Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Heat spreader" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat spreader transfers energy as heat from a hotter source to a colder heat sink or heat exchanger. There are two thermodynamic types, passive and active. The most common sort of passive heat spreader is a plate or block of material having high thermal conductivity, such as copper, aluminum, or diamond. An active heat spreader speeds up heat transfer with expenditure of energy as work supplied by an external source.

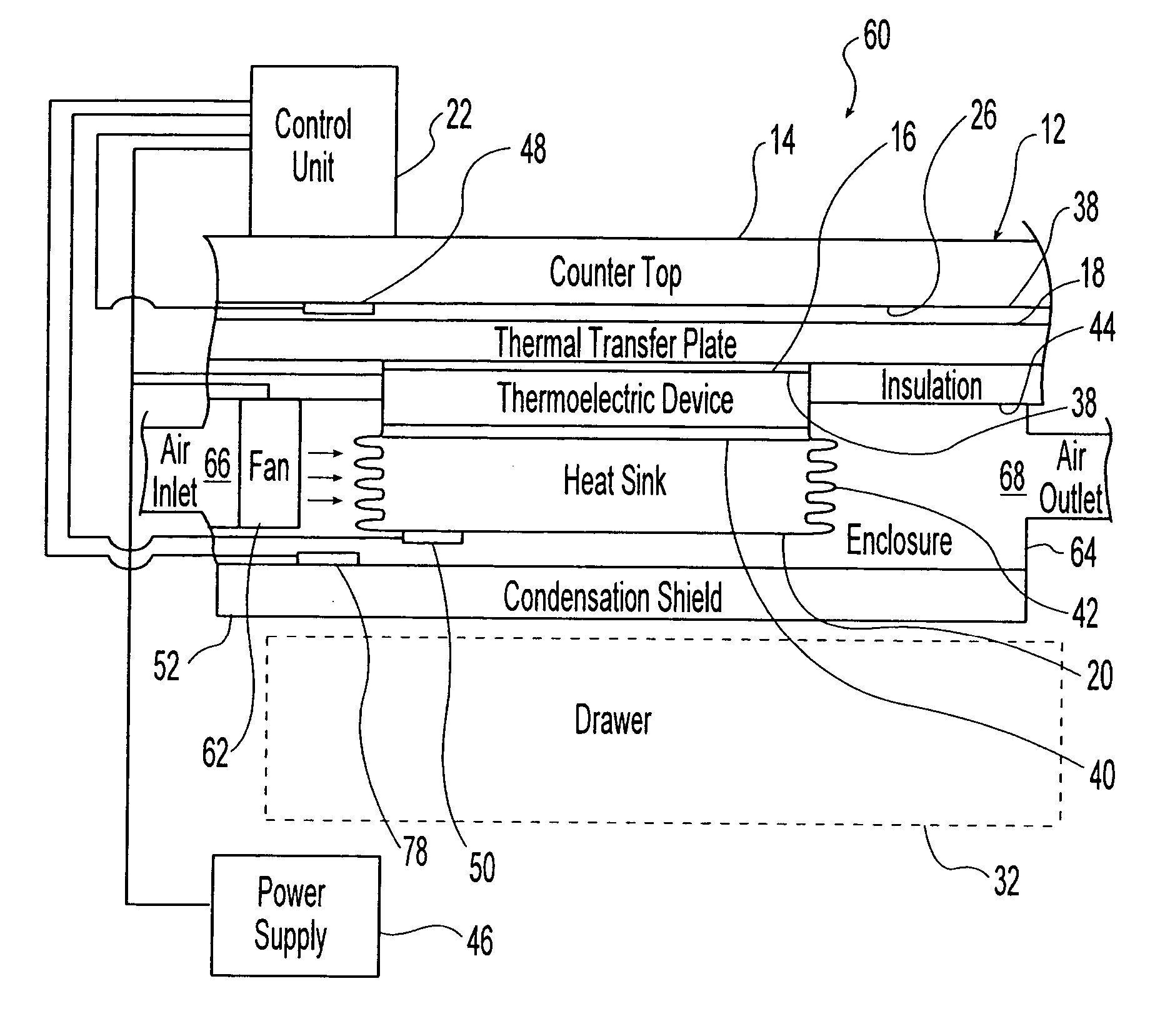

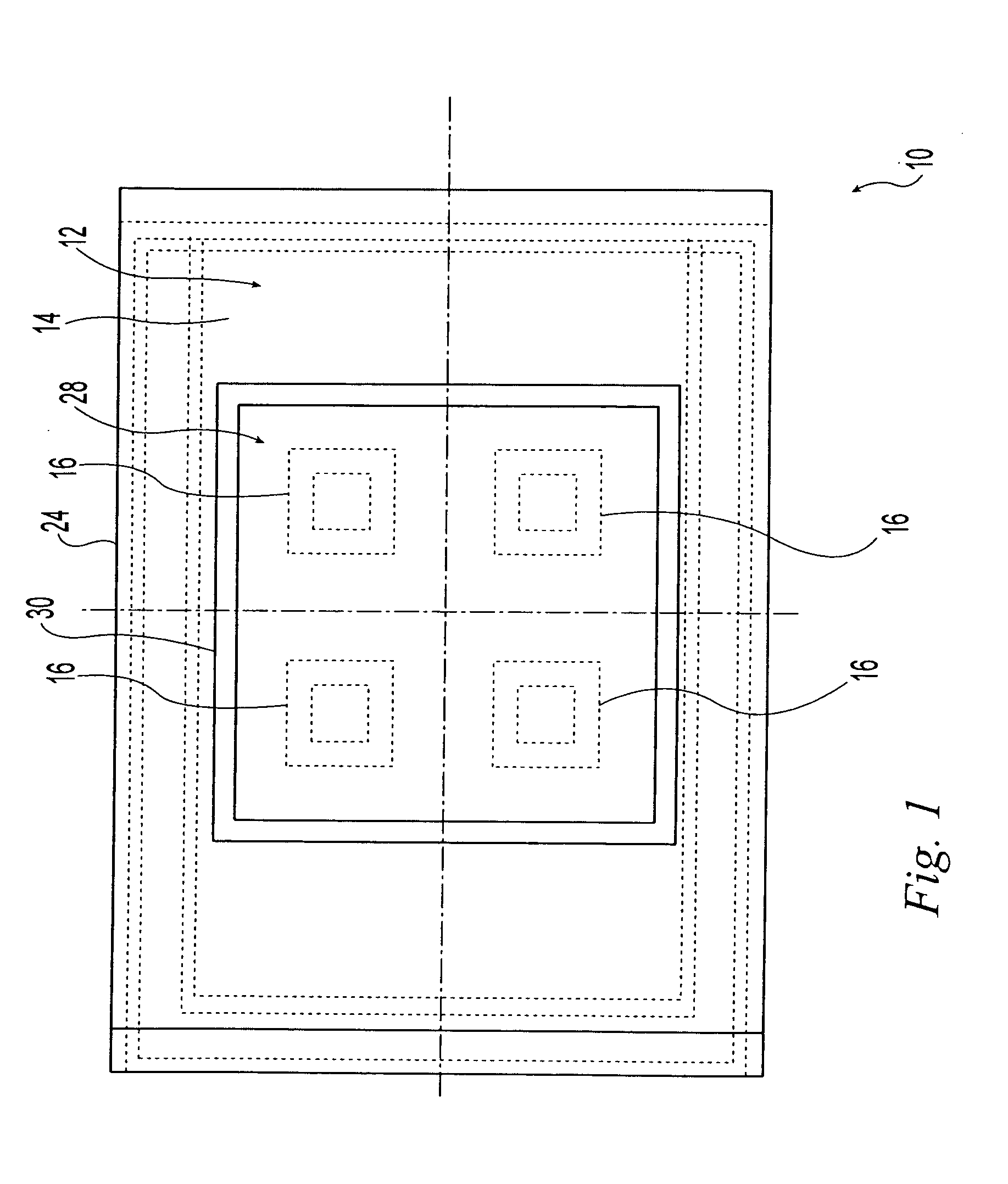

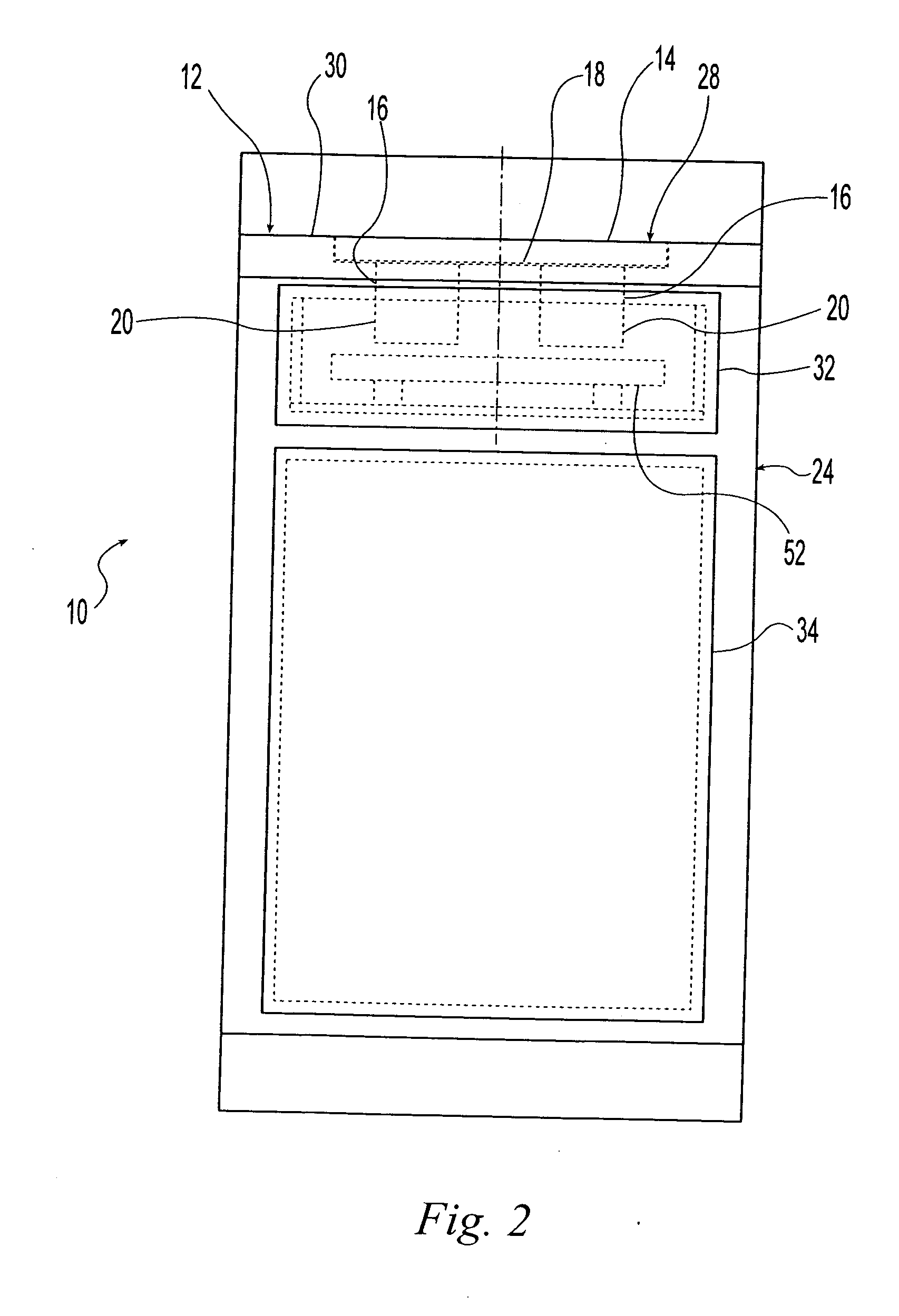

Countertop thermoelectric assembly

Owner:RUCKSTUHL KEITH

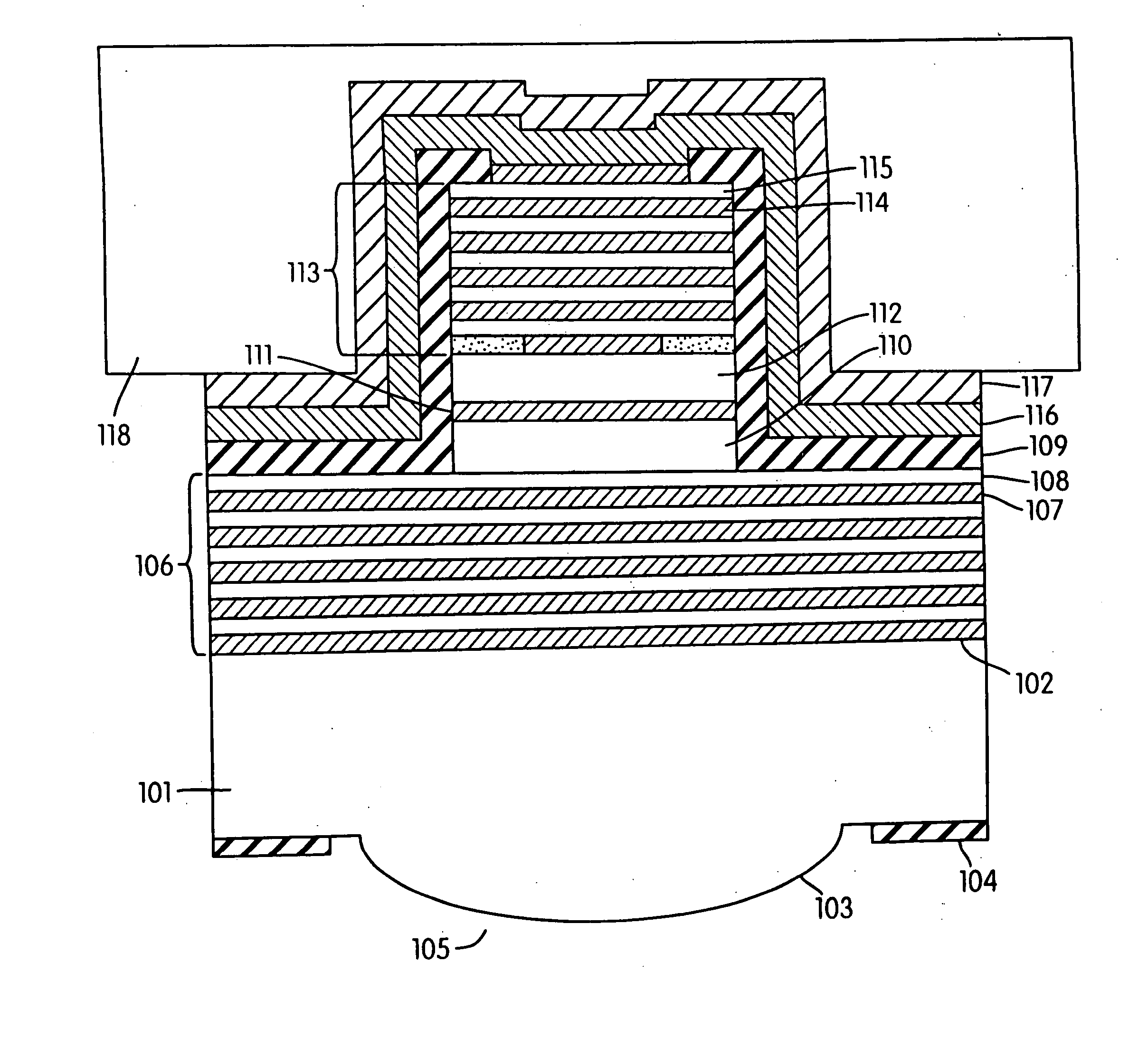

VCSEL and VCSEL array having integrated microlenses for use in a semiconductor laser pumped solid state laser system

InactiveUS20050025211A1High power outputImprove cooling effectSemiconductor laser structural detailsOptical resonator shape and constructionVertical-cavity surface-emitting laserLight beam

Owner:PRINCETON OPTRONICS

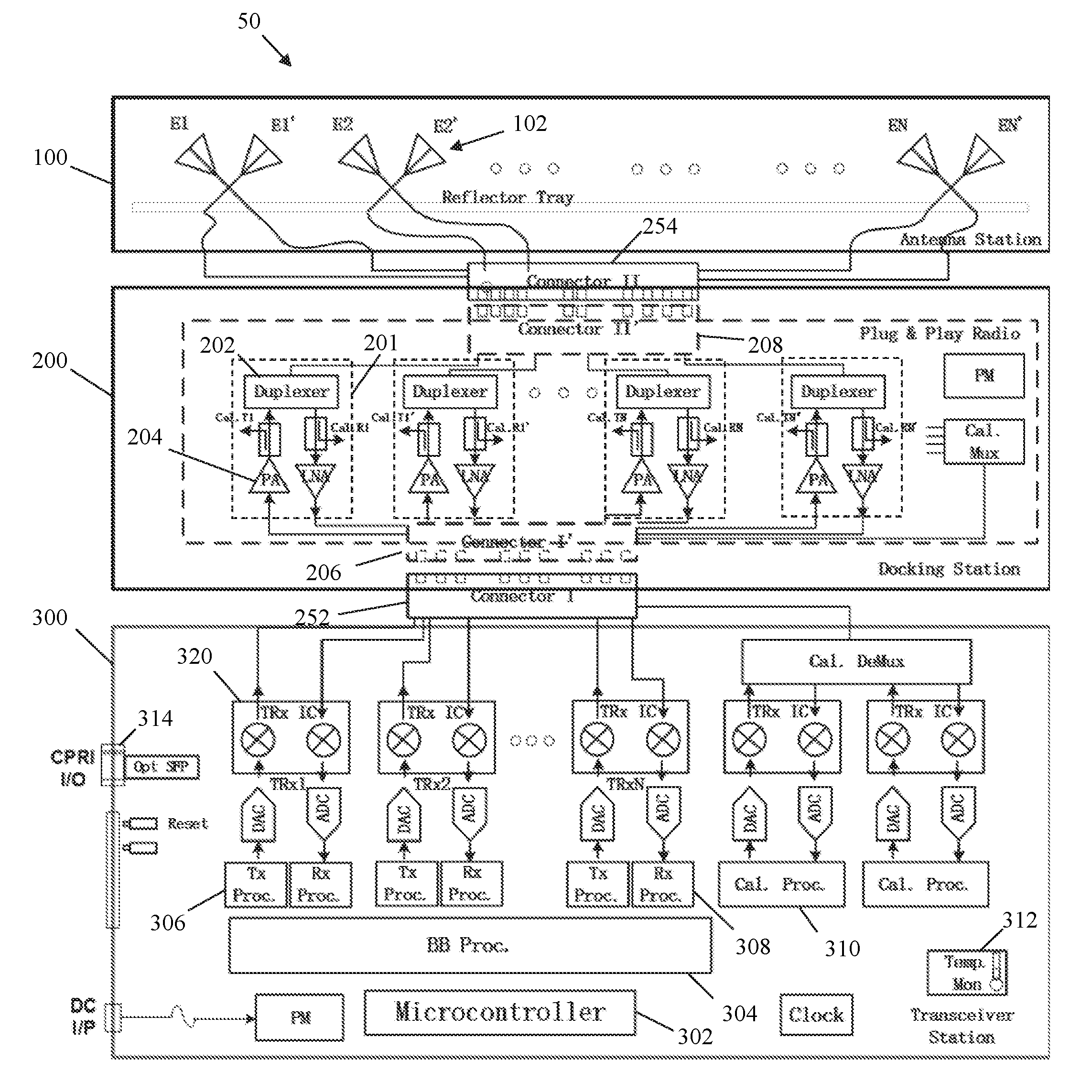

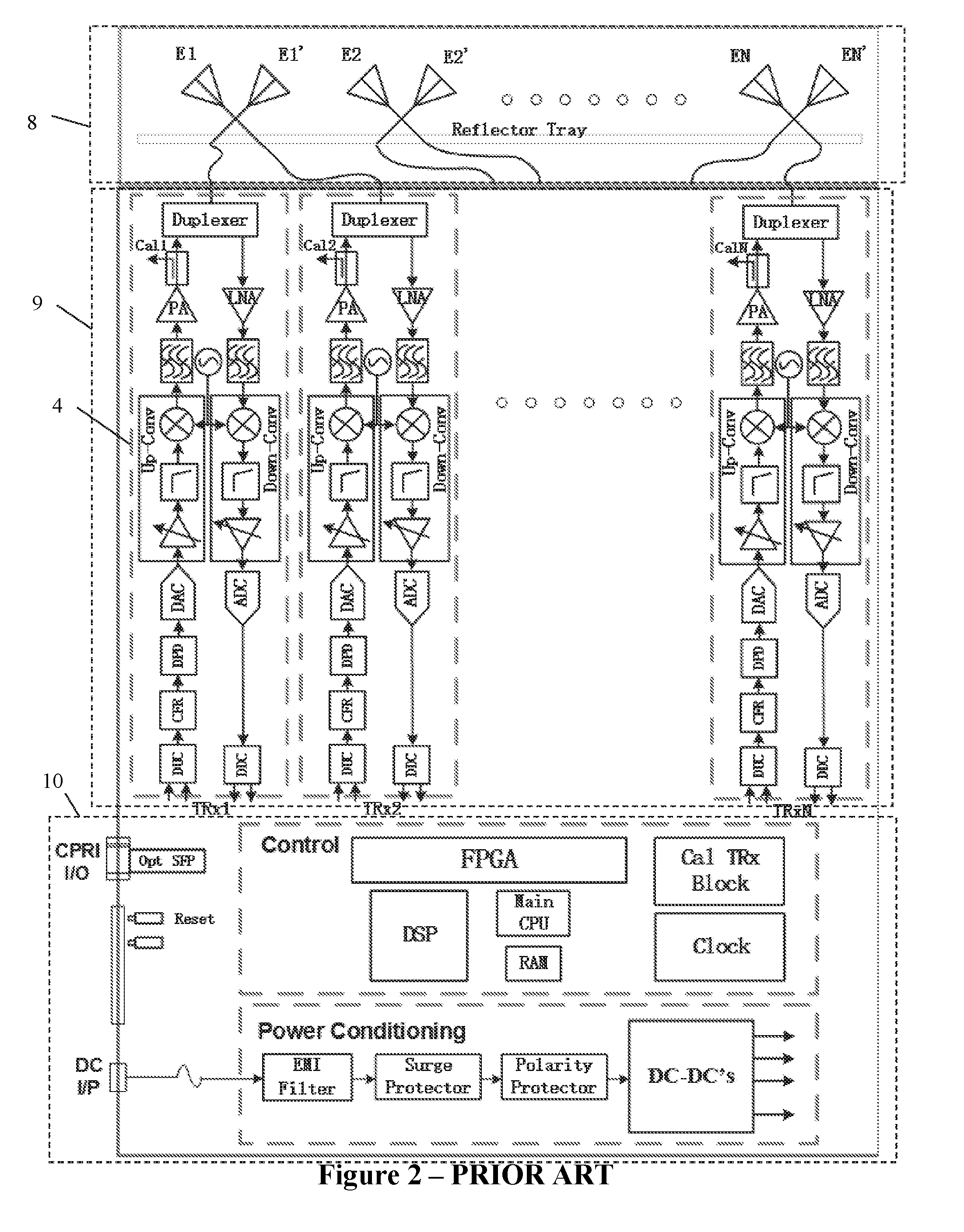

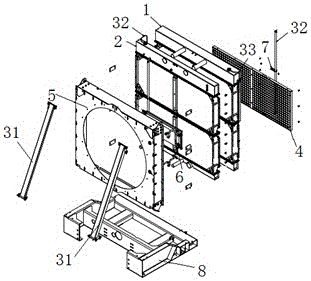

Active antenna array

ActiveUS20160119796A1Improve reliabilityReduced installation weightWireless commuication servicesTransmissionUltra-widebandDocking station

Owner:AMPHENOL ANTENNA SOLUTIONS

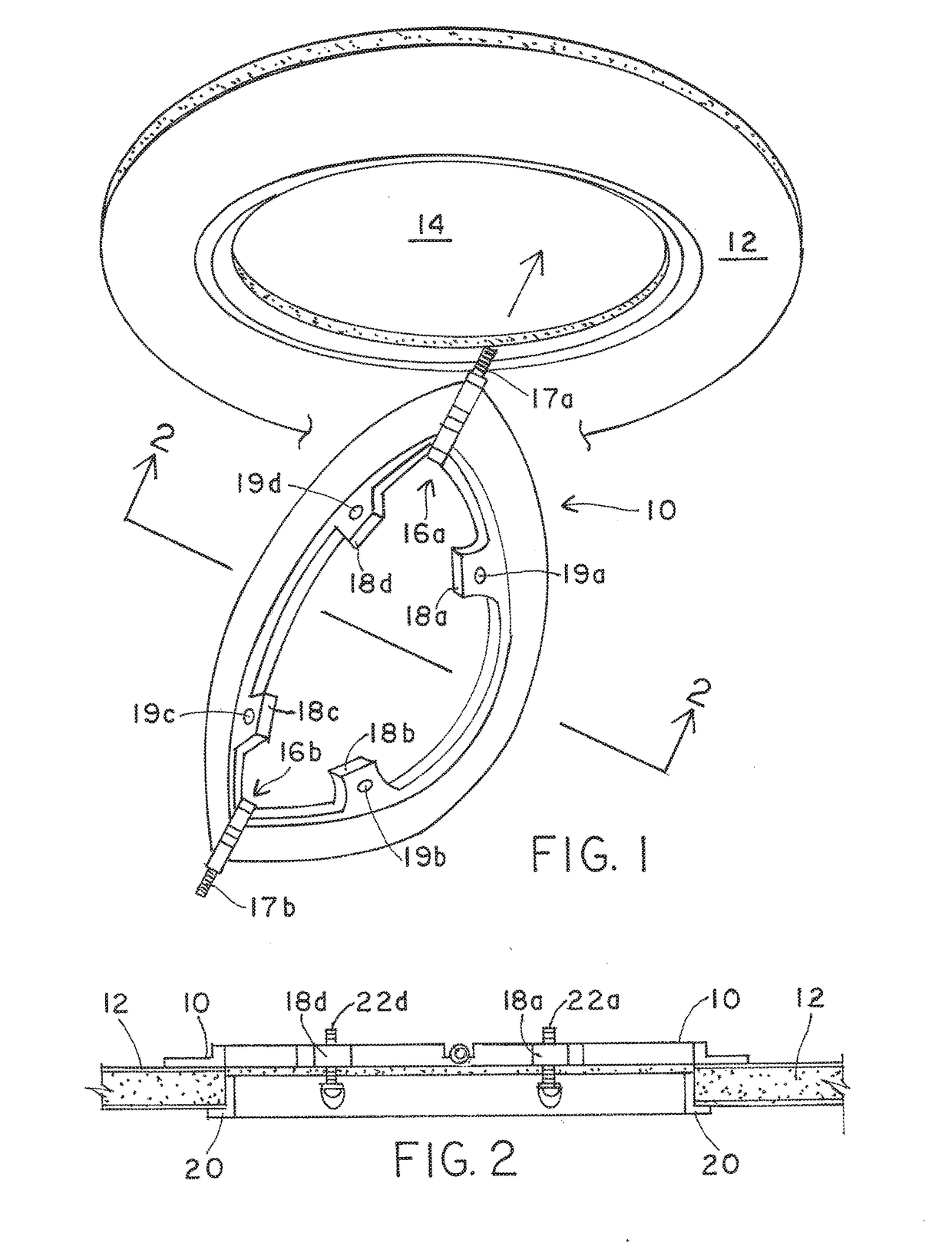

LED festoon lighting

Light emitting diode (LED) modules useable in festoon-type lighting applications and lighting systems incorporating such modules. The LED module generally includes a circuit board having one or more LEDs mounted in a heat sink member. Contact members are attached to opposing ends of device. The heat sink is not required to conduct electrical current when the LED(s) is / are illuminated. High powered LEDs (greater than ½ Watt) may be employed.

Owner:J & J ELECTRONICS LLC

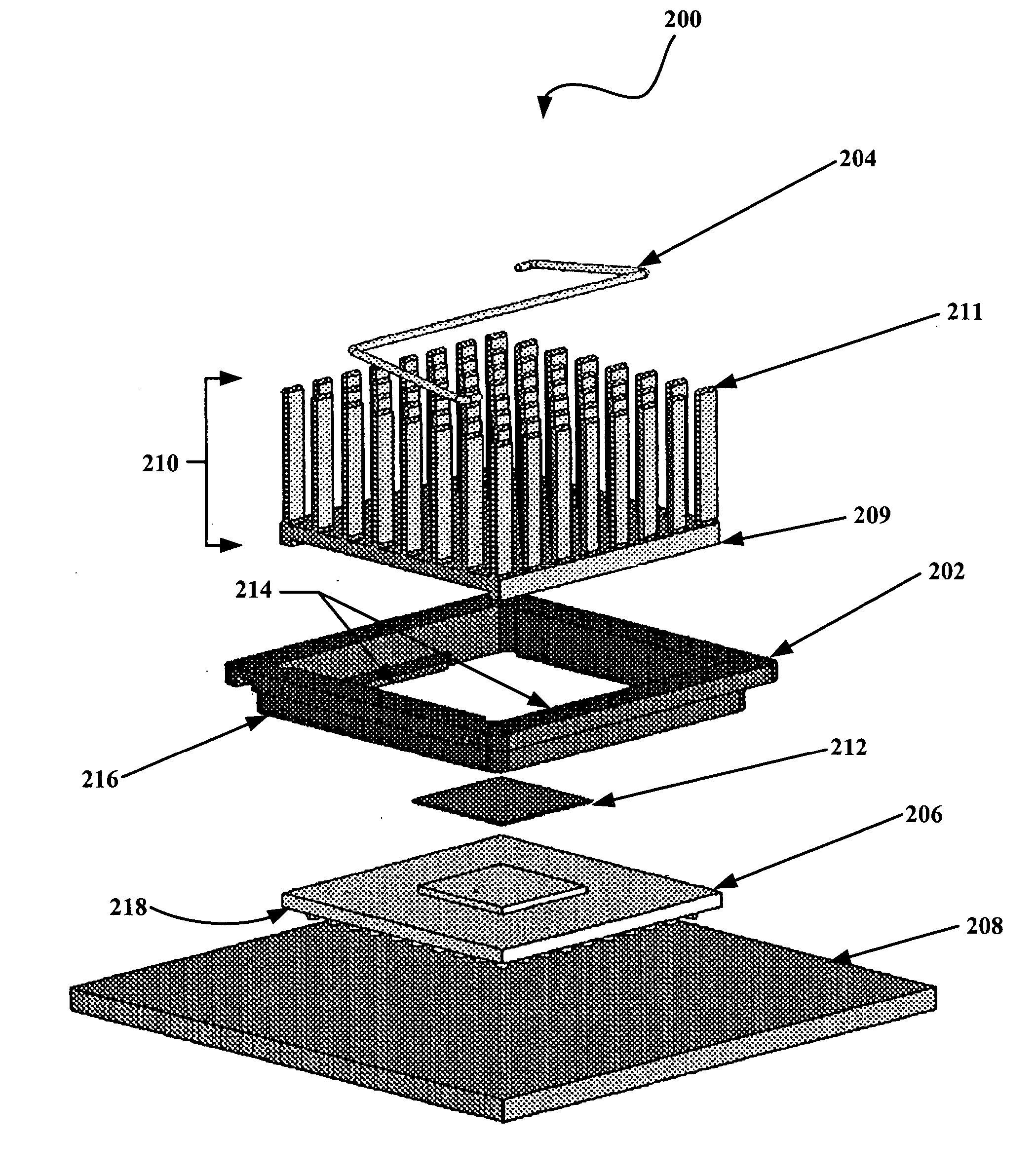

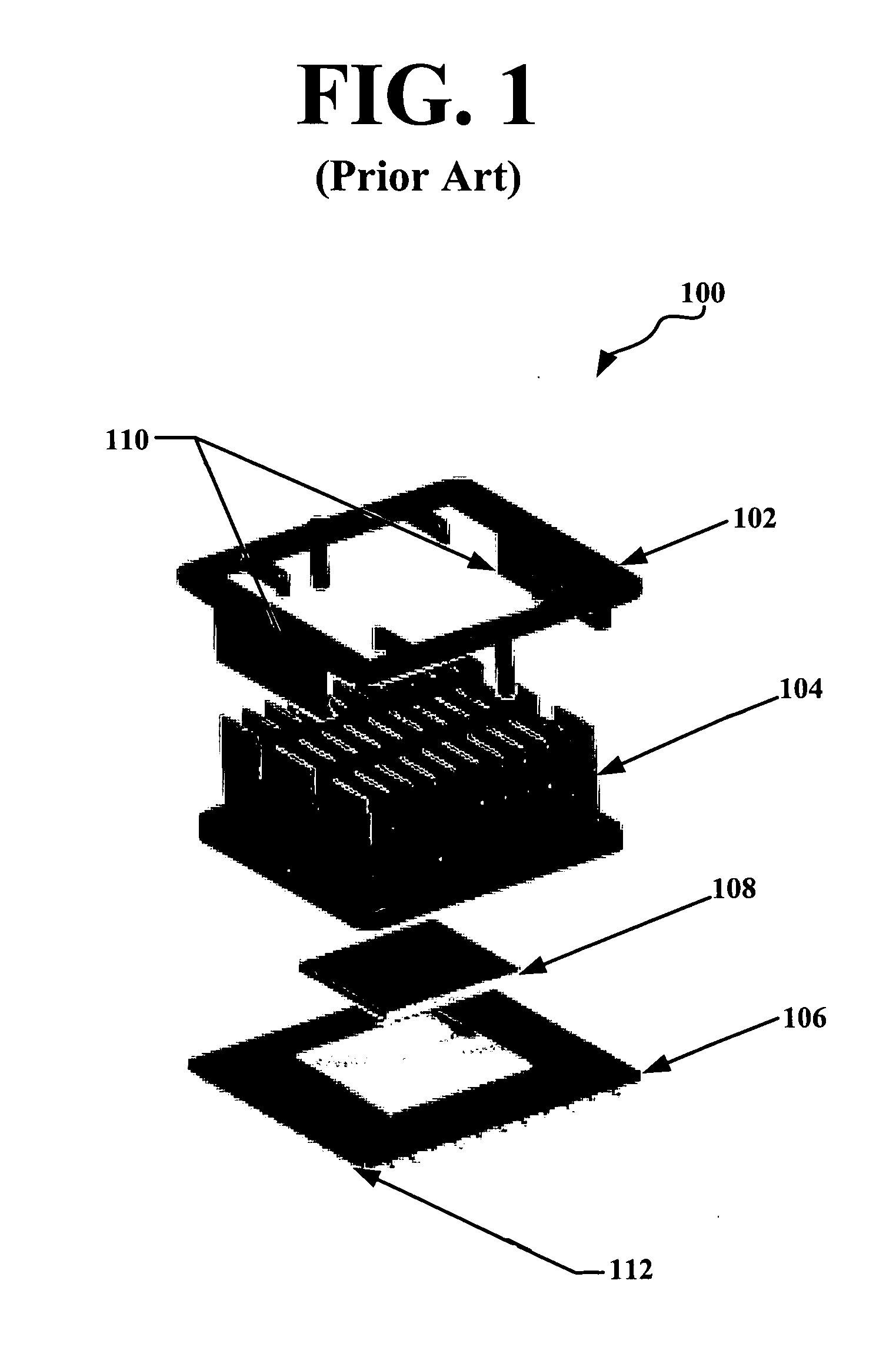

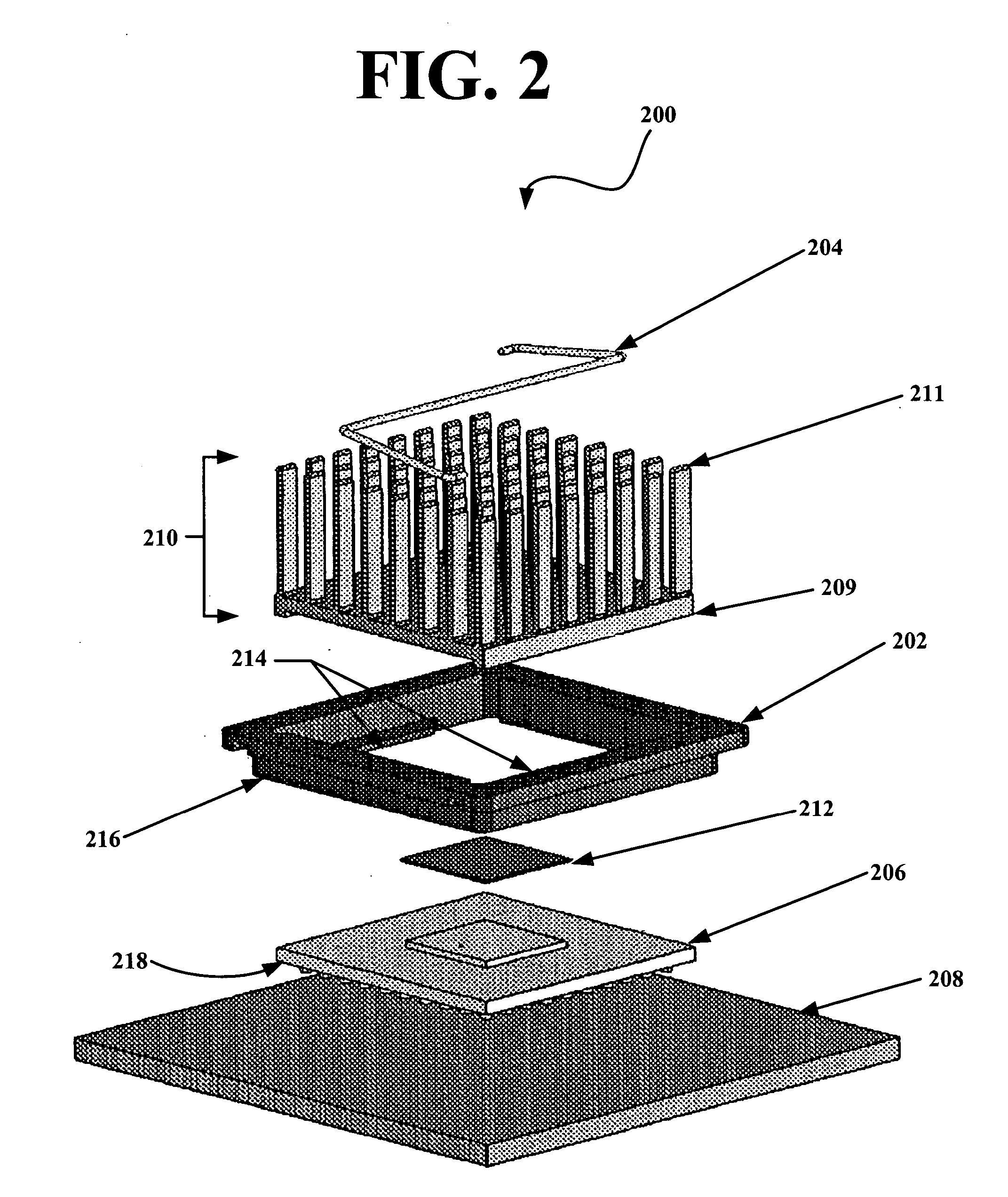

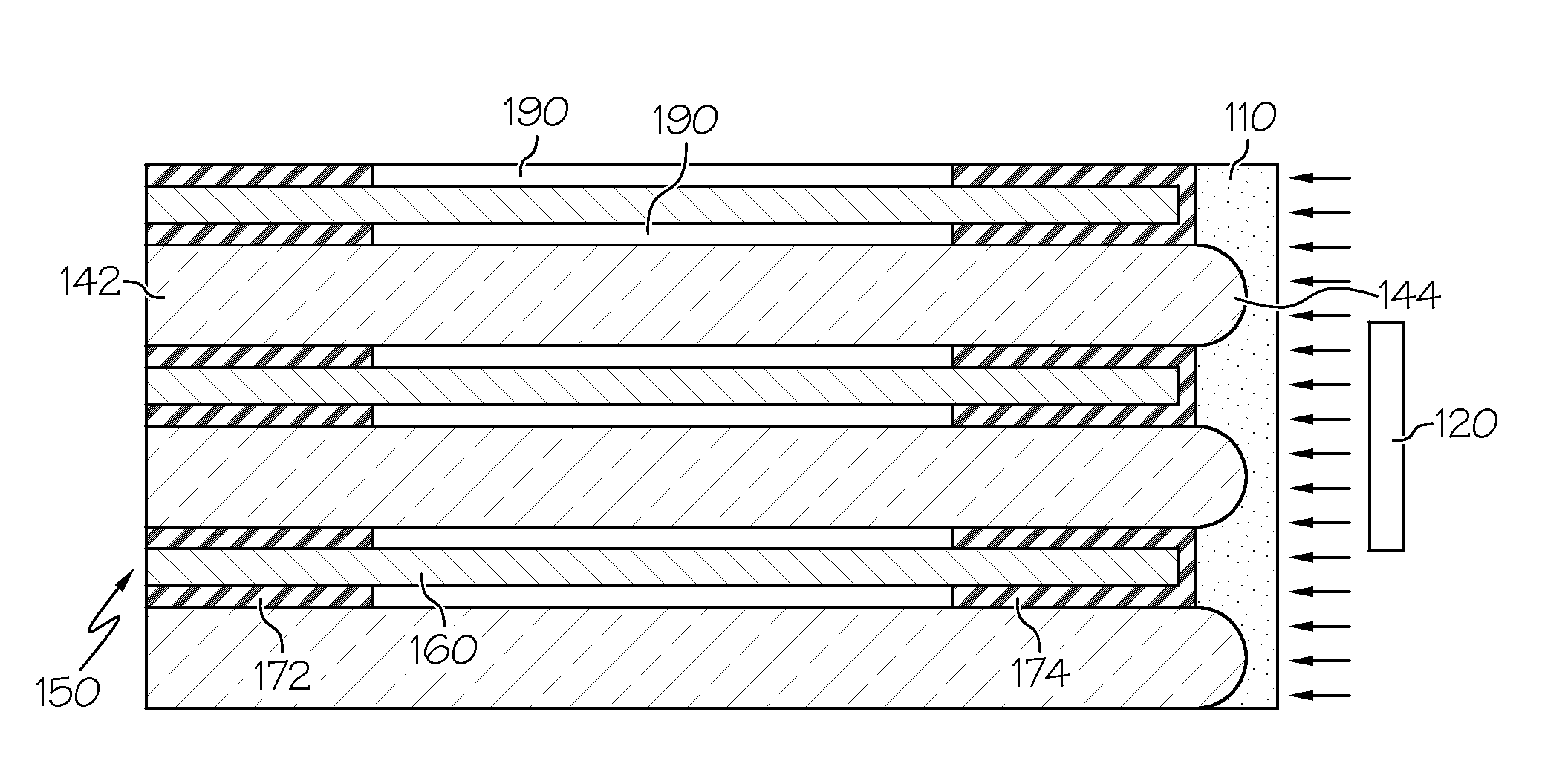

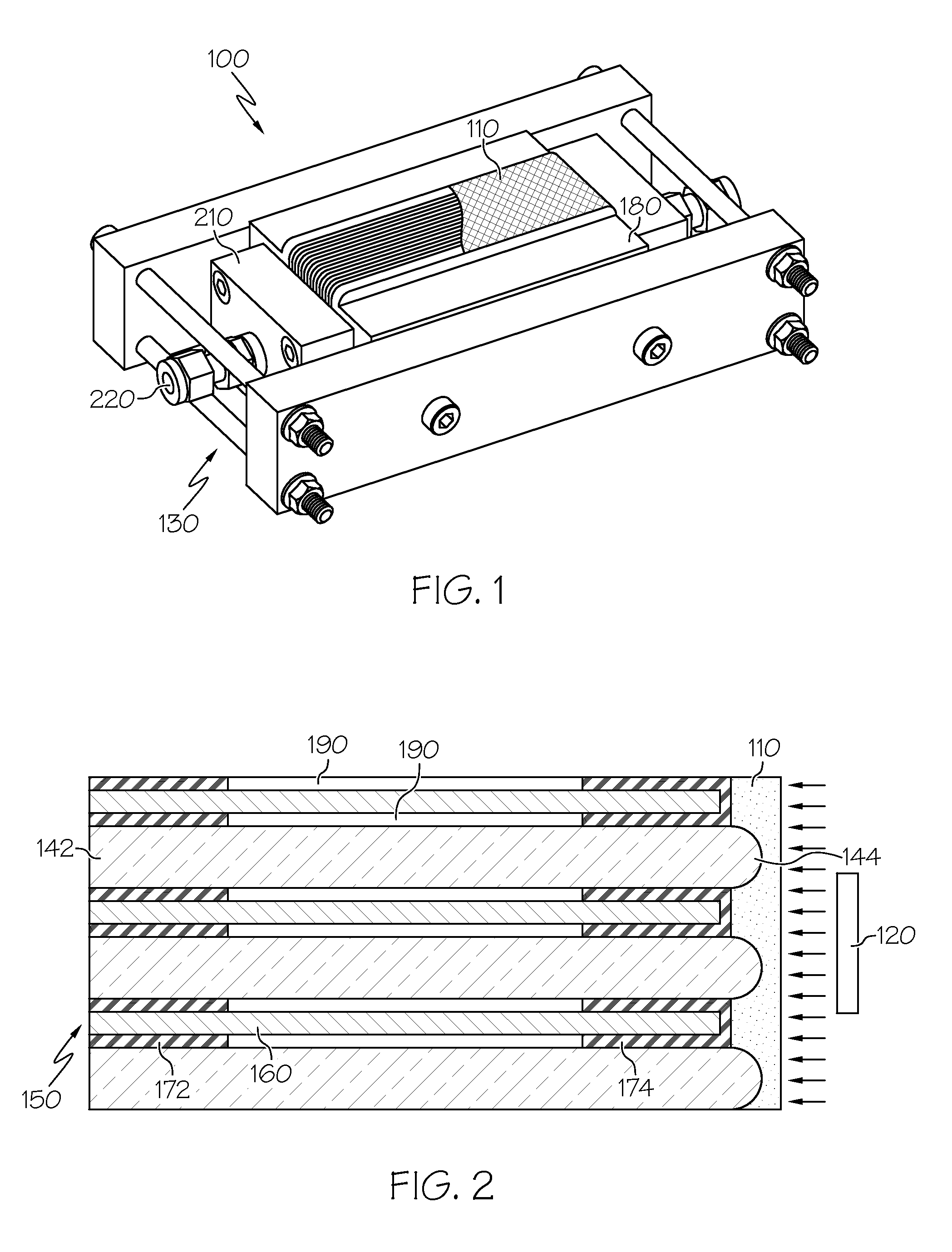

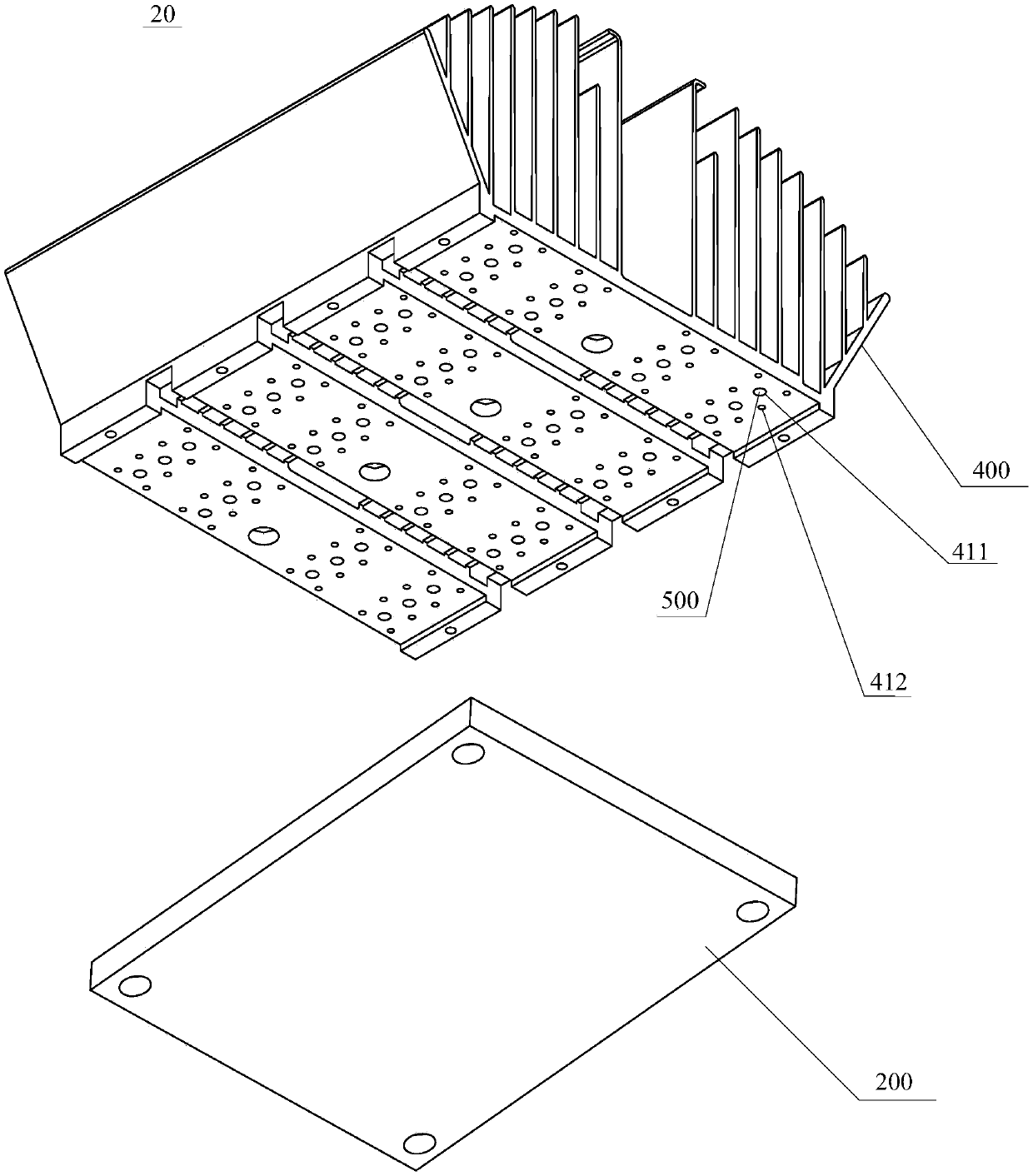

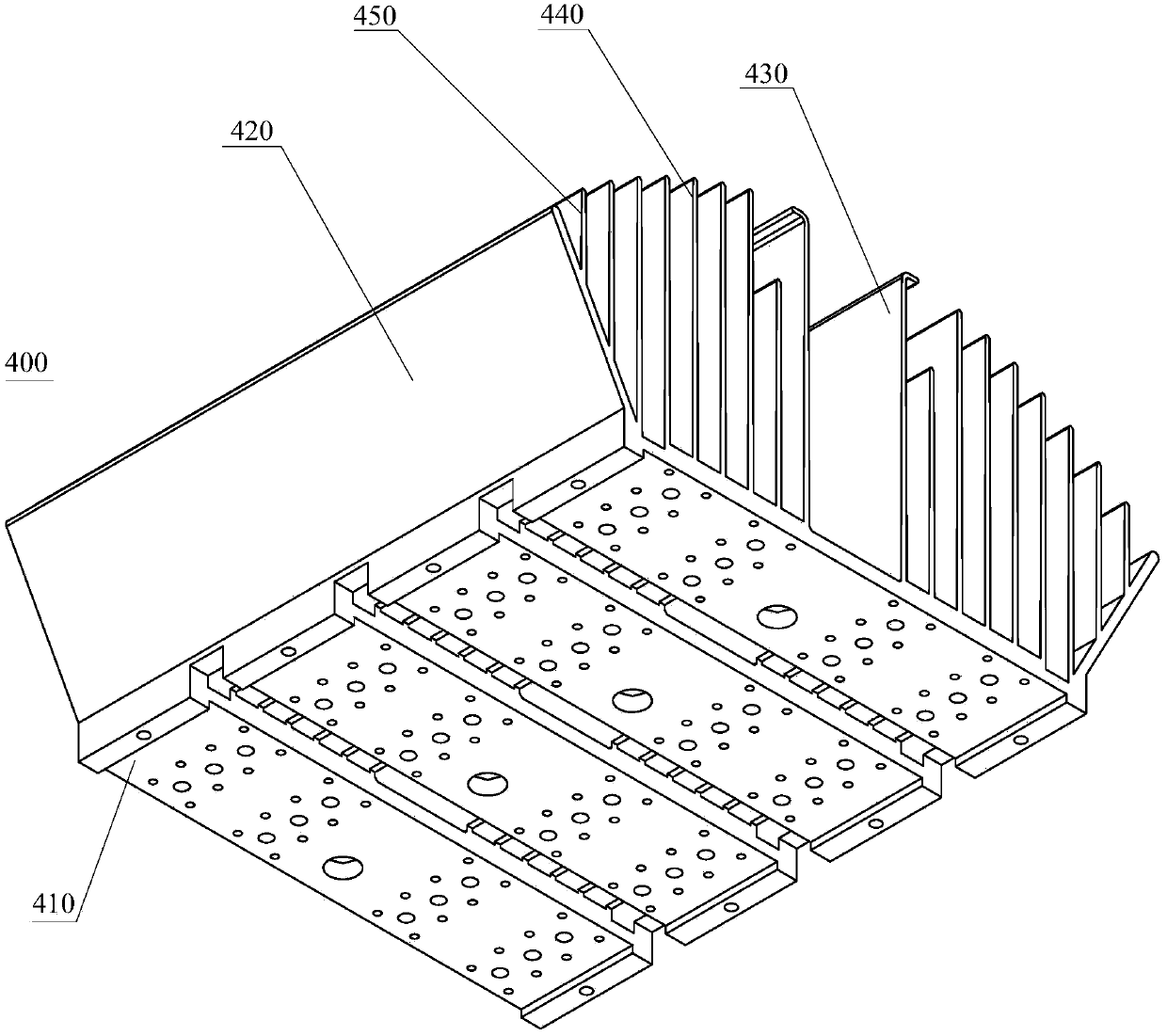

Heat sink assembly

ActiveUS20060198107A1Digital data processing detailsSemiconductor/solid-state device detailsHeat spreaderVertical force

Owner:ADVANCED THERMAL SOLUTION

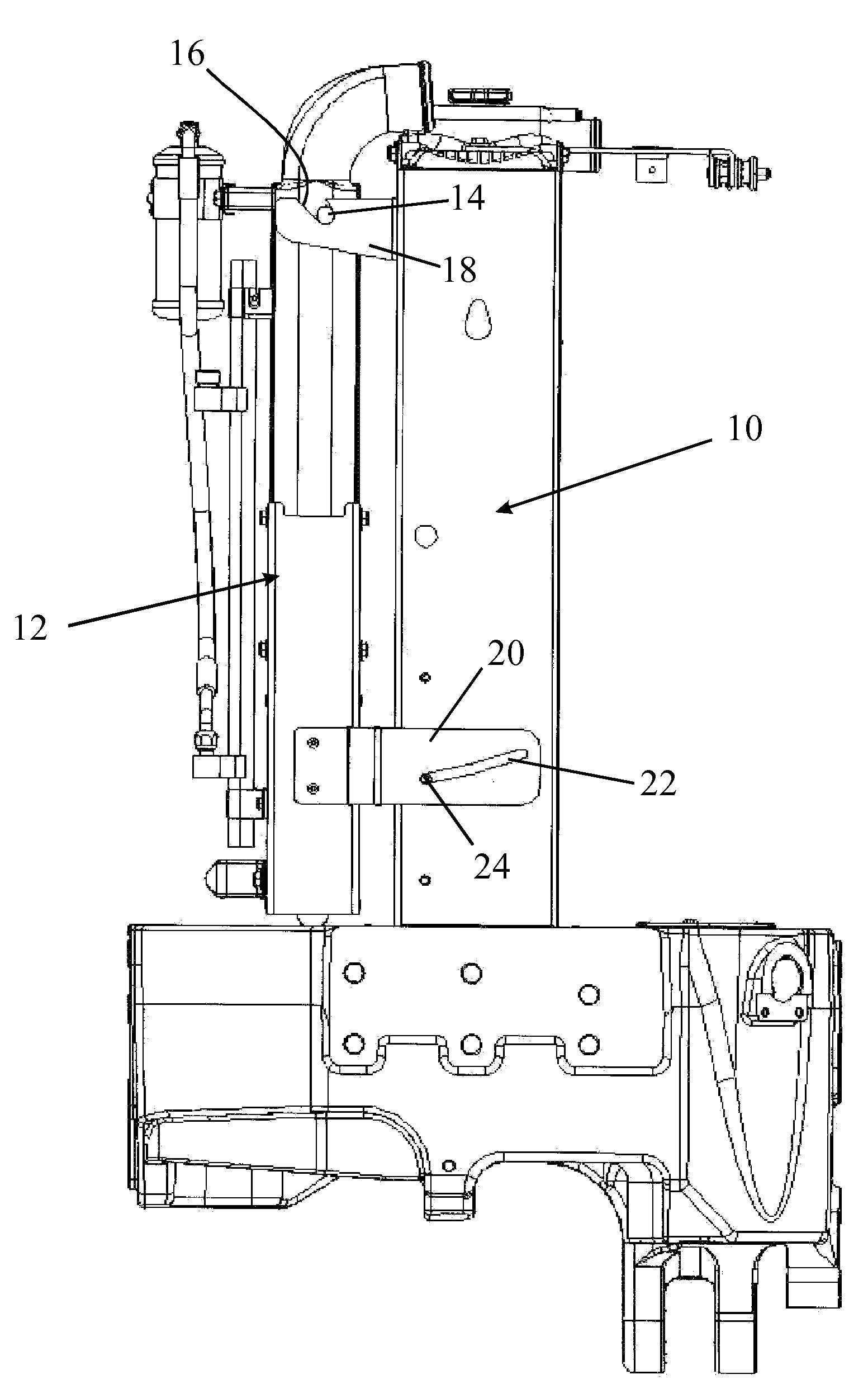

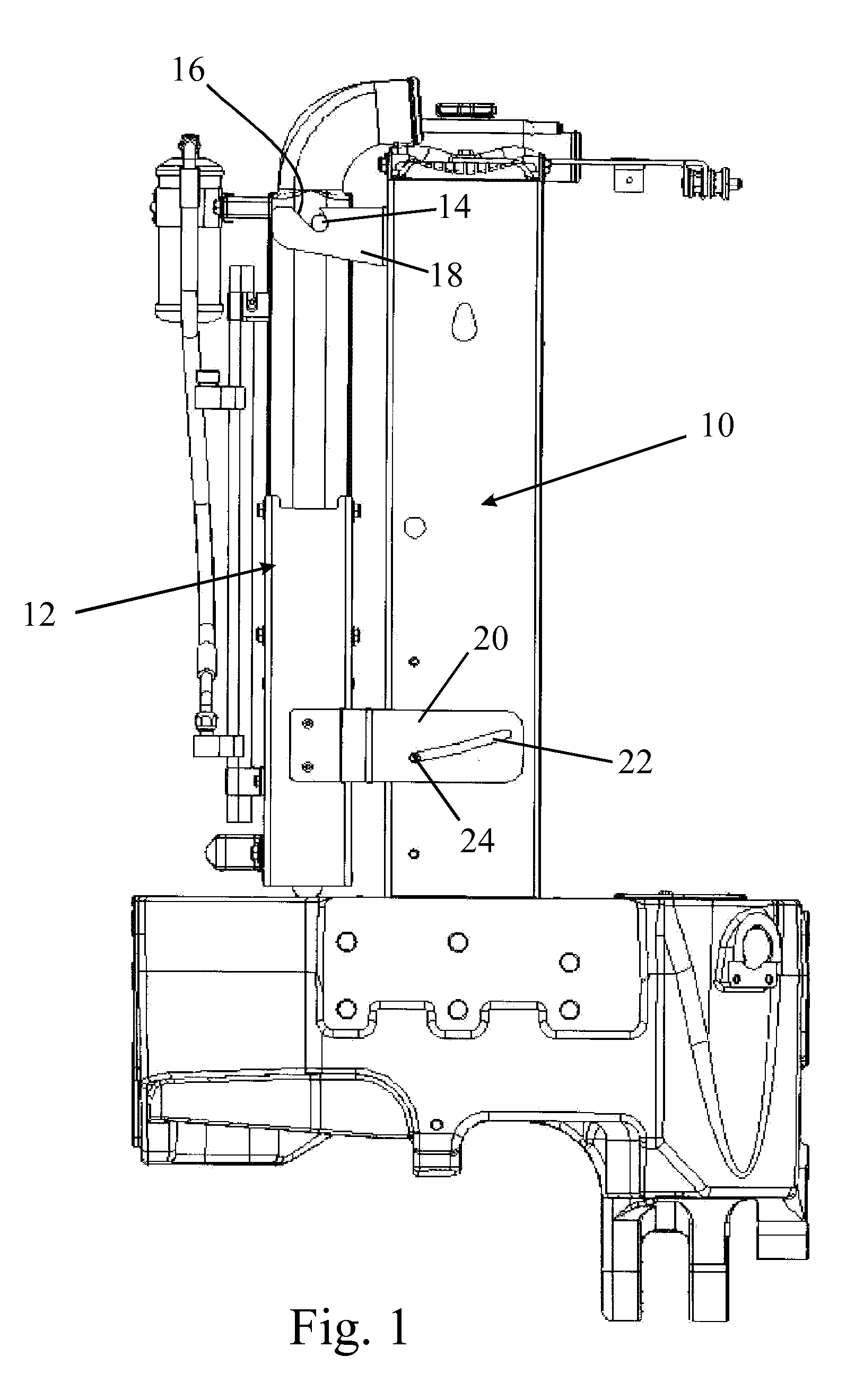

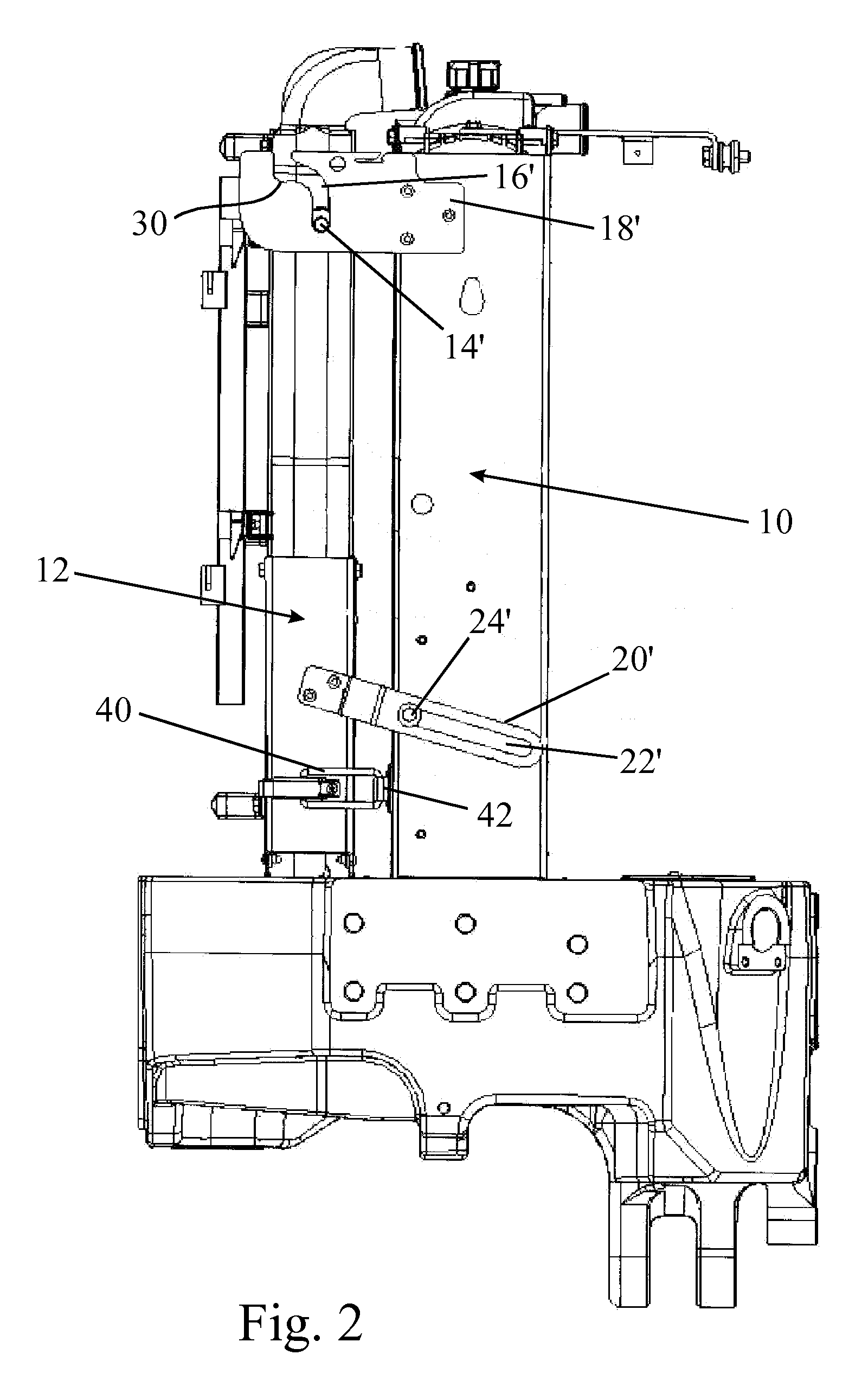

Heat Exchanger Mounting

Owner:BLUE LEAF I P

Device, Method and Vessel Assembly for the Measurement of Heat Flow at Least One Sample

ActiveUS20090092169A1Controlled and stable measurement environmentQuick measurementThermometer detailsMaterial thermal conductivityHeat flowBiomedical engineering

Owner:SYMCEL SVERIGE

Integrated thermal door component for head mounted display

InactiveUS20190104650A1Near-field for read/write/interrrogation/identification systemsDetails for portable computersDisplay deviceConductive materials

A head mounted display (HMD) device for supporting virtual reality and augmented reality includes a frame and a thermal door component between which a mobile device may be sandwiched. The thermal door component includes a first portion that is substantially planar for reversibly coupling with a portion of a back surface of the mobile device and a heat sink. The heat sink includes a substantially planar portion coupled to a surface of the first portion of the thermal door component. The heat sink may be made of magnesium or other thermally conductive material. A second portion is coupled to the back of the first portion. An opening, channel, or recess that allows access to the interior of the thermal door component by ambient air to allow the thermal door component to draw heat away from the mobile device and the HMD device.

Owner:GOOGLE LLC

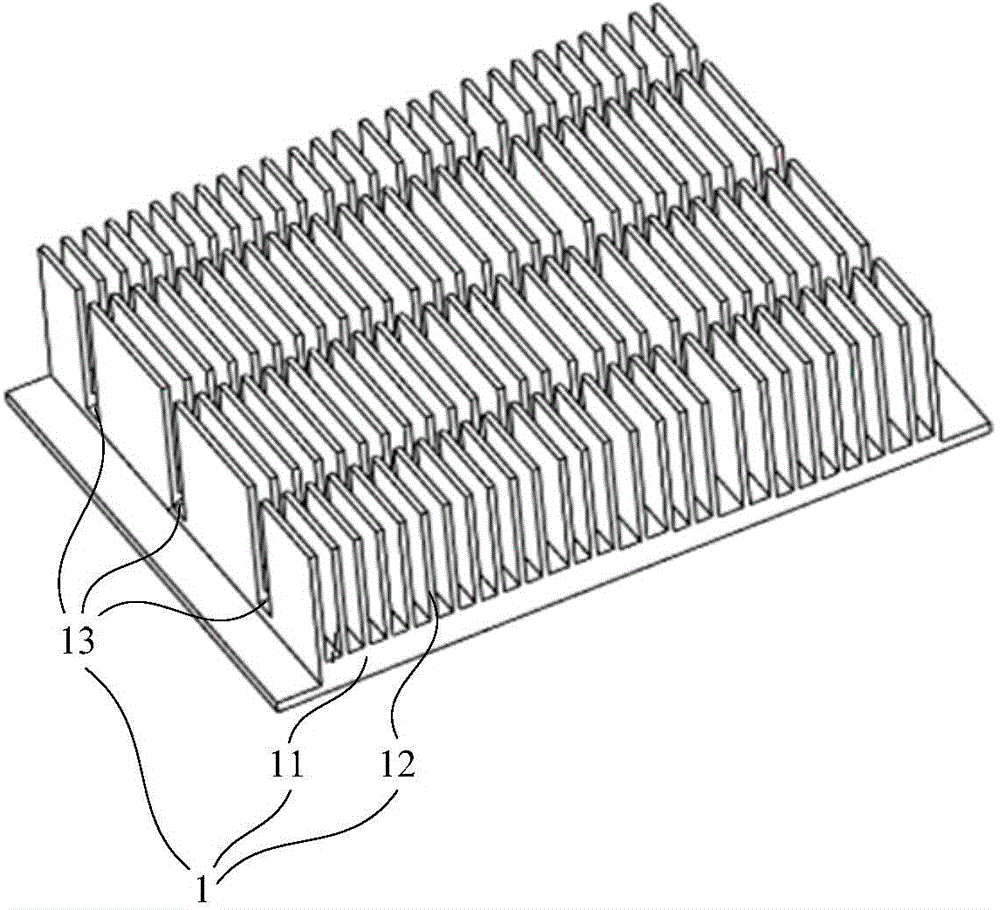

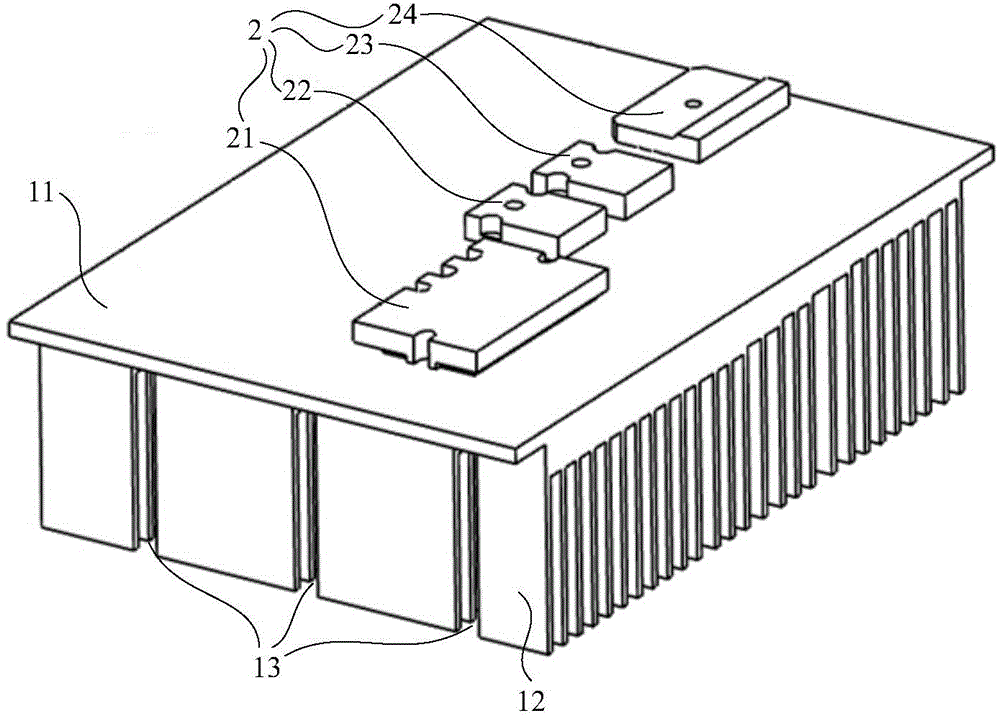

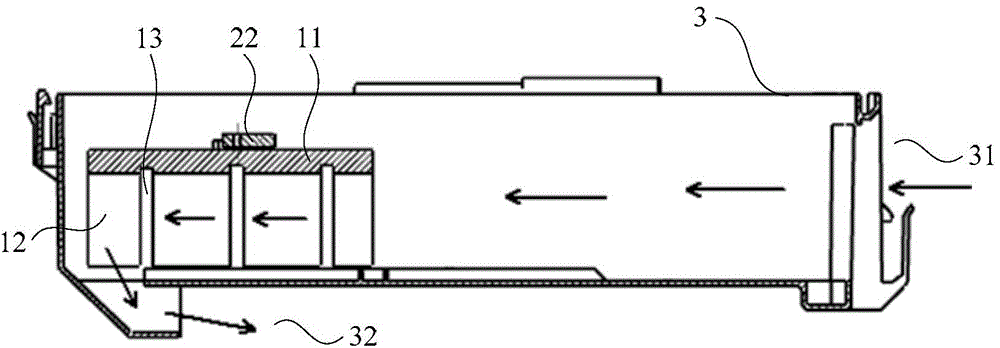

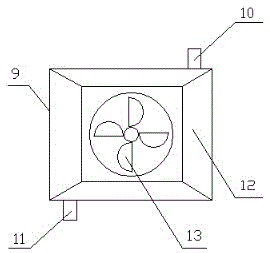

Air conditioner heat radiator and variable-frequency air conditioner

InactiveCN105571014AReduce distribution densityIncrease cooling areaLighting and heating apparatusSpace heating and ventilation safety systemsEngineeringElectron

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

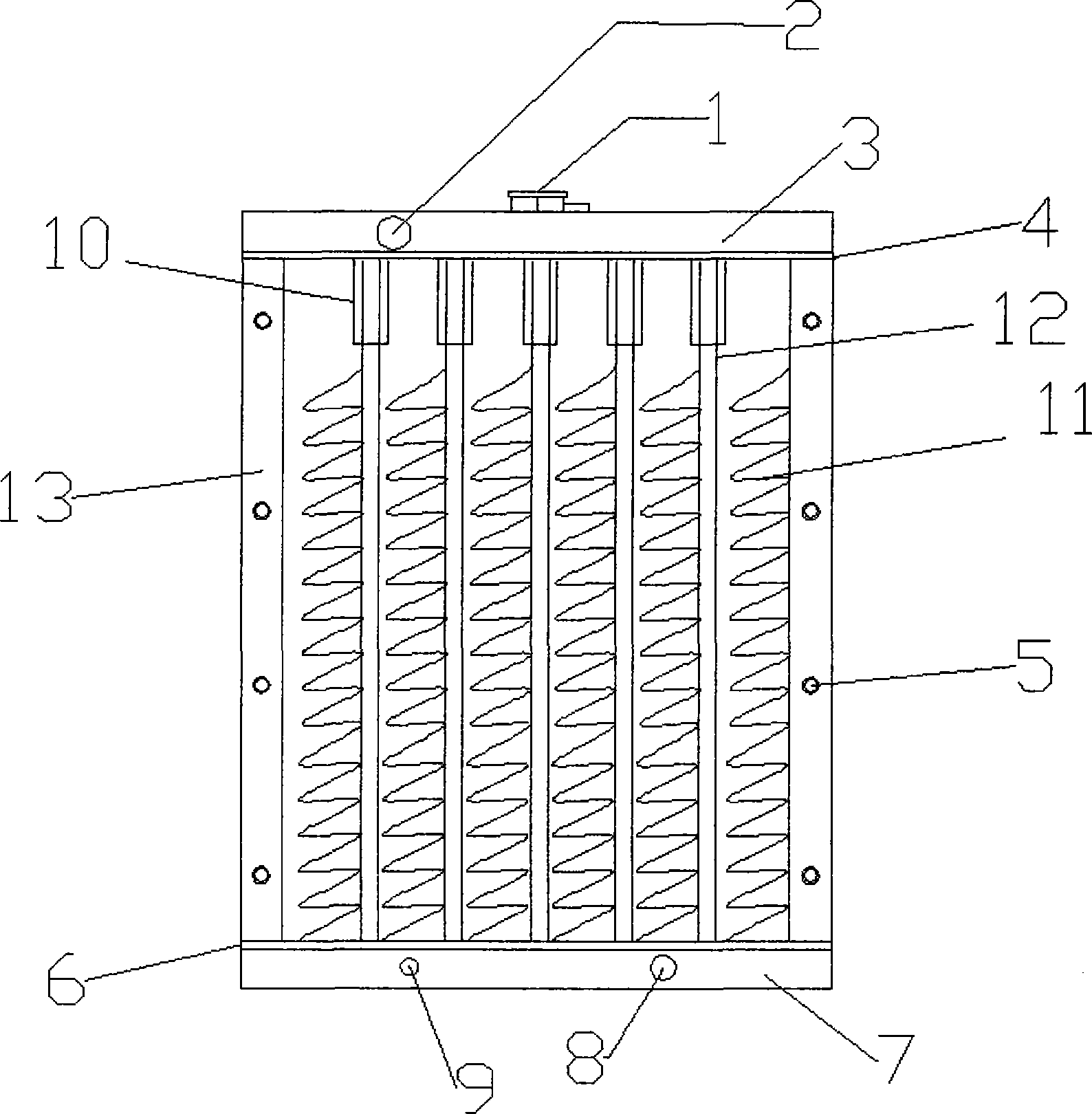

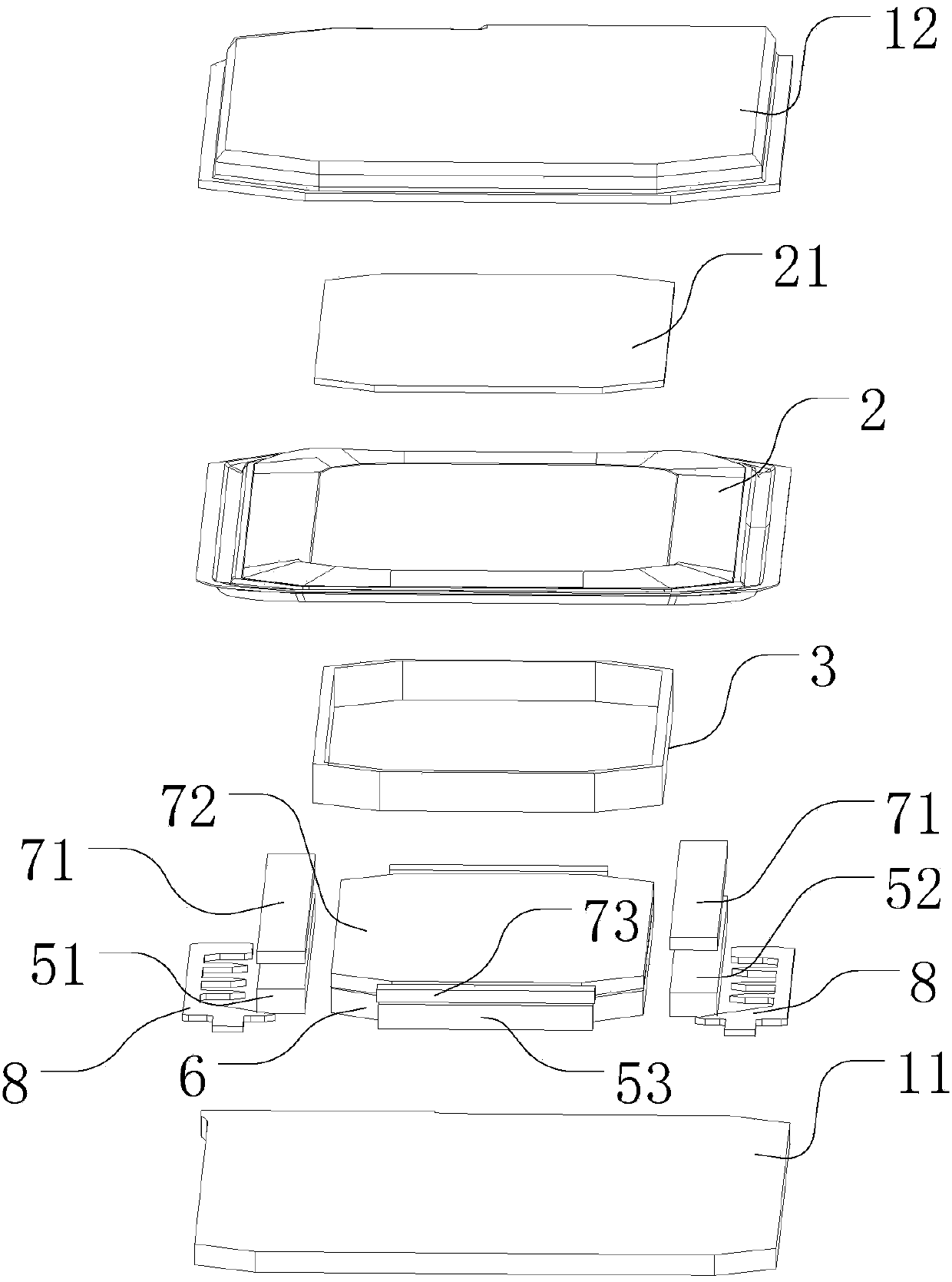

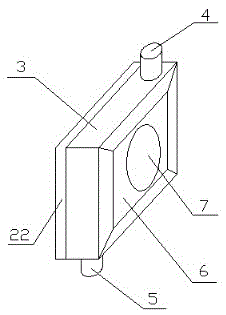

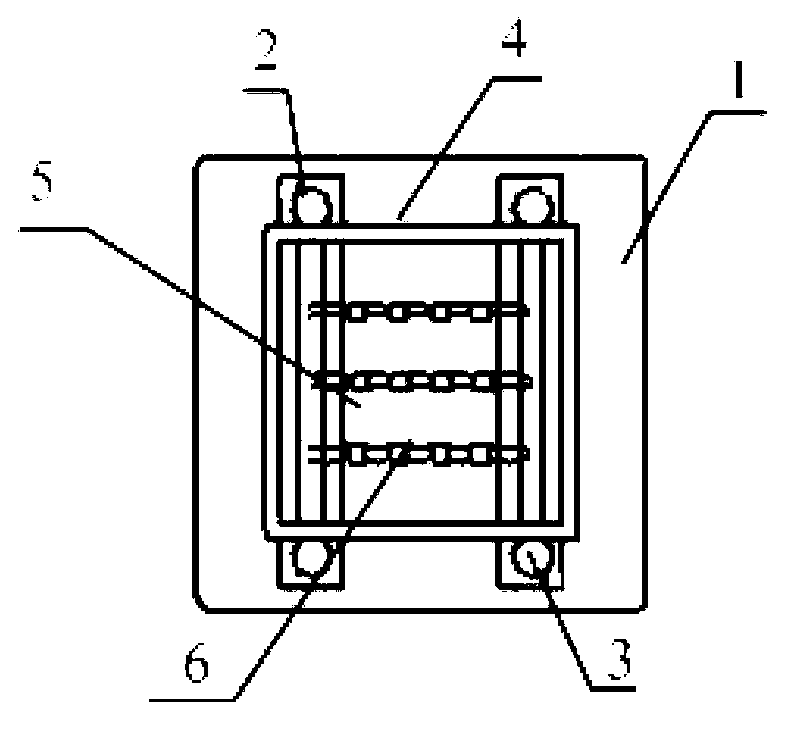

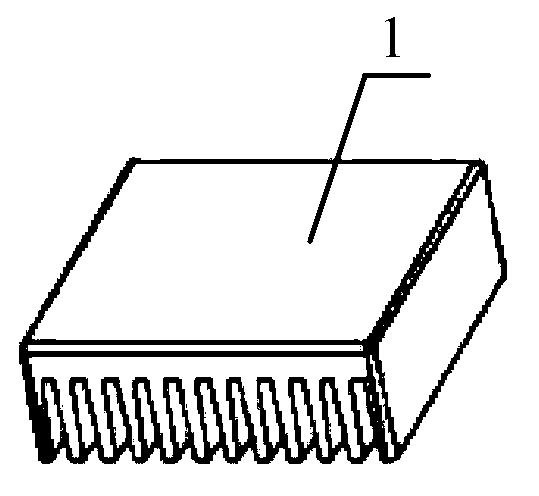

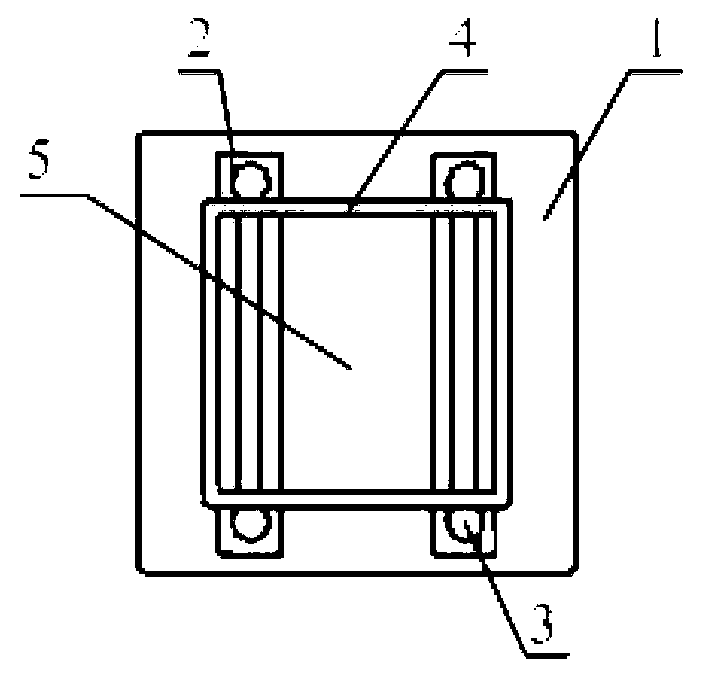

Composite type heat pipe radiator for heating

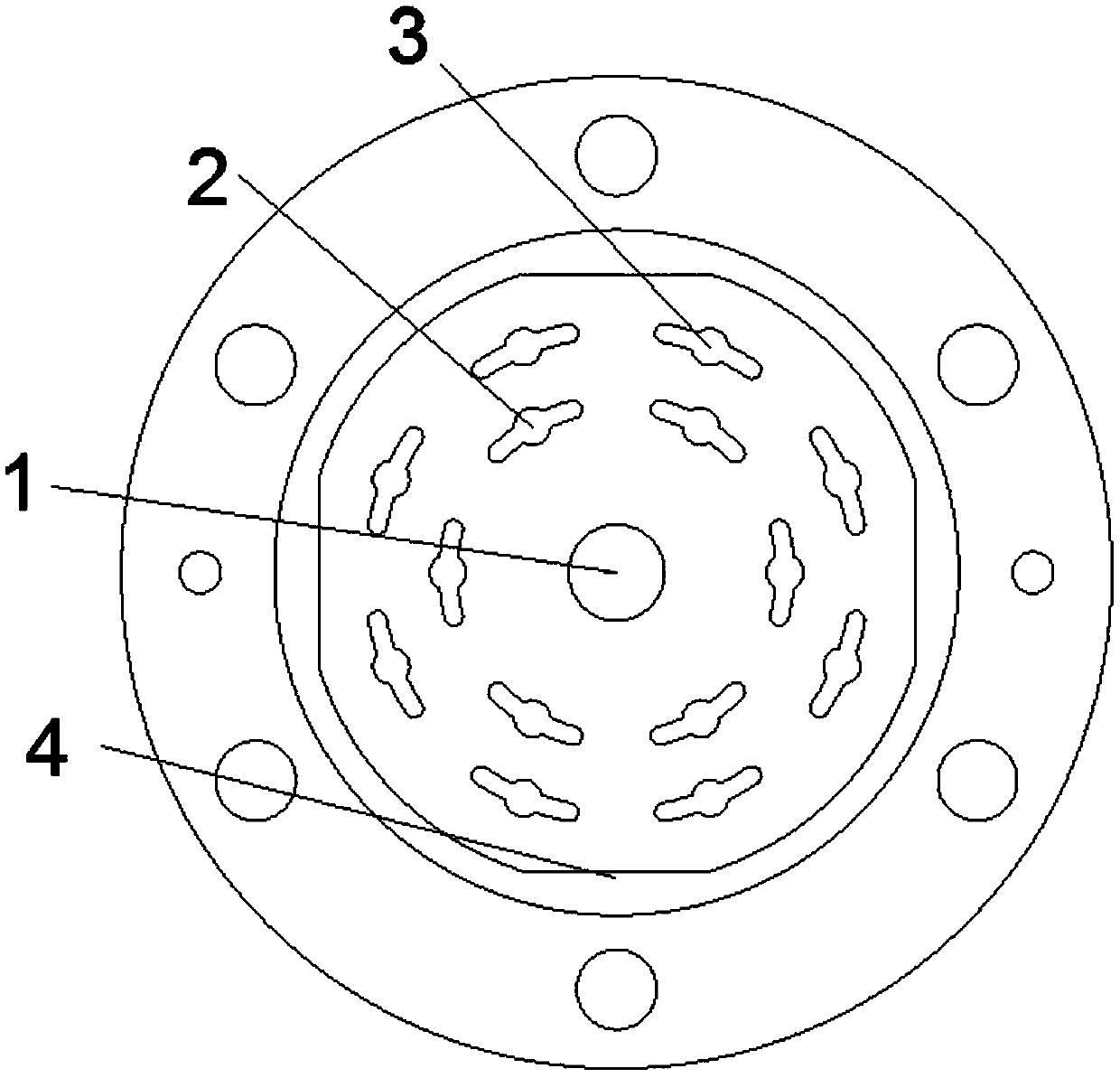

InactiveCN101373121AReduce useless energy consumptionWill not fail or even be scrappedIndirect heat exchangersVacuum pumpingHeat conducting

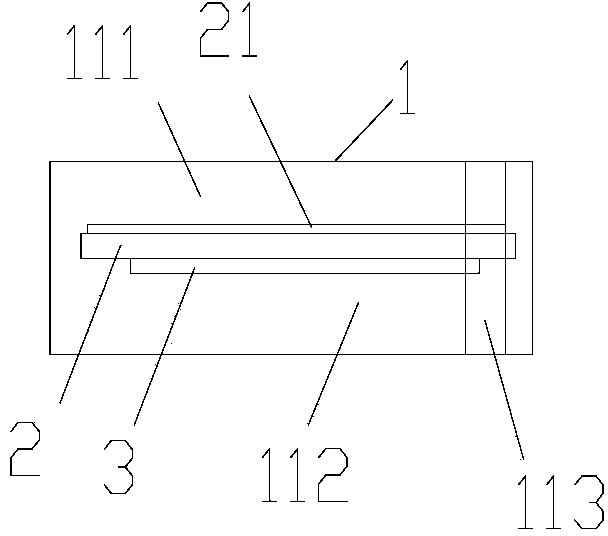

A composite type heat pipe radiator for heating relates to the heating ventilating field and comprises an upper header pipe (1), a lower header pipe (2), a radiating fin (3), a fin heating medium pipe (4), a vacuum pumping head (5), a vacuum regulating valve (6), a heat-conducting medium (7) and a heating medium (8). A cavity body formed by the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) with the vacuum pumping head (5) and the vacuum regulating valve (6) after a vacuum device extracts the air in the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) from the vacuum pumping head (5); and after the air in the cavity body is extracted, a vacuum hollow cavity is formed. The heat-conducting medium absorbs heat from a heat source and transfers the heat to the heating medium (8) through the fin heating medium pipe (4); the heating medium is heated and gasified and transfers the heat to the air so as to serve the heating function. The invention has the advantages of high efficiency, safety, water and energy conservation, beauty, duration, light weight, and high borne pressure. The invention can manufactured into composite type vacuum ultra heat conducting pipe energy-saving efficient radiators of various types and specifications, such as the plate type, the pipe type, the cylindrical type, various wing types, and the like.

Owner:肖建选

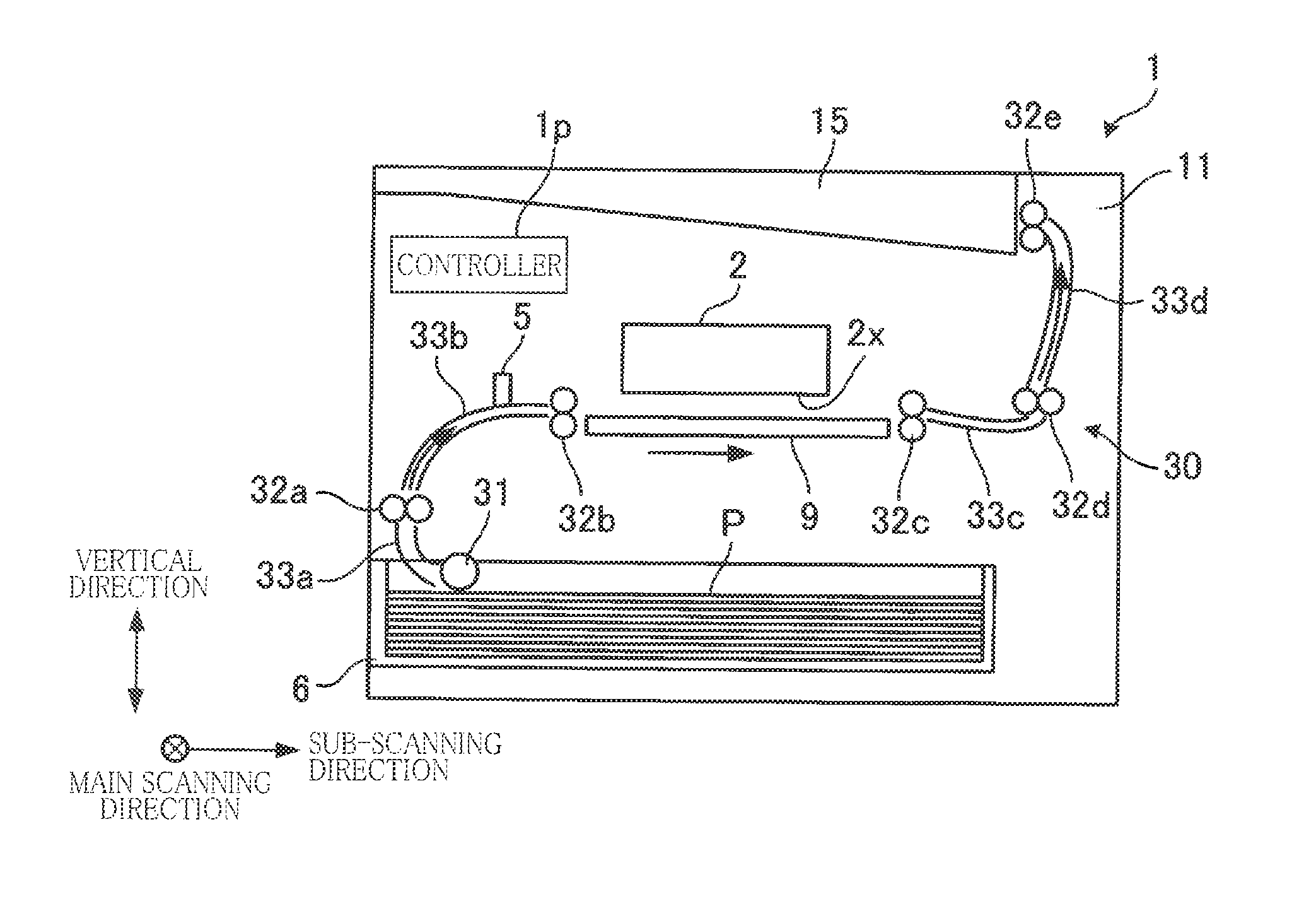

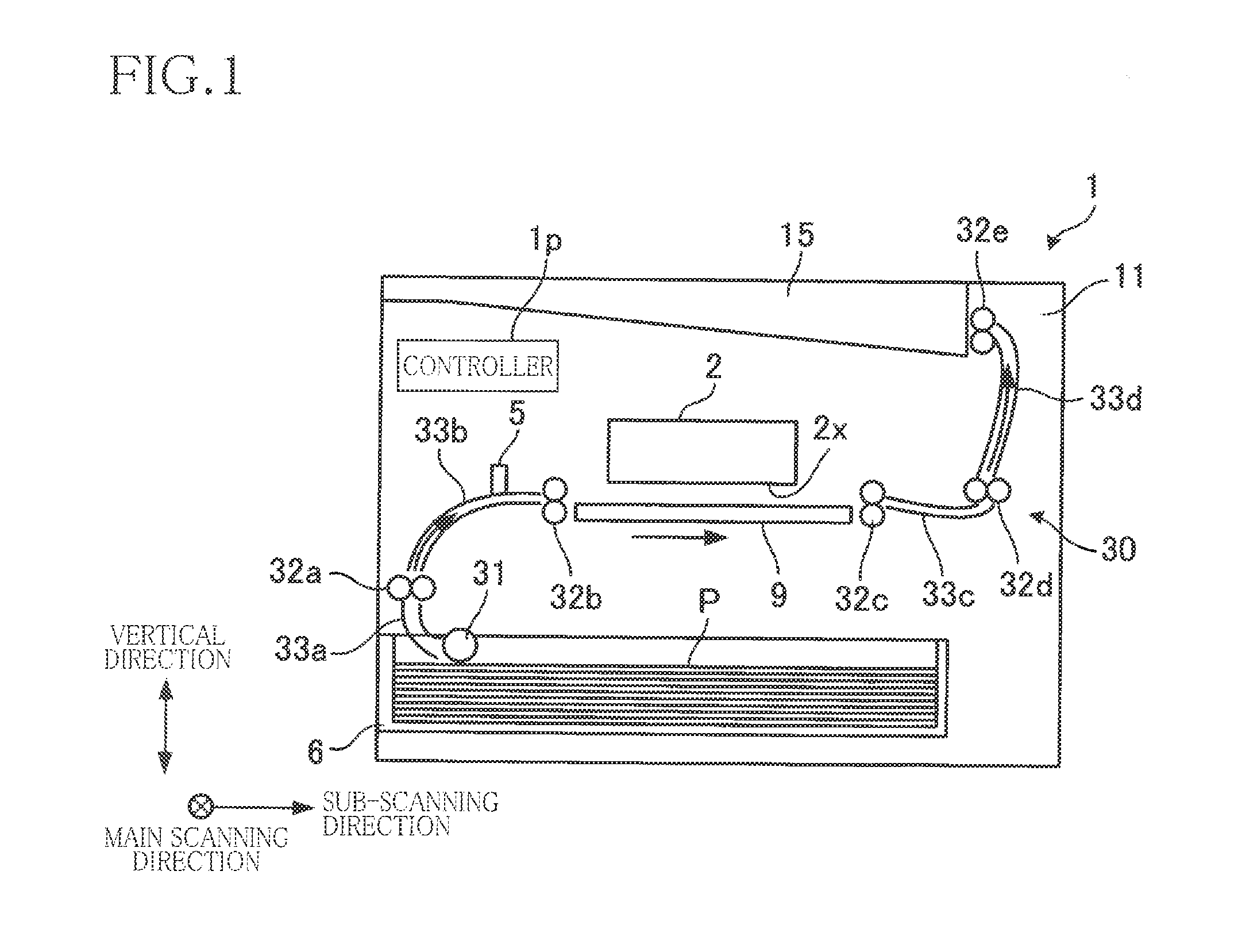

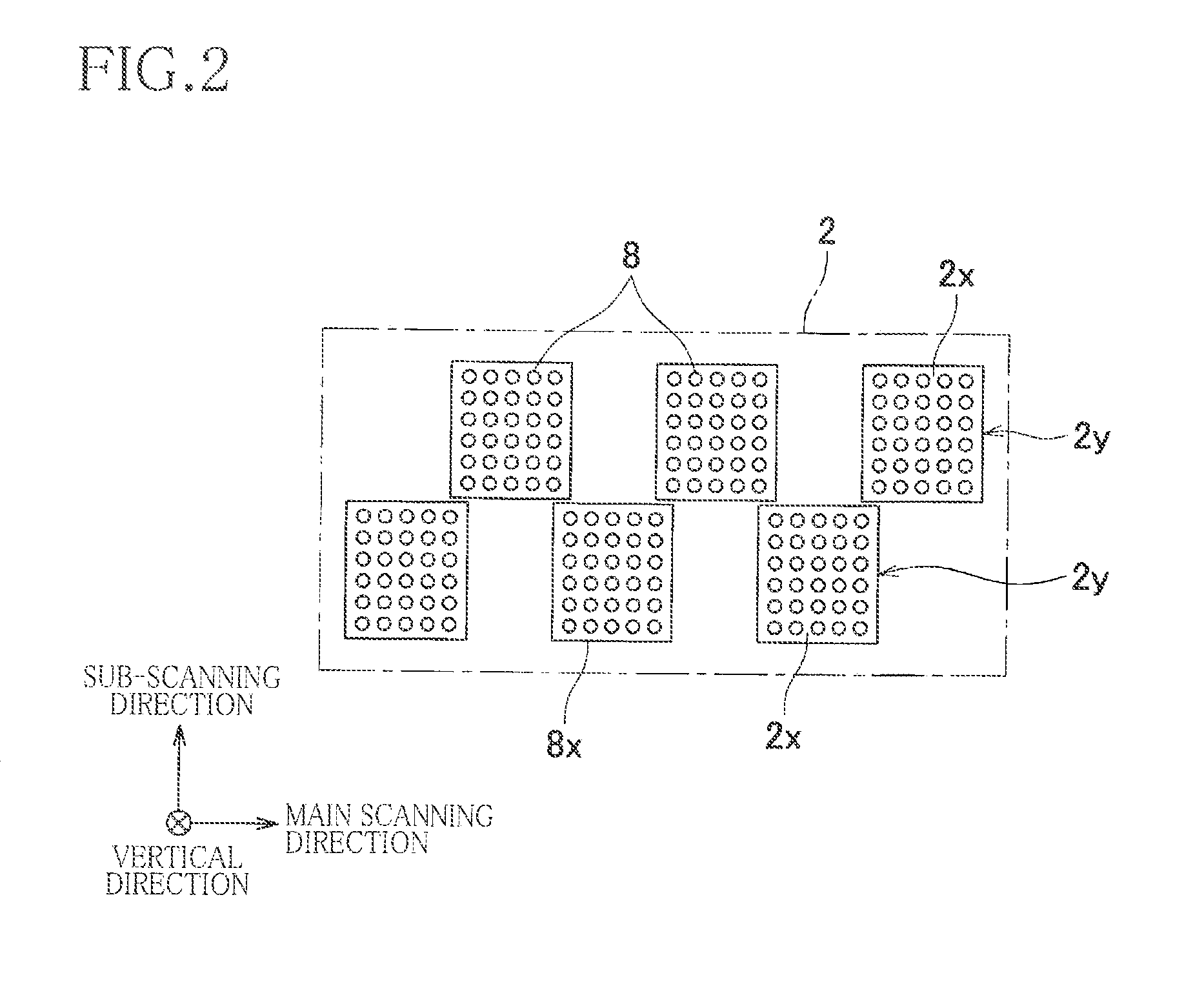

Liquid ejection apparatus

ActiveUS20140292887A1Reduce the differenceDeterioration can be suppressedInking apparatusOther printing apparatusHeat resistanceEngineering

Owner:BROTHER KOGYO KK

Edge treating a cut edge of a glass piece

InactiveUS20150218045A1Improve mechanical propertiesDifficult to restoreGlass tempering apparatusEngineeringHeat spreader

Owner:CORNING INC

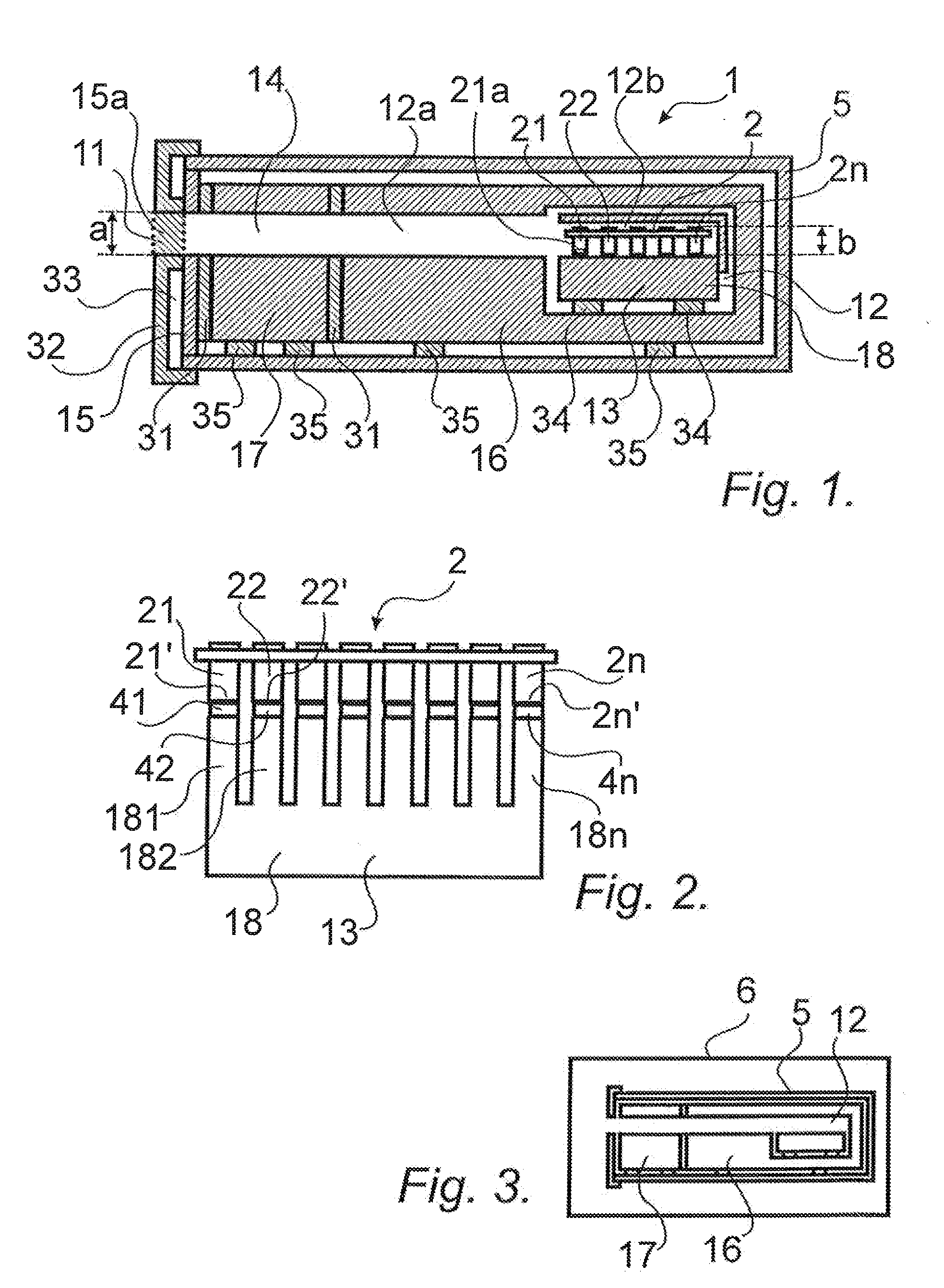

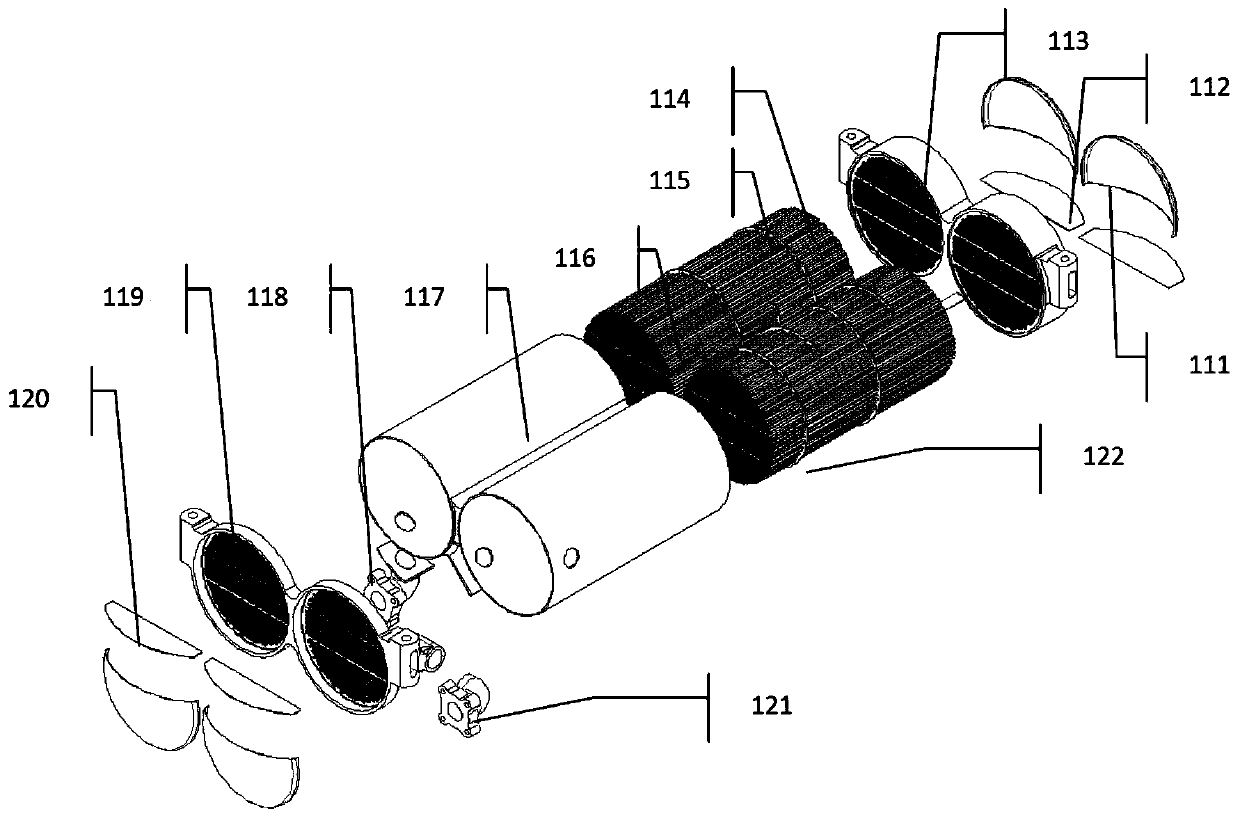

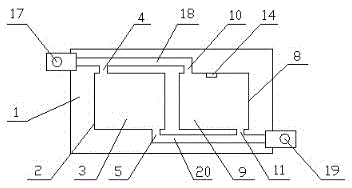

Semiconductor laser array device

InactiveUS20050286592A1Increase powerImprove cooling efficiencySemiconductor laser arrangementsLaser arrangementsLaser arrayHeat spreader

A semiconductor laser array device for outputting a higher power includes: a plurality of semiconductor laser chips, arranged in a predetermined pitch; a submount for mounting each semiconductor laser chip; and a heat sink for dissipating heat from the semiconductor laser chip through the submount; wherein a distance S between the centers of the chips and a thickness T of the submount satisfy the following inequality: 2×T≦S≦10×T, whereby improving efficiency of heat dissipation with a good process yield.

Owner:MITSUBISHI ELECTRIC CORP

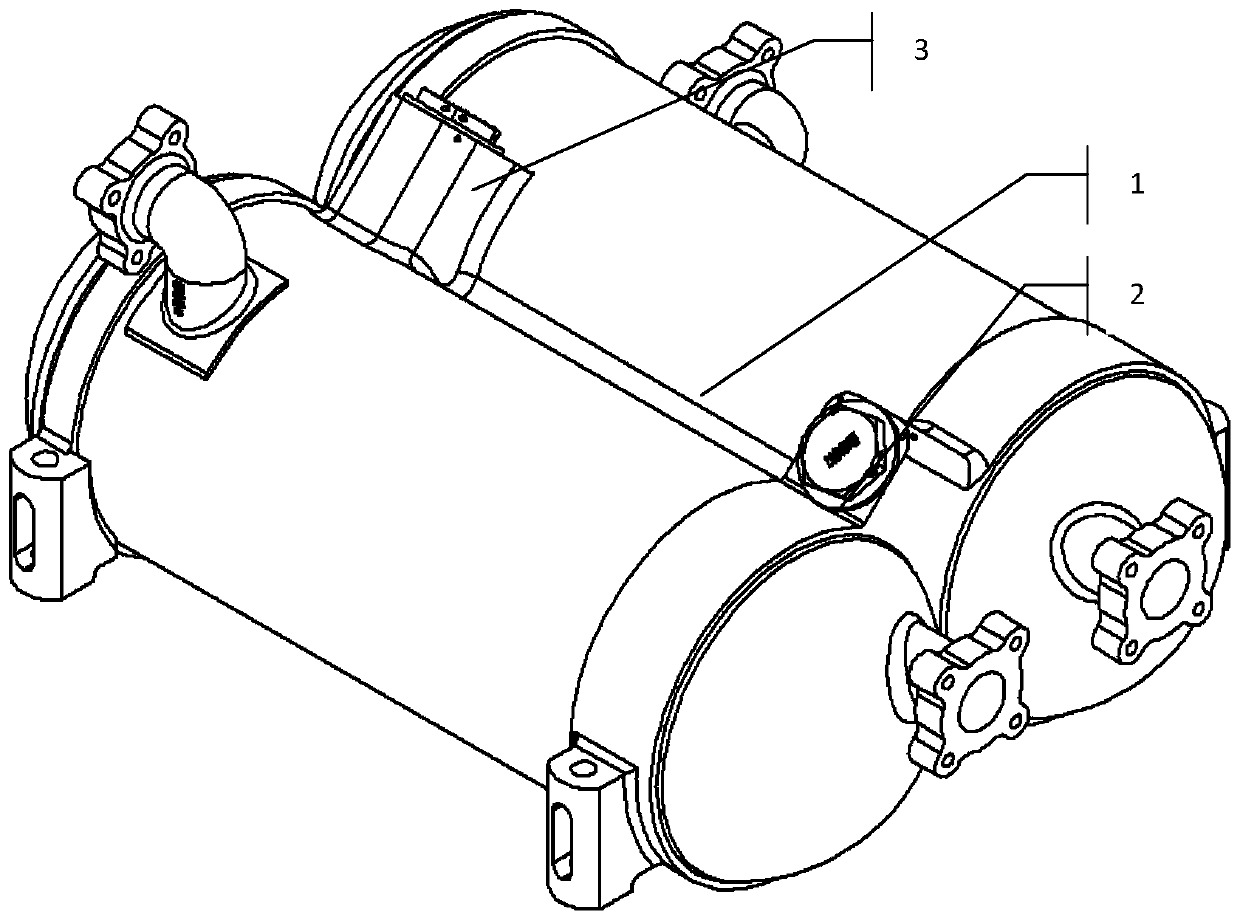

Reinforcing pipe sleeve and clamping sleeve for automobile radiator and intercooler, and use method

ActiveCN103382878AExtended service lifeReduce replacement rateInternal combustion piston enginesEngine cooling apparatusEngineeringIntercooler

Owner:李冬根

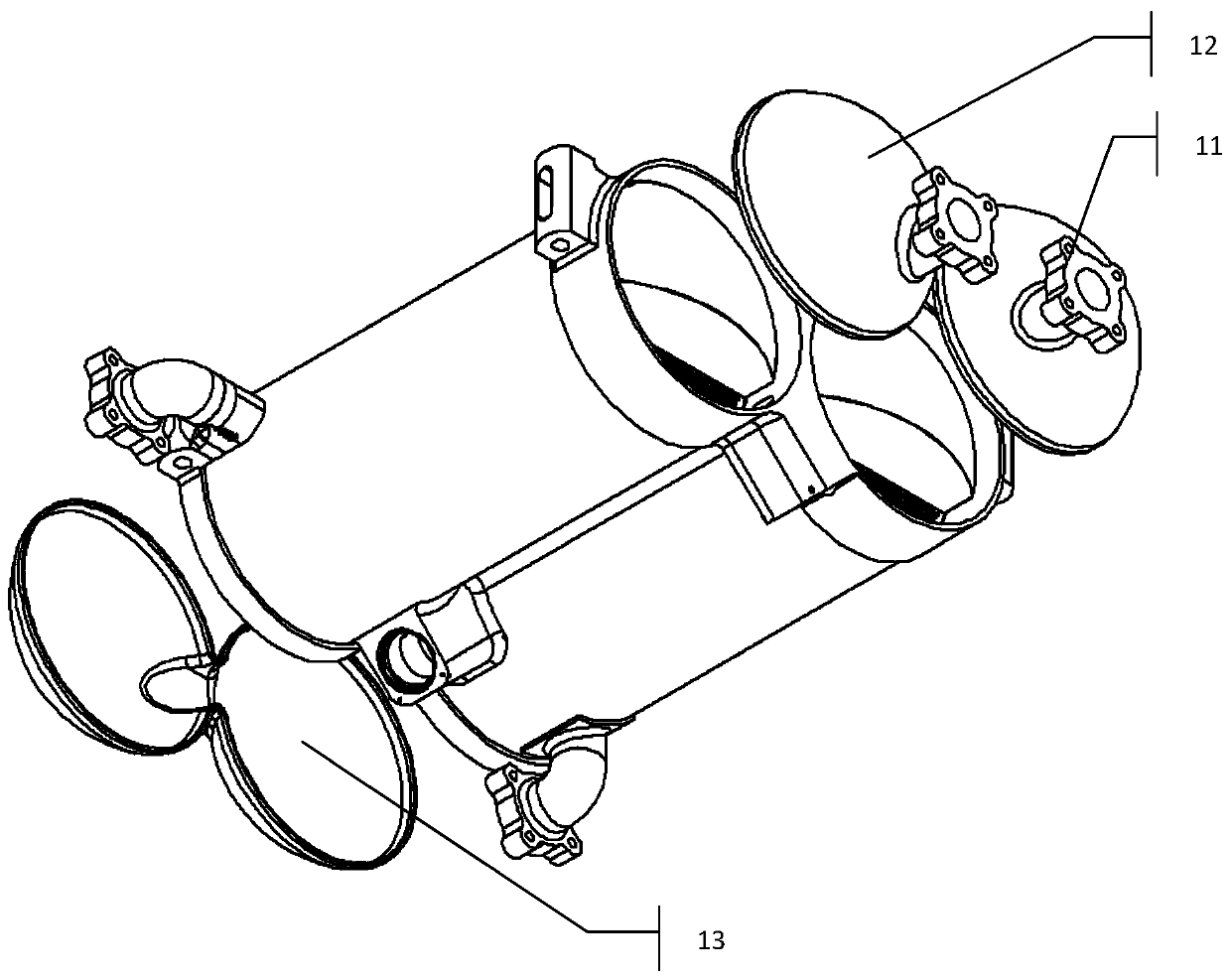

Aero-engine high-pressure fuel and grease heat radiator

InactiveCN110043342AGuarantee the safety of useReduce weightMachines/enginesThermal treatment of fuelModel engineHigh pressure

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

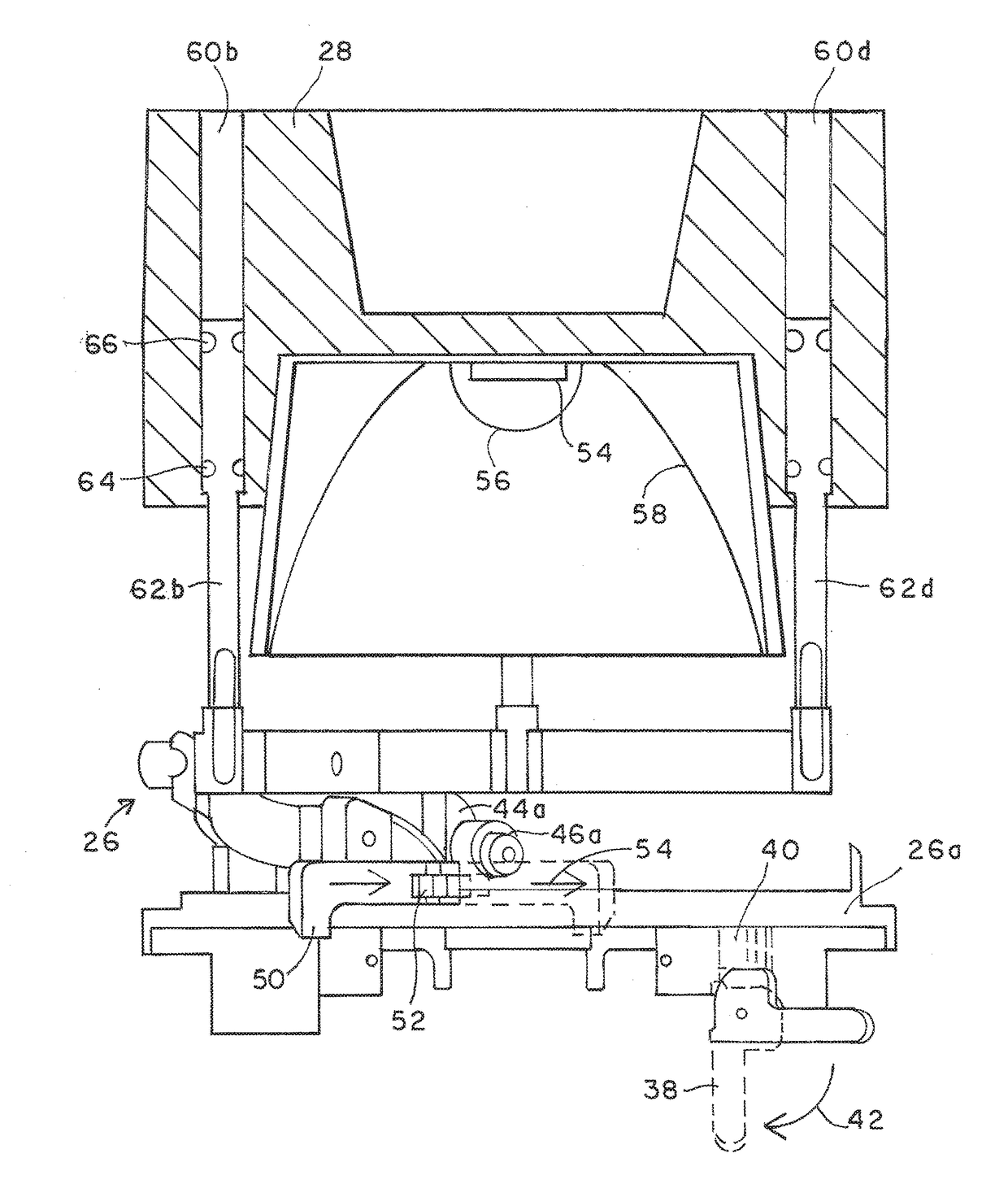

Recessed downlight fixture and method for installing and universally adjusting the fixture in a retrofit application

ActiveUS20170284643A1Easy to adjustLighting support devicesSemiconductor devices for light sourcesEngineeringHeat spreader

Owner:LUTRON TECH CO LLC

Holding device of LED lamp radiator

Owner:SUZHOU CHENGYUAN PHOTOELECTRIC TECH

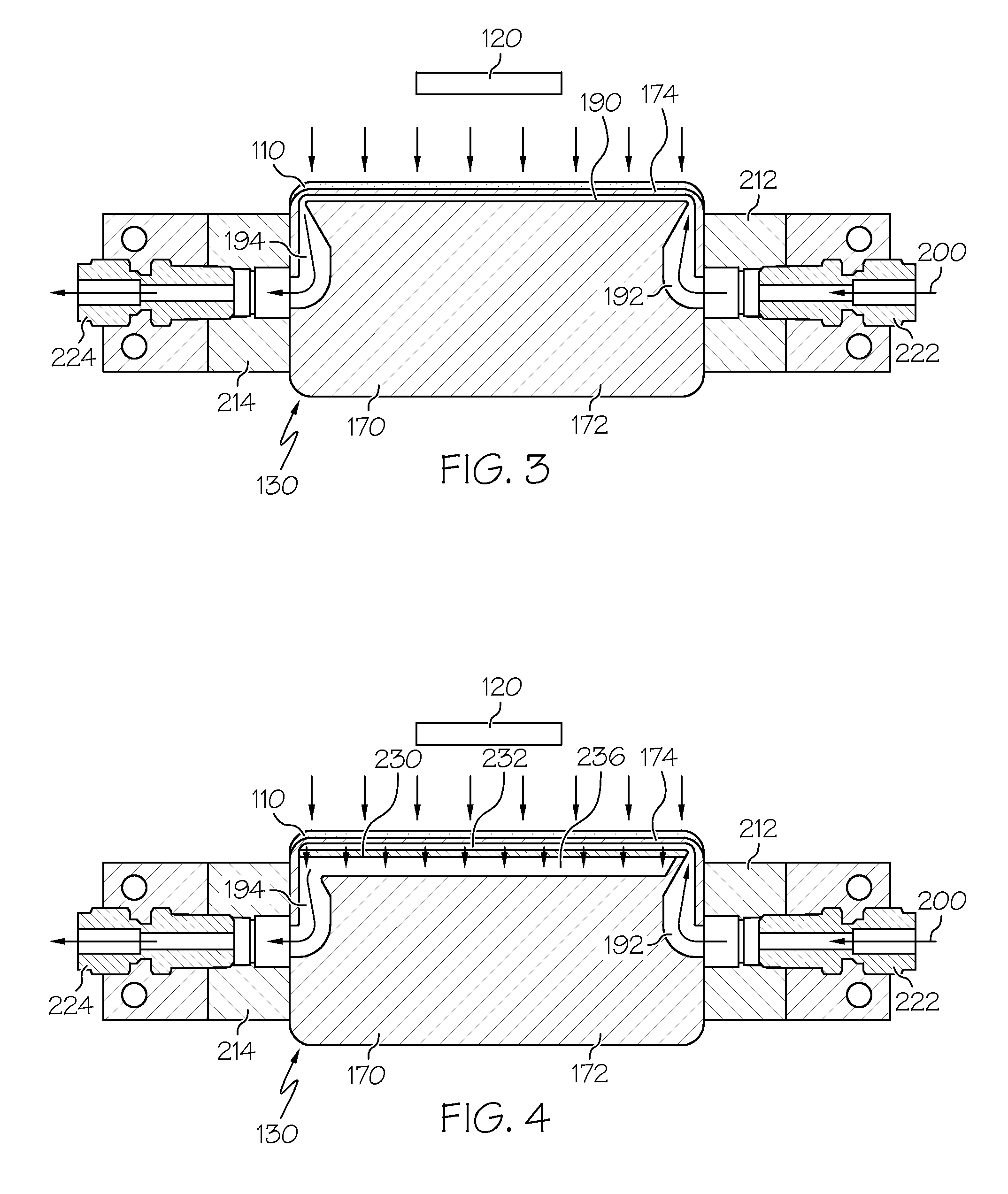

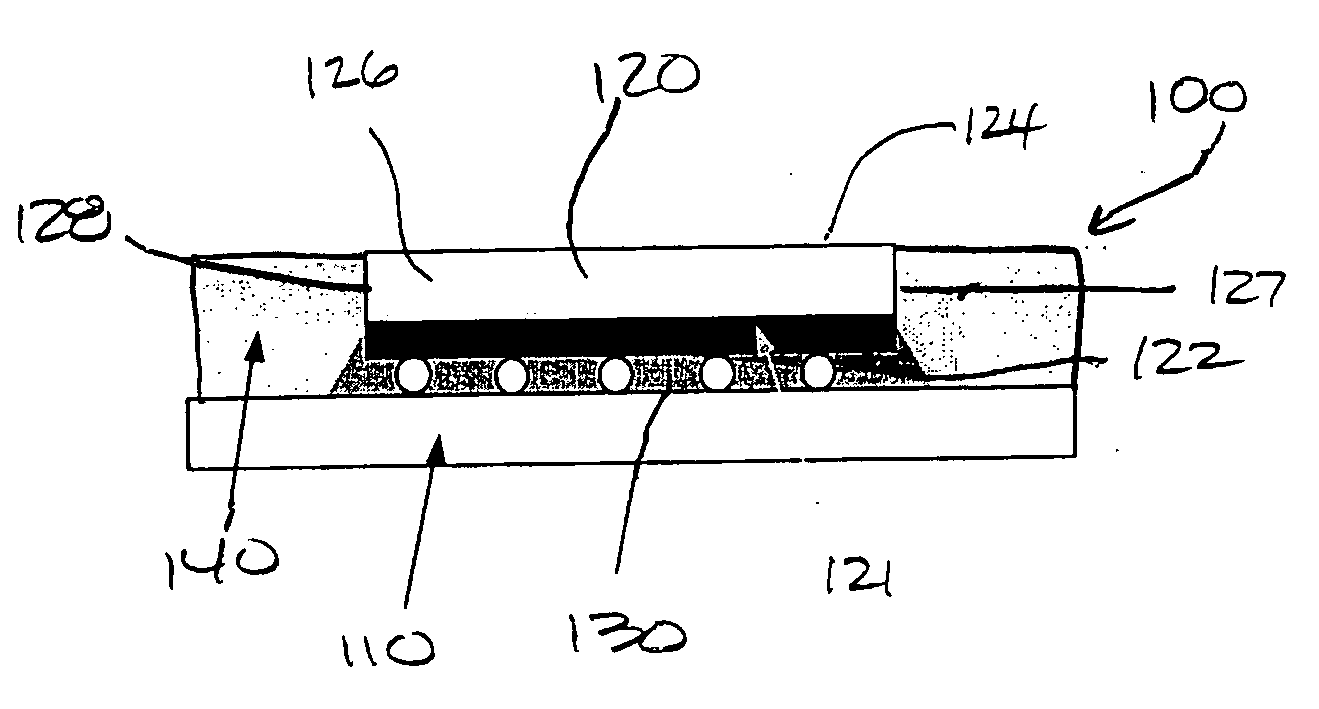

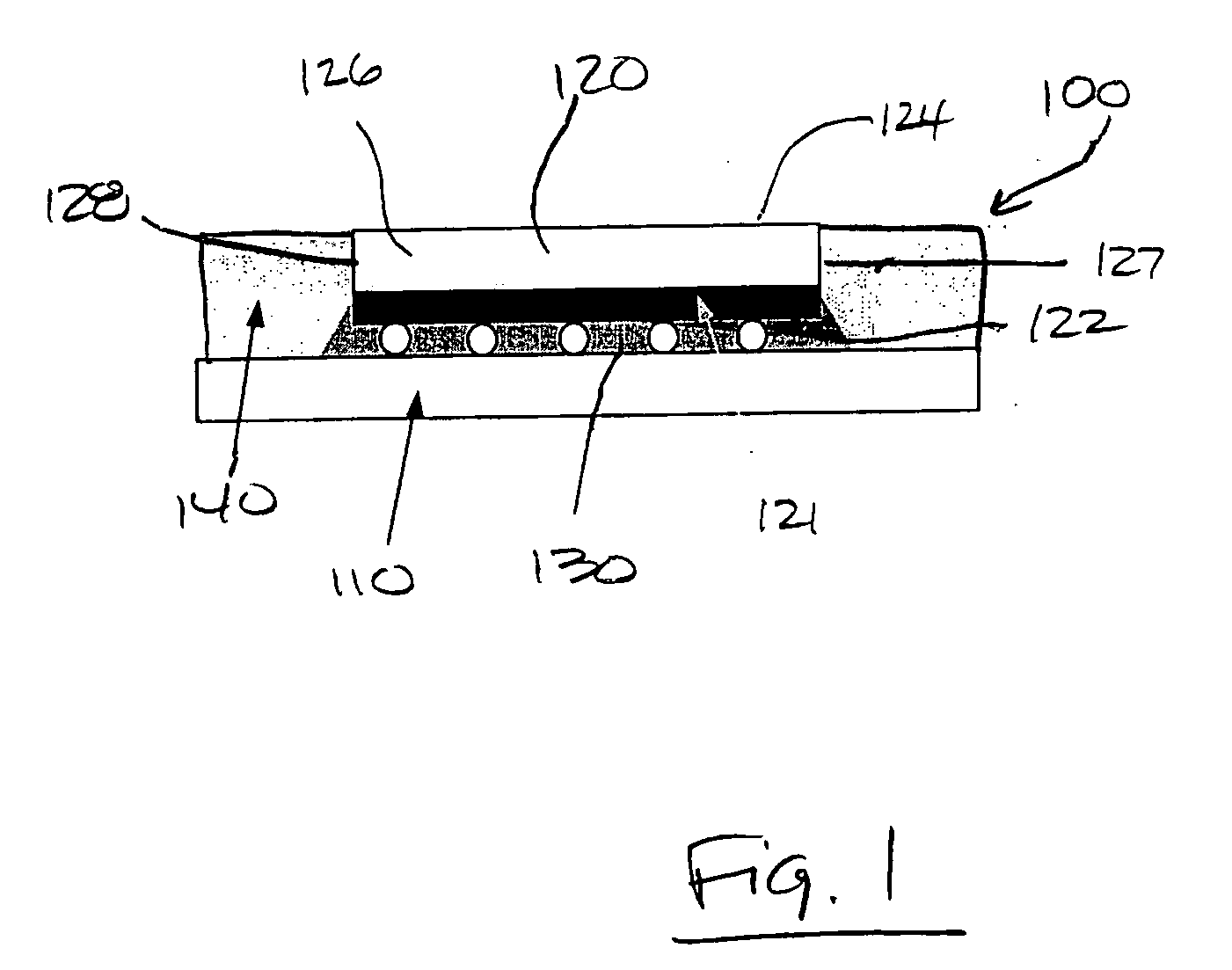

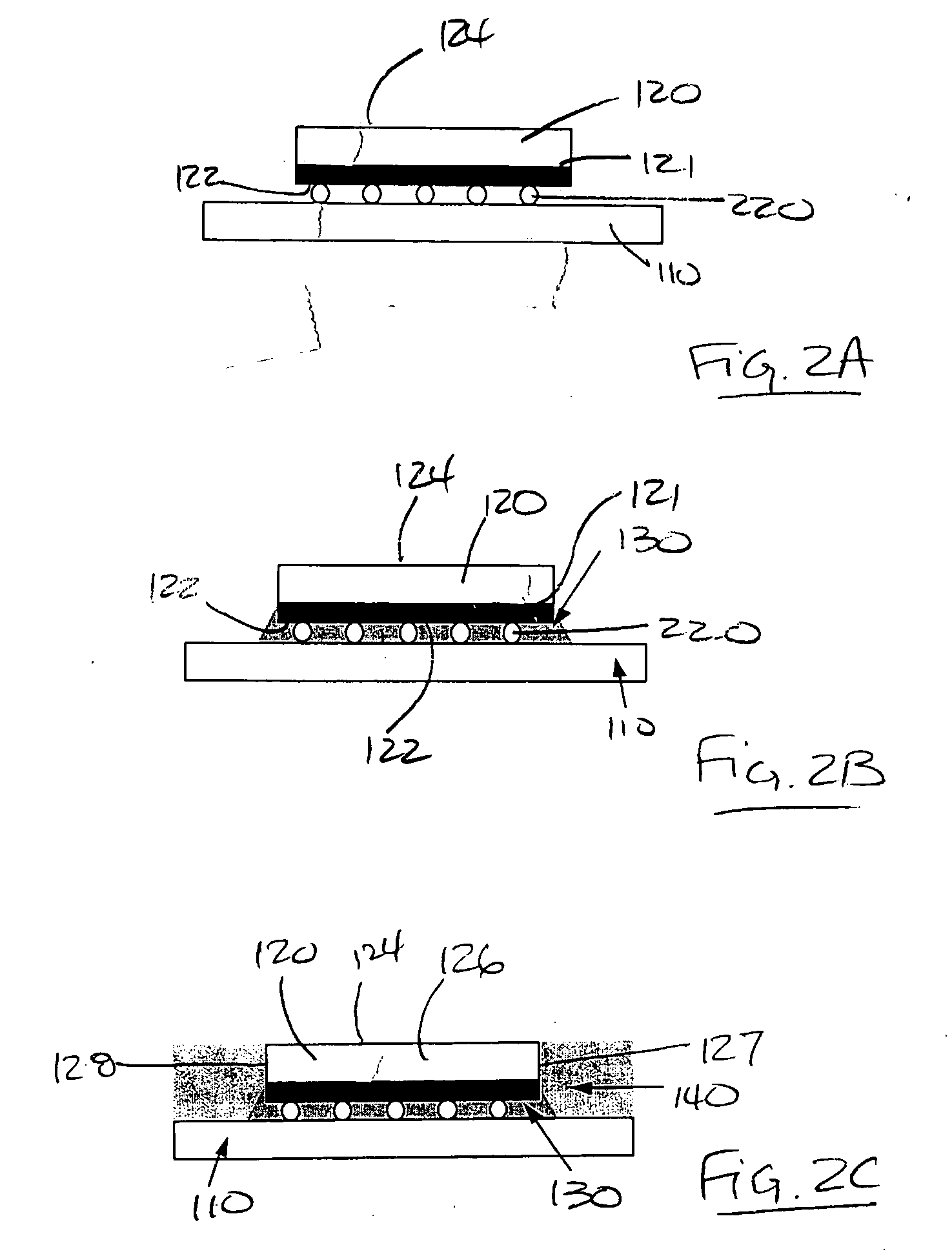

Capillary underfill and mold encapsulation method and apparatus

ActiveUS20060214311A1Semiconductor/solid-state device detailsSolid-state devicesHeat spreaderThermal contact

Owner:INTEL CORP

Fuel cell system

ActiveUS20160129808A1Easy to operateAvoid flowFuel cell heat exchangeBattery/fuel cell control arrangementFuel cellsWater flow

A flow control valve 26 can adjust the percentage of the flow rate of cooling water to a radiator 23 to a predetermined value (50%) or smaller. When the temperature of the cooling water in a fuel cell 11 is determined to be a predetermined temperature (0° C.) or higher after the cooling water is supplied to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger, a controller 41 performs a predetermined percentage supply operation for controlling the flow control valve 26 and a pump 22 to supply the cooling water to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger.

Owner:TOYOTA JIDOSHA KK

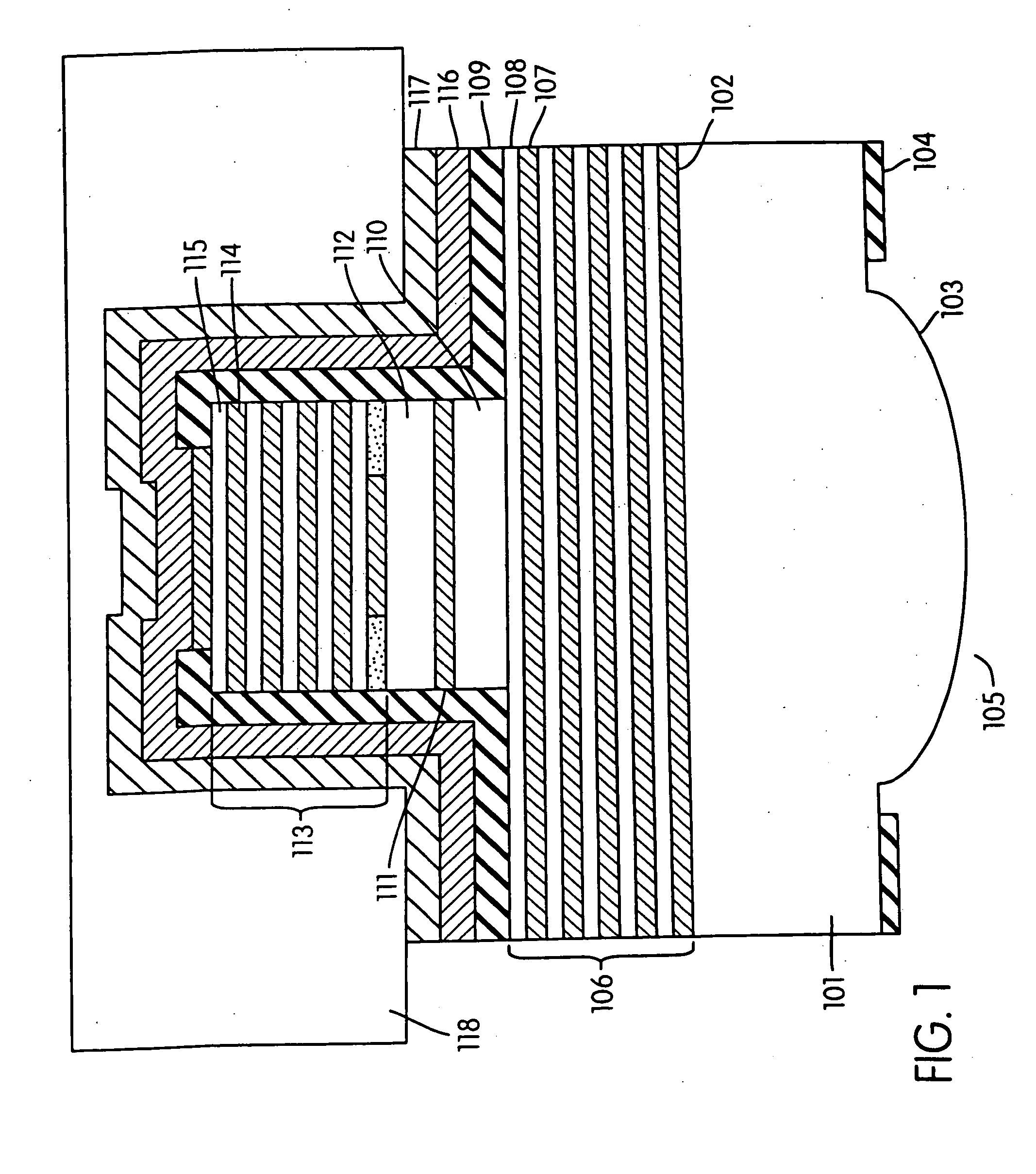

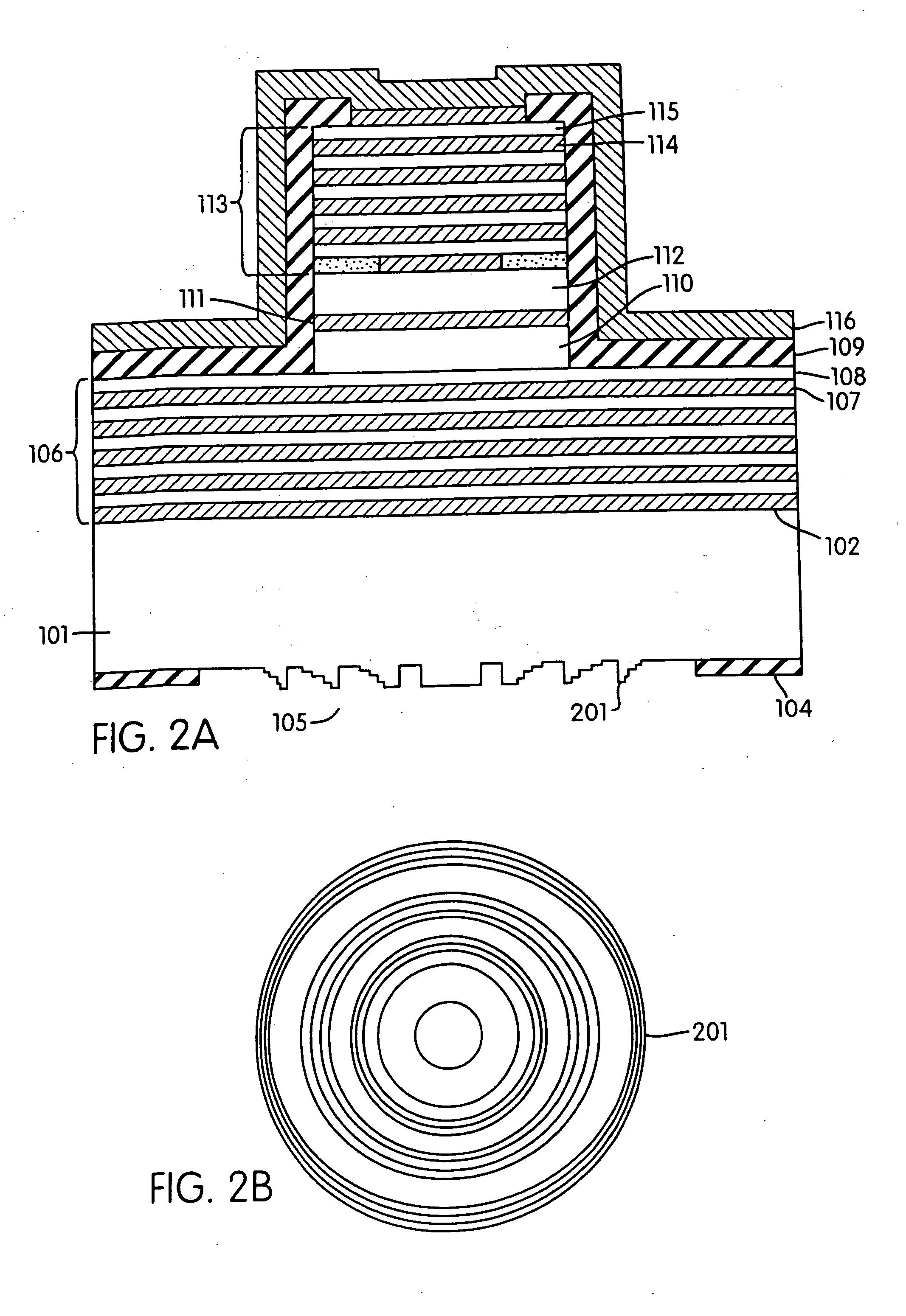

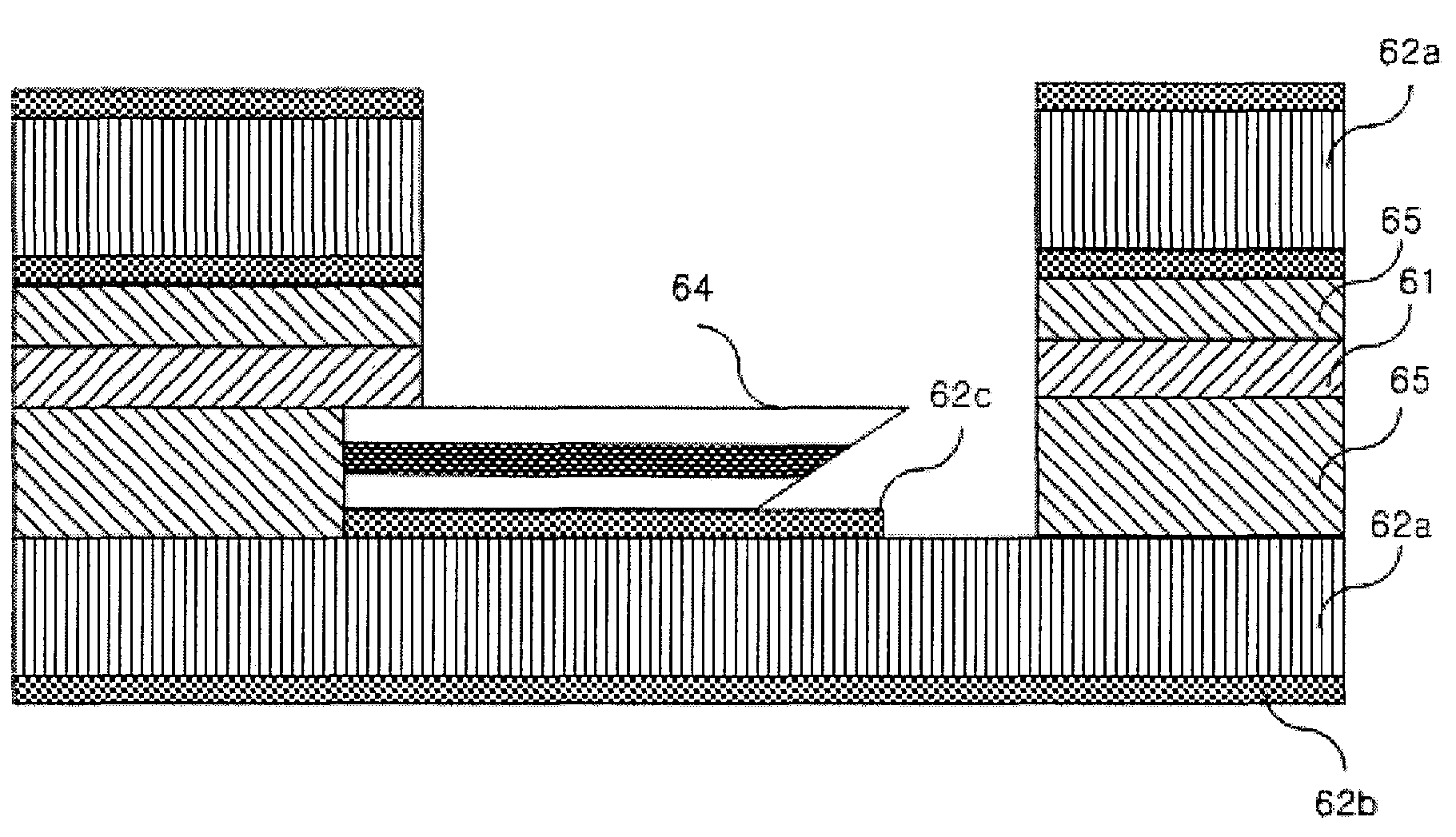

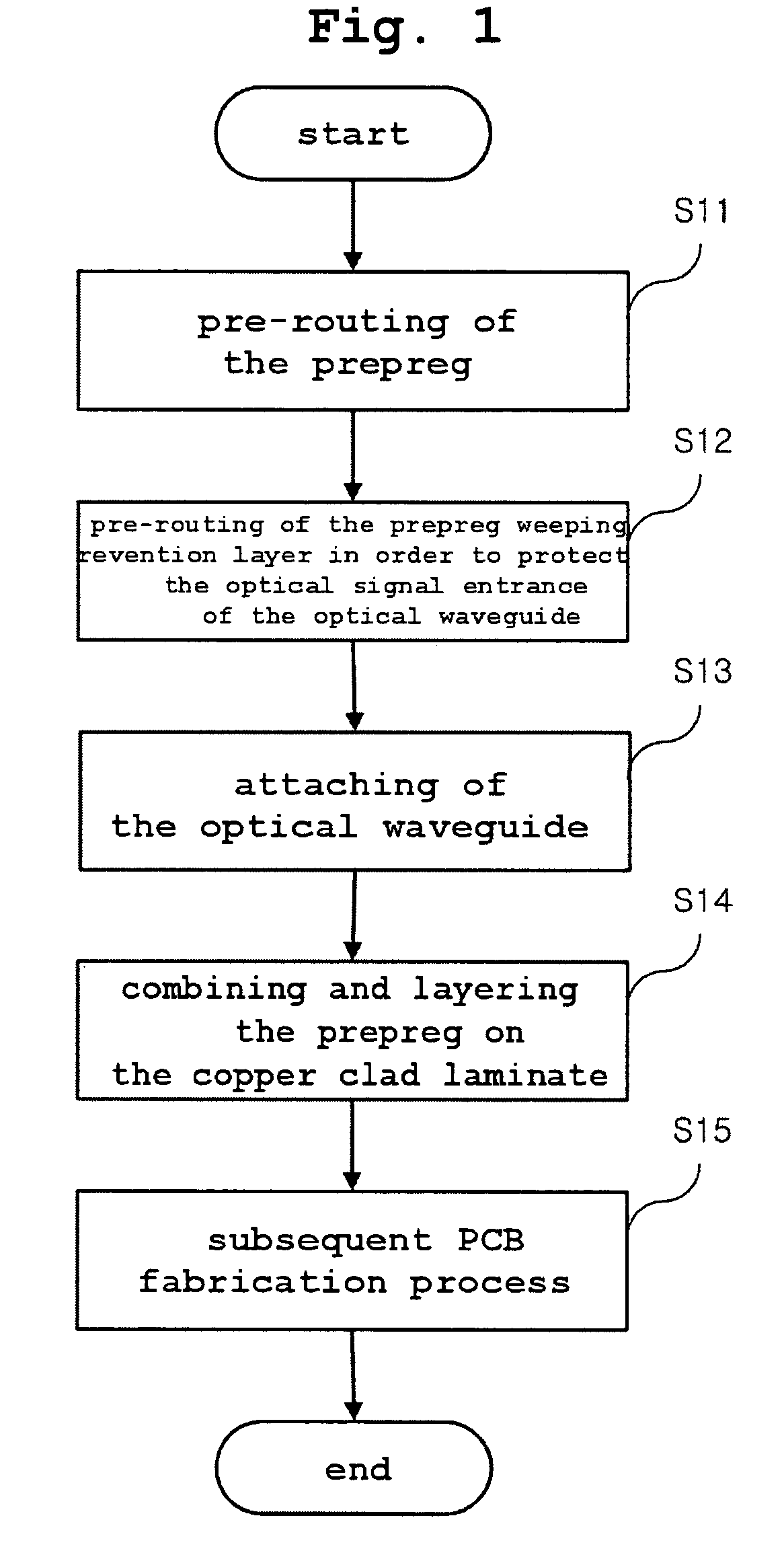

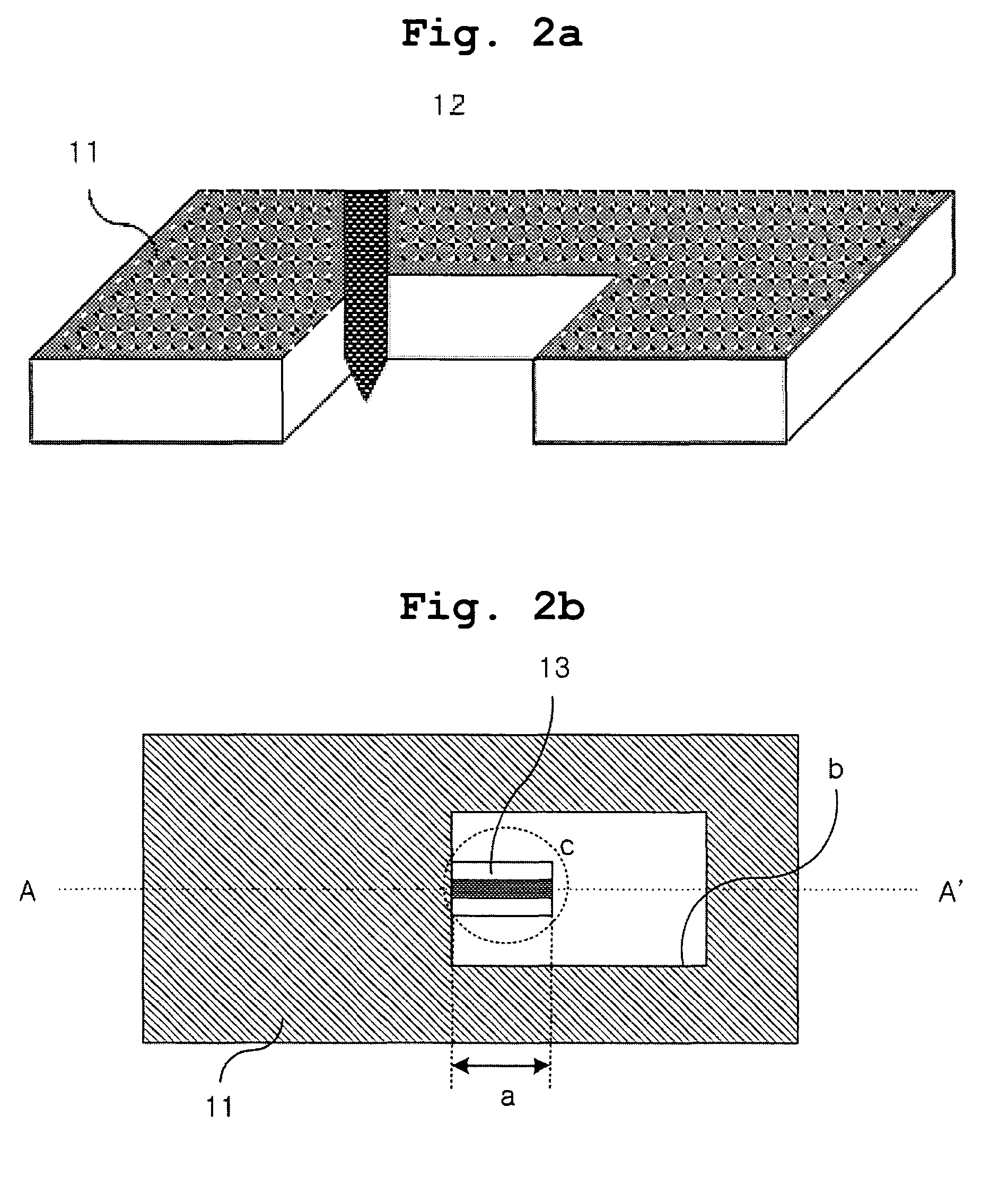

Method of fabricating multi-layered printed circuit board for optical waveguides

InactiveUS7046870B2Facilitating precise interfacing of optical signalPrinted circuit assemblingLine/current collector detailsAdhesiveCopper foil

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Ultrathin loudspeaker-type radiator and damping ultrathin radiator

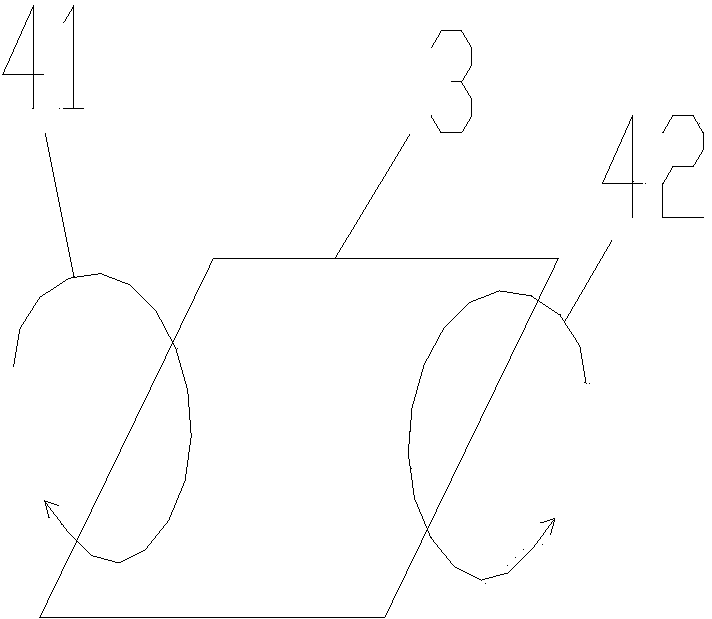

ActiveCN103747395AIncrease vibration intensityReduce vibrationElectrical transducersEngineeringAlternating current

Owner:GUOGUANG ELECTRIC +1

Major loop structure for vacuum circuit-breaker

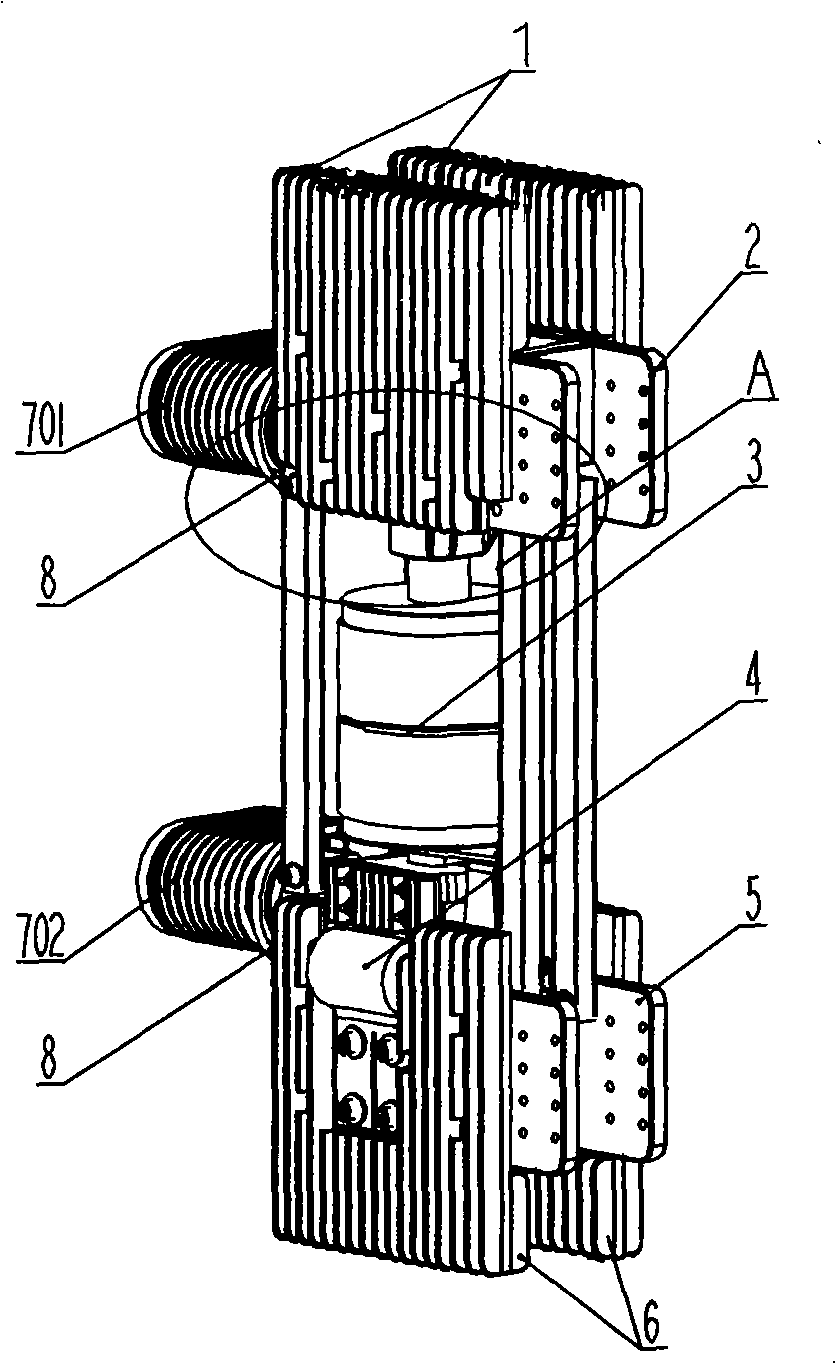

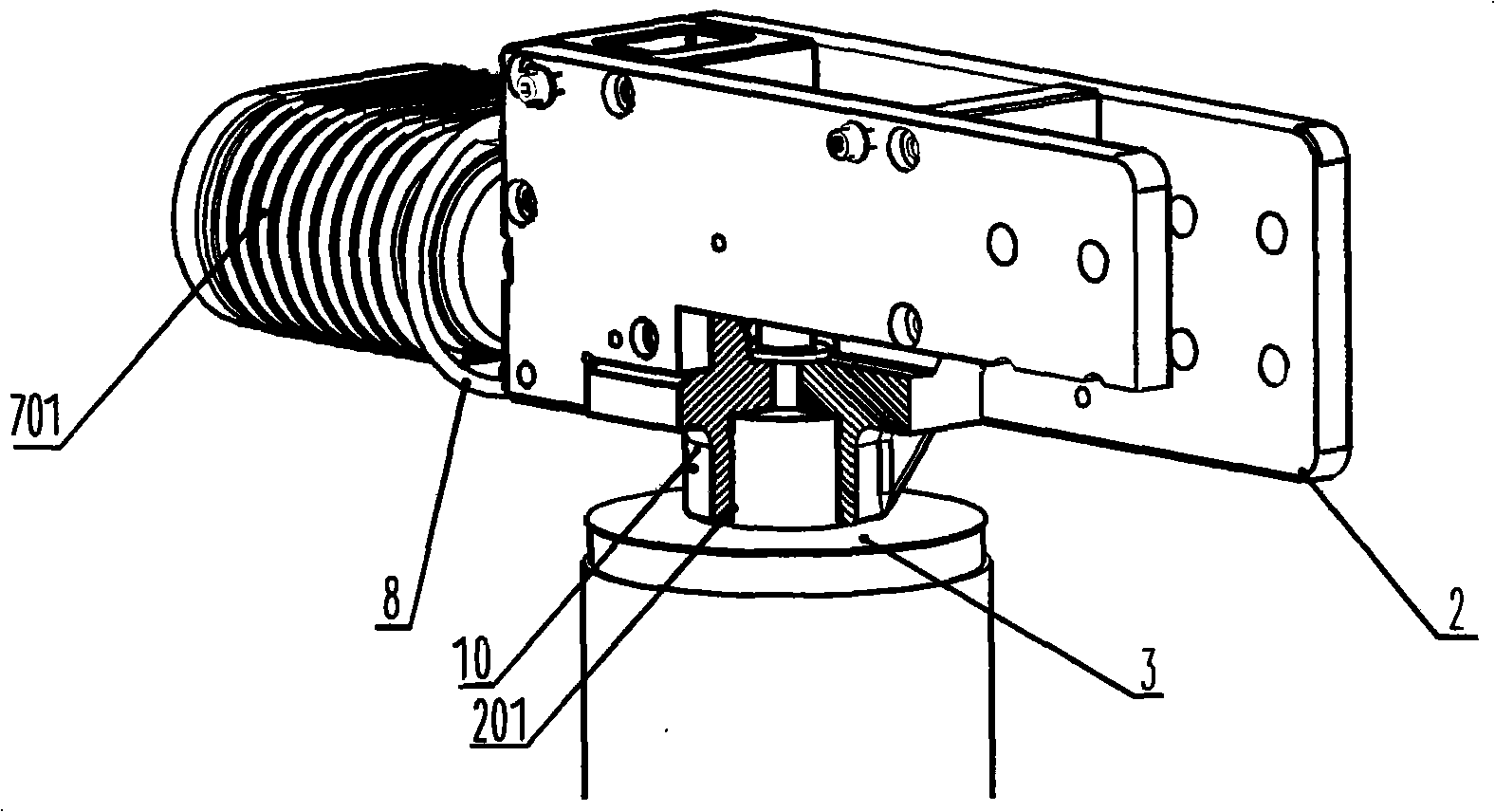

ActiveCN101409176ALow calorific valueIncrease the current flow cross sectionHigh-tension/heavy-dress switchesAir-break switchesVacuum interrupterVacuum arc

Owner:CHINA TIANSHUI CHANGCHENG SWITCHGEAR CO LTD

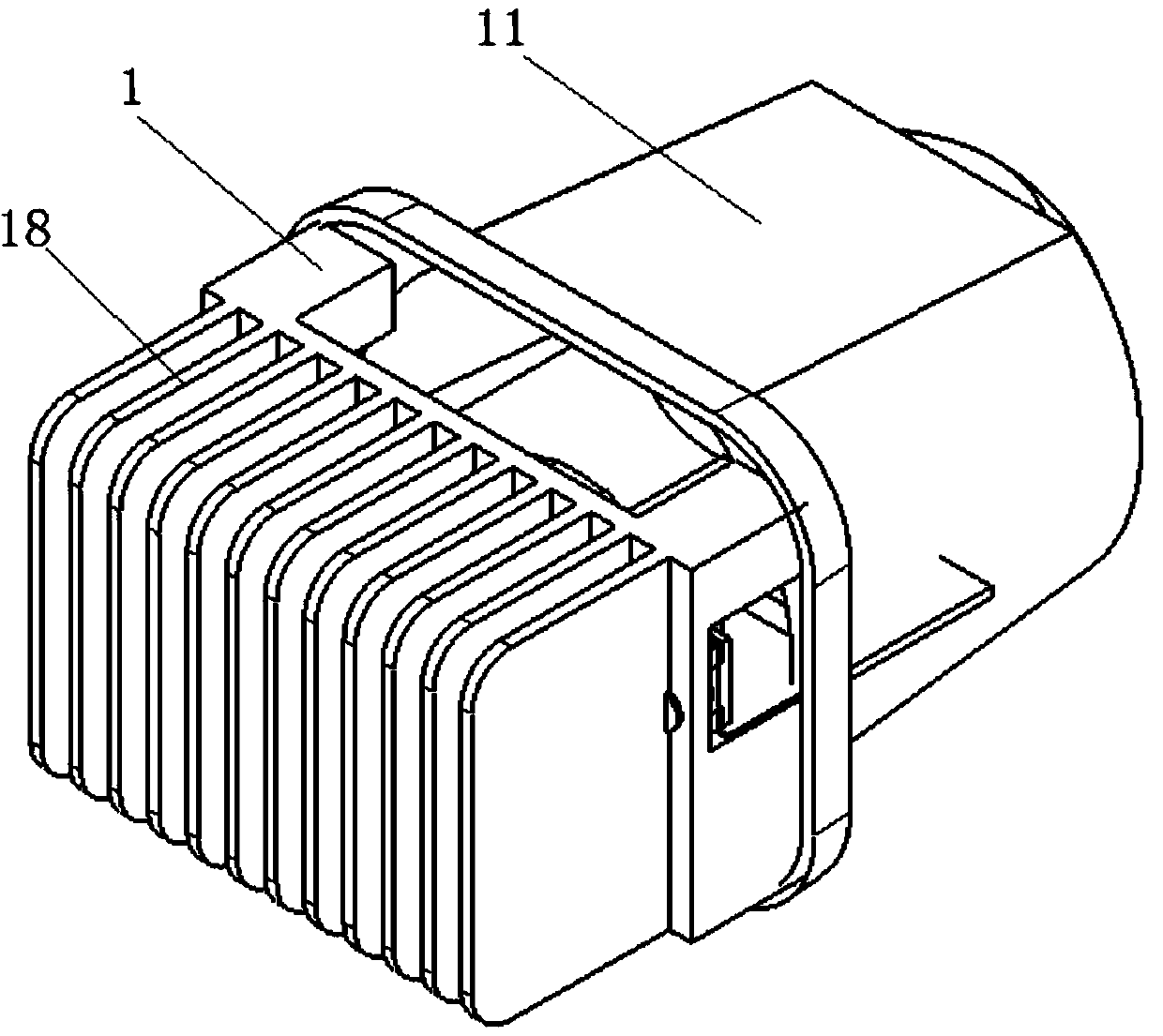

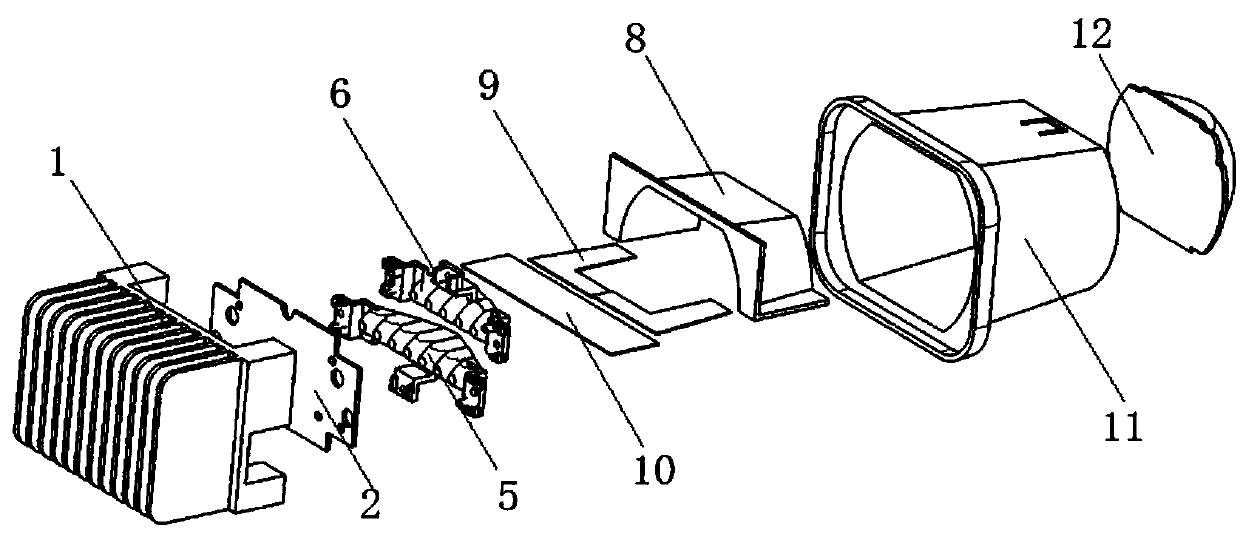

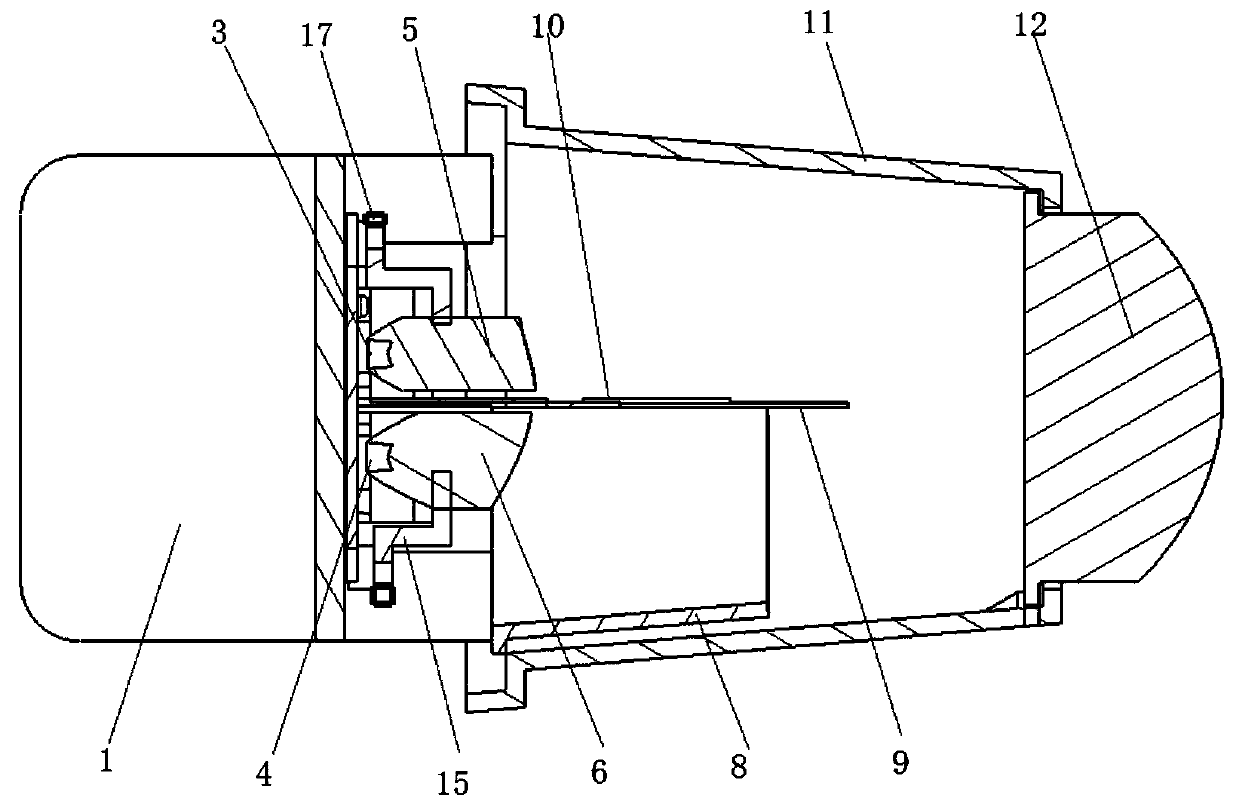

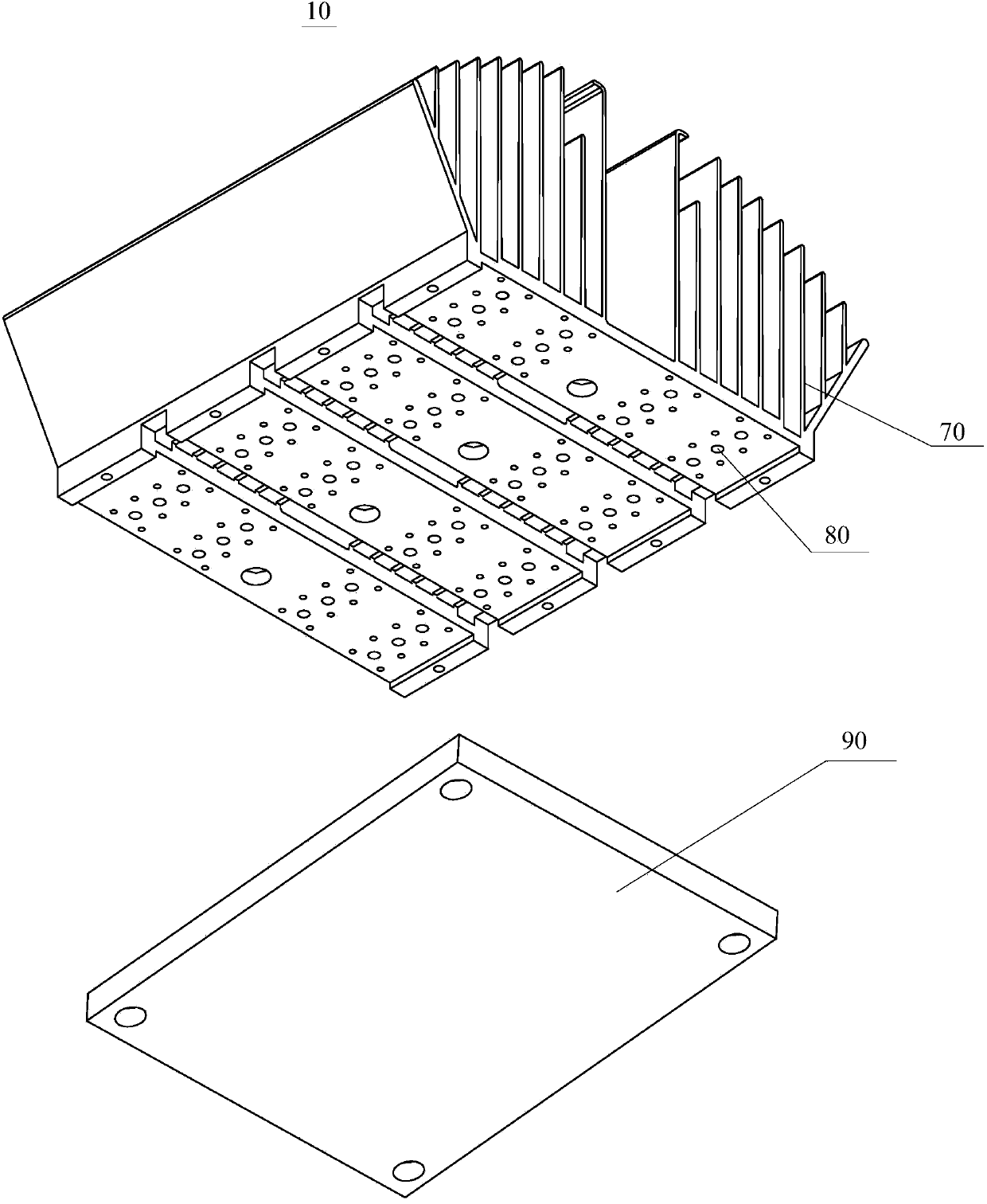

Automobile LED bifocal lens headlamp

PendingCN110397889AGuaranteed styleProcess to avoid bendingVehicle headlampsRoad vehiclesBeam splitterOptoelectronics

Owner:帝宝车灯制造(合肥)有限公司

Integrated LED lamp

ActiveCN104197220ASimple structureAchieving a one-piece structurePoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

Owner:东莞市闻誉实业有限公司

Radiator of large bus

InactiveCN105545456AIncrease contact areaIncrease the areaMachines/enginesEngine cooling apparatusWater dischargeEngineering

Owner:TIANJIN QINGPU RADIATOR TECH CO LTD

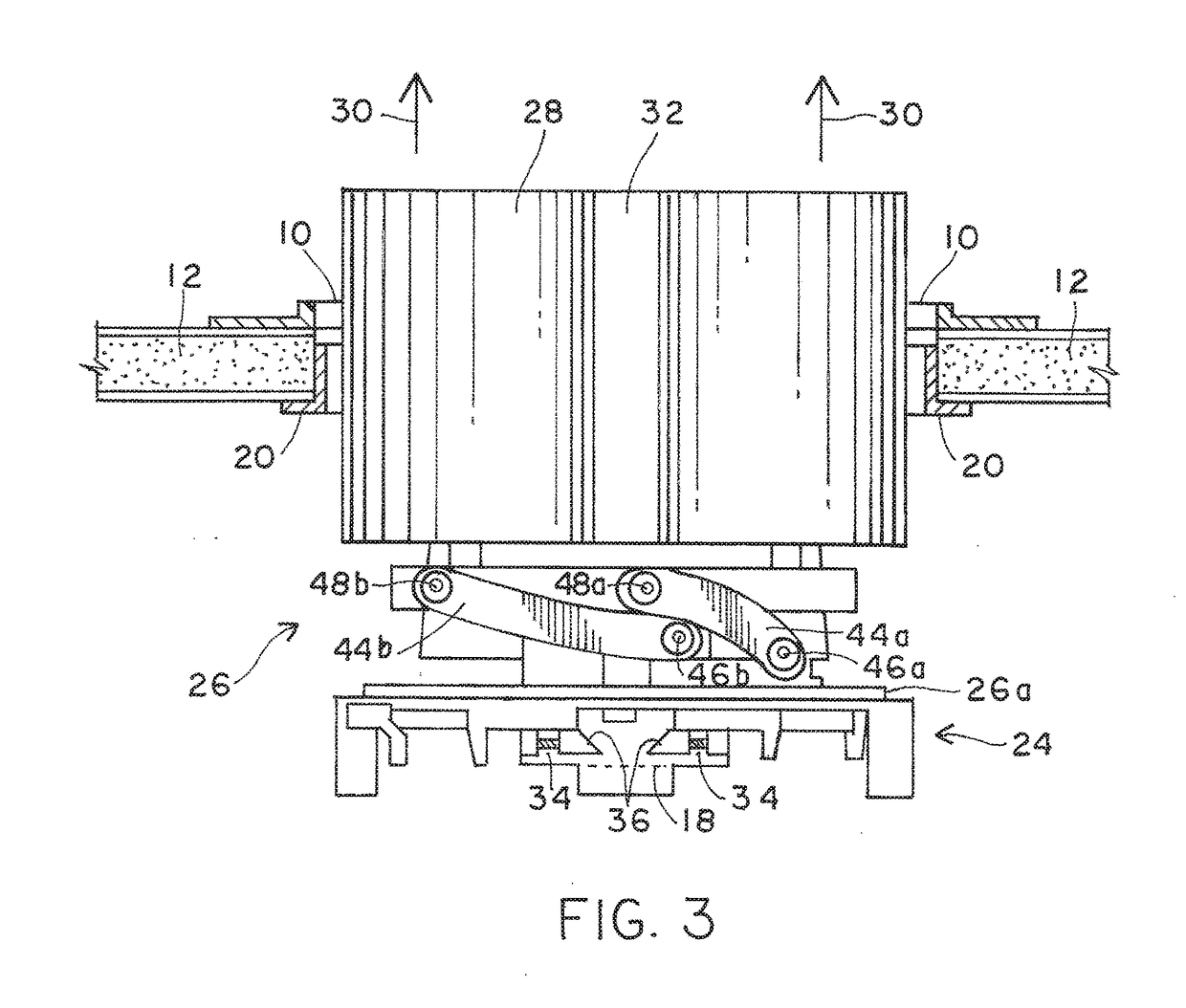

System and apparatus for controlling light intensity output of light emitting diode arrays

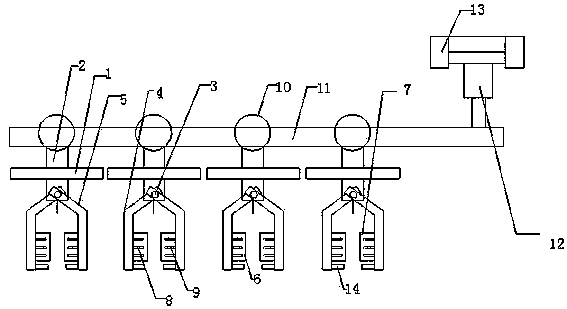

Disclosed herein is a system for controlling a drive current of an LED that includes a controller configured to estimate a junction temperature of the LED at a location of a heat sink. The system also includes a driver configured to change a drive current to the LED in response to a command from the controller. Also disclosed is a method of determining drive currents for LEDs in an array that includes determining a required light output intensity at a first time for each LED; estimating heat generated by each LED at the first time; solving heat flow equations for the array at the first time; estimating a junction temperature for each of the LEDs at the first time; and determining a drive current for the required light intensity at the first time for each of the LEDs based on the junction temperature.

Owner:SIGNIFY HLDG BV

Mounting structure of radiator of internal-combustion engine

InactiveCN1657748AIncrease configuration freedomImprove rigidityLiquid coolingMachines/enginesInterior spaceDrive wheel

A radiator installing structure to an internal combustion engine body in a power unit, is rockingly supported by a car body by integrating the internal combustion engine body composed of a cylinder and a cylinder head, a crankcase for storing a crankshaft, and a motive power transmission case for supporting a driving wheel. The radiator installing structure is separately provided with a radiator support member installed in the crankcase, surrounding the periphery of a cooling fan arranged on one end of the crankshaft and supporting the radiator oppositely arranged to the cooling fan, and a ventilation guide member forming a cooling air passage reaching the cooling fan from the radiator in an inside space of the radiator support member.

Owner:HONDA MOTOR CO LTD

Light-emitting diode (LED) light emitting module and manufacturing method thereof

InactiveCN103165807AOvercome the technical problem of low heat dissipation efficiencyImprove cooling efficiencySemiconductor devicesEngineeringLight-emitting diode

Owner:朱小春

Semiconductor radiator and processing method thereof

ActiveCN109531083AImprove processing strengthImprove surface roughnessBearing componentsSemiconductorMaterials science

Owner:同共(湖北)精密成形有限公司

Fin penetrating type heat sink of generator set

InactiveCN106121804AImprove diversion capacityEnhanced turbulence effectMachines/enginesEngine cooling apparatusForeign matterNuclear engineering

Owner:API HEAT TRANSFER SUZHOU

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap