Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Lithium-ion battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lithium-ion battery or Li-ion battery (abbreviated as LIB) is a type of rechargeable battery. Lithium-ion batteries are commonly used for portable electronics and electric vehicles and are growing in popularity for military and aerospace applications. The technology was largely developed by John Goodenough, Stanley Whittingham, Rachid Yazami and Akira Yoshino during the 1970s–1980s, and then commercialized by a Sony and Asahi Kasei team led by Yoshio Nishi in 1991.

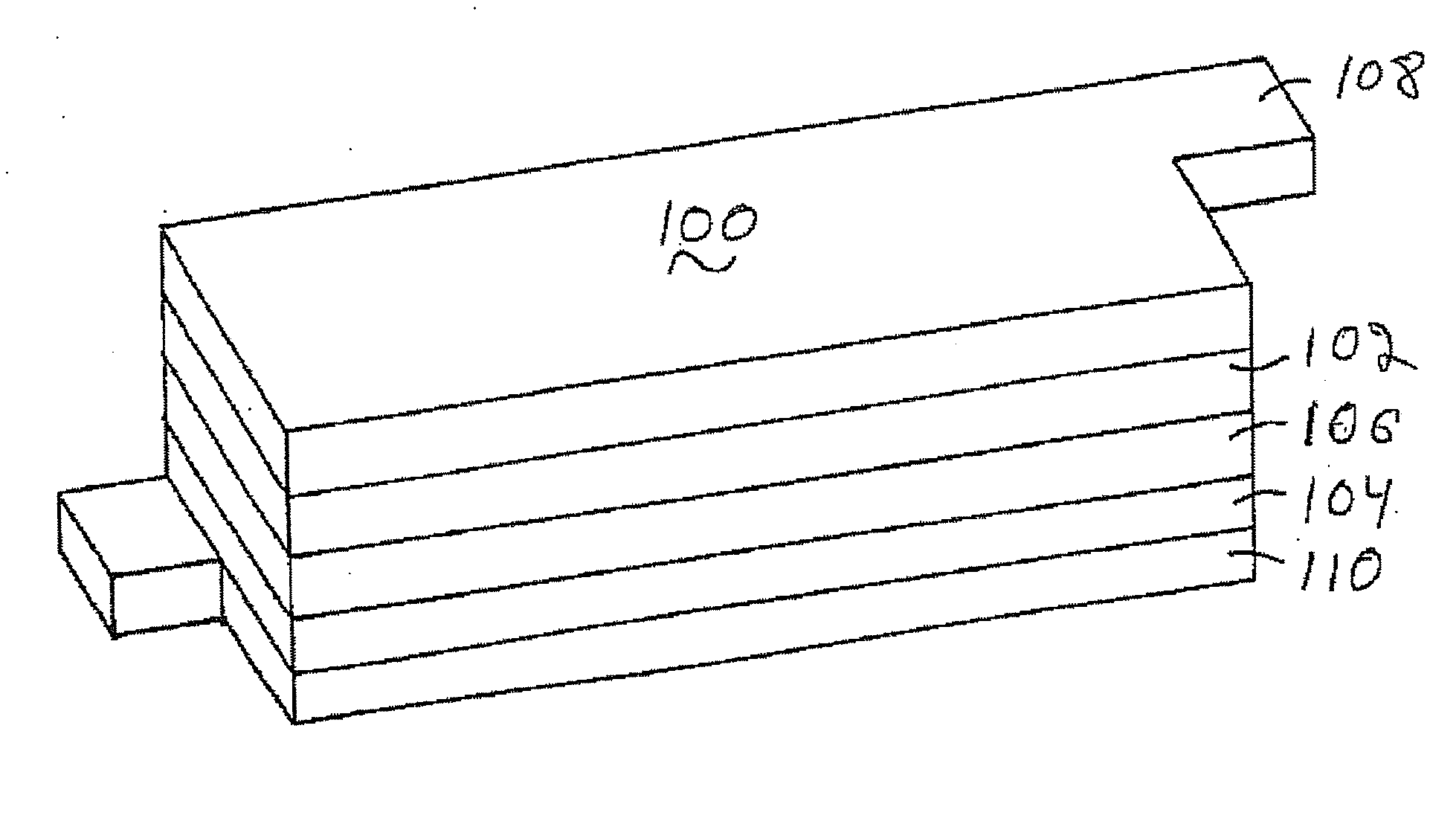

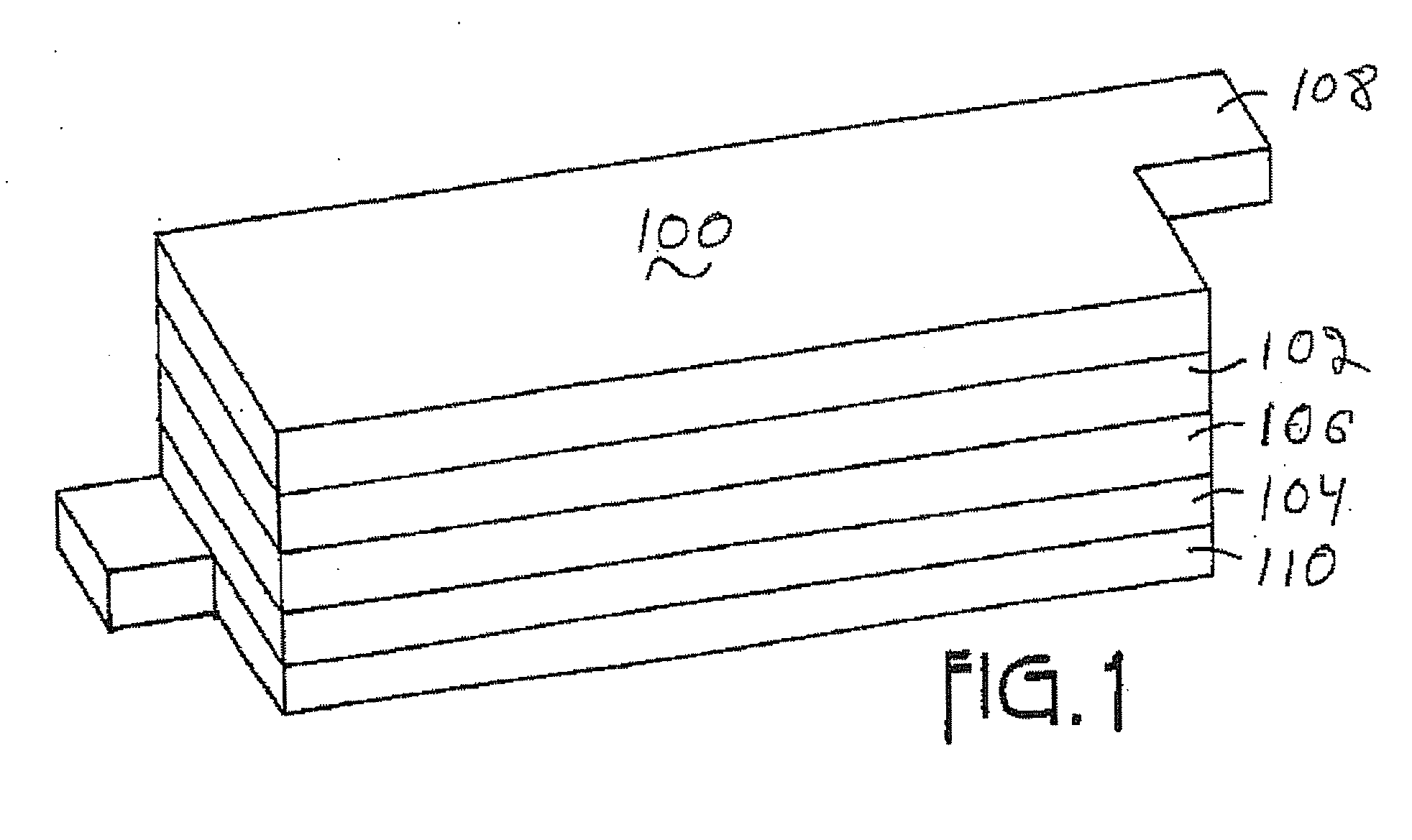

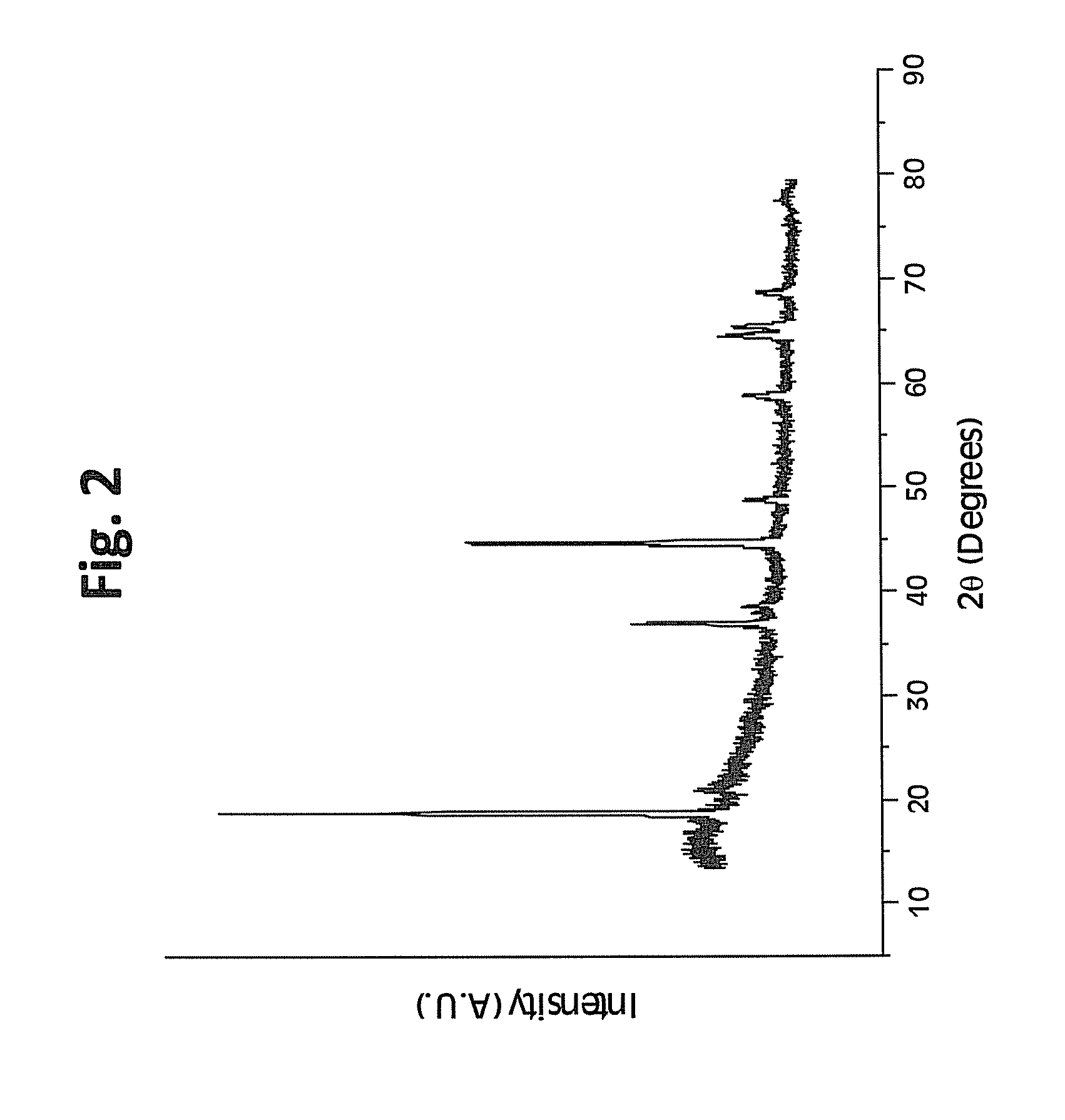

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

Method for evaluating performance states of automotive power batteries

The invention belongs to the technical field of batteries, and particularly relates to a method for evaluating performance states of automotive power batteries. Through performing second-order equivalent circuit modeling on automotive power batteries (including lead-acid batteries, nickel-metal hydride batteries, lithium ion batteries, fuel batteries, super batteries and the like), the performance states of the batteries (a state of charge (SOC) and a state of health (SOH)) are transformed to parameters of an equivalent circuit model. An impulse charging-discharging experiment result of each automotive power battery is handled by using a second-order exponential damping fitting method in Origin software, so that the parameters of equivalent resistance and equivalent capacitance in the power batteries are obtained. A database of the power battery model parameters and the battery performance states is established as the basis of evaluating the performance states of the batteries in an operating process of an automobile, so that the power management can be optimized, problems can be found timely, and accidents are avoided.

Owner:BEIJING UNIV OF TECH

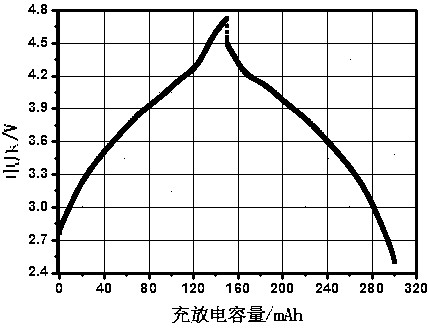

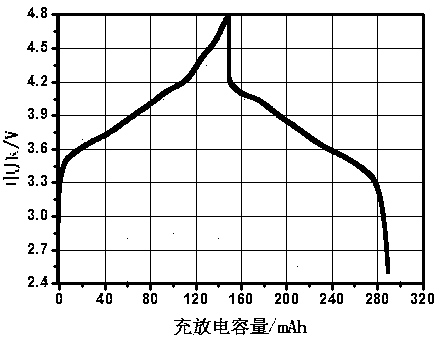

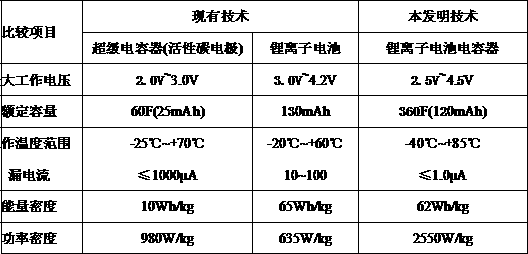

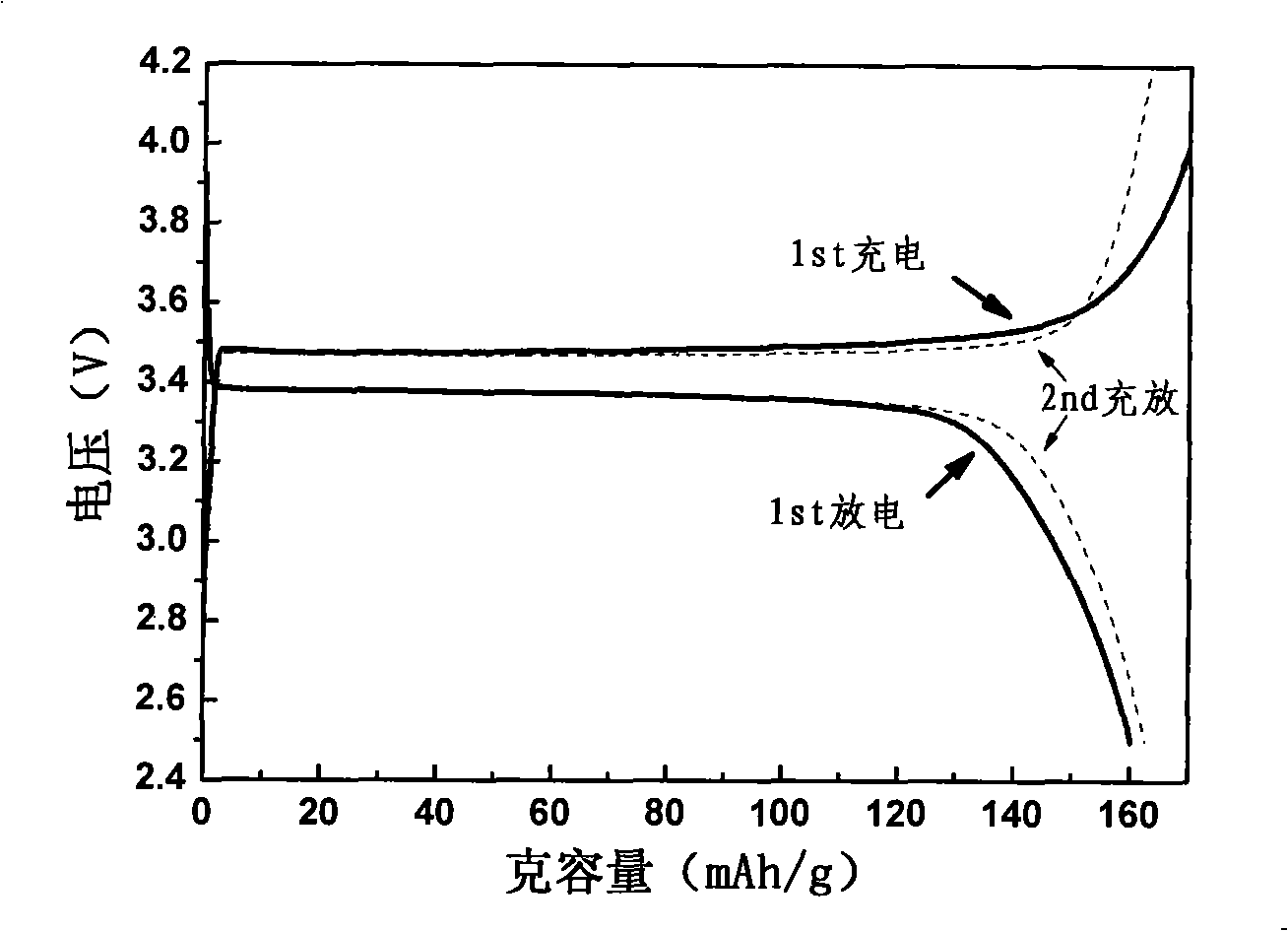

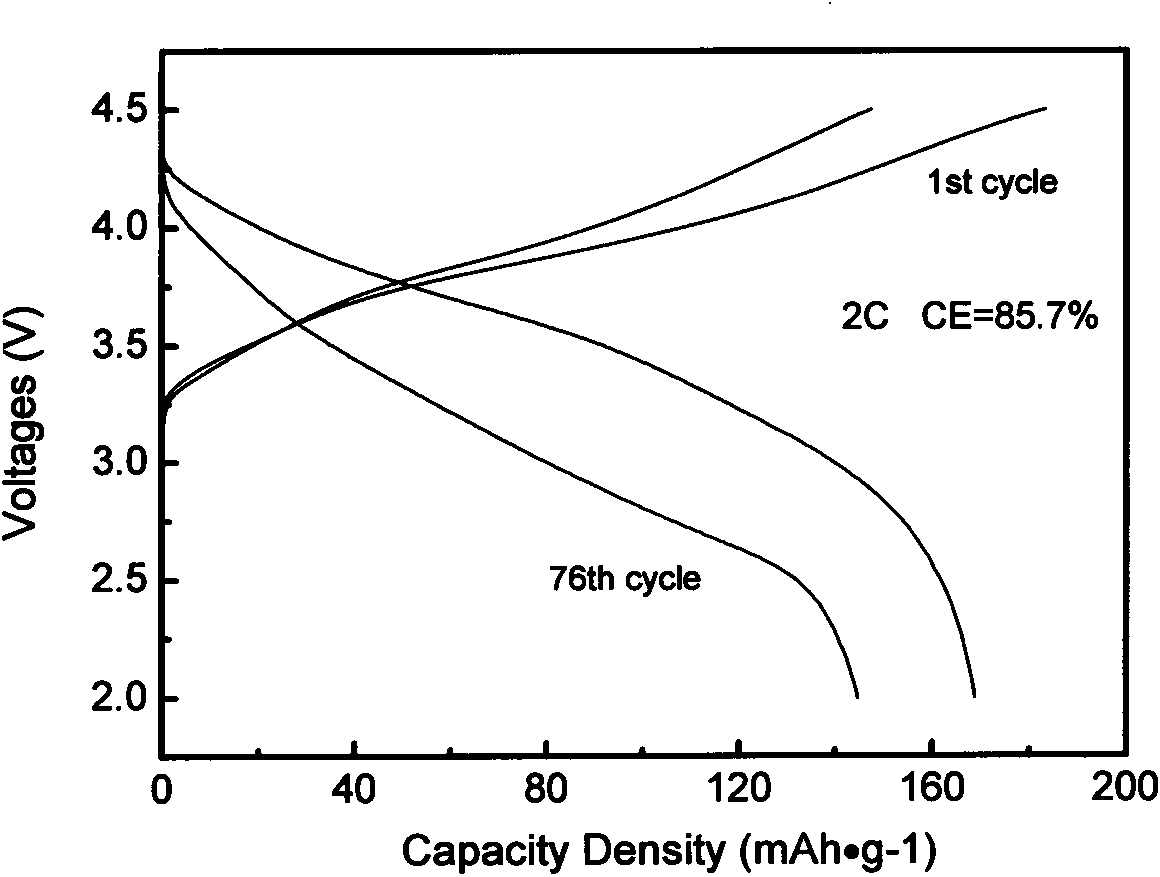

Capacitor of lithium ion battery

InactiveCN103021671ATypical charge and discharge characteristicsHigh energy density characteristicsHybrid capacitor electrolytesHybrid capacitor electrodesHigh energyPhysical chemistry

Owner:EVE ENERGY CO LTD

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

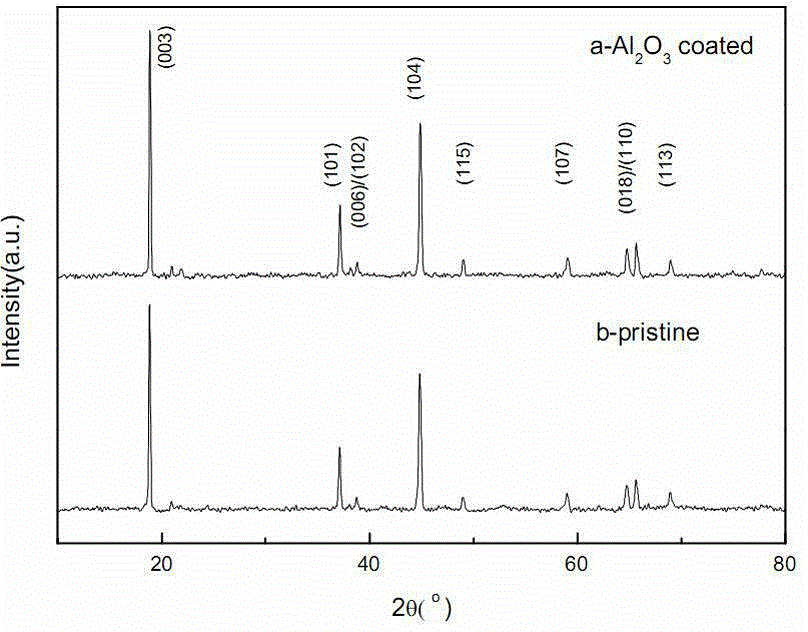

Alumina coating method of lithium ion battery positive electrode material

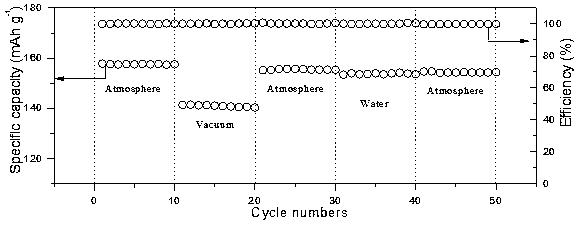

InactiveCN104577128AImprove cycle stabilitySmall capacity attenuationCell electrodesSecondary cellsAir atmosphereLithium-ion battery

Owner:WUXI XINGBO ENERGY TECH

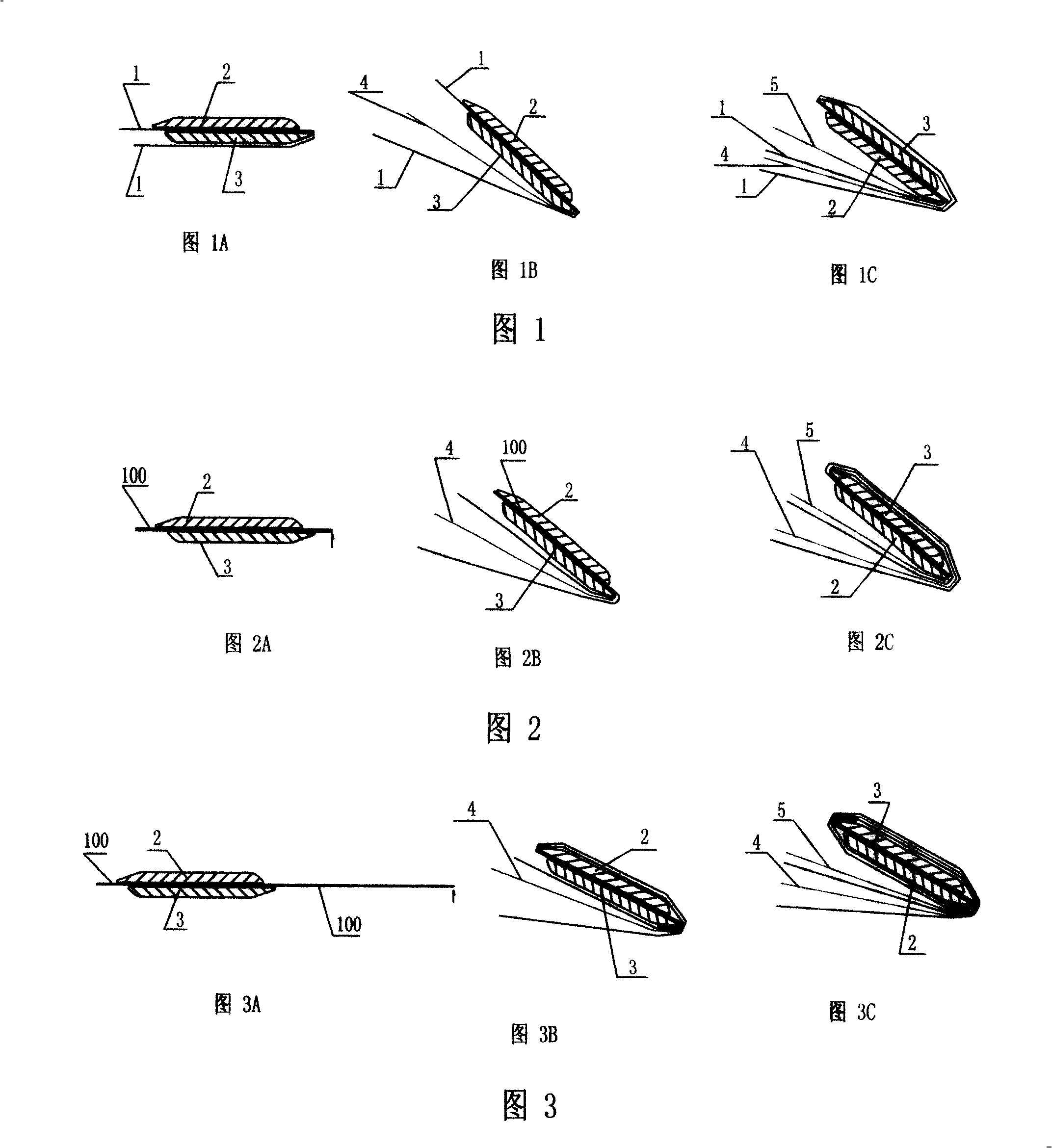

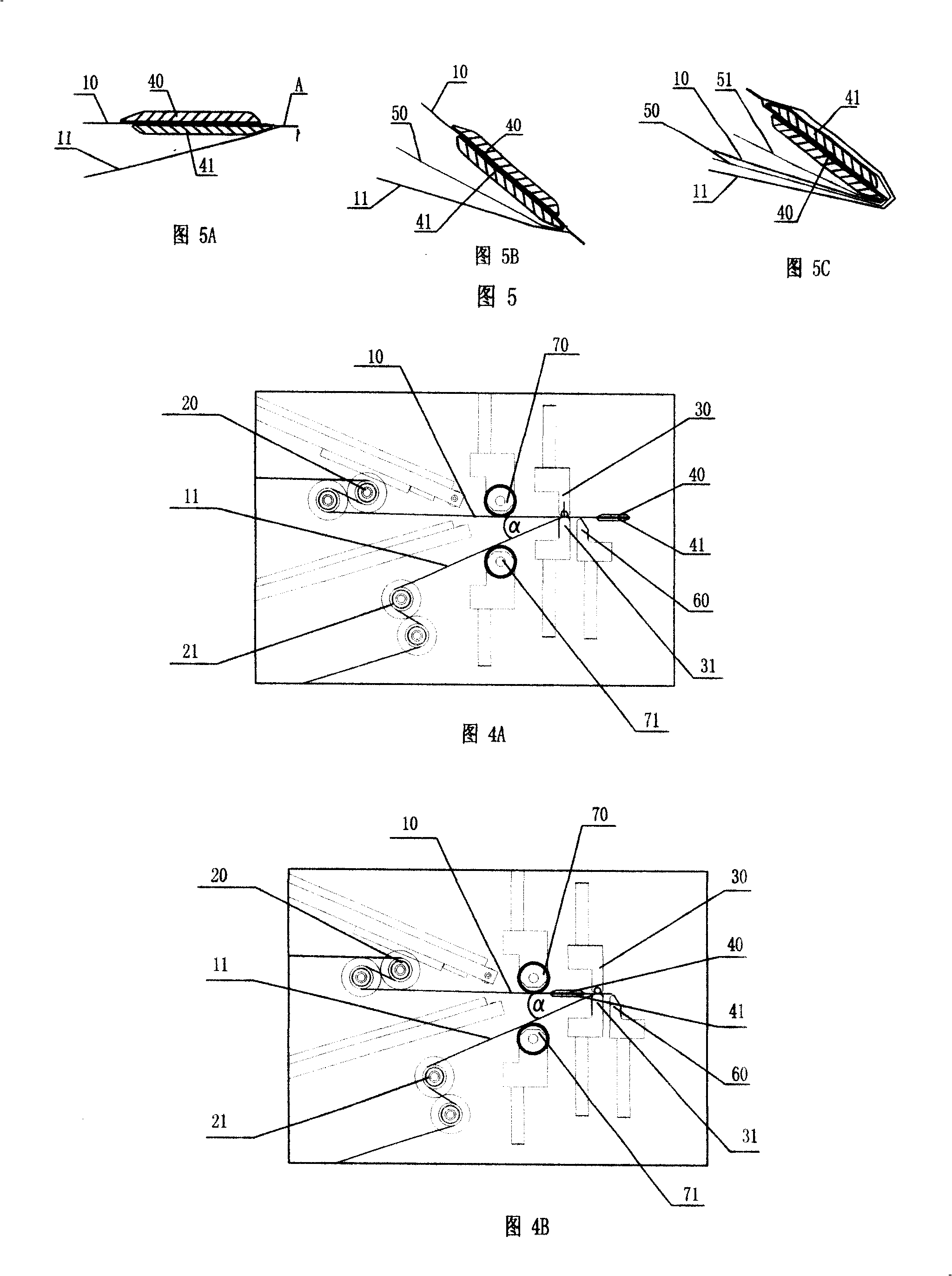

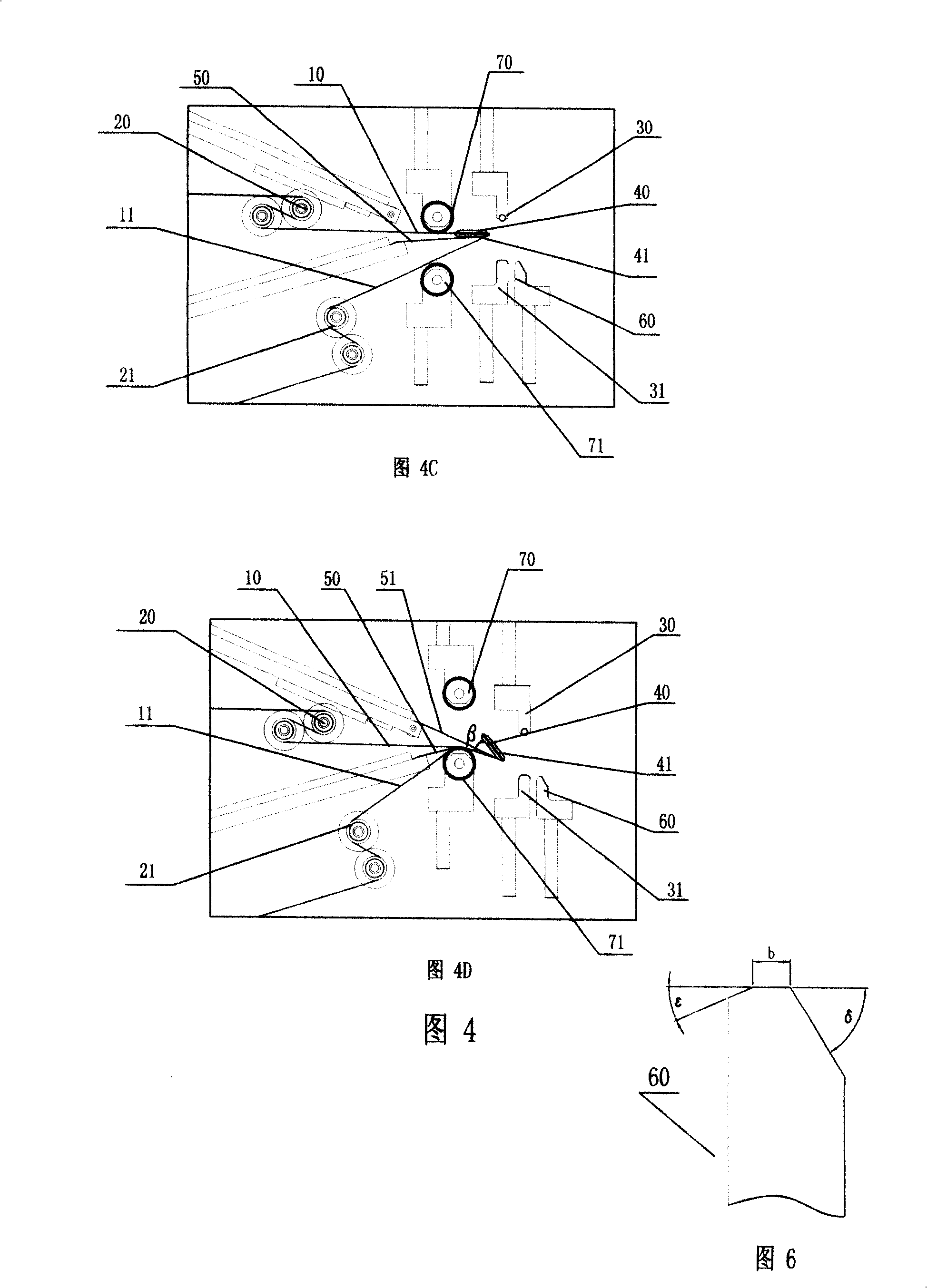

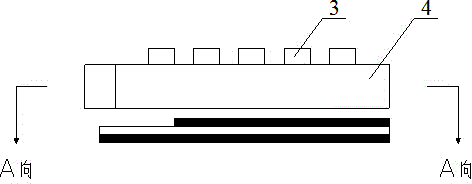

Winding method of lithium ion battery coiled core

ActiveCN101246970AConsistent tensionGuaranteed reliabilityFinal product manufactureSecondary cellsSemi automaticEngineering

Owner:GEESUN AUTOMATION TECH

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

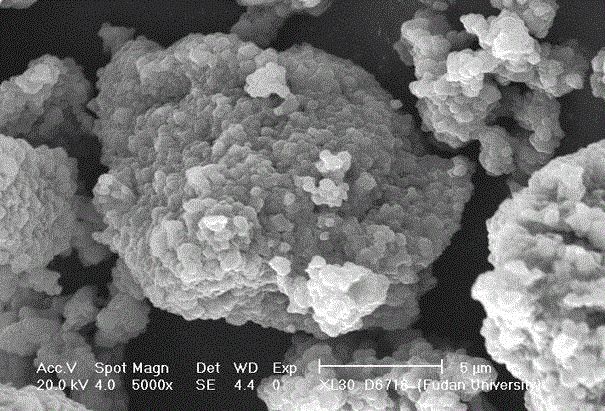

Preparation method of positive electrode material of lithium-ion battery

InactiveCN106207167AObvious lamellar structureUniform sizeElectrode manufacturing processesSecondary cellsUltrasonic cavitationLithium-ion battery

The invention discloses a preparation method of a positive electrode material of a lithium-ion battery. The method comprises the specific steps of dropwise adding a metal salt solution and a mixed solution of a precipitant and a complexing agent to a surfactant solution; controlling a pH value and a temperature under a synergistic effect of an inert atmosphere, ultrasonic cavitation and stirring dispersion until the metal salt solution is dropwise added; carrying out spray drying and roasting to obtain a spherical product, mixing the spherical product with a lithium source and roasting the mixture again to obtain the positive electrode material of the lithium-ion battery. The crystalline morphology can be effectively controlled by using a surfactant; the early synthesized material has an obvious sheet structure; particles agglomerated by a spray-dried product are uniform in size; a foundation is laid for later roasting to obtain the spherical particles with uniform sizes; and meanwhile, another foundation is laid for a relatively good morphology of the final product positive electrode material.

Owner:KUNMING UNIV OF SCI & TECH

Method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries

InactiveCN111690813AStrong penetrating powerPromote leachingWaste accumulators reclaimingProcess efficiency improvementEnvironmental engineeringLithium-ion battery

The invention discloses a method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries and relates to the technical field of comprehensive recovery and utilization of waste lithium ion battery materials. The method comprises the following steps that firstly, the waste lithium ion battery materials are added into eutecticevaporate solvent, ultrasonic oscillation is carried out on the condition of 20 DEG C-40 DEG C, and standing is carried out; and secondly, slurry obtained after ultrasonic treatment is filtered, and separated to obtain a leaching solution containing the valuable metal. The method has the beneficial effects that the eutecticevaporate solvent is adopted for leaching the valuable metal in the waste lithium ion batteries, ultrasonicwaves are adopted for treating a solution obtained after the eutecticevaporate solvent and the waste lithium ion battery materials are mixed, by means of the cavitation effect of the ultrasonic waves,penetrating power of the eutecticevaporate solvent can be increased, the eutecticevaporate solvent can leach out the valuable metal in the waste lithium ion battery materials in a reinforced manner,and thus the leaching efficiency and the leaching rate of the valuable metal in the waste lithium ion battery materials can be improved greatly.

Owner:NANCHANG HANGKONG UNIVERSITY

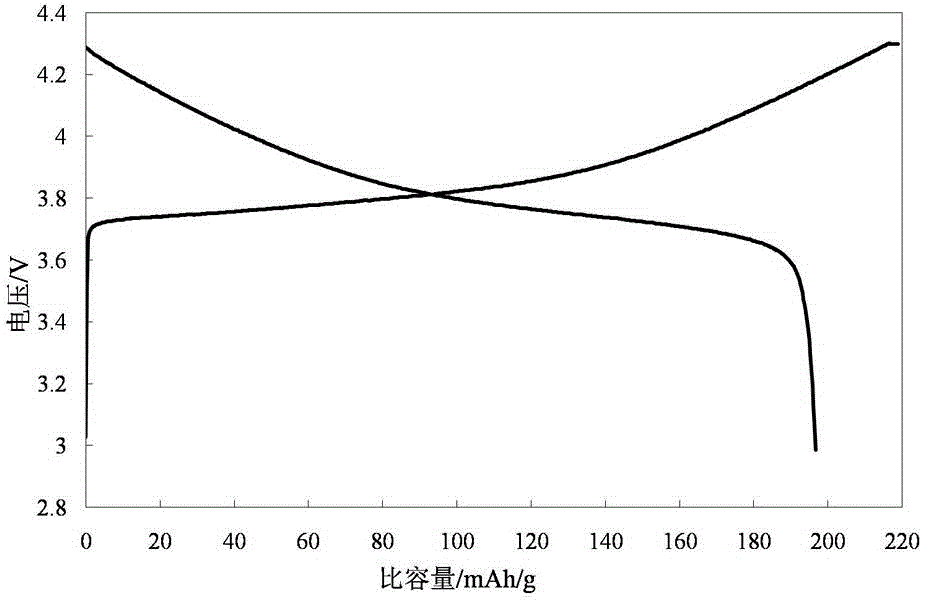

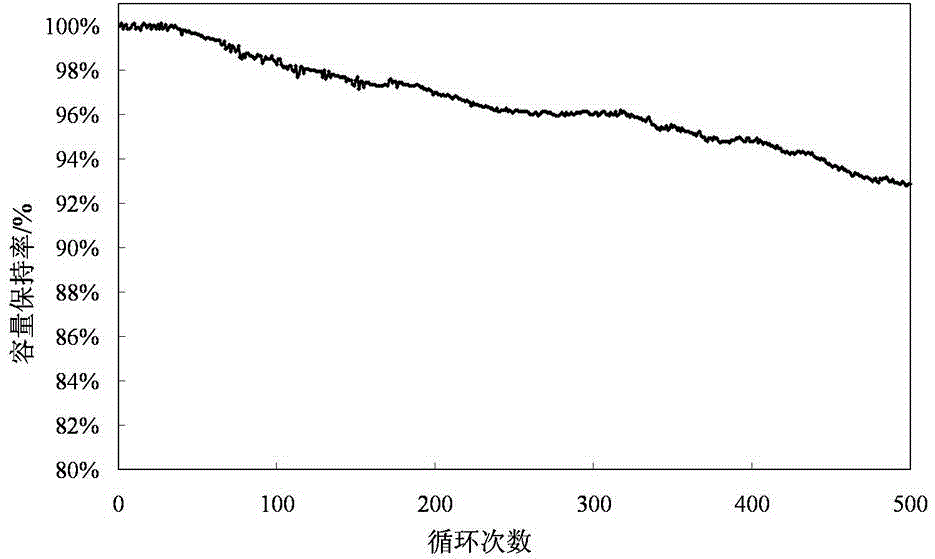

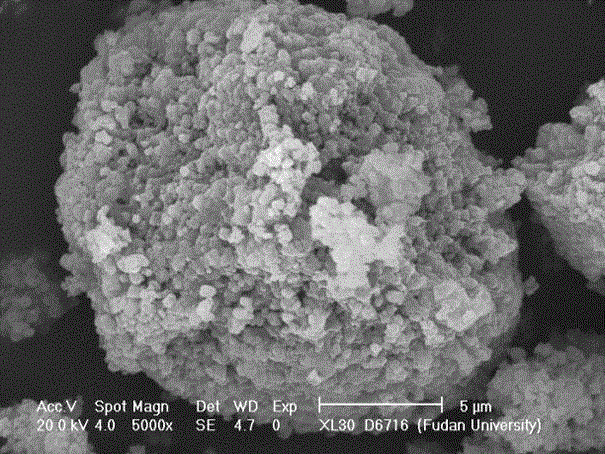

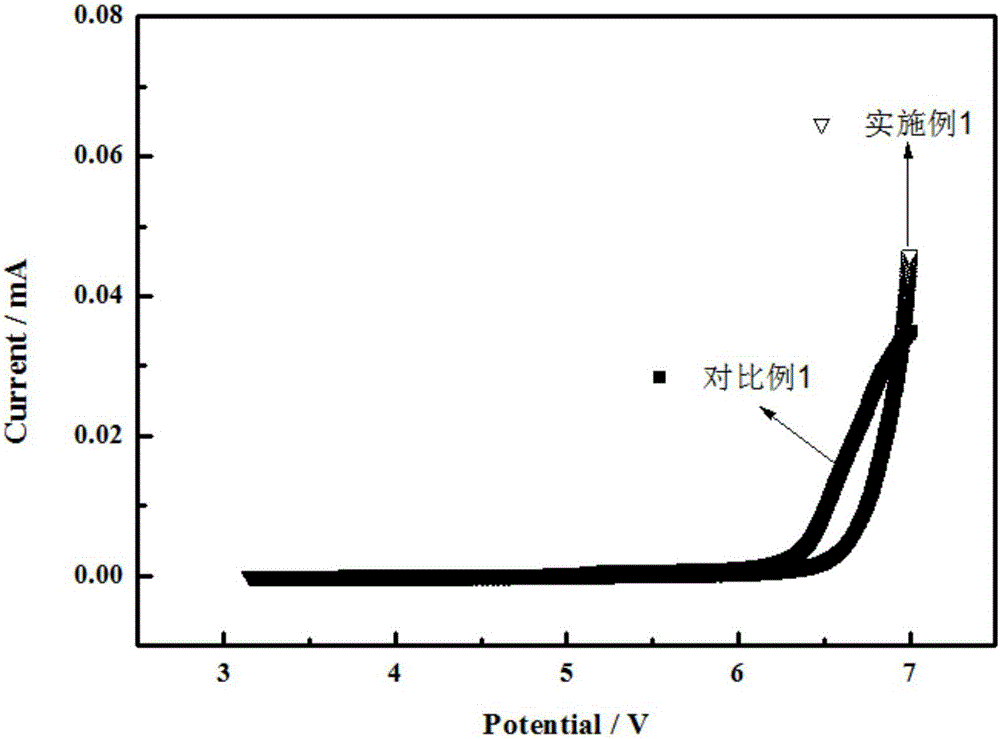

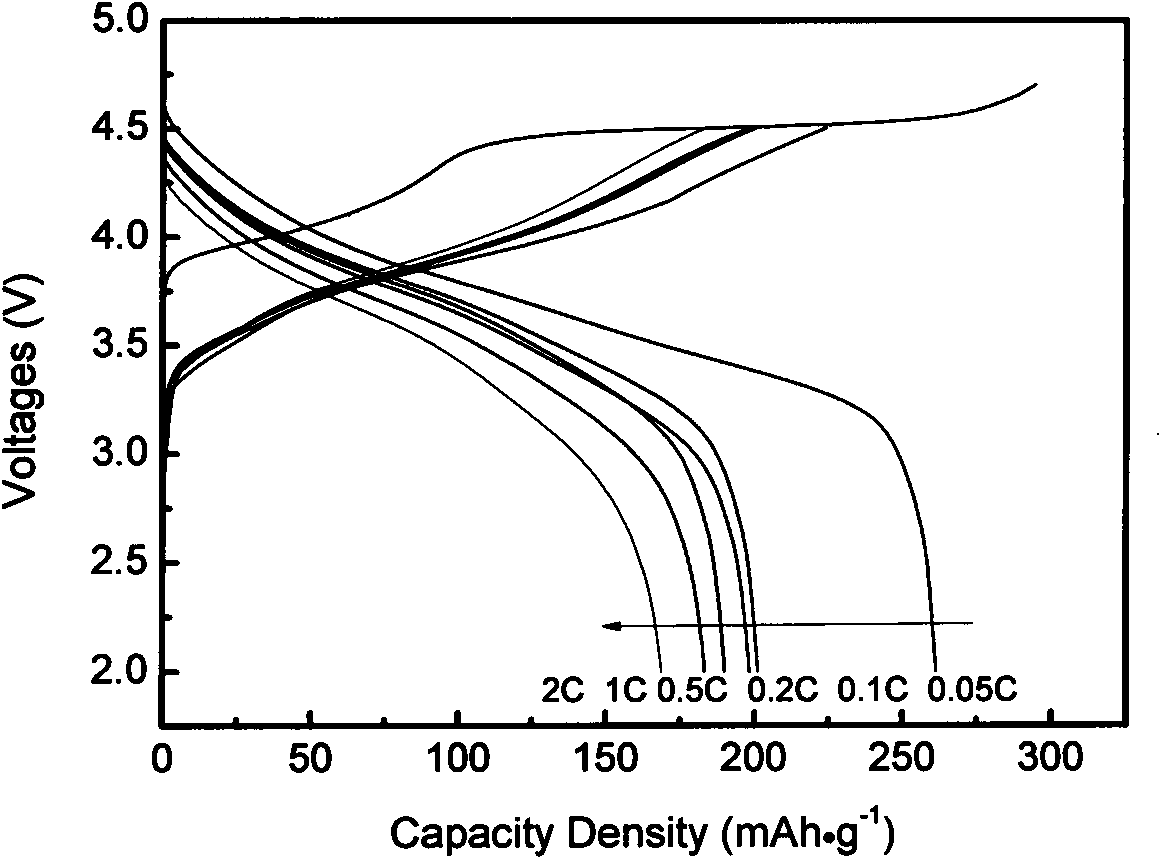

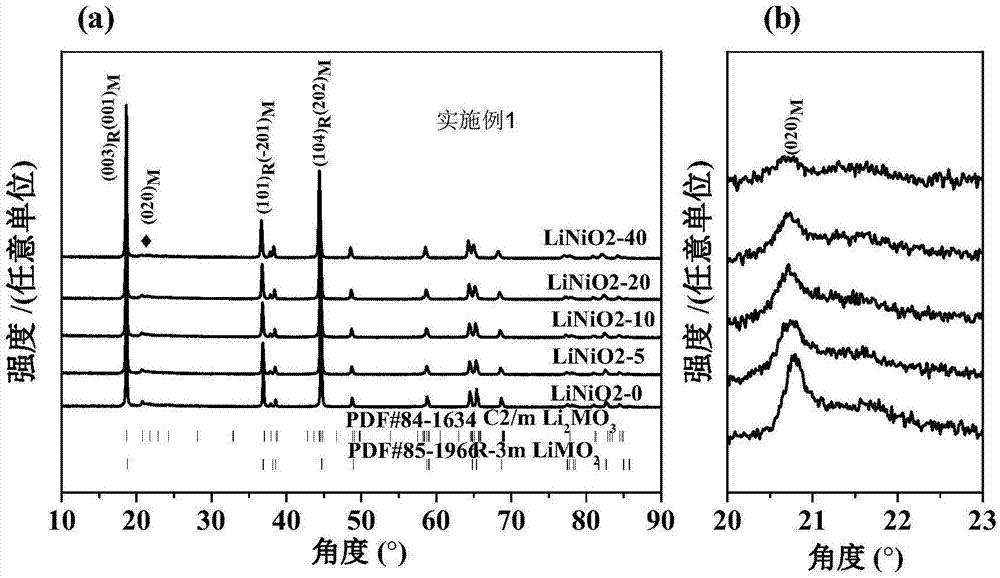

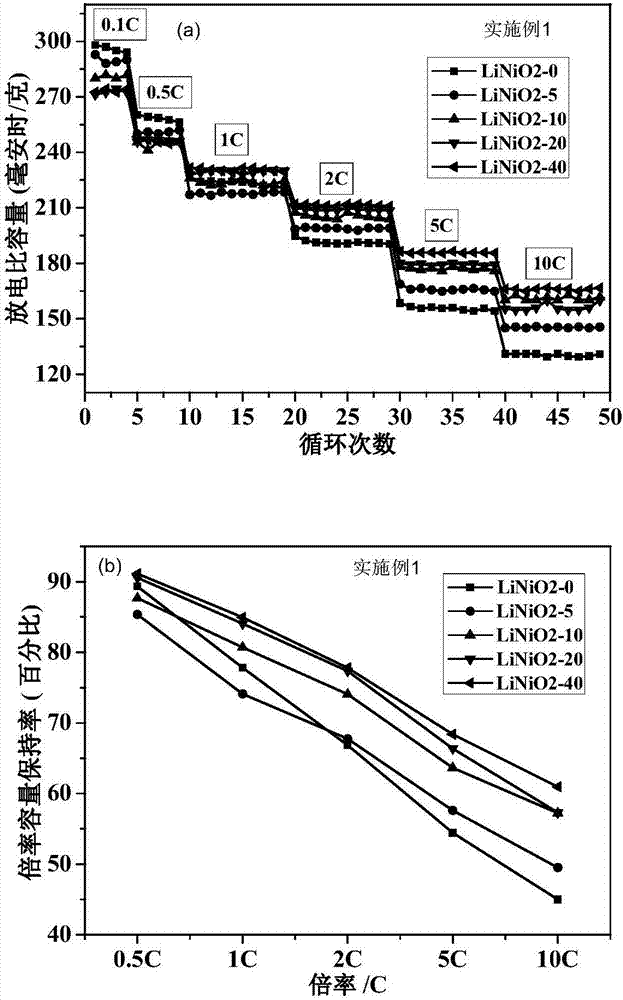

LiAlO2 coated LiNi1-xCoxO2 lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105185954AImprove thermal stabilityGood discharge specific capacityCell electrodesSecondary cellsPower batteryElectrical battery

The present invention belongs to the field of lithium-ion batteries, and provide a modified lithium-ion battery positive electrode material LiNi1-xCoxO2@LiAlO2 with high thermal-stability LiAlO2 coated on the LiNi1-xCoxO2 surface, and a preparation method thereof. A purpose of the present invention is to overcome the disadvantages of overcharging intolerance and pool thermal-stability of the lithium-ion battery LiNi1-xCoxO2 (x is more than 0 and is less than or equal to 0.5) positive electrode material. According to the present invention, the positive electrode material of the present invention has characteristics of good thermal-stability, good discharge specific capacity and excellent cycle stability compared with the LiNi1-xCoxO2 positive electrode material, can meet the large rate charge and discharge requirements, and is especially suitable for the positive electrode material of the electric vehicle power battery; and the product prepared through the preparation method has characteristics of high purity, high chemical uniformity, good coating effect, high crystal quality, fine particle, uniform distribution, excellent electrochemical performance and low manufacturing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for improving low-temperature performance of lithium iron phosphate anodic material for lithium batteries and lithium batteries

InactiveCN101958416ASecondary cellsNon-aqueous electrolyte accumulator electrodesLithium vanadium phosphate batteryLithium-ion battery

Owner:FULLYMAX BATTERY CO LTD

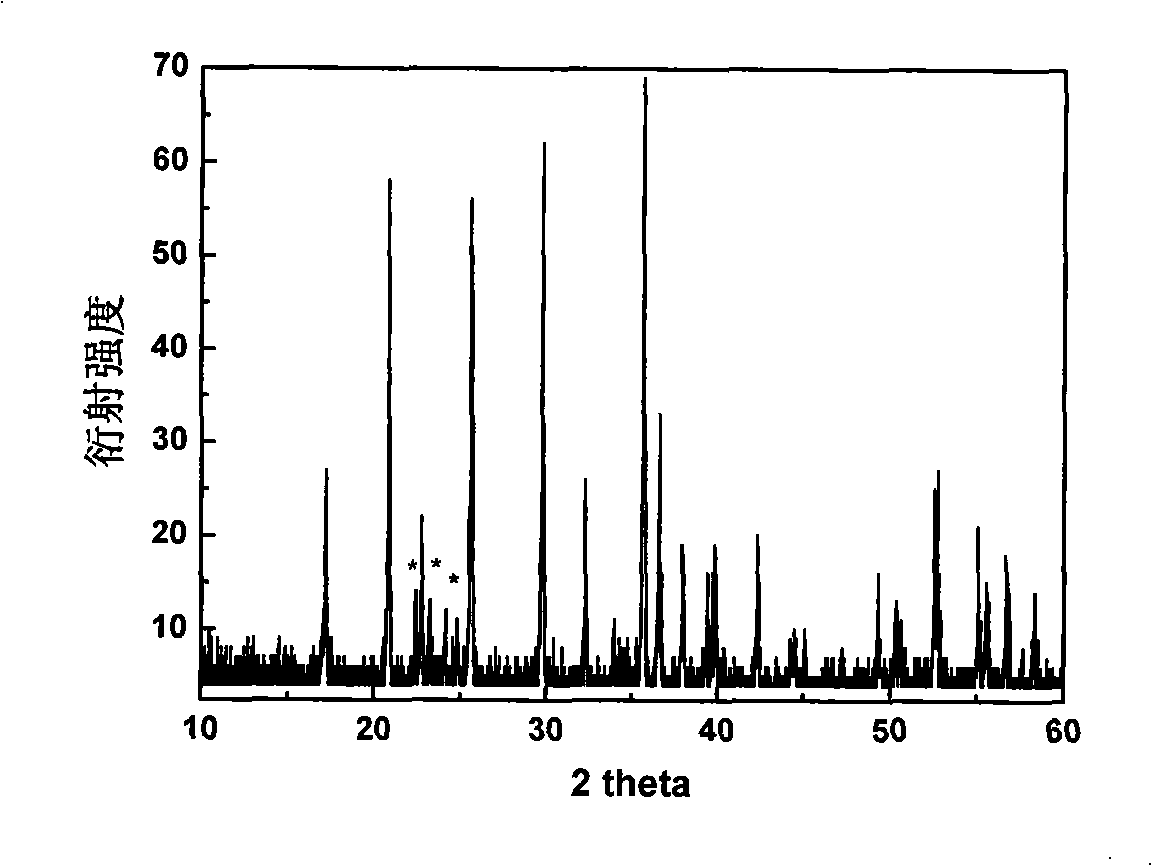

Compound phosphate type positive material of lithium ionic cell and method for making same

ActiveCN101284658AGood electrochemical propertiesImprove electrochemical performanceCell electrodesPhosphorus compoundsPhosphateReducing atmosphere

Owner:龚思源

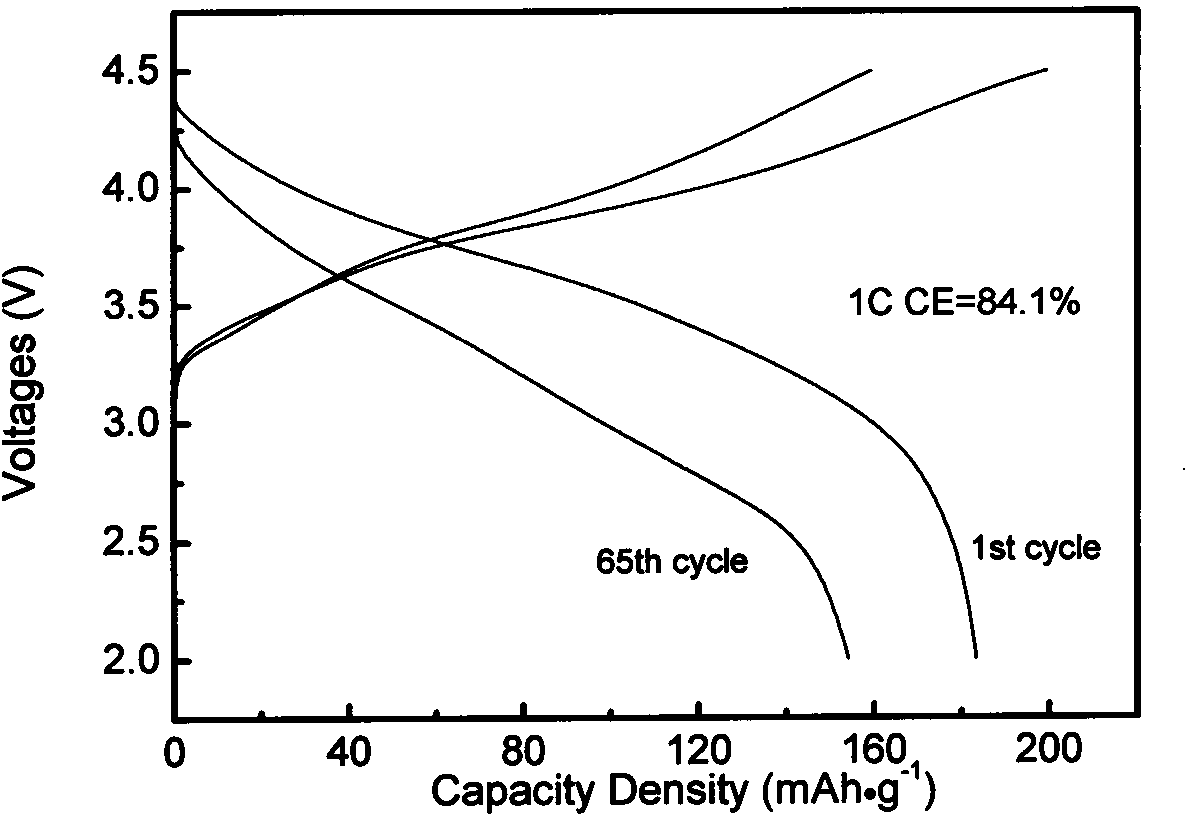

Modified lithium-rich manganese-based cathode material for lithium ion battery

ActiveCN103682290AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesManganeseStrontium

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Solid-state electrolyte, lithium battery cell and lithium battery

InactiveCN109935896AImprove interfacial adhesionImprove wettabilityMaterial nanotechnologyFinal product manufactureSolid state electrolyteShear modulus

The invention relates to the field of lithium batteries, in particular to a solid-state electrolyte, a lithium battery cell and a lithium battery. The solid-state electrolyte is an anti-perovskite solid-state electrolyte, and includes one or more super base clusters selected from Li3Se+, Li3S+ and Li3O+ and one or more super halogen clusters selected from BH4-, AlH4-, BF4-, FeH4-, CoH4- and NiH4-.The solid-state electrolyte exhibits a nanowire morphology. Therefore, the solid-state electrolyte has an electrochemical window above 5V and excellent interfacial adhesion, wettability and lithium ion conductivity, and the molecular skeleton of the solid-state electrolyte has good tolerance. Based on the structural characteristics of the solid-state electrolyte, the solid-state electrolyte has the advantages of high shear modulus, high Young's modulus and capability of inhibiting the growth of lithium dendrites.

Owner:CHENGDU DACHAO TECH CO LTD

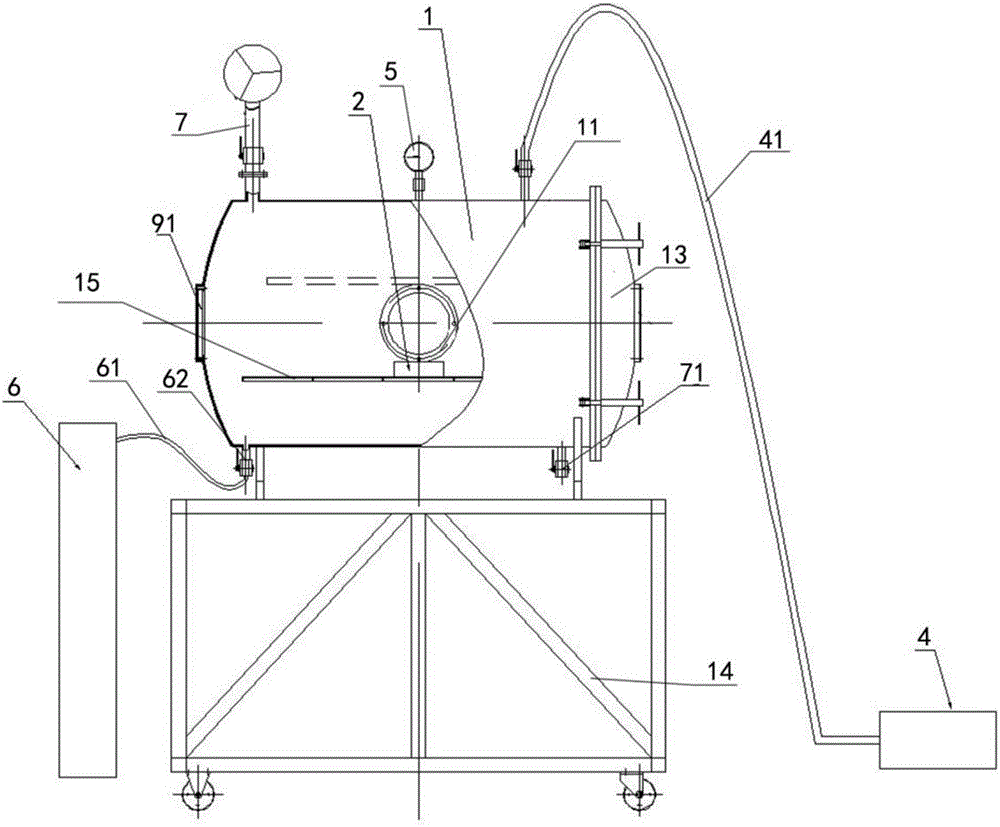

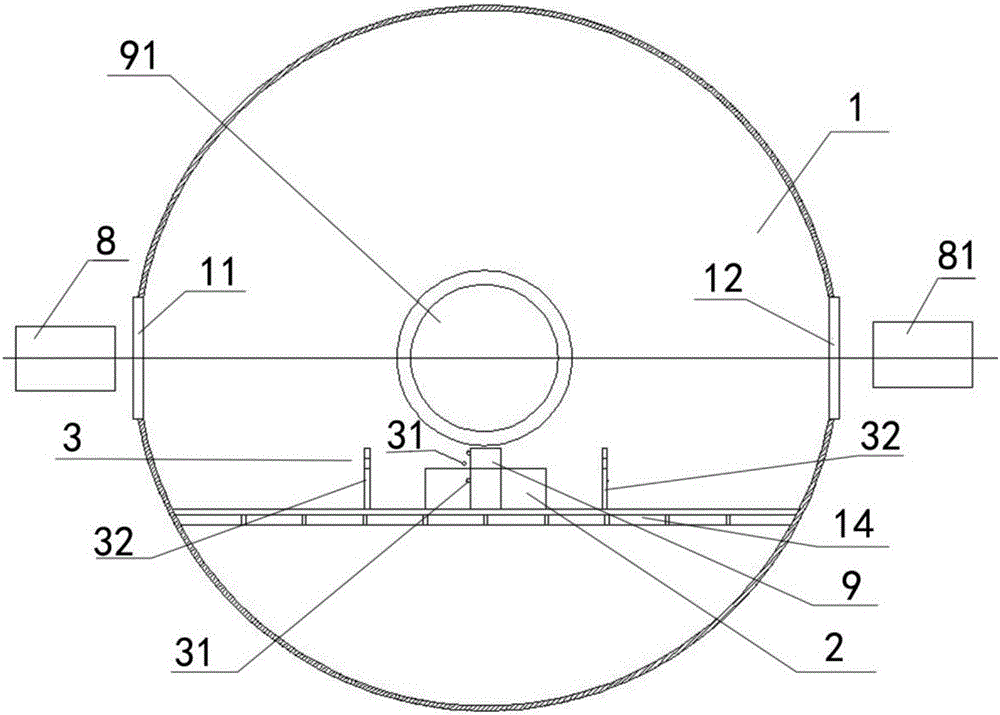

Device and method for detecting environmental parameter in lithium ion battery explosion process

ActiveCN106093779AAccurate collectionAchieve separationElectrical testingElectricityElectrical battery

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

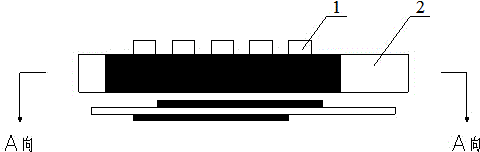

Production method of lithium-ion power battery improving battery consistency

InactiveCN102280665AImprove consistencyTotal weight controlCell electrodesFinal product manufacturePower batteryEngineering

The invention discloses a production method of a lithium ion power battery with consistency improved. According to the invention, anode sheets and cathode sheets are obtained through coating and cutting technologies, and are graded according to the weight of each sheet; a total weight of anode sheets in a single battery is controlled through steps that: a group of anode sheets with a total anode sheet number required by the single battery is weighed, wherein the anode sheets can be selected from a middle weight grade, or can be randomly selected from at least two weight grades; according to ameasured weight, anode sheets in the grade of a larger weight are replaced by anode sheets in the grade of a smaller weight, or anode sheets in the grade of a smaller weight are replaced by anode sheets in the grade of a larger weight; finally, the total weight of the anode sheets is controlled within a required total weight range. With the production technology modification provided by the invention, consistency of the lithium ion power battery is greatly improved, service life of the lithium ion power battery is prolonged, and application safety of the lithium ion power battery is ensured.

Owner:SHANDONG SHANGCUN ENERGY

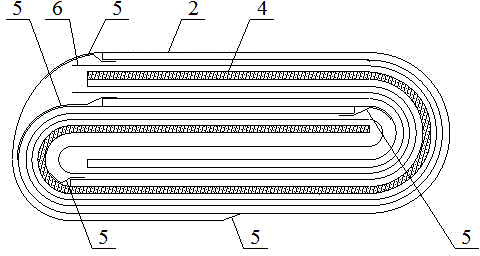

Manufacturing method of winding type lithium ion battery and winding type lithium ion battery

InactiveCN104681878AIncrease productivityImprove securityFinal product manufactureSecondary cellsPower flowInternal resistance

Owner:王文斌

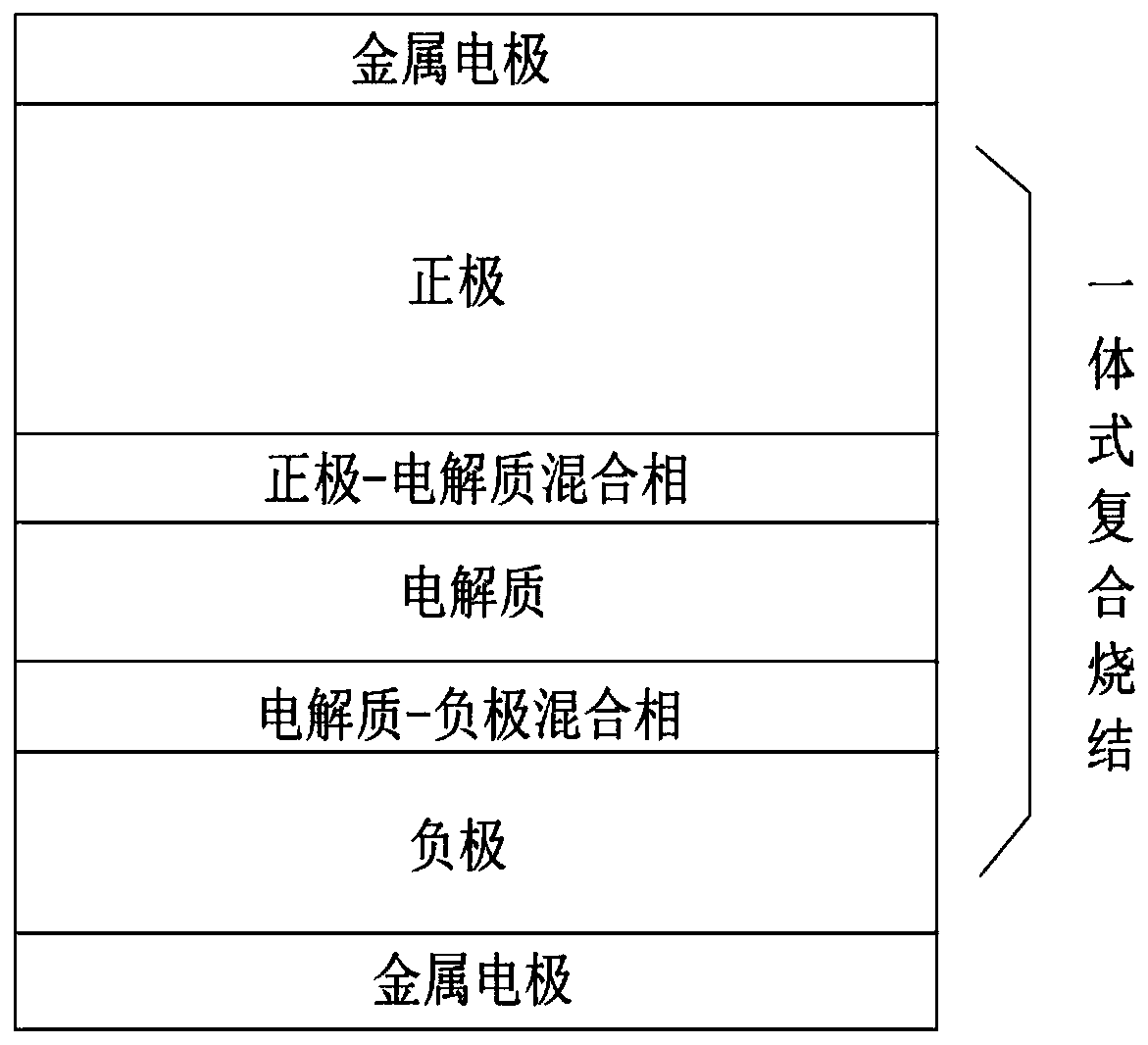

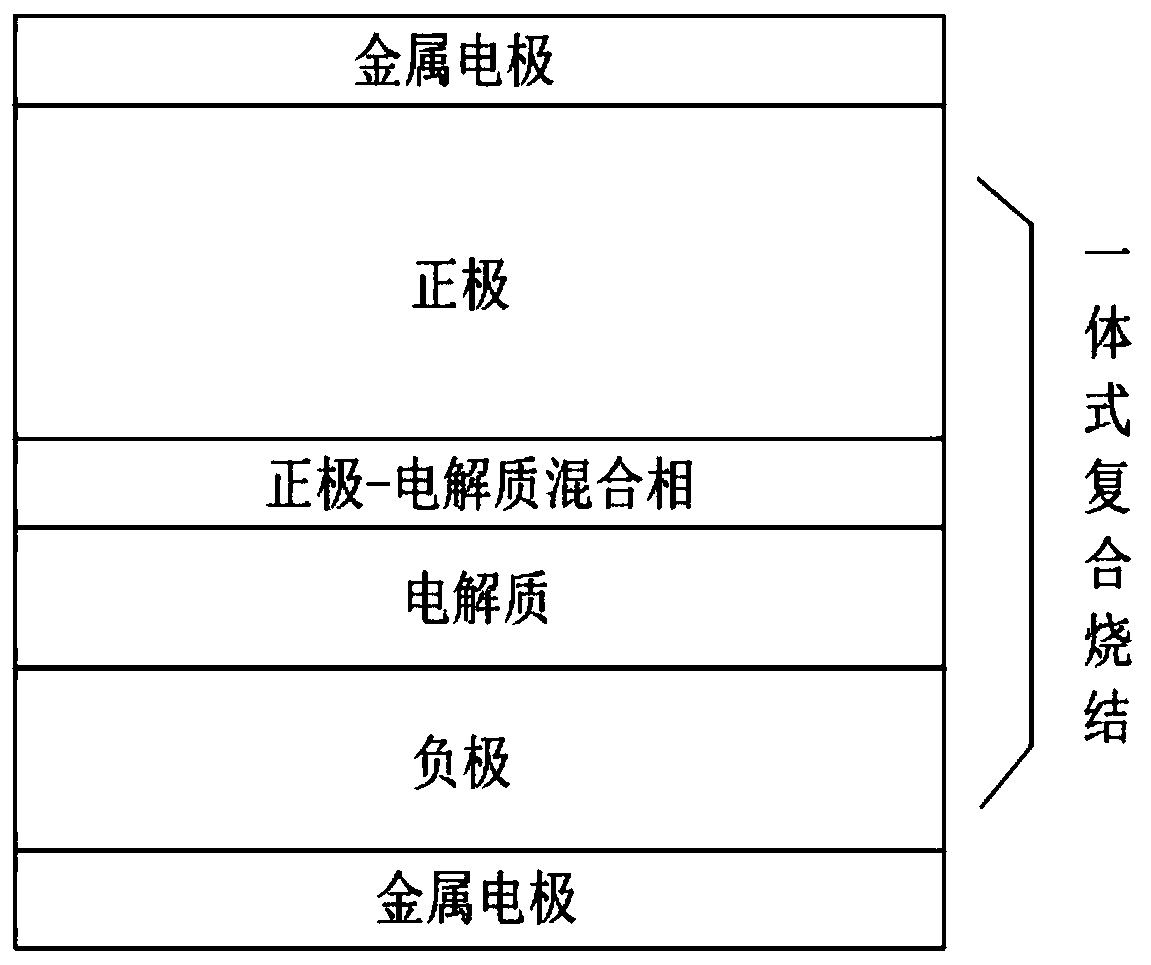

All-solid-state lithium ion battery and integrated composite sintering preparation process thereof

InactiveCN110165286AImprove Interface StabilityEnhanced interfacial transport propertiesFinal product manufactureSecondary cells manufactureLithium oxideSolid state electrolyte

Owner:浙江国能锂业有限责任公司

Flexible lithium-ion battery capable of working around clock and preparation method thereof

ActiveCN108649230AHigh degree of orderImprove electrochemical performanceFinal product manufactureElectrode carriers/collectorsCarbon nanotubeEngineering

Owner:JIANGXI UNIV OF SCI & TECH

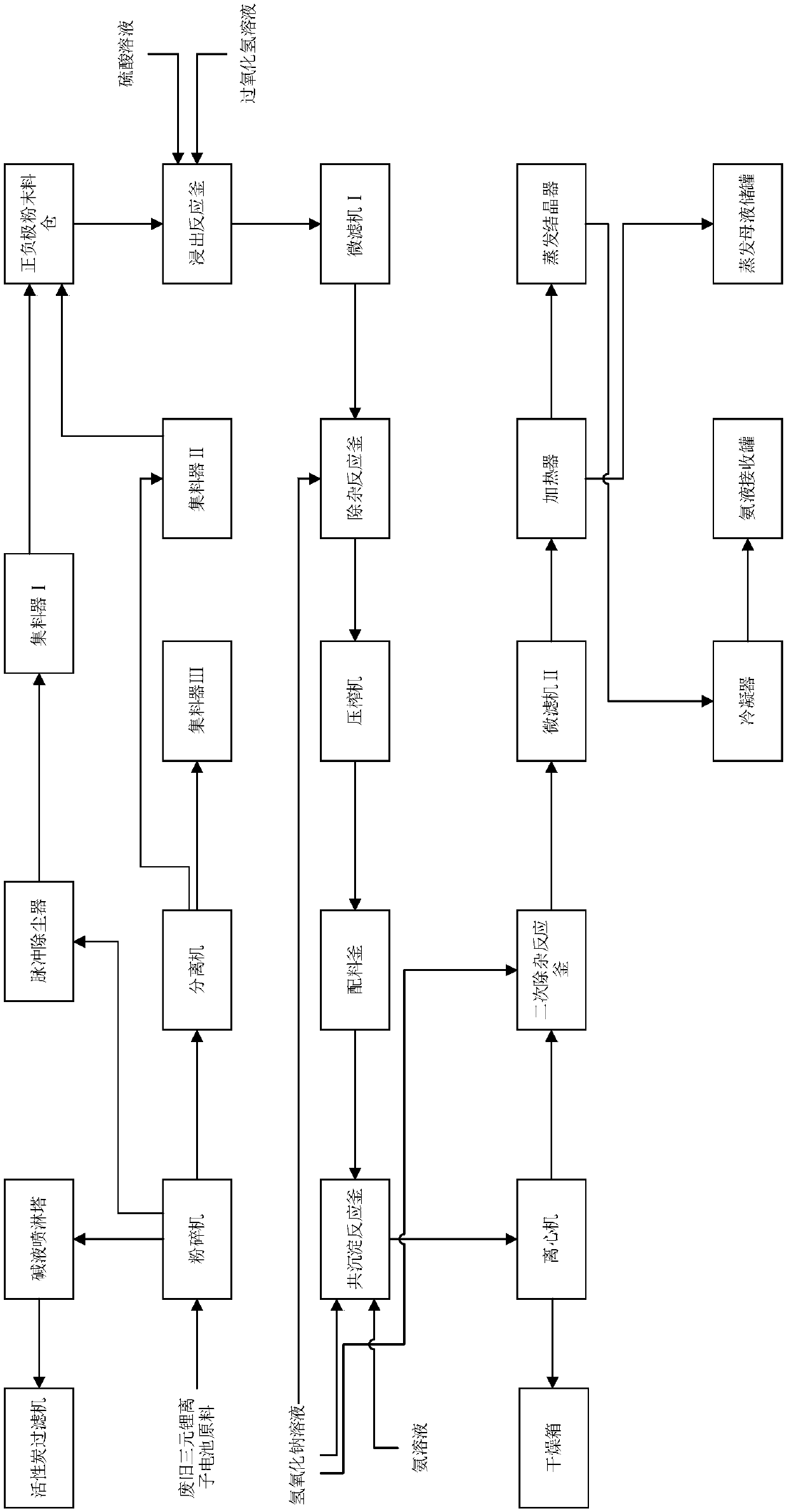

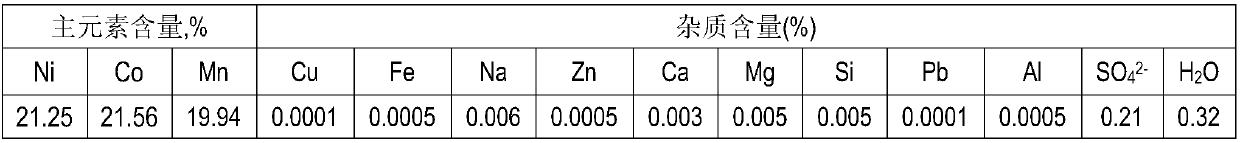

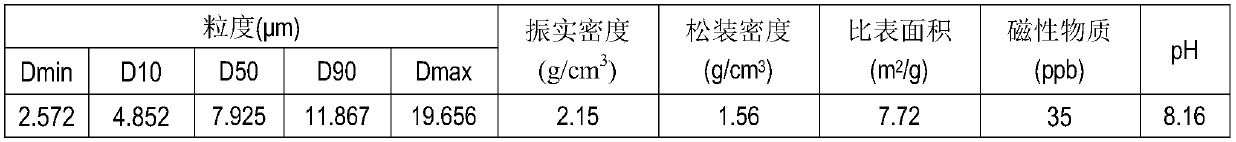

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

Layered lithium-rich manganese oxide positive electrode material suppressing capacity/voltage attenuation during circulation process effectively and preparation method therefor and application thereof

InactiveCN107069026AIncrease energy densityImprove cycle stabilityCell electrodesSecondary cellsCyclic processHigh energy

Owner:ZHEJIANG UNIV

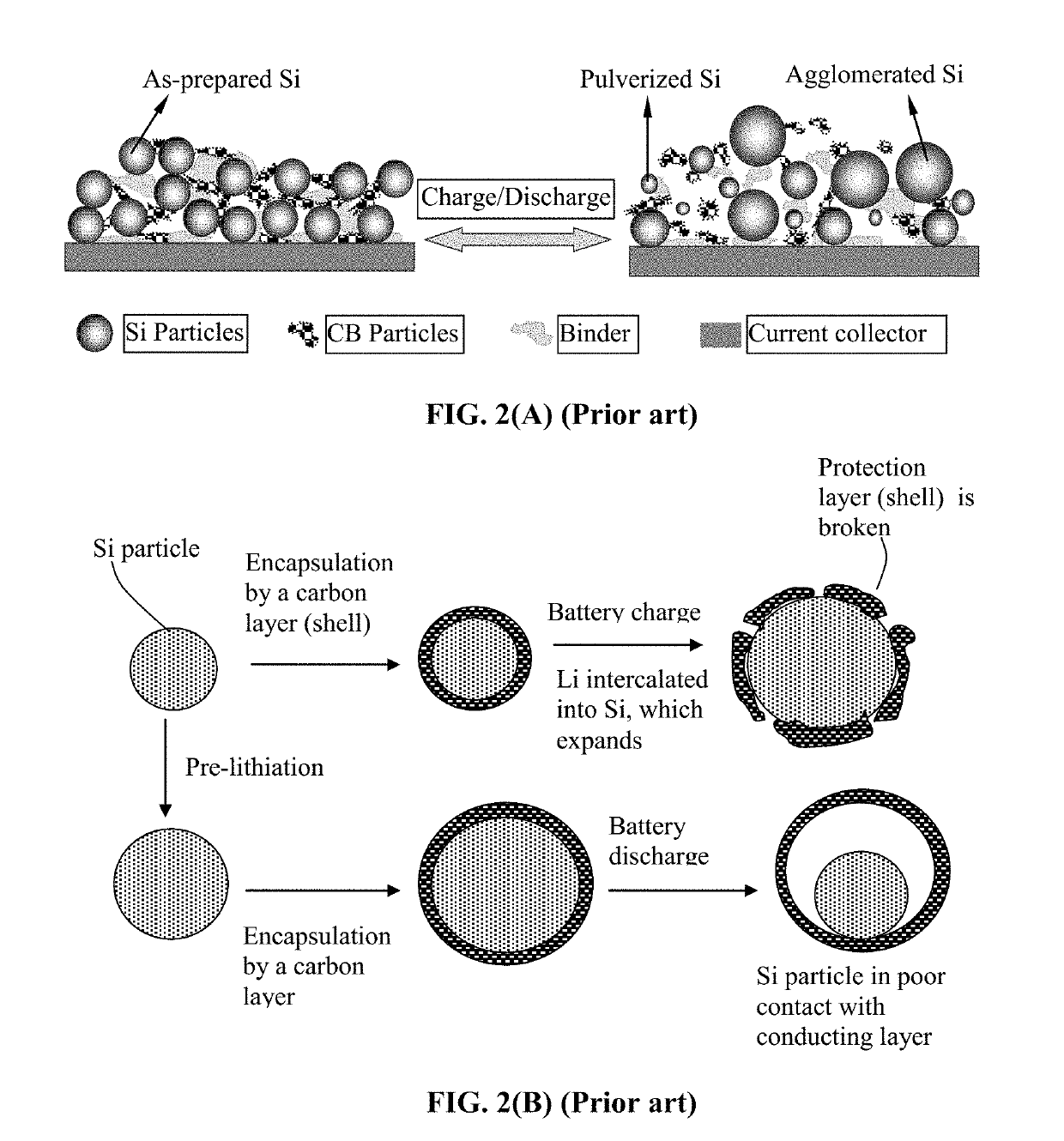

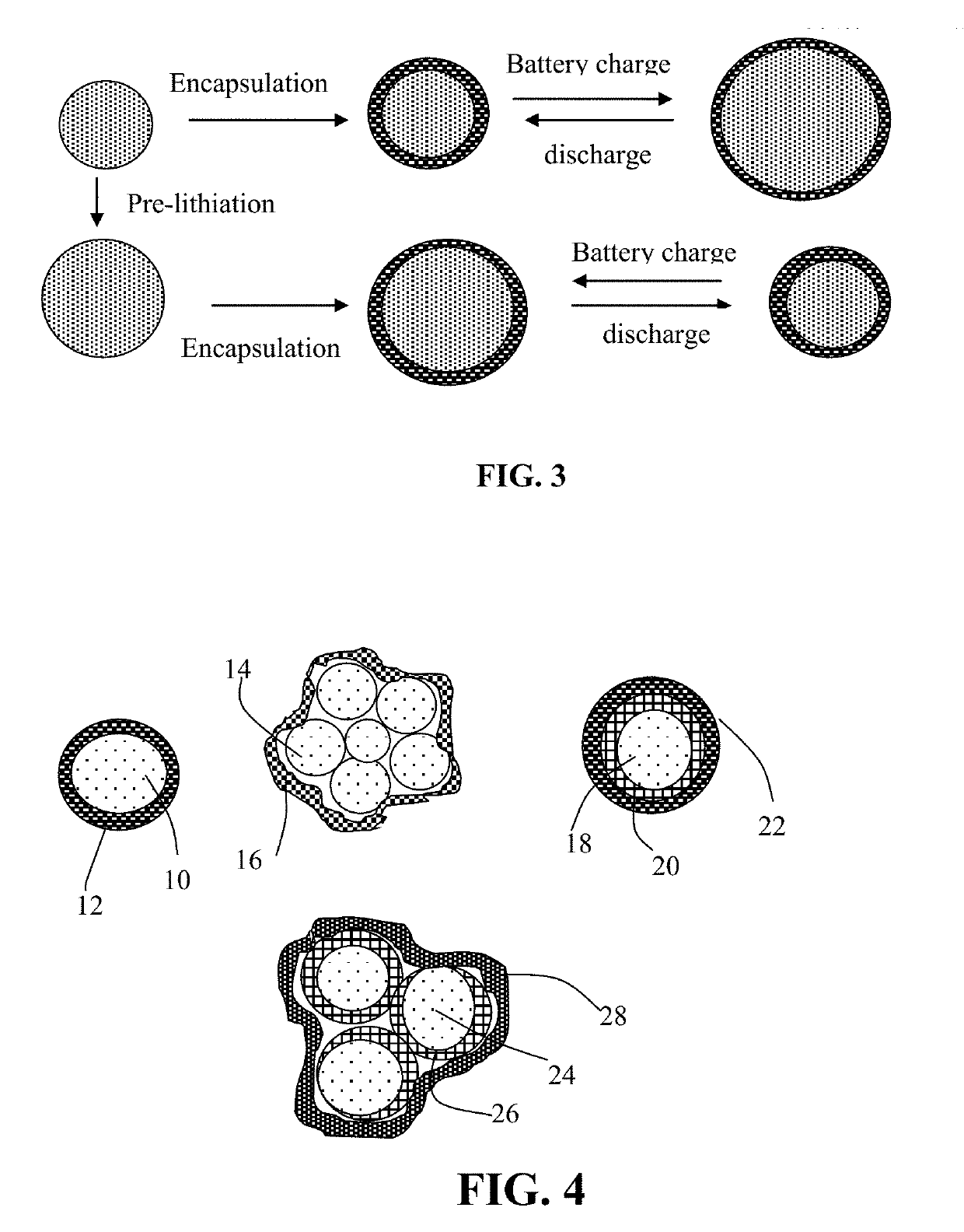

Method of Producing Elastomer Composite-Encapsulated Particles of Anode Active Materials for Lithium Batteries

PendingUS20190267663A1Easy to packFaster lithium ion transportNegative electrodesSecondary cellsParticulatesLiquid medium

Owner:GLOBAL GRAPHENE GRP INC

Positive Electrode Active Material for Lithium Secondary Battery

Provided is a novel positive electrode active material which can effectively suppress the quantity of gas generated by the reaction with an electrolytic solution. Proposed is a positive electrode active material for a lithium secondary battery including positive electrode active material particles obtained by equipping the entire surface or a part of a surface of lithium manganese-containing composite oxide particles (also referred to as the “core particles”) operating at a charging voltage in a region exceeding 4.3 V in a metal Li reference potential with a layer A containing at least titanium (Ti), aluminum (Al), zirconium (Zr), or two or more kinds of these.

Owner:MITSUI MINING & SMELTING CO LTD

Lithium secondary battery possessing stress relaxation layer

InactiveCN102420339AImprove cycle lifeFinal product manufactureElectrode carriers/collectorsAdhesiveEngineering

The invention provides a high-capacity lithium secondary battery which relaxes the stress on the electrode to prevent the falling or loosing of the electrode. The degradation of the lithium secondary battery caused by the charging-discharging circulation is not serious. The lithium secondary battery includes a winding group which is formed by winding the anode and the cathode together, and a baffle plate is arranged between the anode and the cathode. The anode and the cathode can absorb and discharge lithium ions reversibly. The lithium secondary battery also includes an organic electrolyte solution which dissolves the electrolytes containing the lithium ions. The cathode s formed by coating an agent-mixed layer which contains an active material and an adhesive on a collector electrode. The collector electrode is formed by arranging the stress relaxation layer possessing the inner stress on at least one side of a surface or the back of a copper foil.

Owner:HITACHI LTD

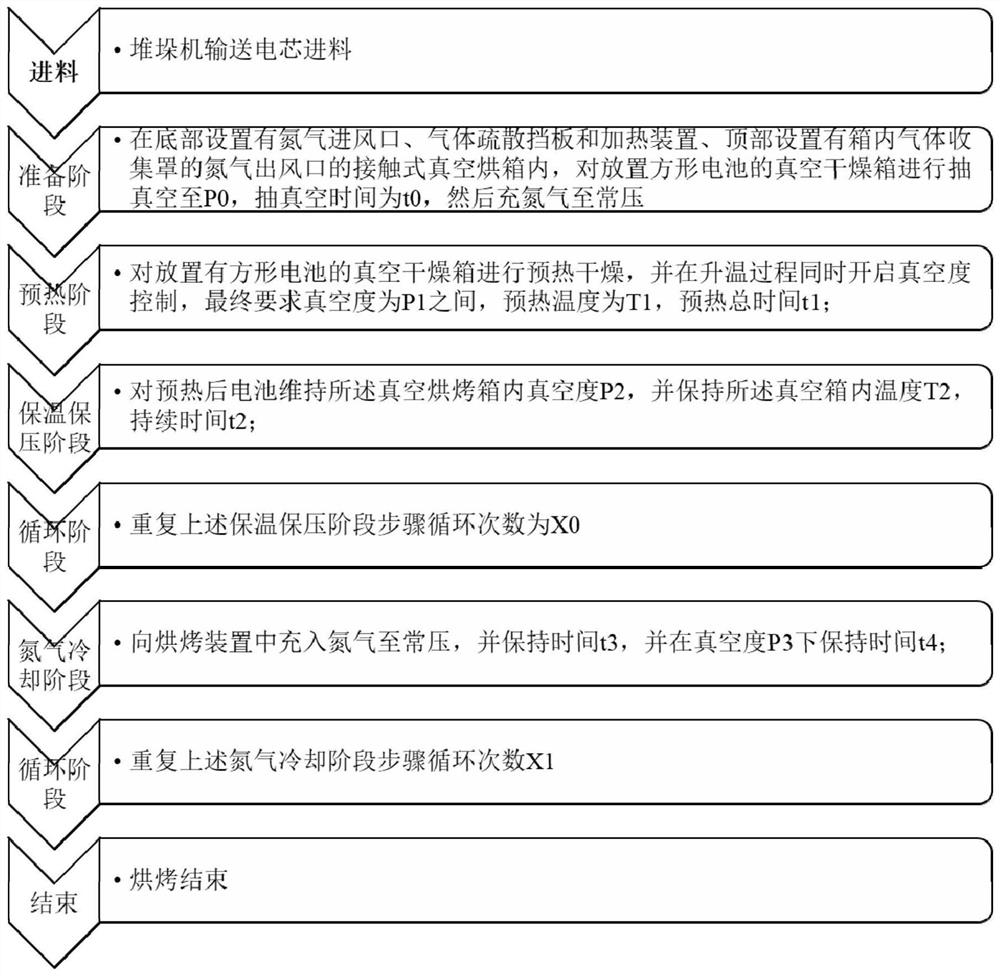

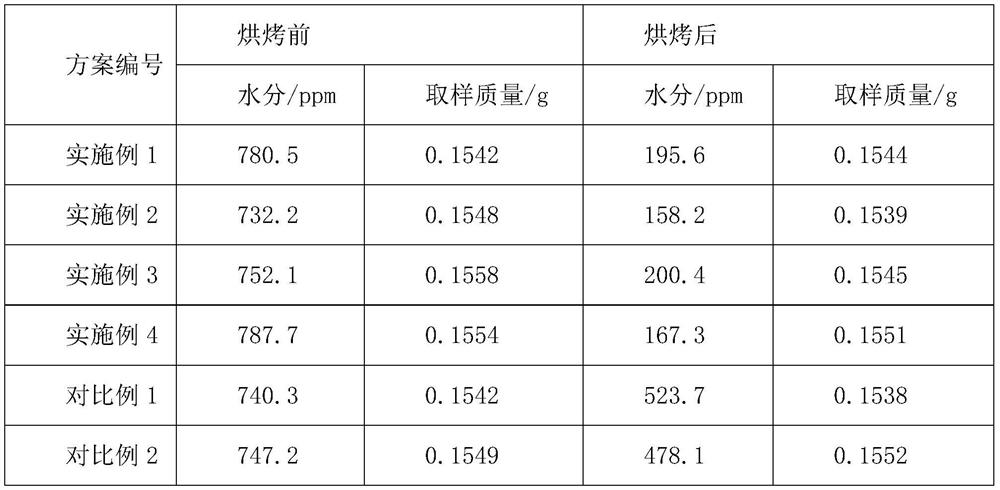

Rapid baking method for square lithium ion battery

ActiveCN112864463AReduce moistureImprove playbackFinal product manufactureDrying machines with local agitationEngineeringNitrogen gas

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

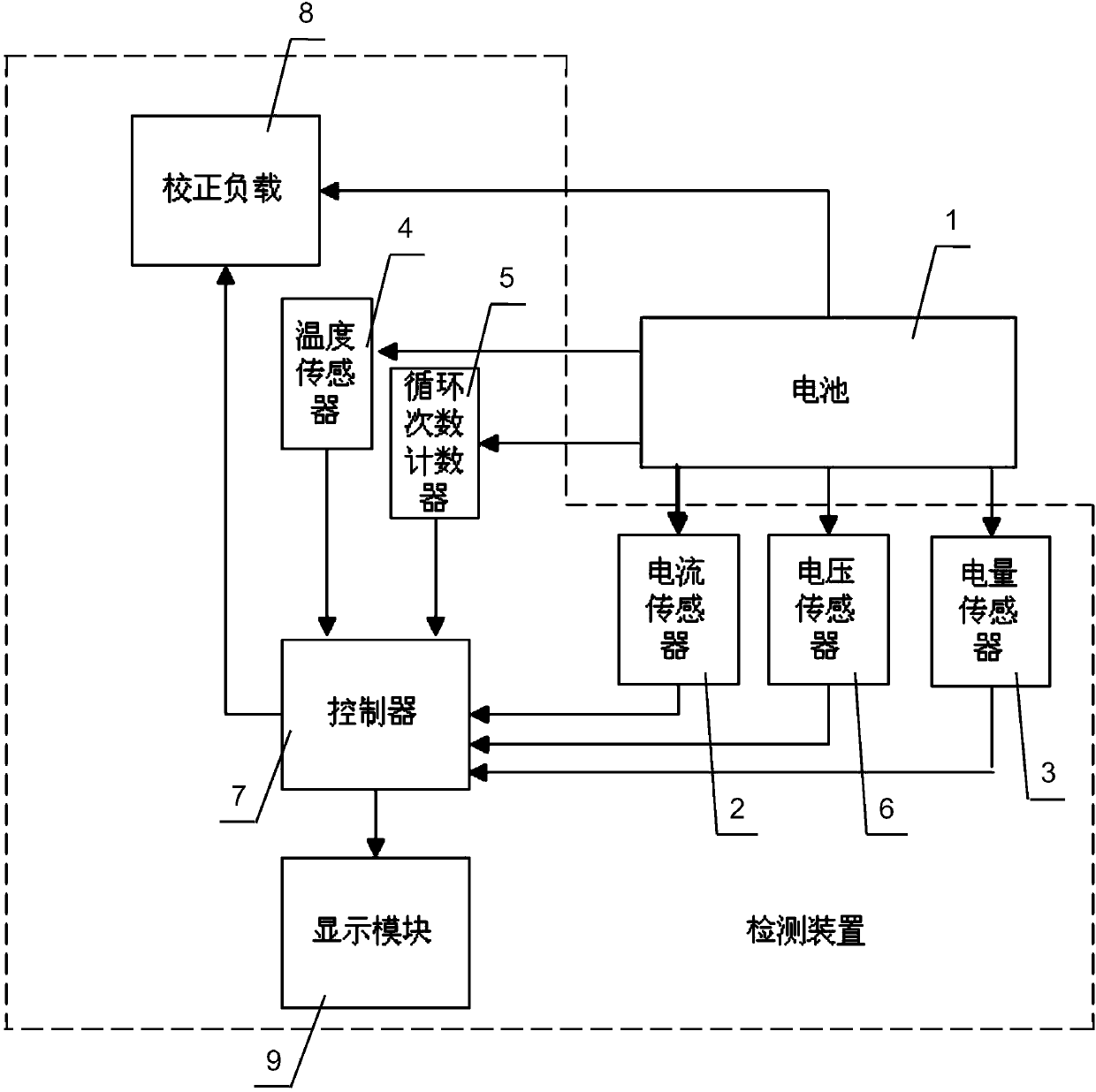

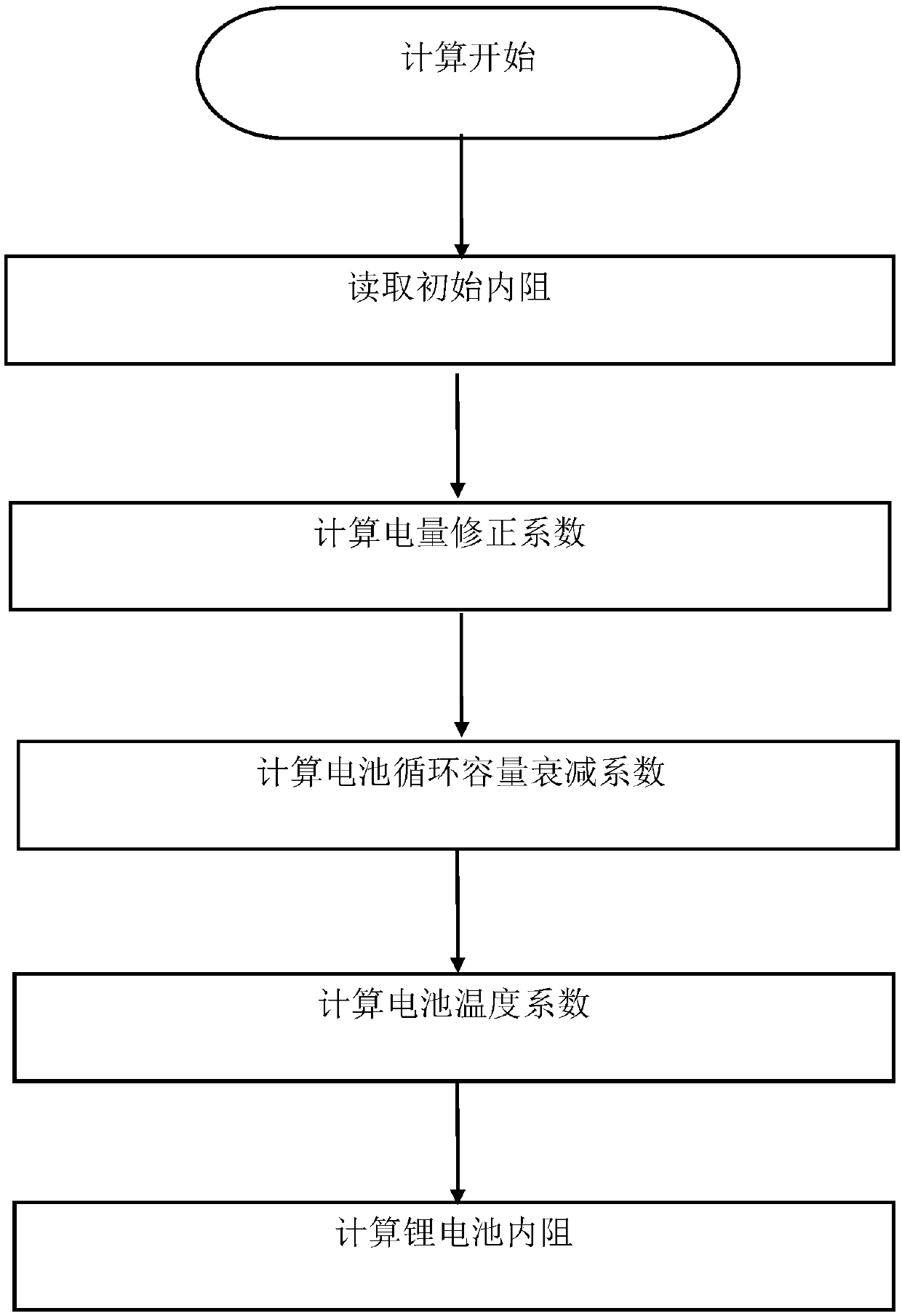

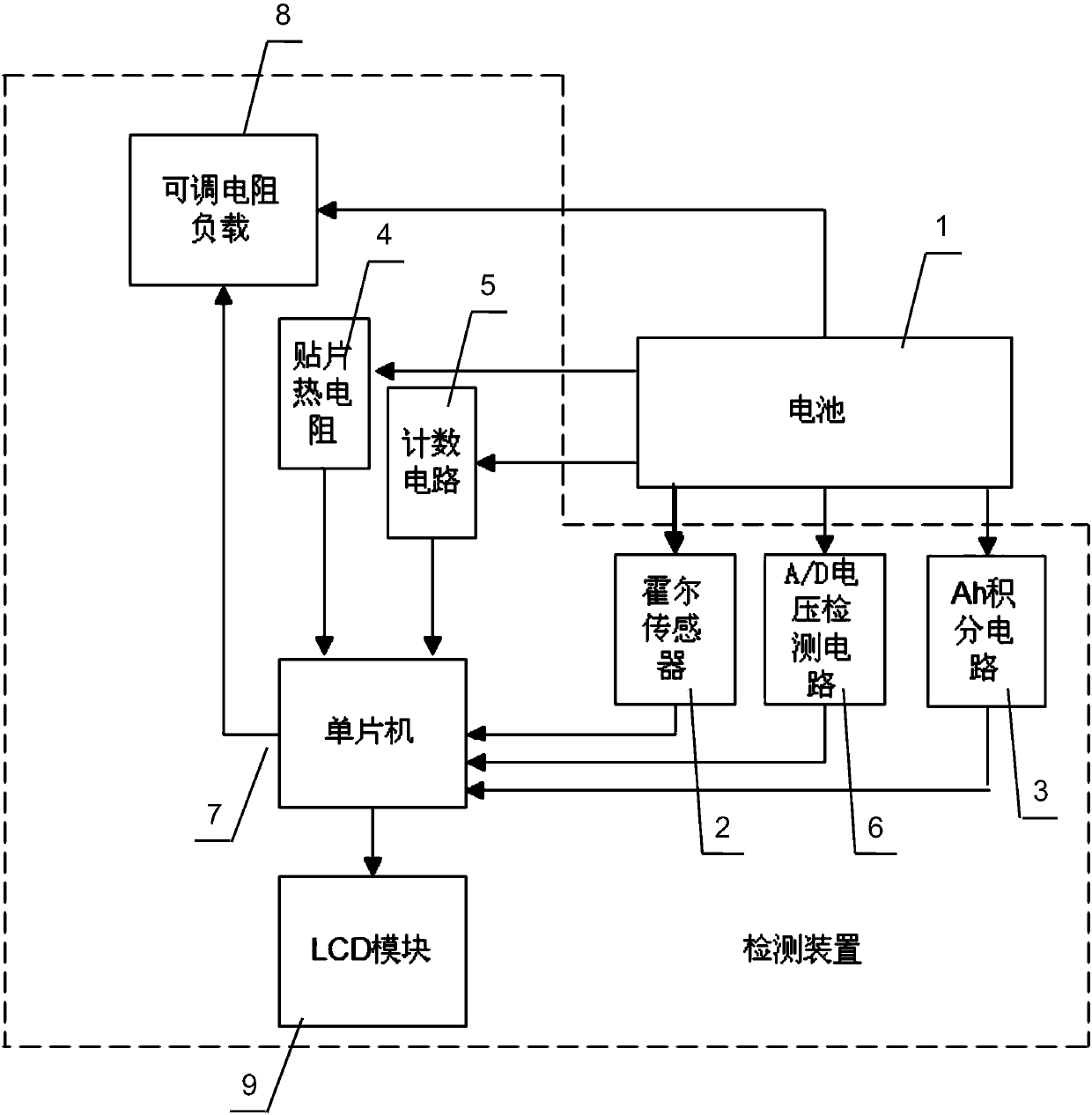

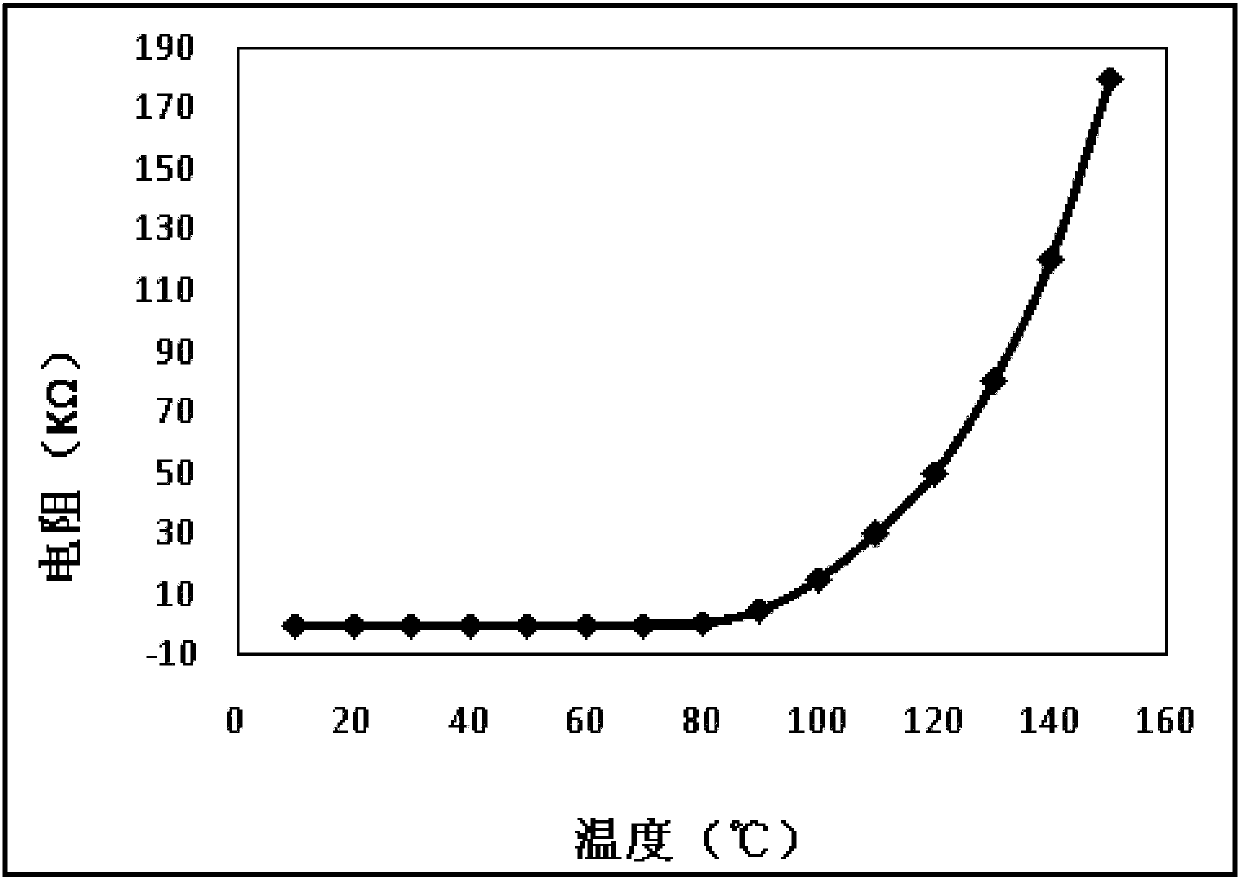

Online self-learning measurement device for internal resistance of lithium battery and measure method thereof

ActiveCN110133528AHigh precisionImprove robustnessElectrical testingMeasurement deviceTerminal voltage

Owner:BAOSHAN IRON & STEEL CO LTD

Silicon-based negative electrode material and preparation method thereof, lithium ion battery and electric appliance

InactiveCN112820847AImprove cycle stabilityHigh reversible capacityElectrode thermal treatmentNegative electrodesElectrical batteryCopper foil

The invention discloses a silicon-based negative electrode material and a preparation method thereof, a lithium ion battery and an electric appliance and relates to the technical field of battery electrode material preparation. The preparation method of the silicon-based negative electrode material comprises the following steps: annealing a primary negative electrode material which is obtained by cold spraying and is loaded with a Si-Cu coating on the surface in an inert gas atmosphere at the temperature of 500-800 DEG C, and preserving heat for 7-9 hours. The silicon-based negative electrode material is prepared by the preparation method. The lithium ion battery adopts the silicon-based negative electrode material as a negative electrode. The electric appliance takes the lithium ion battery as a power supply. After the primary negative electrode material of the Si-Cu coating is obtained through cold spraying on the copper foil, the Si-Cu3Si-Cu composite material obtained through annealing treatment at the proper temperature and the proper heat preservation time is used as the negative electrode material of the lithium ion battery and has good cycle stability and reversible capacity.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for producing ytterbium-doped lithium nickel cobalt manganese oxide material used for lithium ion battery

ActiveCN106257715ALoose tube wallAlleviate volume expansionCell electrodesSodium-ion batteryManganese oxide

Owner:ZHEJIANG CHANGXING KISUN POWER SUPPLY

Safe flexible package lithium ion battery tab

Owner:WANXIANG 123 CO LTD +1

Stable lithium ion battery with high capacitance

InactiveCN103606666AImproved high-magnification performanceImprove power densityCell electrodesSecondary cellsCapacitanceManganese

The invention discloses a stable lithium ion battery with high capacitance. Two poles are respectively prepared from a composite carbon cathode material and a ternary composite anode material. By adopting the stable lithium ion battery, the high magnification performance and the power density of the lithium ion battery can be effectively improved. The stable lithium ion battery has high-magnification charge and discharge properties. Three transition metals such as nickel, manganese and cobalt are evenly mixed, so that a layered structure of the material is stabilized by synergistic effects of the nickel, manganese and cobalt, and the charge and discharge capacities, the cycle performance and the overcharging tolerance of the material are improved.

Owner:JIANGSU TENPOWER LITHIUM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap