Rapid baking method for square lithium ion battery

A technology of lithium-ion batteries and baking methods, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries. It can solve the problems of affecting battery capacity and life, affecting oven utilization, and long time consumption, so as to improve production. Efficiency, shortening the baking time, and shortening the effect of the baking cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

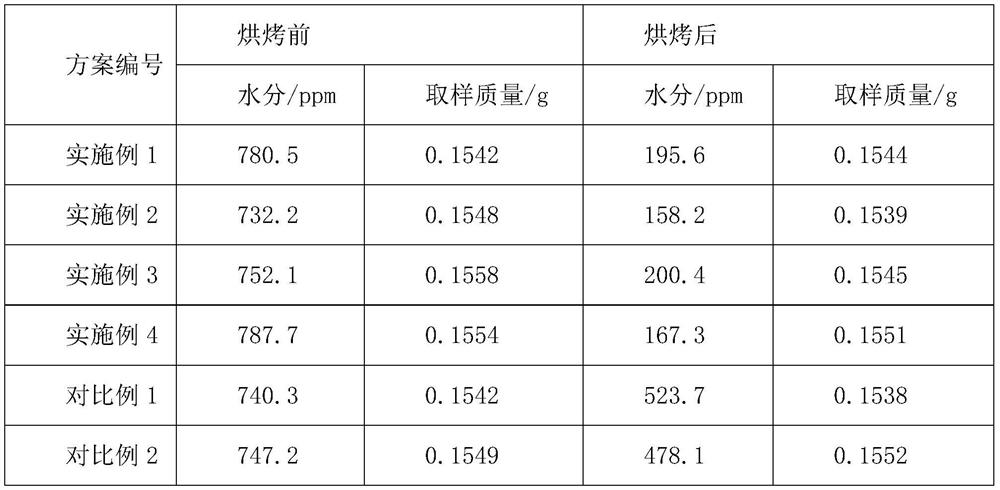

Embodiment 1

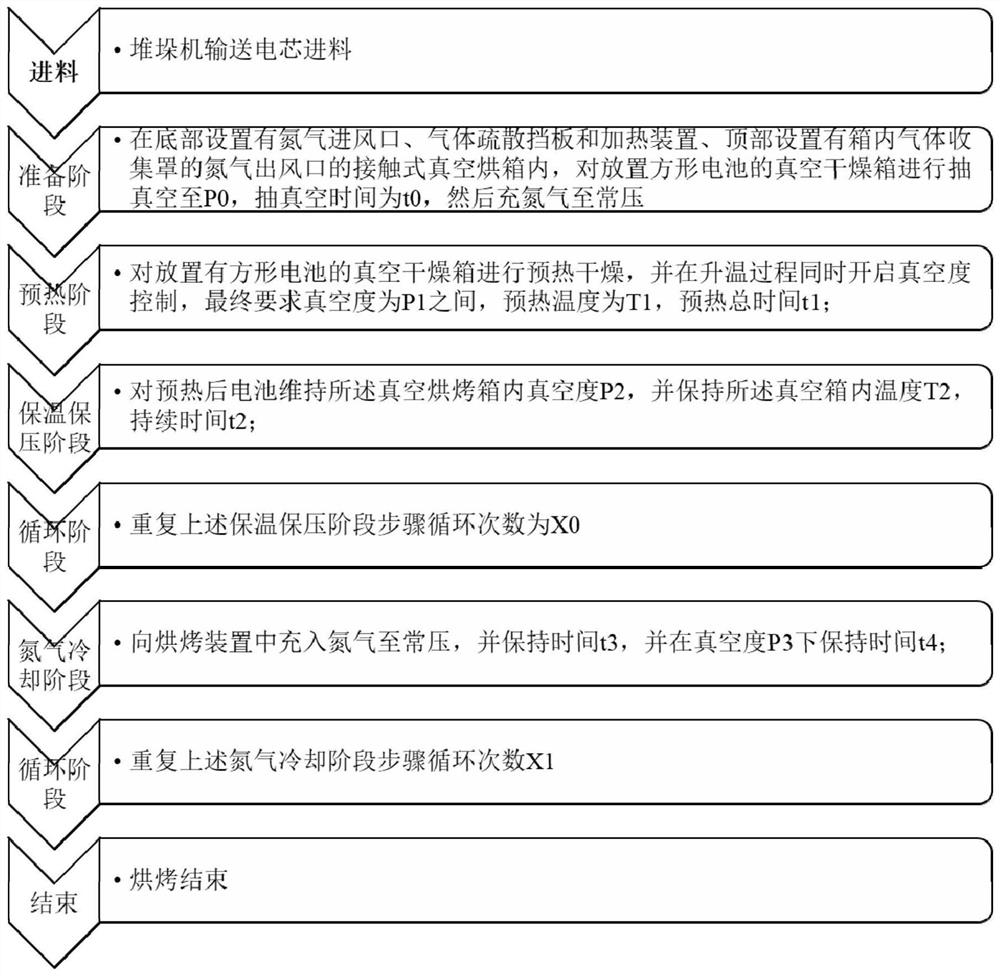

[0040] (1) Preparatory stage: in the contact vacuum oven with nitrogen air inlet, gas evacuation baffle and heating device at the bottom, and nitrogen air outlet with gas collection cover in the box on the top, vacuum drying oven for placing square batteries Vacuumize to vacuum degree ≤ 50Pa, vacuumize for 3 minutes, and then fill with nitrogen to normal pressure;

[0041] (2) Preheating stage: preheat and dry the vacuum drying oven with the square battery placed, and turn on the vacuum degree control at the same time during the heating process, keep the vacuum degree between 10-100Pa, and the vacuum pump will automatically start when the vacuum degree is > 100Pa Vacuumize the program, reduce the vacuum degree to 10Pa, preheat the temperature at 80°C, and the total preheating time is 120min; the temperature rise process is combined with the opening of the vacuum degree control parameters as shown in the following table:

[0042] Table II

[0043] serial number time (

Embodiment 2

[0051] (1) Preparatory stage: in the contact vacuum oven with nitrogen air inlet, gas evacuation baffle and heating device at the bottom, and nitrogen air outlet with gas collection cover in the box on the top, vacuum drying oven for placing square batteries Vacuumize to vacuum degree ≤ 50Pa, vacuumize for 3 minutes, and then fill with nitrogen to normal pressure;

[0052] (2) Preheating stage: preheat and dry the vacuum drying oven with the square battery placed, and turn on the vacuum degree control at the same time during the heating process, keep the vacuum degree between 50-100Pa, and the vacuum pump will automatically start when the vacuum degree is > 100Pa Vacuumize the program, reduce the vacuum degree to 50Pa, preheat the temperature at 85°C, and the total preheating time is 90 minutes; the temperature rise process is combined with the opening of the vacuum degree control parameters as shown in the following table:

[0053] Table three

[0054] serial number t

Embodiment 3

[0062] (1) Preparatory stage: in the contact vacuum oven with nitrogen air inlet, gas evacuation baffle and heating device at the bottom, and nitrogen air outlet with gas collection cover in the box on the top, vacuum drying oven for placing square batteries Vacuumize to vacuum degree ≤ 50Pa, vacuumize for 3 minutes, and then fill with nitrogen to normal pressure;

[0063] (2) Preheating stage: preheat and dry the vacuum drying oven with the square battery placed, and turn on the vacuum degree control at the same time during the heating process, keep the vacuum degree between 10-100Pa, and the vacuum pump will automatically start when the vacuum degree is > 100Pa Vacuumize the program, reduce the vacuum degree to 10Pa, preheat the temperature at 95°C, and the total preheating time is 60 minutes; the temperature rise process is combined with the opening of the vacuum degree control parameters as shown in the following table:

[0064] Table four

[0065] serial number

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap