Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Pole piece" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pole piece is a structure composed of material of high magnetic permeability that serves to direct the magnetic field produced by a magnet. A pole piece attaches to and in a sense extends a pole of the magnet, hence the name.

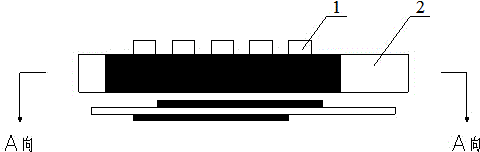

Device for performing surface treatment on pole piece of lithium battery

InactiveCN102151665AQuality improvementReduce the probability of short circuitCell electrodesCleaning using toolsPole pieceEngineering

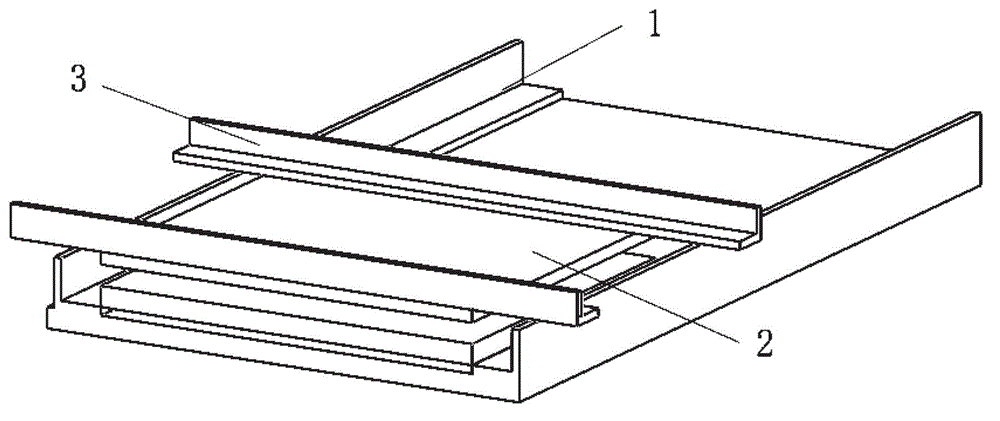

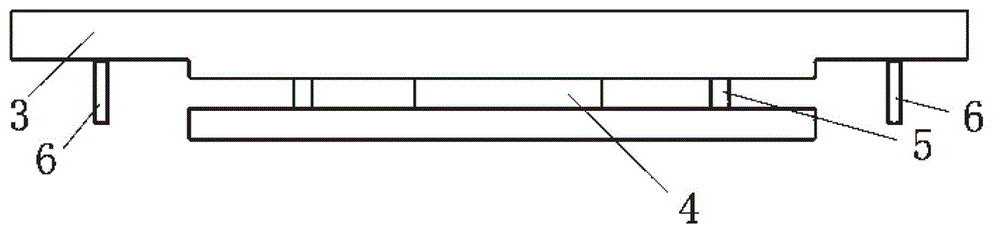

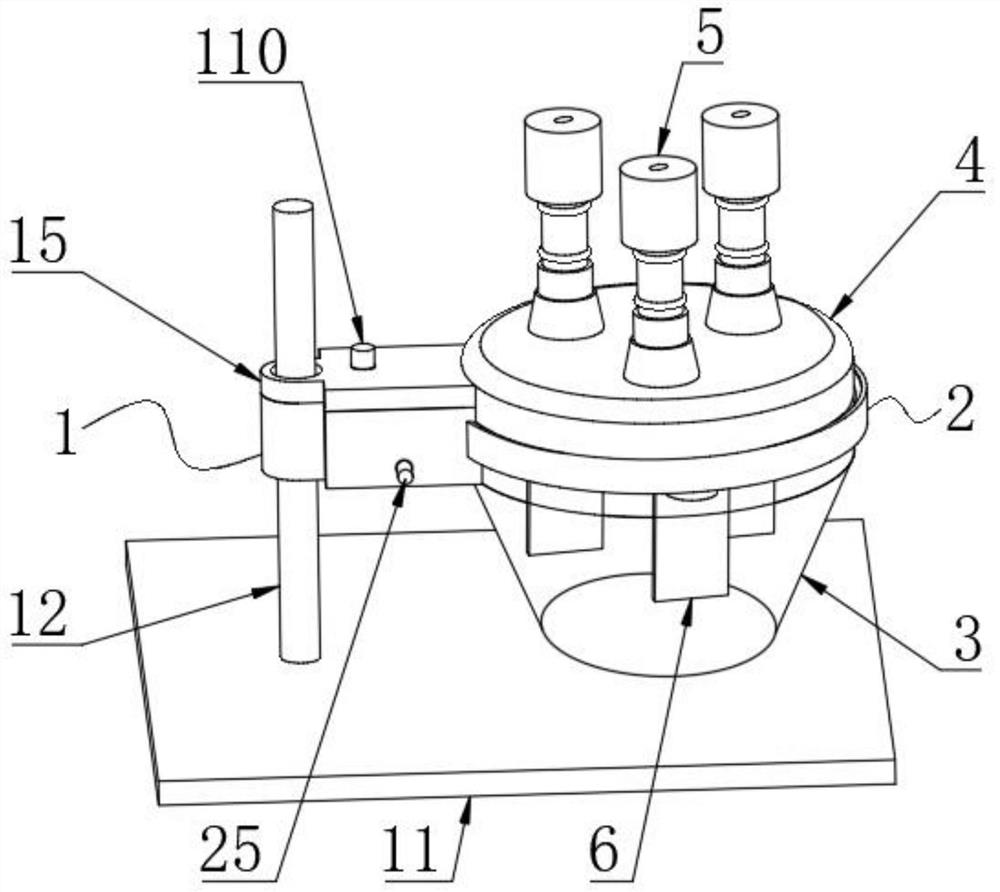

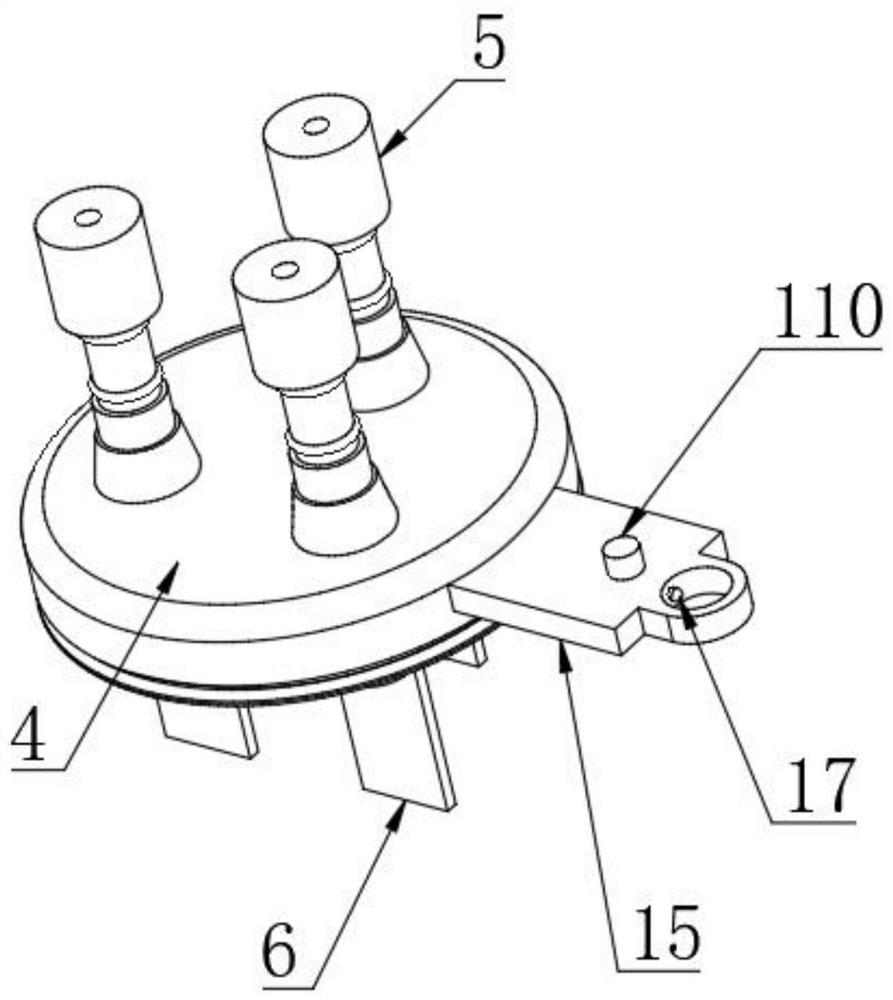

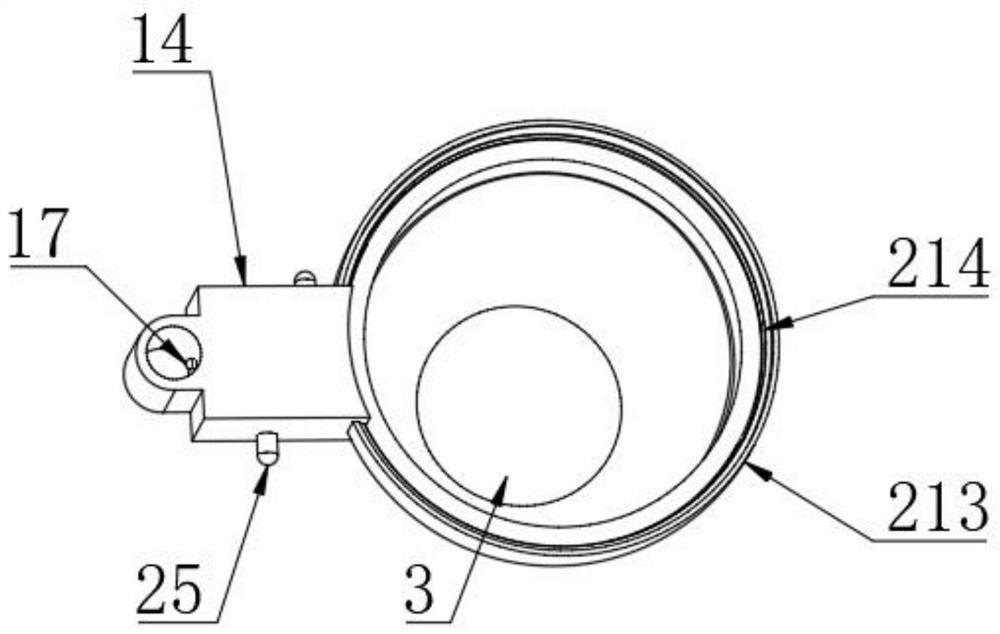

The invention discloses a device for performing surface treatment on a pole piece of a lithium battery. In one piece-brushing process, the front side and the reverse side of the pole piece can be treated simultaneously, so that the treatment efficiency can be improved and the treatment quality can be guaranteed. The device comprises a machine frame, a workbench, an upper sponge, a lower sponge, a negative pressure device and an upper sponge driving cylinder; the lower sponge is fixed on the workbench; the upper sponge driving cylinder is arranged on the machine frame; a piston rod of the upper sponge driving cylinder faces downward; the bottom of the piston rod is fixedly connected with the upper sponge; the upper sponge is positioned above the lower sponge; the negative pressure device comprises an air compressor and a suction pipe; the suction pipe is inserted upward from the bottom of the workbench; and the pipe orifice of the suction pipe is positioned in the lower sponge. The process for brushing the piece is improved, a technology for automatically brushing the two sides of the piece simultaneously is adopted, two sponge plates which are correspondingly arranged up and down are used and when dust adsorbed to the sponge plates is more, the sponge plates can be replaced at any time. The device is high in quality for cleaning the pole piece, and high in yield, and can timely remove the dust and debris and obviously improve the quality of the pole piece, and the battery manufactured by the pole piece is low in short circuit rate.

Owner:JIANGSU YINGTAI ELECTRONICS

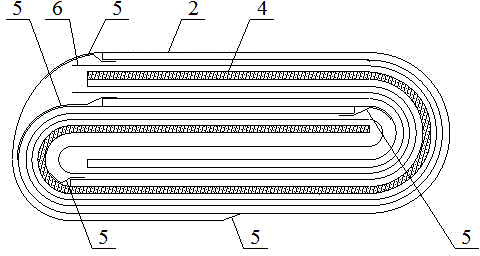

Manufacturing method of winding type lithium ion battery and winding type lithium ion battery

InactiveCN104681878AIncrease productivityImprove securityFinal product manufactureSecondary cellsPower flowInternal resistance

Owner:王文斌

Stator coil winding process

InactiveCN102097899ACompact structureAvoid Stator Performance ImpactManufacturing dynamo-electric machinesBrushless motorsWinding machine

Owner:惠州龙德科技股份有限公司

Battery module capable of improving space utilization rate

ActiveCN108172720AHighly integratedIncrease productivityCell component detailsLow voltageElectrical battery

The invention relates to a battery module capable of improving the space utilization rate. The battery module comprises a battery pack, packing straps, an integrated cover plate, an upper cover, end plates and pressure strips; installation corners are arranged at the outer sides of the end plates; the integrated cover plate comprises a cover plate, a pole piece, a wiring harness and a low-voltageconnector; the low-voltage connector is arranged on the side edge of the cover plate along the thickness direction of a battery through a Z-shaped connecting part; two ends of the cover plate are provided with pole piece connection bases outwards and downwardly in an extension manner along the thickness direction of the battery; the end plates are put at two ends of the battery pack along the thickness direction of the battery; the battery and the end plates are bundled through the packing straps; the integrated cover plate and the battery pack are welded by laser; the integrated cover plate,the upper cover and the end plates are connected in a hooking manner; and the pressure strips and the end plates are connected through a pop rivet. According to the battery module capable of improvingthe space utilization rate disclosed by the invention, the low-voltage connectors and the pole piece connection bases are arranged over the installation corners of the corresponding ends of the module; therefore, the overall height of the module is reduced; and the space utilization rate of the battery module is easily improved.

Owner:JIANGXI ANCHI NEW ENERGY TECH CO LTD

Lithium ion battery positive pole pieceand preparation method thereof

InactiveCN112928240AImprove conductivityEasy to prepareCell electrodesSecondary cellsInternal resistancePole piece

The invention provides a lithium ion battery positive pole piece, which comprises a positive current collector, a conductive coating layer and an active slurry layer, wherein the conductive coating layer and the active slurry layer are sequentially coated on the positive current collector, and the active slurry layer comprises, by mass, 95% of a LiFePO4 active substance, 2.8% of a conductive agent and 2.2% of a binder; the conductive coating layer comprises the following components in percentage by mass: 10% of a conductive agent, 2% of a binder, 1% of ethanol, 1% of acetone and 86% of deionized water; the binder is polyvinylidene fluoride, the conductive agent is conductive carbon black, and the positive active substance is LiFePO4. The preparation method is simple, the conductivity of the pole piece can be effectively improved, the lithium ion transfer impedance in the battery is obviously reduced, the direct-current internal resistance of the battery is obviously reduced, and the cycling stability of the battery can be improved.

Owner:JIANGSU PYLON BATTERY CO LTD

Anti-spatter laser die-cutting device and method

PendingCN107350638AQuality improvementPrevent adhesionLaser beam welding apparatusEngineeringLaser cutting

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Cylinder lithium battery

InactiveCN103296245ALower internal resistanceImprove discharge rateCell component detailsInternal resistancePole piece

The invention discloses a cylinder lithium battery, which belongs to the field of lithium battery. The invention solves the problems of over high internal resistance and insufficient discharge rate of the lithium battery in the prior art. The cylinder lithium battery comprises an anode pole piece and a cathode pole piece, and the cathode pole piece is provided with a first cathode tab, and the cathode pole piece is provided with a second cathode tab. After the lithium battery cathode is arranged with the second cathode tab, the internal resistance of the lithium battery decreases 1 / 3, thereby the discharge rate of the lithium battery increases correspondingly, and the output power of the lithium battery increases.

Owner:ZHEJIANG NUOCISS NEW ENERGY TECH

Deviation rectifying system and method for cutting and stacking all-in-one machine

ActiveCN112875379AHigh accuracy of deviation correctionReduce offsetAssembling battery machinesFinal product manufactureStructural engineeringMachine

Owner:中山科瑞自动化技术有限公司

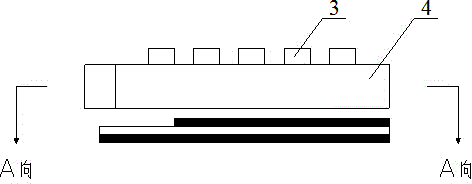

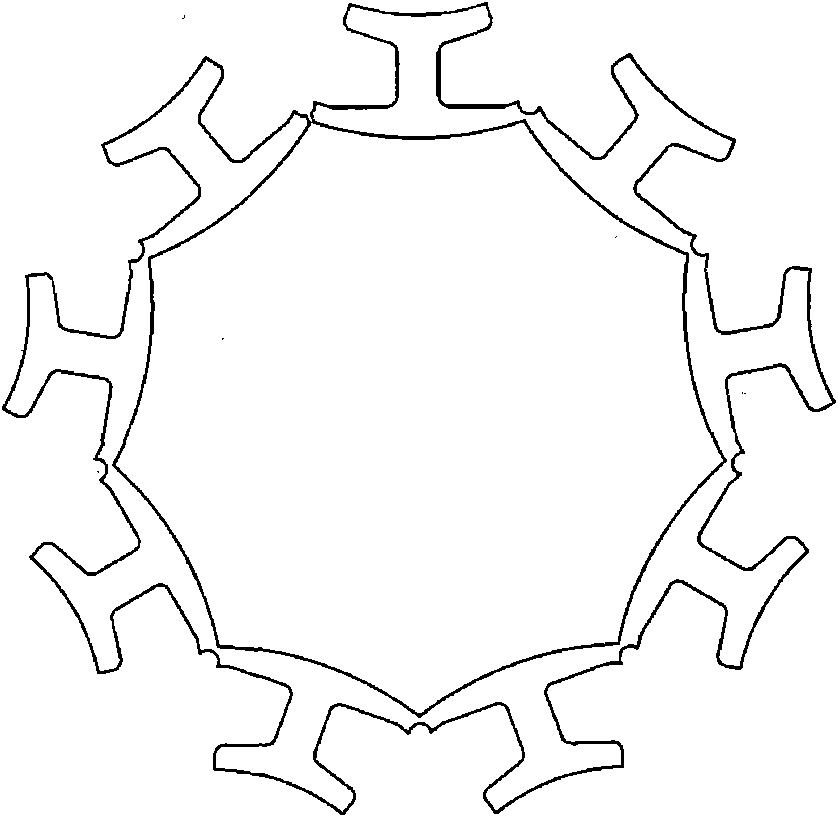

Laminated laminated stator and manufacturing method thereof

ActiveCN102280977AConvenient winding operationFree from space interferenceManufacturing stator/rotor bodiesEngineeringPole piece

Owner:浙江迪贝电气股份有限公司

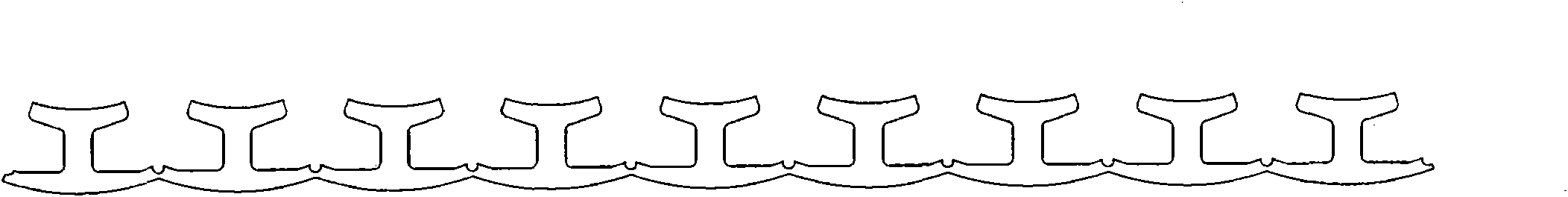

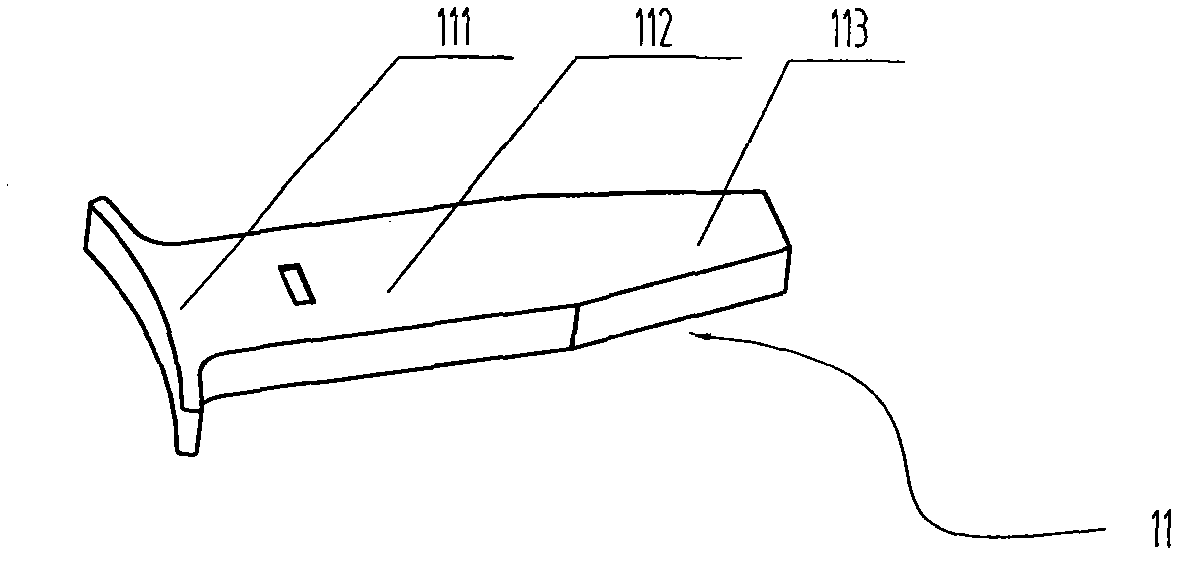

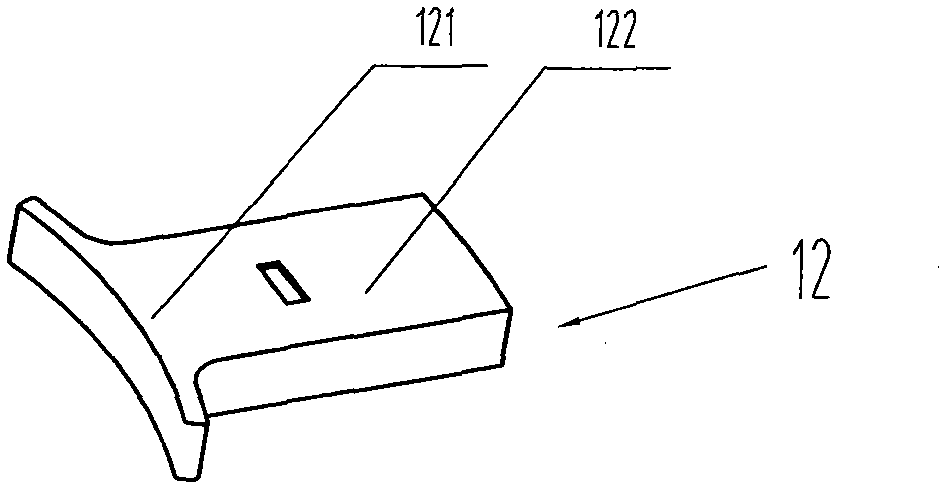

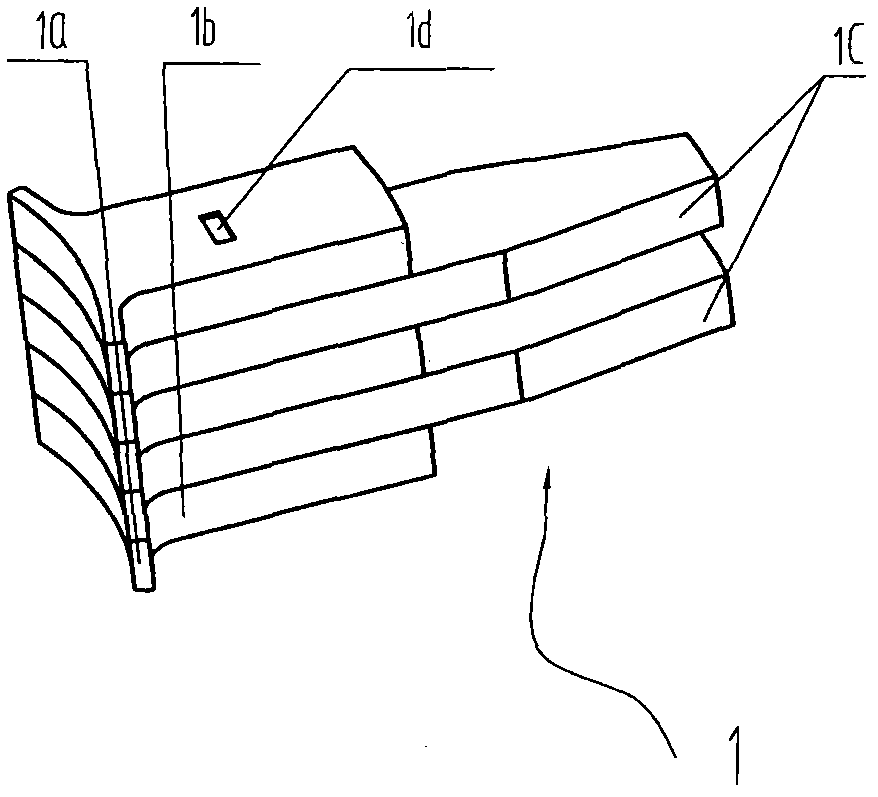

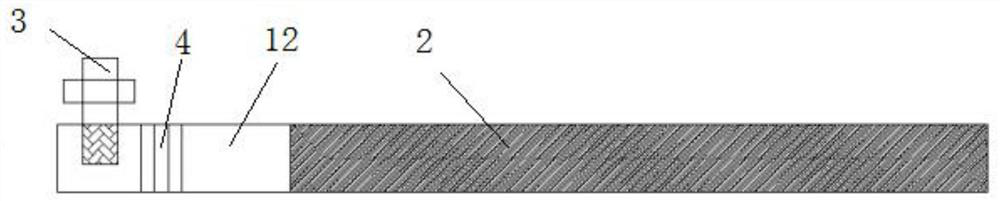

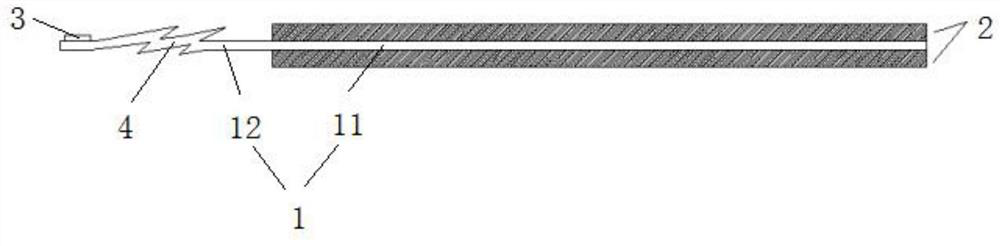

Pole piece for button battery, button battery and production method thereof

PendingCN112635774AAvoid breakingElectrode rolling/calenderingFinal product manufactureButton batteryInternal resistance

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

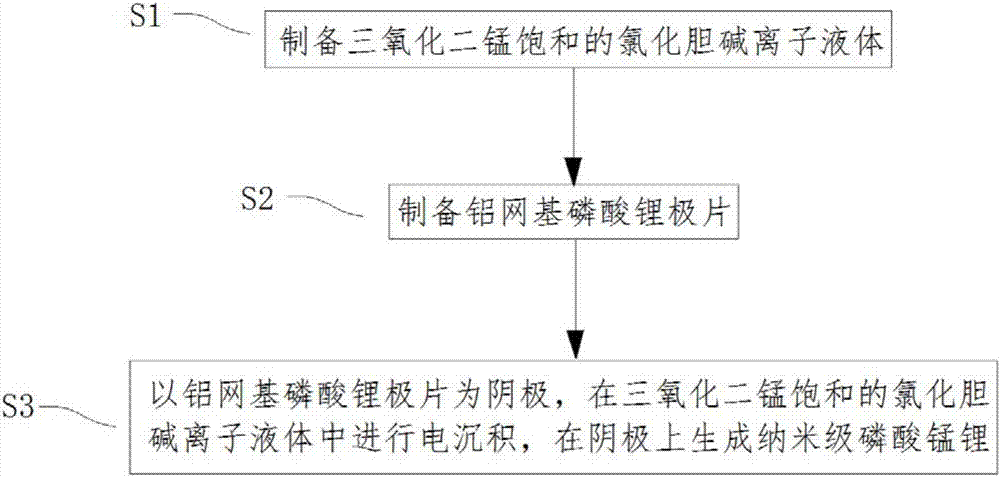

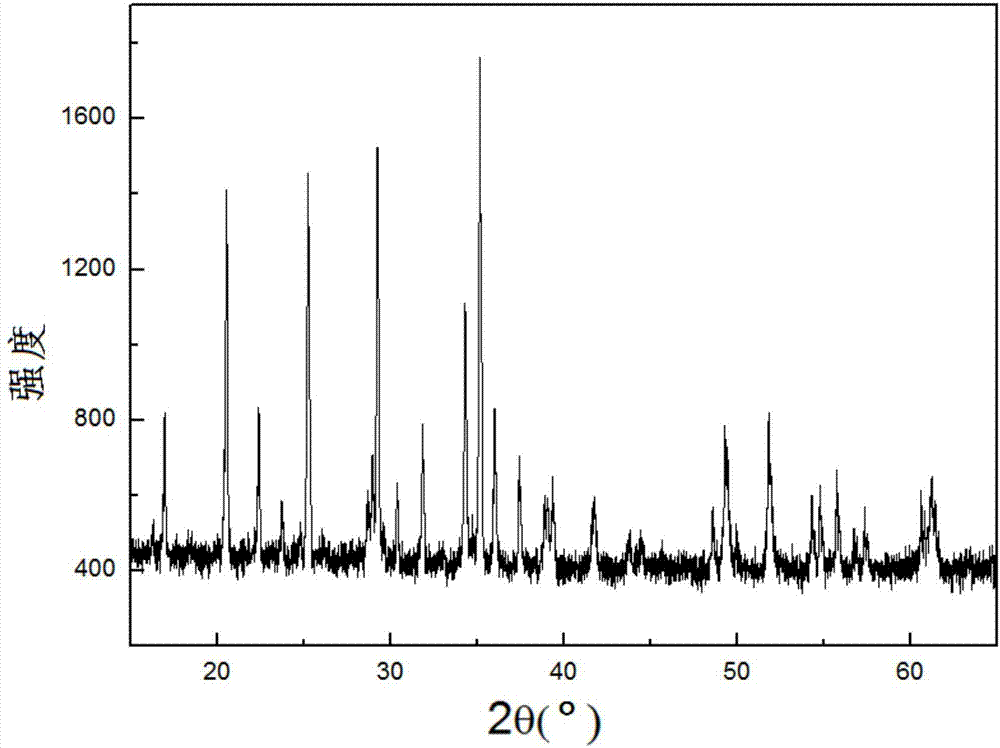

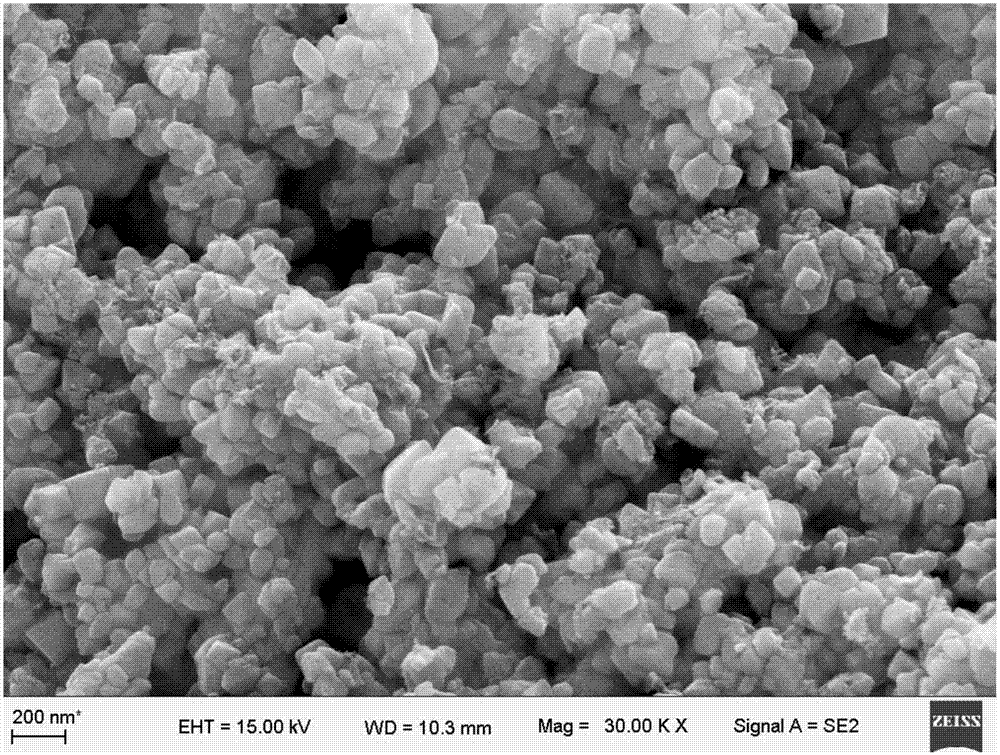

Preparation method of nano-scale manganese lithium phosphate

ActiveCN107134577AEasy to controlControl shapeElectrode manufacturing processesSecondary cellsSesquioxidePole piece

Owner:NORTHEASTERN UNIV

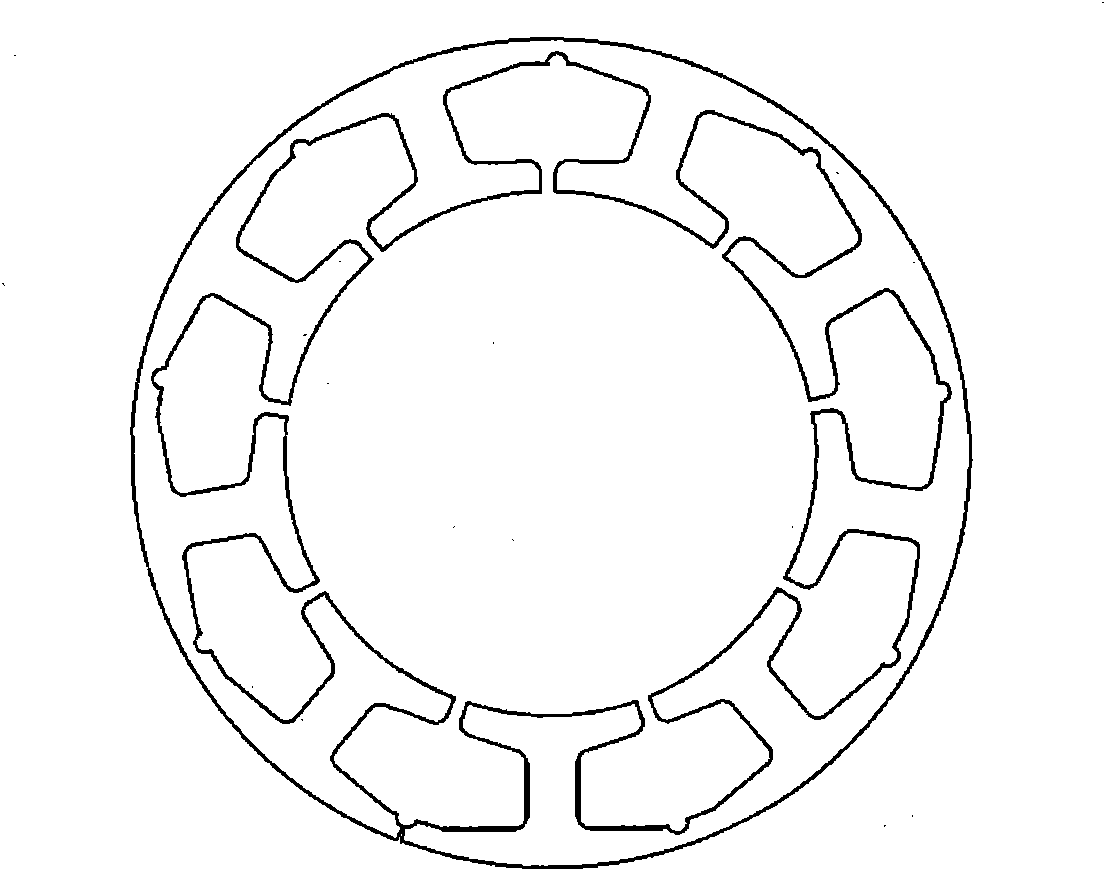

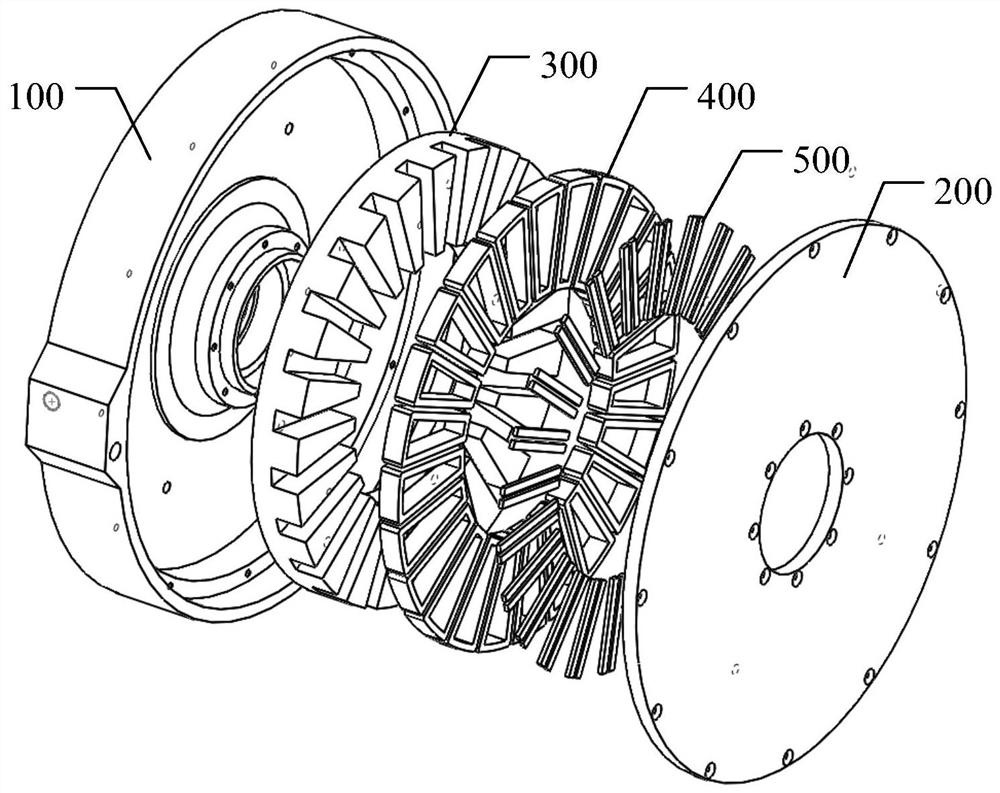

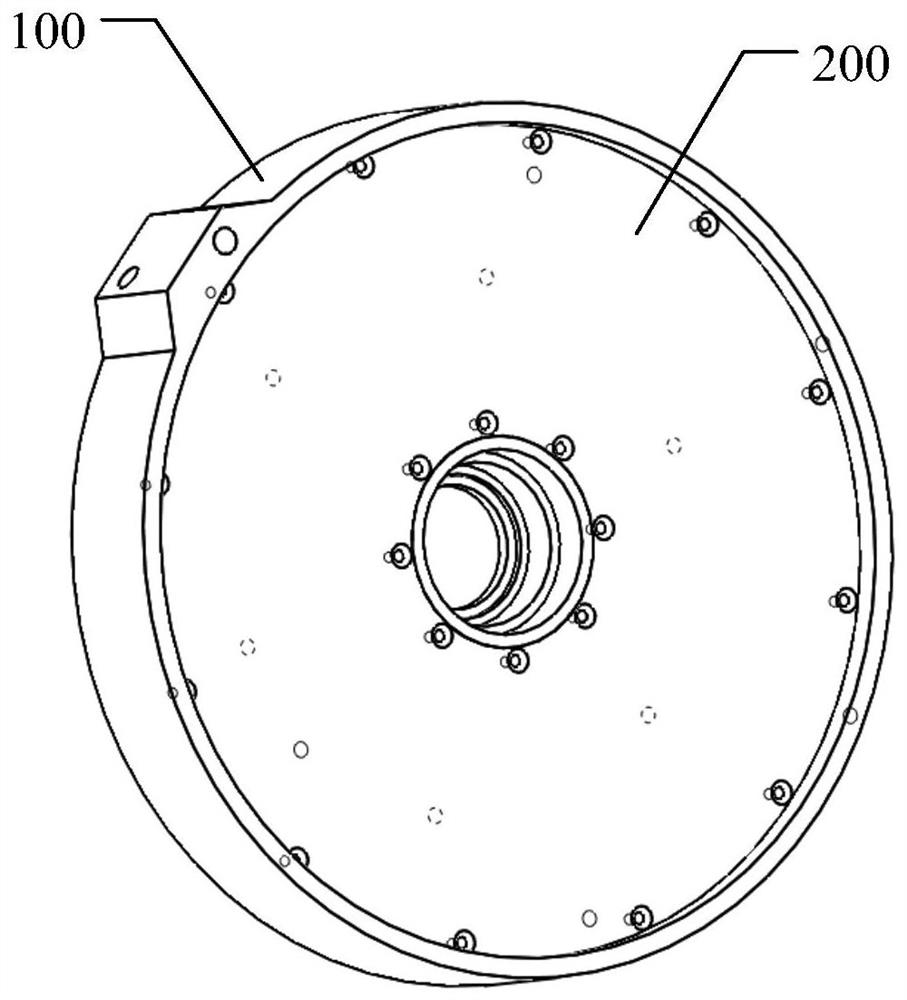

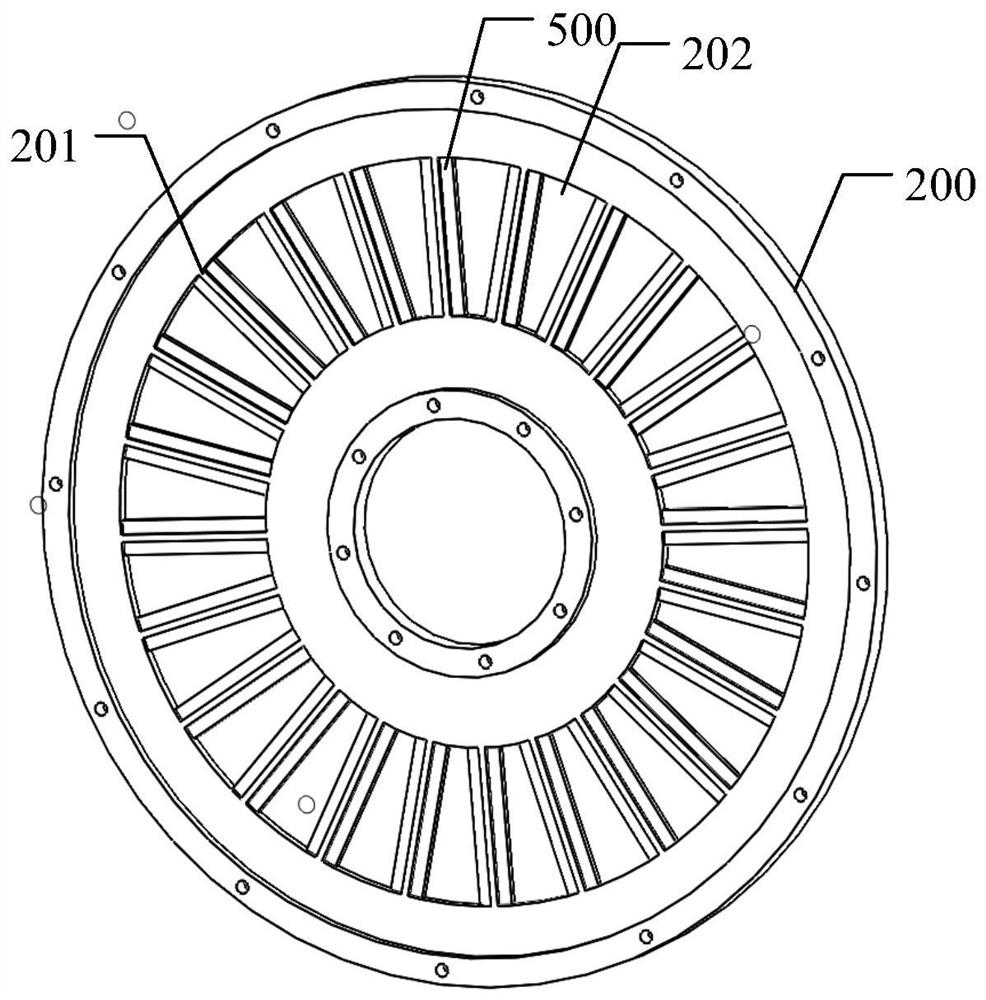

Stator assembly and axial magnetic field motor

Owner:SHANGHAI PANGOOD POWER TECH CO LTD

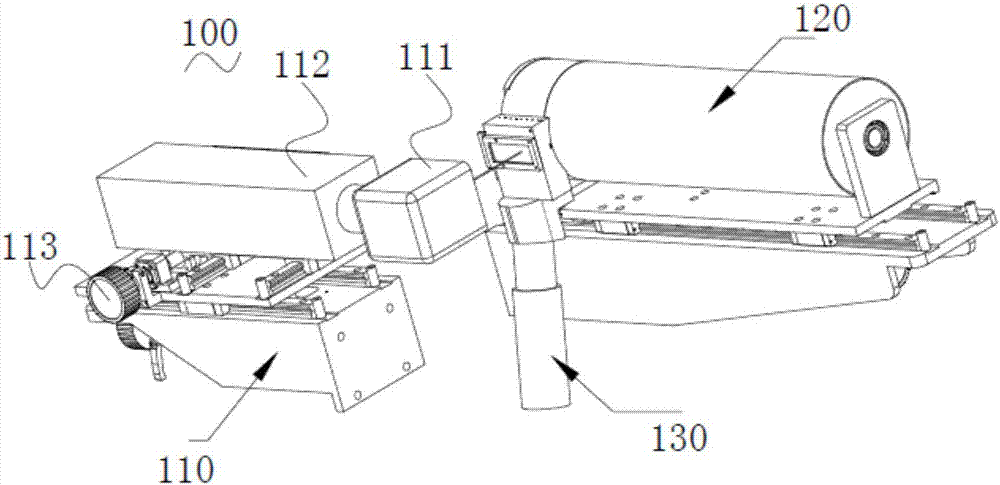

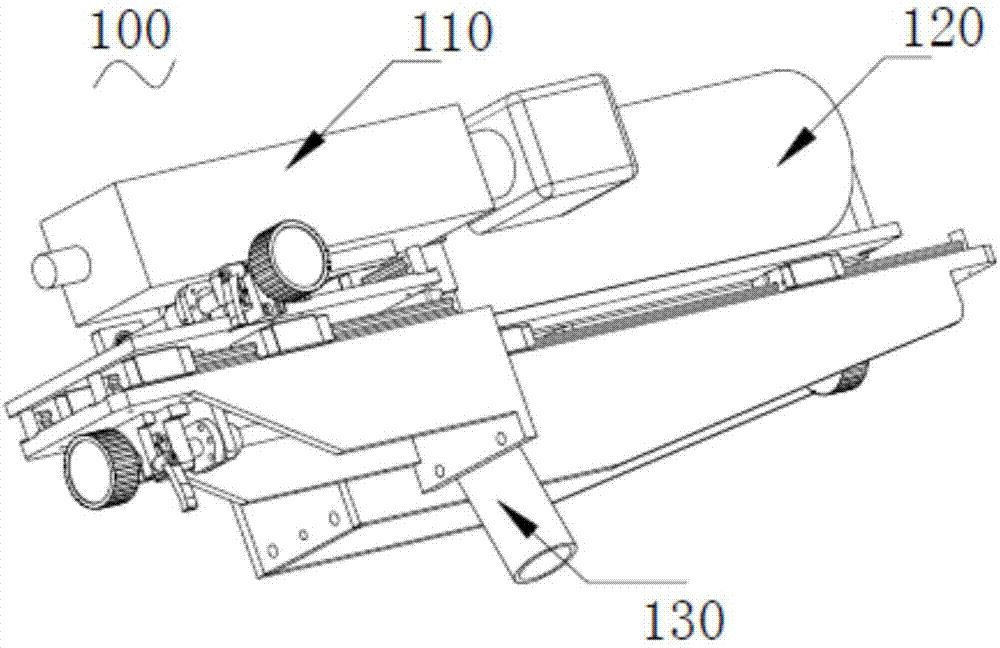

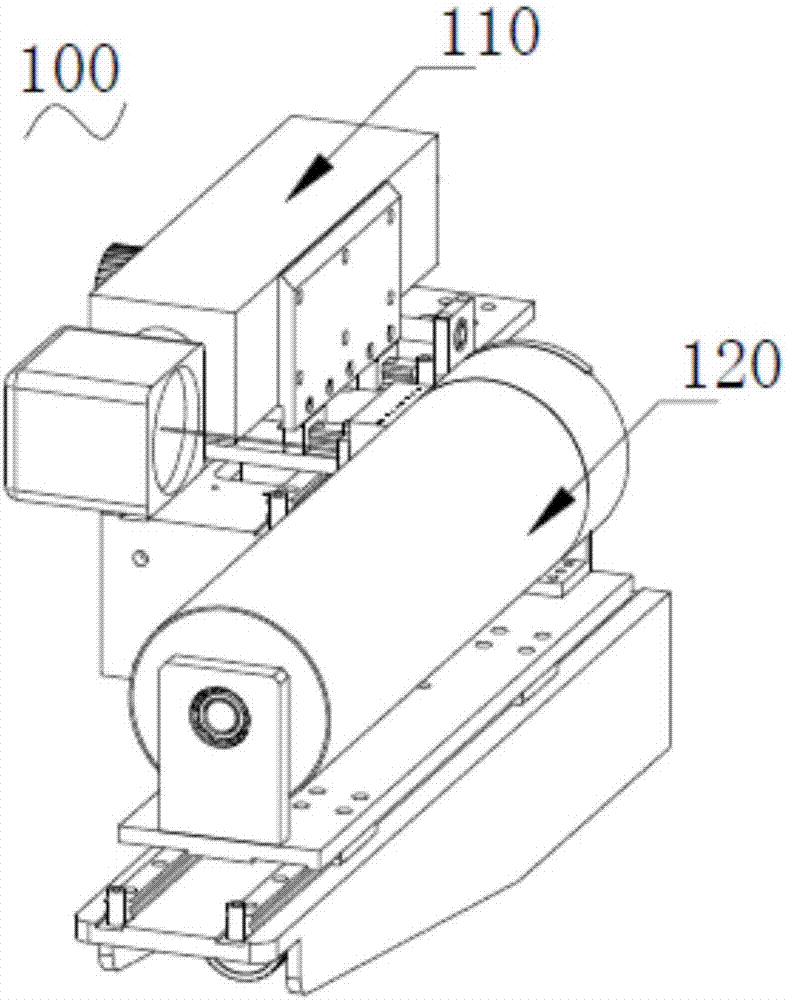

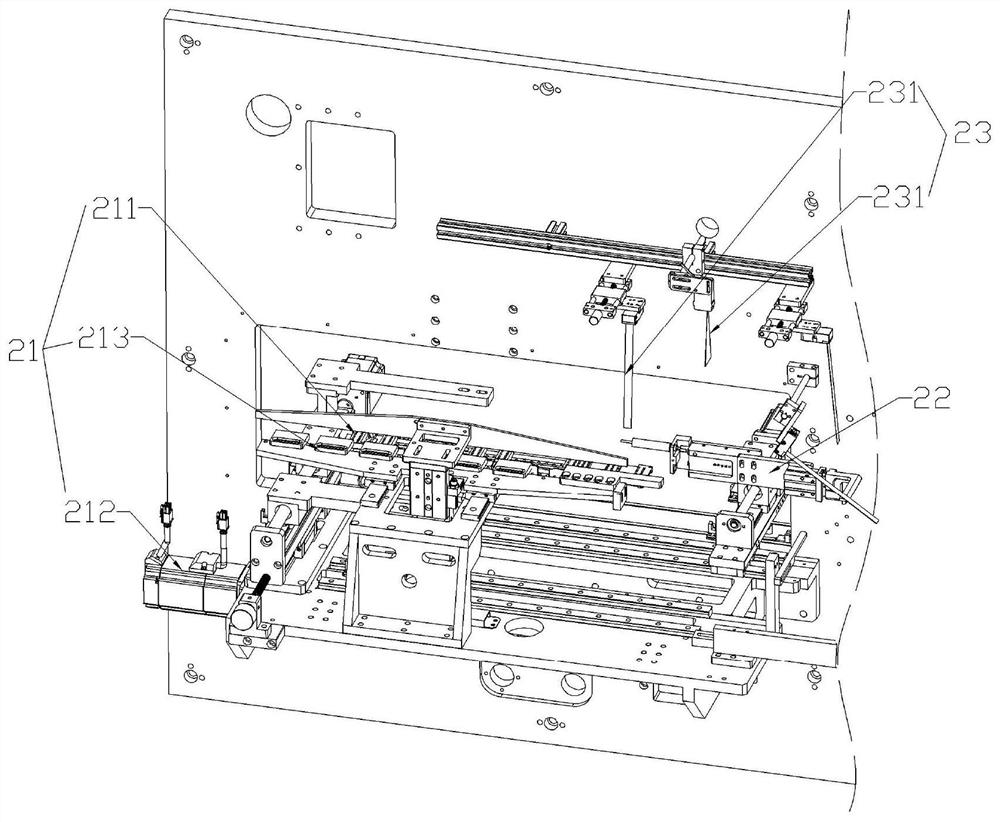

Lithium battery pole piece transportation device

ActiveCN102874567AAvoid displacementAvoid overall overturningMechanical conveyorsAssurance qualityEngineering

Owner:JIANGSU TENPOWER LITHIUM

Photoelectrochemical sensing device and method for analyzing m5C and m6A in RNA

PendingCN113533470AGuaranteed stabilityGuaranteed tightnessMaterial electrochemical variablesPhotoelectrochemistryPole piece

Owner:ARMY MEDICAL UNIV

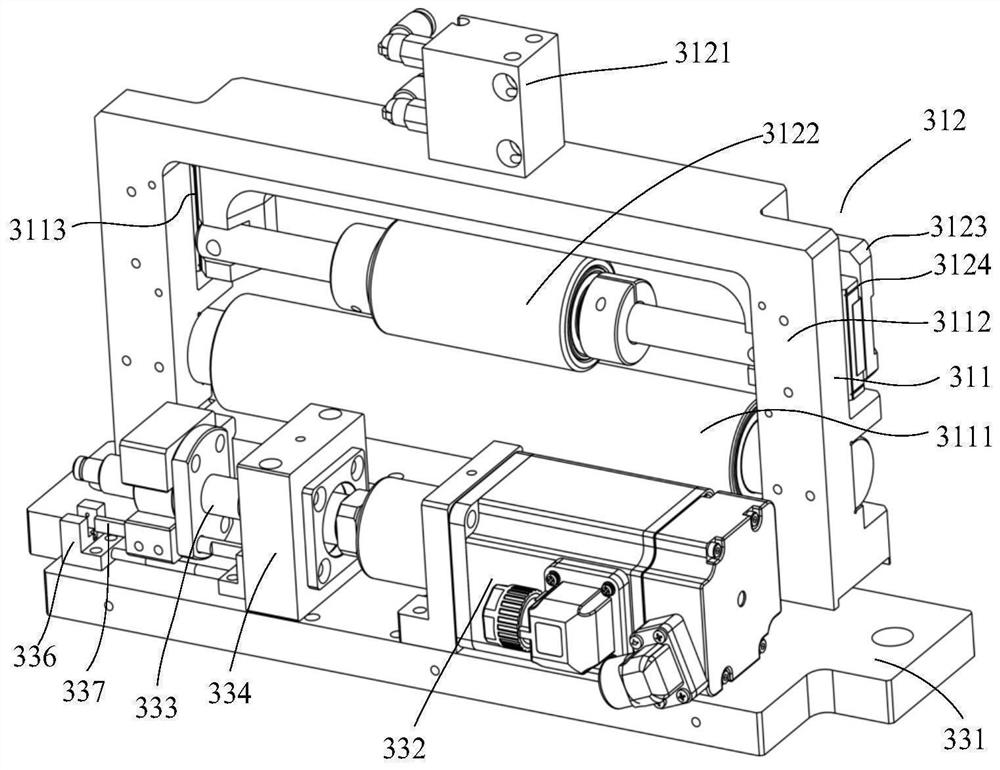

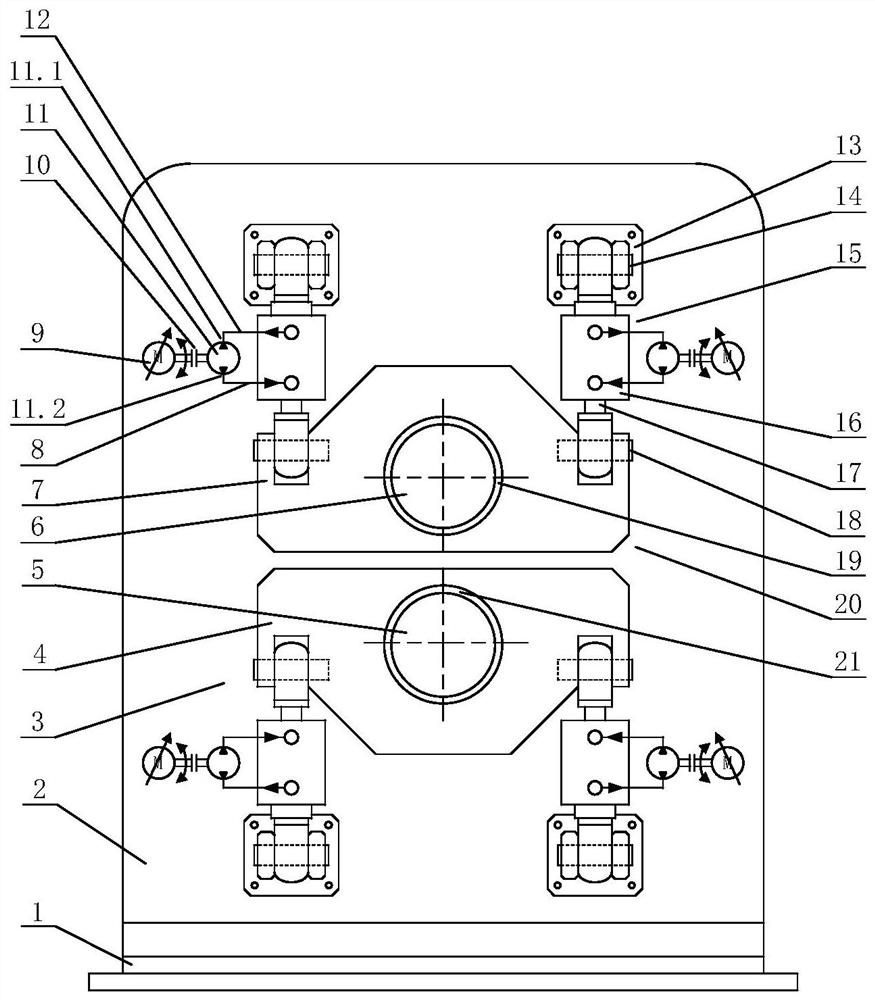

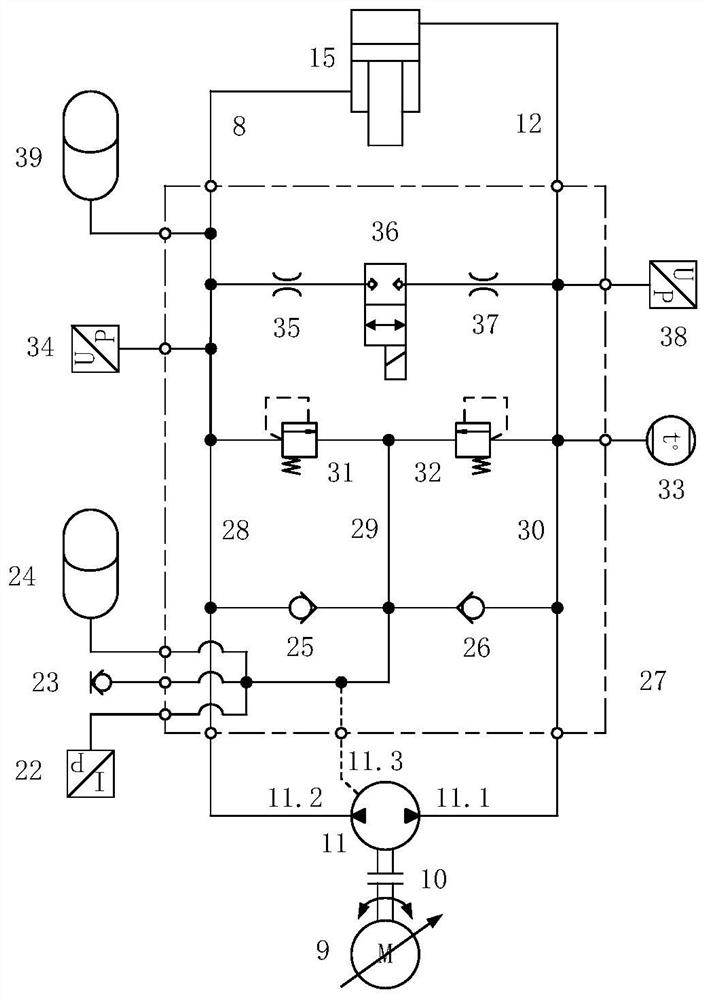

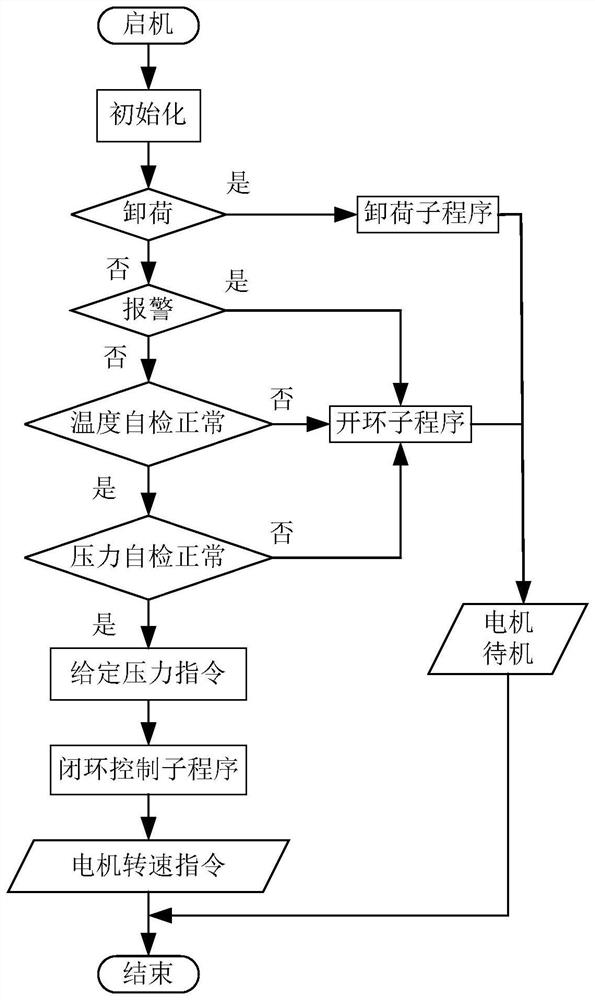

Lithium battery pole piece rolling mill pump control roll bending hydraulic system and roll bending device

PendingCN112253553ATroubleshootingAvoid throttling lossesFluid-pressure actuator safetyRoll force/gap control deviceEngineeringPole piece

Owner:秦皇岛海德科技有限公司

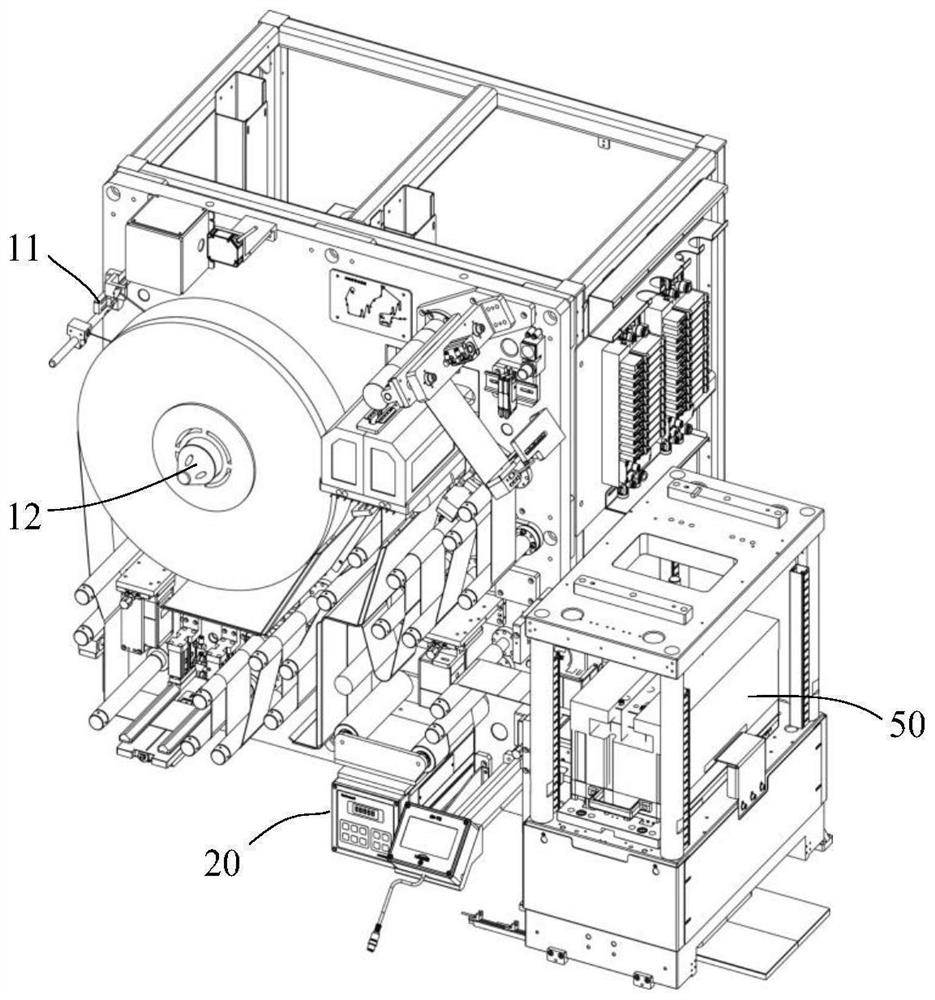

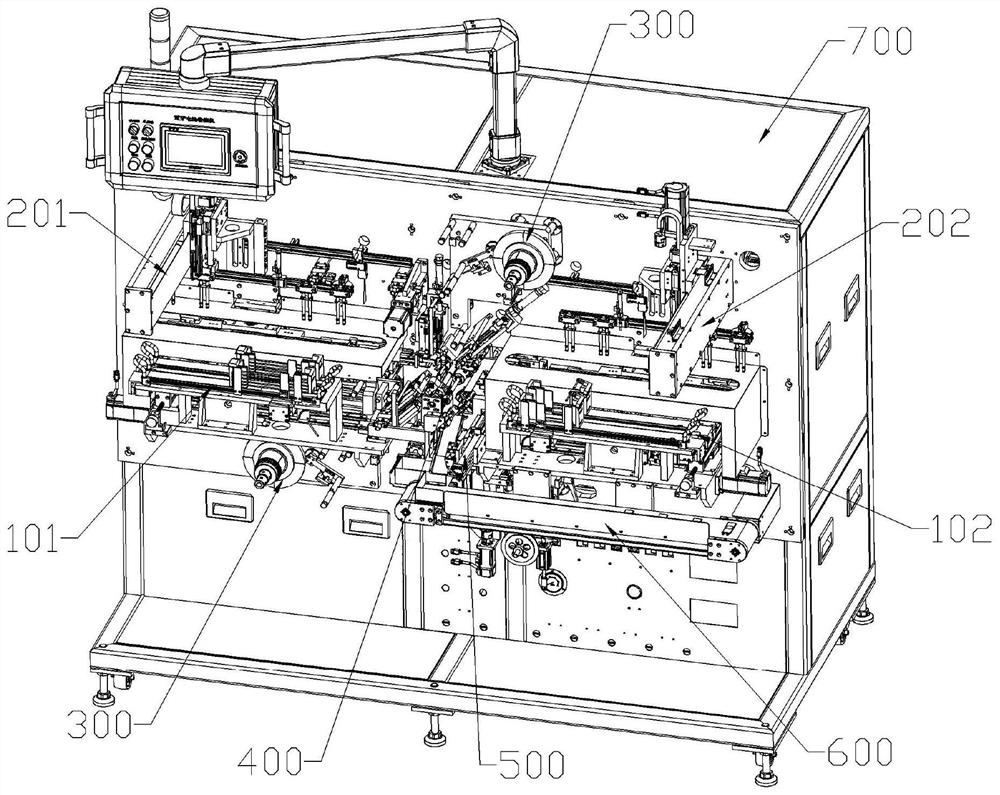

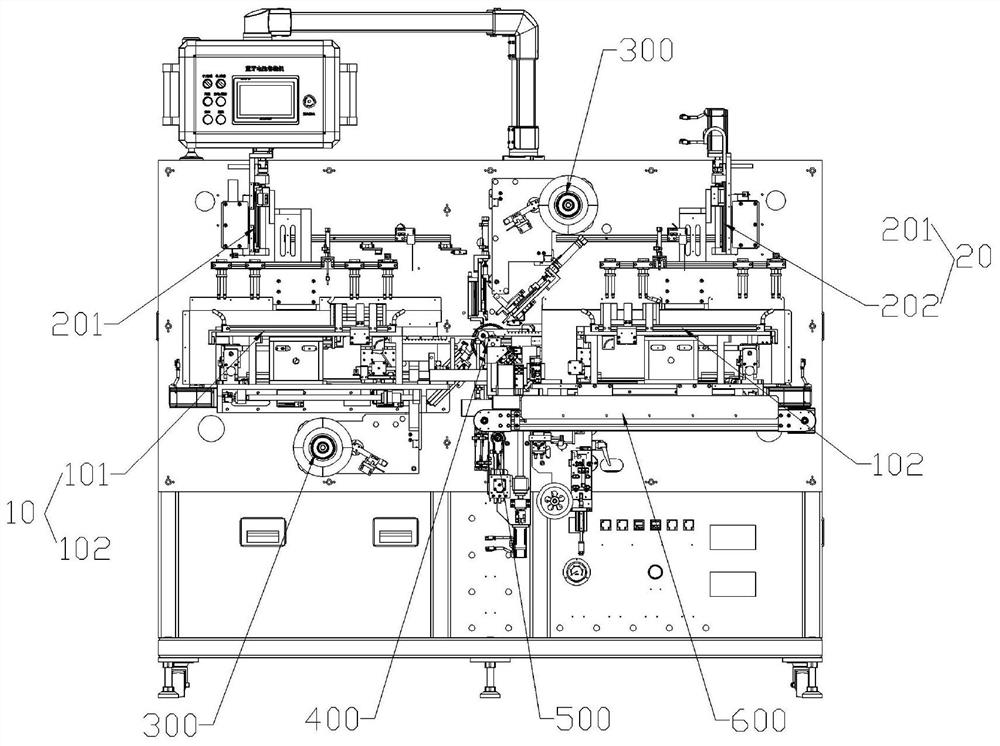

Automatic winding machine for micro battery

PendingCN112271319ARealize the winding processImprove operating precisionPrimary cell manufactureFinal product manufactureWinding machinePole piece

Owner:深圳市鸿德机电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap