Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147results about "Liquid surface applicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

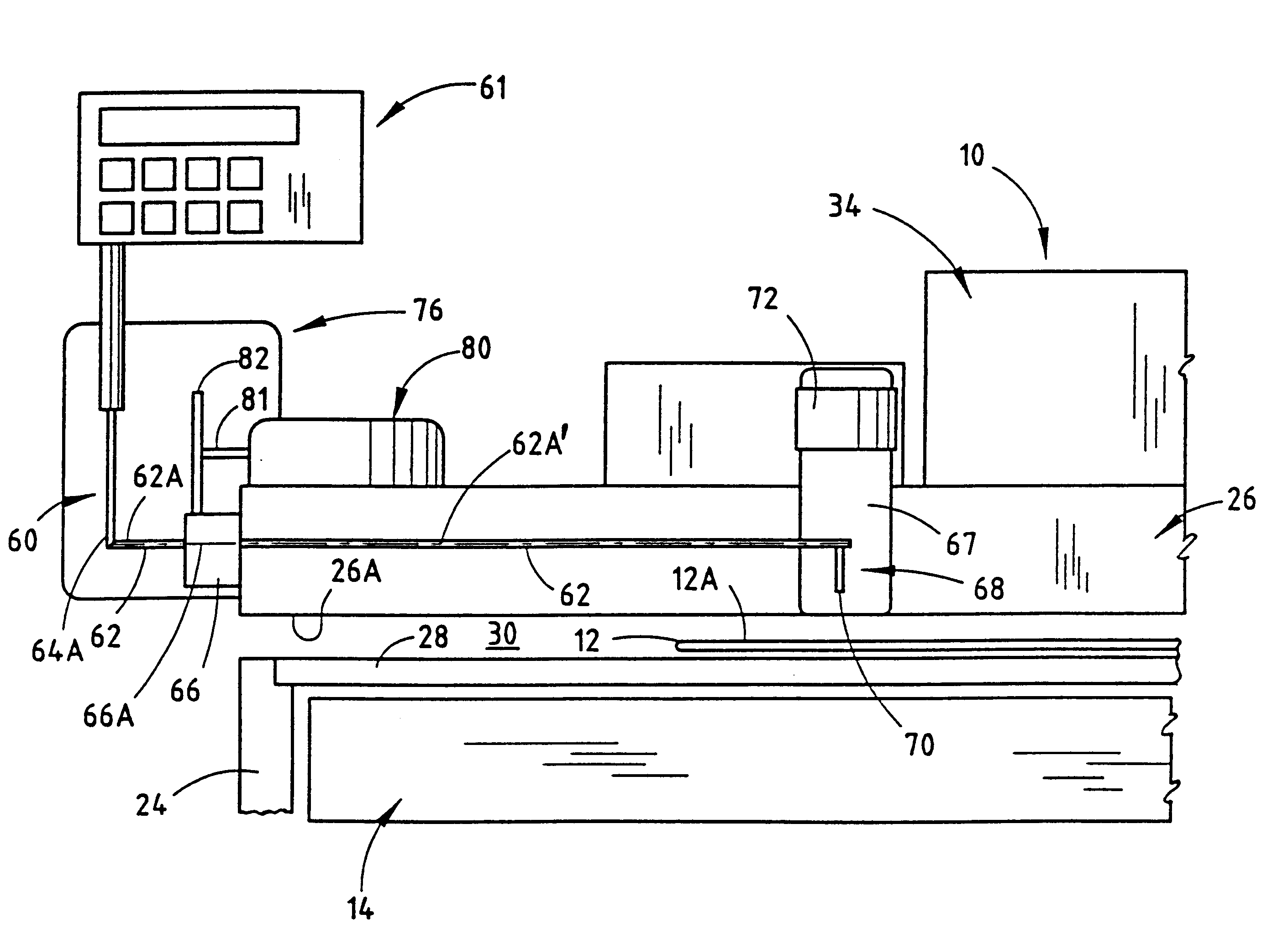

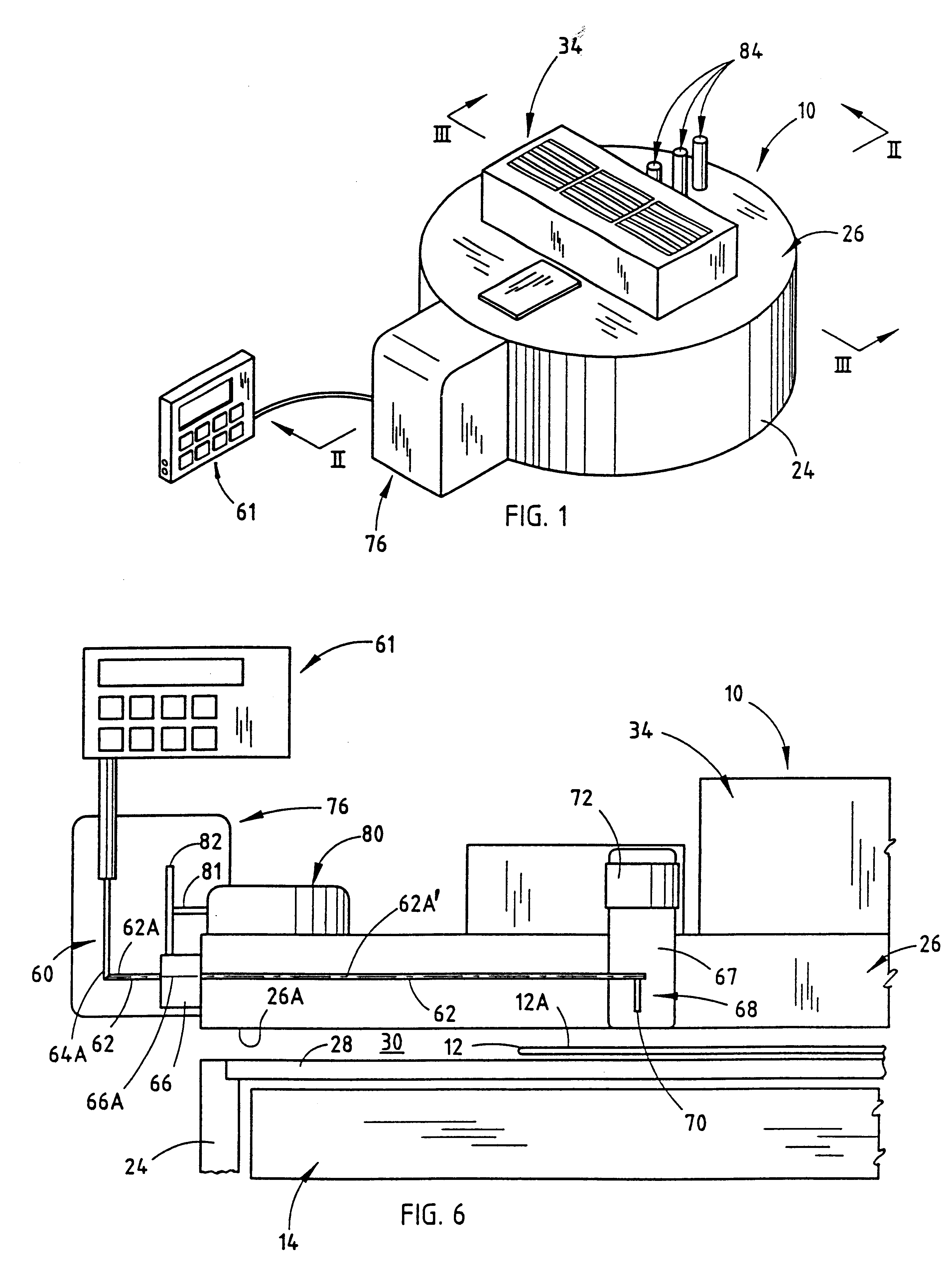

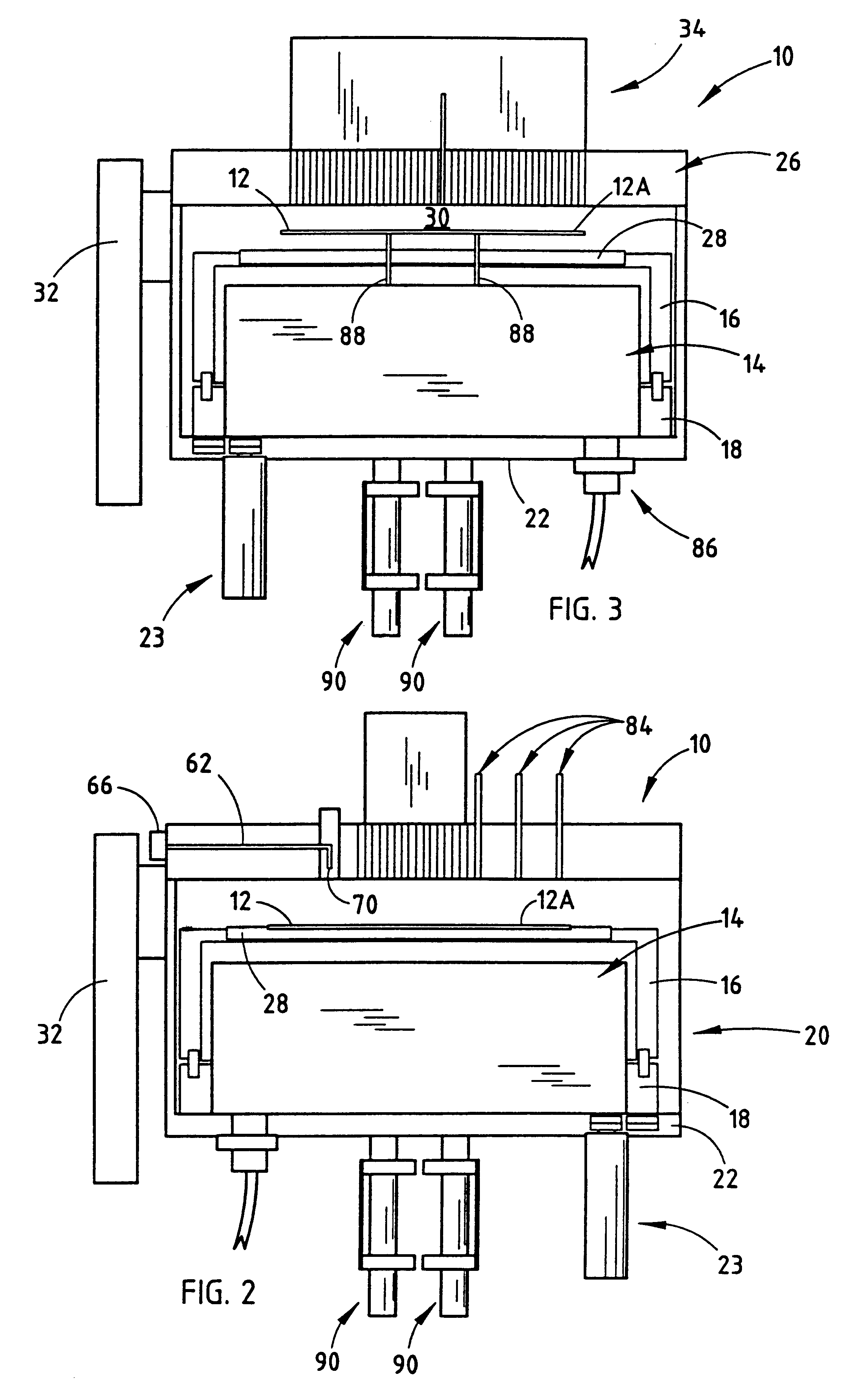

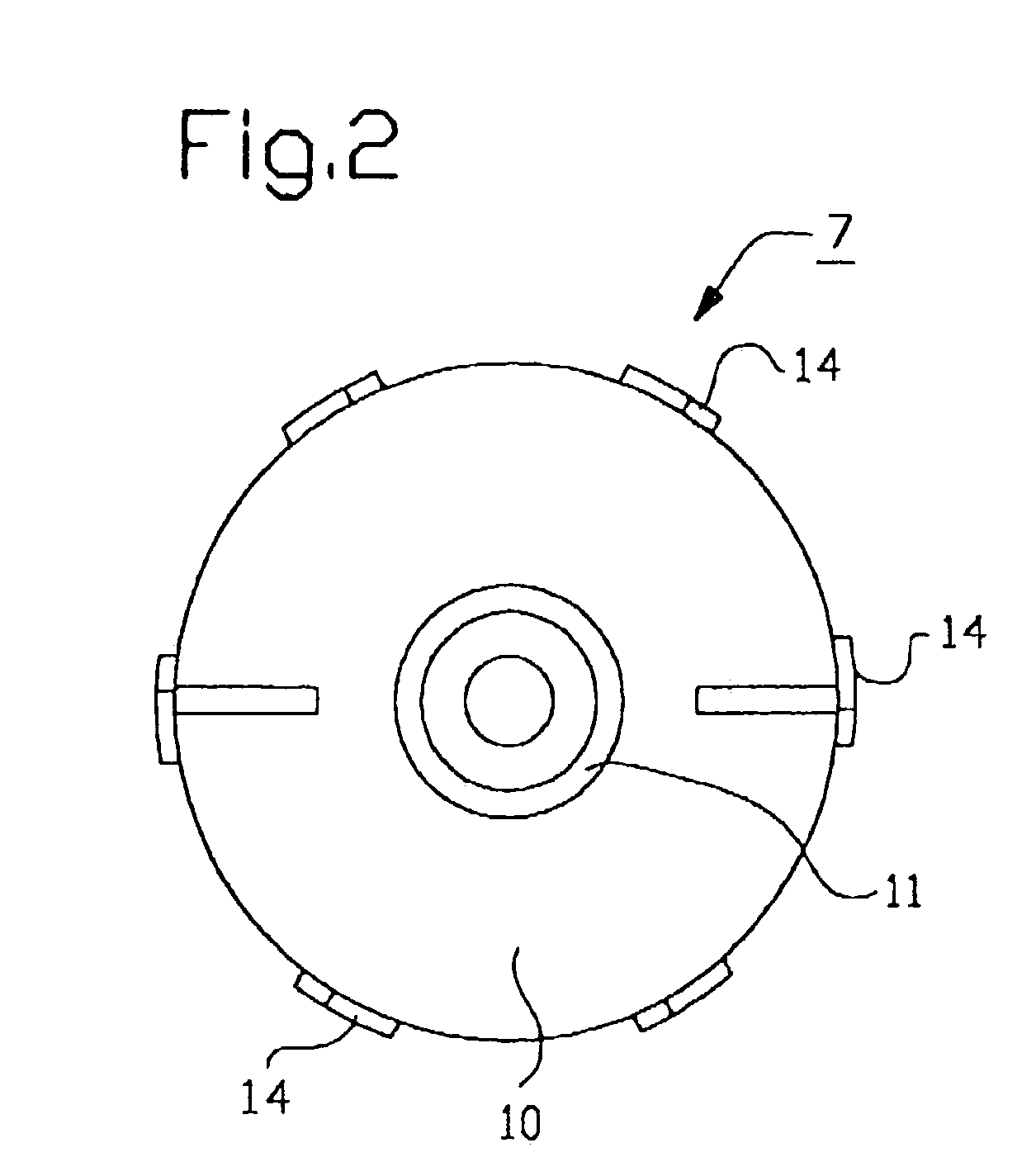

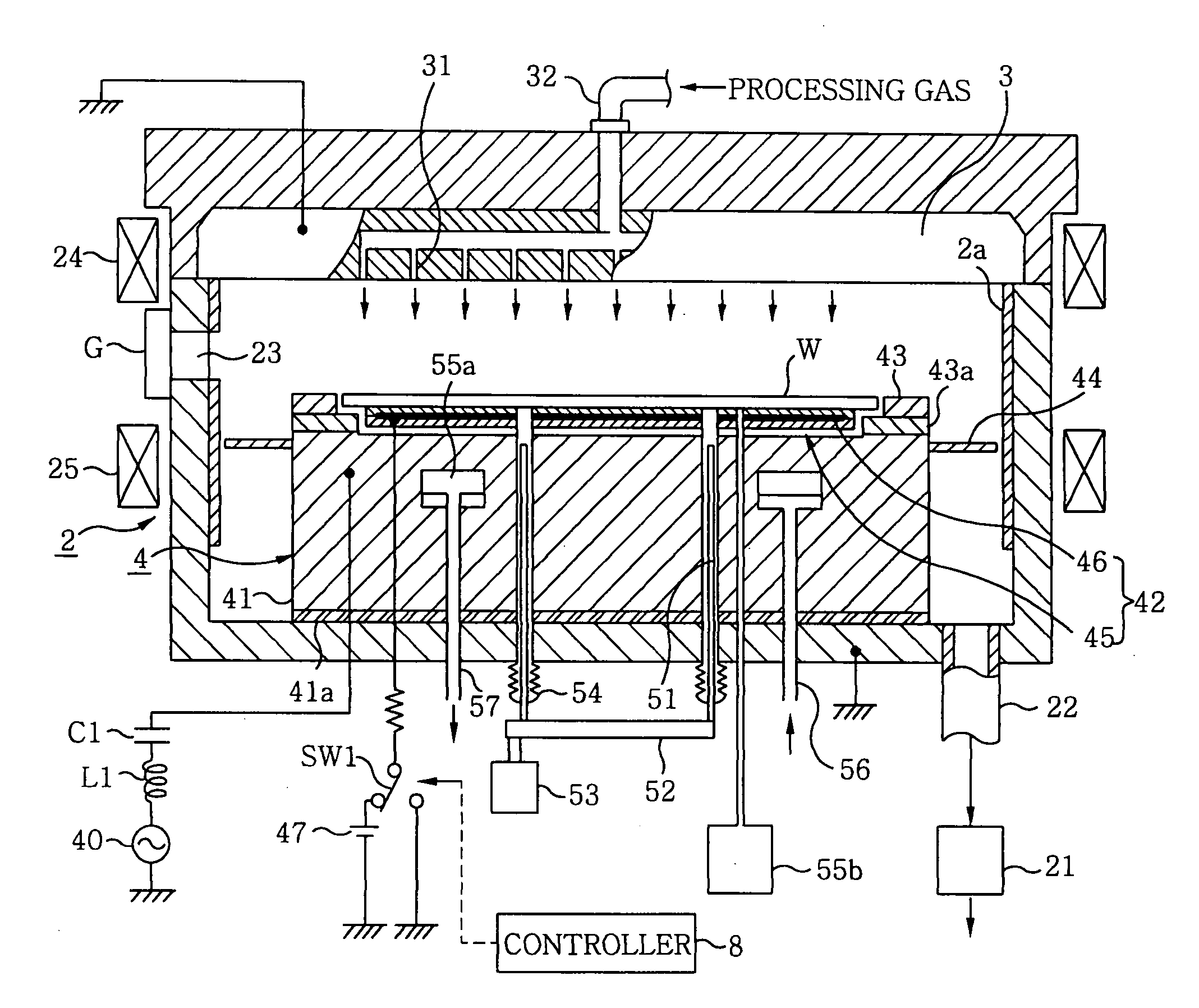

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

Zn-Mg zinc alloy and preparation method and application thereof

Owner:湖南华翔医疗科技有限公司

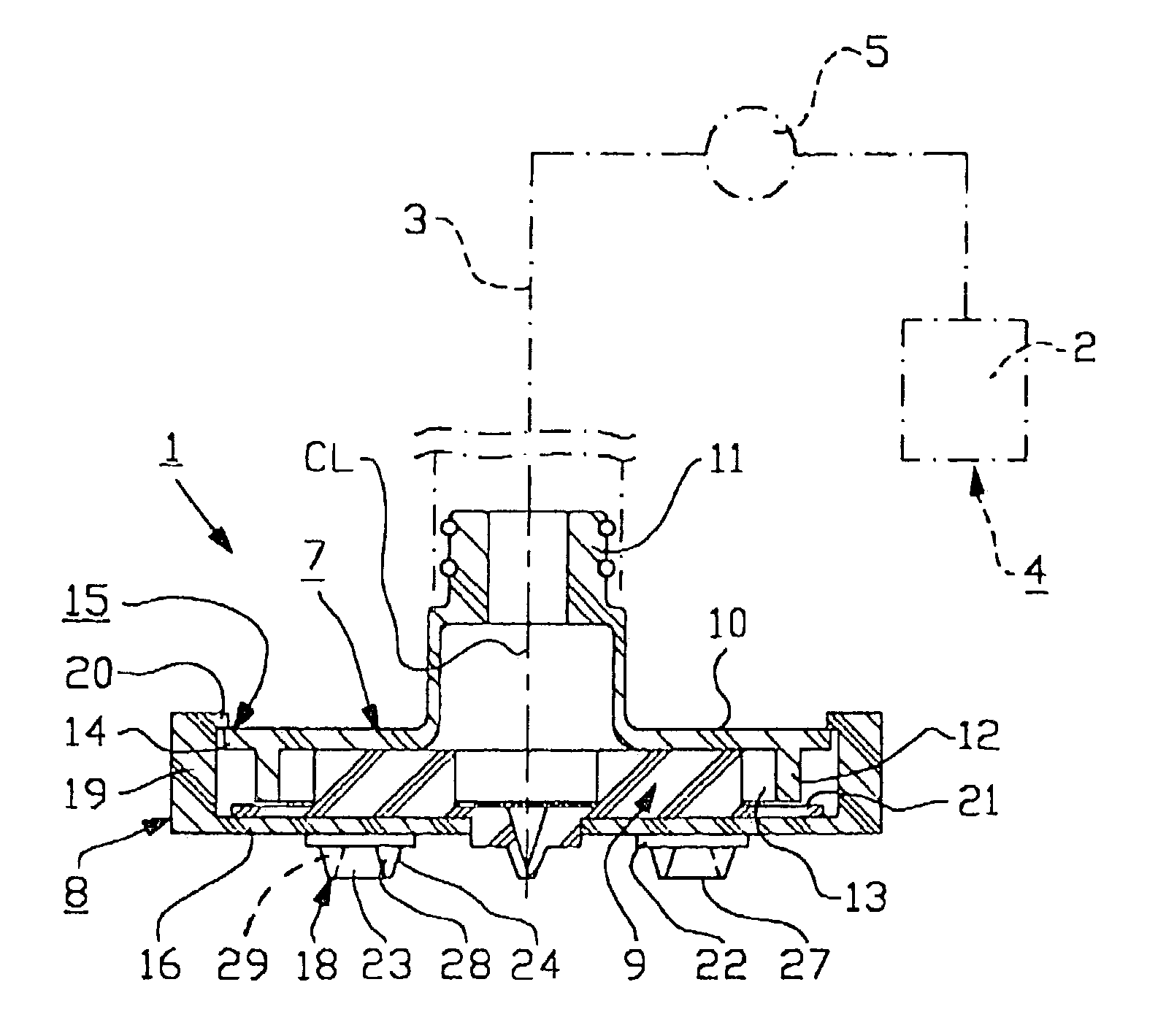

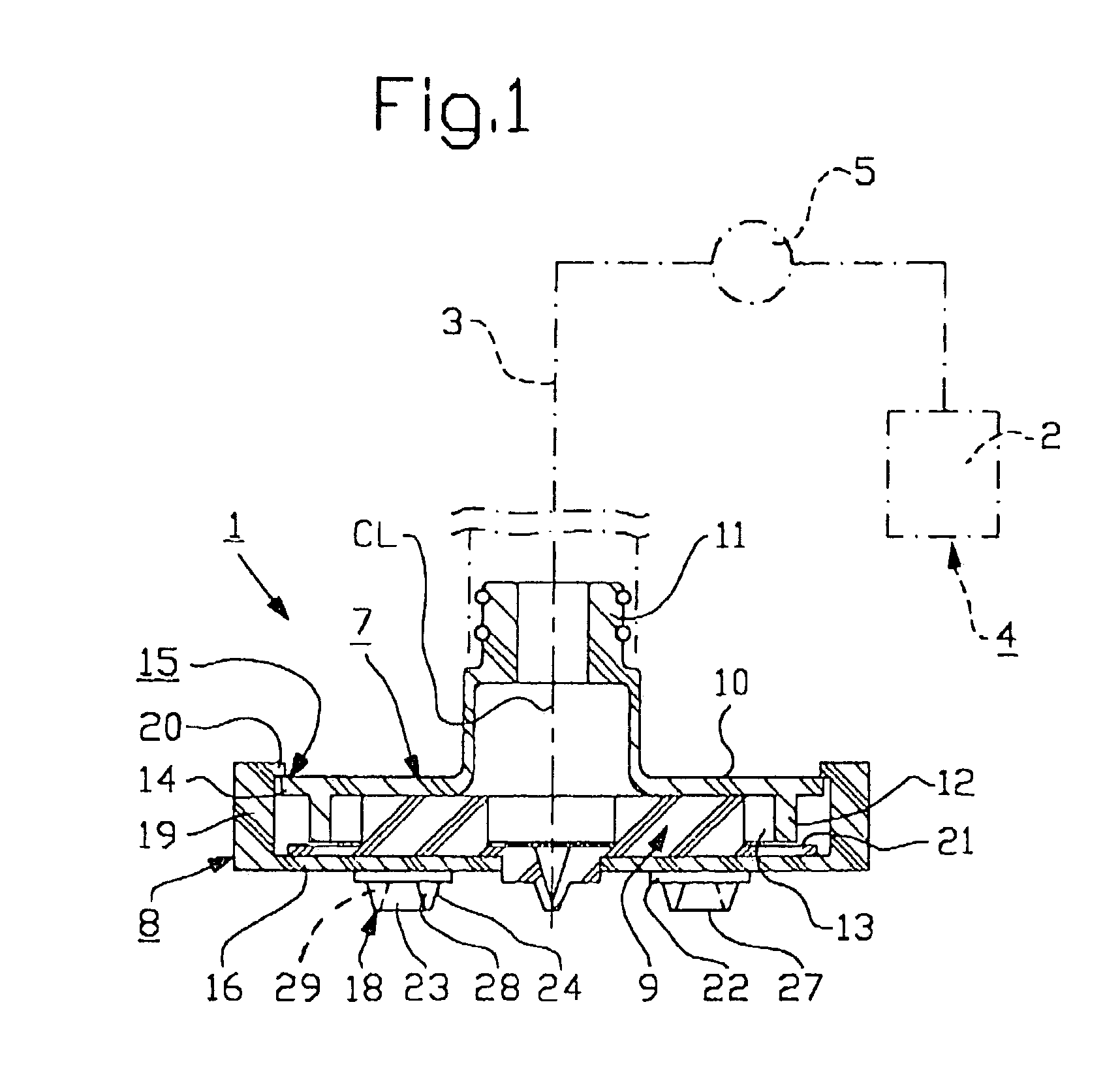

Spray head

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

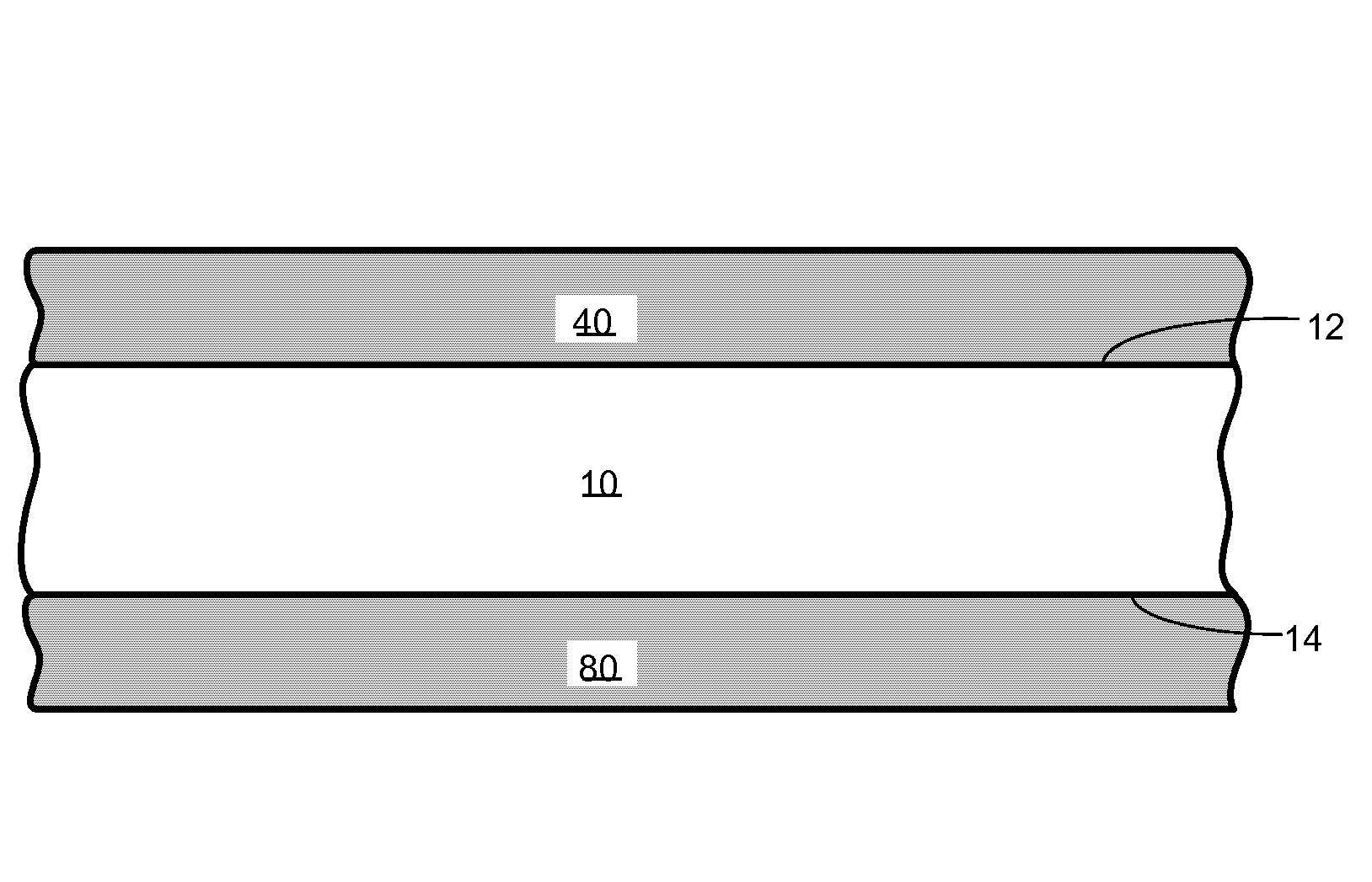

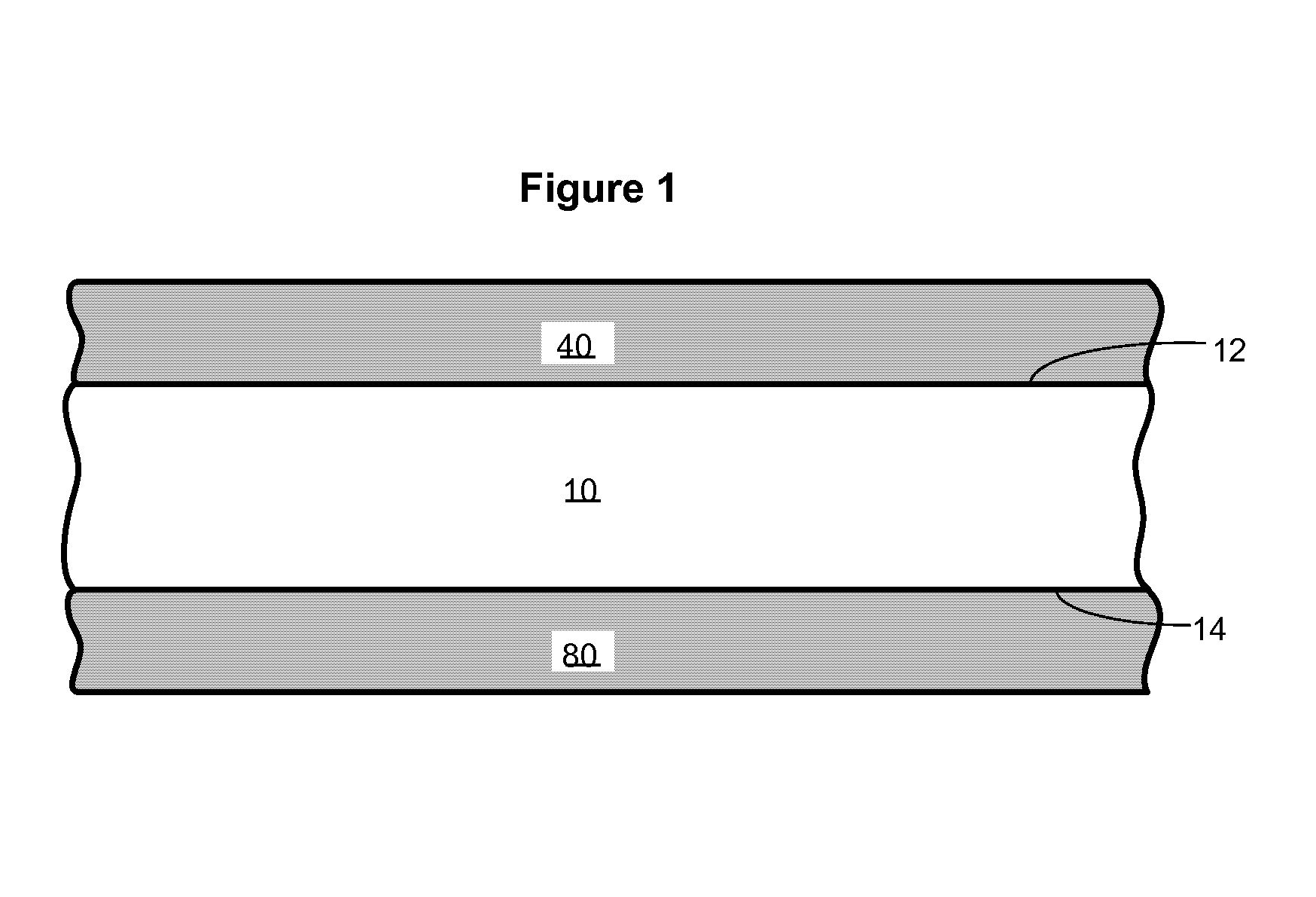

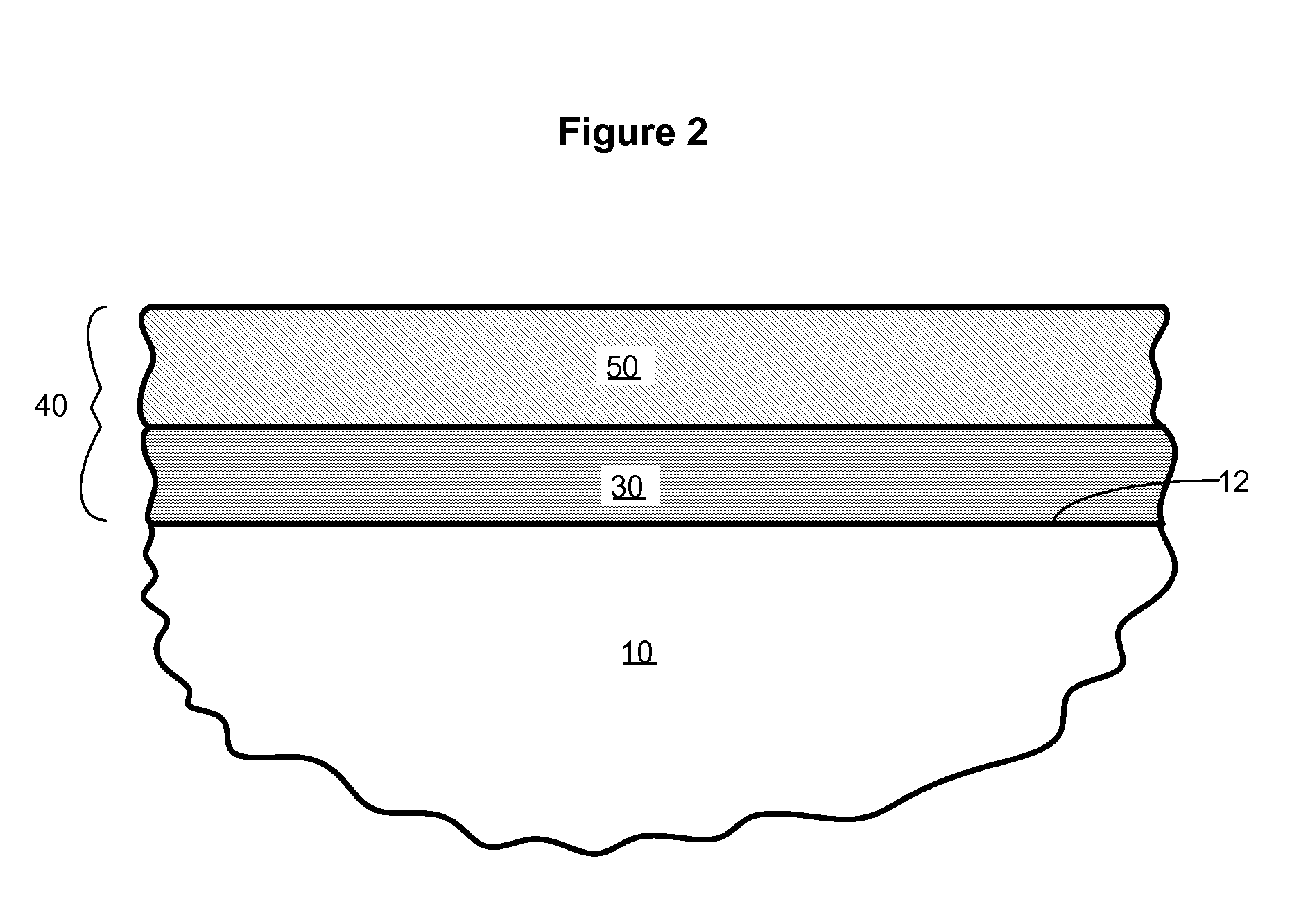

Opposed functional coatings having comparable single surface reflectances

ActiveUS20070248756A1Low-emissivity coatingLiquid surface applicatorsDoors/windowsLow emissivityMetallurgy

Owner:CARDINAL CG

Internal member of a plasma processing vessel

ActiveUS7780786B2Prevent peelingLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

Owner:TOKYO ELECTRON LTD

Surface protection film for polarizer film

InactiveUS20080166549A1Low costGood antifoulingLiquid surface applicatorsSynthetic resin layered productsActive agentWater vapor

The present invention provides a film for the protection of the surface of polarizer film. Said film surface has anti-static coated layer. The coating solution contains polythiophene, surfactant, binding resin and water. According to the present invention, said protection film on the surface on the polarizer film has the excellent anti-static, transmittance, anti-foul and water repellence. It is able to prevent the invasion of imbuing with dust, accumulative anti-static and water vapor from the processing of assembling and transportation so as to influence the quality of polarizer film.

Owner:NANYA PLASTICS CORP

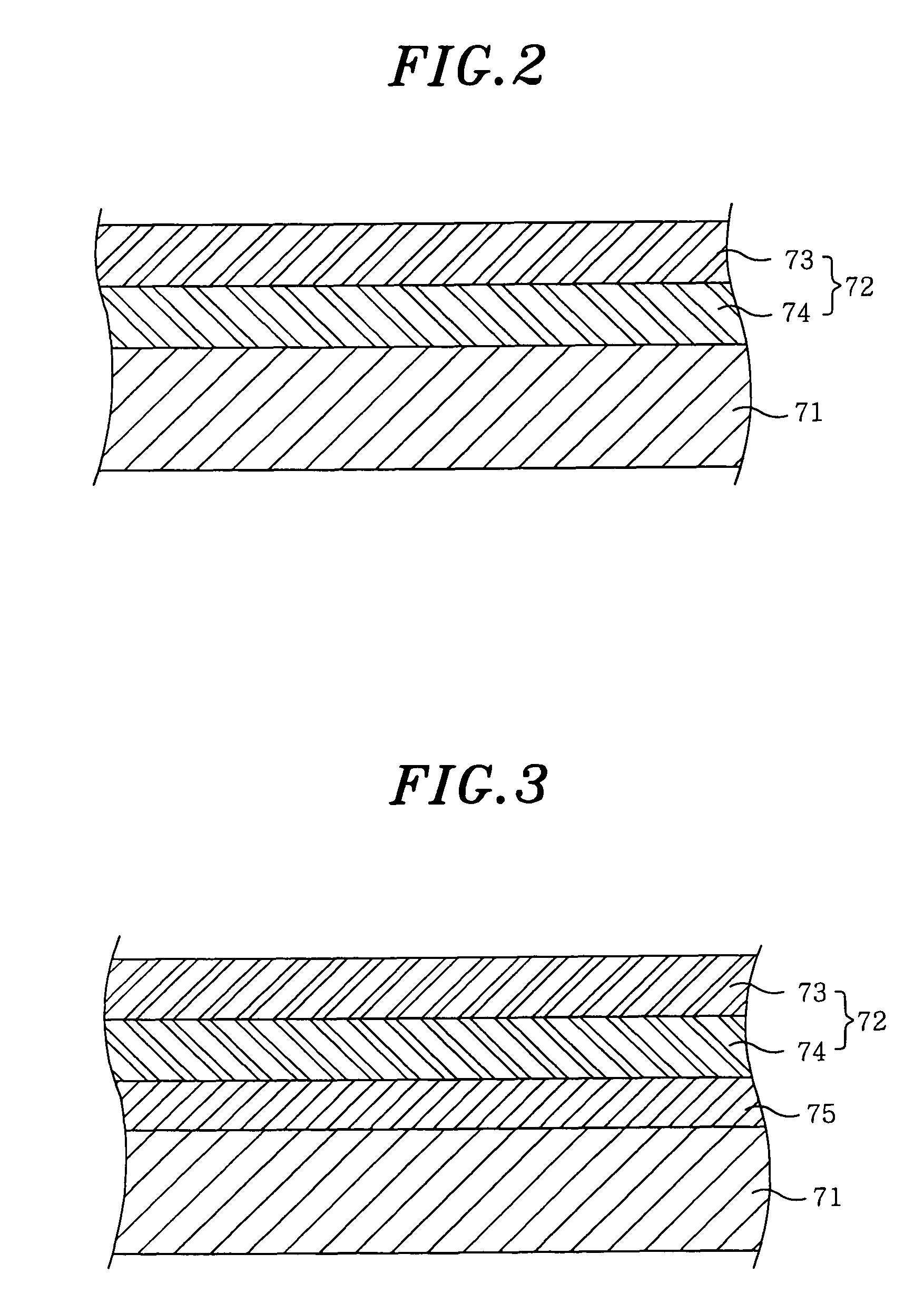

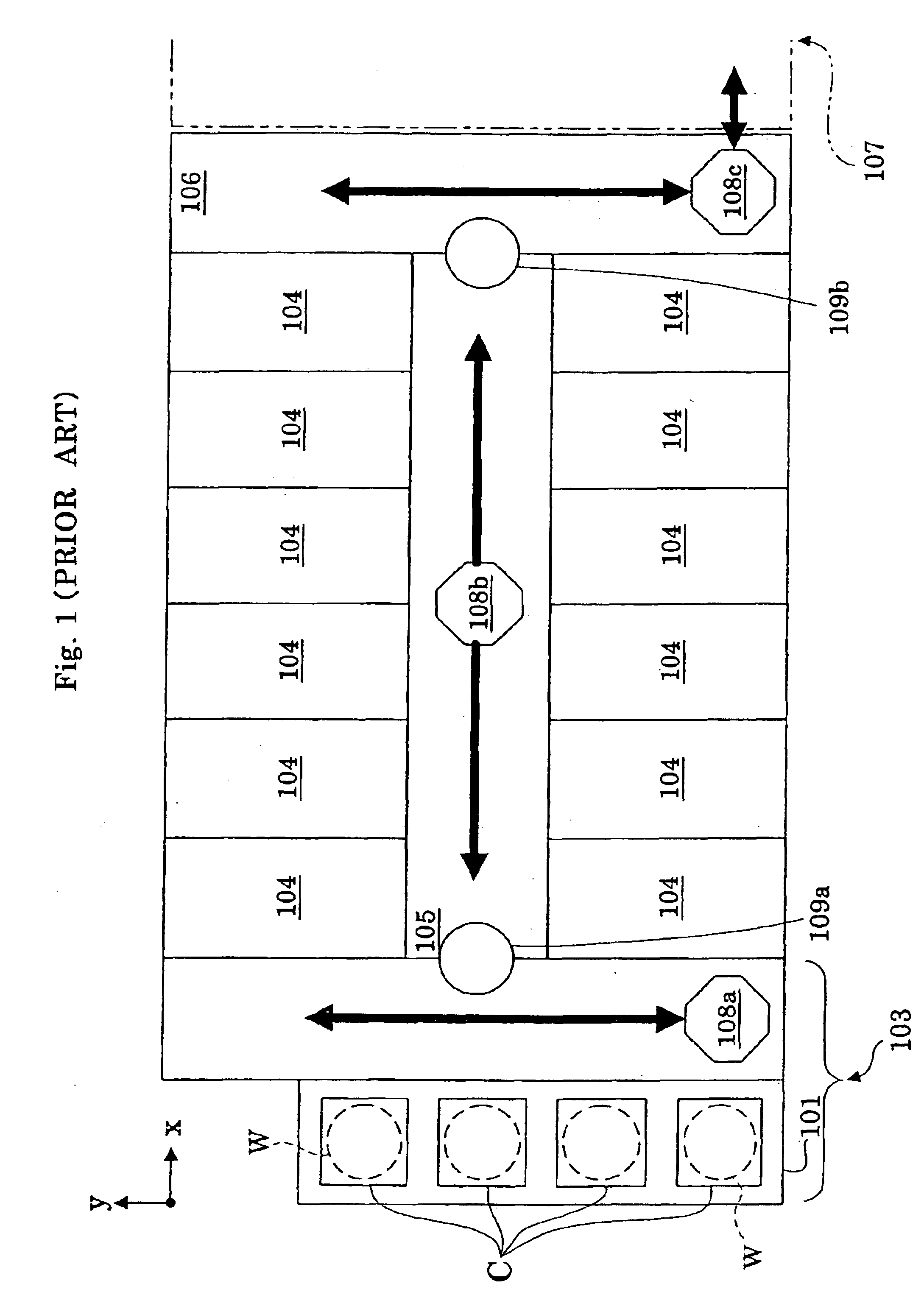

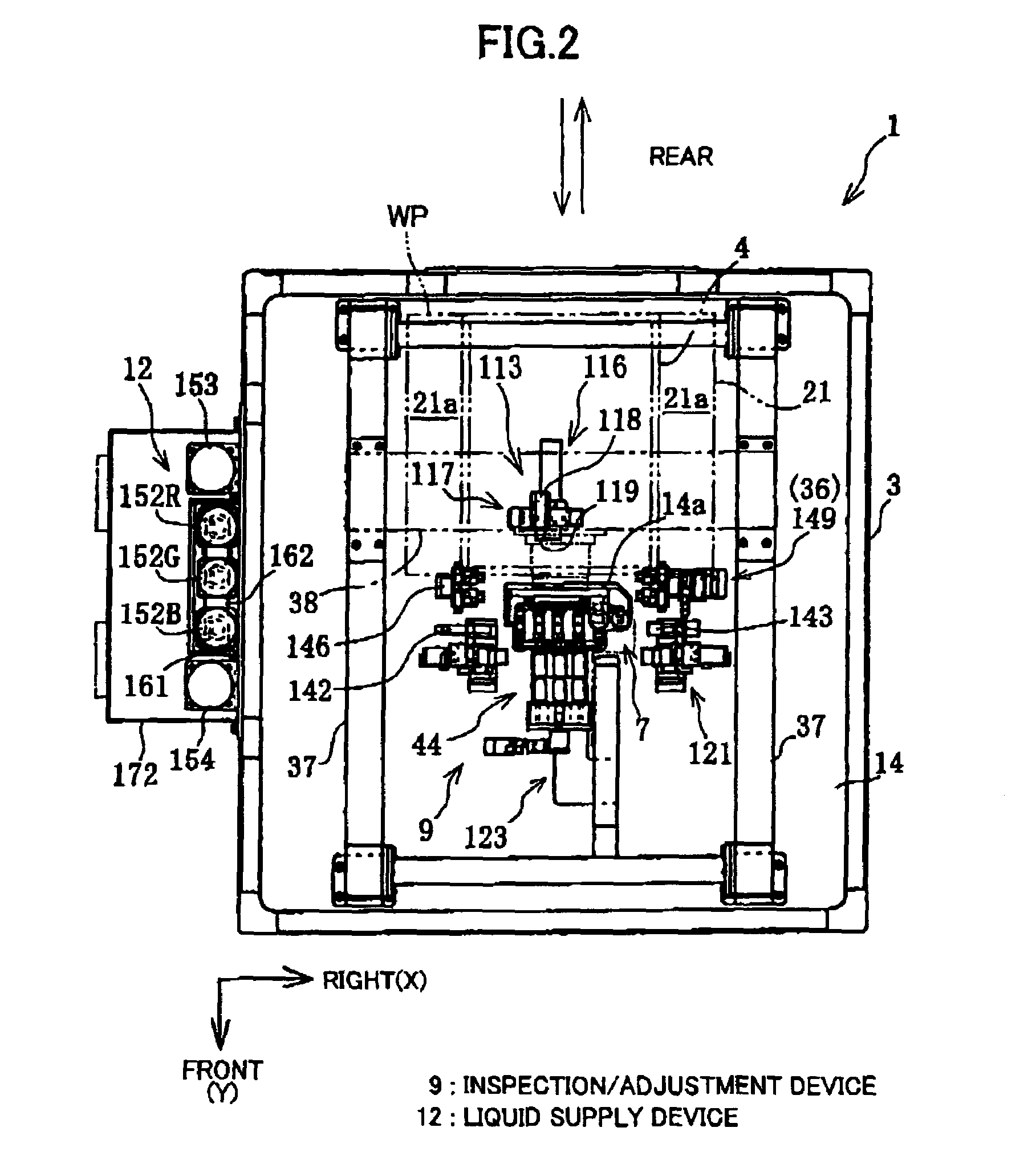

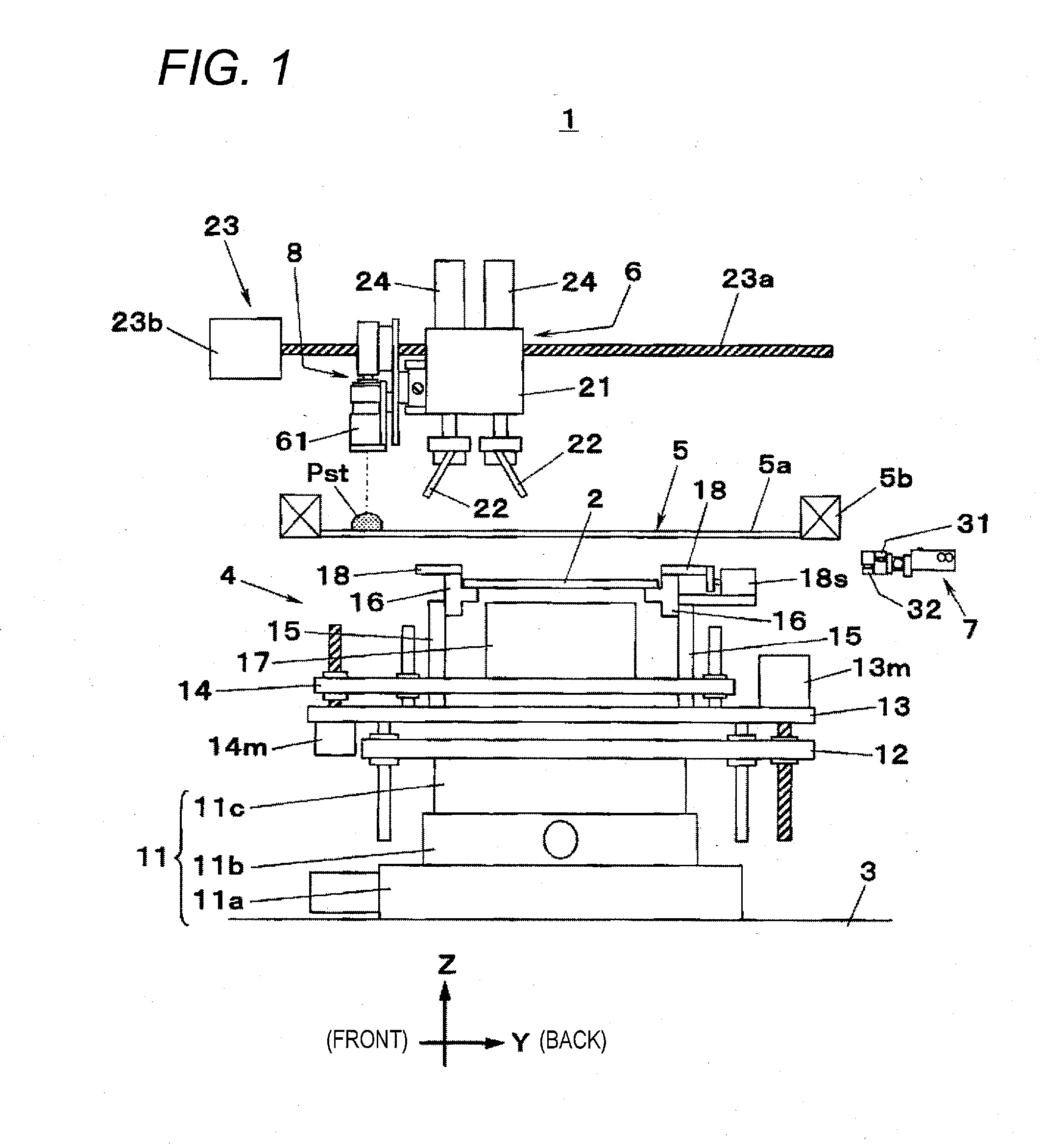

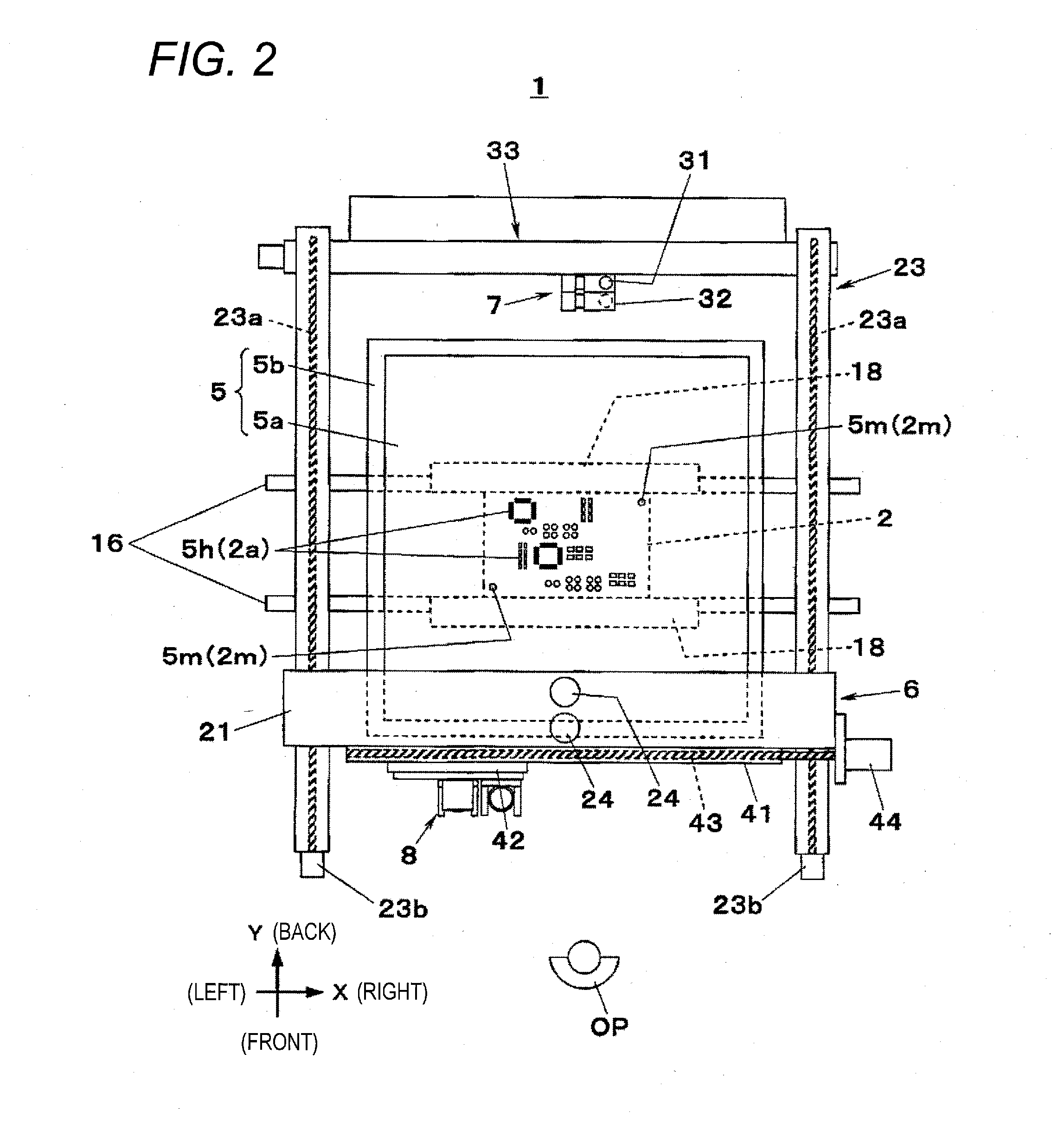

Substrate treating apparatus

ActiveUS6837632B2Efficient substrate transportSmooth trafficLiquid surface applicatorsLiquid processingResistEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Composition of styrene resin, thermoplastic resin and rubber

InactiveUS6013726AImprove heat resistanceHigh mechanical strengthLiquid surface applicatorsFilm/foil adhesivesPolyamidePolystyrene

Owner:IDEMITSU KOSAN CO LTD

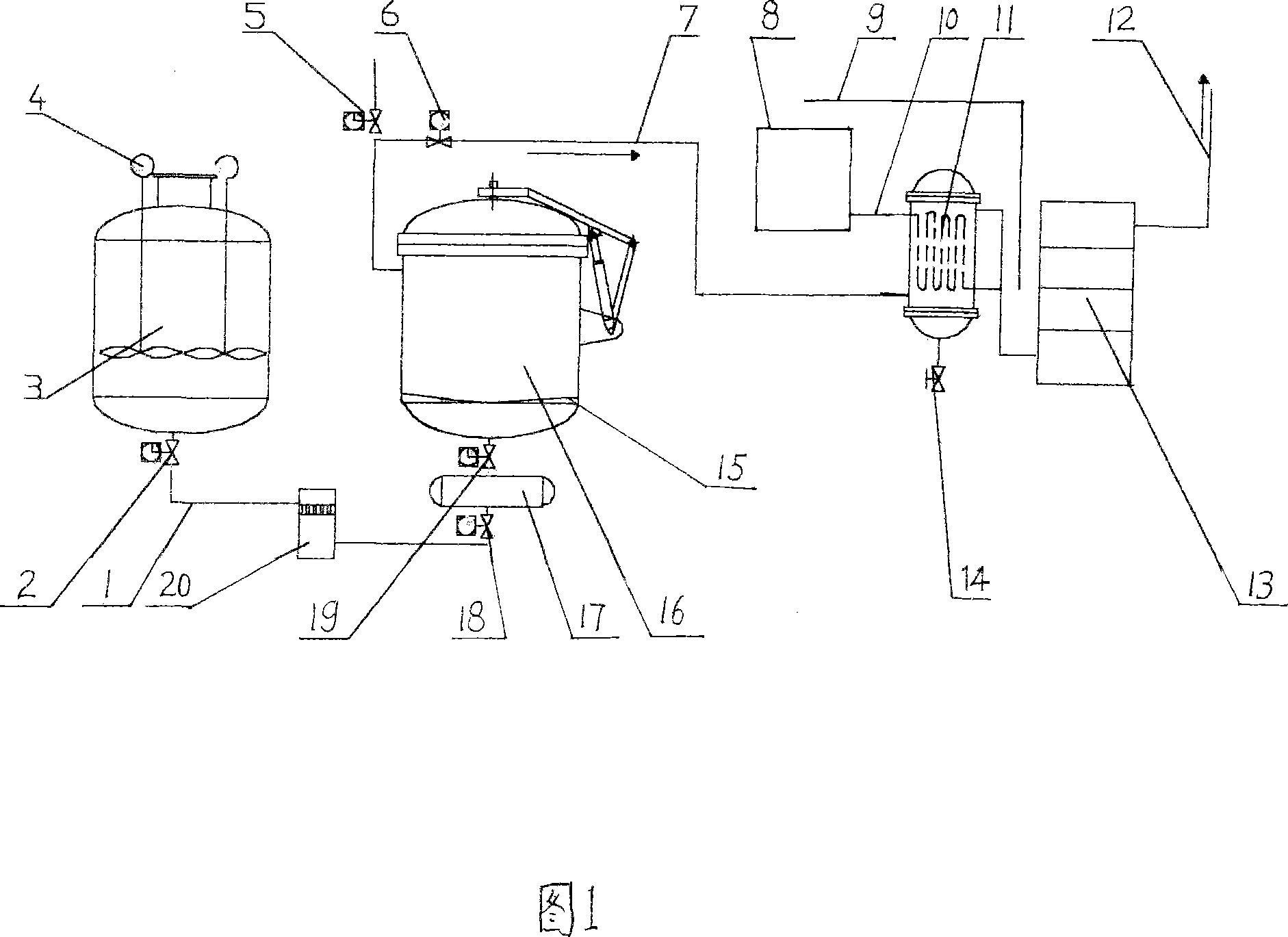

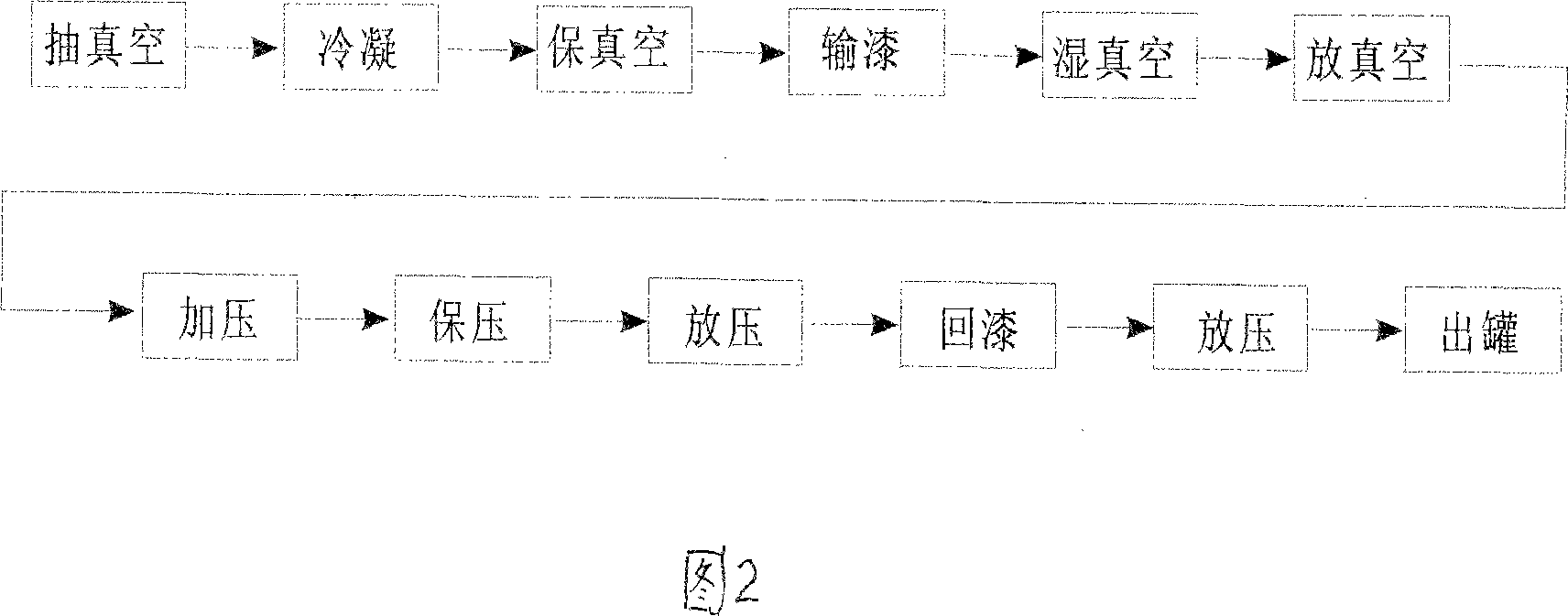

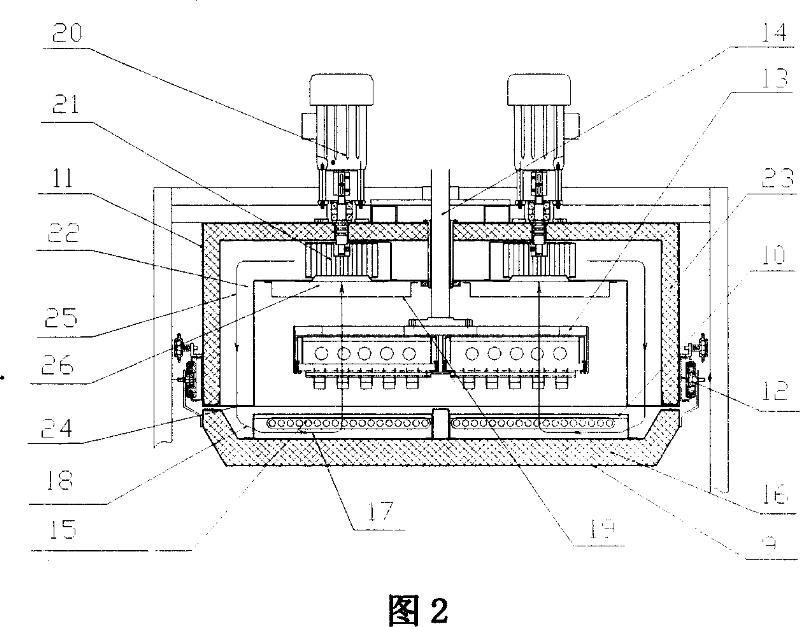

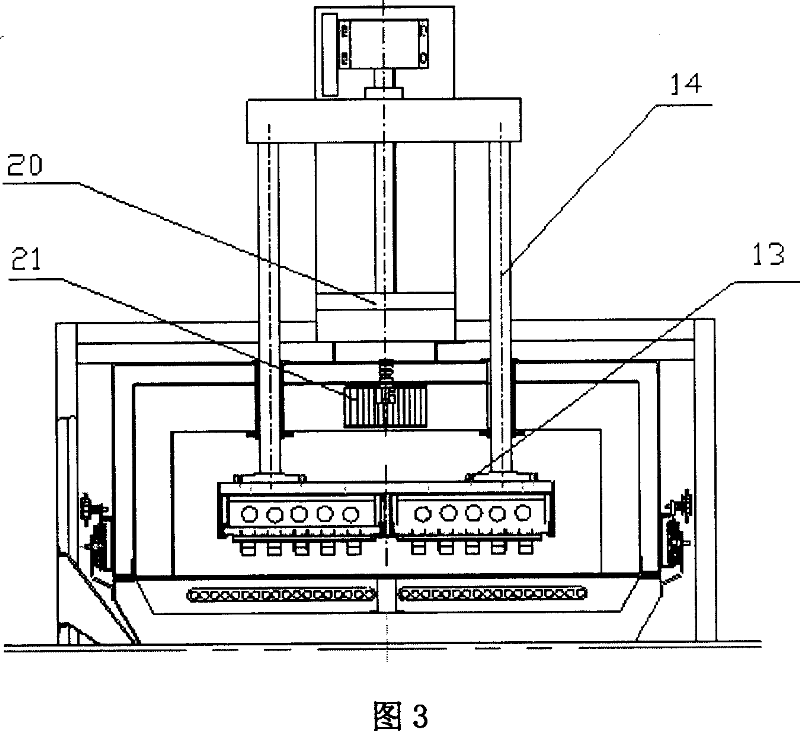

Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

InactiveCN101064456ALiquid surface applicatorsManufacturing dynamo-electric machinesSolventVacuum pressure

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

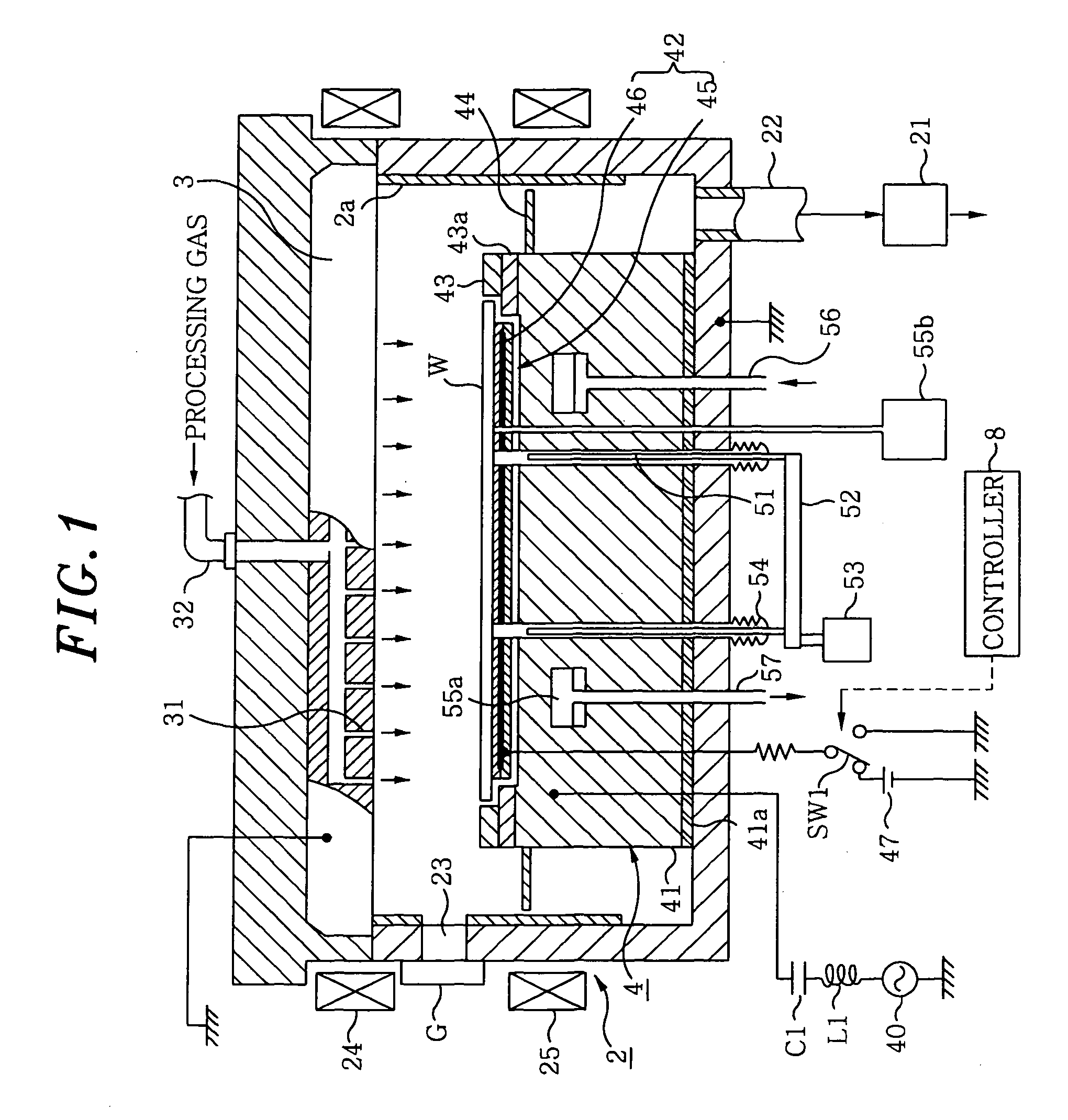

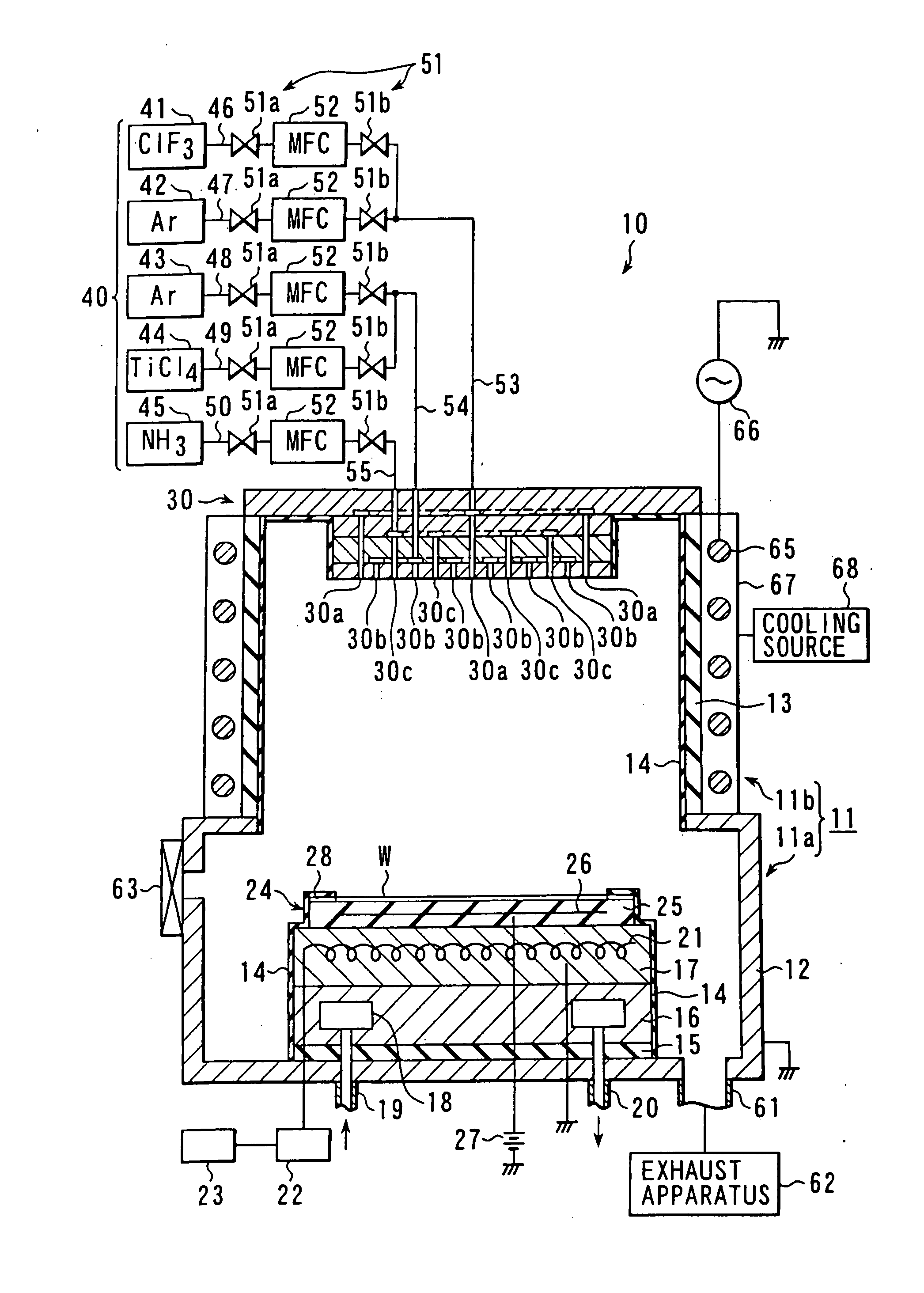

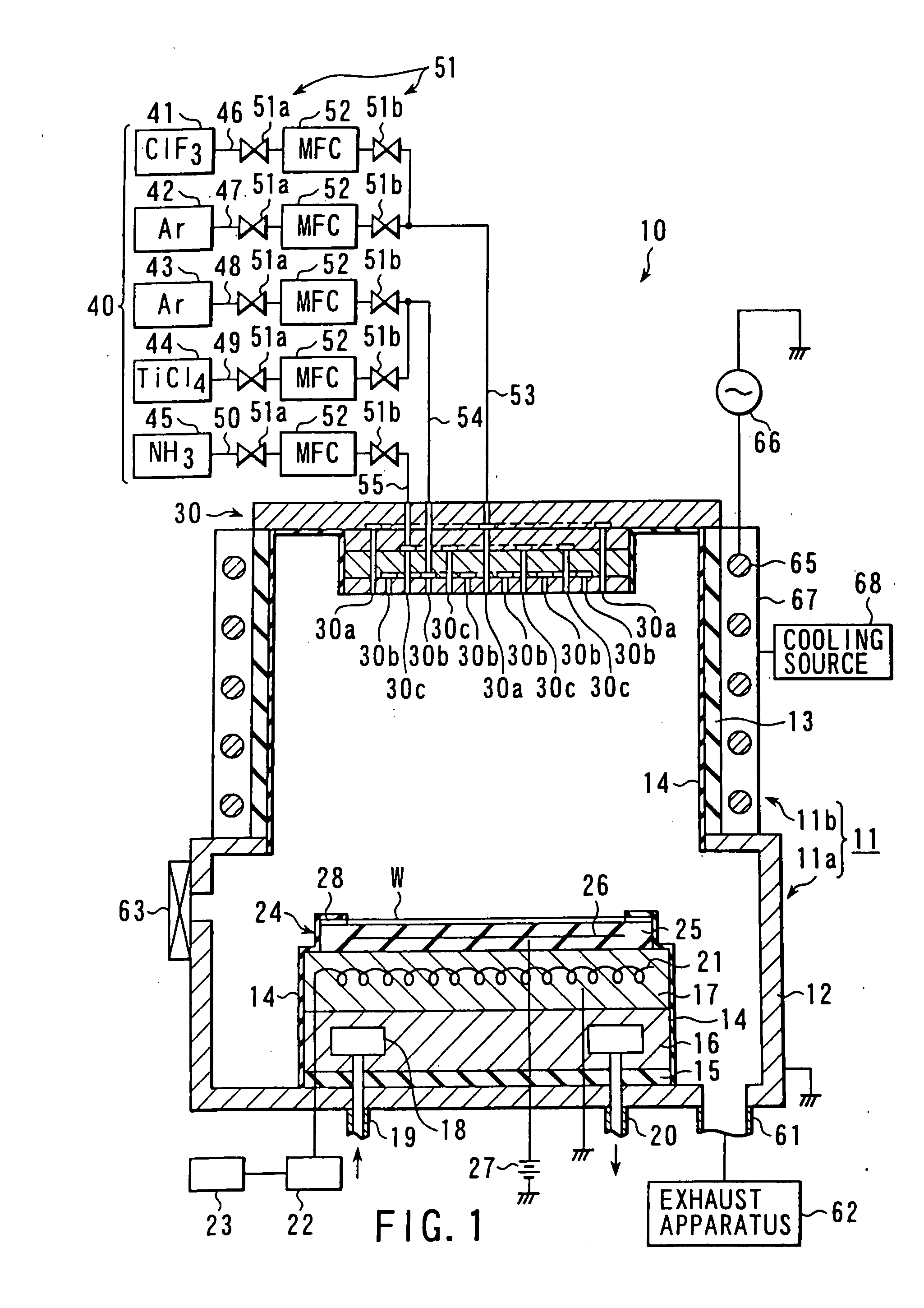

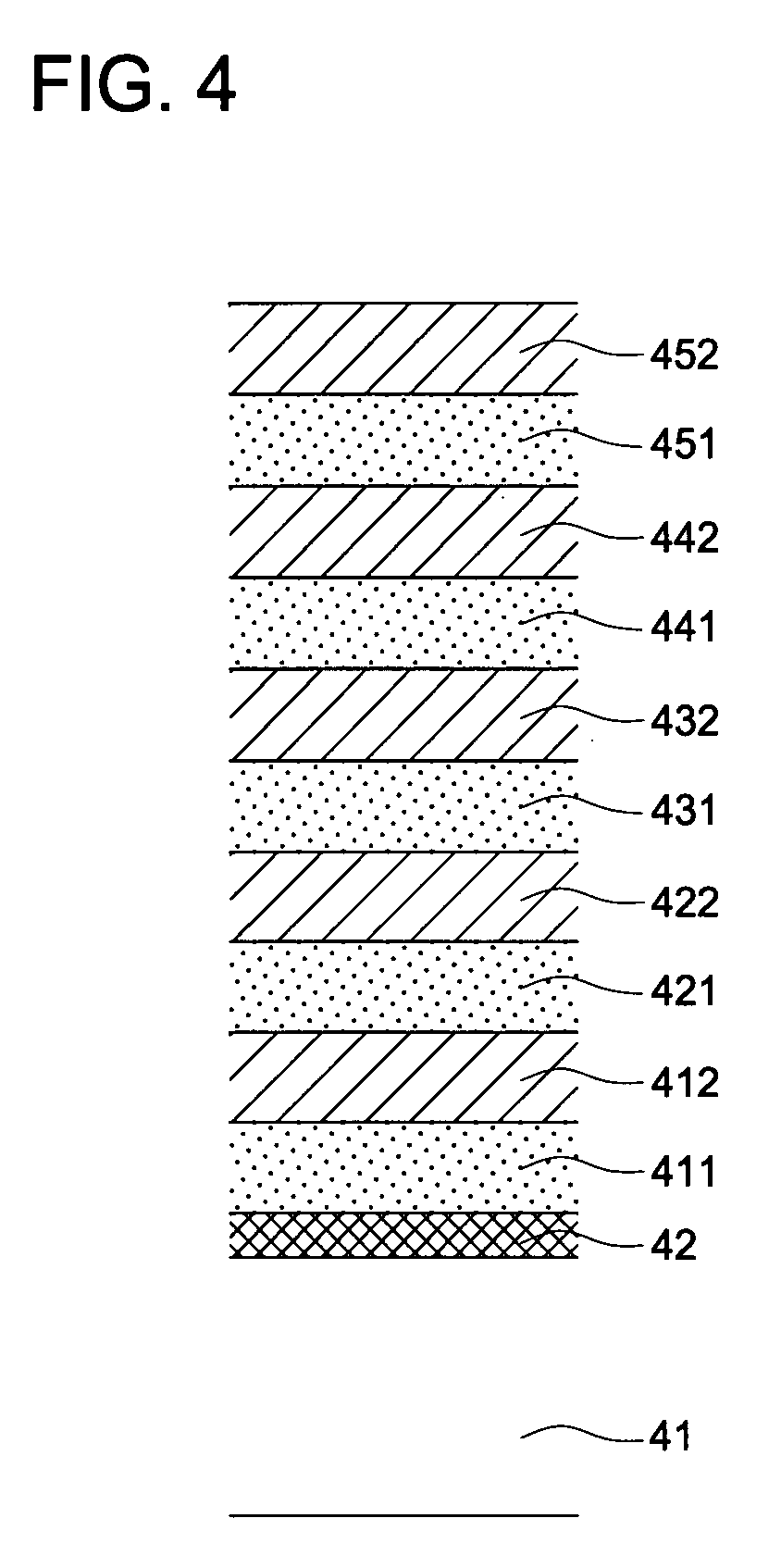

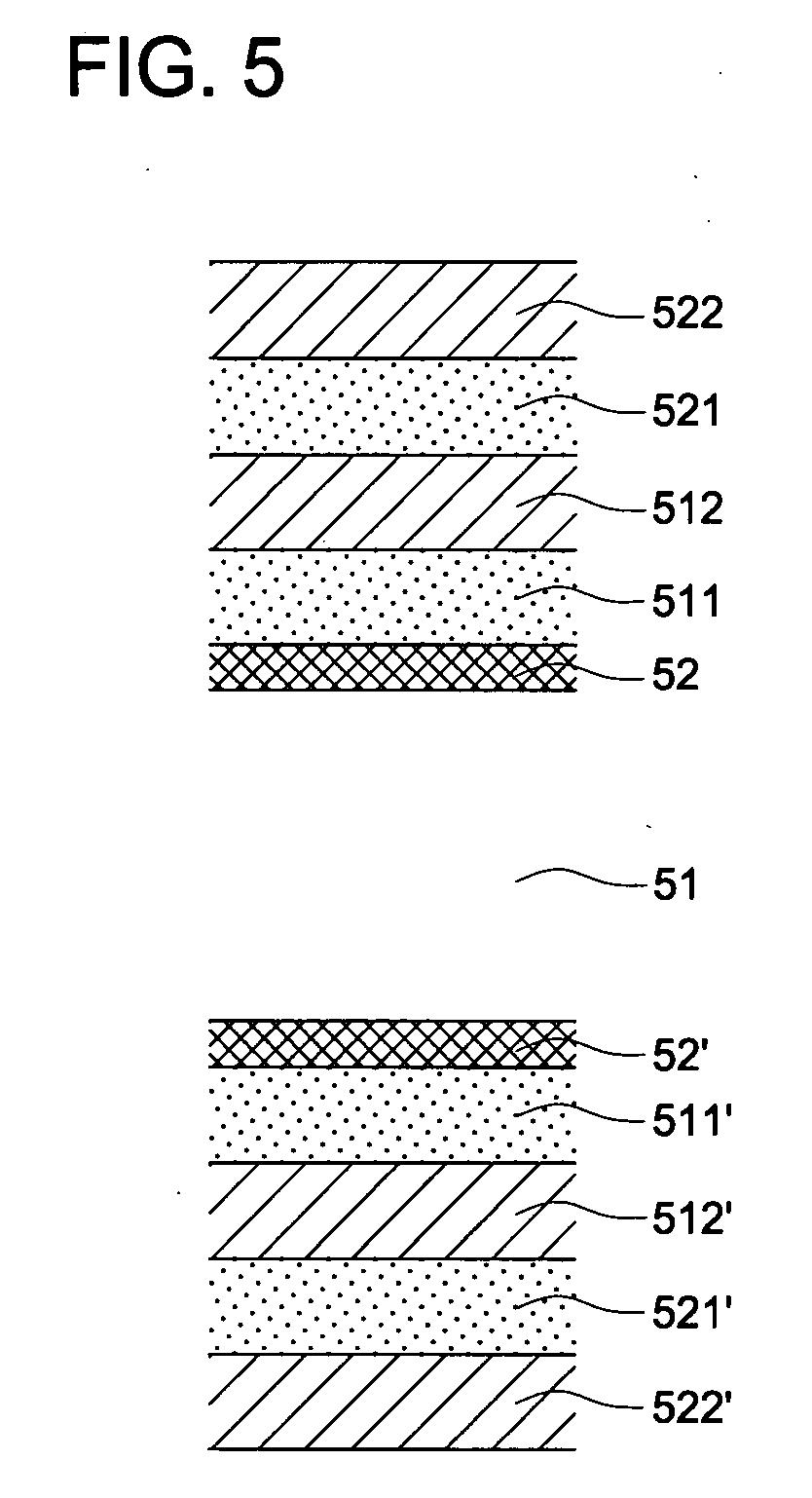

Processing apparatus with a chamber having therein a high-corrosion-resistant sprayed film

InactiveUS20080070032A1High-corrosion-resistant propertyLess depositionLiquid surface applicatorsMolten spray coatingCorrosion resistantEngineering

A processing apparatus of the present invention has a mounted chamber holding a semiconductor wafer and having members for work-processing the substrate under any of heating, plasma and process gas or a combination of them, in which a film of Al2O3 and Y2O3 is formed on an inner wall surface of the chamber and on those exposed surface of the members within the chamber and has a high-corrosion resistance and insulating property and, when the process gas is introduced onto a processing surface of a semiconductor wafer and diffused into it, any product is less liable to be deposited on a plasma generation area and on those members held within the chamber.

Owner:TOKYO ELECTRON LTD

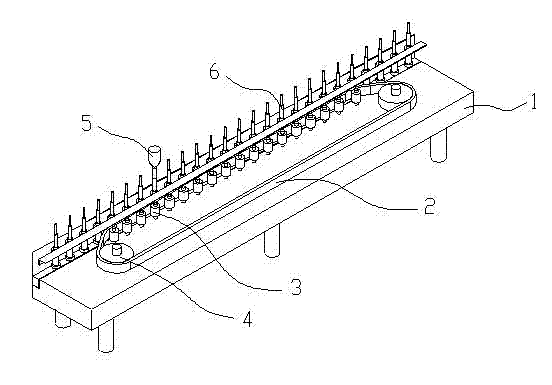

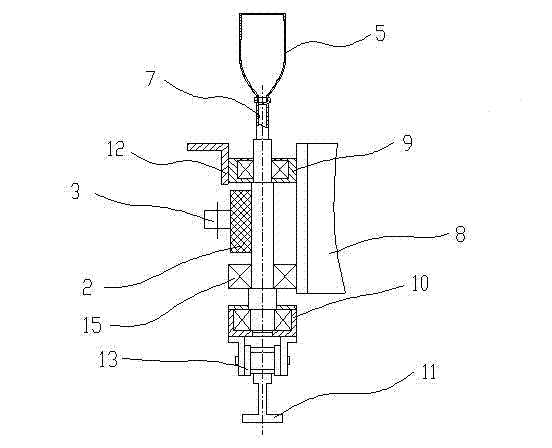

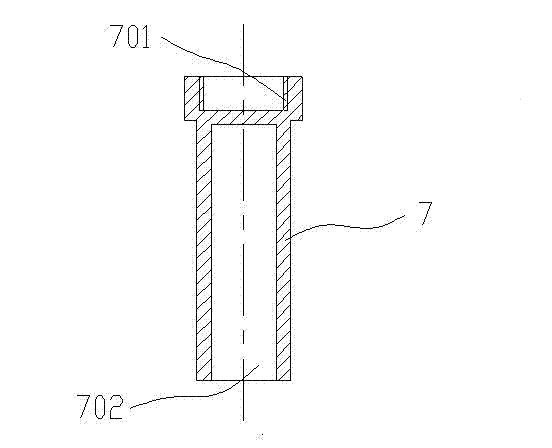

Calibration system, calibration method and fluid spreading device

ActiveCN109013188ACompact structureHigh precisionLiquid surface applicatorsSpraying apparatusBiomedical engineeringLaser

The invention provides a calibration system, a calibration method and a fluid spreading device. The calibration method is used for calibrating the position of a glue dispensing head, the glue clearingposition and the weighing position of the calibration system and used for automatic calibration adopted after a glue dispensing head device of the calibration system is replaced. The calibration method comprises the steps that S1, through cooperation between a calibration camera and the coordinate position of the glue dispensing head, the horizontal position of the glue dispensing head is calibrated; S2, a laser height measuring sensor and a tool setting gauge cooperate to calibrate the vertical position of the glue spreading head; S3, through cooperation between the glue dispensing head or the calibration camera and a glue clearing device, the glue clearing position is calibrated; S4, the glue head or the calibration camera cooperates with the weighting device so as to calibrate the weighing position; S5, after the step S1, the step S2, the step S3 and the step S4 are completed, automatic calibration is achieved after replacement of the glue dispensing head device. According to the calibration method of the calibration system, the precision of the set glue dispensing height can be effectively improved, and good glue dispensing is achieved.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

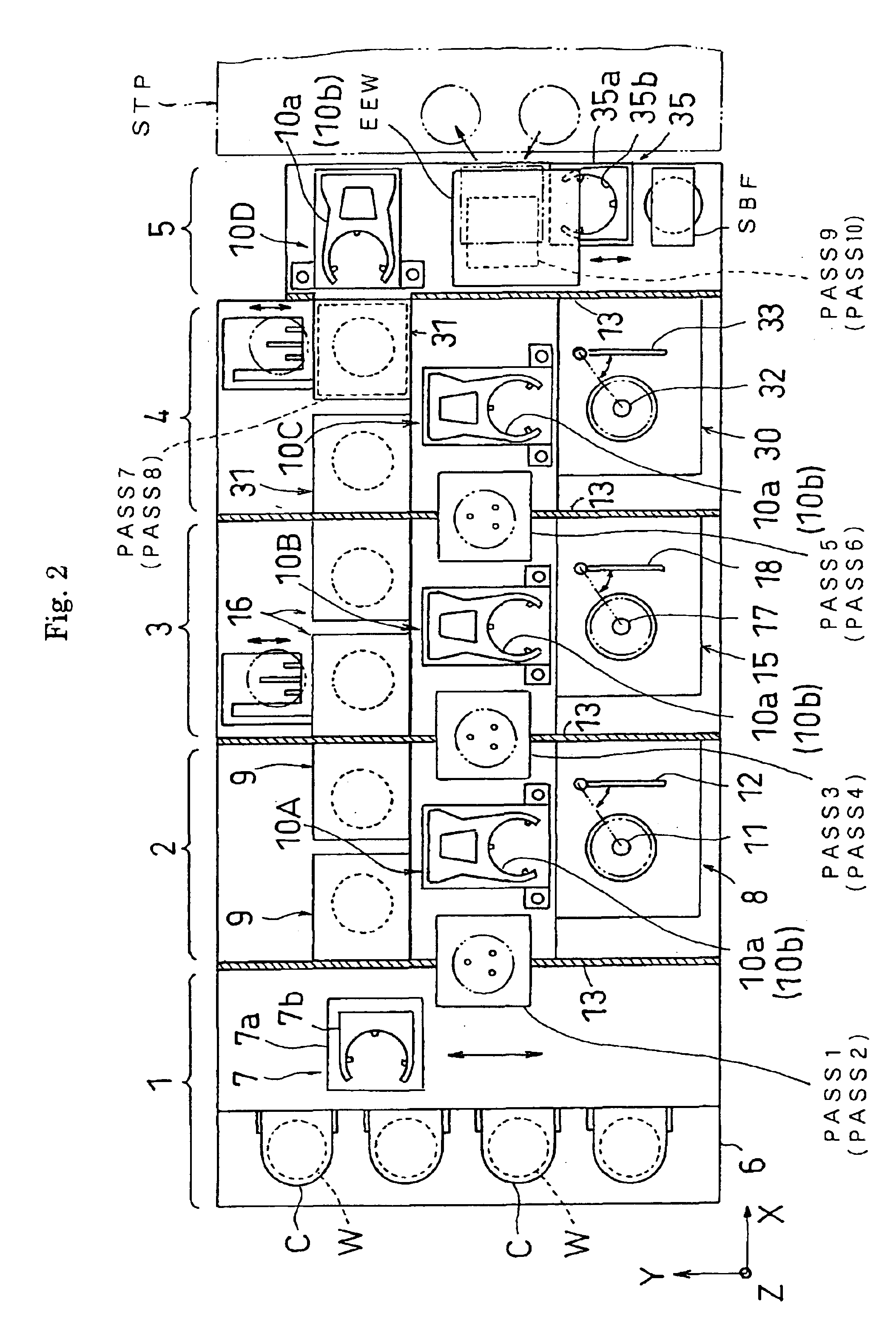

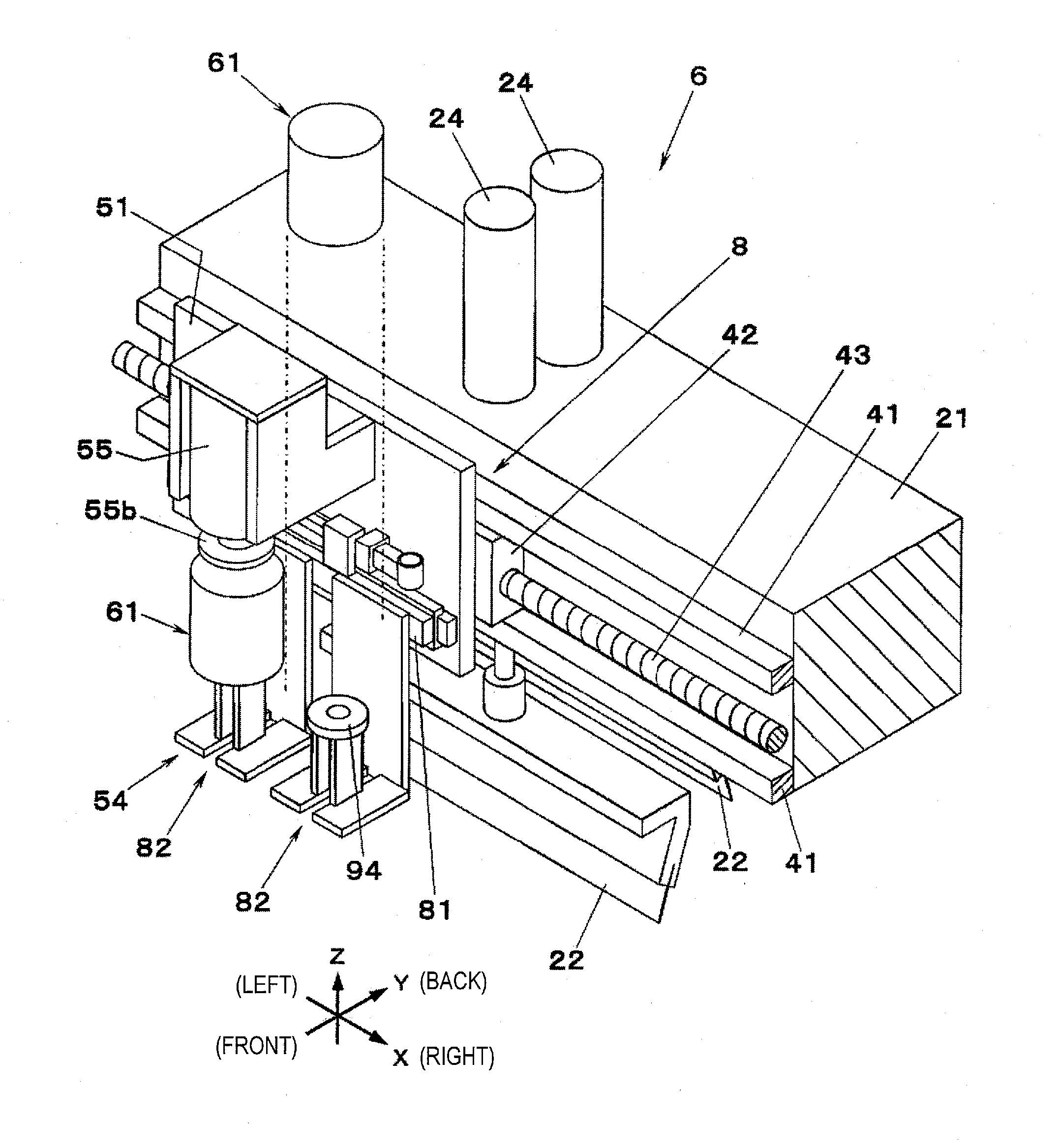

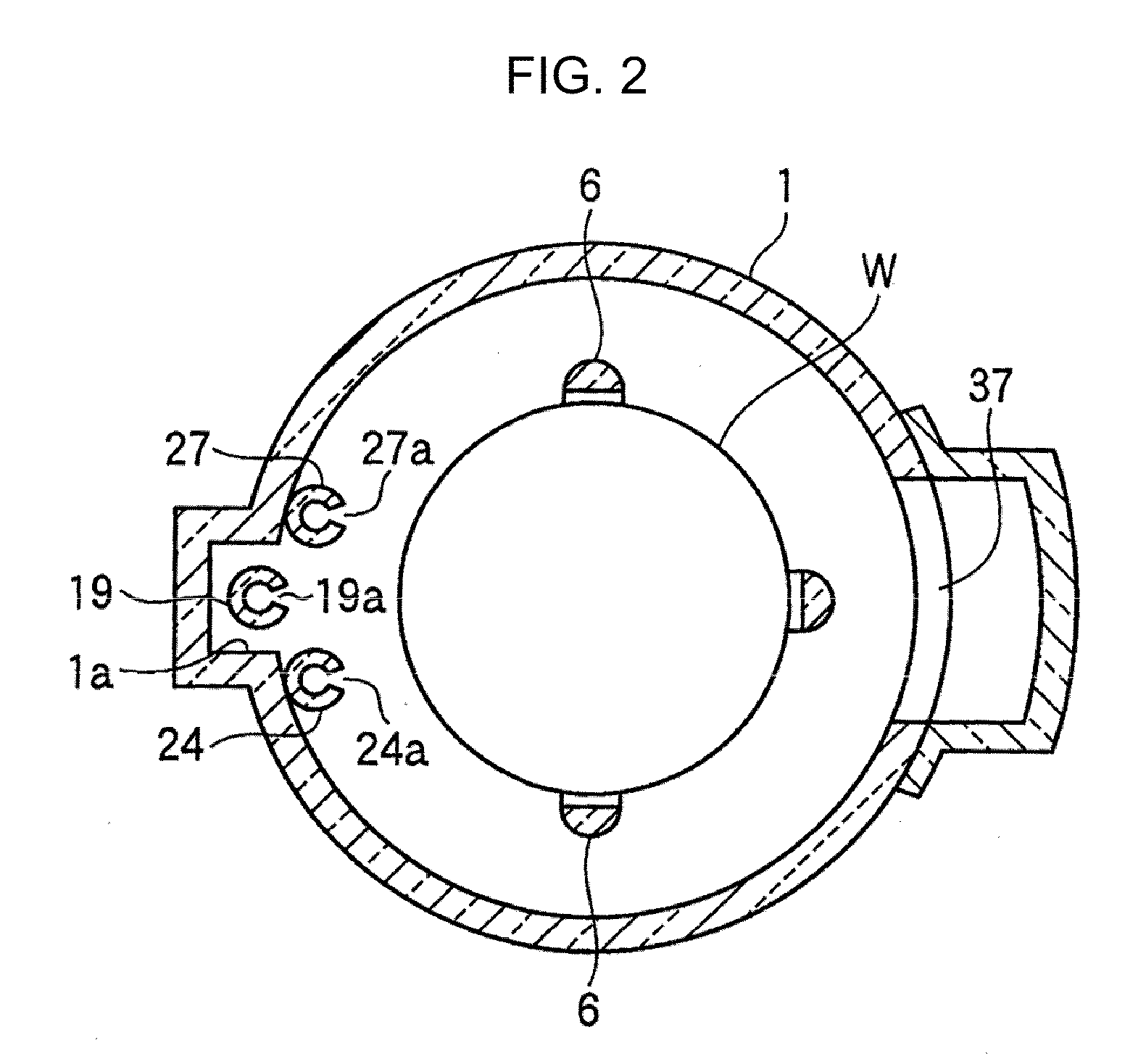

Substrate processing apparatus

PendingUS20090114150A1Easy to operateLiquid surface applicatorsSemiconductor/solid-state device manufacturingWhole bodyEngineering

To simultaneously display a transfer state of substrates (wafers) held on a substrate holding tool and detail-information thereof on the same screen. In a substrate processing apparatus that loads a substrate holding tool, on which a plurality of substrates are placed, into a furnace, and applies prescribed processing thereto, a whole body of boats, as a boat image view of transfer information regarding the substrates on the substrate holding tool, is displayed in an operation screen, and detail-information of a substrate of each area is displayed in the operation screen, with the whole body of the boats divided into a plurality of areas.

Owner:KOKUSAI DENKI KK

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Aqueous Primer Composition

Owner:KANSAI PAINT CO LTD

Self-rotating type bottle body spraying device

ActiveCN102698910AGuaranteed uptimeEasy loading and unloadingLiquid surface applicatorsSpraying apparatusContinuous/uninterruptedBottle

Owner:浙江美易包装科技有限公司

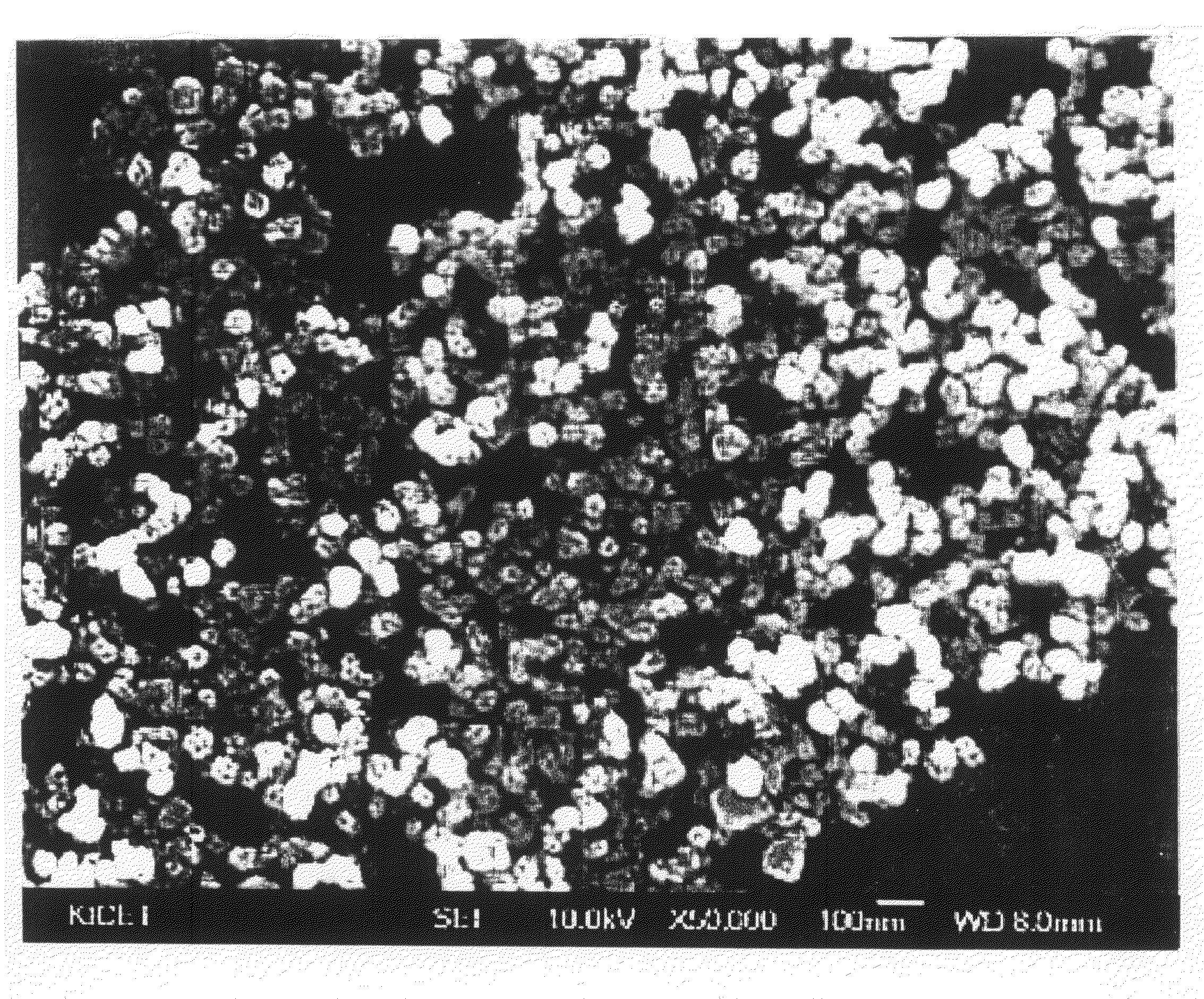

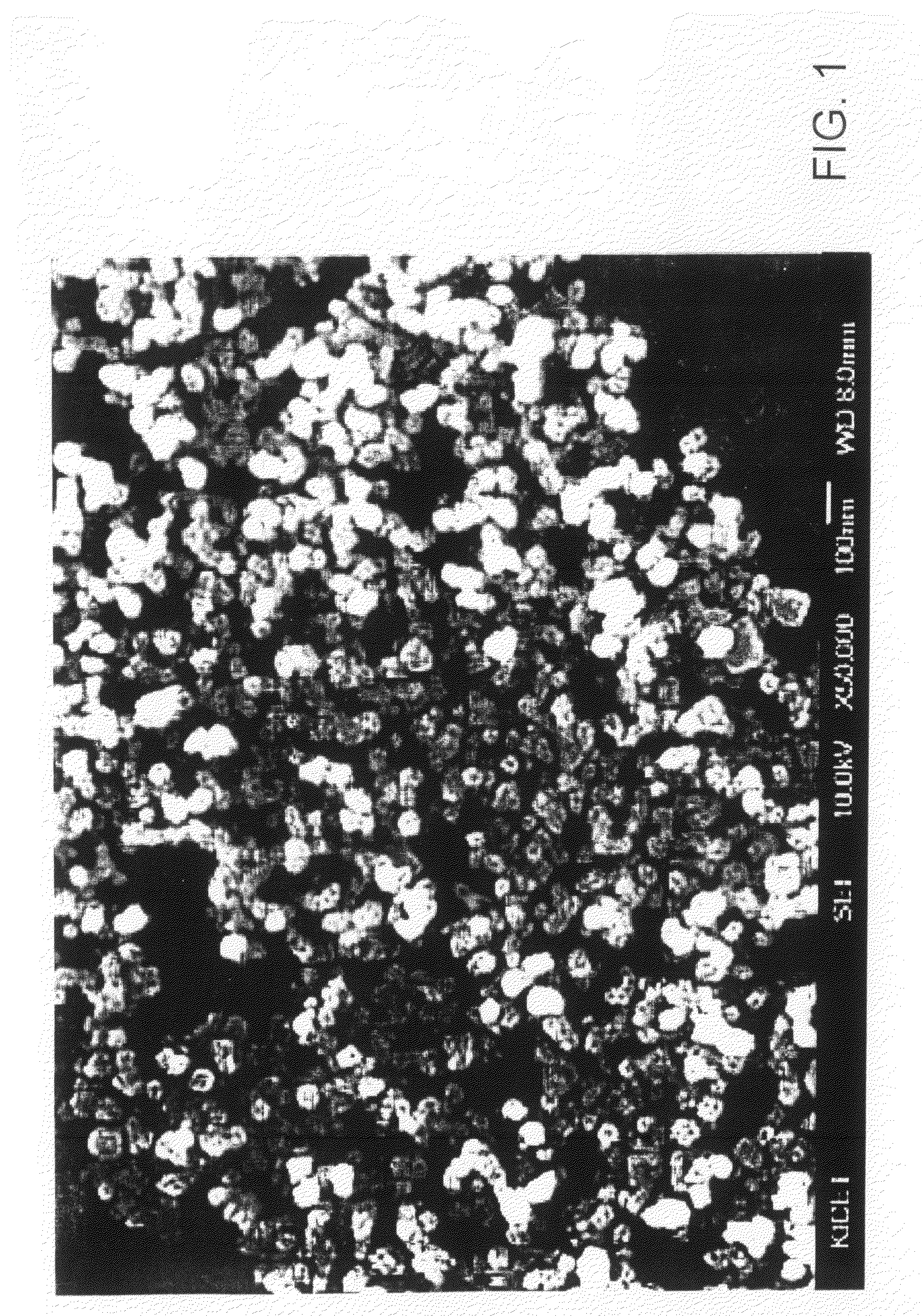

Manufacturing Method of Antimicrobial Fiber Using Nano Silver Powder

InactiveUS20090214771A1Good antimicrobialHigh bactericidal activityLiquid surface applicatorsCoatingsSolventSpray nozzle

Owner:SHIN HYUNKYUNG +1

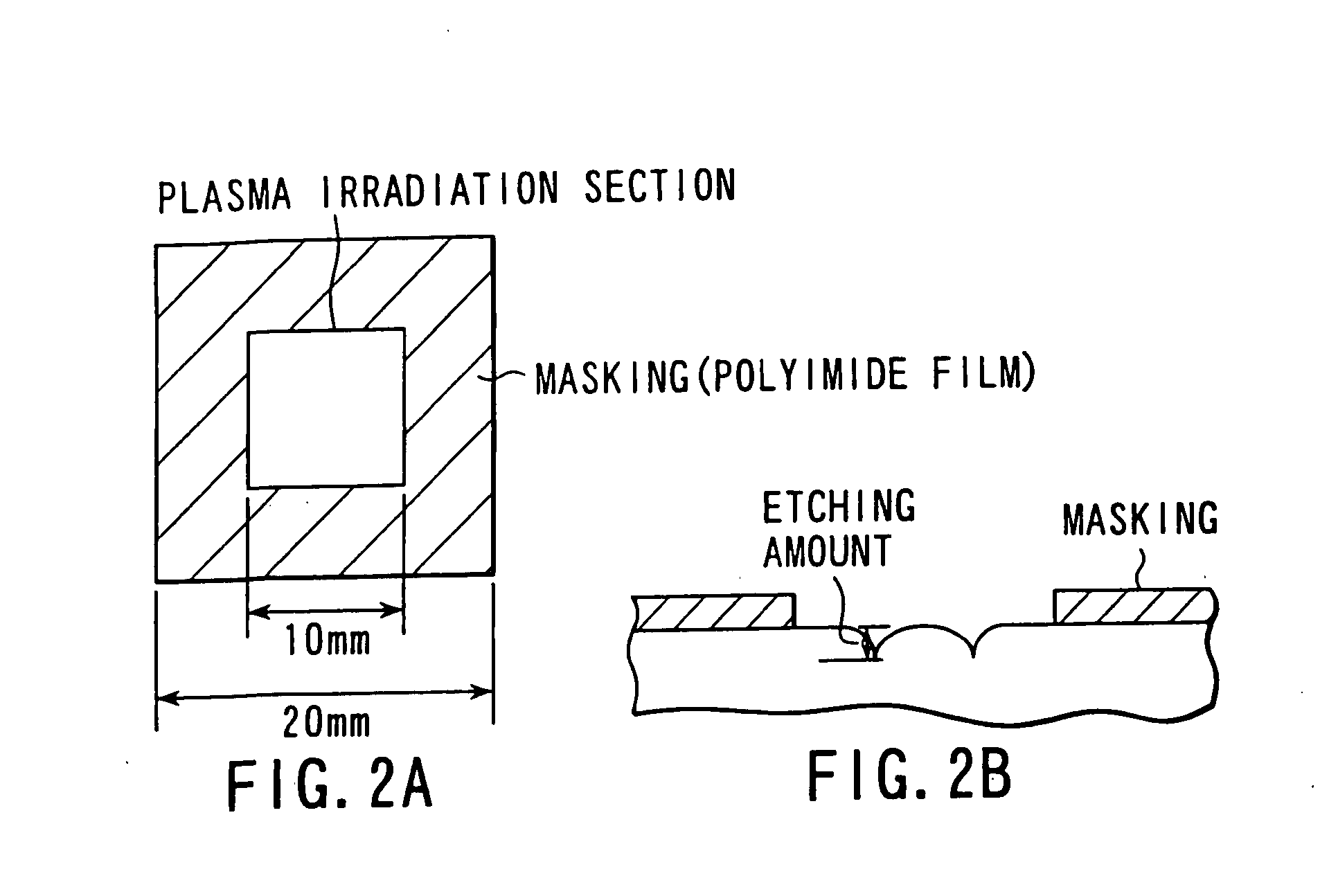

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

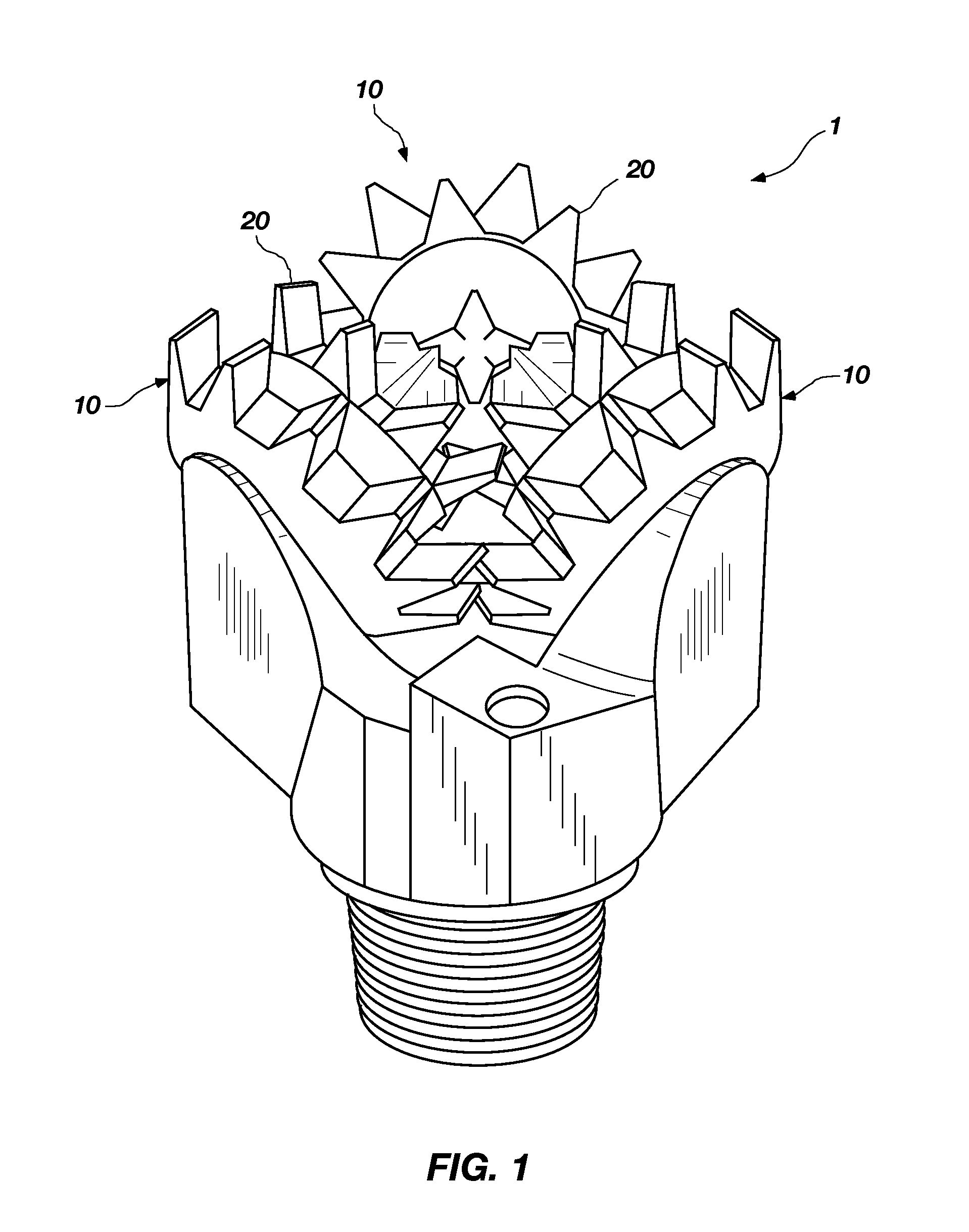

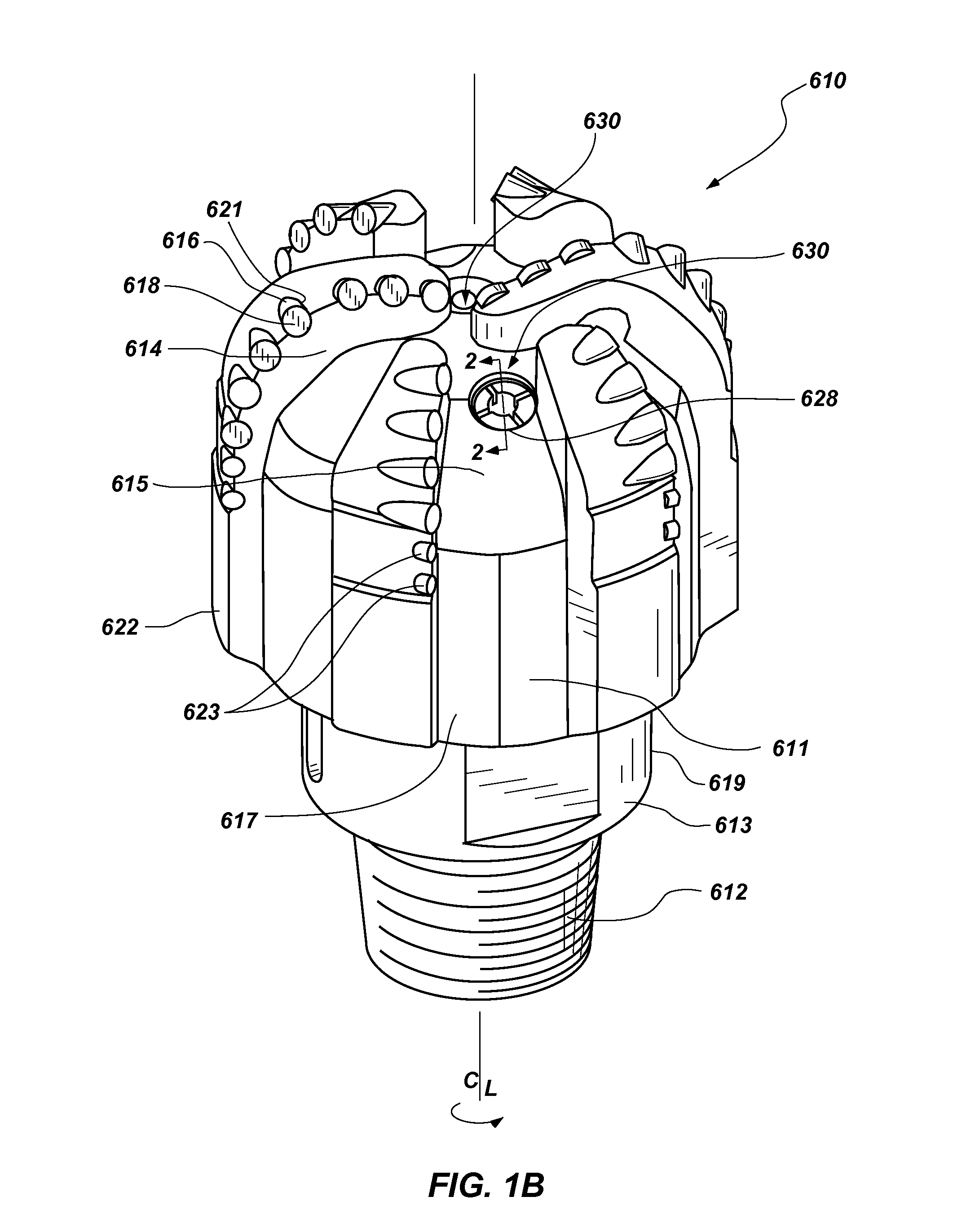

Methods for automated application of hardfacing material to drill bits

Owner:BAKER HUGHES INC

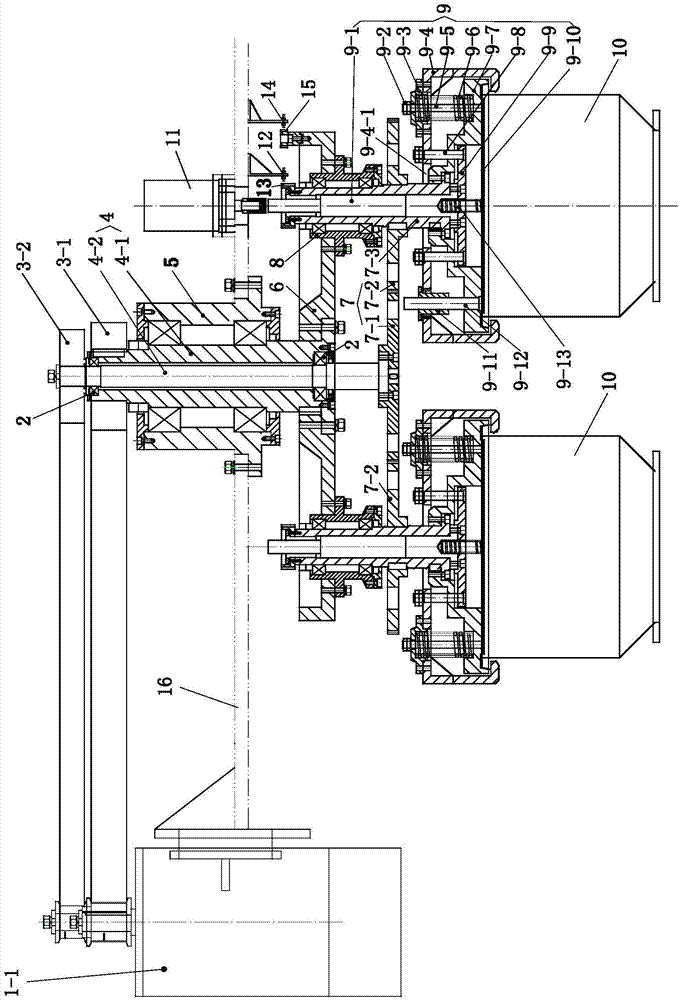

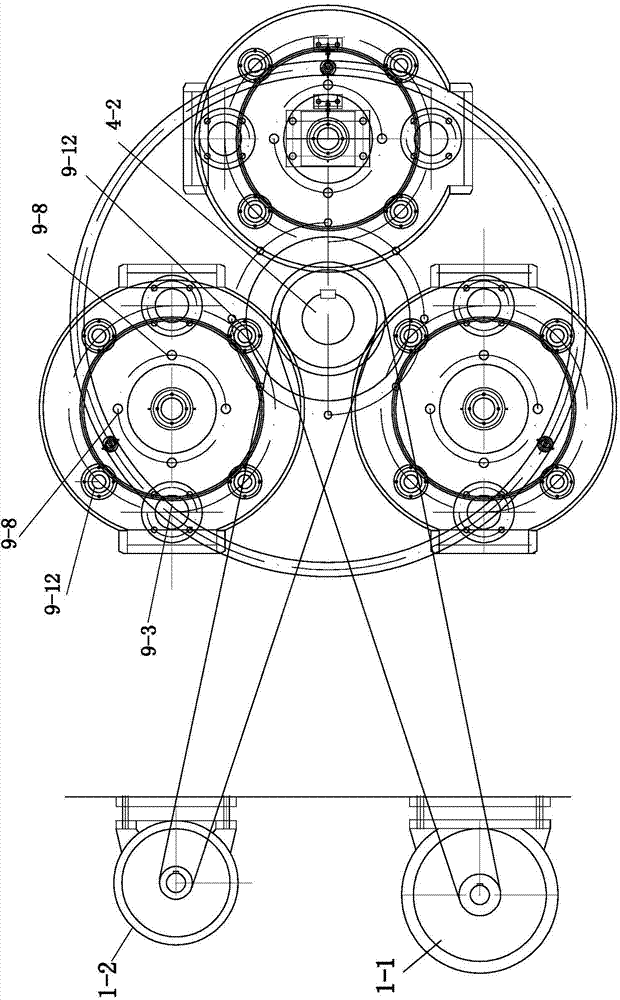

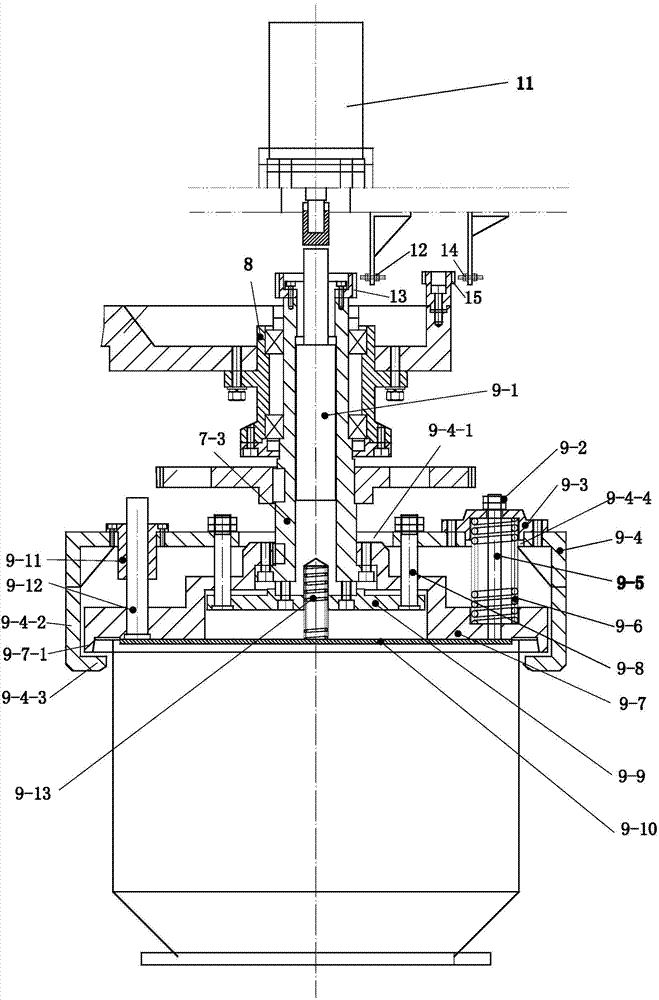

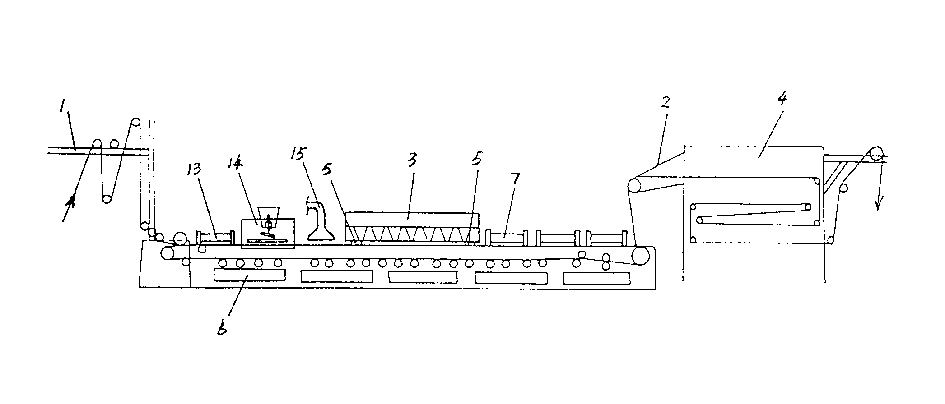

Planetary transmission device of coating machine

ActiveCN103934167AImprove coating qualitySave time at workLiquid surface applicatorsToothed gearingsEngineeringMechanical engineering

Owner:CHANGZHOU JUNHE TECH

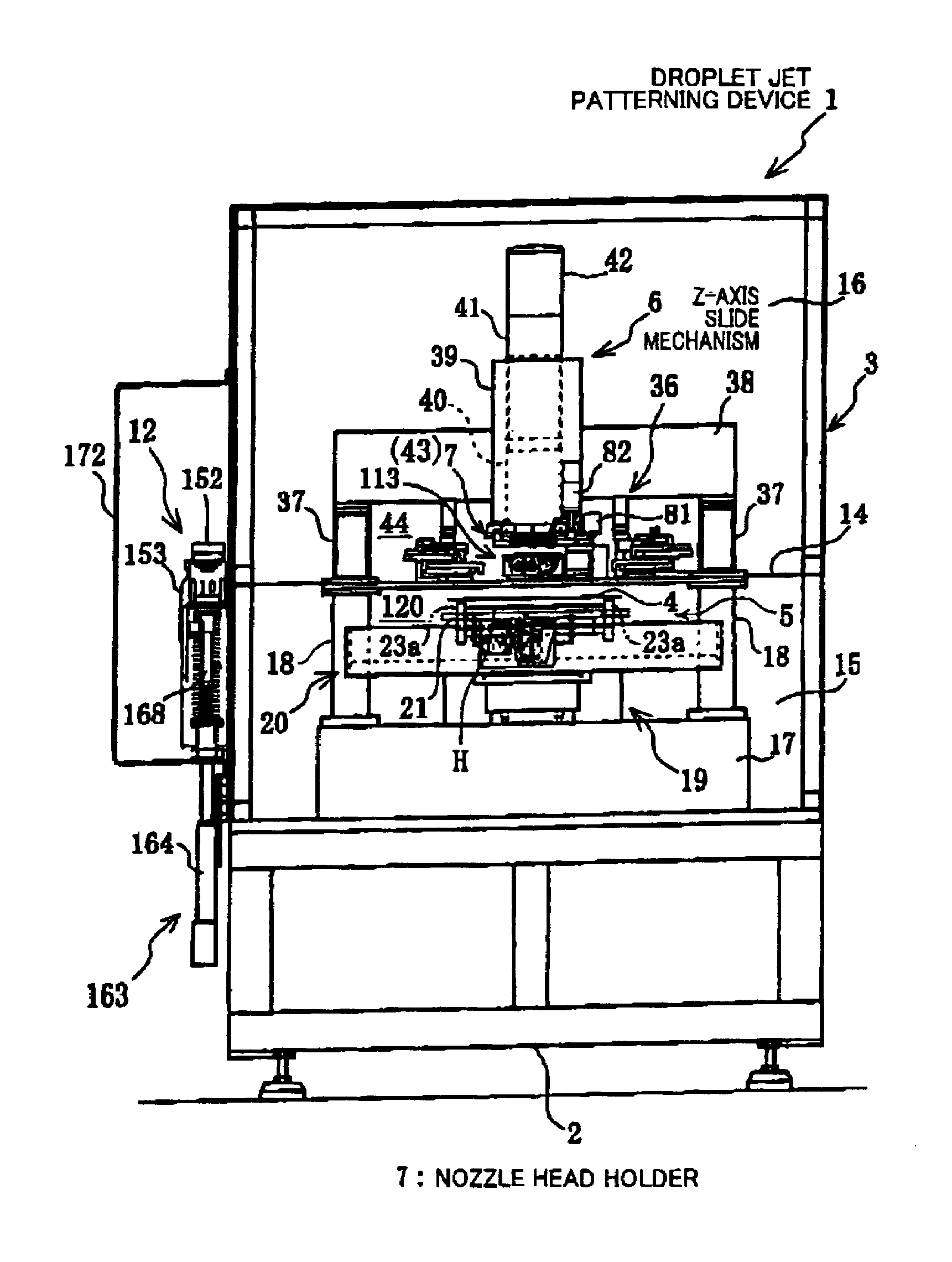

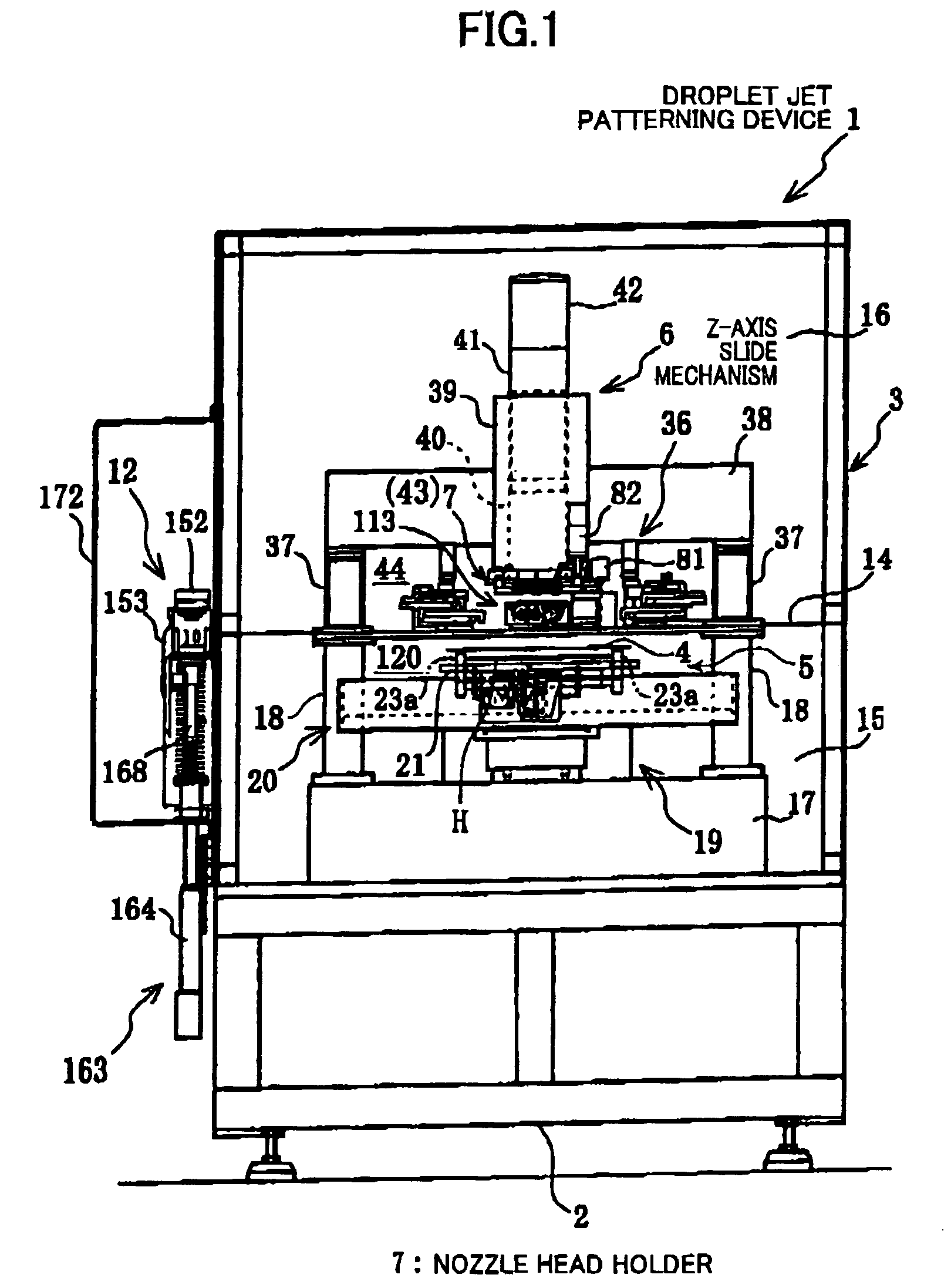

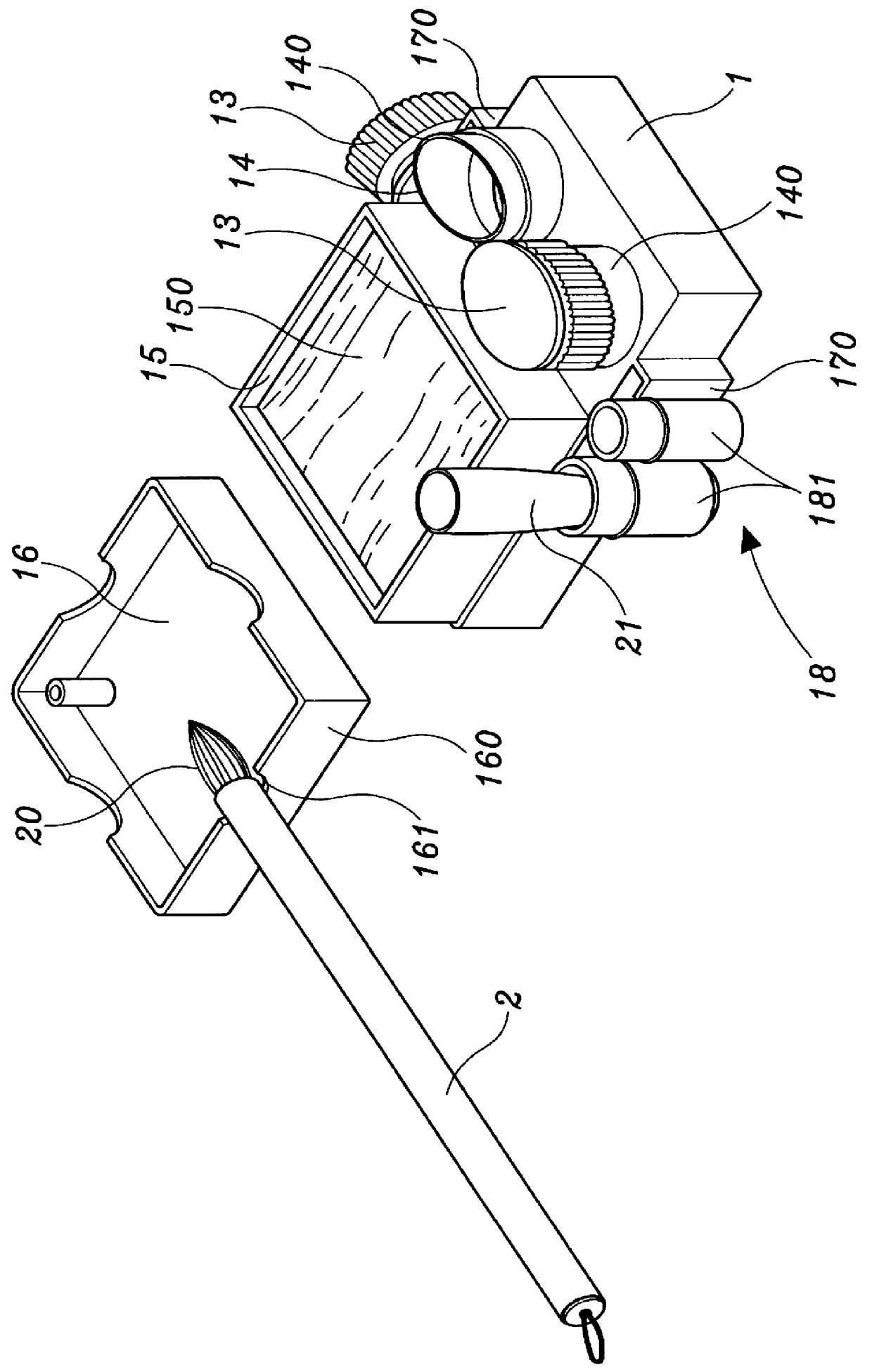

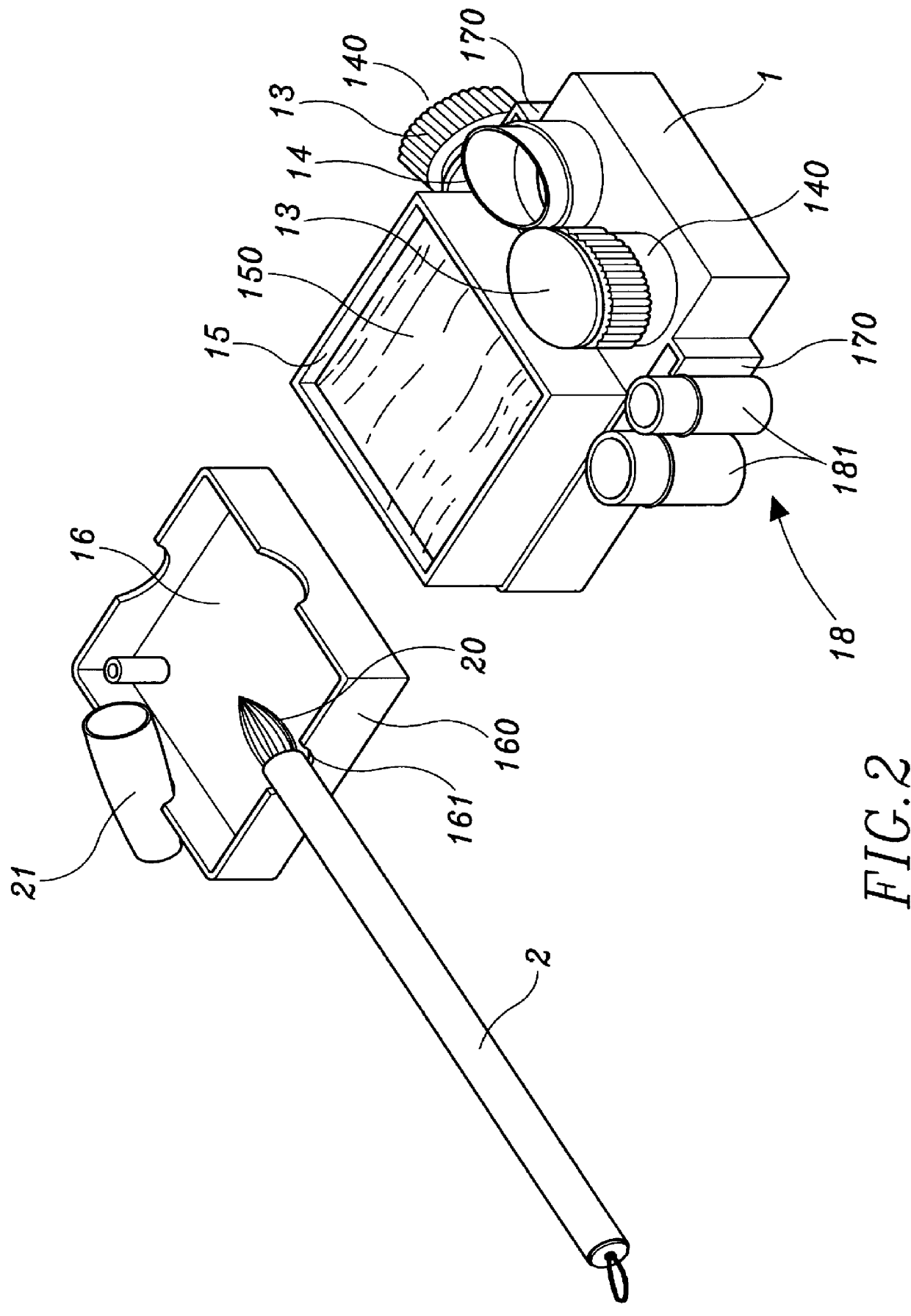

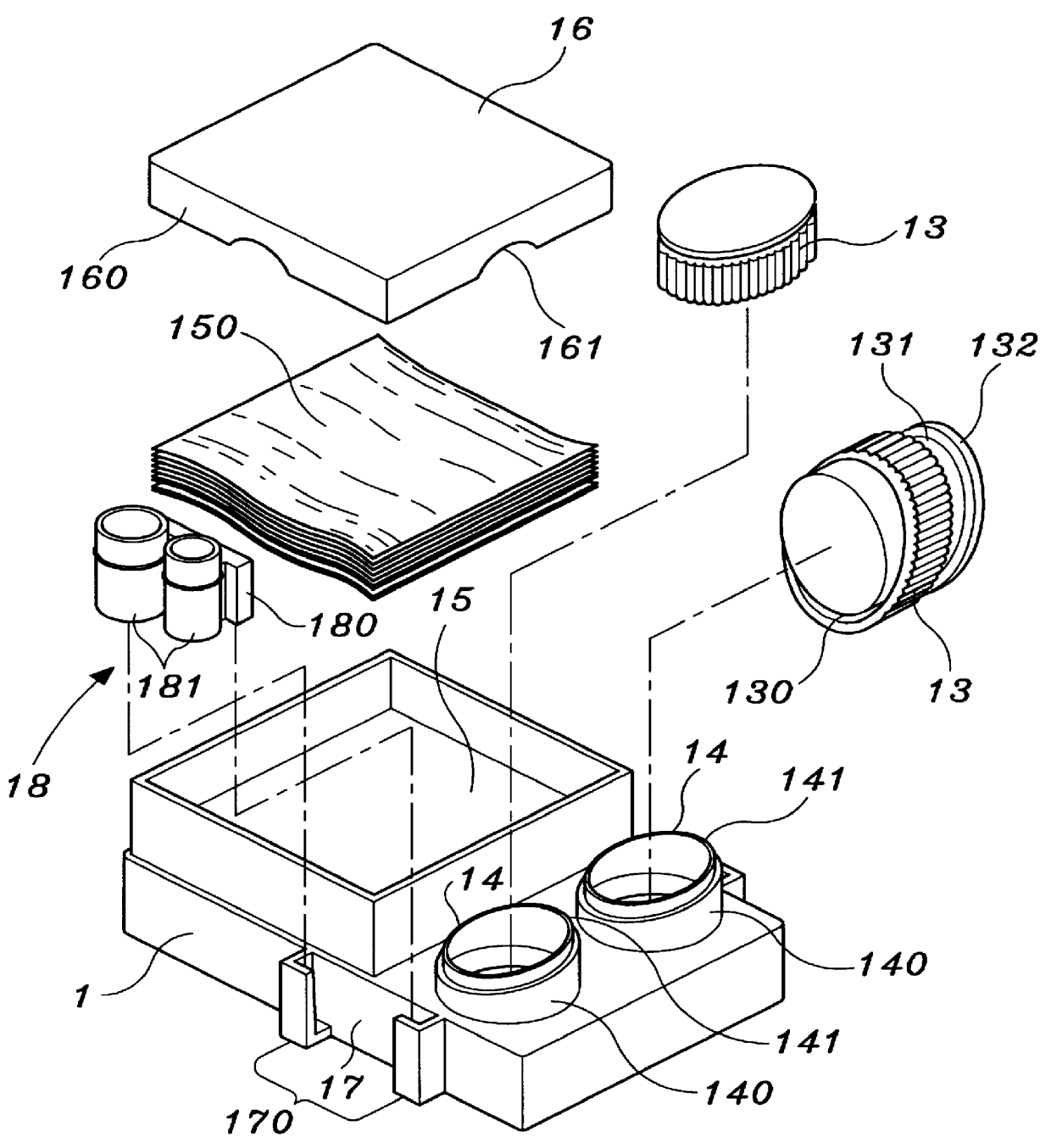

Nozzle head, nozzle head holder, and droplet jet patterning device

InactiveUS7008482B2Data processing is simpleEasy to controlLiquid surface applicatorsMovable spraying apparatusSpray nozzleEngineering

Owner:BROTHER KOGYO KK

Caulking gun

InactiveUS20070181607A1Easy constructionEasy to operateLiquid surface applicatorsMechanical apparatusInternal pressureActuator

A caulking gun includes a cartridge holder, a stock, a plunger, actuator plates, an actuator spring, an adjustable handle, a trigger, a nozzle cutter, a cartridge poker and a retractable arm clip. A handle, able to slide along a lower rail of a cartridge holder, is engaged and disengaged using a trigger. Said handle permits a user to adjust the balance point of the gun at will. To disengage the handle, a trigger is lifted, releasing a forked tab at the rear of the handle that engages the lower rail. Squeezing the trigger reengages the forked tab. The actuator plates are aligned such that a cartridge's internal pressure is relieved each time the trigger is released. A nozzle cutter provides a clean cut, and allows for nozzle tips to be easily discarded. A retractable arm clip is used as a secondary contact point with a user's arm.

Owner:CALVO RAFAEL ADOLFO +1

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Surface drilling device for flocked cloth

InactiveCN107097292AHigh degree of automation integrationIncrease productivityLiquid surface applicatorsCoatingsDrill bitPetroleum engineering

The invention discloses a surface drilling device for flocked cloth. The surface drilling device comprises a base and a movable drilling assembly arranged at the upper end of the base, wherein a fixture is inserted into a fixture fixed groove; the flocked cloth needing to drill is clamped on a sliding panel; the sliding panel is controlled by a servo motor to move leftwards and rightwards; successively, the movable drilling assembly moves by a control shaft fixed base of the servo motor; a drilling head is controlled by a lifting air cylinder to move downwards; and the drilling head is controlled by the motor to rotate to carry out drilling. The surface drilling device for the flocked cloth is high in automatic integration degree, is beneficial for improving production efficiency, and greatly reduces defective rate; meanwhile, by adopting a multi-shaft drilling way, the surface drilling device for the flocked cloth greatly improves the adjustability of the device, and is beneficial for improving the drilling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

Powder packaging device of electronic element based on the heating structure with controllable wind direction and speed

InactiveCN101032715ABreak through the technical problem of uneven thermal claddingLiquid surface applicatorsCoatingsHeat flowFluidized bed

Owner:XI AN JIAOTONG UNIV

Ink-slab for calligraphy

Owner:YOU JIUN FENG

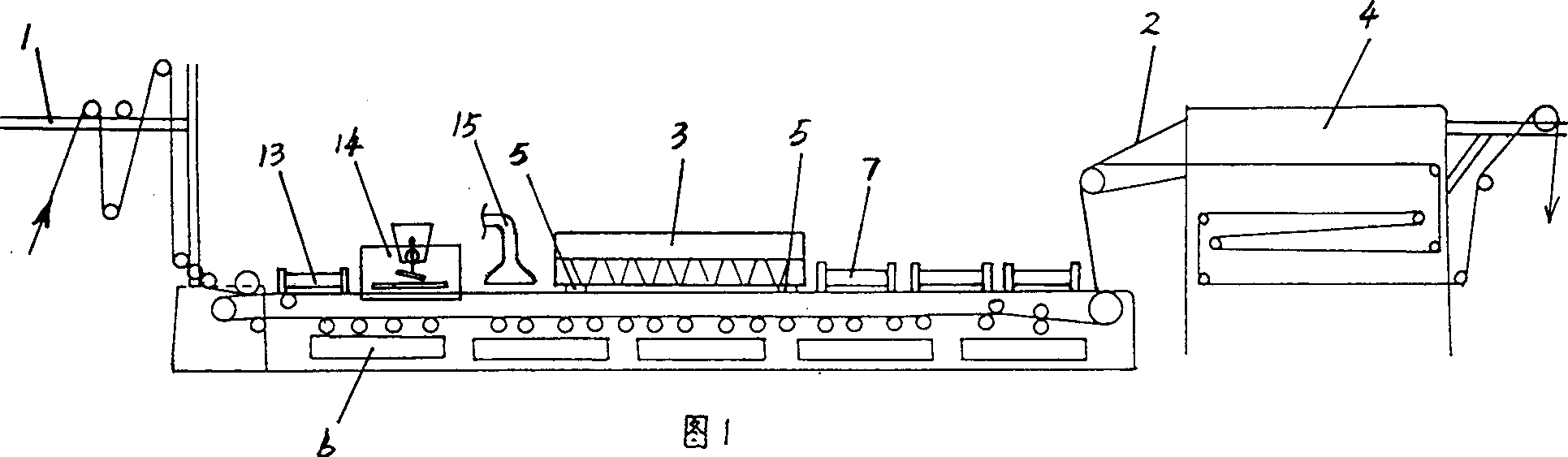

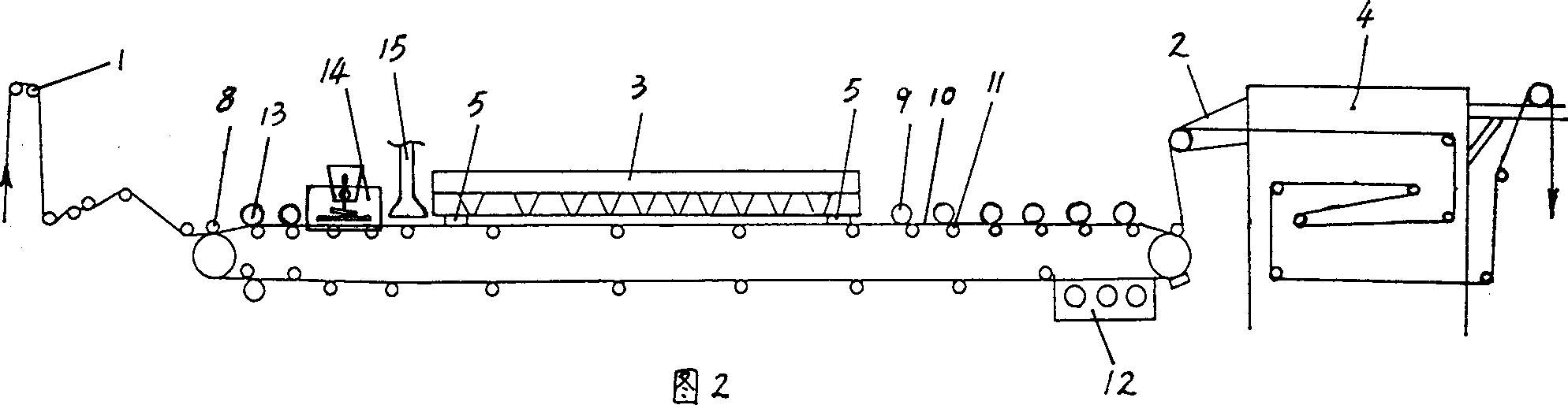

Multi-color flocking printer and its manufacture technology

InactiveCN1365861ARich in colorReduce manufacturing costLiquid surface applicatorsDyeing processManufacturing technologyEngineering

Owner:劳关明

Transparent barrier sheet and preparation method thereof

InactiveUS20070224393A1Improve adhesionAchieve smoothnessLiquid surface applicatorsSynthetic resin layered productsOptoelectronicsSurface roughness

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Aqueous dispersion composition for primer

ActiveCN101405358ALiquid surface applicatorsSynthetic resin layered productsSpecific gravityFilm structure

Owner:DAIKIN IND LTD

Paste supply apparatus, screen printing machine, paste supply method and screen printing method

ActiveUS20140366754A1Improve work efficiencyInking apparatusLiquid surface applicatorsScreen printingEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

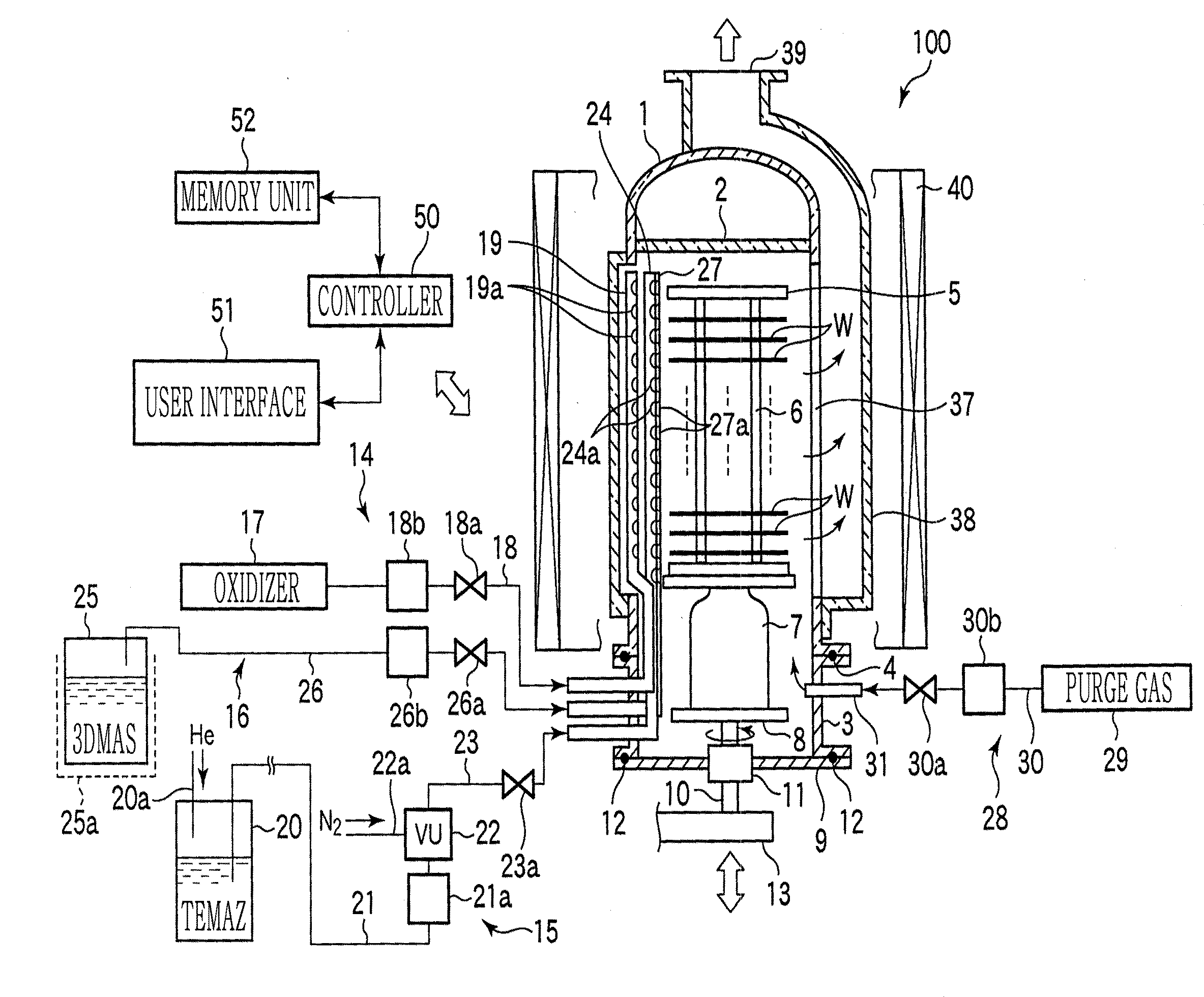

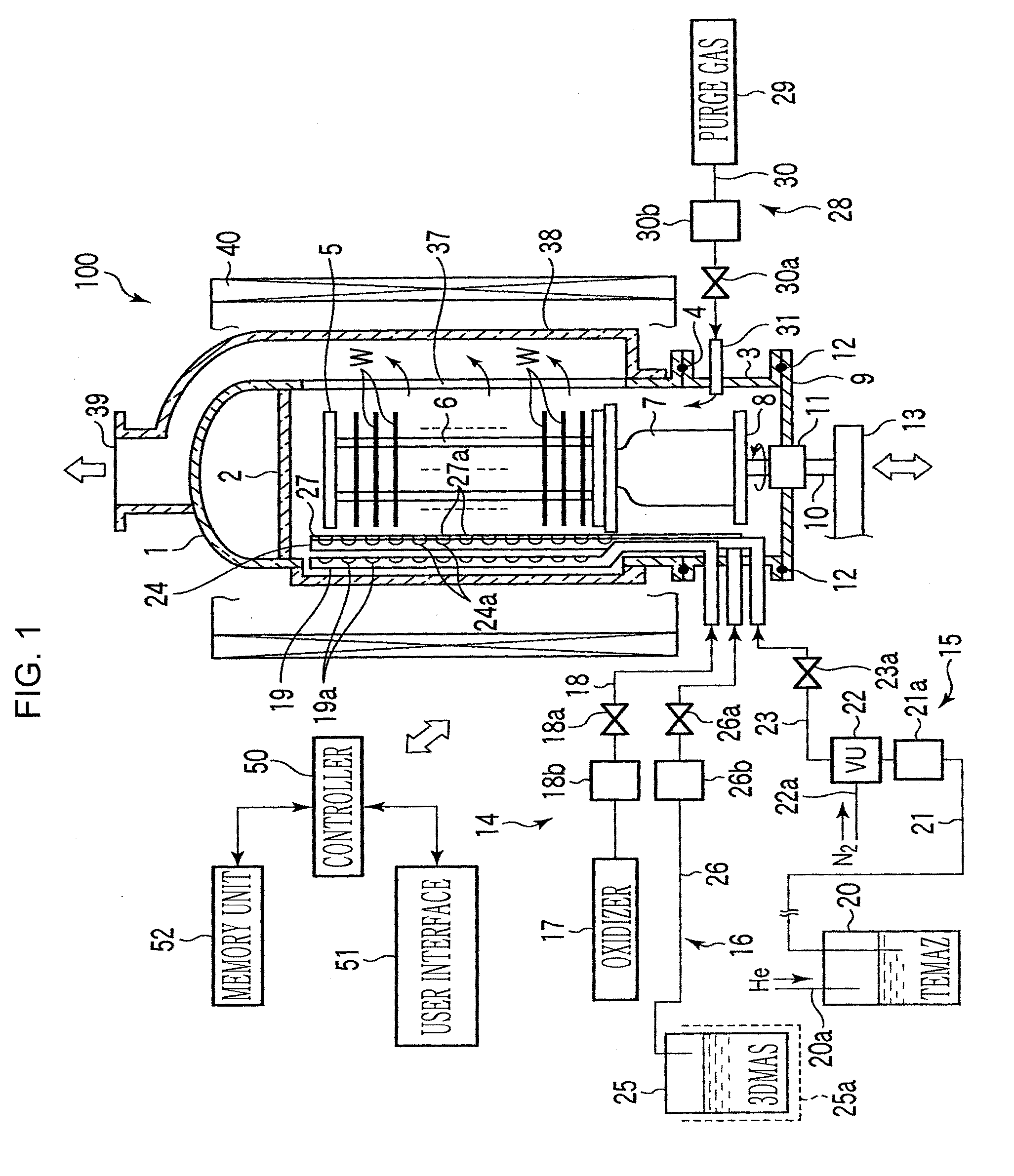

Film forming method and film forming apparatus

ActiveUS20100035439A1Solve the large leakage currentLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringOxidizing agent

Owner:TOKYO ELECTRON LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap