Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about "Metal rolling arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

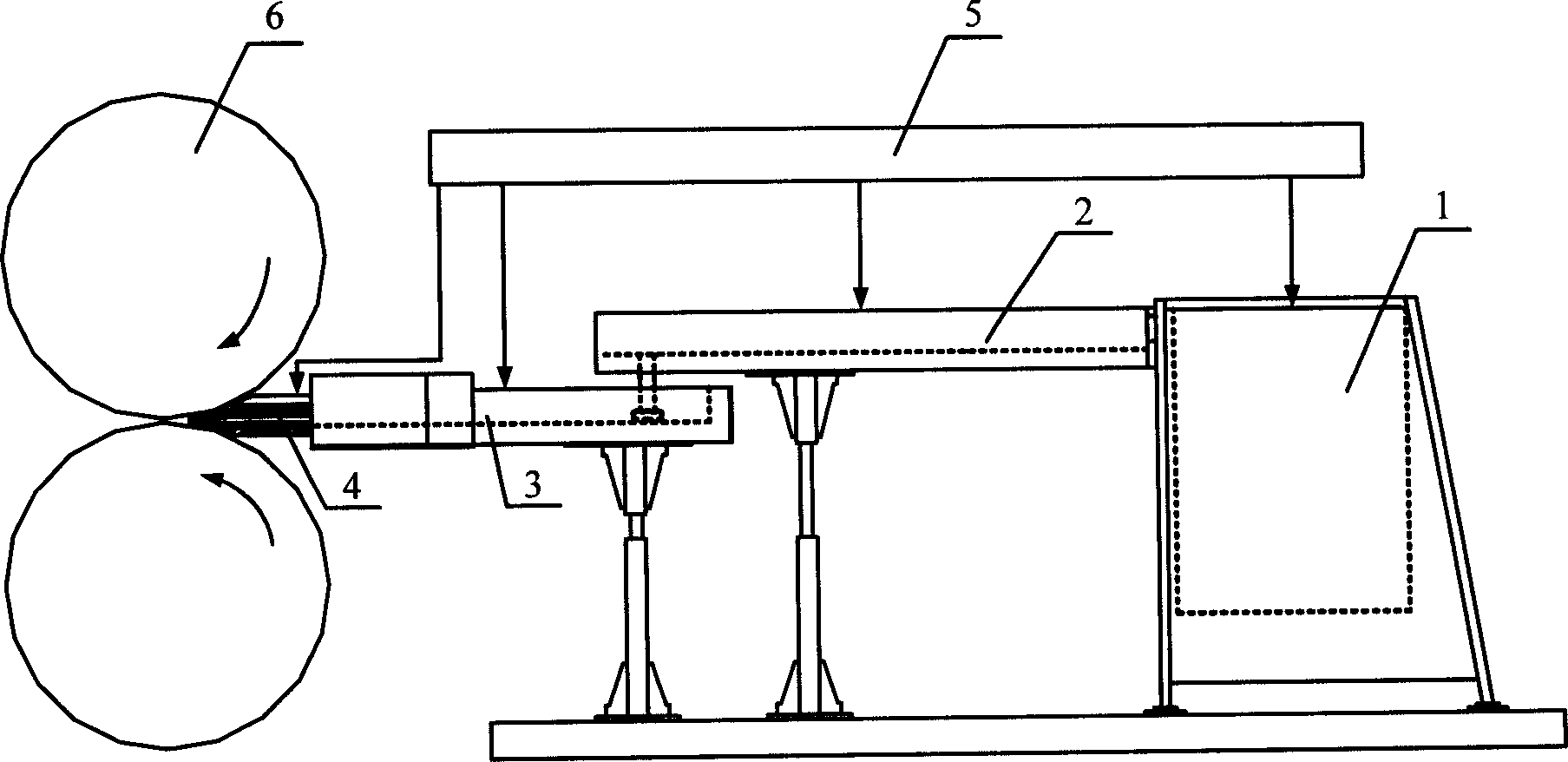

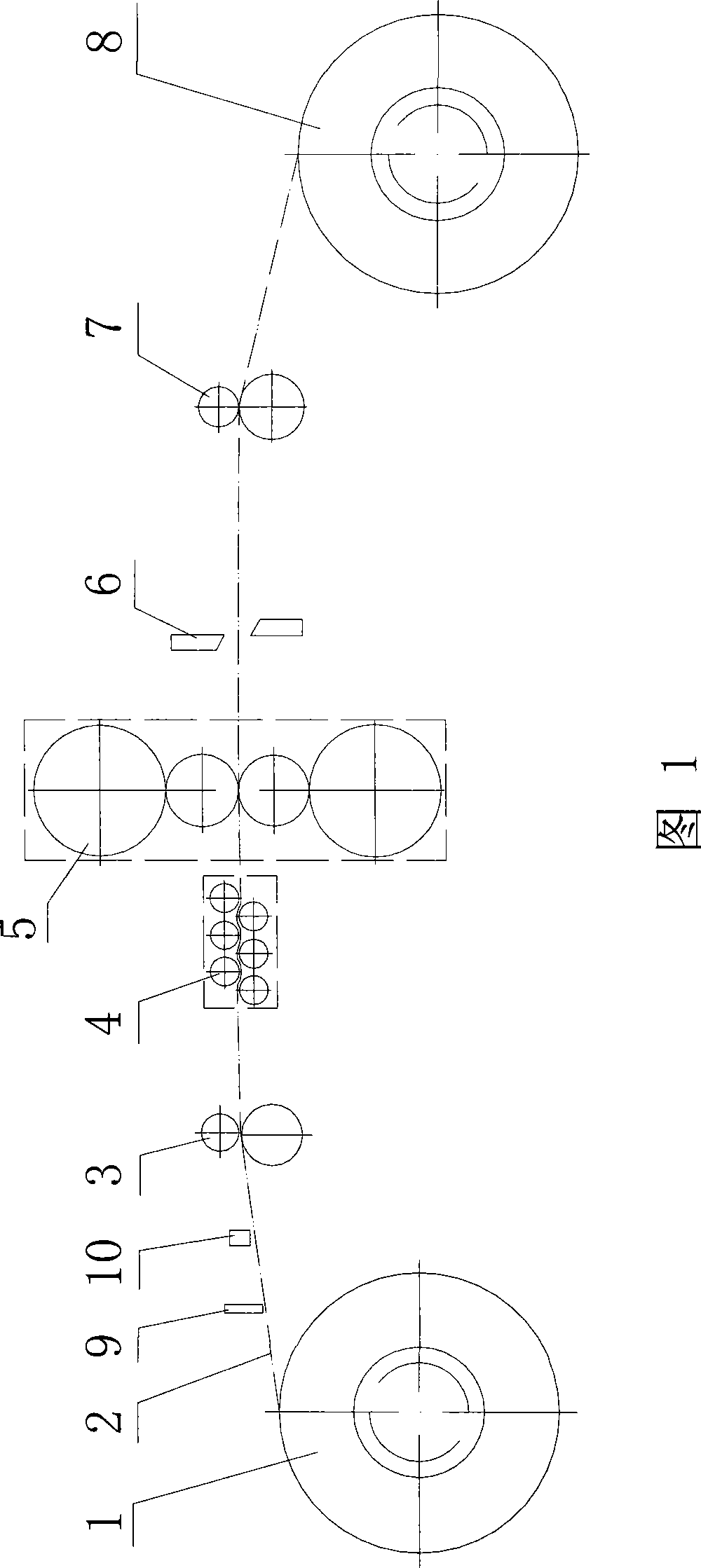

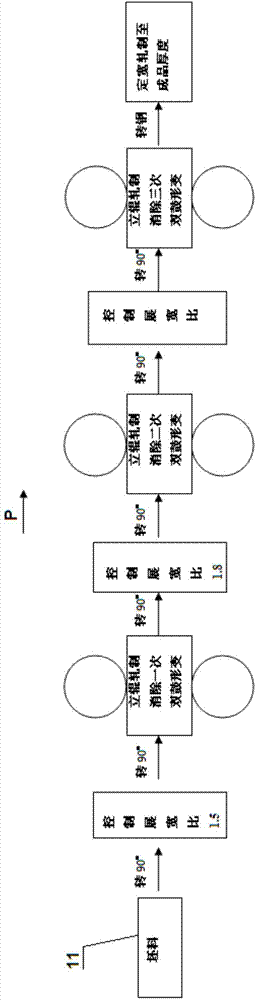

Casting-rolling process and equipment for magnesium alloy slab

InactiveCN1850378AOmit flaw detectionSave on sawingMetal rolling stand detailsRollsShielding gasIngot

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

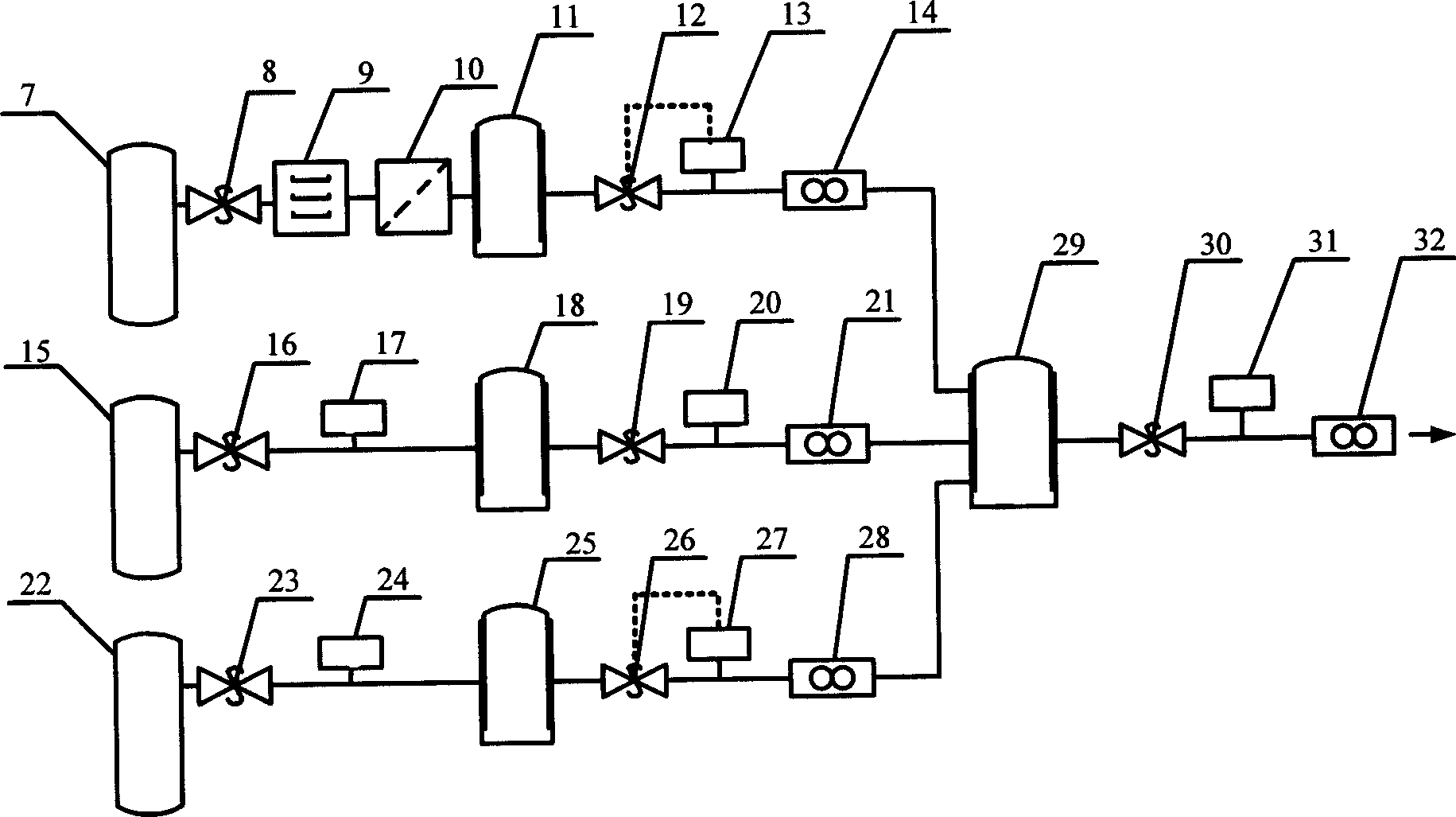

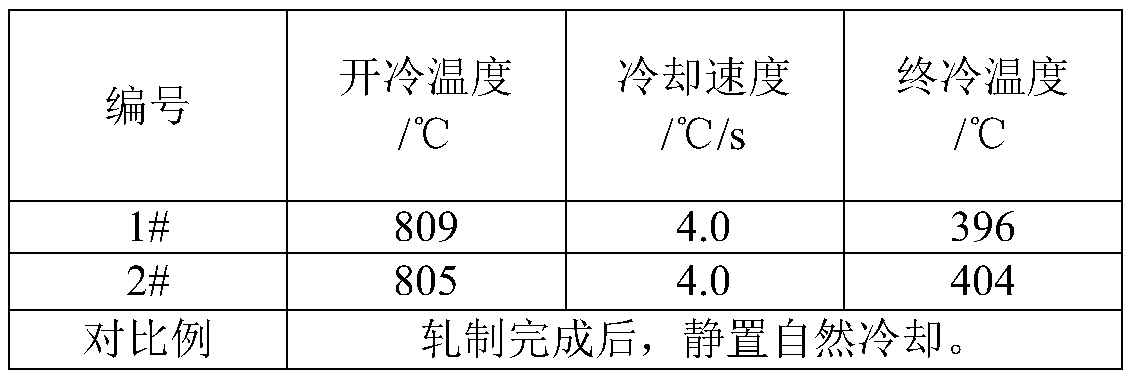

Method for Residual Stress Control of 100-meter Heavy Rail

InactiveCN102284503AControl flatnessImprove straightnessRoll mill control devicesMetal rolling arrangementsRoom temperatureDeformation control

Owner:INNER MONGOLIA UNIV OF SCI & TECH

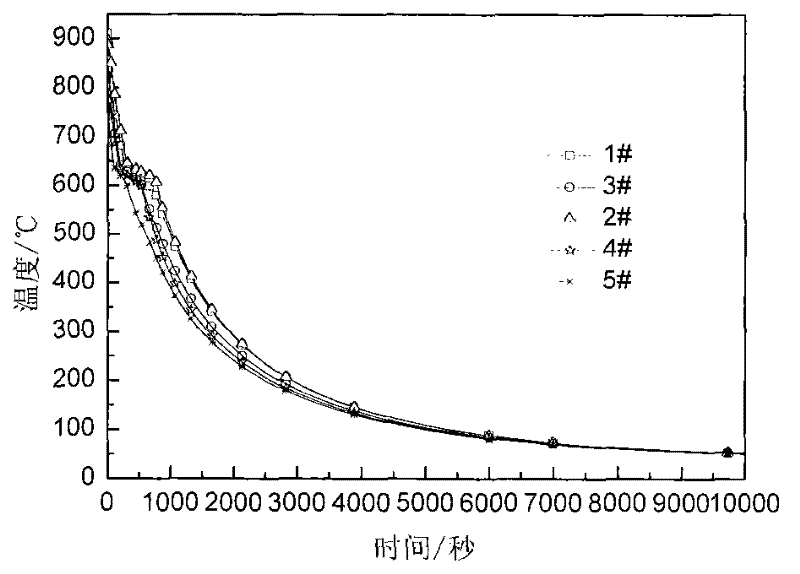

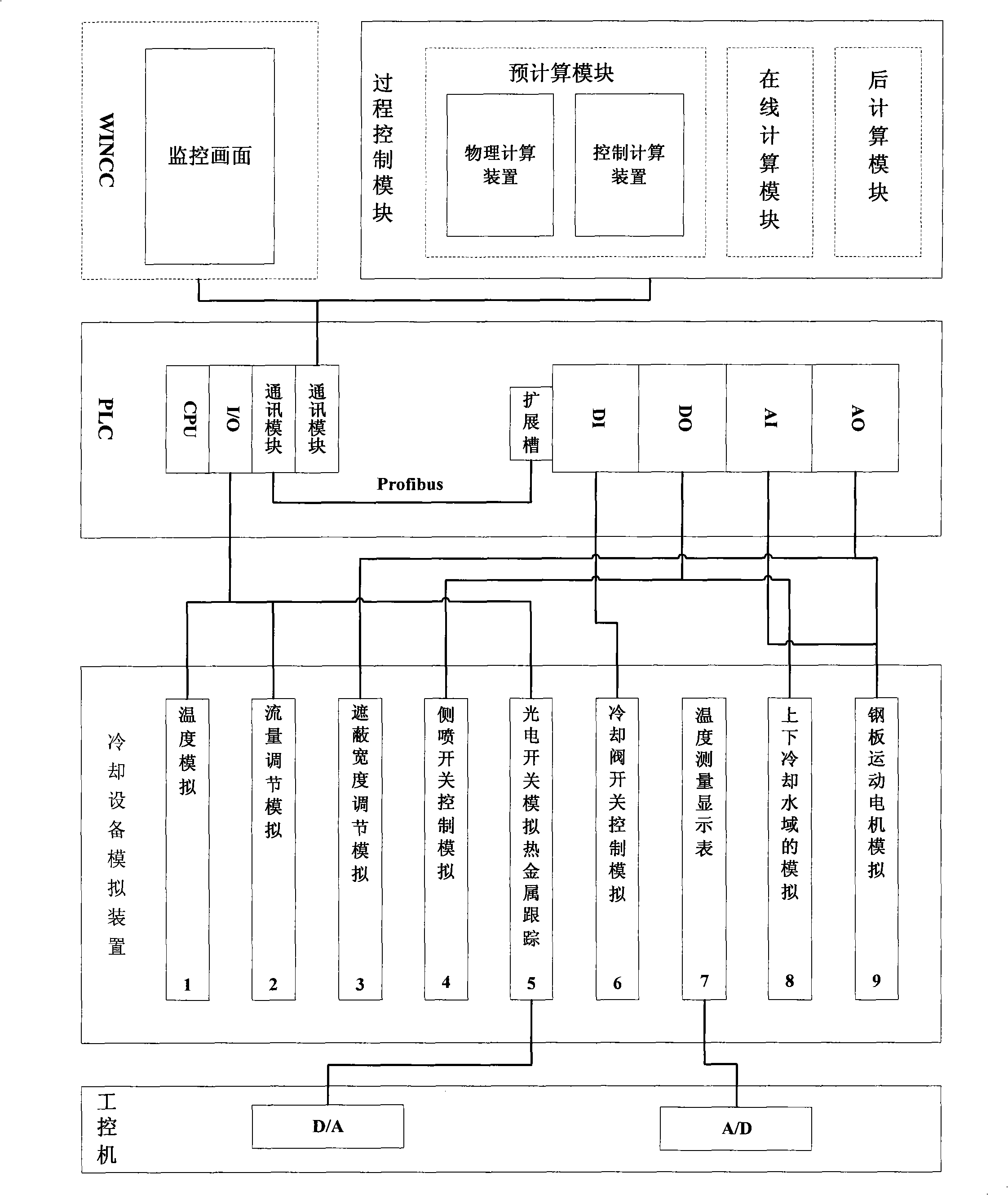

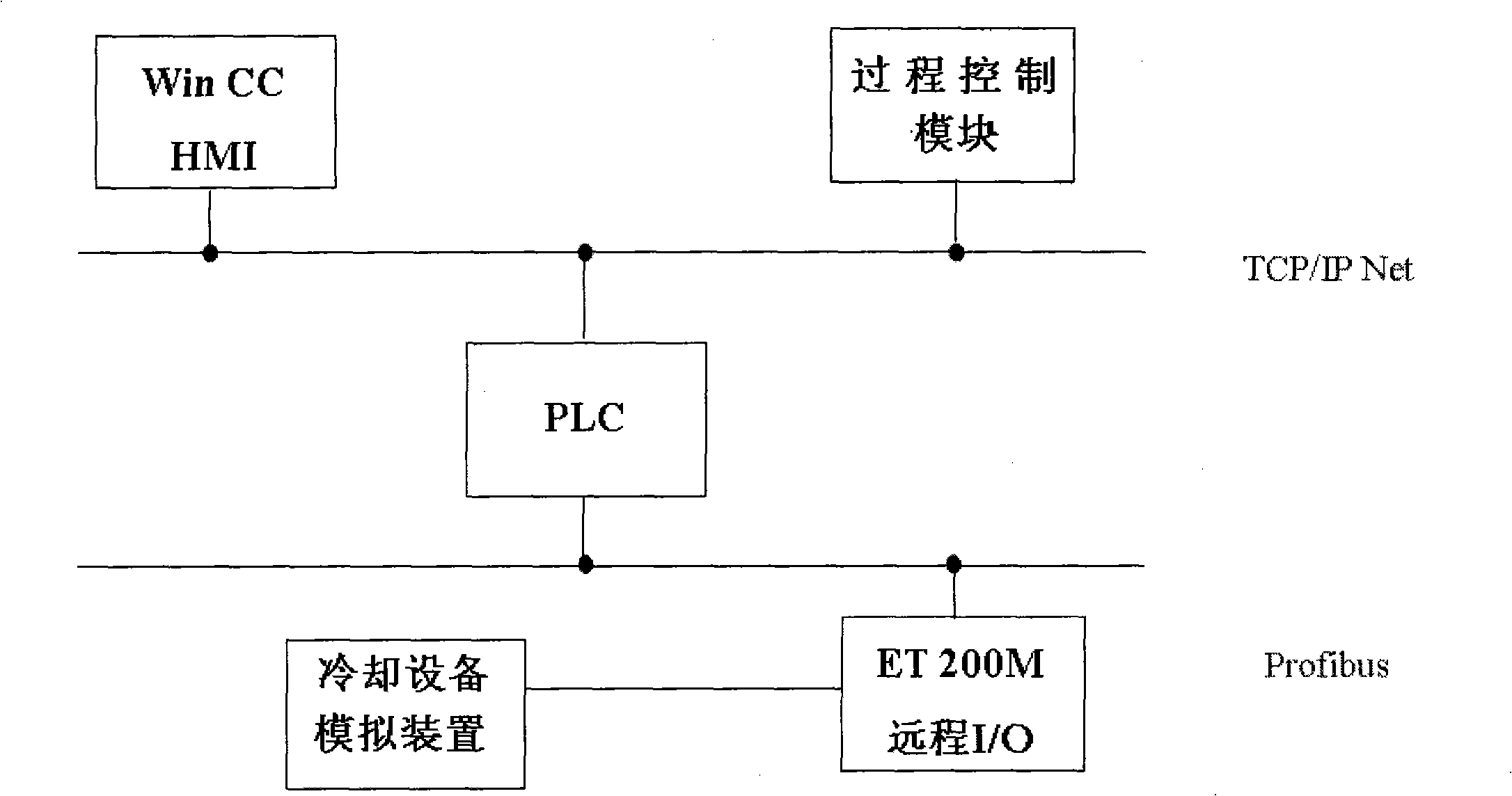

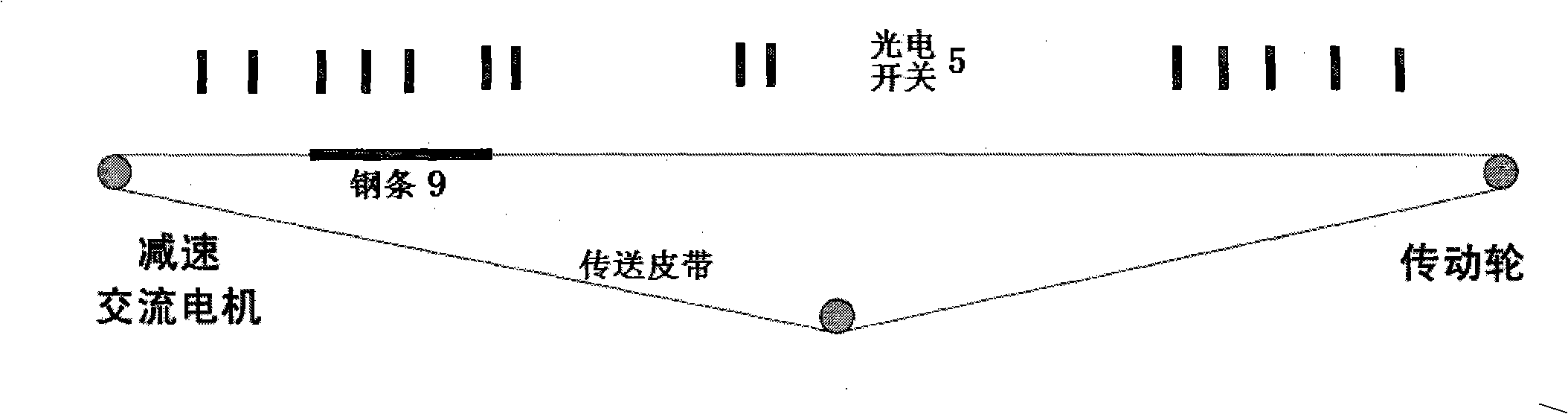

Steel plate cooling control analog system and method

ActiveCN101276209AGood simulation environmentSave time during in-circuit debuggingSimulator controlWork treatment devicesProcess systemsDevice simulation

Owner:BAOSHAN IRON & STEEL CO LTD

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

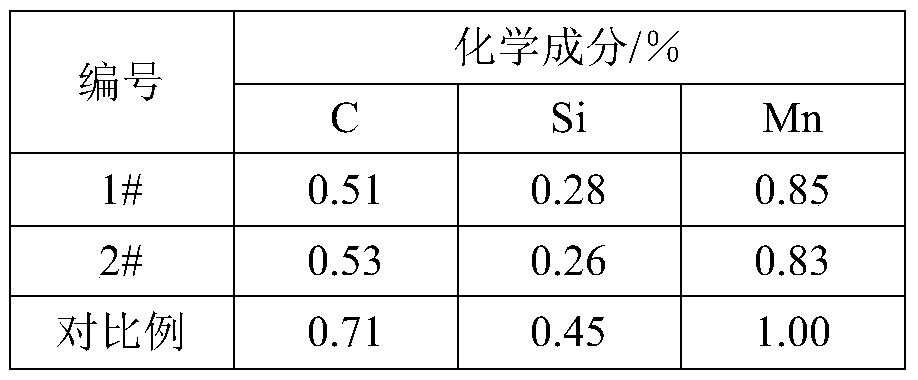

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Stress Free Steel and Rapid Production of Same

Owner:REX ENTERPRISES

Control method for cold-rolled product size precision

ActiveCN107442576AHigh dimensional accuracyHigh yieldMetal rolling stand detailsRoll mill control devicesRegression analysisContinuous annealing

The invention relates to the field of cold rolling, in particular to a control method for the cold-rolled product size precision. The control method comprises the steps that regression analysis is conducted on relevant parameters of the raw material texture, an acid pickling and cold rolling technology of an acid pickling and cold rolling unit and a continuous annealing technology of a continuous annealing unit by adopting a five-stand six-roll UCM rolling mill, and a final reasonable regression equation and main influence factors are determined through multiple times of analysis and selection. According to the control method, the improving direction is provided for size precision control of various cold-rolled varieties, main points of new variety size precision control and size precision control of all unit products obtained after technology optimization are adjusted, and the good guiding significance is achieved. In addition, reference is provided for galvanized product size precision control according to analysis on the factors influencing the product size precision.

Owner:BENGANG STEEL PLATES

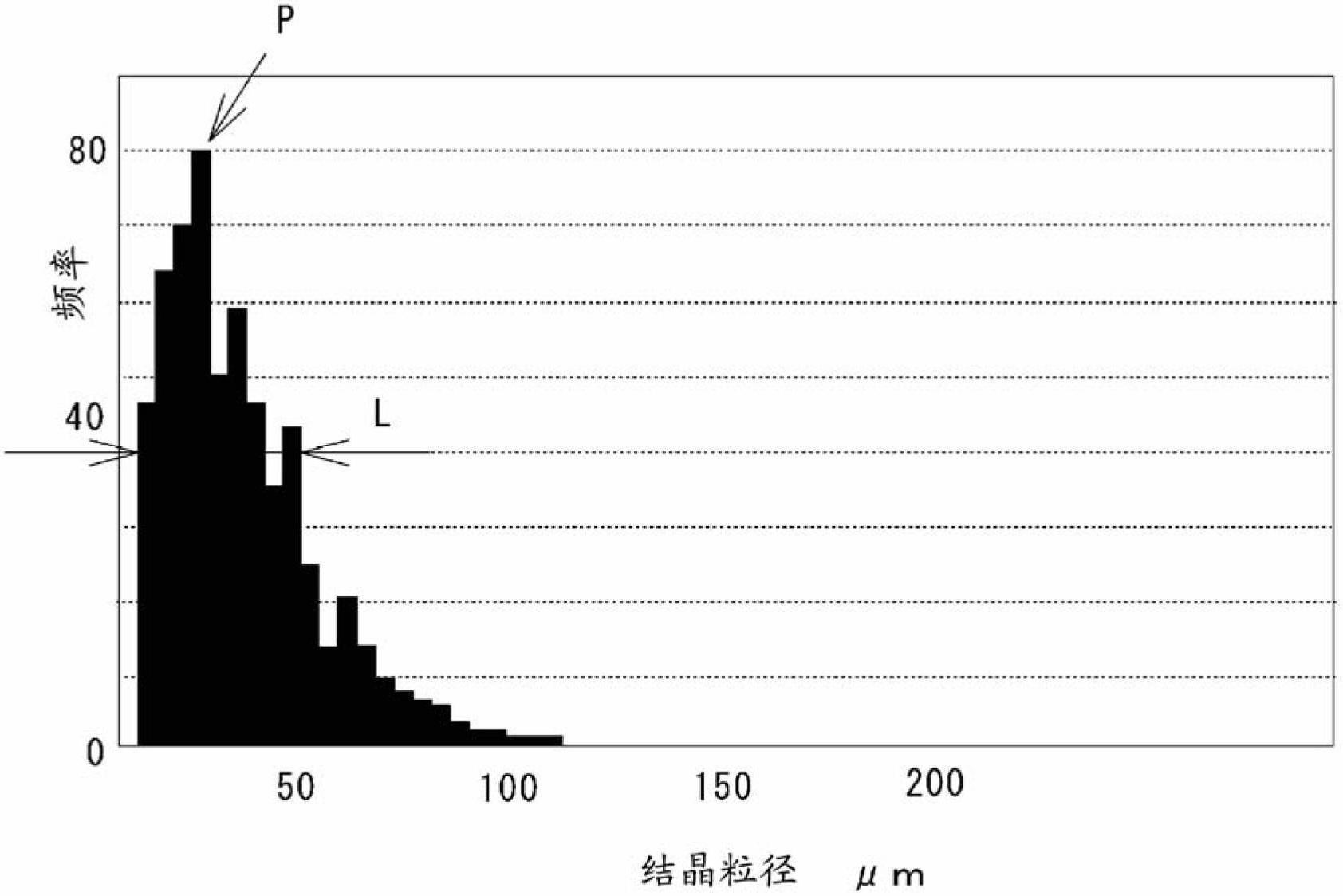

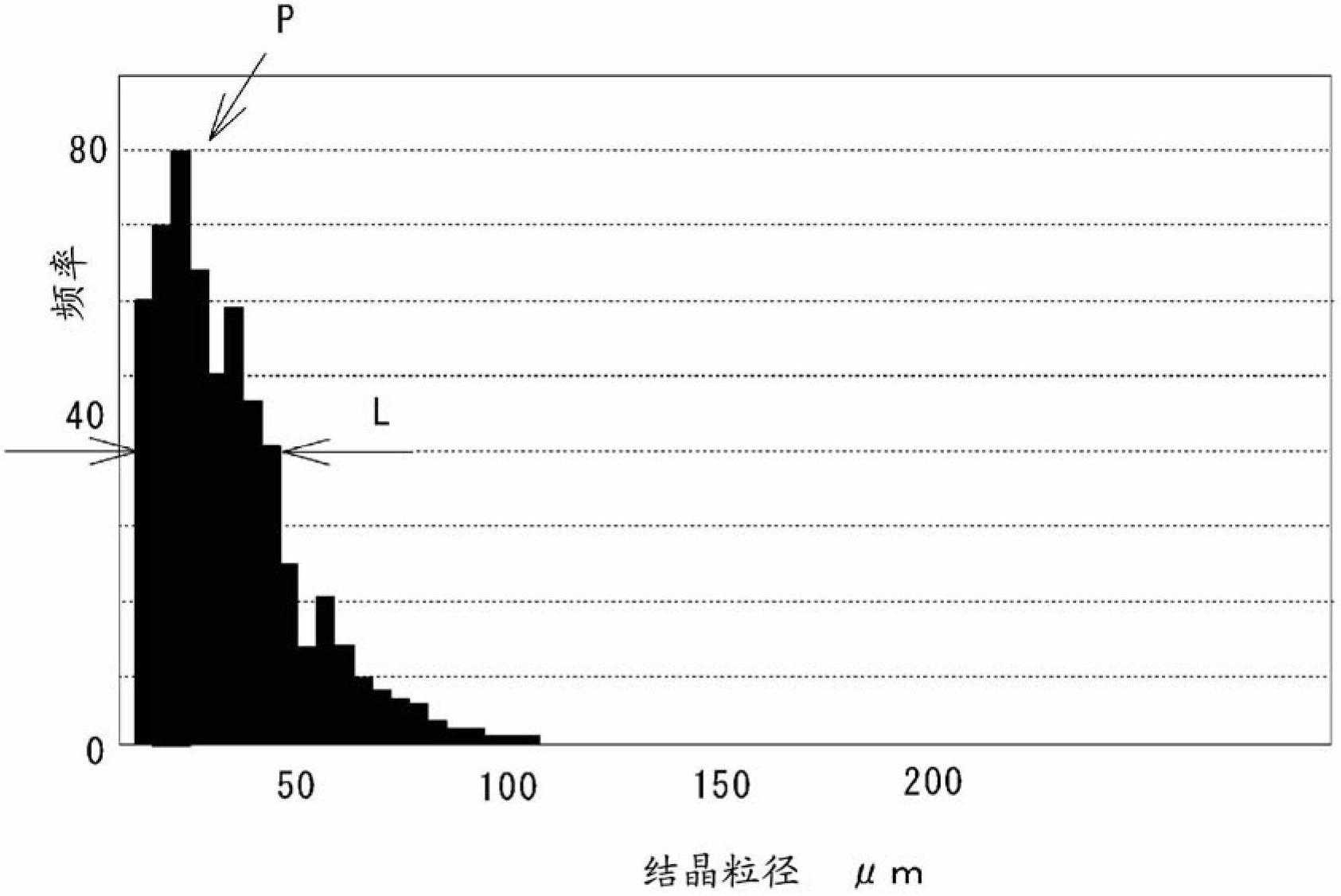

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

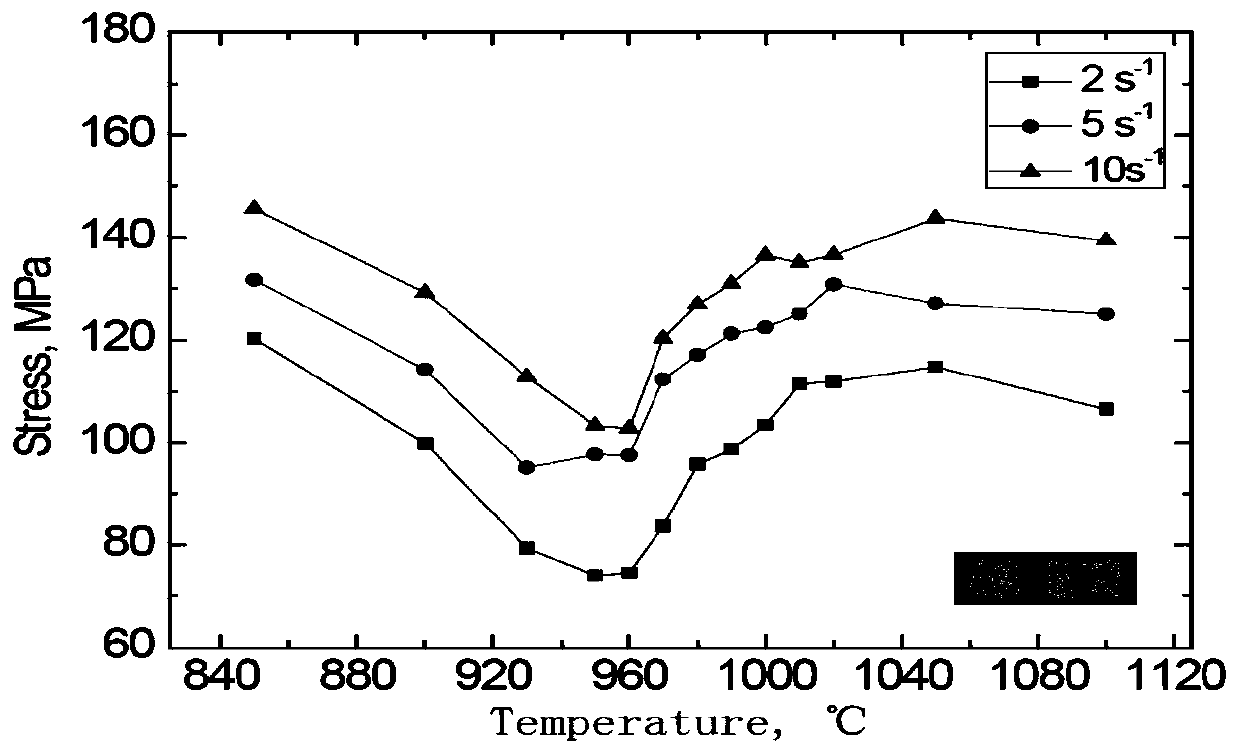

Method for hot-rolling manufacture of ultra-pure ferrite stainless steel

ActiveCN103506383ASolve hot rolling sticking problemSolve sticking problemsMetal rolling arrangementsReduction rateMaterials science

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Laser powered automobile window cleaning system and method

InactiveUS7946301B1Easy to disassembleWork treatment devicesElectrostatic cleaningEngineeringLaser beams

A laser powered cleaning system for cleaning pollutants and debris from both sides of automobile windshields and windows. The system includes an electromagnetic interior block having a top surface having a plurality of focused laser beams, and a magnetic exterior block having a top surface including a reflective surface. The windshield or window is situated between the interior and exterior blocks which pass over the window for cleaning. A power cord connected to an adapter plugs into an automobile power outlet for supplying power. A safety sensor is integrally coupled to the interior block for actuating the system when safe. The system is fixable onto a windshield or window within a door of an automobile. An on-off switch actuates the fixed system.

Owner:WALSH JOHN

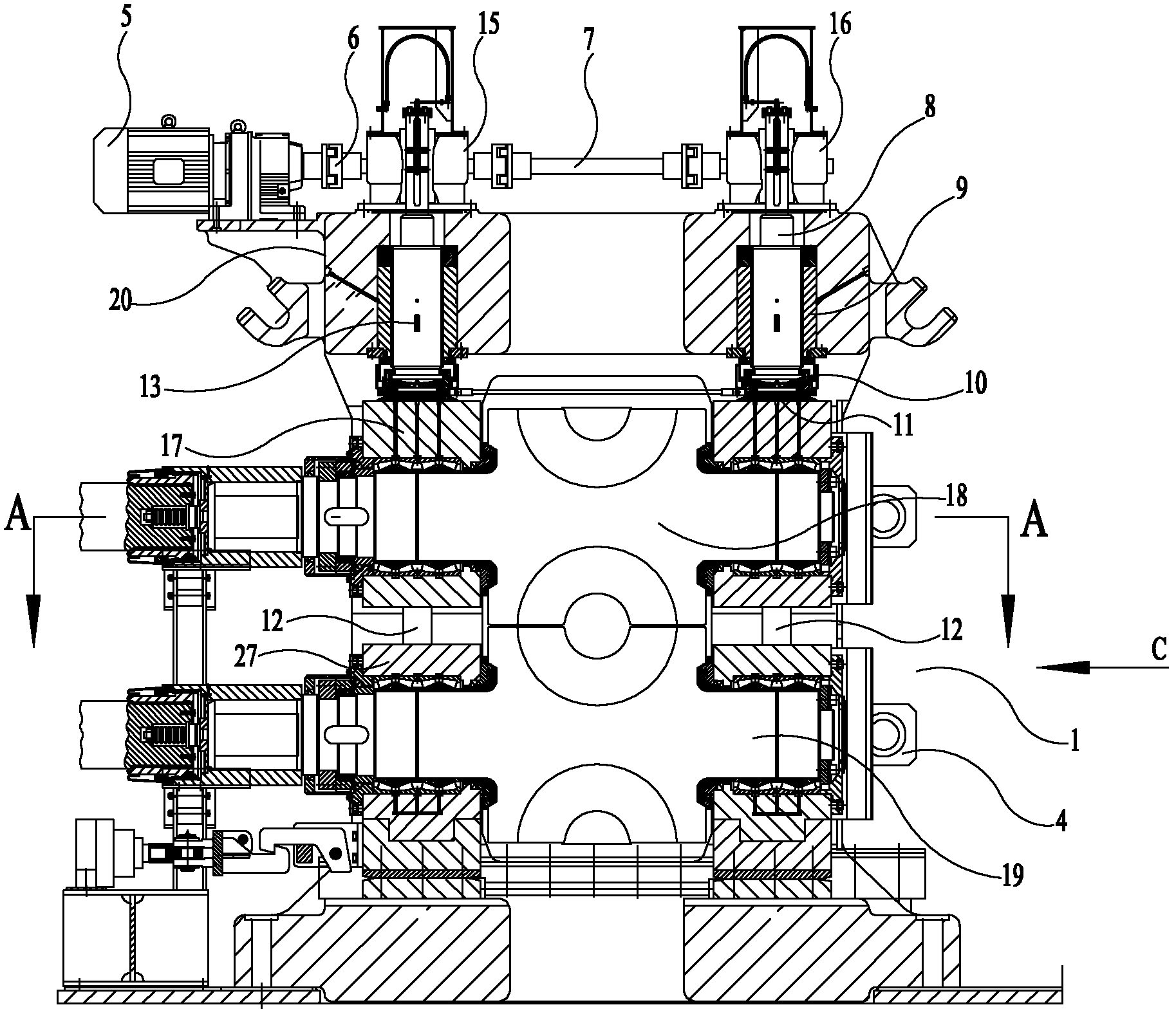

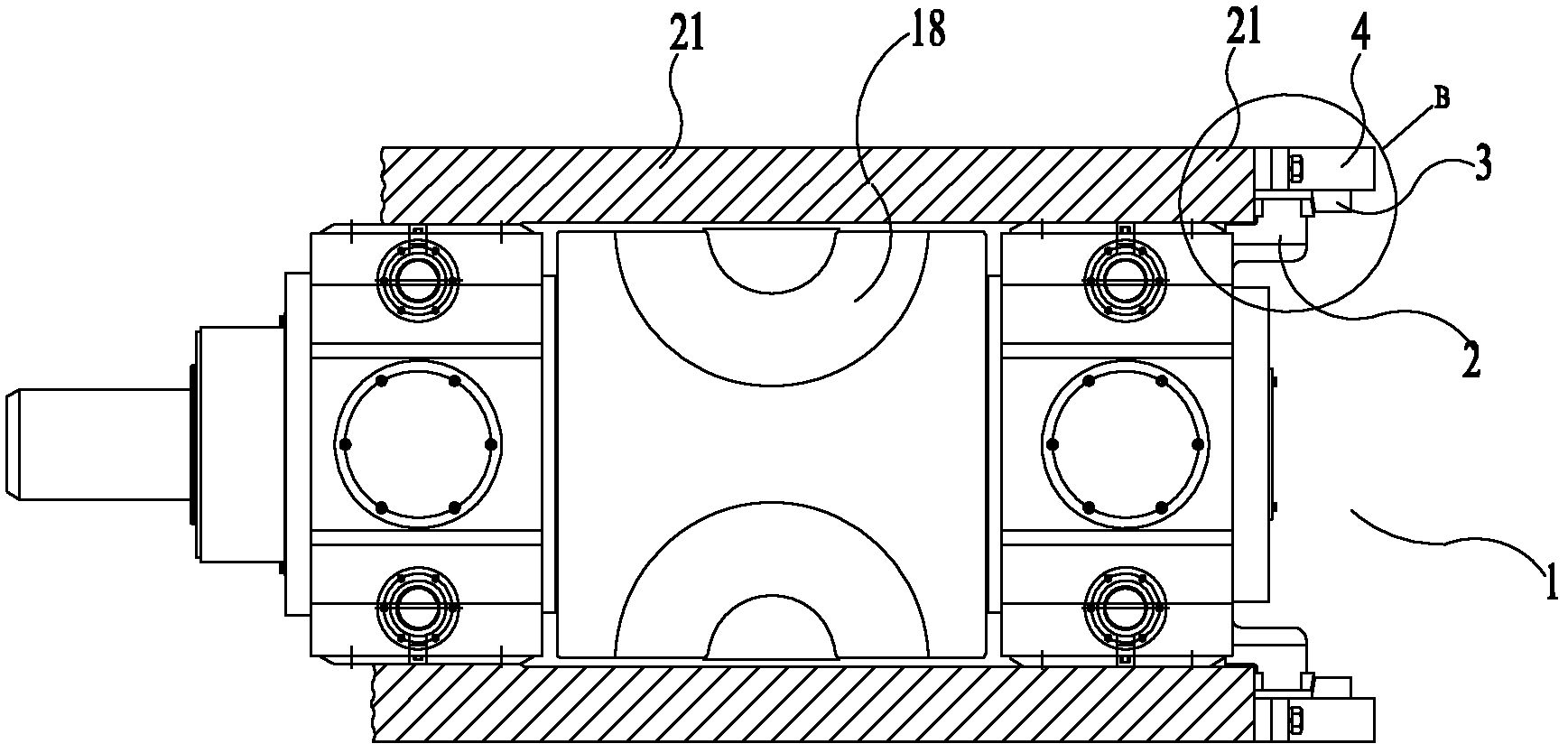

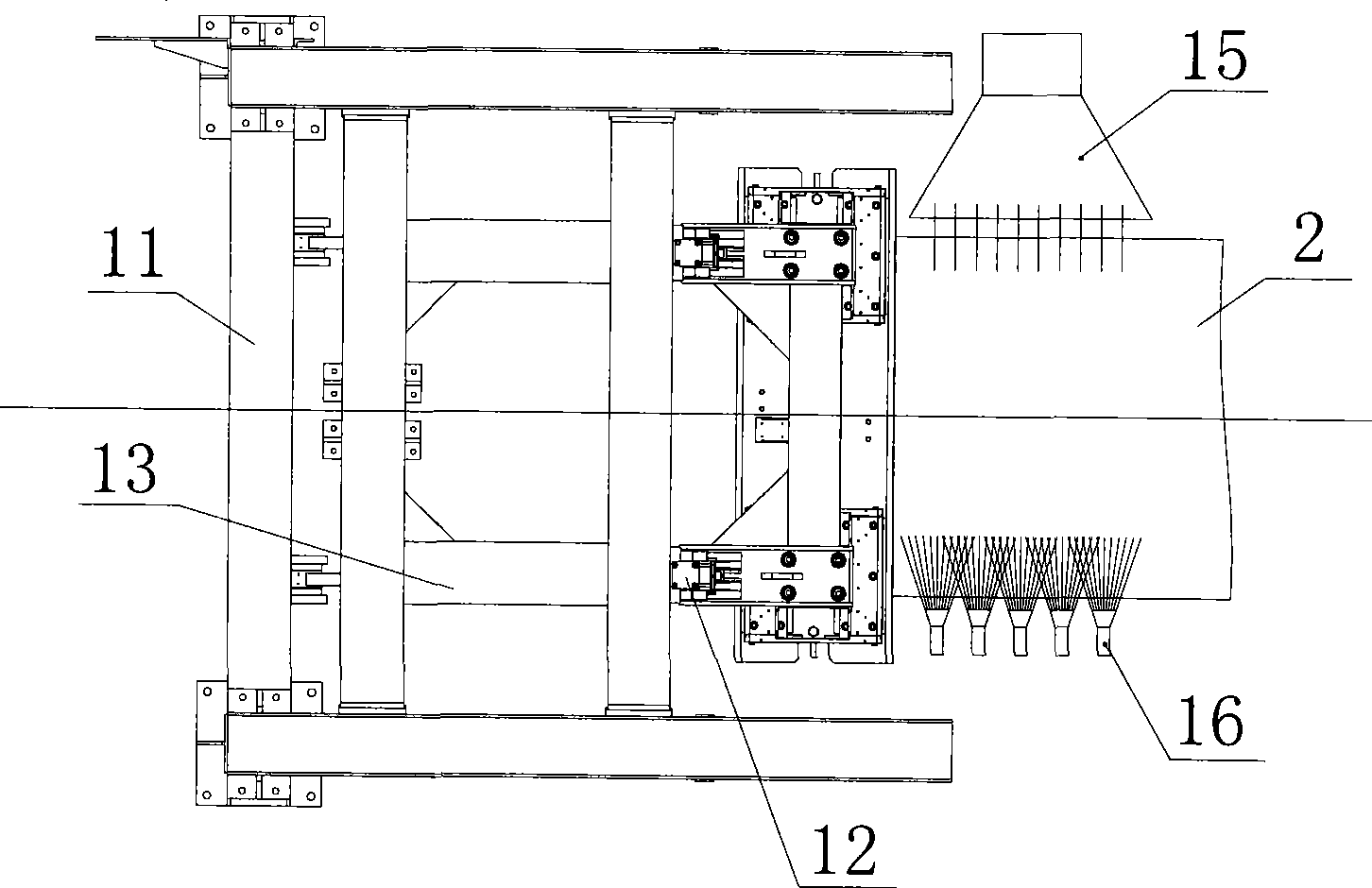

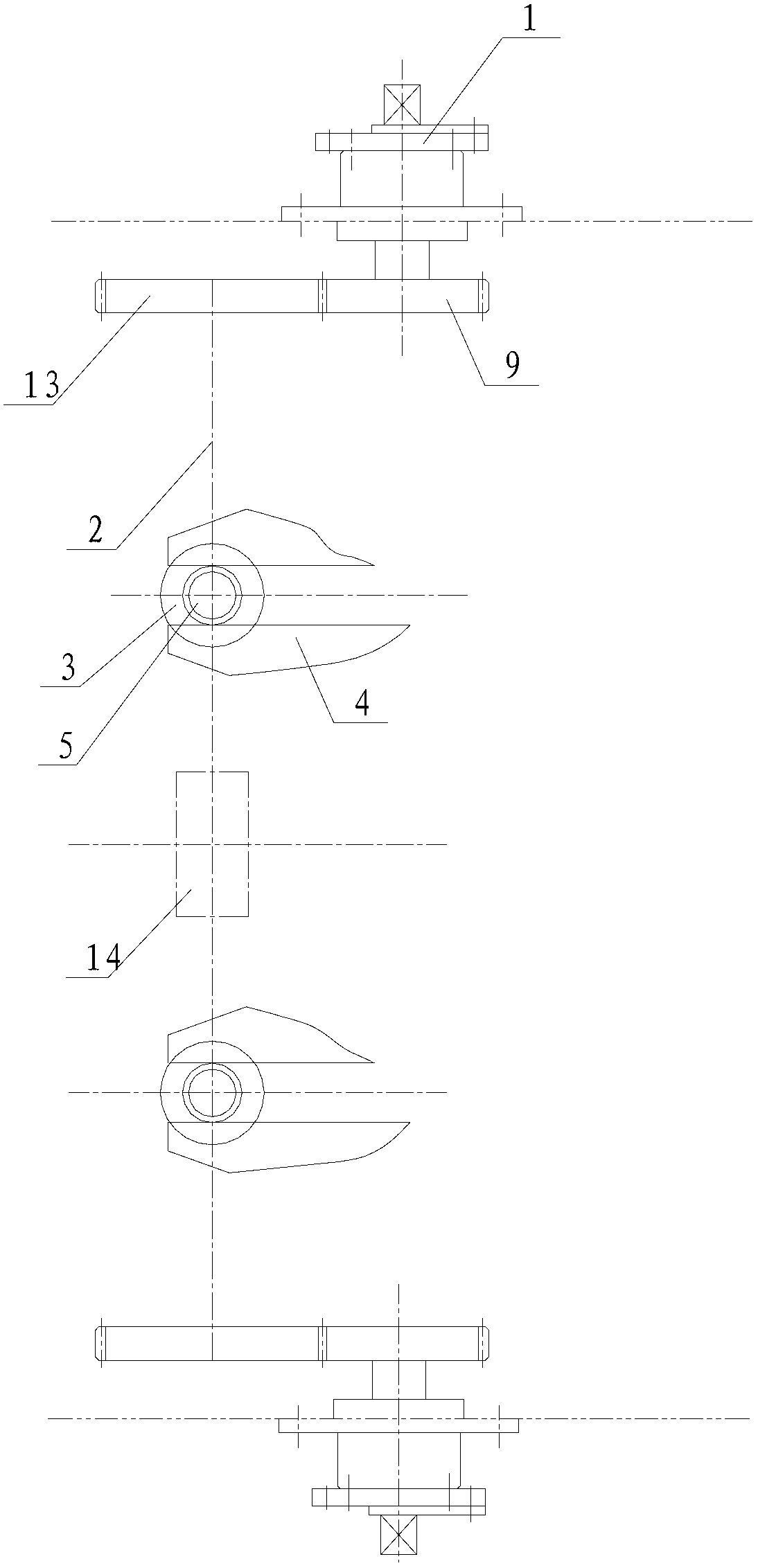

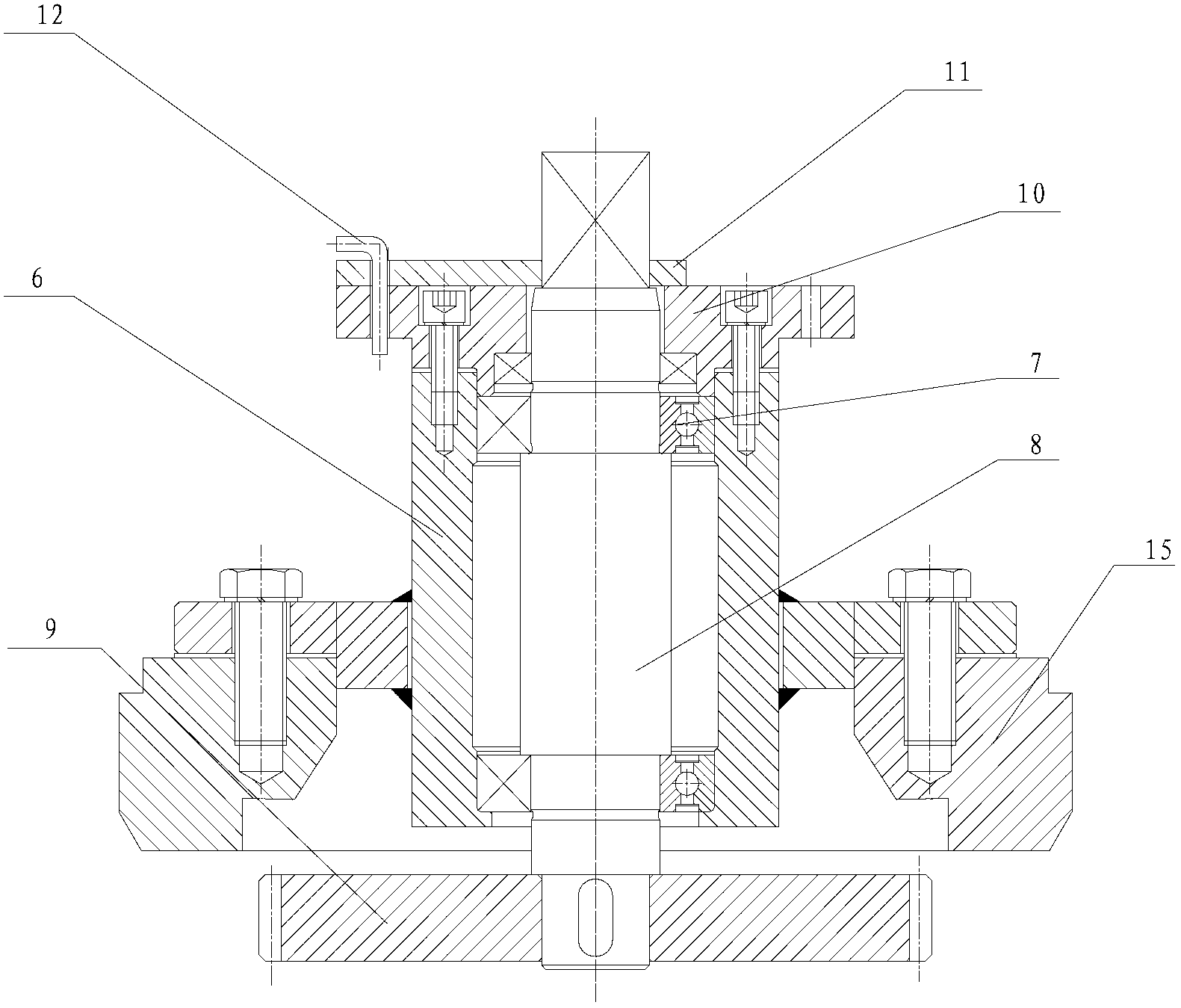

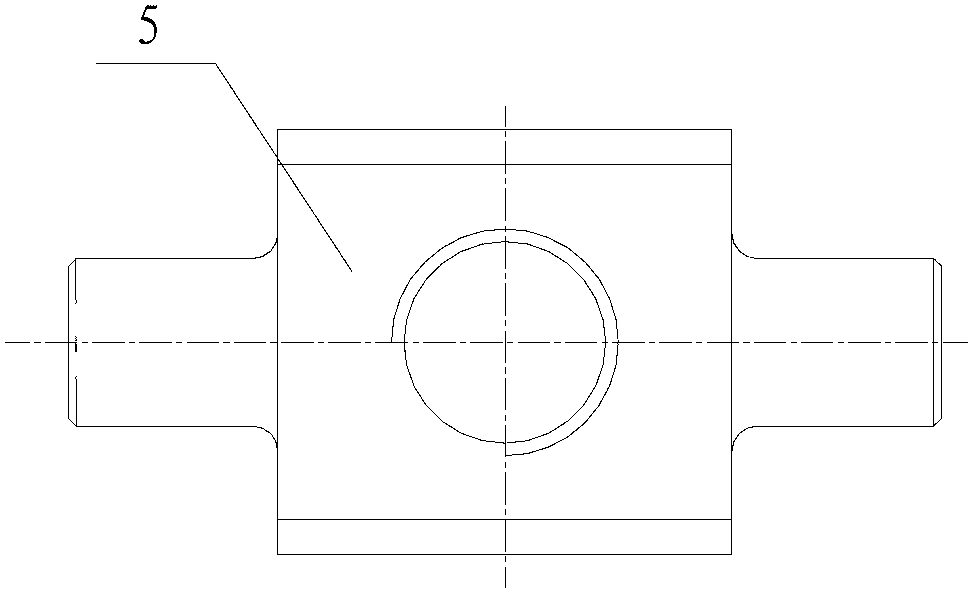

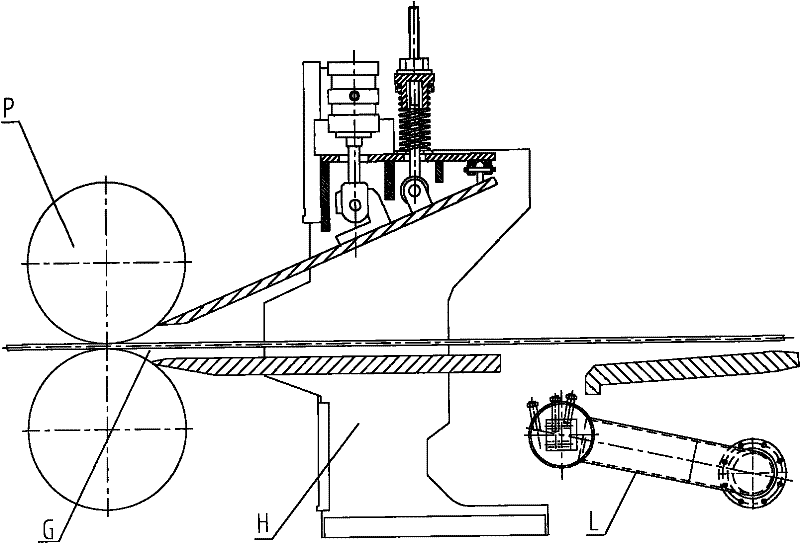

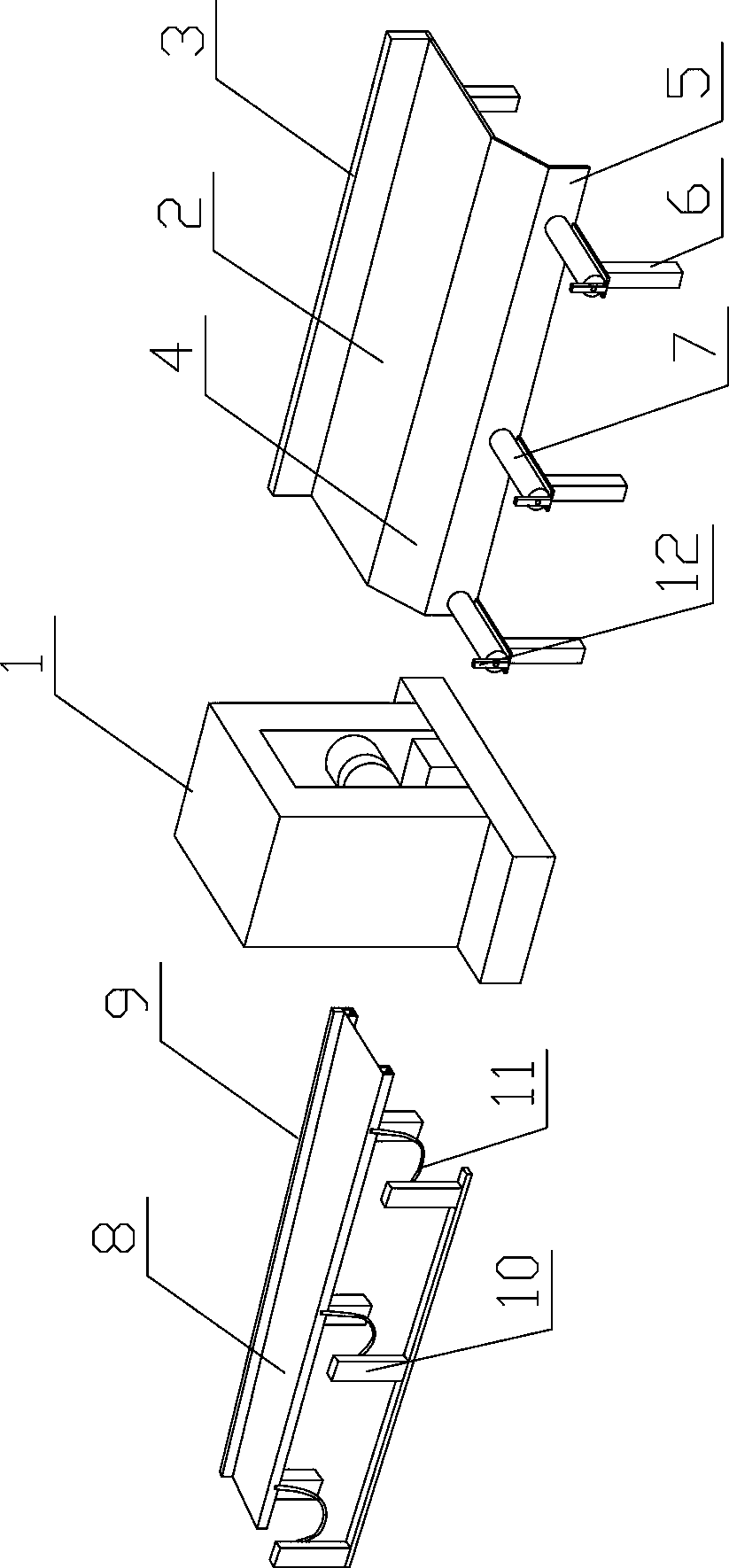

Two-roll tandem pipe mill and roll framework locking device thereof

Owner:TAIYUAN HEAVY IND

Cold rolling production method of medium-chromium ferrite stainless steel for vehicle exhaust system

InactiveCN106140813AGood formabilityUniform shear strainRoll mill control devicesMetal rolling arrangementsReduction rateChromium

The invention discloses a cold rolling production method of medium-chromium ferrite stainless steel for a vehicle exhaust system. Cold rolling steps adopt five passes of continuous cold rolling by a five-stand tandem rolling unit; the reduction rate in the first pass is 19-21%; the reduction rate in the second pass is 34-36%; the reduction rate ratio in the third, fourth and fifth passes is 6-7: 4-5: 3; the total reduction rate is not lower than 70%; and the plate thickness after cold rolling is within 0.8-1.5 mm. The steel has the r value of 1.5-1.8, the yield strength of not less than 240 MPa, the tensile strength of not less than 415 MPa, the ductility of not less than 36% and the roughness of not more than 0.7 microns; the molding strain ratio of the steel is increased; the forming performance is enhanced; the roughness satisfies the use conditions of the vehicle exhaust system; and a new technology is provided for industrial production of the medium-chromium ferrite stainless steel for the vehicle exhaust system.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

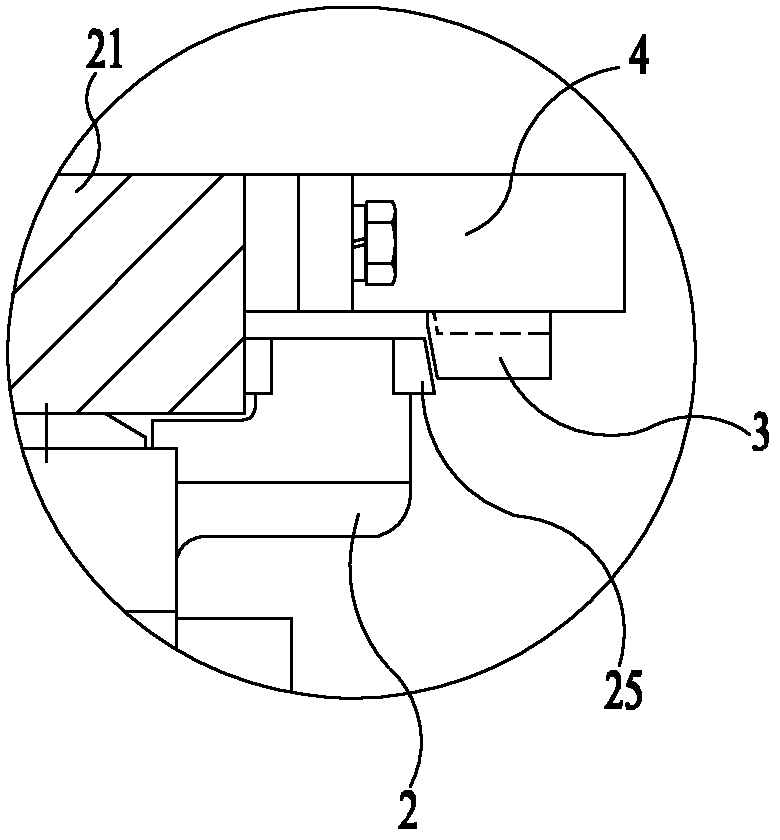

Metal glass micron foil and preparation method thereof

InactiveCN108339853AThickness is easy to controlPrecise thickness controlRoll mill control devicesMetal rolling arrangementsMicron scaleElectromagnetic shielding

Owner:SHANGHAI JIAO TONG UNIV

Aluminum base alloy containing boron and manufacturing method thereof

InactiveUS7125515B2Evenly distributedNuclear energy generationCasting safety devicesBoron containingAlloy

Owner:KOBE STEEL LTD

Method for improving product surface quality of hot rolling and leveling machine group

ActiveCN101433921AReduce the impactReduce destructive strengthWork treatment devicesMetal rolling arrangementsAcid washingEngineering

Owner:WISDRI ENG & RES INC LTD

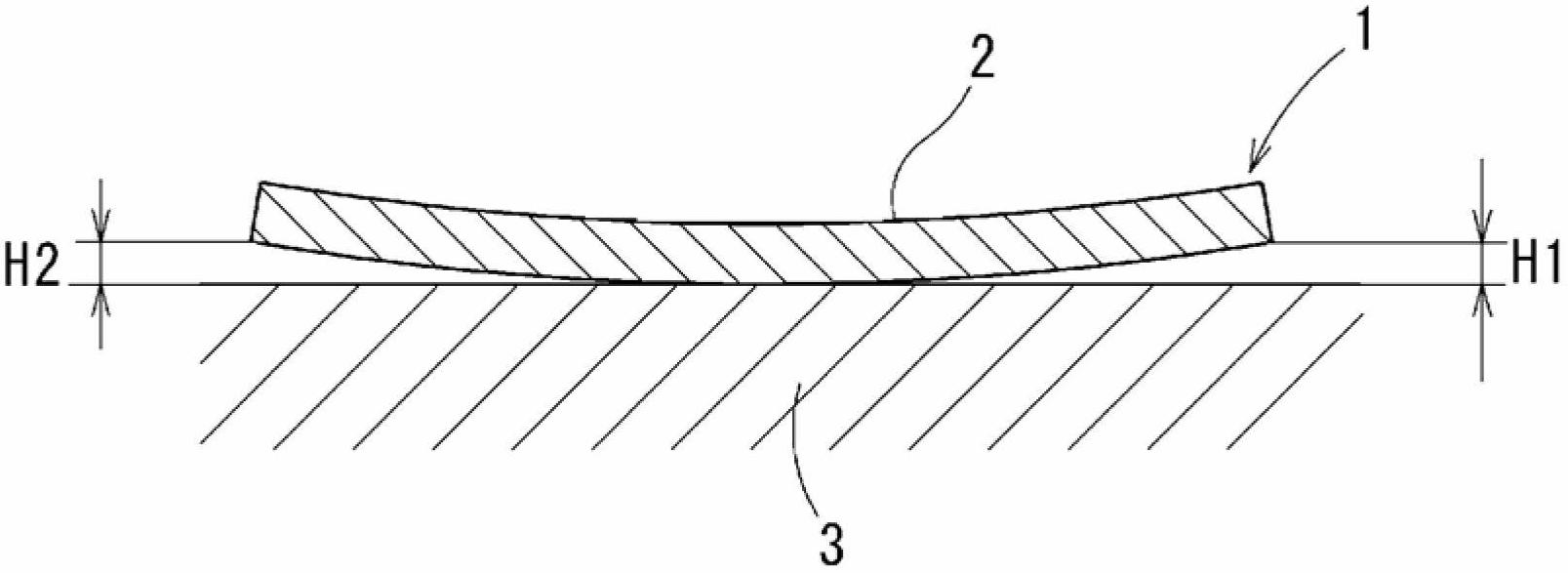

Manufacturing method of pure copper plates, and pure copper plate

ActiveCN102652182AFine uniform grainsEasy to processVacuum evaporation coatingSputtering coatingIngotCopper

Owner:MITSUBISHI SHINDOH CO LTD +1

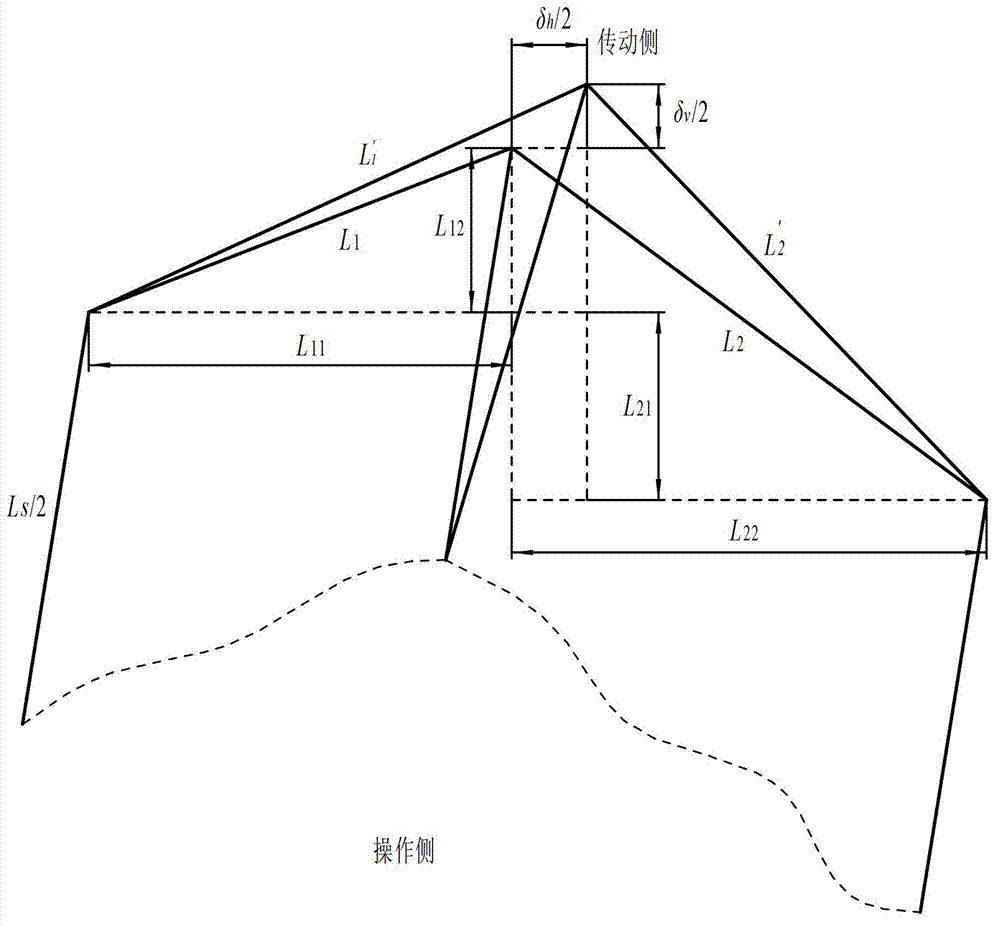

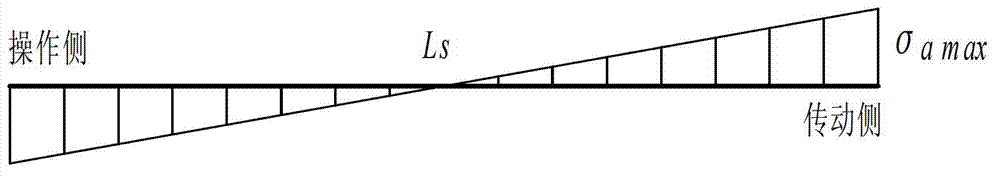

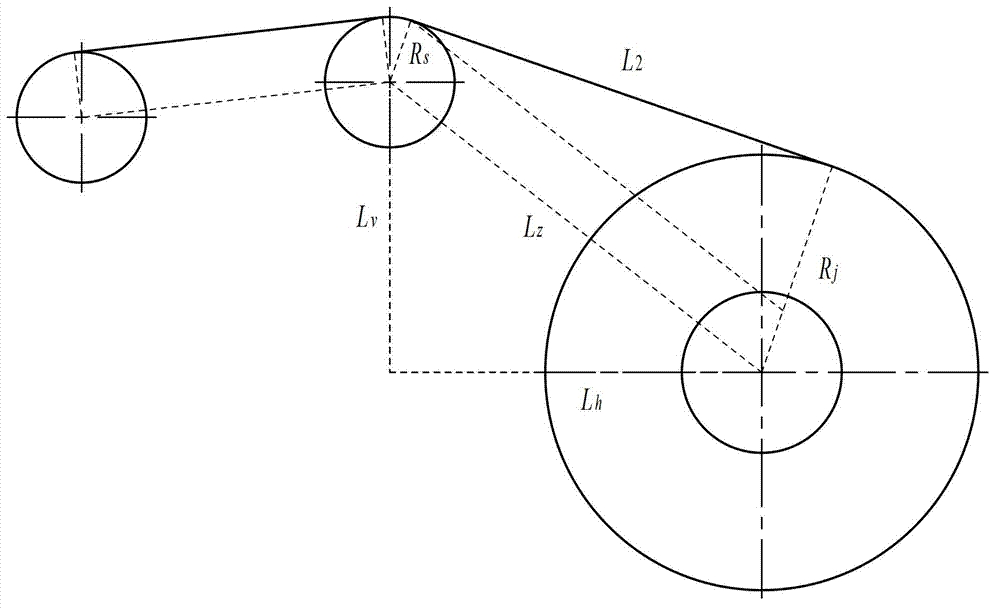

Strip shape signal error compensation method based on strip shape detection roll installation accuracy

Owner:YANSHAN UNIV

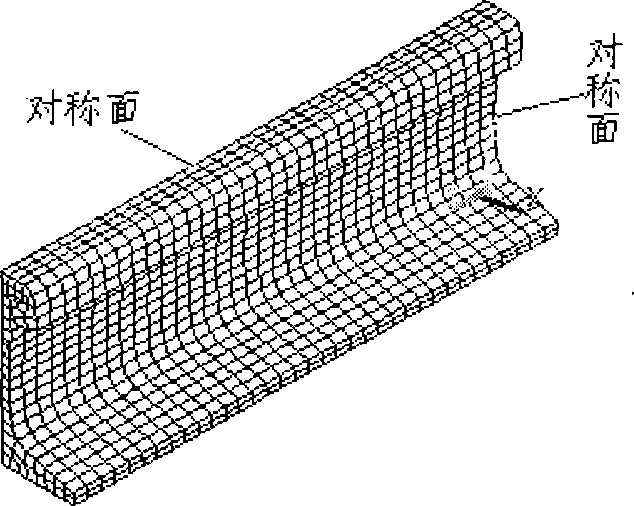

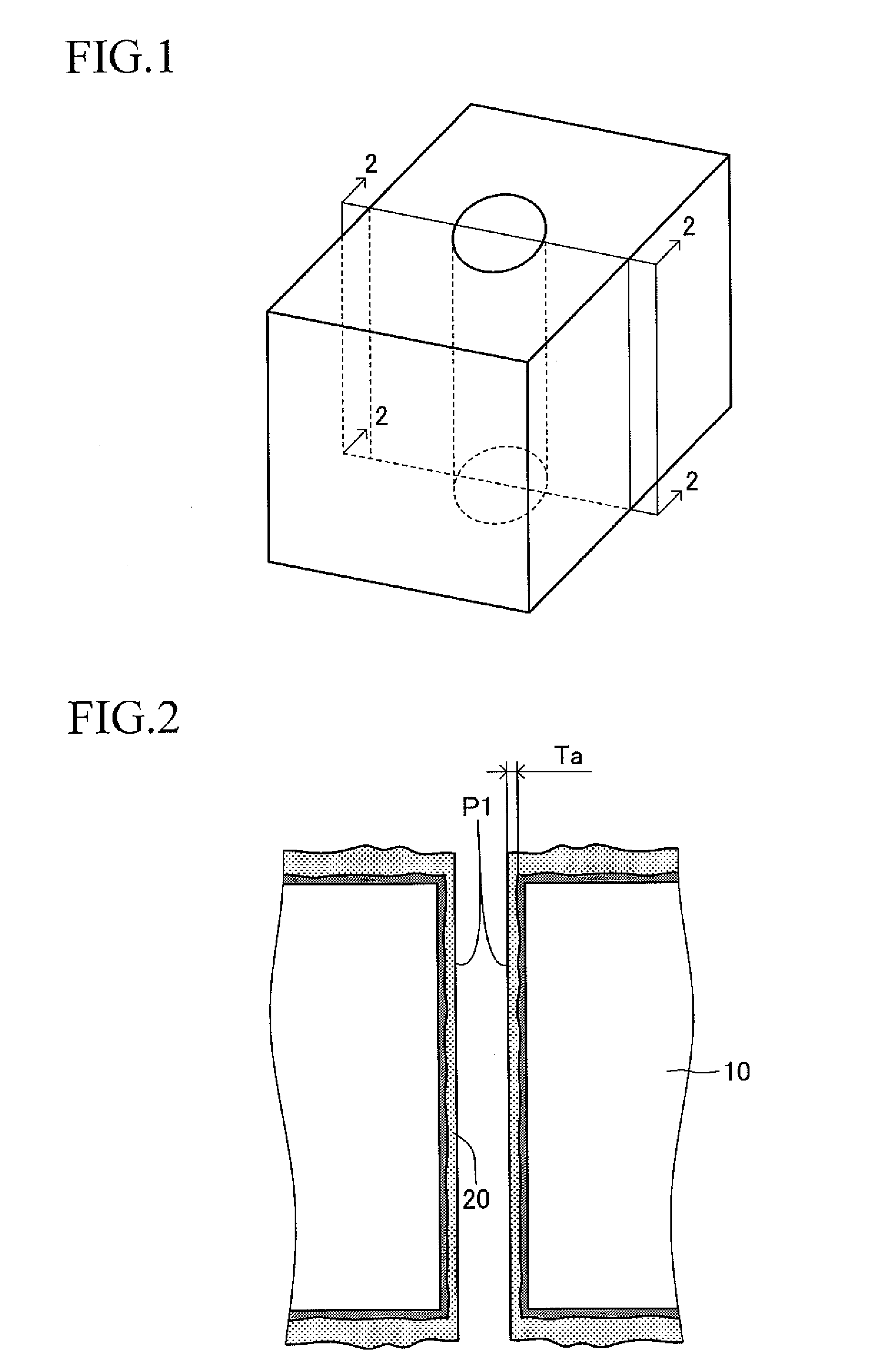

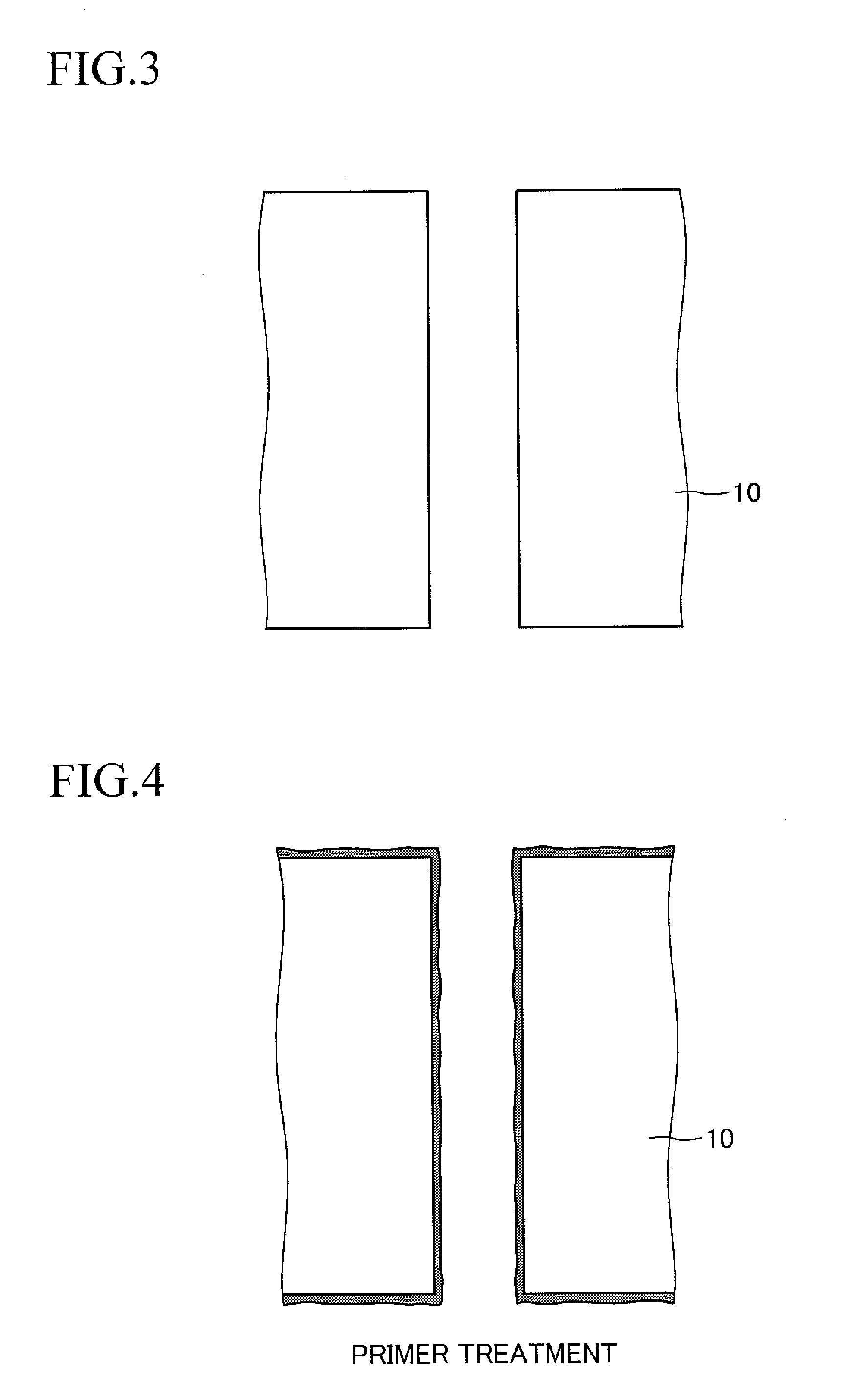

Production method of forming mold

InactiveUS20120240383A1Forming accuracyHigh shape accuracyMetal rolling stand detailsCoatingsEnd millComposite material

Owner:NGK INSULATORS LTD

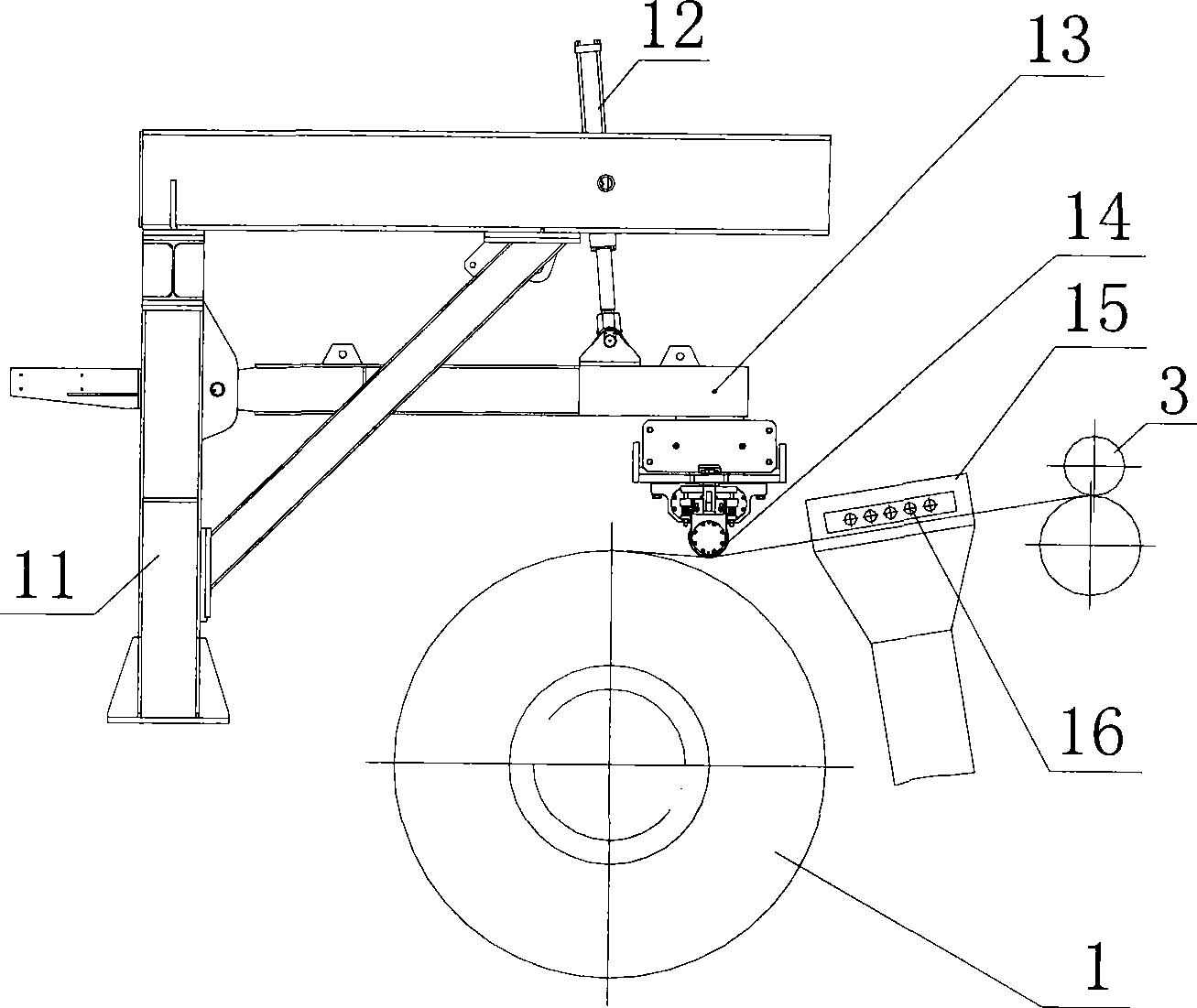

Roll gap adjusting and fixing device

InactiveCN103212583AAvoid the inconvenience of adjustmentEnhanced ability to resist repeated shocks in cyclesMetal rolling stand detailsMetal rolling arrangementsWire rodControl theory

Owner:张家港联峰钢铁研究所有限公司

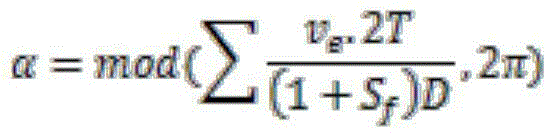

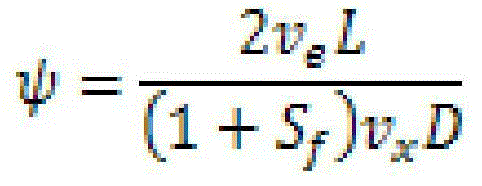

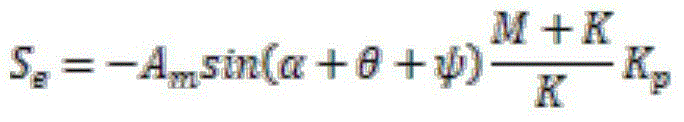

Eccentricity compensation method for cold rolling mill upstream rolling mill roll

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Method and apparatus for reducing and sizing hot rolled ferrous products

Owner:PRIMETALS TECH USA

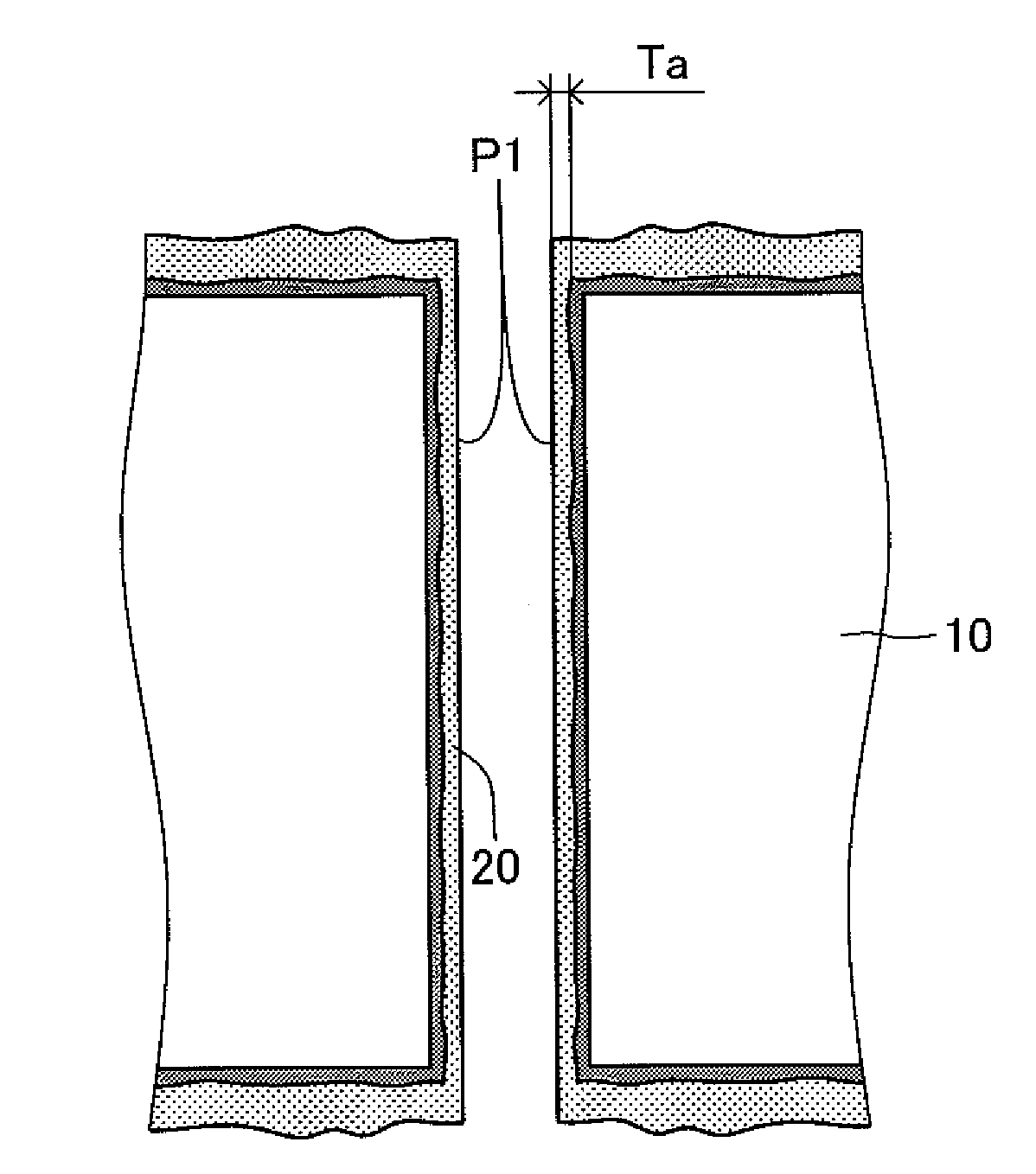

Microporous polyolefin film, separator for battery, and production processes therefor

ActiveUS20170274329A1Increase capacityReduce the numberMembranesSemi-permeable membranesPolymer sciencePolyolefin

A polyolefin microporous membrane is disclosed. The membrane has a width of not less than 100 mm, and a variation range of an F25 value in a width direction is not greater than 1 MPa. The F25 value is a value obtained by dividing a load at 25% elongation of a sample of the laminated polyolefin microporous membrane as measured with a tensile testing machine by a cross-sectional area of the sample.

Owner:TORAY IND INC

Steel rail for high-speed railway and manufacturing method thereof

InactiveCN111349862AImprove wear performanceHigh running densityFurnace typesHeat treatment process controlEngineeringMaterials science

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

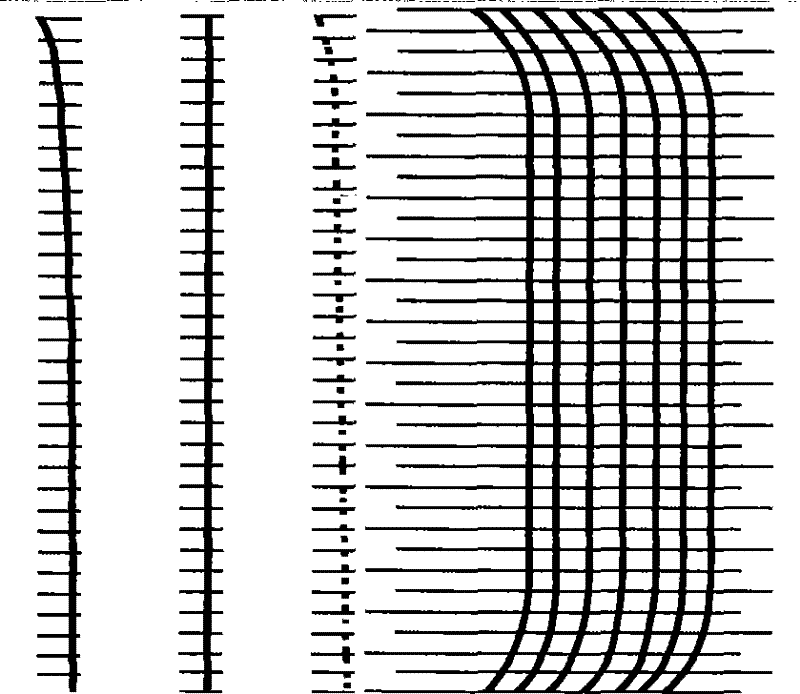

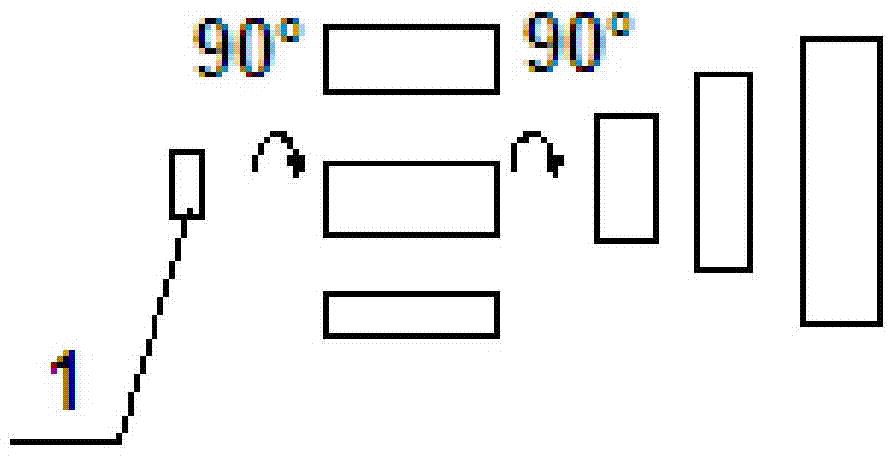

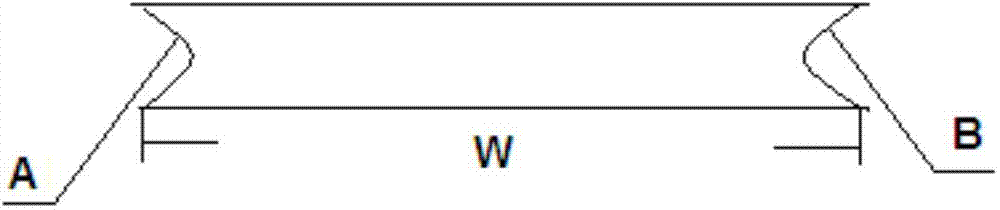

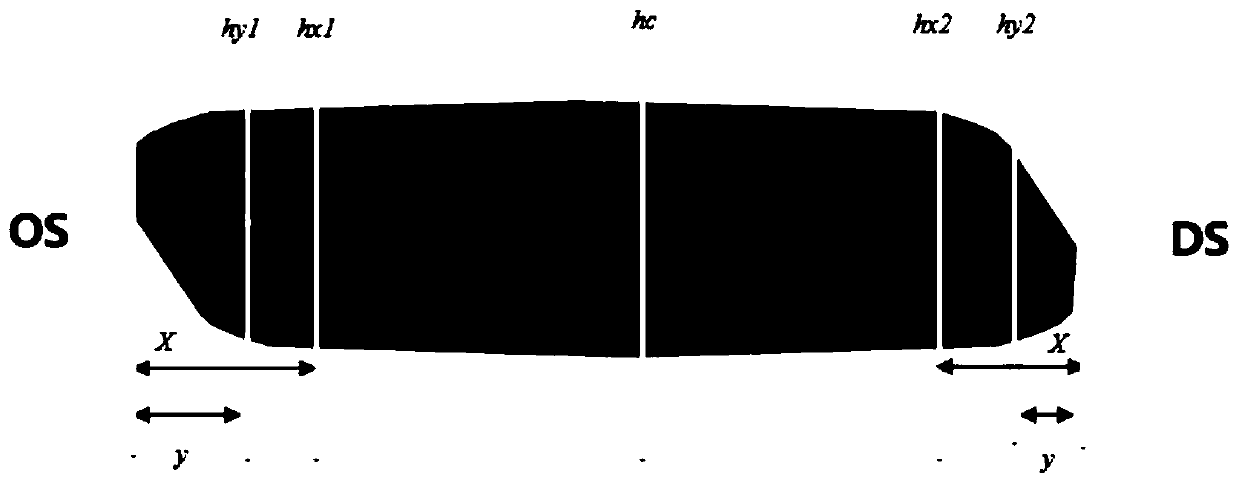

Method for improving double bulges at edge part of broadened intermediate slab in thick plate rolling process

InactiveCN104772332AEliminate double drum deformationImprove plane shapeMetal rolling arrangementsProfile control deviceThick plateSheet steel

Owner:BAOSHAN IRON & STEEL CO LTD

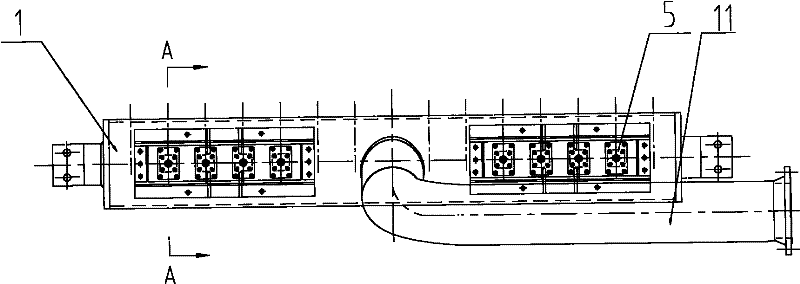

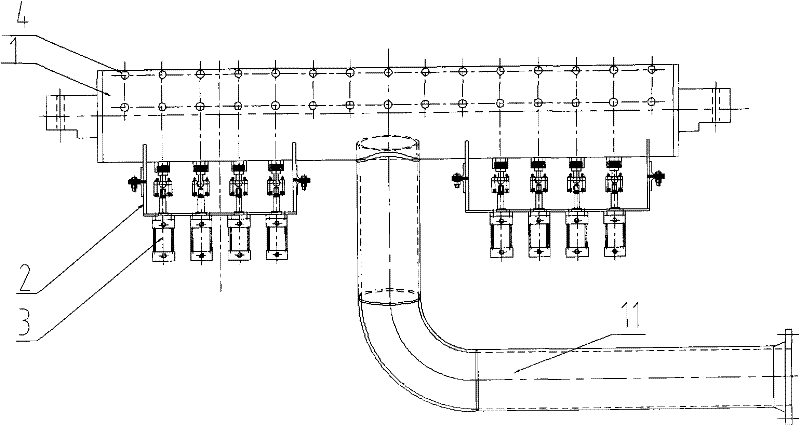

Lower spraying and cooling device arranged between finishing mill frames

ActiveCN102189133AEnsure shapeGuaranteed mechanical propertiesWork treatment devicesMetal rolling arrangementsStrip steelPlunger

Owner:BAOSHAN IRON & STEEL CO LTD +1

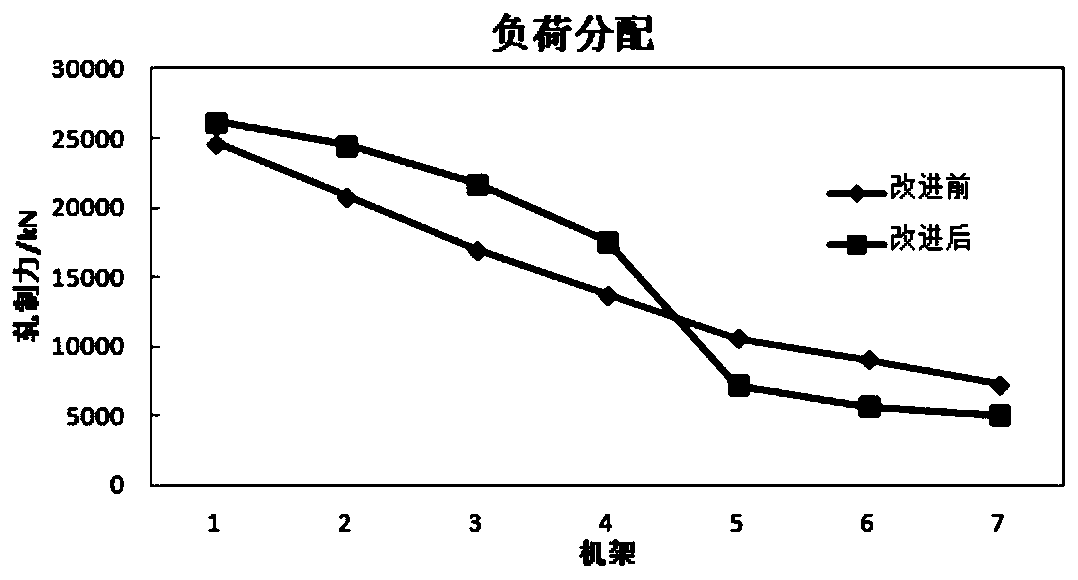

Method of improving wedge control of strip steel during two-phase zone rolling

ActiveCN110216152AReduce rolling forceReduced roll wearMetal rolling arrangementsProfile control deviceReduction rateEngineering

Owner:武汉钢铁有限公司

Improved nodular cast iron rail finishing roll and production method thereof

PendingCN110273100AStrong impact toughnessExtended service lifeRollsMetal rolling arrangementsCrack resistanceDuctile iron

The invention relates to the technical field of finishing rolls, in particular to an improved nodular cast iron rail finishing roll and a production method of the improved nodular cast iron rail finishing roll. The improved nodular cast iron rail finishing roll is provided with a stepped roll body. An upper roll neck is fixed to the upper end of the roll body. A lower roll neck is fixed to the lower end of the roll body. A transmission end is fixed to the lower end of the lower roll neck. According to the improved nodular cast iron rail finishing roll and the production method of the improved nodular cast iron rail finishing roll, the density and red hardness of the roll are greatly improved, the impact toughness and the thermal crack resistance are high, the hardness drop is reduced, and the service life of the roll is prolonged. The production method is simple, the process is reasonable, and wide popularization and use can be conveniently realized.

Owner:CHANGZHOU ZHONGYU FERROALLOY FACTORY

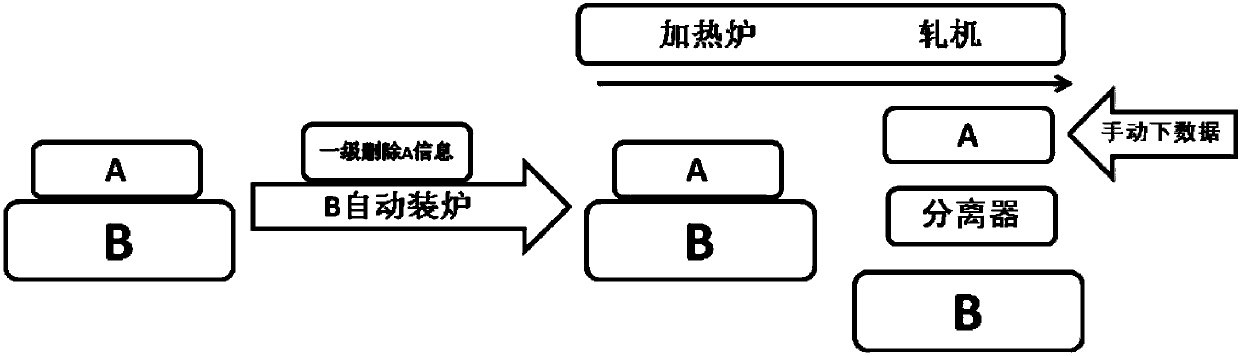

Carrying blank rolling method for producing steel plate of 6mm-thickness limit specification through medium-thickness plate

ActiveCN107790494AAchieve productionOvercome the problem that the specification is limited and cannot be applied to the normal billet size of the heating furnaceMetal rolling arrangementsSheet steelThick plate

Owner:ANGANG STEEL CO LTD

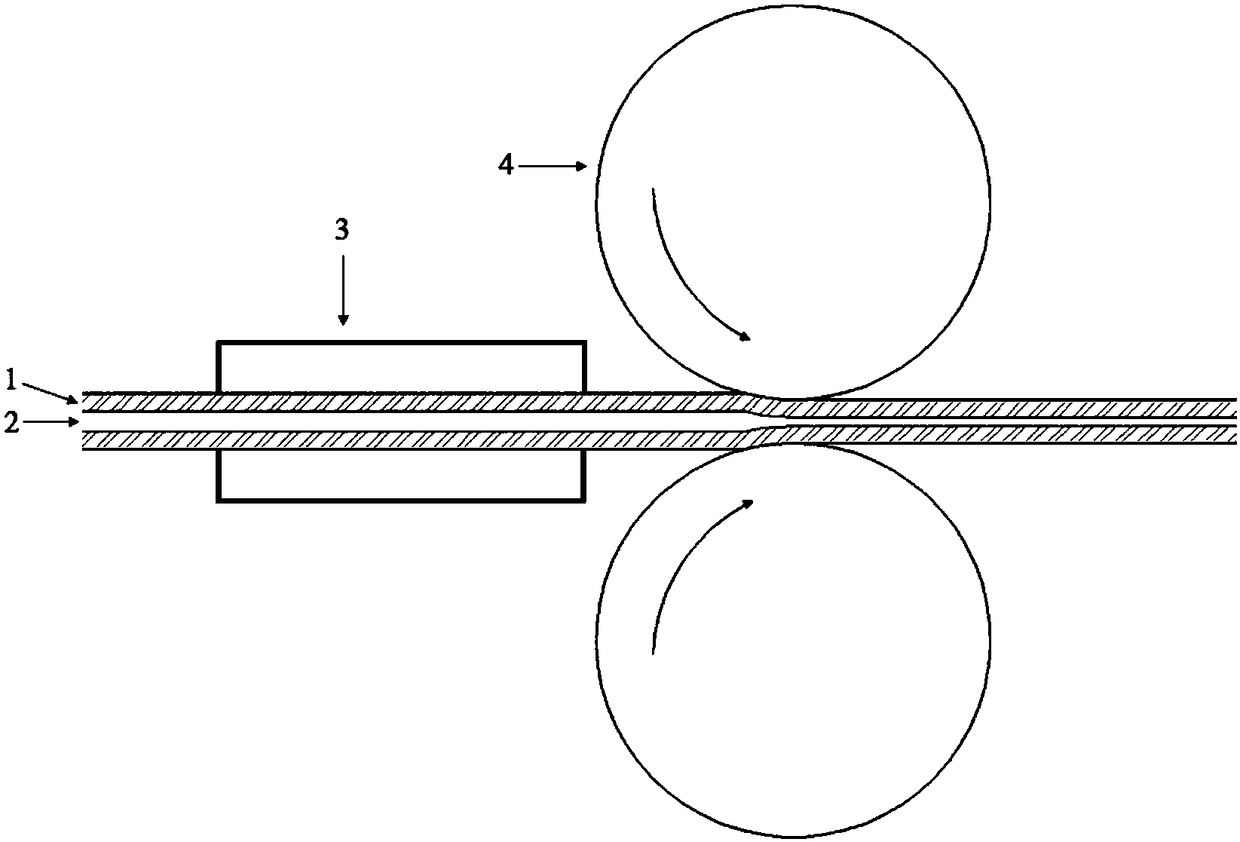

Carrier roller for preventing strip steel from being scratched

InactiveCN112246870AAffect qualityImprove surface qualityMetal rolling arrangementsElectric machineClassical mechanics

The invention provides a carrier roller for preventing strip steel from being scratched. The carrier roller comprises a carrier roller body arranged at an outlet of strip steel manufacturing equipmentand used for lifting the strip steel to be parallel to the outlet; a carrier roller motor assembly arranged at one end of the carrier roller body and used for driving the carrier roller body to rotate in the strip steel moving direction; and a lifting support arranged at two ends of the carrier roller body, wherein the lifting support comprises a first lifting unit and a second lifting unit thatare arranged in a spaced manner, and the first lifting unit and the second lifting unit can support the carrier roller body to enable the carrier roller body to be parallel to the strip steel; the first lifting unit comprises a first lifting support and a first lifting platform movably connected to the first lifting support, and the top of the first lifting platform is connected with the carrier roller motor assembly. As the carrier roller device for lifting the strip steel is arranged at the outlet of the strip steel manufacturing equipment, the strip steel does not fluctuate due to self weight and tension fluctuation after flying shearing, so that the surface of the strip steel is prevented from being scratched, and the quality of the strip steel is not influenced.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

Cold rolling mill with feeding device and discharging device

InactiveCN109719127AEasy to placeSimple structureMetal rolling arrangementsBiochemical engineeringUltimate tensile strength

Owner:黄石市龙飞精密金属加工有限公司

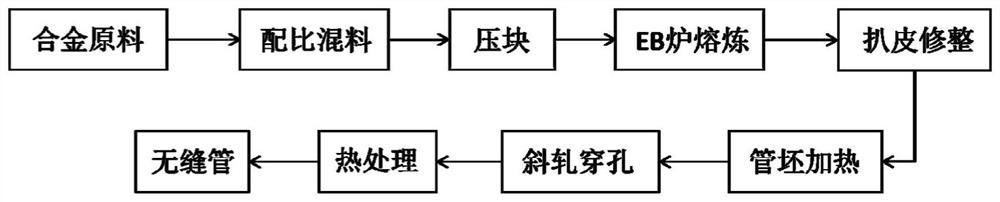

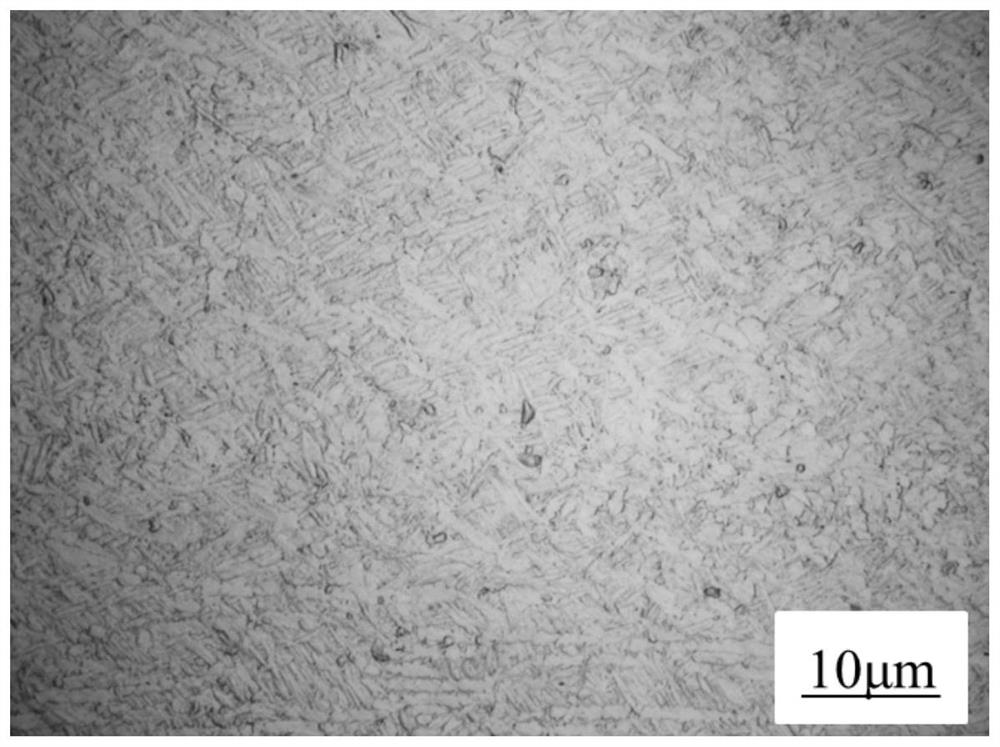

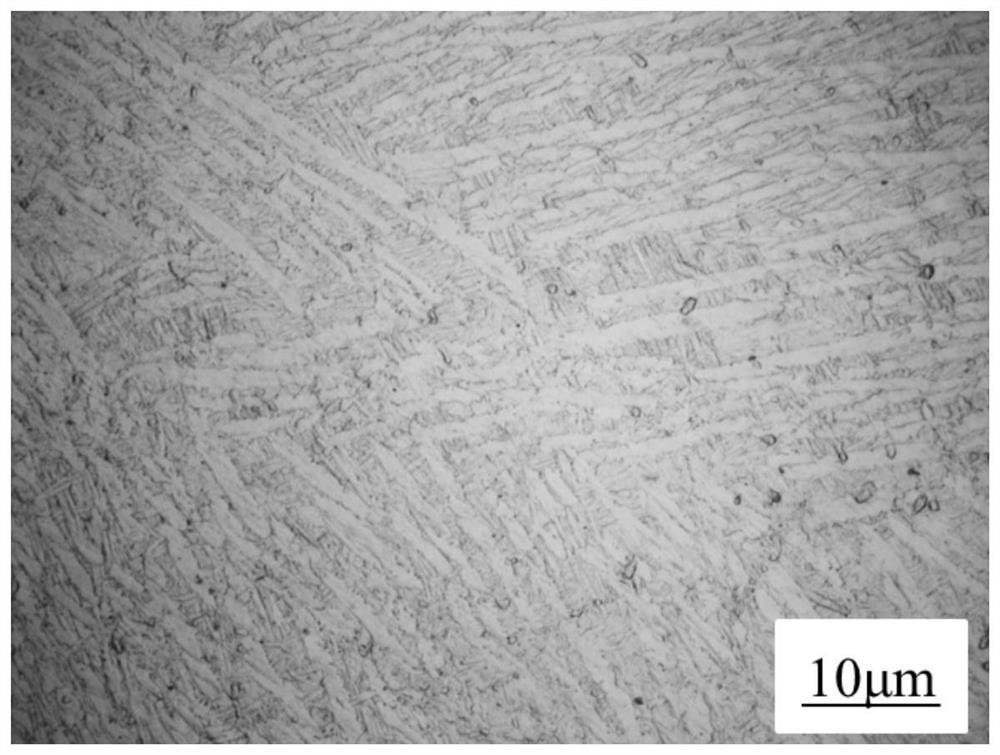

Short-process preparation method of Ti-Al-V-Fe alloy seamless tube

Owner:KUNMING UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap