Technology for desulfurizing coal with large particle size by microwave-assisted halogen elements

A halogen element, microwave-assisted technology, applied in the field of coal desulfurization, can solve the problems of unrecyclable reaction reagents, low desulfurization rate, etc., and achieve the effects of easy purchase, high desulfurization rate, and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

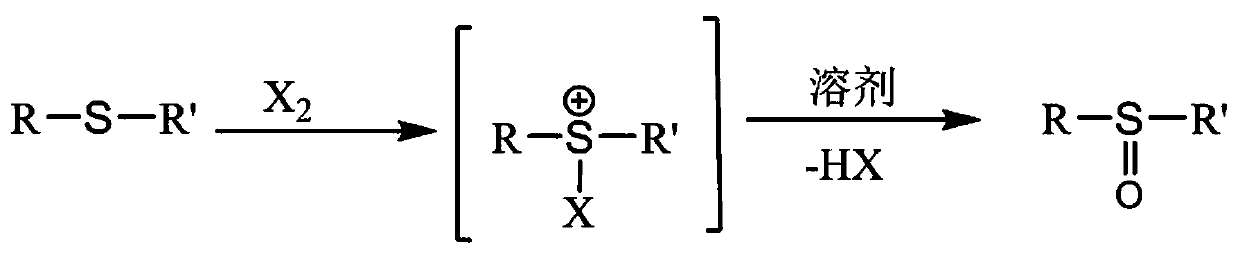

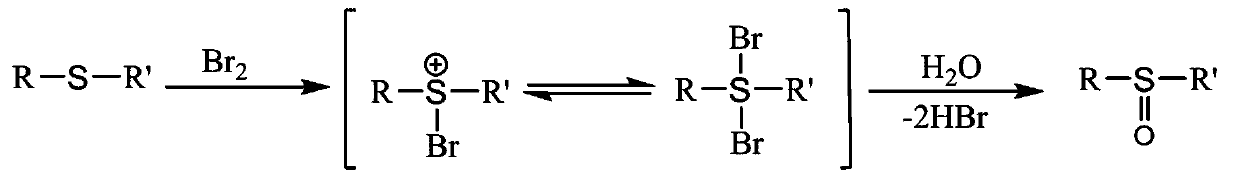

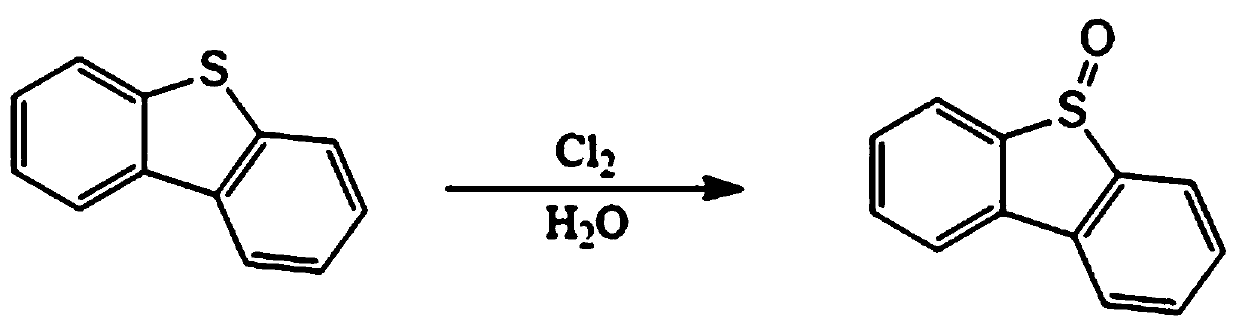

Method used

Image

Examples

Embodiment 1

[0029] The sulfur content in coal is required to be ≤2%, and the steps are as follows:

[0030] S1. Select 100g of Gaoyang coal as raw coal, crush and screen to ensure that the particle size is 1-6mm, and obtain a coal sample; here, the particle size of the coal is preferably within the range of 1-6mm, and the desulfurization efficiency in this range is better. In other embodiments, it is also acceptable if the particle size is >6mm.

[0031] S2. Configure reaction agent: dissolve bromine elemental substance in water to form a bromine aqueous solution with a mass concentration of 3% as a desulfurization reaction agent; here, the concentration of bromine water is preferably 1%-3%, and the concentration within this range can ensure the reaction rate, and can ensure the thoroughness of desulfurization under the premise of not wasting bromine water, wherein, 3% is the most preferred concentration value, and in other embodiments, 1% or 1.5% or 2% or 2.5% can also be selected, as long

Embodiment 2

[0041] The sulfur content in coal is required to be ≤0.5%, and the steps are as follows:

[0042] Step S1~S5 among the embodiment 1 is repeated 5 times, other steps are constant,

[0043] According to the high-temperature combustion coulomb method, the total sulfur content in coal was reduced from 2.13% to 0.22%, and the desulfurization rate was 90.04%.

[0044] The sulfur content and desulfurization rate corresponding to the repeated reaction times of the coal sample are as follows:

[0045] Number of experimental responses 1 time 2 times 3 times 4 times 5 times Sulfur content% 1.63 1.23 0.94 0.53 0.22 Desulfurization rate% 26.24 44.15 57.32 75.81 90.04

Embodiment 3

[0047] The sulfur content in coal is required to be ≤2%, and the steps are as follows:

[0048] S1. Select 100g of Gaoyang coal as raw coal, crush and screen to ensure that the particle size is 1-6mm, and obtain a coal sample; here, the particle size of the coal is preferably within the range of 1-6mm, and the desulfurization efficiency in this range is better. In other embodiments, it is also acceptable if the particle size is >6mm.

[0049] S2. Configure reaction agent: dissolve bromine elemental substance in water to form a bromine aqueous solution with a mass concentration of 3% as a desulfurization reaction agent; here, the concentration of bromine water is preferably 1%-3%, and the concentration within this range can ensure the reaction rate, and can ensure the thoroughness of desulfurization under the premise of not wasting bromine water, wherein, 3% is the most preferred concentration value, and in other embodiments, 1% or 1.5% or 2% or 2.5% can also be selected, as long

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap