Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Duplicating/marking methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink jet ink containing polyurethane dispersant

InactiveUS6136890AResistance to agglomerationResistance to flocculationDuplicating/marking methodsInksPolymer chemistryPigment

Owner:3M INNOVATIVE PROPERTIES CO

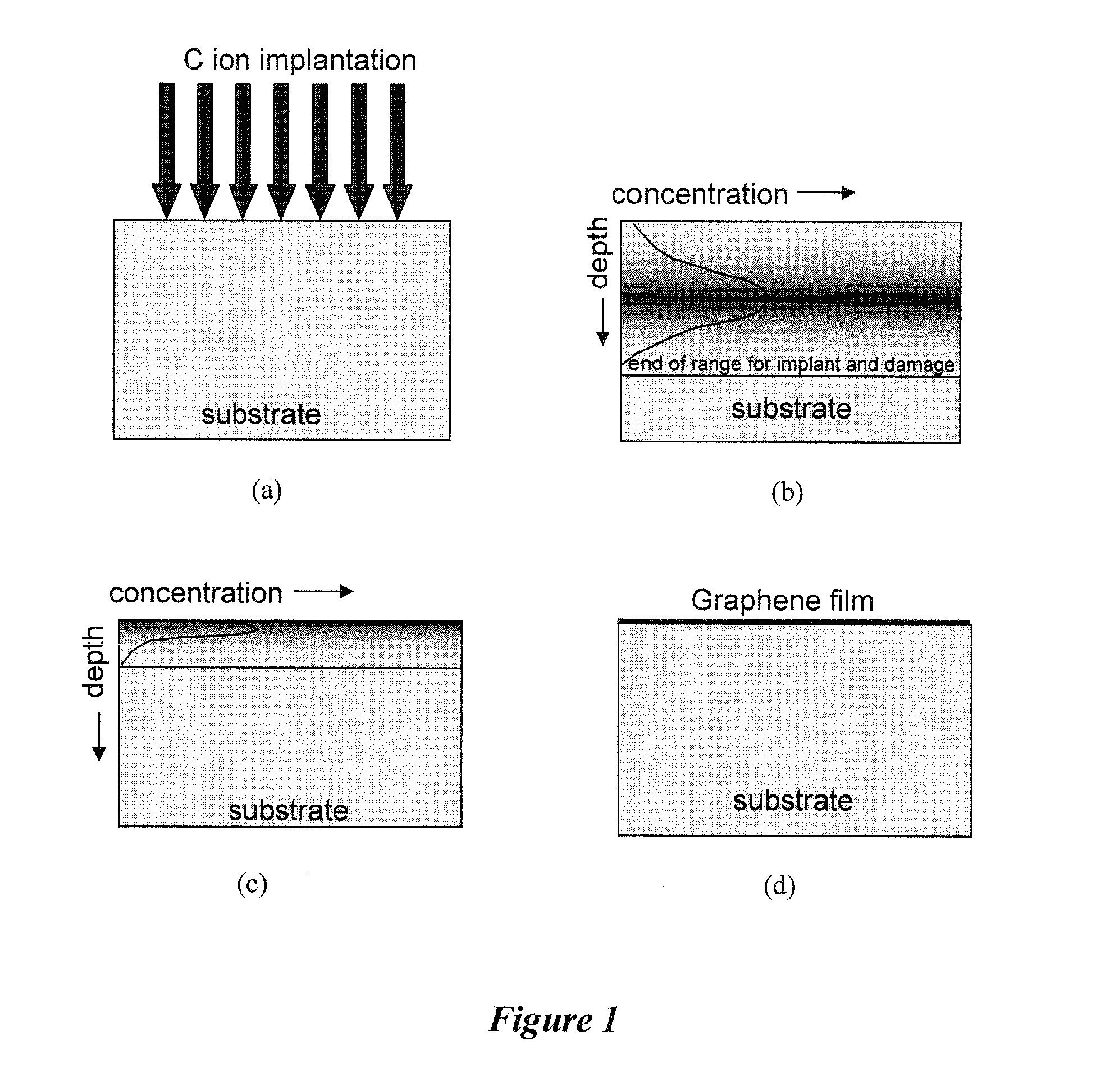

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Ink set for ink-jet recording, ink-jet recording method and ink-jet recording apparatus

InactiveUS20050012796A1Measurement apparatus componentsDuplicating/marking methodsWater solubleSolvent

Owner:FUJIFILM BUSINESS INNOVATION CORP

Water-Based Ink Set For Ink-Jet Recording

ActiveUS20070186812A1Improves not recovery performanceImprove the problemDuplicating/marking methodsInksWater basedMagenta

Owner:BROTHER KOGYO KK

Water-based ink for ink-jet recording

InactiveUS6758559B1Improve light resistanceImprove water resistanceMeasurement apparatus componentsDuplicating/marking methodsCarbon blackInkjet printing

Owner:KAO CORP

Inkjet recording ink set and ink cartridge, and recording device, image forming method, and image-formed article using such ink set

ActiveUS20120242741A1Desirable image densityImprove image qualityDuplicating/marking methodsInksPolymer scienceSURFACTANT BLEND

Owner:RICOH KK

Fluorescent image-printed article and fluorescent ink

ActiveUS20060063036A1Improve security levelOther printing matterDuplicating/marking methodsFluorescenceRare earth

Owner:KK TOSHIBA

Printing superimposed layers

An apparatus and method for making a panel with superimposed layers of marking material in substantially exact registration is provided. An assembly includes a stencil layer sandwiched between a substrate and a transparent coating. The stencil includes a release surface. The coating tends to secure the stencil layer to the substrate, e.g., for storage and / or transport, and may protect the stencil layer from marking materials that might otherwise penetrate the stencil layer. A design and background layers are then printed onto the coating. A force is then applied to remove the background layer, design layer, and coating that are disposed on the stencil layer, leaving the remainder of the background layer, design layer, and coating adhered to the substrate in substantially exact registration within portions of the substrate that are devoid of the stencil layer. The design layer is right-reading visible through the substrates.

Owner:CONTRA VISION

Water-based ink set for ink-jet recording and ink-jet recording method

InactiveUS20070046750A1Reduce graininessExcellent gas resistanceMeasurement apparatus componentsDuplicating/marking methodsWater basedHigh density

Owner:BROTHER KOGYO KK

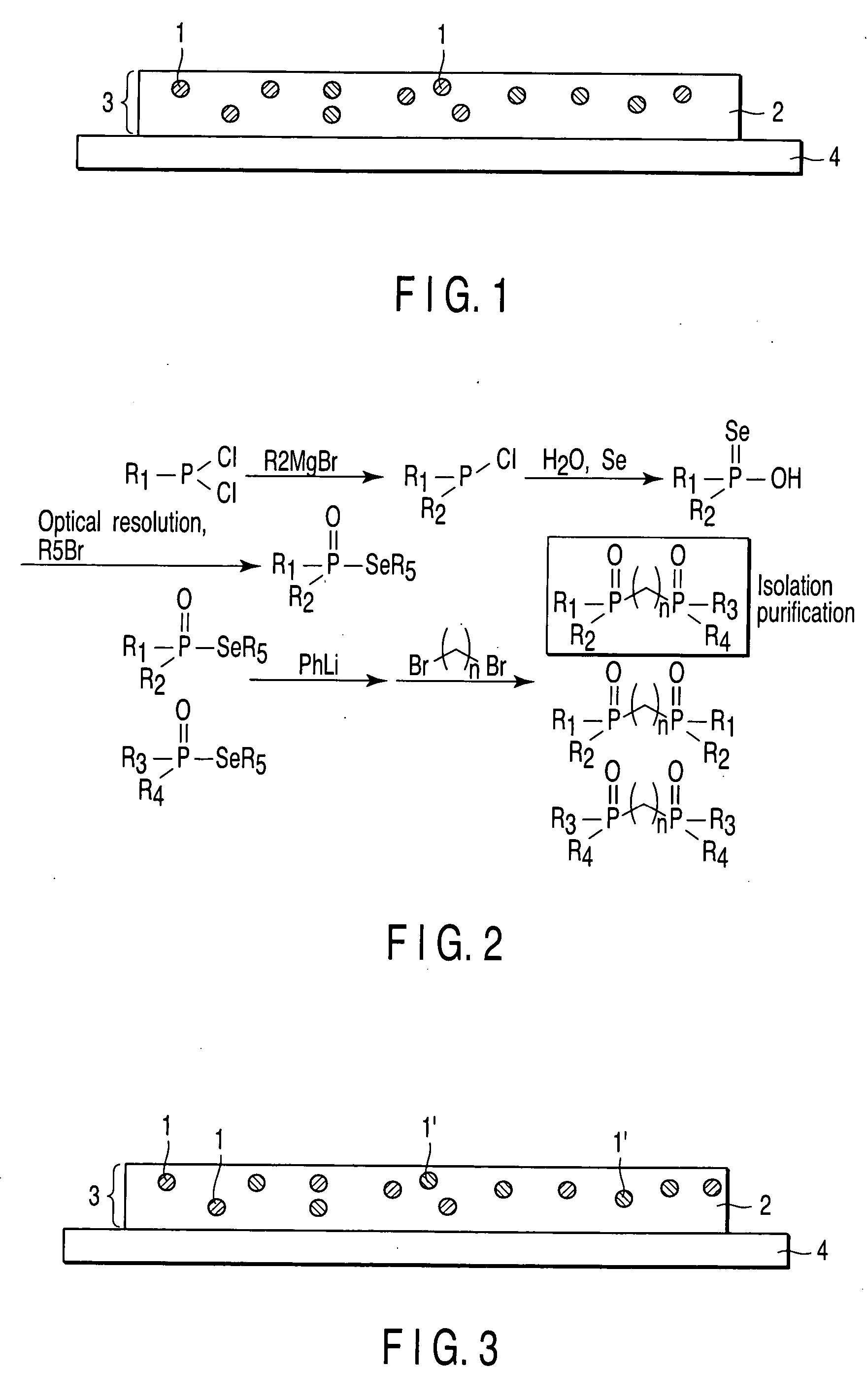

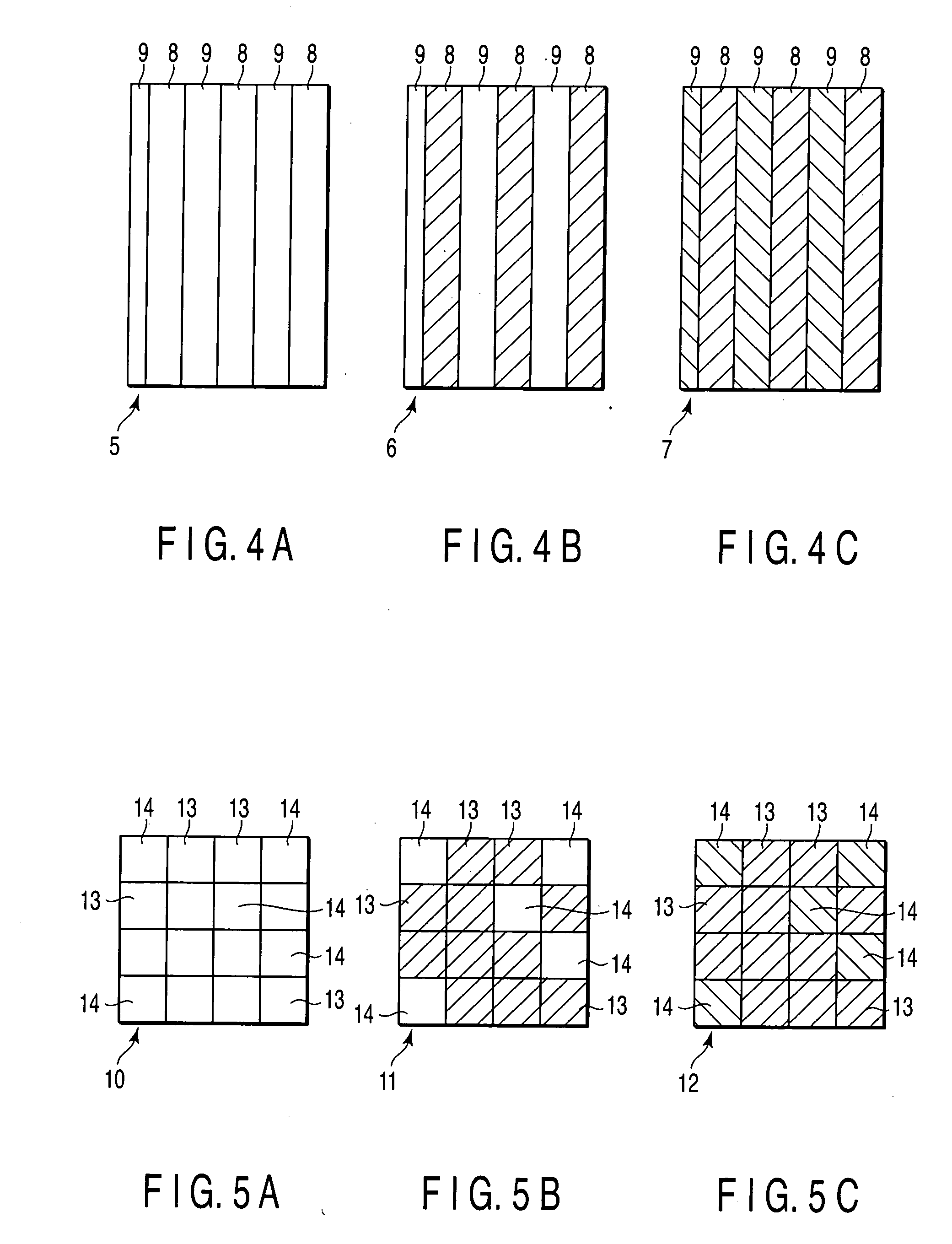

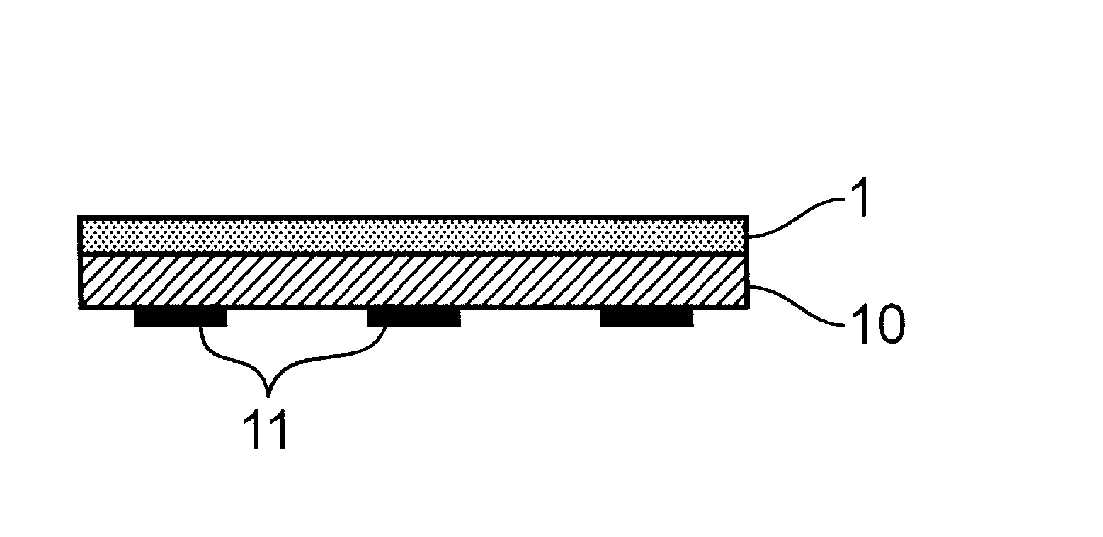

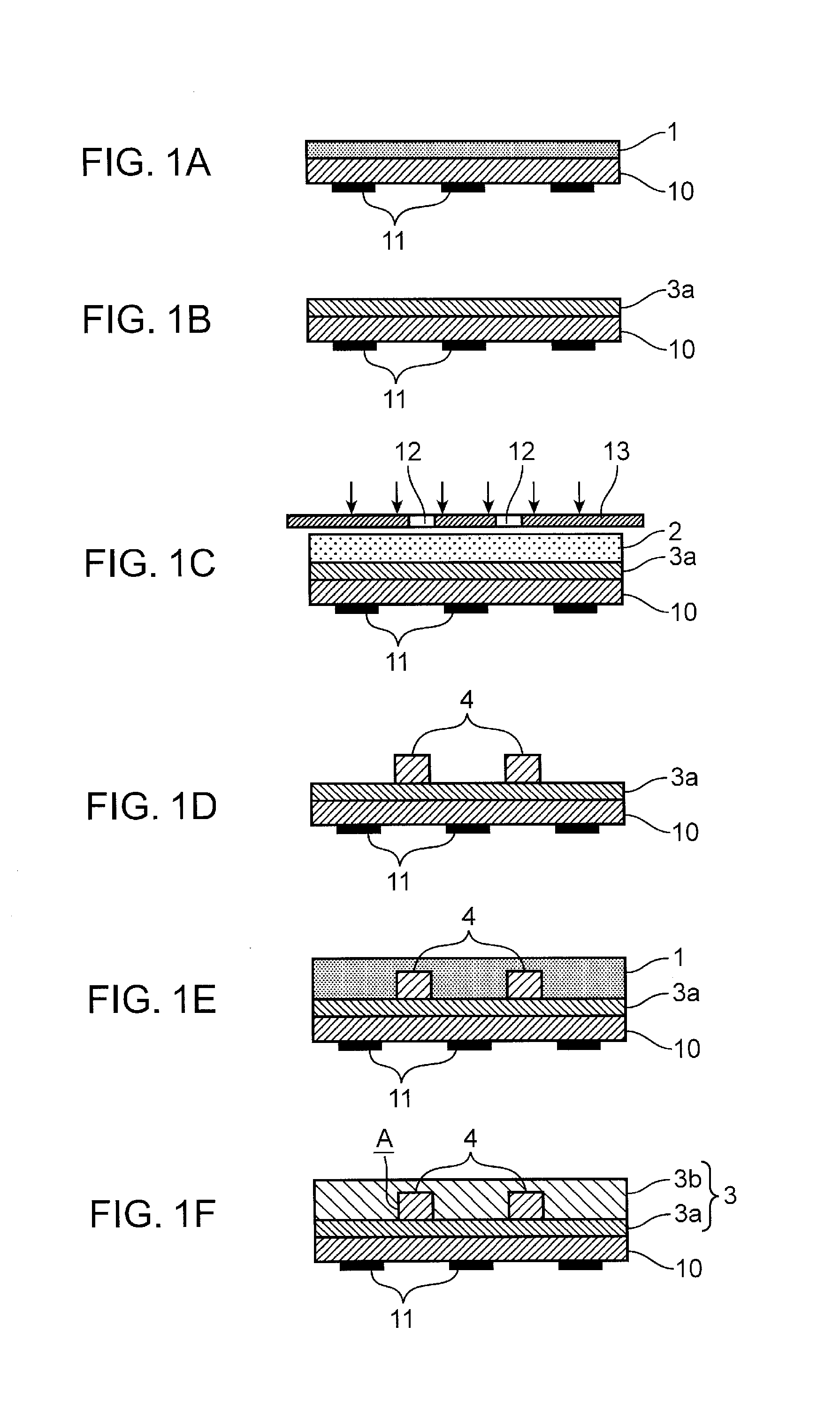

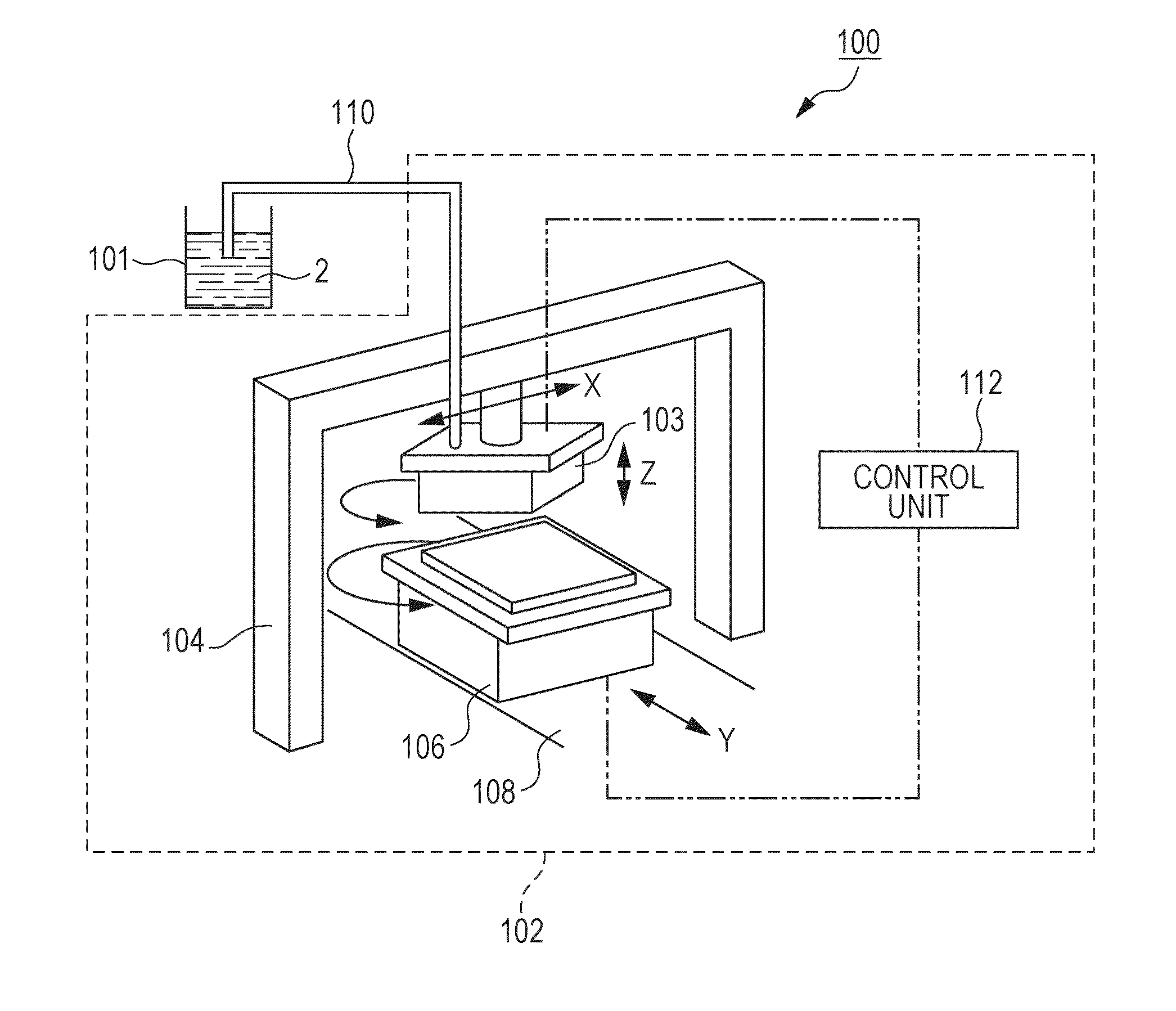

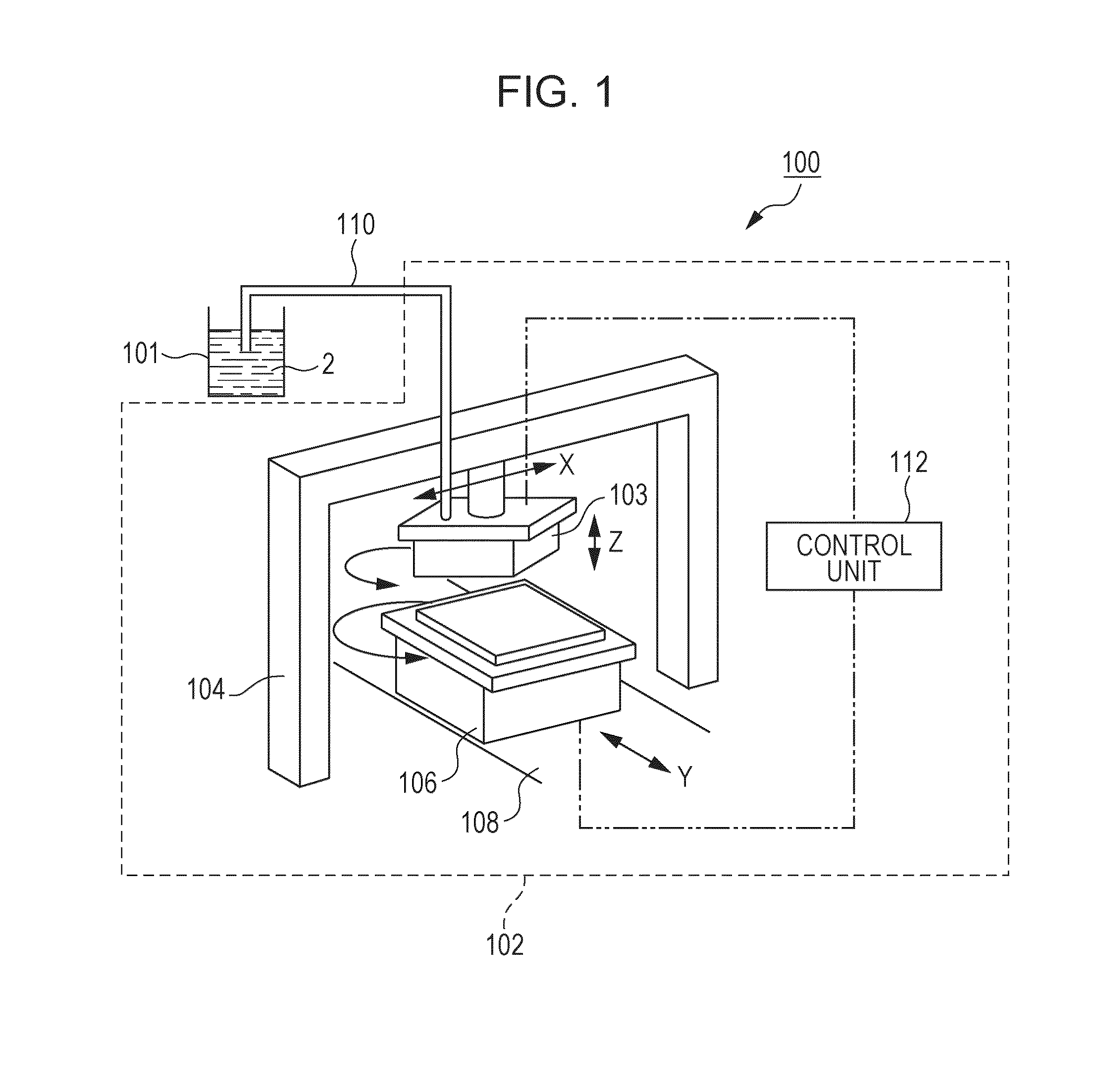

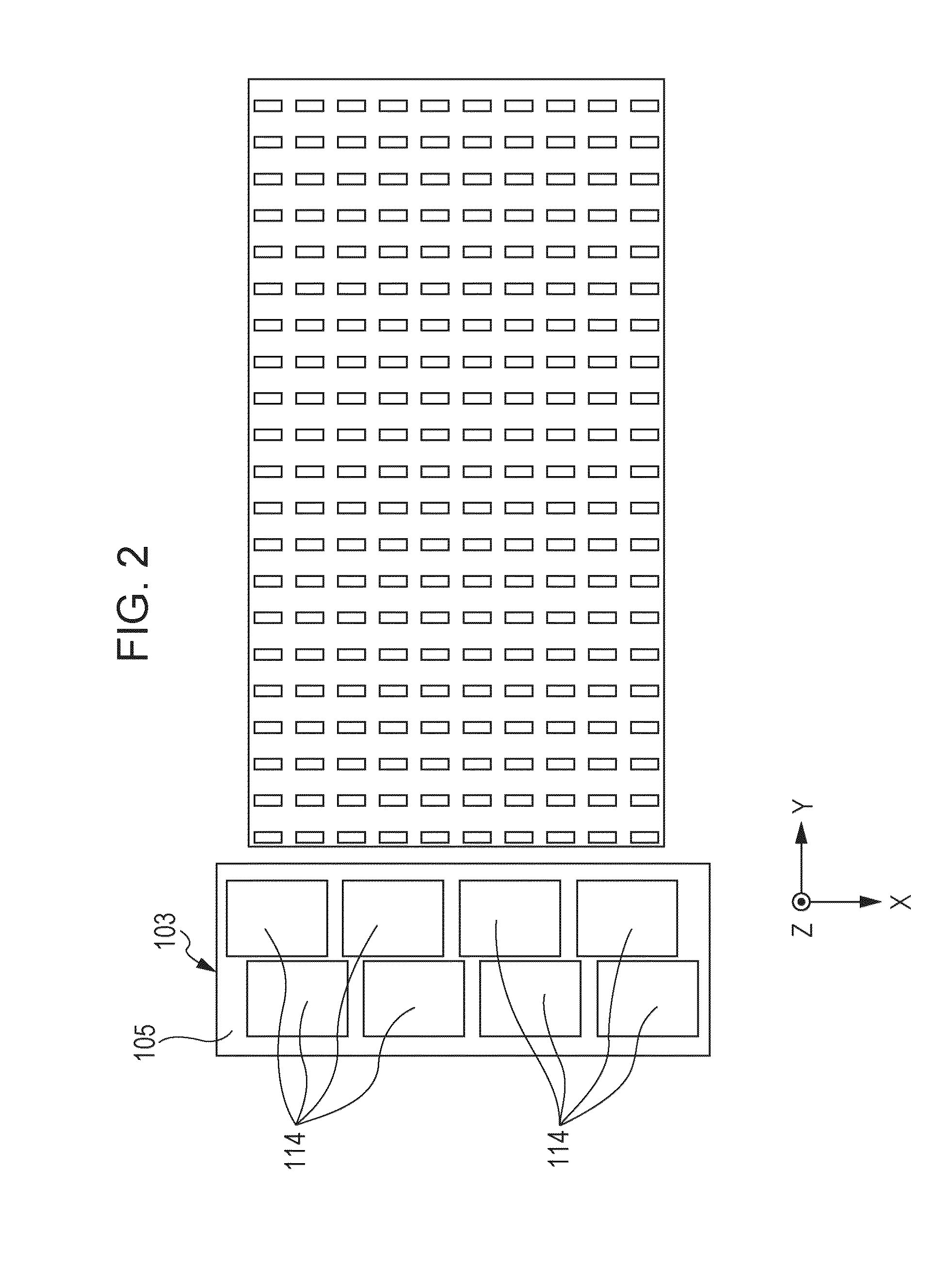

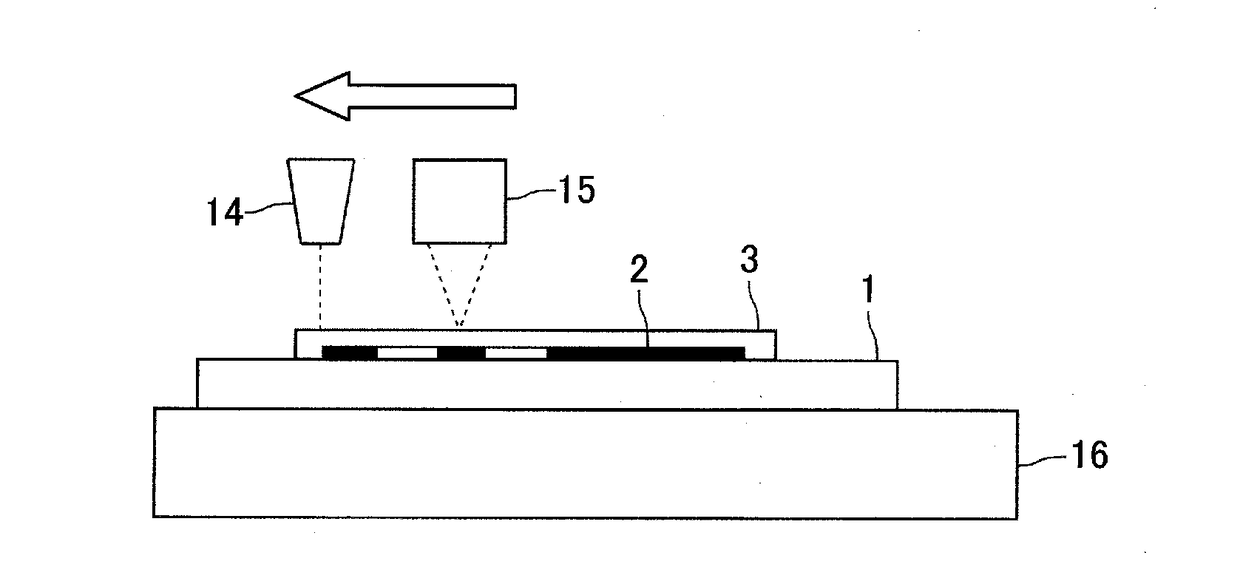

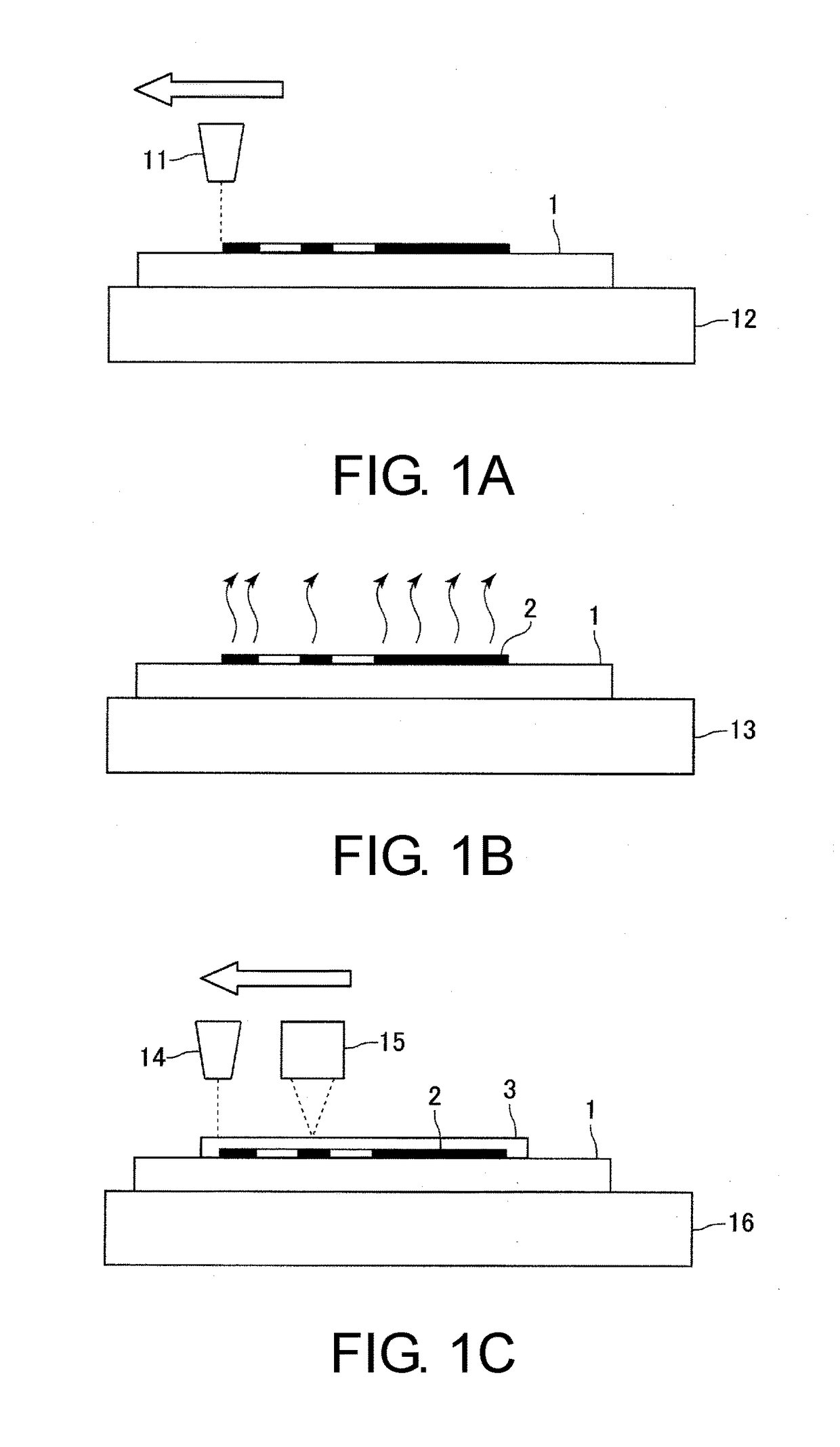

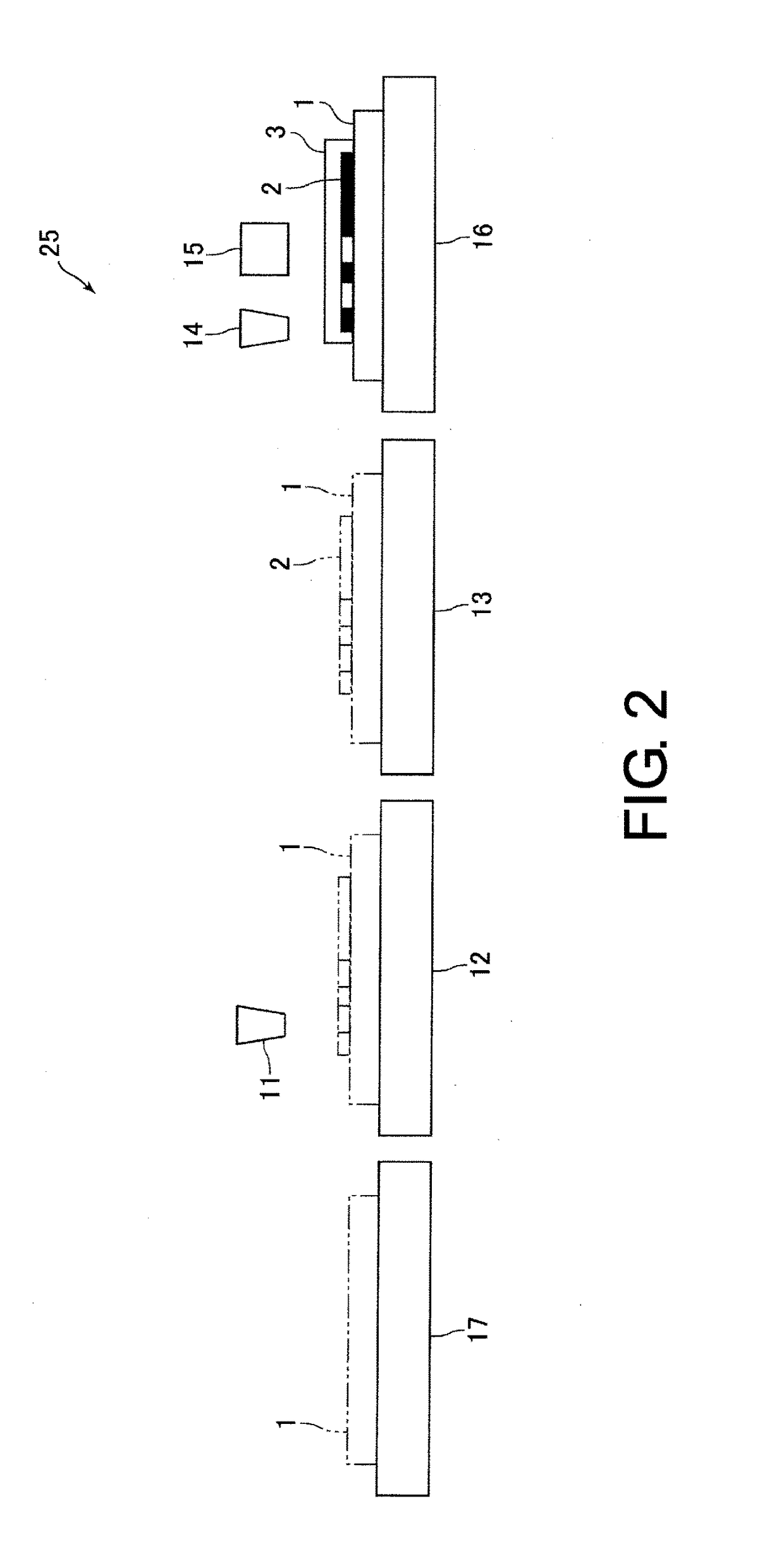

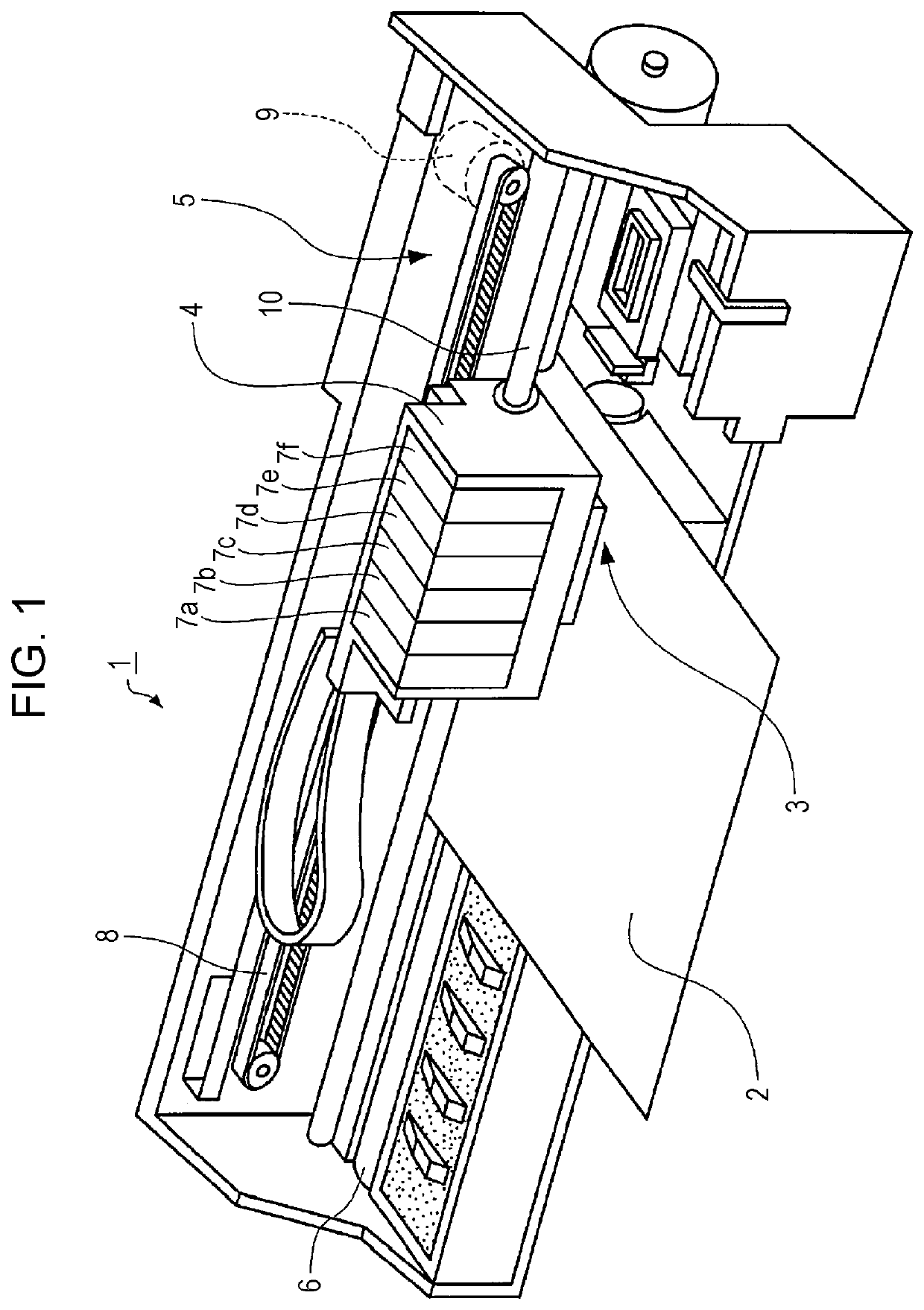

Method of manufacturing display panel

InactiveUS20080299315A1Reducing projection and depressionSimple designDuplicating/marking methodsIndication apparatusColor printingEngineering

In a method of manufacturing a display panel that includes a base and a printed layer printed on the base by inkjet printing, a color UV curable ink is deposited on a predetermined portion of the base for forming a color printed portion of the printed layer, and a transparent UV curable ink is deposited in at least one of a first depression provided by the color printed portion on a surface of the base and a second depression formed on a surface of the color printed portion for forming a transparent printed portion.

Owner:DENSO CORP

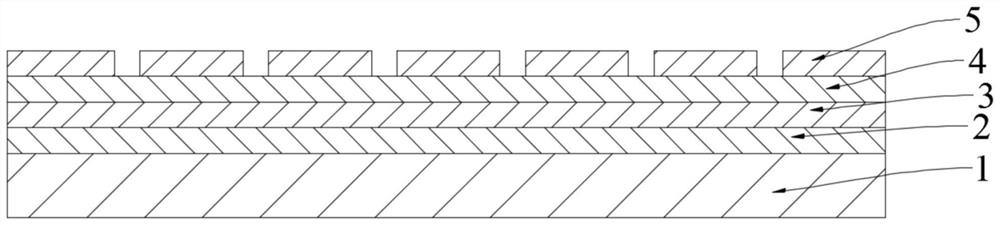

Packaging box printing process for UV-flashing stereoscopic pattern printing

InactiveCN109016906AAccurate printing process positioningGood three-dimensional effectDuplicating/marking methodsPattern printingGraphicsHot stamping

Owner:SUZHOU TONGLI PRINTING TECH

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS20140004321A1High transparencyLow coefficient of linear expansionDuplicating/marking methodsDecorative surface effectsEpoxyPolymer science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

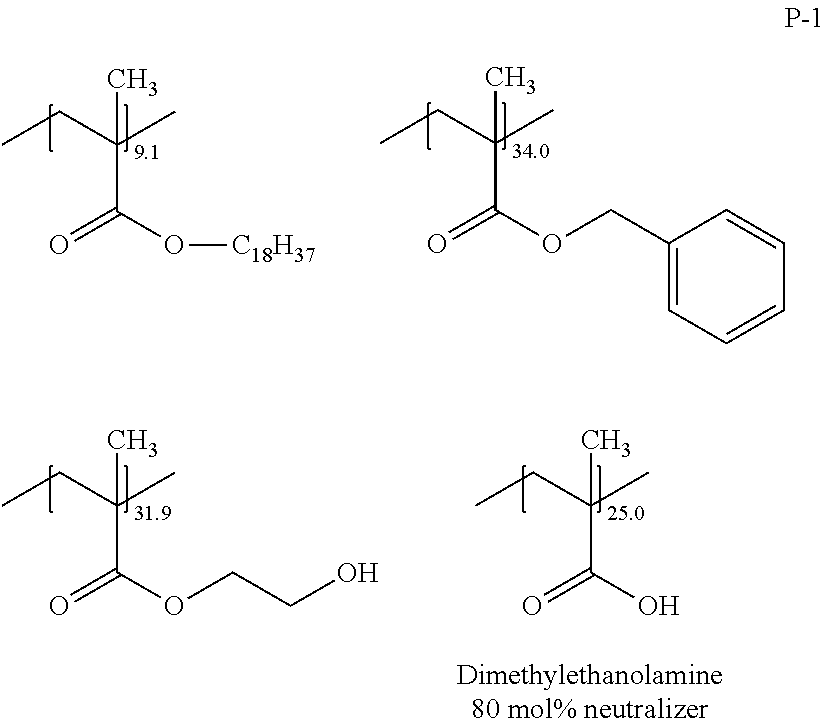

Resin composition for laser engraving, relief printing plate precursor for laser engraving, relief printing plate and method of producing the same

The present invention provides a resin composition for laser engraving, including at least a complex between a layered inorganic compound and a cationic organic compound, and a binder polymer that is insoluble in water and soluble in an alcohol having 1 to 4 carbon atoms; a relief printing plate precursor for laser engraving using the same, a relief printing plate; and a method of producing the relief printing plate.

Owner:FUJIFILM CORP

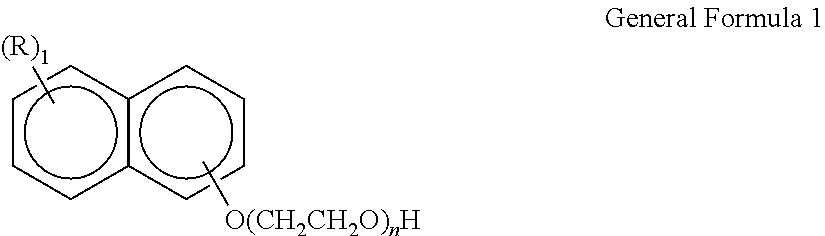

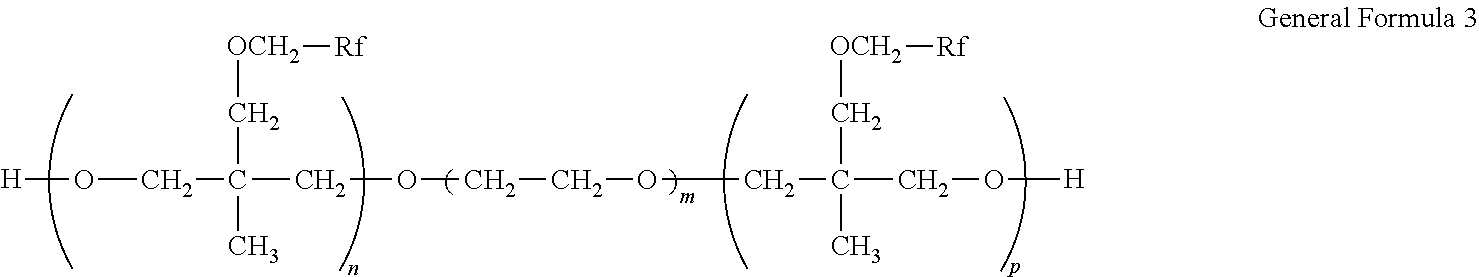

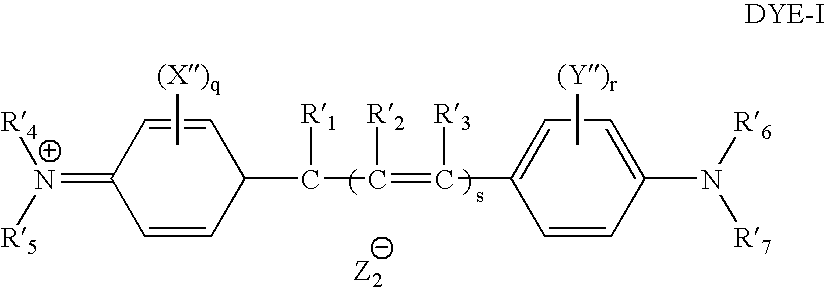

Ink set for inkjet recording, recording method, and colored material produced using the ink set

InactiveUS20130328979A1Convenient lightingIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

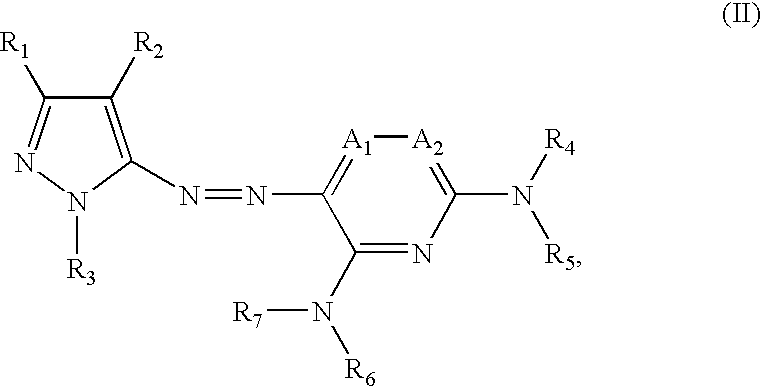

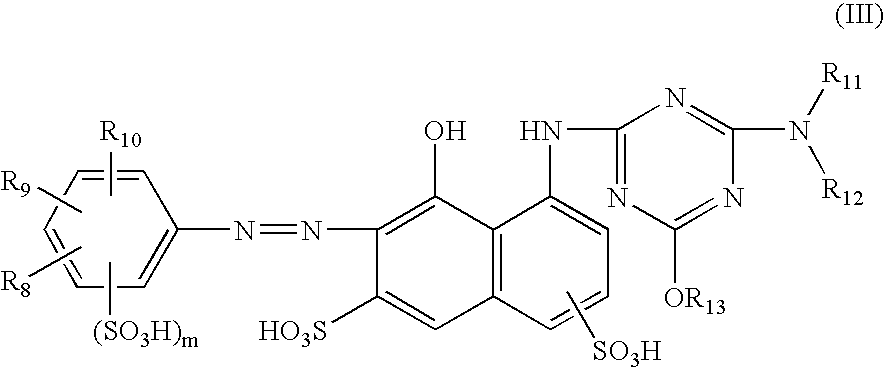

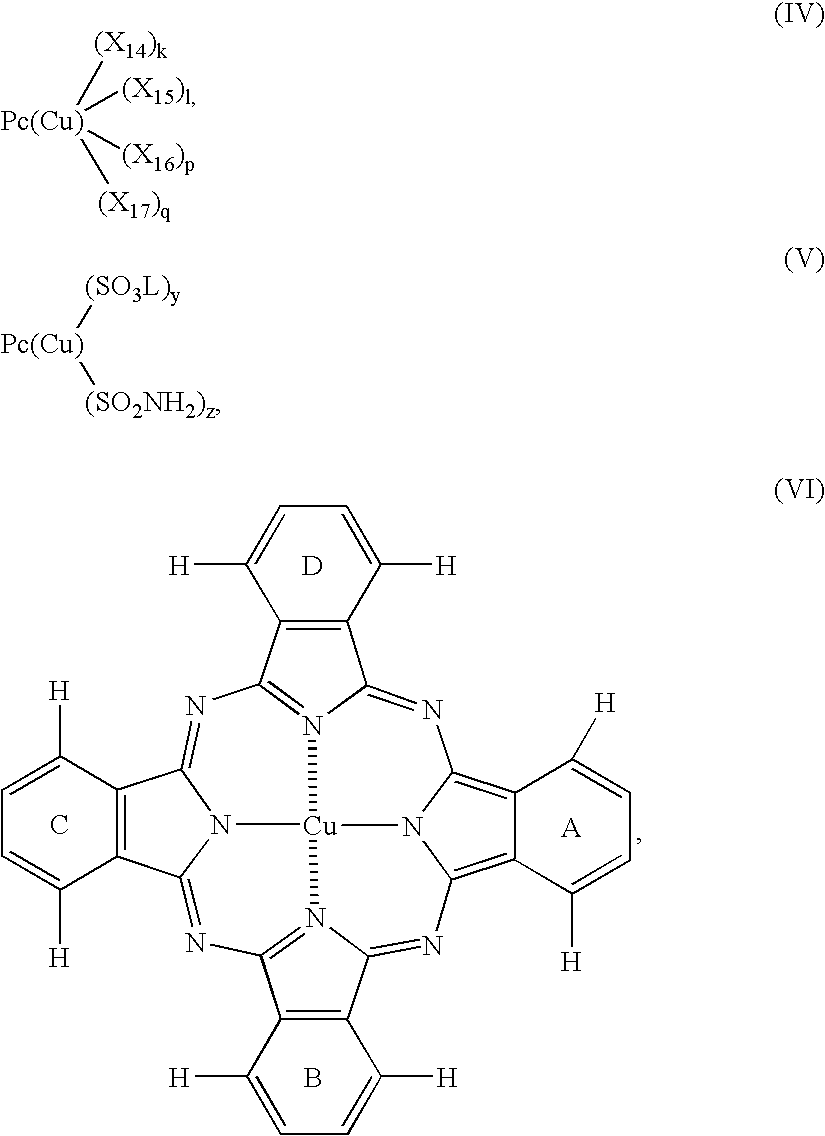

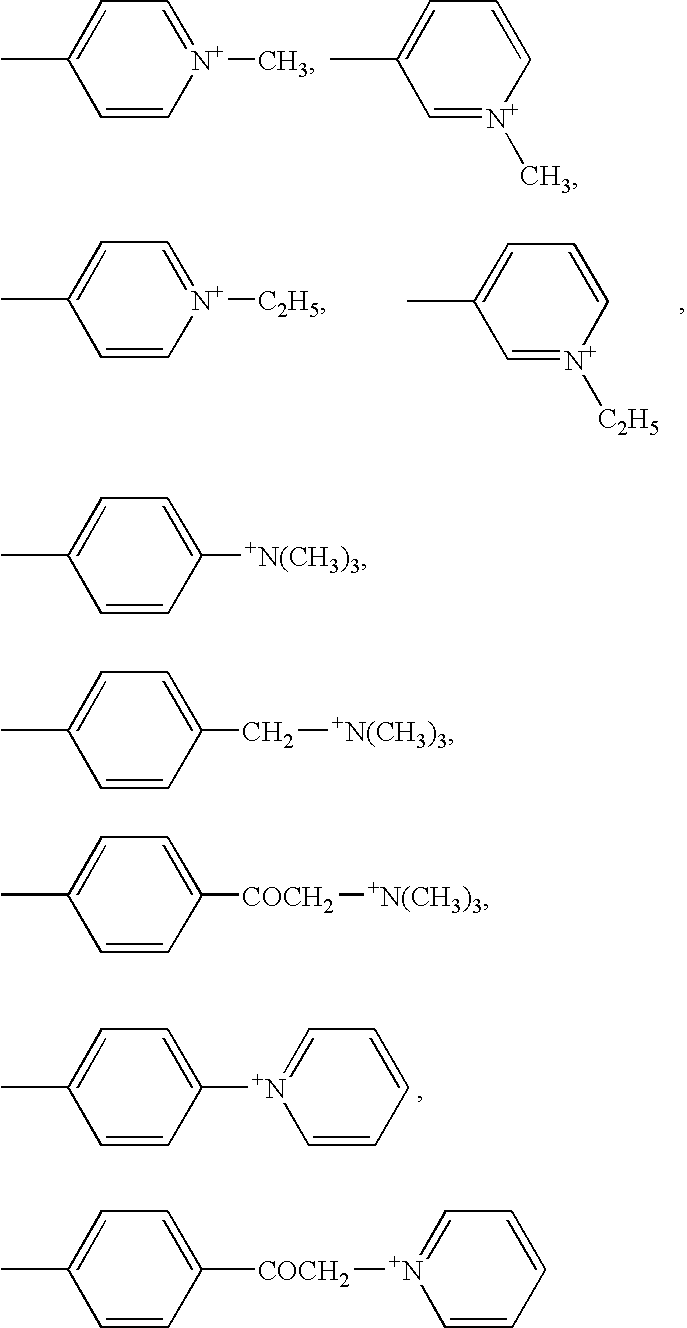

An ink set for inkjet recording, which has excellent water resistance and light resistance in the hue range of yellow-orange-magenta. The ink set includes two-color ink compositions, i.e., a) a magenta ink composition and b) an yellow ink composition, each of which includes a dye, water and a water-soluble organic solvent, wherein the magenta ink composition a) contains a compound produced by sulfonating a compound represented by the formula (1), a salt of the compound, or a mixture thereof as a coloring agent.

Owner:NIPPON KAYAKU CO LTD

Negative-working imageable elements with improved abrasion resistance

ActiveUS20090233227A1Influence overall viscosityHigh viscosityPhotosensitive materialsDuplicating/marking methodsSilica particleFumed silica

Owner:EASTMAN KODAK CO

Ink composition

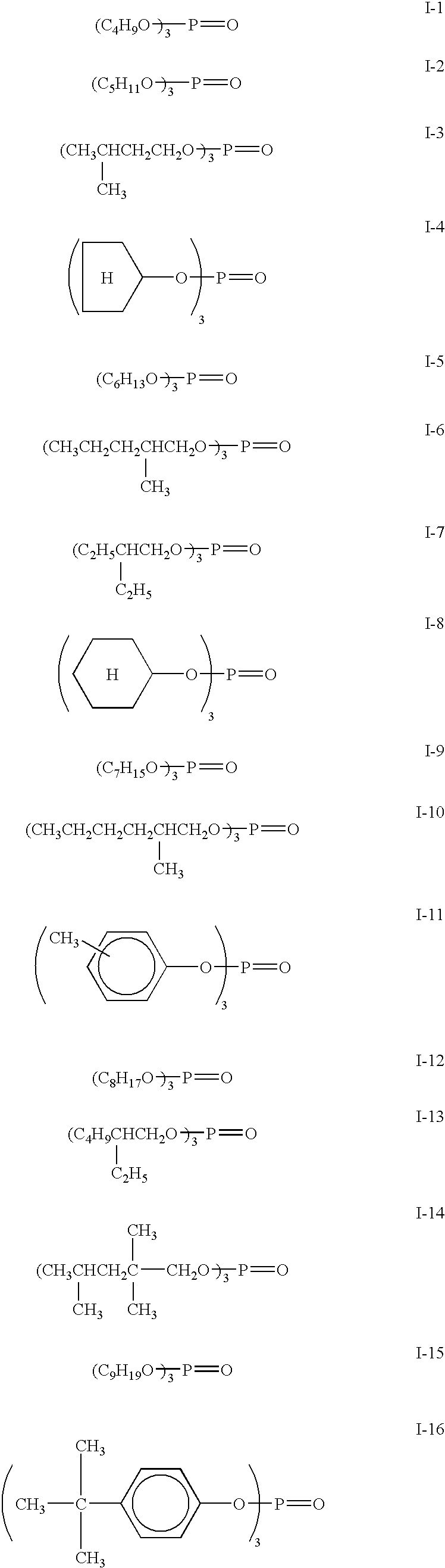

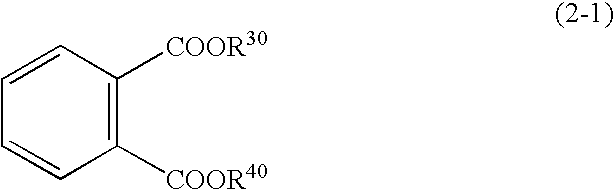

InactiveUS20060213391A1Shrinkage factorPromote wettingDuplicating/marking methodsInksPlasticizerPhosphate

Owner:FUJIFILM CORP +1

Ink jet recording method and recorded matter

ActiveUS20140287198A1Avoid bleedingDuplicating/marking methodsDecorative surface effectsSolventRecording head

Owner:SEIKO EPSON CORP

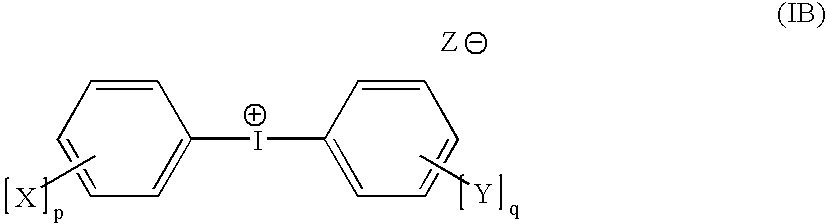

Lithographic printing plate precursor and plate making method thereof

InactiveUS20120199027A1Excellent printing durabilityImprove hydrophilicityDuplicating/marking methodsPlate printingImage recordingPolymer chemistry

Owner:FUJIFILM CORP

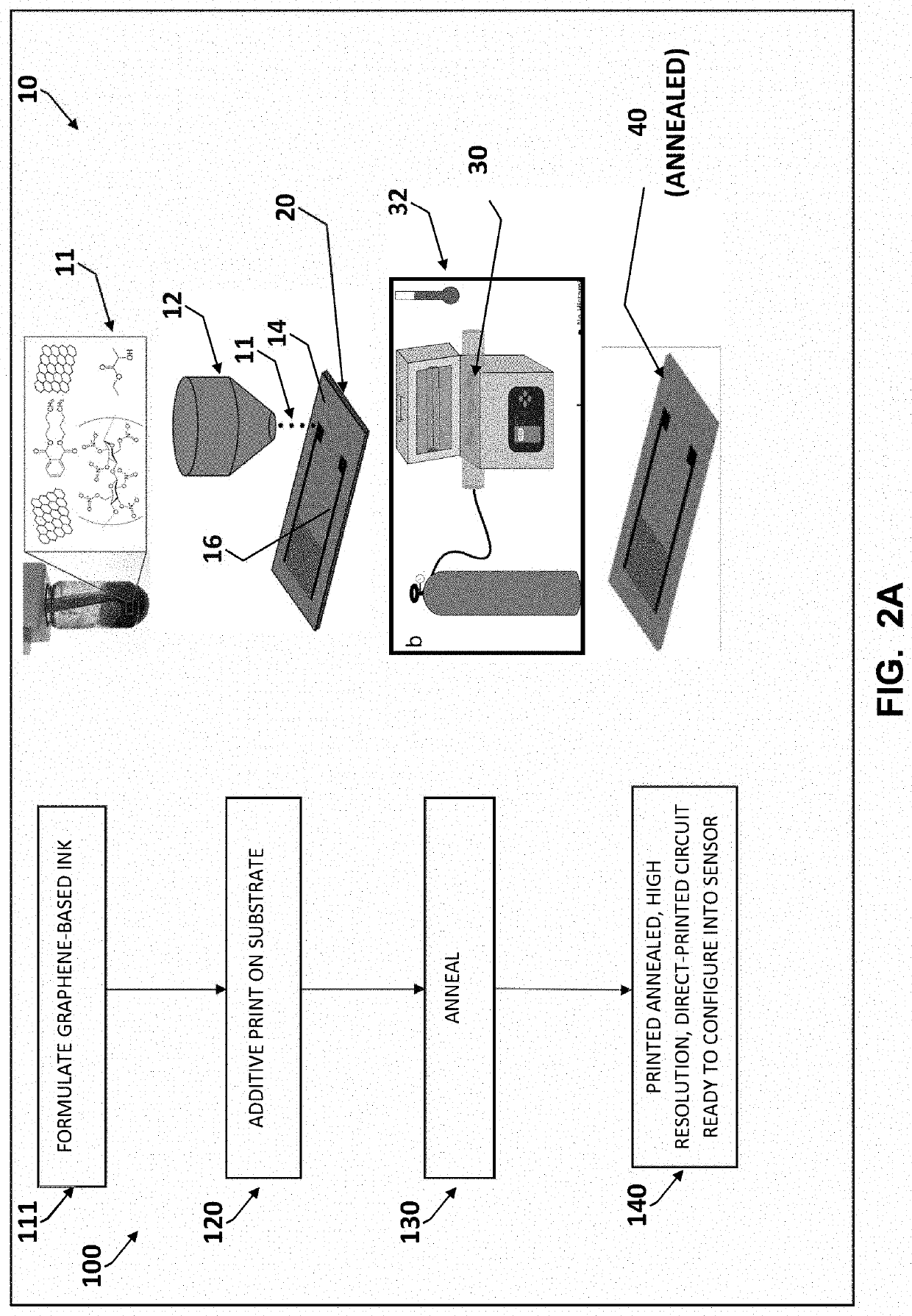

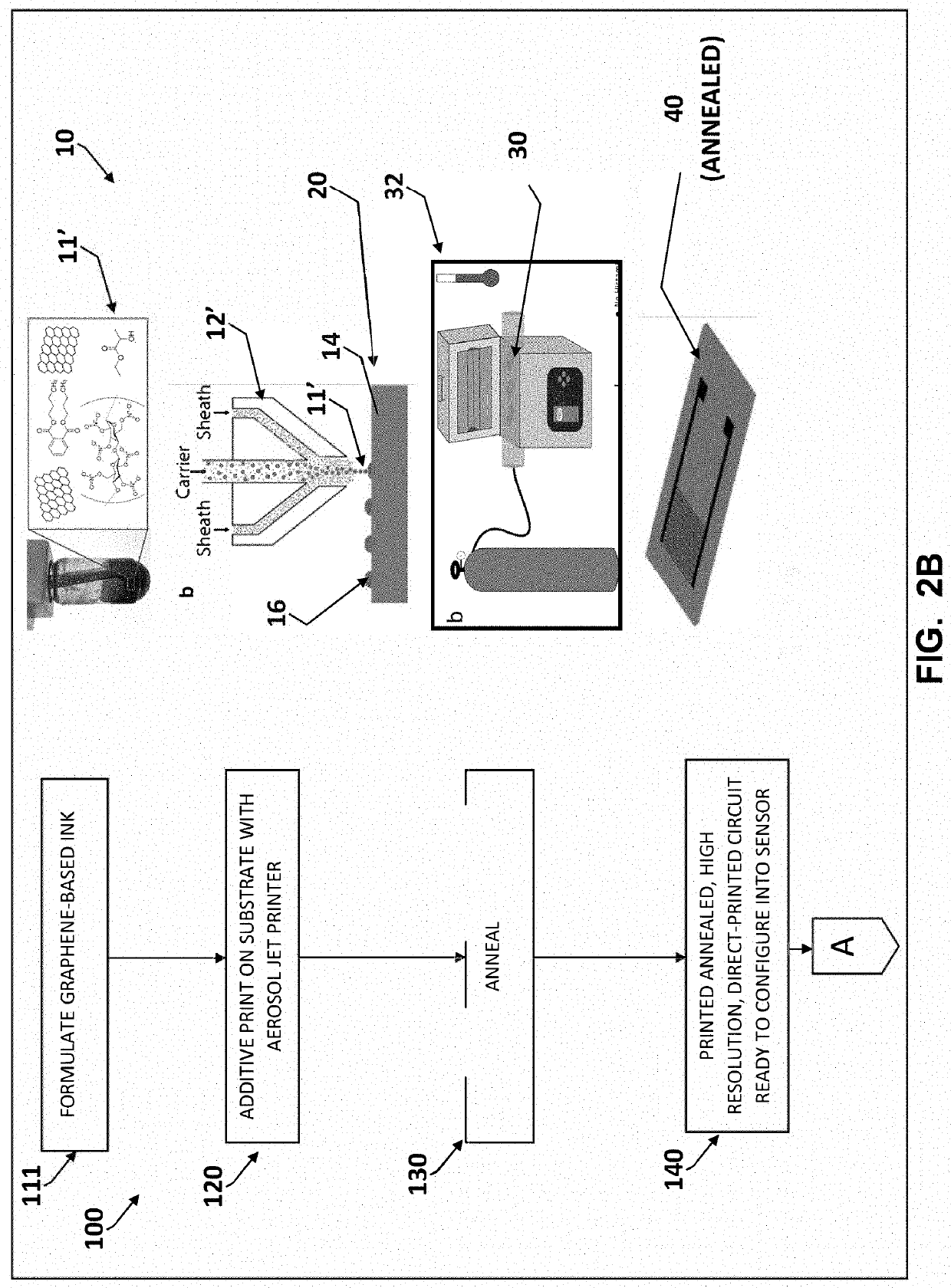

Aerosol jet printed flexible graphene circuits for electrochemical sensing and biosensing

PendingUS20210215636A1High resolutionInexpensive to fabricateAdditive manufacturing apparatusDuplicating/marking methodsInkjet printingAerosol jet printing

Owner:IOWA STATE UNIV RES FOUND +1

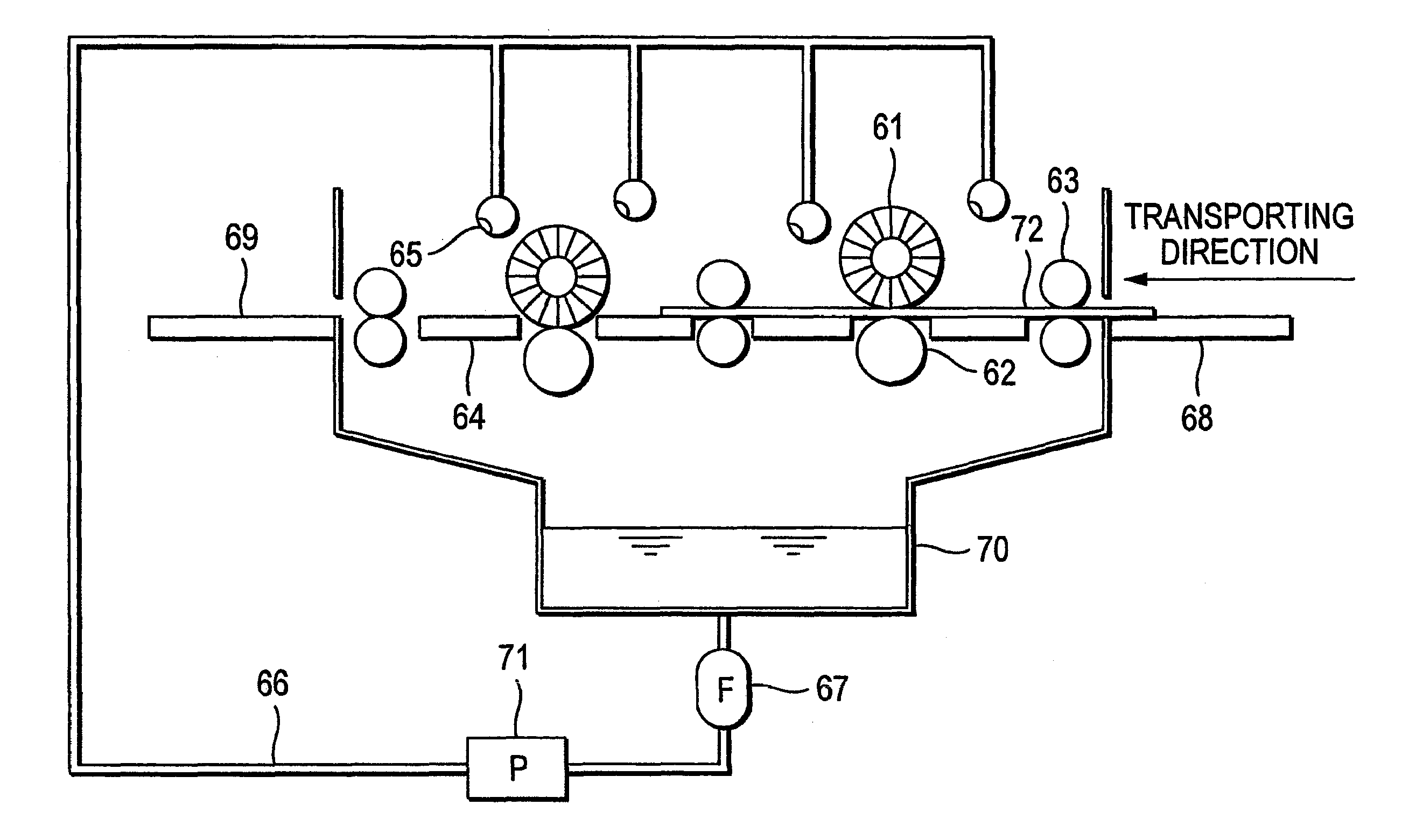

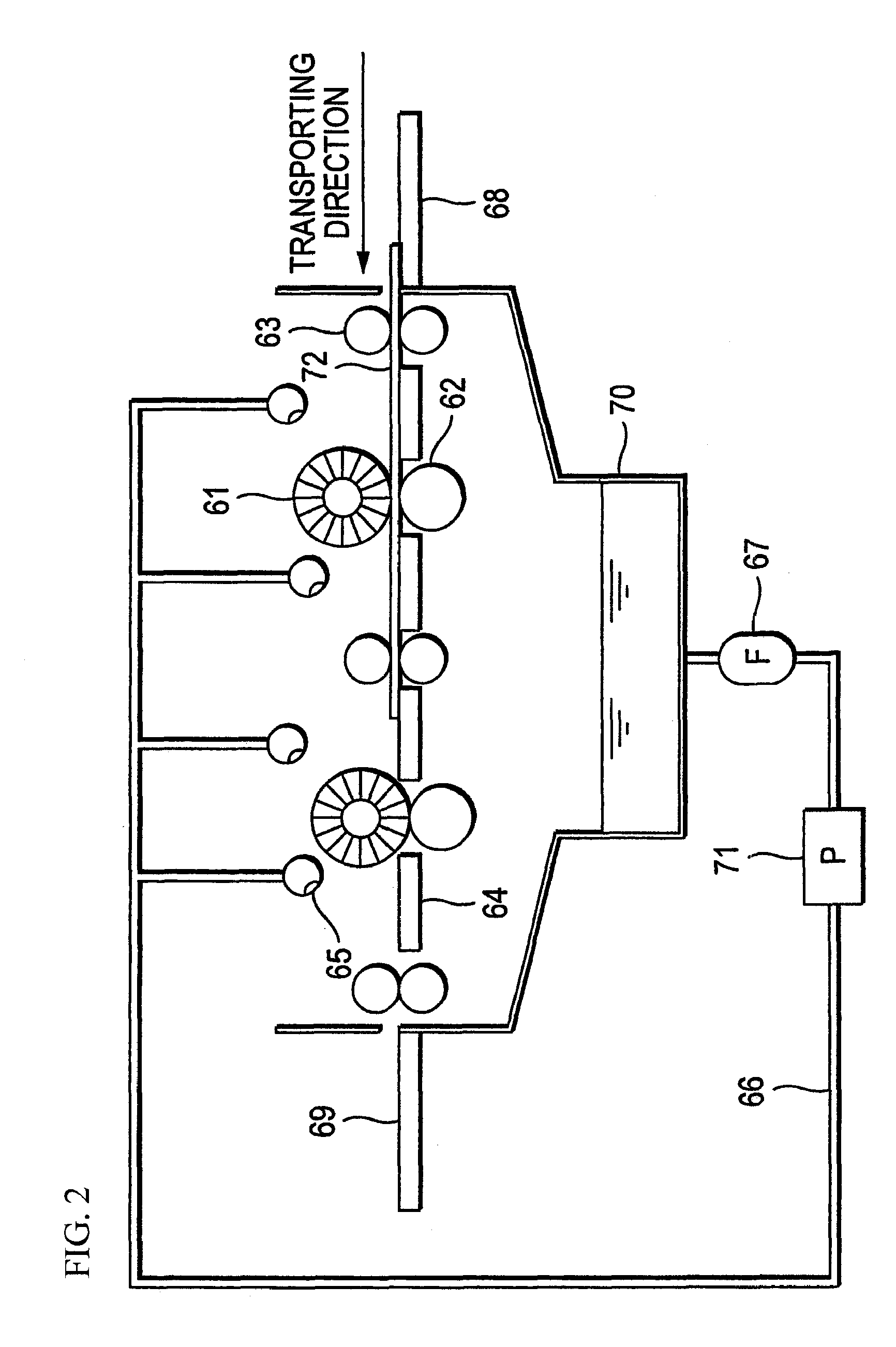

Glass cover plate preparation process

InactiveCN108909223AReduce consumptionIncrease productivityDuplicating/marking methodsOther printing apparatusGlass coverMegasonic cleaning

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

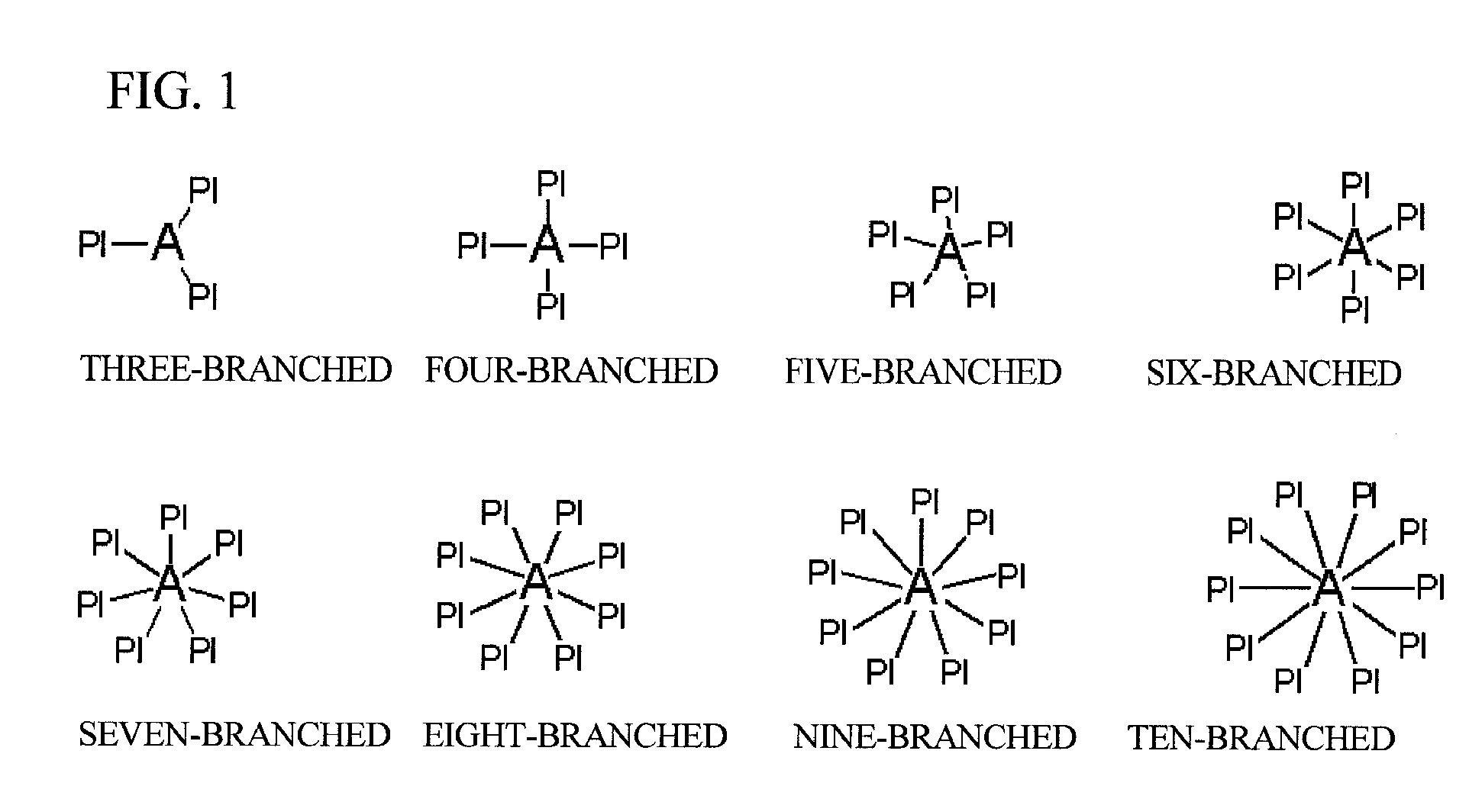

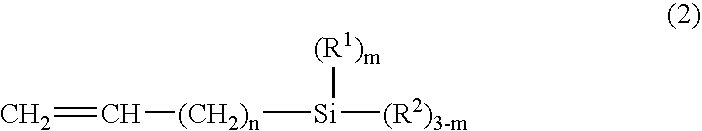

Vinyl alcohol polymer and process for producing vinyl alcohol polymer

A polyvinyl alcohol obtained by hydrolysis of a polyvinyl ester that contains silyl group functionalized monomer units. The polyvinyl alcohol satisfies the following formula (I) and the weight fraction of the polymer molecules contained in the polyvinyl alcohol having the degree of polymerization that is more than 3 times the weight-average degree of polymerization of the whole polyvinyl alcohol molecules is at most 25% by weight: 20<Pw×S<460 (I) wherein Pw is the weight-average degree of polymerization of the polyvinyl alcohol, and S is the content (mol %) of the silyl group functionalized monomer units. The polyvinyl alcohol is readily dissolved in water without need for addition of an alkali or an acid; the aqueous solution have good viscosity stability; film formed of its aqueous solution have excellent water resistance; the binding force with inorganic substances is high; and a film mixture of the polyvinyl alcohol with an inorganic substance has excellent water resistance. The polyvinyl alcohol is favorable for coating agents for inkjet recording materials and thermal recording materials.

Owner:KURARAY CO LTD

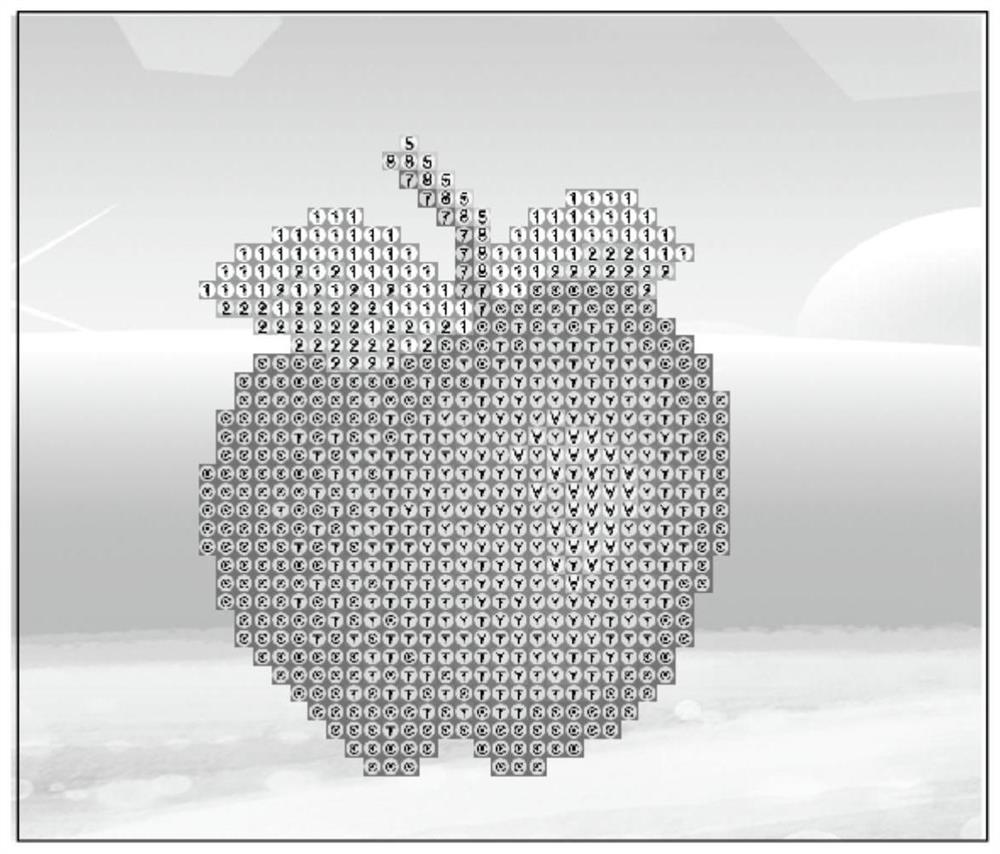

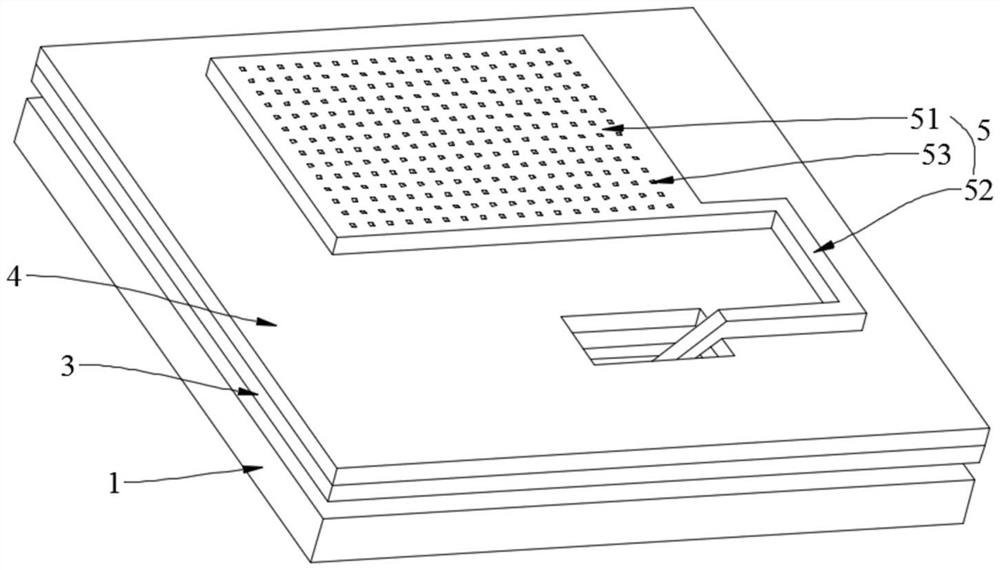

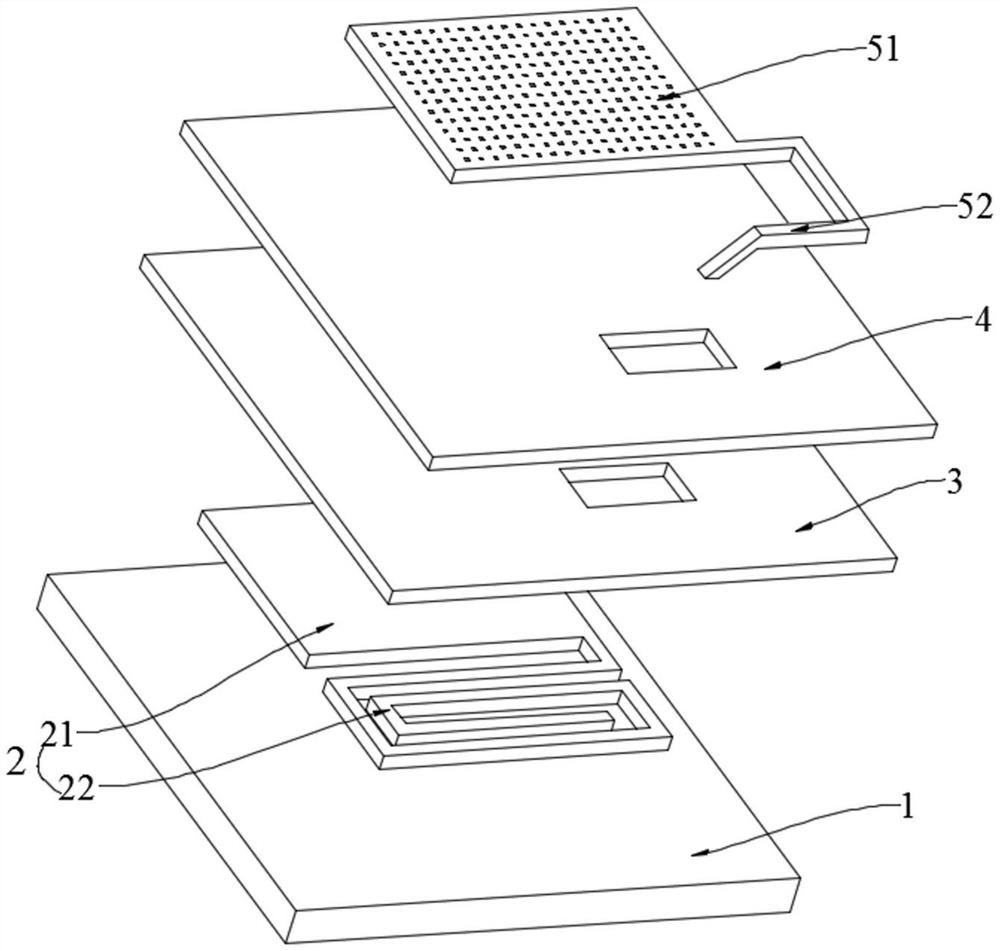

Diamond canvas gluing method

ActiveCN113276580AAchieve precisionImprove aestheticsLiquid surface applicatorsDuplicating/marking methodsDigital printingEngineering

The invention relates to the technical field of diamond canvas gluing, in particular to a diamond canvas gluing method. The diamond canvas gluing method comprises the following steps that 1, gluing positioning points are manufactured; 2, digital printing is carried out so that a diamond picture pattern and the gluing positioning points are jointly printed on a diamond canvas in a jet printing mode; 3, the diamond canvas is fixed and scanned, and gluing positioning point information on the diamond canvas is obtained; and 4, inputting into a gluing machine is performed, and gluing is performed on the diamond canvas according to the scanned and read positioning point information. According to the diamond canvas gluing method, gluing convenience is improved, and gluing is attractive.

Owner:杨振玉

Format-dividing printing method for large-format wall face

Owner:XIAN UNIV OF TECH

Inkjet ink composition and image recording method

Owner:FUJIFILM CORP

Aluminum alloy section character printing process

Owner:HUNAN HENGXIN NEW BUILDING MATERIALS CO LTD

Metallic decoration method and metallic decoration apparatus

InactiveUS20170129257A1Low pour pointSolvent is vaporizedDuplicating/marking methodsTypewritersSolventHeating temperature

Owner:MIMAKI ENG

Treatment solution composition, ink jet textile printing method, and fabric

InactiveUS20200123701A1Reduce generationImprove appearance qualityFibre treatmentDuplicating/marking methodsTextile printerPolymer science

Owner:SEIKO EPSON CORP

Flexible humidity sensor based on ink-jet printing and preparation process thereof

PendingCN114858872ASimple structureAchieve a single responseDuplicating/marking methodsMaterial capacitanceCapacitanceHemt circuits

Owner:WUHAN UNIV

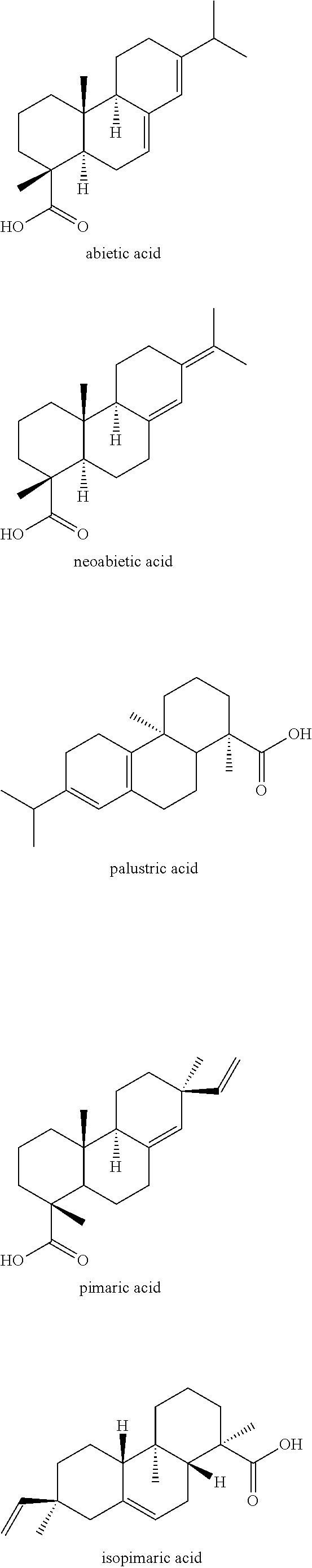

High bio-renewable content printing inks

Owner:SUN CHEM CORP

One-object one-code spray printing method based on coding information and system thereof

Owner:LEADER TECH KUNSHAN DIGITAL TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap