Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooling rate. the rate at which temperature decreases with time (°C/min) immediately after the completion of hyperthermia treatment.

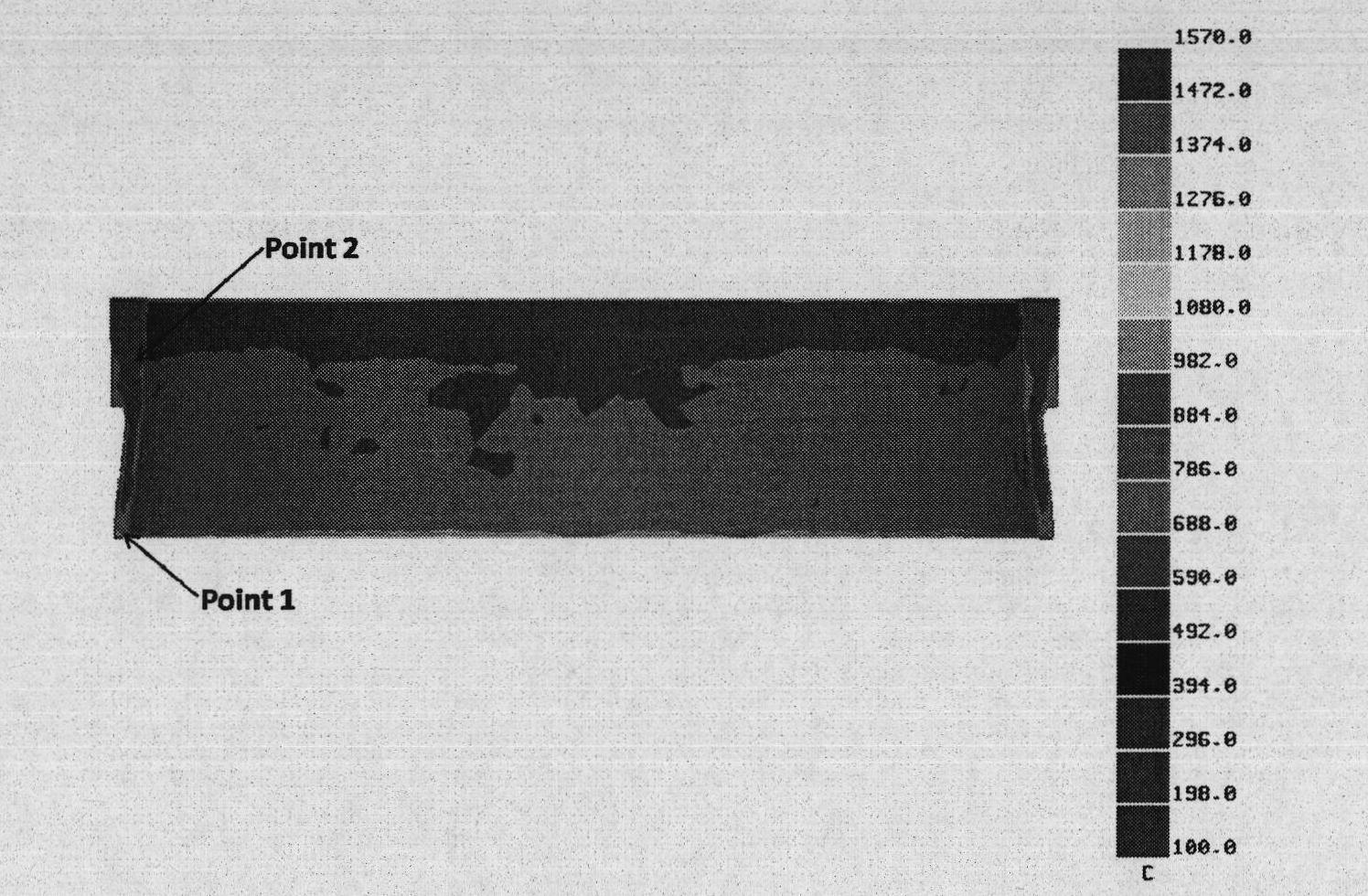

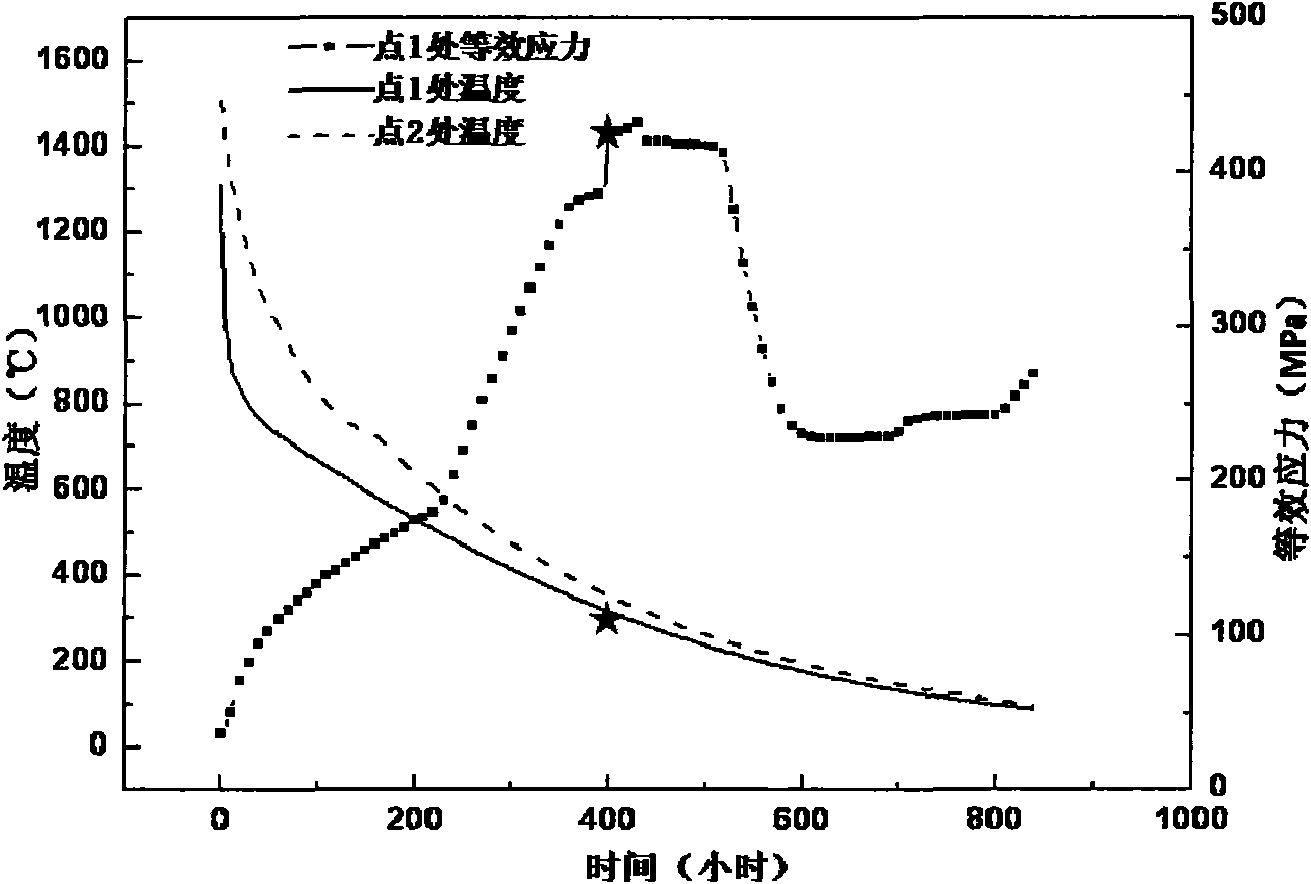

High-temperature shakeout process applied to large-size martensitic stainless steel cast

ActiveCN102211179AReduce the use of sand boxesShorten the timeTemperature controlMartensitic stainless steel

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat processing technology method of austenitic ductile iron wear-resistant casting

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

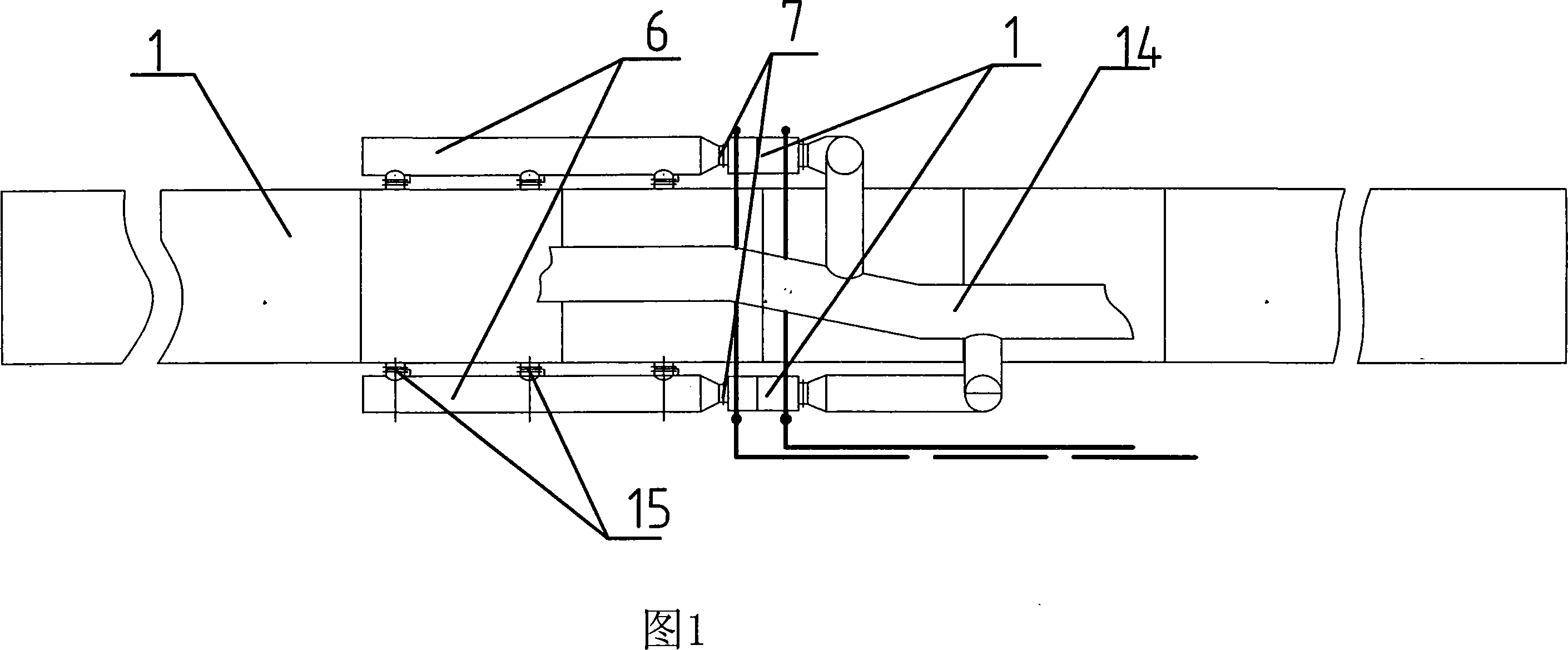

On-line quenching and tempering technology of seamless steel tube

InactiveCN103276180AResistant to bendingImpact resistantFurnace typesHeat treatment furnacesQuenchingMachining

The invention relates to an on-line quenching and tempering technology of a seamless steel tube. The technology comprises the steps as follows: (1), quenching: the temperature quickly rises to 900 DEG C to 920 DEG C at a speed of 25 DEG C-35 DEG C / s, then the temperature is quickly decreased to about 310 DEG C at a speed of 200 DEGC-220 DEG C / s by primary spraying, and secondary spraying is performed until the temperature is lower than 80 DEG C; and (2), tempering: the temperature rising speed is 20 DEG C-30 DEG C / s, the temperature rises to a range from 620 DEG C to 640 DEG C, and air cooling is performed after heat preservation. The on-line quenching and tempering technology of the seamless steel tube can reduce harmful elements and improve purity of steel, so that scrapping caused by harmful defects such as folding, cracks, separation layers, surface decarburization and the like generated in hot and cold machining of a pipe material can be avoided.

Owner:JIAXING XINJIYUAN STEEL TUBE MFG CO LTD

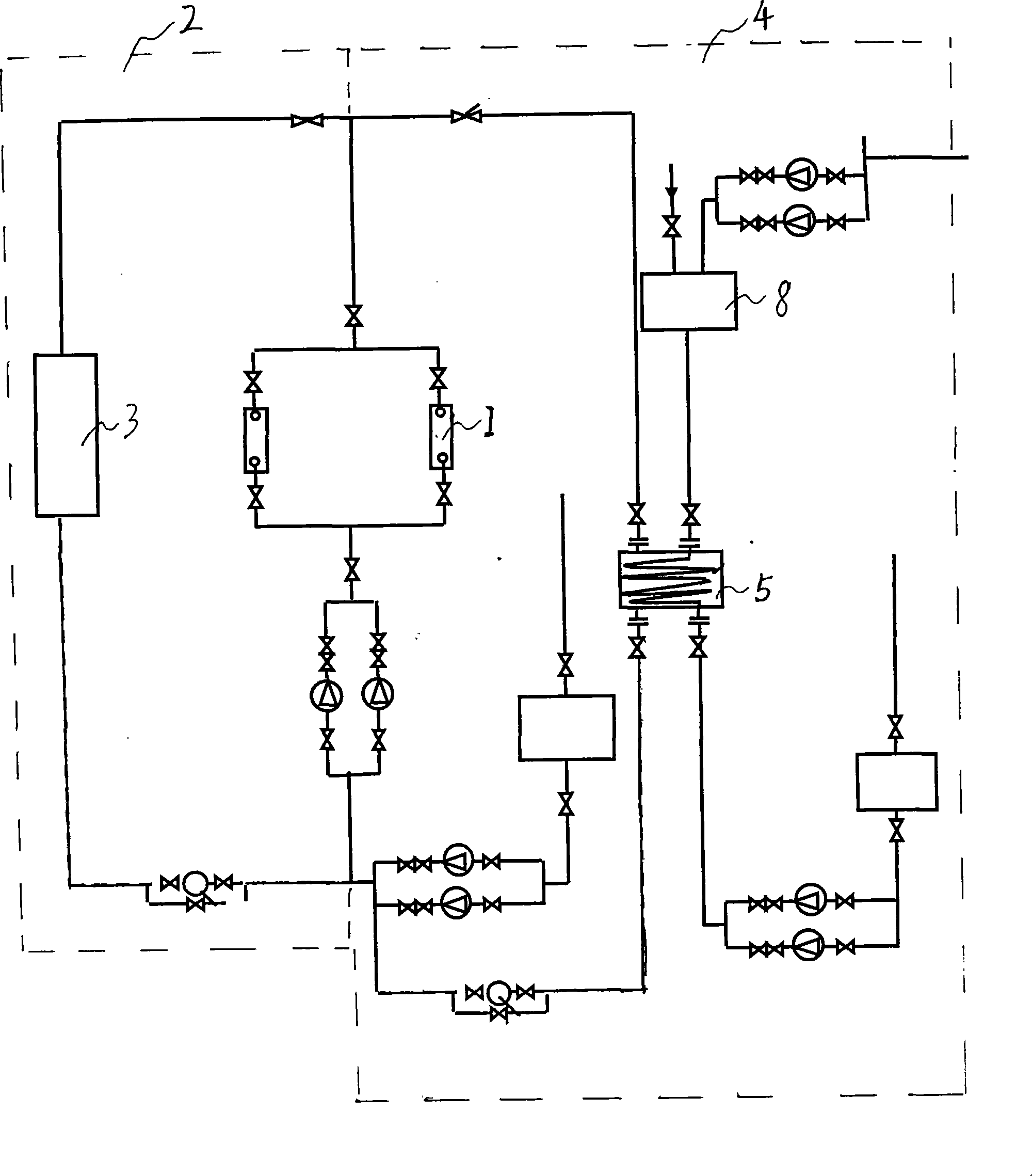

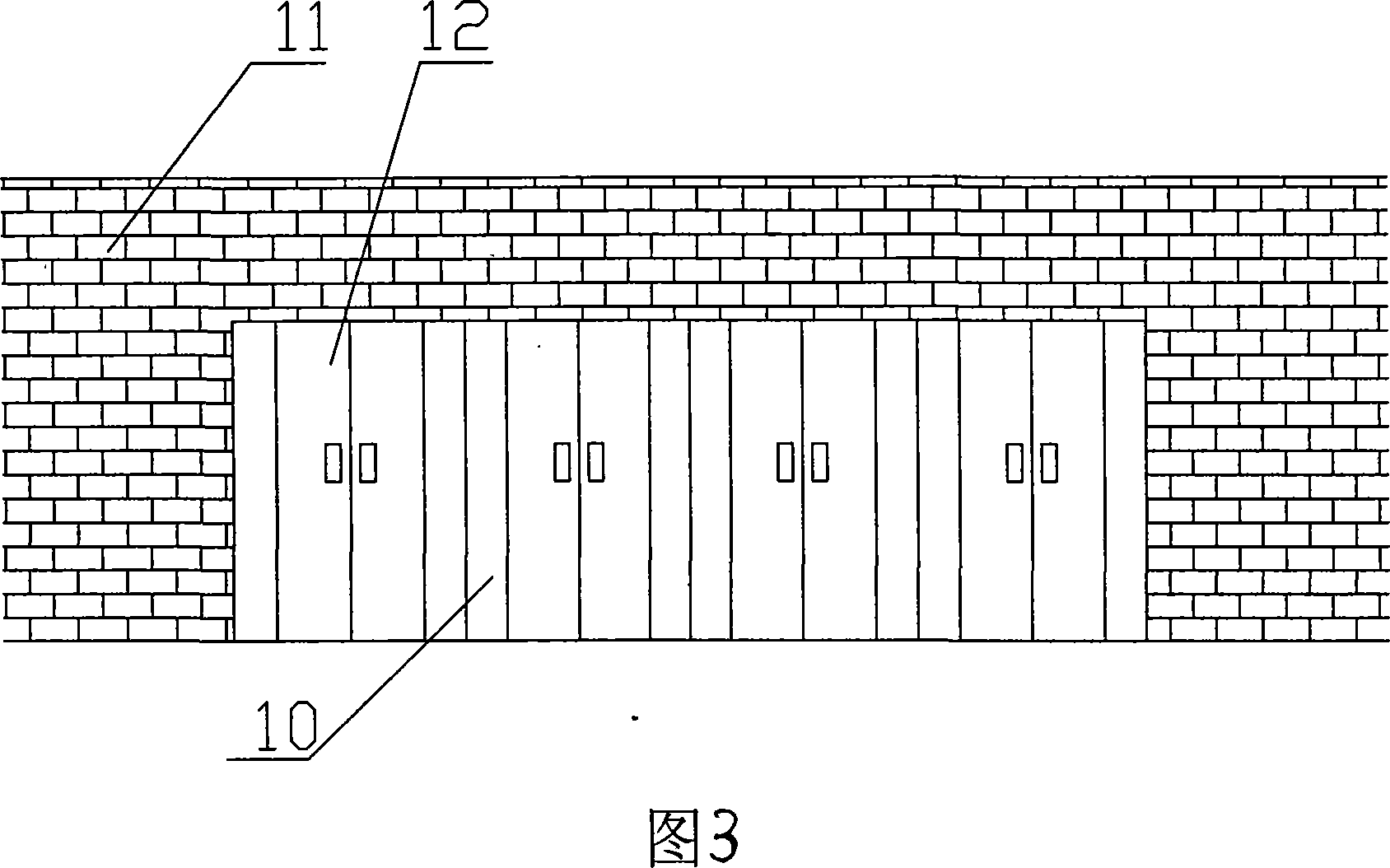

Gangue brick furnace residual heat utilization system

InactiveCN101158555AEmission reductionSpeed up coolingIncreasing energy efficiencyCombustion technology mitigationBrickWater source

Owner:SHANDONG HUAHENG MINING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap