Device for thermal treatment after welding of partition board of steam turbine

A post-weld heat treatment and steam turbine technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as deformation, reduce production costs, avoid repairs, and save raw material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

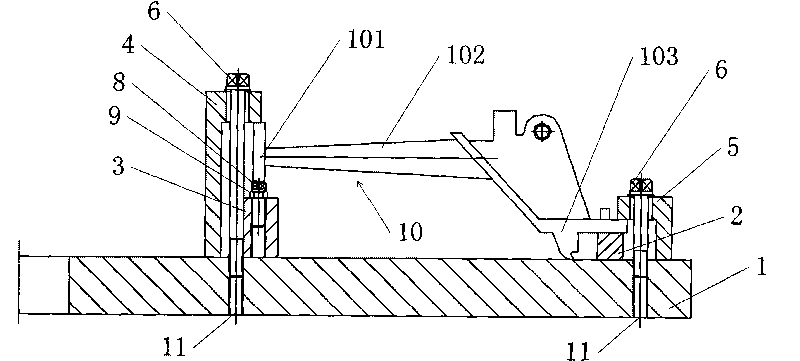

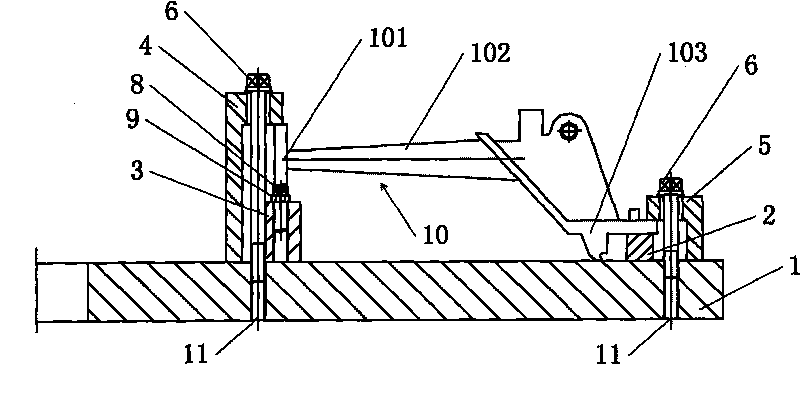

[0014] Such as figure 1 As shown, the present invention is a post-weld heat treatment device for a steam turbine diaphragm, which includes a backing plate 1, a filler block, a pressure plate and a pressure plate screw 6, and the diaphragm 10 includes an inner ring 101, a vane 102 and an outer Ring 103, where:

[0015] The backing plate 1 is placed under the partition plate 10, and the backing plate 1 is respectively provided with n screw holes 11 along the circumferential direction at the inner side of the inner ring 101 of the partition plate 10 and the outer side of the outer ring 103 of the partition plate 10, wherein n is Natural number;

[0016] The filler block is placed on the backing plate 1, which includes the outer ring filler block 2 and the inner ring filler block 3, and the outer ring filler block 2 and the inner ring filler block 3 are respectively located under the outer ring 103 and the inner ring 101 of the separator 10 ;

[0017] The pressure plate includes a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap