Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162 results about "Slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slurry is a mixture of solids with specific gravity greater than 1 suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids, the liquid being a carrier that is pumped on a device such as a centrifugal pump. The size of solid particles may vary from 1 micron up to hundreds of millimeters. The particles may settle below a certain transport velocity and the mixture can behave as a Newtonian or non-Newtonian fluid. Depending on the mixture, the slurry may be abrasive and/or corrosive.

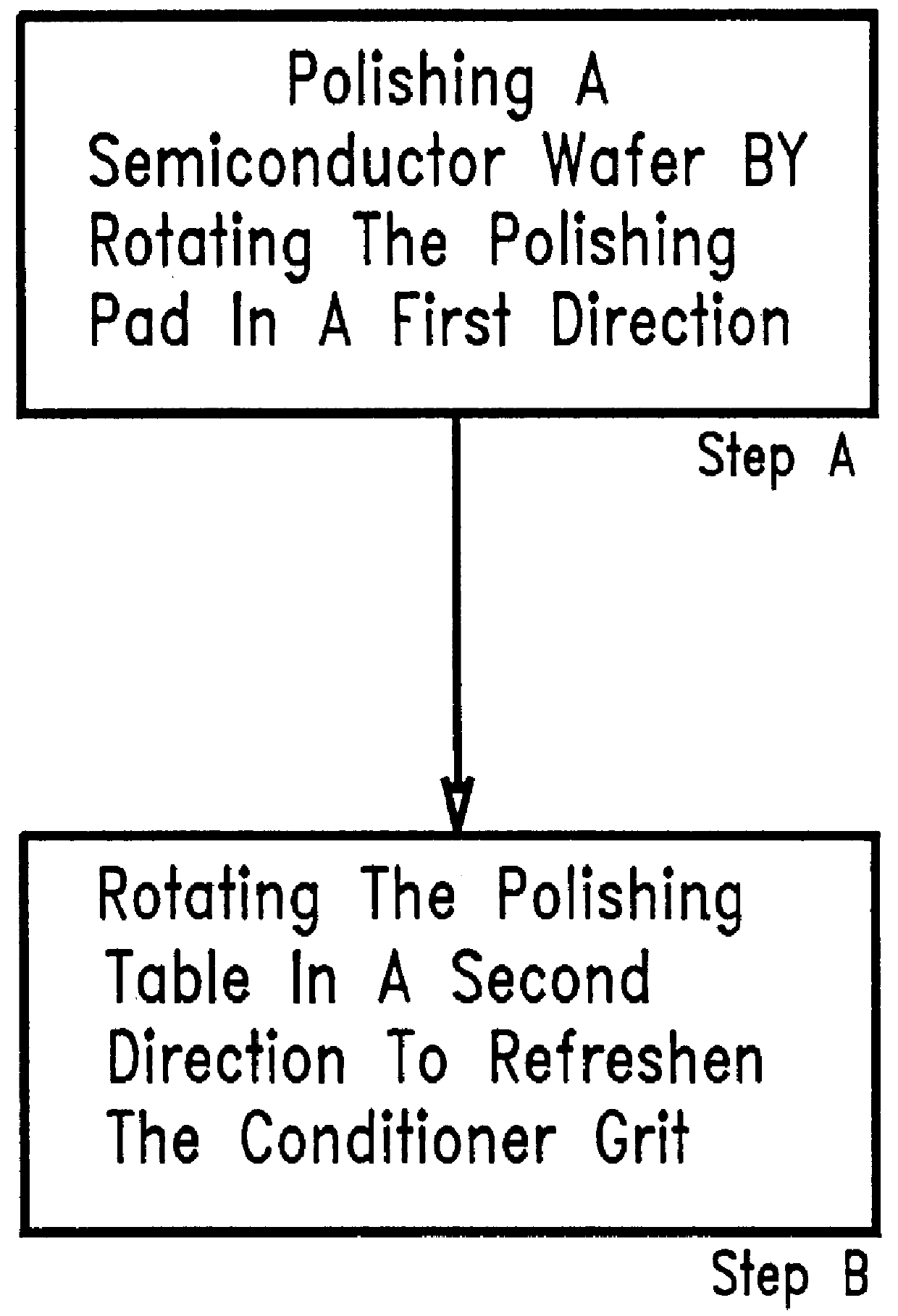

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

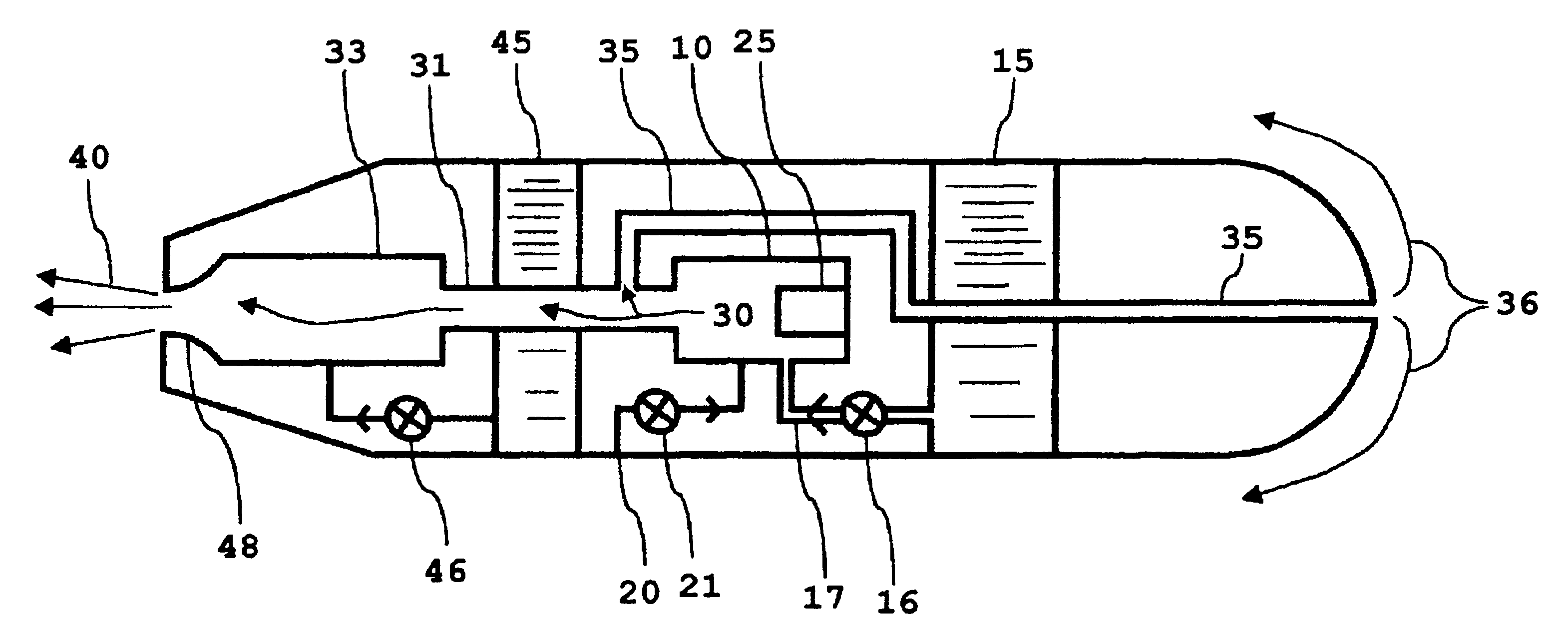

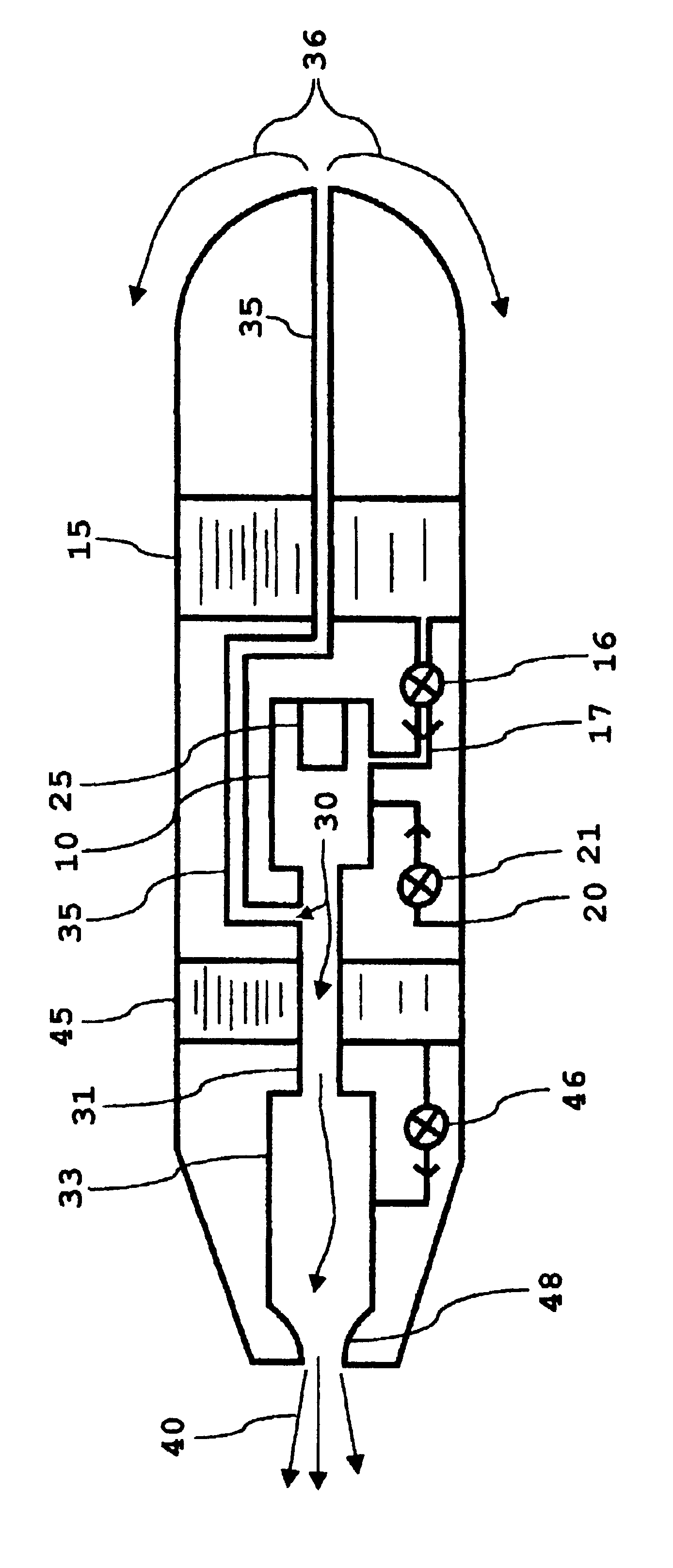

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

Surface-aided melt infiltration for producing a ceramic matrix composite

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

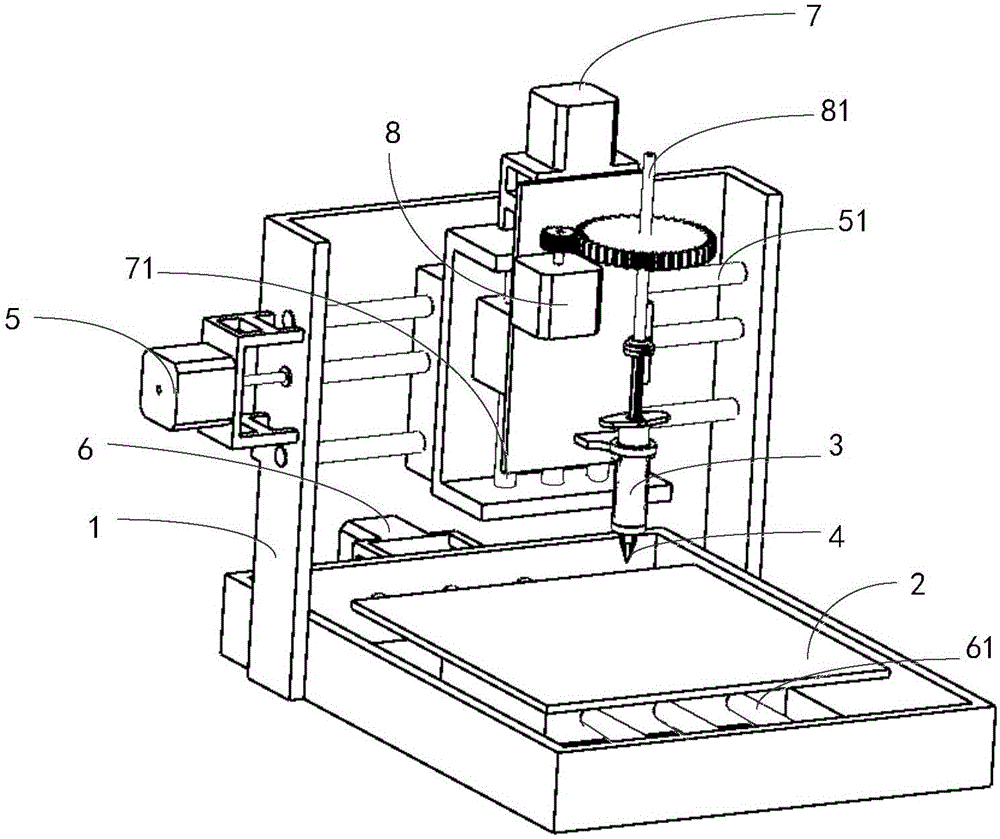

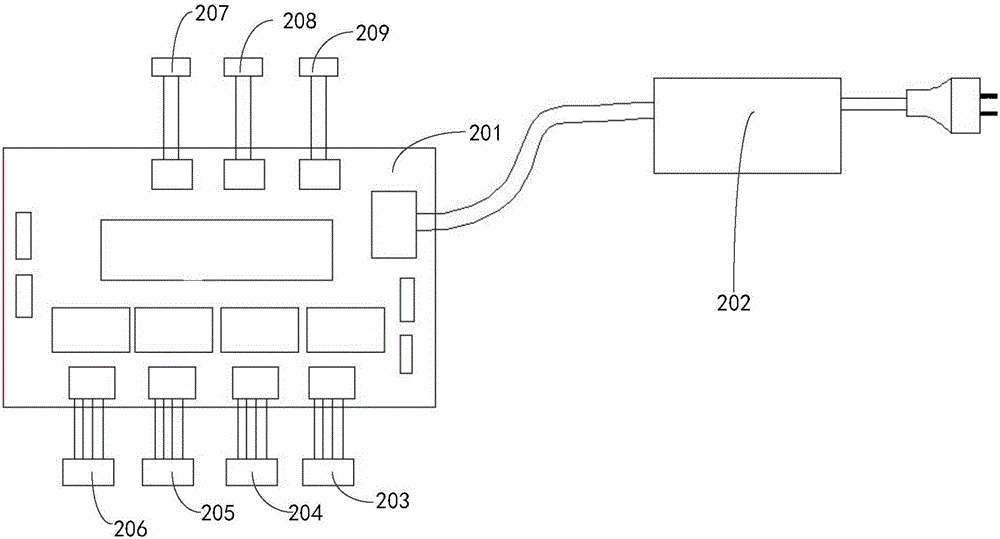

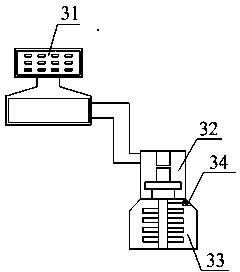

Three-dimensional printer, three-dimensional printing method and preparation method for metal slurry

InactiveCN105108152AGuaranteed printing accuracySimple structureAdditive manufacturing apparatusSpray nozzleSlurry

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

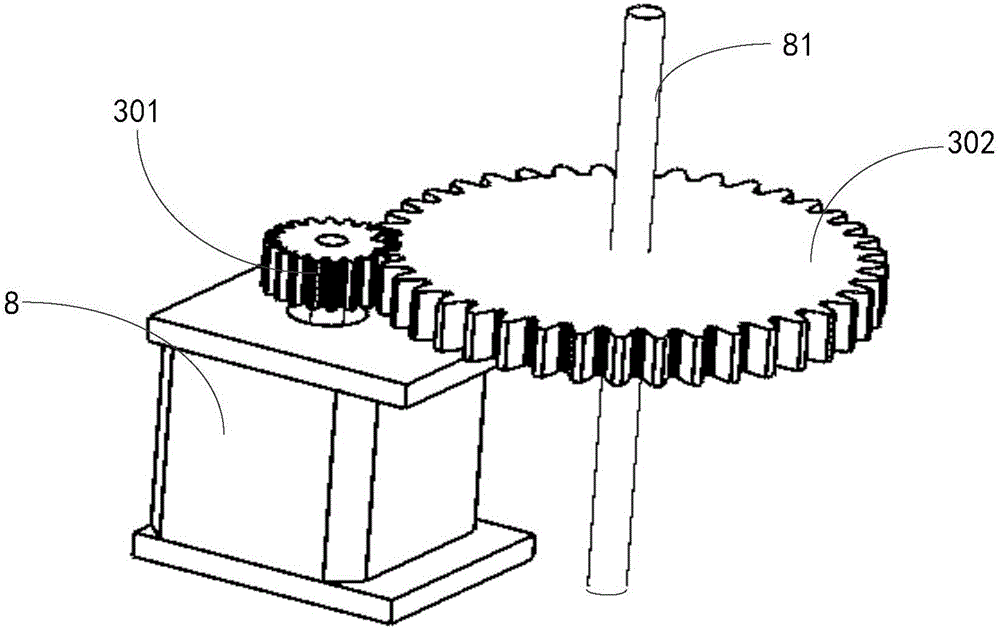

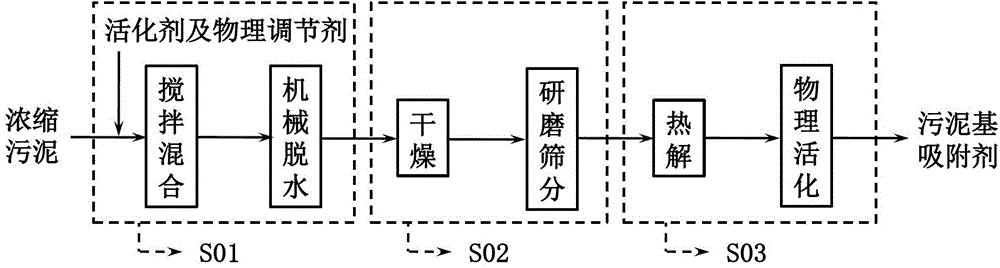

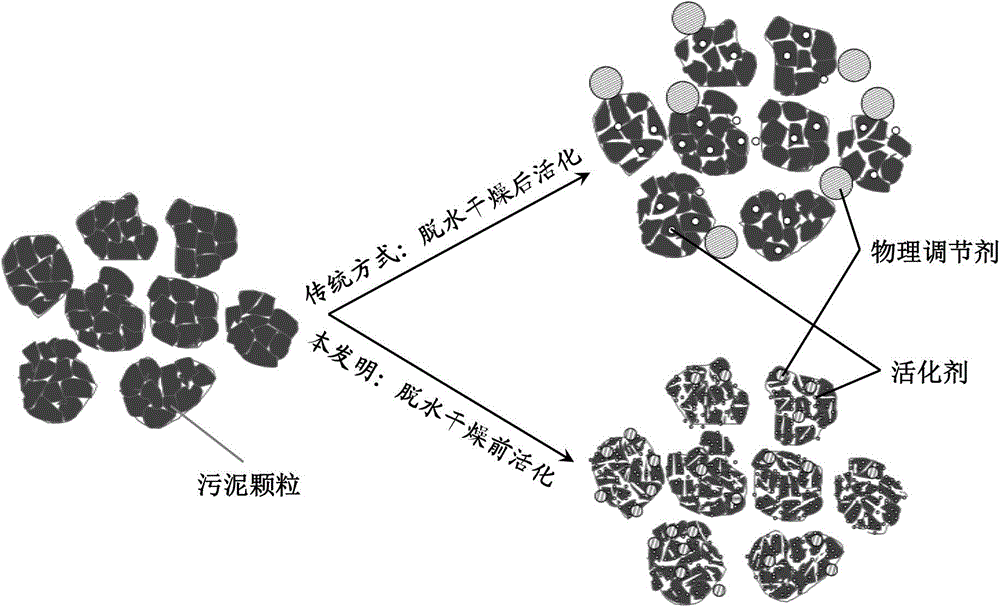

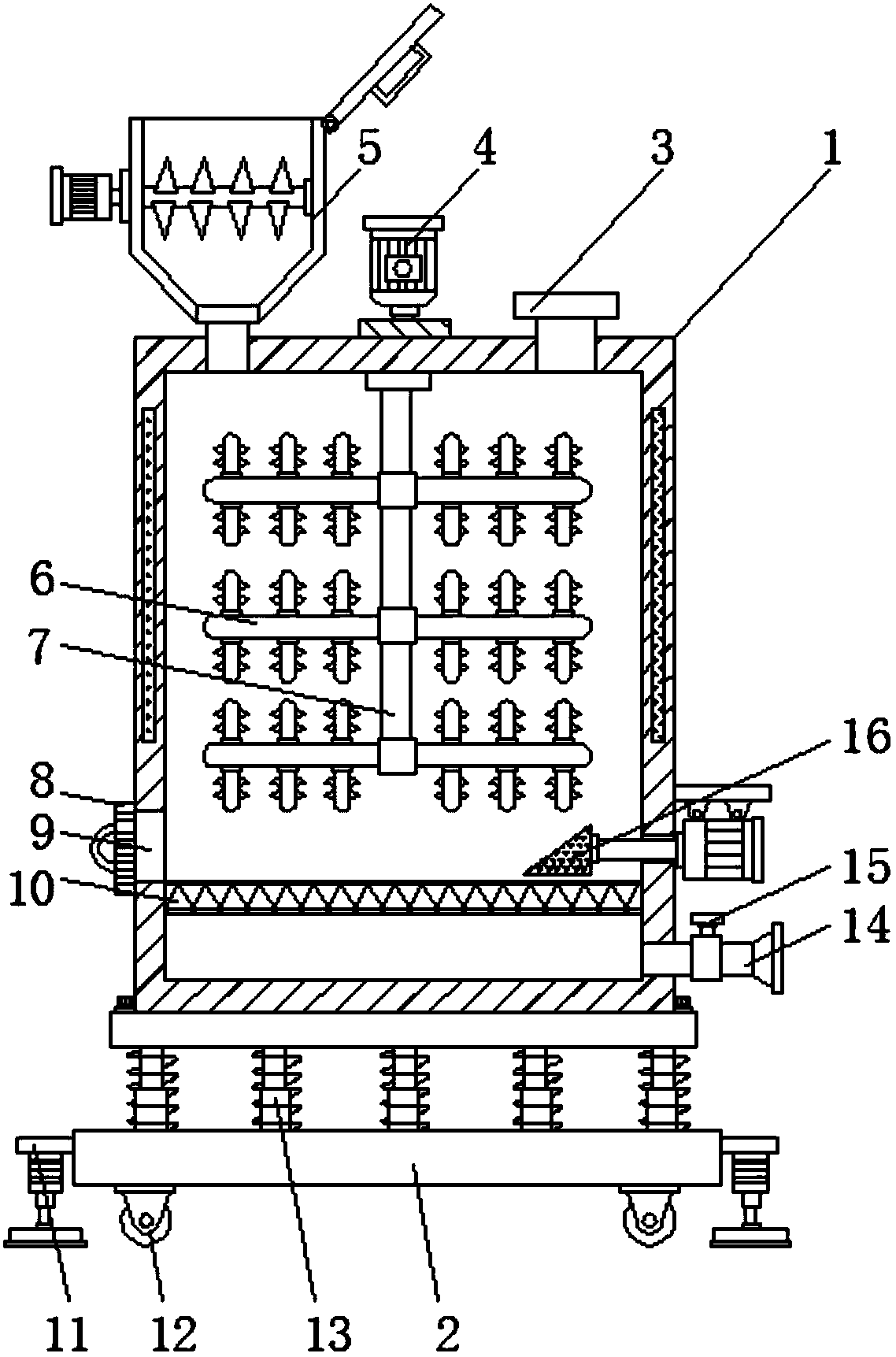

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation process for extracting crude sodium heparin from pig lungs

The invention relates to a preparation process for extracting crude sodium heparin from pig lungs, which comprises the following steps: mincing fresh pig lungs into slurry, carrying out heat insulation and enzymolysis to obtain an enzymolysis liquid, filtering the enzymolysis liquid to collect filtrate, carrying out ion exchange adsorption treatment on the filtrate, washing and eluting resin, precipitating sodium heparin, and drying to obtain crude sodium heparin. The enzymolysis method employed by the invention can thoroughly dissolve pig lung slurry and effectively improve and stabilize the quality of the product and the yield of sodium heparin; and simultaneously, the obtained crude sodium heparin has low impurity content and high titer.

Owner:TIANJIN BAODI AGRI & TECH CO LTD

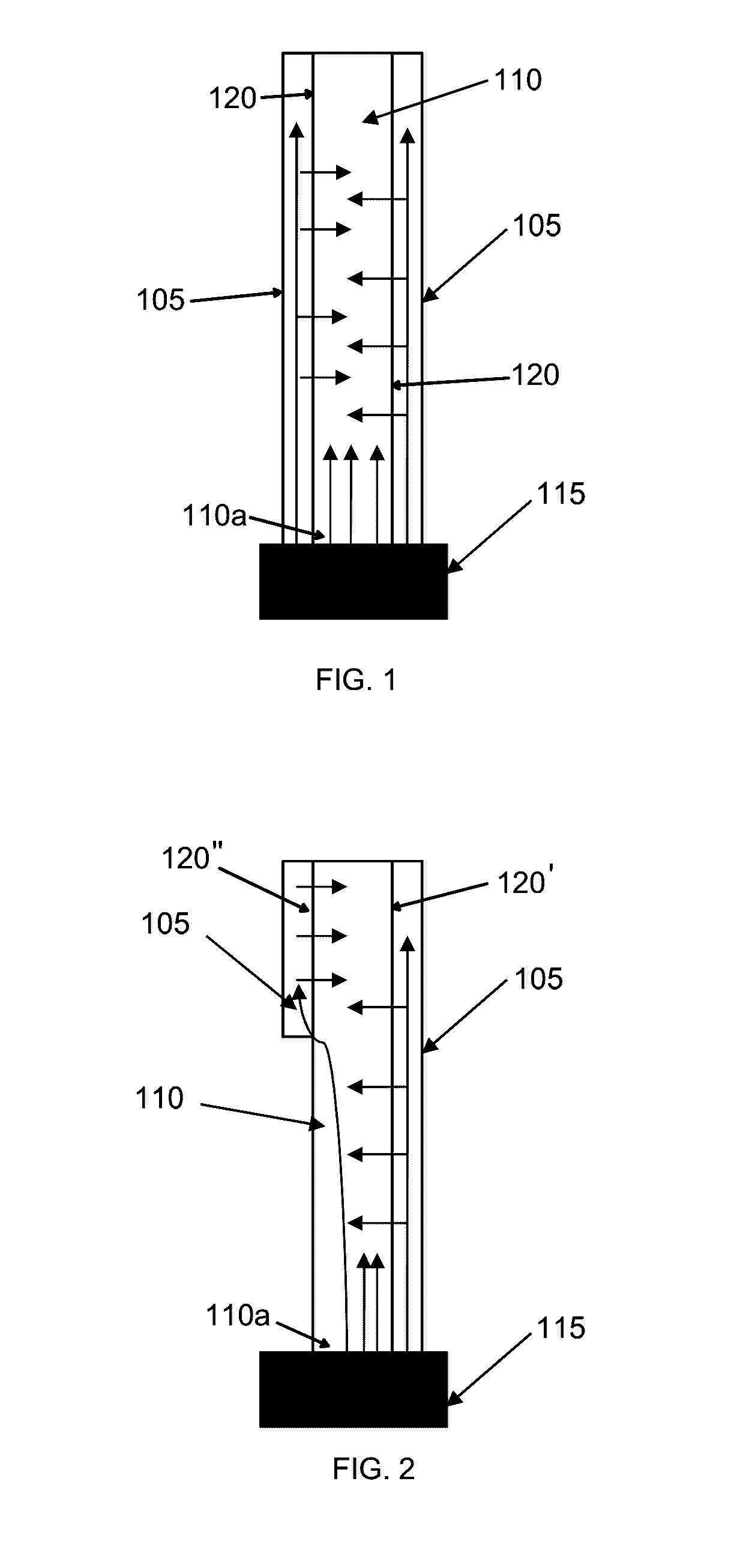

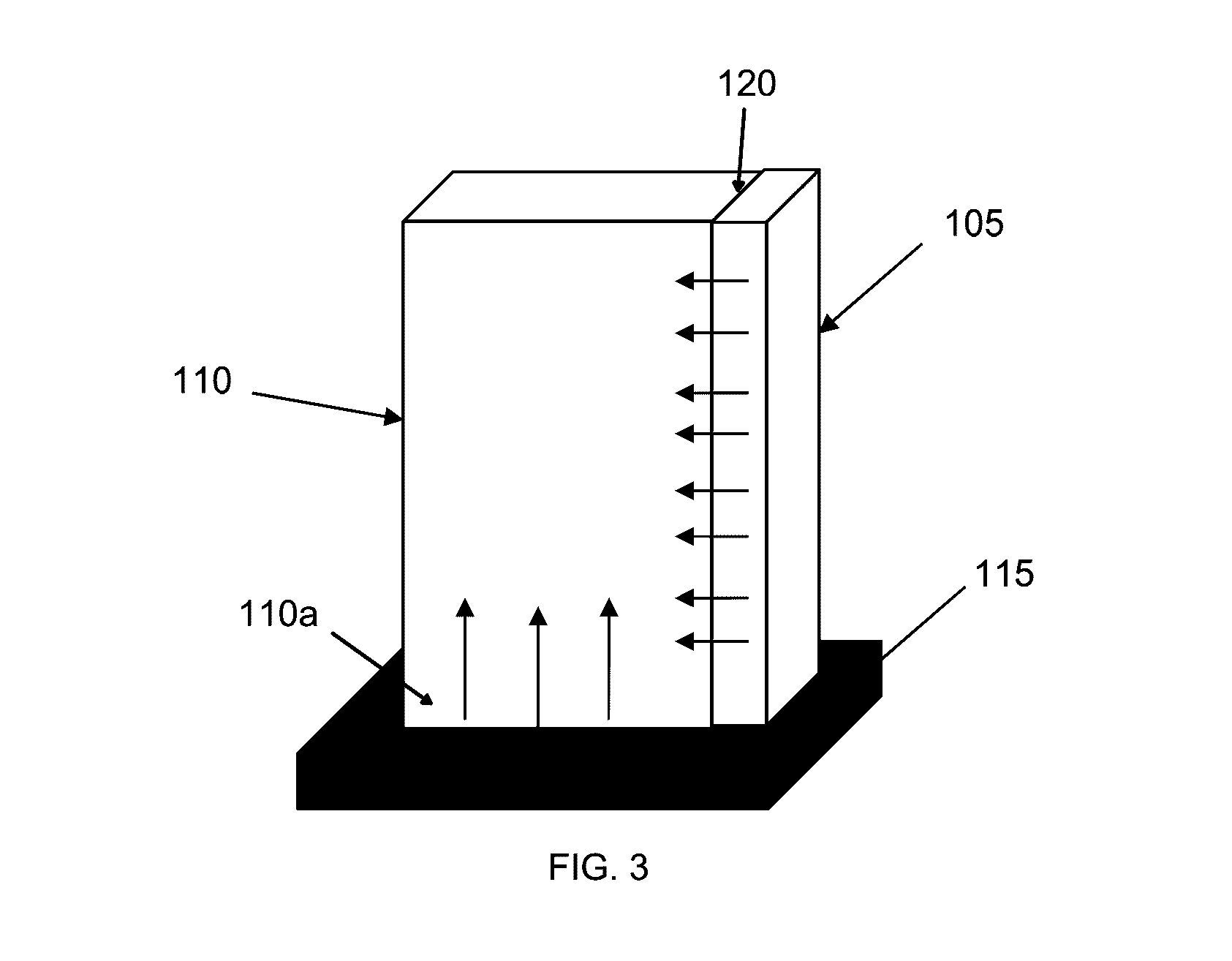

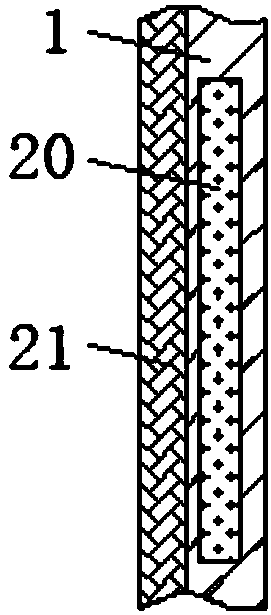

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

Method for preparing vegetation form cellular concrete

InactiveCN101318795AEasy to prepareEasy to operateSolid waste managementCeramicwareGas phaseAgglutination

Owner:SOUTH CHINA UNIV OF TECH

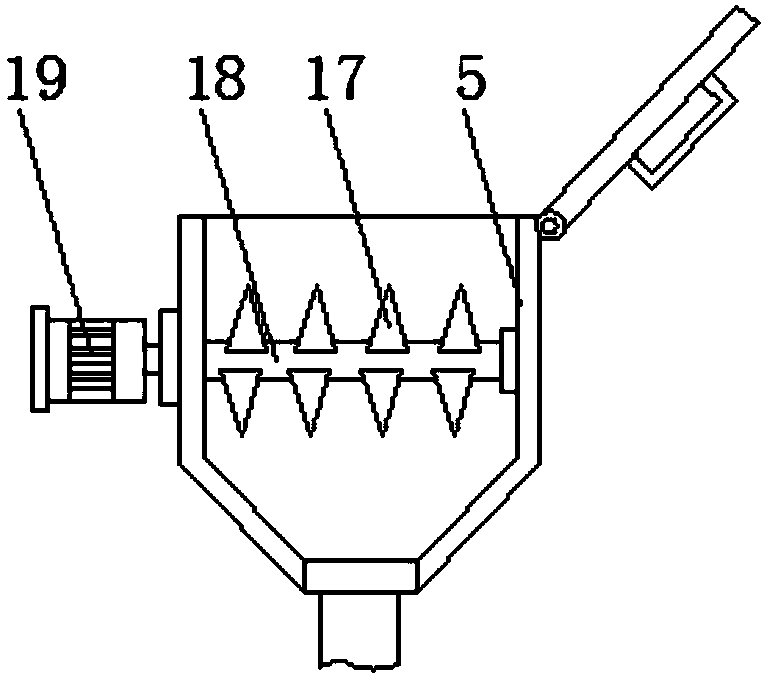

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

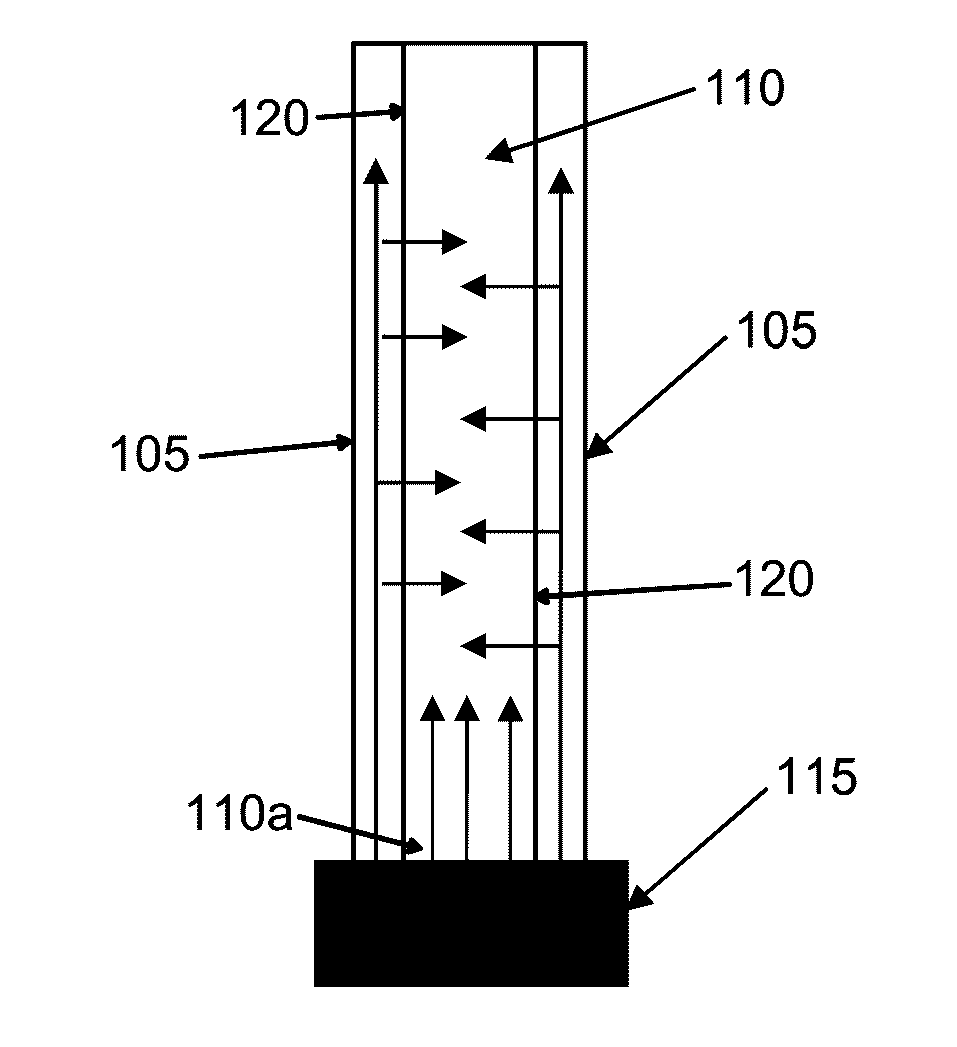

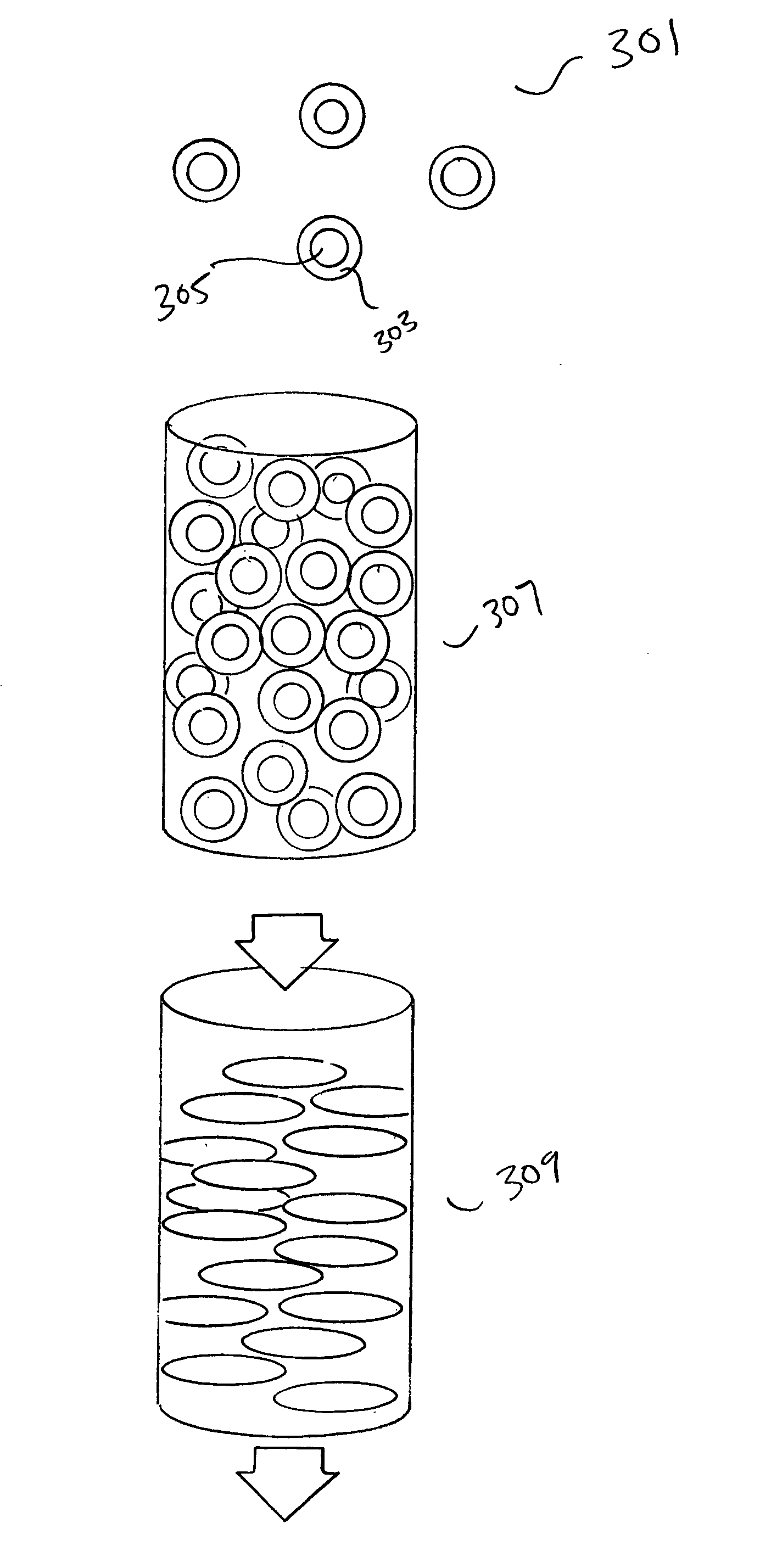

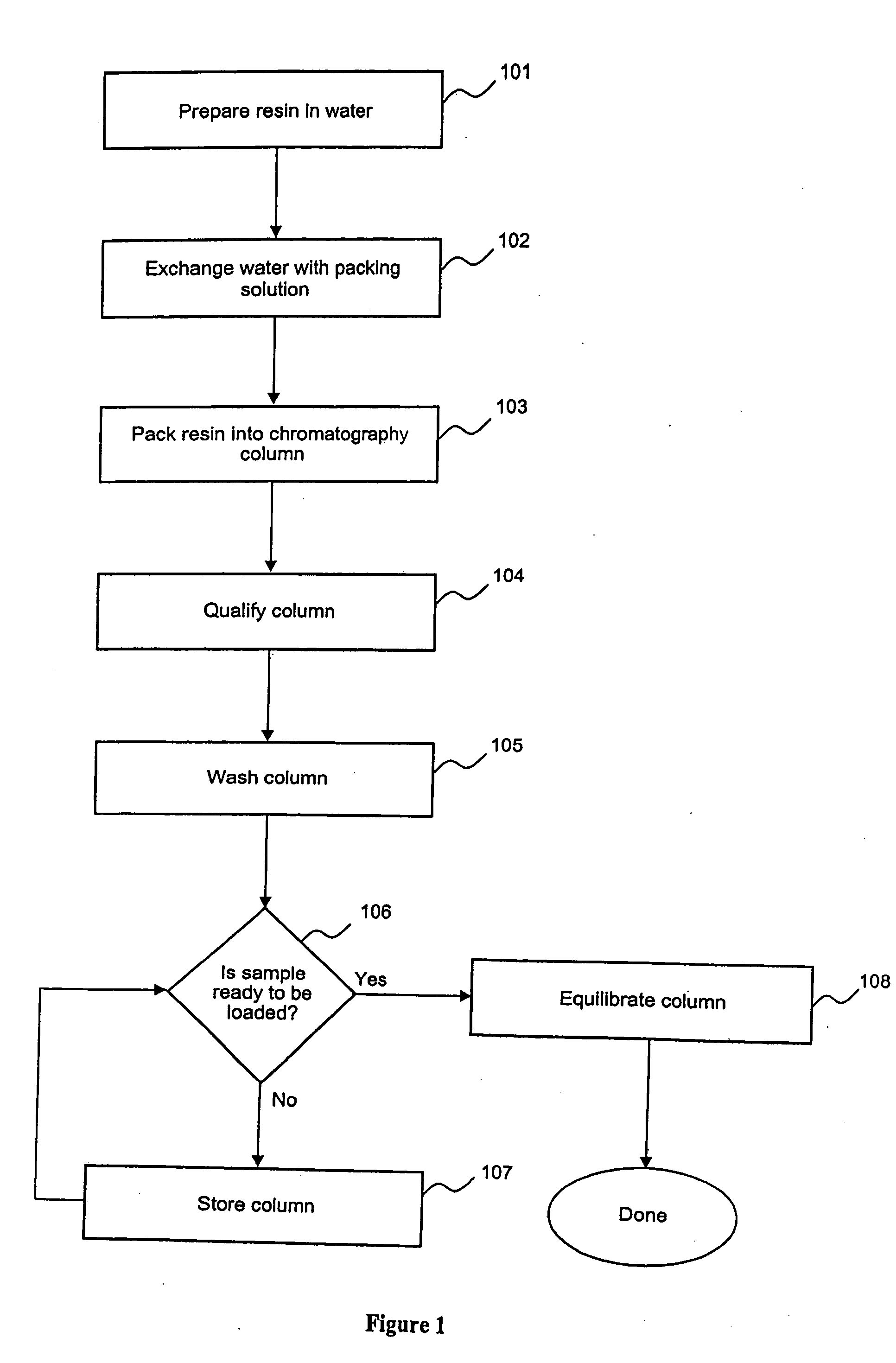

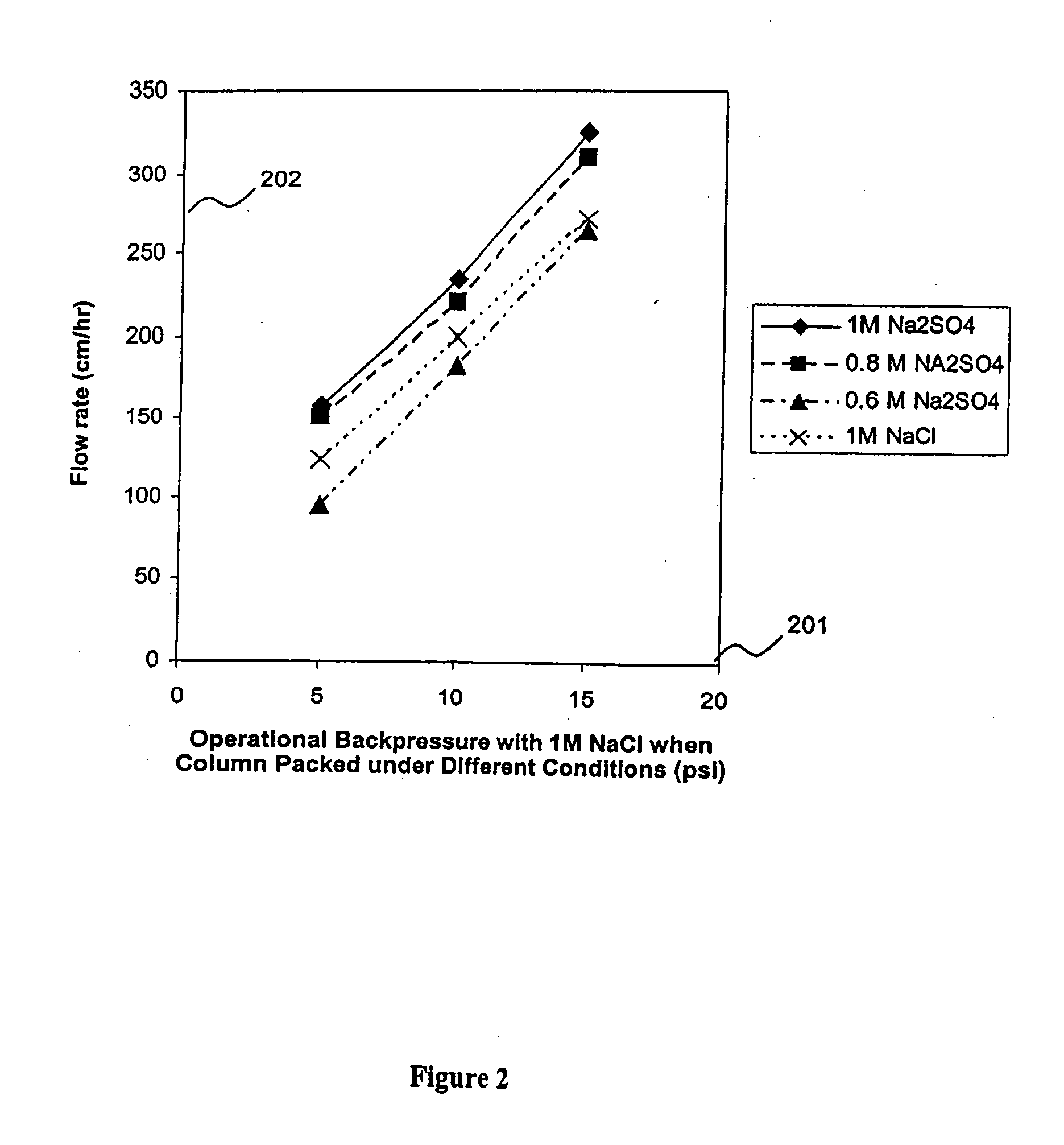

Systems and methods for packing chromatography columns

Owner:AMGEN INC

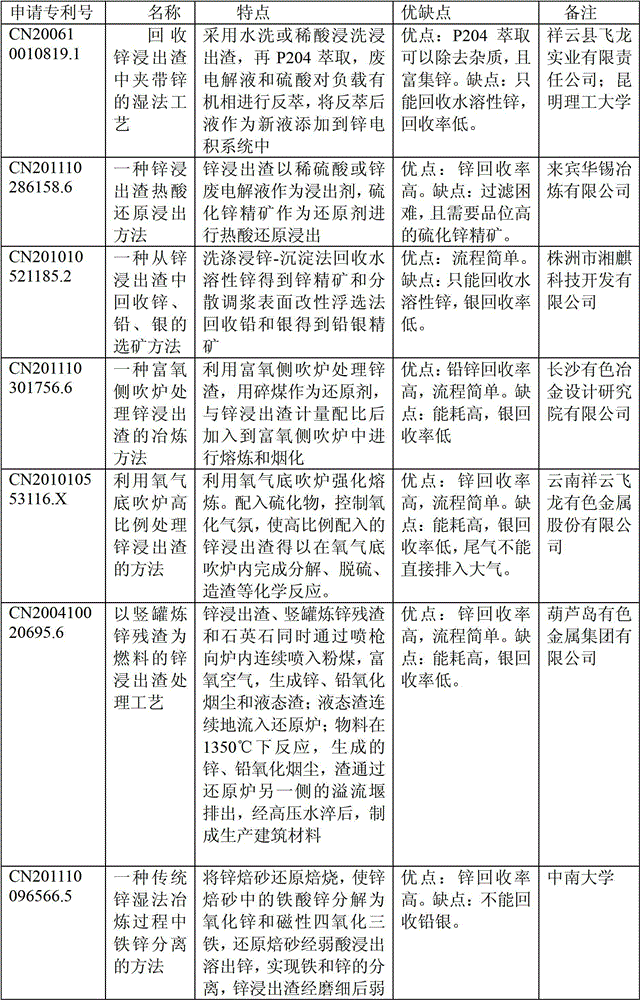

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

Catalyst slurry for fuel cell coating and preparation method thereof

Owner:先进储能材料国家工程研究中心有限责任公司

Recovery of slurry unsupported catalyst

A method of recovering unsupported fine catalyst from heavy oil comprises combining a slurry comprising unsupported fine catalyst in heavy oil with solvent to form a combined slurry-solvent stream. The combined slurry-solvent stream is filtered in a deoiling zone. A stream comprising unsupported fine catalyst and solvent is recovered from the deoiling zone. Unsupported fine catalyst is separated from the stream comprising unsupported fine catalyst and solvent. The deoiling zone can comprise a membrane that is rapidly displaced in a horizontal direction.

Owner:CHEVROU USA INC

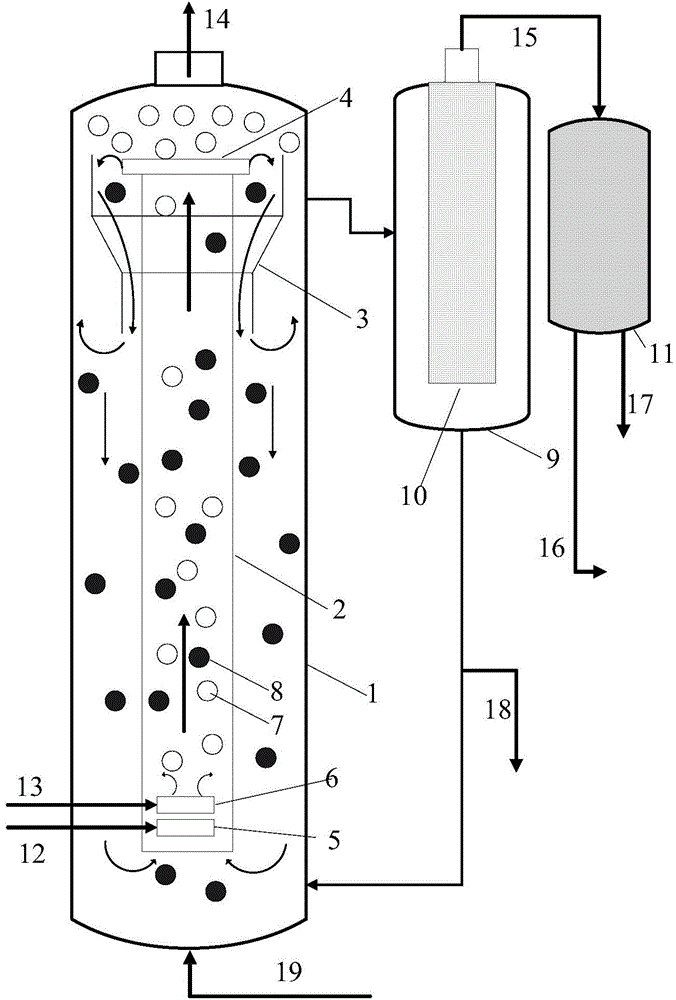

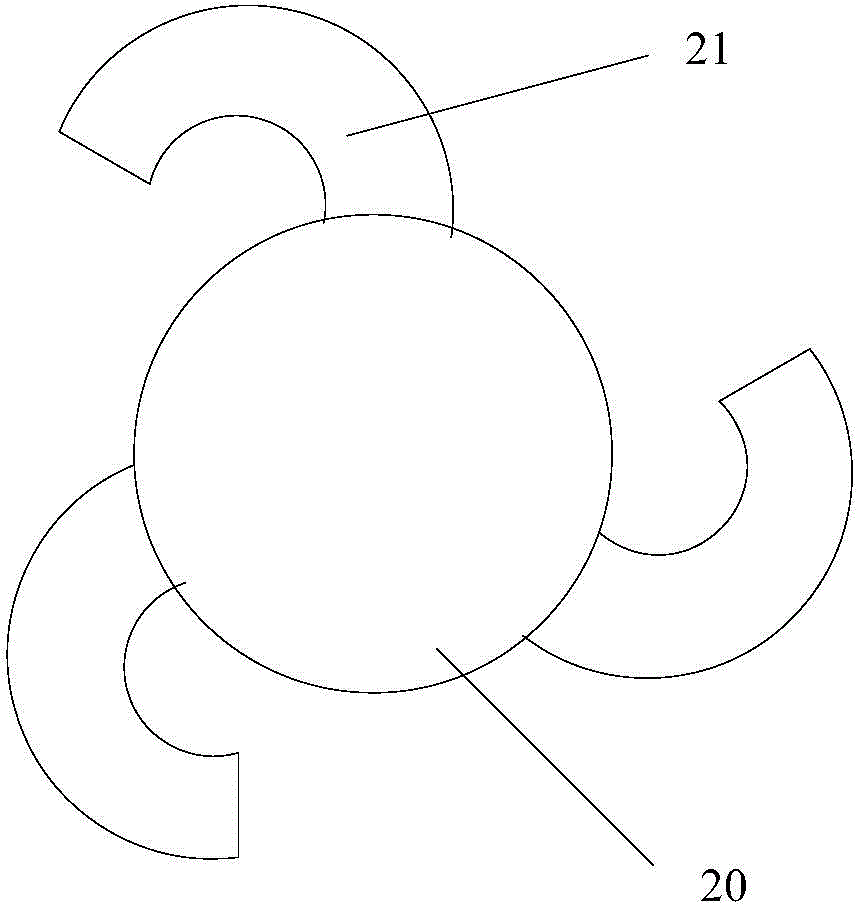

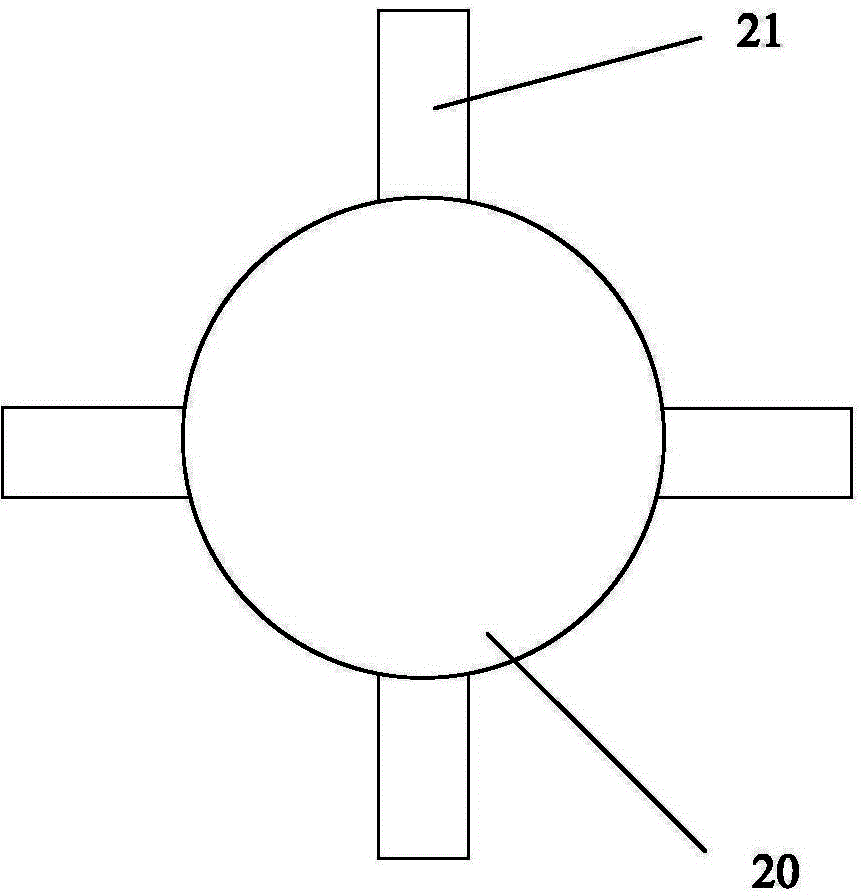

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of silicon dioxide used for tooth paste

The invention discloses a preparation method of silicon dioxide used for tooth paste. According to the invention, a two-stage alkali-adding method is adopted, and the method comprises the steps that: a certain amount of sodium silicate water solution and a certain amount of sulfuric acid water solution are prepared firstly; the sulfuric acid water solution is added into a reaction kettle at ordinary temperature, wherein the adding amount is 50% of needed sulfuric acid; the sodium silicate water solution is added until the pH reaches 7-8; the temperature is increased to 70-80 DEG C; mixing is performed for 1-2 h; the rest sodium silicate solution is added into the reaction slurry; the temperature is increased to 70-80 DEG C; the sulfuric acid water solution is added until the pH reaches 4-5; the heat temperature is preserved for 20-30 min; water washing, drying and smashing are conducted to obtain tooth-paste-used silicon dioxide. The silicon dioxide has proper abrasion amount and good thickening property.

Owner:FUJIAN SANMING TONGSHENG CHEM

Low-silver-content composite conductive silver paste and preparation method thereof

InactiveCN104282356AImprove conductivityReduce silver contentNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteScreen printing

The invention relates to a low-silver-content composite conductive silver paste and a preparation method thereof, and belongs to the technical field of electroconductive slurry. The low-silver-content composite conductive silver paste can be used for screen printing. At present, the conductive silver paste preparation technology in China is high in production cost, complex in preparation technology and the like. According to the low-silver-content composite conductive silver paste, silver-plated copper powder and silver-plated glass powder are adopted to replace pure silver powder, so that the production cost of the silver paste is effectively reduced; the mode that spherical particles and platy particles are combined is selected, so that the conductivity of the silver paste is improved; the silver-plated glass powder with the low specific density is adopted, so that the stability of the conductive silver paste is improved, and the storage life of the silver paste is prolonged. The problems existing in silver paste production at present in China are well solved, the sliver paste preparation technology is simple, the silver paste is good in conductivity and impressionability (including automatic and semi-automatic screen printing and the like), and high in adhesion capacity with various substrates such as a PET film, and has significant application value.

Owner:肖淑勇

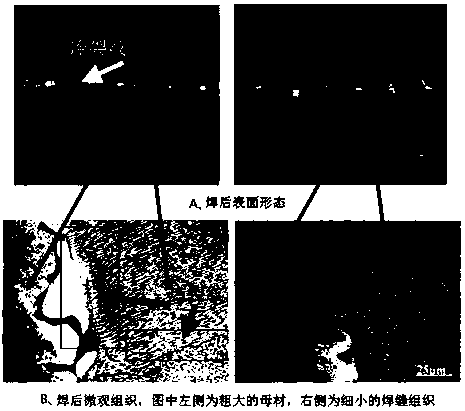

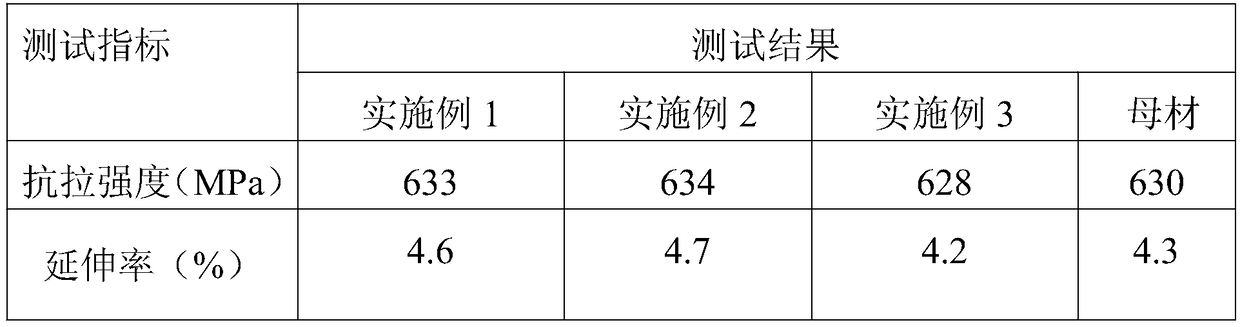

Laser welding method of CoCrCuFeNi high-entropy alloy

ActiveCN108747006AHigh strengthImprove plasticityLaser beam welding apparatusCrazingHigh entropy alloys

Owner:GUIZHOU INST OF TECH

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

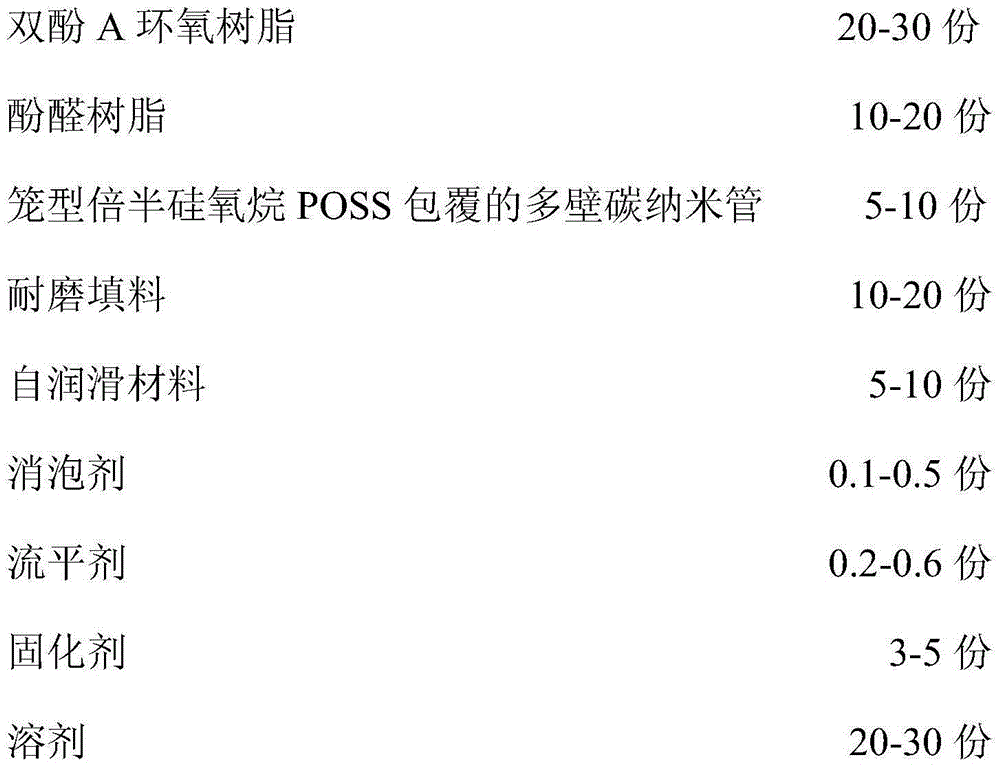

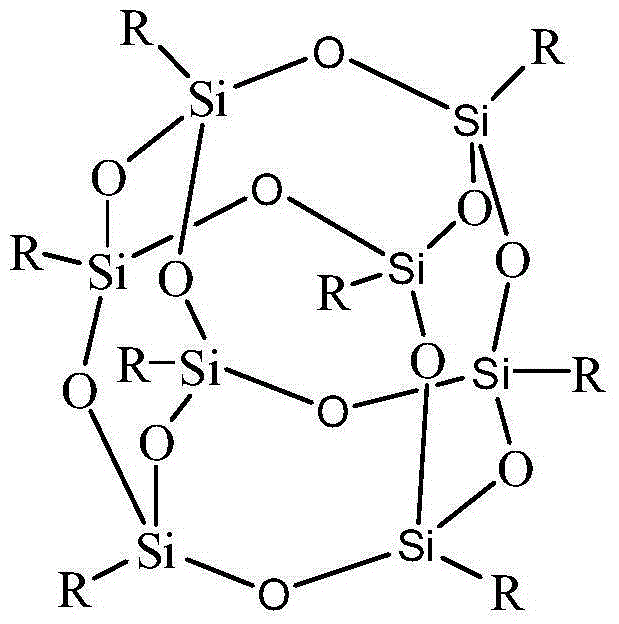

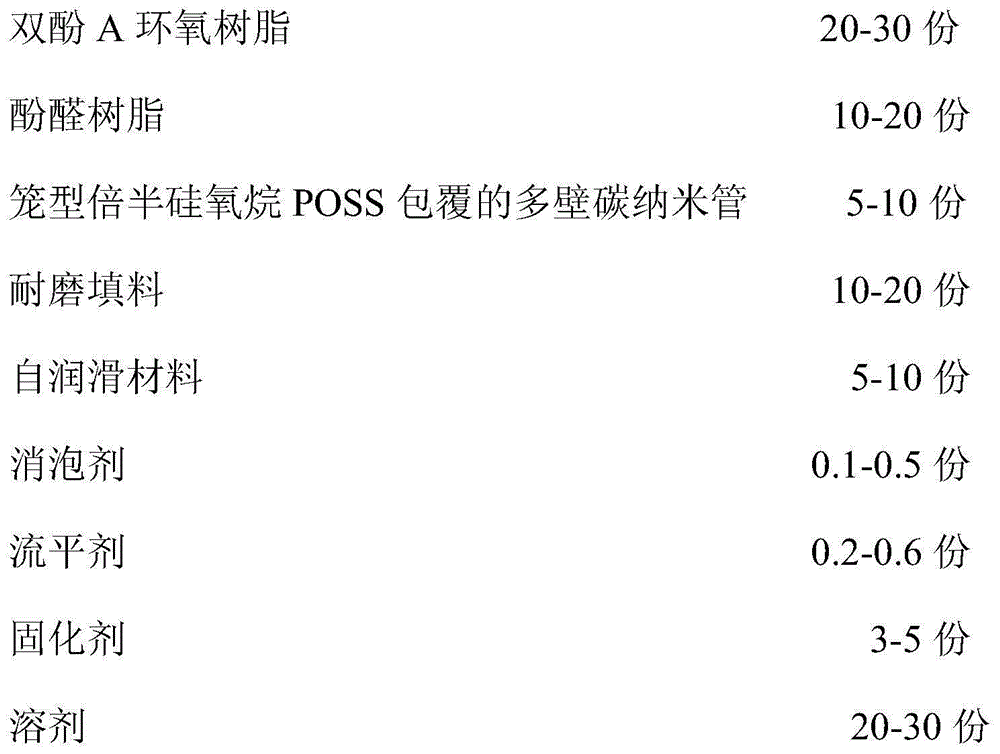

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

Method for forming ultrathin-wall porous metal pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

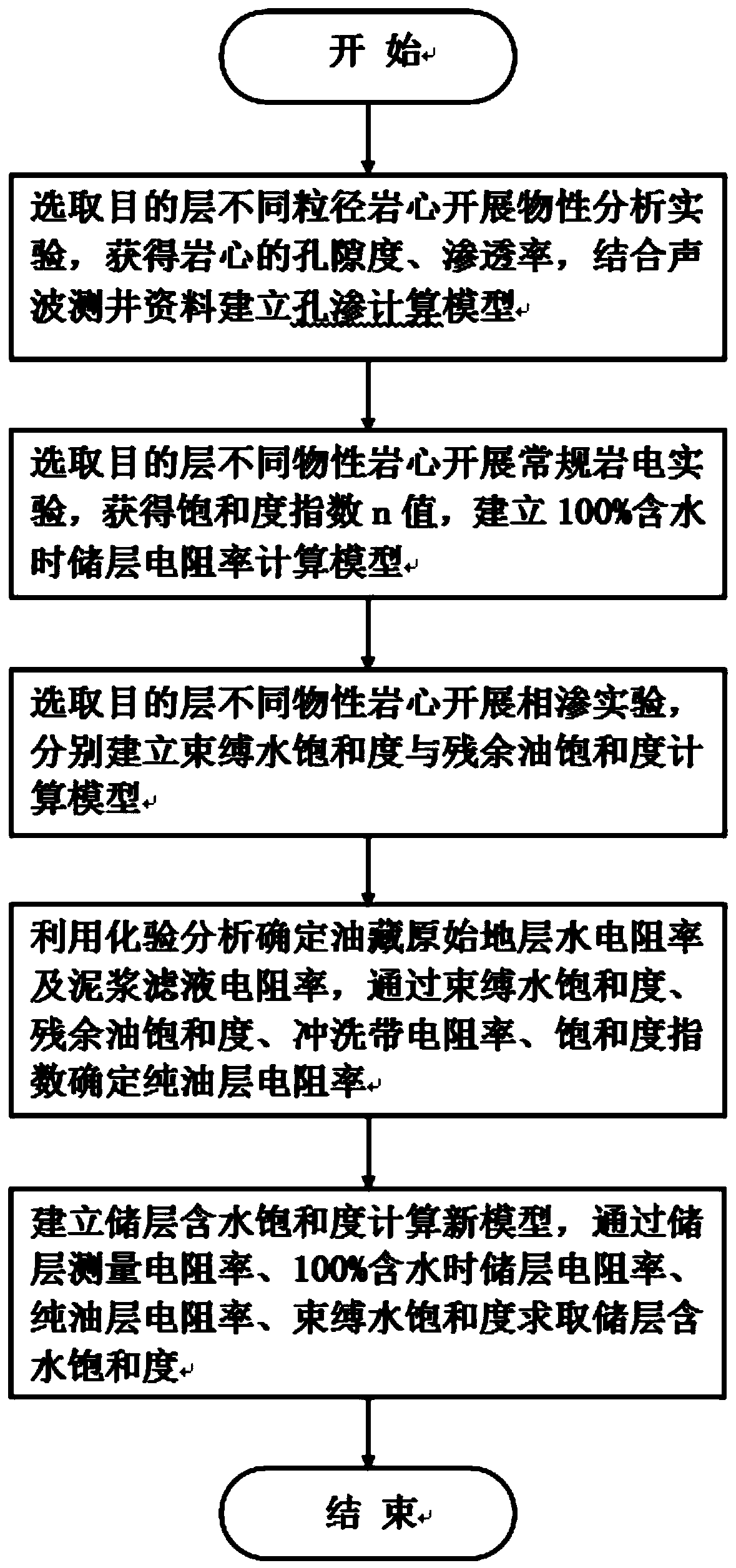

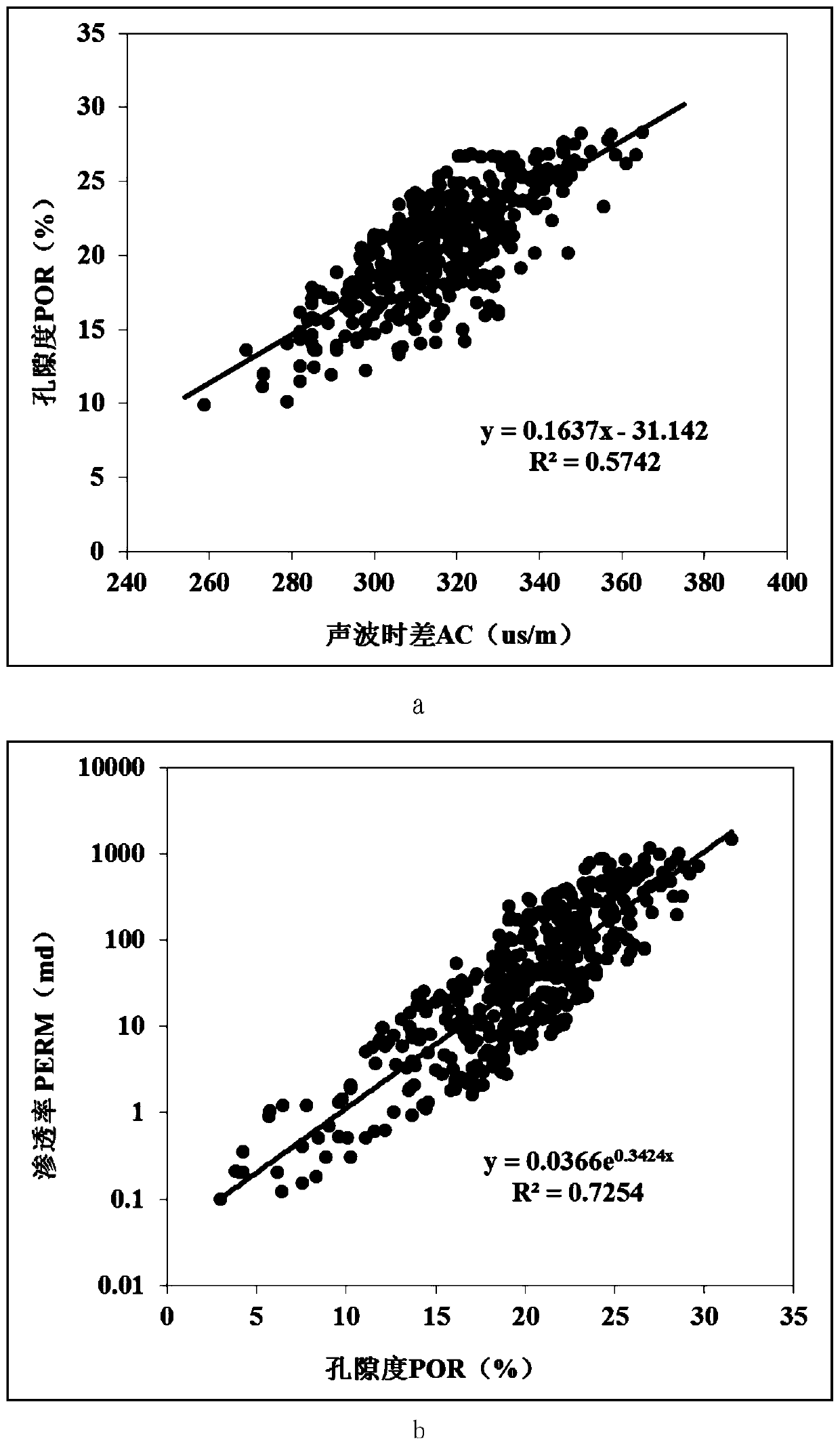

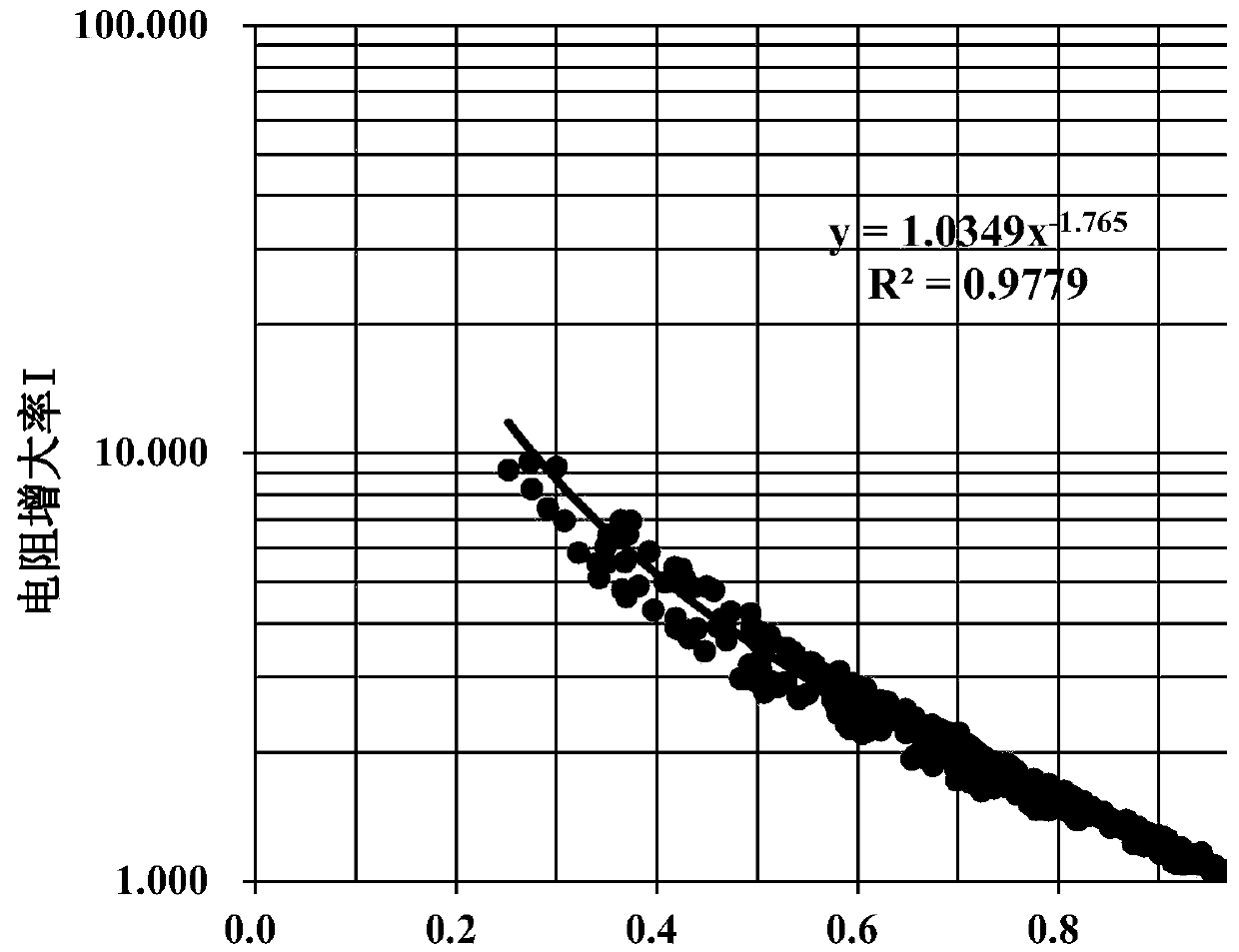

Method of determining reservoir water saturation

PendingCN109753755AAvoiding the Dilemma of Water Resistivity DeterminationSpecial data processing applicationsBorehole/well accessoriesElectrical resistance and conductanceRock core

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for manufacturing plugged honeycomb structure, and plugged honeycomb structure

A method for manufacturing a plugged honeycomb structure, includes: a forming raw material preparation step of mixing and kneading a partition wall base material raw material at least including cordierite powder and binder with water to obtain a partition wall base material forming raw material; a forming / drying step of forming the partition wall base material forming raw material to obtain a honeycomb formed body, and drying the honeycomb formed body to obtain a honeycomb dried body; a slurry application step of applying trapping layer forming slurry including a cordierite forming raw material or alumina to a surface of a not-fired partition wall base material of the obtained honeycomb dried body; a firing step of firing the slurry-applied honeycomb dried body; and a plugging step of disposing a plugging portion at open ends of predetermined cells of the slurry-applied honeycomb dried body or of the honeycomb fired body.

Owner:NGK INSULATORS LTD

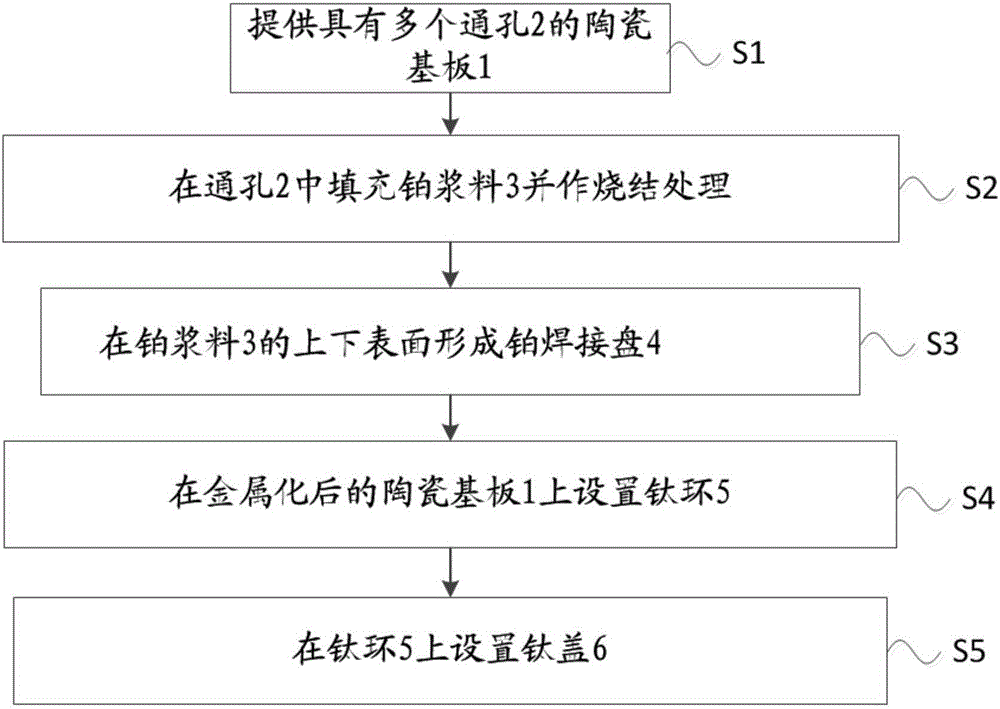

Manufacturing method of implantable artificial retina ceramic packaging body

Owner:深圳市勃望初芯半导体科技有限公司

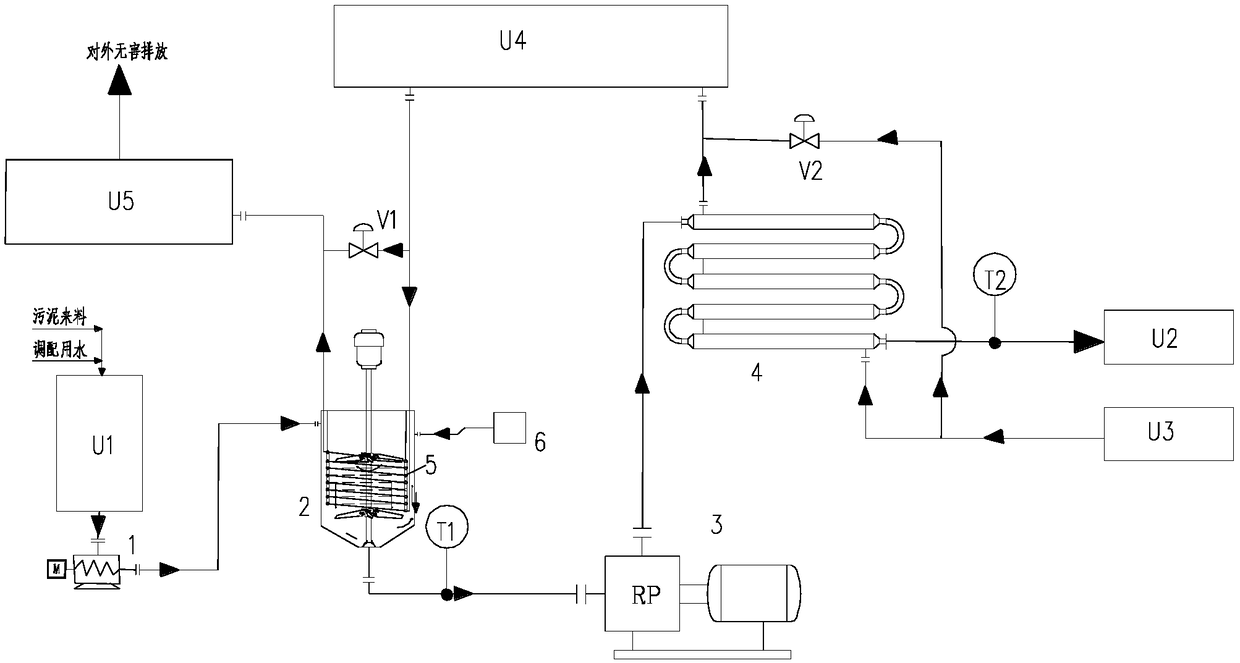

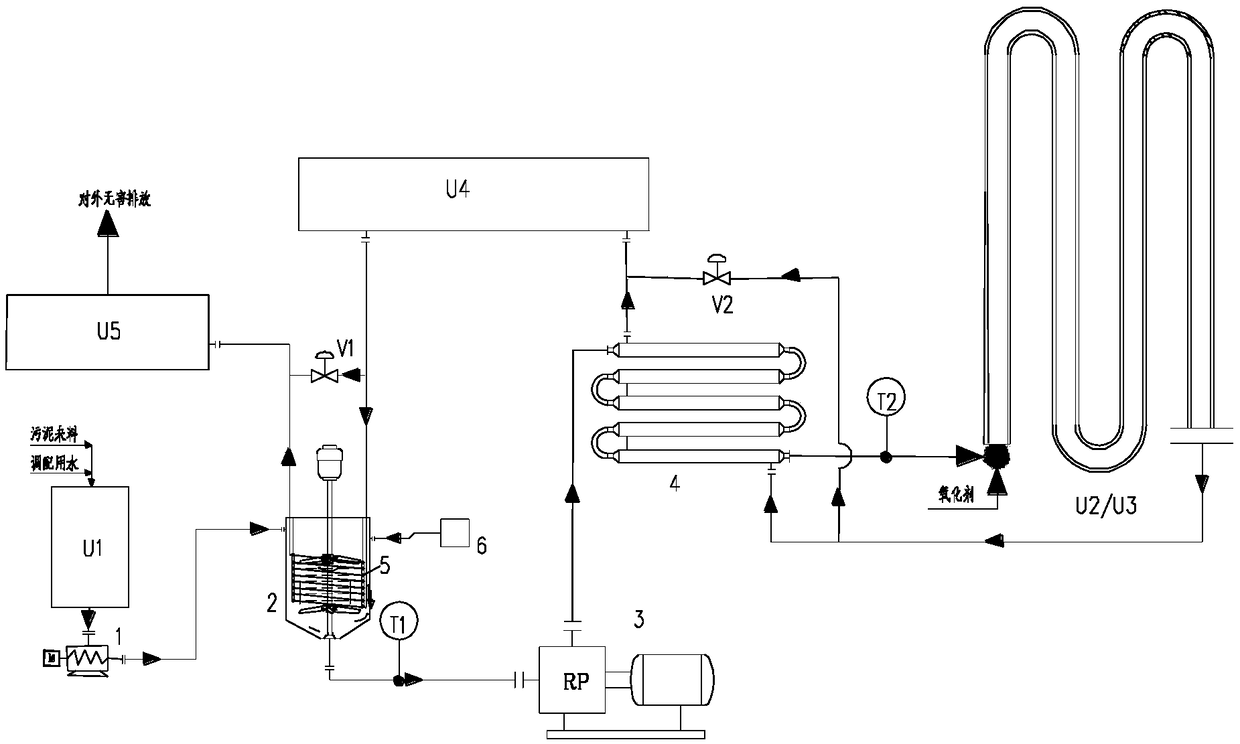

Step-by-step heating system for high-viscosity slurry

InactiveCN108862971AImprove heat transfer coefficientImprove homogeneityWater treatment compoundsSludge treatment by oxidationReduction treatmentResource utilization

Owner:XI AN JIAOTONG UNIV

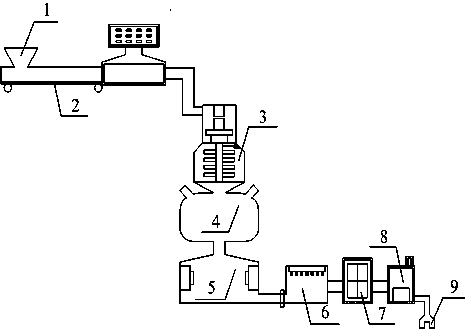

Production equipment of autoclaved aerated concrete blocks

InactiveCN104842446AHigh precisionHigh viscosityMixing operation control apparatusCeramic shaping plantsSlurryMechanical engineering

Owner:HANCHUAN XINXIN TECH

Material delivery pipe mechanism for bottom-mounted power drill rod

The invention belongs to the technical field of building, and relates to a material delivery pipe mechanism for a bottom-mounted power drill rod. The material delivery pipe mechanism comprises a drill rod and a length adjusting rod. A power mechanism is disposed between the drill rod and the length adjusting rod; the power mechanism is in driving connection with the drill rod, and is capable of driving the drill rod to rotate circumferentially. A delivery passage is formed within the drill rod, and a discharge hole is formed in the bottom of the drill rod and is communicated with the delivery passage. A slurry delivery pipe is disposed in the length adjusting rod, and extends into the power mechanism. A slurry delivery connecting pipe is disposed on the outer wall of the power mechanism, and one end of the slurry delivery connecting pipe is detachably connected to the slurry delivery pipe, while the other end of the slurry delivery connecting pipe is detachably connected to the delivery passage. The invention provides a delivery pipe mechanism capable of realizing bottom-mounted power of the drill rod, thereby guaranteeing that material can be delivered to the drill rod when power for the drill rod is mounted at bottom so as to obtain a high-strength cement soil mixing pile; no disturbance is produced for the power structure; and reliable and stable work is achieved.

Owner:ZHEJIANG ZHAODI TECH CO LTD

Method for preparing high-dispersion silver powder for photoetching touch screen silver paste

The invention relates to a method for preparing high-dispersion silver powder for photoetching touch screen silver paste, and belongs to the technical field of conductive metal powder preparing. The method includes the steps of reduced silver powder preparing, reduced silver powder surface modification, ball milling, airflow grading and the like. The method has the beneficial effects that a reaction system is kept at the constant temperature of 35+ / -2 DEG C in the manner that ice blocks are added into a reaction solution, so that the problems that a large amount of heat is emitted in the chemical reaction process, the temperature rises sharply, and silver powder is badly accumulated are solved; the size of a grinding medium is 1 mm, accumulated particles in the reduced silver powder can be sufficiently dispersed, the conductivity of the silver powder in slurry can be improved, and the adhesive force of the silver powder to a base material can be increased; and the prepared high-dispersion superfine silver powder with the largest particle size smaller than 4 microns is particularly suitable for laser engraving of the touch screen silver paste with the line width within the range from 20 microns to 30 microns, conductivity and other performance parameters are excellent, the production technology is simple, cost is low, and industrial production can be achieved.

Owner:KUNMING YINKE ELECTRONIC MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap