Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Mass ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In aerospace engineering, mass ratio is a measure of the efficiency of a rocket. It describes how much more massive the vehicle is with propellant than without; that is, the ratio of the rocket's wet mass (vehicle plus contents plus propellant) to its dry mass (vehicle plus contents). A more efficient rocket design requires less propellant to achieve a given goal, and would therefore have a lower mass ratio; however, for any given efficiency a higher mass ratio typically permits the vehicle to achieve higher delta-v.

Functional seedling culturing substrate formula applicable to crop seedling culture of cucumbers, watermelons and melons

InactiveCN103787744ASeedling safetyRapid seedlingHorticultureFertilizer mixturesEcological environmentMass ratio

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Tackifier for drilling fluid and preparation method thereof

ActiveCN104311730AImproved rock carrying capacityThe preparation method is simple and feasibleDrilling compositionCross-linkSalt resistance

The invention relates to a tackifier for drilling fluid and a preparation method thereof, and belongs to the technical field of synthesis of processing agents for oil-field drilling fluids. The tackifier is a net-like polymer obtained by mixing acrylamide, a sulfo-group-containing monomer A and a pyrrolidone monomer B according to the mass ratio of 10:(3-5):(0.7-1.5), adjusting the pH value of the solution, adding a cross-linking agent C, a molecular-weight adjusting agent D and an initiator and performing copolymerization crosslinking. The preparation method is simple and practicable, and short in reaction time. The obtained tackifier has good salt resistance, has the temperature resistance up to 135 DEG C, has good effects of increasing shear viscosity and reducing filter loss when being applied to drilling fluids, is capable of substantially improving the cutting carrying capability of the drilling fluids under the condition of high temperature, has the effect obviously better than a tackifier normally used on site, is widely applicable to fresh-water drilling fluids and saturated brine drilling fluids, and has relatively good application prospect.

Owner:CHINA PETROCHEMICAL CORP +1

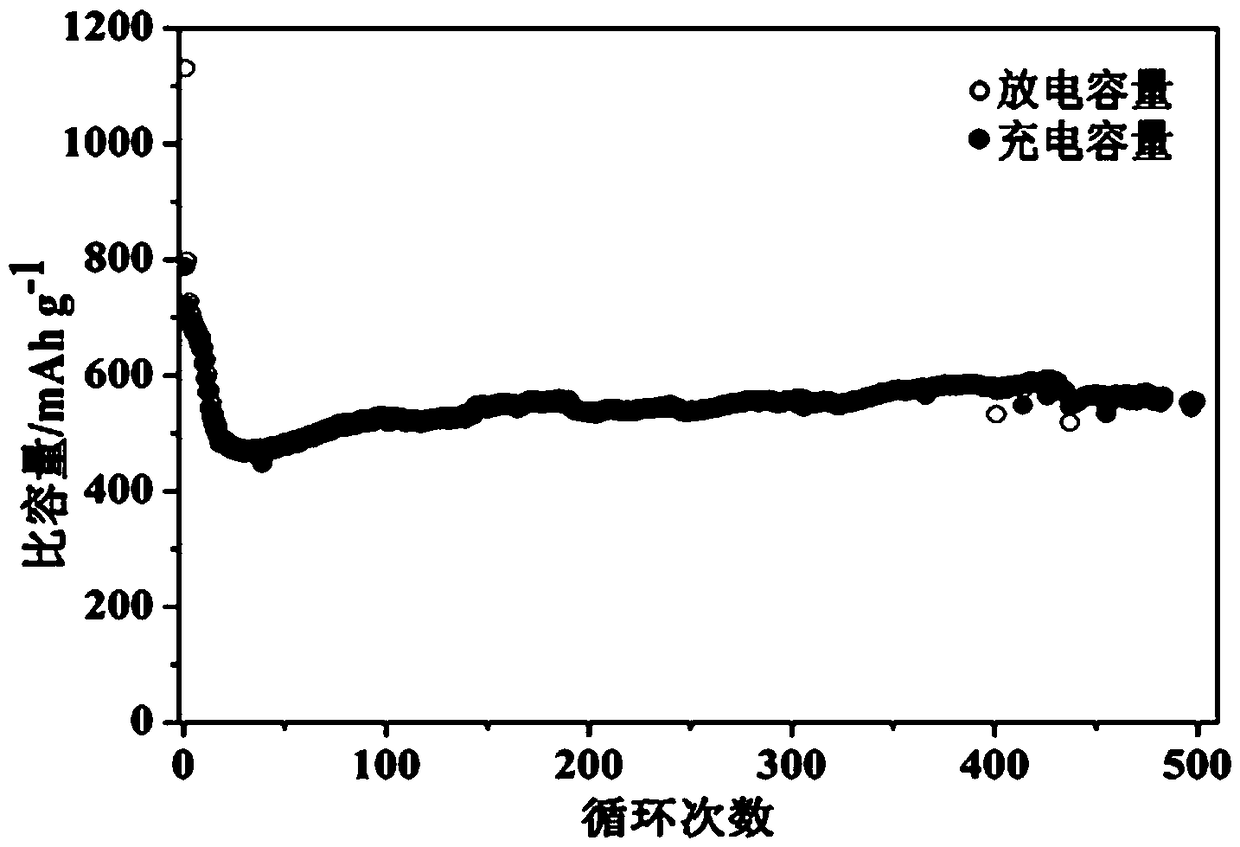

Ferrous carbonate/graphene composite material and preparation method and applications thereof

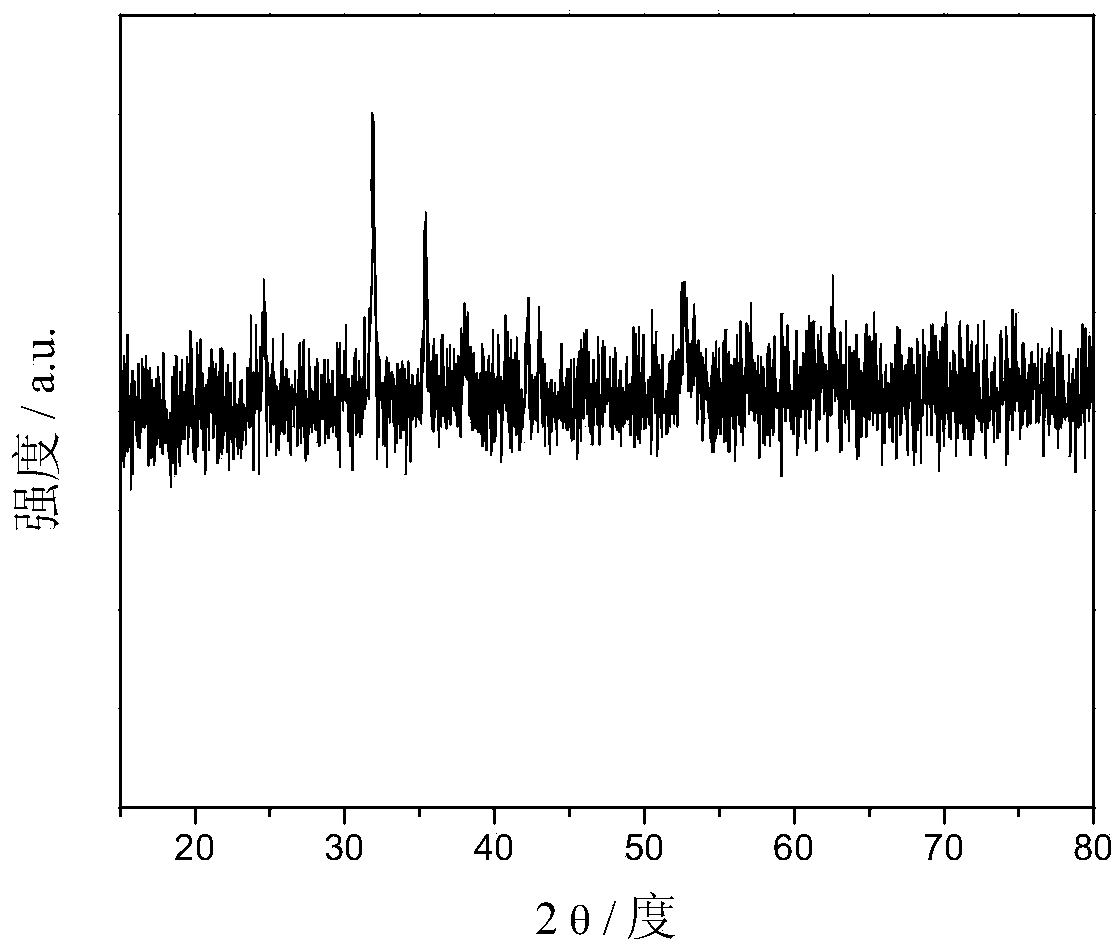

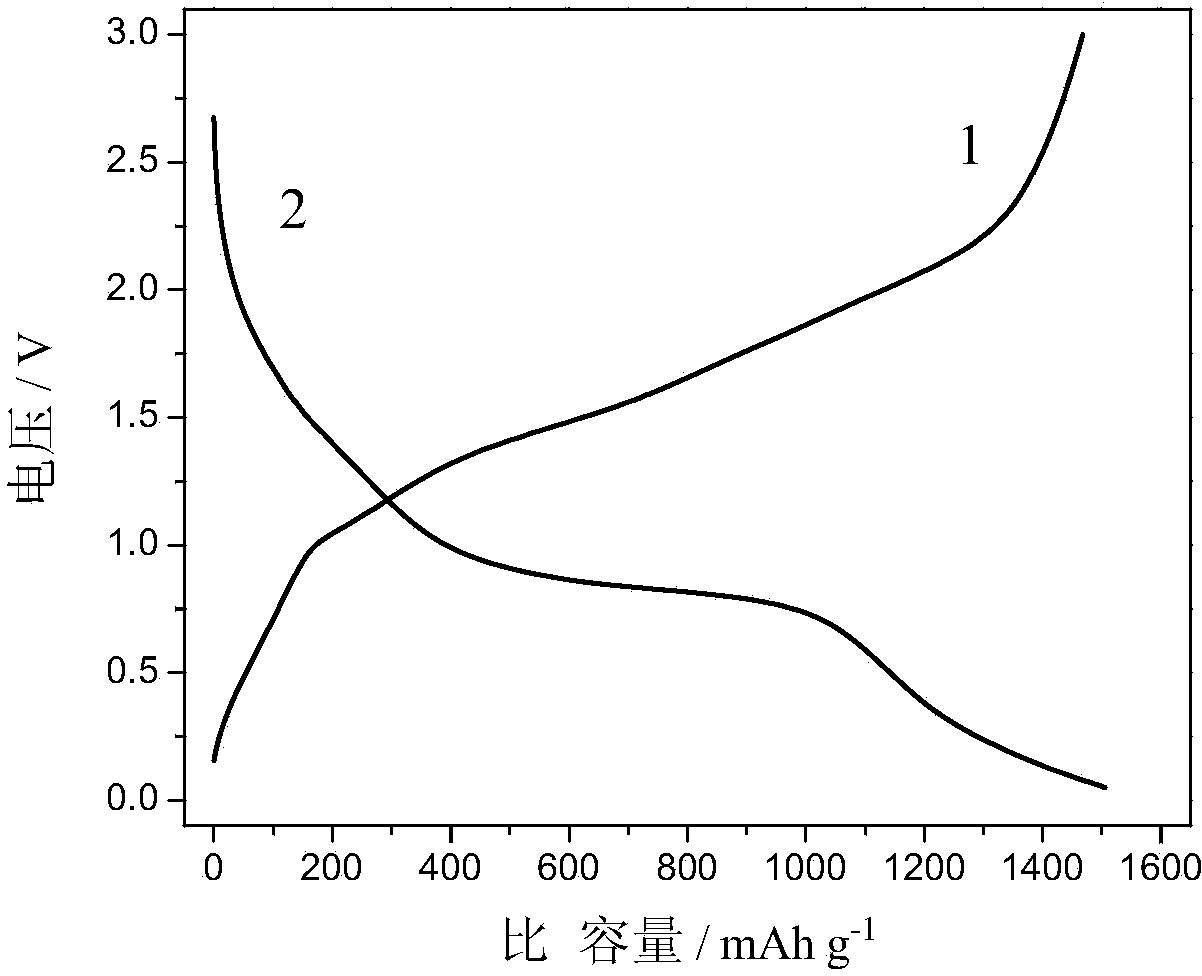

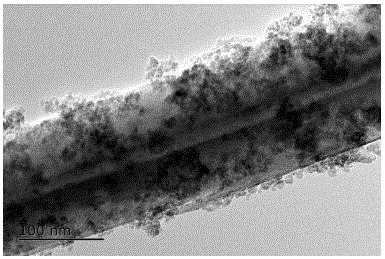

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Preparation method of halloysite nanotube/nanometer titania composite material

InactiveCN106732498ARaw materials are easy to getReduce manufacturing costPhysical/chemical process catalystsOther chemical processesIonMass ratio

The invention relates to a preparation method of a halloysite nanotube / nanometer titania composite material. The technical scheme is that 15 to 60 mass parts of halloysite or halloysite subjected to heat treatment, 100 mass parts of deionized water, 0 to 2 mass parts of surfactants and 0 to 20 mass parts of alcohol type dispersants are uniformly mixed; acid is added until a pH value is greater than or equal to 3 and is smaller than 7, or alkali is added until the pH value is greater than 7 and is small than or equal to 10; slurry is prepared. A titanium-containing material is added into the slurry according to the mass ratio of titania to the halloysite of (1 to 5):10; uniform dispersion is performed; then, the dispersed mixed material is charged into a reaction kettle; reaction is performed for 6 to 24h under the condition of 100 to 220 DEG C; washing and drying are performed to prepare the halloysite nanotube / nanometer titania composite material. The preparation method has the advantages that the process is simple; the production cost is low; the environment-friendly effect is achieved; the scale production is easily realized. The halloysite nanotube / nanometer titania composite material prepared by the method has the advantages of large specific surface area, good adsorption performance and high photocatalysis efficiency.

Owner:WUHAN UNIV OF SCI & TECH

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

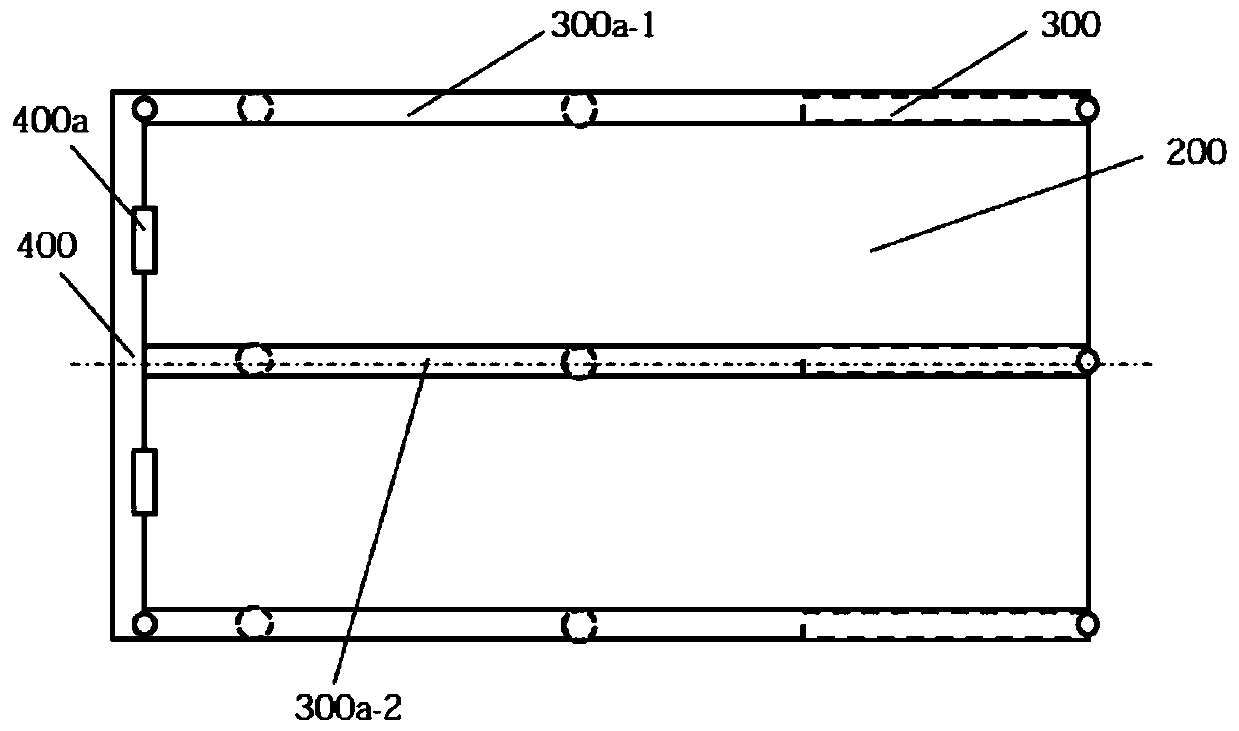

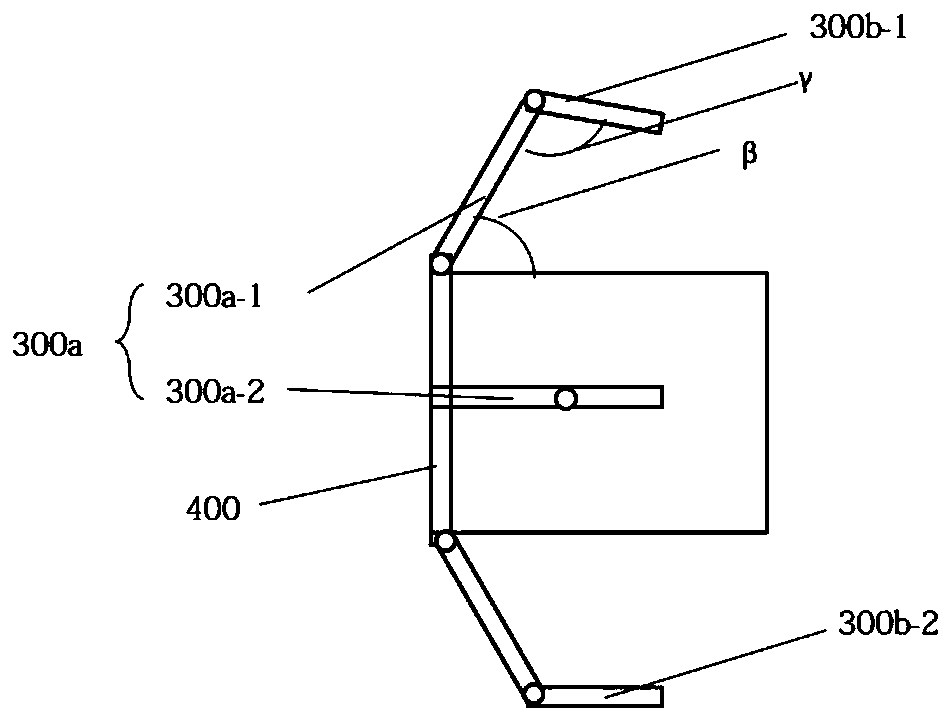

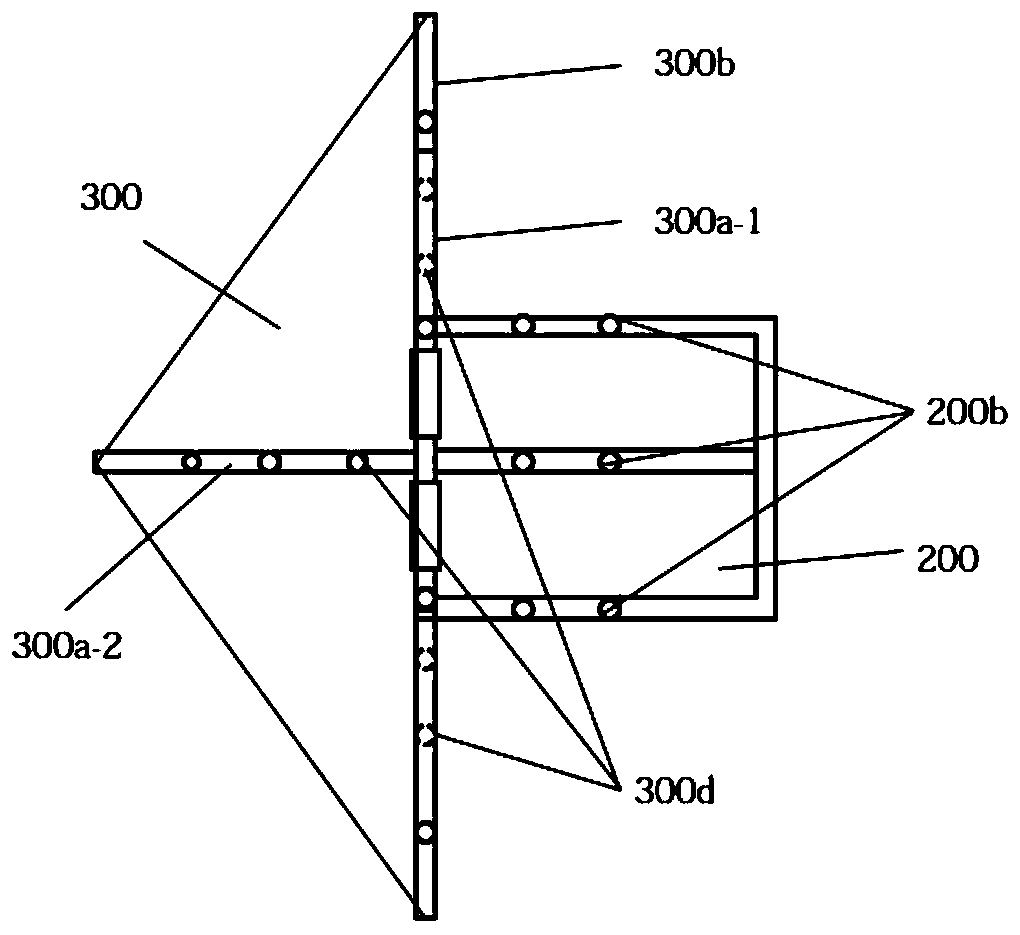

De-orbiting sail unfolding method and device thereof

ActiveCN110525687ASave spaceReduce the impactLaunch systemsSystems for re-entry to earthMass ratioEngineering

Owner:SPACETY CO LTD (CHANGSHA)

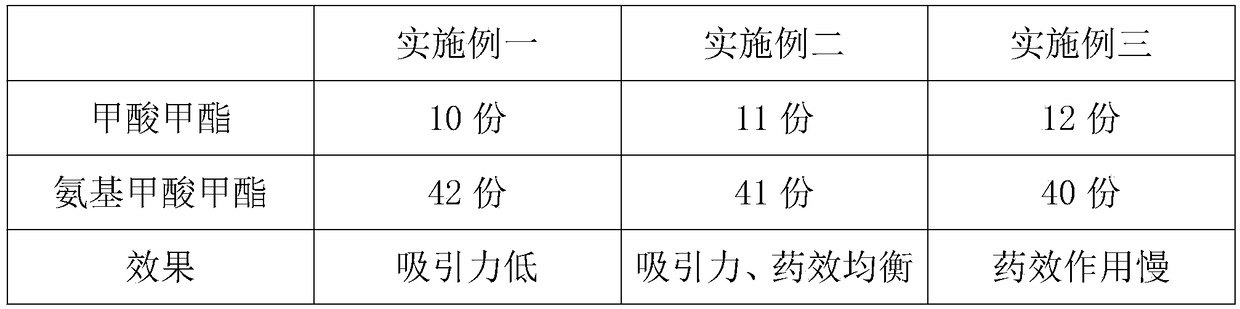

Novel biological material for plant disease and pest control

InactiveCN108184878AIncrease the fragranceImprove durabilityBiocidePest attractantsDehydroacetic acidDisease

Owner:陈益德

Cationic macromolecular proteolipid gene medicine carrier, preparation method and application

InactiveCN102716500ARich varietyHigh transfection efficiencyGenetic material ingredientsMacromolecular non-active ingredientsLipid formationPositive control

Owner:SHANGHAI INST OF ONCOLOGY

Preparation method of lithium niobate single crystal

ActiveCN105839178AHigh purityUniform compositionPolycrystalline material growthBy pulling from meltMass ratioLithium carbonate

Owner:YANCHENG GENION ELECTRONICS MATERIALS FACTORY

Method for detecting content of blue dyestuff in textile and leather product

ActiveCN104535684AThe pretreatment process is convenient and fastGood repeatabilityComponent separationOrganic solventMass ratio

Owner:广东省中鼎检测技术有限公司

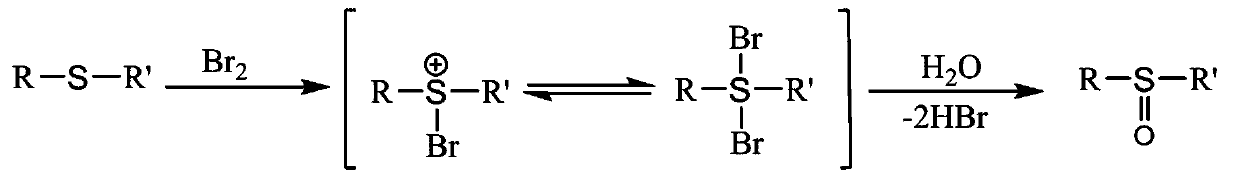

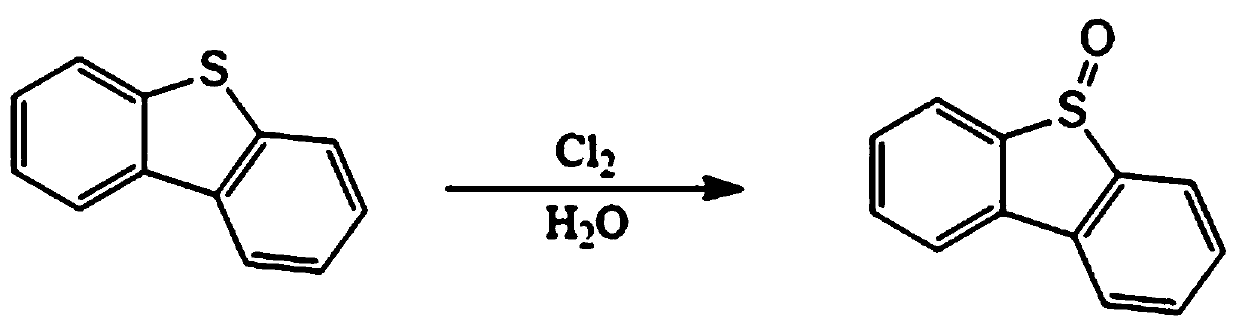

Technology for desulfurizing coal with large particle size by microwave-assisted halogen elements

Owner:SHANXI COKING COAL GROUP

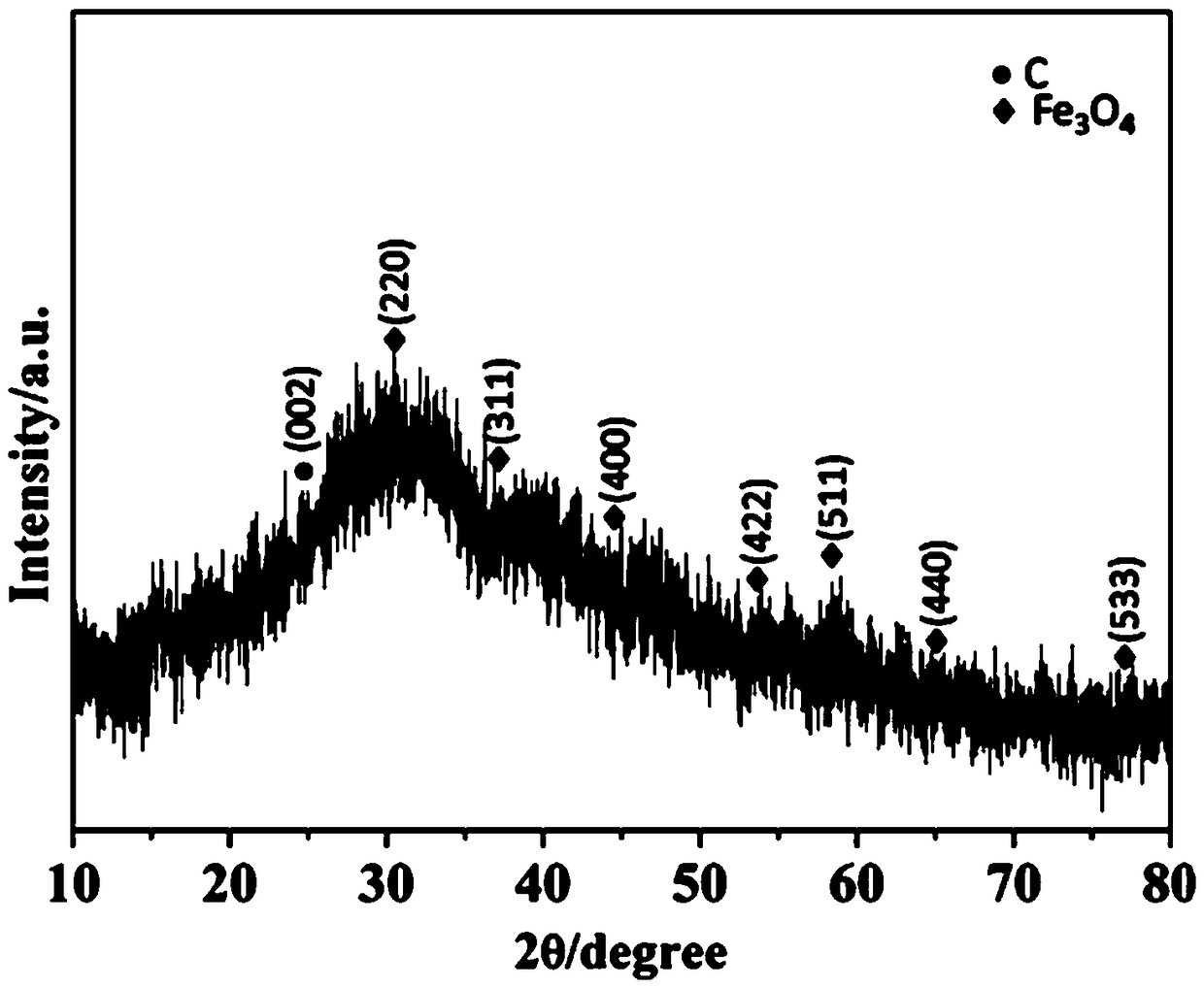

Preparation method of magnetic carbon material

ActiveCN108311100AReduce pollutionSimple process routeOther chemical processesAlkali metal oxides/hydroxidesMass ratioCombustion products

Owner:SHANXI UNIV

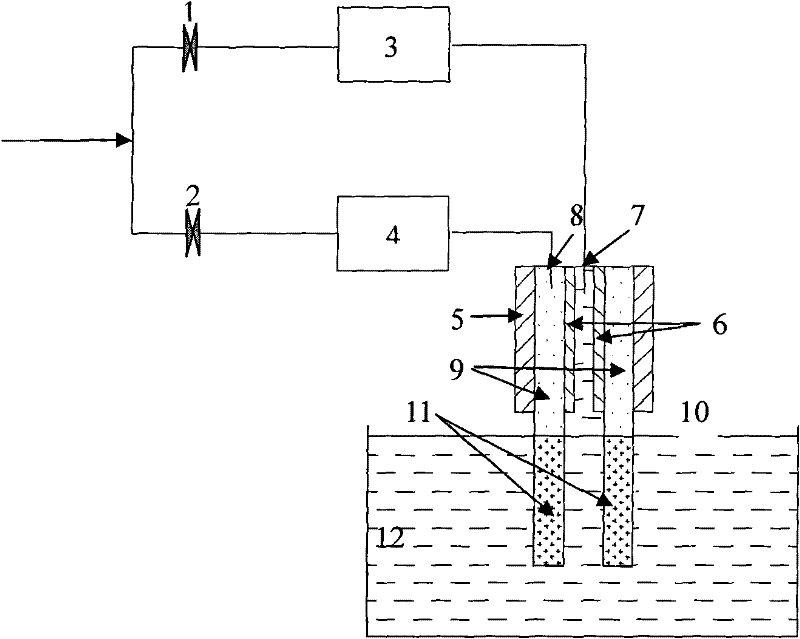

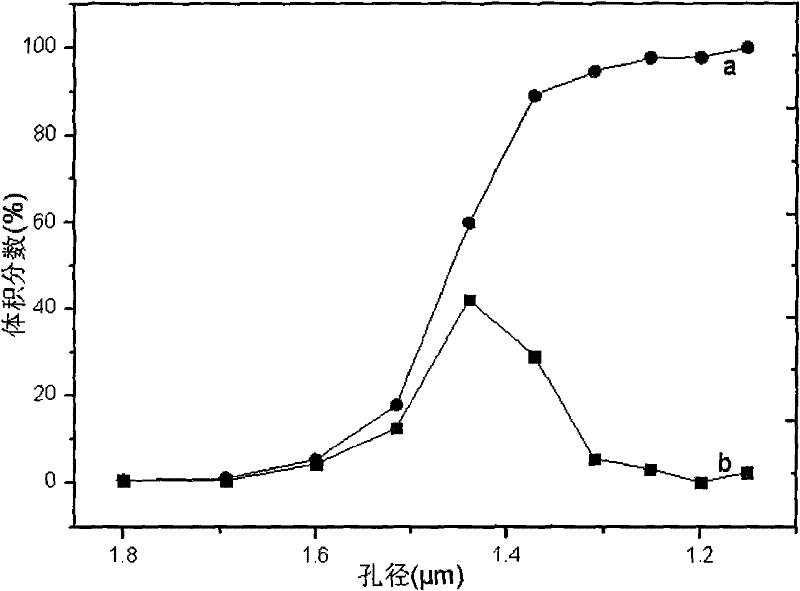

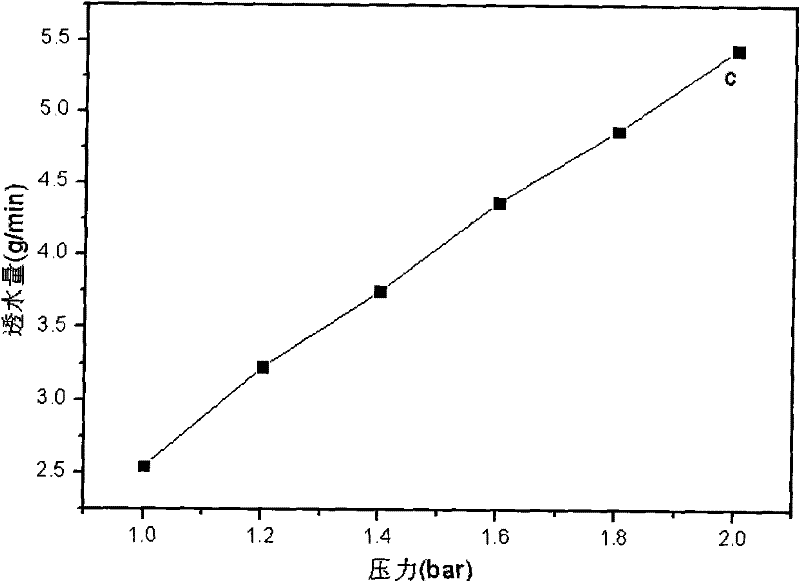

Metal-ceramic composite fibrous membrane tube and preparation method thereof

Owner:UNIV OF SCI & TECH OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap