Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Phosphate is a chemical derivative of phosphoric acid. The phosphate ion (PO₄)³⁻ is an inorganic chemical, the conjugate base that can form many different salts. In organic chemistry, a phosphate, or organophosphate, is an ester of phosphoric acid. Of the various phosphoric acids and phosphates, organic phosphates are important in biochemistry and biogeochemistry (and, consequently, in ecology), and inorganic phosphates are mined to obtain phosphorus for use in agriculture and industry. At elevated temperatures in the solid state, phosphates can condense to form pyrophosphates.

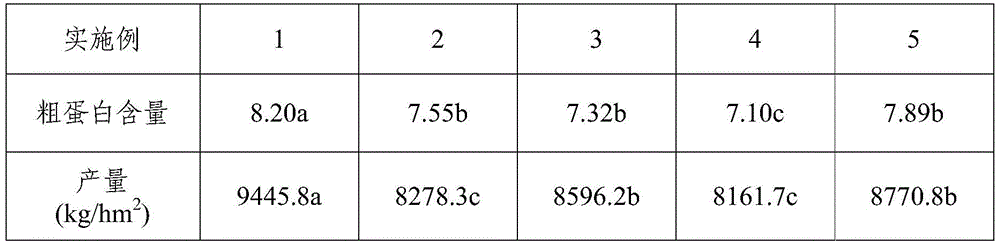

Method for producing amino acid tobacco-specific foliar fertilizer by using abandoned fur

InactiveCN102718605AWell developed root systemQuality improvementFertilizer mixturesDiseasePhosphate

Owner:HUNAN TOBACCO CHENZHOU

Cement composition

InactiveUS20050016421A1High strengthImprove abilitiesOrganic fertilisersSoil conditioning compositionsPhosphateSilicic acid

To provide a novel cement which is alkalescent, capable of solidifying a wide range of soil and applicable to biological environment. That is, a cement composition comprising 100 parts by weight of magnesium oxide comprising 5 to 25% by weight of at least any one of silicic acid, alumina and iron oxide, 3 to 35 parts by weight of a phosphate, 2 to 30 parts by weight of gypsum and 0.005 to 7 parts by weight of an oxycarboxylic acid or a ketocarboxylic acid.

Owner:NAT AGRI & FOOD RES ORG +1

Mineral recovery processes

InactiveUS6077441AQuality improvementEffective sedimentationSeparation devicesDifferential sedimentationPhosphateEvaporation

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

Alkali/transition metal halo- and hydroxy-phosphates and related electrode active materials

InactiveUS6964827B2PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHalogenPhosphate

Owner:VALENCE TECH INC

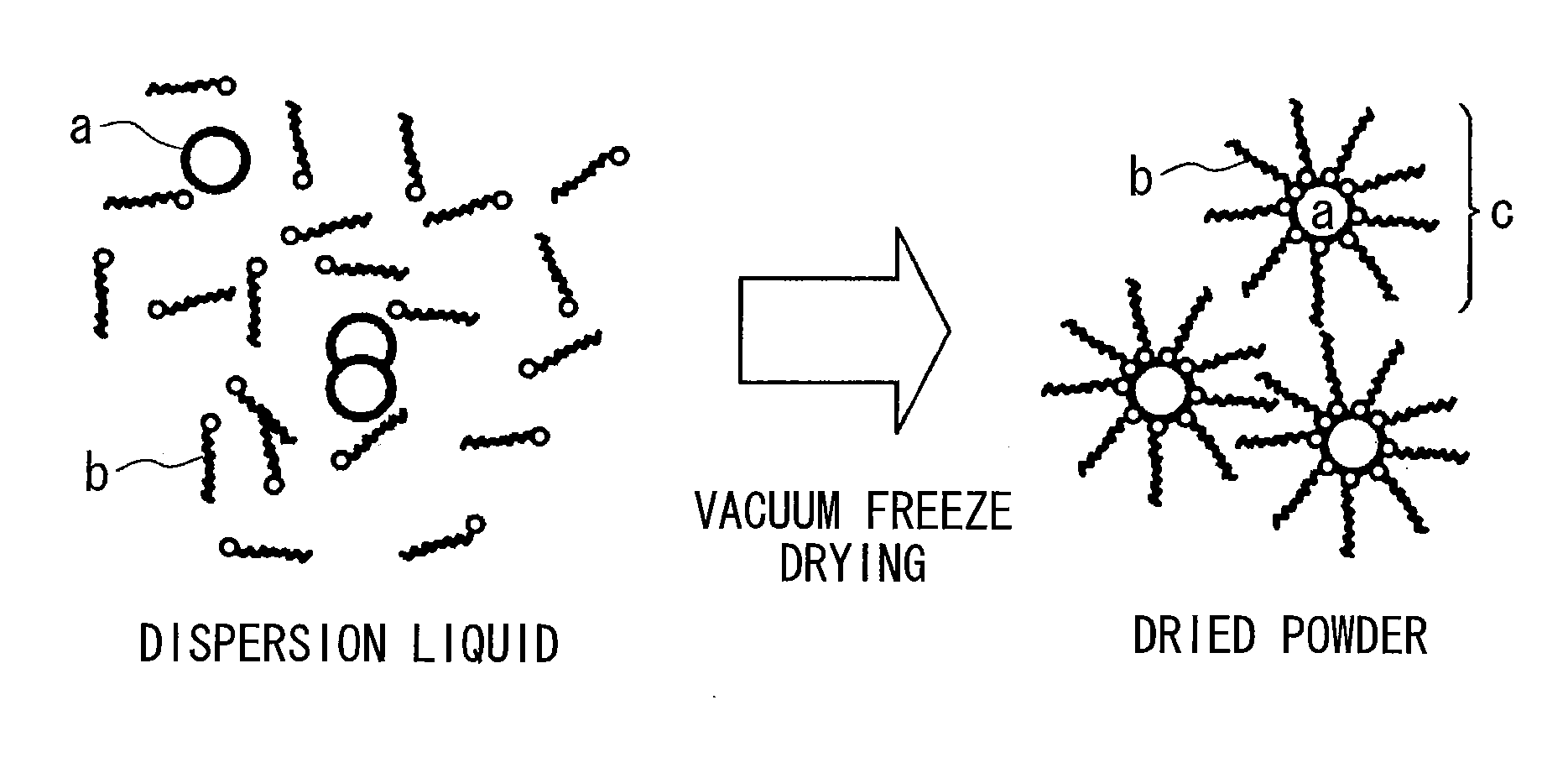

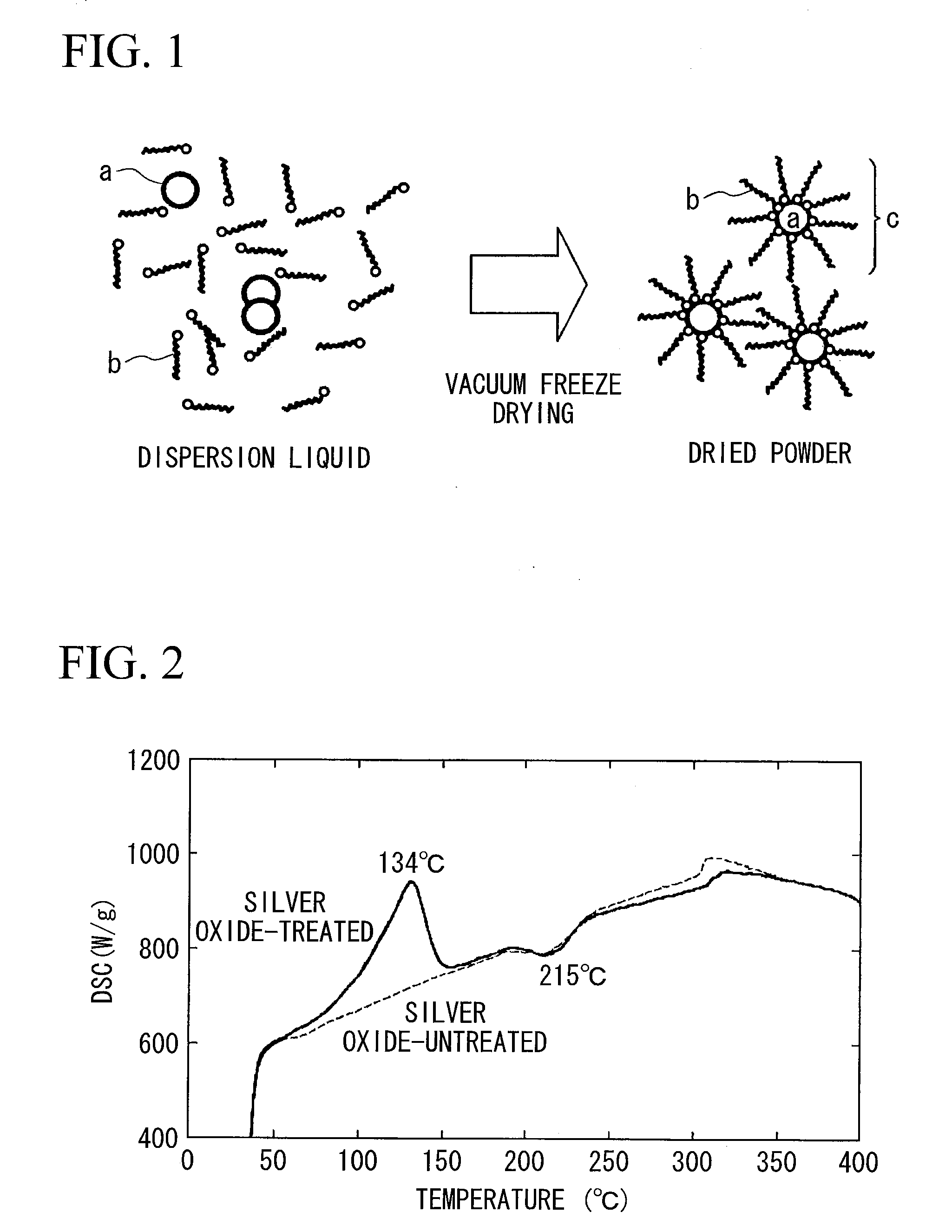

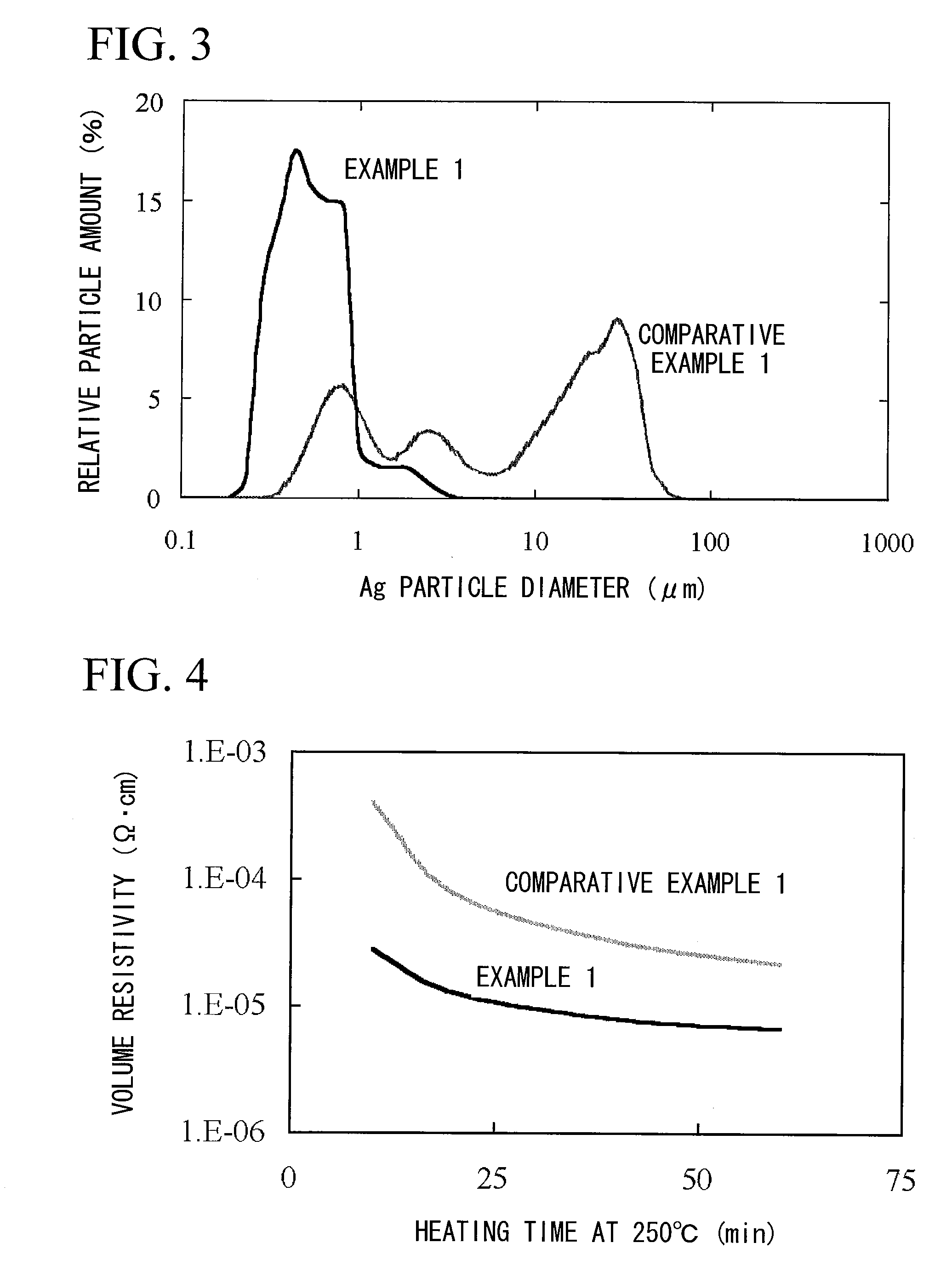

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveUS20090146117A1Easy to produceConvenient and stableMetal-working apparatusConductive materialSilver pastePhosphate

Owner:DAINIPPON INK & CHEM INC

Magnesium alloy surface zinc-calcium series phosphating solution and conversion treatment process thereof

InactiveCN101671824AImprove corrosion resistanceStrong adhesionMetallic material coating processesMg alloysPhosphate

The invention discloses magnesium alloy surface zinc-calcium series phosphating solution and a conversion treatment process thereof; the magnesium alloy surface phosphating solution is aqueous solution formed by the following constituents, namely, every liter solution contains: 10-30g of disodium hydrogen phosphate, 4-6g of zinc nitrate, 2-4g of sodium nitrite, s0.5-2g of sodium fluoride, and 0.-2g of calcium nitrate; the process for carrying out surface conversion treatment to the phosphating solution comprises the following process flows: alkaline washing and degreasing->rinsing->acidity activation->rinsing->surface activation->rinsing->phosphating->rinsing->drying; the working temperature is 40-70 DEG C, and the time is 5-60 minutes. The conversion treatment process can obtain phosphateconversion coating on the surface of the magnesium alloy, wherein the conversion coating has good protectiveness, is fine and uniform and stable, and has strong adhesive force, and can improve the corrosion-resisting property of magnesium alloy parts; the conversion treatment process is stable and easy to control, and has low cost.

Owner:CHONGQING UNIV OF TECH

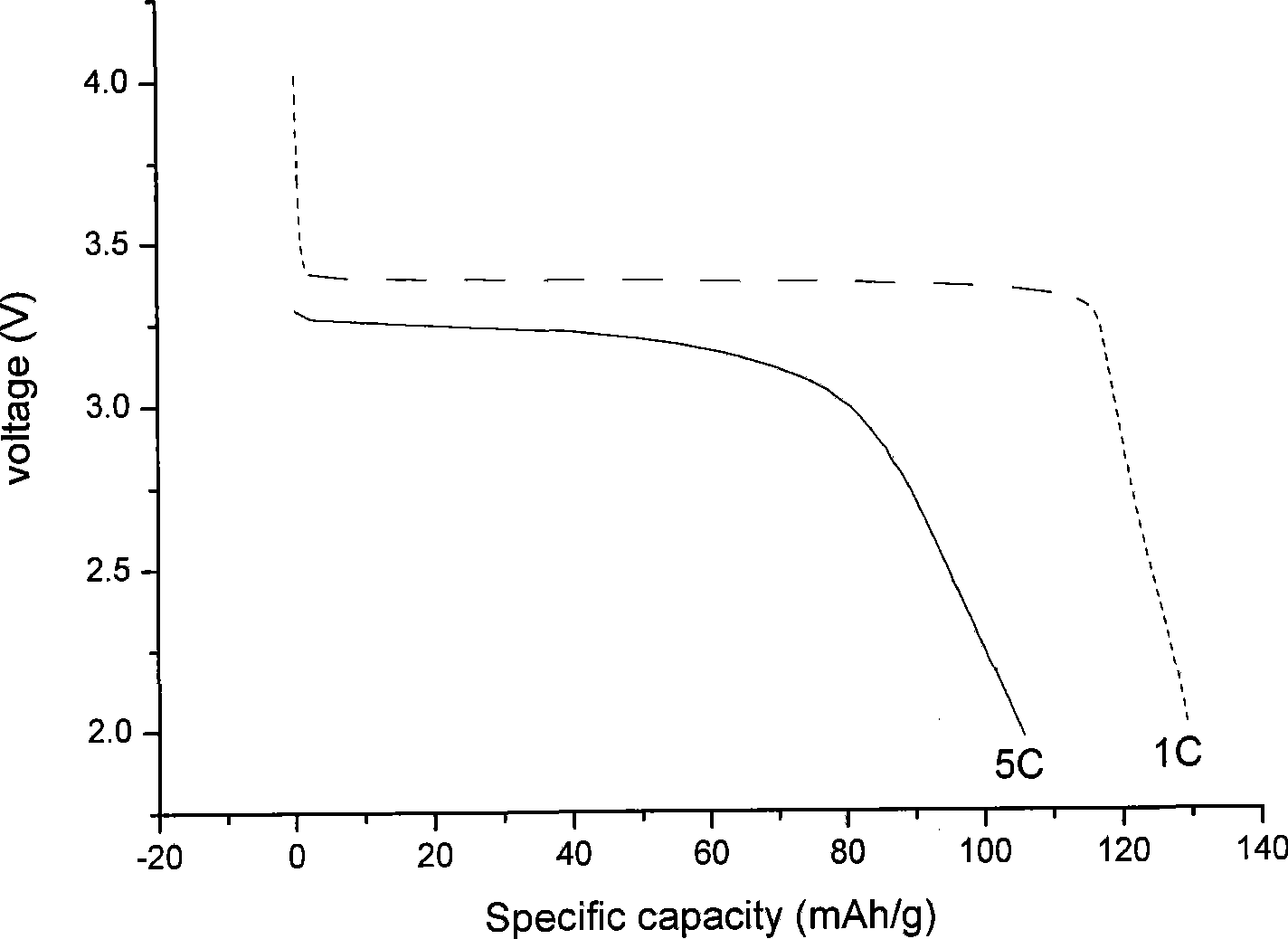

Preparation of lithium ionic cell positive pole material lithium ferrous phosphate/carbon composite

InactiveCN101483236ASimple processEase of mass productionElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

Owner:NORTHEAST NORMAL UNIVERSITY

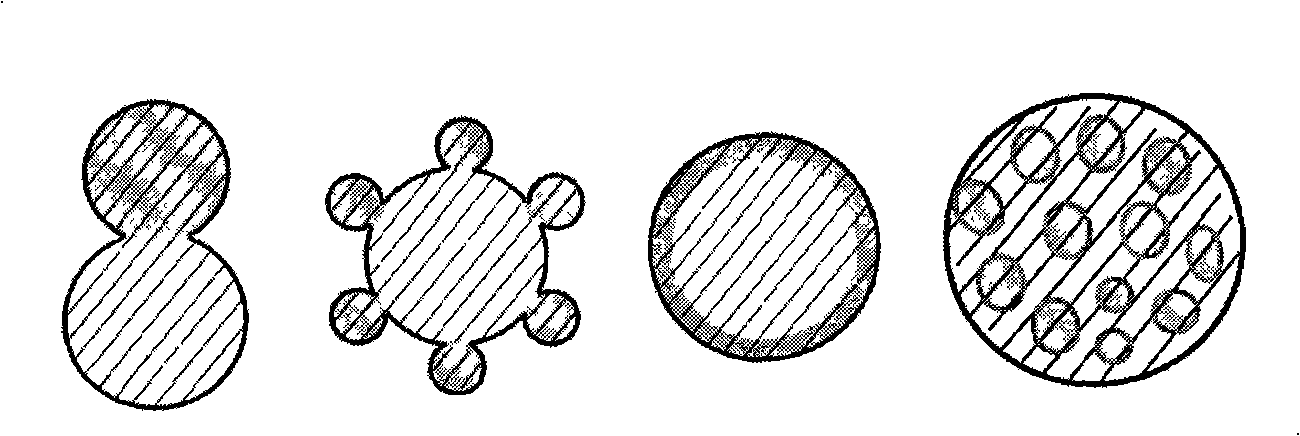

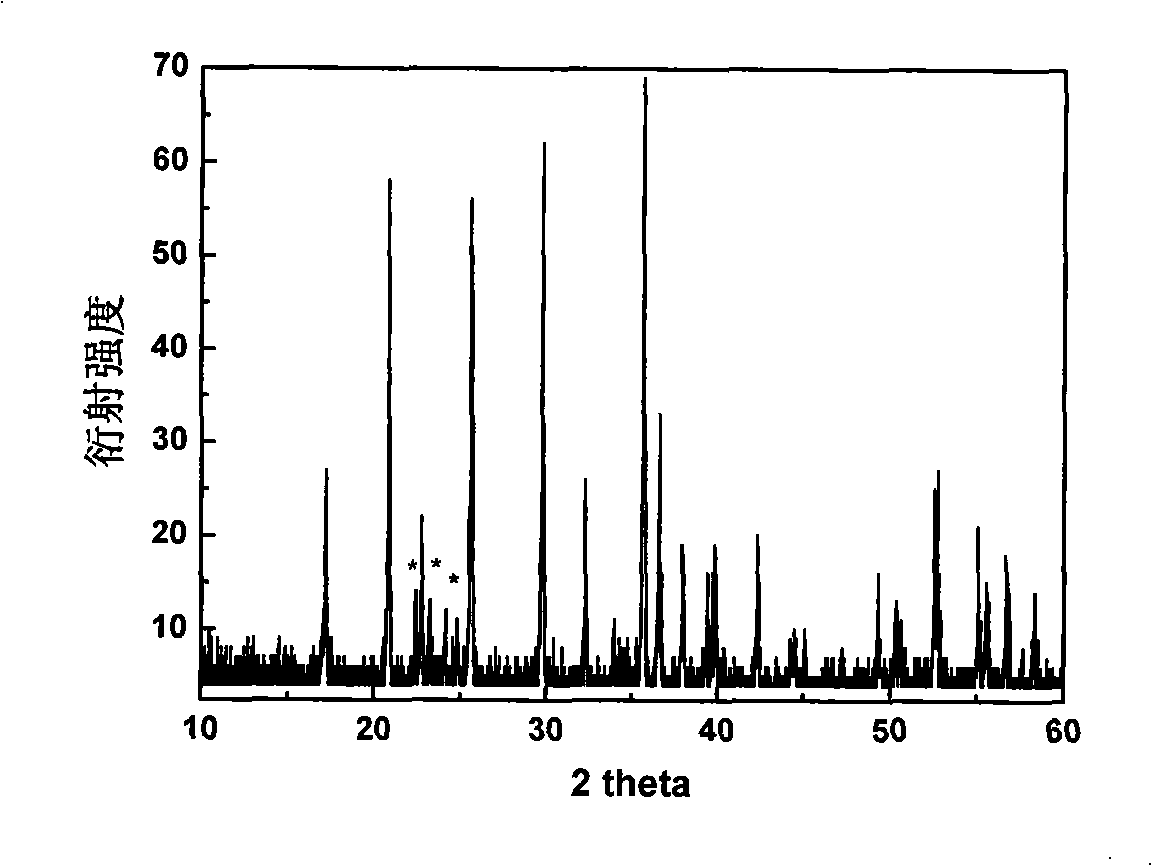

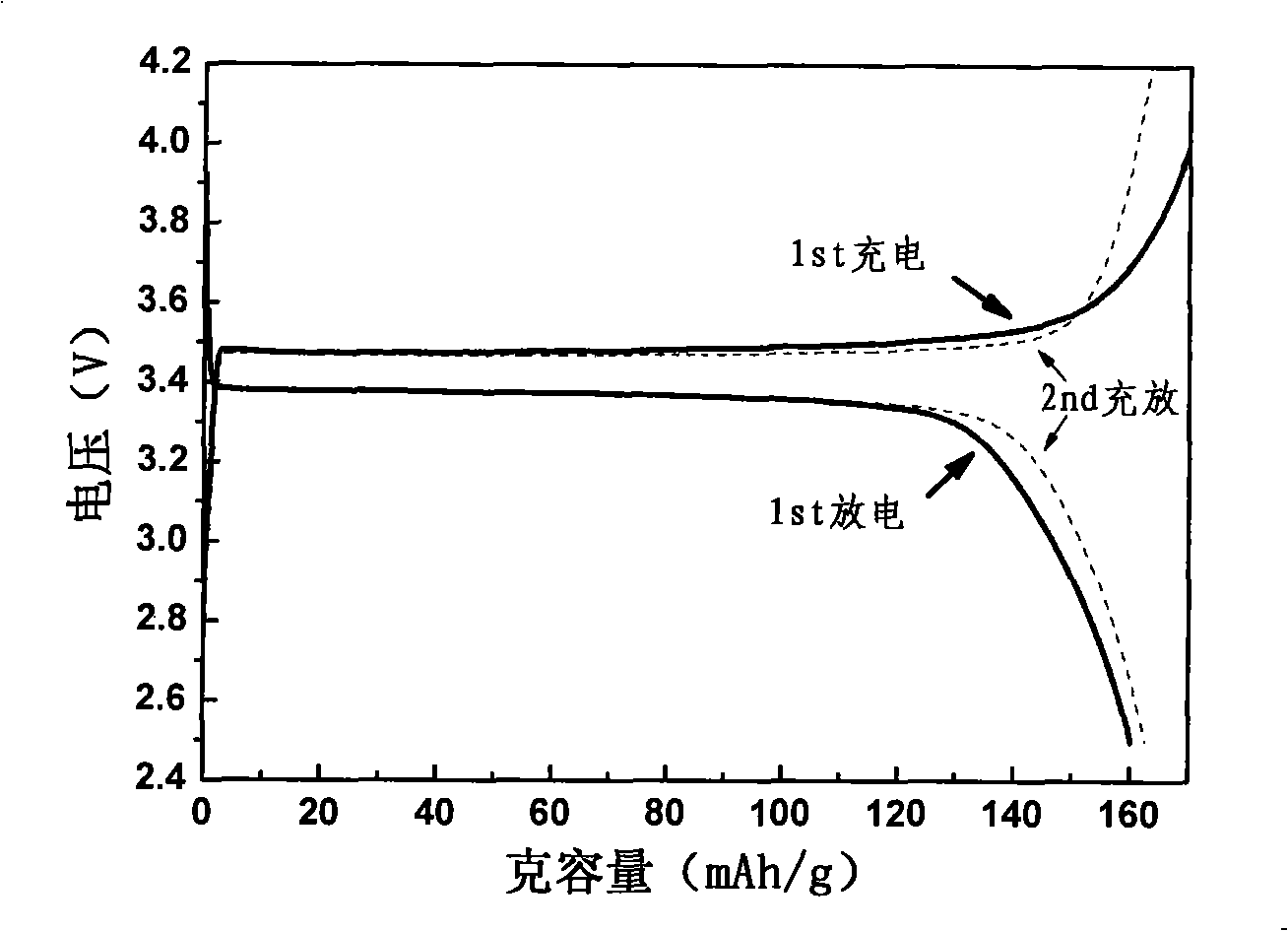

Compound phosphate type positive material of lithium ionic cell and method for making same

ActiveCN101284658AGood electrochemical propertiesImprove electrochemical performanceCell electrodesPhosphorus compoundsPhosphateReducing atmosphere

Owner:龚思源

Method for preparing positive pole material for ferrous phosphate lithium battery from low-valence oxygen-containing acid of phosphorus

InactiveCN101332984ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphateFerrous salts

Owner:FUJIAN NORMAL UNIV

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

Method for producing microbial grease by fermenting inulin serving as raw material

InactiveCN102417915AExpand sourceLow costBiofuelsMicroorganism based processesBiodiesel feedstockBiodiesel

Owner:HENAN UNIV OF SCI & TECH

Soil bio-activator for ginseng continuous cropping

InactiveCN103254022AImprove the growing environmentPrevent Soilborne DiseasesFertilizer mixturesContinuous croppingPhosphate

Owner:JILIN AGRICULTURAL UNIV

Preparation method of oryzenin antioxidant peptide

InactiveCN101748182AOptimize composition ratioHigh in proteinFermentationAlkaline proteaseProteinase activity

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Soil ecological system restoring organic fertilizer

InactiveCN105565959AHigh substance contentReduce in quantityFertilizer mixturesMicrobial agentPhosphate

Owner:广西天利丰农林科技有限公司

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

Culture medium and culture method for culturing haematococcus pluvialis by using brewery wastewater

The invention relates to a culture medium for culturing haematococcus pluvialis by using brewery wastewater, of which the formula is as follows: 80 ml of brewery wastewater, 28 mg of sodium citrate, 20 mg of urea, 12 mg of potassium dihydrogen phosphate, 150 mg of fructose, 45 mg of yeast extract powder, 50 mg of casein tryptone, 12 mg of ammonium citrate, 25 mg of whey powder, 30 mg of lactose, 60 mg of glucose, 1.8 ml of horse manure leachate, 2 ml of fermented soya-bean milk, 100 mg of sorbitol, 24 mg of soluble starch, 25 mg of soytone, 28 mg of beta-sodium glycerophosphate, 12 mg of an edetic acid, 10 mcg of vitamin B1, 21 mcg of vitamin B1, 1.8 ml of soil extract, 1.5 ml of human urine, 2.4 ml of chicken manure leachate, and 1000 ml of pure fresh water disinfected by sodium hypochlorite. An important bioactive substance-astaxanthin can be obtained. The culture medium is low in cost, uneasily polluted, and can be reused; and due to the mixed utilization of organic fertilizers and inorganic fertilizers, the growth rate and astaxanthin content of haematococcus pluvialis are significantly increased, and the yield is increased by 270%.

Owner:LINYI UNIVERSITY

Humic acid-containing complete-element water soluble fertilizer, and preparation method and application thereof

InactiveCN105669297AIncrease profitPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserSolubilityPhosphate

Owner:HUNAN TAIGU BIOTECH

Deep-fried chicken steak filled with cheese and preparation method thereof

Owner:NEW HOPE LIUHE

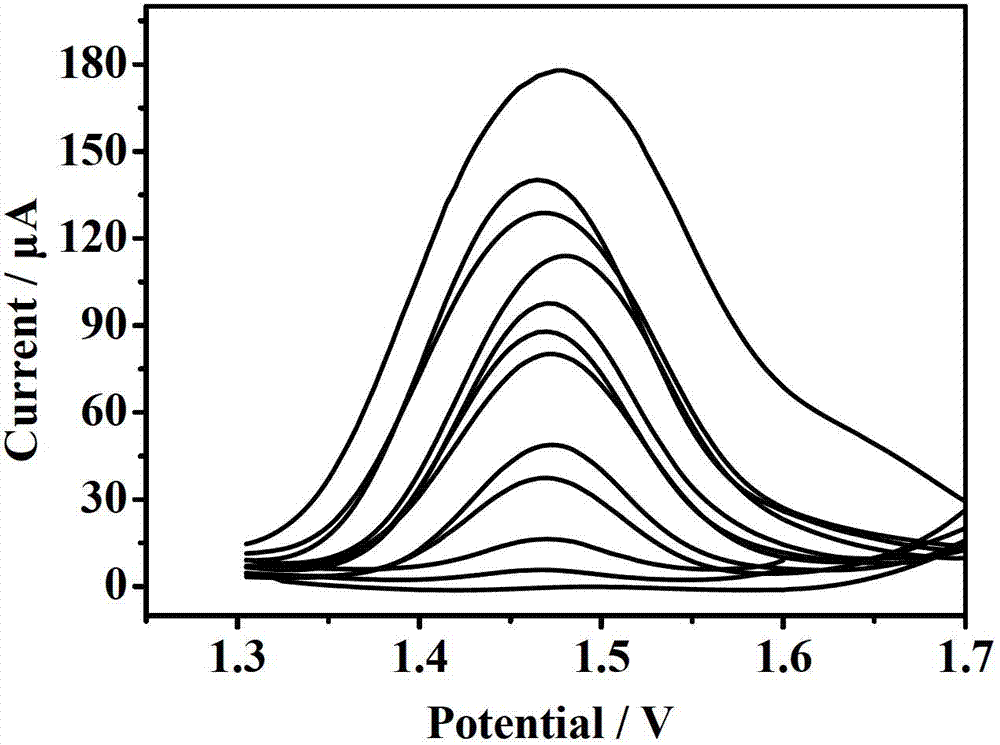

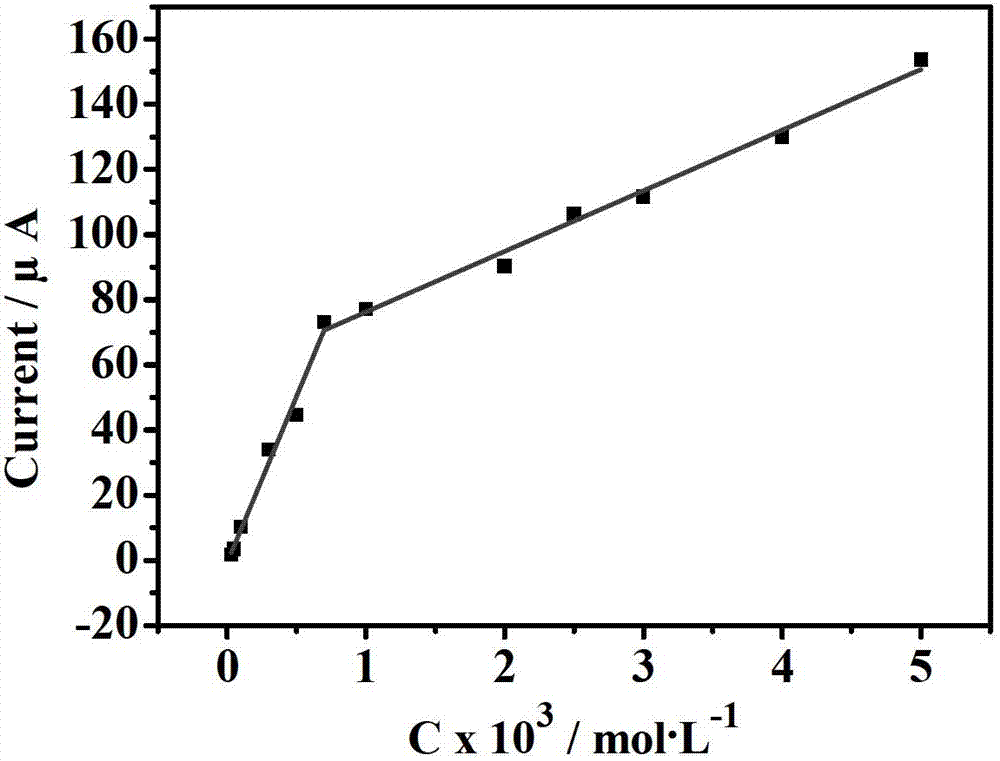

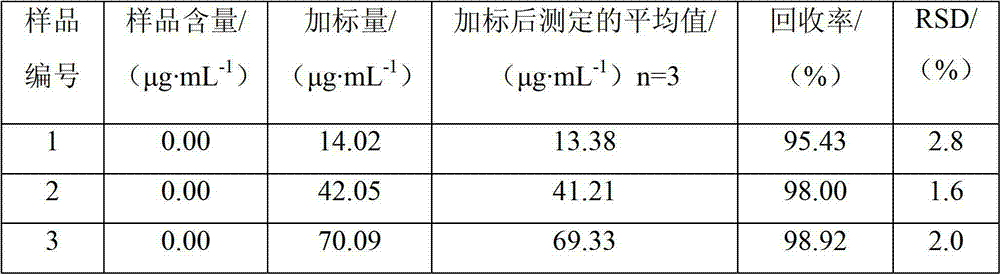

Electrochemical method for detecting banned additive urotropin in food

InactiveCN102735739AEasy to makeImprove performanceMaterial electrochemical variablesHexamethylenetetraminePhosphate

Owner:CHANGZHOU UNIV +1

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Iron and steel product surface treating agent and preparation method thereof

InactiveCN105256321AReduce productionReduce wasteMetallic material coating processesIndustrial waste waterO-Phosphoric Acid

The invention provides an iron and steel product surface treating agent and a preparation method thereof, and relates to the technical field of metal surface treating agents. The surface treating agent comprises, by weight, 12%-17% of phosphoric acid with the concentration of 85%, 3%-8% of composite phosphate, 7%-12% of nitric acid with the concentration of 65%, 5%-10% of corrosion inhibitor(s), 1%-3% of aqueous surface active agent(s), 3%-6% of zinc chrome, 4%-7% of polyol ester, and the balance water. The iron and steel product surface treating agent can be used for carrying out derusting, deoiling and phosphating on iron and steel products at the same time, and the generation amount of industrial waste water in the production process can be greatly reduced; the iron and steel product surface treating agent can be stored for a long time without lowering of the effectiveness, and uniform and compact phosphating films still can be formed on the surfaces of the iron and steel products even if the iron and steel product surface treating agent is stored for a long time; in addition, when the iron and steel product surface treating agent is used for carrying out comprehensive surface treating on the iron and steel products, the replacement frequency of bath solutions is low, the utilization rate of acid liquor is high, and the production cost of enterprises is low.

Owner:NANHUA UNIV +1

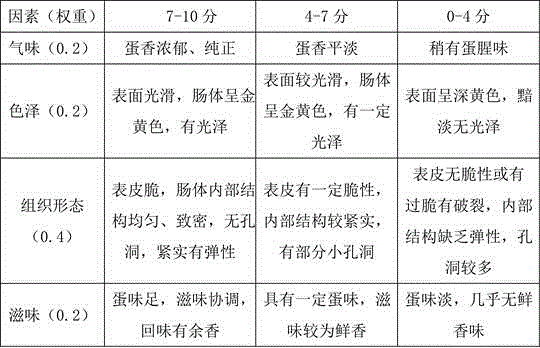

Crispy skinned egg sausages and preparation method thereof

ActiveCN106071988AImprove high temperature resistancePrevent partial melting of epidermisFood scienceSODIUM METAPHOSPHATEPresent method

Owner:SICHUAN UNIV

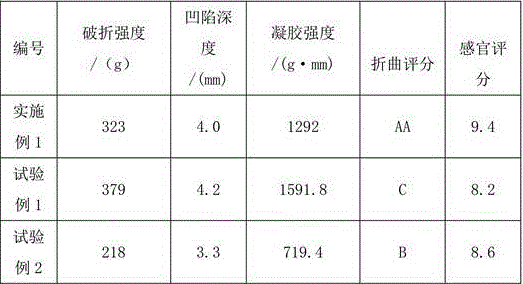

Drying device containing a titanium aluminum phosphate

InactiveUS20120159804A1Low costWeaken energyAluminium compoundsSilicon halogen compoundsSodium aluminium phosphatePhosphate

Owner:CLARIANT INT LTD

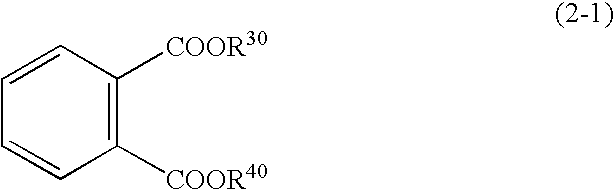

Ink composition

InactiveUS20060213391A1Shrinkage factorPromote wettingDuplicating/marking methodsInksPlasticizerPhosphate

Owner:FUJIFILM CORP +1

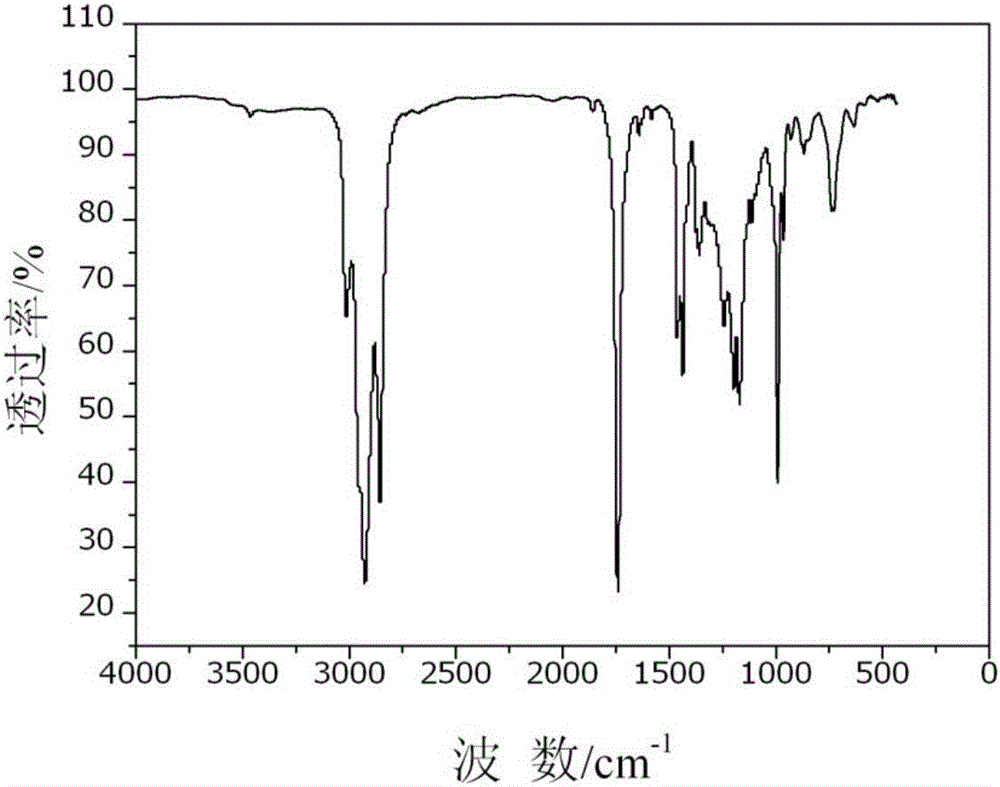

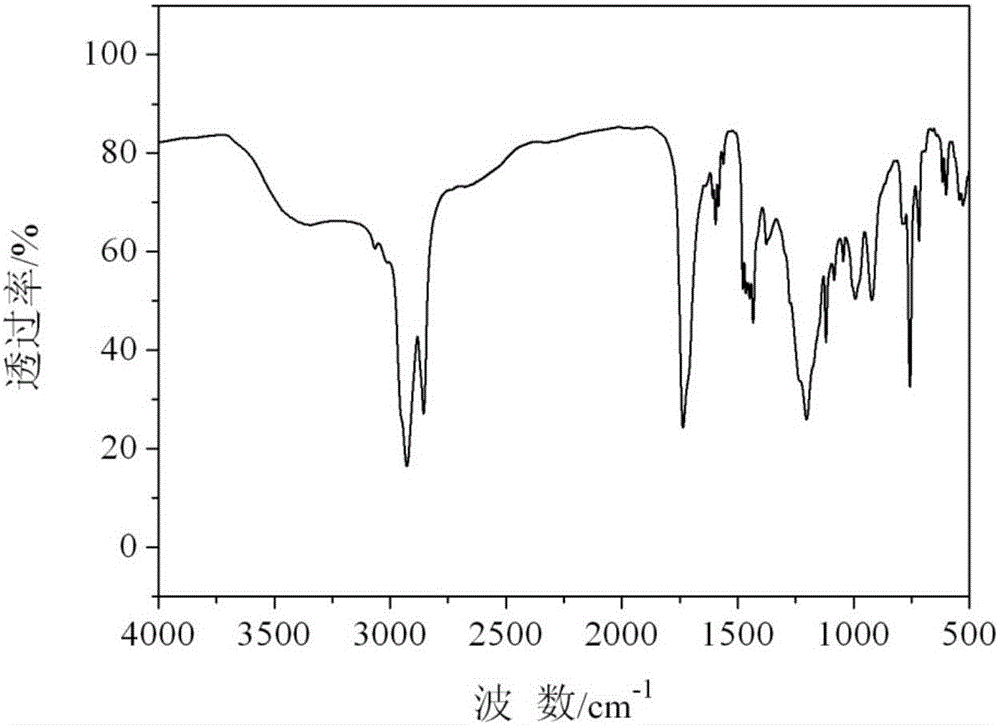

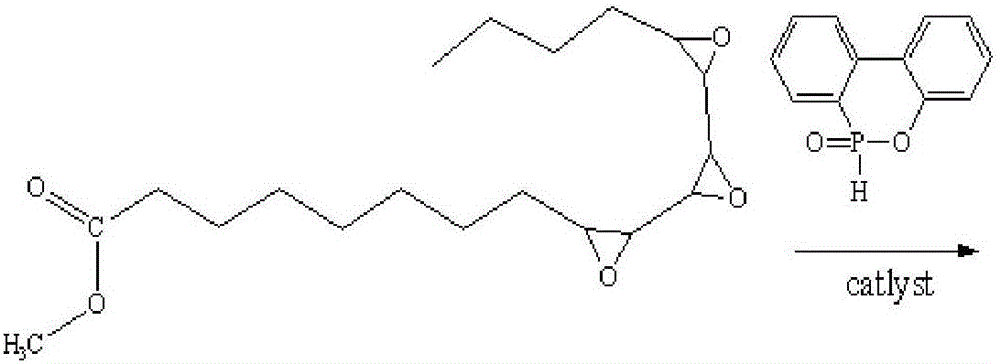

Phosphorus-containing vegetable oil based flame-retardant polyol and preparation method and application thereof

ActiveCN106349290AGood storage stabilityGood compatibilityGroup 5/15 element organic compoundsVegetable oilPhosphate

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Efficient total-nutrient chelate fertilizer and preparation method thereof

InactiveCN109467475ACan't overcomeOvercoming the defects of phosphate for compoundingCalcareous fertilisersMagnesium fertilisersRare-earth elementPhosphate

Owner:HENAN JIENONG BIOLOGICAL & CHEM CO LTD

Additive for maximizing light olefins in fcc and process for preparation thereof

InactiveUS20090099006A1Improve performanceCatalytic crackingMolecular sieve catalystsAlkaline earth metalPhosphate

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

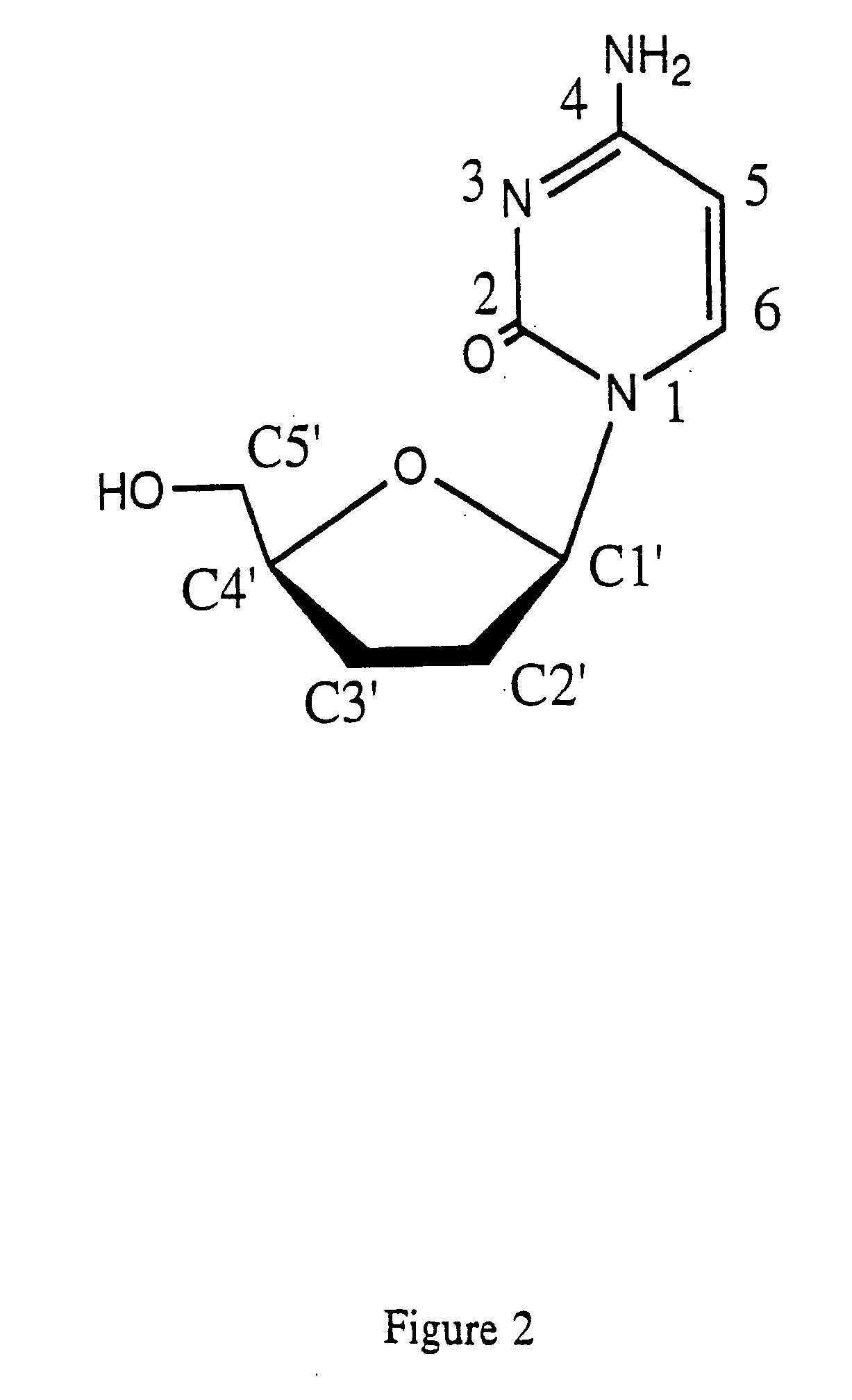

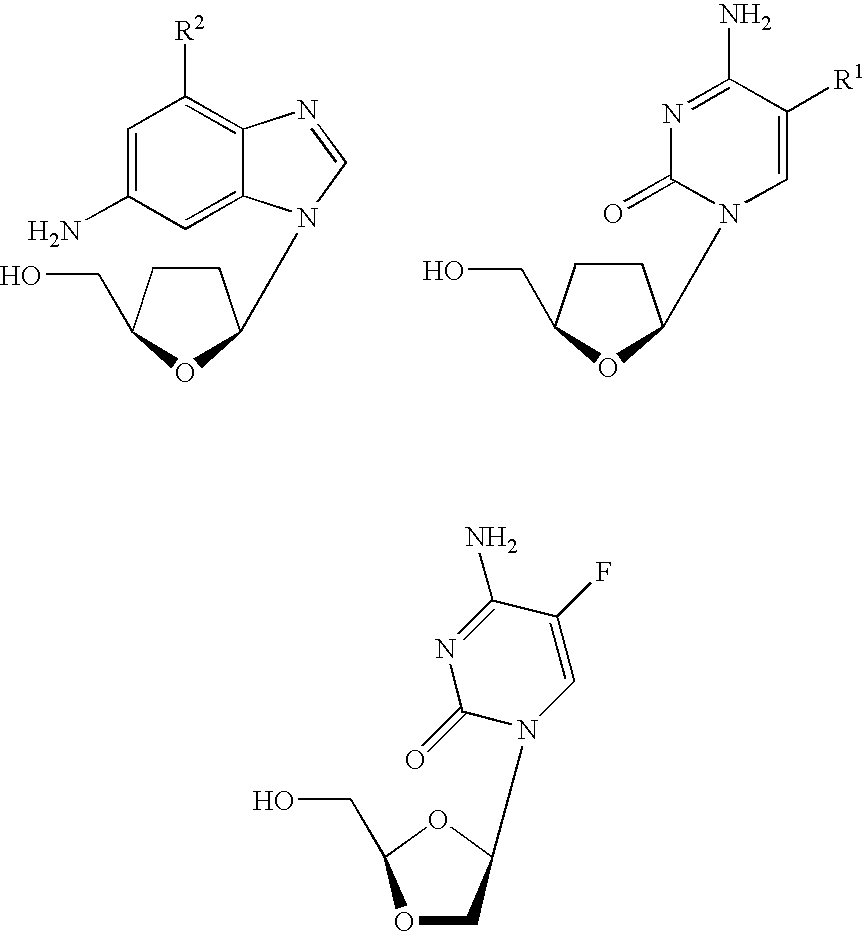

Thymine nucleosides with anti-hepatitis B virus activity

InactiveUS20050277616A1Prevent and retard progressionReduce usageBiocideSugar derivativesPhosphateThymine

Owner:OWENS HOWARD JR

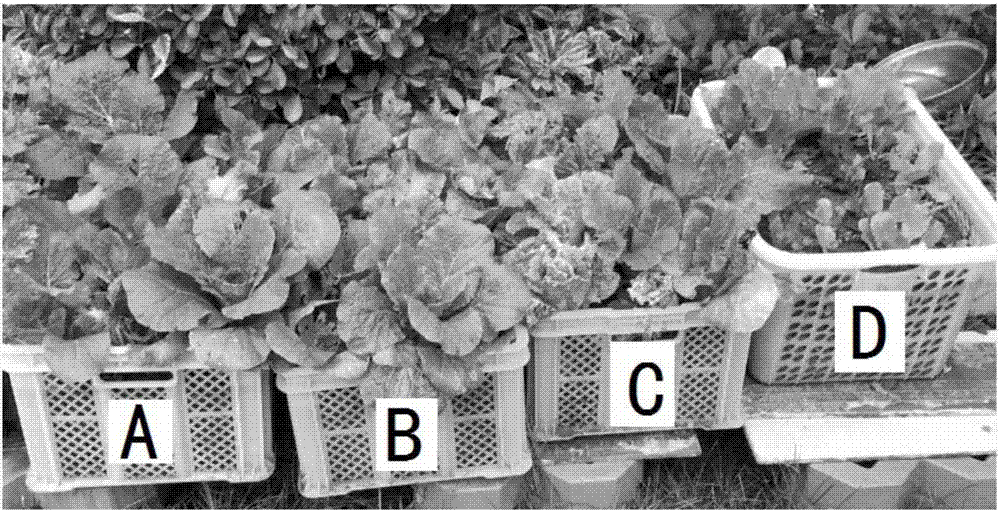

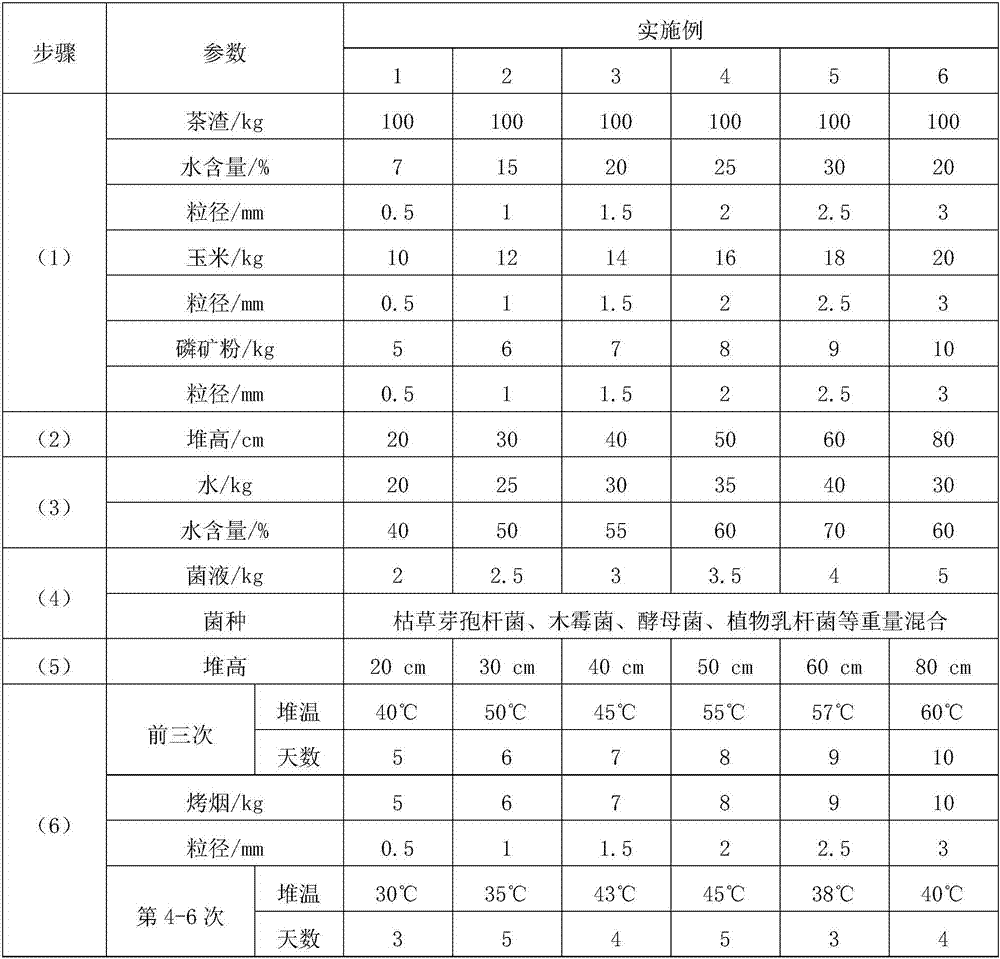

Tea-leaf organic fertilizer and preparation method thereof

InactiveCN107162837AHigh in NPKGood fertilizer effectBio-organic fraction processingOrganic fertiliser preparationPhosphatePotassium

Owner:MENGHAI TEA IND +1

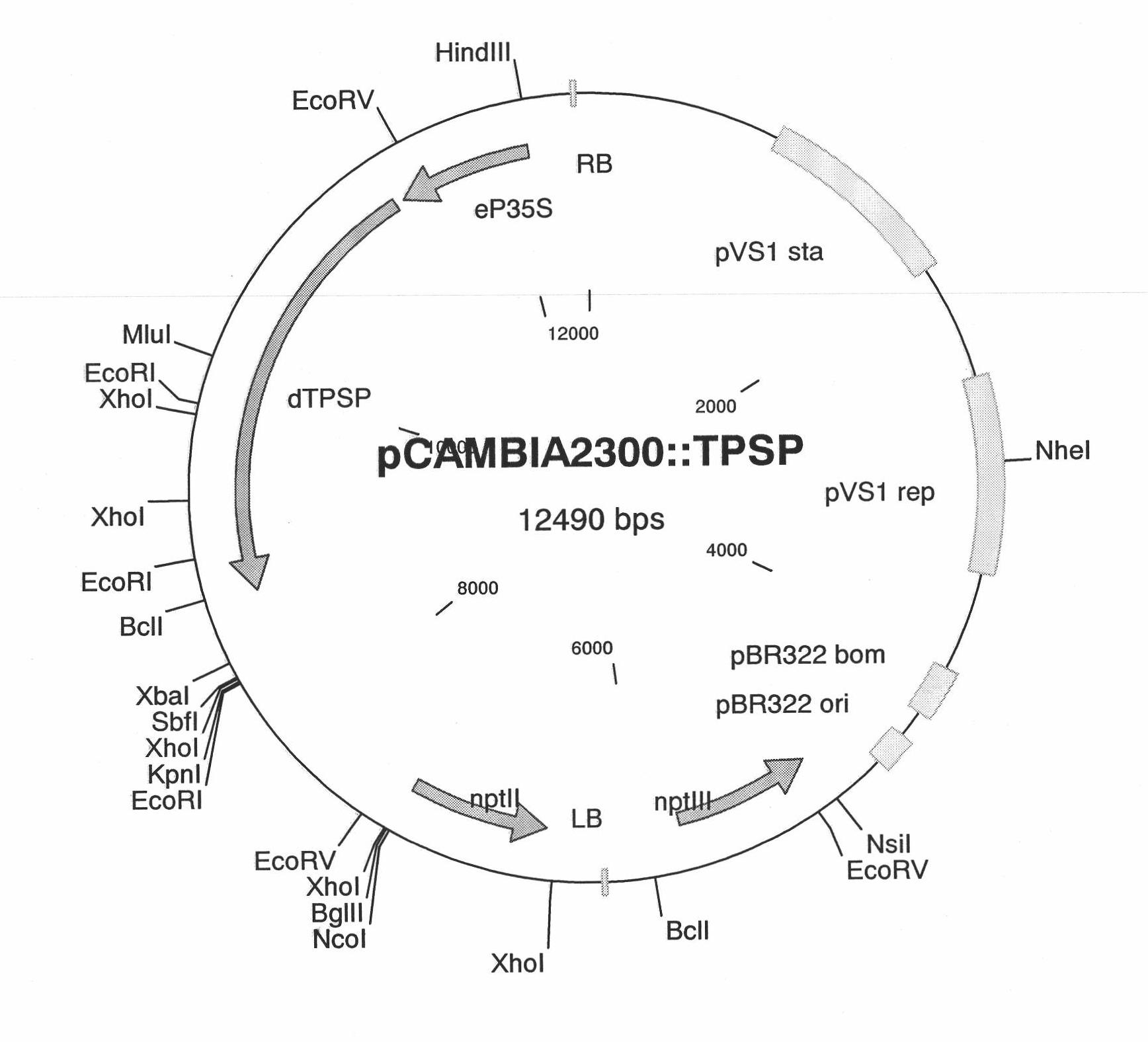

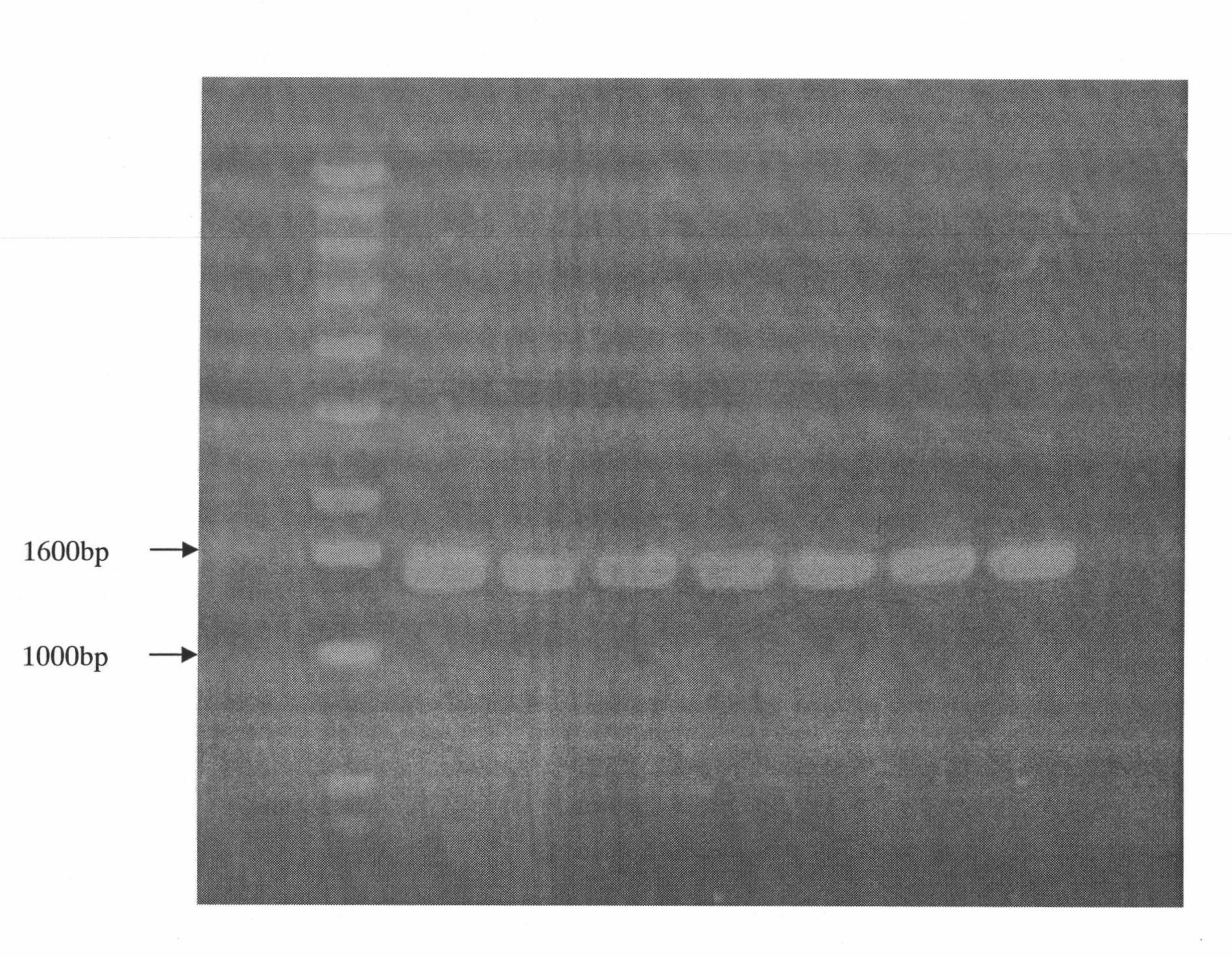

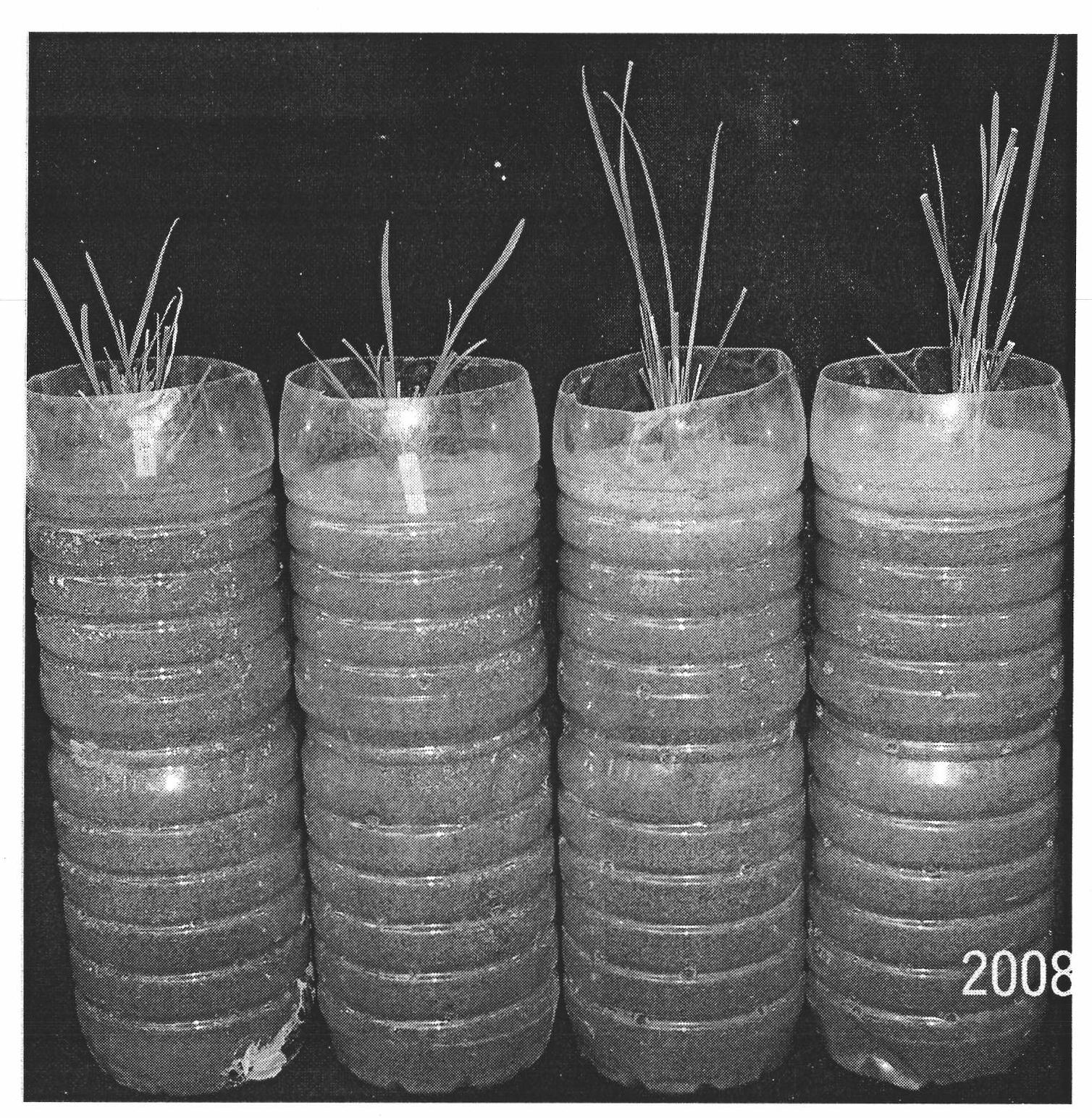

Fusion protein capable of synthetizing trehalose and application thereof in culture of dwarfed lawn grass

Owner:BEIJING NORTH ELITE BIOTECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap