Three-dimensional printer, three-dimensional printing method and preparation method for metal slurry

A 3D printer and metal paste technology, applied in the field of 3D printing, can solve the problem of high equipment cost, and achieve the effect of ensuring printing accuracy, reducing restrictions and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

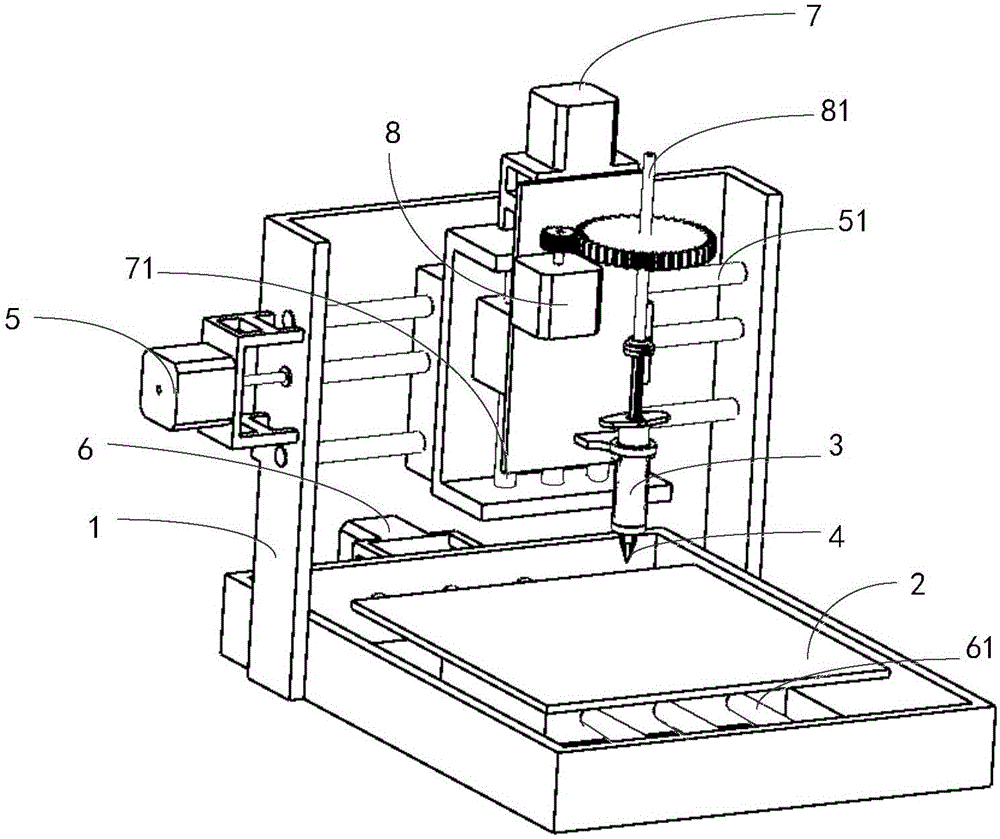

[0060] A 3D printer is provided in Embodiment 1, please refer to figure 1 , figure 1 It is the structural diagram of the 3D printer in the embodiment of the present application, such as figure 1 As shown, the printer includes:

[0061] bracket 1;

[0062] A printing base plate 2, the printing base plate 2 is arranged on the support 1;

[0063] Injector 3, described injector 3 is arranged on described support 1; Described injector 3 is used for accommodating metal slurry; The outlet of described injector 3 is equipped with nozzle 4; The center line of described nozzle 4 is in line with the printing The bottom plates 2 intersect vertically, and the ejection direction of the nozzle 4 points to the printing bottom plate 2, so that the metal paste can be injected onto the printing bottom plate 2;

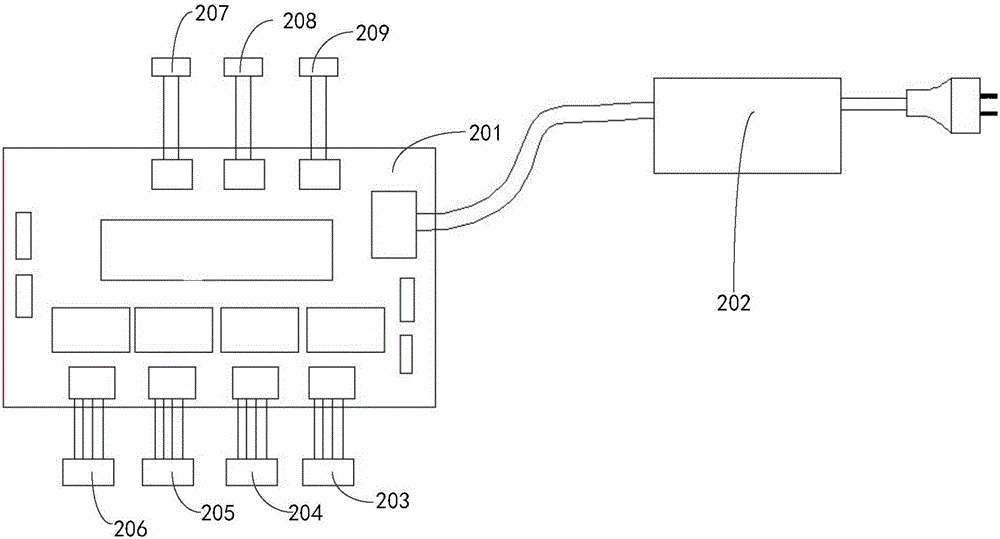

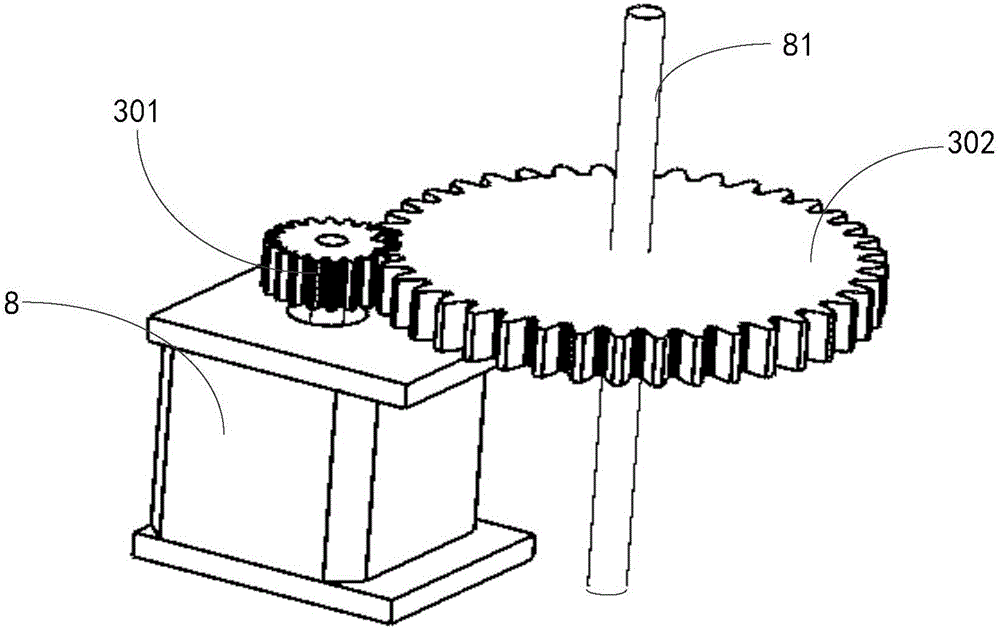

[0064] The X-axis stepping motor 5, the Y-axis stepping motor 6, the Z-axis stepping motor 7 and the E-axis stepping motor 8 arranged on the support 1; the X-axis stepping motor 5 and t

Embodiment 2

[0089] In Embodiment 2, a 3D printing method is provided, and the method is applied to the 3D printer provided in Embodiment 1, such as Figure 5 As shown, the method includes:

[0090] Step S501, receiving the printing control signal carrying the parameters of the model to be printed;

[0091] Step S502, according to the printing control signal, control the rotation direction and rotation speed of the X-axis stepping motor 5, the Y-axis stepping motor 6, and the E-axis stepping motor 8, so as to print the The metal paste is injected onto the printing base plate to complete the printing of the Nth layer model;

[0092] Step S503, according to the printing control signal, control the rotation direction and rotation speed of the Z-axis stepping motor 7, so that the syringe 3 moves a first distance in a direction away from the printing base 2; the first distance is the thickness of each layer model characterized in the parameters;

[0093] Step S504, according to the printing con

Embodiment 3

[0106] In embodiment three, a method for preparing metal paste is provided, and the metal paste is the printing material of the 3D printer provided in embodiment one, such as Figure 6 As shown, the method includes:

[0107] Step S601, screening raw metal raw materials to obtain metal powders with a size smaller than 300 mesh;

[0108] Step S602, mixing the wax and the metal powder into a mixture;

[0109] Step S603, heating the mixture;

[0110] Step S604, adding stearic acid into the mixture and mixing thoroughly to obtain the metal paste.

[0111] Taking the metal paste as copper paste as an example, the specific preparation method is:

[0112] Since the copper powder often agglomerates, before preparing the copper paste, use a 200-300-mesh sieve to screen the copper powder to prevent the copper powder particles from being too large and blocking the nozzle during printing;

[0113] Then mix wax and copper powder according to the mass ratio of 100:10, and make copper slurry

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap