Method for preparing nanometer barium sulfate particles by water in oil type micro-emulsion method

A nano-barium sulfate and microemulsion method, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, large amount of surfactant, and small amount of water for capacity expansion, and achieves convenient operation and equipment. Simple, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

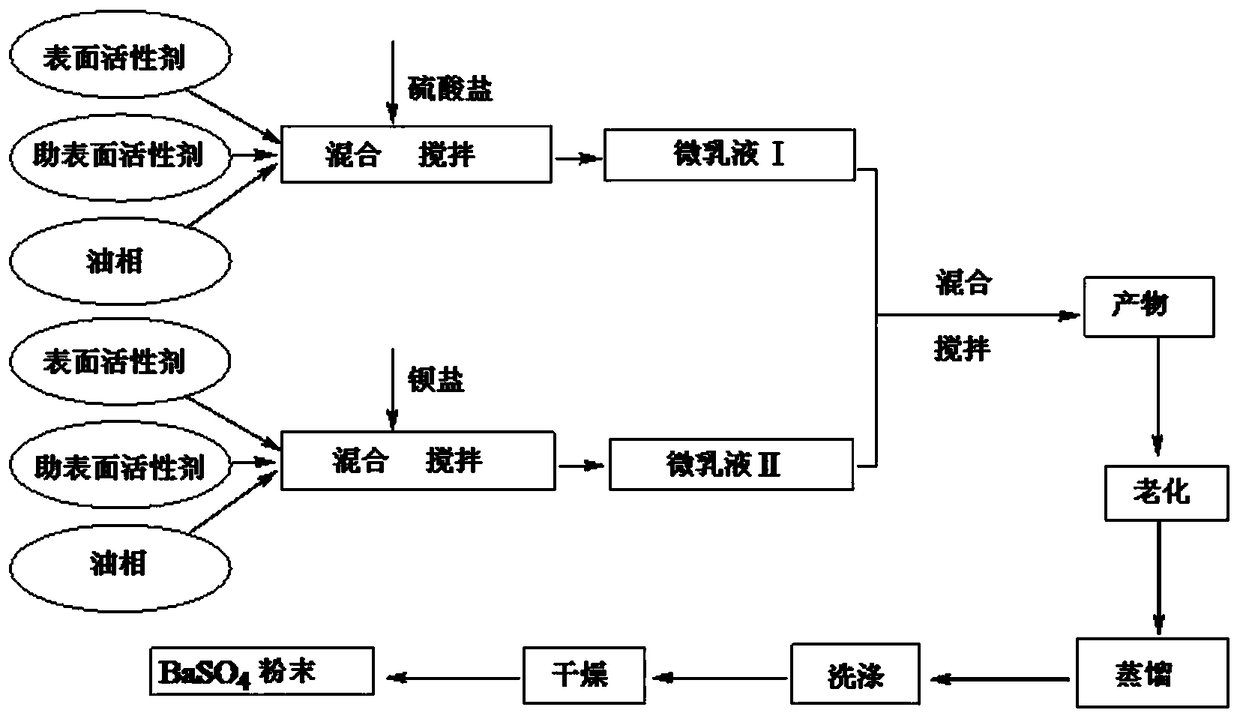

[0024] (1) Put 0.05mol / L ammonium sulfate aqueous solution, Tween 60, n-pentanol, and cyclohexane in a three-necked flask according to the mass ratio of 1:7.5:2.3:87.2, and stir well to form microemulsion I;

[0025] (2) Put 0.05mol / L barium chloride aqueous solution, Tween 60, n-pentanol, and cyclohexane in a three-necked flask according to the mass fraction ratio of 1:7.5:2.3:87.2, and stir well to form microemulsion II;

[0026] (3) Quickly add the microemulsion I to the microemulsion II, seal the three-neck flask, stir at 25°C for 30 minutes, stop the reaction, and age for 12 hours;

[0027] (4) The reaction solution obtained in step (3) is heated at 80°C to break the emulsion, centrifuge, wash, and dry to obtain cubic nano barium sulfate particles with an average particle diameter of 15nm. The SEM diagram is as follows figure 2 shown.

Embodiment 2

[0029] (1) Put 0.1mol / L ammonium sulfate aqueous solution, Tween 40, n-pentanol, and n-hexane in a three-necked flask according to the mass ratio of 1:5:3.8:15, and stir well to form microemulsion I;

[0030] (2) Put 0.1mol / L barium chloride aqueous solution, Tween 40, n-pentanol, and n-hexane into a three-necked flask according to the mass fraction ratio of 1:5:3.8:15, and stir well to form microemulsion II;

[0031] (3) Quickly add the microemulsion I to the microemulsion II, seal the three-neck flask, stir at 25°C for 30 minutes, stop the reaction, and age for 12 hours;

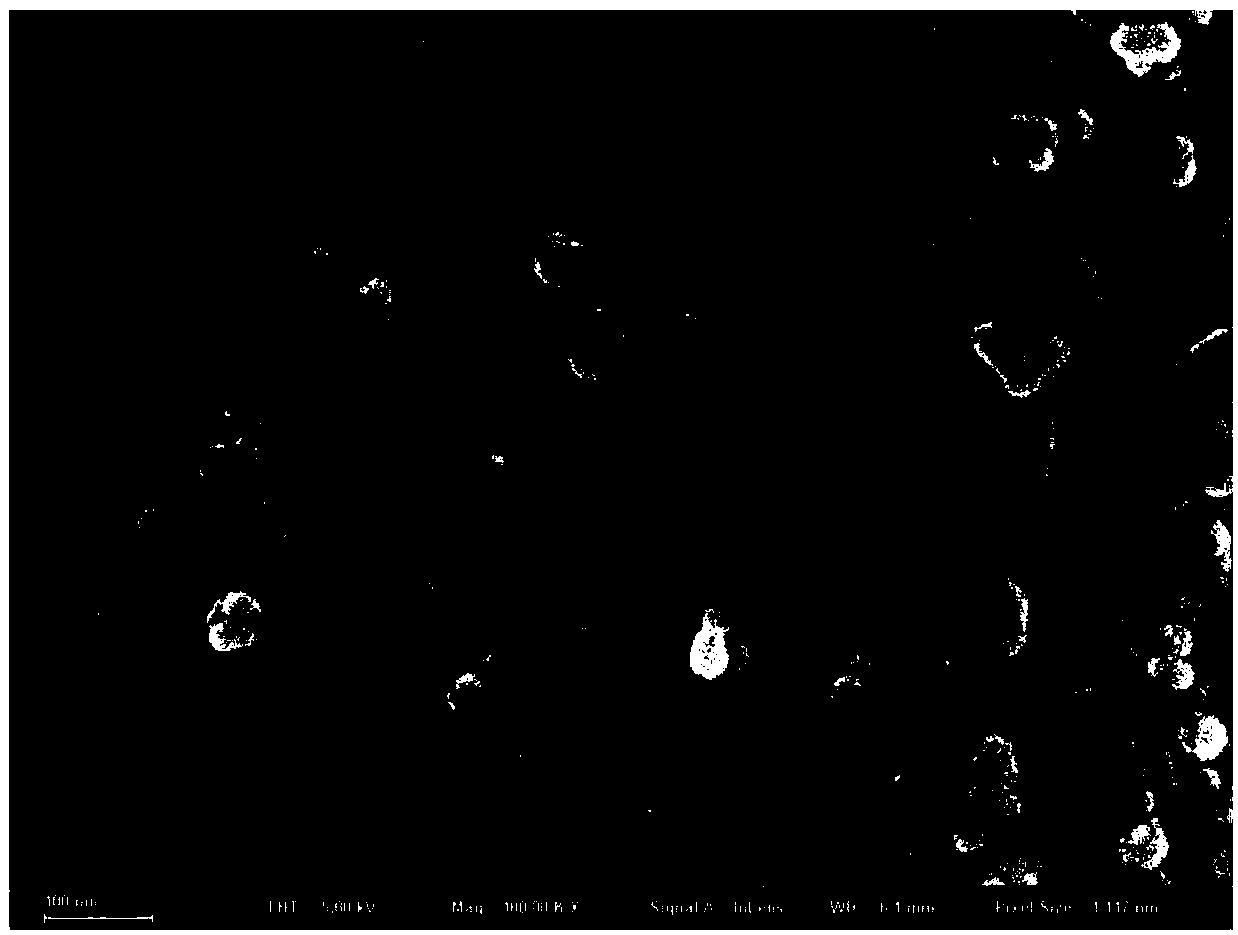

[0032] (4) After the reaction solution obtained in step (3) is heated at 100°C to break the emulsion, centrifuge, wash, and dry, the amorphous nano-barium sulfate particles with a particle size of 21-80nm are obtained, and the SEM diagram is as follows image 3 shown.

Embodiment 3

[0034] (1) Put 0.15mol / L sodium persulfate aqueous solution, Tween 60, n-hexanol, and n-hexane in a three-necked flask according to the mass ratio of 1:12.5:3.1:23.5, and stir well to form microemulsion I;

[0035] (2) Put 0.15mol / L barium acetate aqueous solution, Tween 60, n-hexanol, and n-hexane into a three-necked flask according to the mass fraction ratio of 1:12.5:3.1:23.5, and stir well to form microemulsion II;

[0036] (3) Quickly add the microemulsion I to the microemulsion II, seal the three-neck flask, stir at 25°C for 30 minutes, stop the reaction, and age for 12 hours;

[0037] (4) After the reaction solution obtained in step (3) is heated at 80° C. to demulsify, centrifuge, wash, and dry, the cubic nano-barium sulfate particles with a particle diameter of 32-100 nm are obtained. The SEM diagram is as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap