Radiator of large bus

A technology for radiators and passenger cars, which is applied in the direction of machines/engines, engine cooling, engine components, etc. It can solve the problems of limited contact area between the cooling plate and the air, inconvenient maintenance and replacement of cooling pipes, and inconvenient heating of the engine, so as to facilitate disassembly , prevent pollution, expand the effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

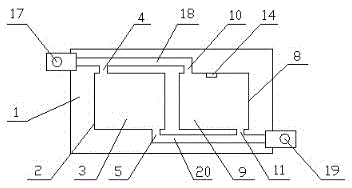

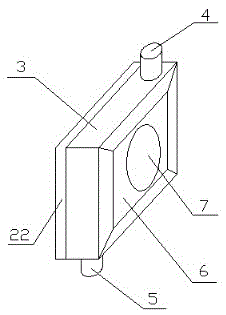

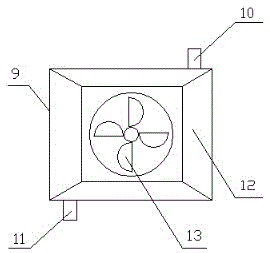

[0013] The upper water port 17 and the lower water port 19 are installed on both sides of the heat dissipation box body 1, and the first water chamber assembly 2 and the second water chamber assembly 8 are installed in the heat dissipation box body 1. The first water chamber assembly 2 includes the first radiator 3, the first water chamber assembly Water inlet 4, first water outlet 5, first windshield 6 and main fan 7, the first water inlet 4 and the first water outlet 5 are respectively installed on both sides of the first radiator 3, the first radiator 3- The side is connected to the first windshield 6, and the main fan 7 is installed on one side of the first windshield 6. The second water chamber assembly 8 includes a second radiator 9, a second water inlet 10, a second water outlet 11, a second Windshield 12, auxiliary fan 13 and temperature sensing device 14, the second water inlet part 10 and the second water outlet part 11 are respectively installed on the two sides of the

Embodiment 2

[0015] During use, the coolant flows into the upper water pipe 18 through the upper nozzle 17, and then enters the first radiator 3 and the second radiator 9 through the first water inlet 4 and the second water inlet 10 respectively, and then flows from the cooling pipe 15 respectively The first water outlet part 5 and the second water outlet part 11 flow out and enter the water outlet 19 through the downpipe 20. When the radiator is working, the temperature sensing device 14 monitors the internal temperature of the second radiator 9. When the temperature is higher than the set value, The controller 21 receives the signal and starts the auxiliary fan 13 to assist in heat dissipation, and the main fan 7 is always in the working state during the process.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap