Ink composition

a technology of composition and ink, applied in the field of ink composition, can solve the problems of high running cost, waste, high manufacturing cost, etc., and achieve the effects of reducing the shrinkage factor, improving the wetting to the substrate, and reducing the surface tensile of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

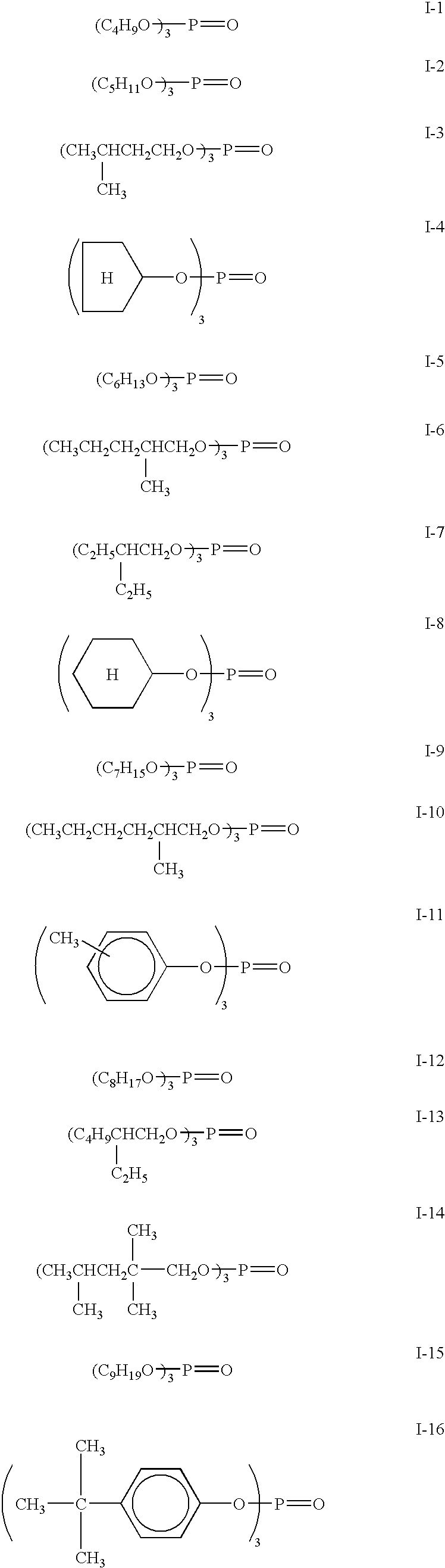

Method used

Image

Examples

example

Example 1

(Preparation of Pigment Dispersion)

[0230] Each pigment dispersion 1 of yellow, magenta, cyan and black was prepared according to the following method. A dispersion condition was appropriately adjusted with a well-known dispersion device so that the average particle size of each pigment particle ranged 0.2 to 0.3 μm, and then filtration under heating was performed to prepare the pigment dispersions.

(Yellow Pigment Dispersion 1)C.I. Pigment Yellow 1210 parts by weightPolymer Dispersant 5 parts by weight(Solsperse series made by Zeneca Company)OXT-22185 parts by weight(Oxetane compound made by Toagosei Co. Ltd.)(Magenta Pigment Dispersion 1)C.I. Pigment Red 57:115 parts by weightPolymer Dispersant 5 parts by weight(Solsperse series made by Zeneca Company)OXT-22180 parts by weight(Oxetane compound made by Toagosei Co. Ltd.)(Cyan Pigment Dispersion 1)C.I. Pigment Blue 15:320 parts by weightPolymer Dispersant 5 parts by weight(Solsperse series made by Zeneca Company)OXT-22175 p

examples 2 to 5

(Preparation of Ink)

[0238] Magenta ink 2 to 6 were prepared according to the following method.

[0239] (Magenta Ink 2)

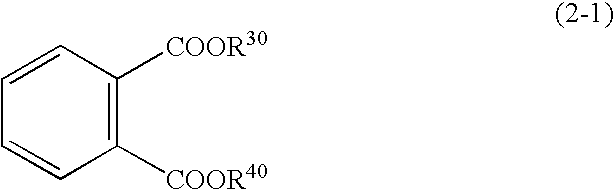

(a) Cationically polymerizable compoundSELLOXIDE 2021 (Epoxy compound: Daicel UCB Co. Ltd.)35 gOXT-221 (Oxetane compound: Toagosei Co. Ltd.)55 g(b) Photo-generating agentInitiator 1 5 g(c) Colorant (said Pigment Dispersion)Magenta Pigment Dispesion1 5 g(d) Plasticizer (the invention compound, di-butyl phthalate)0.5 g

[0240] (Magenta Ink 3)

(a) Cationically polymerizable compoundSELLOXIDE 2021 (Epoxy compound: Daicel UCB Co. Ltd.)35 gOXT-221 (Oxetane compound: Toagosei Co. Ltd.)55 g(b) Photo-generating agentInitiator 1 5 g(c) Colorant (said Pigment Dispersion)Magenta Pigment Dispesion1 5 g(d) Plasticizer (the invention compound, tricyclohexyl phosphate)0.5 g

[0241] (Magenta Ink 4)

(a) Cationically polymerizable compoundSELLOXIDE 2021 (Epoxy compound: Daicel UCB Co. Ltd.)35 gOXT-221 (Oxetane compound: Toagosei Co. Ltd.)55 g(b) Photo-generating agentInitiator 1 5 g(c)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap