Diamond canvas gluing method

A diamond painting and gluing technology, applied in the directions of copying/marking methods, coatings, devices for applying liquid to the surface, etc., can solve the problem of inability to achieve no excess glue around the affixed drill, inability to fully control the size, and increase the amount of squeegee. Problems such as the difficulty of matching the version, to achieve the effect of eliminating the silk screen random glue process, improving efficiency and quality, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

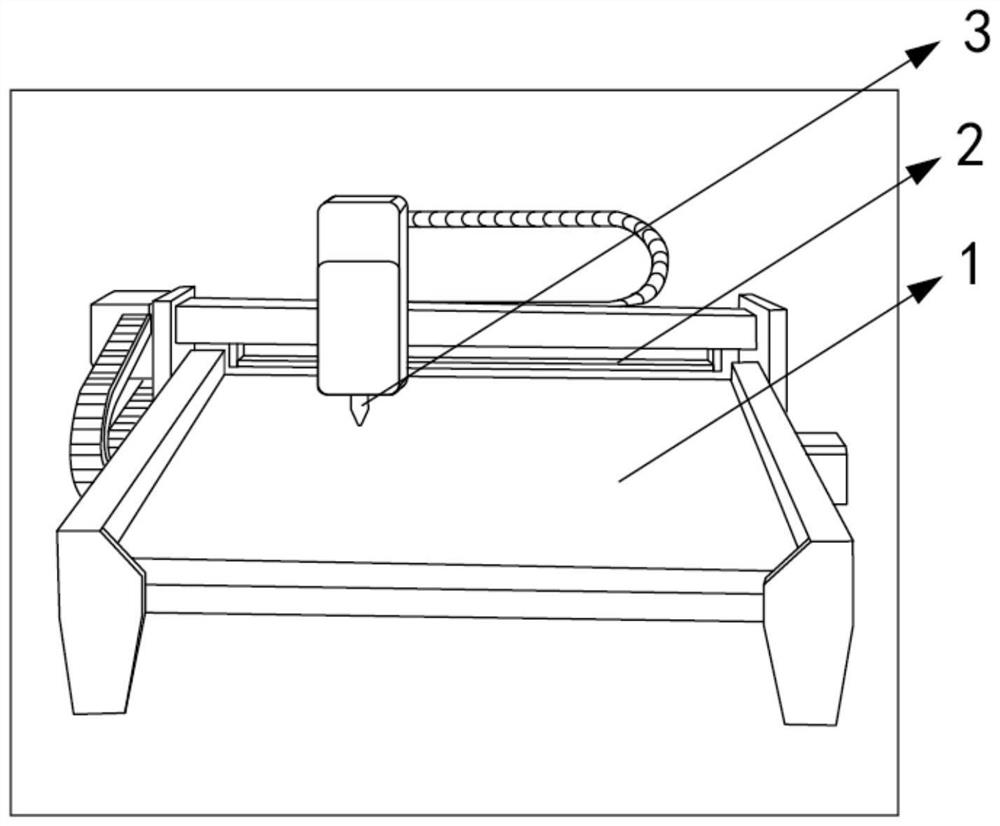

[0025] Such as Figure 1-4 As shown, the gluing operation is carried out on the diamond canvas through a numerical control gluing machine. The gluing machine includes a fixed platform 1 for fixing the diamond canvas, a scanning imaging system 2 for scanning, a removable nozzle 3, and a driving nozzle 3 to move the coating. Glue and scanning imaging system 2 moves the driving mechanism for scanning, and the driving mechanism adopts the existing three-axis numerical control system, which will not be repeated here.

[0026] Specifically include the following steps:

[0027] Step 1: Determine the gluing pattern and make gluing positioning points; in step 1, set the positioning points according to the corresponding diamond sticking position of the diamond painting pattern. The gluing positioning point file, the gluing positioning point file includes several central positioning points, and each central positioning point corresponds to the positioning point on the diamond painting p...

Embodiment 2

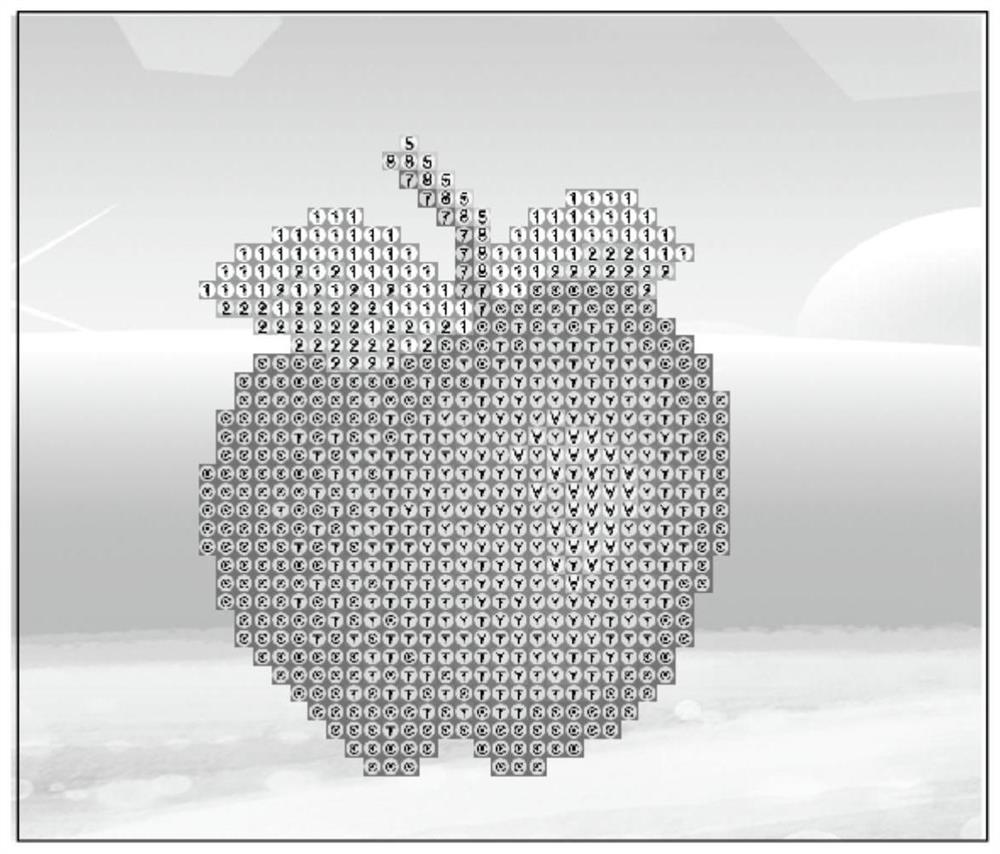

[0033] by figure 2 Take Apple as an example. Apple is the pattern to be pasted with diamonds, that is, the glued pattern. Other patterns are patterns without diamonds. Set the positioning points according to the corresponding diamonds of the diamond painting pattern. Each positioning point is the pattern that will be pasted with diamonds later. The central positioning point of , thus generating the gluing positioning point file;

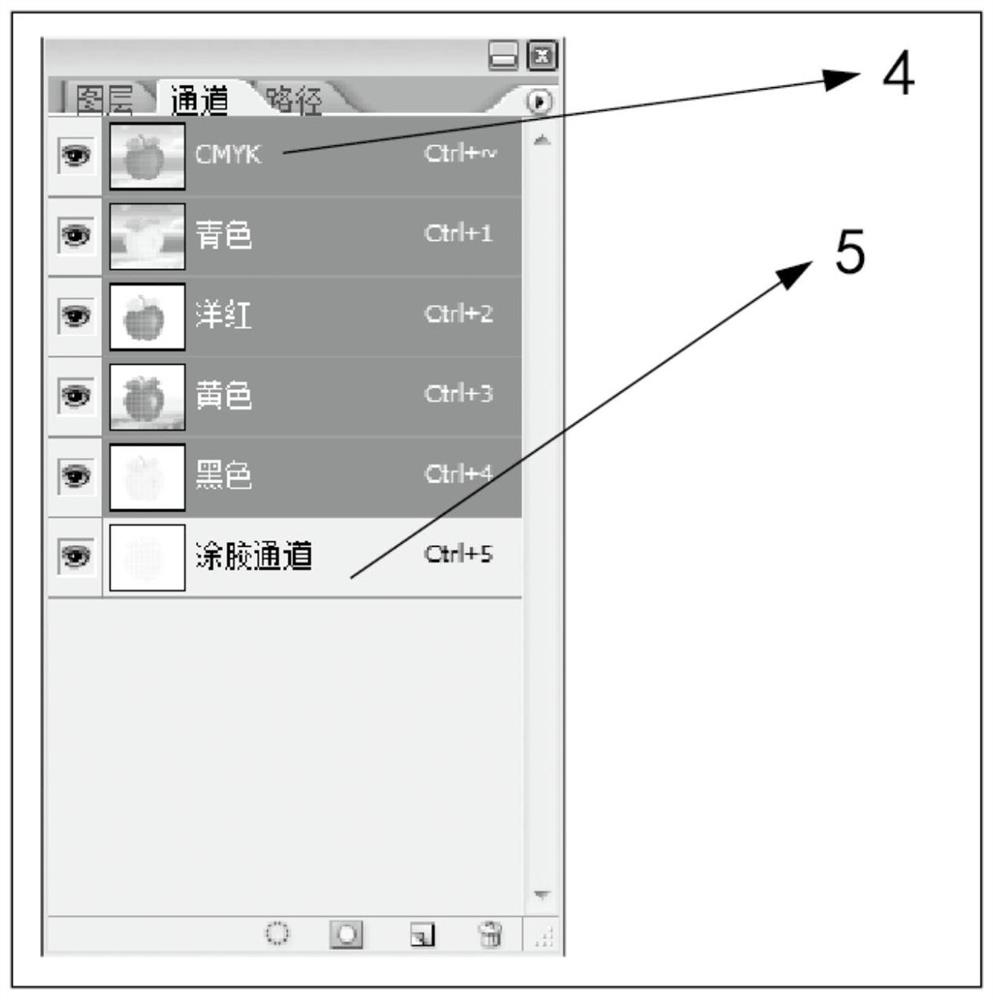

[0034] Put the diamond canvas on the digital printing machine for printing, the diamond painting pattern and the gluing positioning points are printed on the canvas together, and a set of nozzles of the digital printing machine reads image 3 In the figure, the data of CMYK color channel 4 is printed with dye-sublimation ink. Another set of nozzles read image 3 Spot color channel data is gluing channel 5, printing and scanning to read ink. Note: Some digital printing machines on the market can combine two pictures and print together, that is, se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap