Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Evenly distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

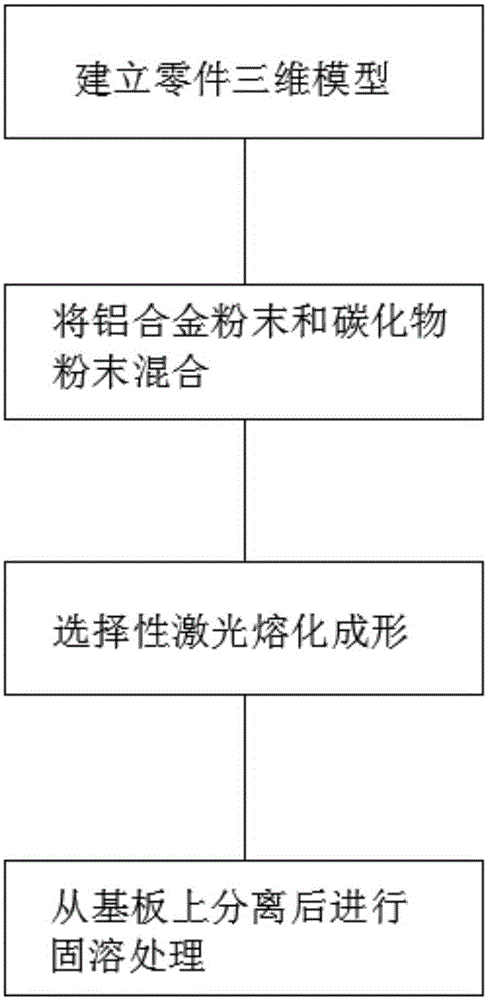

Rapid manufacturing method for laser remelting scanning carbide dispersion strengthened aluminum alloy

ActiveCN105112708AFast preparationMade preciselyAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional modelMuffle furnace

The invention discloses a rapid manufacturing method for laser remelting scanning carbide dispersion strengthened aluminum alloy. The method includes the following steps that (1) a three-dimensional part model is established on a computer, and then the three-dimensional part model is converted to be in an STL format and imported into selective area laser melting forming equipment; (2) aluminum alloy powder and carbide powder are mixed, and then are ball-milled through a ball grinder to be evenly mixed; (3) the ball-milled mixed powder is transferred into the selective area laser melting forming equipment, and the mixed powder is formed according to three-dimensional model data under the protection of inert gases; and (4) a formed part is separated from a substrate by the adoption of the wire-electrode cutting technology, and then is subjected to solution treatment in a muffle furnace, afterwards, quenching is carried out, ceramic bead sand blasting treatment is conducted, and accordingly a finished product is obtained. By the adoption of the method, dispersion strengthening phases can be evenly distributed, and therefore the purposes of obtaining the ceramic phase dispersion strengthened aluminum alloy and improving the high-temperature performance of the aluminum alloy are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Mullite-based ceramic material and preparation method thereof

Owner:长沙中瓷新材料科技有限公司

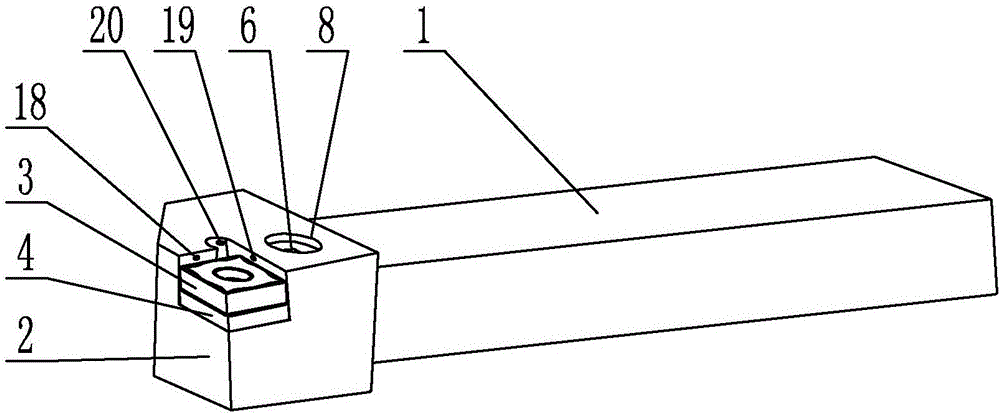

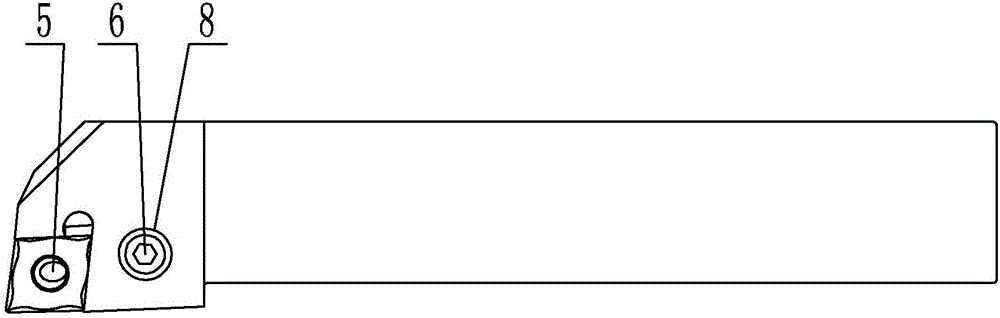

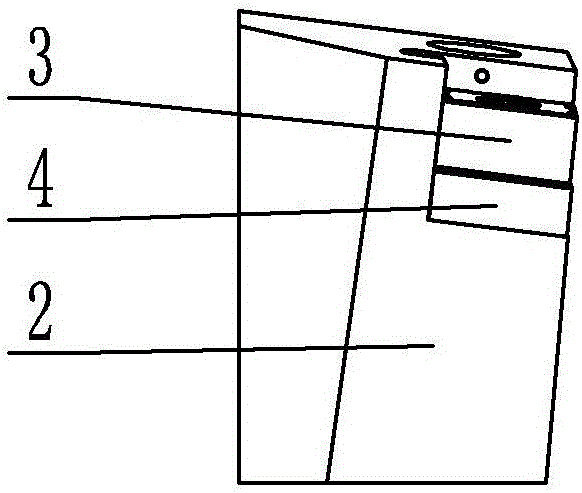

High-pressure cooling turning tool

InactiveCN106424786AEvenly distributedExtended service lifeCutting insertsTurning toolsBreaking capacityCoolant channel

Owner:HARBIN UNIV OF SCI & TECH

Vanadium phosphorus oxygen catalyst for preparing acrylic acid and acetic acid by oxidation of propane and preparation method thereof

InactiveCN1557549ASmall particlesEvenly distributedPhysical/chemical process catalystsOrganic compound preparationIsobutanolPolyethylene glycol

The VPO catalyst is prepared with V2O2 and phosphoric acid in mixed isobutanol-benzyl alcohol solvent, and has polyglycol as dispersant. It has P / V atom rati of 1.1, specific surface area as high as 70-78 sq m / g and main material phase of vanadyl pyrophosphate. It is used the catalyst for oxidizing propane with air to preparing acrylic acid and acetic acid, and has single pass converting rate at the reaction temperature range of 380-400 deg.c of 37-72 % typically, acrylic acid selectivity of 5-35 % and total acrylic acid and acetic acid selectivity of 19-83 %. Under proper reaction condition, it has the propane converting rate of 40.3 %, acrylic acid selectivity of 33.8 %, acetic acid selectivity of 49.4 %, acrylic acid yield of 13.6 %, total acrylic acid and acetic acid yield of 33.5 % and space-time yield obviously higher than that with available similar catalyst. The preparation process of the catalyst is also disclosed.

Owner:NANJING UNIV

Method for preparing high-viscosity chitosan quick hemostatic patch

InactiveCN103386146AIncrease viscosityHigh degree of deacetylationAbsorbent padsBandagesCross-linkFreeze-drying

The invention discloses a method for preparing a high-viscosity chitosan quick hemostatic patch. The method comprises the following steps: preparing chitosan gel from high-viscosity chitosan having a deacetylation degree in the range from 80% to 90%, drying the chitosan gel and then immersing one single side of the chitosan gel into a mixed solution of chloroacetic acid and isopropanol for carboxymethylation, and then soaking the chitosan gel into a 30% glycerol solution for 30 minutes and then draining; and finally, carrying out a cross-linking reaction by using a calcium chloride solution so as to introduce calcium ions and thrombin, and then carrying out vacuum freeze-drying, thereby obtaining the high-viscosity chitosan quick hemostatic patch. Raw materials used for the process of the method are low in cost; the process is simple and convenient, and short in period; the obtained chitosan hemostatic patch is high in adhesiveness, and capable of quickly stopping bleeding of a wound under the promotion effect of the calcium ions and the thrombin.

Owner:黄耀江 +2

Silicon-containing water repellent finishing agent

Owner:浙江东进新材料有限公司

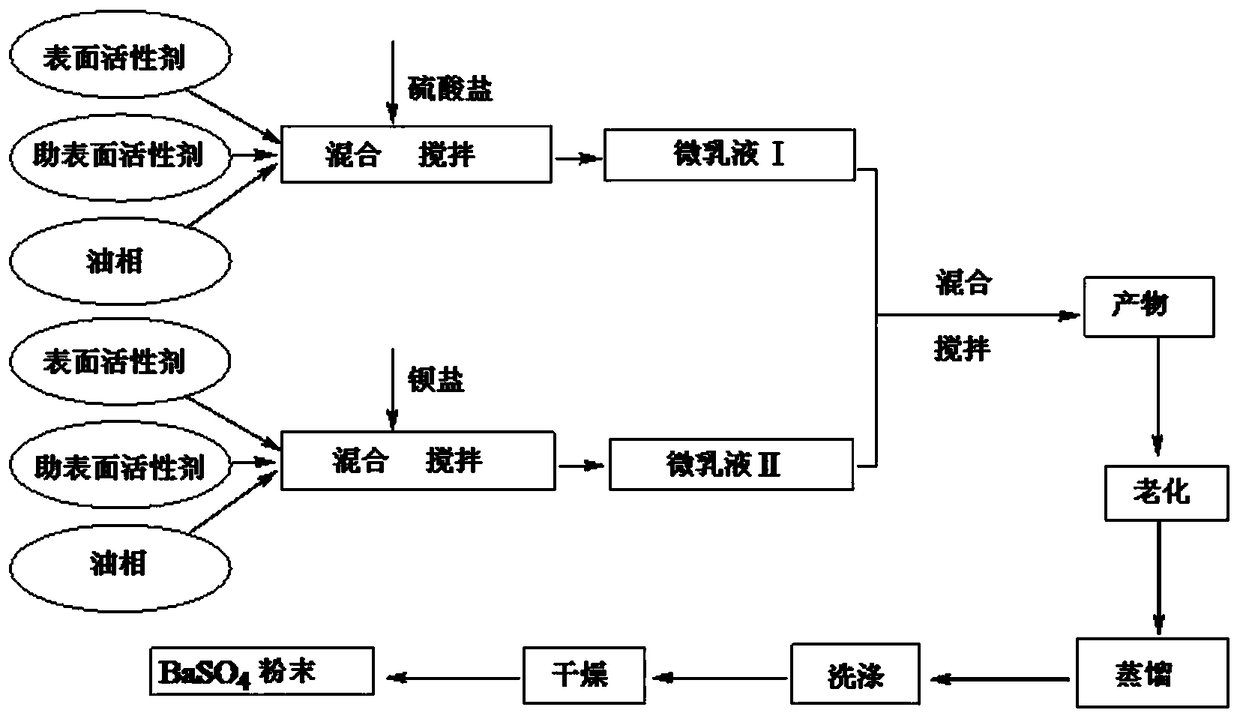

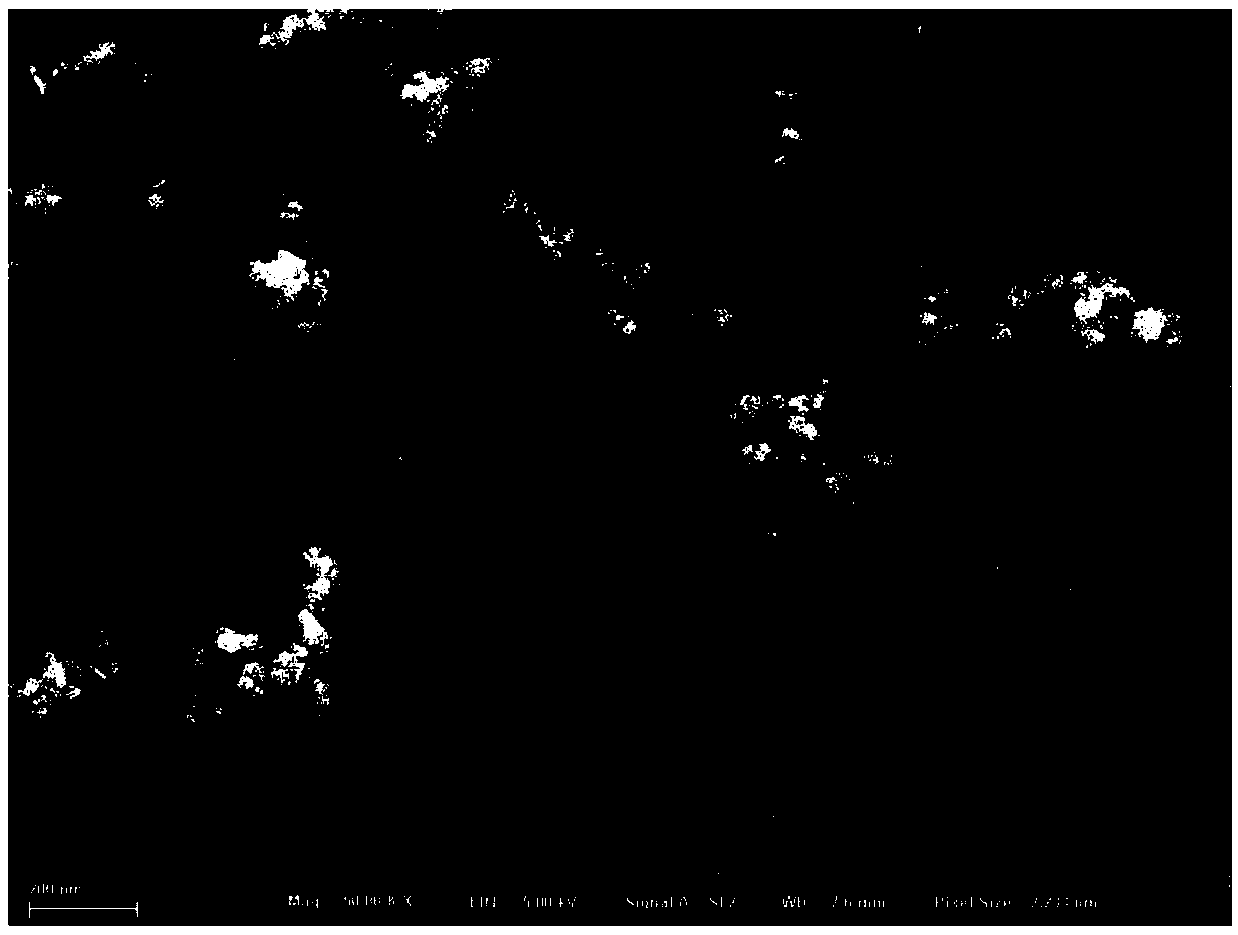

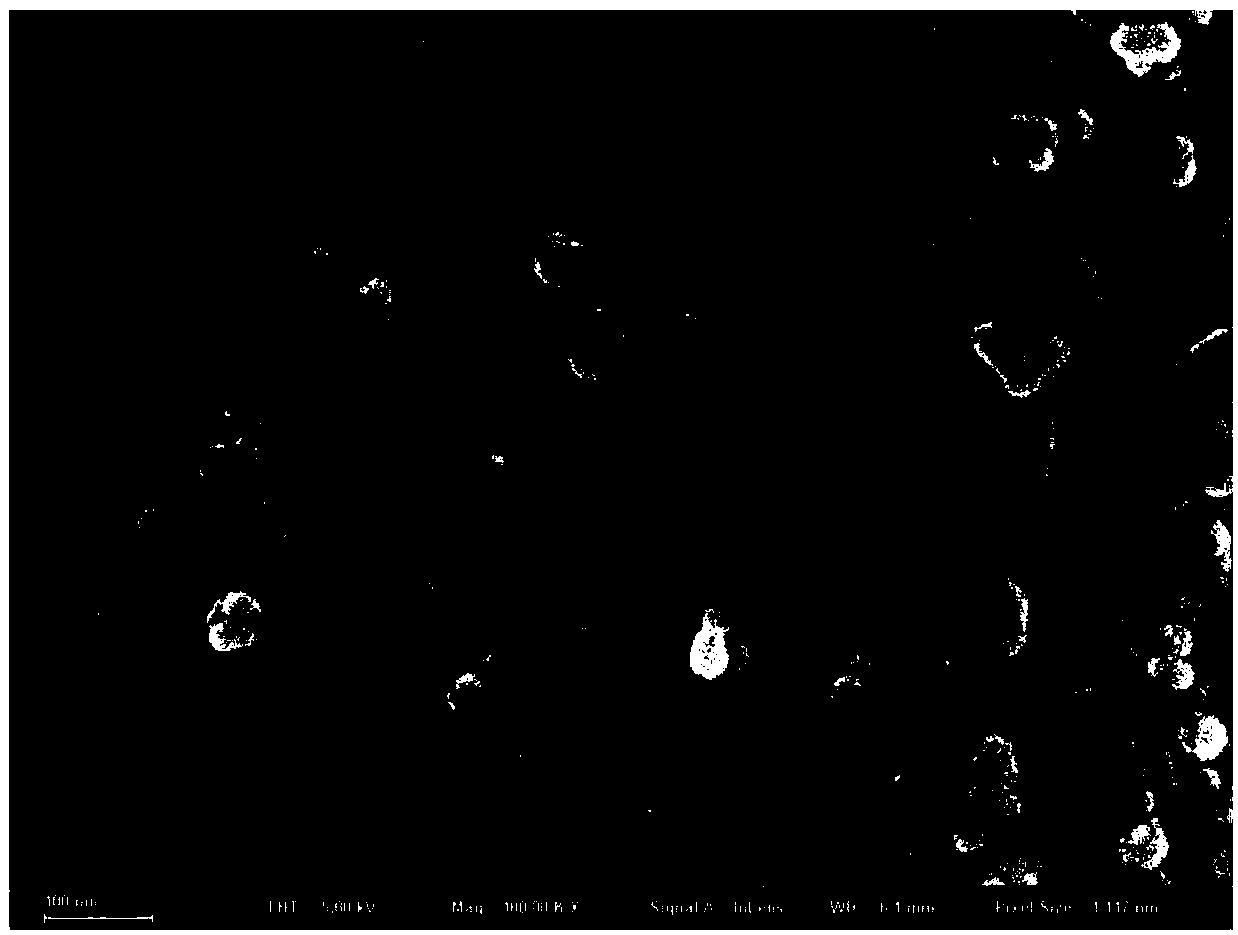

Method for preparing nanometer barium sulfate particles by water in oil type micro-emulsion method

InactiveCN108862356ARegular shapeSmall particle sizeMaterial nanotechnologyCalcium/strontium/barium sulfatesWater in oilMineralogy

The invention belongs to a method for preparing nanometer barium sulfate particles by a water in oil type micro-emulsion method, and belongs to the technical field of nanometer material preparation. Surfactants, cosurfactants, oil phases, sulfate or barium salt water solution are uniformly mixed to respectively obtain micro emulsion I and micro emulsion II; after the mixed reaction of the micro emulsion I and the micro emulsion II, distillation demulsification, centrifugation, washing and drying are performed to obtain the nanometer barium sulfate particles. The high system volume increase water quantity ratio, i.e., the low surfactant and oil phase consumption is used for obtaining the barium sulfate particles with the regular appearance and uniform particle diameter distribution; the particle size and particle diameter distribution are controllable; the reaction cost is effectively reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

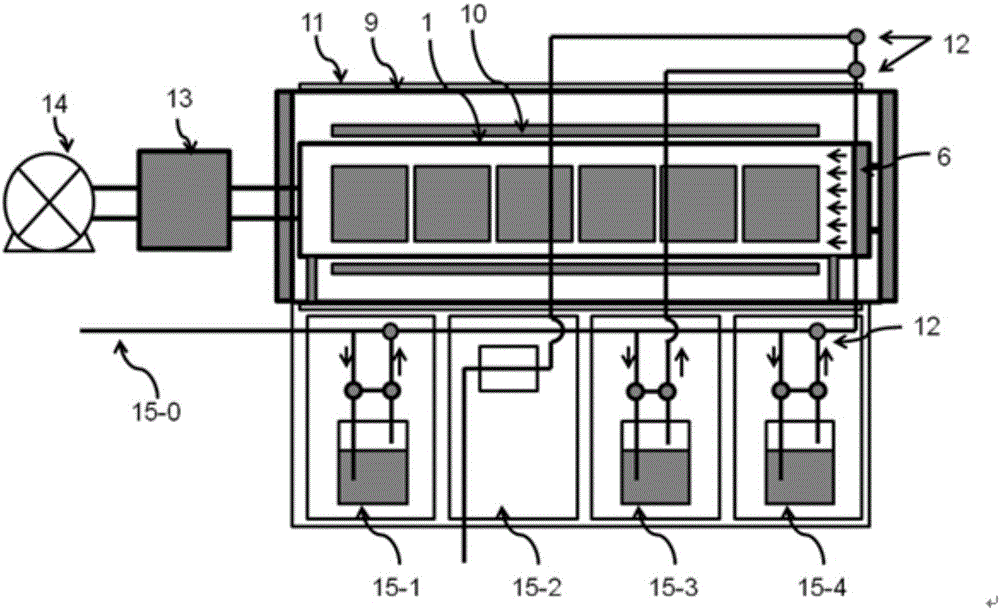

Atomic layer deposition-based vacuum coating device for solar cell production

ActiveCN105925960AUniform and stable flow directionEvenly distributedChemical vapor deposition coatingExhaust gasGas pipeline

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

TDA dehydrating tower

InactiveCN101444677AEvenly dispersedImprove throughputAmino compound purification/separationFractional distillationGas phaseEngineering

The invention disclose a TDA dehydrating tower, which comprises a tower body, a circumfluence supply pipe, a recycle gas phase inlet and a TDA feeding hole. An upper distributing groove communicated with the circumfluence supply pipe is formed at the top in the tower body, an upper packing layer is arranged below the upper distributing groove, a liquid catch plate is arranged at the lower part of the upper packing layer, a liquid receiving tank is fixed at the lower part of the liquid catch plate, a liquid downtake communicated thereof is arranged at the bottom of the liquid receiving tank, the liquid downtake is communicated with a lower distributing groove formed at the lower part of the liquid downtake, and a lower packing layer is arranged at the lower part of the lower distributing groove. The TDA dehydrating tower has the advantages of simple structure, easy disassembly and assembly, low cost, high degree of the heat change and quality change of two phases of gas and liquid, good separating effect and high efficiency.

Owner:YANTAI JULI ISOCYANIC ESTER

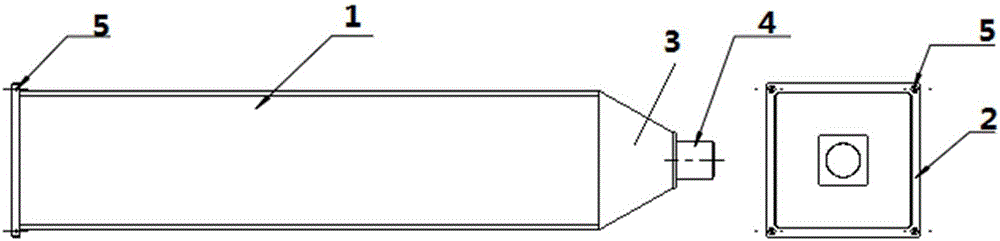

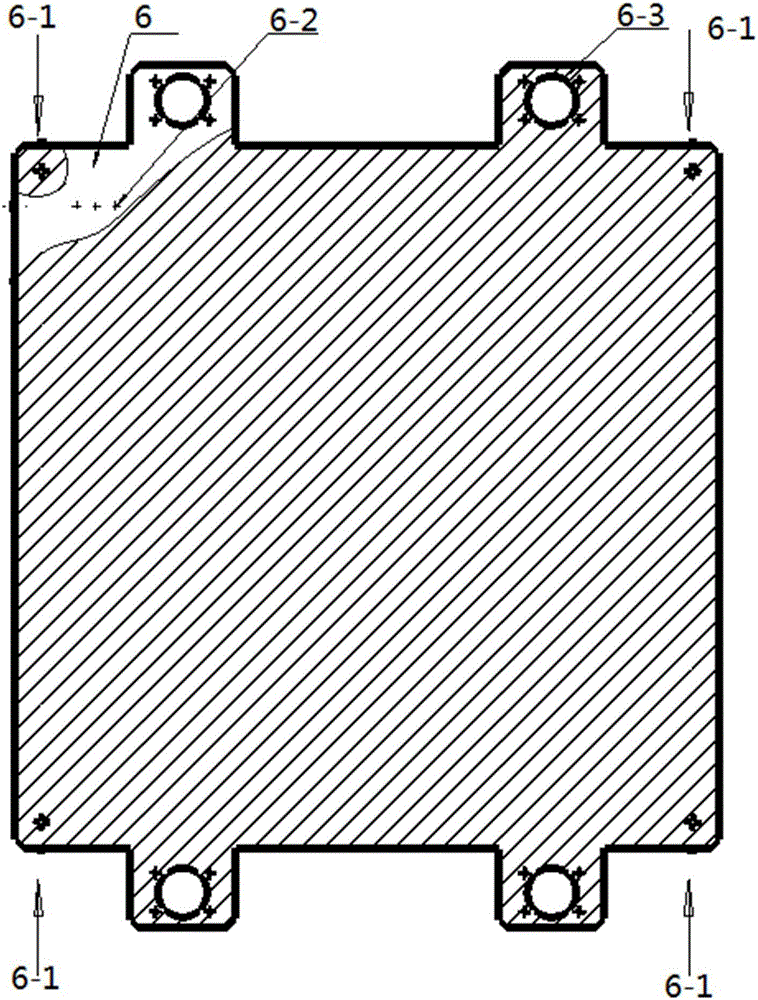

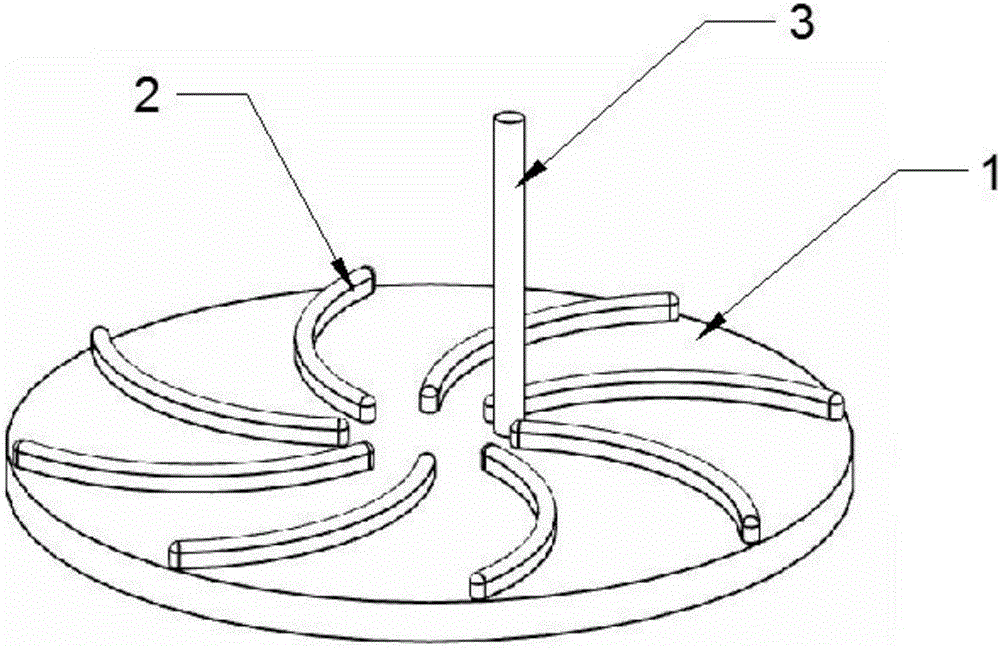

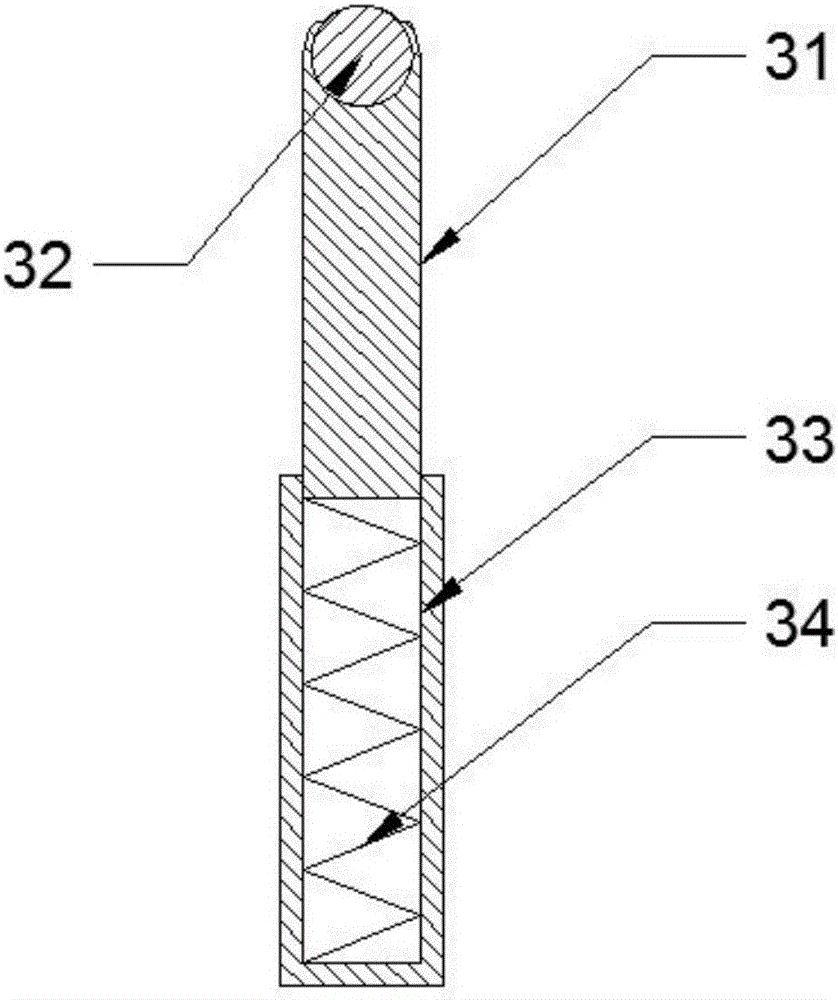

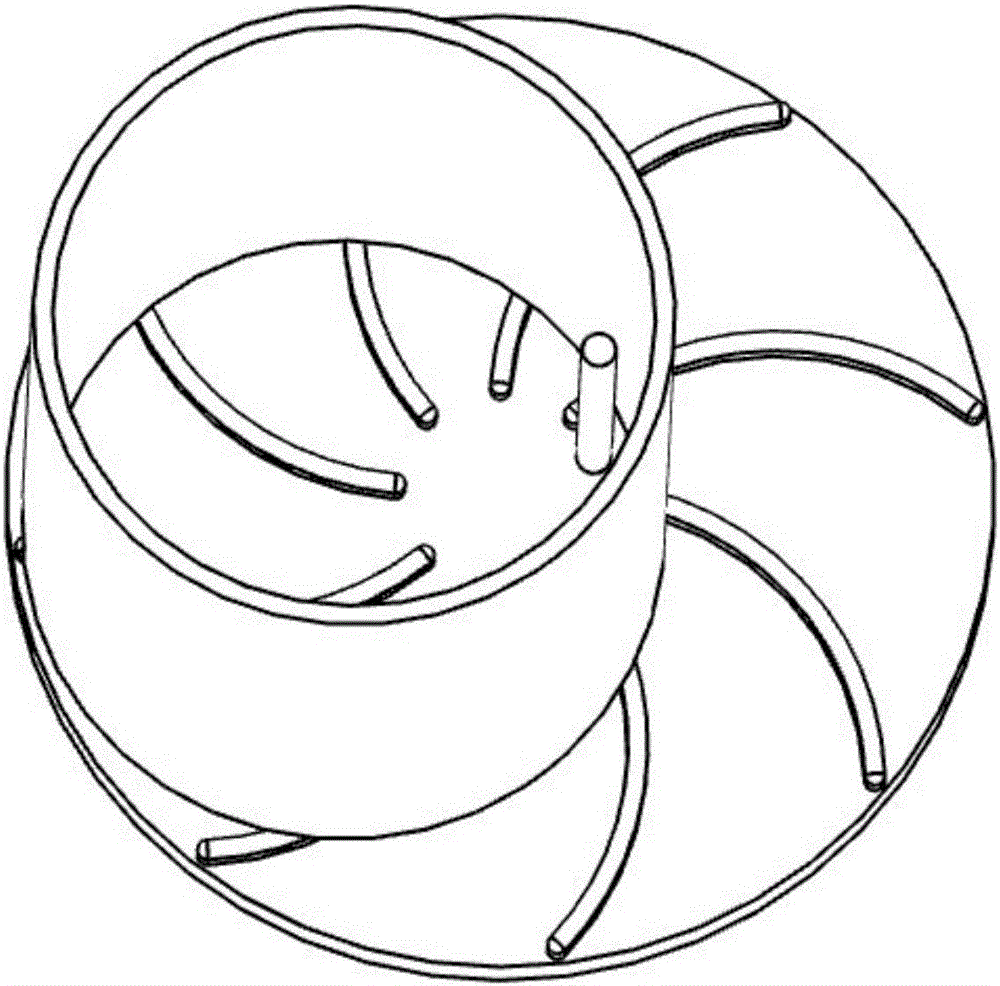

Rolling disk of tea leaf rolling machine

The invention belongs to the filed of rolling machines, and particularly relates to a rolling disk of a tea leaf rolling machine. In order to solve the problem that tea leaves cannot be sufficiently rolled when a conventional rolling machine is used for rolling tea leaves and especially under the condition that a large quantity of tea leaves are rolled, the invention provides the rolling disk of the rolling machine. The rolling disk comprises a rolling disk body (1), battens (2) and a stirring rod (3), wherein the rolling disk body (1) adopts a circular disk-shaped structure; the battens (2) are arc-shaped protrusions radiating all around from the center of the rolling disk body (1); the stirring rod (3) is arranged on the rolling disk body (1), the distance from the stirring rod to the center of a circle is not more than the difference value of the diameter of a rolling barrel and the radius of the rolling disk, and the height of the stirring rod can be adjusted along with the extrusion height of a pressing disk. The stirring rod (3) is arranged for stirring the tea leaves in the rolling process, so that the tea leaves are uniform to roll.

Owner:CHIZHOU JIULONGPU ECO AGRI COMPREHENSIVE DEV CO LTD

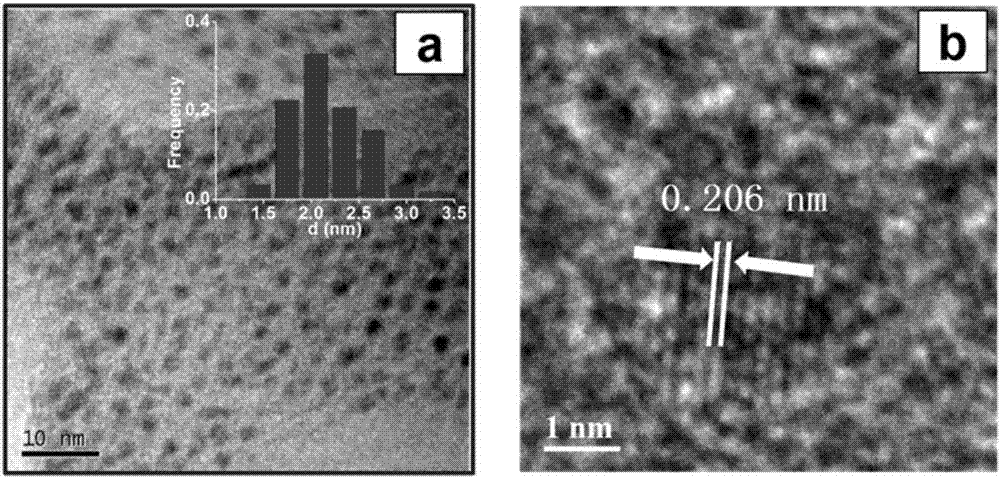

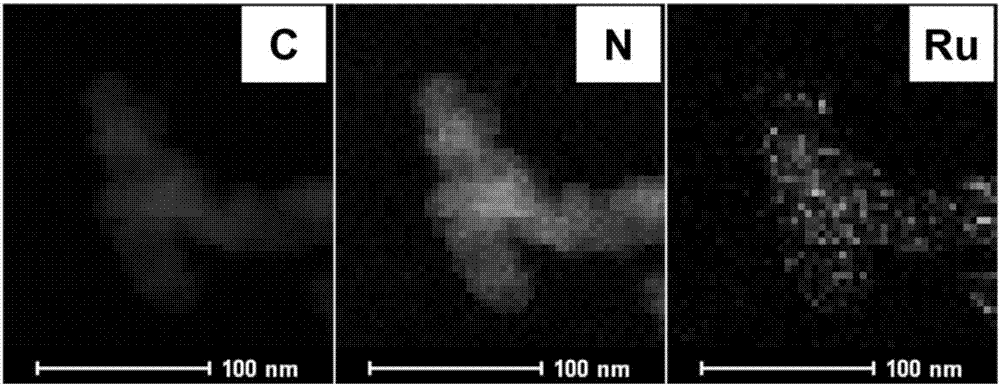

Application of carbon-supported ruthenium nanomaterial in preparation of N-alkyl aromatic amine compound

ActiveCN107954879AAtom utilization is highEvenly distributedAmino compound preparationAmino-hyroxy compound preparationAlkylAromatic amine

Owner:SUZHOU UNIV

Medium for plantation of mushrooms and preparation method

InactiveCN107324916AImprove the growing environmentNutritiousBiocideBio-organic fraction processingBiotechnologyEggshell

The invention provides a medium for plantation of mushrooms and a preparation method. The medium comprises the following components: dried manure, plant straw, chitosan, Stevia rebaudiana residues, eggshells, shell powder, peptone, soybean meal, wheat bran, lime, attapulgite clay, diatomite, an additive, and a bacterial strain. The preparation method comprises the following steps: the additive is extracted at first, the additive and attapulgite clay are mixed and adsorbed, residual components are mixed and fermented, and the medium is obtained. The medium can provide sufficient nutrition for growth of mushrooms, also has good water retention and permeability, and provides a better growth environment for mushrooms.

Owner:ANHUI FARMING NIANHUA AGRI DEV CO LTD

High-thermal-conductivity corrosion-resistant CuFe alloy, plate strip and preparation method of high-thermal-conductivity corrosion-resistant CuFe alloy

ActiveCN114075633AEasy to operateEvenly distributedFurnace typesHeat treatment furnacesAlloyCorrosion resistant

Owner:CENT SOUTH UNIV +1

Fuel cell leveling layer composition and preparation method thereof as well as gas diffusion layer

InactiveCN101540405AEvenly distributedHigh mechanical strengthCell electrodesFuel cell detailsCarbon paperChemistry

Owner:HANERGY TECH

Method for improving distribution uniformity of LED (Light Emitting Diode) encapsulated fluorescent powder

InactiveCN103151434AEliminate "external electric fieldImprove light and color yieldSemiconductor devicesPotential differenceSilica gel

The invention belongs to the field of semiconductor illumination and particularly relates to a method for improving LED (Light Emitting Diode) encapsulation. The method for improving the LED encapsulation comprises the following steps that LED chips are fixedly arranged on a substrate containing a printed circuit layer; cathodes of the chips are connected with the cathode of the printed circuit layer of the substrate; anodes of the chips are connected with the anode of the printed circuit layer of the substrate; the anode of the printed circuit layer of the substrate is connected with the cathode of the printed circuit layer; the anode and the cathode of the printed circuit layer are connected in a short-circuit way; a mixture of well-proportioned fluorescent powder and silica gel is stirred and then coated onto the chips; and a light source semi-finished product is put in a roaster for roasting. With the adoption of the method for improving LED light source encapsulation provided by the invention, through the short-circuit connection between the anode and the cathode of the substrate, the anodes and the cathodes of the chips are located on the same potential difference, so that an external electric field resulting from LED intrinsic absorption is eliminated; and therefore, the purpose of evenly distributing the fluorescent powder is realized, and the light color yield of a light source product is further improved.

Owner:SHANGSHUN ELECTRONIC TECH (CHINA) CO LTD

Method for preparing nanometer flaky yttrium oxide powder

InactiveCN102531023ACalcination temperature is lowEvenly distributedNanotechnologyRare earth metal compoundsAcid radicalAlcohol

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Red cell membrane encapsulated polyester-type As2O3-supported nano particles and preparation method thereof

ActiveCN106943378AEvenly distributedGood sustained releaseAntineoplastic agentsInorganic active ingredientsAgglutinationBlood concentration

Owner:SHANGHAI JIAO TONG UNIV

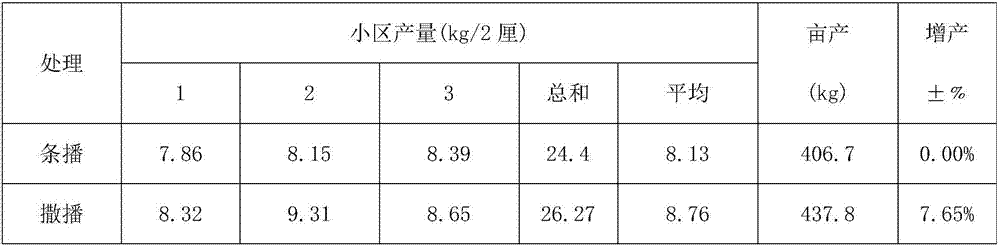

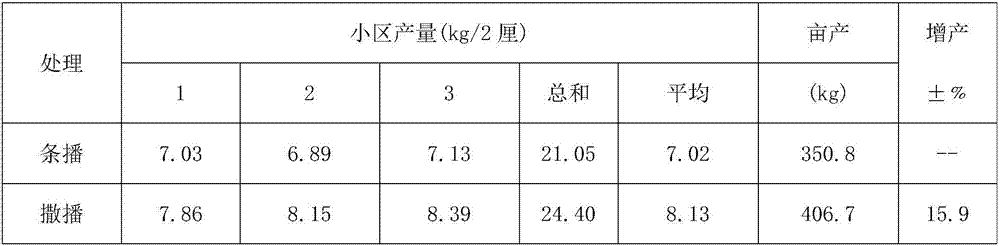

Broadcast sowing planting method for millets

ActiveCN106912289AConducive to full developmentEvenly distributedCultivating equipmentsPlant cultivationEarth surfaceIrrigation

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Preparing method for modified fluorgypsum powder for plastering anhydrite

Owner:ANHUI JINYANG FLUORINE CHEM

Heat pump unit and gas-liquid two-phase uniform distribution method

ActiveCN105805970ASolve the uniform distributionAvoid wastingMechanical apparatusCompression machines with non-reversible cycleElectronic expansion valveElectromagnetic valve

The invention relates to the technical field of heat pump units, in particular to a heat pump unit and a gas-liquid two-phase uniform distribution method. The heat pump unit comprises a compressor, an oil separator communicating with the compressor, a condenser communicating with the oil separator, and a parallel two-phase flow distribution type evaporator communicating with the compressor; a first ball valve, a drying filter, an electronic expansion valve and a second ball valve are sequentially arranged between the condenser and the parallel two-phase flow distribution type evaporator to form a first loop; an oil return angular ball valve and an oil return filter are sequentially arranged between the oil separator and the compressor to form a second loop; an oil return electromagnetic valve, a jet pump and a compressor input end ball valve are sequentially arranged between the parallel two-phase flow distribution type evaporator and the compressor; and the jet pump communicates with the condenser to form a third loop. The heat pump unit has the beneficial effect that uniform distribution of expansion valve throttling gas-liquid two-phase refrigerants can be achieved.

Owner:ZHEJIANG YINGGU ENERGY SAVING EQUIP

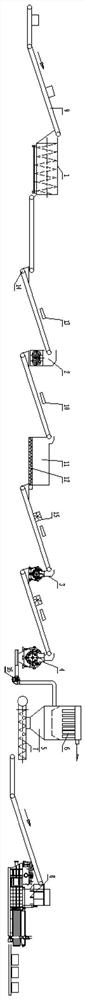

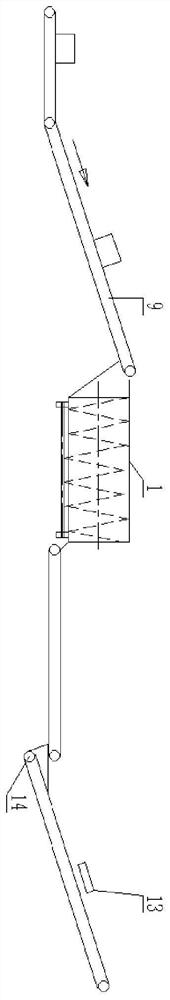

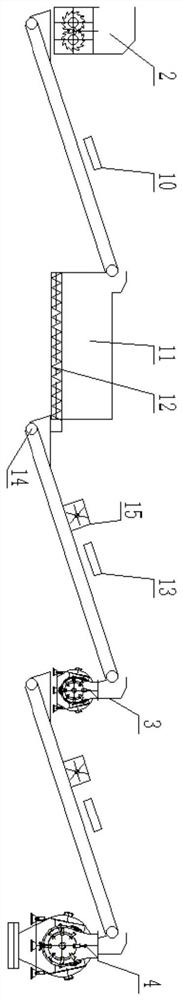

Dry pulping system and dry pulping process

ActiveCN112853788AAvoid water pollution and wasteAvoid dust pollutionPaper recyclingFibrous raw materialsMaterial SeparationProcess engineering

The invention provides a dry pulping system. The dry pulping system comprises a scattering unit, a crushing unit, a material separation unit, an impurity removal unit and a packaging unit, wherein the scattering unit comprises a bale breaking machine; the crushing unit comprises a shredding machine, a scattering and crushing machine and a fiber regeneration machine; the material separation unit comprises a material separation bin and a pulse dust collector; the impurity removal unit comprises a light impurity removal mechanism and a heavy impurity removal mechanism; the packaging unit comprises a screw extruder and a packaging machine; and the bale breaking machine, the shredding machine, the scattering and crushing machine, the fiber regeneration machine and the packaging machine are connected through a belt conveyor. The invention further provides a dry pulping process. The dry pulping process comprises the dry pulping system and further comprises the step that (1) waste paperboards are scattered and fed into the shredding machine for coarse crushing so as to obtain a long-strip-shaped material with a width ranging from 60 mm to 80 mm and a length ranging from 170 mm to 300 mm.

Owner:SHANDONG JIEFENG MACHINERY MFG

LED fluorescent lamp

ActiveCN107906391AEvenly distributedImprove mechanical propertiesGlobesLighting heating/cooling arrangementsAluminium alloyFluorescent lamp

Owner:NINGBO DUOLIPU IND & TRADE CO LTD

Manufacturing technology of curtain fabric capable of releasing negative ions

InactiveCN111893755AConducive to fixationUniform fixationCurtain accessoriesWoven fabricsFlax fiberChemistry

The invention discloses a manufacturing technology of a curtain fabric capable of releasing negative ions. The manufacturing technology comprises the following steps that S1, flax fibers and polyesterfibers are blended into warps and wefts; S2, the warps and the wefts are woven into a main fabric through warp-weft knitting; S3, bleaching is carried out, wherein the main fabric obtained in S2 is bleached; S4, a finishing liquid is prepared, and the main fabric bleached in S3 is added into the finishing liquid and subjected to dipping; S5, residual liquid is discharged, wherein the residual liquid of the main fabric subjected to dipping in S4 is discharged; and S6, the main fabric without the residual liquid is dried to obtain the main fabric capable of releasing the negative ions. The finishing liquid in S4 comprises, by weight, 6-7 parts of tourmaline ultra-fine powder, 5-7 parts of seaweed carbon ultra-fine powder; 3-4 parts of dispersant, 2-4 parts of a fixing agent, 1-2 parts of apermeating agent and 30-40 parts of deionized water. The curtain fabric has the function of releasing the negative ions, so that volatile gases such as formaldehyde and ammonia in new furniture can beeliminated, and the damage of gases such as formaldehyde to the human body can be reduced.

Owner:SHANGHAI YUQI IND CO LTD

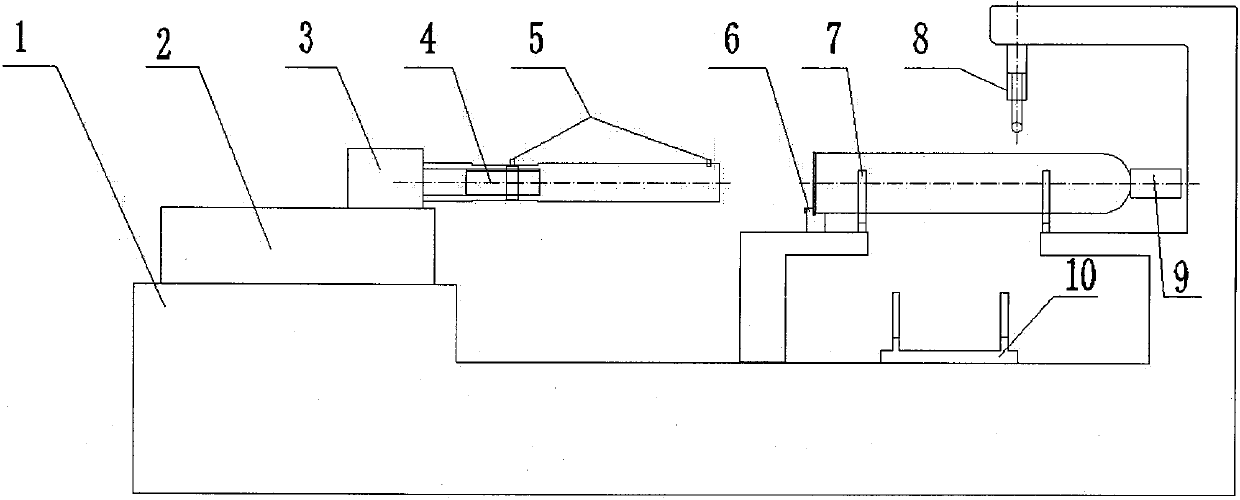

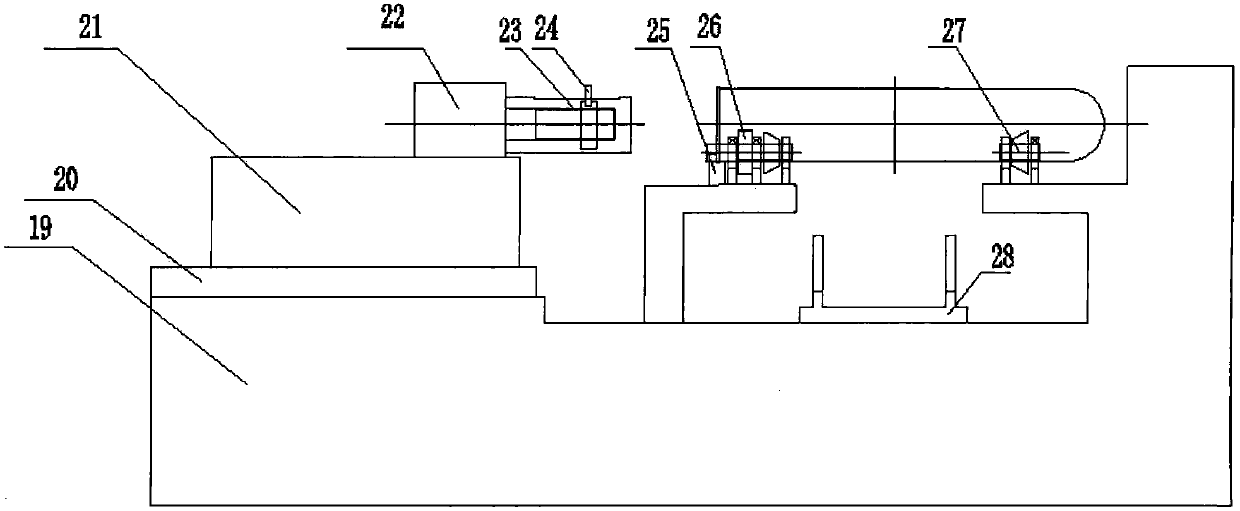

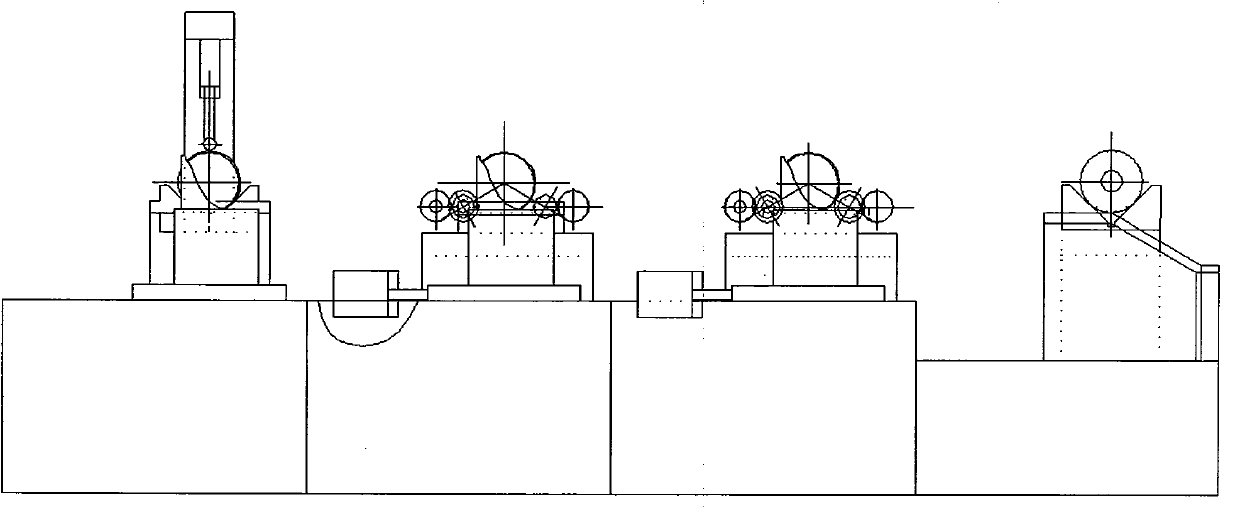

Device for manufacturing electrode for power-adjustable electric heating tube

InactiveCN104270837AImprove detection and electrode preparation accuracyImprove productivity and qualityOhmic-resistance electrodesData transmissionElectric heating

The invention discloses a device for manufacturing an electrode for a power-adjustable electric heating tube. The accuracy of electrodes manufactured through the power-adjustable electrode manufacturing device is high, and the power of the electric heating tube can be adjusted. A mechanical structure of the power-adjustable electrode manufacturing device is composed of a detection mechanism, spraying mechanisms and a separating mechanism. The mechanisms are linked through data transmission. The detection mechanism serves as a core part of the electrode manufacturing device, the resistance value inside the electric heating tube is measured through two measuring heads, the distance between the two measuring heads can be adjusted in the mode that a lead screw is driven by a servo motor, and the adjustment data are recorded in a control device for making preparations for the follow-up spraying mechanisms. The spraying mechanisms of the power-adjustable electrode manufacturing device work on the basis of the detection data and include the fixed spraying mechanism and the adjustable spraying mechanism, and position adjustment is completed through the lead screw. The separating mechanism is used for removing defective products obtained by detecting by the detecting mechanism.

Owner:ZHEJIANG NORMAL UNIVERSITY

Fluorescent powder applying device for LED chip packaging

The invention relates to a fluorescent powder applying device for LED chip packaging, and belongs to the technical field of LED chip packaging. The technical problem to be solved in the invention is that static electricity of fluorescent powder is easy to disappear and the distribution of fluorescent powder on the upper surface and the side surfaces of an LED chip is not uniform when fluorescent powder is applied to the surface of the LED chip by an electric field method. According to the invention, a special applying device is designed. The device comprises a fluorescent powder tank, a pressing rod, a direct-current power source and other components. During fluorescent powder applying by the device, silicone fluorescent powder mixture in the fluorescent powder tank can flow onto an LED chip when the pressing rod presses a circuit board, and is under the action of an electric field. Thus, fluorescent powder with static electricity can quickly move to the surface of the chip, and the distribution of fluorescent powder on the side surfaces and the top surface of the chip is basically uniform.

Owner:SILICON OPTOELECTRONIC TECH (SHANGHAI) CO LTD

Method for preparing polynary nano-cage composite material

InactiveCN107487790AEvenly distributedGood lookingCobalt compoundsHybrid capacitor electrodesChemistryCrystallinity

Owner:JIANGSU UNIV

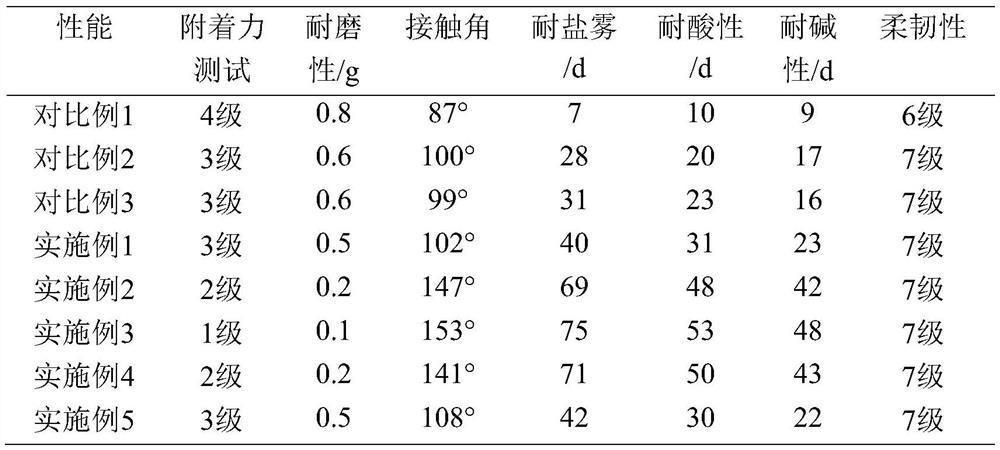

High-performance anti-corrosion composite coating material and preparation method thereof

ActiveCN113337212AHigh temperature control accuracyIncreased durabilityAnti-corrosive paintsAlkaline activationPolythylene glycol

The invention relates to a high-performance anti-corrosion composite coating material, which is prepared from the following components in parts by weight: 30 to 45 parts of a fluororesin monomer, 30 to 45 parts of a styrene monomer, 10 to 40 parts of a hexamethylcyclotrisiloxane monomer, 4 to 8 parts of polyethylene glycol octylphenol ether, 4 to 6 parts of polyethylene glycol, 3 to 8 parts of polyethylene glycol stearate, 20 to 30 parts of water glass 100 to 150 parts of fly ash, 2 to 4 parts of an initiator, 100 to 200 parts of water, 1 to 3 parts of defoaming powder, 5 to 10 parts of sericite powder, 0.2 to 0.5 part of a water reducing agent, 5 to 8 parts of a dispersing agent and 3 to 7 parts of a flatting agent. The invention further discloses a preparation method of the high-performance and high-corrosion-resistance composite coating material. According to the invention, a durability-improved modified fluororesin emulsion is synthesized and prepared in an efficient and environment-friendly mode, and the composite coating obtained after the modified fluororesin and the alkali-activated fly ash are fully mixed and stirred can effectively improve the compressive strength, tensile strength, low permeability, alkali resistance and good corrosion resistance of concrete.

Owner:HUBEI UNIV OF TECH

Submicron Eu<3+>: beta-Li2TiO3 high-purity red fluorescent powder and preparation method thereof

InactiveCN104893721AEvenly distributedHigh color purity of red lightLuminescent compositionsCalcinationDistilled water

Owner:SHAANXI UNIV OF SCI & TECH

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AEvenly distributedFacilitate cross-linkingSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberFiltration

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap