Layered lithium-rich manganese oxide positive electrode material suppressing capacity/voltage attenuation during circulation process effectively and preparation method therefor and application thereof

A cathode material and oxide technology, which is applied in the field of layered lithium-rich manganese oxide cathode material and its preparation, can solve the problems of reducing the electrochemical capacity of the electrode material, the modification effect is not very obvious, etc., and achieves the inhibition of spinel phase. The formation of , the suppression of capacity/voltage fading, the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of LiNiO by Spray Pyrolysis 2 Doped with 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO) cathode material

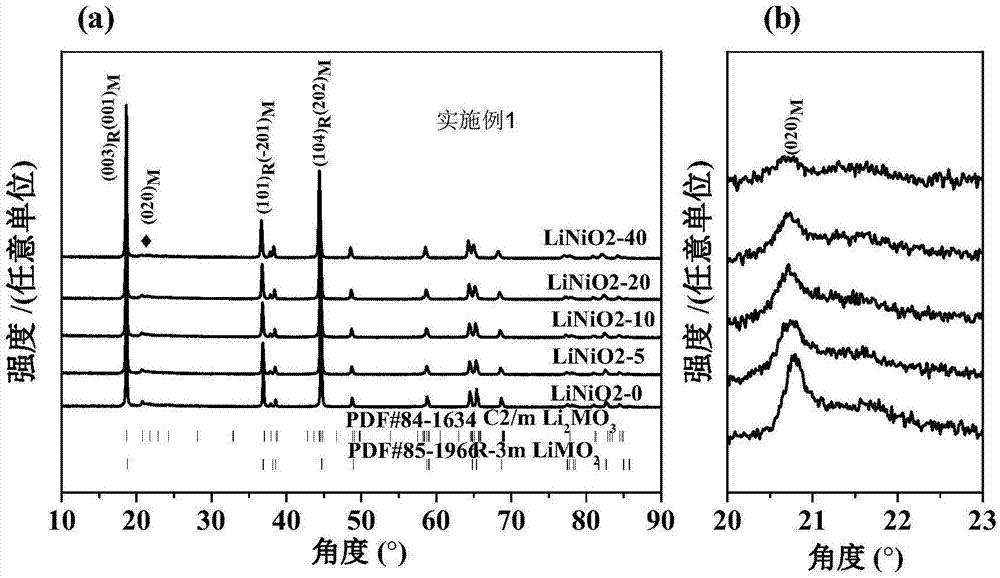

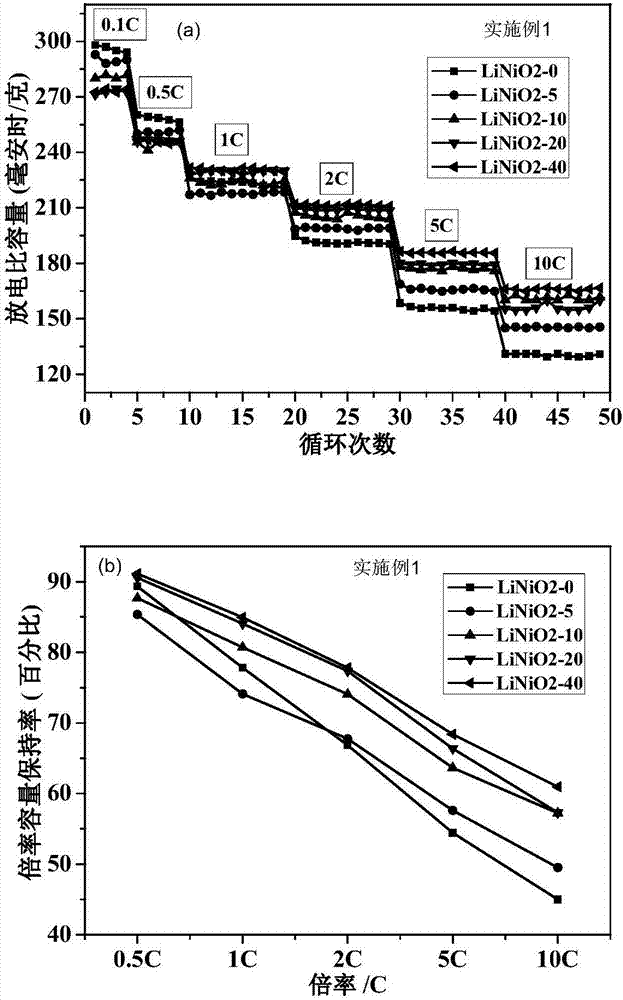

[0049] Add Li, Ni, Co, Mn acetate into a certain amount of deionized water according to the stoichiometric ratio, and use mechanical stirring to obtain a uniform reaction solution; then press LiNiO 2 Adding molar percentages (0, 10, 20, 40 mol%), lithium acetate and nickel acetate are added to the reaction solution; the reaction solution is sprayed and pyrolyzed to obtain the precursor. The resulting precursor was heat-treated at 900 °C for 10 hours to obtain LiNiO 2 Doped 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 The positive electrode materials are respectively marked as LiNiO2-0, LiNiO2-5, LiNiO2-10, LiNiO2-20, LiNiO2-40.

[0050] LNCMO-LiNiO 2 The positive electrode material and the binder are mixed in a certain proportion, and magnetically stirred for 4 hours to obtain a uniform slurry, and then the slurry is evenly coate

Embodiment 2

[0055] Preparation of LiNiO by Spray Pyrolysis 2 doped with 0.7Li 2 MnO 3 -0.3LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO-1) cathode material

[0056] Add Li, Ni, Co, Mn acetate into a certain amount of deionized water according to the stoichiometric ratio, and use mechanical stirring to obtain a uniform reaction solution; then press LiNiO 2 Adding mole percentages (0, 10, 20, 40 mol%), lithium acetate and nickel acetate are added to the reaction solution; the reaction solution is sprayed and pyrolyzed to obtain a precursor. The resulting precursor was heat-treated at 900 °C for 10 hours to obtain LiNiO 2 The doped LNCMO-1 cathode materials are labeled LiNiO2-1-0, LiNiO2-1-5, LiNiO2-1-10, LiNiO2-1-20, LiNiO2-1-40, respectively.

[0057] Electrode material preparation and battery assembly are the same as in Example 1.

[0058] Figure 4 (a) is the cycle performance curve of LiNiO2-1-0, LiNiO2-1-5, LiNiO2-1-10, LiNiO2-1-20, LiNiO2-1-40 electrode materials. As shown, increasing

Embodiment 3

[0060] Preparation of LiNiO by Spray Pyrolysis 2 Doped with 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2(LNCMO) Cathode Material - Nitrate

[0061] Add Li, Ni, Co, and Mn nitrates into a certain amount of deionized water according to the stoichiometric ratio, and use mechanical stirring to obtain a uniform reaction solution; then press LiNiO 2 Adding mole percentages (0, 10, 20, 40 mol%), lithium nitrate and nickel nitrate are added to the reaction solution; the reaction solution is sprayed and pyrolyzed to obtain a precursor. The resulting precursor was heat-treated at 900 °C for 10 hours to obtain LiNiO 2 The doped LNCMO cathode materials are labeled LiNiO2-2-0, LiNiO2-2-5, LiNiO2-2-10, LiNiO2-2-20, LiNiO2-2-40, respectively.

[0062] Electrode preparation and battery assembly are the same as in Example 1.

[0063] Figure 5 Shown are the XRD patterns of LiNiO2-0, LiNiO2-5, LiNiO2-10, LiNiO2-20, LiNiO2-40 electrode materials. Such as Figure 5 As shown, all the d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap