Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Ferric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, iron(III) refers to the element iron in its +3 oxidation state. In ionic compounds (salts), such an atom may occur as a separate cation (positive ion) denoted by Fe³⁺. The adjective ferric or the prefix ferri- is often used to specify such compounds — as in "ferric chloride" for iron(III) chloride, FeCl3. The adjective "ferrous" is used instead for iron(II) salts, containing the cation or Fe²⁺. The word ferric is derived from the Latin word ferrum for iron.

Preoxidized-composite electrolyzing method for removing arsenic in groundwater

InactiveCN101139150ALow toxicityImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisFenton reagent

A method to remove arsenic in underwater by preoxidation-combined electrolyzing relates to a method to remove arsenic from underwater, belonging to the technical field of water treatment. The present invention has solved the defect that more expensive pure nulvalent iron and slower corrosion speed of the pure nulvalent iron have limited the absorption of arsenic on the nulvalent iron. The present invention includes the following steps: the underwater containing arsenic is pre-oxidized by ozone, potassium ferrate, potassium permanganate, H2O2, photocatalysis oxidation reagent or Fenton reagent, thereby transferring As(III) to As(V). The water pre-oxidized passes through a filtering bed containing cast-iron scrap and carbon granules. The oxidizer left in the preoxidation section promotes the reaction of the step.

Owner:HARBIN INST OF TECH

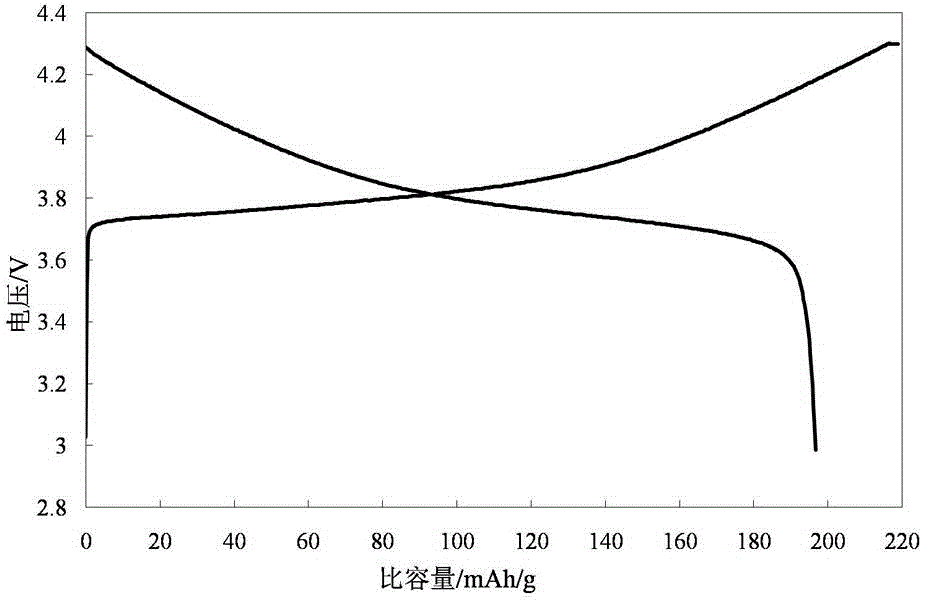

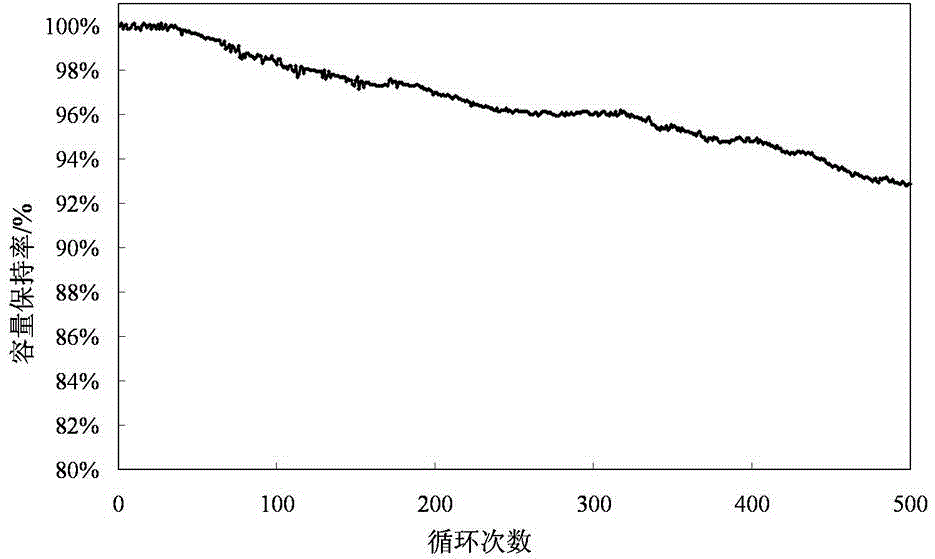

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

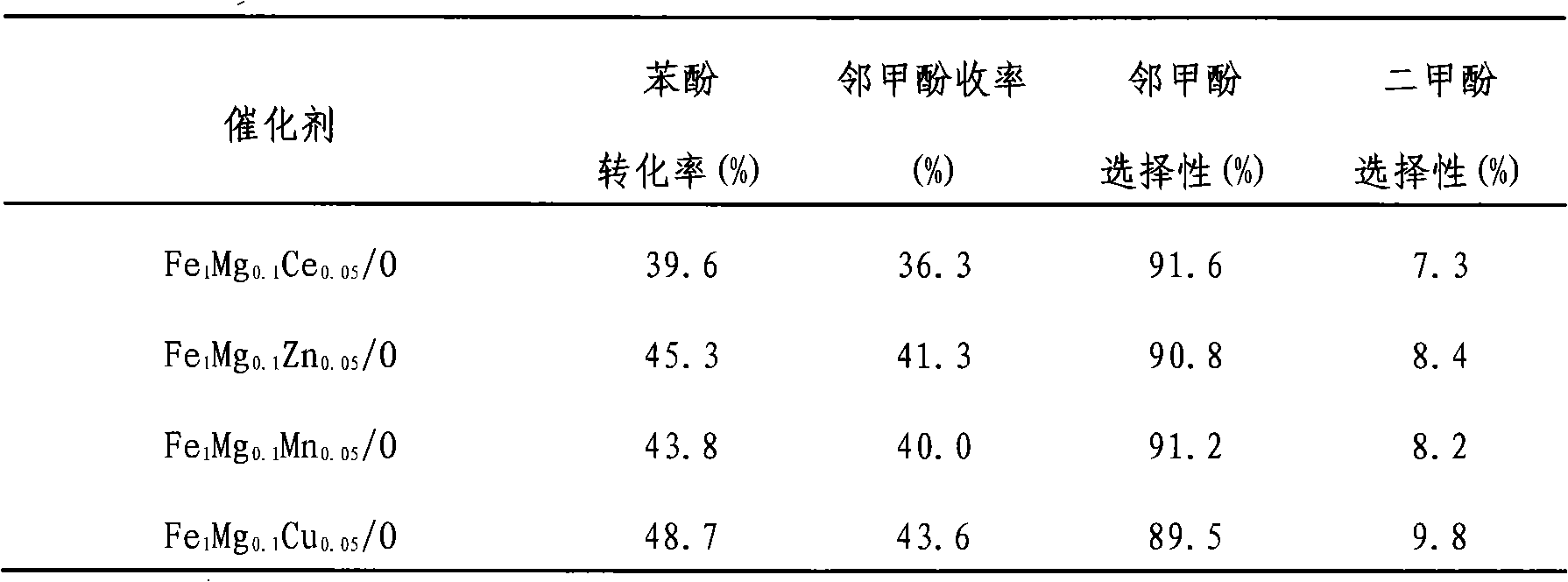

Phenol ortho-methylation catalyst and preparation method thereof

ActiveCN101513614AEasy to makeLow reaction temperatureOrganic chemistryOrganic compound preparationMagnesium saltOrtho position

Owner:HUNAN XINLING CHEM CO LTD

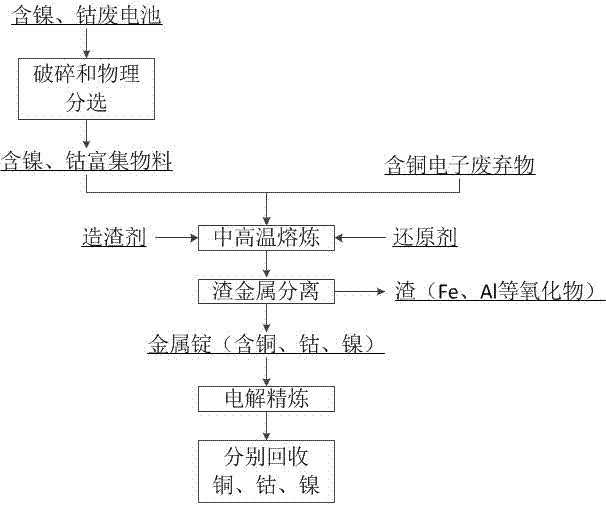

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

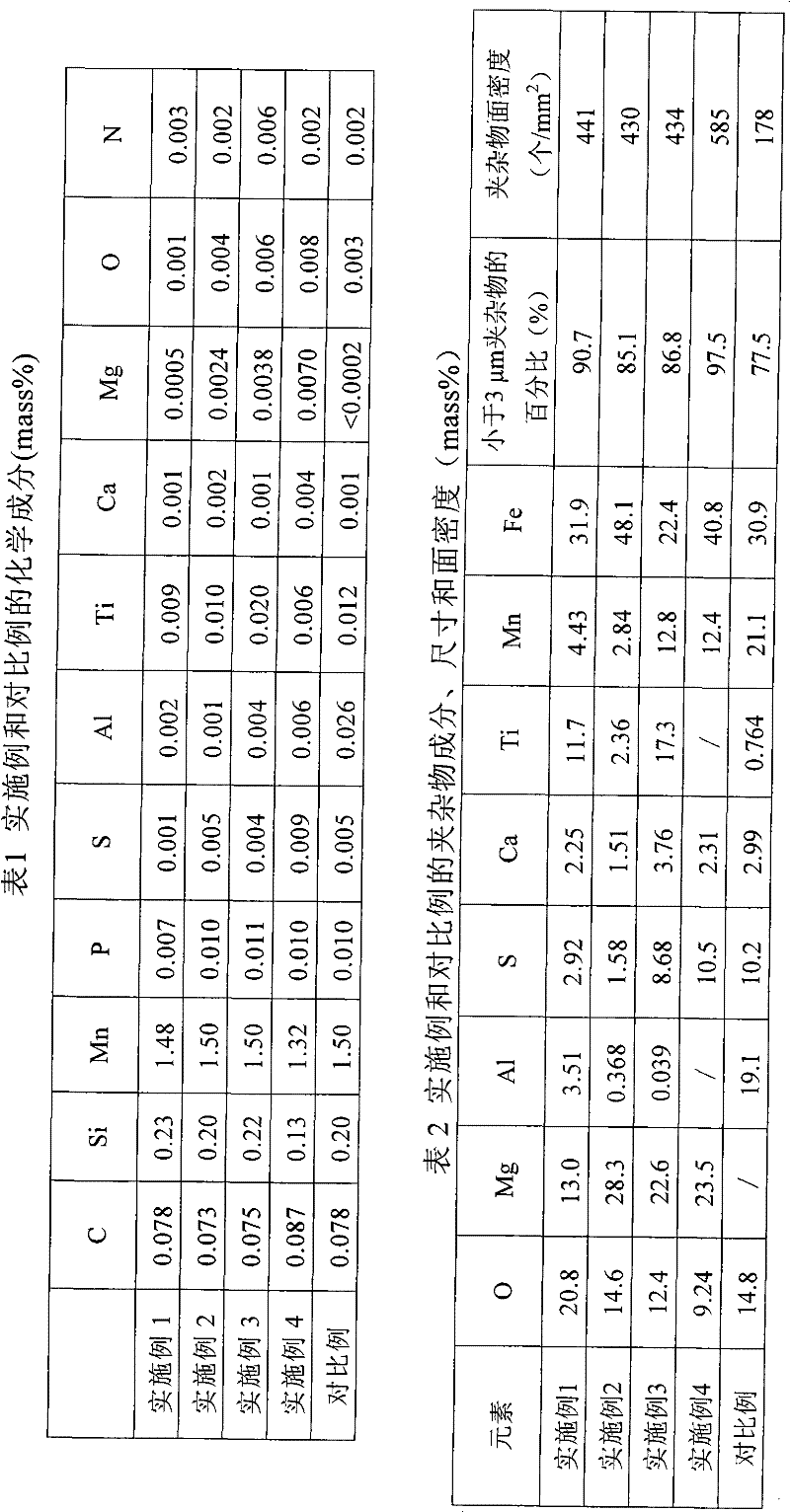

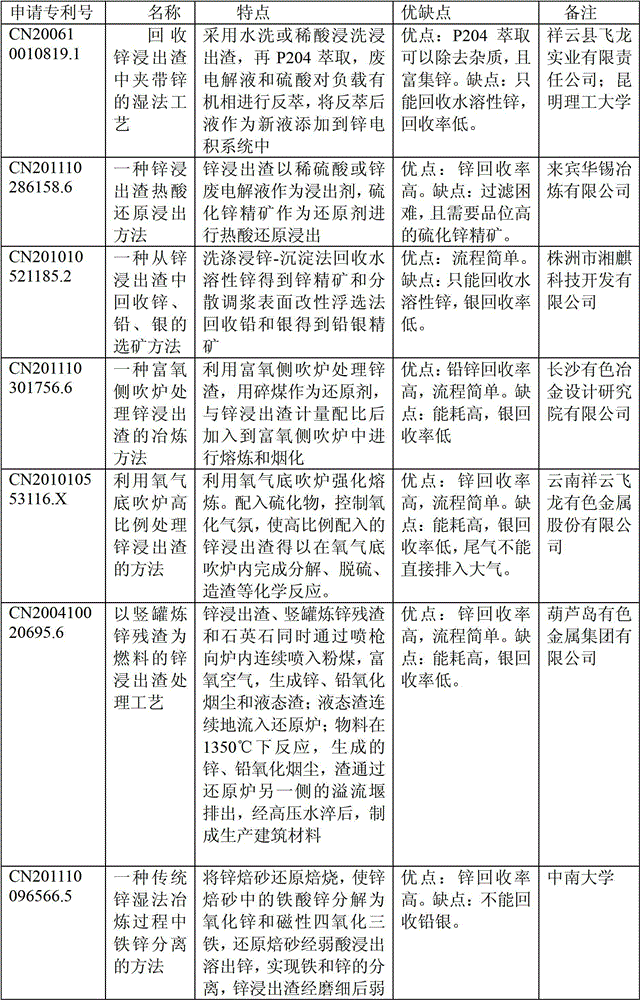

Control method of inclusions in thick steel plate used for high heat input welding

Owner:BAOSHAN IRON & STEEL CO LTD

Micro-electrolytic filler containing catalyst

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

Methods for purifying and stabilizing hydrofluoroolefins and hydrochlorofluoroolefins

Owner:ARKEMA INC

Titanium-carbide-based steel-bonded cemented carbide material and preparation method thereof

Owner:WUXI XINQUN NEW MATERIAL TECH CO LTD

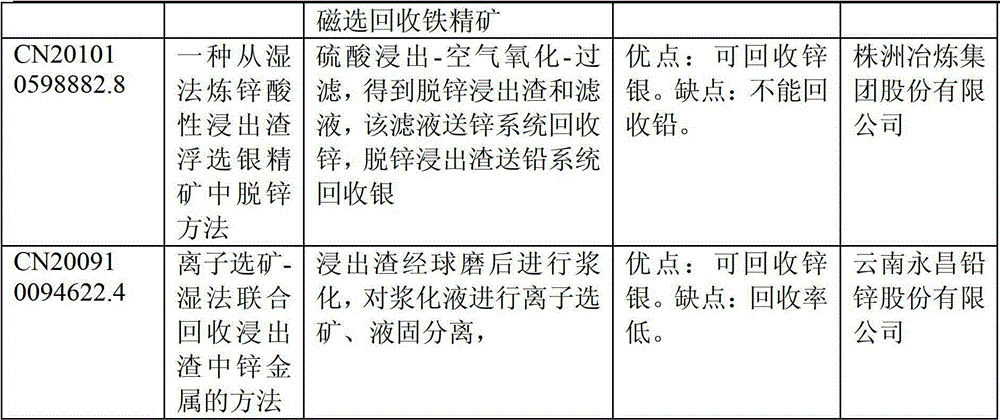

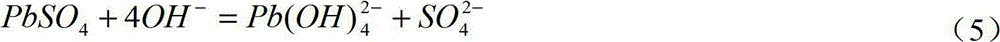

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

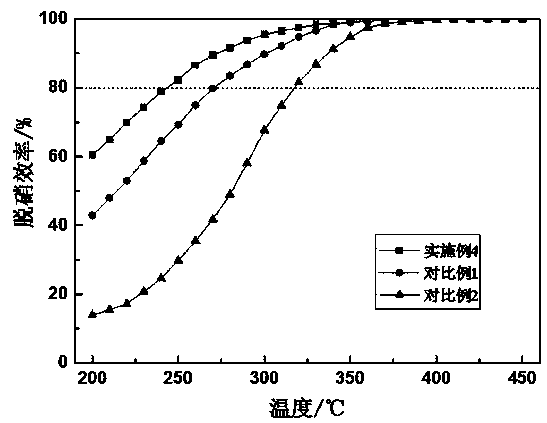

Copper and iron compound honeycomb coating type denitrification catalyst as well as preparation method and application thereof

InactiveCN109499607AImprove thermal stabilityImprove anti-sulfur poisoning performanceMolecular sieve catalystsDispersed particle separationIon exchangeVacuum coating

Owner:VALIANT CO LTD

Composite reinforced multinutrition rice and process thereof

ActiveCN102067969AMeeting nutritional needsShorten soakFood preparationCALCIUM LACTOBIONATEGluconates

Owner:天津知味米有限公司

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

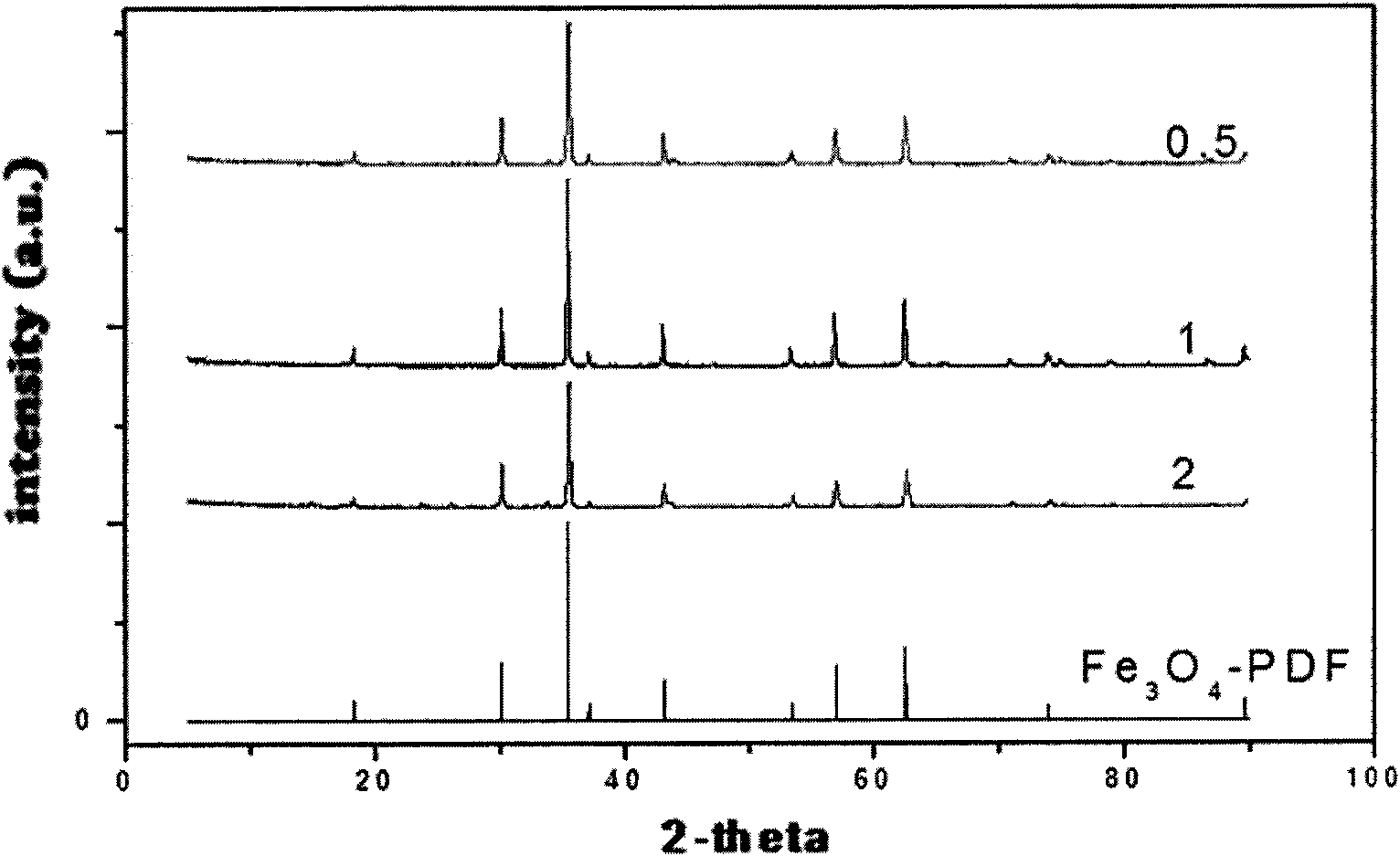

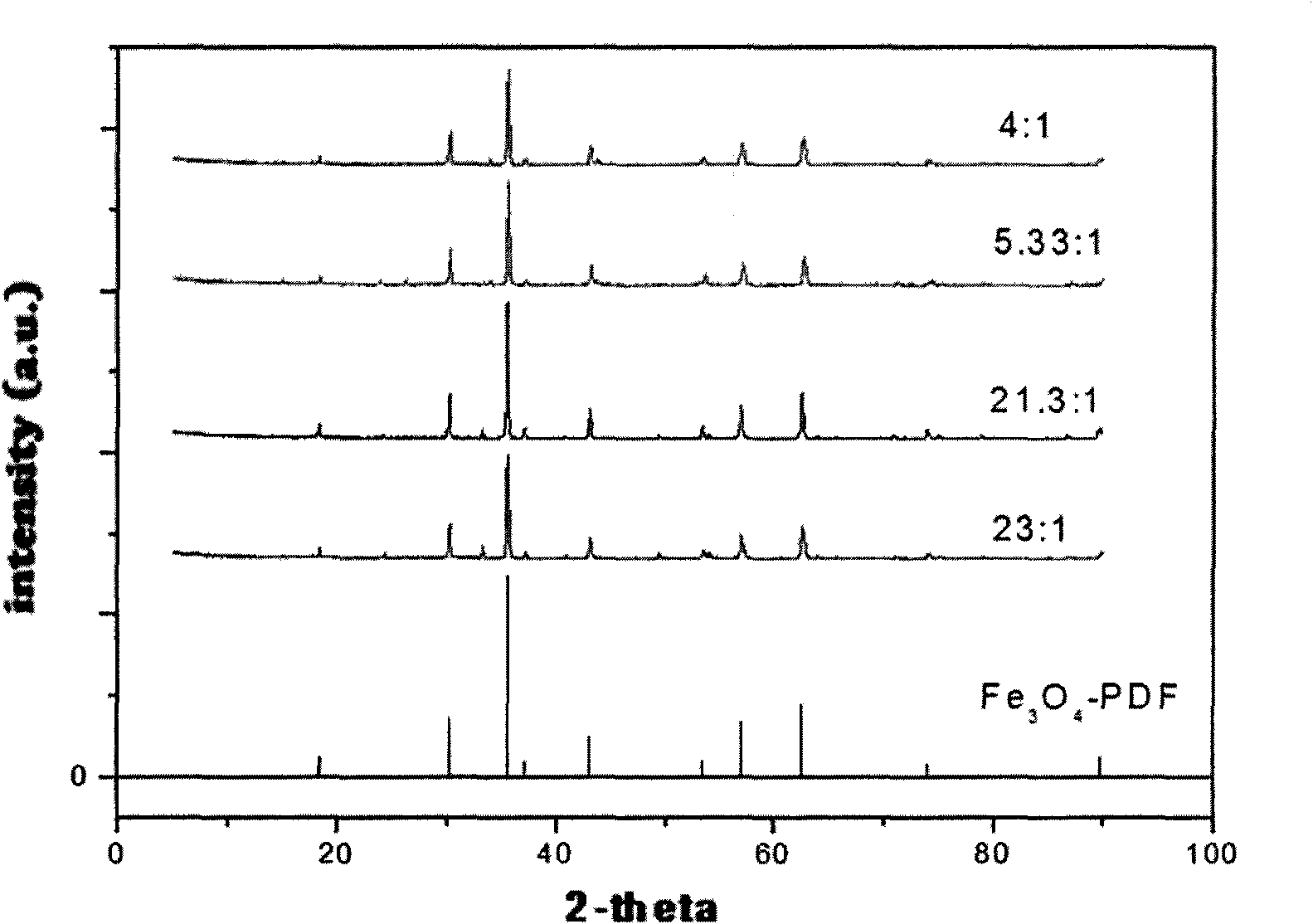

Magnetic granule and attapulgite nanometer composite material, and hydrolytic method for preparing its ferrous salts

InactiveCN1830884AWith characteristicsResolve separabilityWater/sewage treatment by sorptionClaywaresFerrous saltsMagnetite Nanoparticles

Owner:HEFEI UNIV OF TECH

Flux for removing iron from Mg alloy and its preparing process

Owner:SHANGHAI JIAO TONG UNIV

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

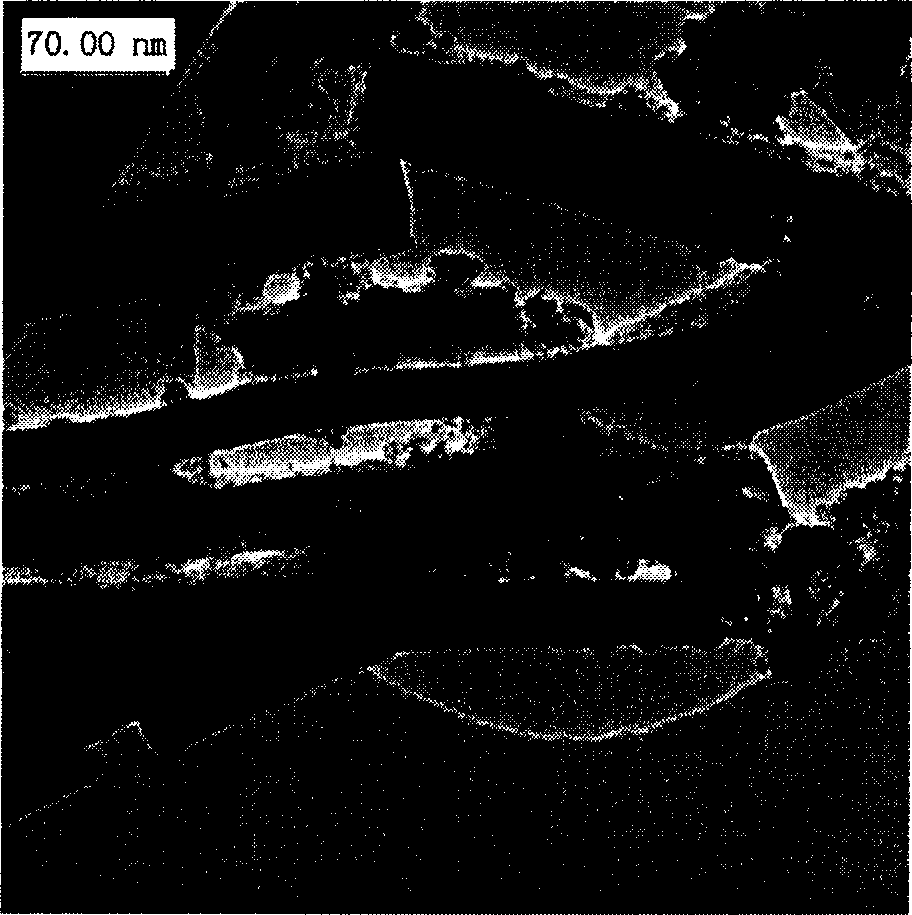

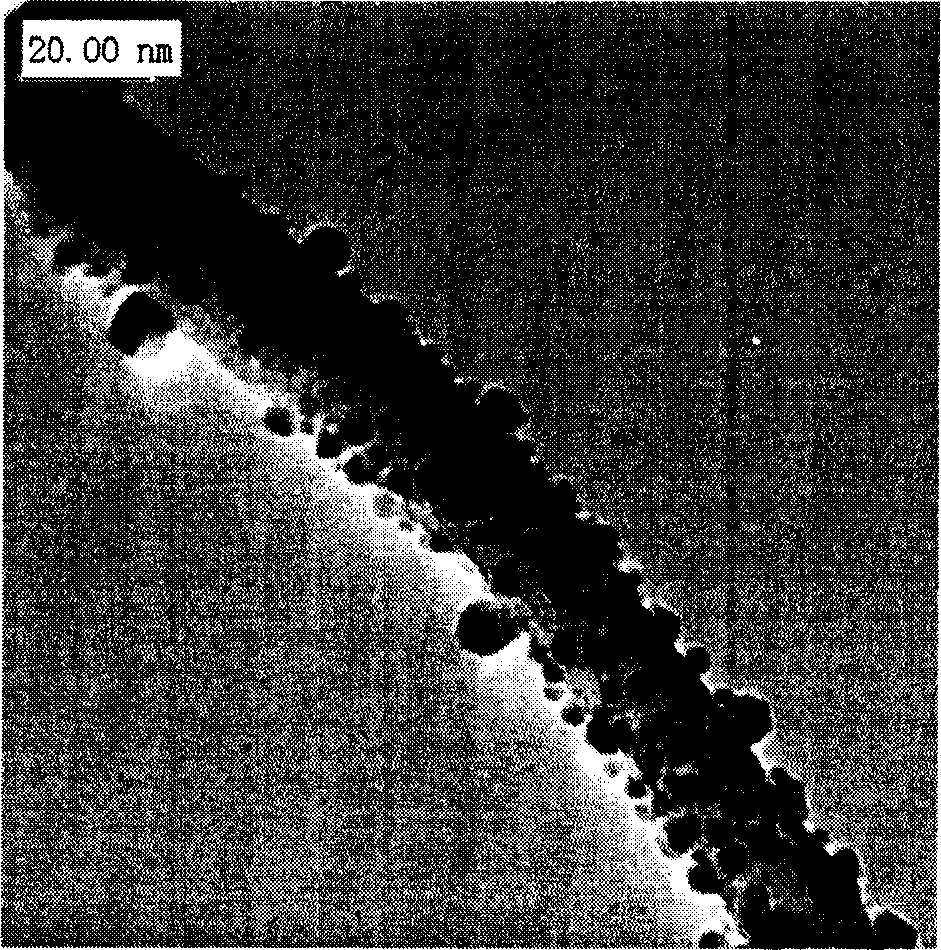

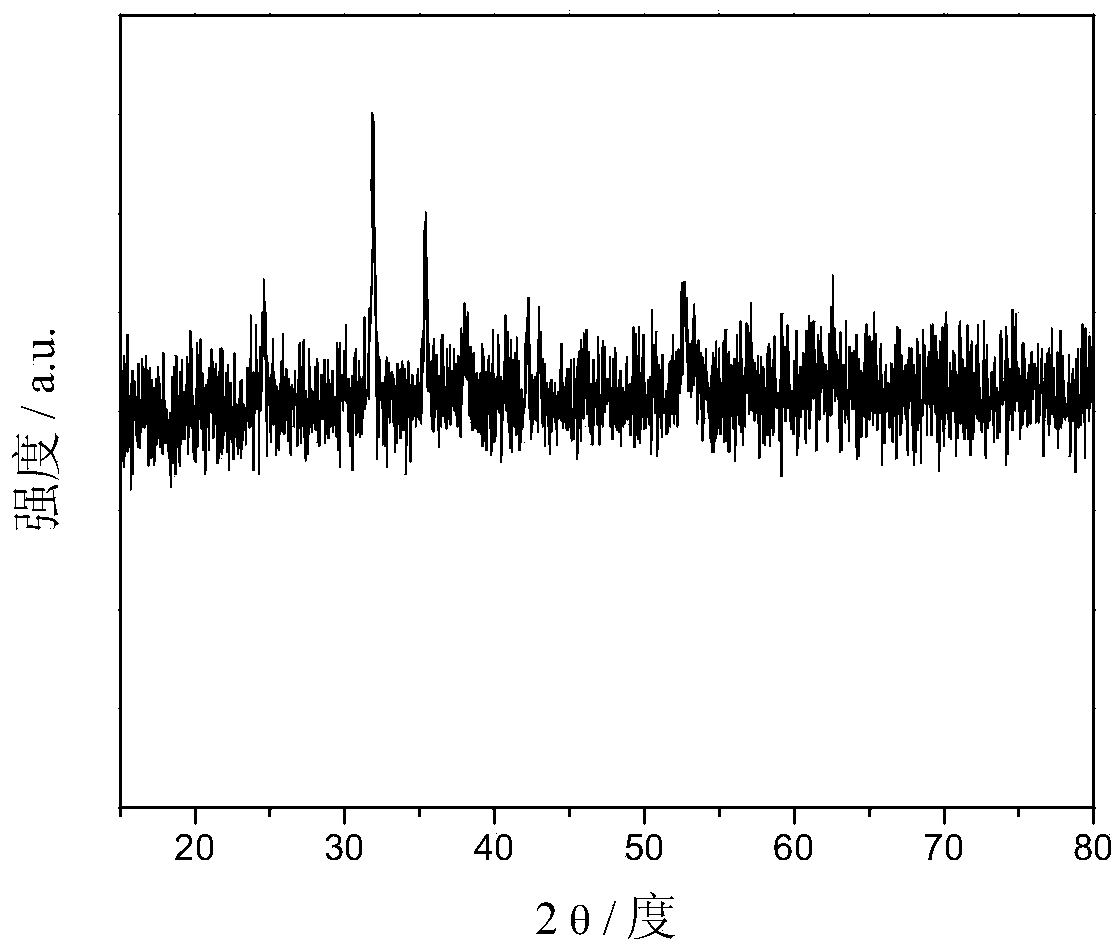

Method for preparing ferric vanadate-graphene negative electrode composite material

ActiveCN104766975AUniform textureGood dispersionNegative electrodesSecondary cellsDispersityReaction rate

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

Method for processing red mud by utilizing iron pyrites

Owner:BEIJING UNIV OF CHEM TECH

Low-temperature photo-irradiation preparation method for rare earth doped bismuth titanate ferro-electricity membrane

InactiveCN101269957APromoting solidification and densificationImprove ferroelectric propertiesElectricityPhoto irradiation

Owner:HARBIN INST OF TECH

NiCuSiFe alloy

Owner:WUFAN ALLOY ALUMINUM WUJIN

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

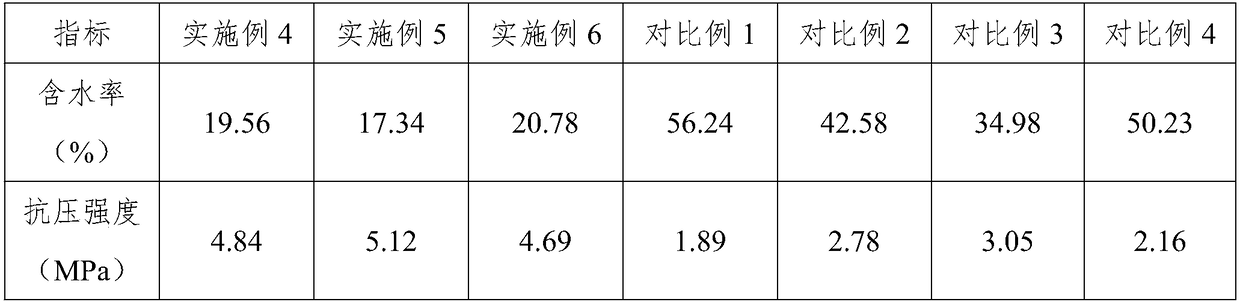

Sludge solidifier and preparation method thereof

ActiveCN108314280AImprove water qualityReduce pollutionFixation/solidifcation sludge treatmentSulfateSludge

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Ductile cast iron material, composition containing same and production method of bearing saddle and ductile cast iron

Owner:CRRC QIQIHAR ROLLING CO LTD

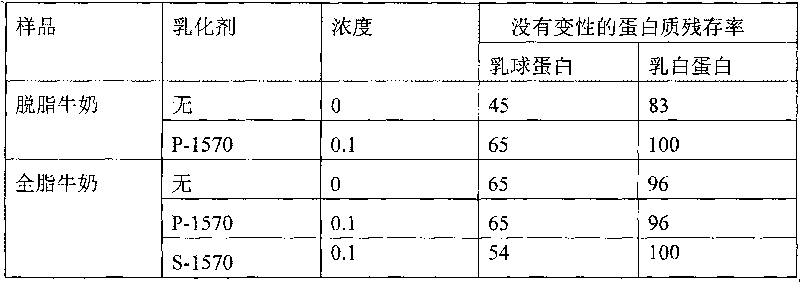

Milk oligopeptide added liquid milk and preparation method thereof

ActiveCN101731346AImprove absorption rateAdd high absorption rate to high temperature liquid milkMilk preparationSucroseLiquid milk

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

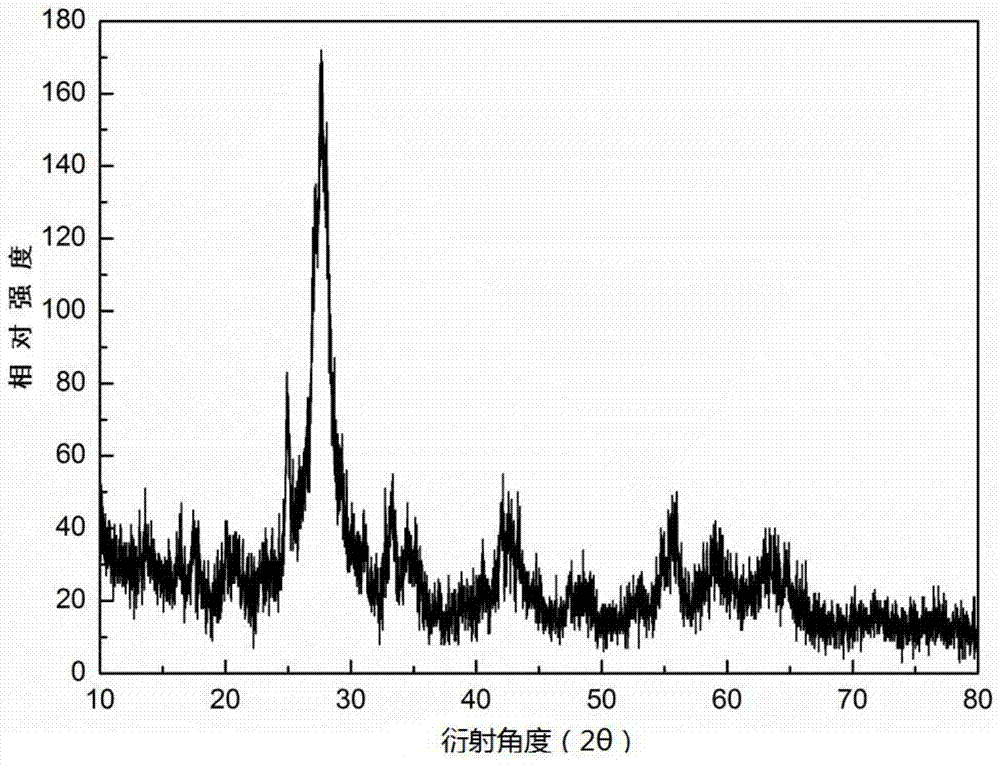

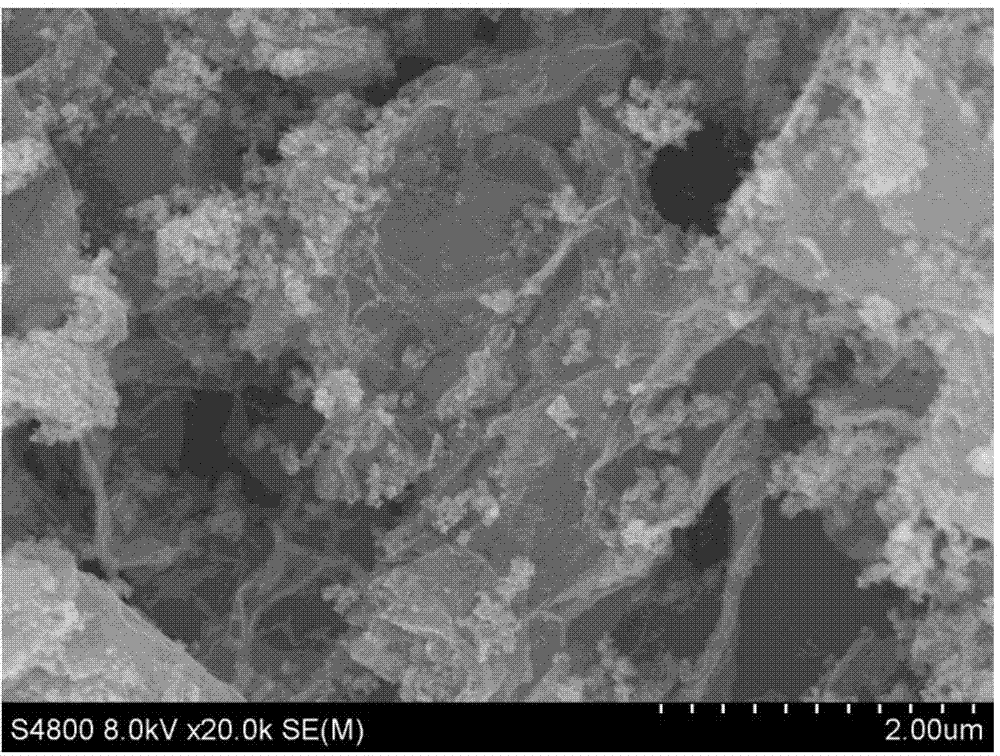

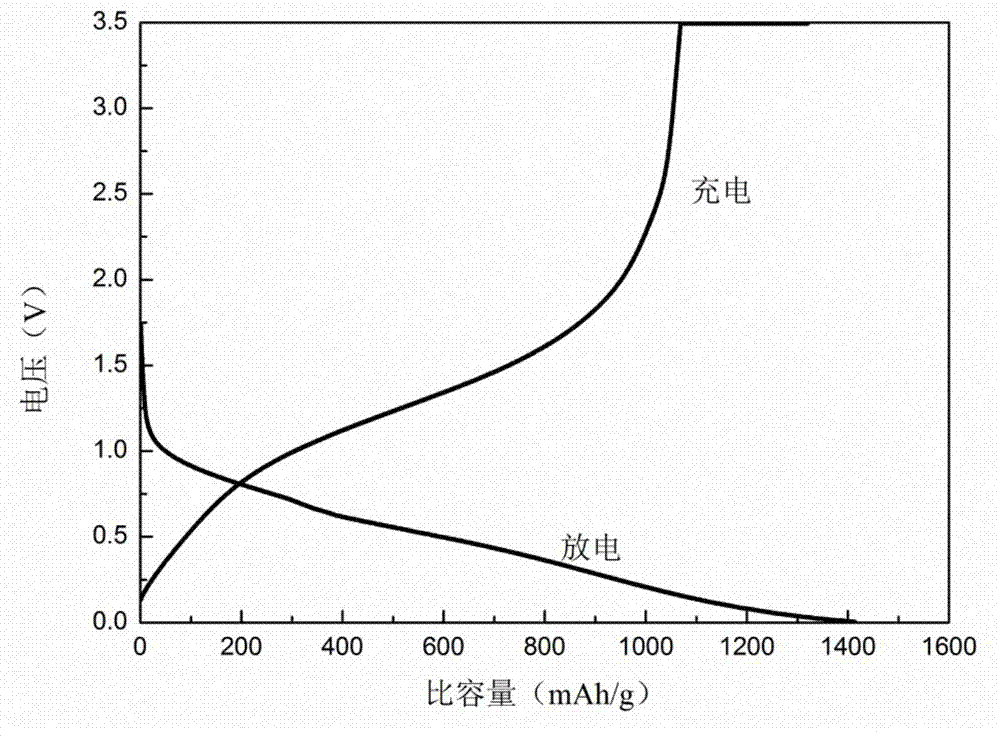

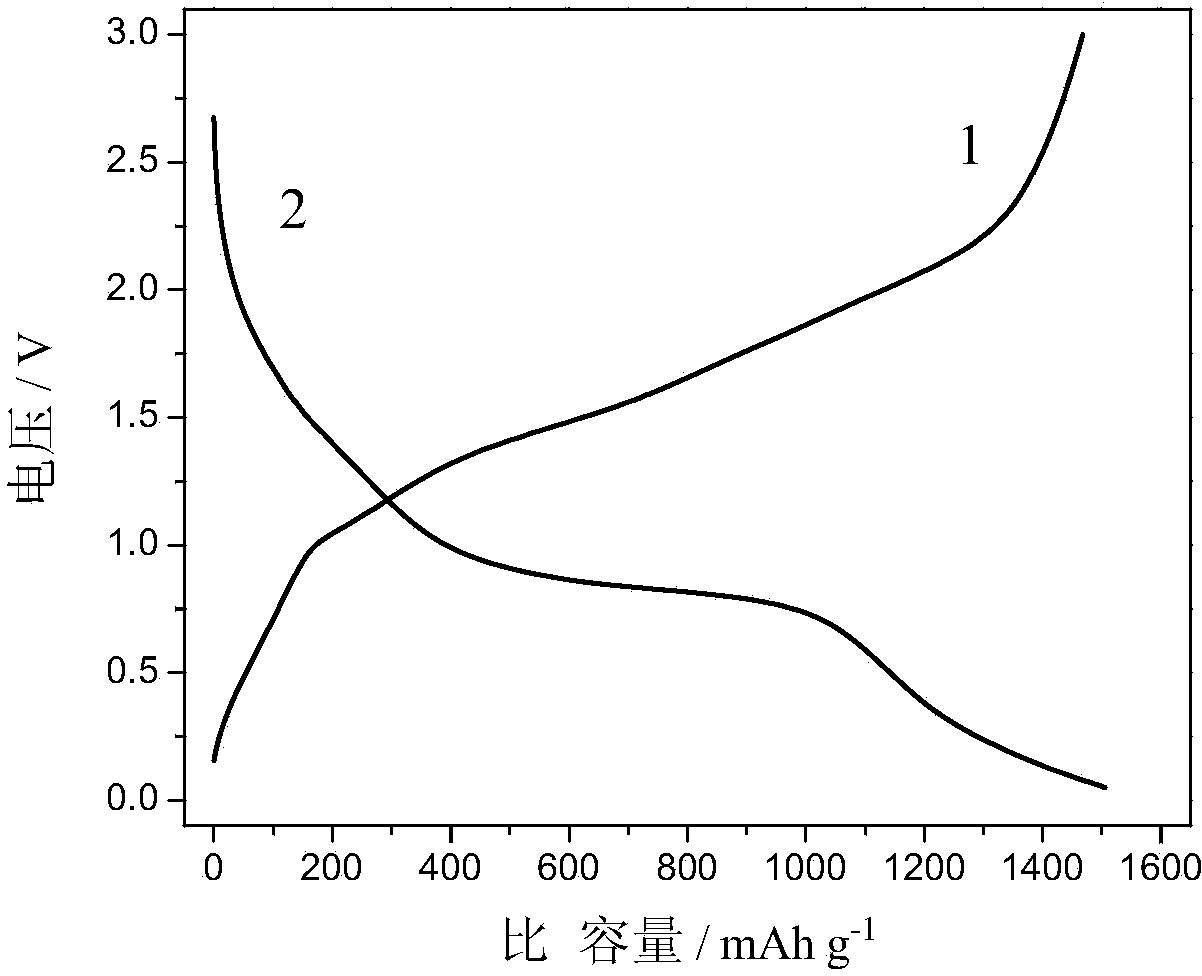

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Hexavalent chromium reducing agent and preparation method thereof

The invention provides a hexavalent chromium reducing agent and a preparation method thereof. The reducing agent contains the following components in parts by weight: 50-90 parts of an iron-based reducing agent, 0.57-3.6 parts of nanometer zero-valent iron and 0.9-7.1 parts of a dispersing agent. According to the hexavalent chromium reducing agent provided by the invention, an iron-based reducingagent is uniformly packaged by a dispersing agent solution containing nanometer zero-valent iron particles, and very high reaction activity is achieved by mixing nanometer zero-valent iron with the iron-based reducing agent, so that hexavalent chromium in the reducing agent solution can be rapidly reduced; dispersing agent molecules are capable of stabilizing nanometer zero-valent iron and packaging the iron-based reducing agent, so that the oxidation of the iron-based reducing agent by oxygen in the air is prevented, the hexavalent chromium reducing agent has a moisture preserving function, and the situations that because the partial water-entraining iron-based reducing agent is dehydrated under a high temperature condition, the solubleness is reduced, and the iron-based reducing agent isunlikely to participate in the reducing reaction of hexavalent chromium are prevented.

Owner:DONGYUAN HONGCHAO TECH

Boron-phosphorus alloy cast iron used in air compressor cylinder block and its manufacturing process

InactiveCN102268587AImprove wear resistanceImprove tensile propertiesProcess efficiency improvementElectric furnaceAlloyCylinder block

Owner:ZHUJI HUAJIA AIR COMPRESSOR

Method for melting purification of magnesia by using waste magnesium product

InactiveCN101837996ADoes not affect normal useQuality is not affectedChemical industryMagnesiaCompression moldingTunnel kiln

Owner:DASHIQIAO WEIMING FURNACE MATERIAL

Method for preparing lithium manganate by wet-doping method

InactiveCN103337619AIncrease the average oxidation stateSuppress purityCell electrodesManganates/permanganatesOxidation stateManganate

Owner:HUNAN DAHUA NEW ENERGY

High-temperature-resistant high-performance rare earth permanent magnet material

InactiveCN105374488AHigh temperature resistance and high performanceImprove stabilityInorganic material magnetismRare-earth elementTemperature resistance

Owner:南通长江电器实业有限公司

Dandelion-shaped iron phosphate microspheres and preparation method thereof through electrochemical anode oxidation

InactiveCN103556169ASynthesis temperature is lowEasy to embedElectrolysis componentsMicrosphereElectrochemical anodization

The invention discloses dandelion-shaped iron phosphate microspheres and a preparation method thereof through electrochemical anode oxidation, relating to dandelion-shaped iron phosphate microspheres and a method for preparing the dandelion-shaped iron phosphate microspheres through electrochemical anode oxidation, and aiming to solve the problems that iron phosphate micro nanoparticles prepared by the prior art are long in synthesis time, high in synthesis temperature and complex in operation step. The method disclosed by the invention comprises the steps of preparing a mixed solution of phosphoric acid and ammonium fluoride of a certain molar concentration to serve as electrolyte for anode oxidation, and generating the dandelion-shaped iron phosphate microspheres on the surface of an iron foil under conditions of certain current by taking a high-purity iron foil as an anode and a platinum sheet as a cathode. The iron phosphate obtained by the invention is used as a precursor when being used for preparing lithium iron phosphate.

Owner:HARBIN INST OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap