Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about "Heat treatment furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

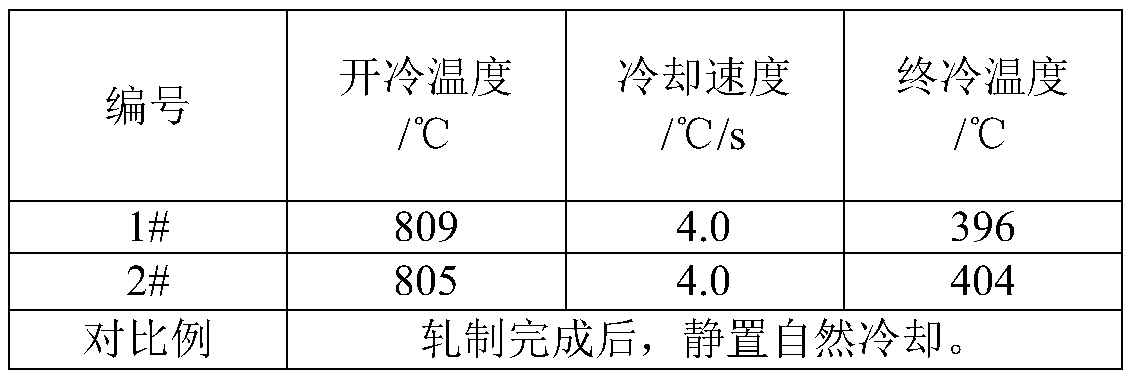

High-strength steel plate and manufacturing method thereof

Owner:BAOSHAN IRON & STEEL CO LTD

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

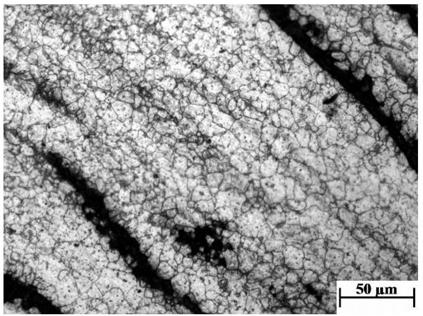

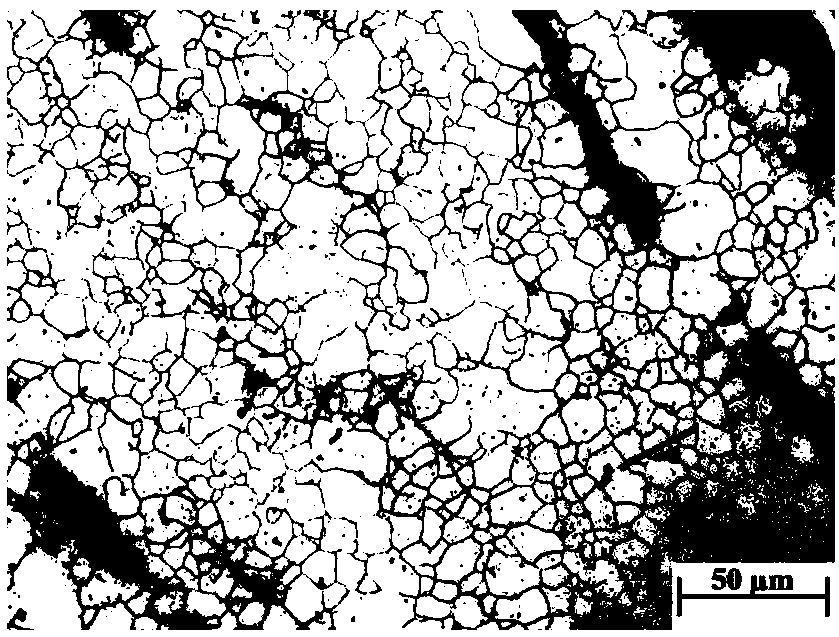

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

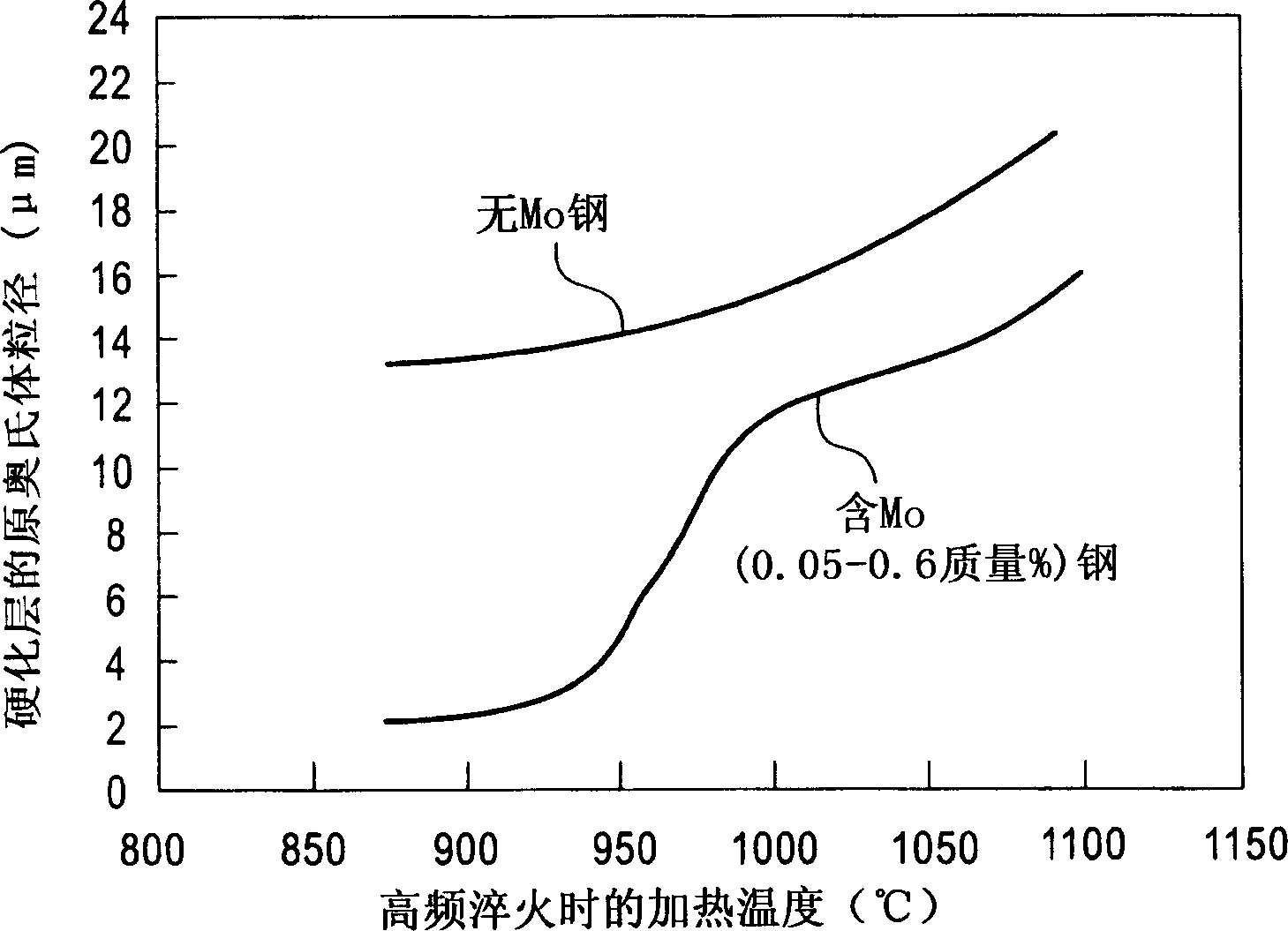

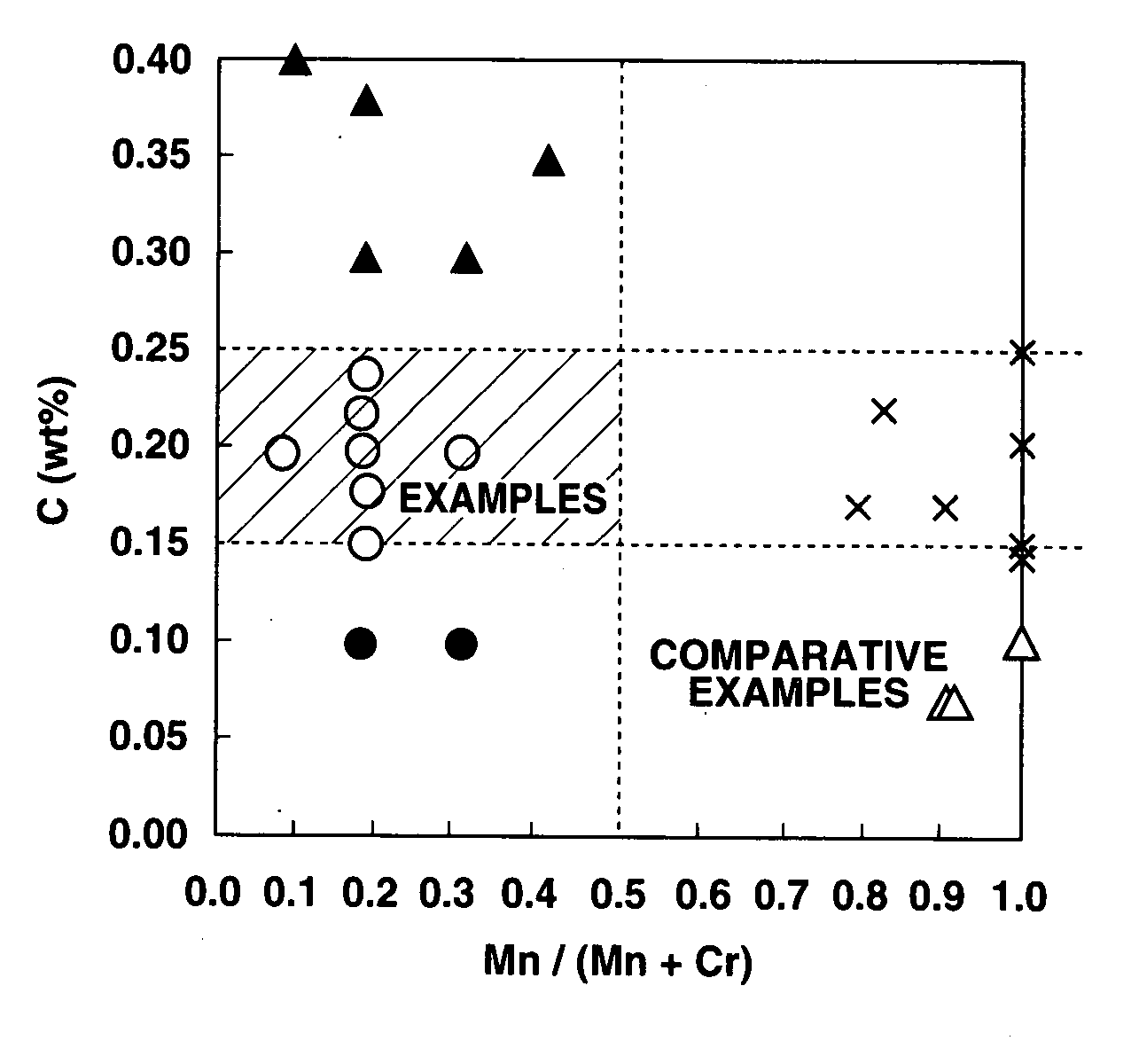

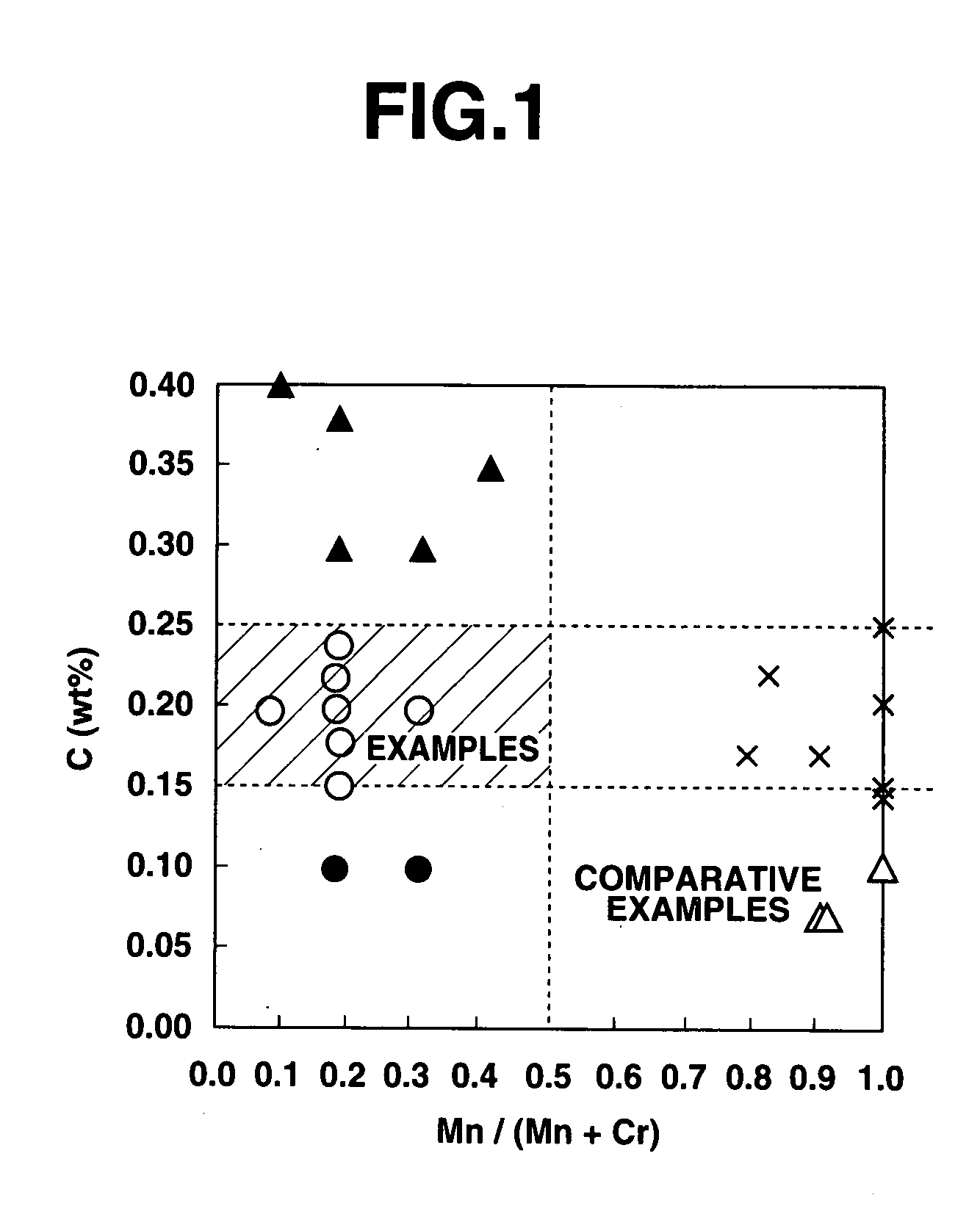

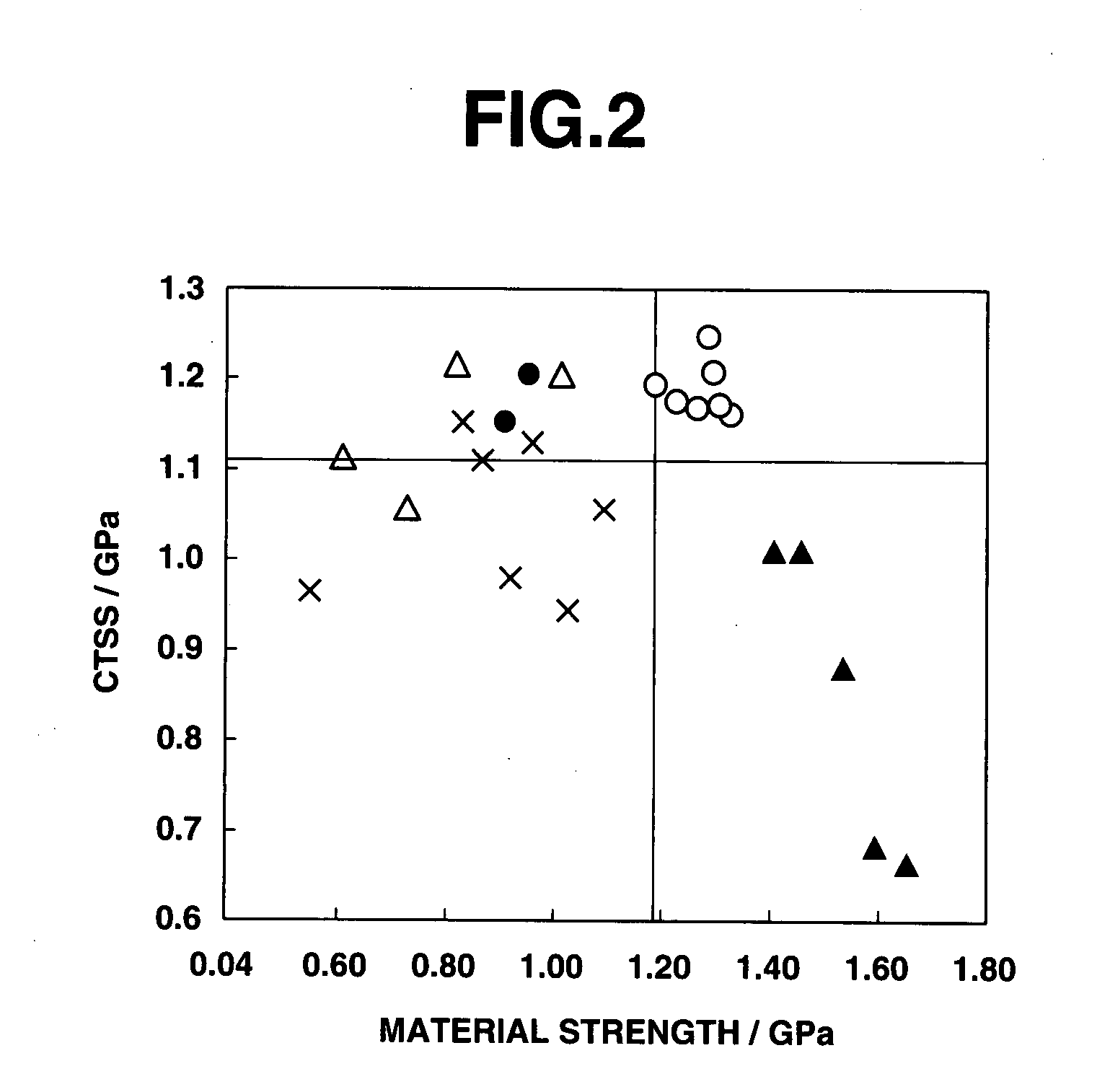

Steel product for induction hardening, induction-hardened member using the same, and methods for producing them

Owner:JFE STEEL CORP

High-tensile steel sheet, steel sheet joining process and high-strength automotive part

InactiveUS20070269678A1No deterioration in resistance welding strengthDeteriorating hardenabilityFurnace typesThin material handlingMetallurgyHigh intensity

Owner:NISSAN MOTOR CO LTD

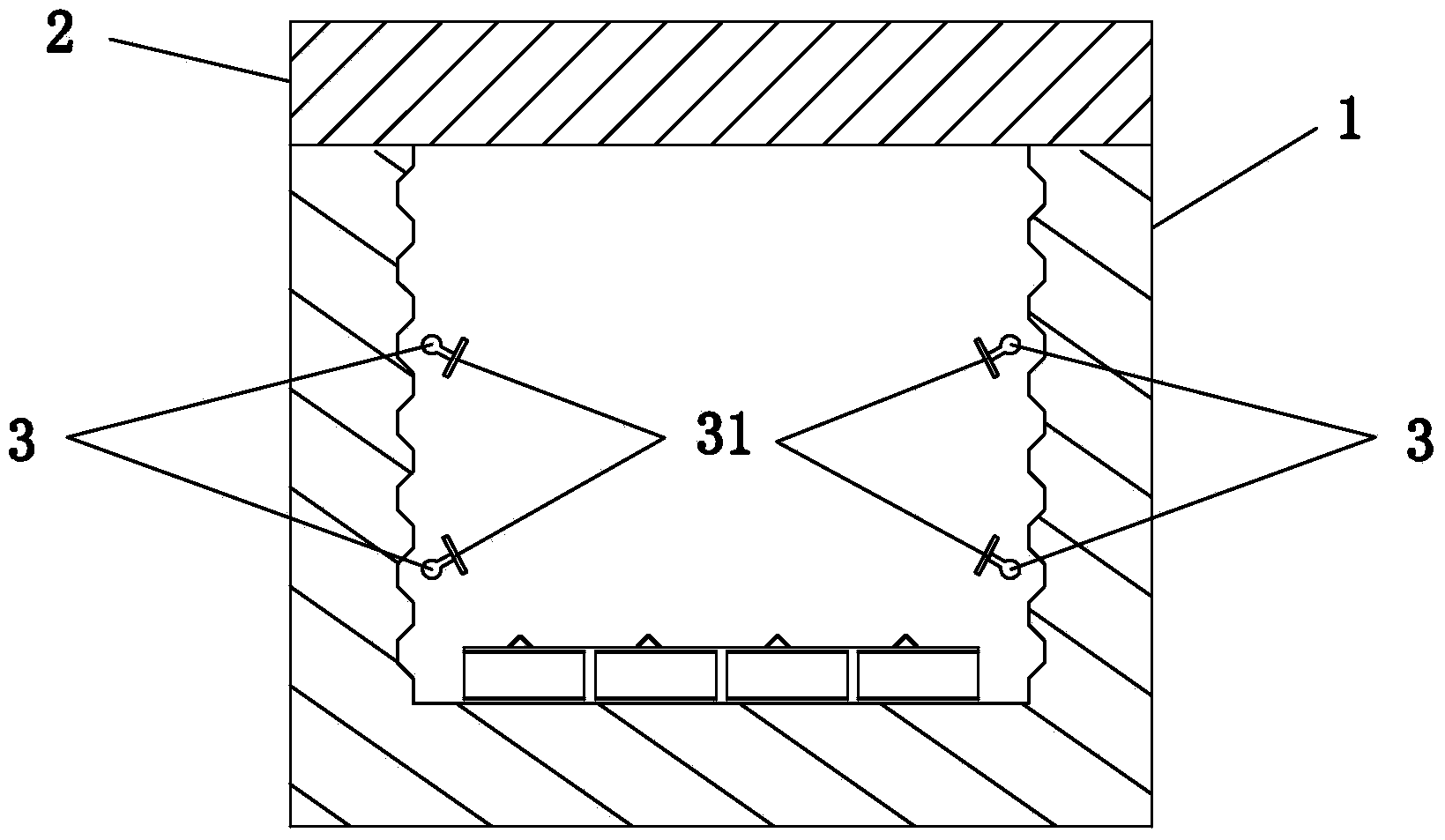

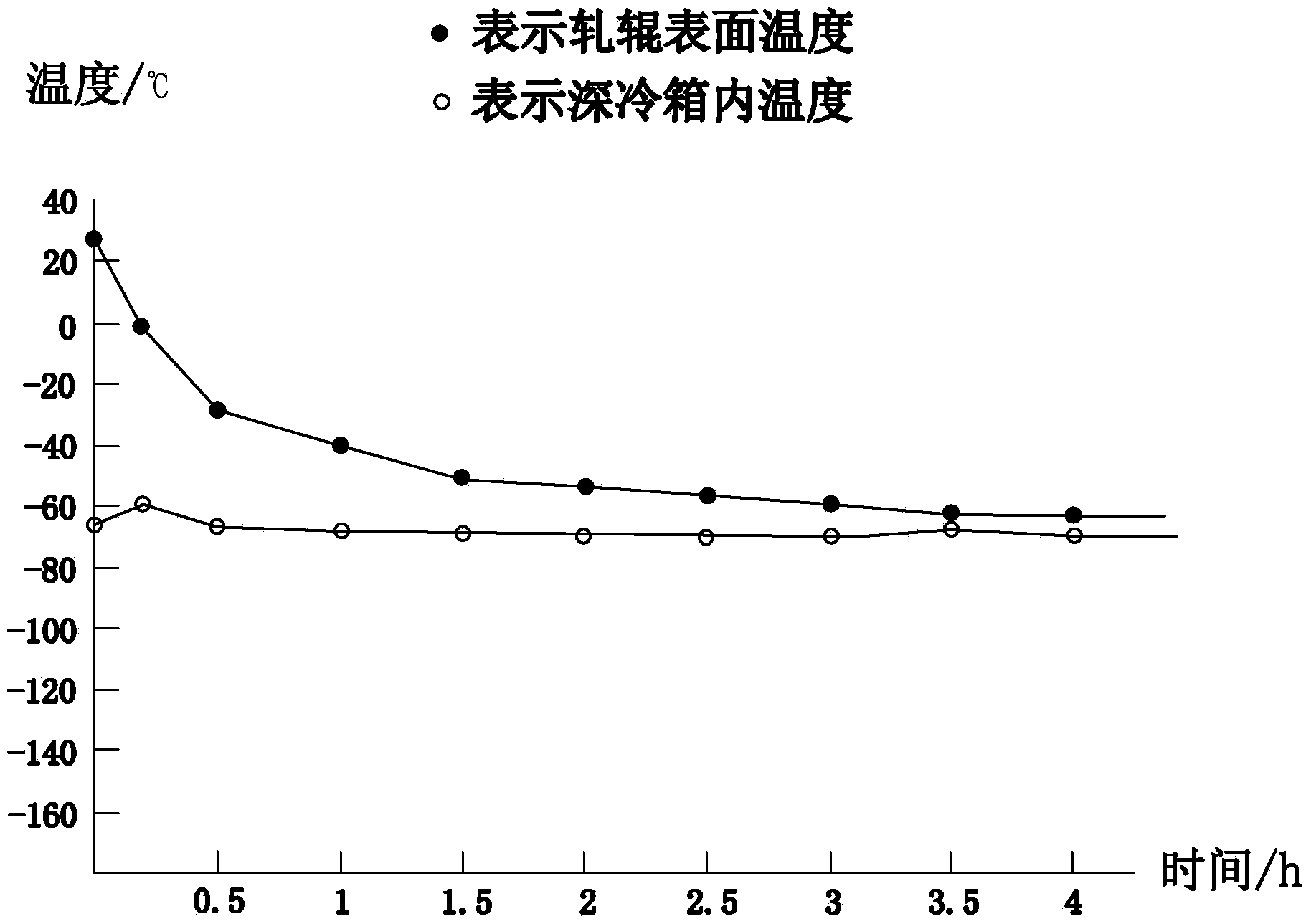

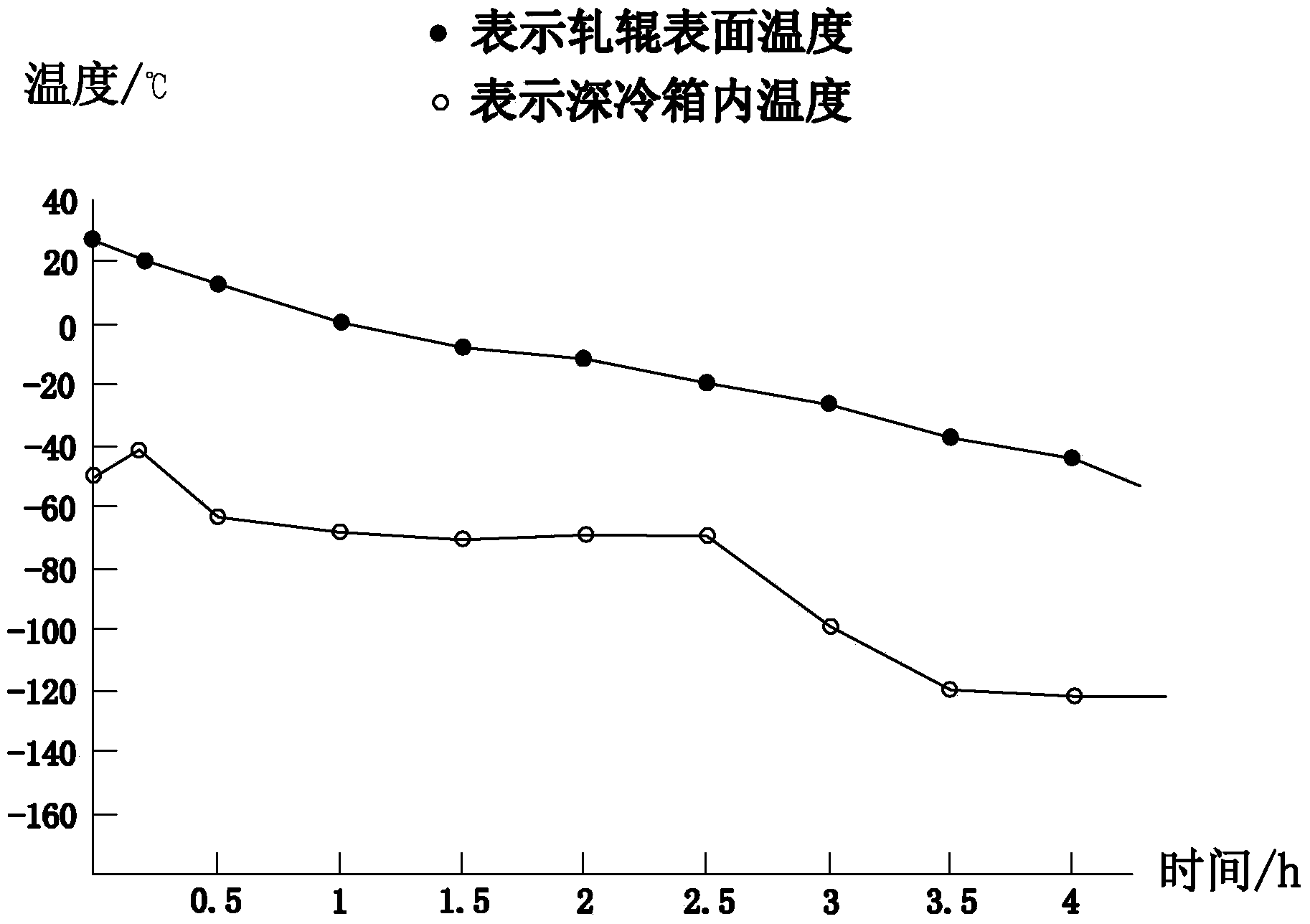

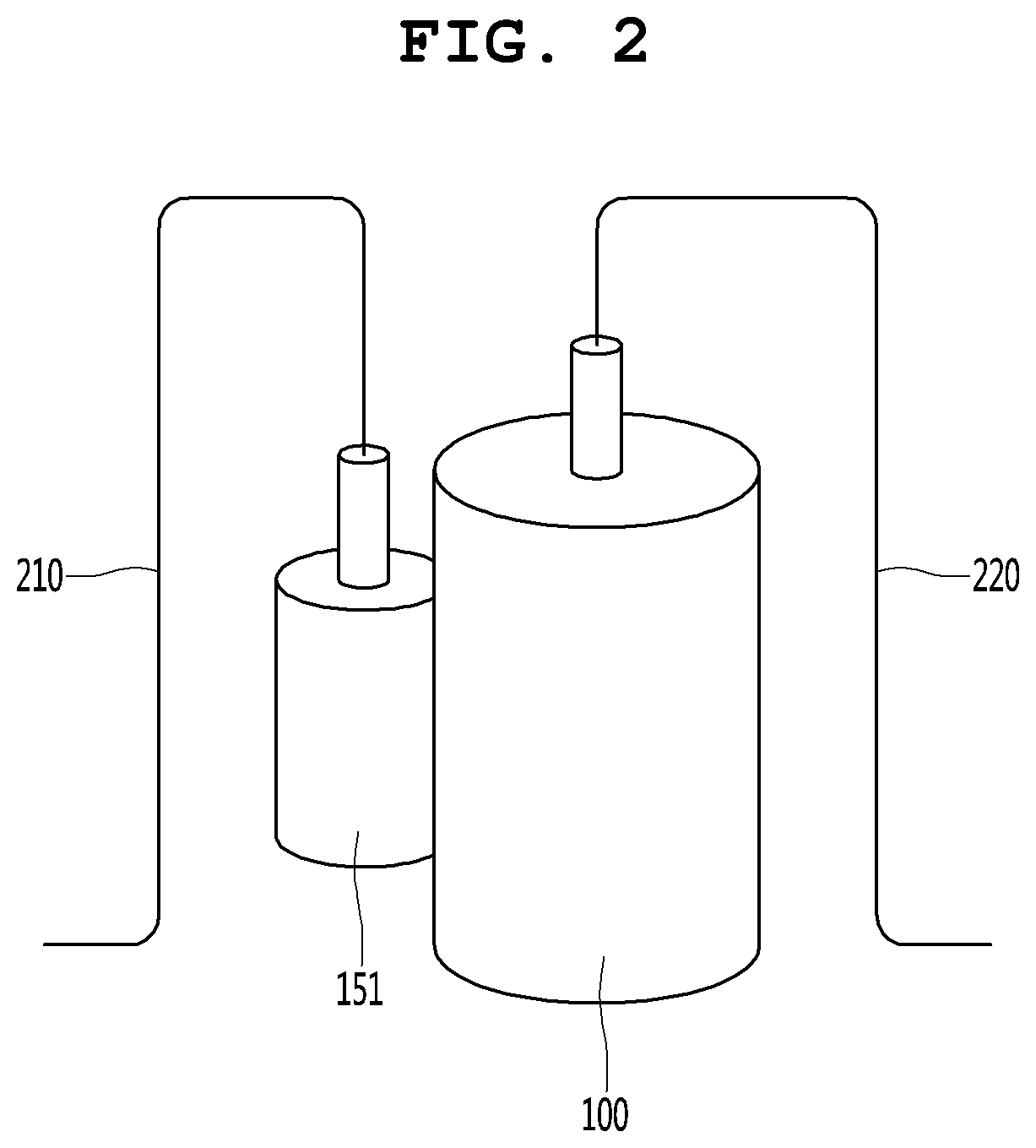

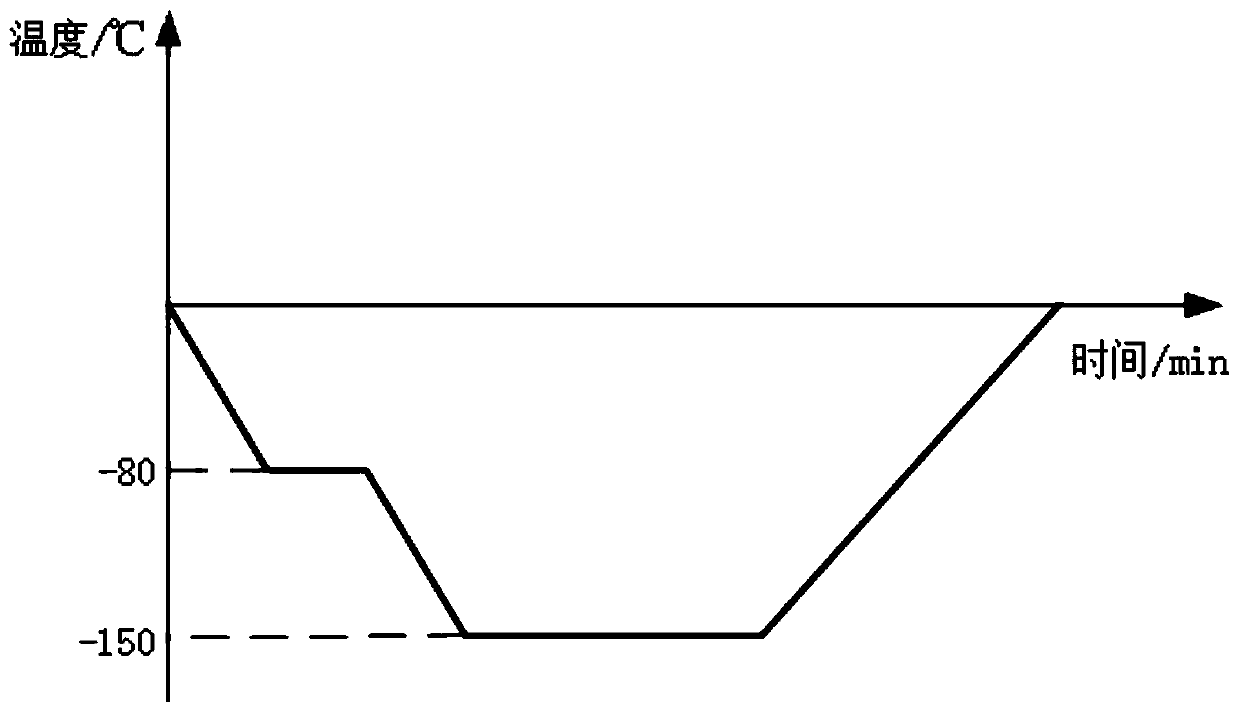

Subzero treatment method for large-diameter cold rolling work roller and copious cooling box thereof

ActiveCN103468918AReduce the temperatureImprove work efficiencyFurnace typesHeat treatment furnacesEngineeringElectromagnetic valve

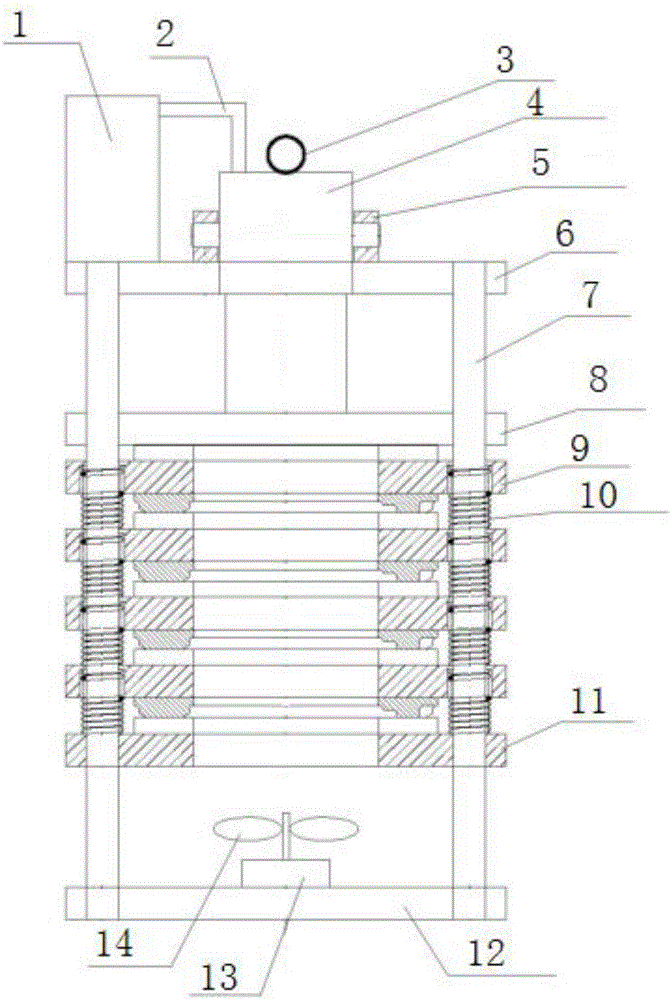

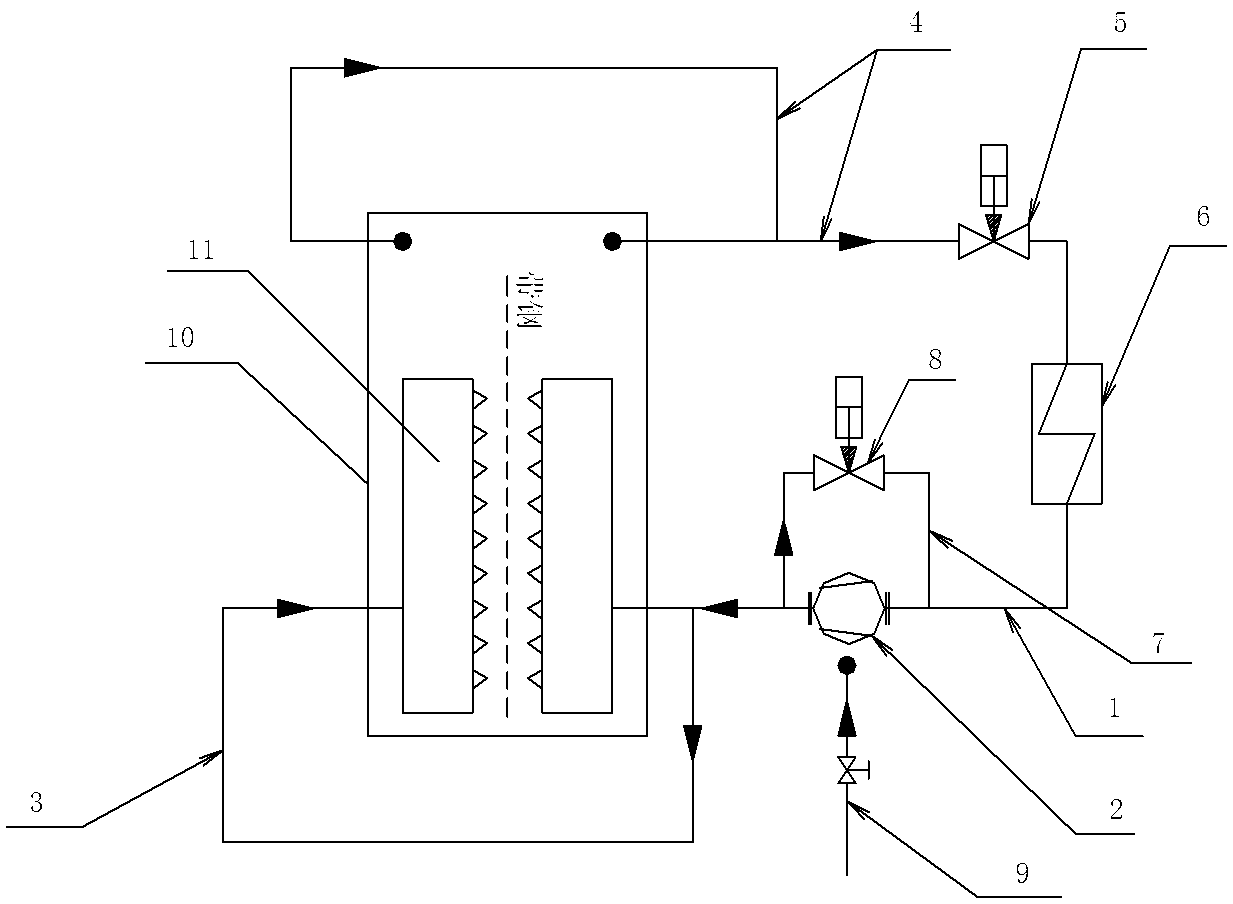

The invention discloses a subzero treatment method for a large-diameter cold rolling work roller and a copious cooling box thereof. The copious cooling box comprises a box body with an insulating layer, an insulating box cover and liquid nitrogen spray pipes arranged in the box body. Two liquid nitrogen spray pipes are respectively arranged on the upper side and the lower side, nozzles of the two liquid nitrogen spray pipes on the upper side are inclined downwards, nozzles of the liquid nitrogen spray pipes on the lower side are inclined upwards, and net covers are arranged at the nozzles of the liquid nitrogen spray pipes. The subzero treatment method comprises the steps of enabling the temperature in the copious cooling box to fall to -80 DEG C to -120 DEG C and insulating for 1h-3h, then arranging the large-diameter cold rolling work roller in the copious cooling box, and controlling ultralow temperature electromagnetic valves on pipelines between the liquid nitrogen spray pipes and a liquid nitrogen storage tank to enable liquid nitrogen to be sprayed out of liquid nitrogen spray pipes to cool the large-diameter cold rolling work roller. The subzero treatment method achieves low temperature cooling, enables the low temperature limitation to be about -180 DEG C, can quickly reduce the surface temperature of the roller and improves cooling efficiency.

Owner:BAOSTEEL ROLL SCI & TECH

Three-segment opposite-opening type fatigue and high temperature test integrated furnace

InactiveCN1789441AUniform temperature riseEvenly heatedFurnace typesHeat treatment furnacesBrickThree stage

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Continuous vacuum carburizing furnace

ActiveUS7029625B2Inhibit productionConvenient and efficient controlFurnace typesSolid state diffusion coatingCooling chamberAtmospheric pressure

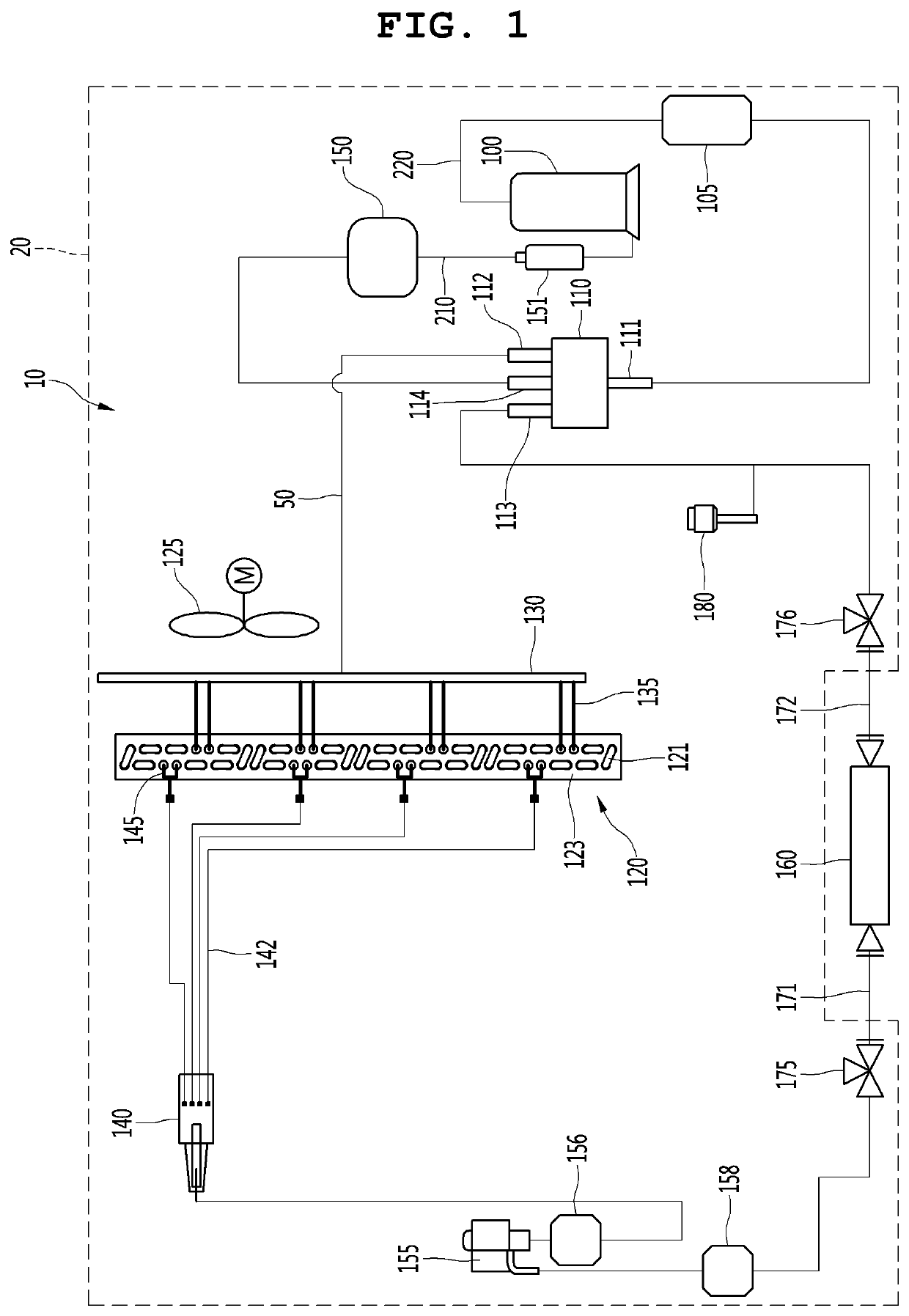

A continuous vacuum carburizing furnace of the invention includes: a heating chamber for heating a workpiece under a atmospheric pressure; a first conditioning chamber in which the pressure is reduced from the atmospheric pressure after the receipt of the workpiece from the heating chamber; a carburizing / diffusing chamber receiving plural workpieces from the first conditioning chamber and conducting plural cycles of carburizing and diffusing processes under the reduced pressure; a second conditioning chamber in which the reduced pressure is returned to the atmospheric pressure after the receipt of the workpiece treated in the carburizing / diffusing chamber; and a cooling chamber for cooling the workpiece introduced from the second conditioning chamber under the atmospheric pressure, the furnace further comprising a door member disposed between a respective adjoining pair of the above chambers, the door member opened / closed only when the workpiece is transported from one chamber to another.

Owner:CHUGAI RO CO LTD

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Special-steel-material flexible wheel of harmonic reducer, and cyclic heat treatment method thereof

InactiveCN109280851AImprove fatigue lifeImprove stabilityFurnace typesHeat treatment furnacesAustenite grainReduction drive

Owner:XINING SPECIAL STEEL +1

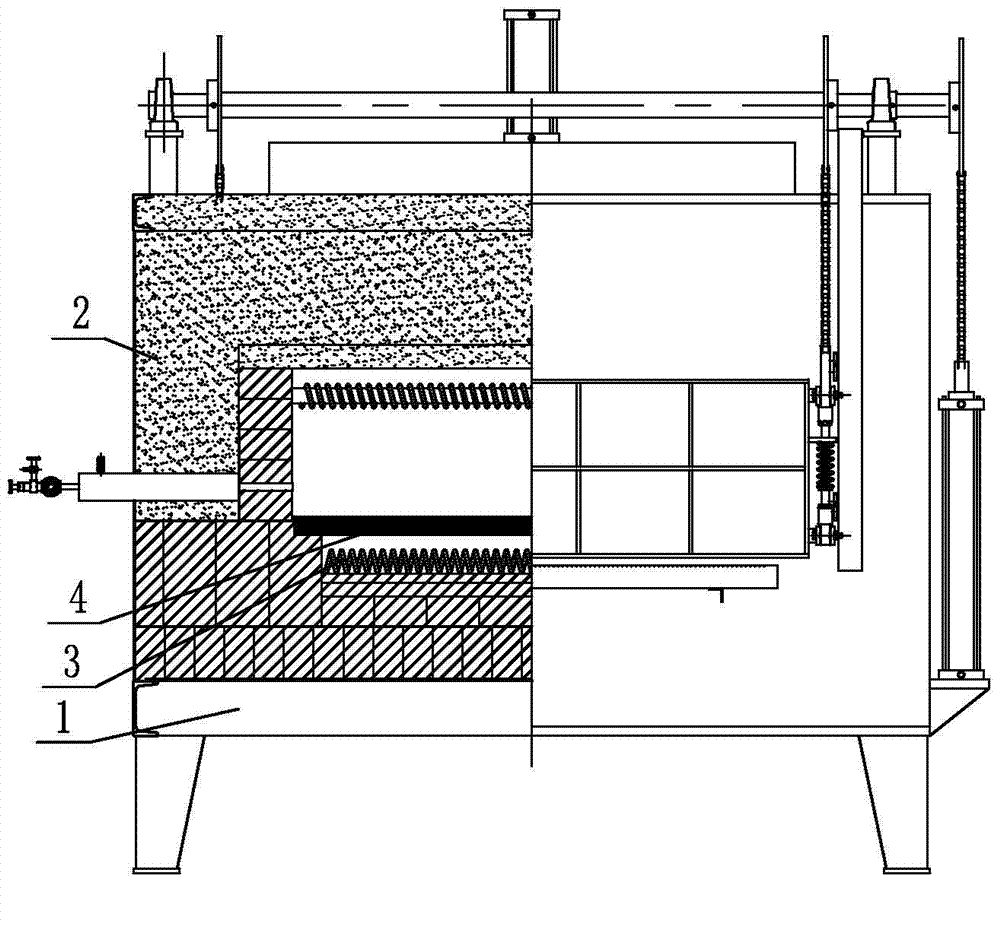

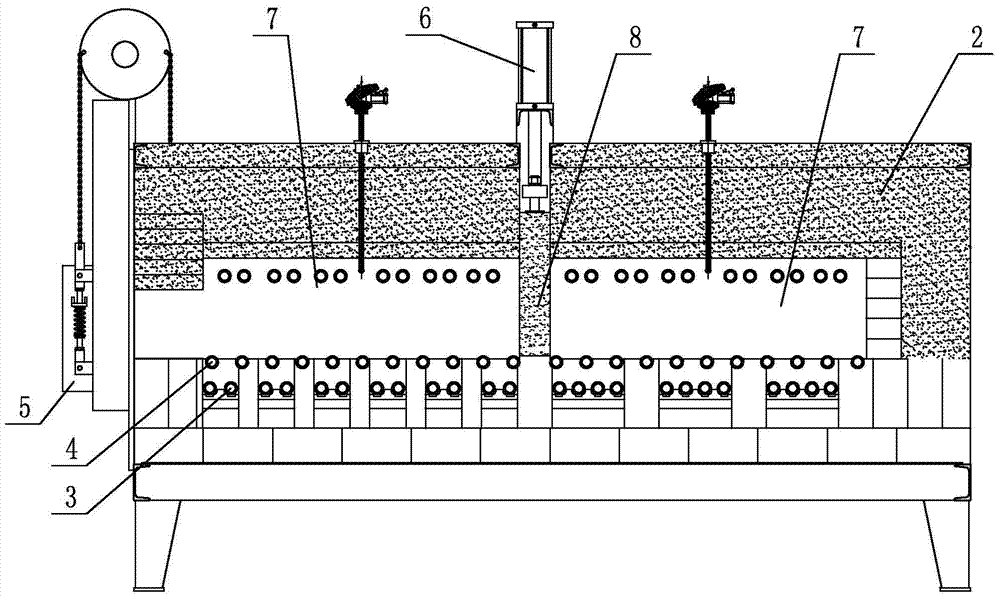

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

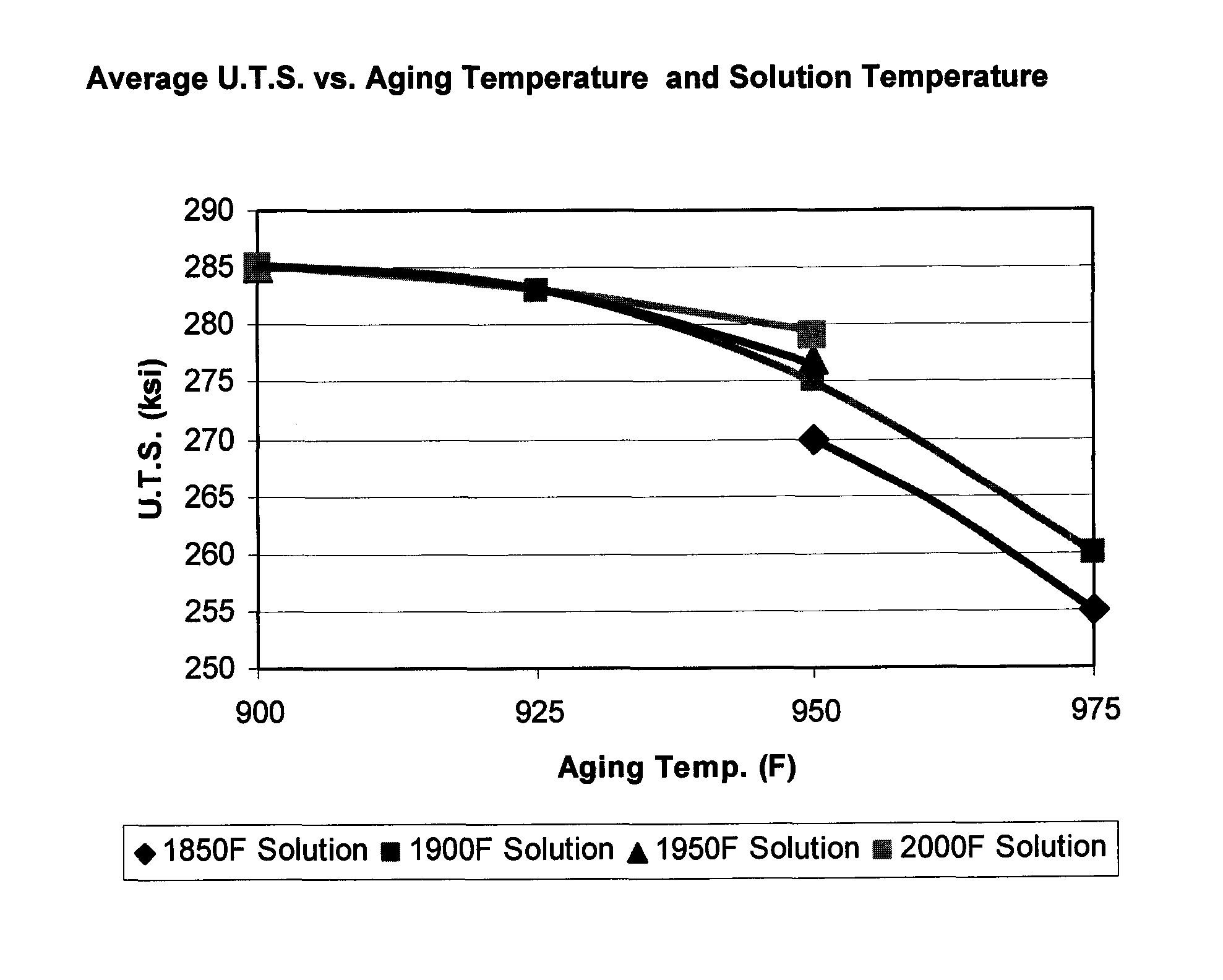

Ultra-High Strength Stainless Alloy Strip, a Method of Making Same, and a Method of Using Same for Making a Golf Club Head

InactiveUS20100108203A1Benefit machinabilityBenefit processabilityFurnace typesHeat treatment furnacesGolf clubCorrosion resistant alloy

Owner:KOSA THEODORE +1

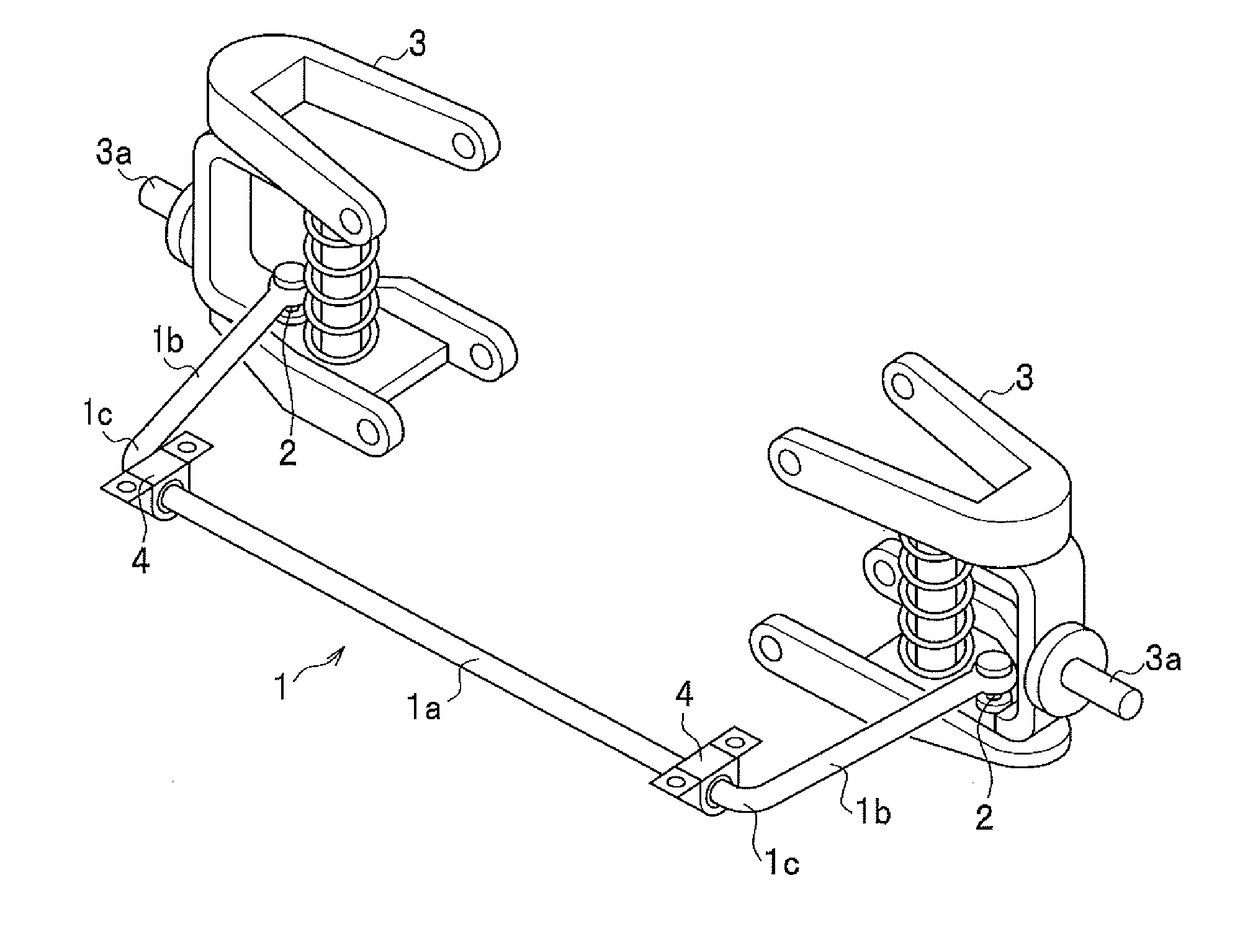

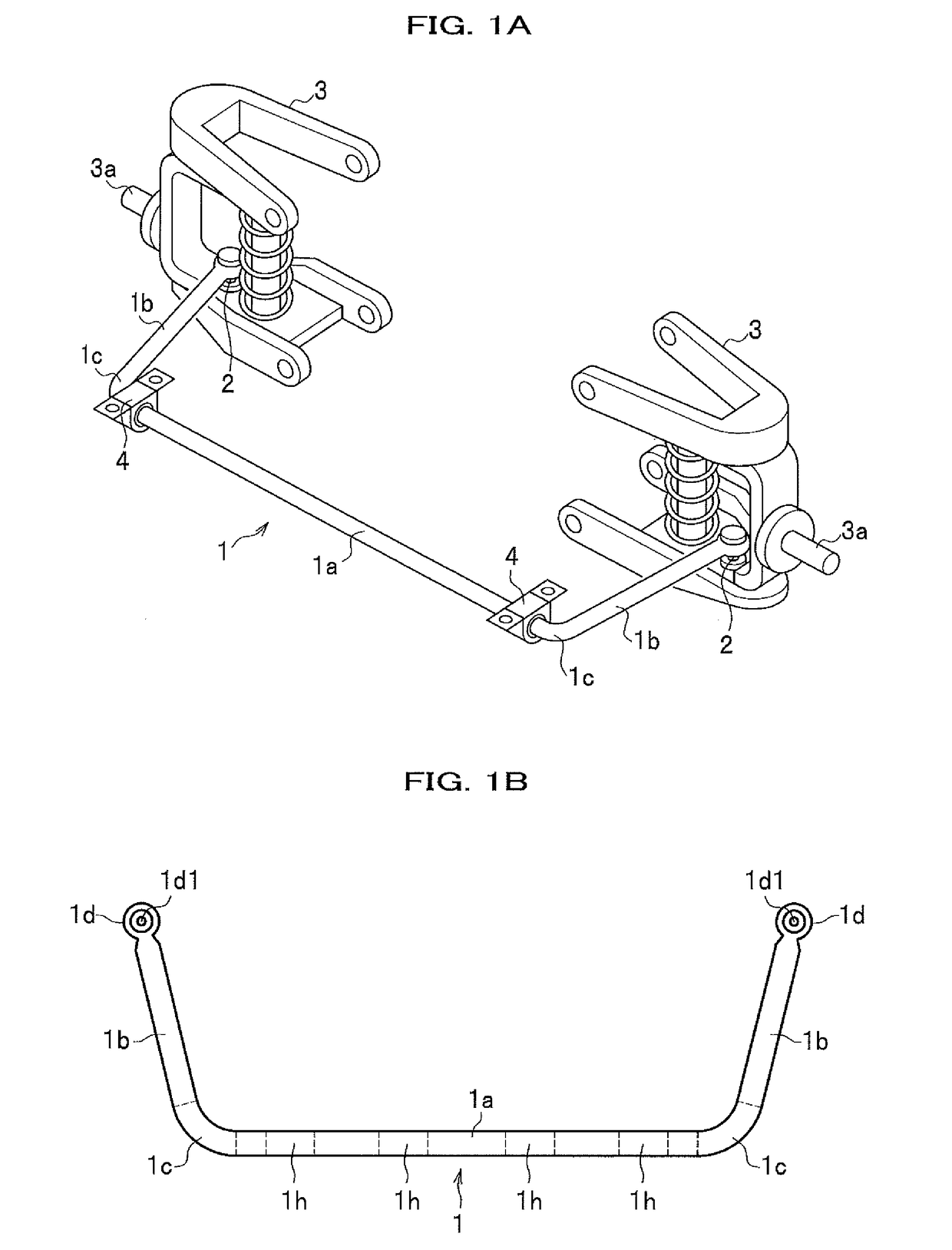

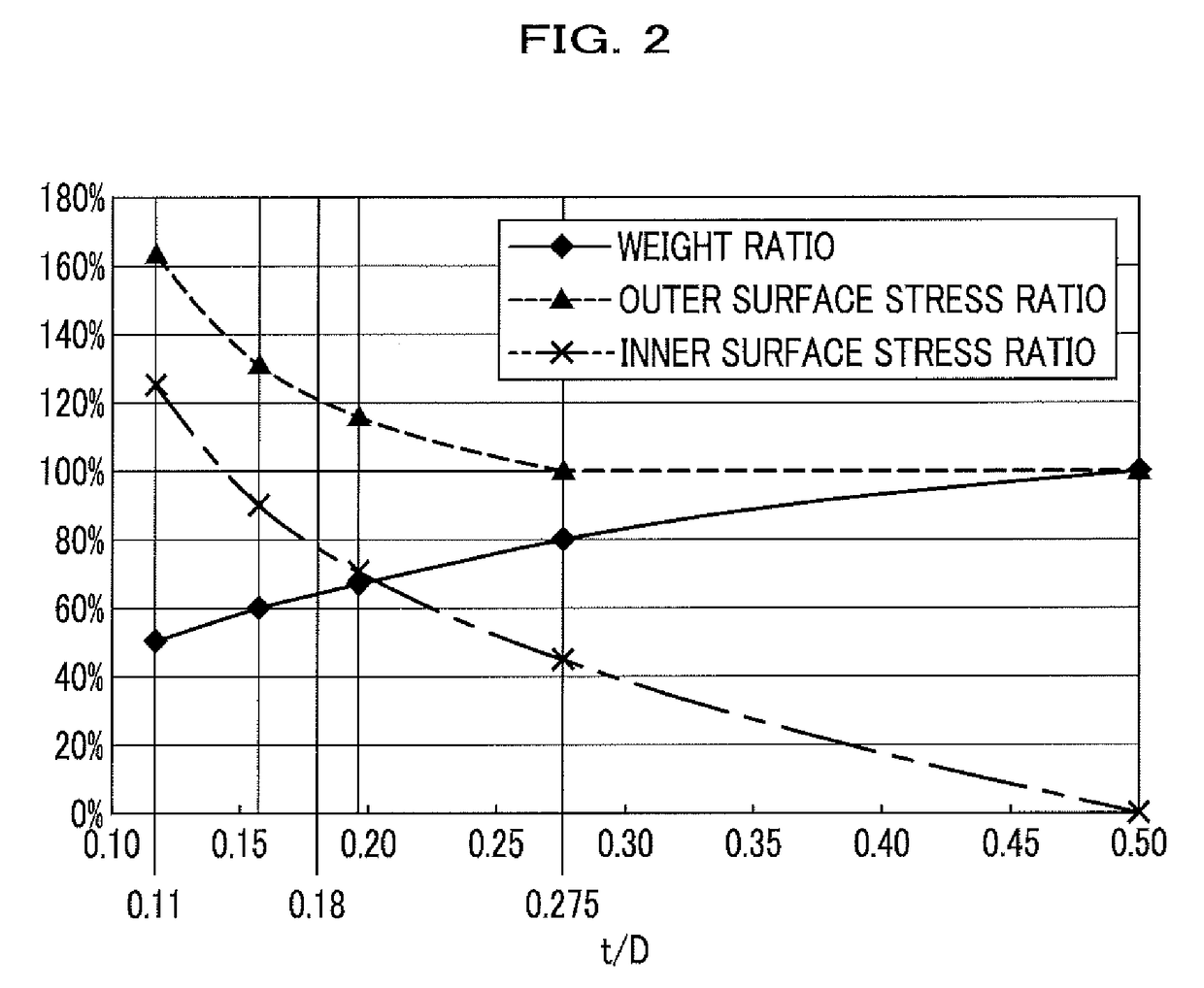

Method for producing hollow stabilizer

ActiveUS20180073096A1Good quenching hardnessHigh hardnessFurnace typesSolid state diffusion coatingQuenchingCoolant

Owner:NHK SPRING CO LTD

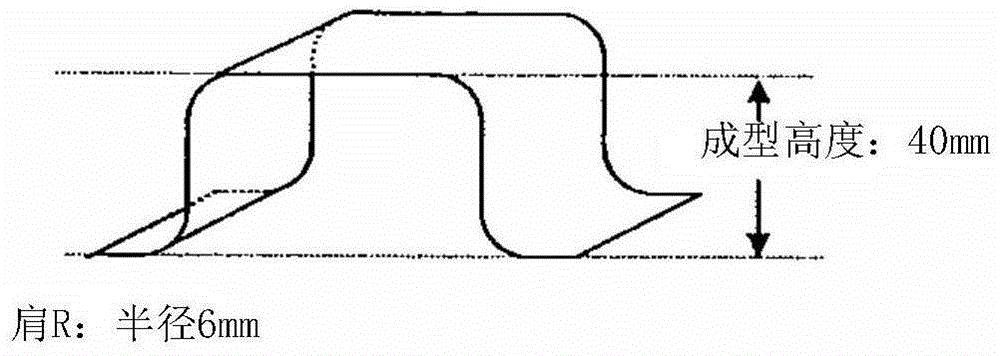

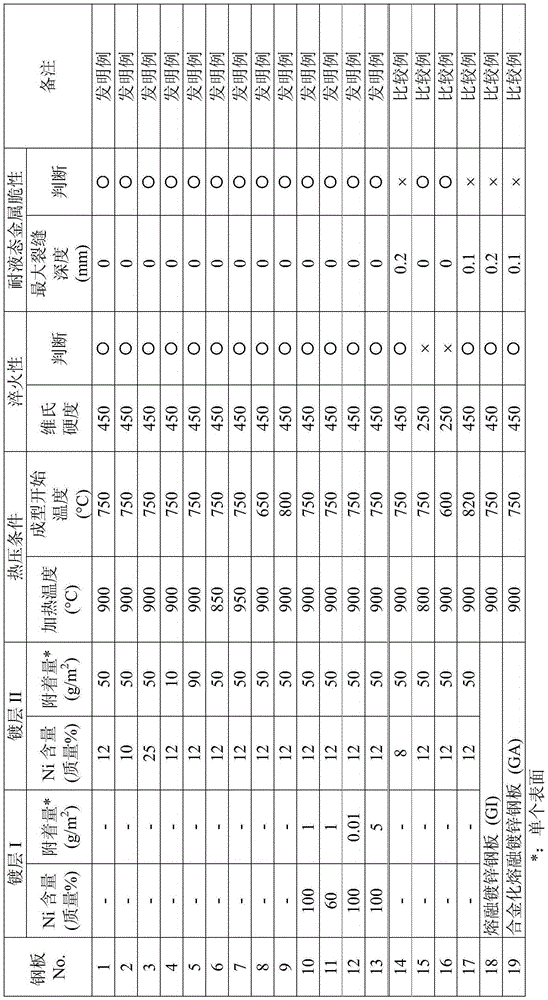

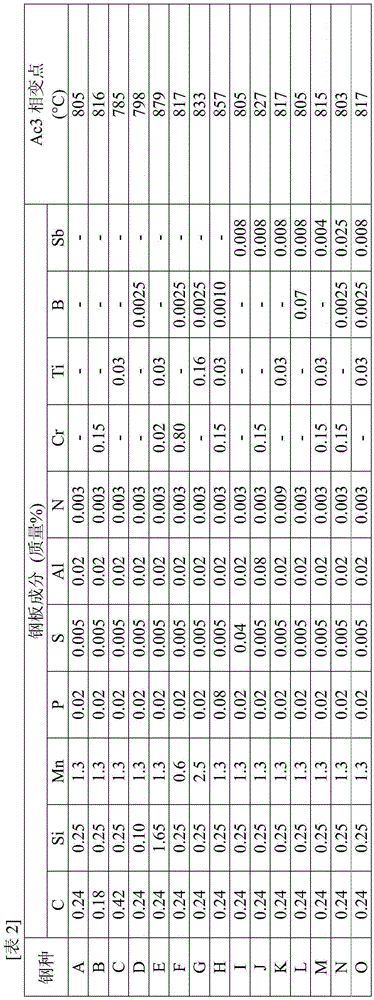

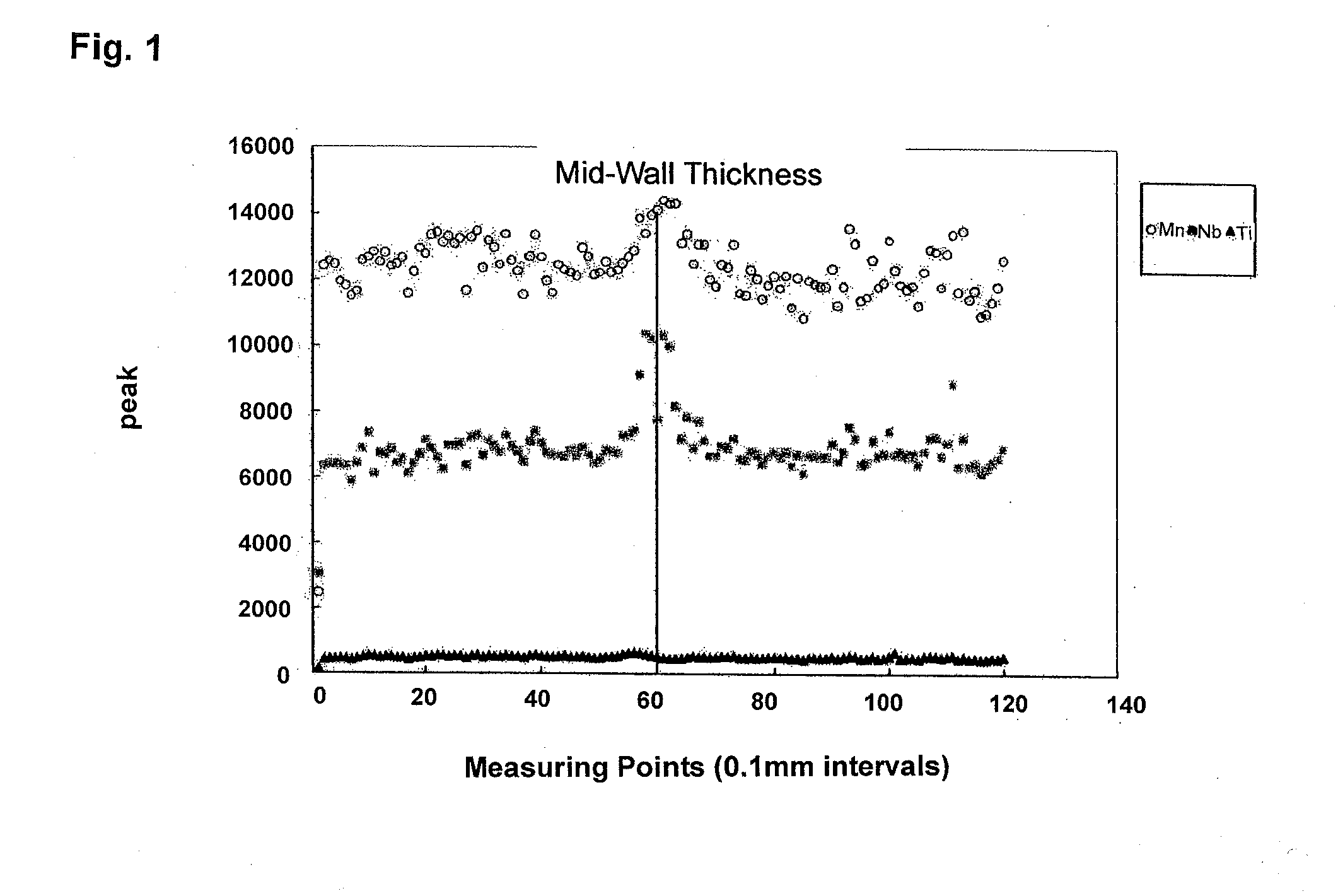

Method of manufacturing hot press member

InactiveCN105339106AImprove brittlenessImprove corrosion resistanceFurnace typesHeat treatment furnacesLiquid metalZinc

Owner:JFE STEEL CORP

Hic-resistant thick steel plate and uoe steel pipe

InactiveUS20120121453A1Easily segregatedIncrease resistanceFurnace typesHeat treatment furnacesSteel platesChemical composition

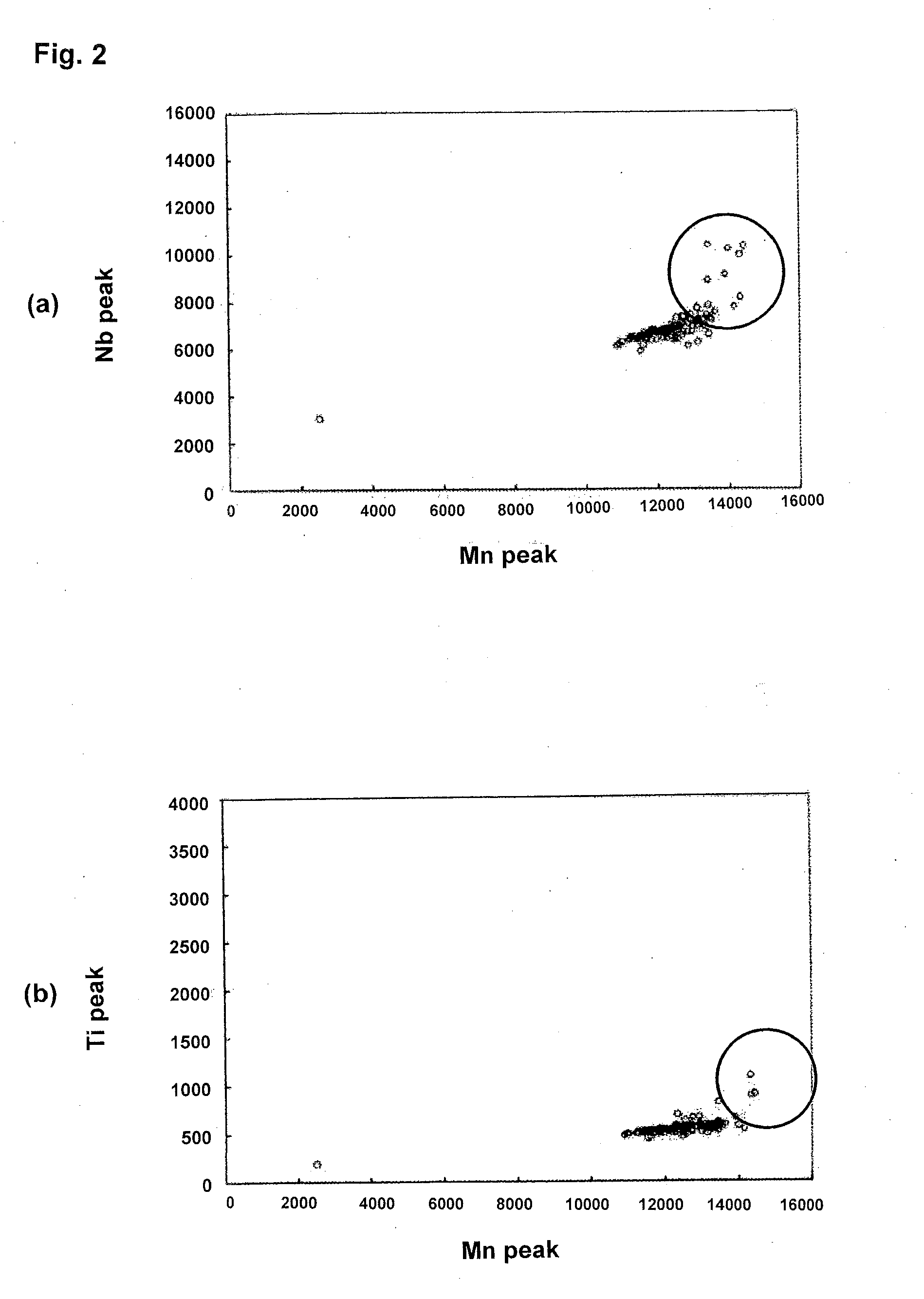

A thick steel plate and a UOE steel pipe having a high strength of at least X60 grade and improved resistance to HIC have a chemical composition consisting essentially of, in mass percent, C: 0.02-0.07%, Si: 0.05-0.50%, Mn: 1.1-1.6%, P: at most 0.015%, S: at most 0.002%, Nb: 0.005-0.060%, Ti: 0.005-0.030%, Al: 0.005-0.06%, Ca: 0.0005-0.0060%, N: 0.0015-0.007%, at least one of Cu, Ni, Cr, and Mo in a total amount of greater than 0.1% and less than 1.5%, and a remainder of Fe and impurities, wherein the degrees of segregation of Nb and Ti are both at most 2.0, and the ratio of (the degree of Nb segregation) / (the degree of Mn segregation) and the ratio of (the degree of Ti segregation) / (the degree of Mn segregation) are both at least 1.0 and at most 1.5.

Owner:SUMITOMO METAL IND LTD

Rolling-cut type bilateral scissors and manufacturing method thereof

ActiveCN104233101AMeet normal cutting needsFurnace typesHeat treatment furnacesThick plateIngot casting

Owner:TAIER HEAVY IND

Heat treatment method for recovering performance of K465 alloy turbine blade

ActiveCN103643188ARecovery performance (creep) effect is obviousSquare shapeFurnace typesHeat treatment furnacesTurbine bladeAlloy

The invention discloses a heat treatment method for recovering the performance of a K465 alloy turbine blade and belongs to the technical field of metallurgy. The heat treatment method comprises the following steps of 1, blade feeding, 2, furnace heating and then heat preservation: in vacuum or inert gas protective atmosphere, carrying out heat preservation at a temperature of 950-960 DEG C for 40-45min, carrying out heat preservation at a temperature of 1190-1200 DEG C for 2-2.5h and carrying out heat preservation at a temperature of 1230 DEG C for 4-4.5h, and 3, furnace cooling: (1), carrying out cooling from a temperature of 1230 DEG C to a temperature of 1000 DEG C at a cooling rate of 40+ / -25 DEG C / min by inert gas-based differential pressure cooling, and (2), feeding inert gas at a temperature of 1000 DEG C, carrying out cooling to a temperature of 300 DEG C, and opening a furnace door at a temperature below 300 DEG C and carrying out cooling. The heat treatment method can obviously recover the performance (such as creep deformation) of the K465 alloy turbine blade after a service cycle. Through the heat treatment method, transgranular gamma' polygonal or flower basket-shaped morphology is transformed into the cubical morphology so that morphology squaring is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

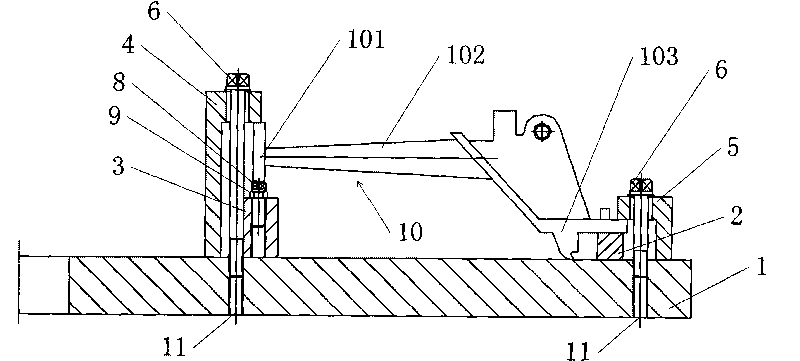

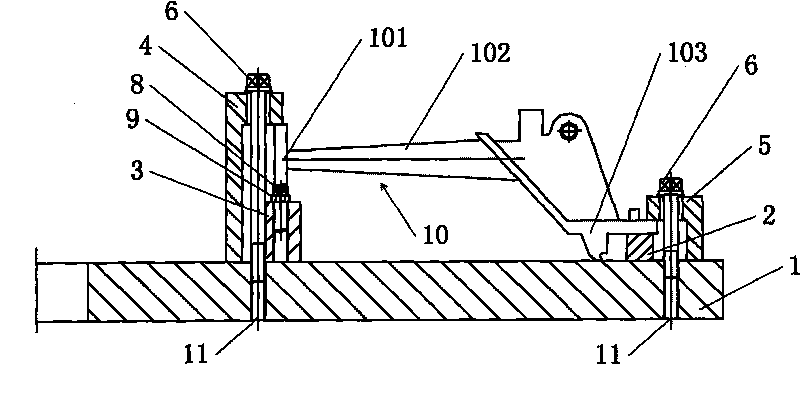

An inlet sealing device used for an annealing furnace

ActiveCN104593581AAchieve isolationWill not polluteFurnace typesHeat treatment furnacesStrip steelAtmosphere

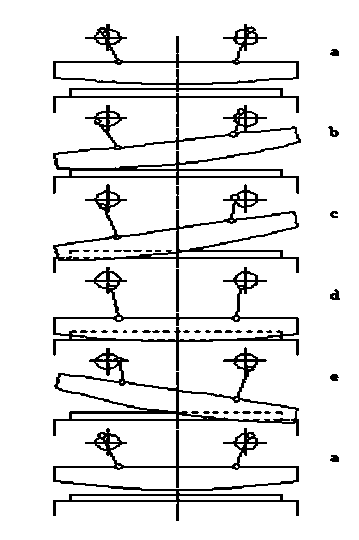

An inlet sealing device used for an annealing furnace is provided. The inlet sealing device comprises sealing rollers disposed at the inlet of the annealing furnace. The sealing rollers are respectively disposed at the lower parts of two vertically disposed supports. An air cylinder is disposed between the two supports, and is separately connected to the upper parts of the supports through a connecting rod device. The supports are driven to rotate around rotating shafts disposed at the middle parts of the supports by the connecting rod device driven by the air cylinder, so as to drive the two sealing rollers to adjust the roller gap between the two sealing rollers. A handle adjusting assembly is disposed at the outside of each of the supports. The positions of the two handle adjusting assemblies are corresponding to each other. A sealing plate assembly is disposed in a gap between each of the sealing rollers and a furnace shell at the inlet of the annealing furnace. The inlet sealing device separates the atmosphere in the furnace from the atmosphere outside the furnace and prevents scratch defects on surfaces of steel. The sealing plate assemblies are disposed between the roller surfaces and the furnace shell and are adjustable in position. The inlet sealing device is suitable for the field of inlet sealing of various annealing furnaces in process sections of galvanization units.

Owner:BAOSHAN IRON & STEEL CO LTD

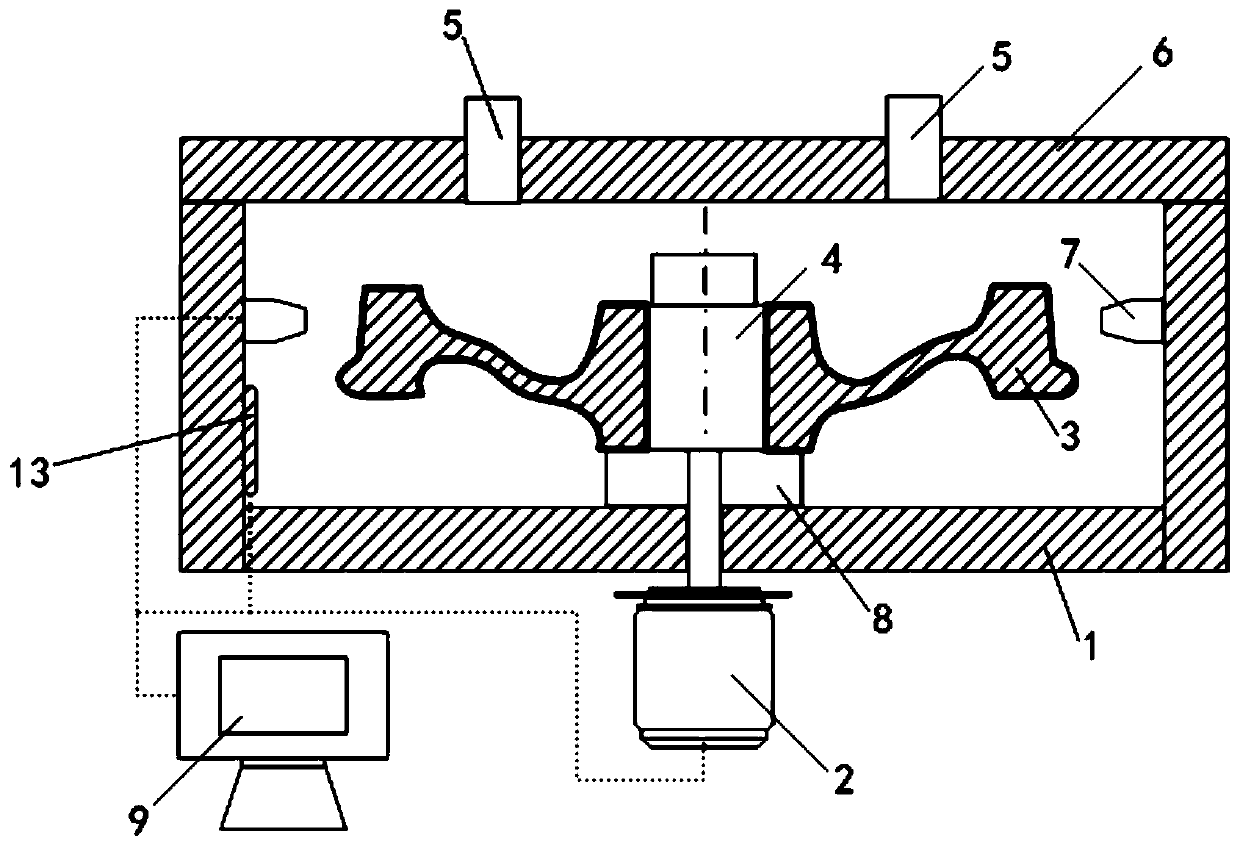

Quenching anti-deformation clamping device for series connection type brake disc

Owner:南京中盛铁路车辆配件有限公司 +1

Air conditioner

ActiveUS20210140726A1Operation efficiency can be improvedIncrease freedomMechanical apparatusCompression machines with non-reversible cycleFerritic matrixEngineering

Owner:LG ELECTRONICS INC

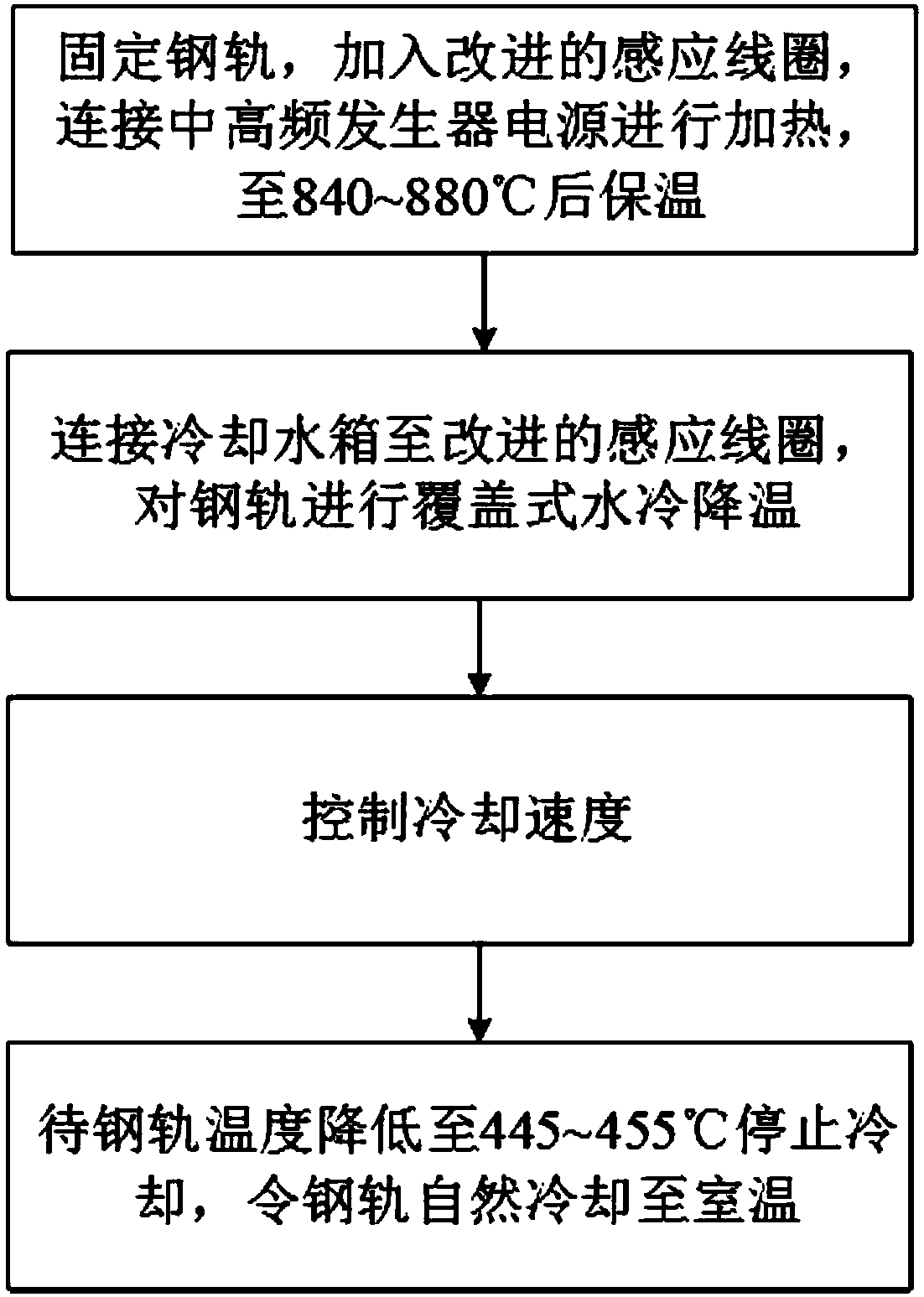

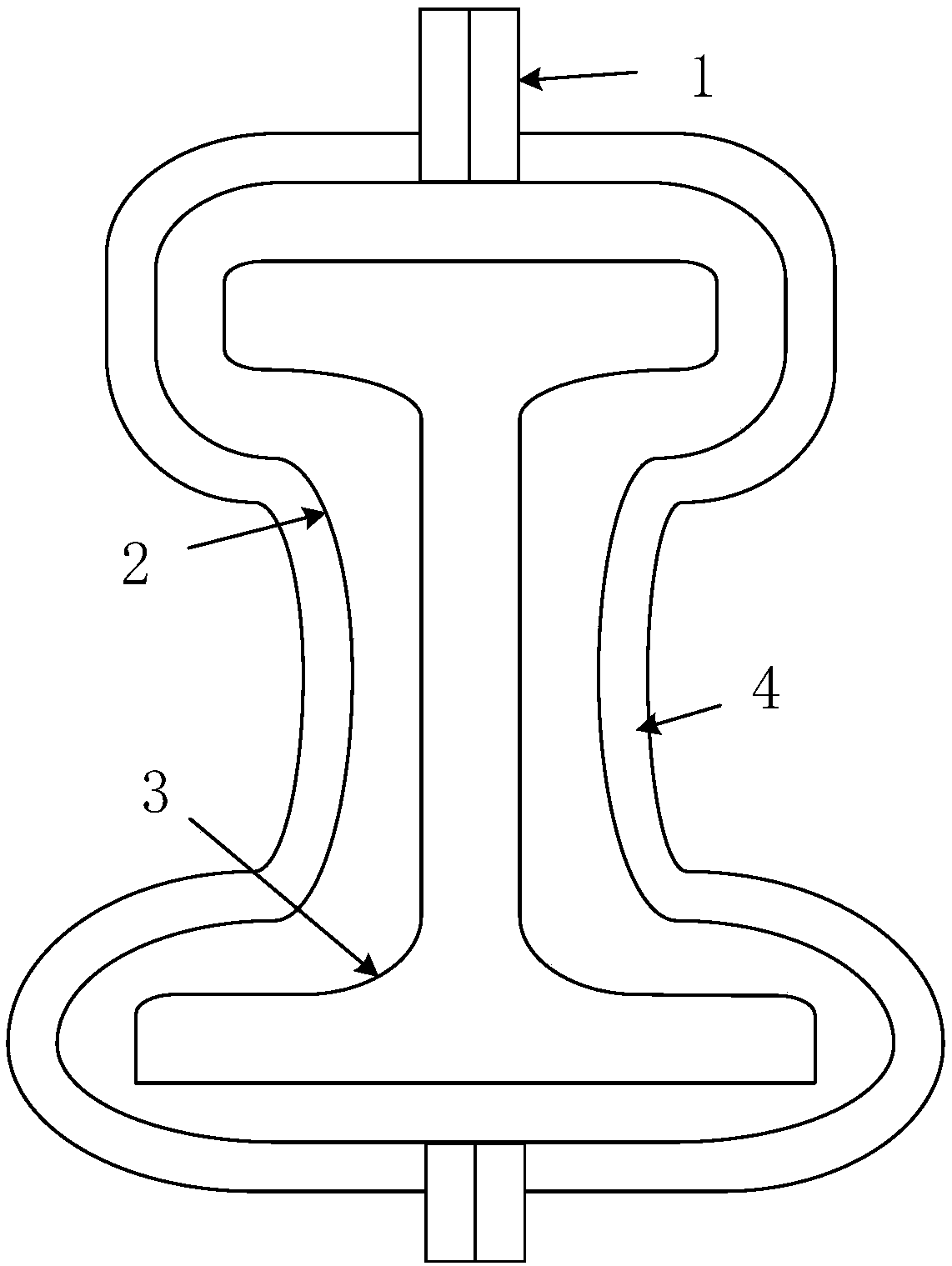

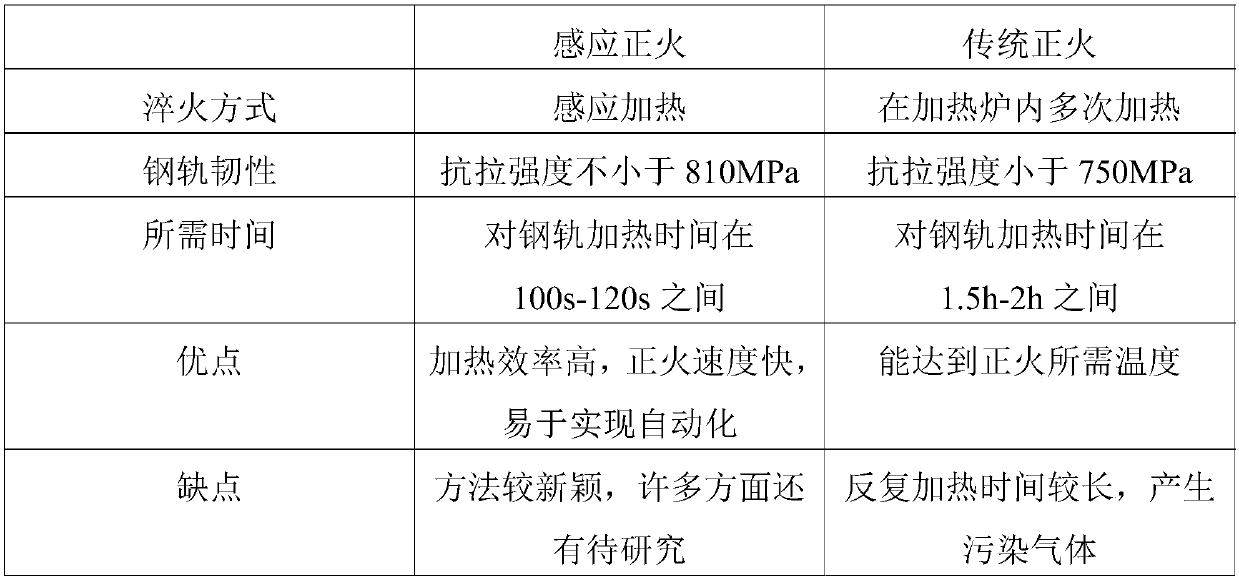

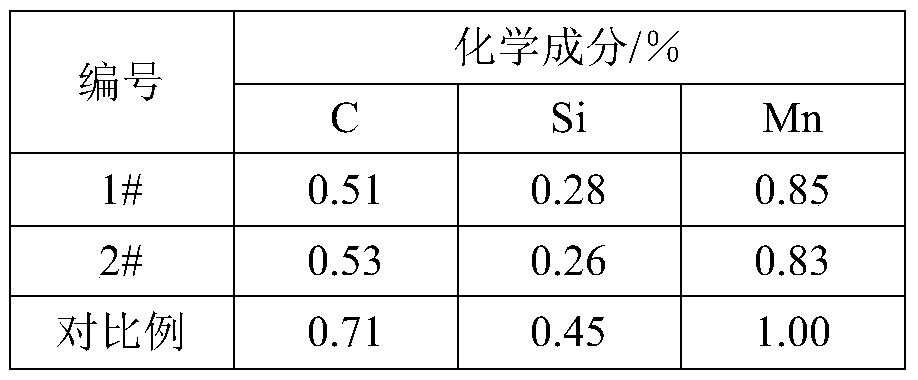

Induction normalizing method for steel rail

InactiveCN109593941AThe skin effect is obviousCool down in timeFurnace typesIncreasing energy efficiencyMedium frequencyFree cooling

Owner:SHANGHAI UNIV OF ENG SCI

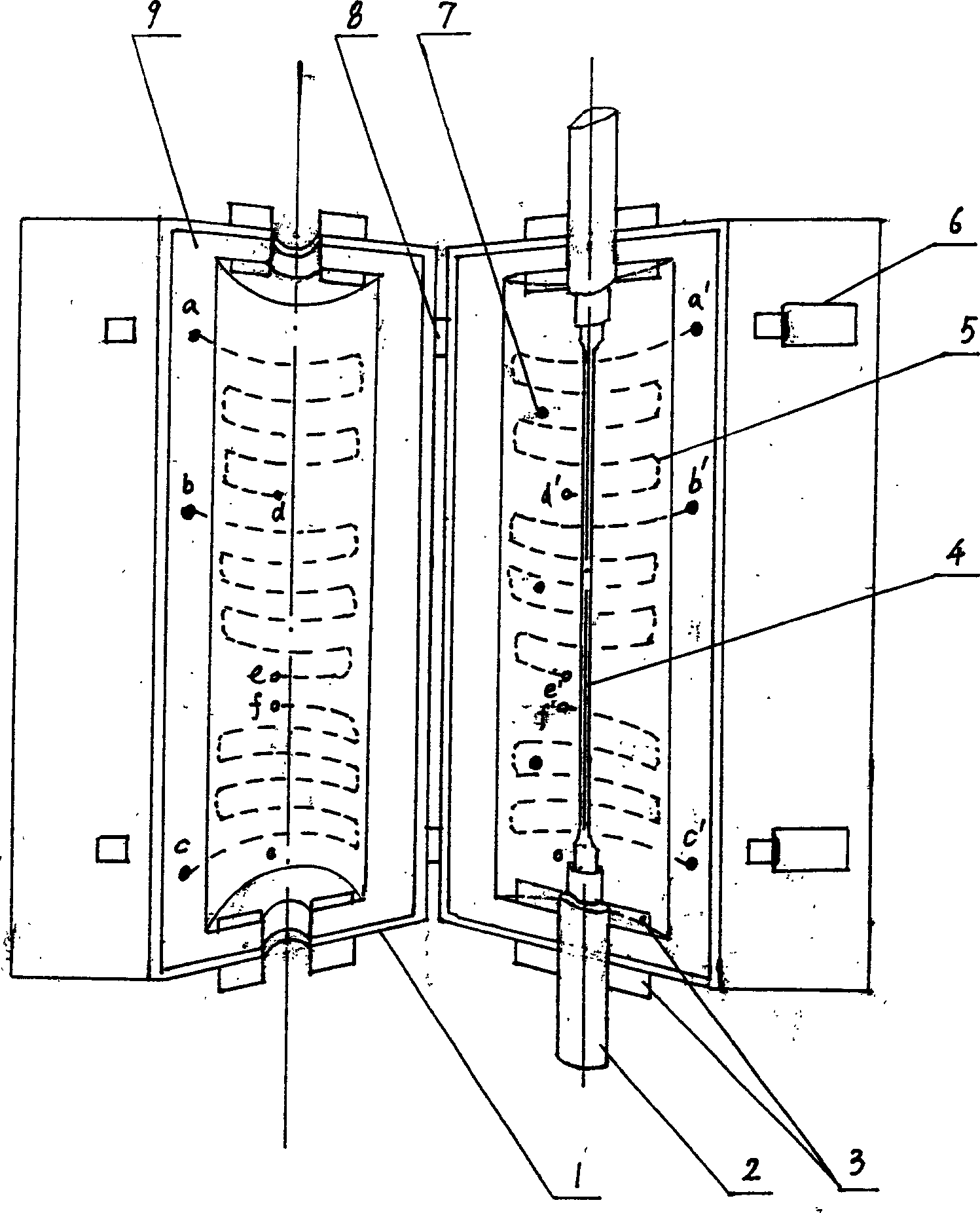

Train wheel cryogenic treatment device and treatment method

PendingCN111235368AGood dimensional stabilityImprove wear resistanceFurnace typesQuenching agentsCryogenic treatmentConvection heat

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Steel rail for high-speed railway and manufacturing method thereof

InactiveCN111349862AImprove wear performanceHigh running densityFurnace typesHeat treatment process controlEngineeringMaterials science

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Device for thermal treatment after welding of partition board of steam turbine

ActiveCN101724739ASolve the deformationGuaranteed sizeFurnace typesHeat treatment furnacesEconomic benefitsEngineering

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

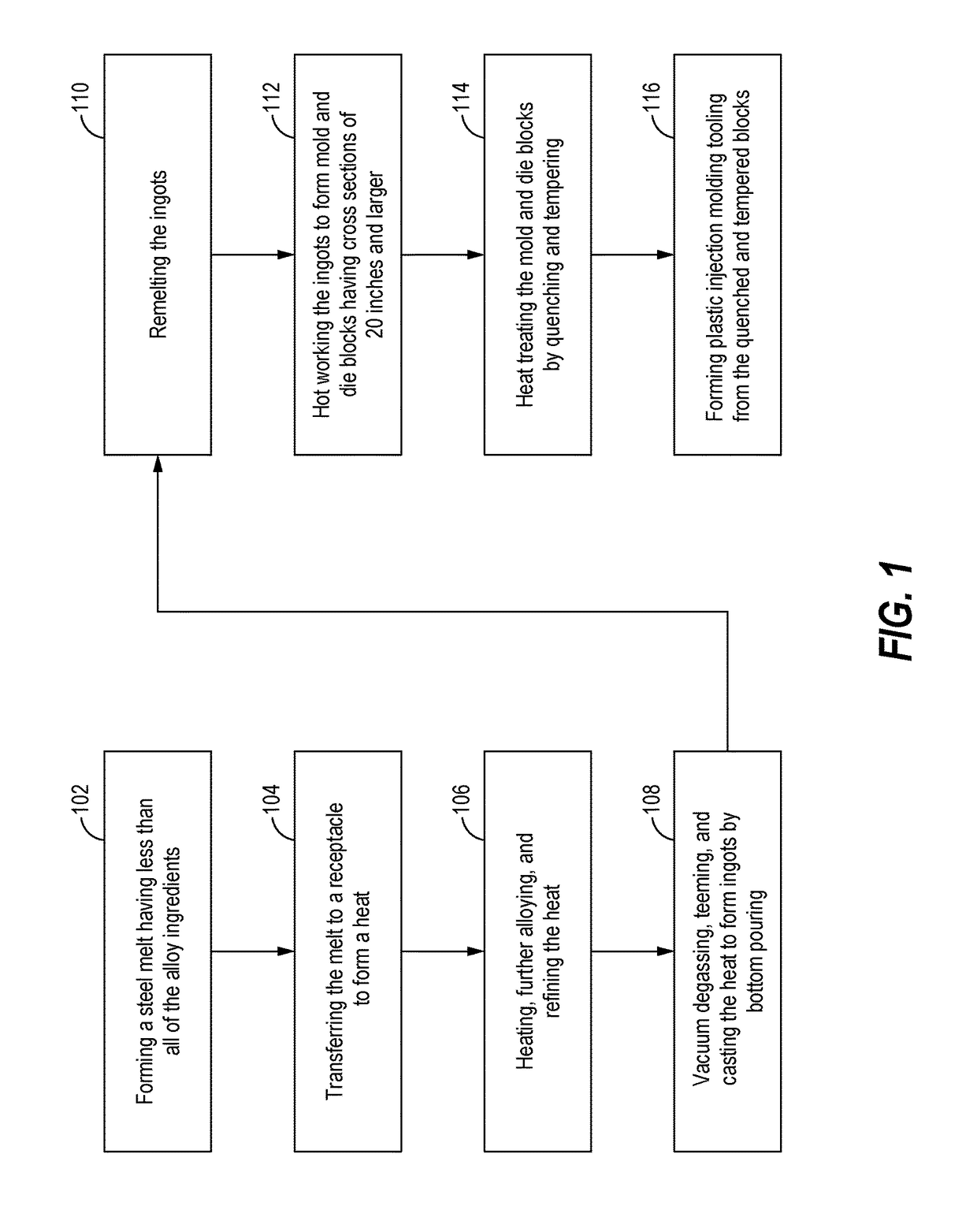

Plastic Injection Mold Tooling And A Method Of Manufacture Thereof

Owner:A FINKI & SONS

Cooling air supply device for cold-strip steel continuous annealing furnace

InactiveCN103014309AReduce leakageImprove securityFurnace typesHeat treatment furnacesHydrogen concentrationOperational safety

The invention provides a cooling air supply device for a cold-strip steel continuous annealing furnace. The cooling air supply device for the cold-strip steel continuous annealing furnace comprises a water cooled heat exchanger, and a circulating fan, wherein the outlet of the water cooled heat exchanger is connected with the inlet of the circulating fan through a front pipeline of the circulating fan; the outlet of the circulating fan is connected with a blowing cooling bellow inside the annealing furnace body through a high-hydrogen protective gas injection pipeline; the inlet of the water-cooled heat exchanger is connected with an exhaust port of the annealing furnace body through a protective gas extracting pipeline; a negative pressure-proof pipeline is arranged between the outlet and the inlet of the circulating fan; and the flow direction of the gas in the negative pressure-proof pipeline is the direction from the outlet of the circulating fan to the inlet of the circulating fan. By using the device, leakage of high-hydrogen concentration gas is reduced to the maximal extent by matching with a few of detecting instruments; energy consumption is reduced; expenses are saved; the operational safety of personnel around a circulating air duct is ensured; the chance that the air enters inside the air duct is reduced; and the security of high-hydrogen gas inside the circulating air duct is increased.

Owner:WISDRI WUHAN WIS IND FURNACE

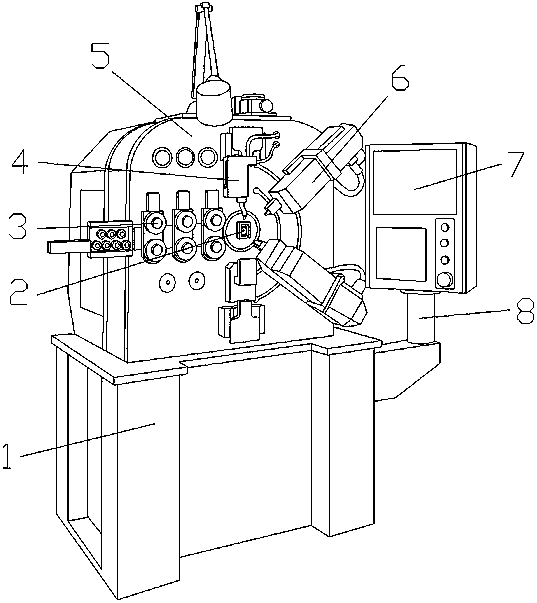

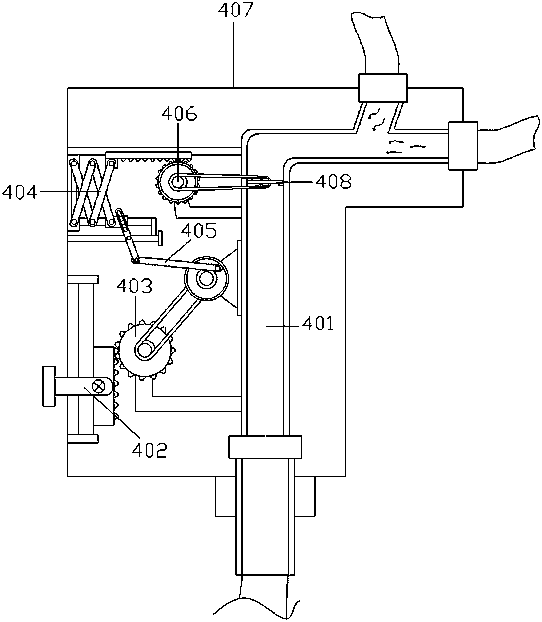

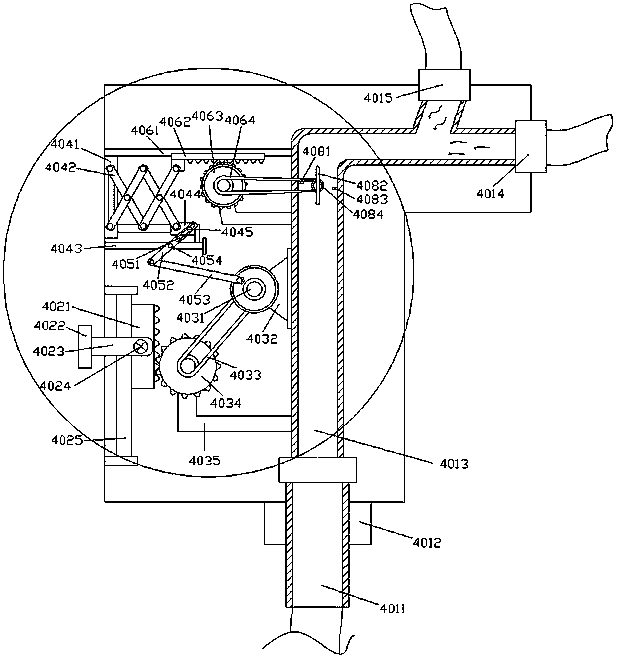

High-efficiency spring production shaping device

InactiveCN108555194AAvoid softening and deformationQuality assuranceFurnace typesWire springsEngineeringMechanical engineering

Owner:长沙熙迈机械制造有限公司

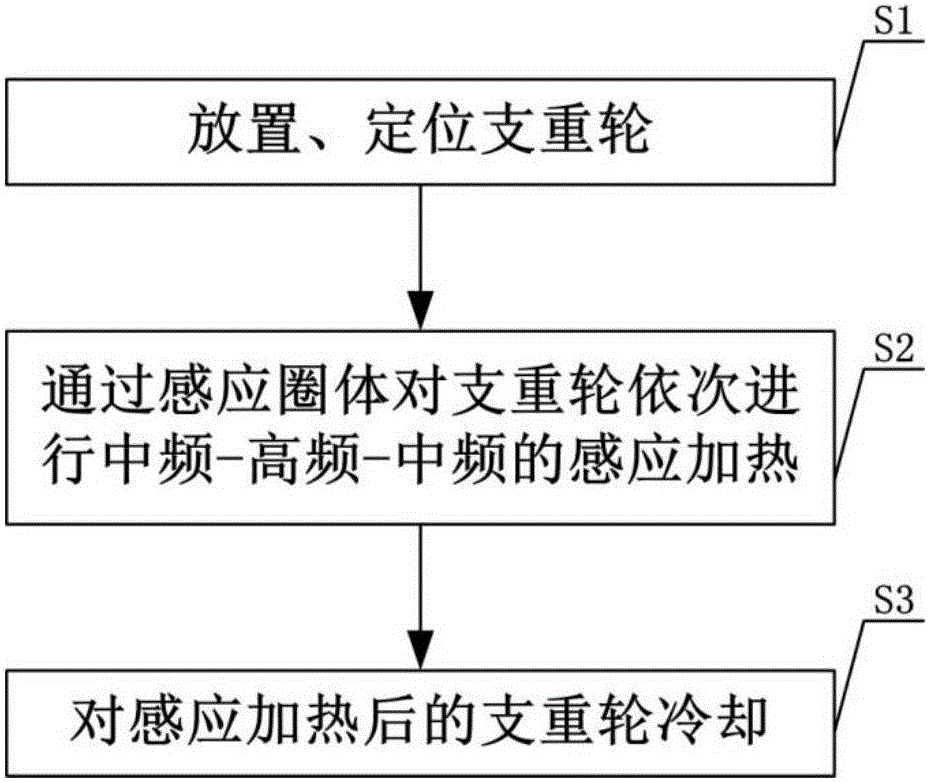

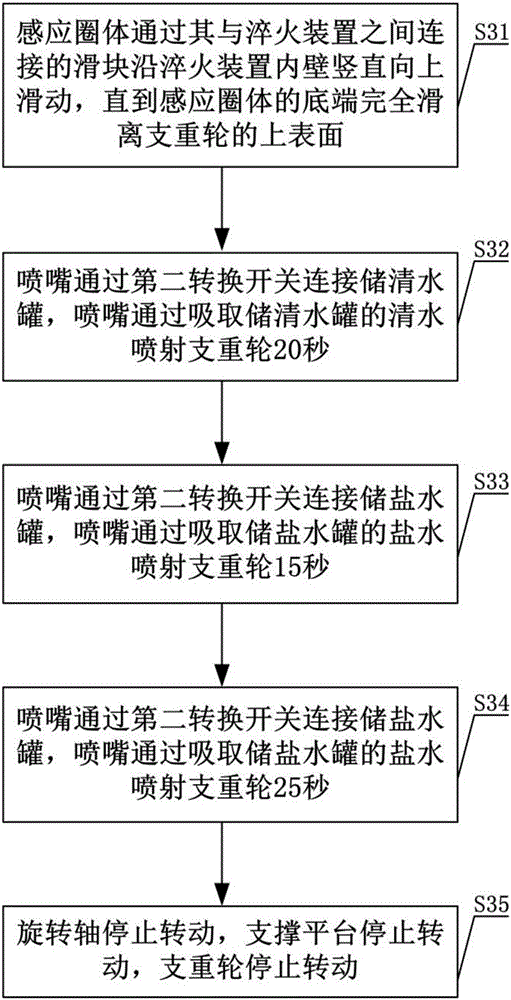

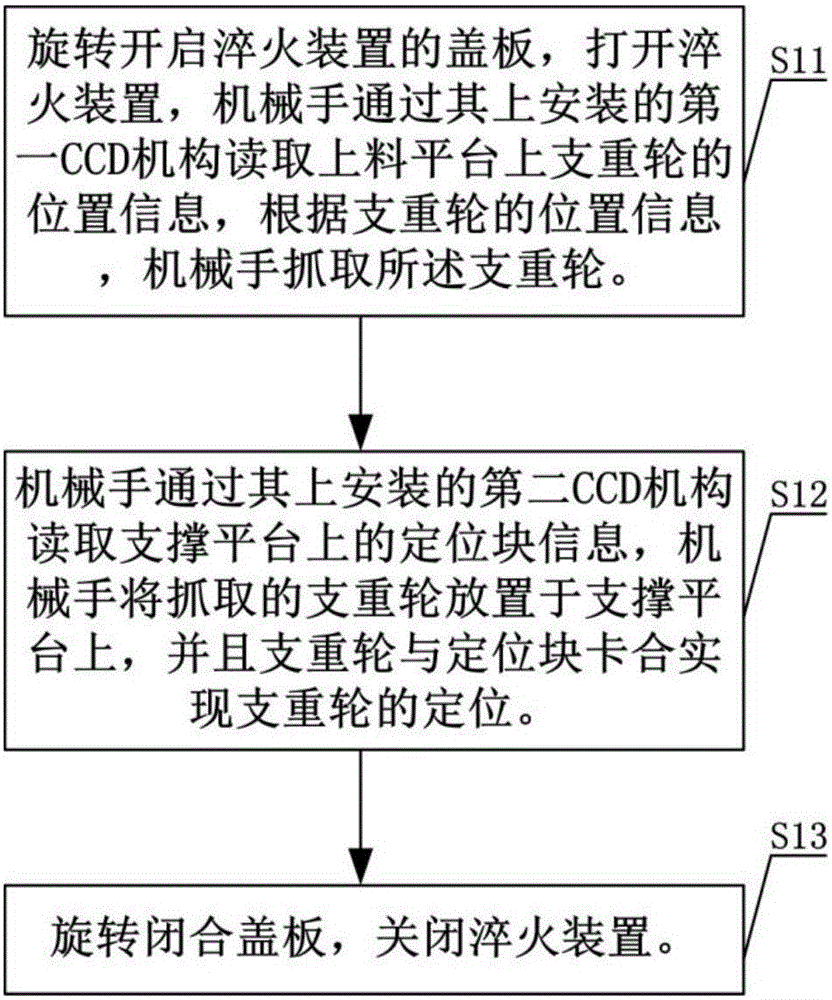

Segmented heating and cooling quenching process for wheel body of thrust wheel

ActiveCN105821195ASolve the speed problemSolve cracking and deformationFurnace typesIncreasing energy efficiencySaline waterIntermediate frequency

Owner:KUSN KENSETABU BUHIN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap