Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Resist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A resist, used in many areas of manufacturing and art, is something that is added to parts of an object to create a pattern by protecting these parts from being affected by a subsequent stage in the process. Often the resist is then removed.

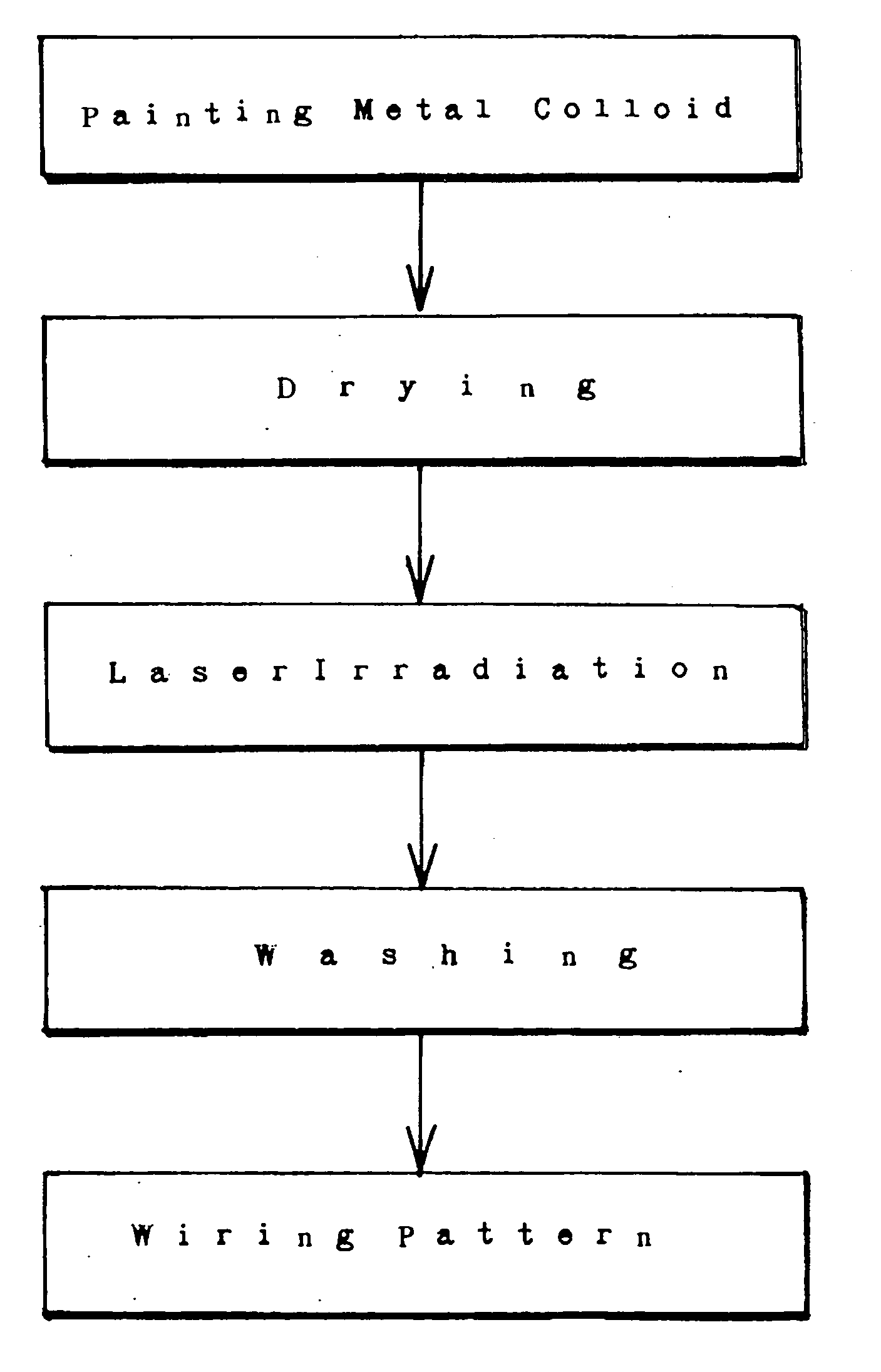

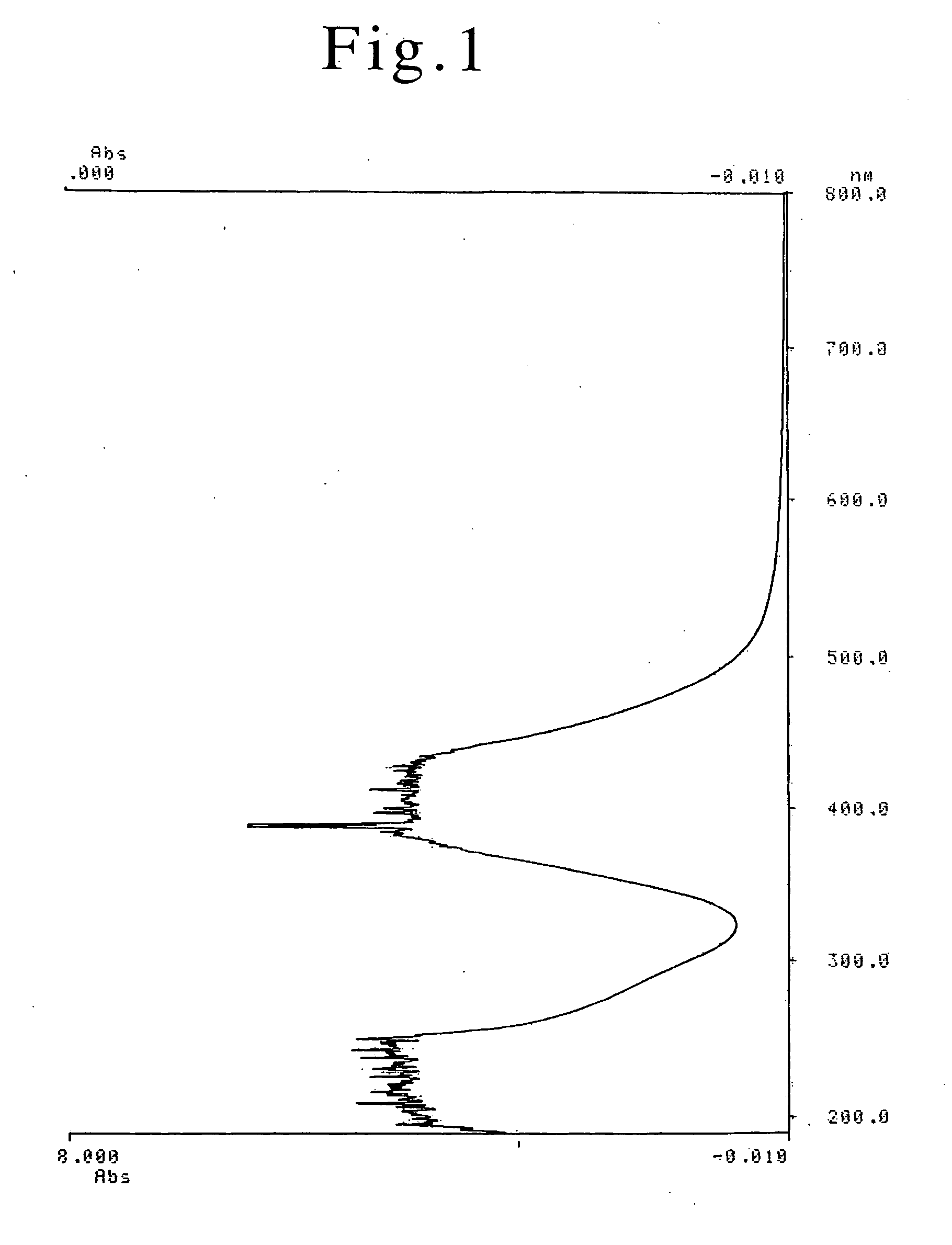

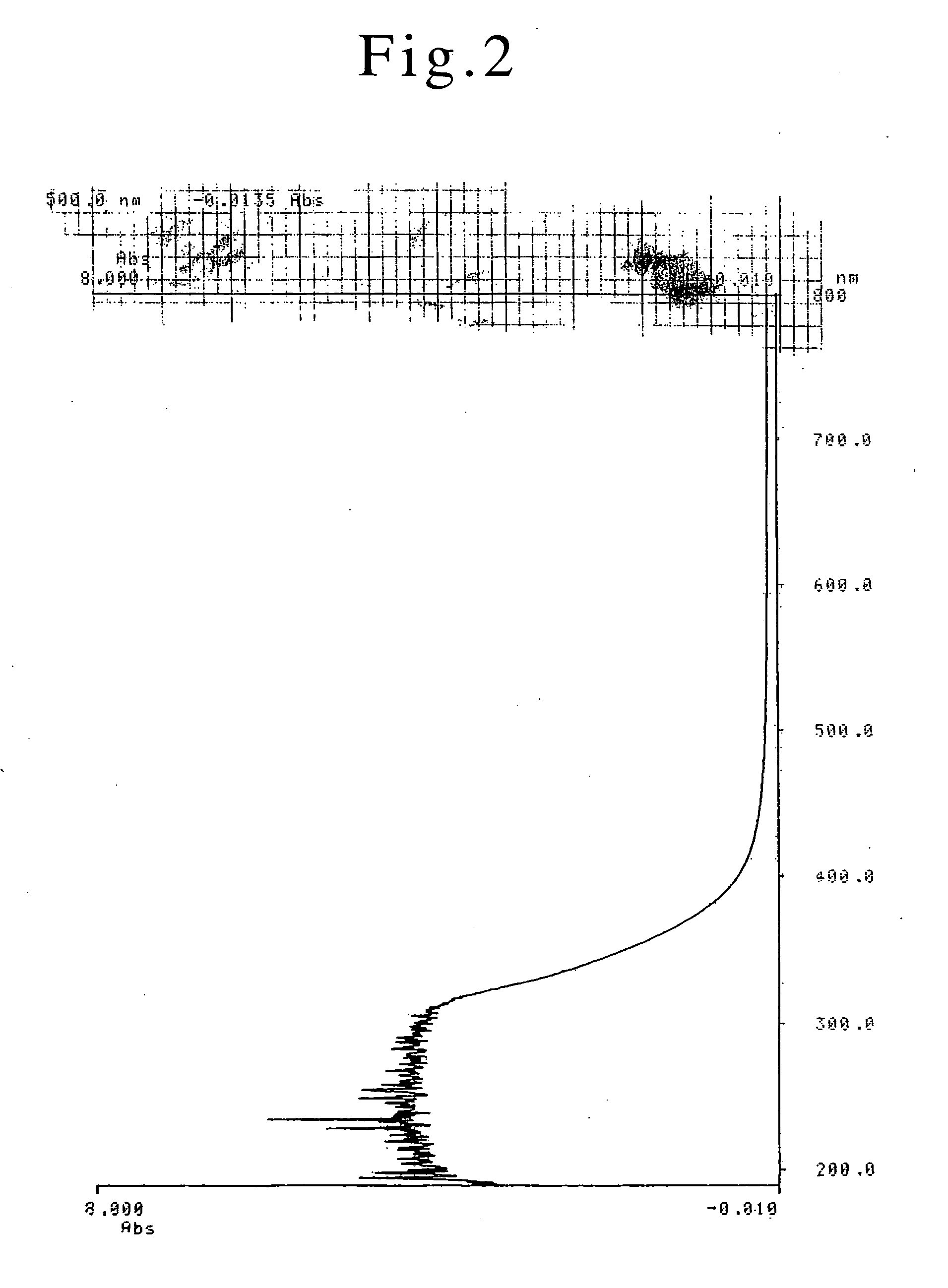

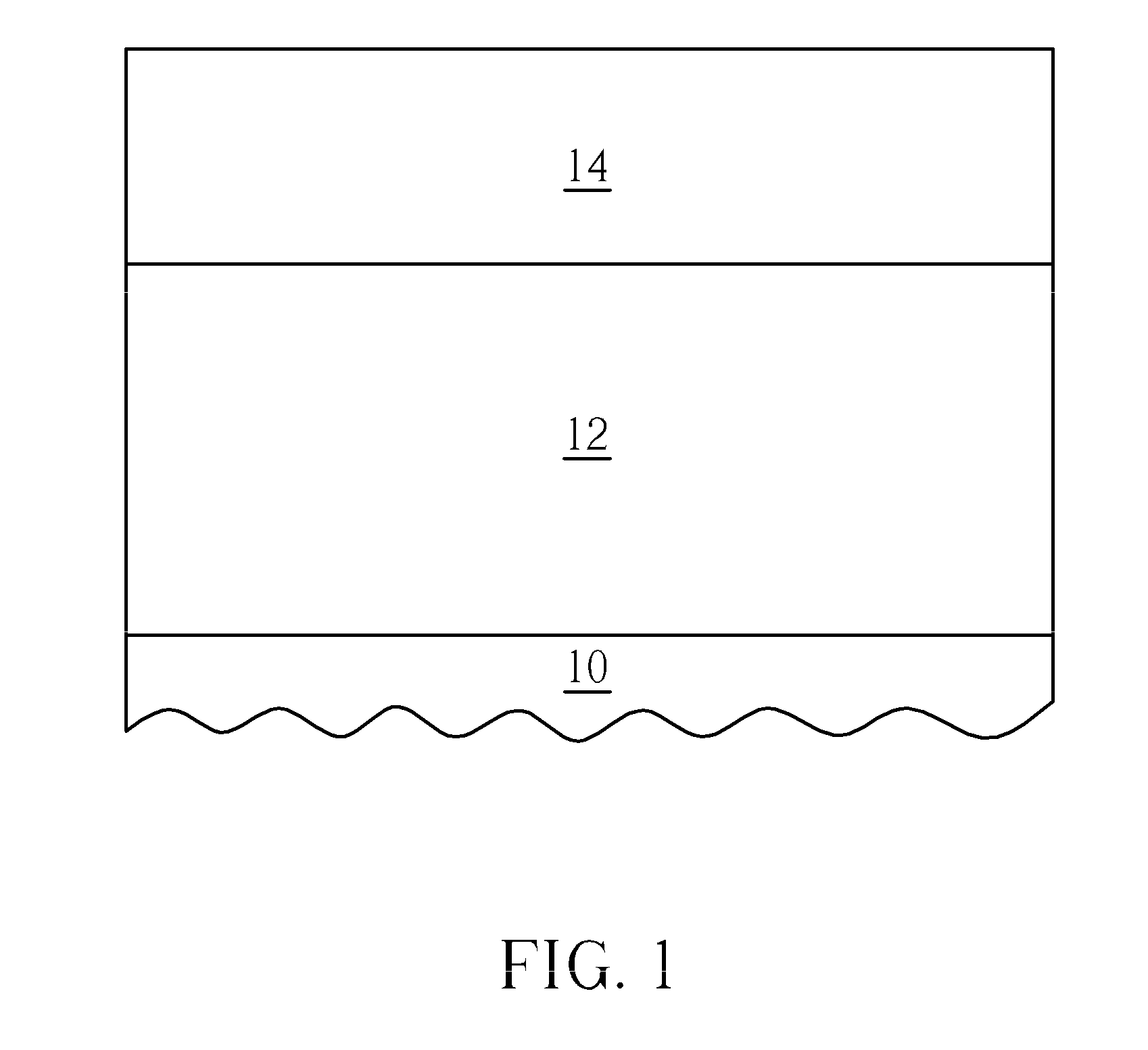

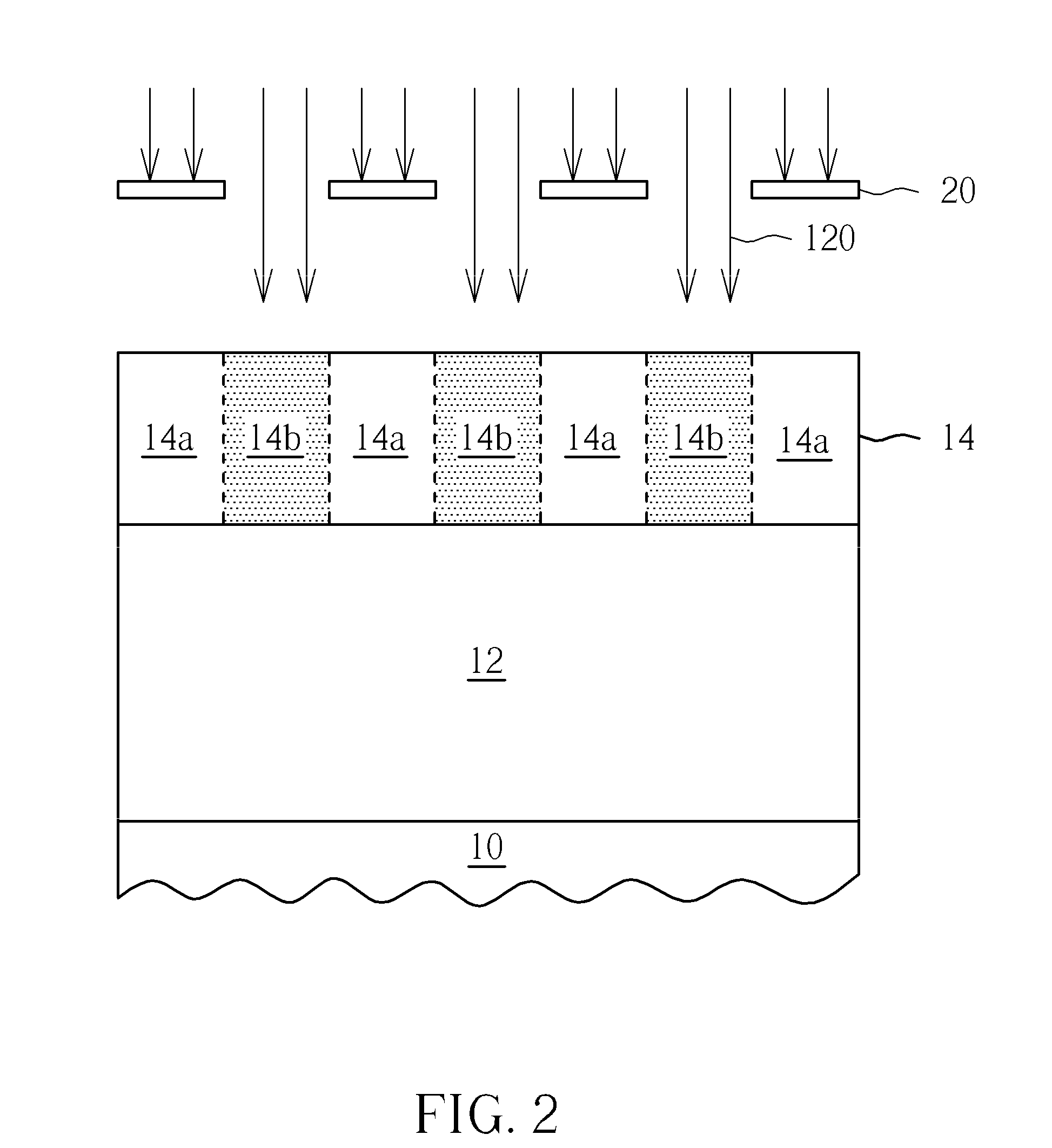

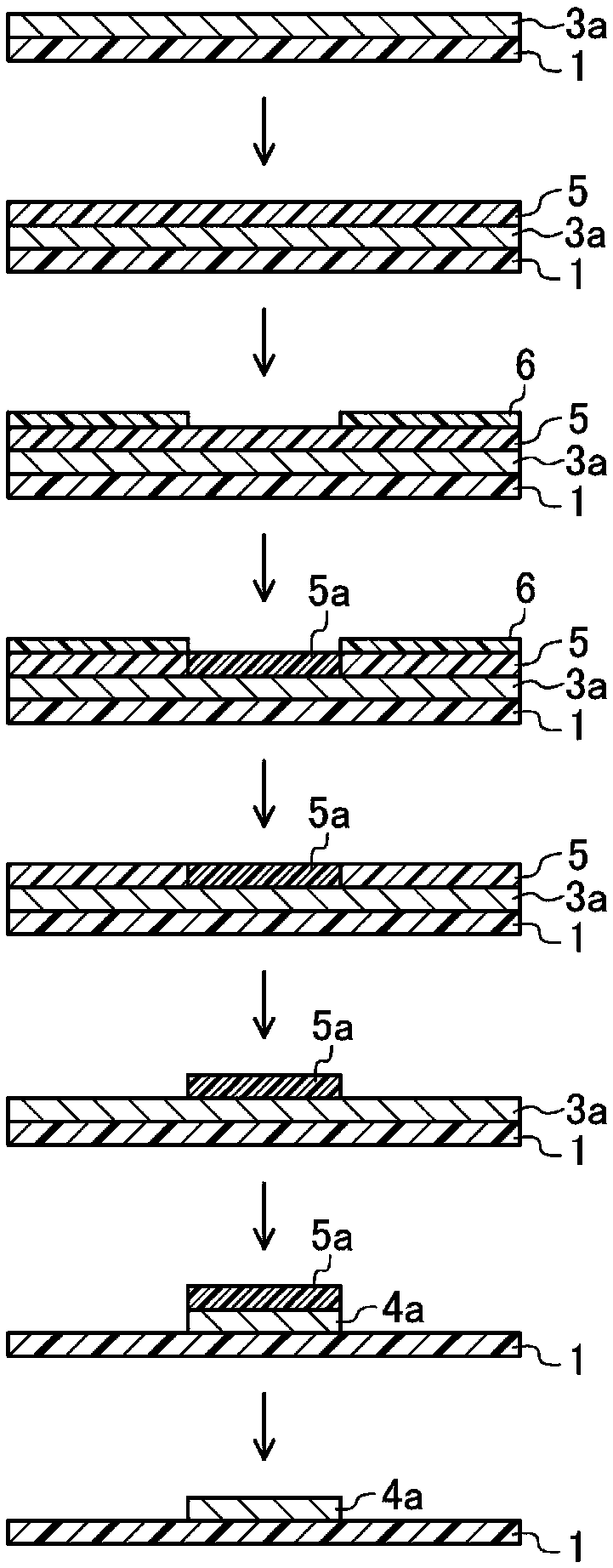

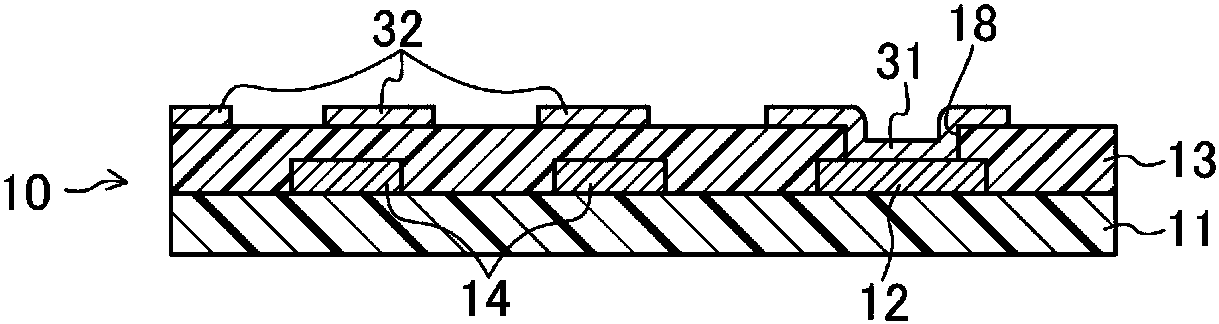

Method of forming a conductive wiring pattern by laser irradiation and a conductive wiring pattern

InactiveUS20060057502A1Poor adhesionEasy to eliminateMaterial nanotechnologyPhotomechanical apparatusResistCompound (substance)

Owner:SUMITOMO ELECTRIC IND LTD

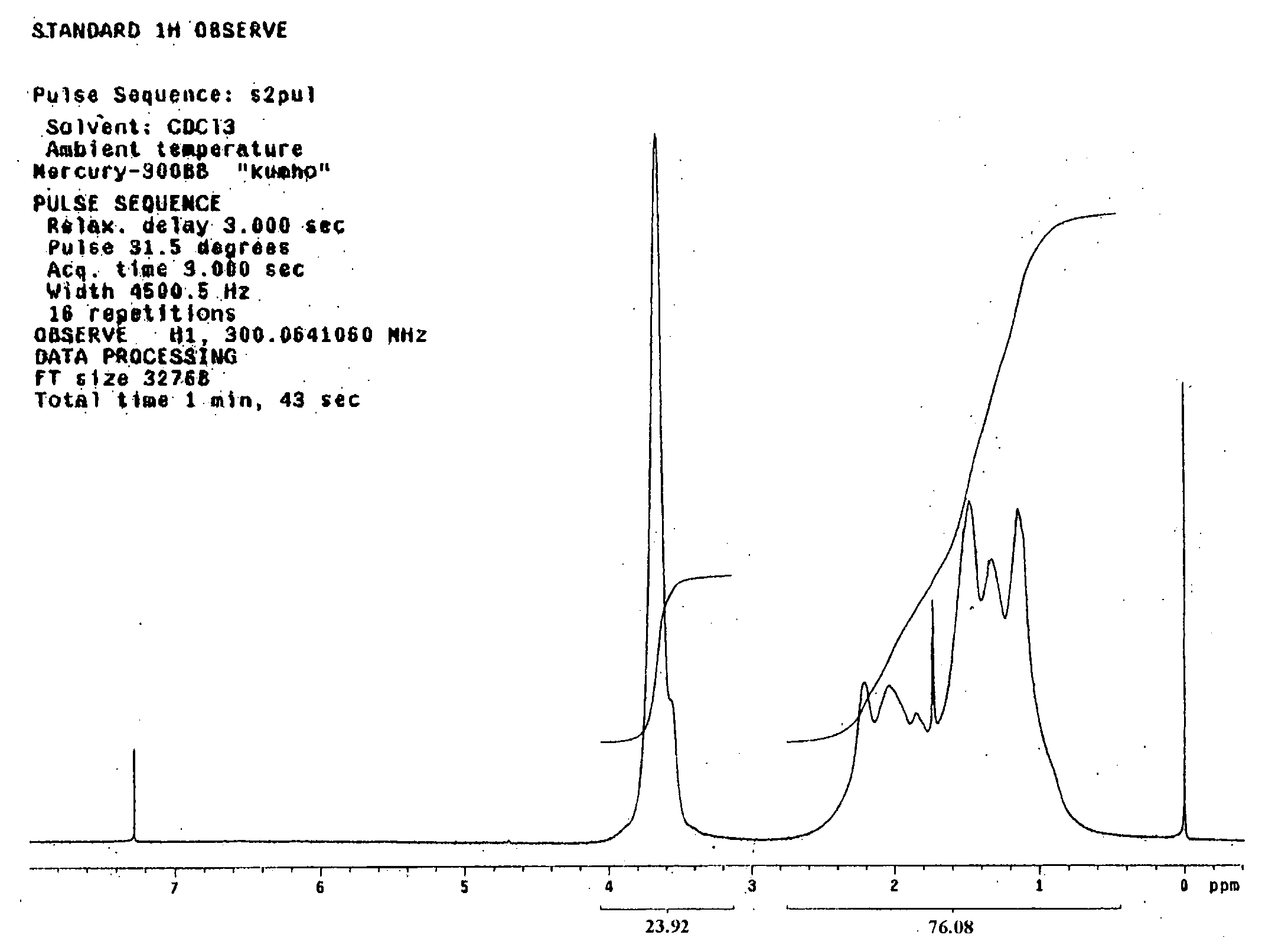

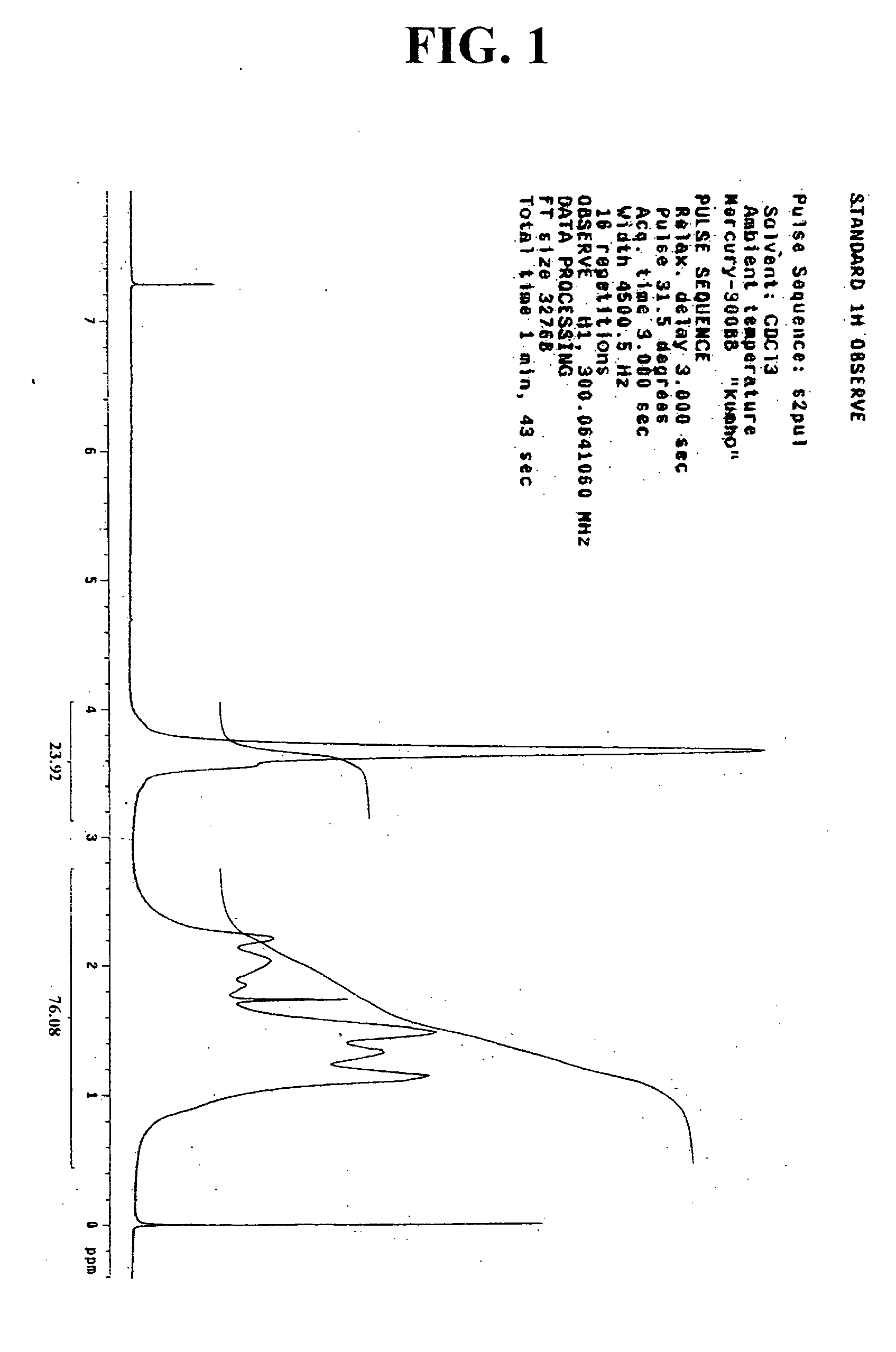

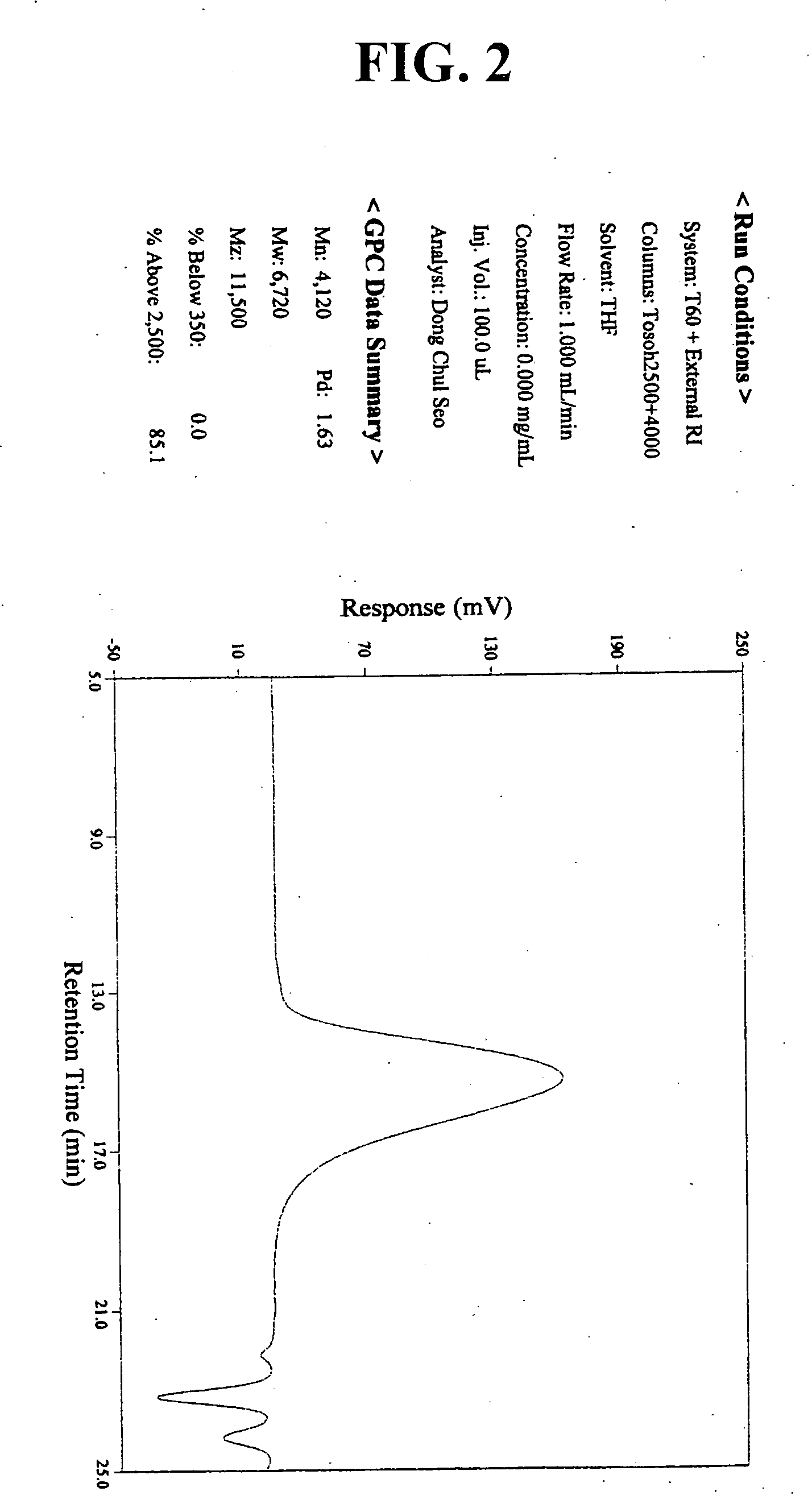

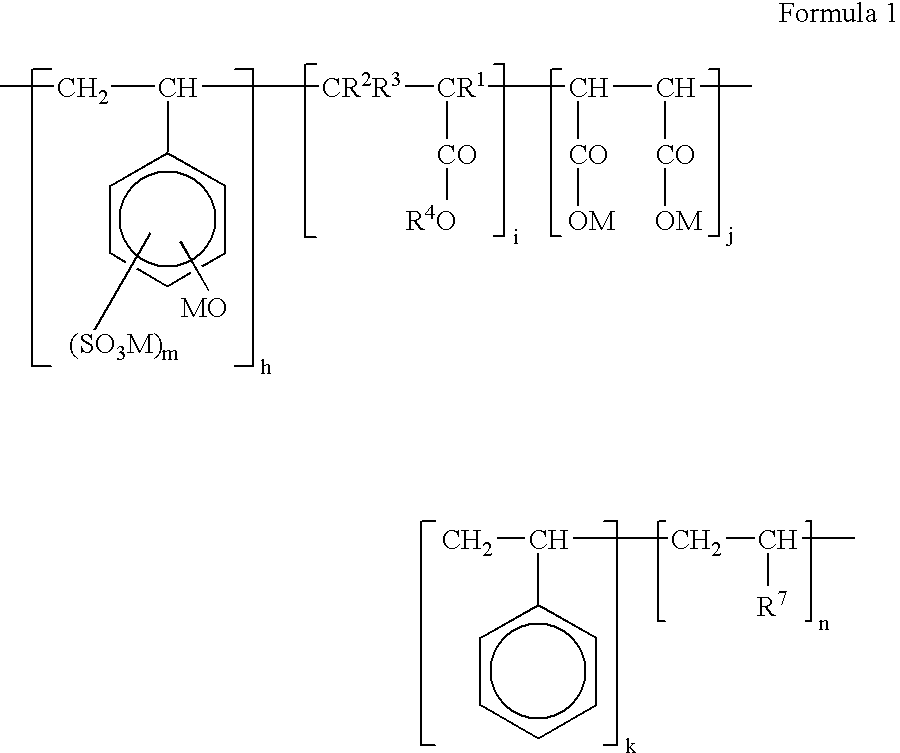

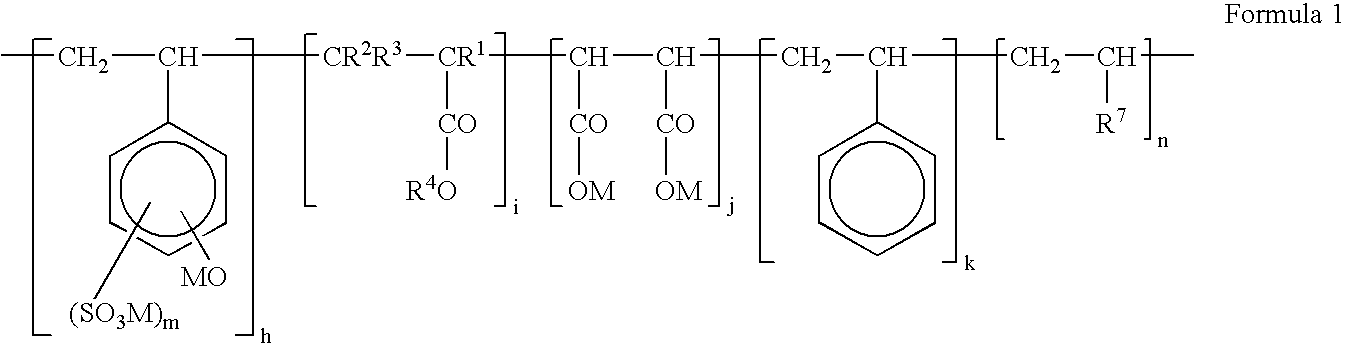

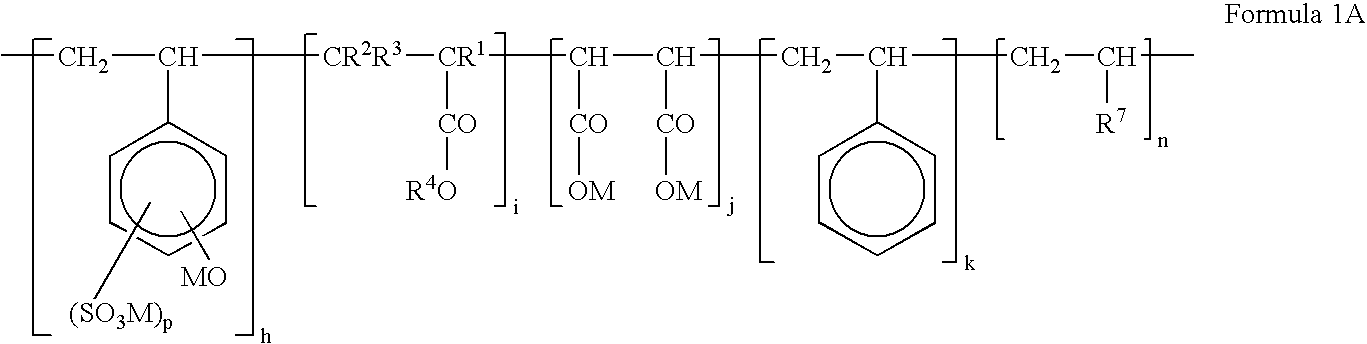

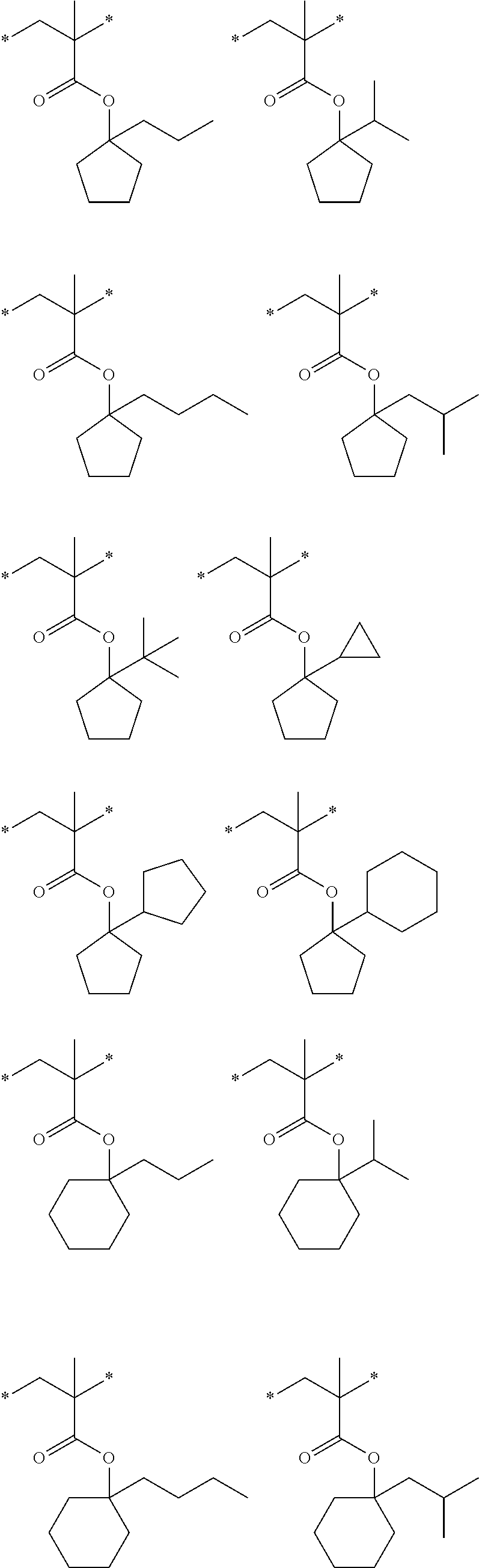

Copolymer, process for producing the same, and resist composition

InactiveUS6706826B1Improve adhesionImprove solubilityOriginals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusSolventResist

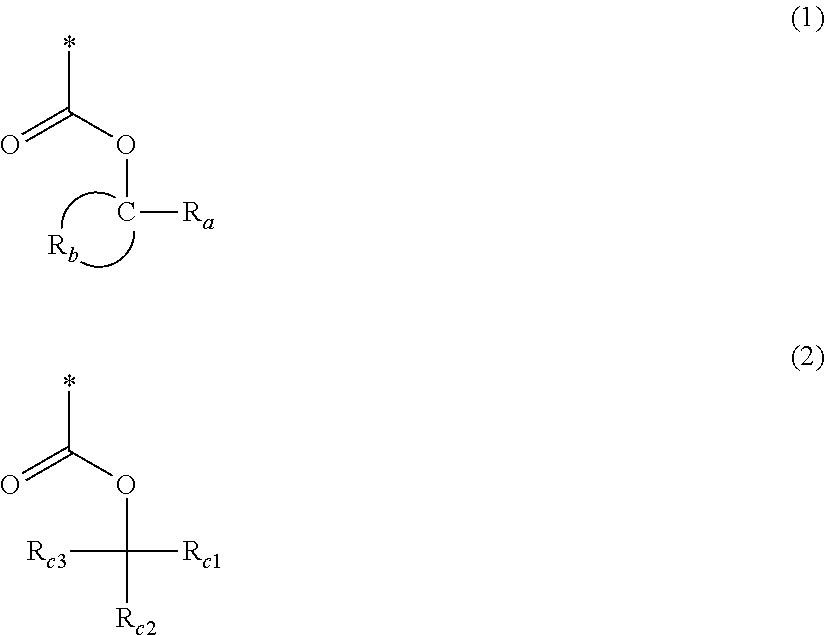

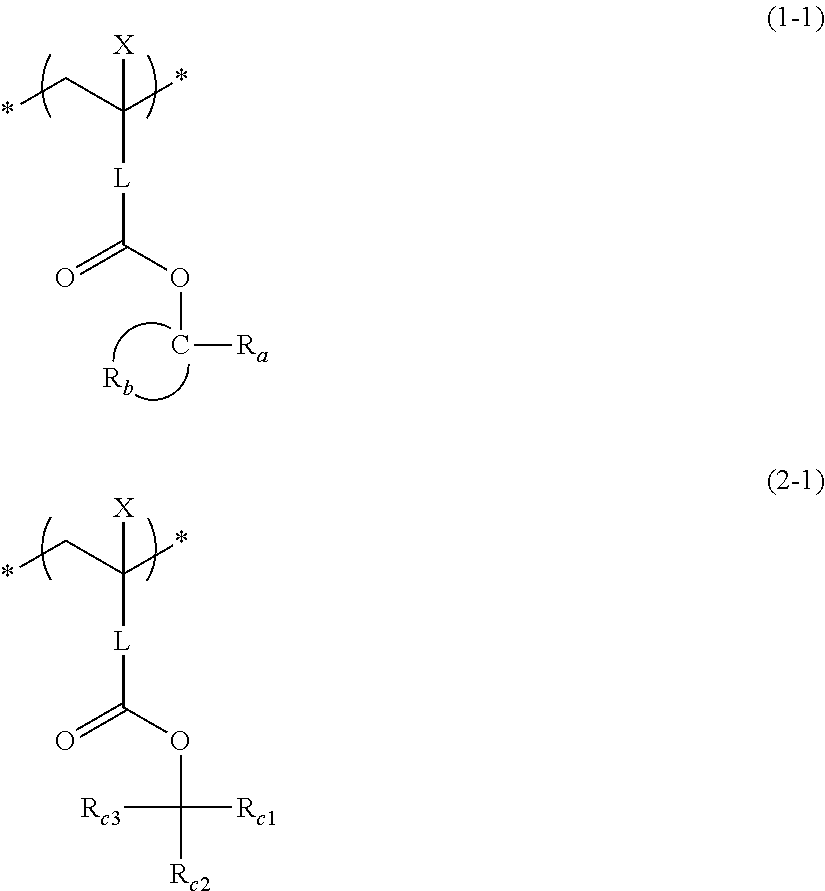

The present invention relates to a copolymer for use in paints, resists, and the like; a method for manufacturing the same; and a resist composition using the same. The copolymer according to the present invention is obtained by means of polymerizing at least one monomer containing an alicyclic structure and one monomer containing a lactone structure, and the distribution of the copolymer composition of said monomer containing a lactone structure in said copolymer is in the range of -10 to +10 mol % of the average copolymer composition of said monomer containing a lactone structure in said entire copolymer. In addition, the copolymer according to the present invention is obtained by means of polymerizing a monomer containing an alicyclic structure, a monomer containing a lactone structure, and another vinyl monomer comprising a higher polarity than said monomer containing an alicyclic structure, but a lower polarity than said monomer containing a lactone structure. The copolymer according to the present invention exhibits superior adhesion properties to surfaces possessing a high polarity, such as metal surfaces and the like, in addition to excellent hydrophobic and thermal resistance properties, and also displays a favorable solubility in solvents used for paints, resists, and the like.

Owner:MITSUBISHI CHEM CORP

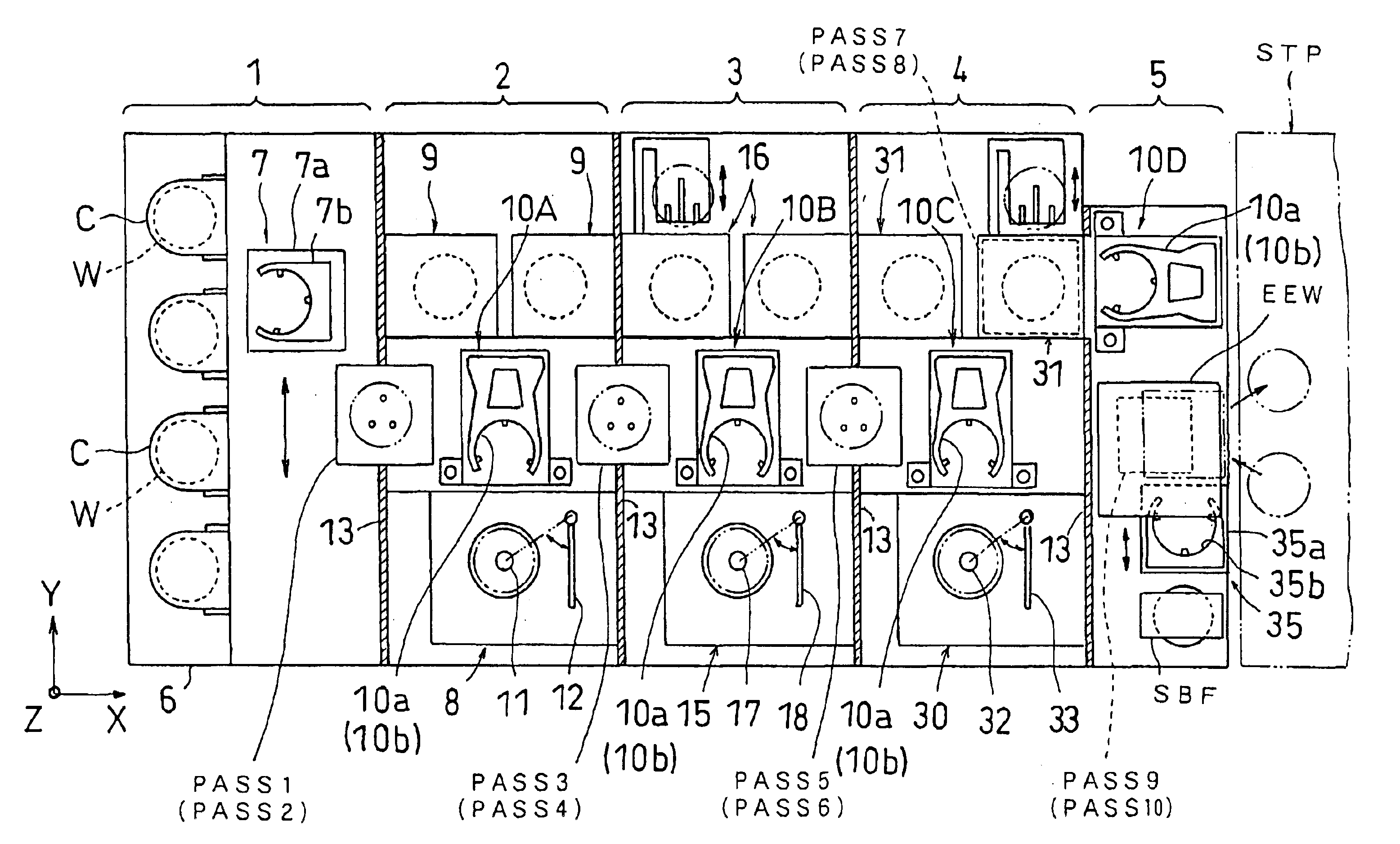

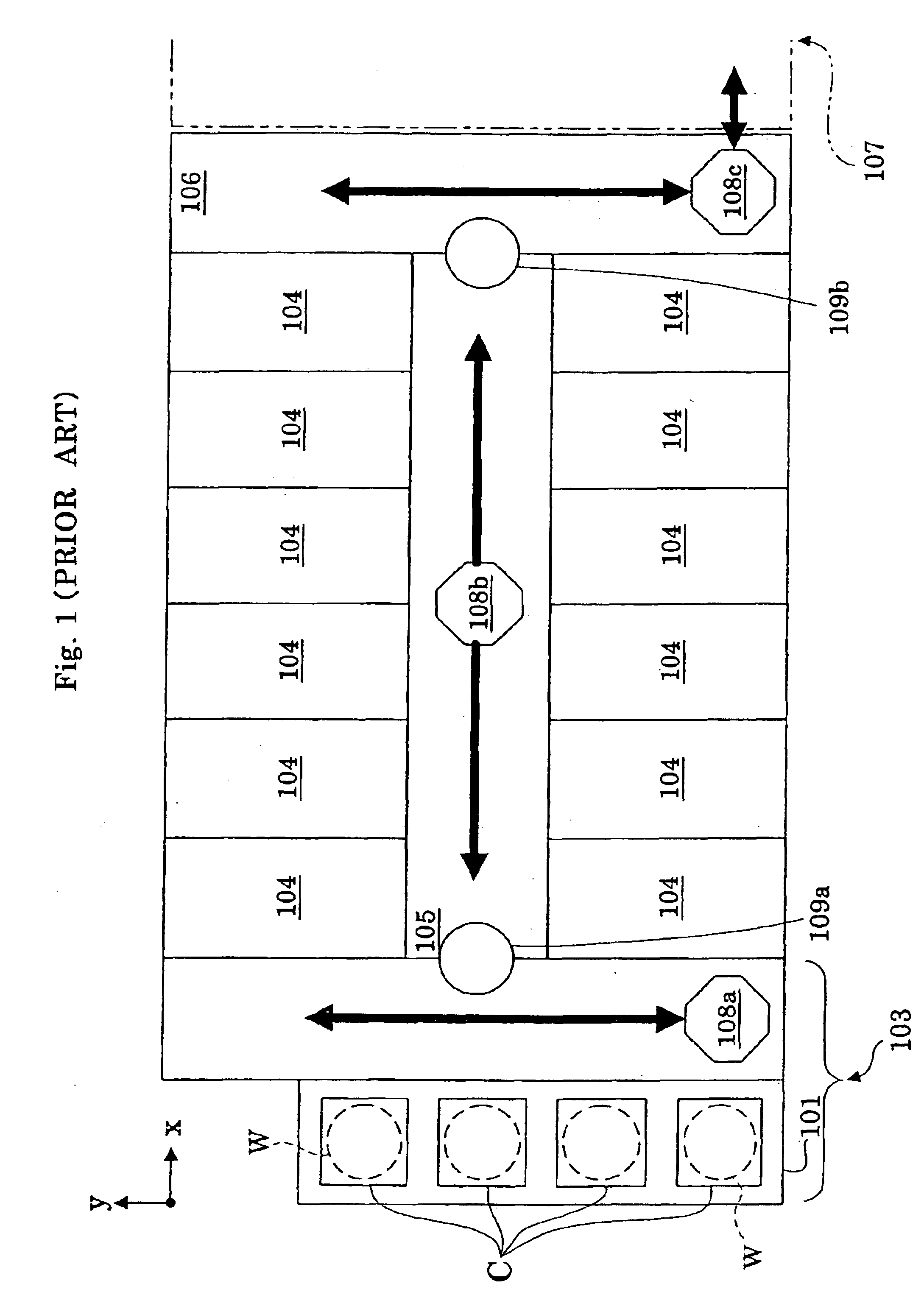

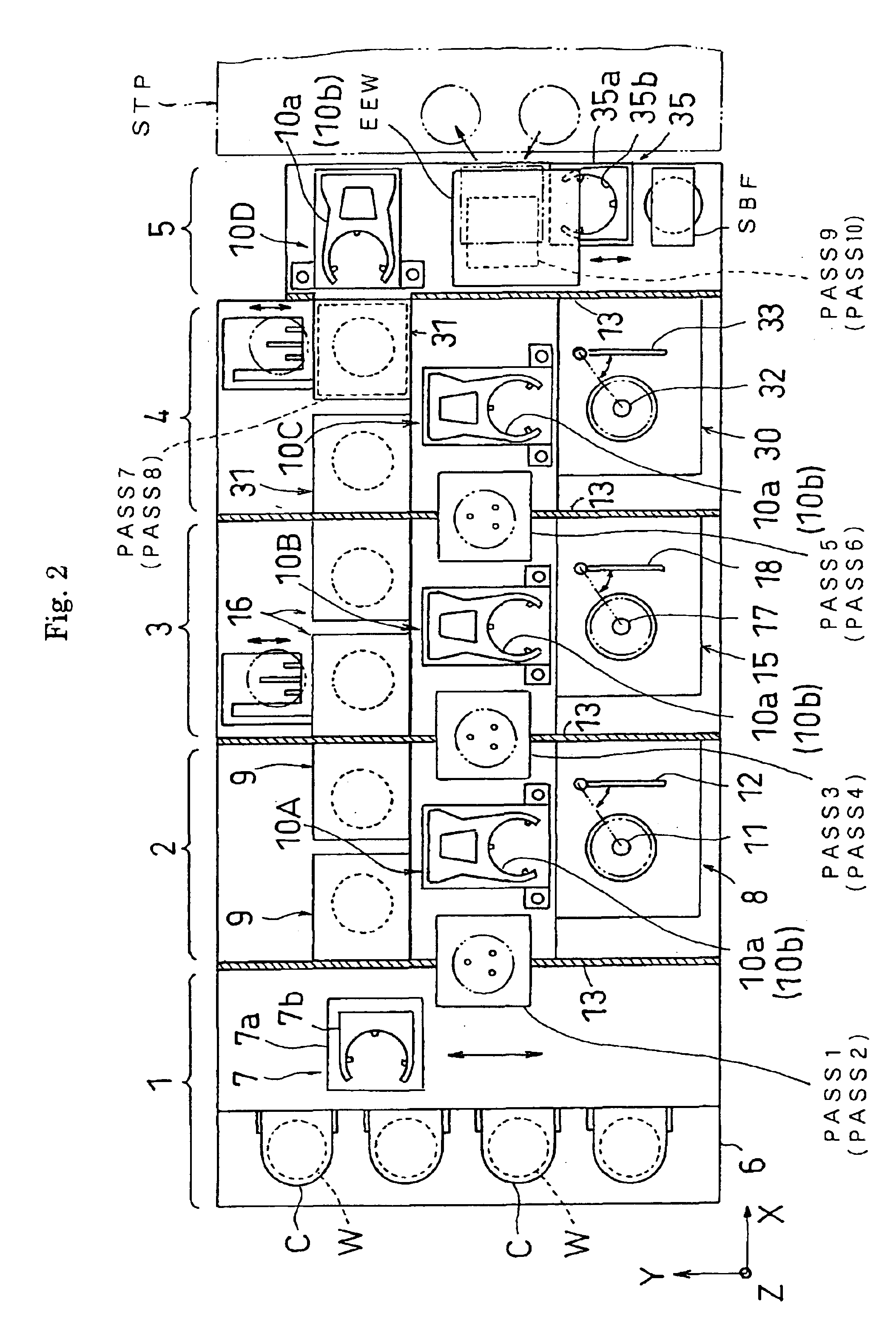

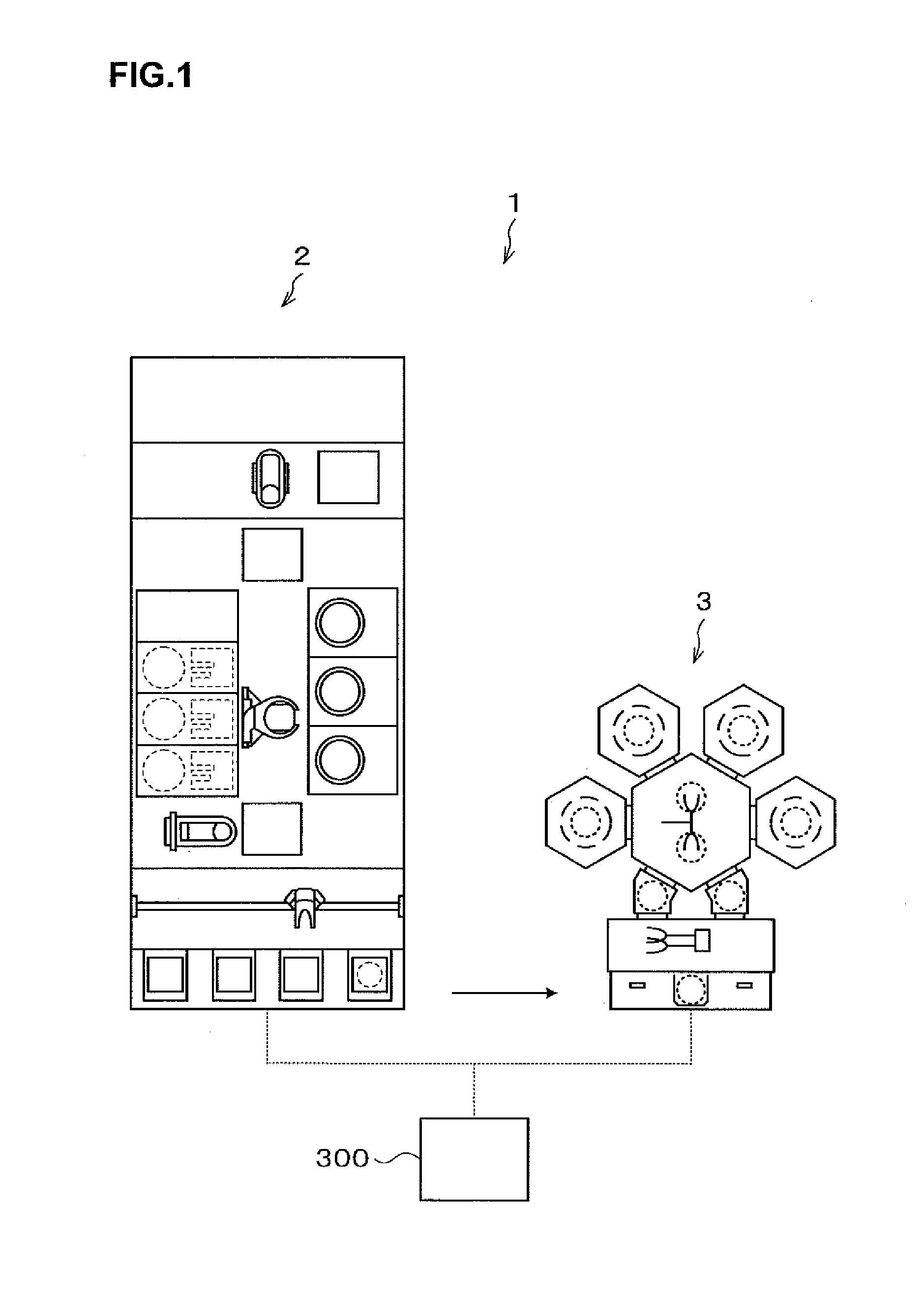

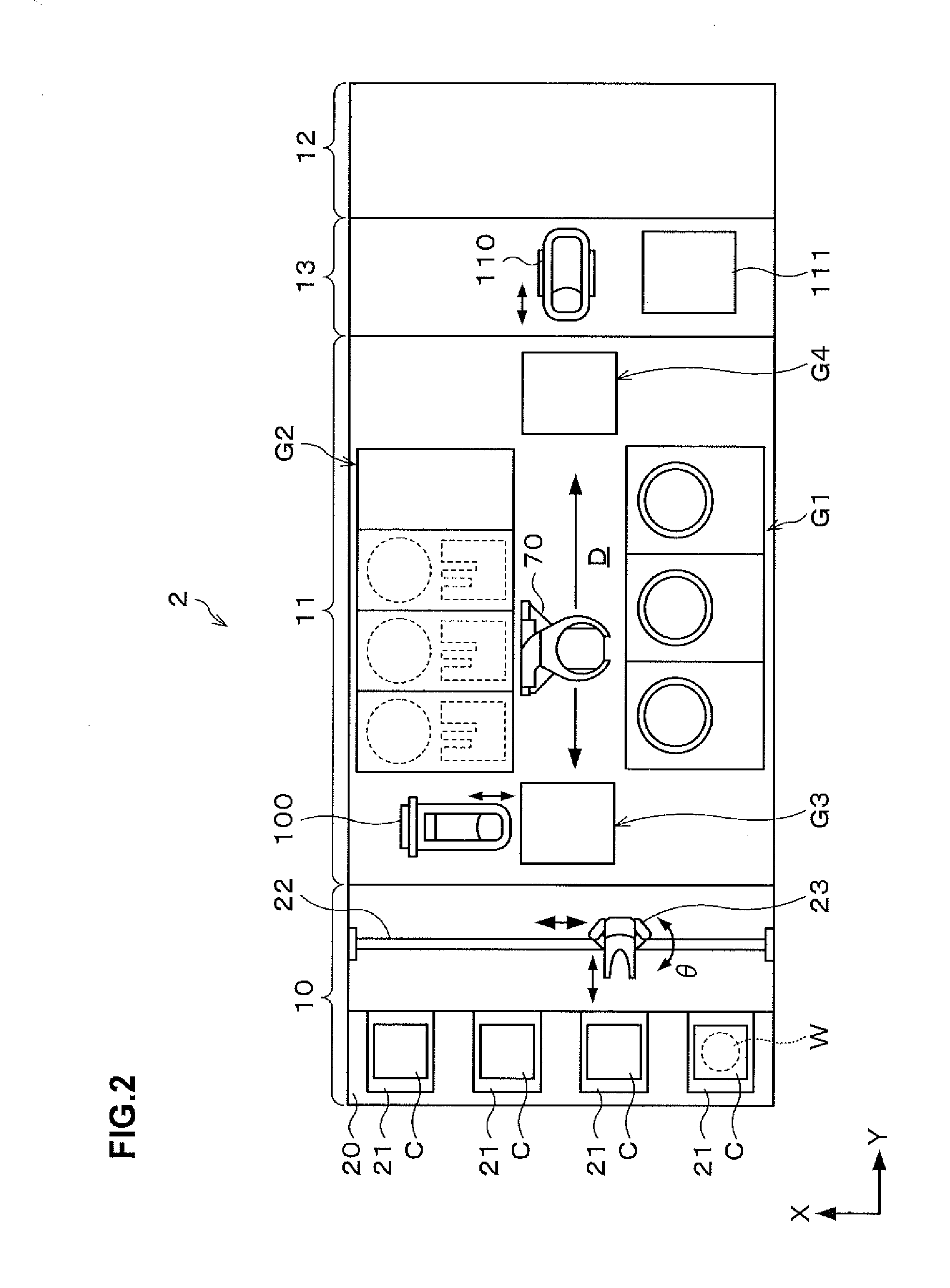

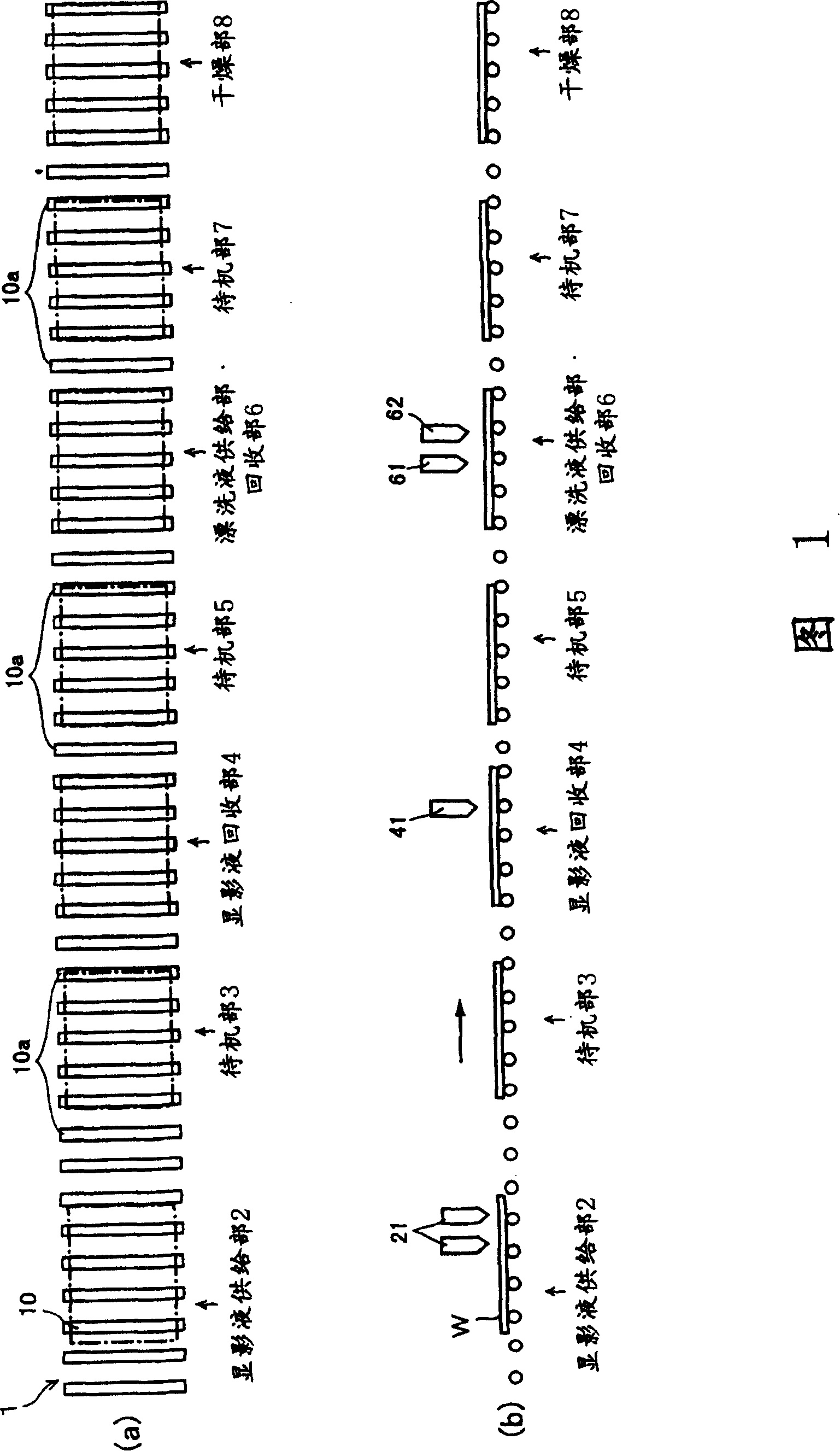

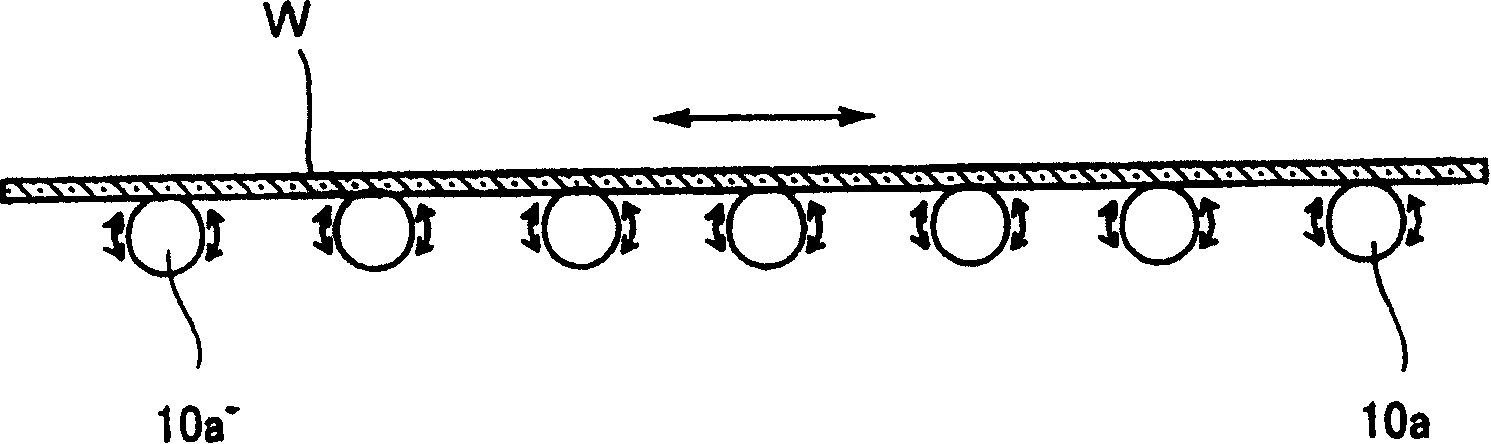

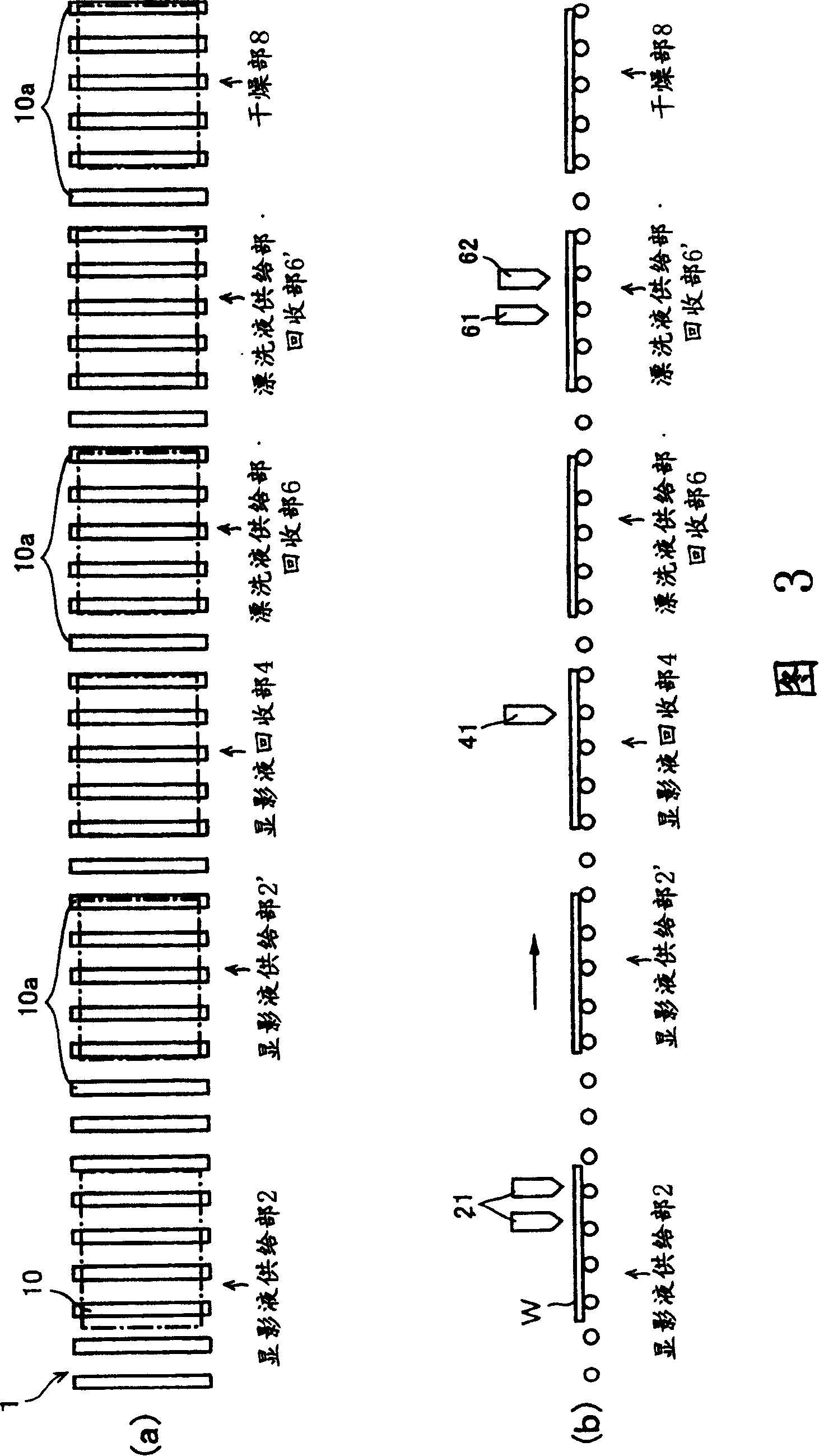

Substrate treating apparatus

ActiveUS6837632B2Efficient substrate transportSmooth trafficLiquid surface applicatorsLiquid processingResistEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Microencapsulated botanical insect-resist agent

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

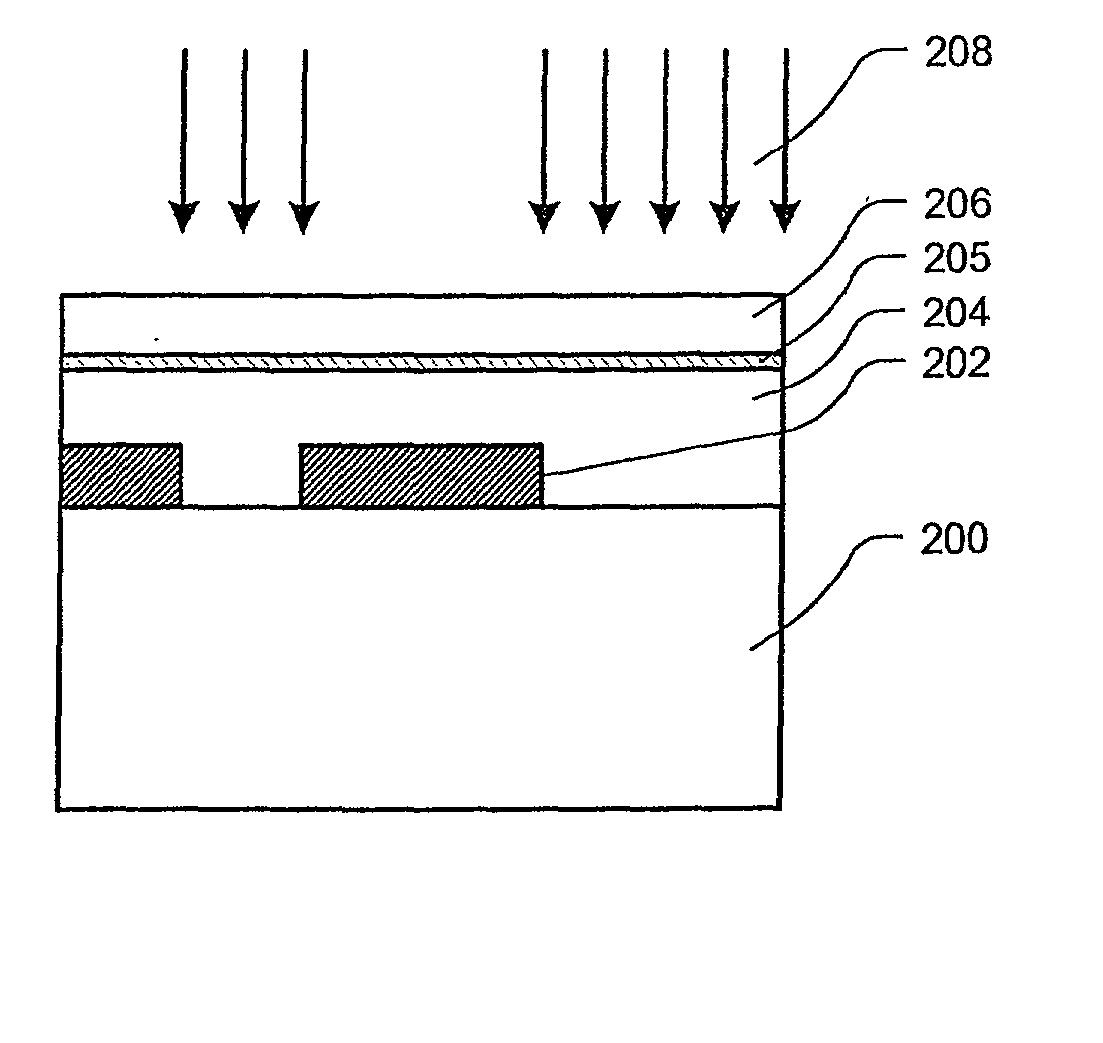

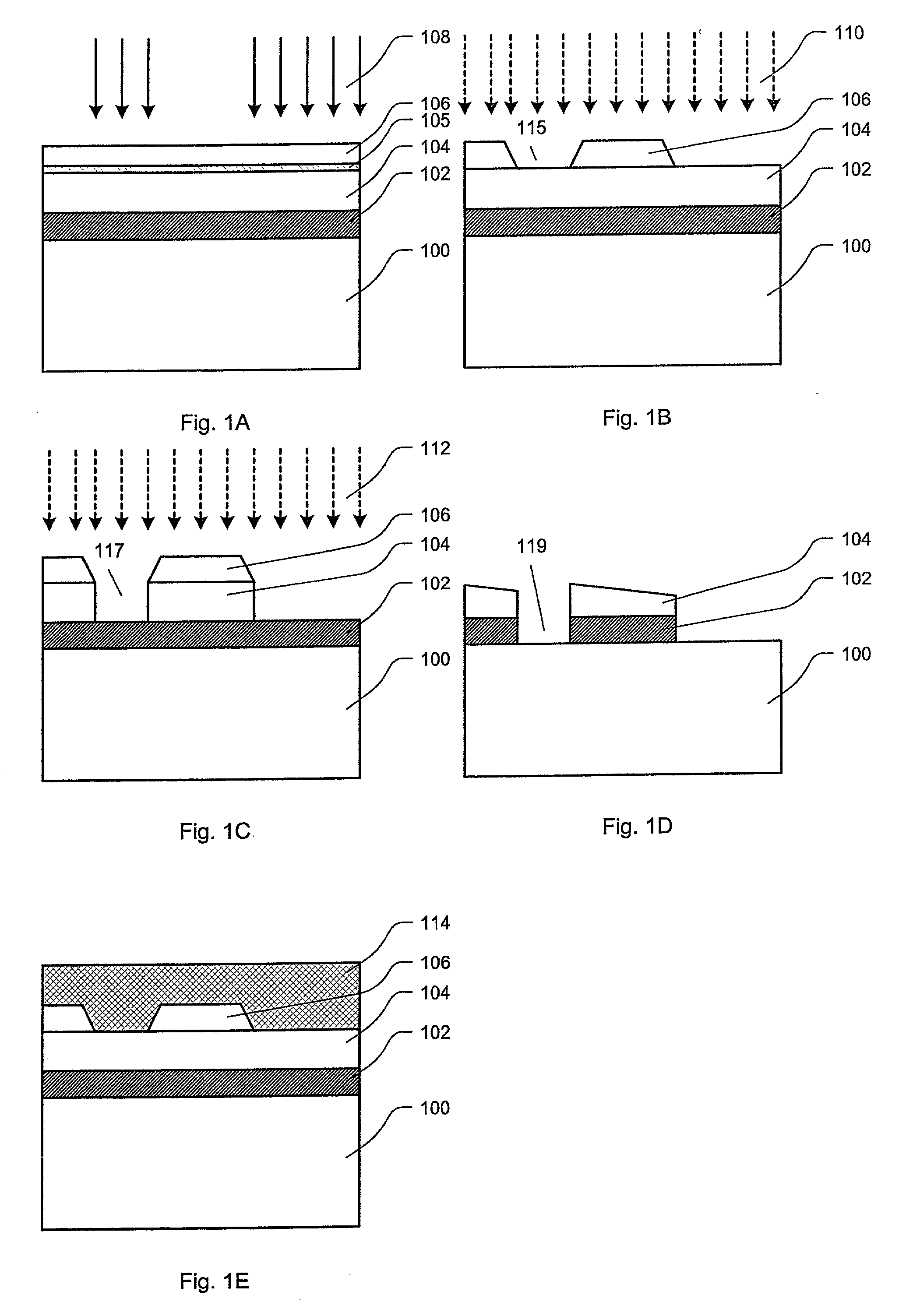

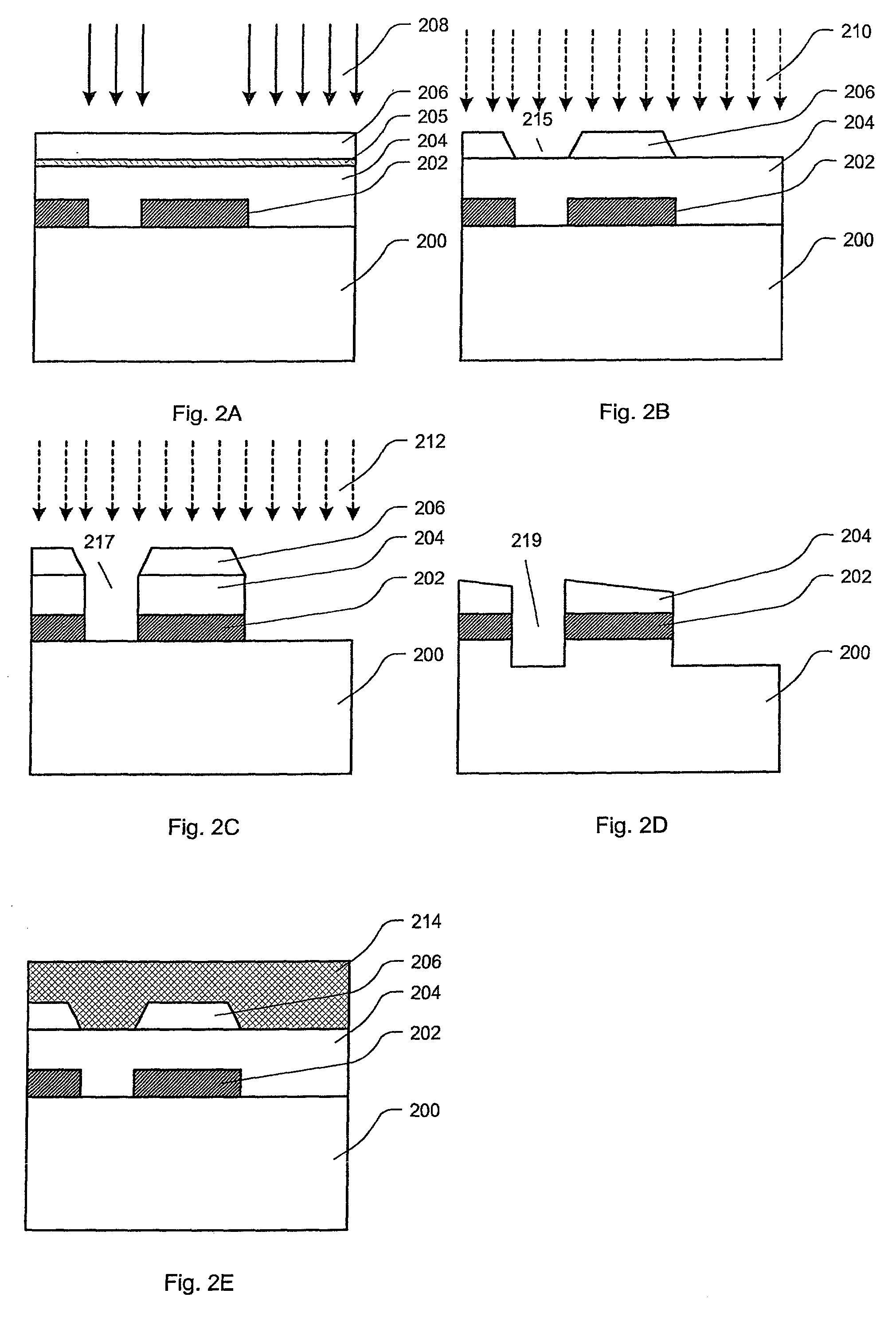

Novel polymer and chemically amplified resist composition containing the same

ActiveUS20050153236A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersSolventResist

Owner:SK MATERIALS PERFORMANCE CO LTD

Dielectric anti-reflective coating surface treatment to prevent defect generation in associated wet clean

InactiveUS7125783B2Reduce silicon contentDensifying layerSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricResist

A method for preventing the formation of watermark defects includes the steps of forming a pad oxide, a silicon nitride layer and a silicon oxynitride layer over a semiconductor substrate. A photoresist mask is formed over the resulting structure, with the silicon oxynitride layer being used as an anti-reflective coating during exposure of the photoresist material. An etch is performed through the photoresist mask, thereby forming a trench in the substrate. The photoresist mask is stripped, and the silicon oxynitride layer is conditioned. For example, the silicon oxynitride layer may be conditioned by a rapid thermal anneal in the presence of oxygen or nitrogen. A wet clean step is subsequently performed to remove a native oxide layer in the trench. The conditioned silicon oxynitride layer prevents the formation of watermarks during the wet clean process.

Owner:INTEGRATED DEVICE TECH INC

Dual layer reticle blank and manufacturing process

Owner:ASML NETHERLANDS BV

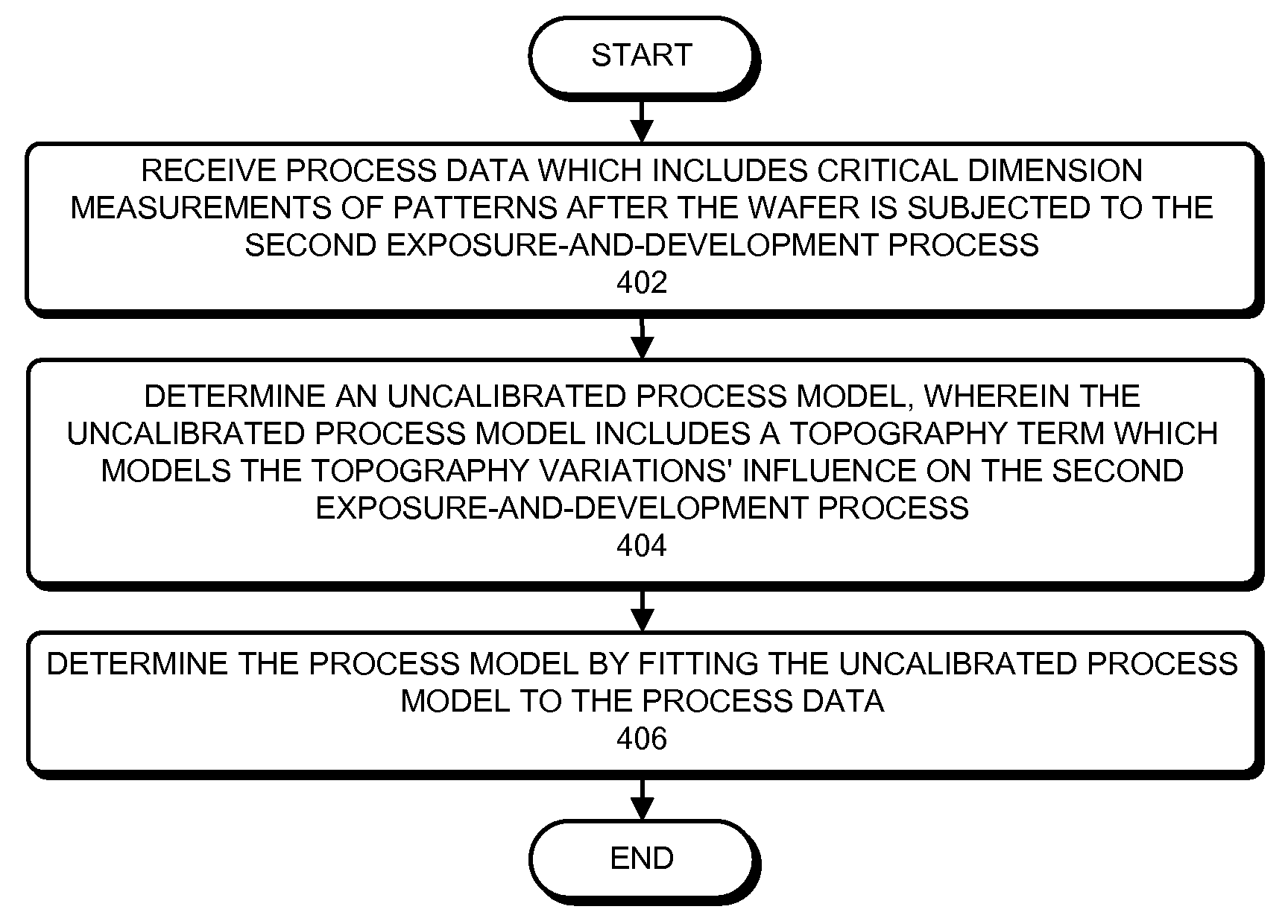

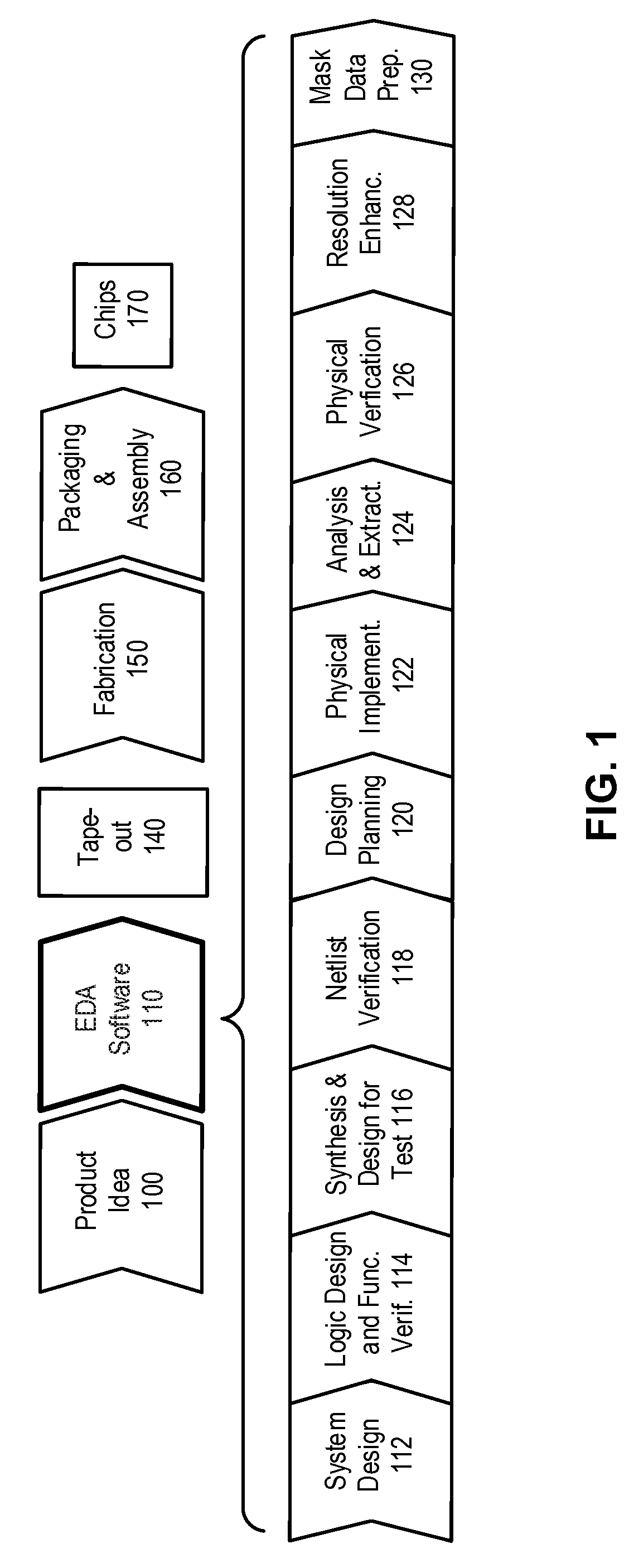

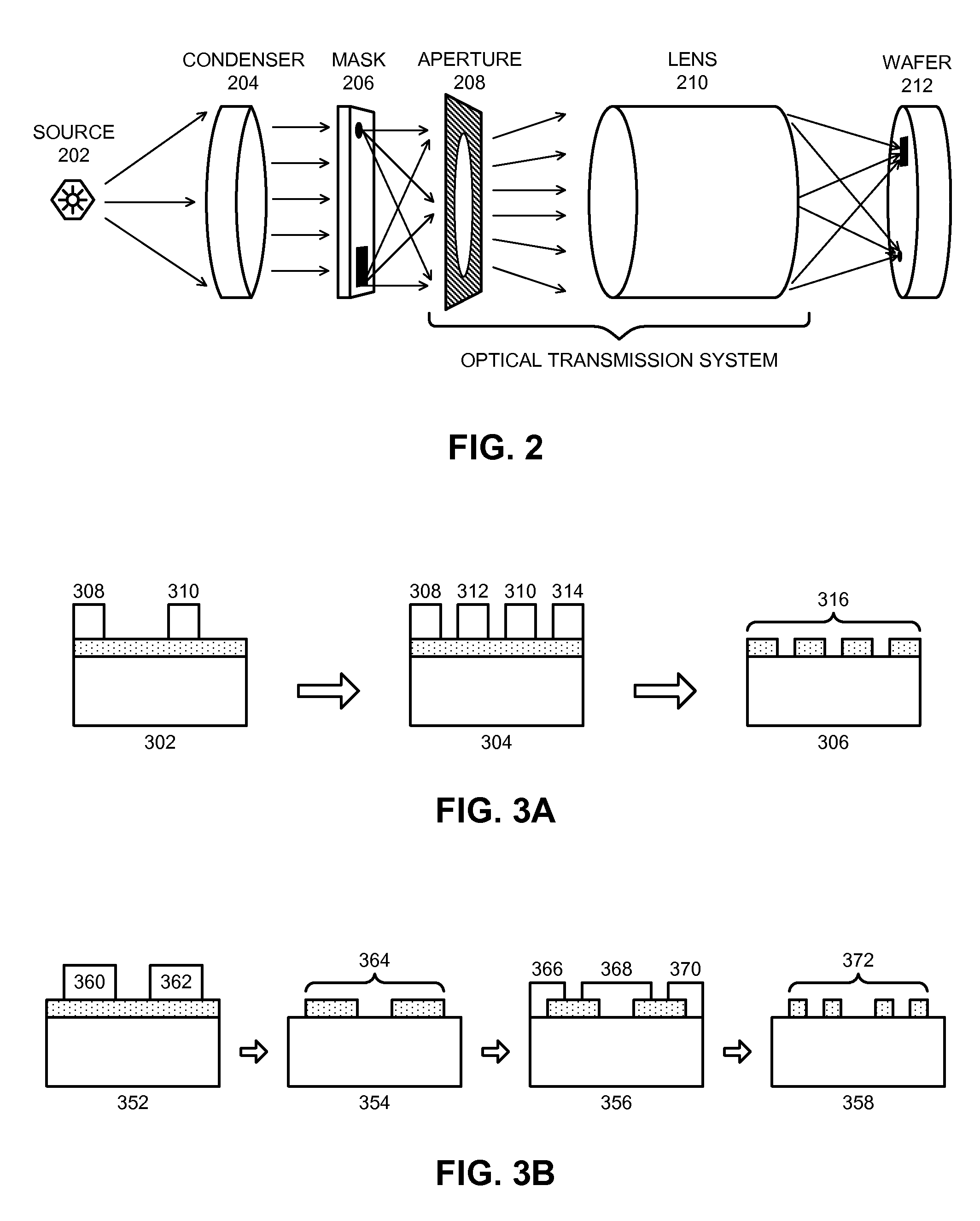

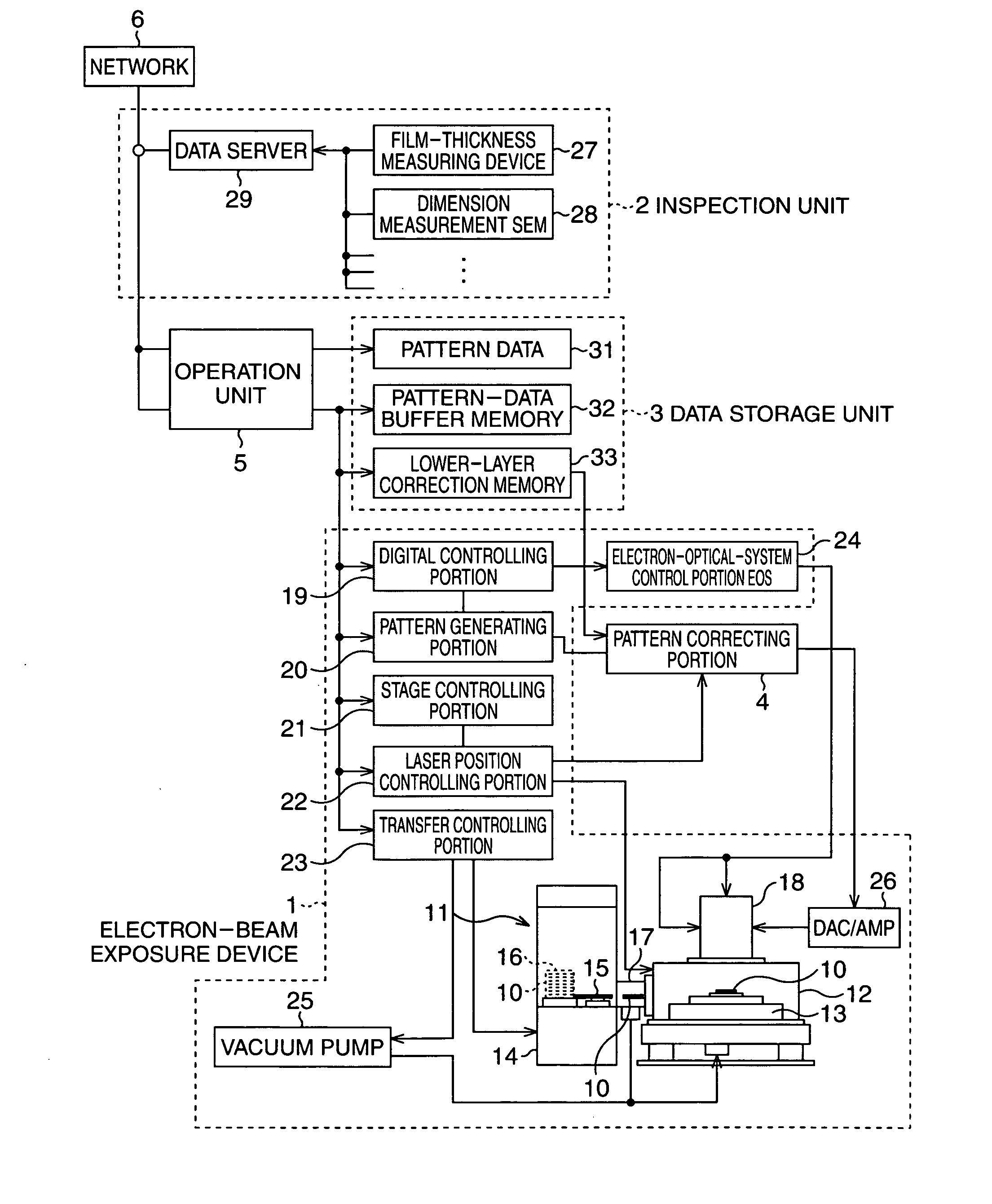

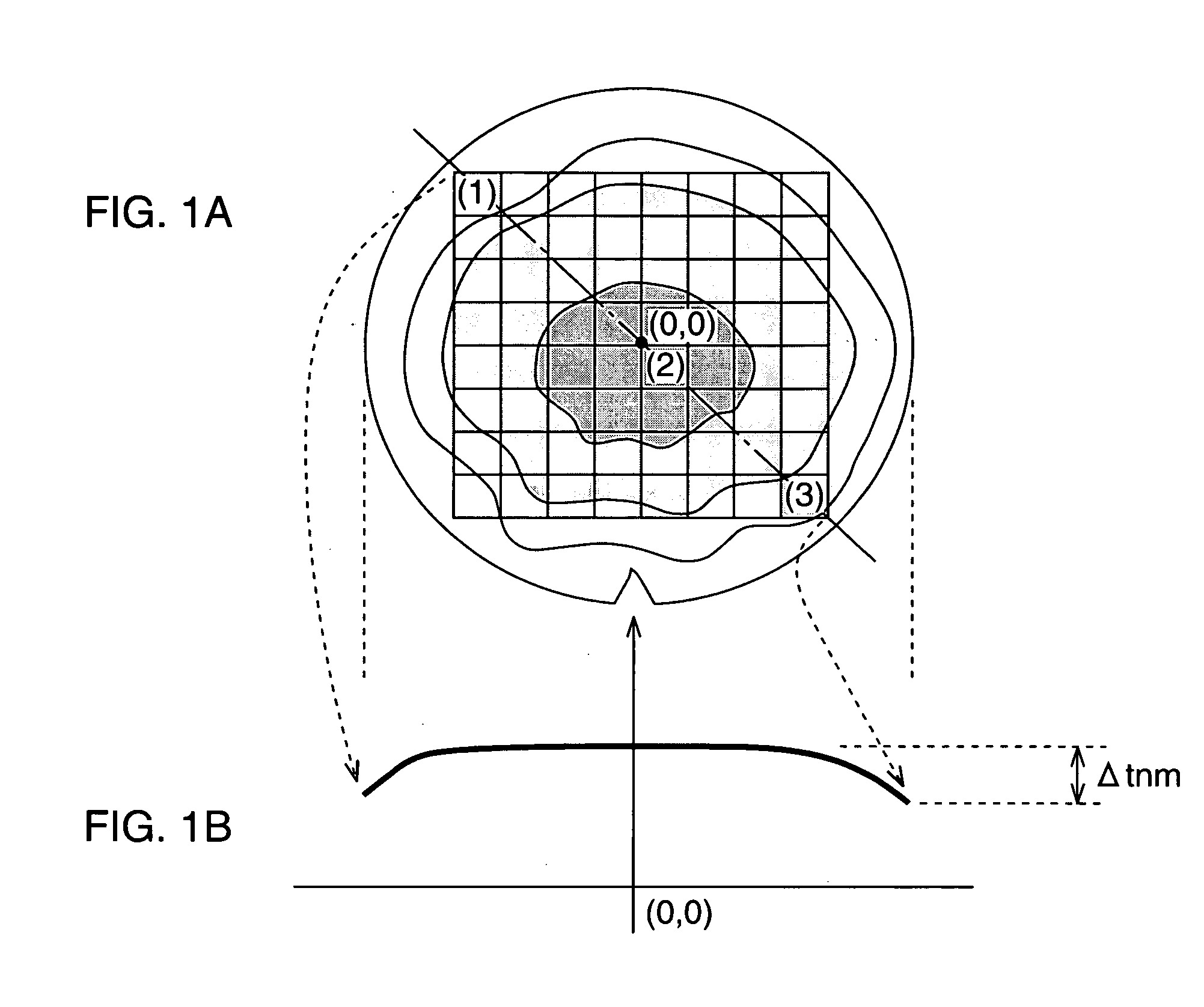

Method and apparatus for determining a photolithography process model which models the influence of topography variations

ActiveUS20100095264A1Accurate imagingImprove accuracyComputer programmed simultaneously with data introductionOriginals for photomechanical treatmentResistEngineering

Owner:SYNOPSYS INC

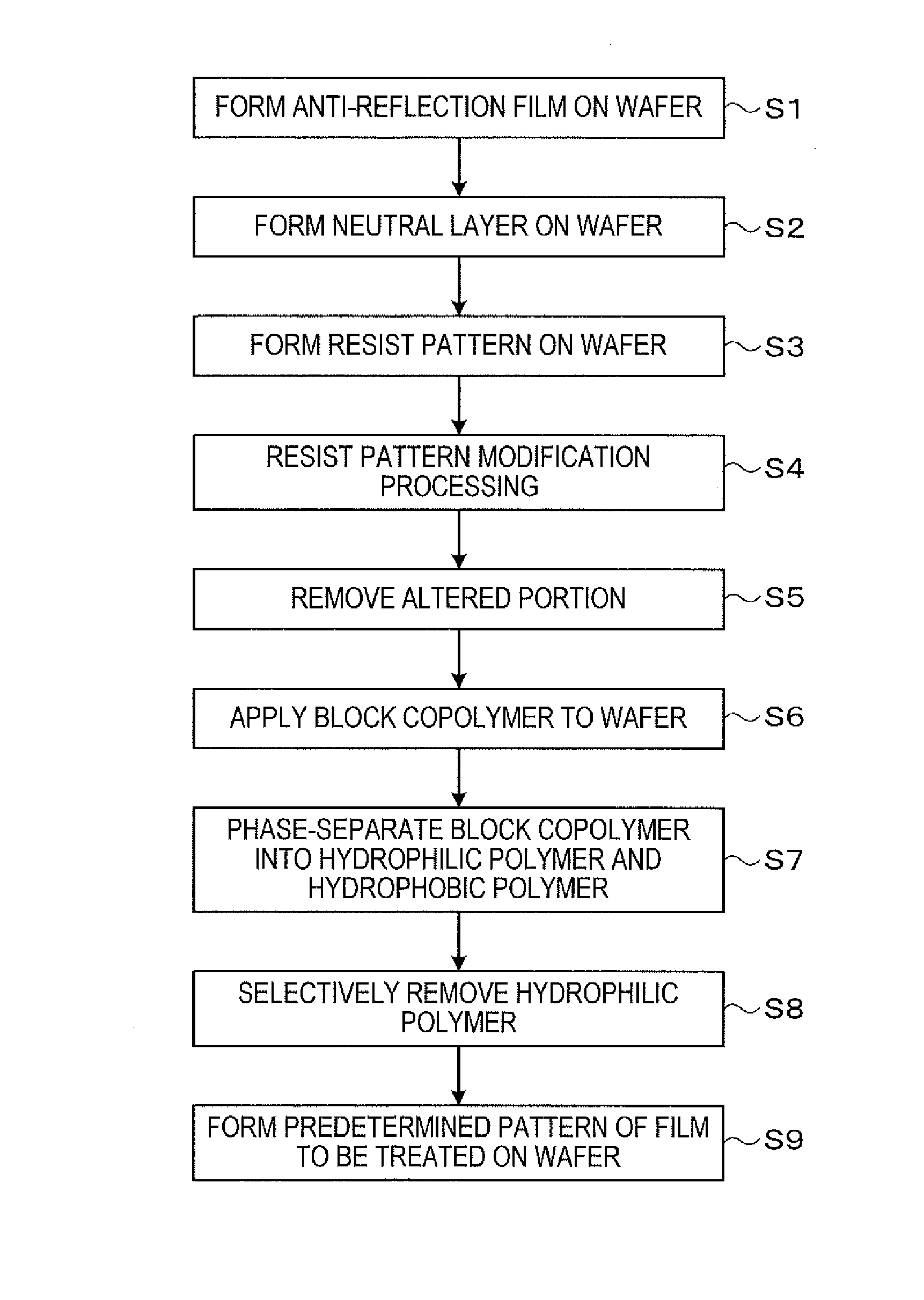

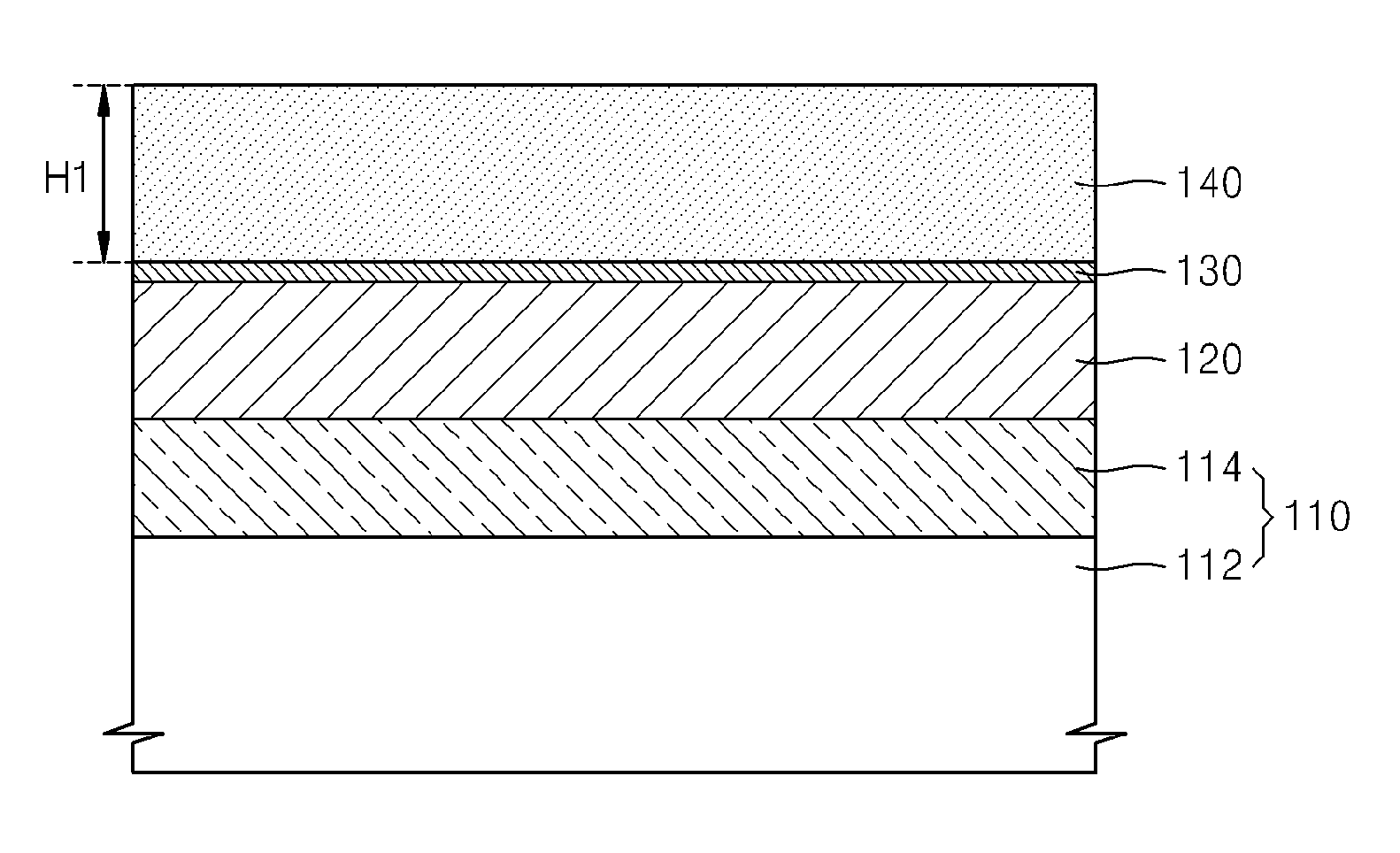

Substrate treatment method, computer storage medium, and substrate treatment system

ActiveUS20150255271A1Electric discharge tubesSemiconductor/solid-state device manufacturingResistHydrophilic polymers

Owner:TOKYO ELECTRON LTD

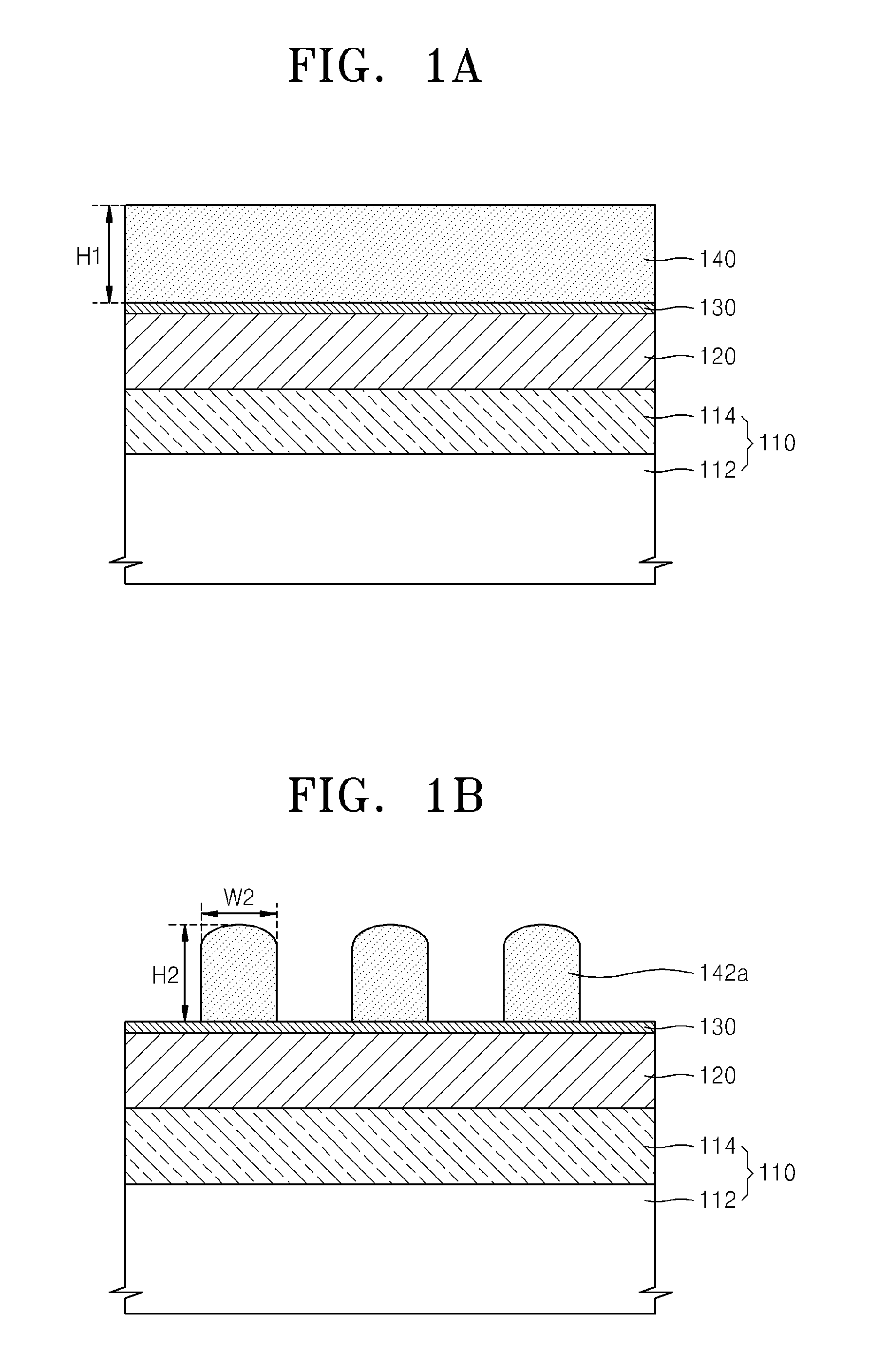

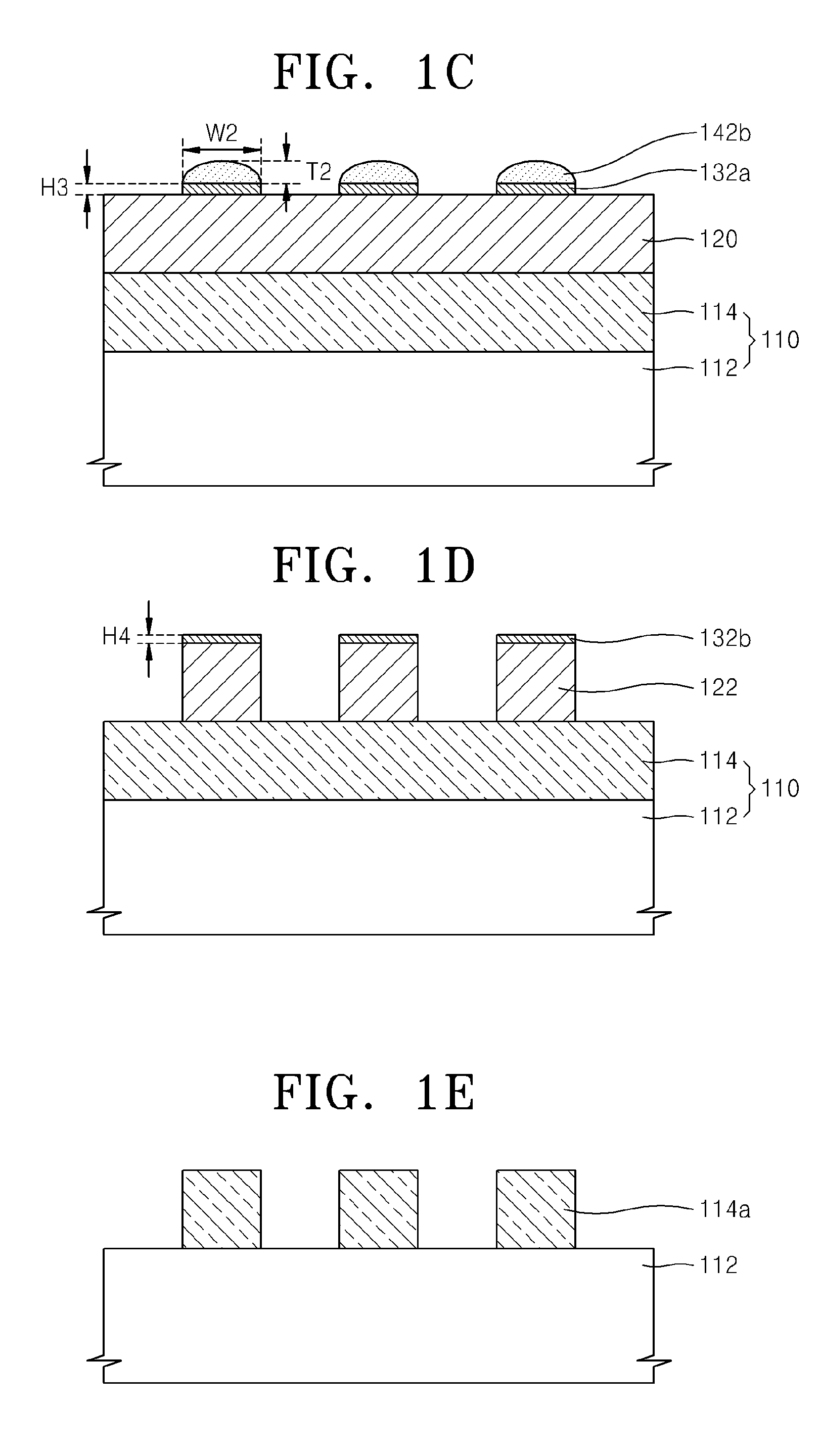

Methods of forming fine patterns and methods of fabricating semiconductor devices

Owner:SAMSUNG ELECTRONICS CO LTD

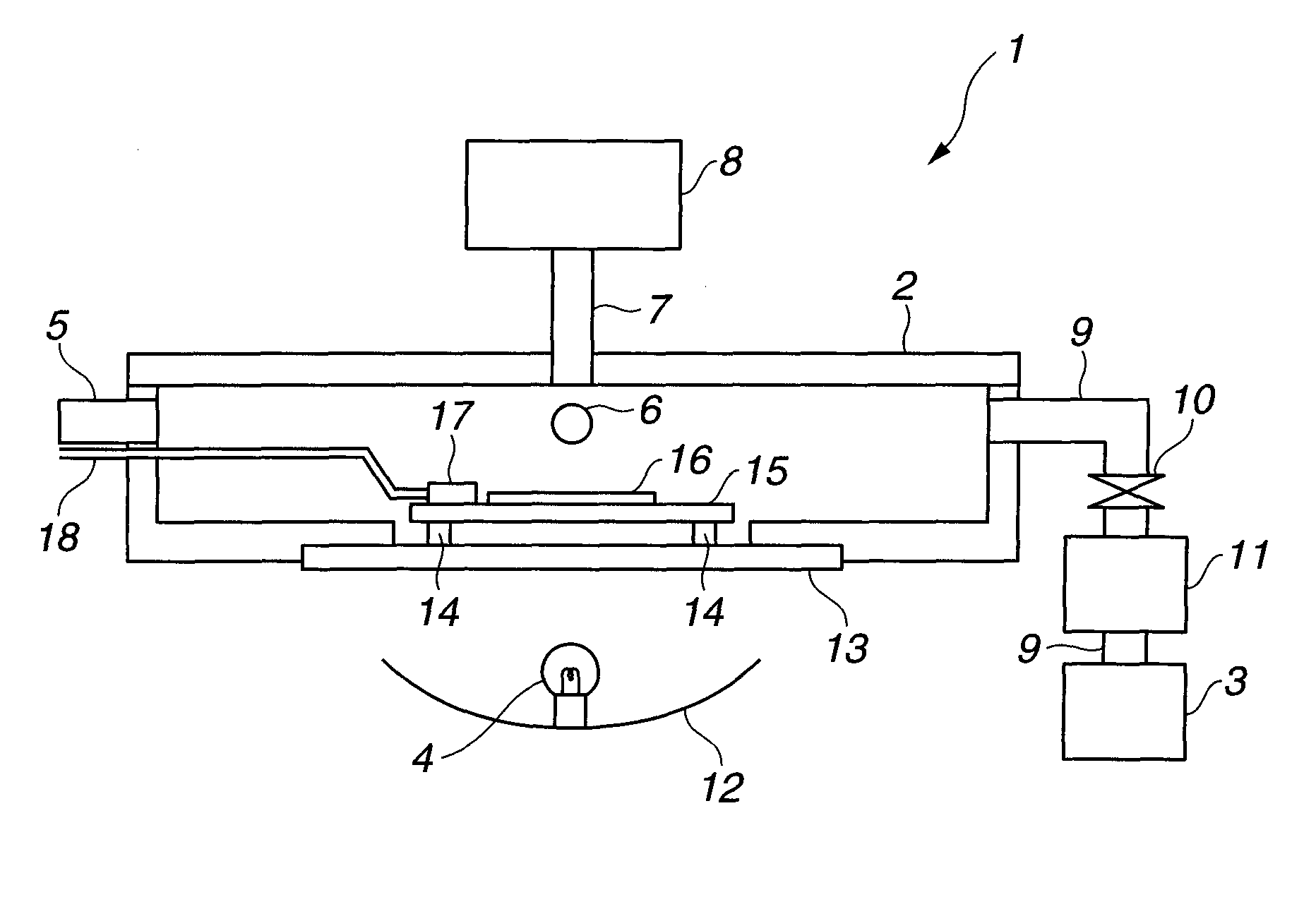

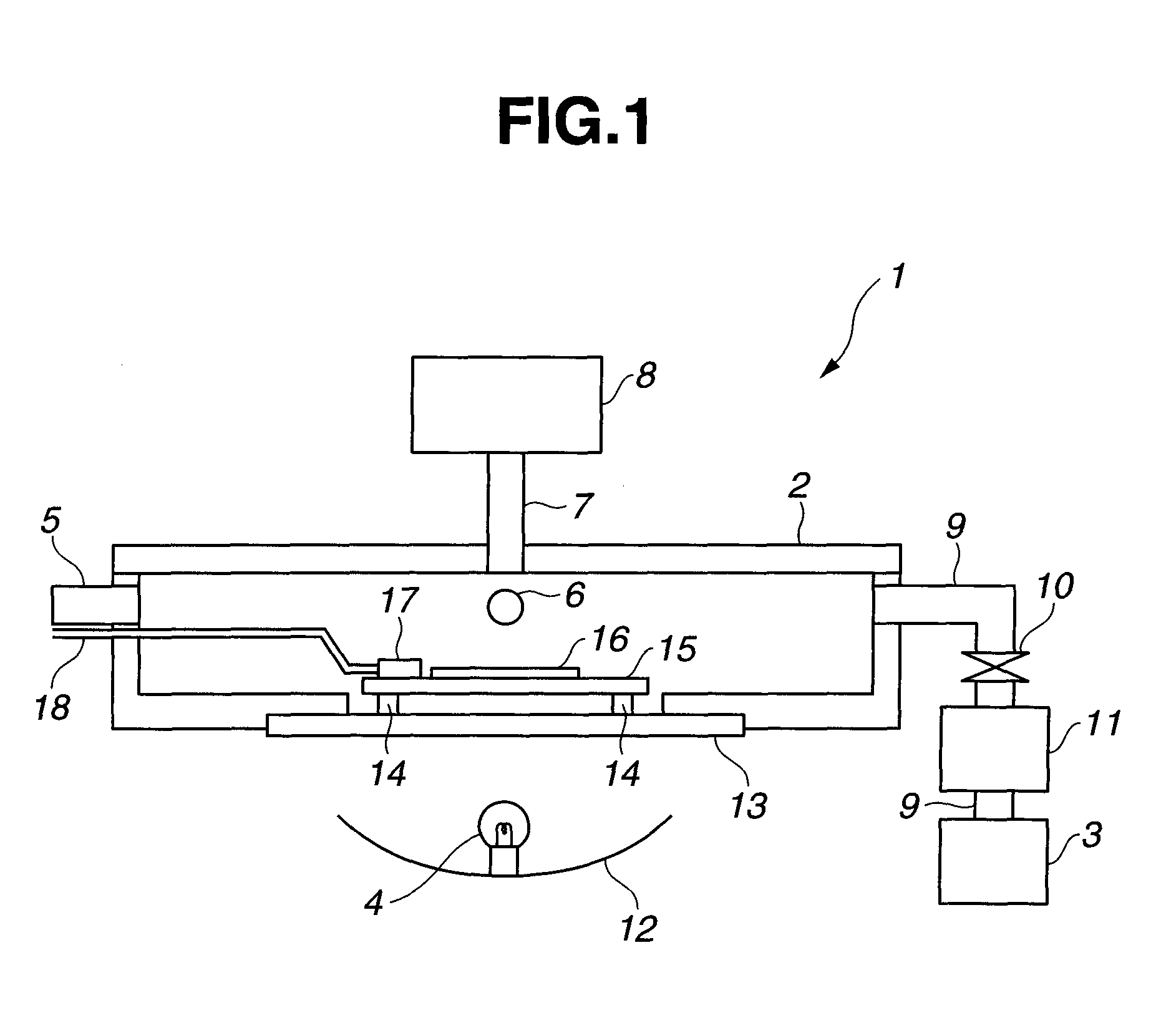

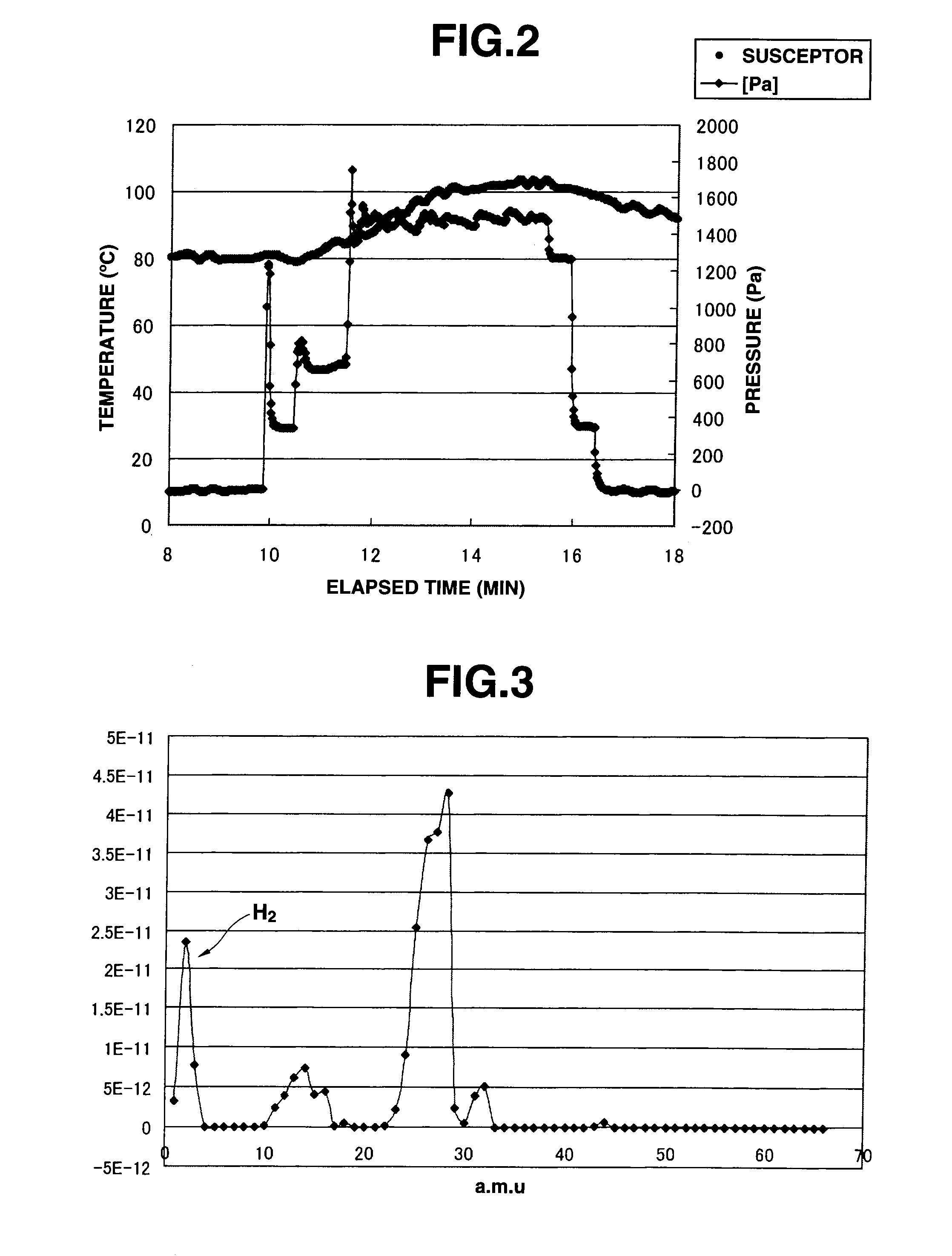

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

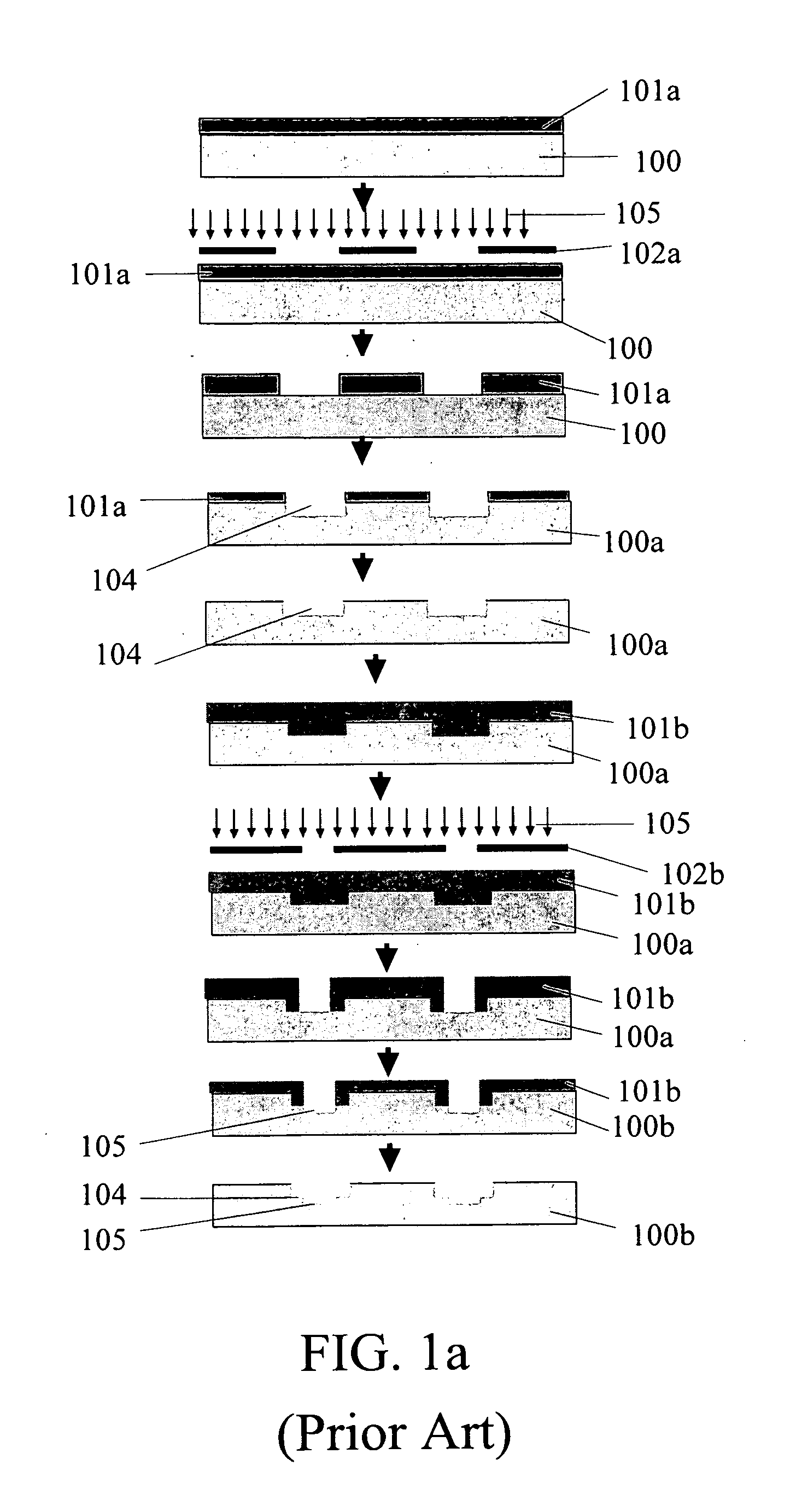

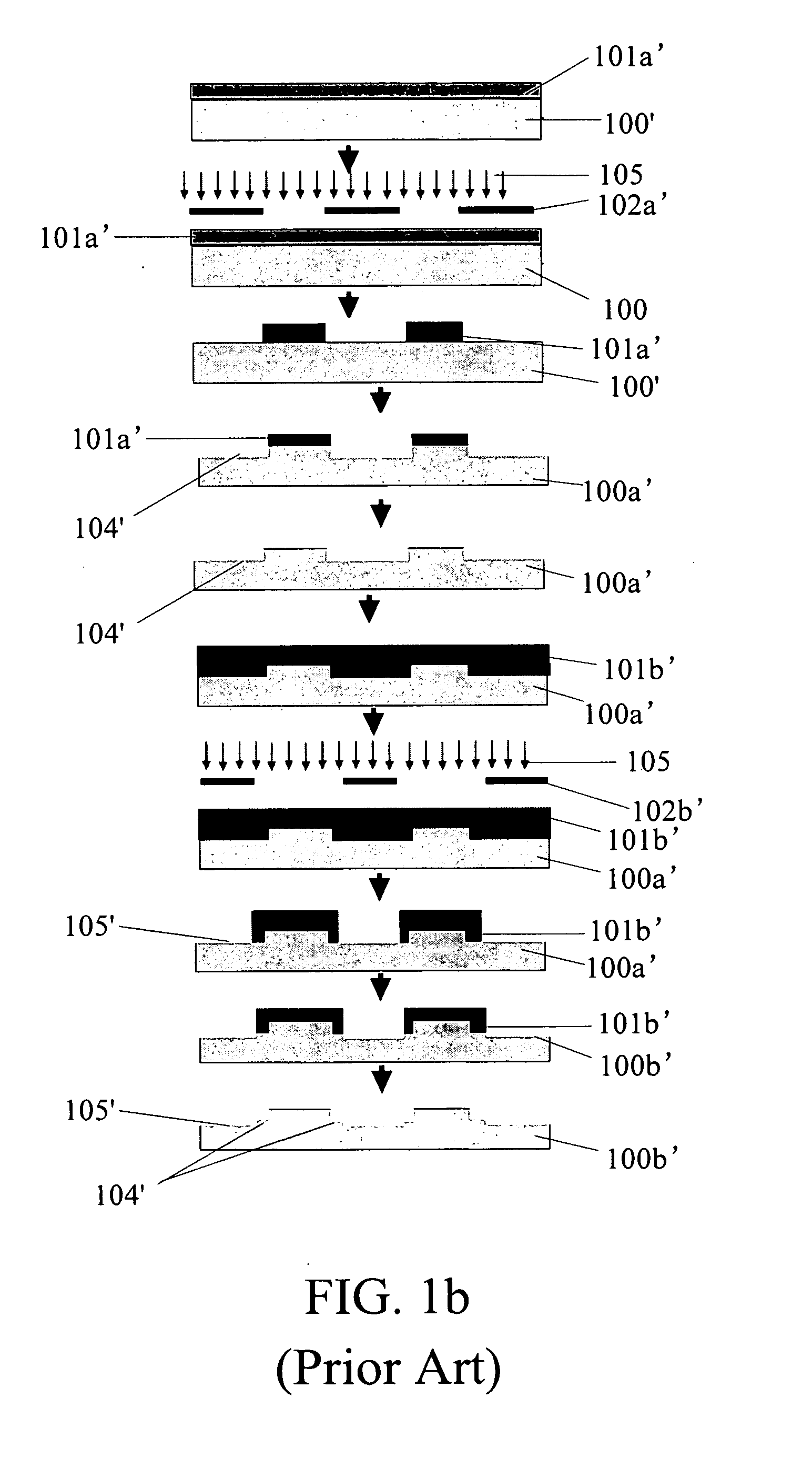

Etching method for forming a multi-step surface on a substrate

InactiveUS20100003621A1Issue time alleviatedSimple manufacturing processSemiconductor/solid-state device manufacturingRecord information storageResistPhysics

Owner:SAE MAGNETICS (HK) LTD

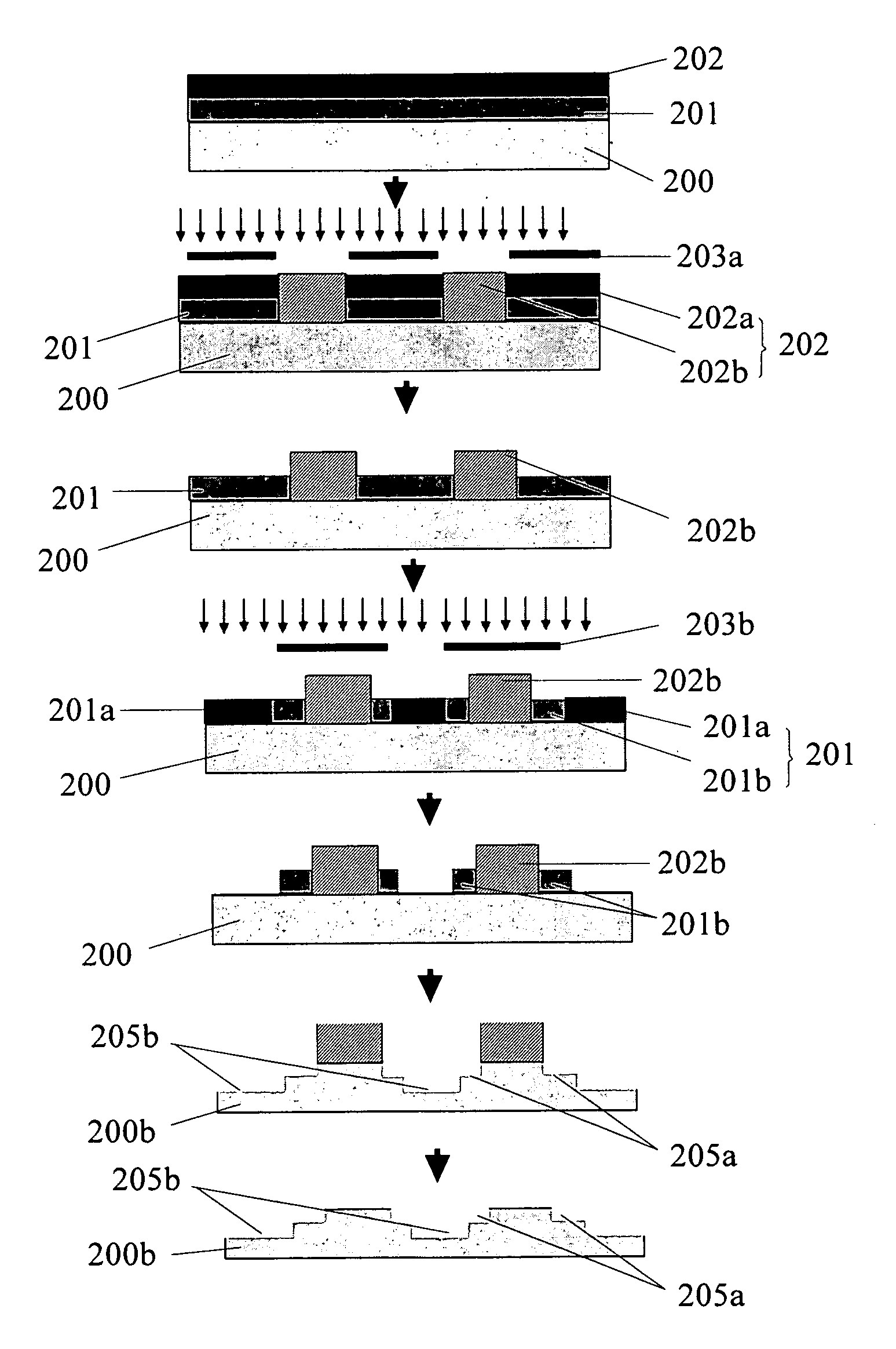

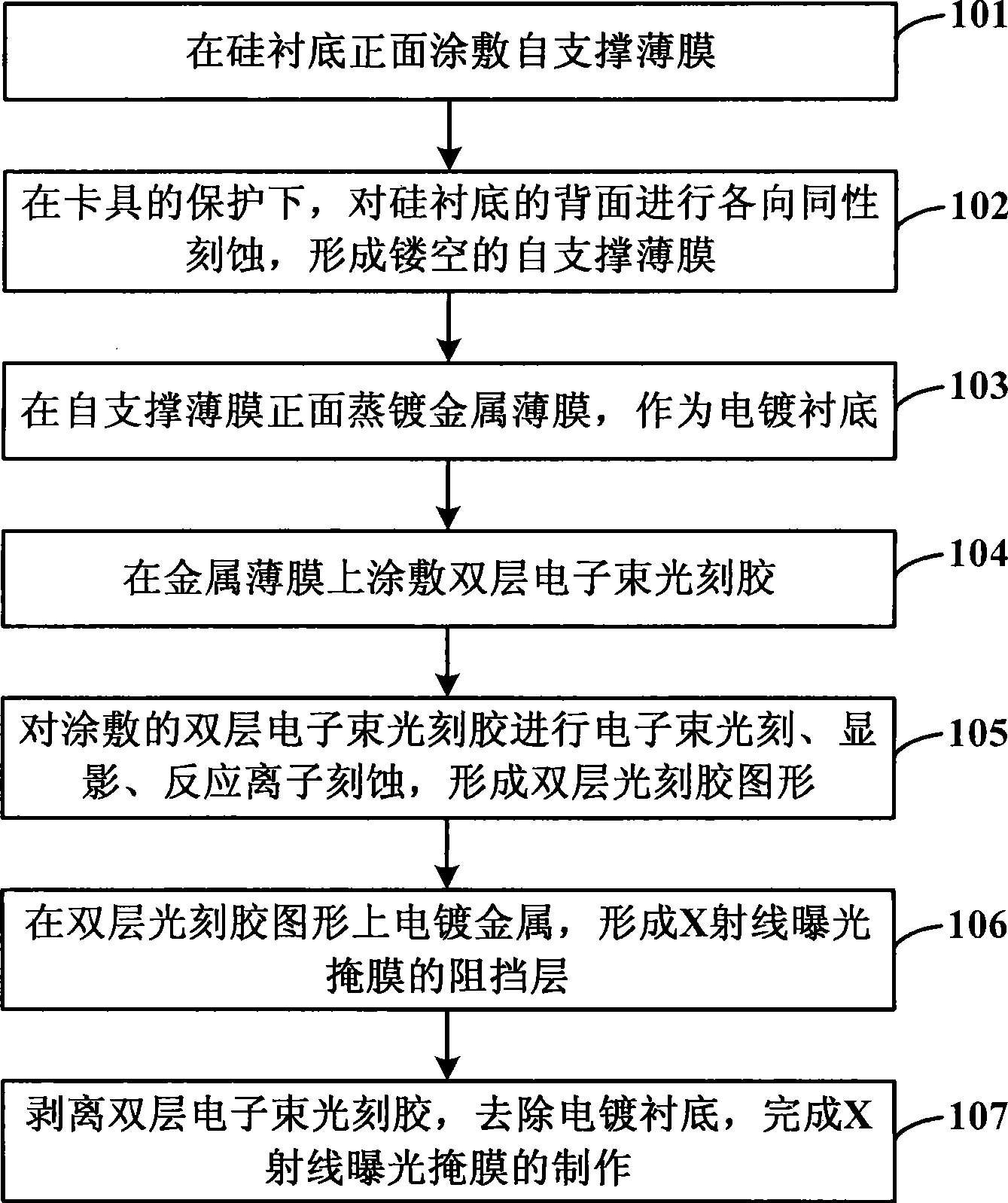

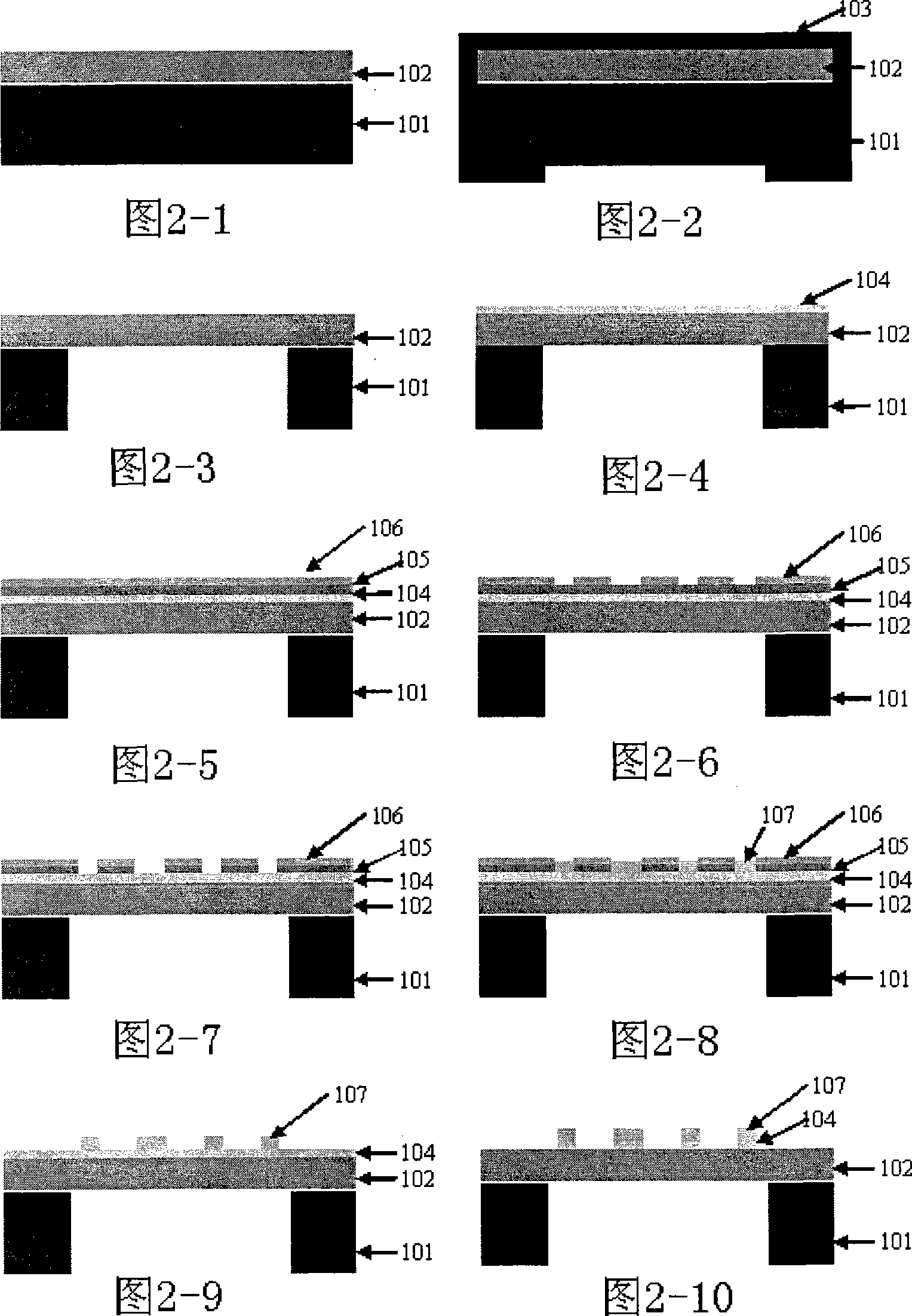

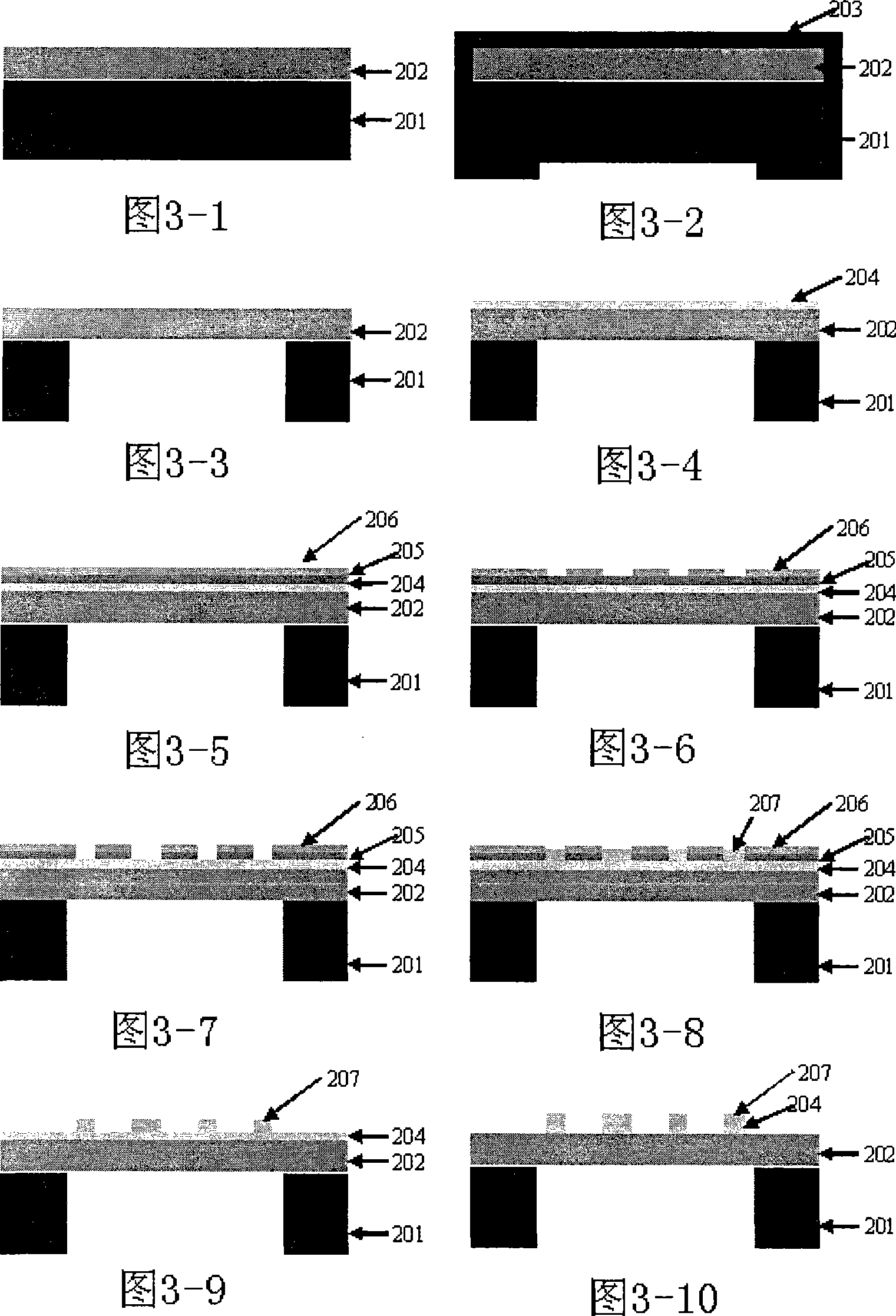

Method for producing X ray exposure mask based on double-layer gum process

InactiveCN101452203ASemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistElectron beam resist

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

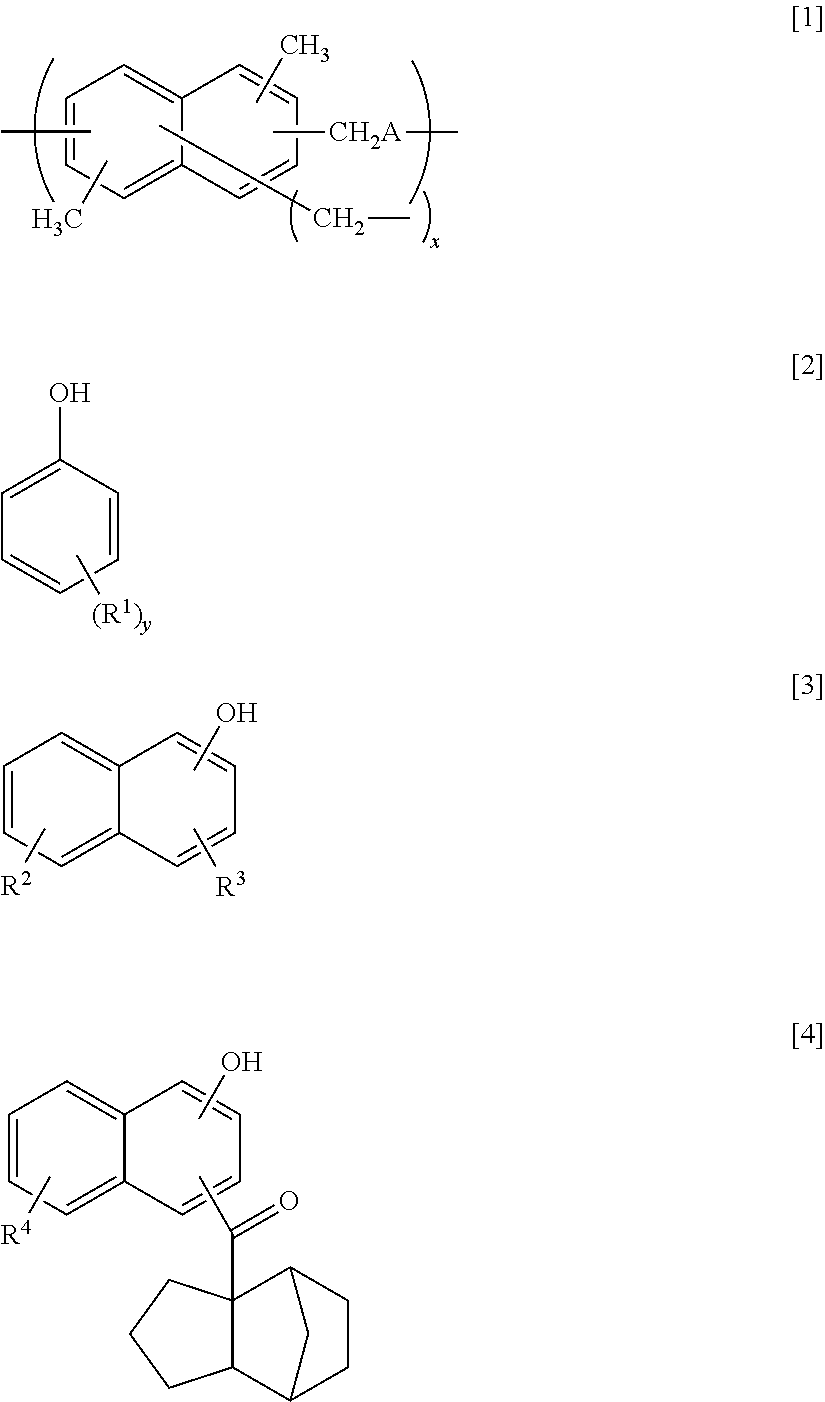

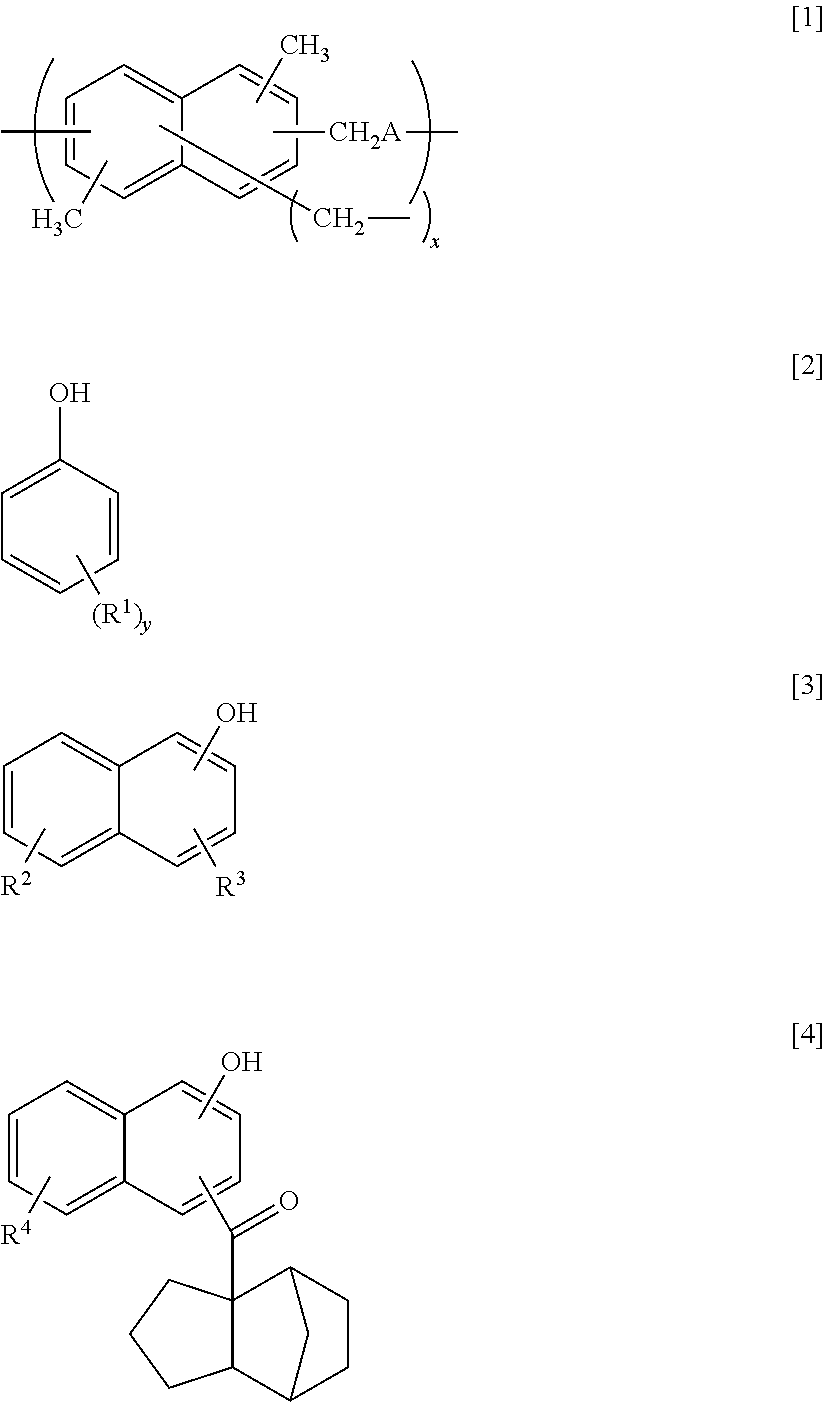

Modified naphthalene formaldehyde resin, tricyclodecane skeleton-containing naphthol compound and ester compound

ActiveUS20110009574A1Improve heat resistancePreparation from carboxylic acid halidesOrganic compound preparationFiberResist

Owner:MITSUBISHI GAS CHEM CO INC

Horn shaped contact production method

InactiveCN101295665APrevent proliferationSemiconductor/solid-state device manufacturingResistMetal silicide

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method of forming an etch mask

ActiveUS20130071790A1Simple methodElectric discharge tubesSemiconductor/solid-state device manufacturingResistSolvent

Owner:NAN YA TECH

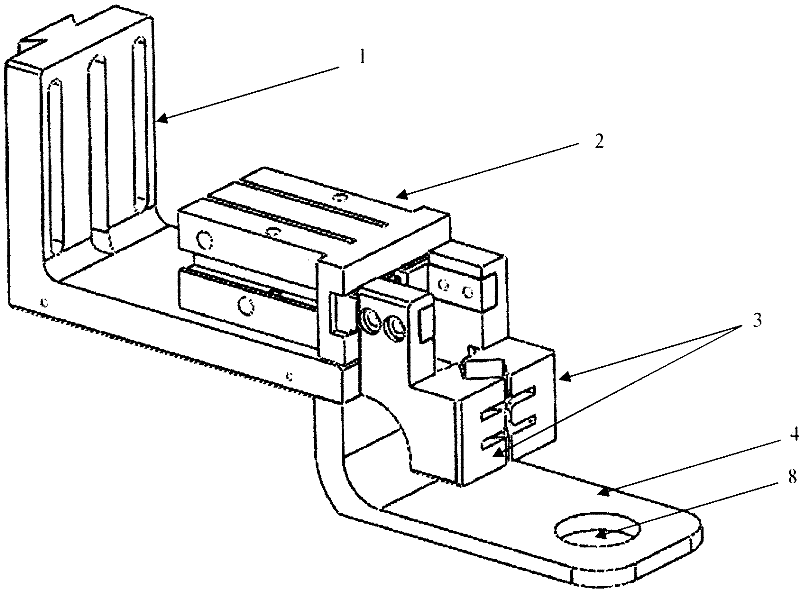

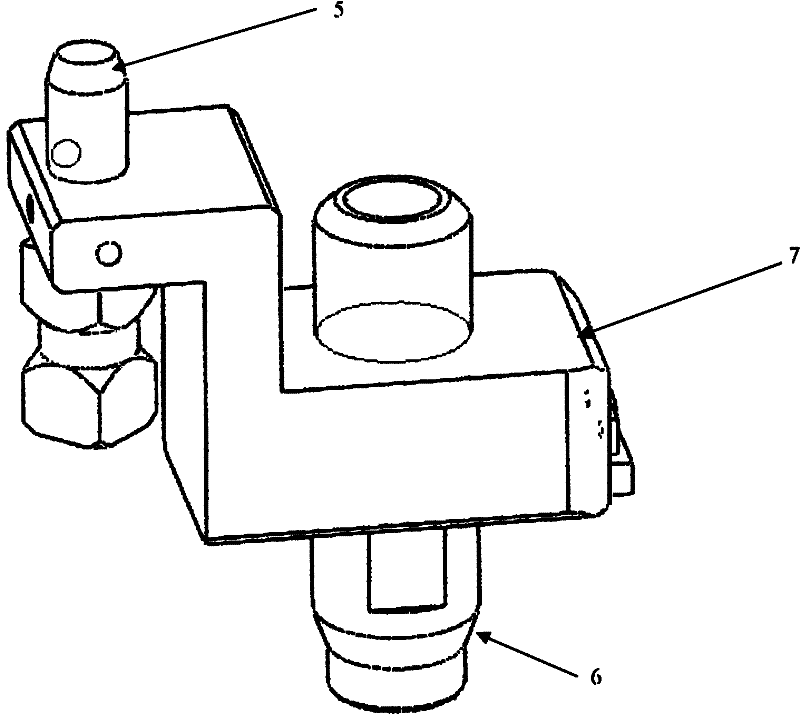

Photoresist nozzle replacement auxiliary positioning semi-automatic fixture

Owner:SHENYANG KINGSEMI CO LTD

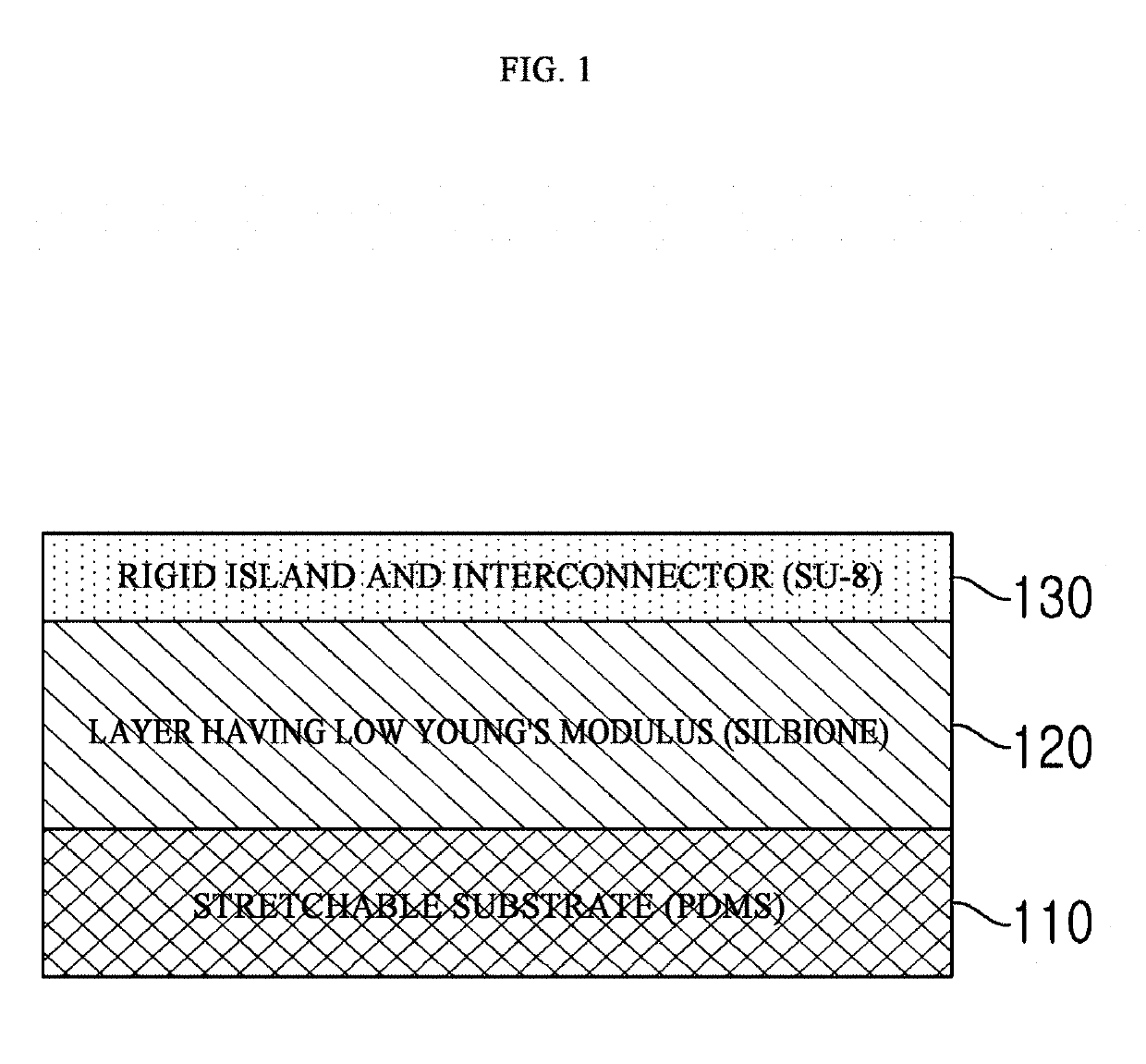

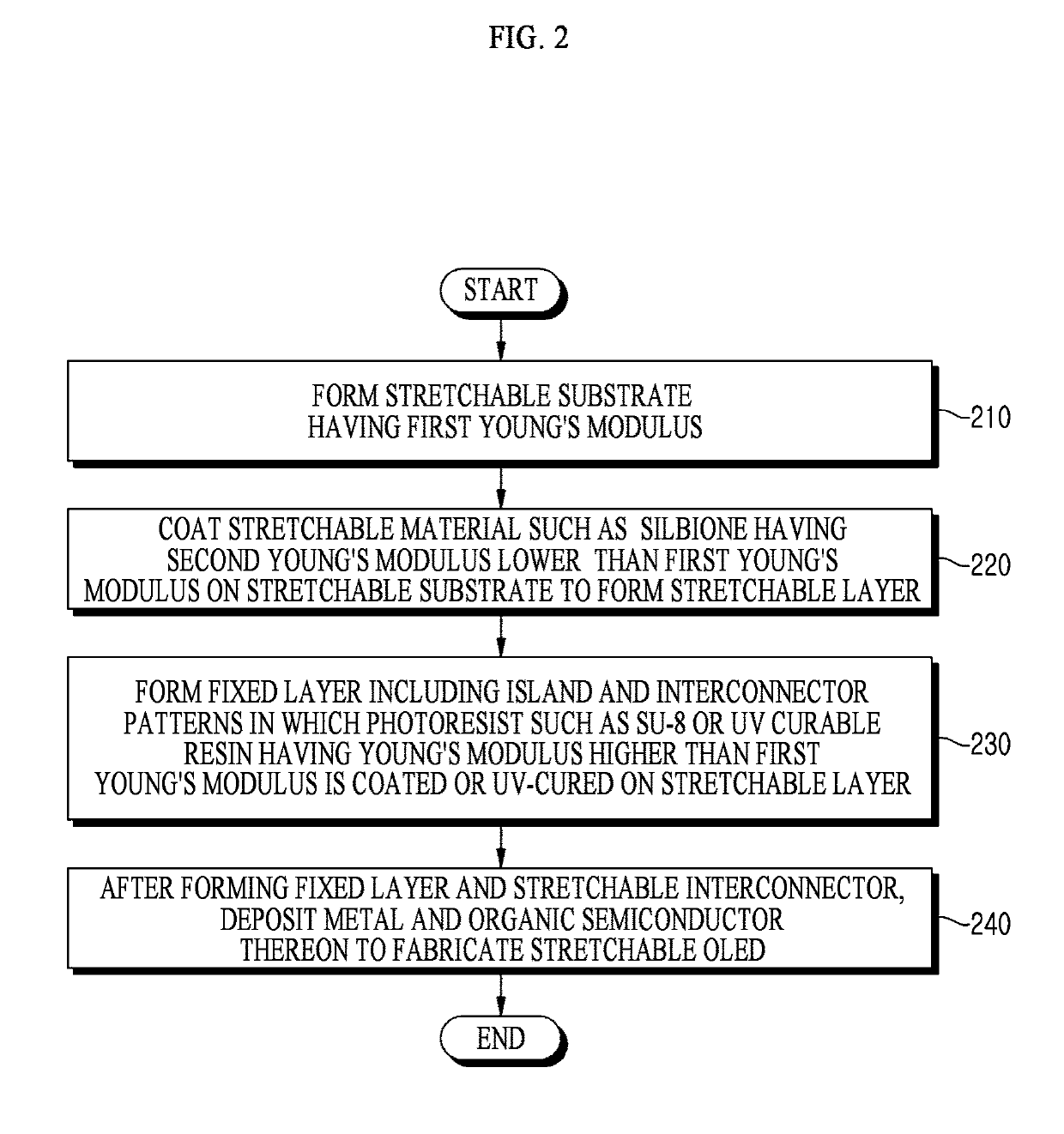

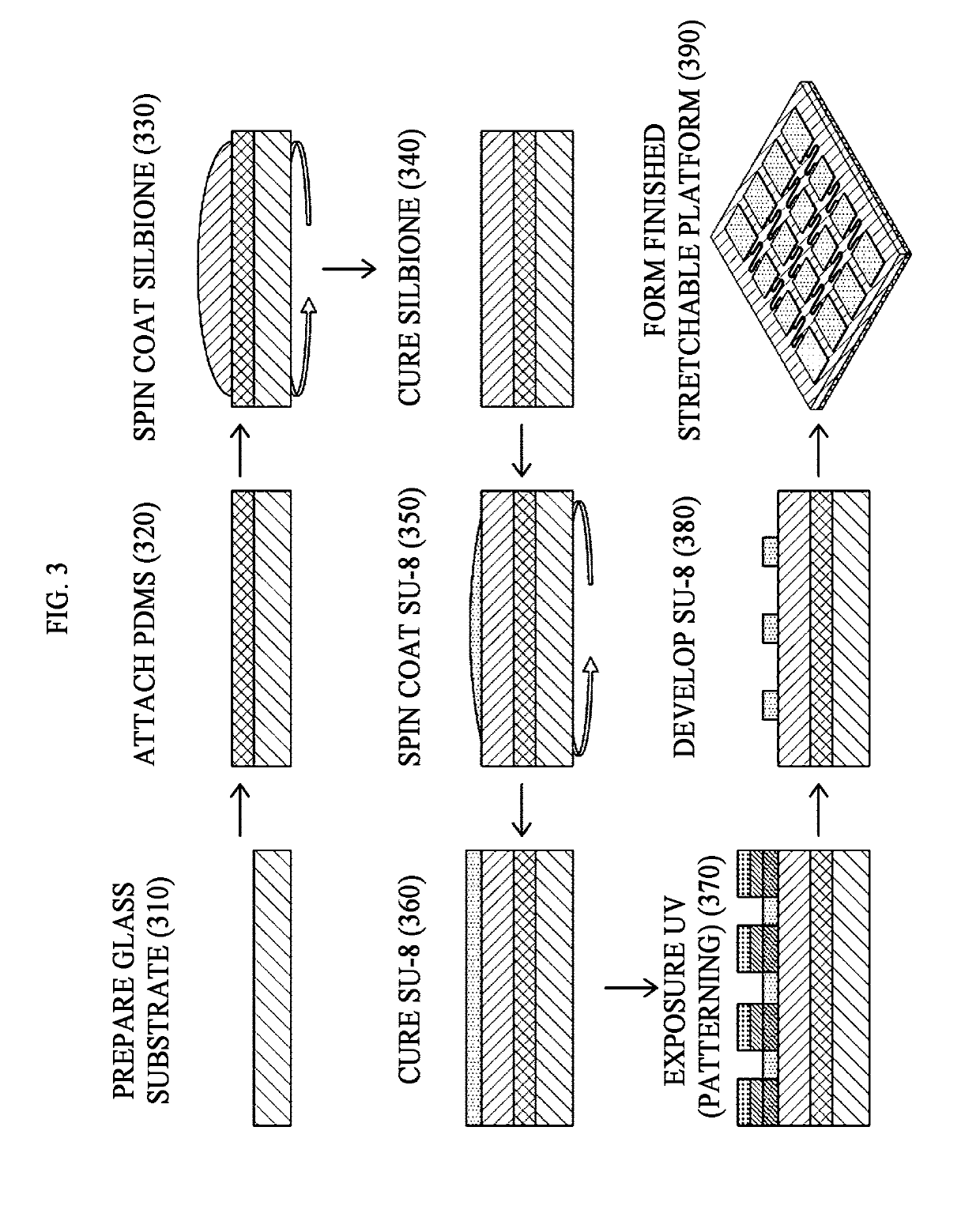

Method of fabricating rigid island pattern on stretchable layer with low young's modulus and stretchable electronic device platform using the same

ActiveUS20190305233A1Simplify the manufacturing processEnsuring stretchabilityCircuit bendability/stretchabilityFinal product manufactureStretchable electronicsResist

Owner:KOREA ADVANCED INST OF SCI & TECH

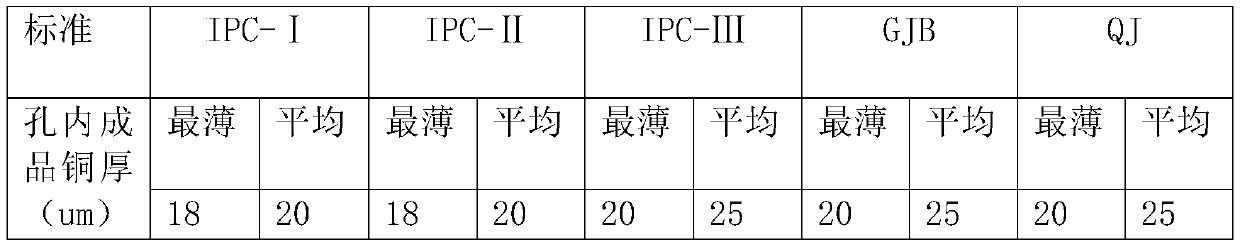

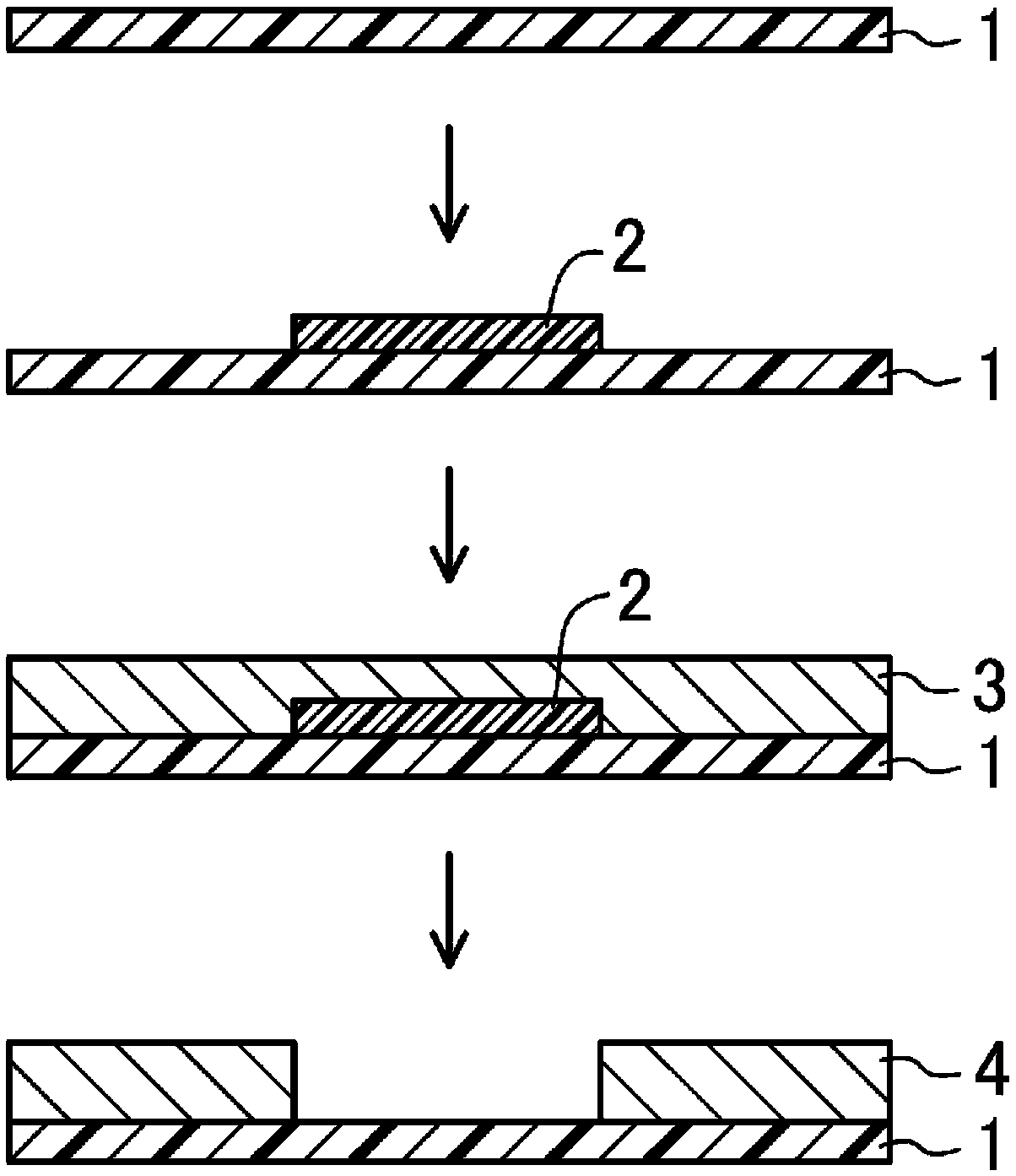

Manufacturing method of printed circuit board solder-resist plug hole structure, and printed circuit board

ActiveCN105451437AAvoid short circuitElectrical connection printed elementsPrinted element electric connection formationResistTime condition

The embodiment of the invention discloses a manufacturing method of a printed circuit board solder-resist plug hole structure, and a printed circuit board. The manufacturing method comprises the steps of: acquiring the printed circuit board after completing inner layer graph manufacturing and press-fit operation, and forming a via hole in a solder-resist region on an outer layer copper foil of the printed circuit board; filling the via hole with solder-resist ink after plating a metal layer on the hole wall of the via hole; baking the via hole filled with the solder-resist ink in a segmented manner for curing under preset temperature and time conditions; forming openings in portholes on both ends of the via hole filled with the solder-resist ink; and printing resin at the portholes on both ends of the via hole. The manufacturing method can solve the problems of open circuit of dense lines and open circuit of the via hole due to inexistence of metal therein.

Owner:SHENNAN CIRCUITS

Poly(hydroxystyrene) stain resist

Owner:EI DU PONT DE NEMOURS & CO

Polysiloxane, method of manufacturing same, silicon-containing alicyclic compound, and radiation-sensitive resin composition

InactiveUS6846895B2Silicon organic compoundsPhotosensitive materials for photomechanical apparatusResistHalogen

A novel polysiloxane having the following structural units (I) and / or (II) and the structural unit (III), wherein A1 and A2 are an acid-dissociable monovalent organic group, R1 is hydrogen, monovalent (halogenated) hydrocarbon, halogen, or amino, R2 is monovalent (halogenated) hydrocarbon group, or halogen. A method of preparing such a polysiloxane, a silicon-containing alicyclic compound providing this polysiloxane, and a radiation-sensitive resin composition comprising this polysiloxane are also provided. The polysiloxane is useful as a resin component for a resist material, effectively senses radiation with a short wavelength, exhibits high transparency to radiation and superior dry etching properties, and excels in basic resist properties required for resist materials such as high sensitivity, resolution, developability, etc.

Owner:JSR CORPORATIOON

Exposure system, exposure method and semiconductor device manufacturing method

InactiveUS20070070314A1Easy to integrateMinimal restrictionElectric discharge tubesRadiation applicationsResistIn plane

Owner:FUJITSU SEMICON LTD

Bacteriostatic foot powder and preparation method thereof

InactiveCN106619519AMild performanceEffective treatmentPowder deliveryCosmetic preparationsResistAllergy

Owner:叶宗瑞

Methods and apparatus for the optimization of photo resist etching in a plasma processing system

InactiveUS6949469B1Minimize the differenceSemiconductor/solid-state device manufacturingResistFluorine containing

In a plasma processing system, a method of minimizing the differences in an etch rate of a photo resist material in different regions of a substrate is disclosed. The method includes introducing the substrate having in sequential order thereon, an underlying layer and the photo-resist layer. The method also includes flowing the etchant gas mixture into a plasma reactor of the plasma processing system, the etchant gas mixture comprising a flow of a fluorine containing gas between about 0.1% and about 10% of the etchant gas mixture. The method further includes striking a plasma from the gas mixture; etching the photo-resist layer with the plasma; and, removing the substrate from the plasma reactor.

Owner:LAM RES CORP

Stitch crease-resist device for sewing machine

Owner:SUZHOU JUKANG SEWING ROBOT

Photoresist remover composition and method for removing photoresist

ActiveCN102124414AImprove corrosion resistanceExcellent resist stripping performanceSemiconductor/solid-state device manufacturingPhotosensitive material processingResistOrganic solvent

Owner:NAGASE CHEMTEX CORPORATION

Single-line arrangement development processing apparatus

InactiveCN100405544CSemiconductor/solid-state device manufacturingPhotosensitive material processingResistEngineering

Owner:TOKYO OHKA KOGYO CO LTD

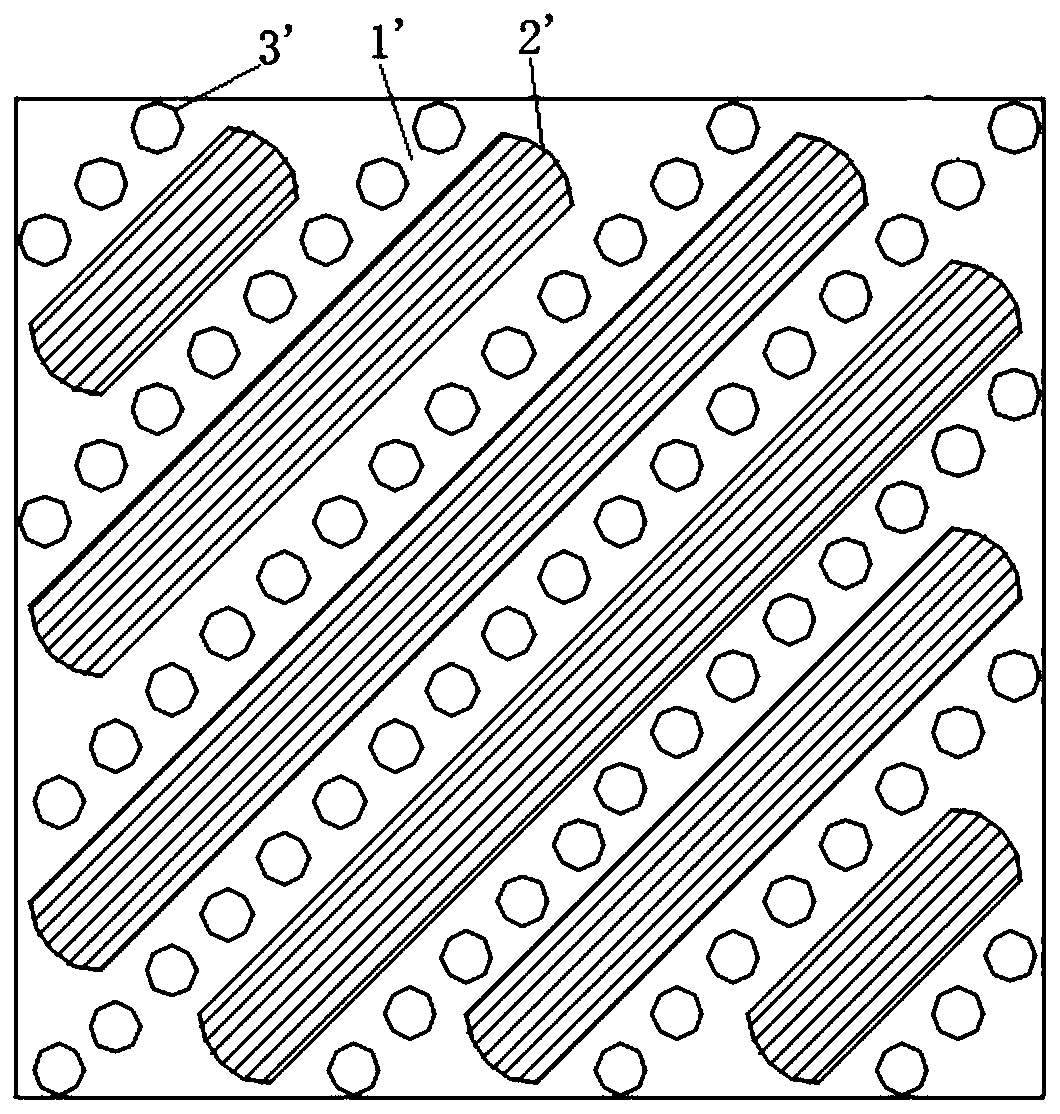

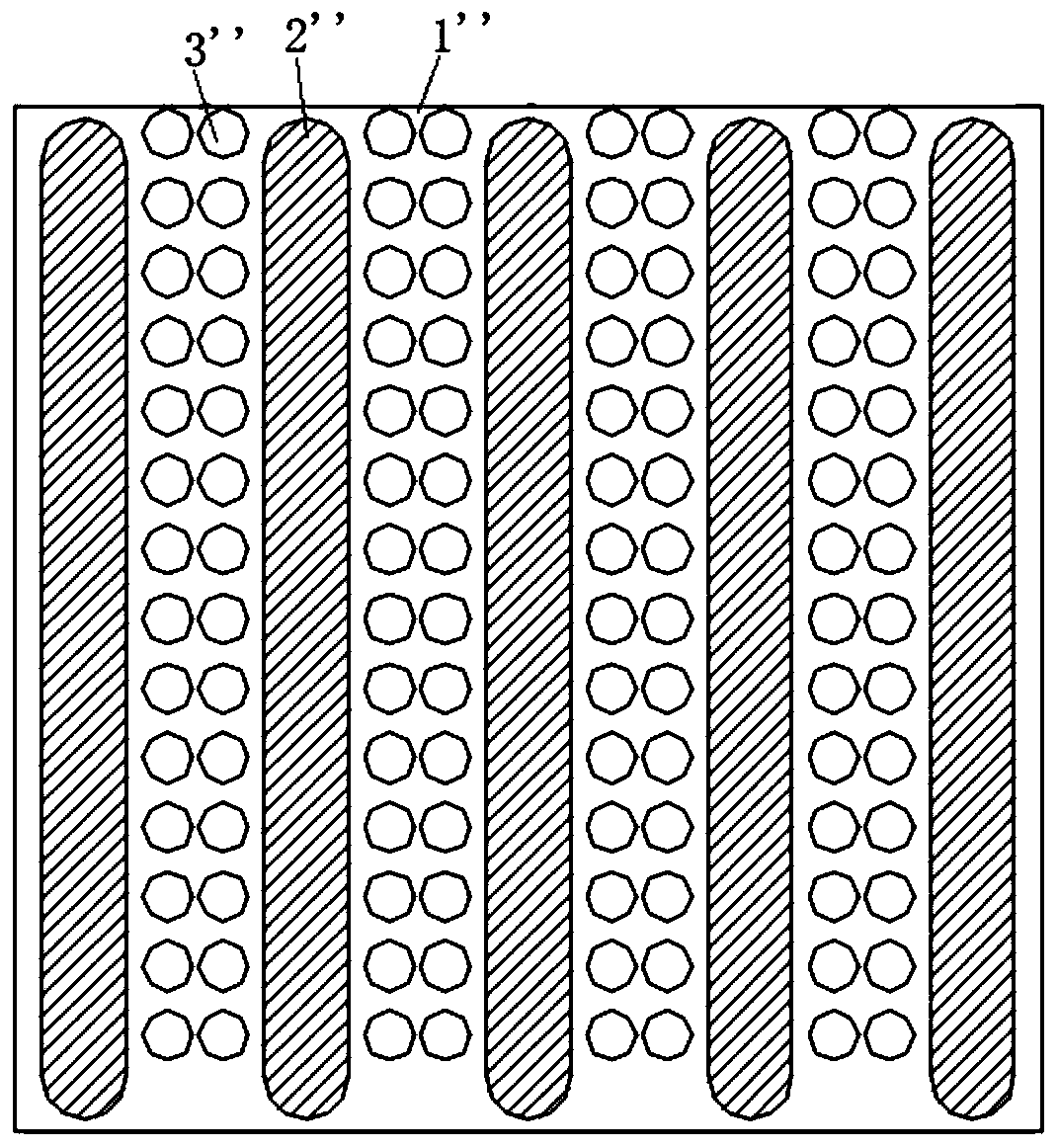

PCB and manufacturing method thereof

ActiveCN110446328AAvoid WeldingImprove thermal efficiencyPrinted circuit assemblingPrinted circuit aspectsResistEngineering

Owner:WUHAN JINGLI ELECTRONICS TECH +1

Method for manufacturing shield printed wiring board

InactiveCN108029195AMagnetic/electric field screeningCross-talk/noise/interference reductionResistEngineering

Owner:TATSUTA ELECTRICWIRE & CABLE

Method for forming negative tone pattern, method for manufacturing electronic device, and active-light-sensitive or radiation-sensitive resin composition

InactiveUS20170199455A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistOrganic solvent

Owner:FUJIFILM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap