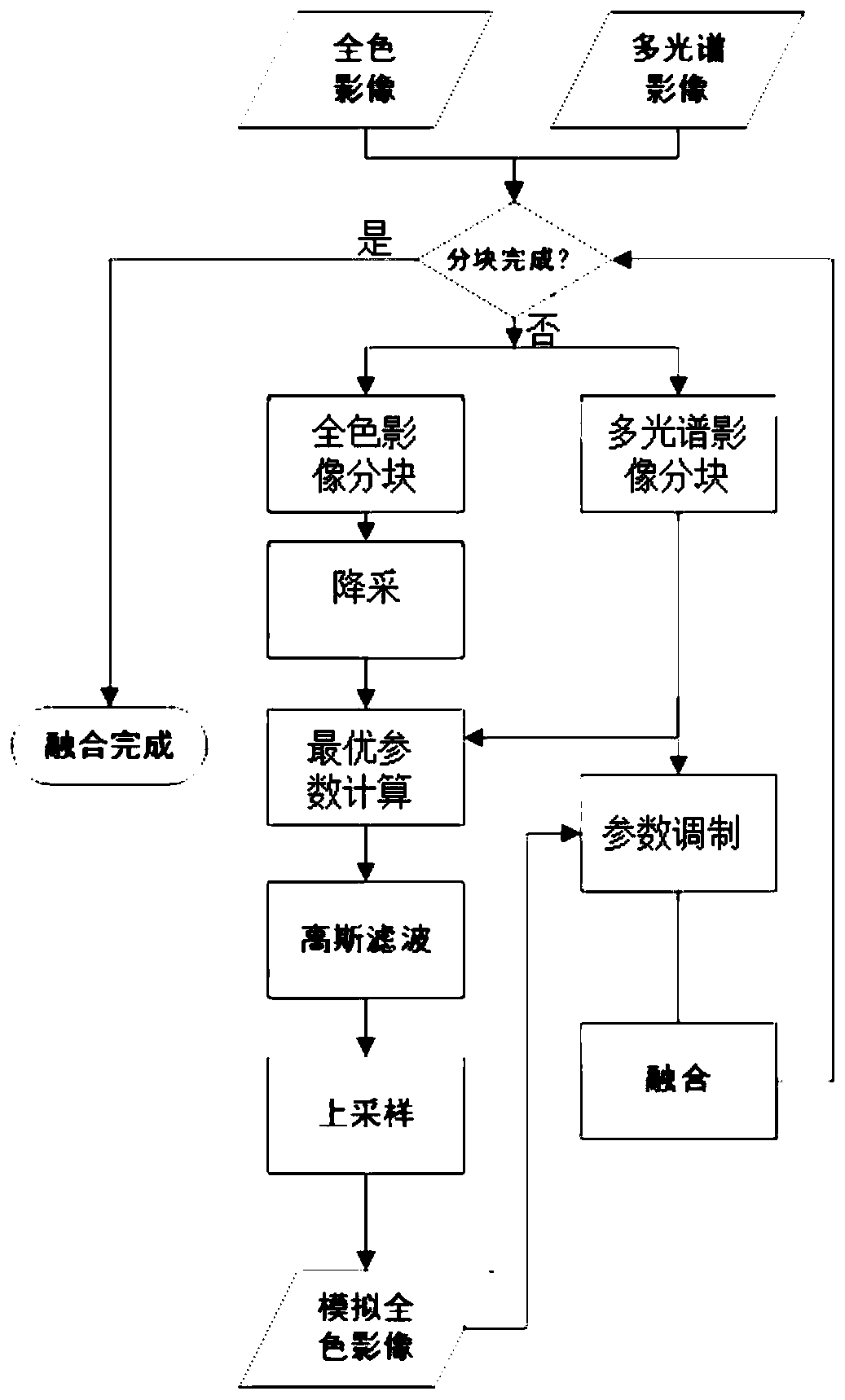

Automatic production system suitable for high-resolution remote sensing image advanced products

Owner:CHANGGUANG SATELLITE TECH CO LTD

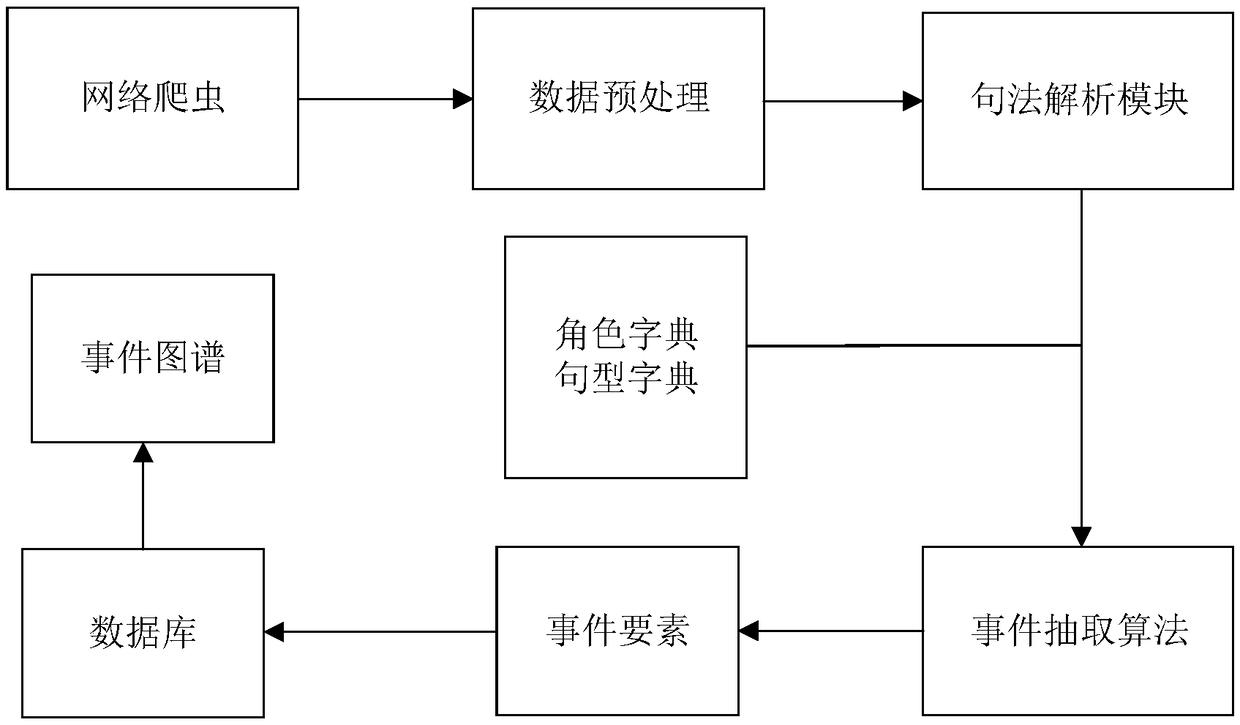

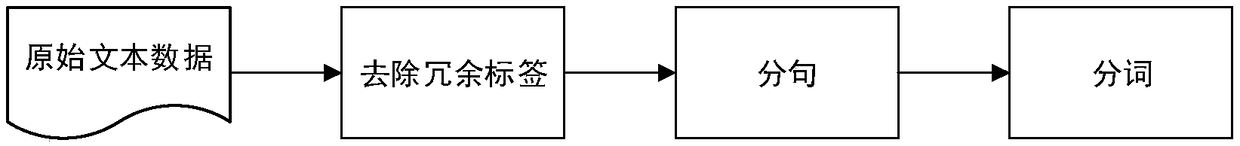

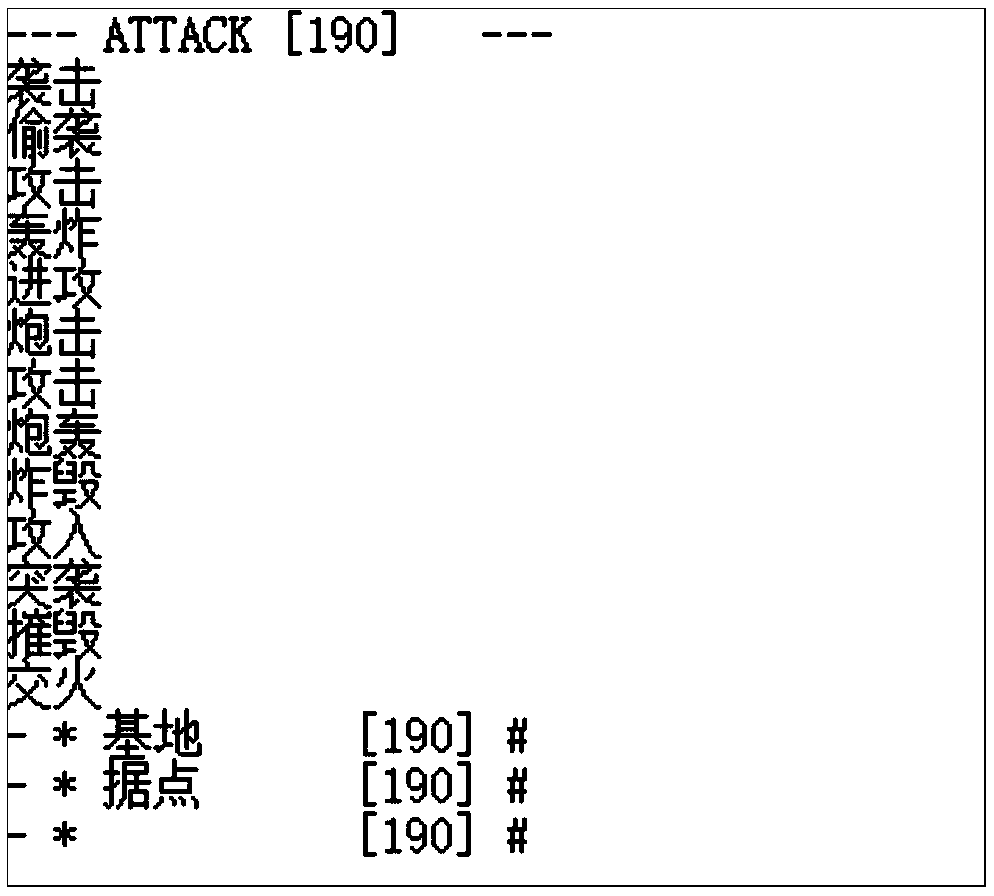

Domain-specific Chinese event extraction method

ActiveCN108920447AReal-time accessGet goodNatural language data processingSpecial data processing applicationsOriginal dataPattern matching

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT +1

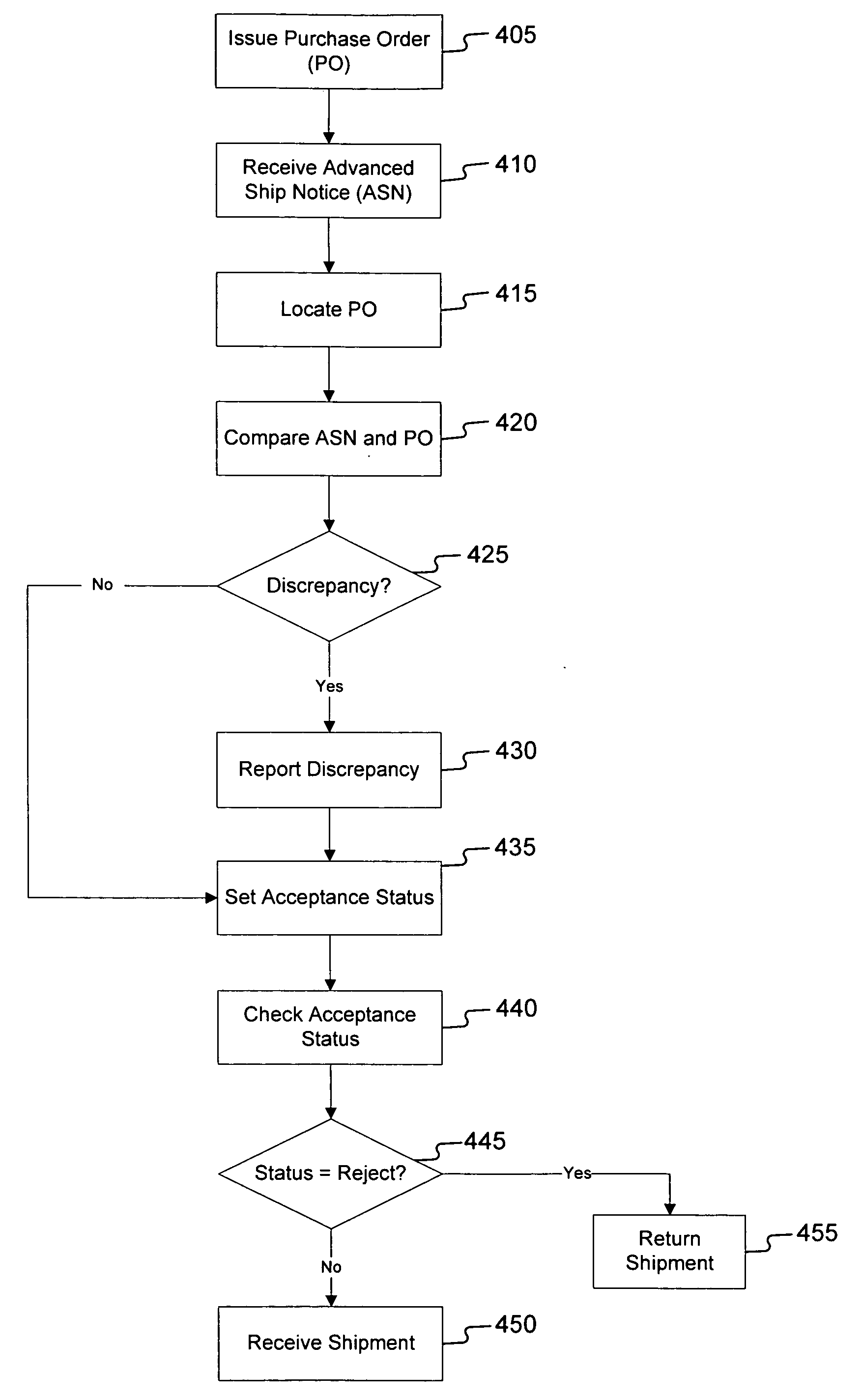

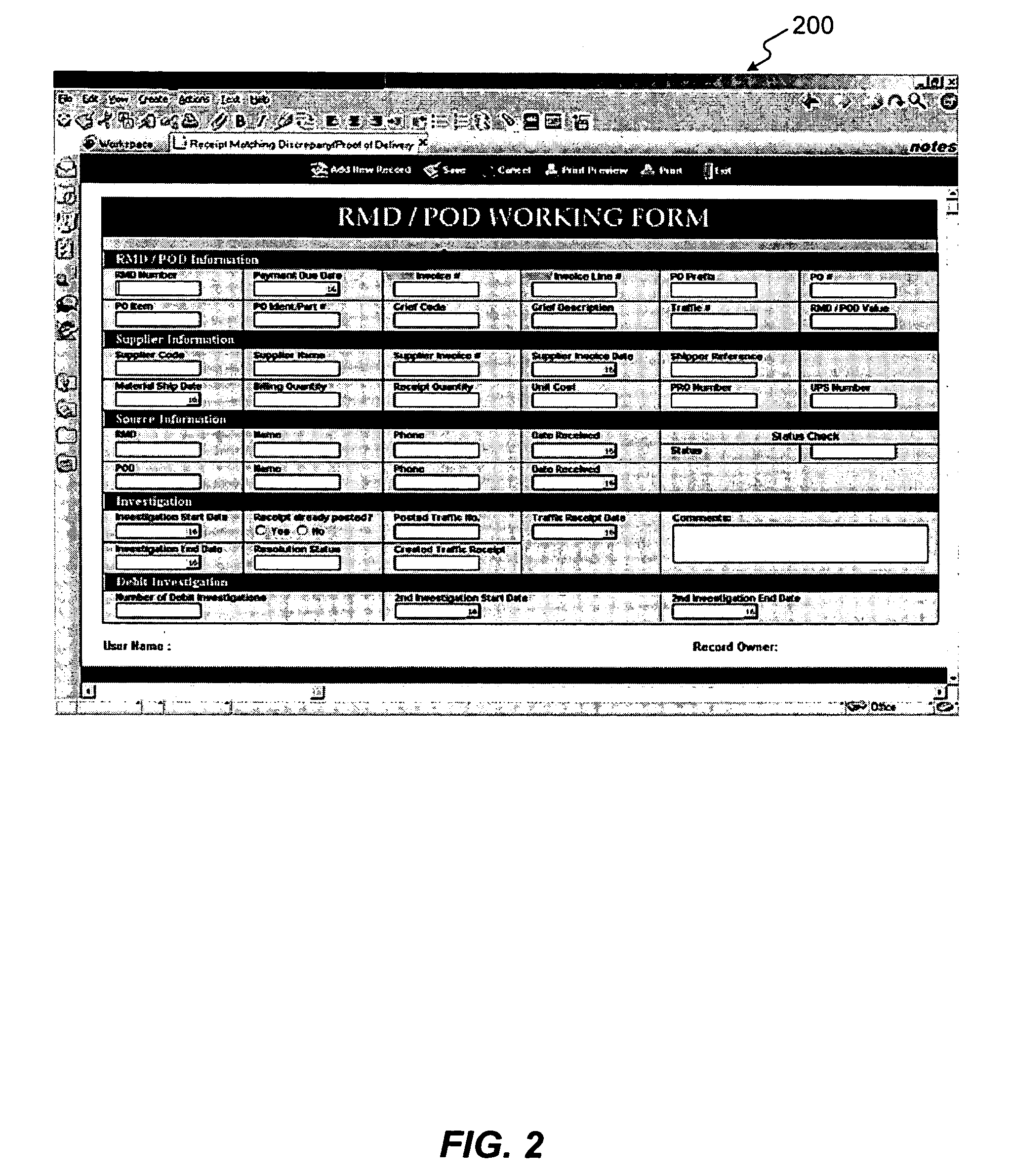

Method for processing advanced ship notices (ASNs)

Owner:CATERPILLAR INC

Cutting die processing device and cutting die automatic processing technology

ActiveCN102699177ASolve the defect that the cutting method of the olecranon at the front and rear ends of the mold cannot be realized automaticallyFast processingCutleryEngineeringMachining time

Owner:深圳同致精工技术有限公司

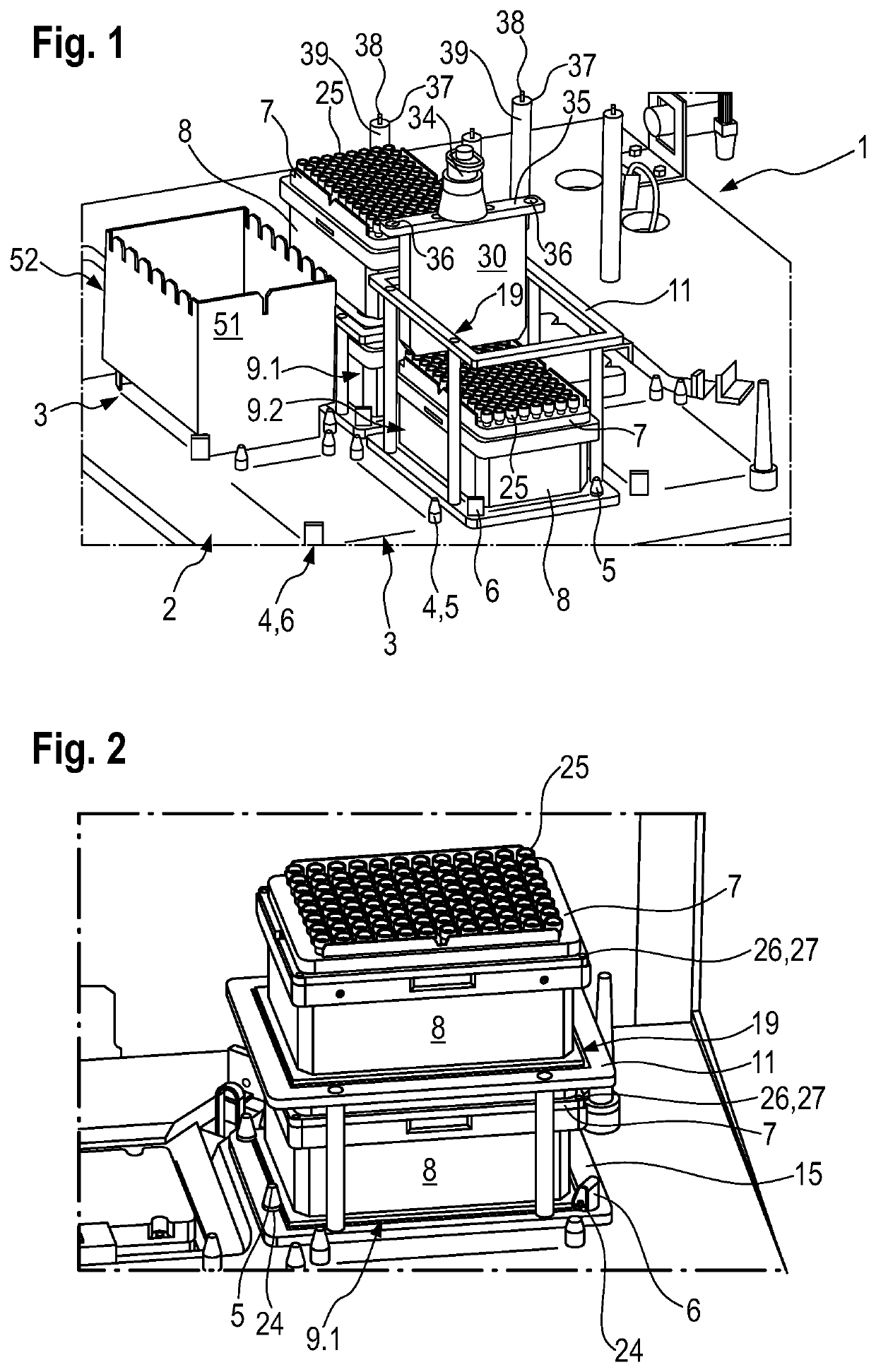

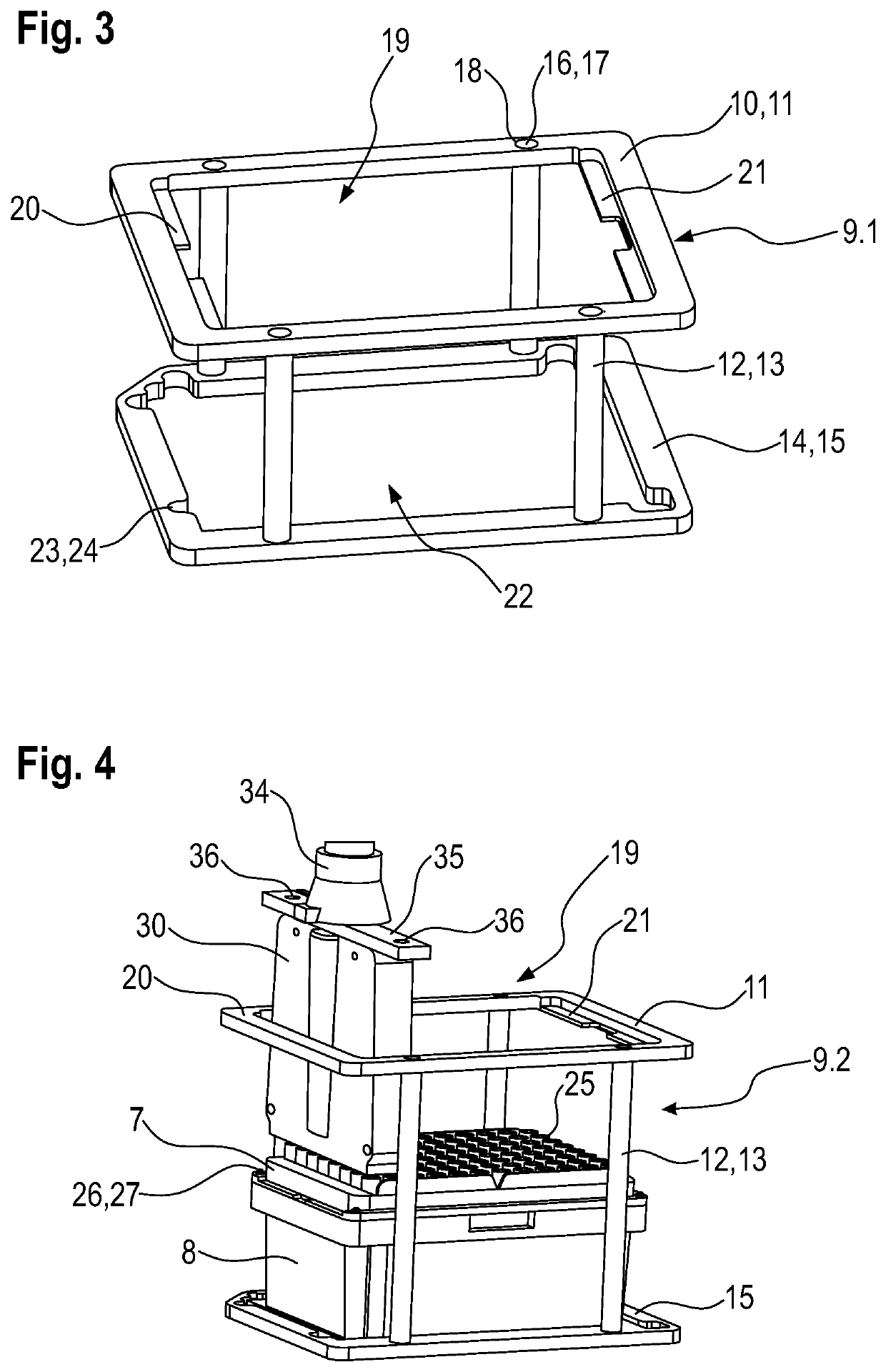

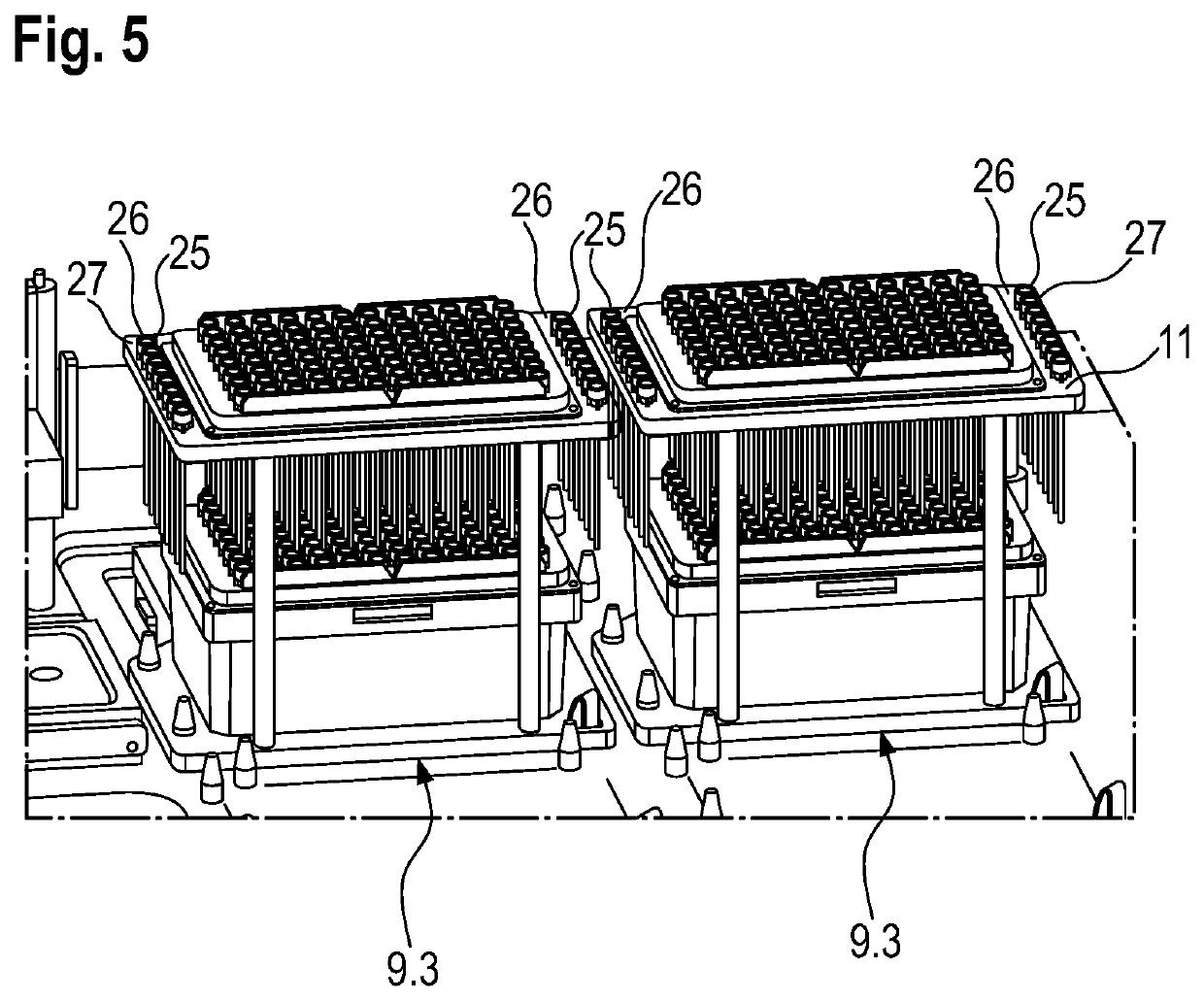

Automated laboratory system for automatically handling laboratory samples

PendingUS20220065885A1Retooling time can be reducedMaterial analysisAutomatic processingProcess engineering

Owner:EPPENDORF SE

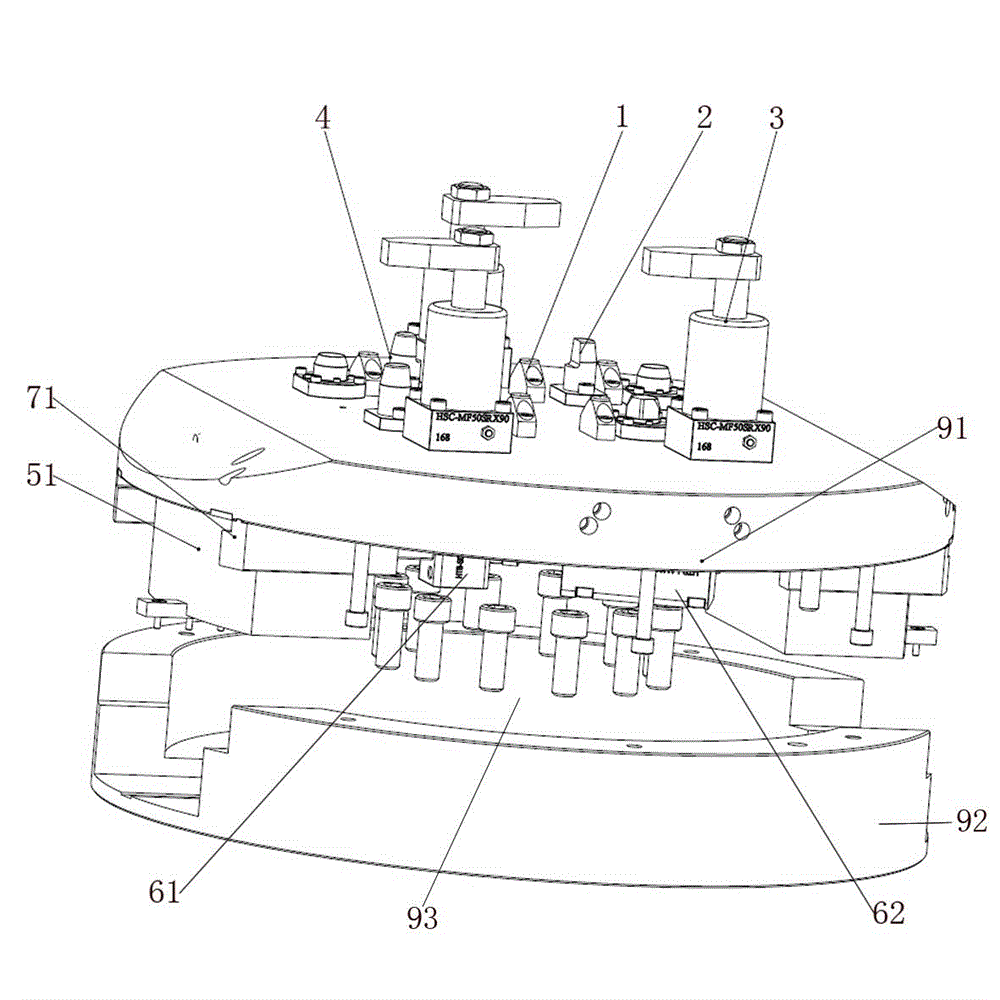

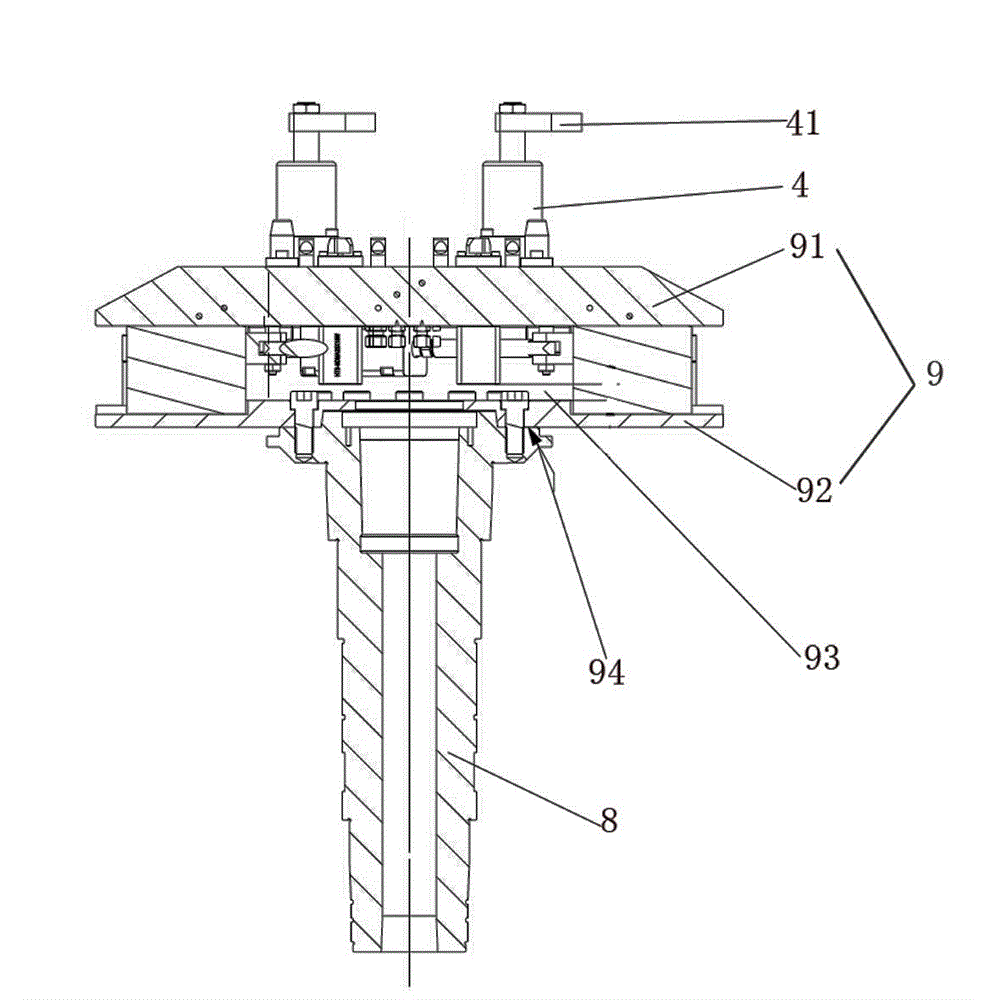

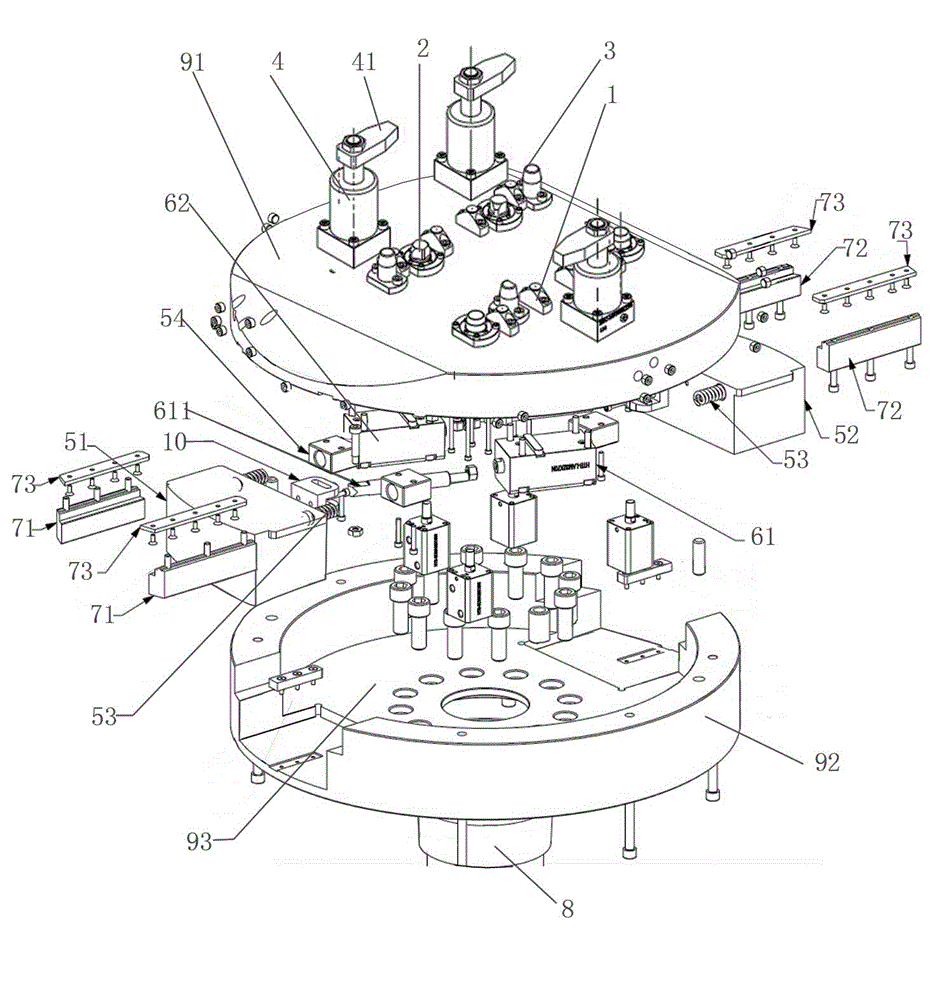

Self-balancing type lathe fixture

ActiveCN104476287APositioning apparatusMaintainance and safety accessoriesAutomatic processingEngineering

Owner:JIANGXI JUST NUMERICAL CONTROL TECH

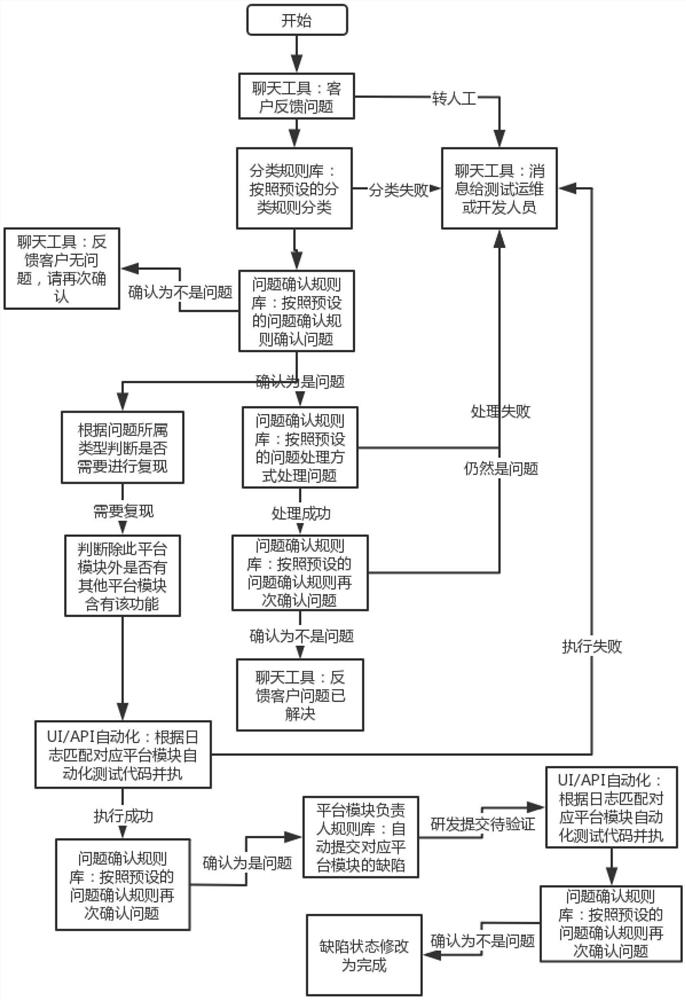

Automatic test operation and maintenance system of financial cloud platform

ActiveCN112348653AImprove efficiencyImprove timelinessFinanceSoftware testing/debuggingTest managementComputer science

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Gas burning shaft kiln damping-down and re-blowing system and control method

Owner:SGIS SONGSHAN CO LTD

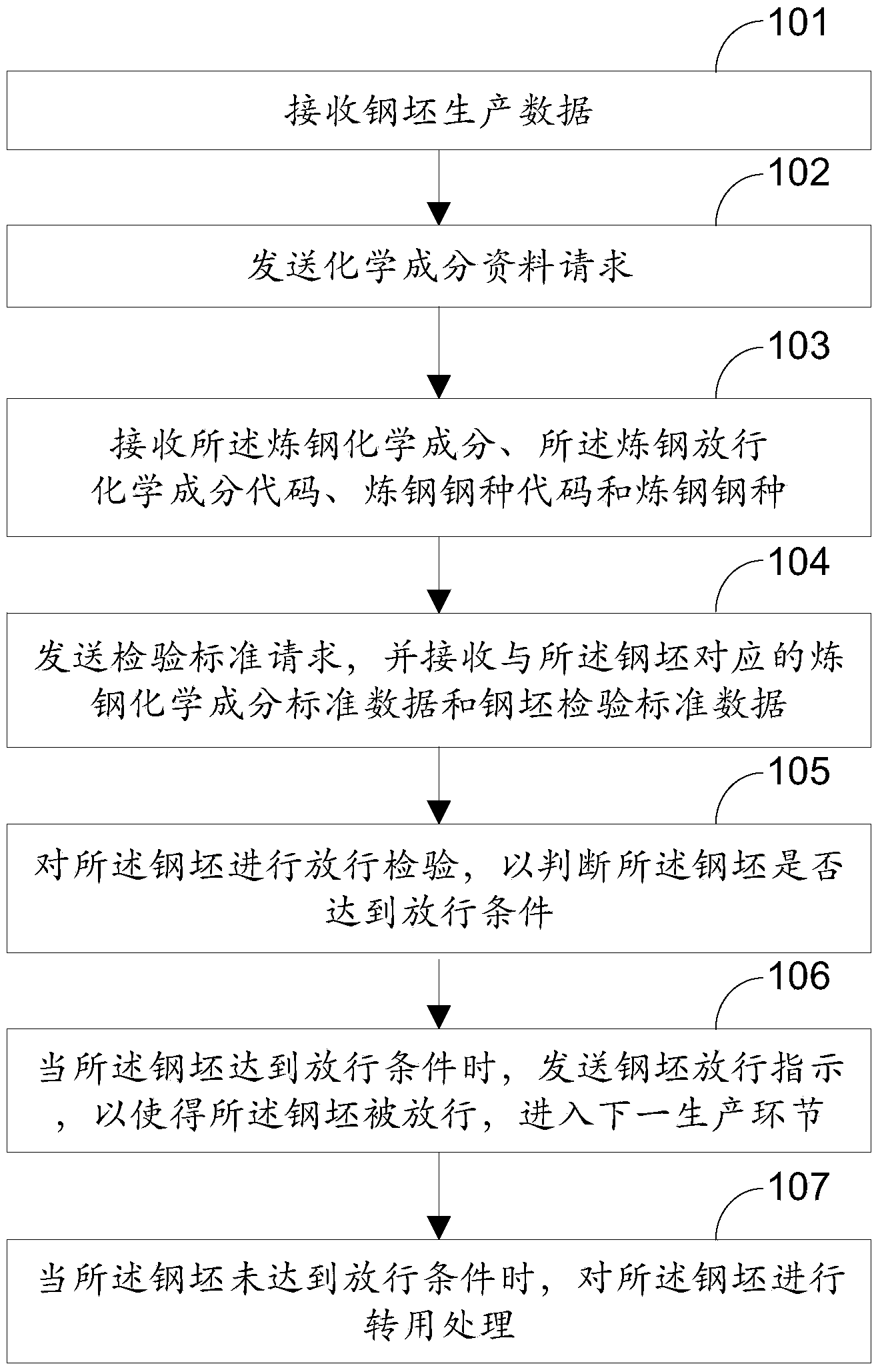

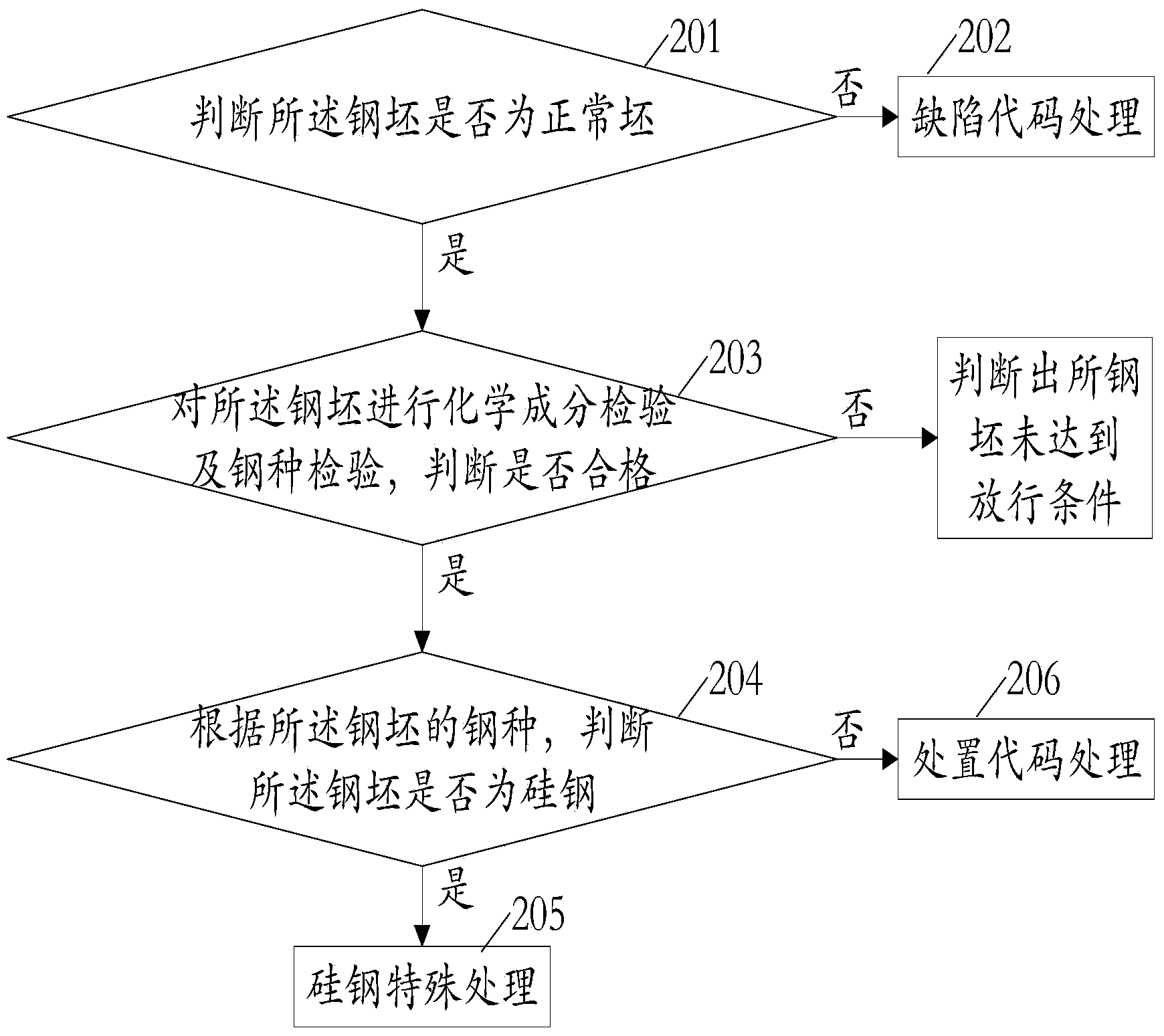

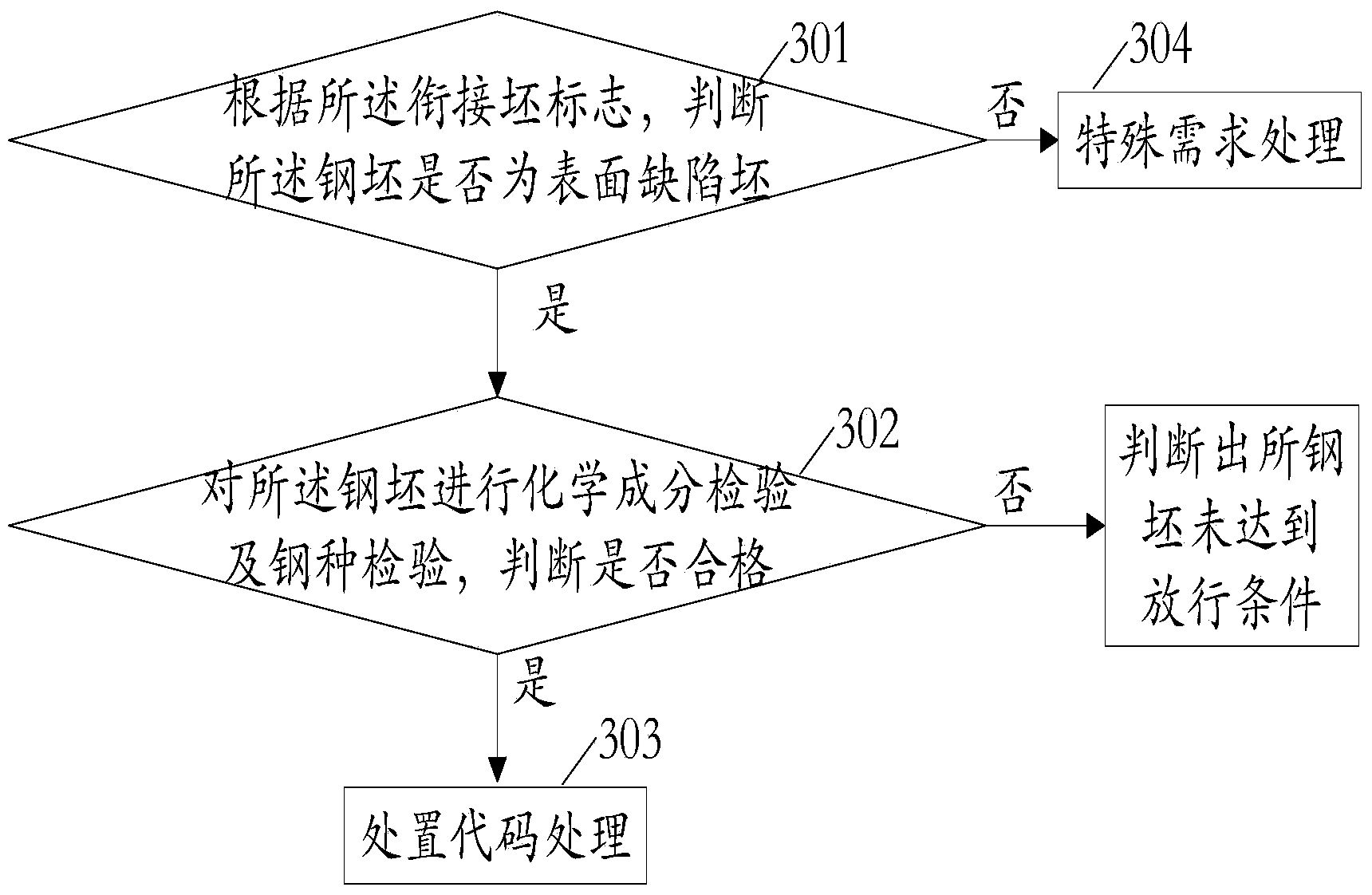

Steel billet testing method, device and system

InactiveCN103729561AAutomate processingImprove inspection efficiencySpecial data processing applicationsSteelmakingChemical composition

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

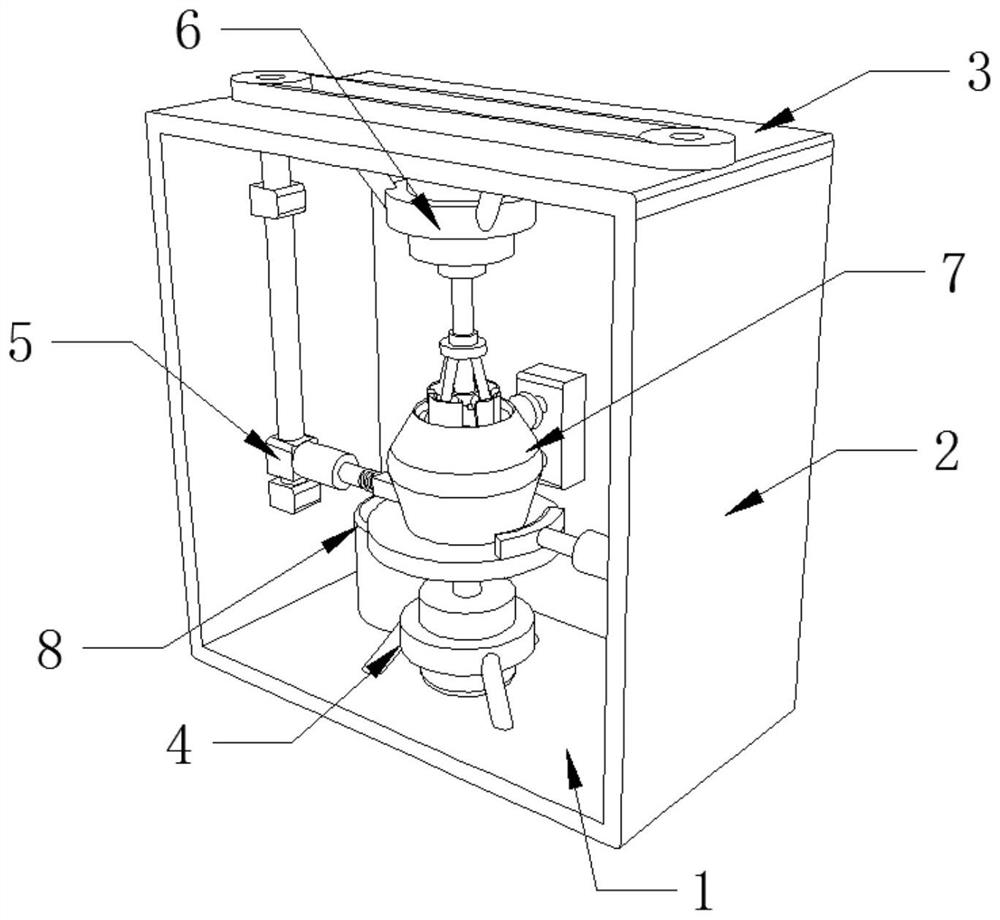

Automatic packaging device for fast food

InactiveCN113120288AAchieve a single separationPrecise positioningPackaging foodstuffsRice dishesAssembly line

The invention relates to an automatic packaging device for fast food, in particular to a packing device for automatically subpackaging rice and dishes in box-packed fast food. The device is characterized in that assembly line type working equipment is arranged, the equipment automatically grabs a fast food box for operation, and the fast food box operates under the fixation of a clamping jaw of an arranged fast food box clamping conveyor, when the fast food box passes through an automatic food distribution machine area where rice and dishes are placed, a food distribution machine places the rice and the dishes into the fast food box according to the quantity according to set requirements, the fast food box continues to operate backwards after placement is completed, automatic cover sealing is achieved when the fast food box passes through a cover adding area, and finally the fast food box is conveyed out of a packaging area through a fast food box conveyor to complete the automatic fast food packaging function. The automatic packaging device is easy to operate, the rice and the dishes can be quantitatively and rapidly subpackaged, soup separation can be achieved when the dishes are subpackaged, the quality and taste of the dishes are ensured, full-automatic processing is achieved in the working process of the device, and the device is convenient, rapid and sanitary and is an intelligent automatic fast food packaging device meeting the current social requirements.

Owner:JINLING INST OF TECH

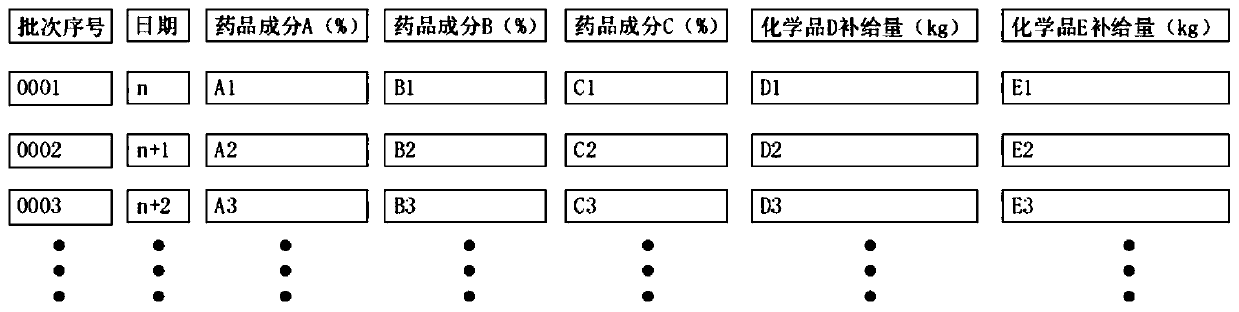

PCB chemical liquid medicine analysis data automatic processing system

Owner:DONGGUAN MEADVILLE CIRCUITS

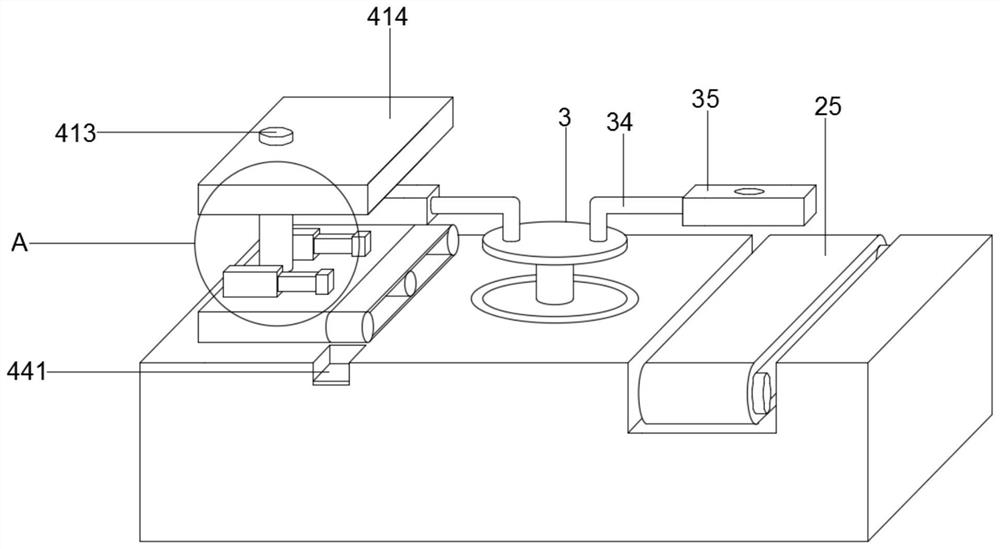

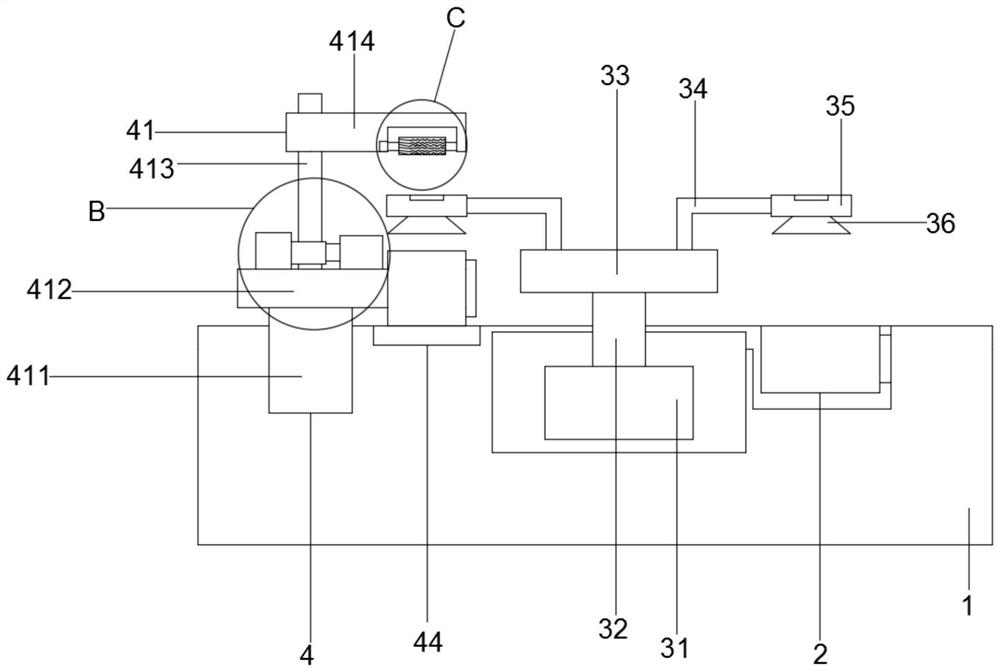

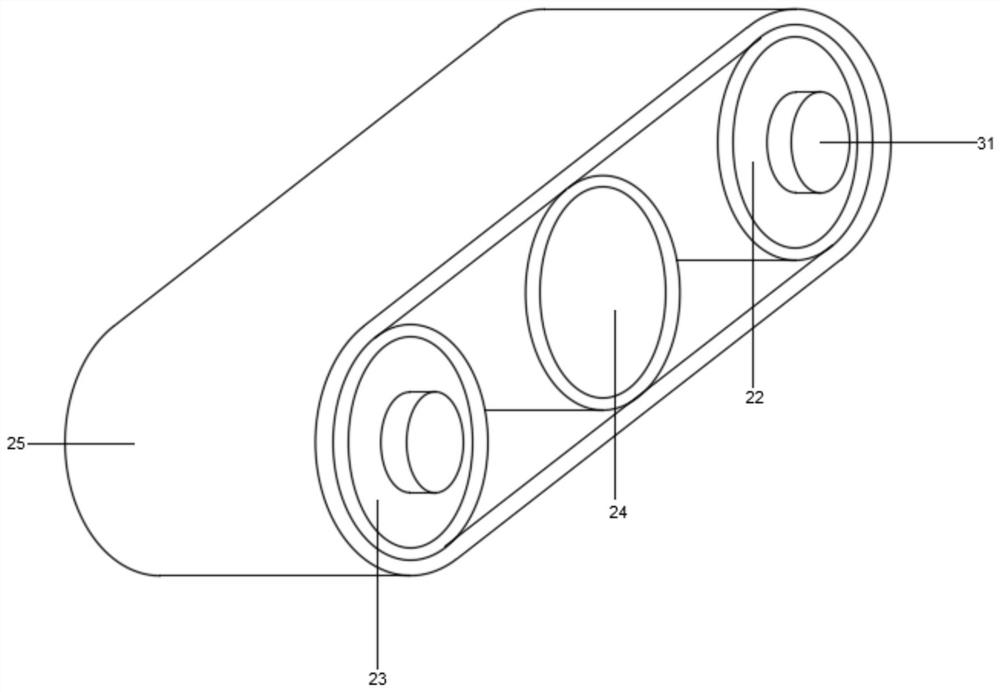

Automatic laminating machine for lithium battery production

PendingCN112670594ALamination is efficient and accurateGet rid of manual operationFinal product manufactureSecondary cellsAutomatic processingProcess engineering

The invention relates to the field of battery production equipment, in particular to an automatic laminating machine for lithium battery production. The laminating machine comprises an equipment base; a conveying mechanism for feeding is arranged at one end of the top of the equipment base, and a raw material carrying mechanism for moving raw materials is arranged in the middle of the top of the equipment base; and the other end of the top of the equipment base is provided with a raw material processing mechanism for processing a pole piece. According to the invention, full-automatic processing of lithium battery laminations is realized through the conveying mechanism, the raw material carrying mechanism and the raw material processing mechanism, and manual operation is completely avoided, so the lithium battery laminations are more efficient and accurate; the correction mechanism is used for correcting and correcting the laminated pieces of the lithium battery after the laminated pieces are laminated, so the difference between a manufacturing method and an individual is smaller when the laminated pieces of the lithium battery are laminated, and the product quality is more excellent.

Owner:湖南久森新能源有限公司

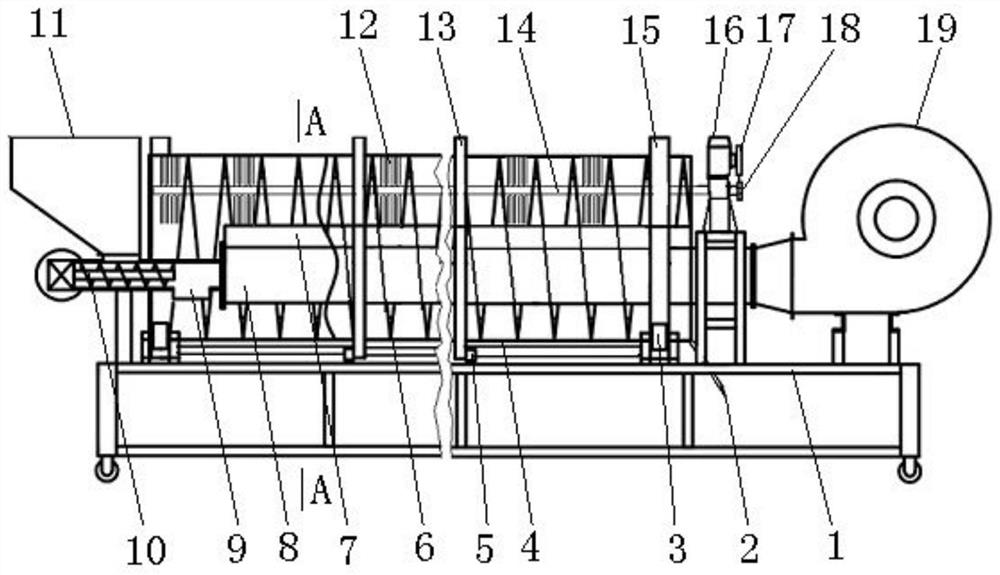

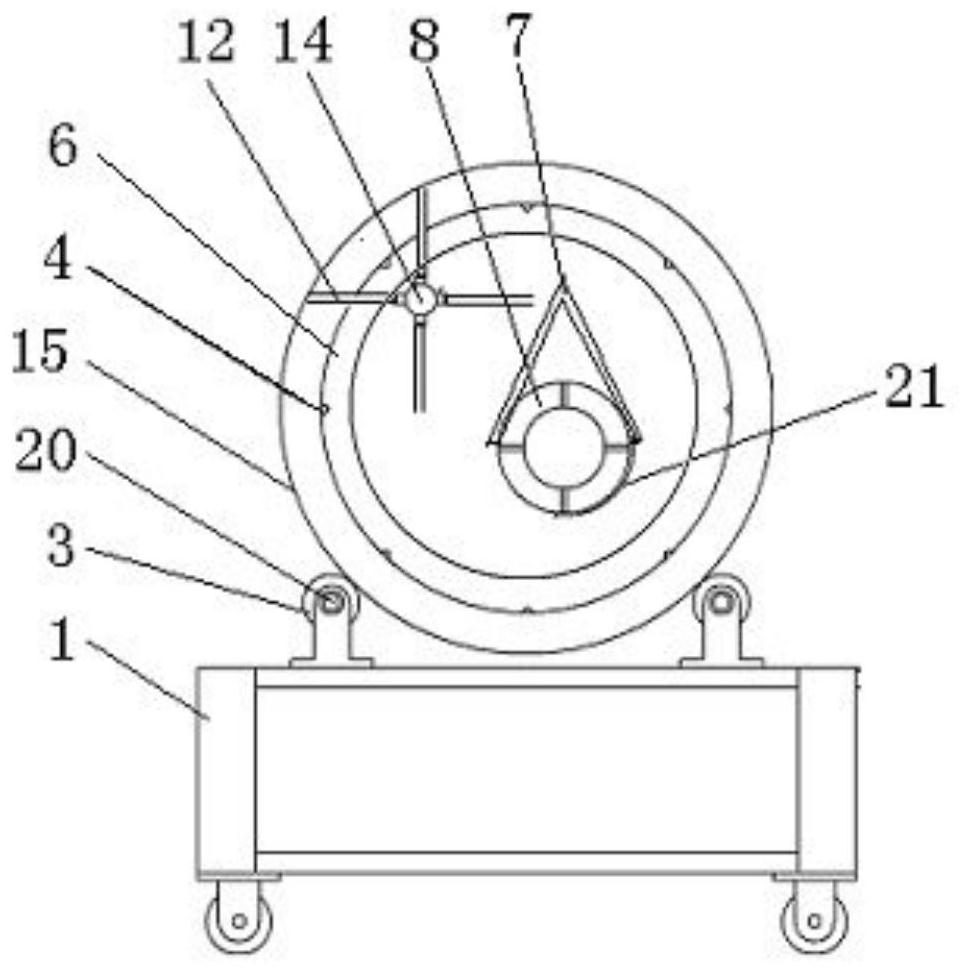

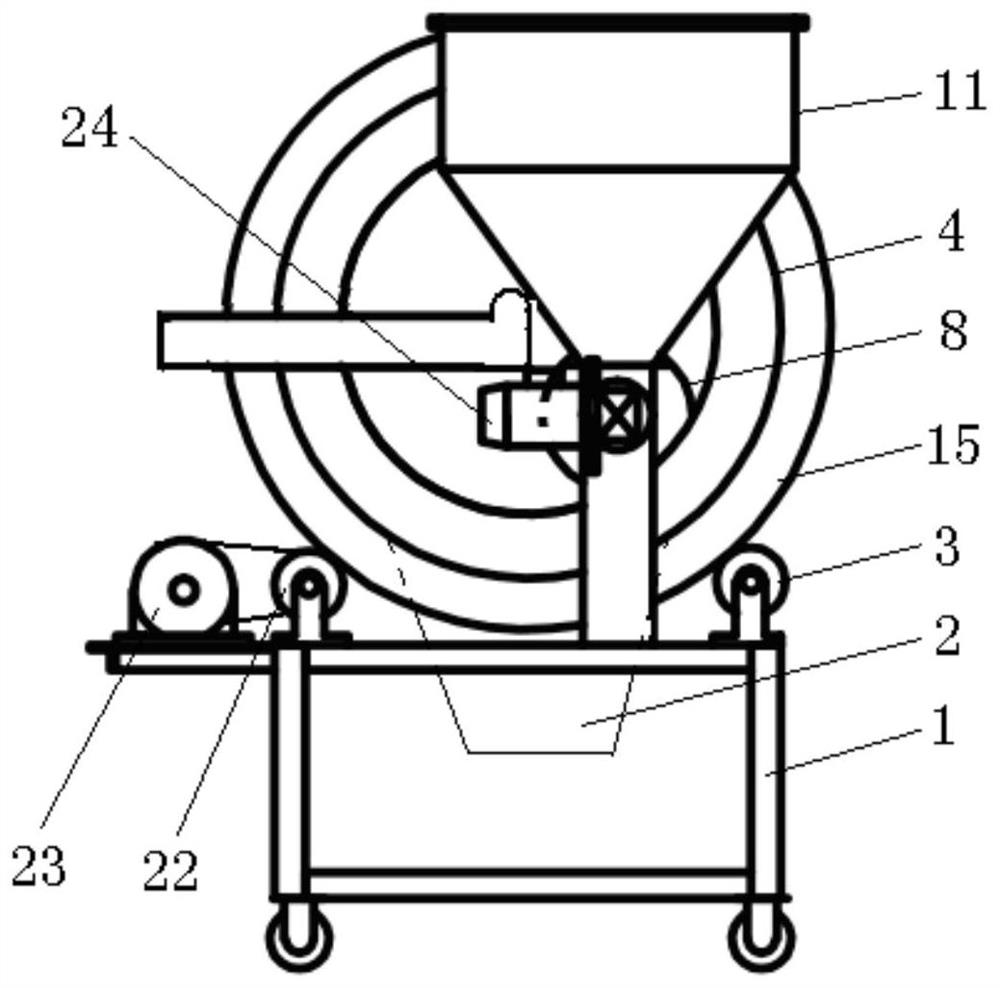

Drum-type coffee surface water air dryer

PendingCN112956713AImprove drying efficiencyLarge amount of processingFood treatmentCoffeaAutomatic processing

The invention provides a drum-type coffee surface water air dryer which comprises a rack and a rotary drum which is arranged on the rack, the rotary drum is provided with a feeding port and a discharging port, a cavity is provided in the rotary drum and a spiral pushing plate is provided in the cavity. The air dryer is characterized in that a first mesh wall is arranged on the rotary drum, an air pipe connected with an air source is arranged in the cavity of the rotary drum, and a second mesh wall is arranged on the air pipe. According to the invention, when the materials are moved from the feeding port to the discharging port, air drying can be completed at a time, water on the surfaces of the materials can be thoroughly removed, the air drying efficiency is high, the treatment capacity is large, the structure is simple, will not be affected by sites or weather, reliable guarantee can be provided for subsequent material processing, subsequent processing energy consumption is greatly reduced, the processing time is shortened, is conducive to mechanization and automatic processing, and the labor intensity is low.

Owner:普洱富民农业装备有限公司

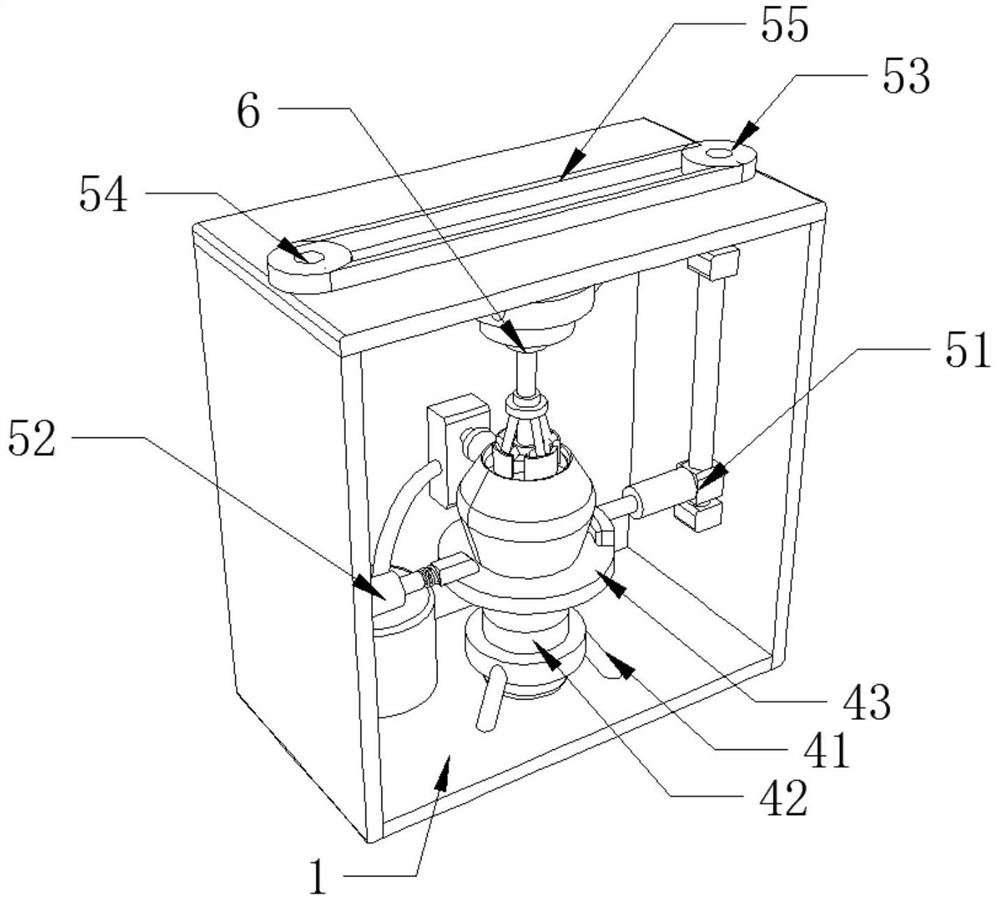

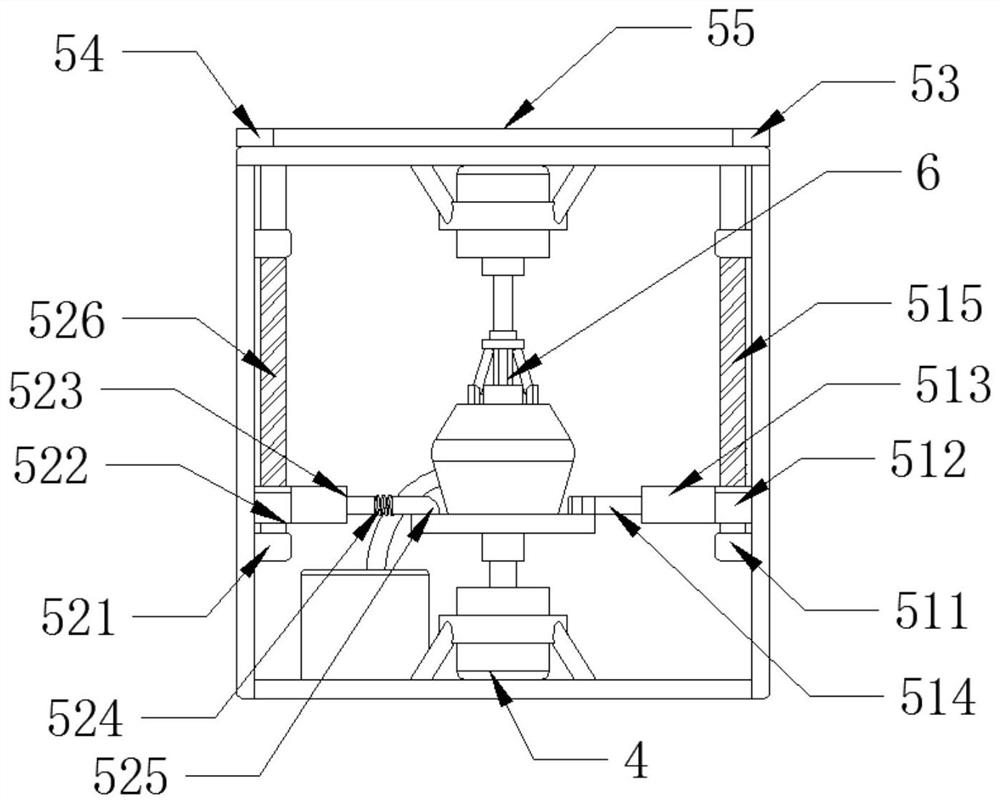

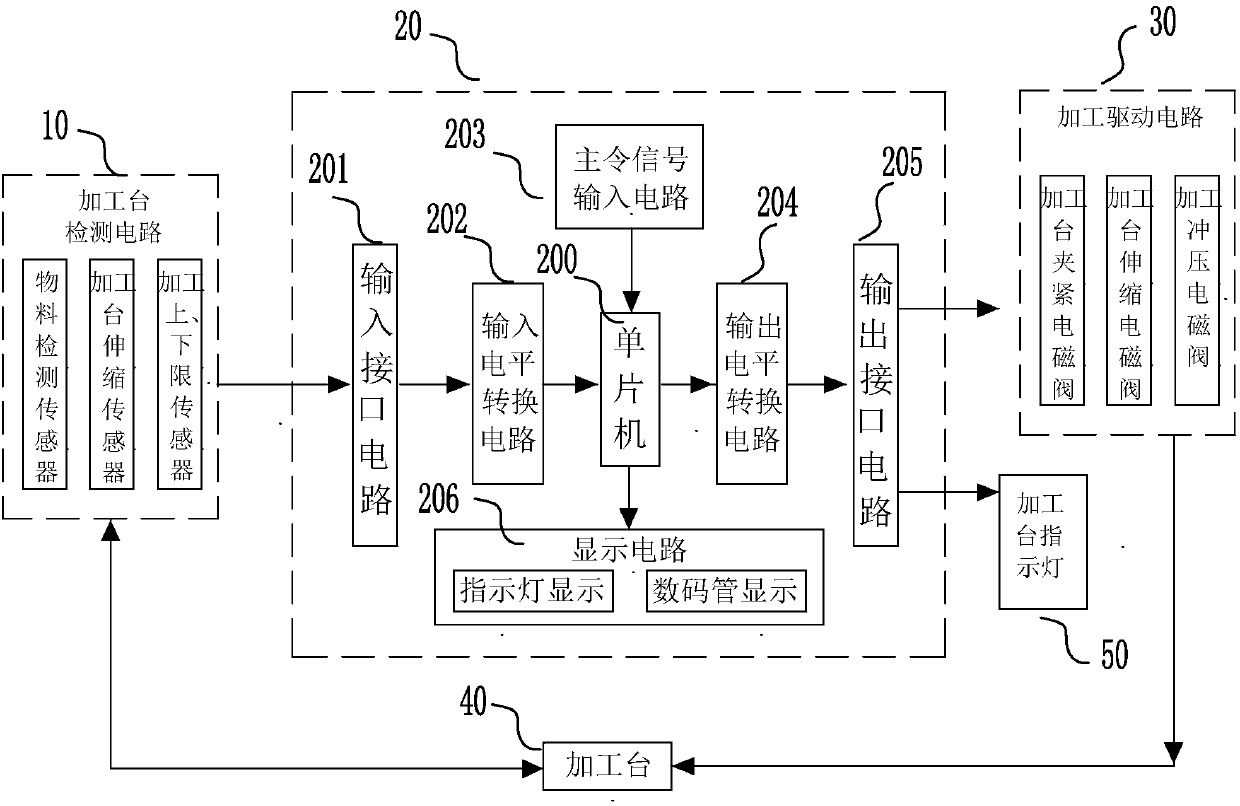

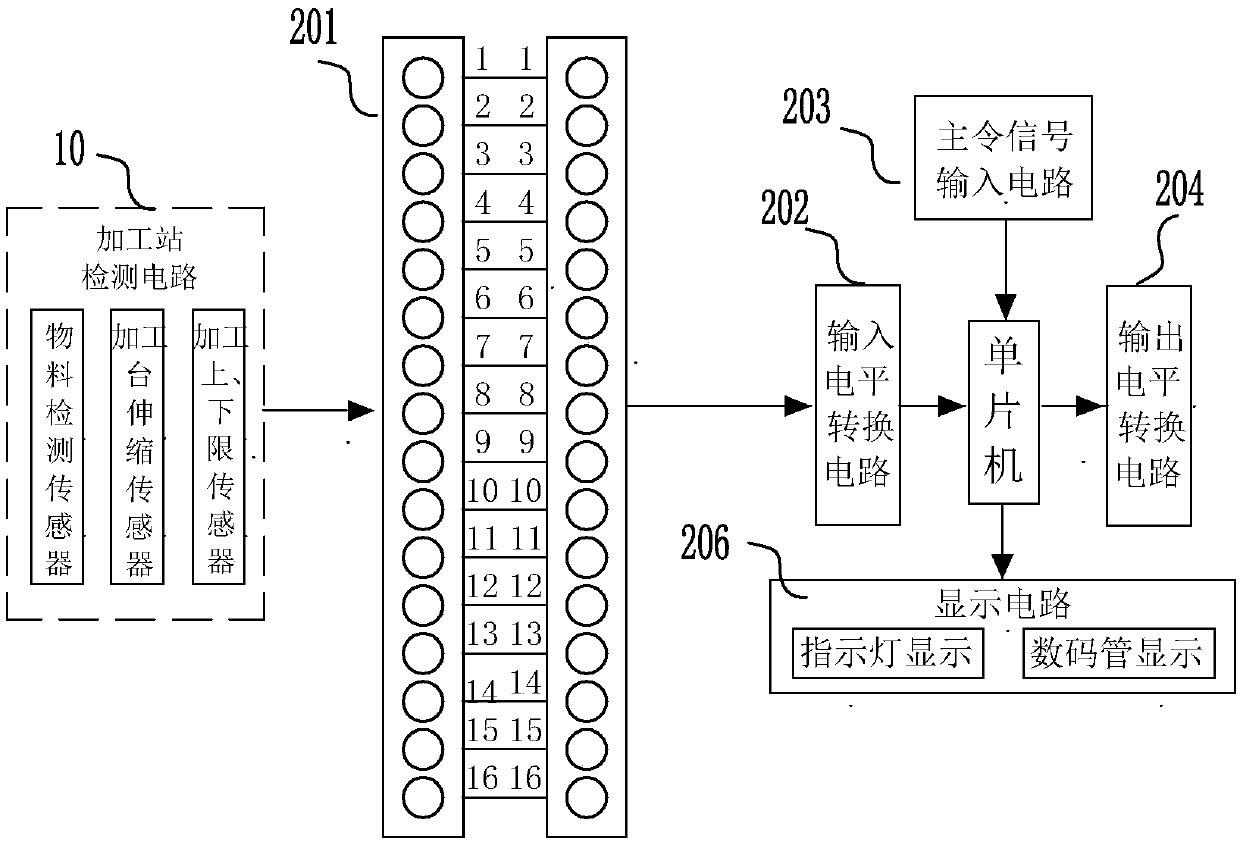

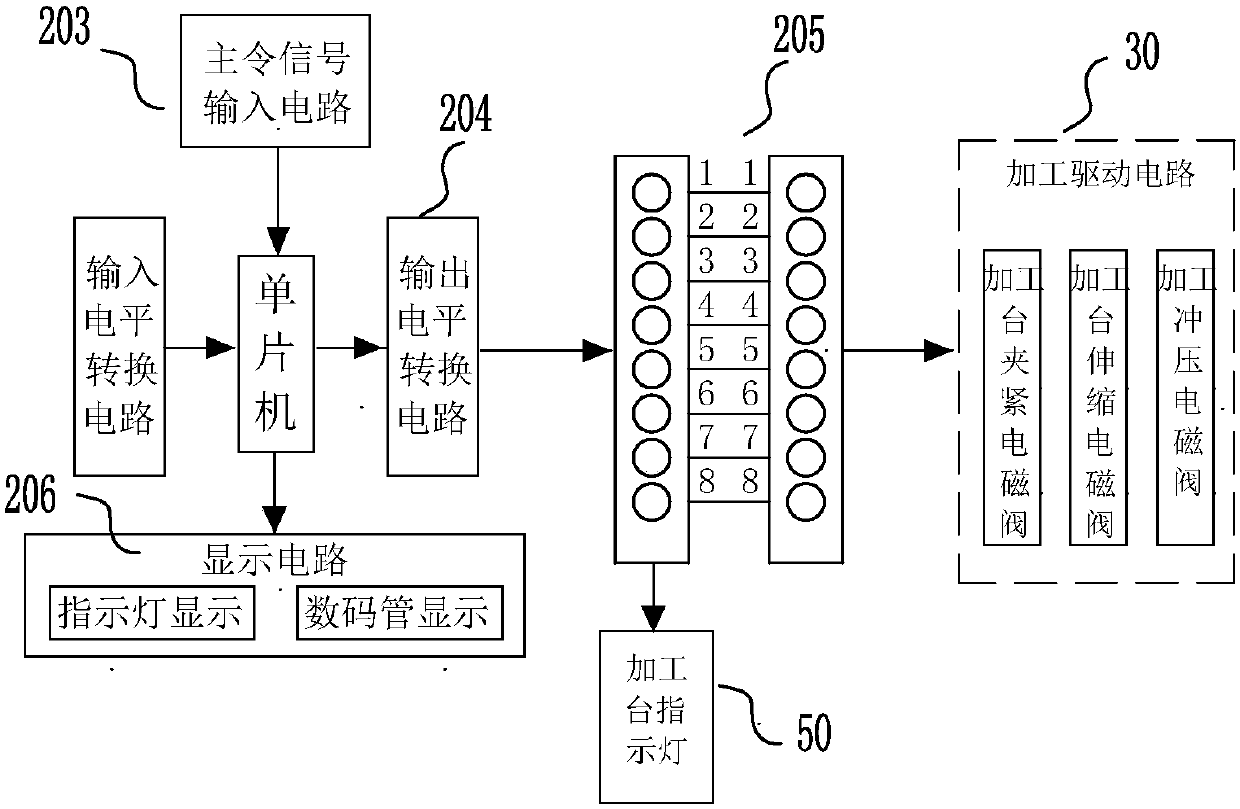

Automatic processing practical training system based on single-chip microcomputer

PendingCN107942827AAchieve control effectLow costProgramme controlComputer controlComputer hardwareComputer architecture

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap