Planetary transmission device of coating machine

A technology of transmission device and coating machine, which is applied in the direction of transmission device, gear transmission device, and device for coating liquid on the surface. The speed cannot be adjusted independently, etc., to save working time, simple structure and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

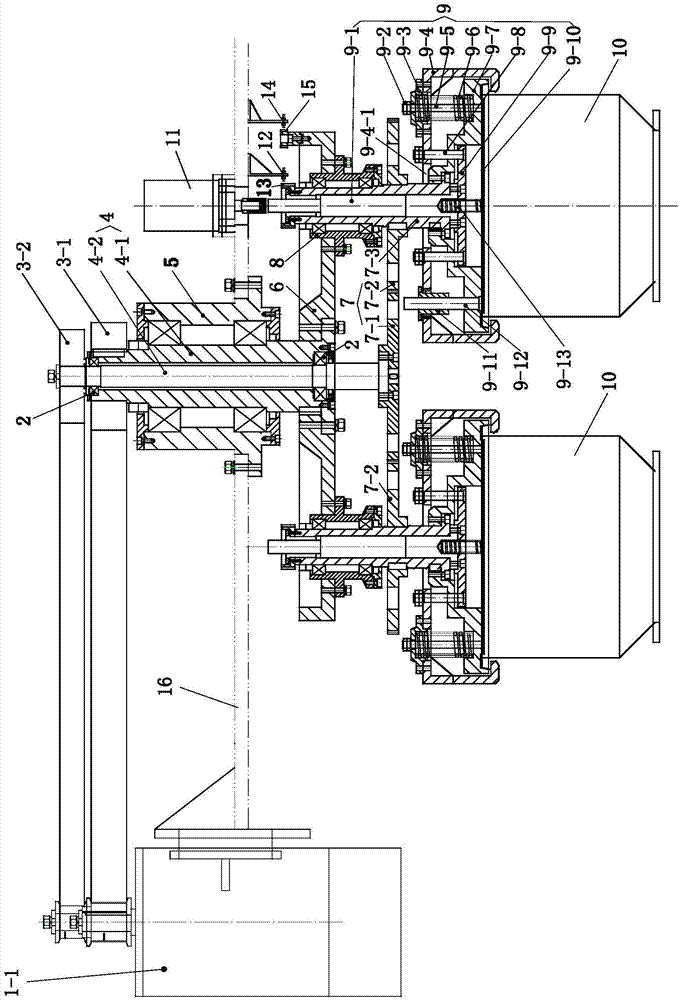

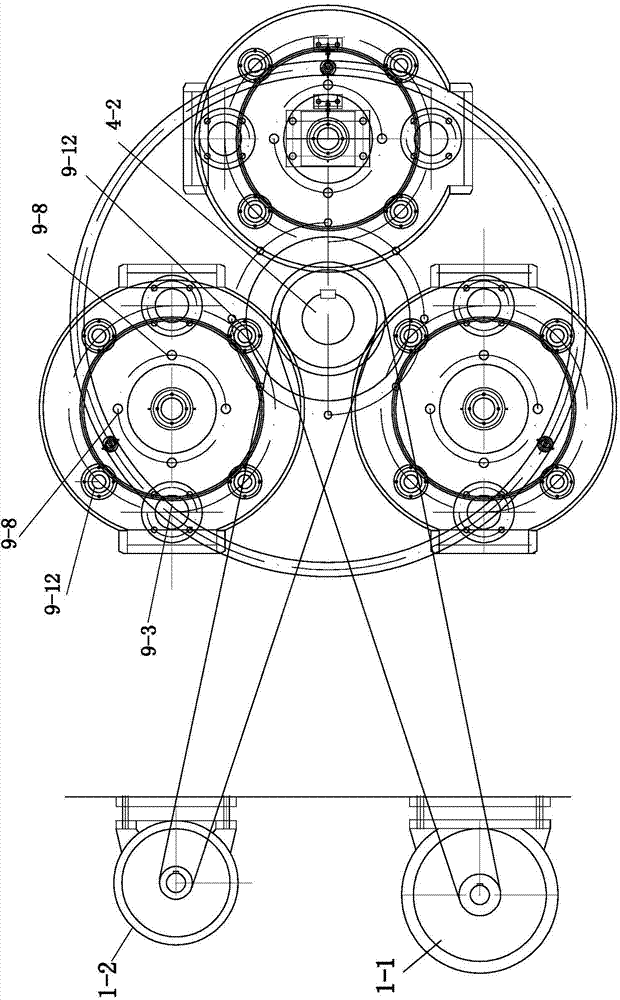

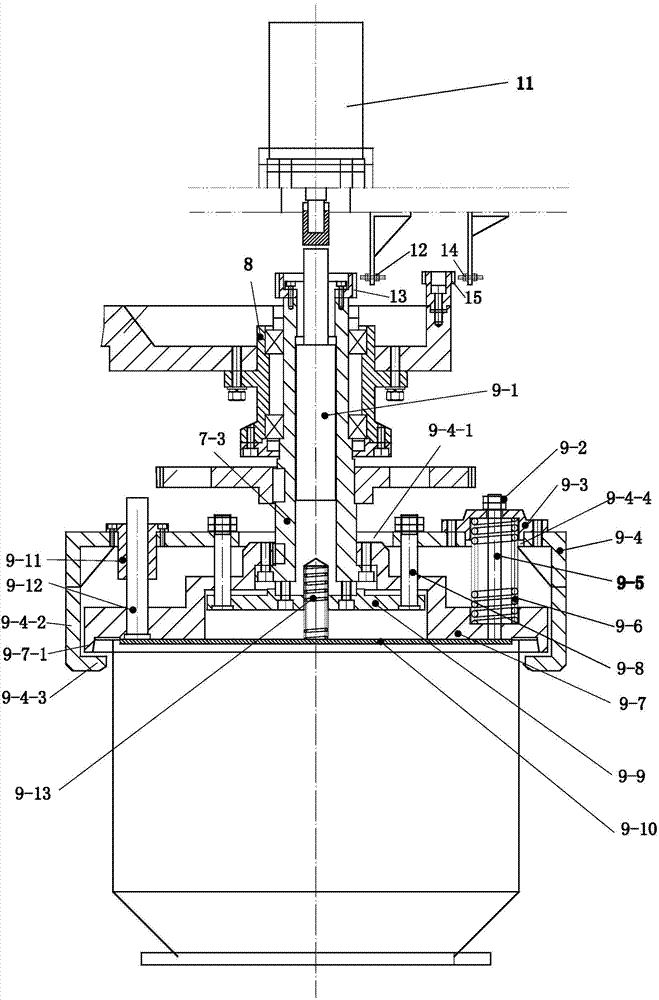

[0018] See Figure 1 to Figure 3 , the present embodiment has a main shaft 4, a planetary gear mechanism 7 and a frame 16, and the planetary gear mechanism 7 includes a sun gear 7-1 and three planetary gears 7-2 meshed with the sun gear 7-1 and evenly distributed.

[0019] Described main shaft 4 is made up of hollow main shaft 4-1 and central main shaft 4-2, is fixed with hollow main shaft bearing seat 5 on frame 16, and hollow main shaft 4-1 is supported by a pair of bearings in hollow main shaft bearing seat 5. The central main shaft 4-2 and the hollow main shaft 4-1 are connected by two central main shaft bearings 2, and the two central main shaft bearings 2 are respectively arranged at both ends of the hollow main shaft 4-1, and the central main shaft 4-2 is composed of two central main shaft bearings 2 supports.

[0020] The upper end of the hollow main shaft 4-1 is provided with a pulley 3-1, the upper end of the central main shaft 4-2 is provided with a belt pulley 3-2, a

Embodiment 2

[0033] See Figure 4 , The planetary gear mechanism of this embodiment has 2 planetary wheels, so it has 2 sets of workpiece basket clamping mechanisms. Refer to Example 1 for the specific structure.

Embodiment 3

[0035] See Figure 5 , The planetary gear mechanism of this embodiment has 4 planetary gears, so it has 4 sets of workpiece basket clamping mechanisms. Refer to Example 1 for the specific structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap