Gangue brick furnace residual heat utilization system

A brick kiln and gangue technology is applied in the field of waste heat utilization system to achieve the effects of improving production efficiency, reducing exhaust gas emissions, and saving construction costs and investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical contents not mentioned below can adopt or learn from the prior art.

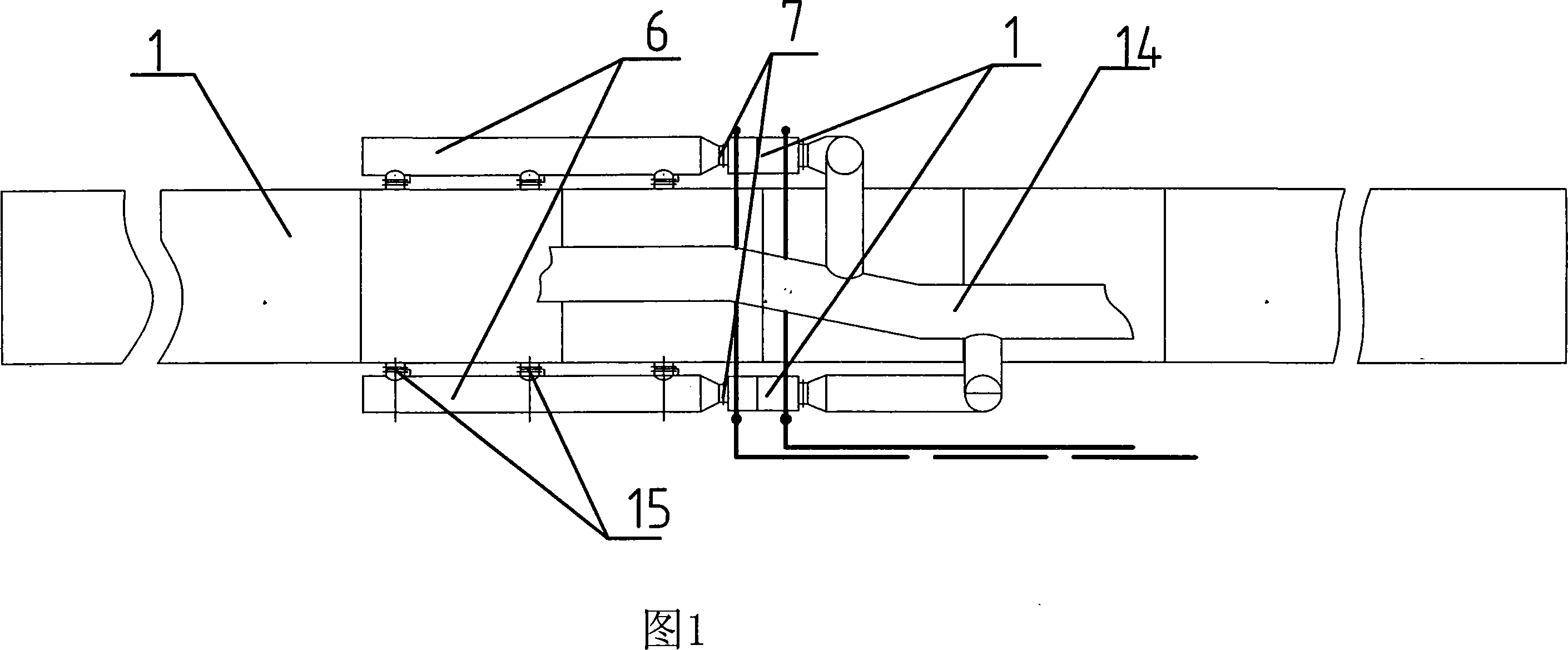

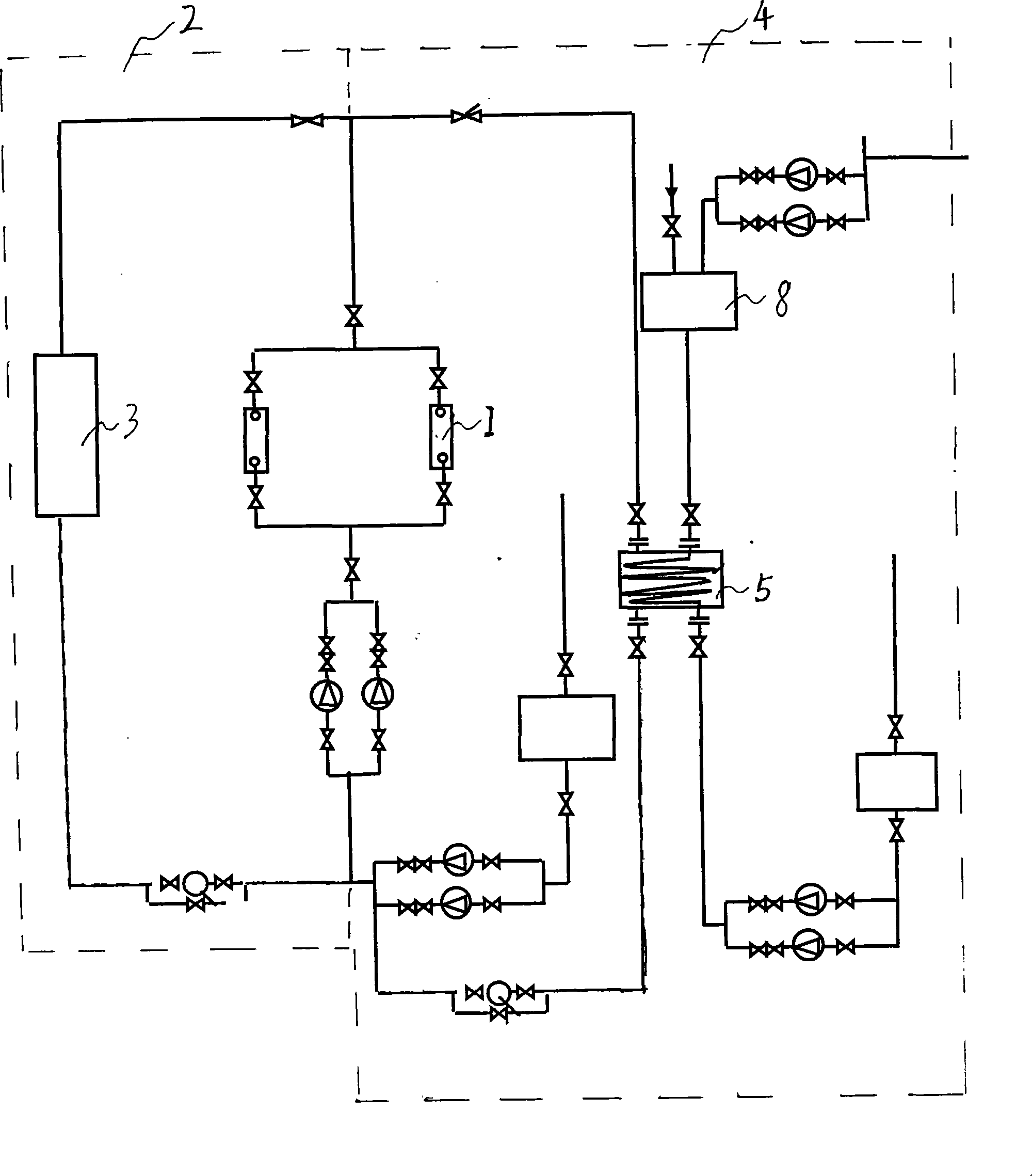

[0014] As shown in Figure 1 and Figure 2, the present invention includes a flue gas heat exchanger 1, the smoke inlet of the flue gas heat exchanger 1 is connected to the cooling section of the gangue brick kiln 15 through a pipeline 6, and the smoke exhaust port is connected to the gangue brick kiln through a pipeline The flue exhaust duct 14, the water circulation pipeline of the flue gas heat exchanger 1 is divided into two parallel branches, one branch is the heating branch 2, which flows through the heating radiator 3 from the water outlet and returns to the flue gas Radiator 1, the other branch is bathing branch 4, this branch flows through the secondary heat exchanger 5 from the water outlet and returns to the flue gas radiator 1, one end of the secondary heat exchanger 5 is connected to the water source, and the other end is connected to the bathroom 8. As shown in Figure 2, in ord

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap