Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Heat treated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat Treating. Heat Treatment is a method of controlled heating and cooling of metals to alter their mechanical and physical properties without changing the product shape. The technique involves the use of heating or chilling, usually to extreme temperatures, to attain a desired result, such as - hardening or softening of a metal.

Method for drawing and forming parabola revolution body

The invention relates to a method for drawing shaped parabola revolving body, belonging to the technical field of the plastic forming of material processing engineering. The method comprises the following steps: (1) a set of mould is designed according to the final shape of revolving body parts; (2) the first drawing: when being drawn, a movable soft punch cushion block is arranged on a mould punch; the inner shape of the movable soft punch cushion block is similar to the shape of the punch; a movable rigidity limit cushion block is arranged below a blank holder with a belt drawbead; (3) the annealing heat treatment, the annealing heat treatment is carried out on the parts after the first drawing is carried out on the parts; (4) the second drawing, the same set of module is used; when in drawing, the movable soft punch cushion block and the movable rigidity limit cushion block are removed. In the invention, the movable soft punch cushion block is added on a drawing mould rigidity punch for enlarging the plastic forming of the materials in the first drawing; only one set of drawing module is used on an ordinary hydraulic press, therefore, the parahola revolving body parts which are usually formed with 3-4 sets of moulds by the common drawing processing are successfully formed by twice drawing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Heat treatment method for aluminum alloy

InactiveCN101463453ASolution treatment5005 aluminium alloy

A heat treatment method of aluminium alloy comprises the steps: the aluminium alloy is sequentially treated by solid solution, quenching, cold rolling and ageing, wherein, the cold rolling treatment is ultralow temperature cold rolling treatment carried out at the ultralow temperature of 170 DEG C below zero to 200 DEG C below zero; and the method comprises that low temperature annealing treatment is carried out after the cold rolling treatment and before the ageing treatment. The heat treatment method of the aluminium alloy provided by the invention not only can improve the elongation percentage of the aluminium alloy, namely, breaking elongation, but also can greatly enhance the strength of the aluminium alloy.

Owner:JIANGSU HAIYU MACHINERY

Manufacture method of slip sheet of air conditioner compressor

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

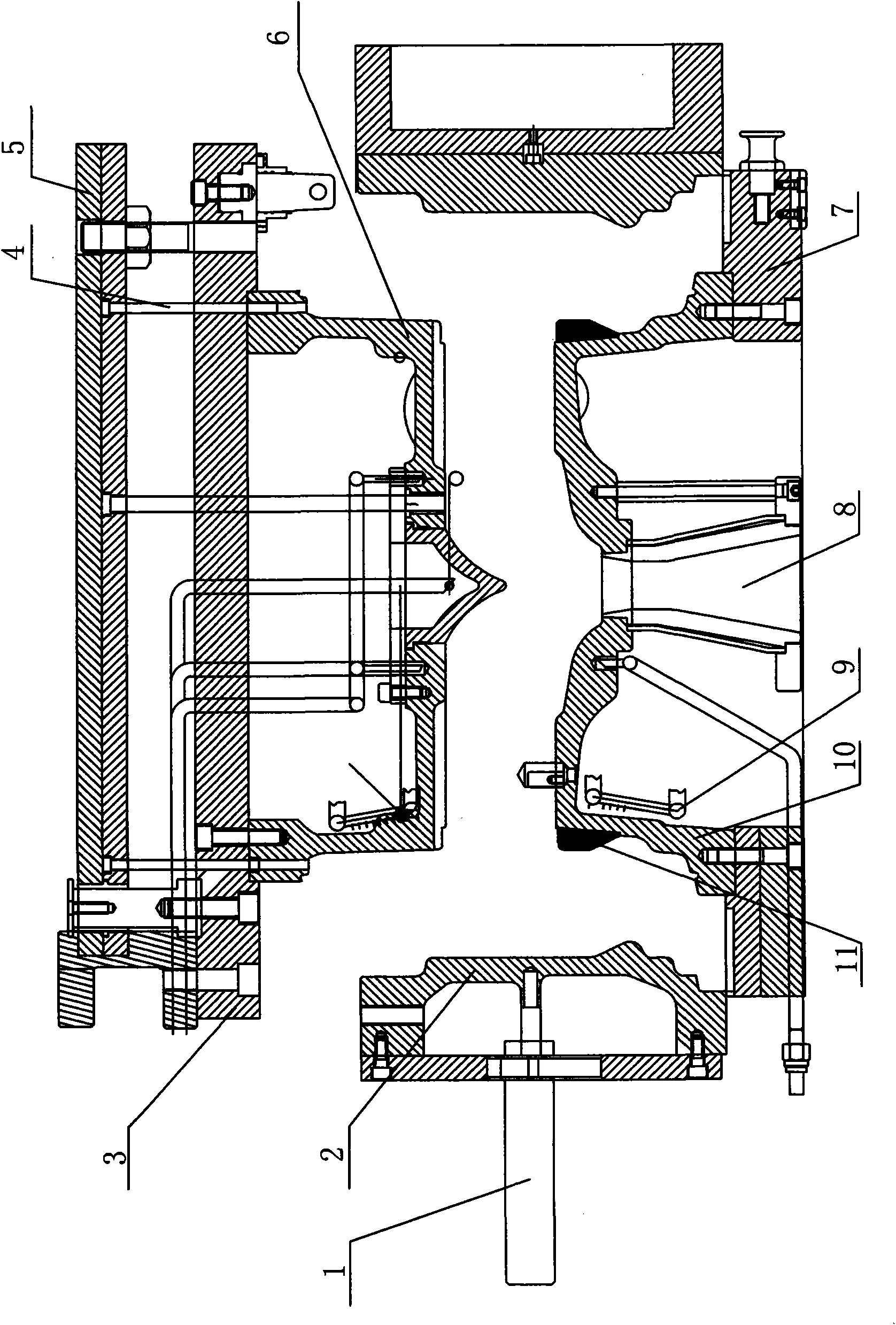

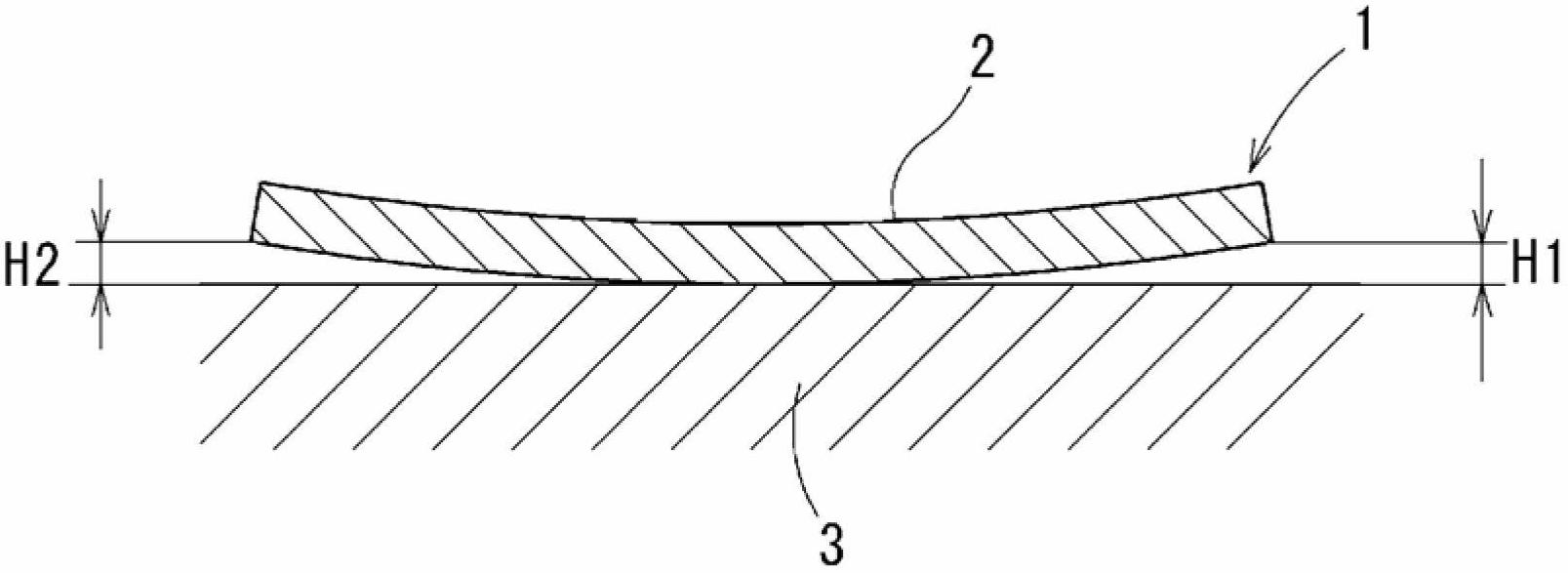

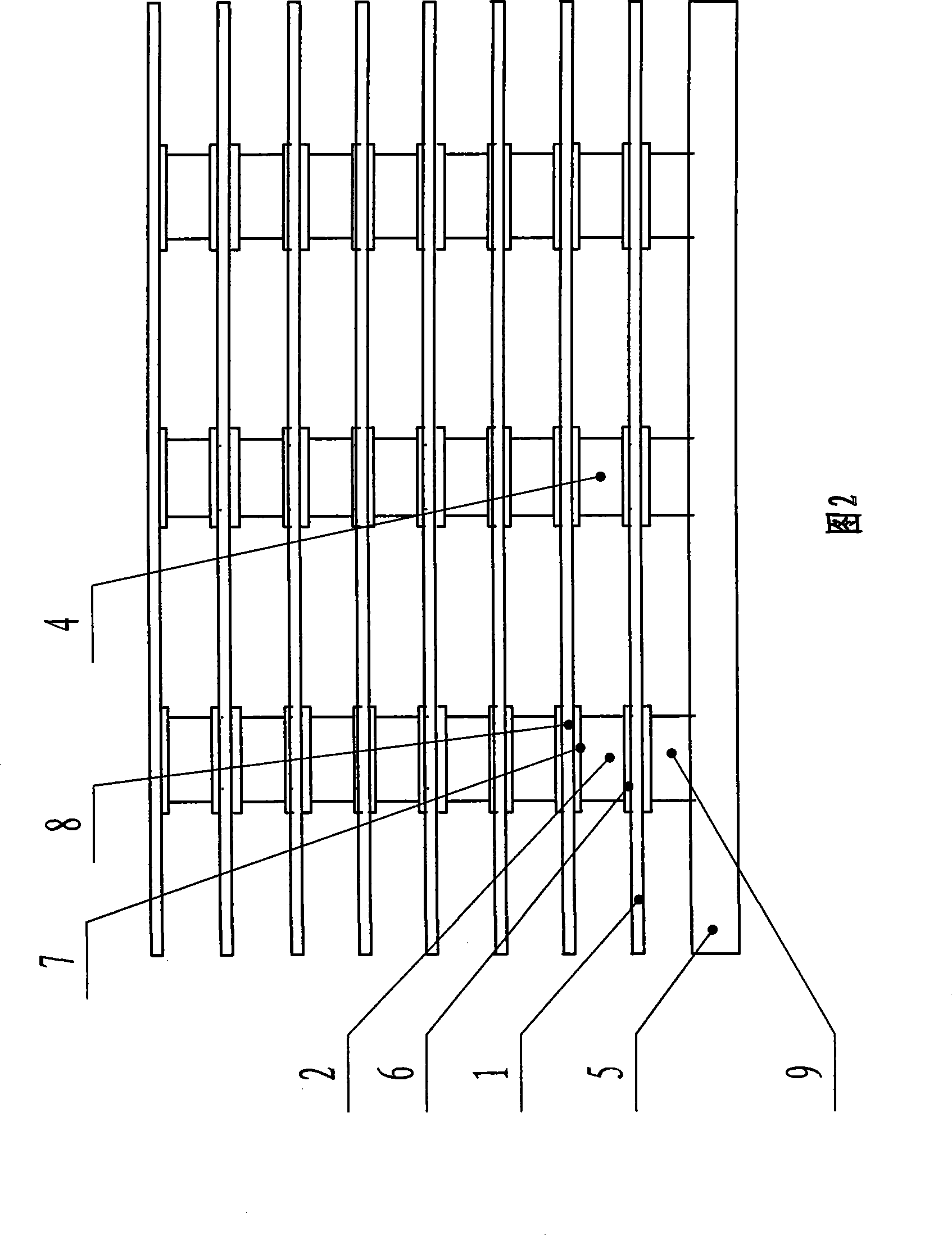

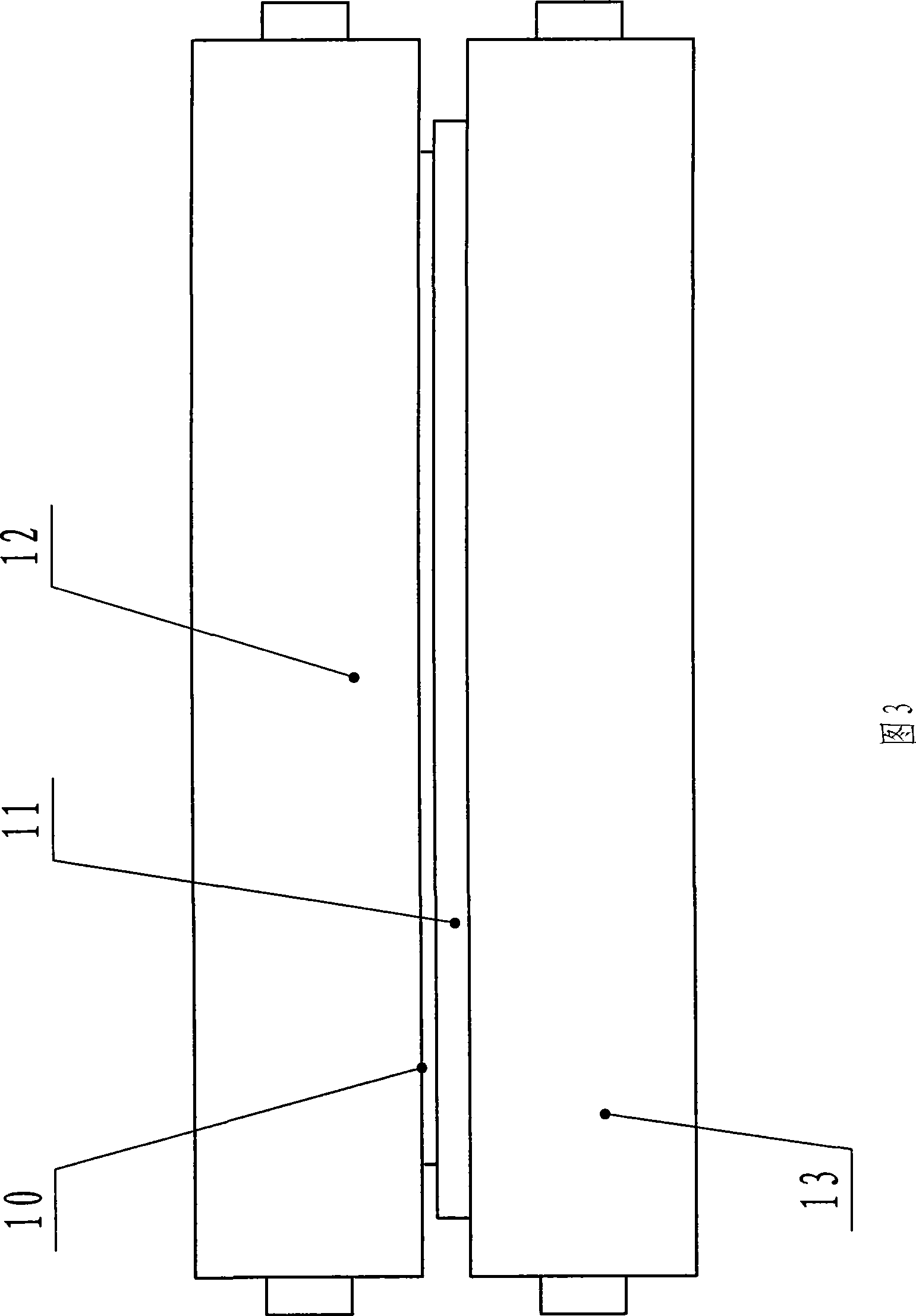

Mold/non-mode combined pulling process and device

InactiveCN102133582AImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsEngineeringMechanical engineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

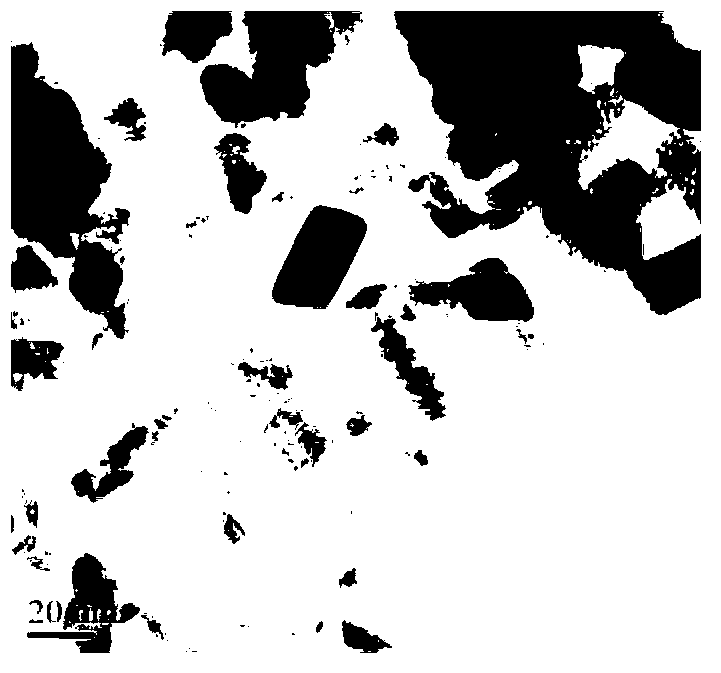

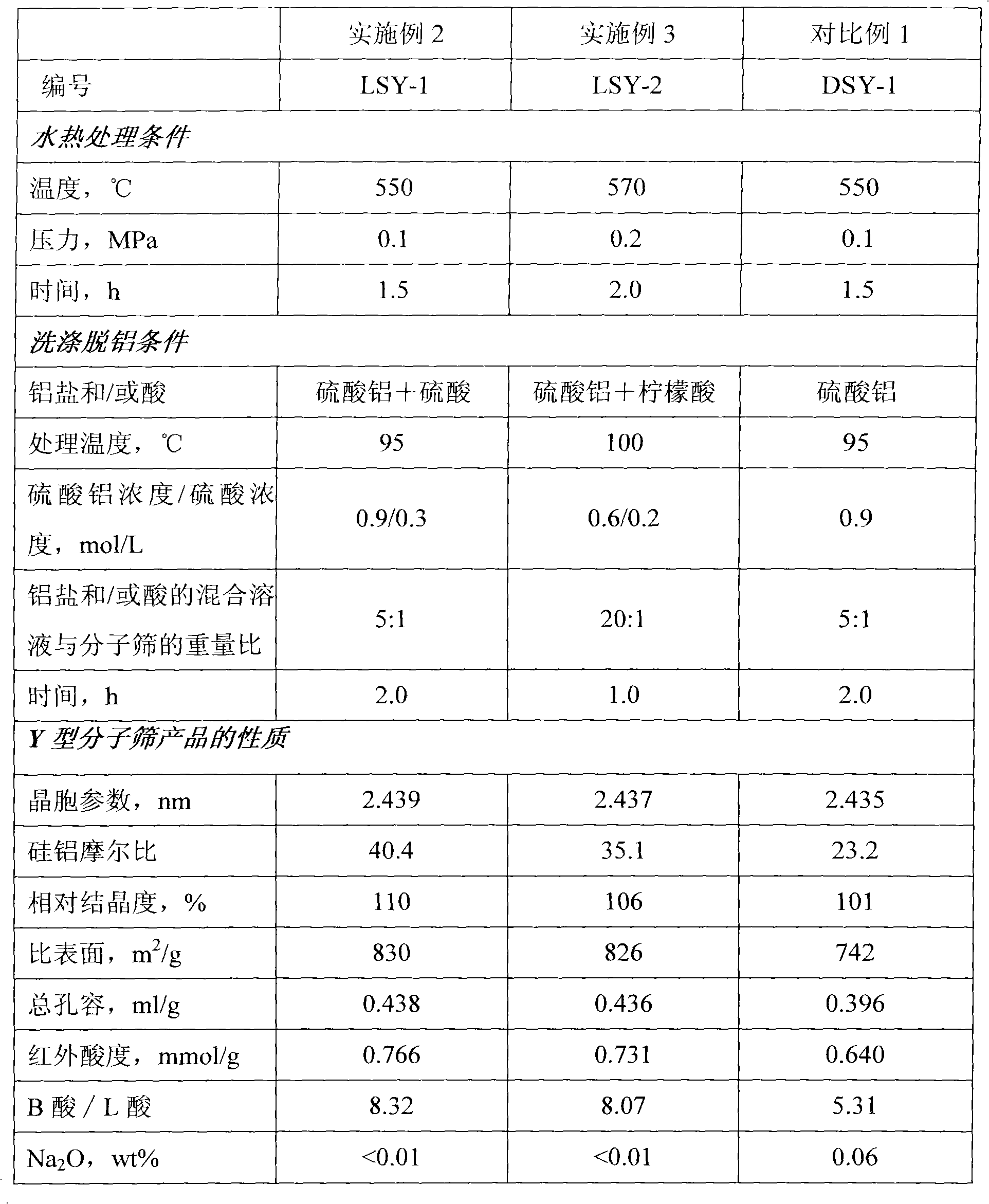

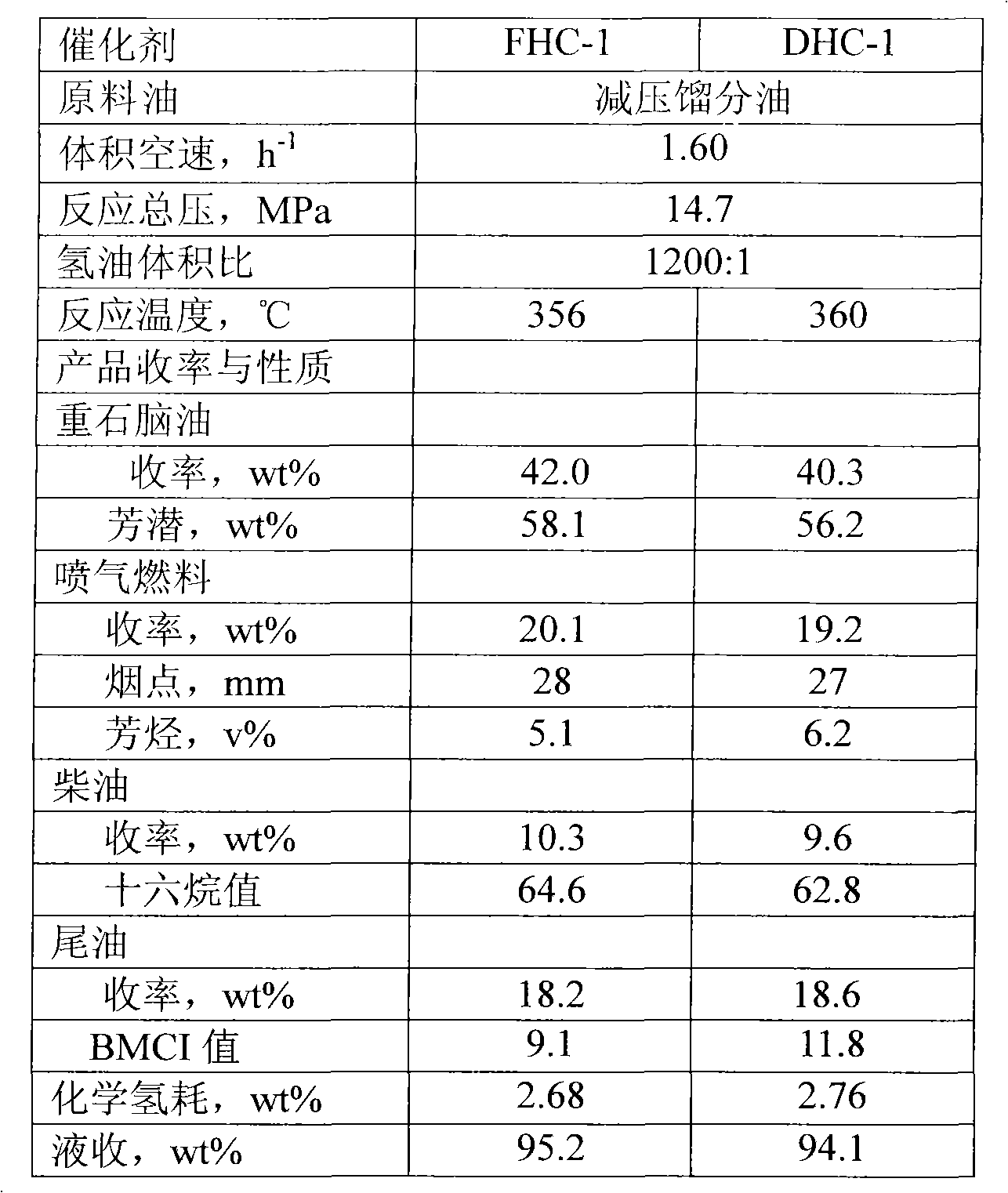

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

Particle control in laser processing systems

ActiveUS20130087547A1Reduce pollutionElectric heating for furnacesLaser beam welding apparatusLaser processingOxygen

Owner:APPLIED MATERIALS INC

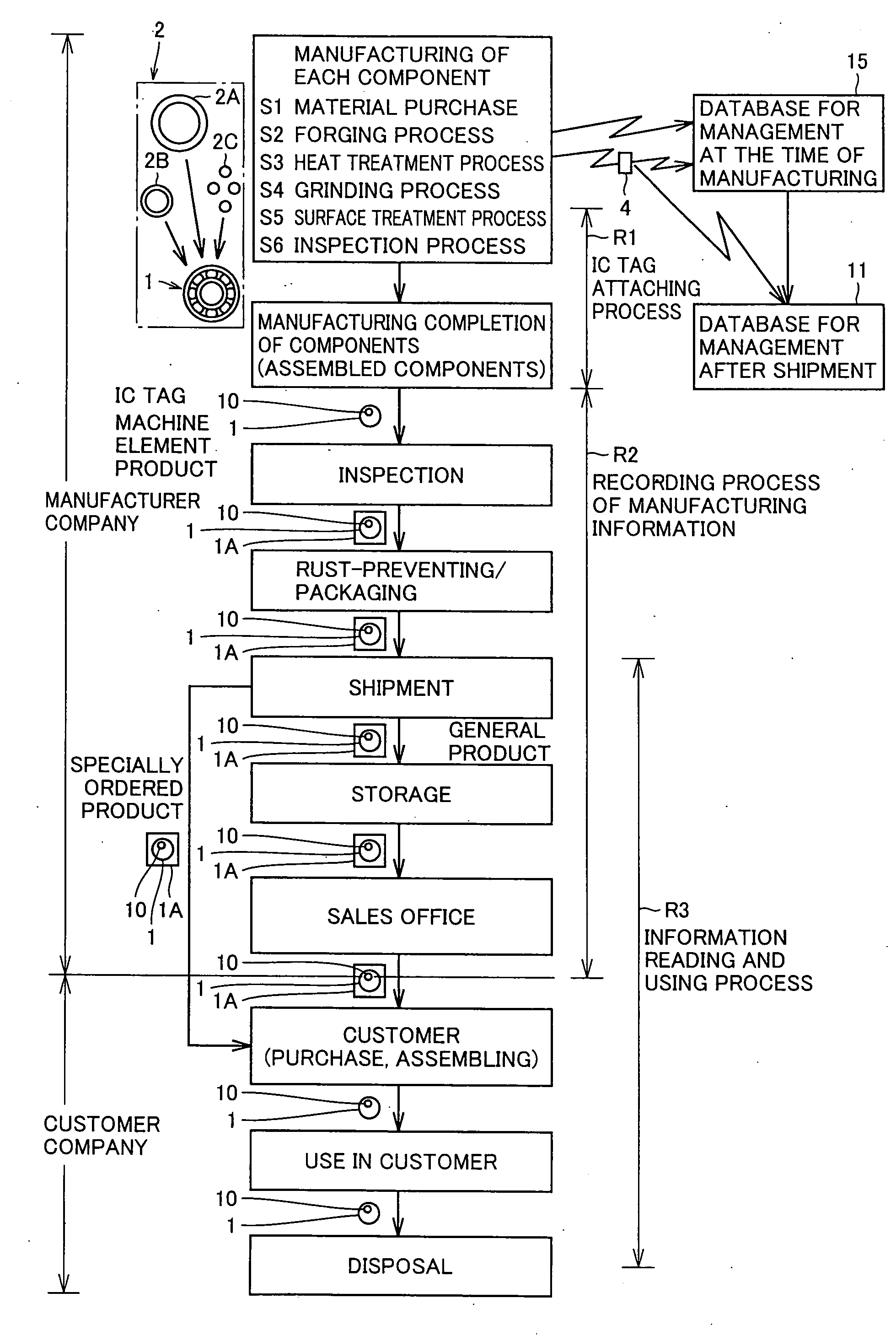

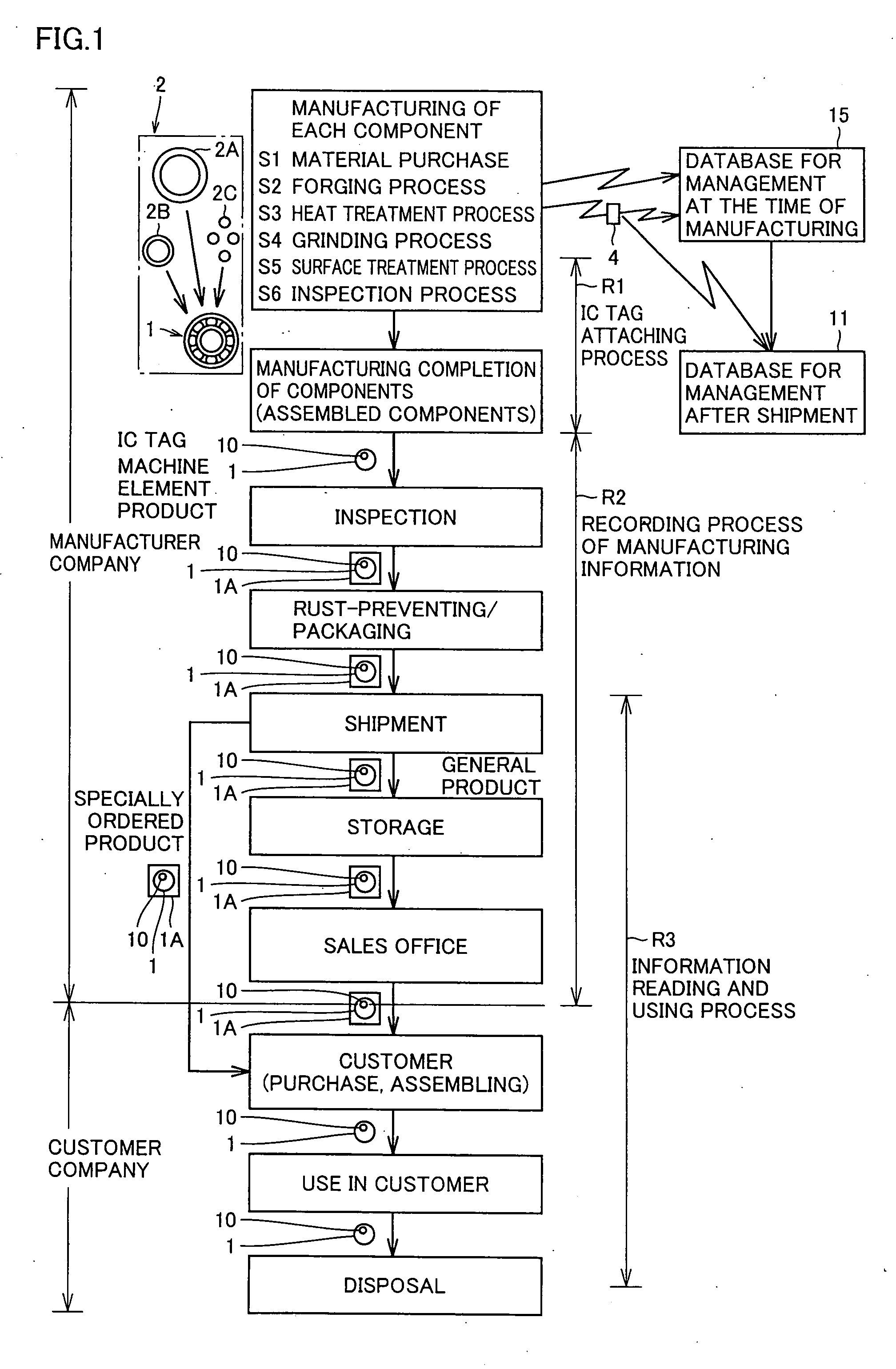

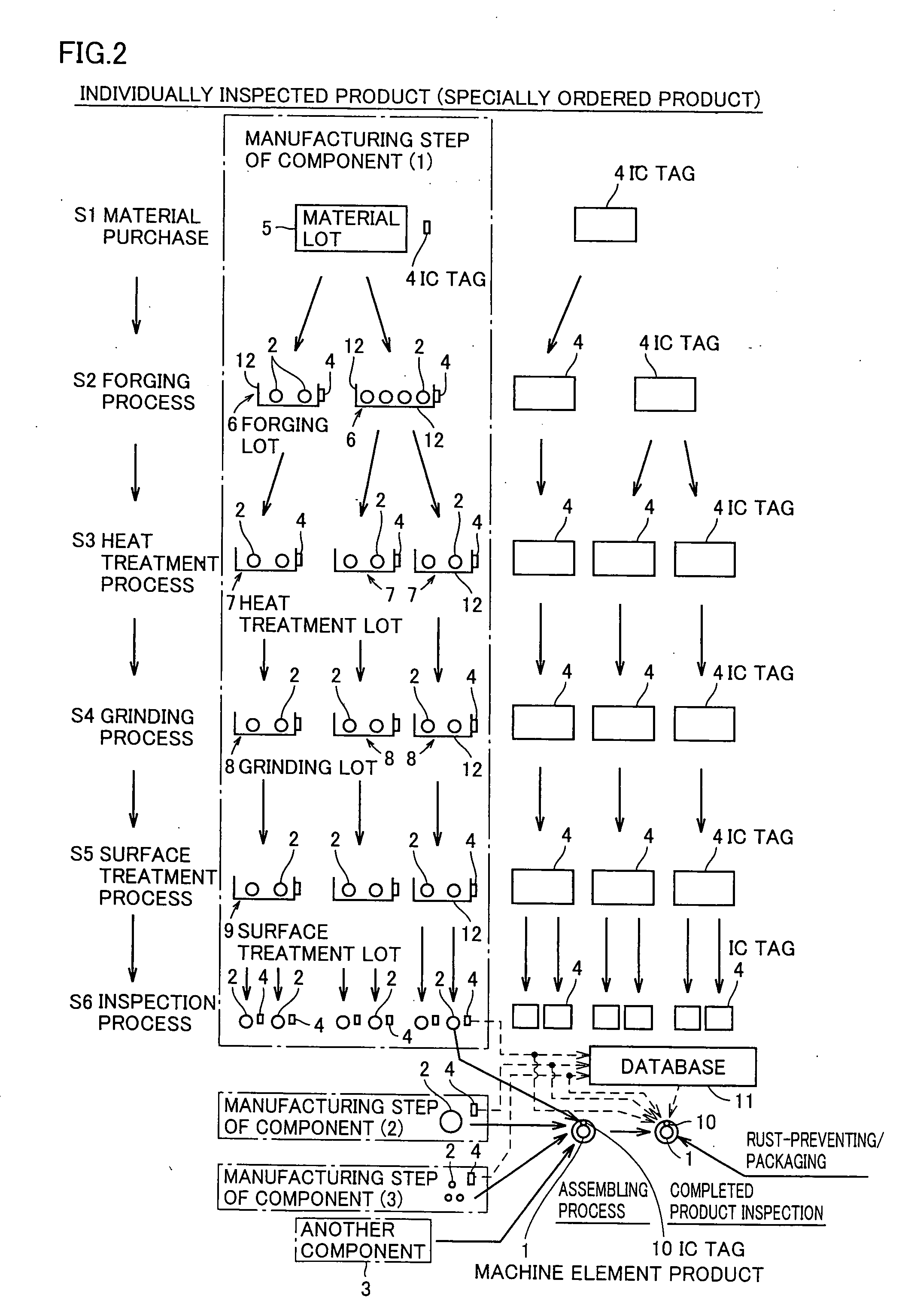

Quality Management Method For Aerospace Machine Element Product and Aerospace Bearing

InactiveUS20080191004A1Easy to manageRolling contact bearingsBearing assemblyAviationQuality management

Owner:NTN CORP

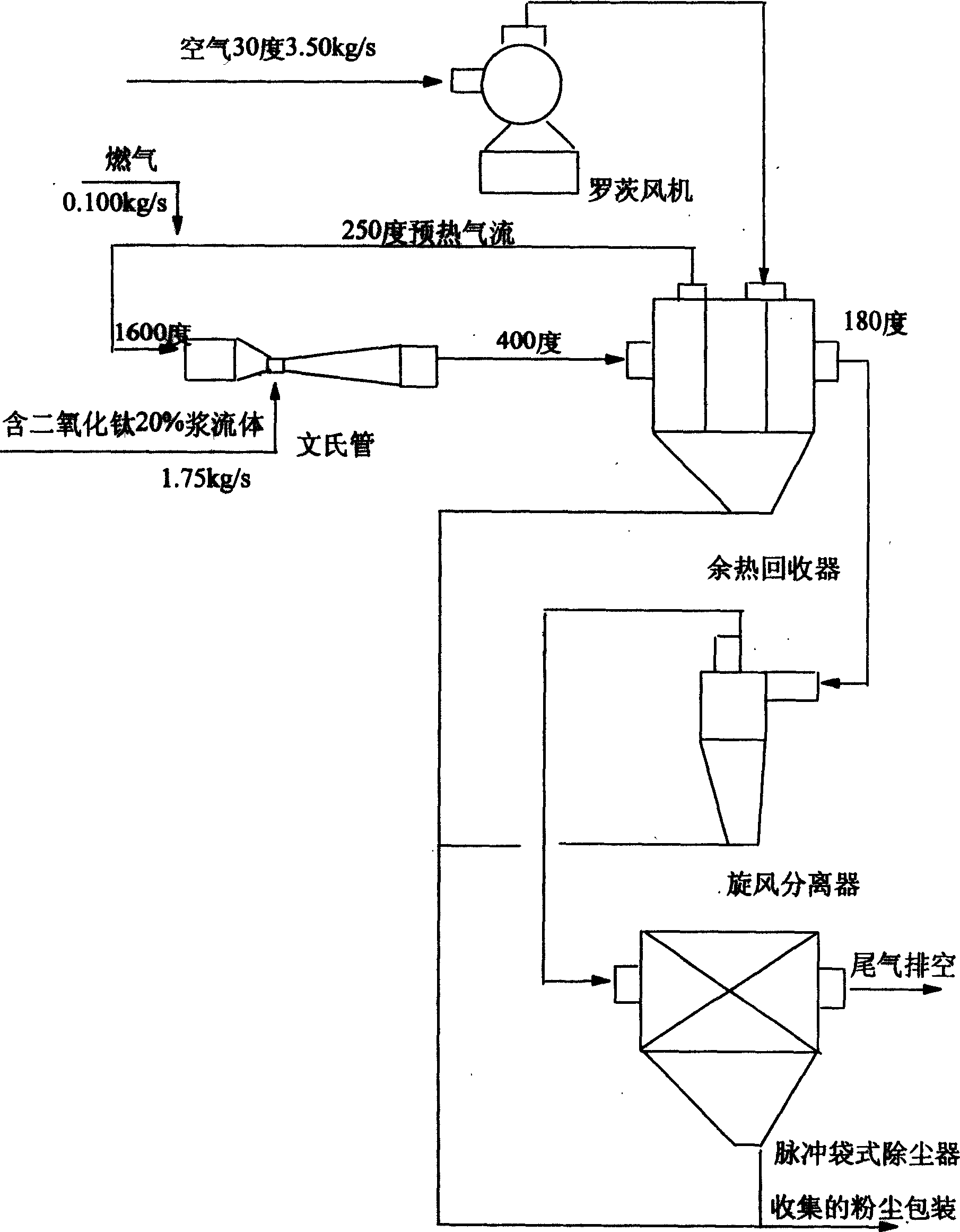

Drying and pulverizing process for preparing powder material with high dispersibility

InactiveCN1605824AIncrease temperatureConvenient heat treatmentDrying solid materials with heatHearth type furnacesPolymer scienceIron oxide

Owner:曾维兴

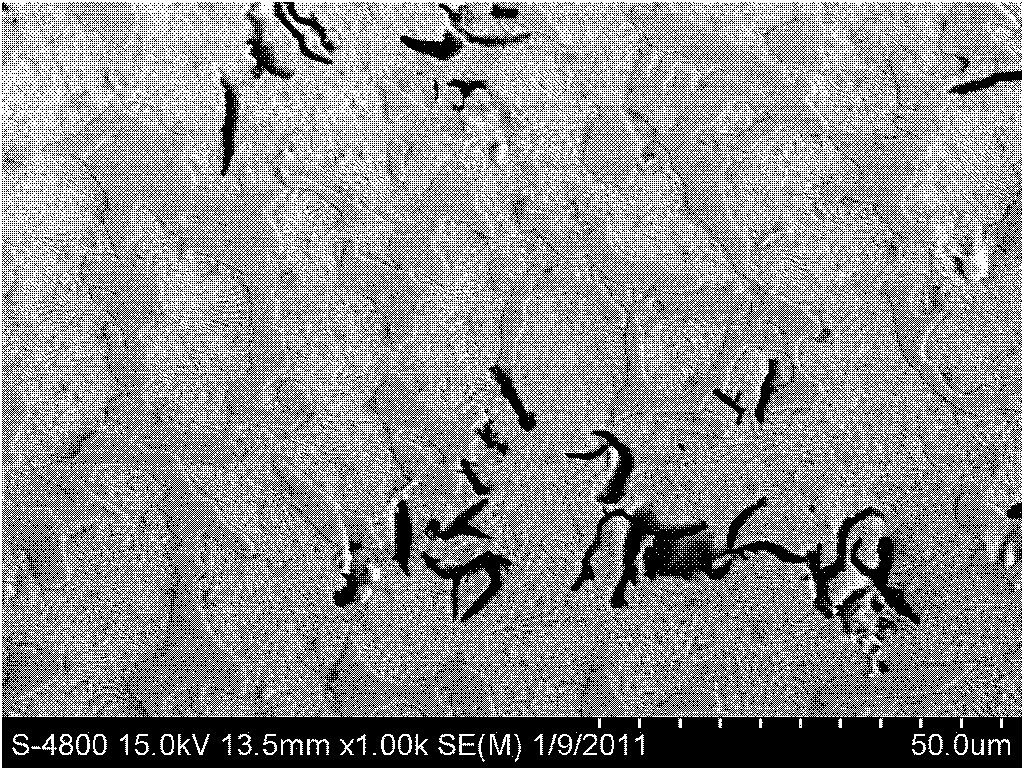

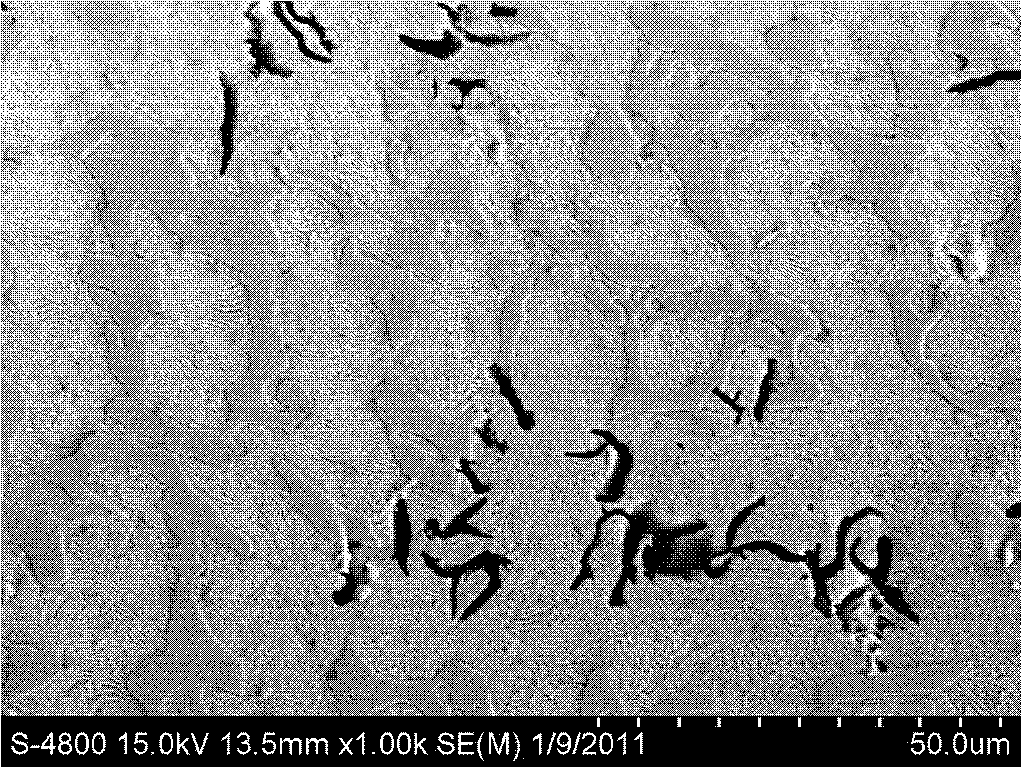

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

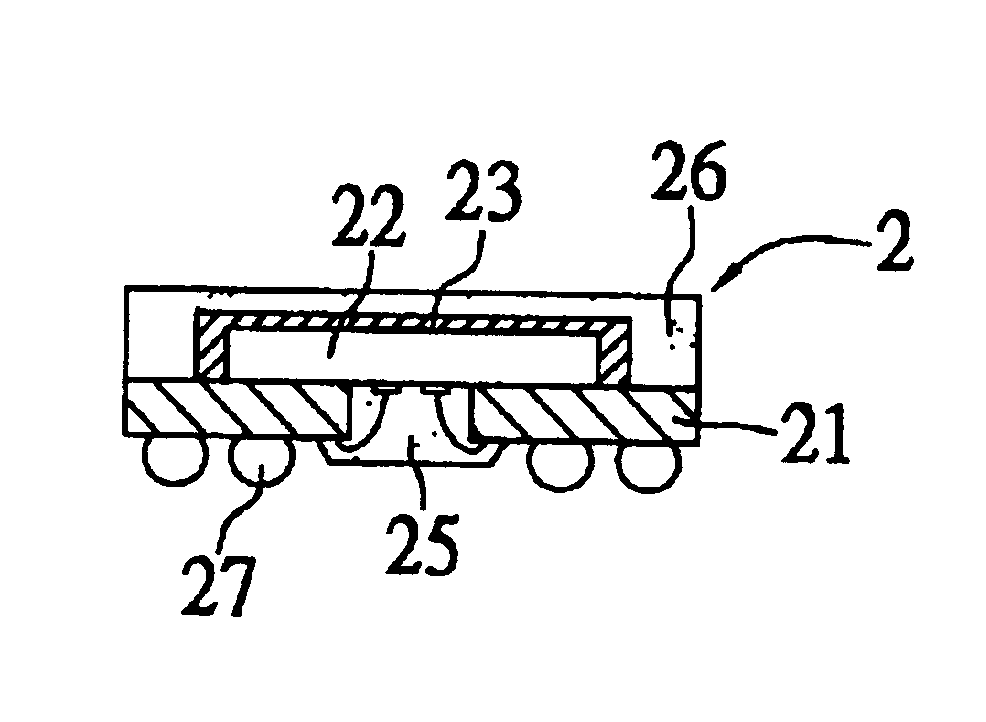

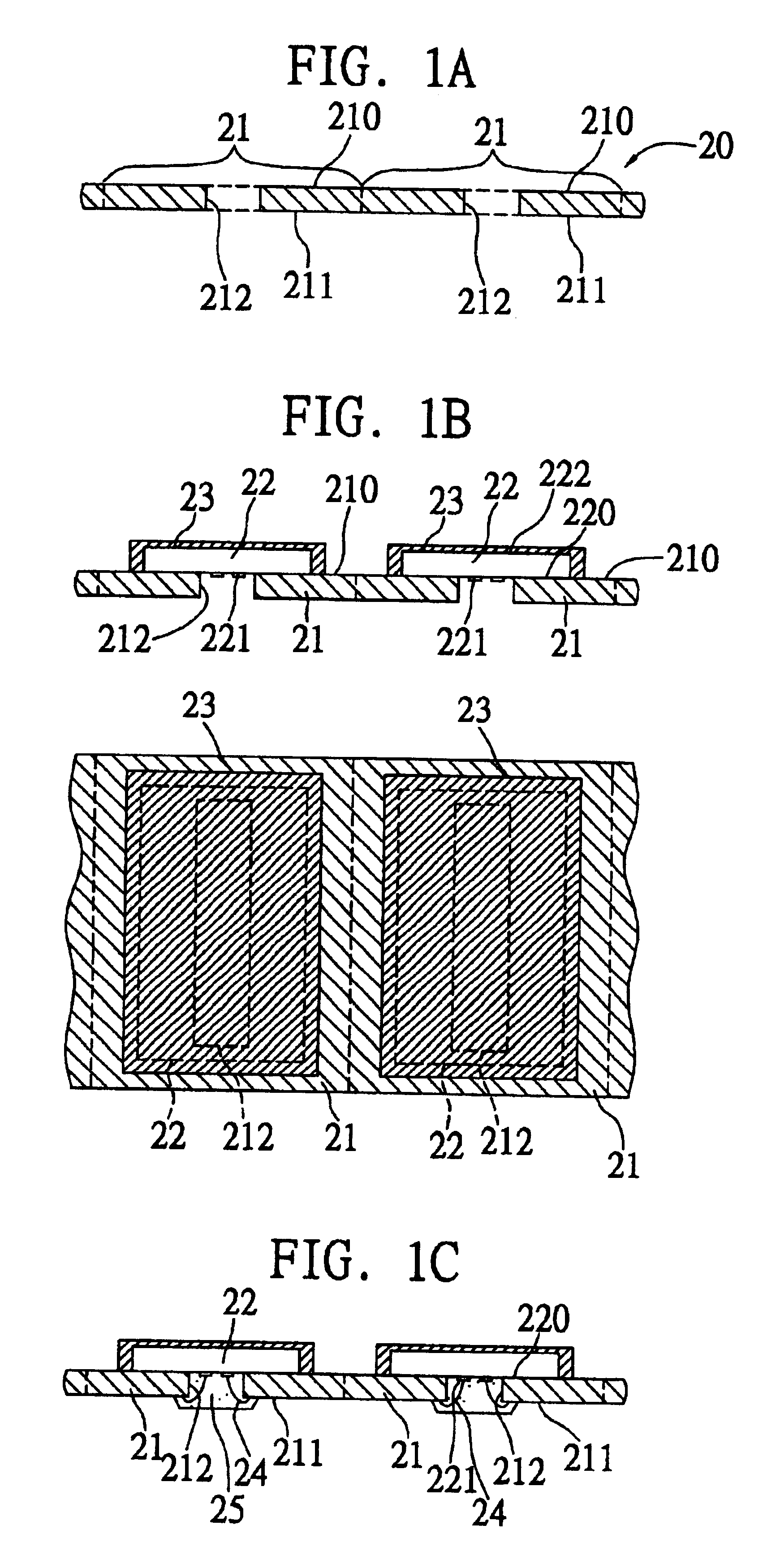

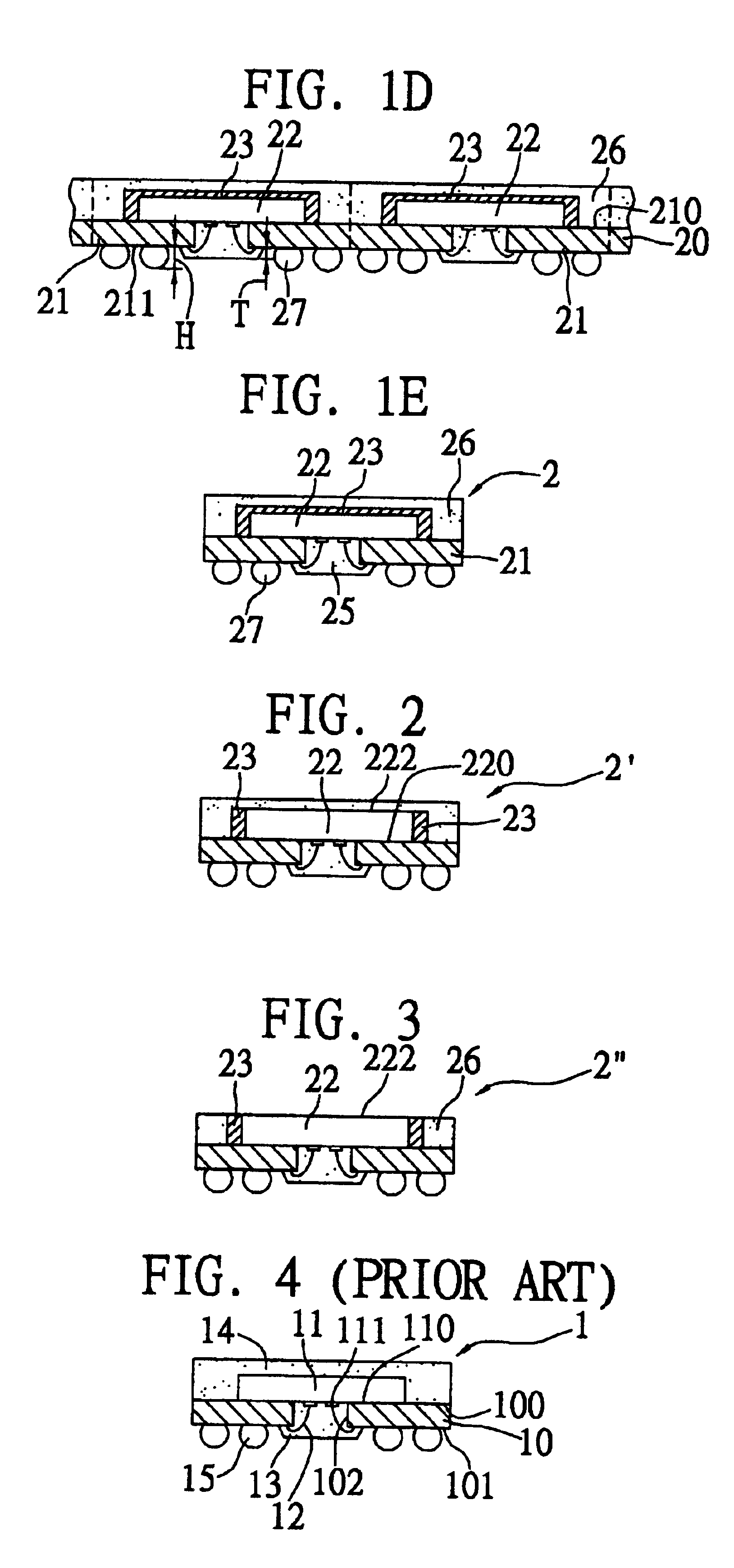

Strengthened window-type semiconductor package

InactiveUS6879030B2High mechanical strengthAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageConductive materials

Owner:SIGURD UTC CORP

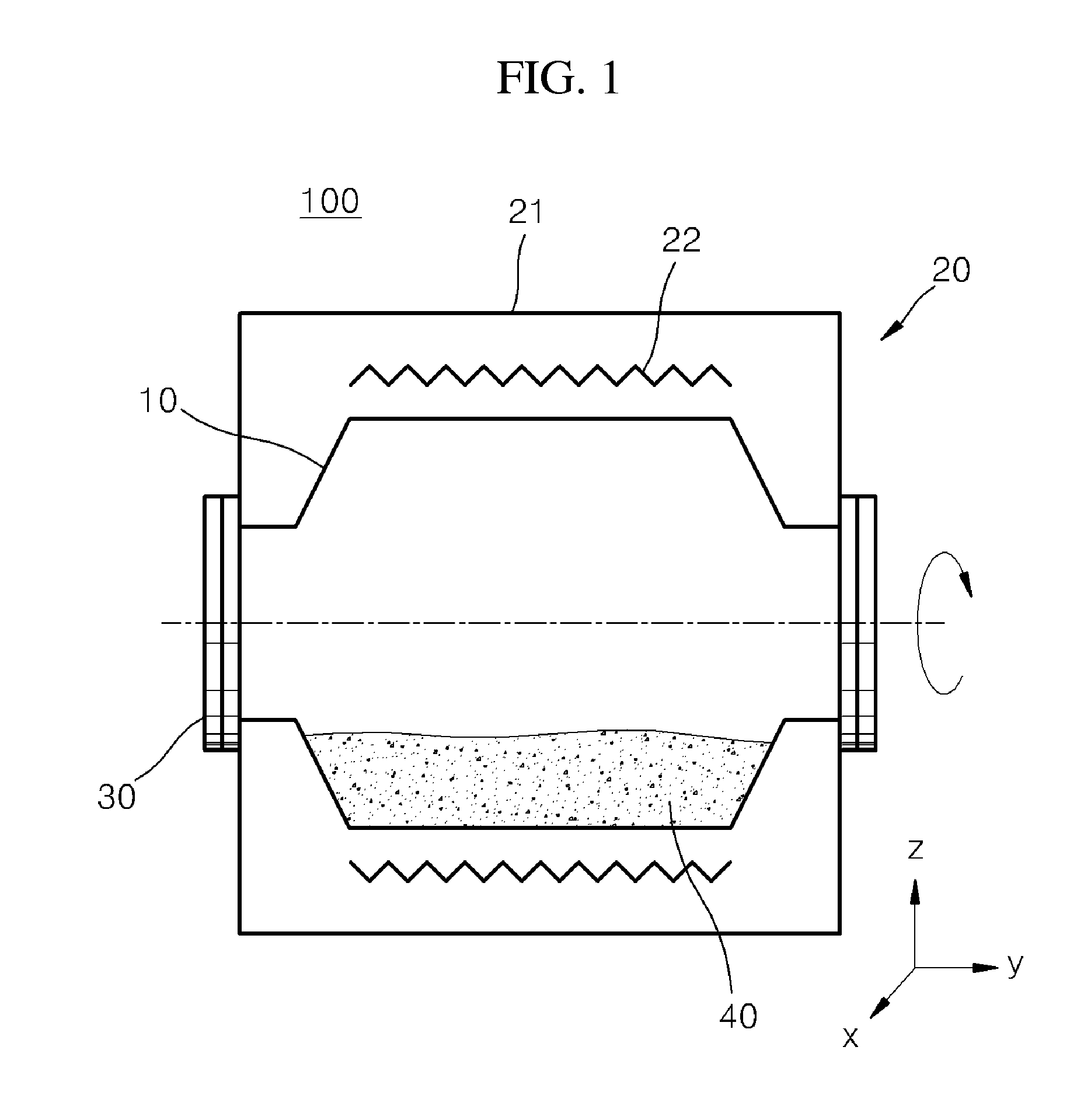

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

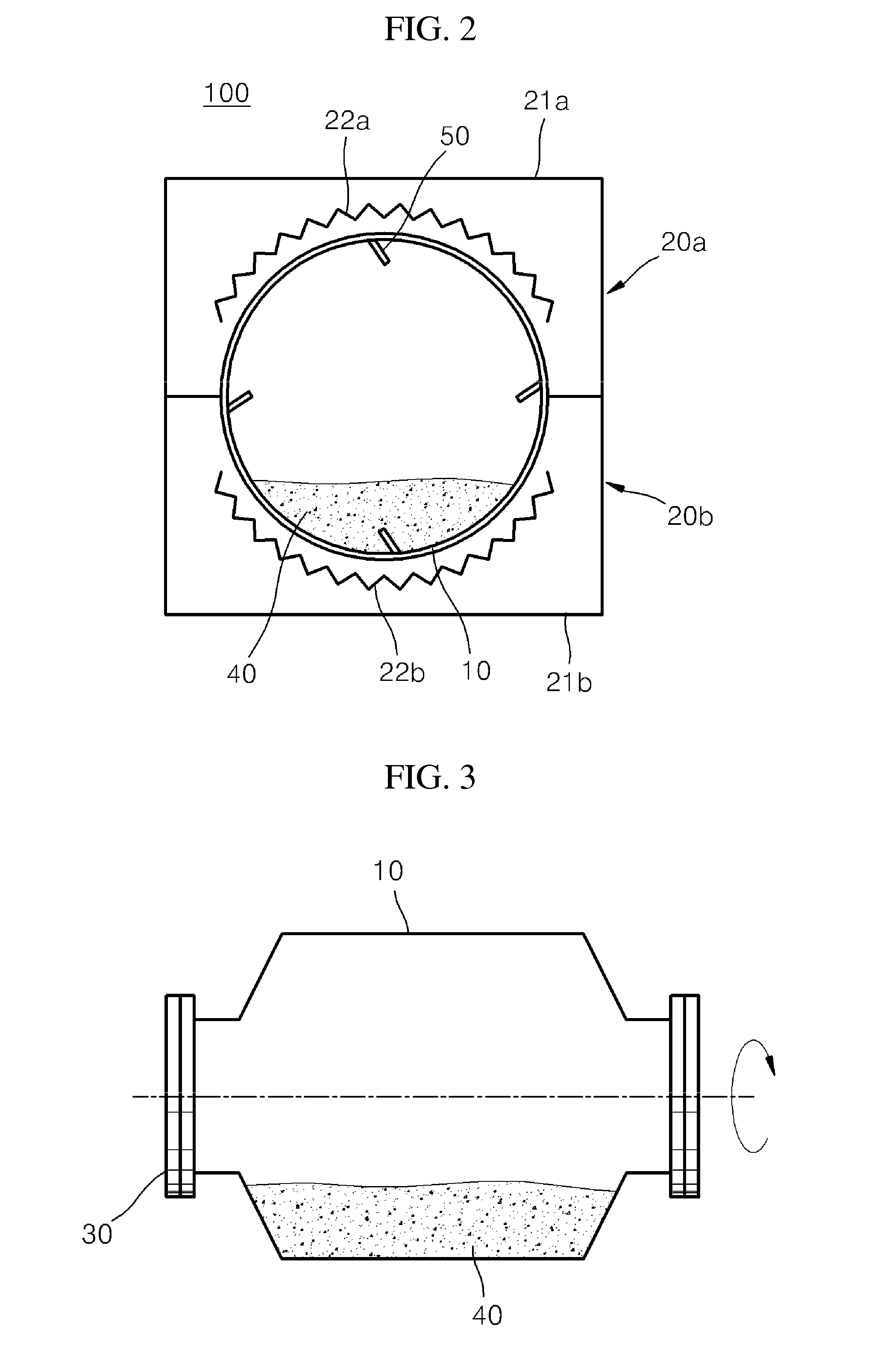

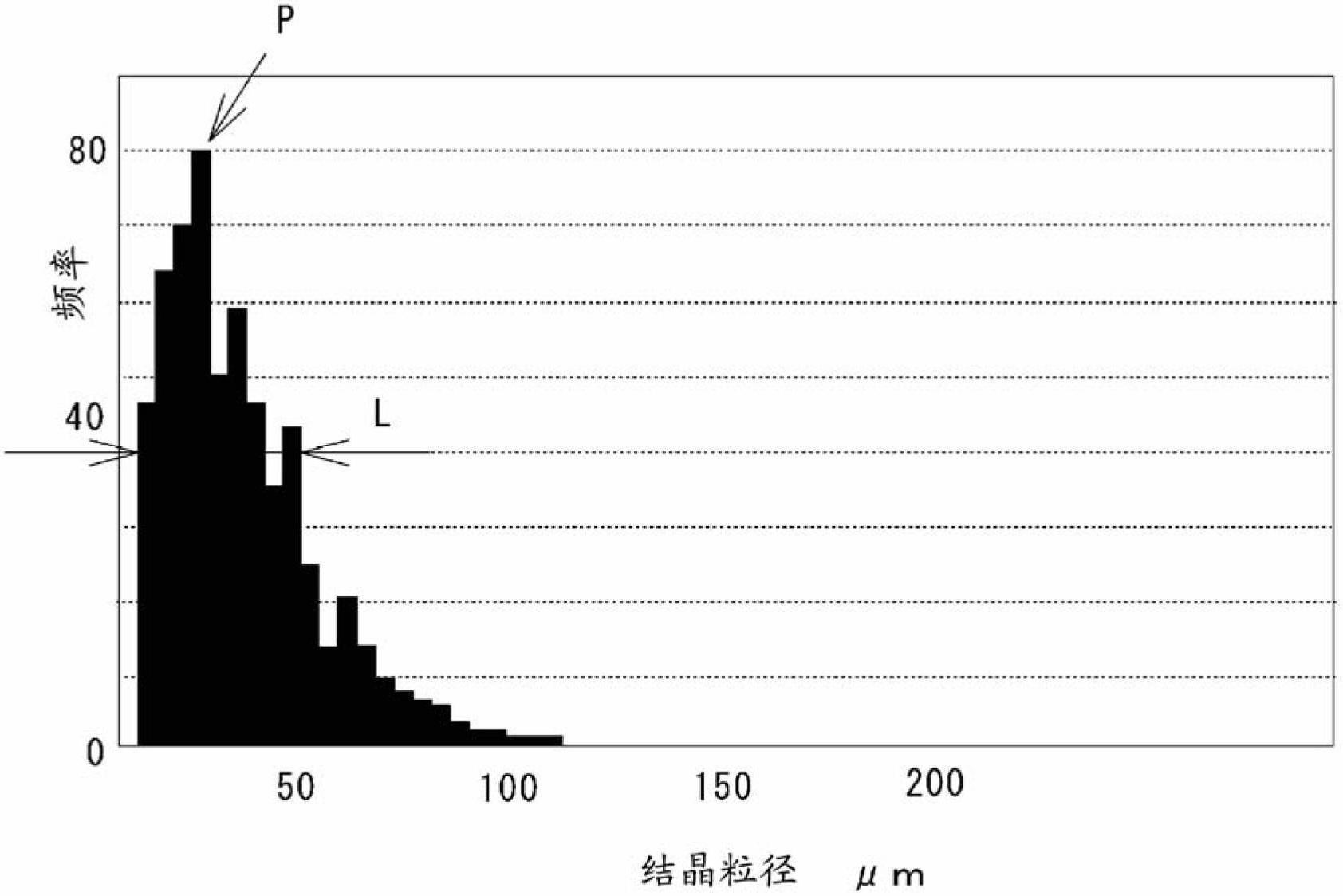

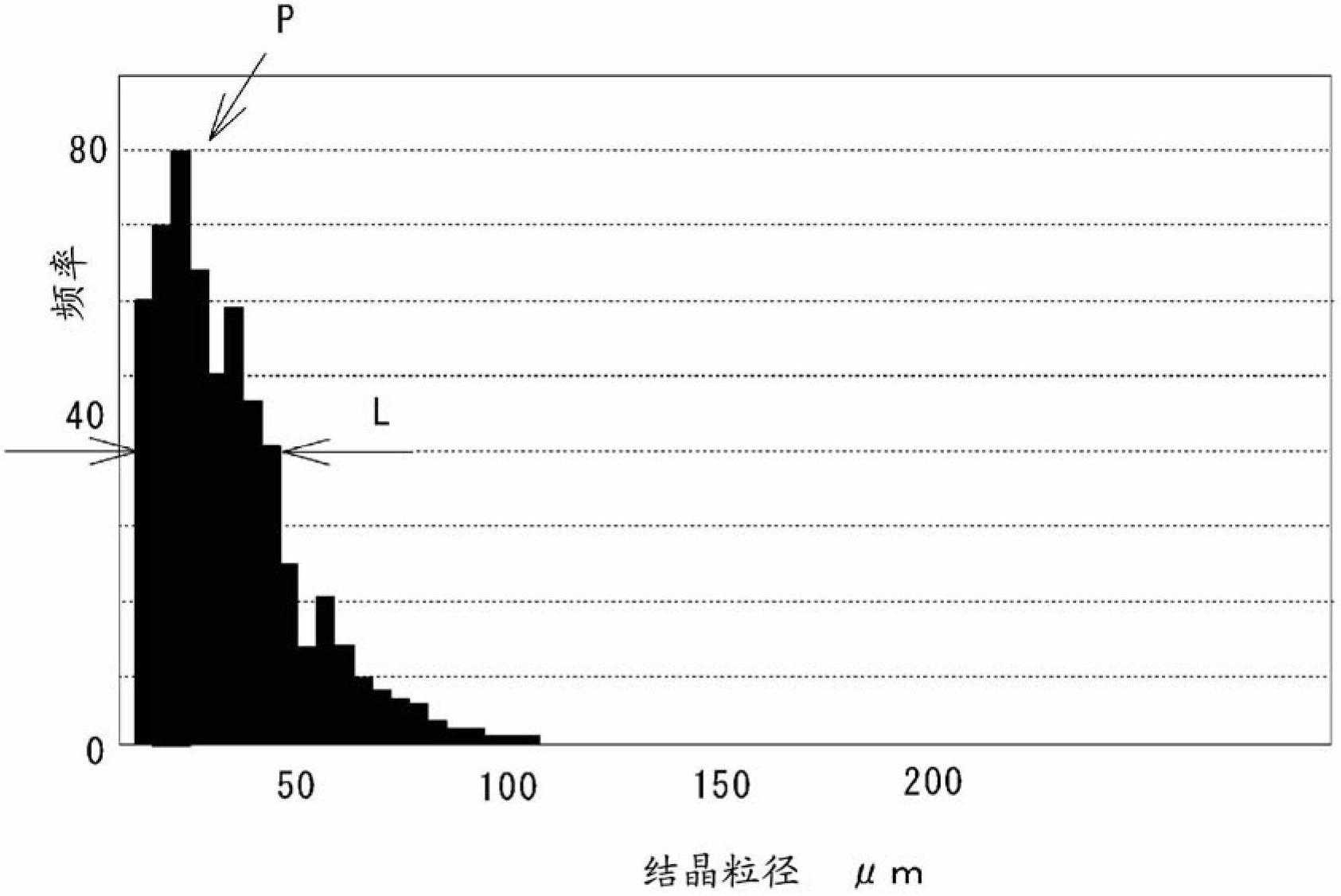

Manufacturing method of pure copper plates, and pure copper plate

ActiveCN102652182AFine uniform grainsEasy to processVacuum evaporation coatingSputtering coatingIngotCopper

Owner:MITSUBISHI SHINDOH CO LTD +1

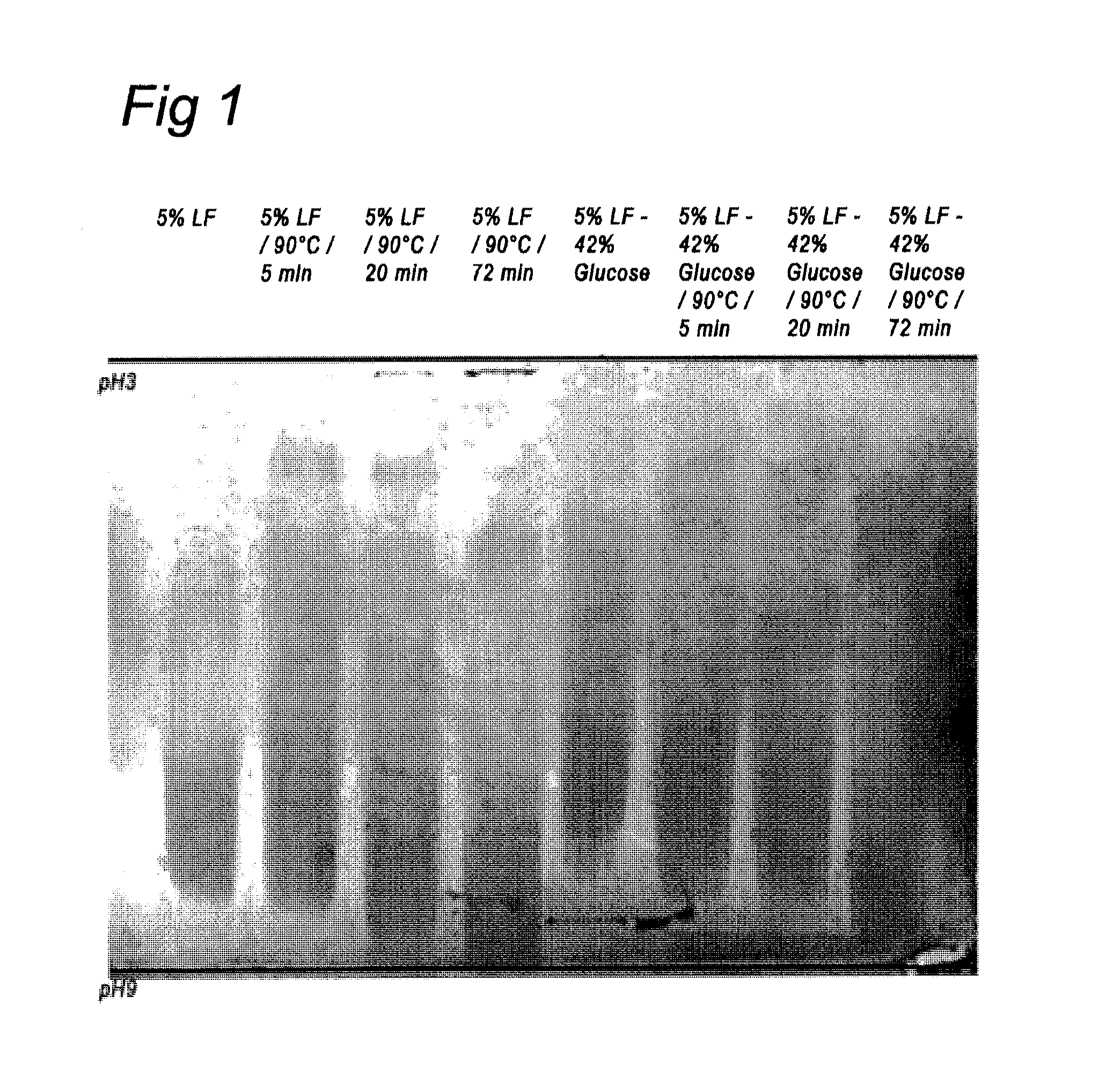

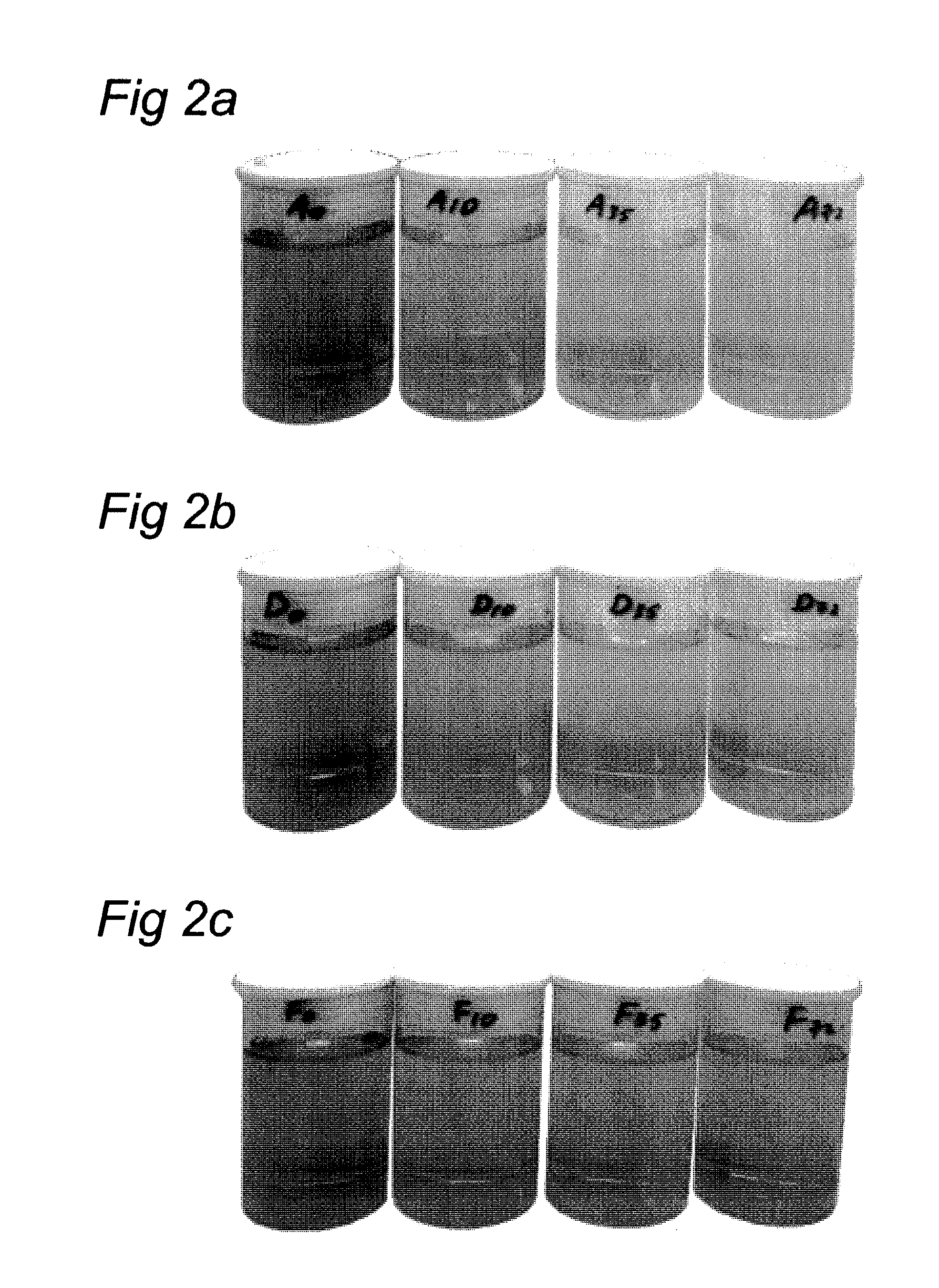

Heat-stable, aqueous lactoferrin composition and its preparation and use

Owner:FRIESLANDCAMPINA NEDERLAND BV

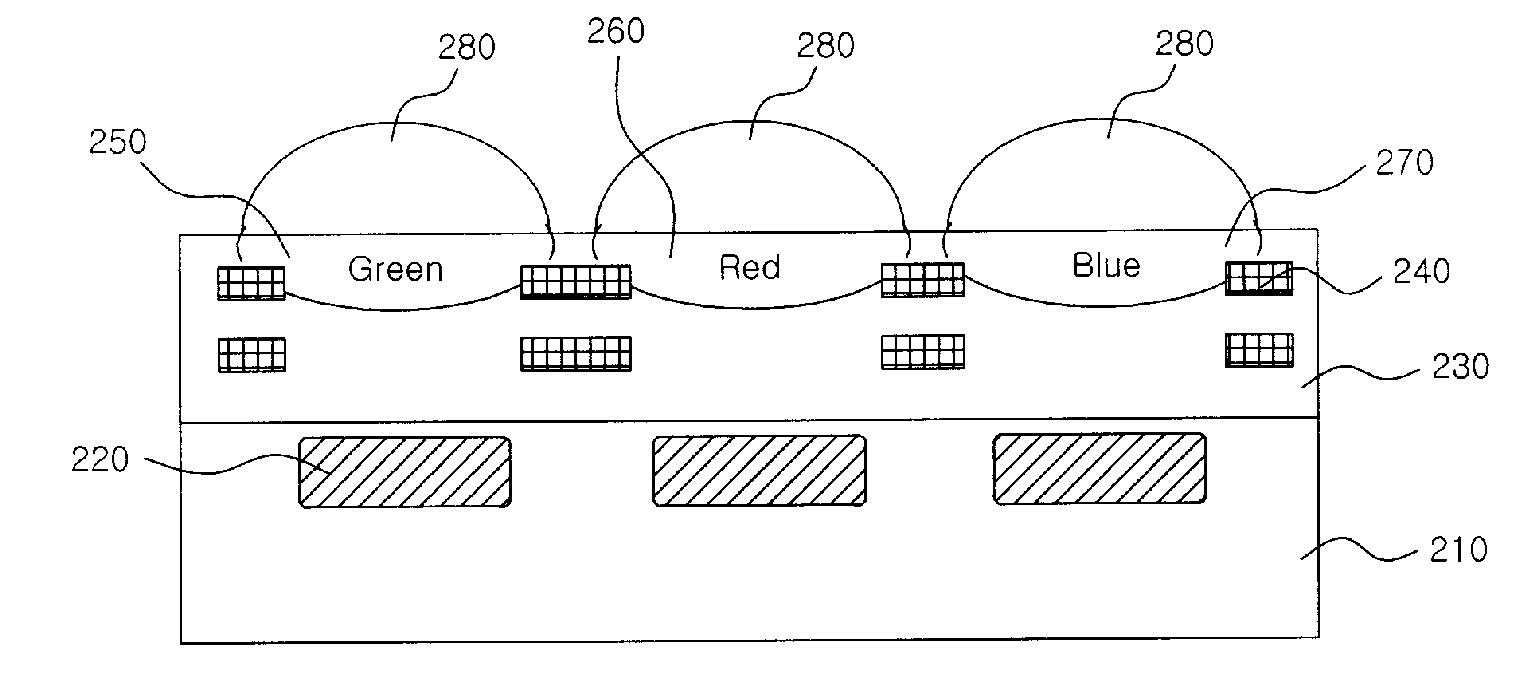

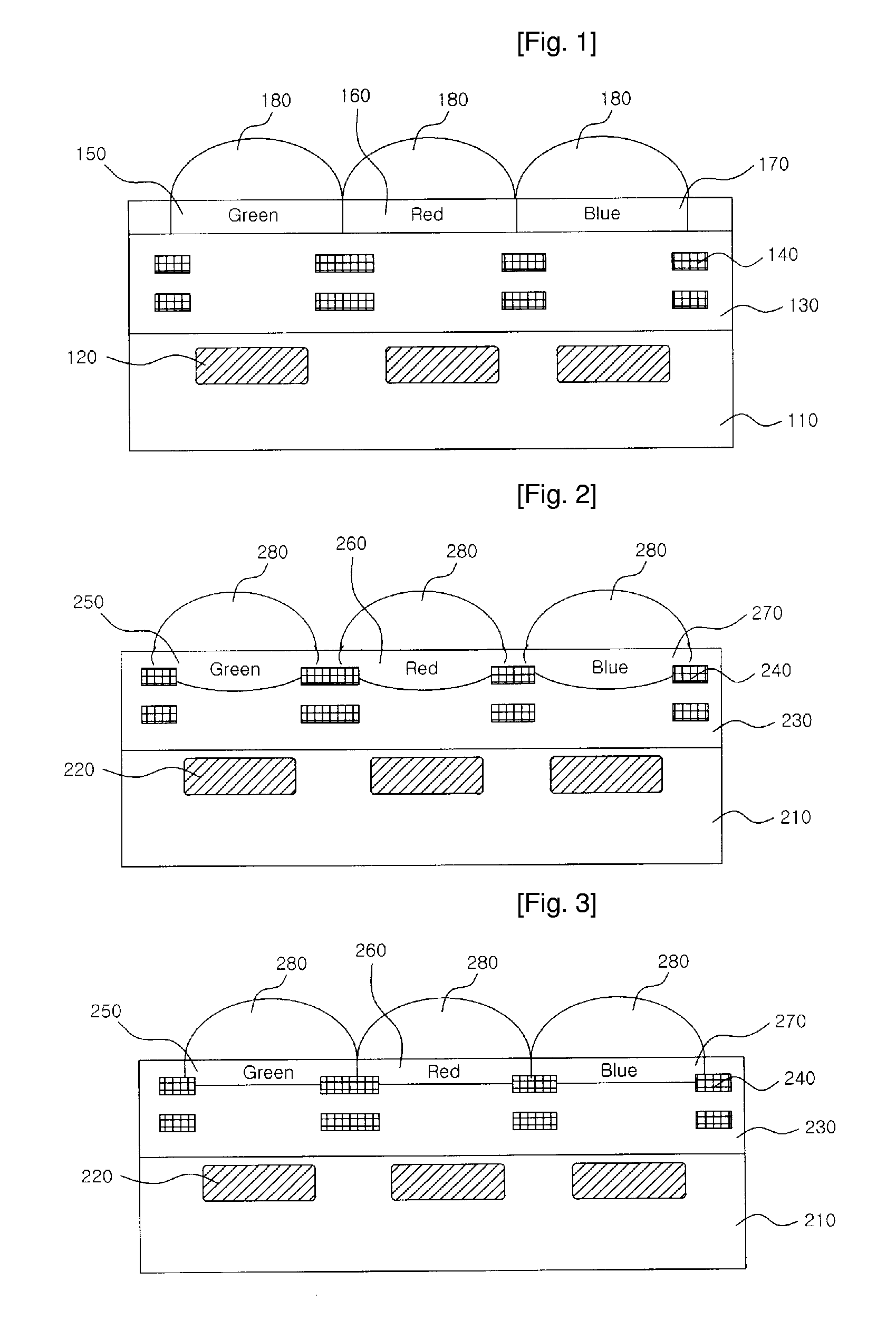

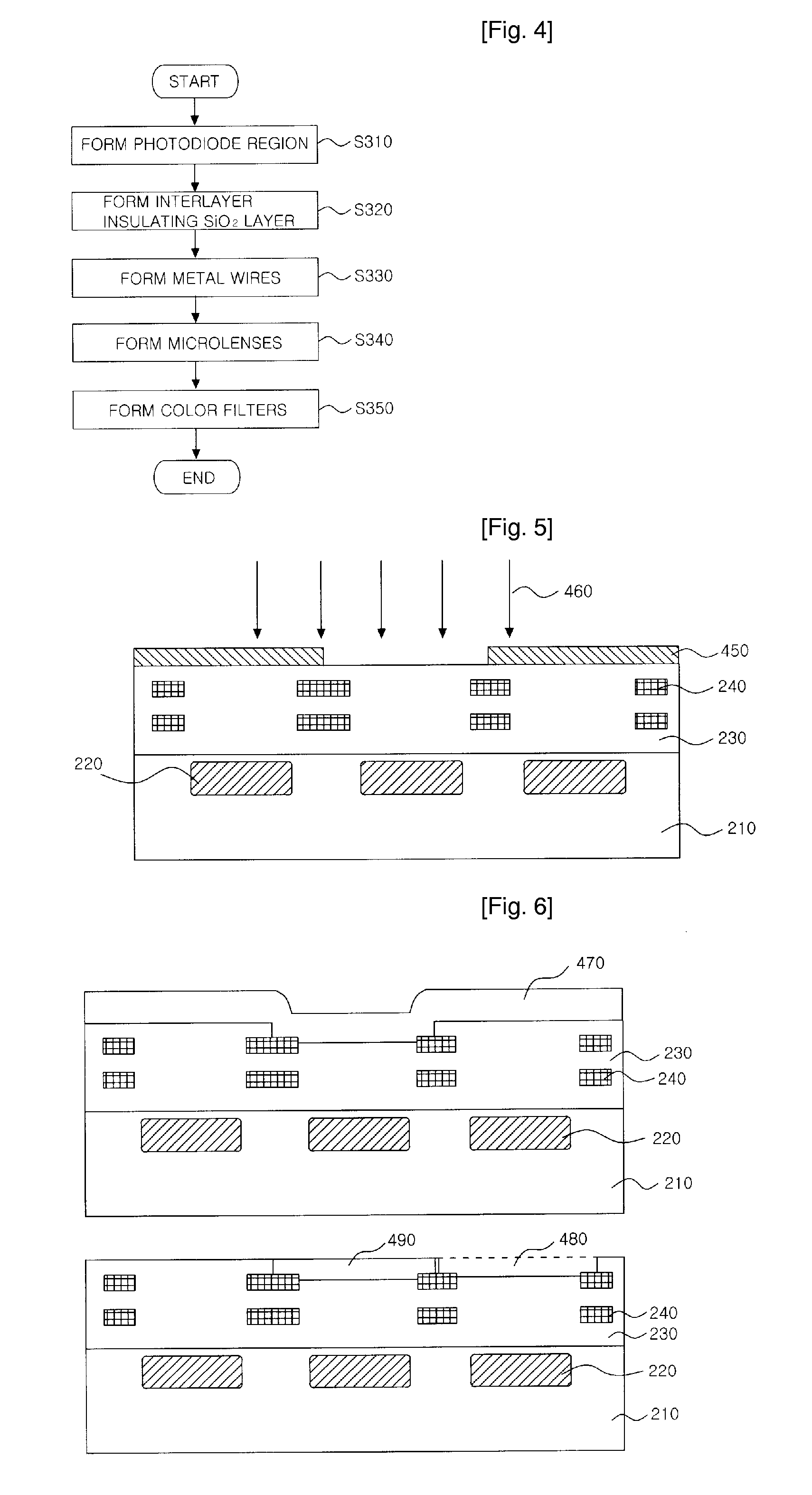

Image Sensor with Color Filters and Method of Manufacturing the Same

InactiveUS20080296713A1High imaging sensitivityReduce distanceSolid-state devicesSemiconductor/solid-state device manufacturingStep heightLight filter

Owner:SILICONFILE TECH INC

Heat treatment method for recovering performance of K465 alloy turbine blade

ActiveCN103643188ARecovery performance (creep) effect is obviousSquare shapeFurnace typesHeat treatment furnacesTurbine bladeAlloy

The invention discloses a heat treatment method for recovering the performance of a K465 alloy turbine blade and belongs to the technical field of metallurgy. The heat treatment method comprises the following steps of 1, blade feeding, 2, furnace heating and then heat preservation: in vacuum or inert gas protective atmosphere, carrying out heat preservation at a temperature of 950-960 DEG C for 40-45min, carrying out heat preservation at a temperature of 1190-1200 DEG C for 2-2.5h and carrying out heat preservation at a temperature of 1230 DEG C for 4-4.5h, and 3, furnace cooling: (1), carrying out cooling from a temperature of 1230 DEG C to a temperature of 1000 DEG C at a cooling rate of 40+ / -25 DEG C / min by inert gas-based differential pressure cooling, and (2), feeding inert gas at a temperature of 1000 DEG C, carrying out cooling to a temperature of 300 DEG C, and opening a furnace door at a temperature below 300 DEG C and carrying out cooling. The heat treatment method can obviously recover the performance (such as creep deformation) of the K465 alloy turbine blade after a service cycle. Through the heat treatment method, transgranular gamma' polygonal or flower basket-shaped morphology is transformed into the cubical morphology so that morphology squaring is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

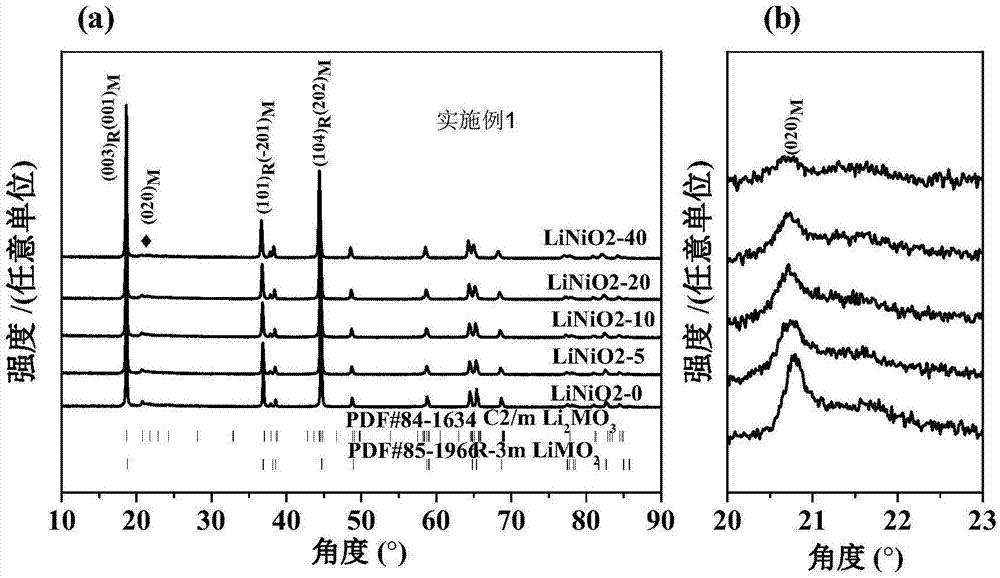

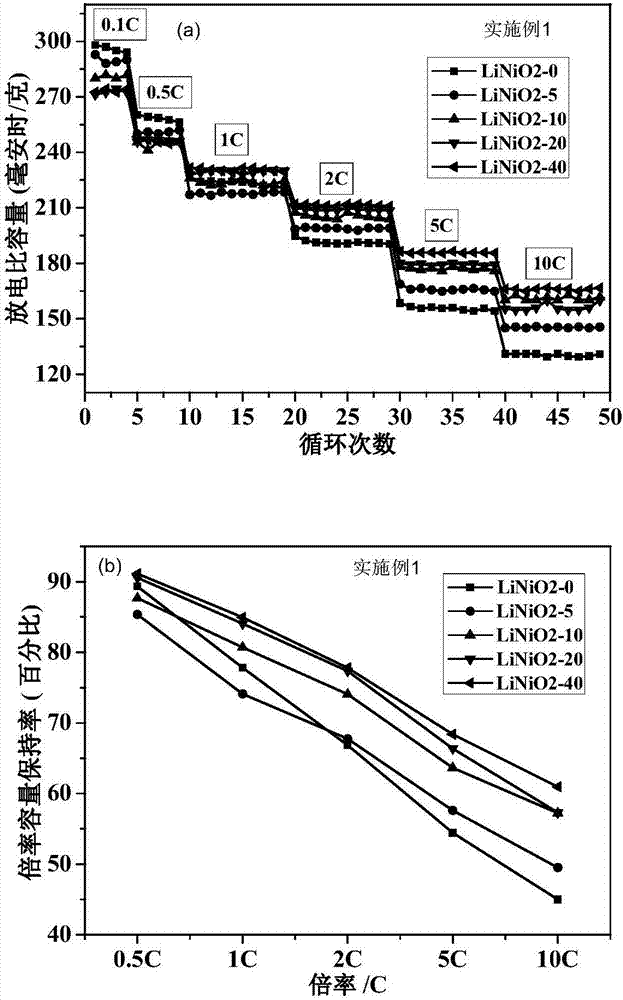

Layered lithium-rich manganese oxide positive electrode material suppressing capacity/voltage attenuation during circulation process effectively and preparation method therefor and application thereof

InactiveCN107069026AIncrease energy densityImprove cycle stabilityCell electrodesSecondary cellsCyclic processHigh energy

Owner:ZHEJIANG UNIV

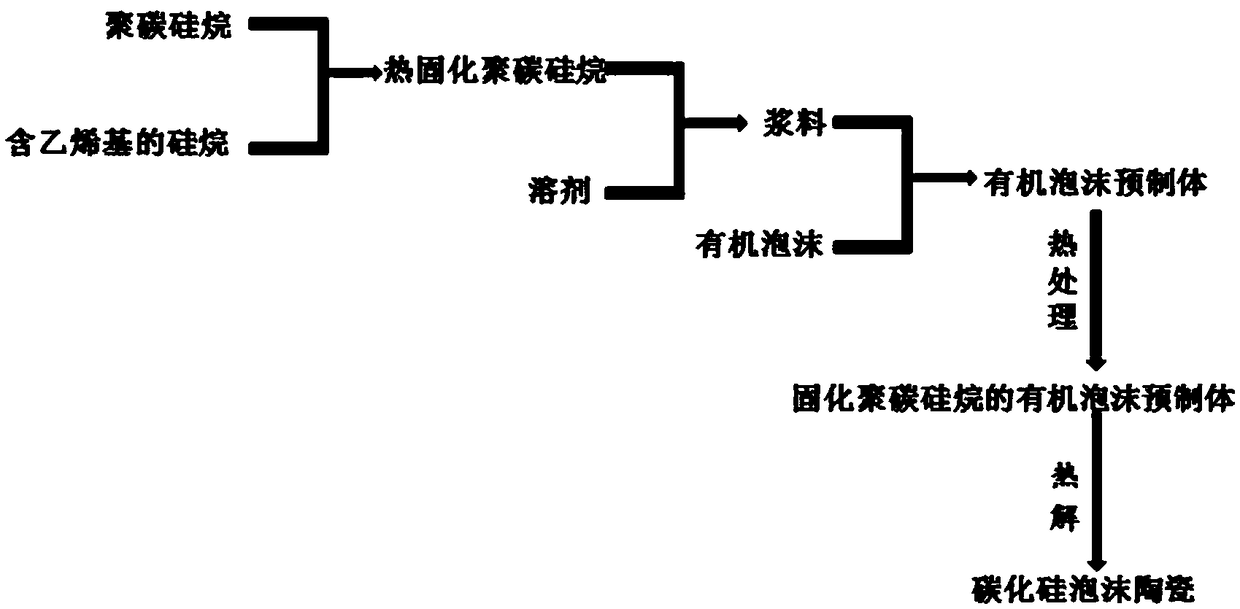

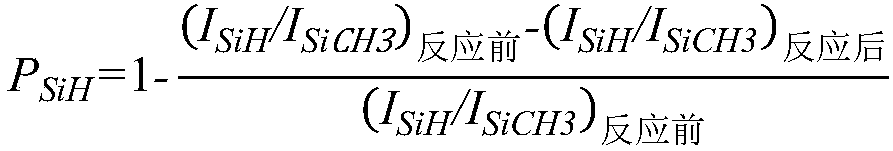

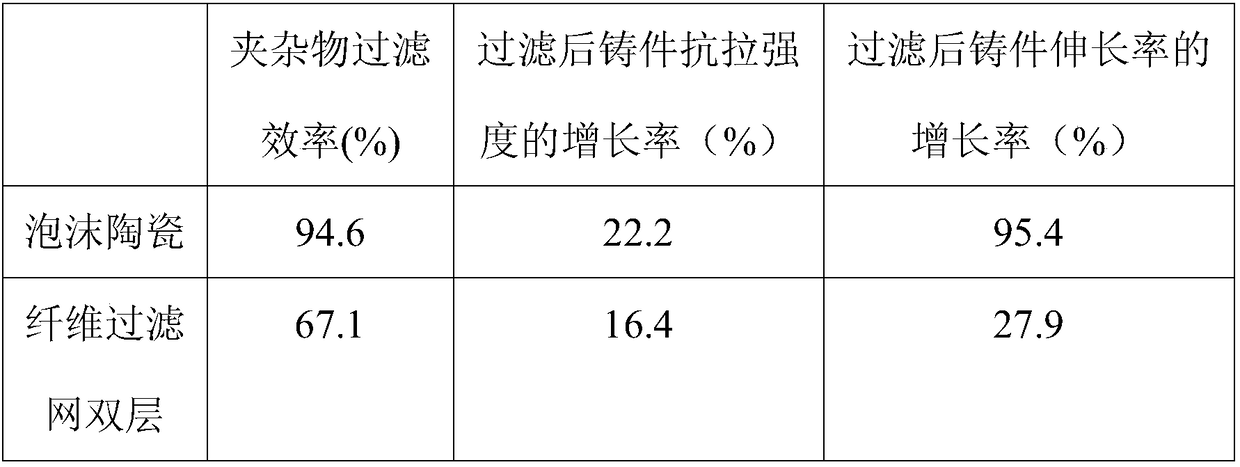

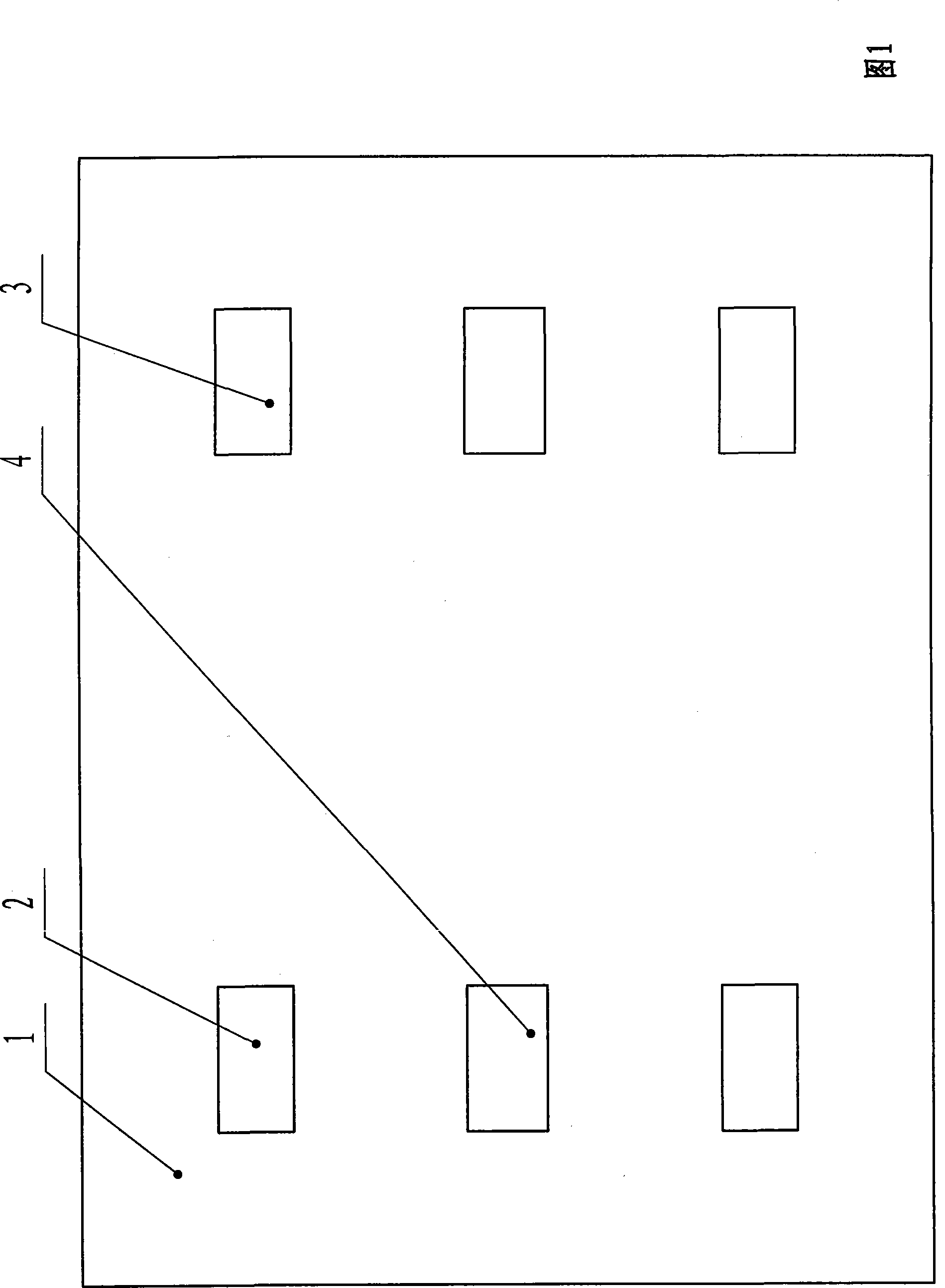

Silicon carbide foamed ceramic, and liquid metal filter produced therefrom

InactiveCN108558409ANo foamingControl pore structureCeramicwareStationary filtering element filtersFiltrationHydrosilylation

Owner:俞雪利

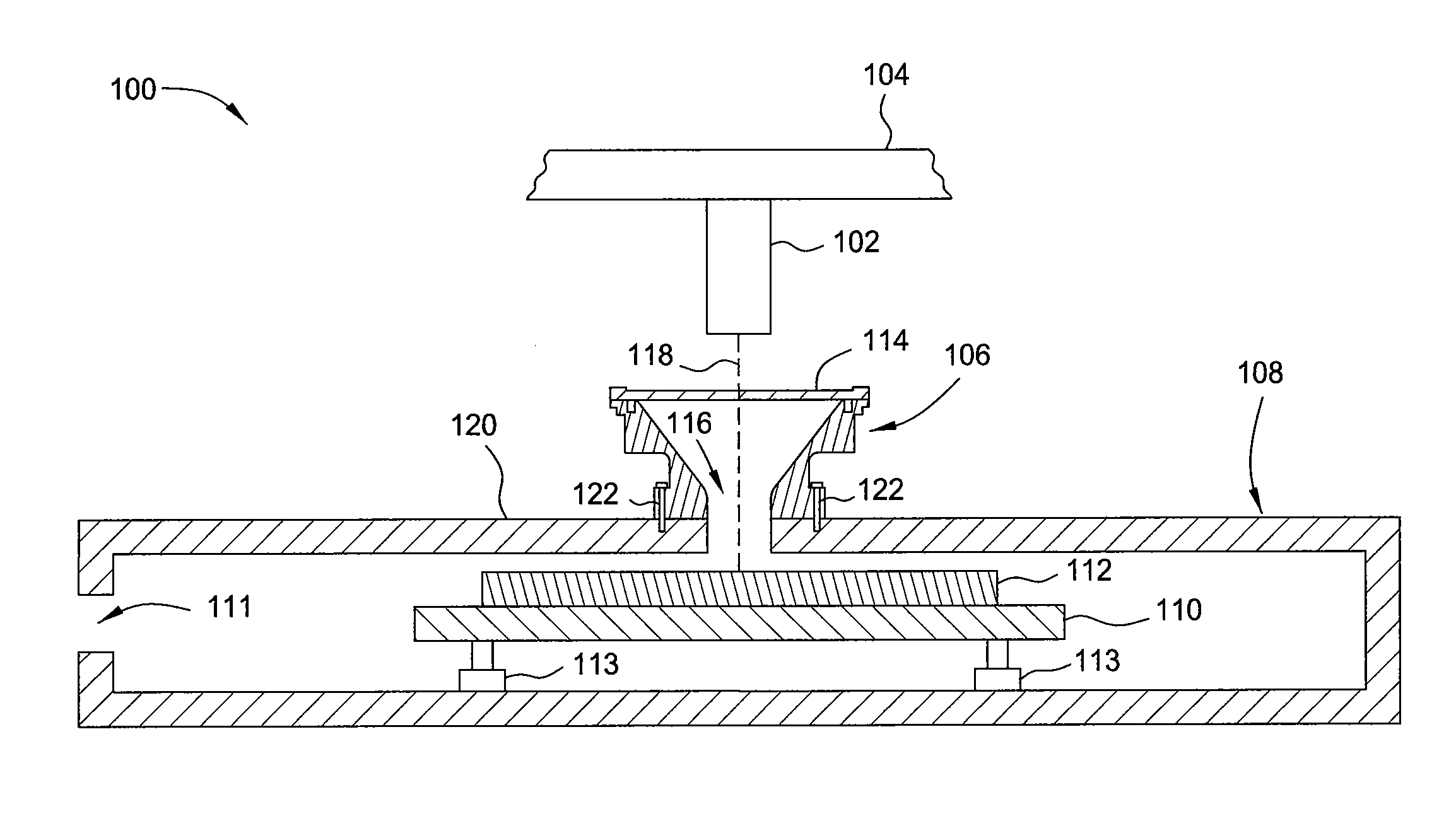

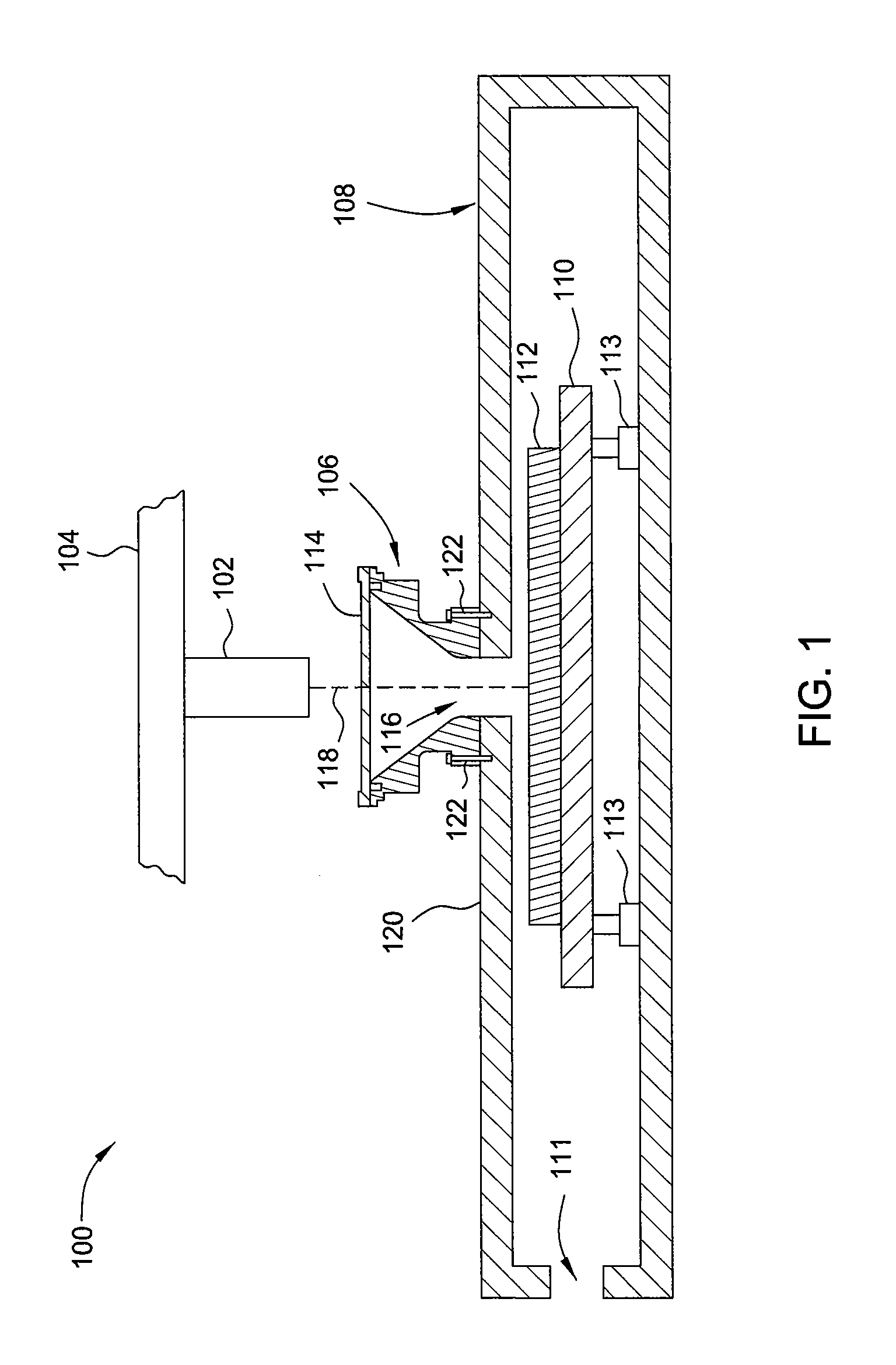

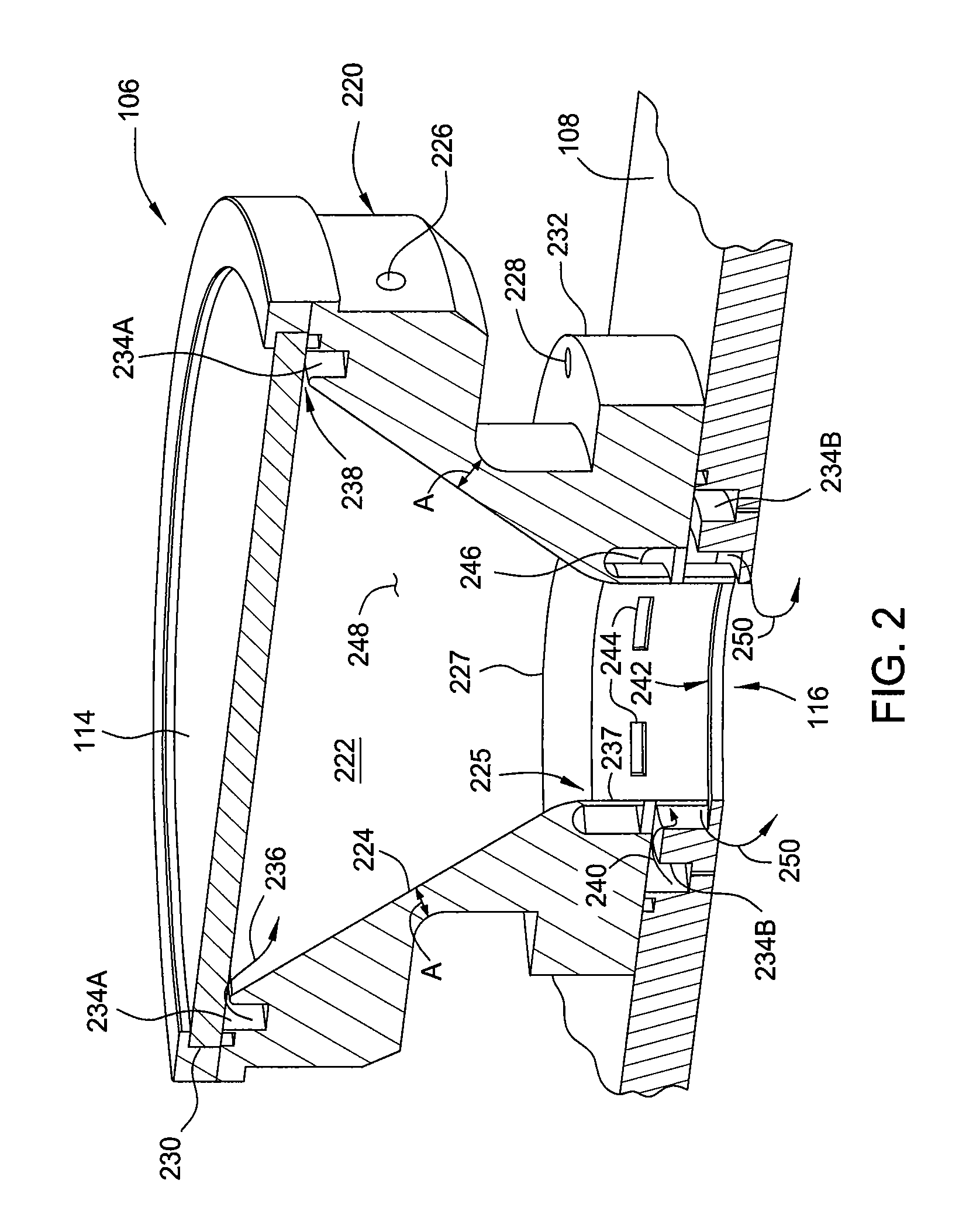

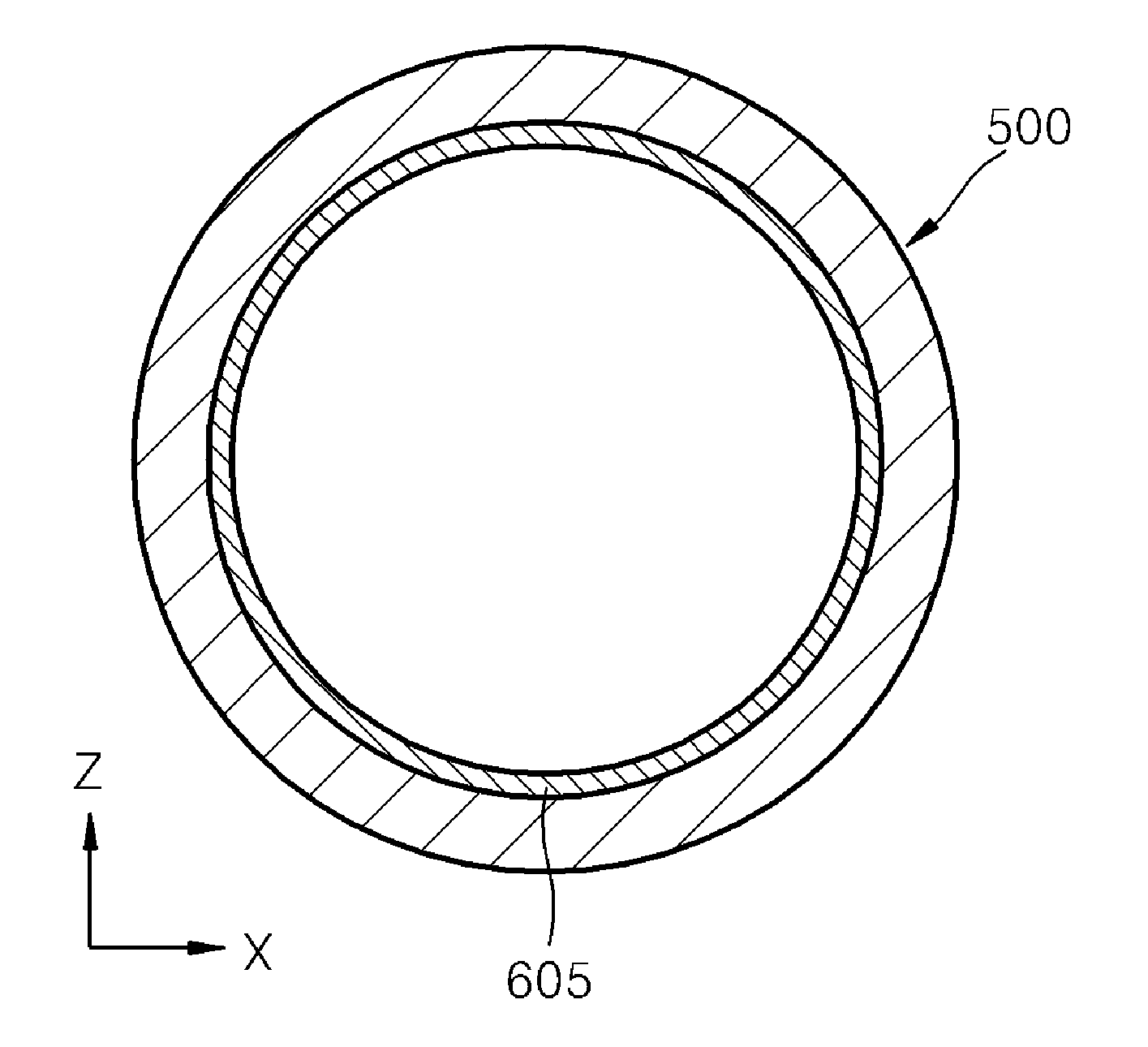

Wafer spot heating with beam width modulation

ActiveUS20190371631A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLight beamHeat treated

Embodiments of the present disclosure provide a thermal process chamber that includes a substrate support, a first plurality of heating elements disposed over or below the substrate support, and a spot heating module disposed over the substrate support. The spot heating module is utilized to provide local heating of regions on a substrate disposed on the substrate support during processing. Localized heating of the substrate alters temperature profile. The shape of the beam spot produced by the spot heating module can be modified without making changes to the optics of the spot heating module.

Owner:APPLIED MATERIALS INC

Method for reducing unevenness of composite stainless steel plates in manufacturing composite steel plates

Owner:TAIYUAN IRON & STEEL GROUP

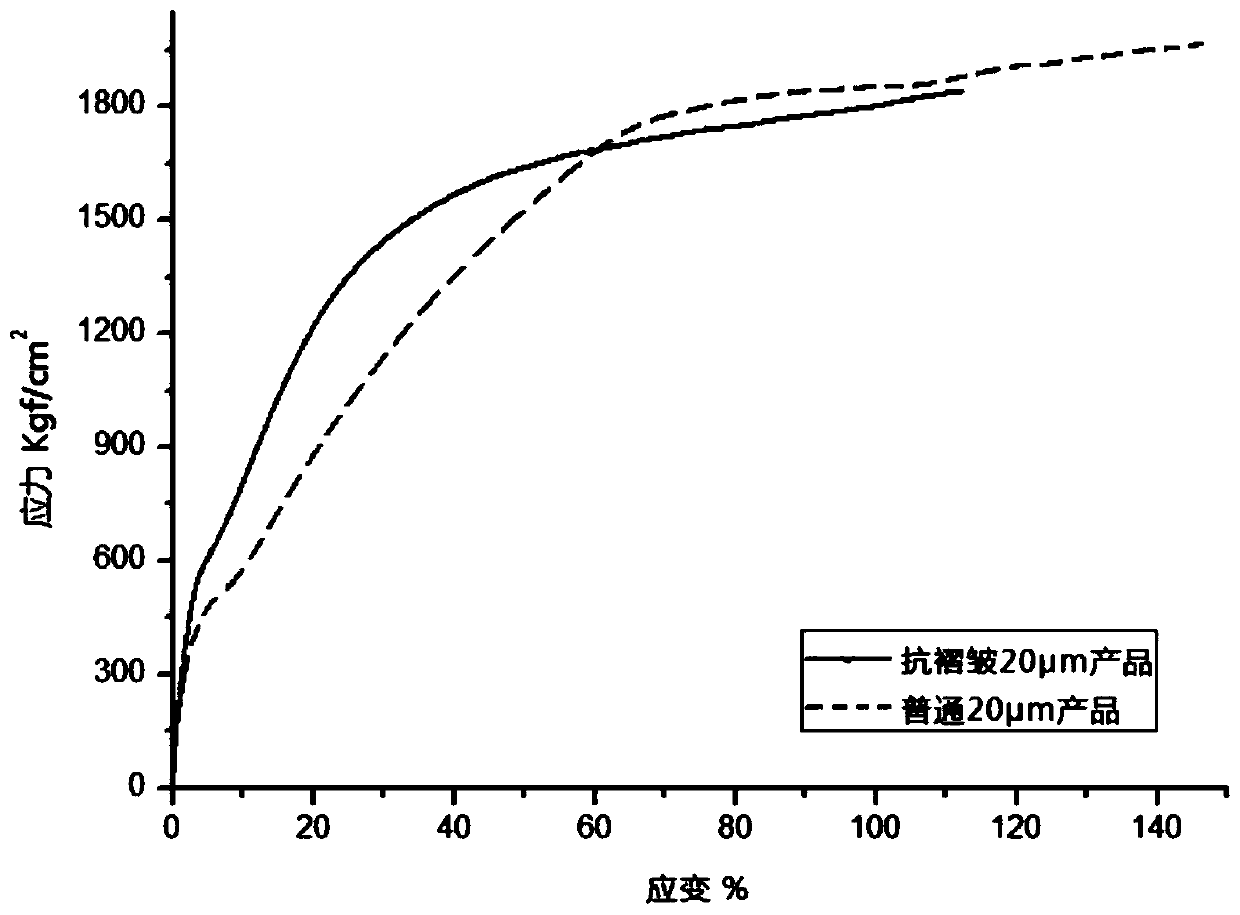

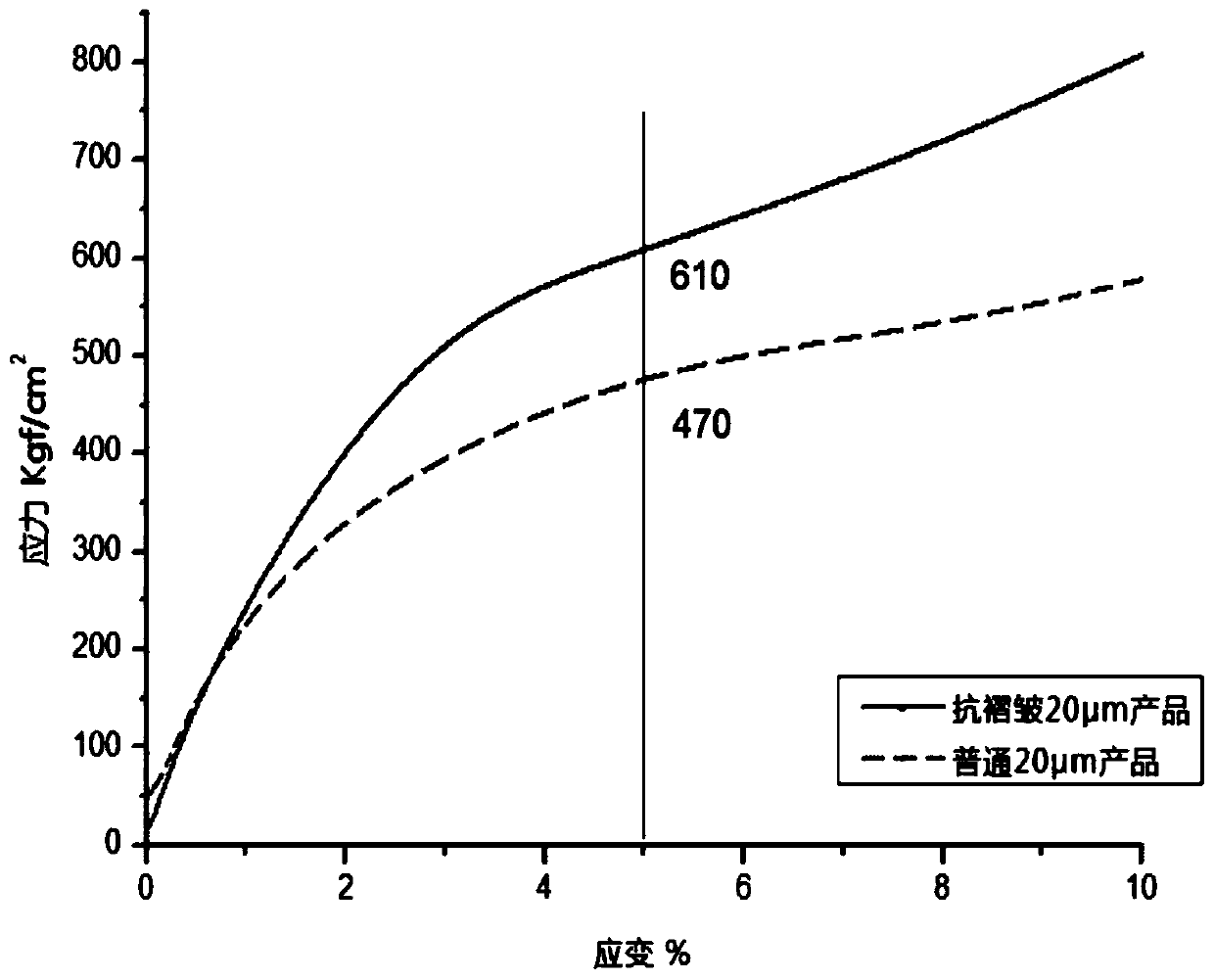

Preparation method of anti-wrinkle battery diaphragm, battery diaphragm and battery

InactiveCN109980157AReduce or even avoid flatnessReduce or even avoid securitySecondary cellsCell component detailsWrinkle skinInternal stress

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Antibacterial stainless steel for handrails or handles

ActiveCN108728767AIncrease Ga contentImprove antibacterial propertiesSeparated stateChemical composition

The invention discloses antibacterial stainless steel for handrails or handles, and belongs to the technical field of stainless steel materials. The stainless steel comprises the following chemical components of, by weight, less than or equal to 0.08% of C, less than or equal to 0.50% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.05% of P, less than or equal to 0.05% of S, 8.0-12.0% of Ni, 18.0-20.0% of Cr, 3.0-5.0% of Cu, 0.50-1.50% of Ga and the balance Fe. The antibacterial stainless steel is subjected to solid solution heat treatment, and then based on the supersaturation and solid solution of the Ga and the Cu in a matrix, the Ga and the Cu exist in two forms, namely a solid solution state and a gallium-rich phase separated state. The use environment of the handrails or the handles is generally the air environment, and when the handrails or the handles are in contact with sweat, gallium ions can be effectively dissolved out due to the existence of the gallium-rich phase, so that the effects that reproduction and propagation of pathogenic bacteria among human hands are obviously inhibited, and the probability of occurrence of group-occurring bacterial infection events is reduced are achieved. According to the antibacterial stainless steel, the propagation risk of the pathogenic bacteria among the human hands is reduced, and the antibacterial stainless steel can be widely applied to the stair handrails, railings, the door handles and the like for living decoration.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

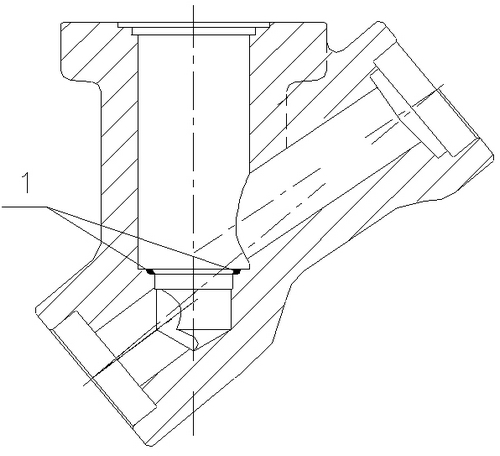

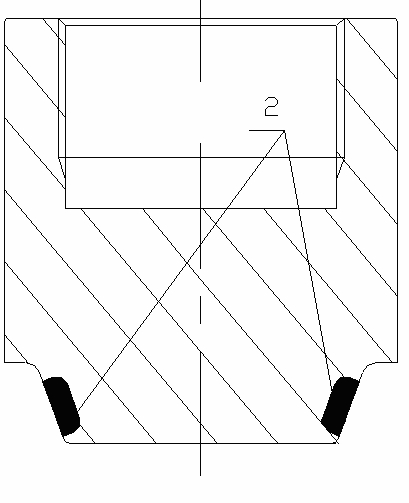

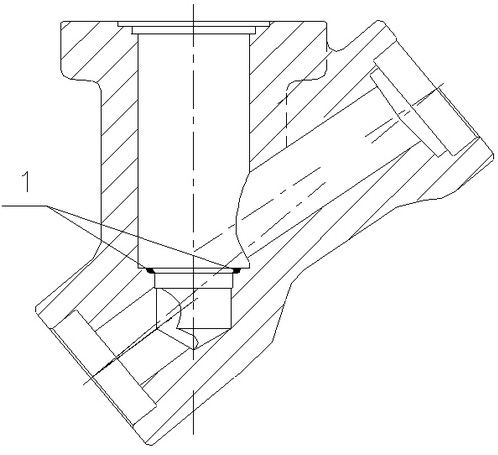

Argon arc welding surfacing process for cobalt-free material ERFeCr-A5

Owner:DALIAN DAGAO VALVE

Socket head cap screw processing technology

Owner:重庆沁煌实业有限公司

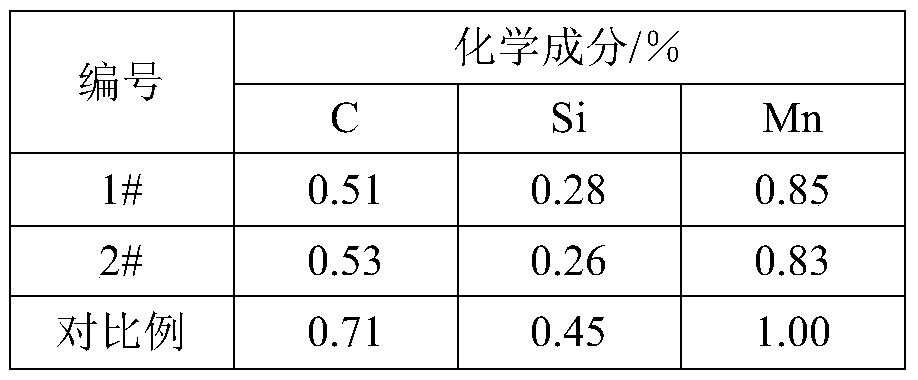

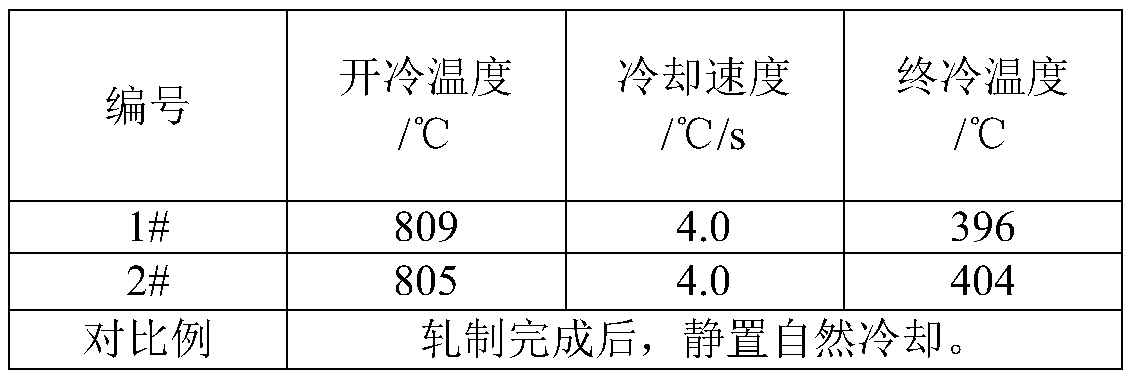

Steel rail for high-speed railway and manufacturing method thereof

InactiveCN111349862AImprove wear performanceHigh running densityFurnace typesHeat treatment process controlEngineeringMaterials science

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

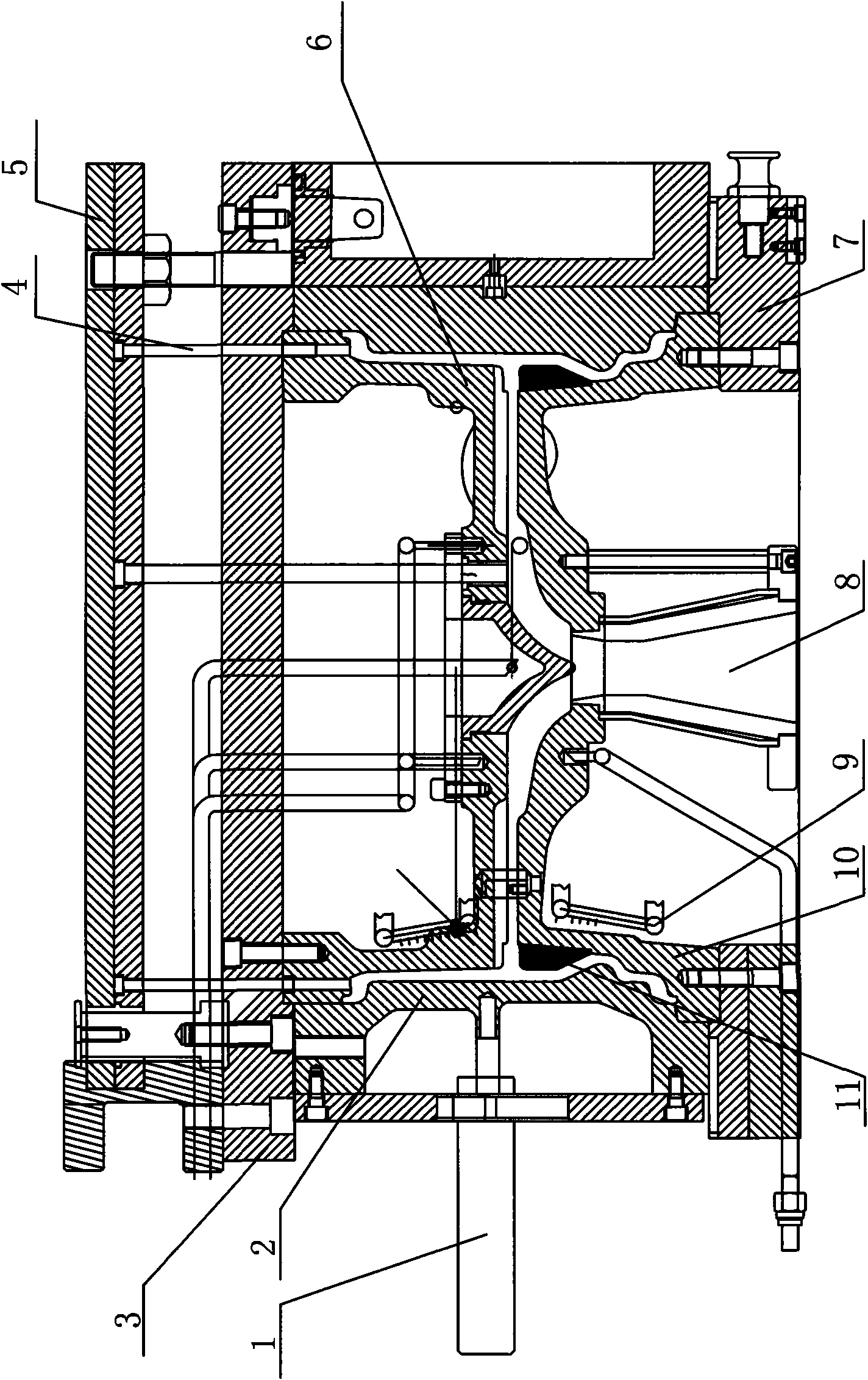

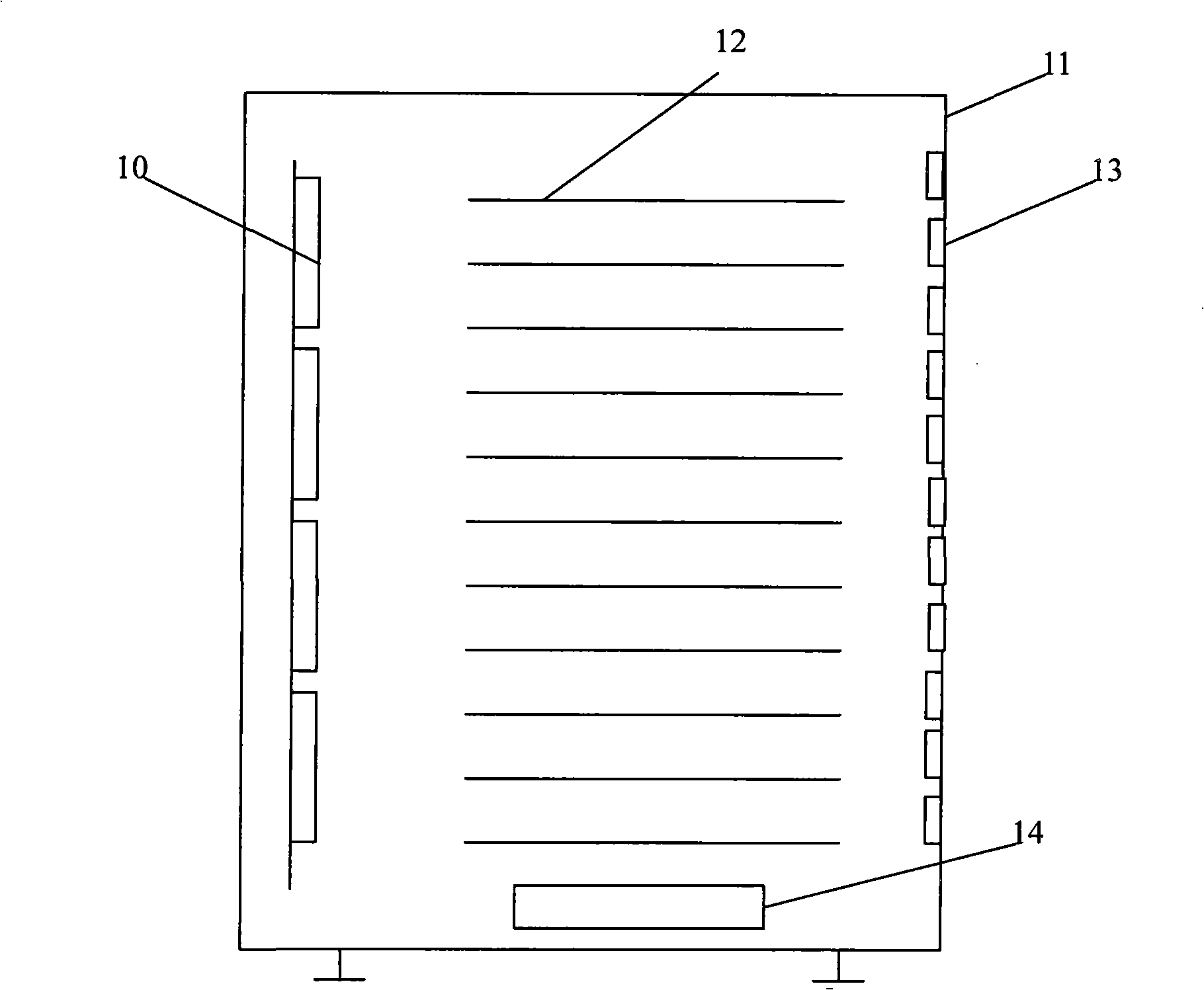

Seal heat treatment apparatus, manipulator apparatus and rigidification substrate method thereof

InactiveCN101349504ASimple structureDoes not affect the placementGripping headsCharge supportsHigh intensityEngineering

Owner:INESA DISPLAY MATERIALS

Steel rail damaged connector in-situ welding construction technology

ActiveCN105507097AReduce processing timeShorten the timeRailway track constructionMaterial consumptionArchitectural engineering

The invention discloses a steel rail damaged connector in-situ welding construction technology. Damaged connectors are mainly processed according to the steps of making preparation for construction, sawing the connectors at low temperature, releasing a steel rail fastener, making the steel rail elongation meet requirements, bending a steel rail, aligning the correctors, thermally processing the connector after welding and finally locking the steel rail. The construction technology is applicable to processing damaged connectors of a newly-built line and an existing line steel rail. Processing time can be shortened, time is saved for intensive later-period welding construction of the steel rail, transporting and rail welding construction staff are reduced, and material consumption of the steel rail and connector welding is reduced. The number of the steel rail connectors is not increased, it is avoided that because the number of the connectors is increased, the risk of the damaged connectors is increased, and the later-period running and maintaining workload is not increased; raw materials of the steel rail are saved, and the damaged connectors can be processed in a more economical and efficient mode.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

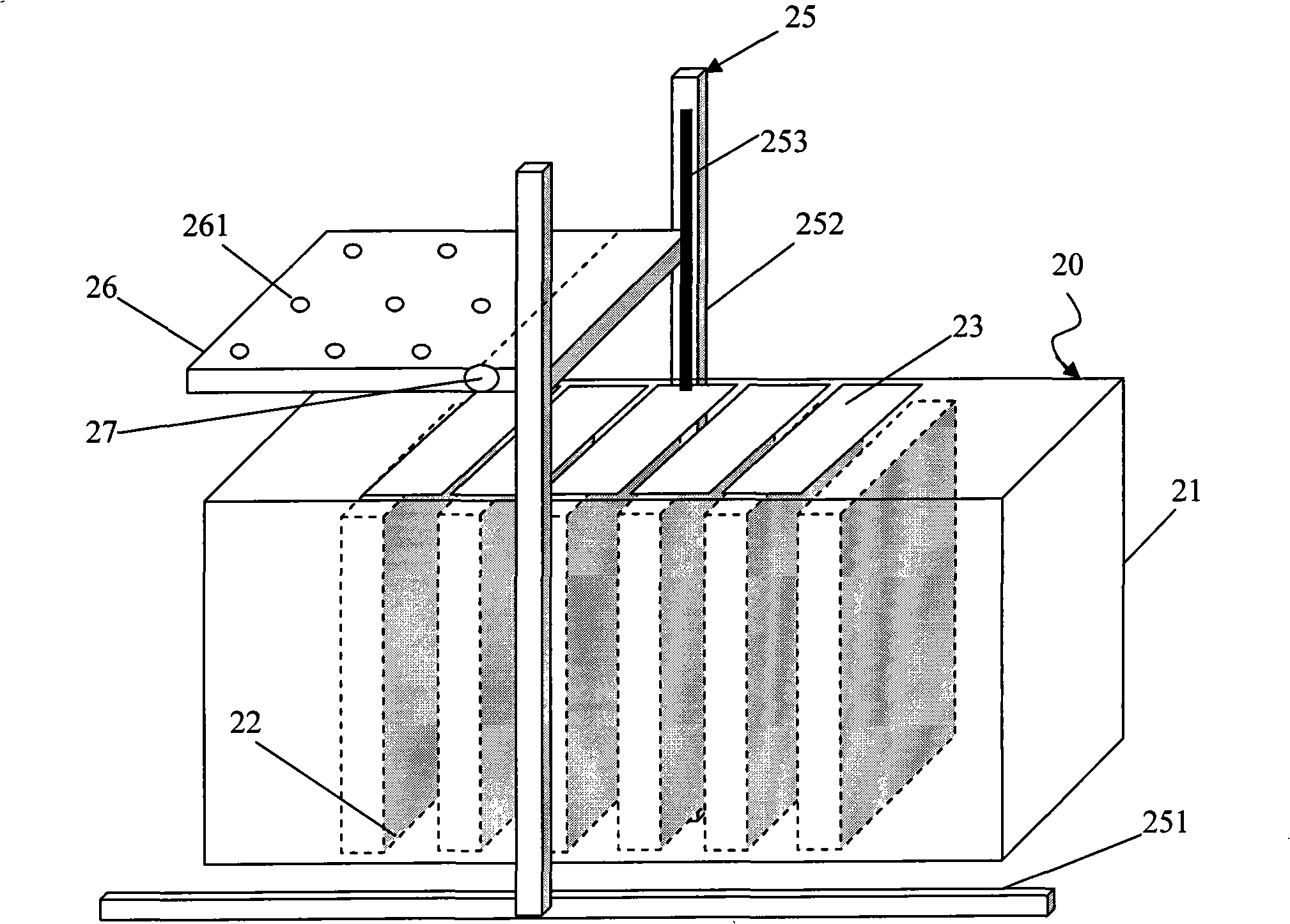

Heat treatment process for powder part

InactiveCN102732699AReduce the temperature difference between inside and outsideReduce crackingIncreasing energy efficiencyTemperature differenceHeat treated

Owner:鑫光热处理工业(昆山)有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap