Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Laser beams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

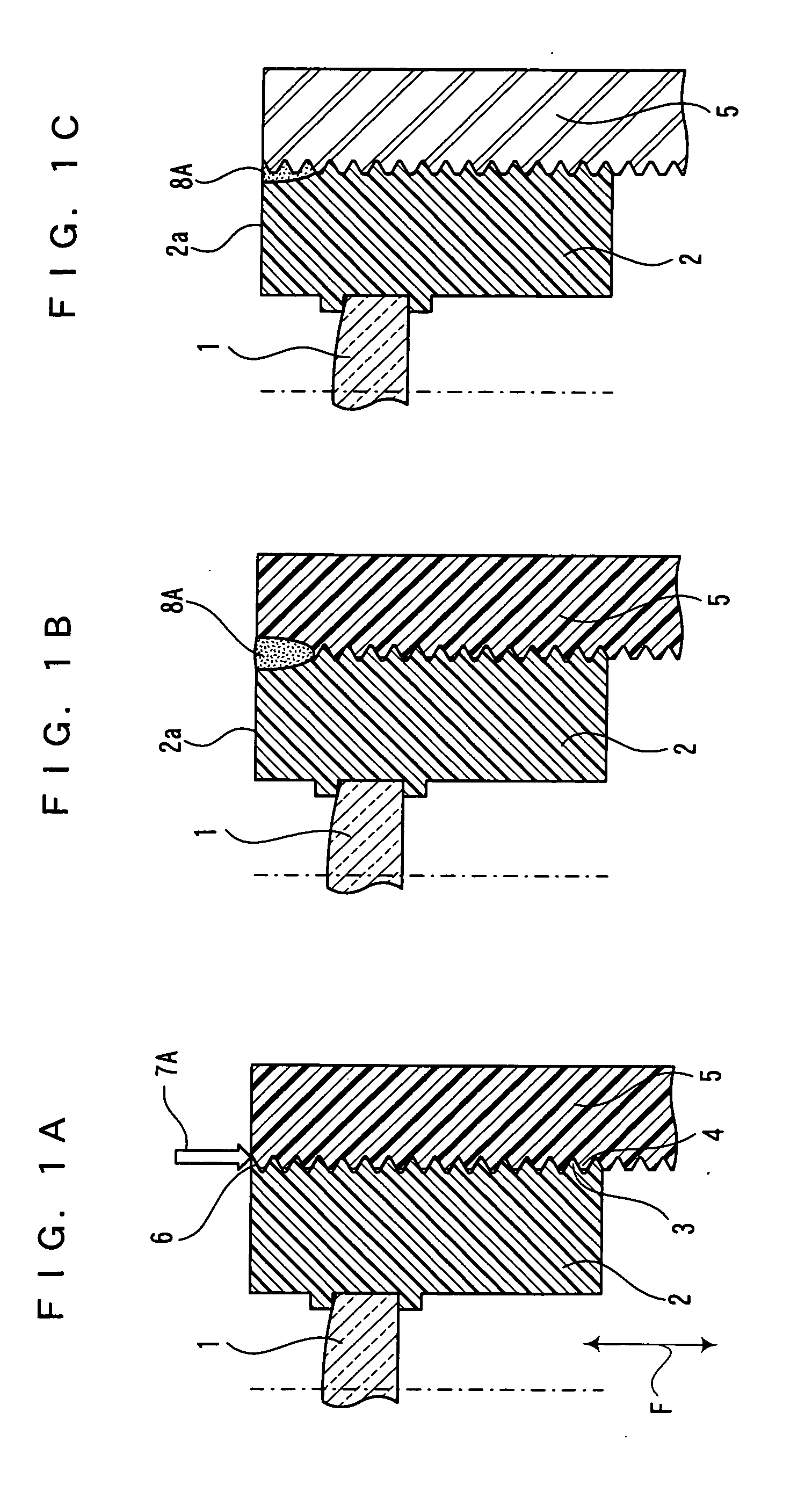

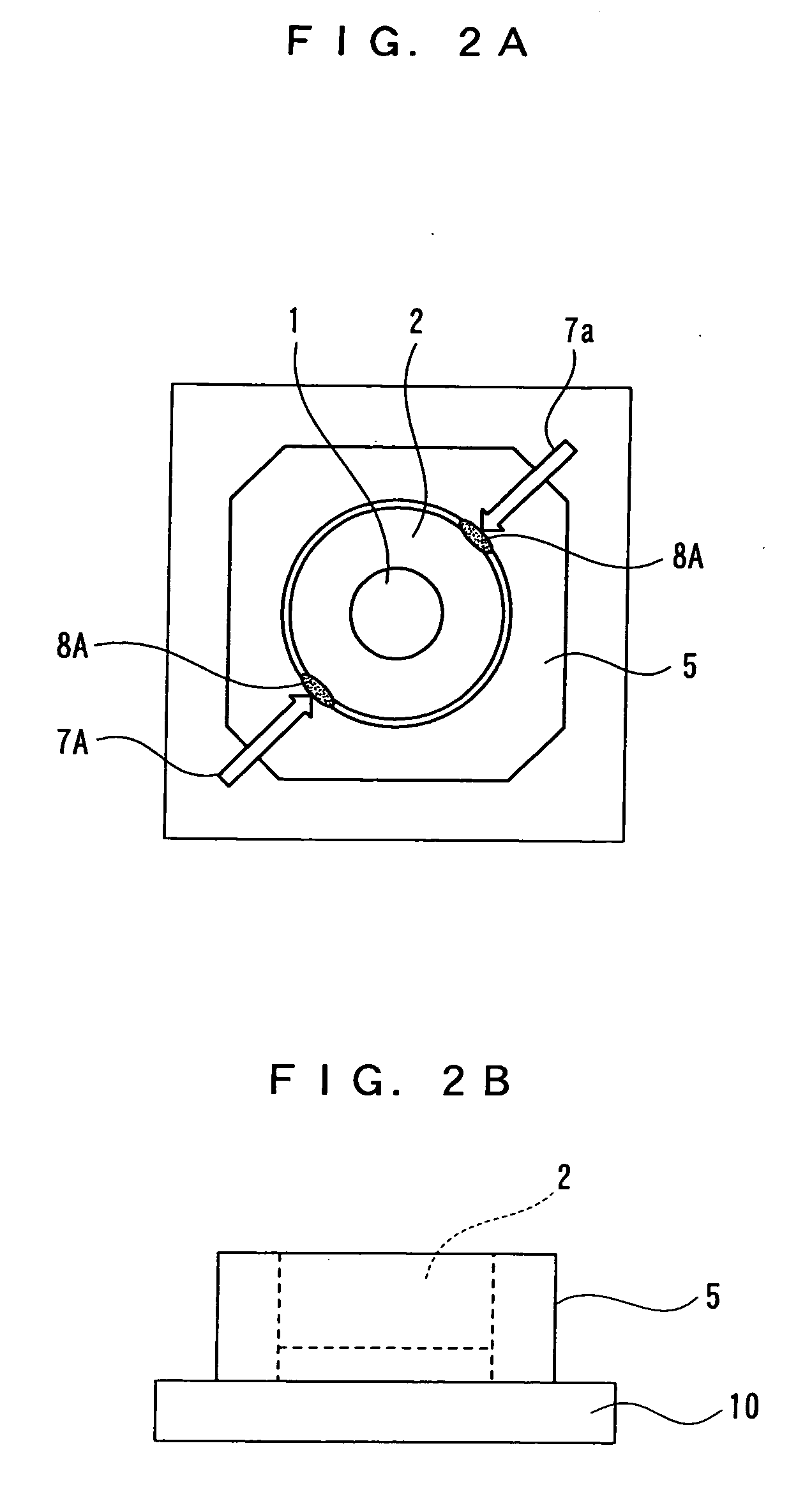

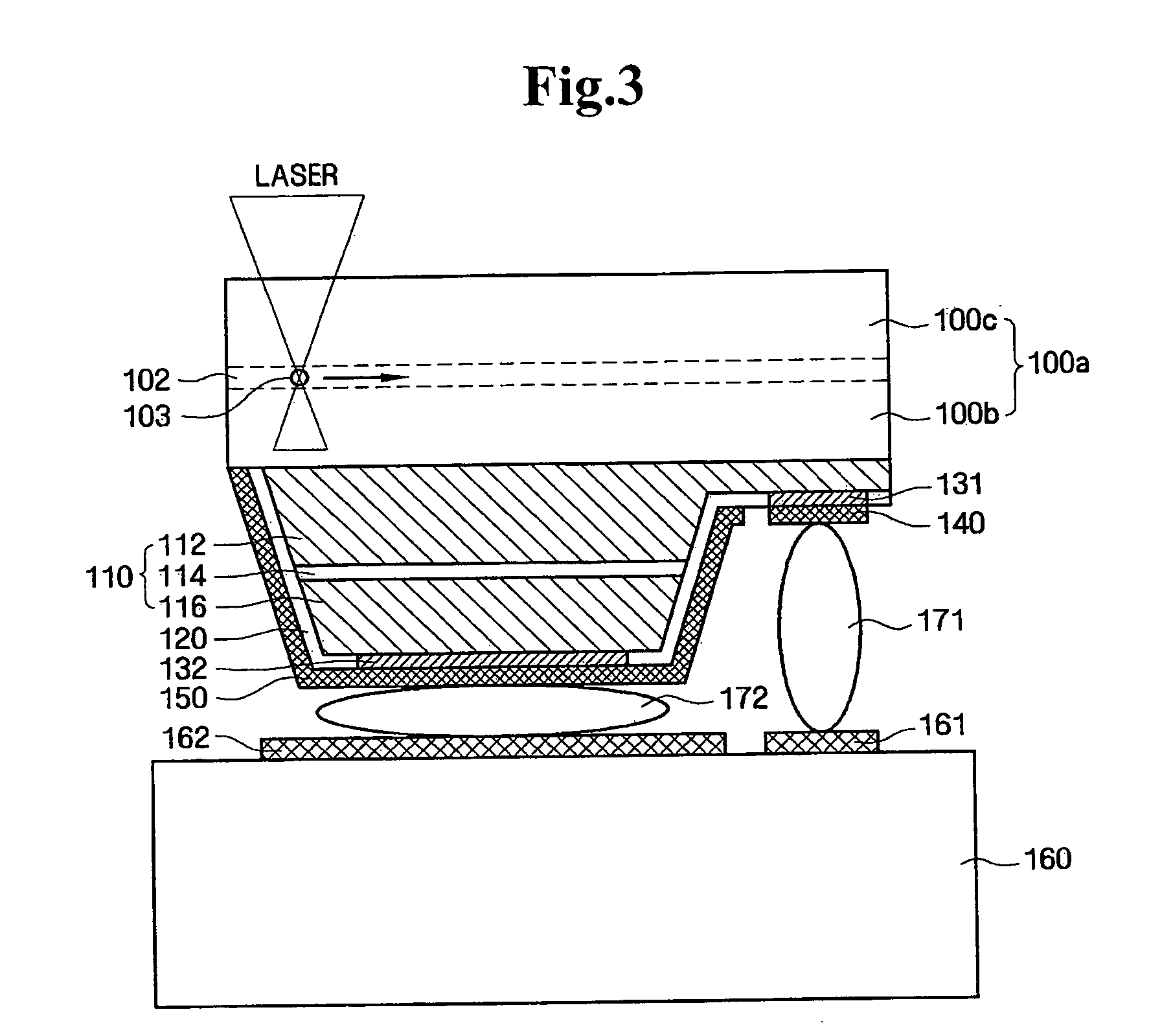

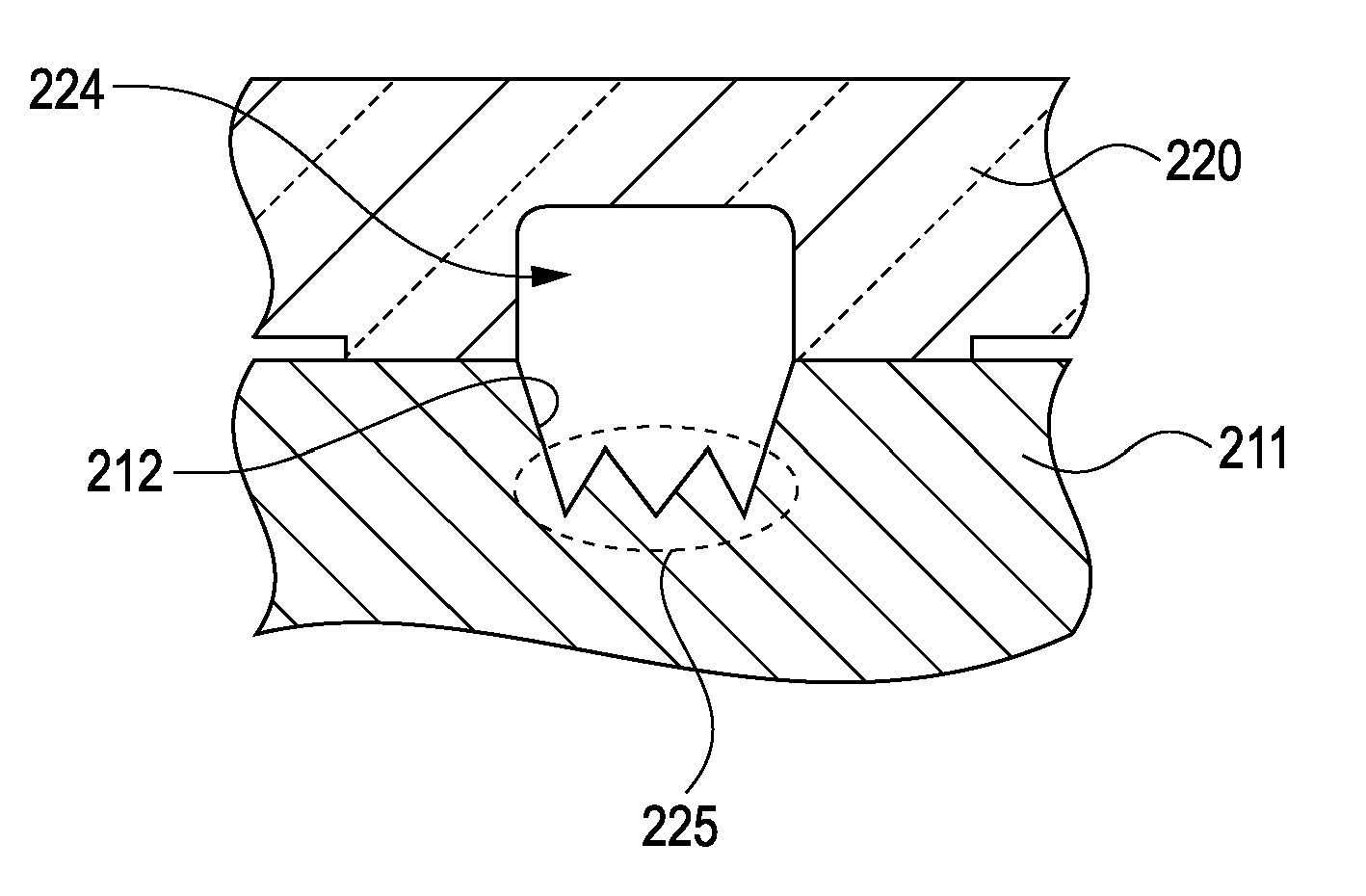

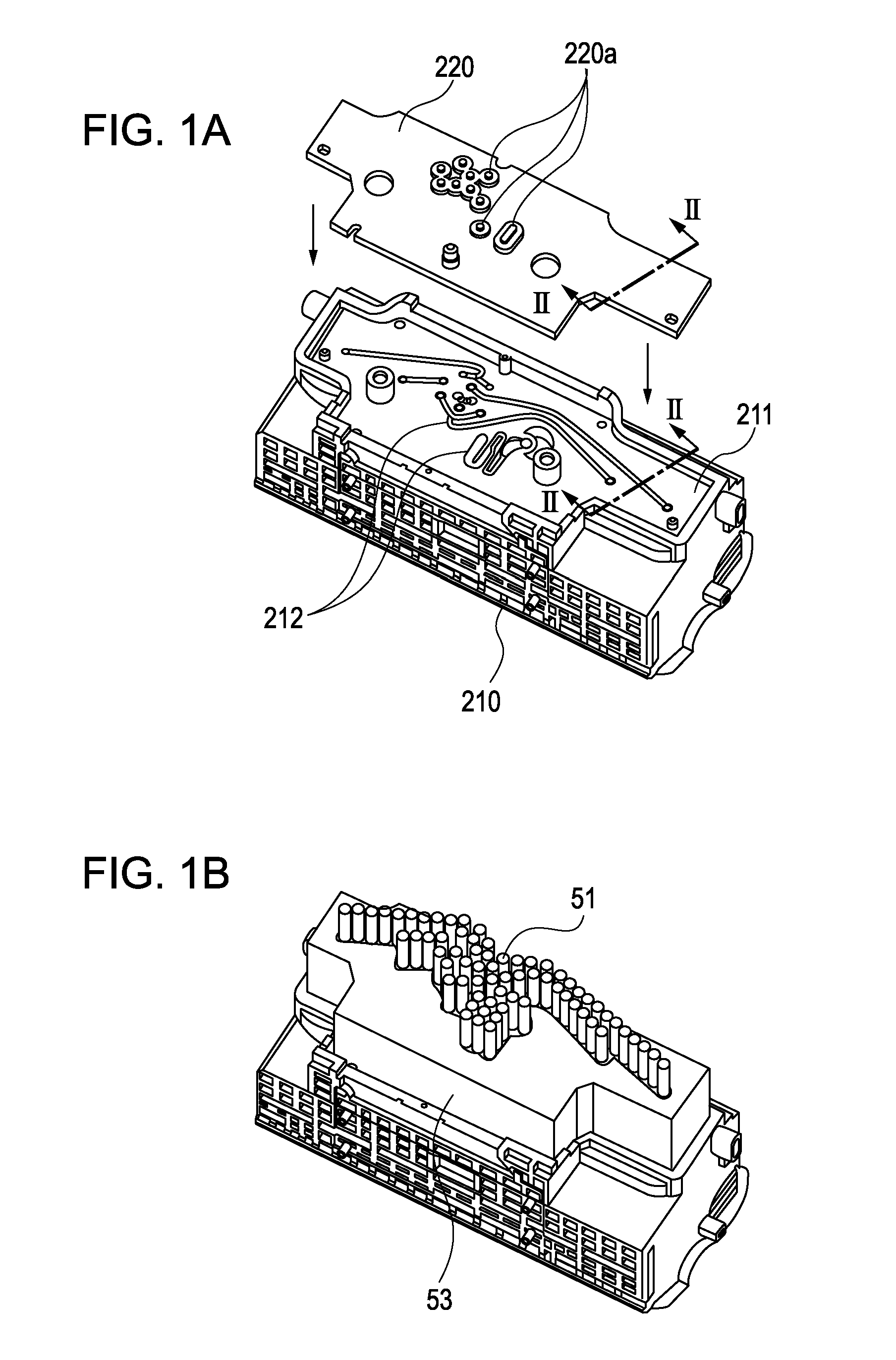

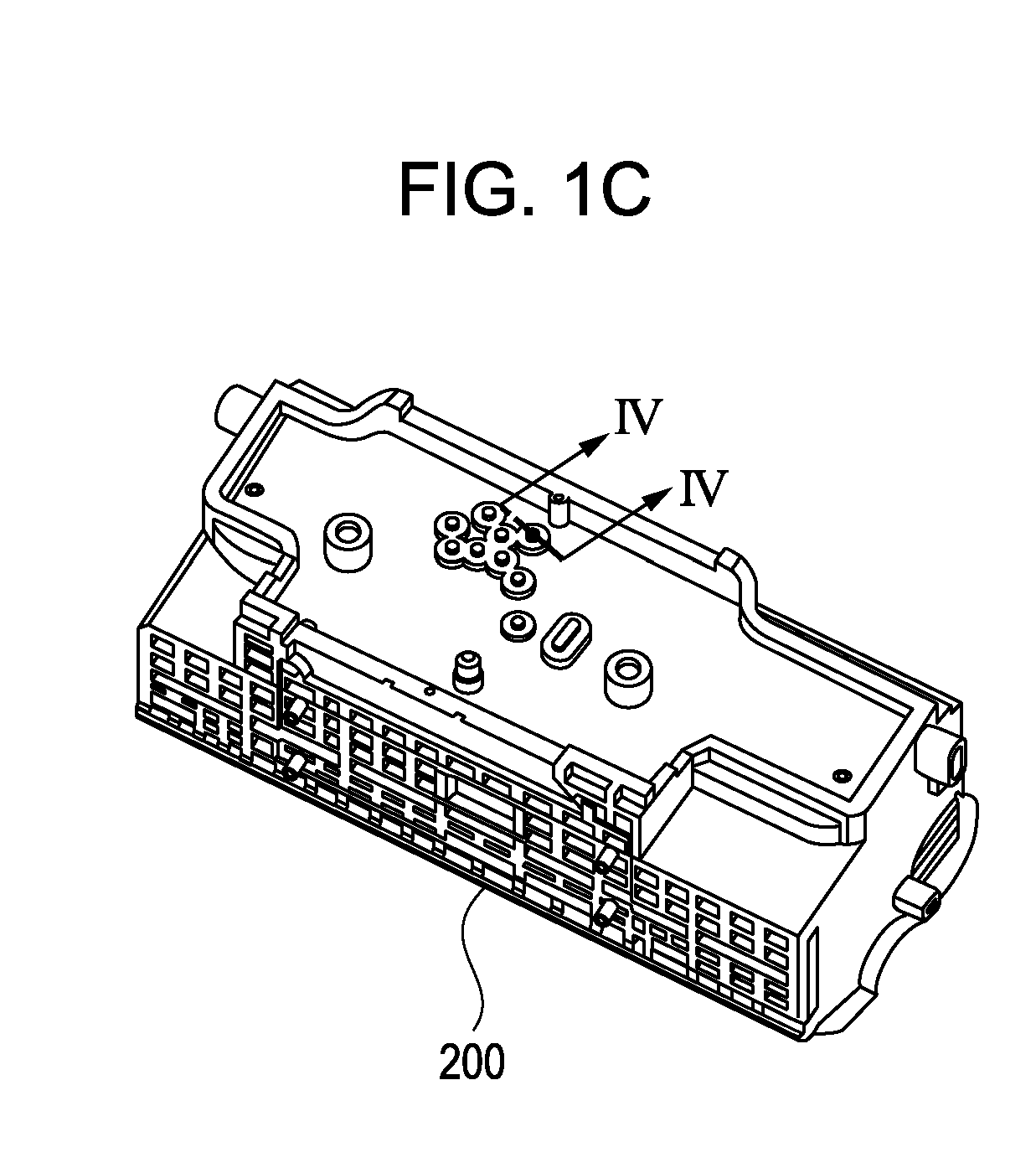

Manufacturing method of optical component and camera module

InactiveUS20060077575A1Slow changeAccurate fixing methodTelevision system detailsOptical articlesCamera moduleOptoelectronics

Owner:PANASONIC CORP

Visualizing ablation device and procedure

InactiveUS6902526B2Prevent slippingRelieve low back painEar treatmentLaproscopesSurgical departmentTarget tissue

A medical needle set for visualized tissue ablation within a subject's body includes a cannula and components configured for inclusion in the cannula, including a trocar for occlusion of the cannula lumen during needle placement, and a visualizing ablation probe used for simultaneous endoscopic viewing and ablation of tissue sites with a laser beam. The cannula can include a tissue-gripping surface for stabilization of the needle set on the target tissue. A surgical system for tissue ablation includes a visualizing ablation needle set operably connected to an endoscope and a laser. A surgical procedure using this system permits simultaneous visualization and ablation of tissues, including those of the facet joints of the spine.

Owner:ARDENT MEDICAL CORP

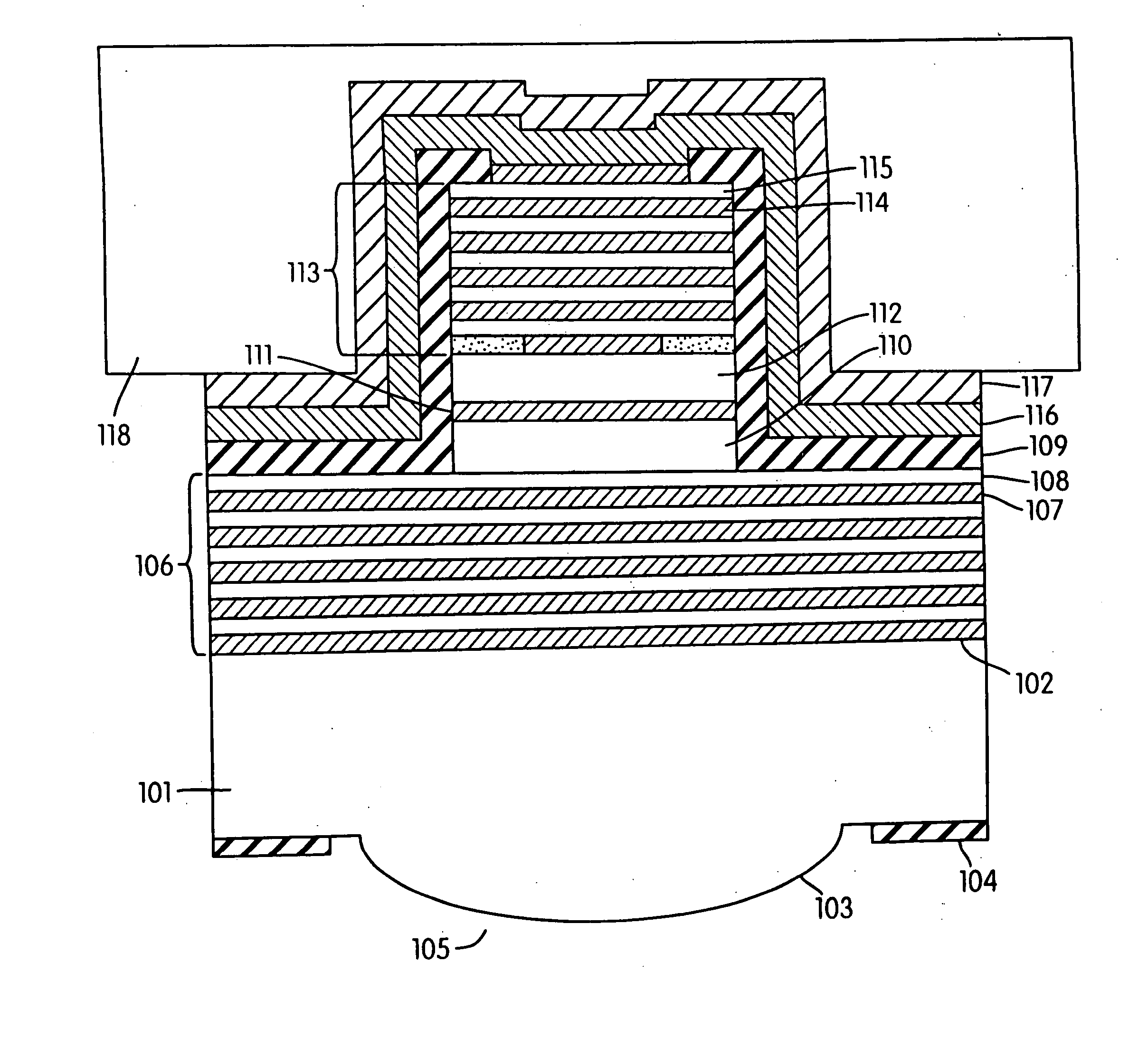

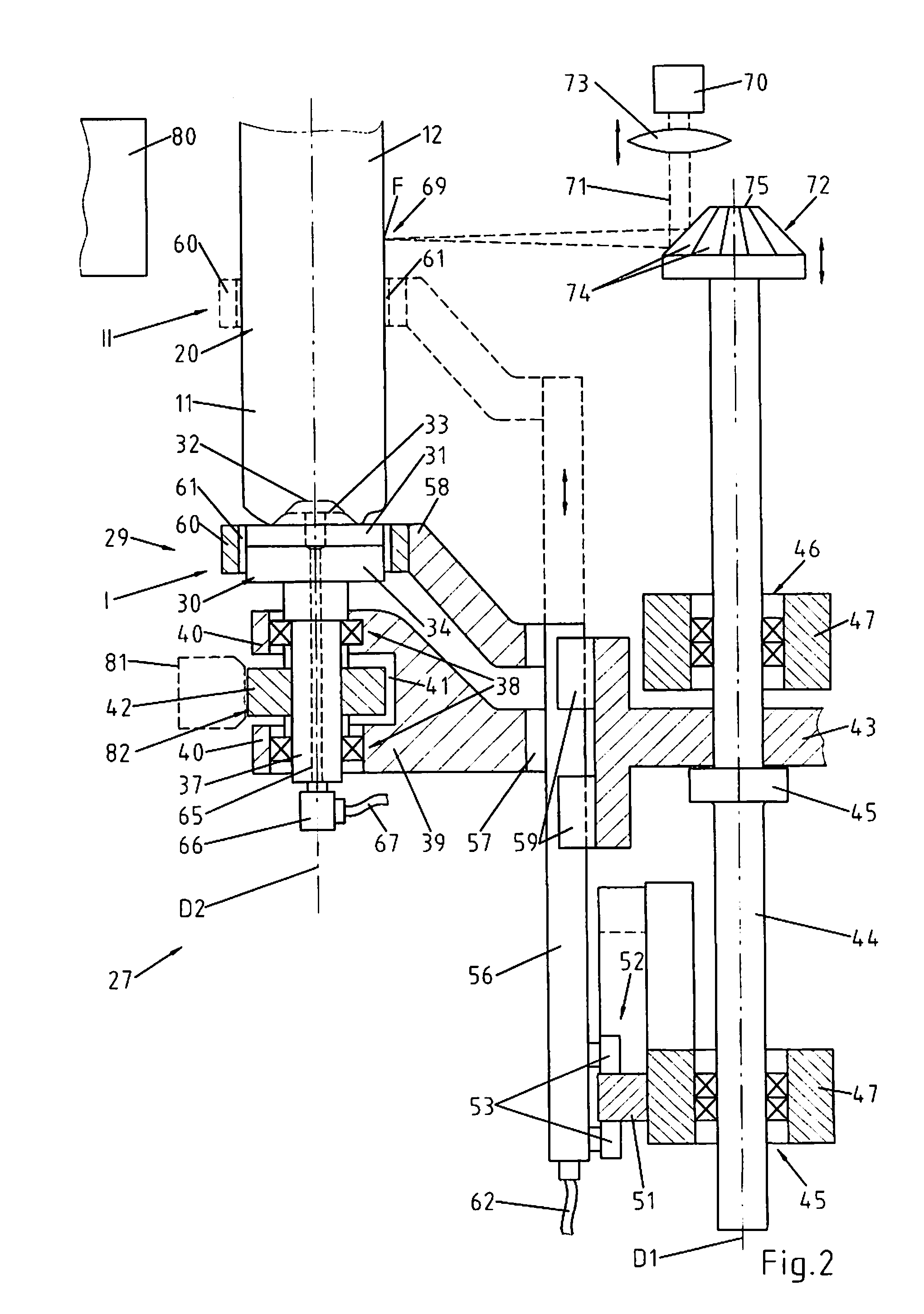

VCSEL and VCSEL array having integrated microlenses for use in a semiconductor laser pumped solid state laser system

InactiveUS20050025211A1High power outputImprove cooling effectSemiconductor laser structural detailsOptical resonator shape and constructionVertical-cavity surface-emitting laserLight beam

Owner:PRINCETON OPTRONICS

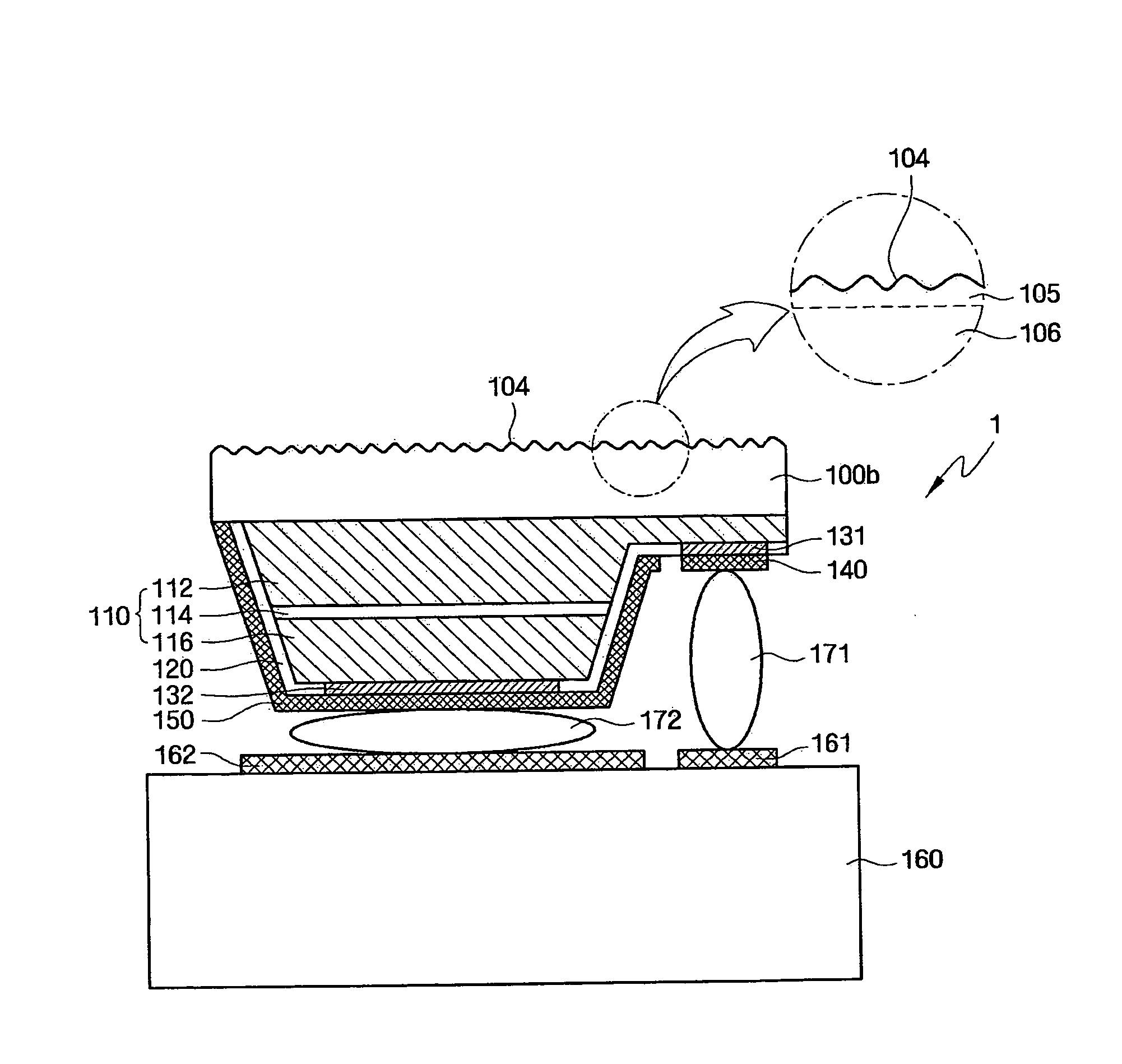

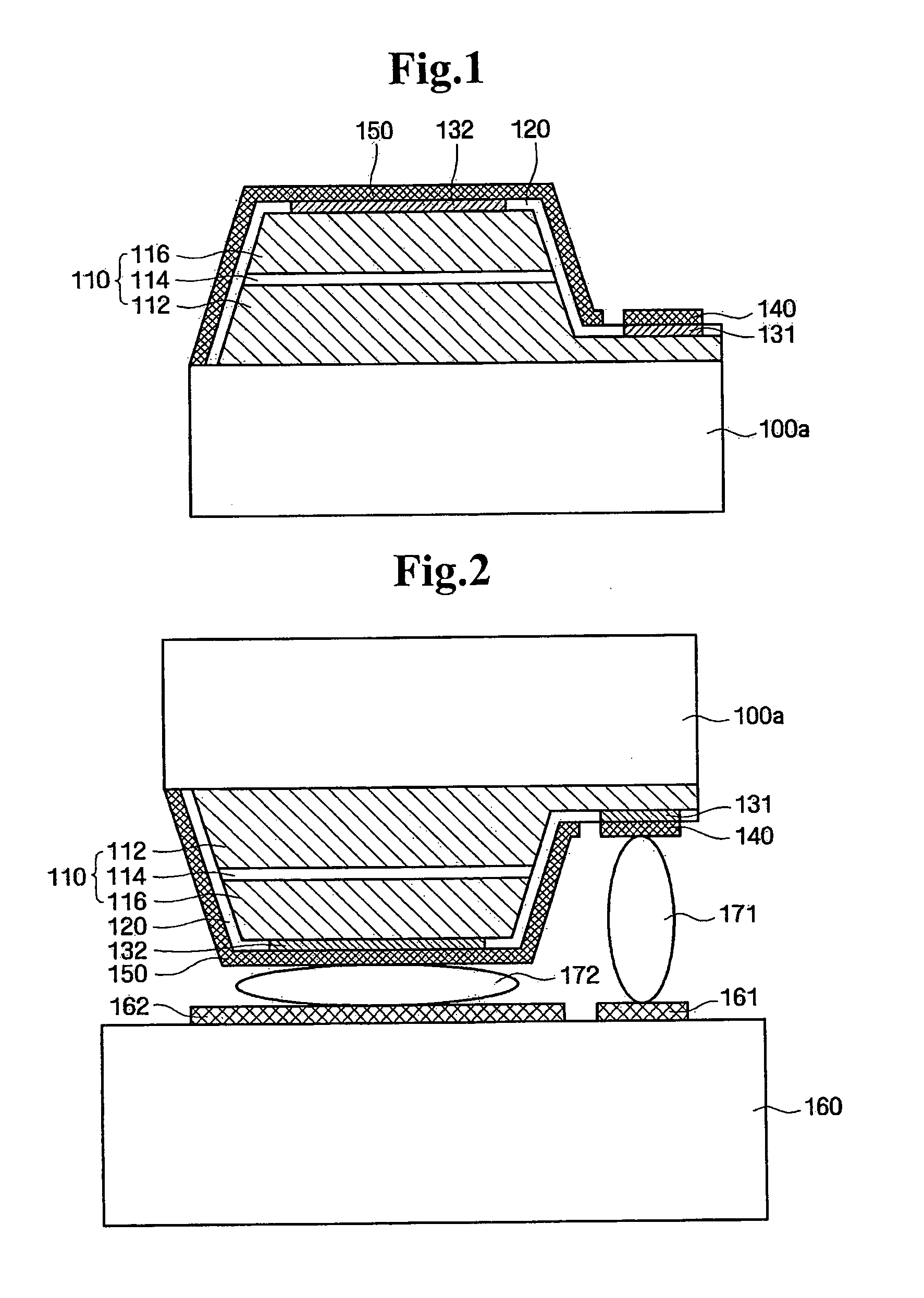

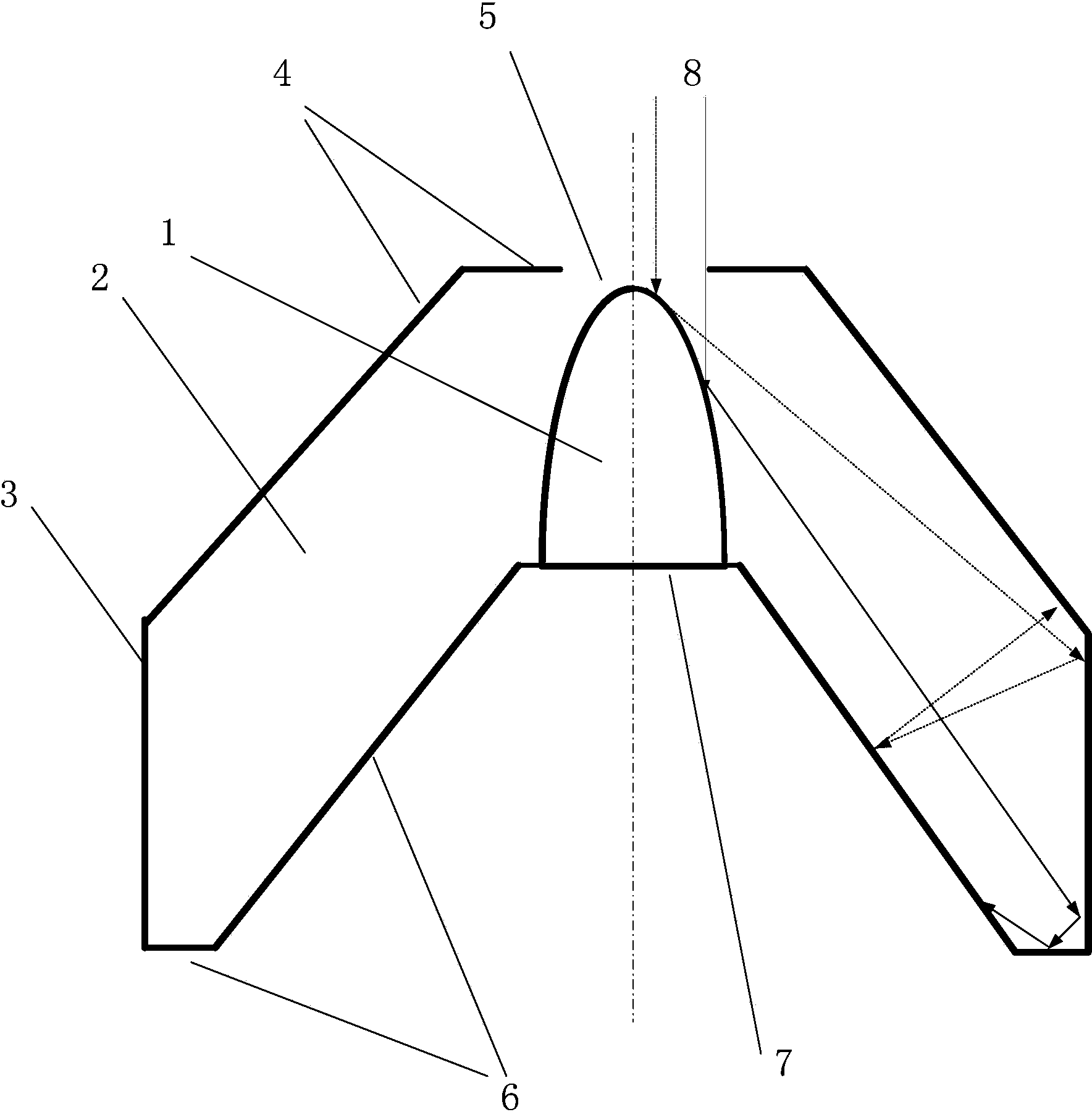

Method of fabricating light-emitting apparatus with improved light extraction efficiency and light-emitting apparatus fabricated using the method

ActiveUS20100120183A1Light extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingLight beamSingle crystal

Owner:SAMSUNG ELECTRONICS CO LTD

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Flexible laser cleaning system applicable to bend pipeline

InactiveCN109821819AImprove motor coordinationControl switch stateHollow article cleaningFiberDrive wheel

Owner:SOUTH CHINA NORMAL UNIVERSITY

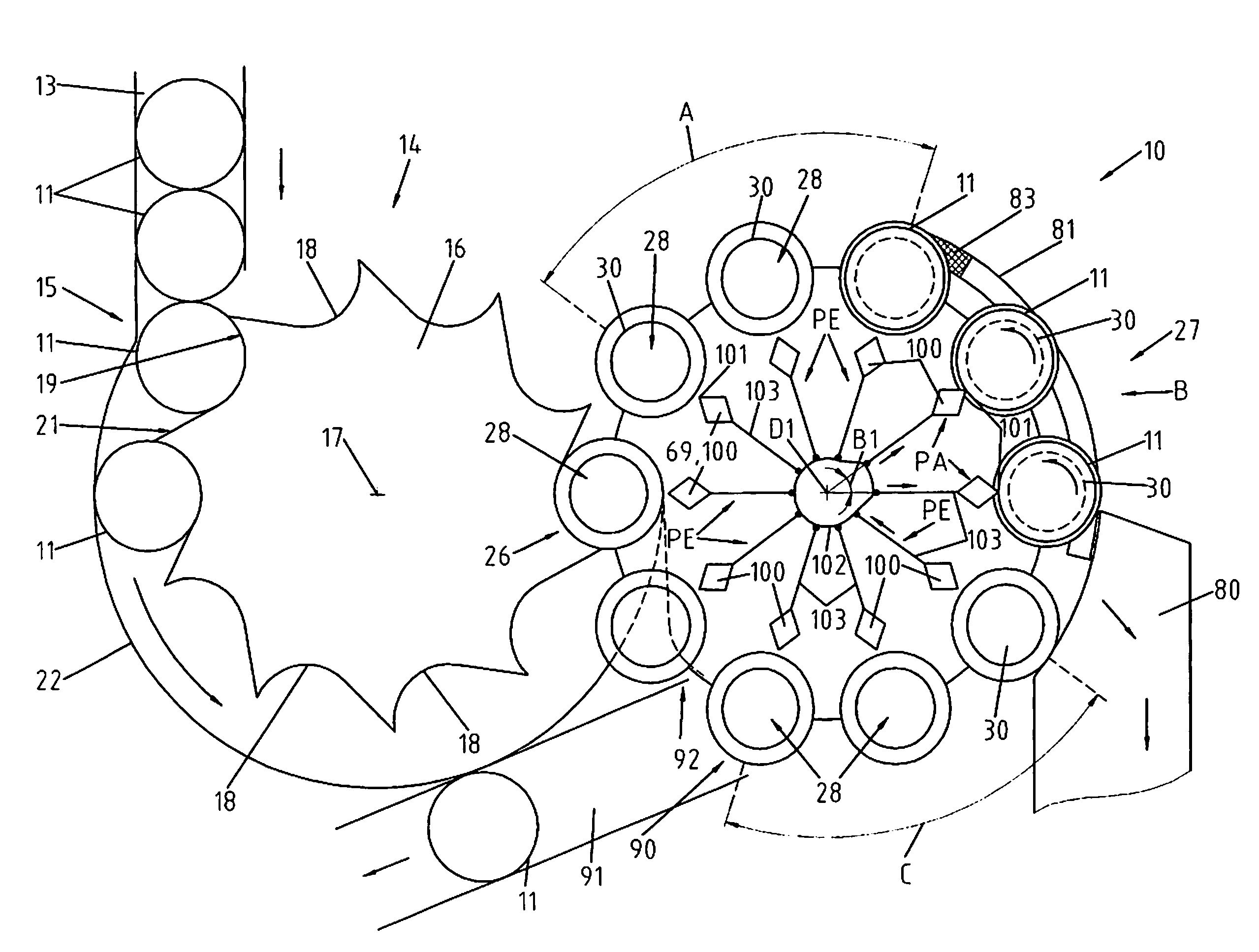

Device and method for cutting off an end section of a can blank

InactiveUS20140346154A1Sufficient time availableStock shearing machinesMetal working apparatusEngineeringLaser cutting

Owner:SCHULER PRESSEN GMBH & CO KG

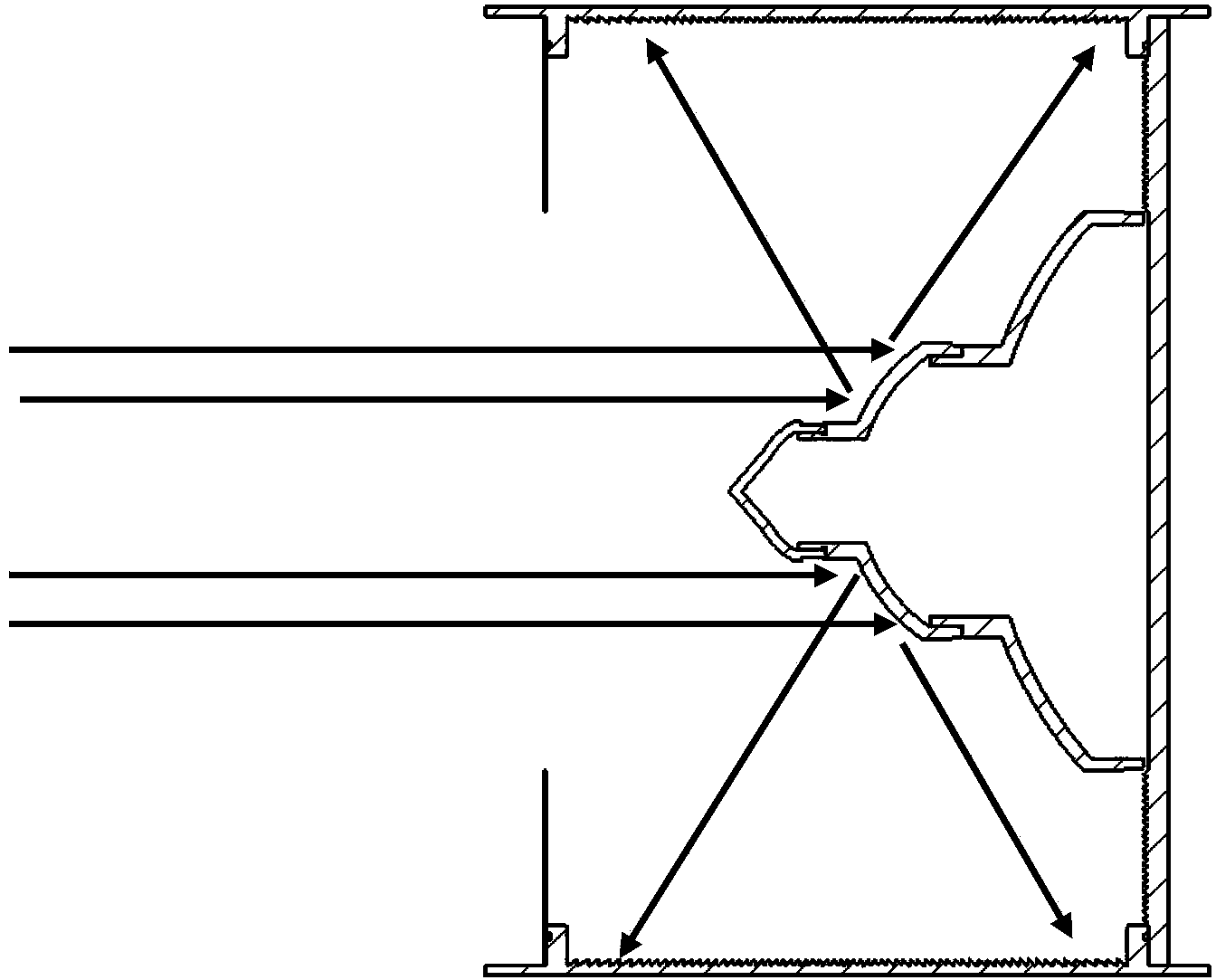

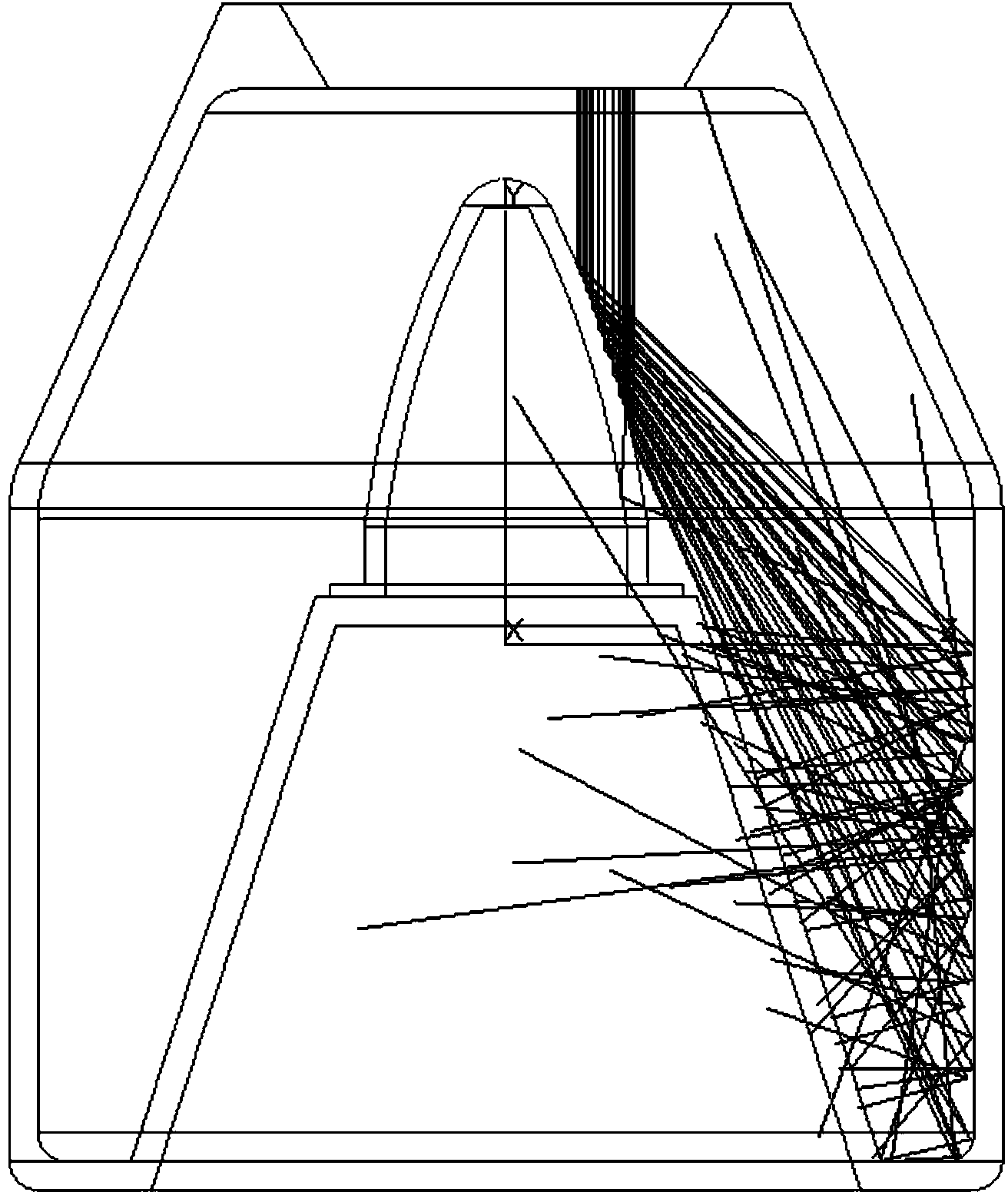

Total absorption superlaser energy meter

ActiveCN104048755AReduce laser power densityIncrease light receiving areaPhotometryLaser power densityCollimated light

The invention disclose a total absorption superlaser energy meter which comprises a reflection cone and an absorption cavity, wherein the generatrix of the reflection cone is arc-shaped, the absorption cavity is formed by sealed connection of a base plate, an inner lateral plate, an absorption cylinder and a cover plate, the whole structure of the absorption cavity is concave, the wall of the absorption cylinder is arranged on the light path of a superlaser beam after the superlaser beam is reflected through the reflection cone, and the absorption cylinder is located behind the reflection cone in the front and back direction. According to the total absorption superlaser energy meter, the incident collimated light beam is reflected onto the wall of the absorption cylinder in an axial and circumferential two-dimensional beam expansion mode, the power density of laser irradiating on the wall of the absorption cylinder is reduced greatly, the light receiving area of the reflection cone is increased at the same time, and the laser irradiation bearing capacity of the reflection cone is improved; furthermore, due to the adoption of the cavity structure, the probability that the reflection cone is polluted by dust is effectively reduced, and meanwhile, the exit escape rate of laser is reduced and measurement accuracy of the energy meter is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

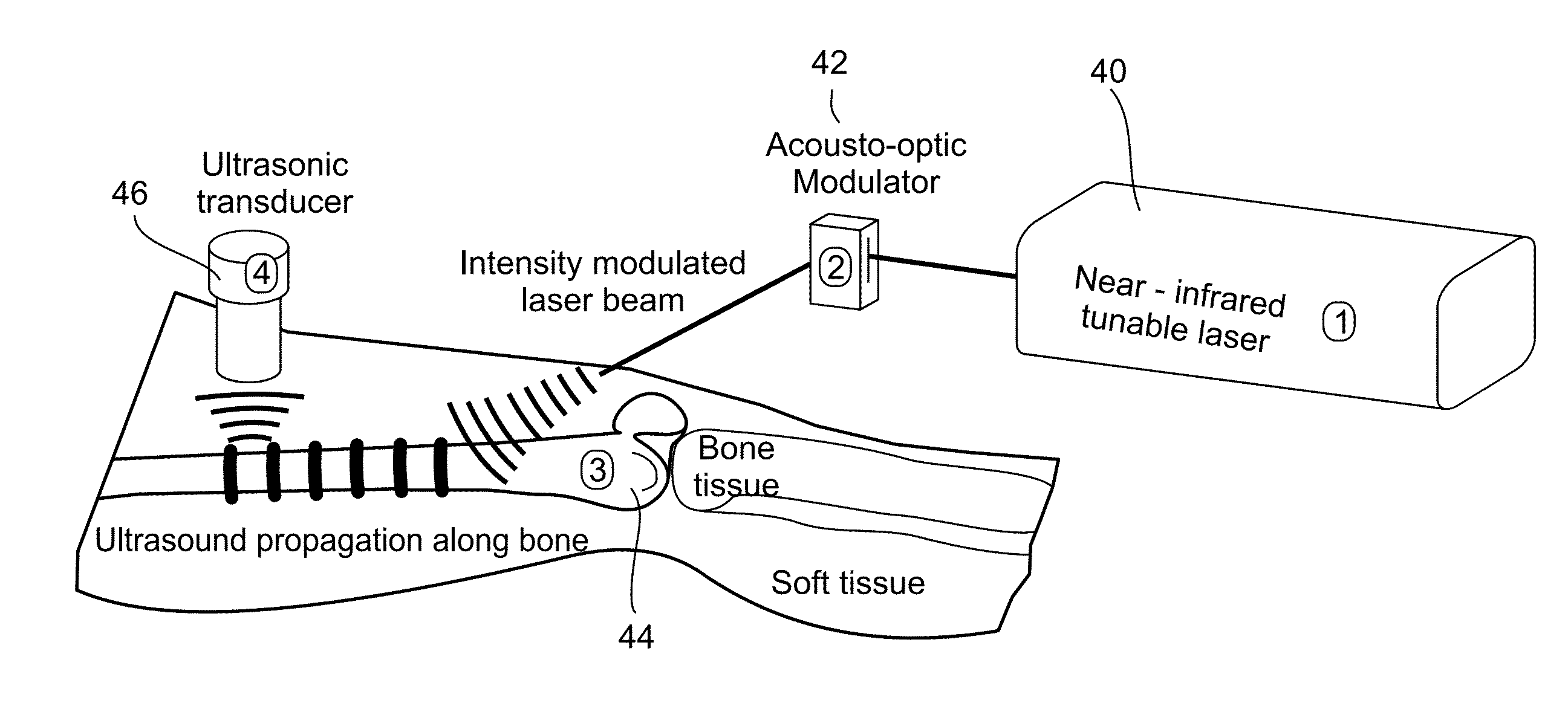

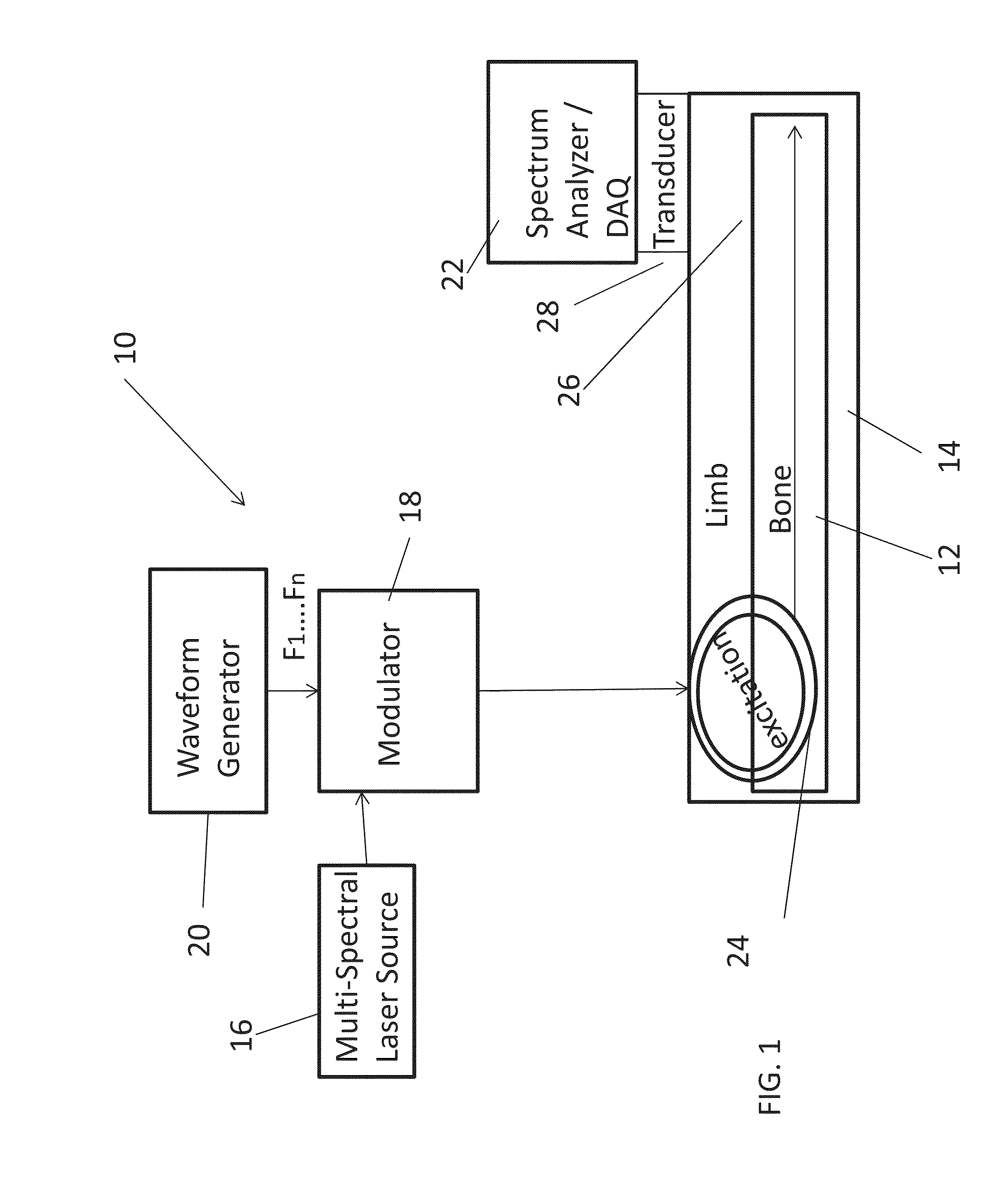

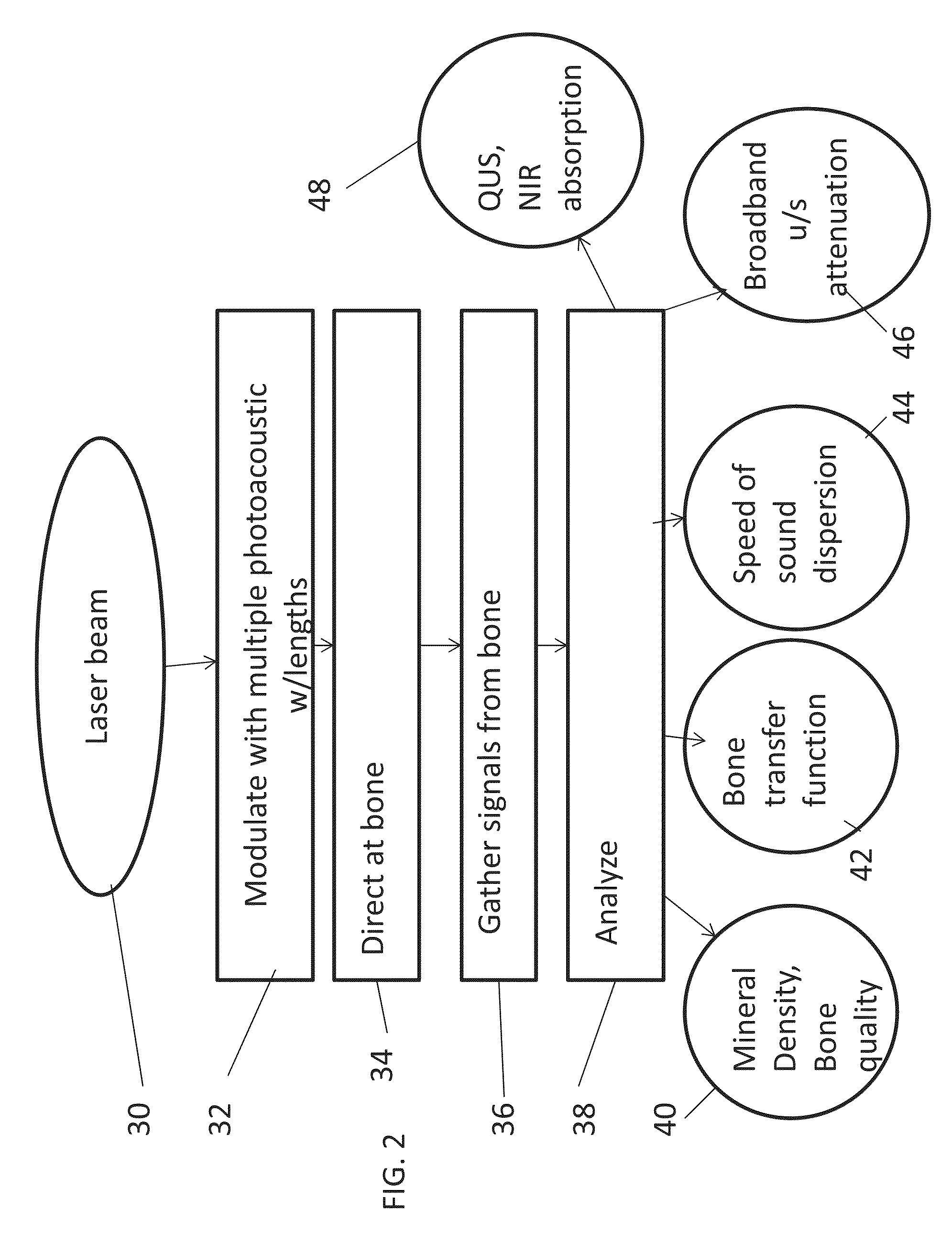

Detection, diagnosis and monitoring of osteoporosis by a photo-acoustic method

Owner:RAMOT AT TEL AVIV UNIV LTD

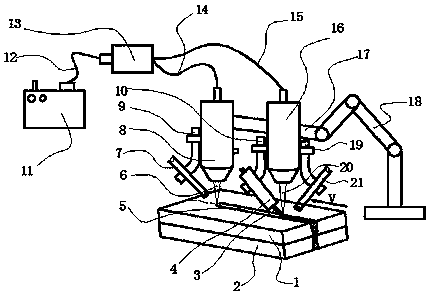

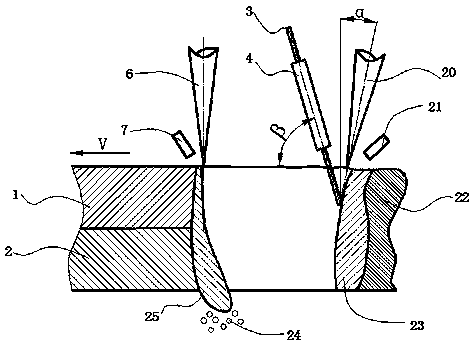

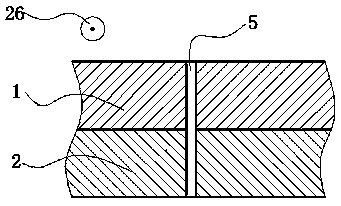

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

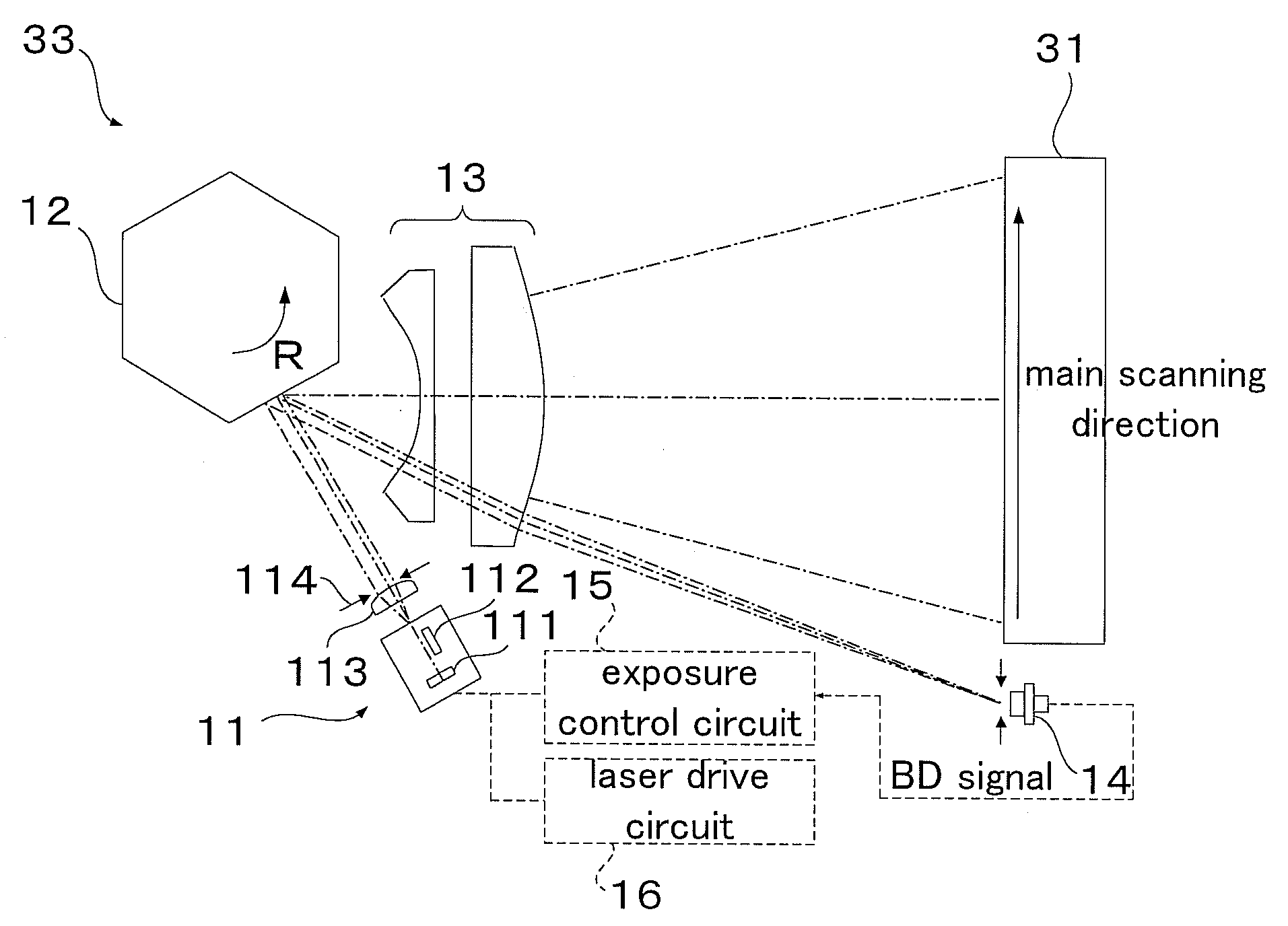

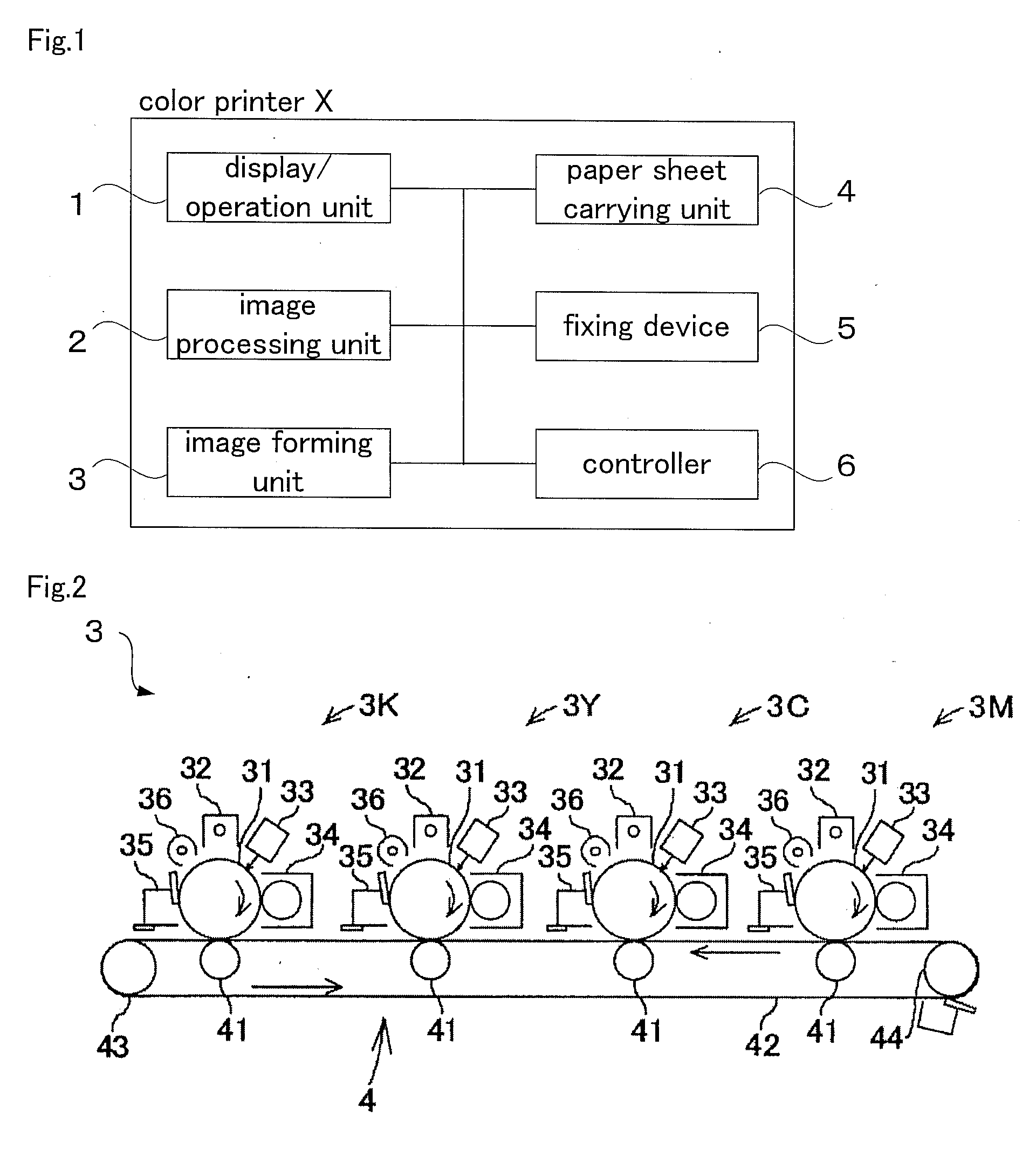

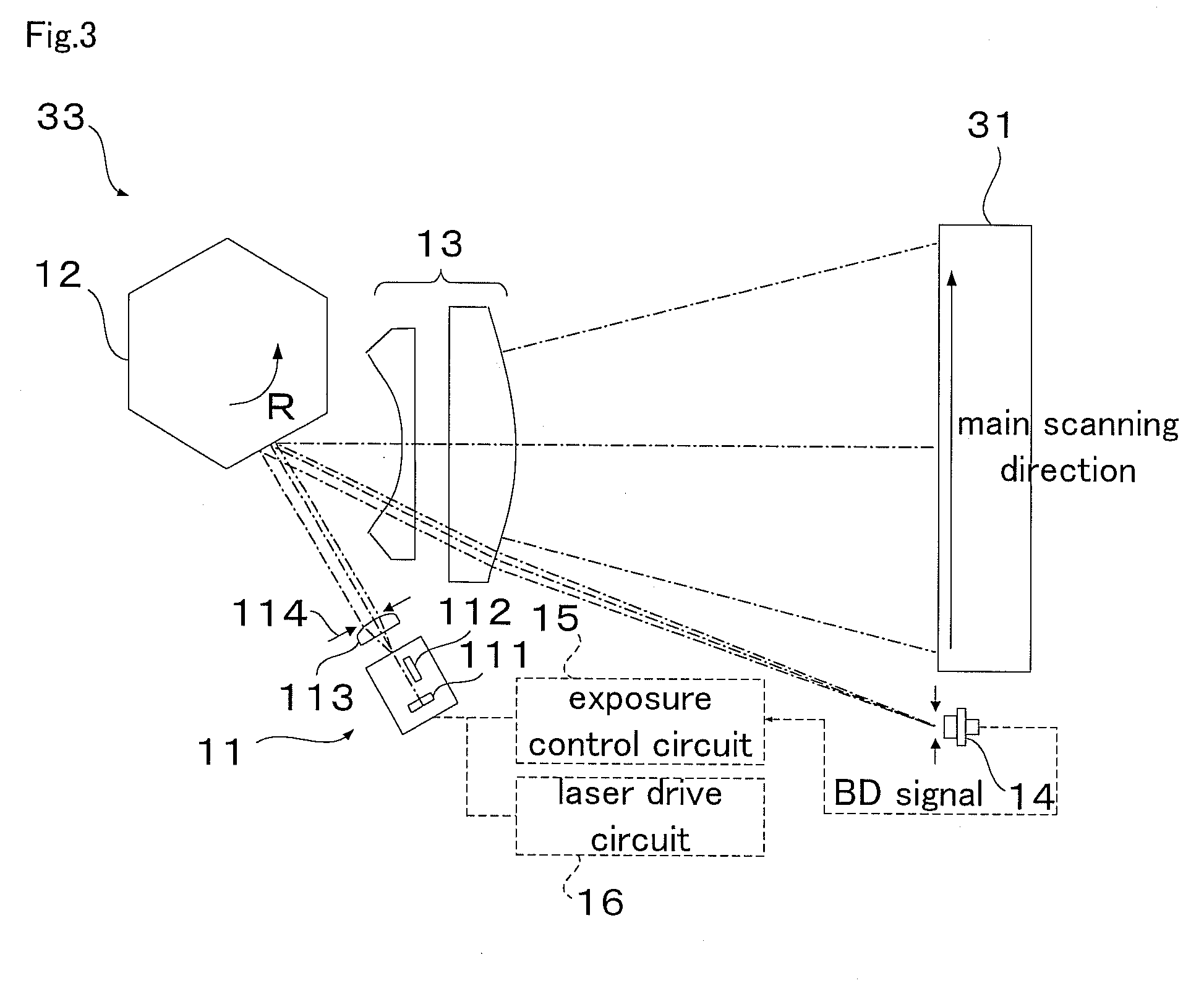

Optical scanner, image forming apparatus, and image forming method

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Vacuum cell for optical components

A moisture sensitive optically nonlinear crystal is enclosed in a hermetically sealed elongated vacuum cell. The vacuum cell has an input window at one end and an output window at an opposite end providing optical access to the crystal by a laser beam. The windows are attached to the cell by cold-formed, indium-metal ram-seals. In an example of the cell in which the crystal is arranged to generate UV radiation from the laser beam, the output window is located at a sufficient distance from the crystal that the flux of UV radiation incident on the output window is below the damage threshold of the window for the UV radiation.

Owner:COHERENT INC

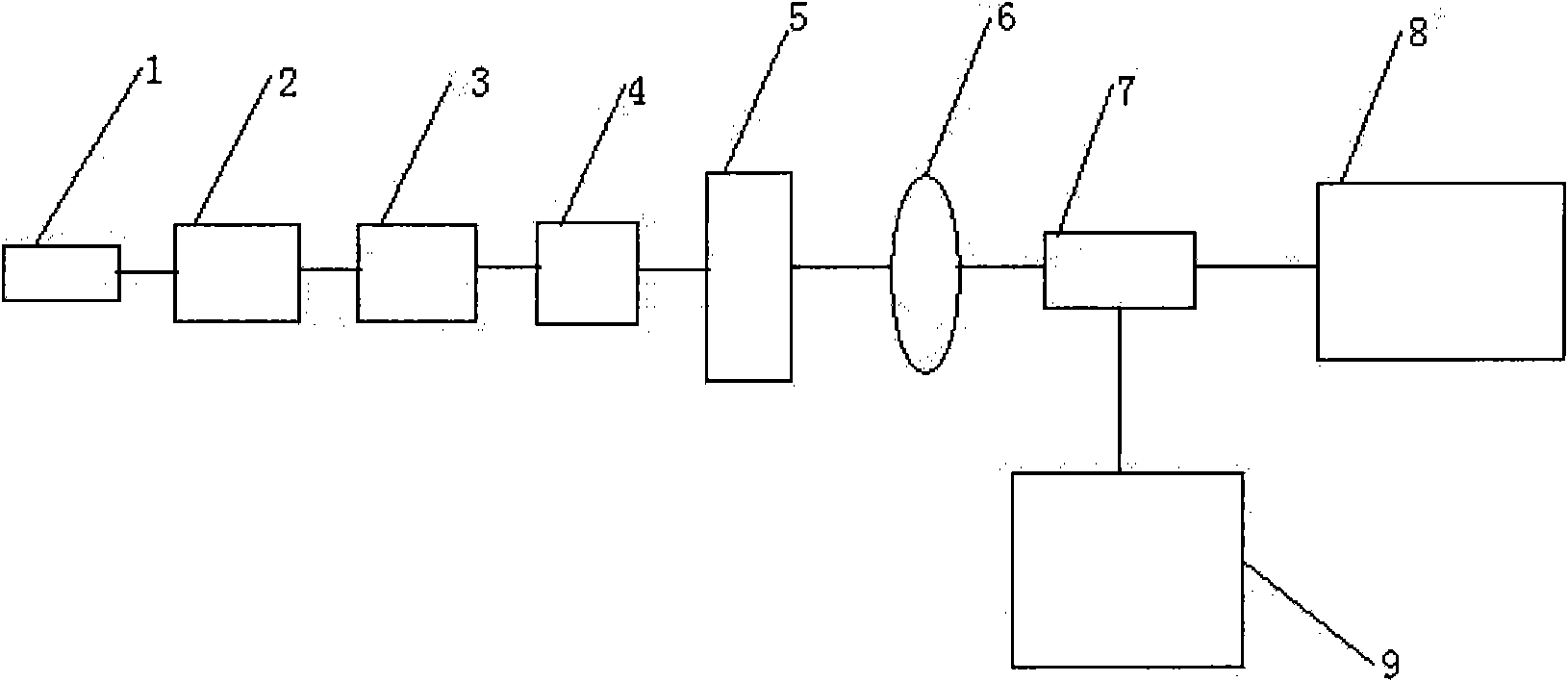

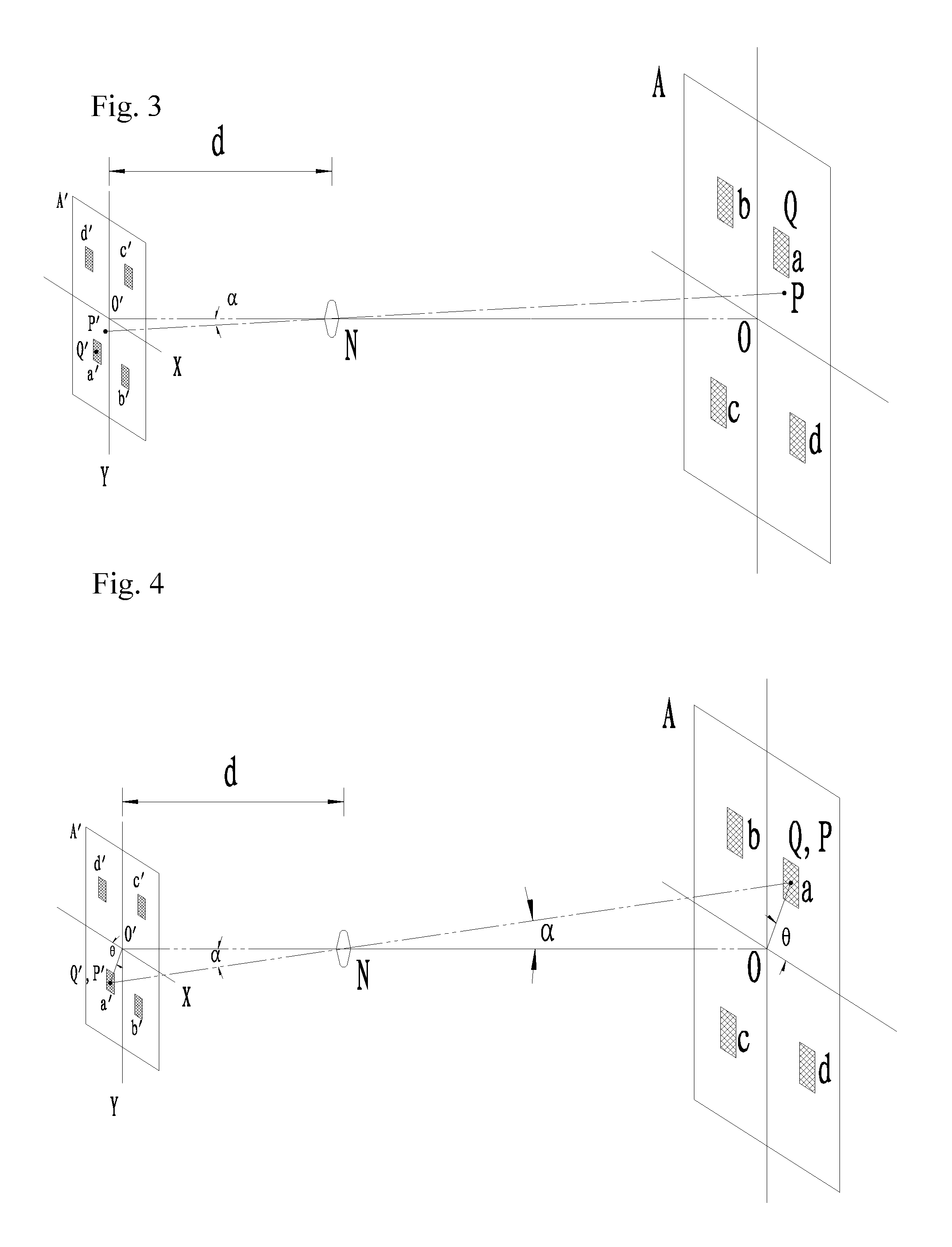

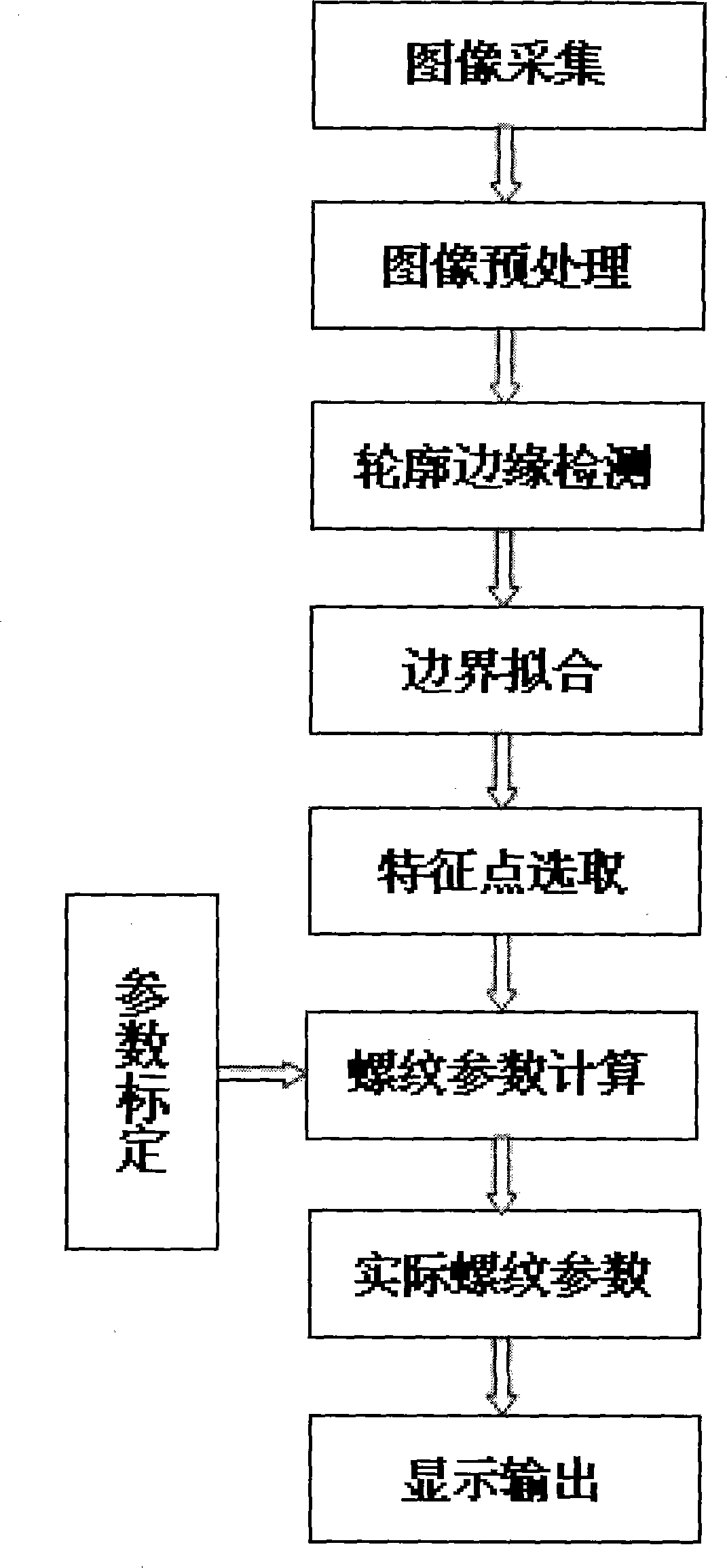

Method and device for measuring position and line width of laser beam by using line array CCD (Charge Coupled Device)

The invention relates to a method and device for measuring position and line width of a laser beam by using a line array CCD (Charge Coupled Device). The method comprises the following steps of: 1, obtaining a Gaussian curve of an incident laser line beam; and 2, detecting the position and the line width of the laser beam according to the Gaussian curve. The method and the device can be used for detecting the absolute and the relative positions of the laser line beam and detecting the line width of the line beam, and can be converted into a mode of measuring displacement, length, angle displacement and the like; and by using the method, the deformation and the amplitude of a platform are detected, the line linearity of the straight line laser is measured, and a laser instrument is comprehensively detected.

Owner:XIAN HUANIC OPTOELECTRONICS CORP

Avoiding hot cracks during laser welding of a workpiece stack-up assembly of aluminum alloy workpieces

ActiveUS20180243861A1Vehicle componentsWelding/soldering/cutting articlesIntermediate stageOptoelectronics

A method of laser welding a workpiece stack-up that includes two or more overlapping aluminum alloy workpieces is disclosed. The method involves controlling the power level of the laser beam during at least one of an initial stage or a final stage of advancing the laser beam along a weld path so as to limit a line energy of the laser beam during such stage or stages to being no greater than 10% above a line energy of the laser beam during an intermediate stage of laser beam advancement that is performed between the initial and final stages. By limiting the line energy during the initial and / or final stages of laser beam advancement along the weld path, excessive fusion of the workpiece stack-up assembly can be avoided in those locations to help protect against hot-cracking in the resultant laser weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Laser mosquito killing cleaning robot

ActiveCN111316964AAchieving Active KillingNo pollution in the processAutomatic obstacle detectionImage analysisControl mosquitoEngineering

The invention relates to the technical field of mosquito killing robots, in particular to a laser mosquito killing cleaning robot. The laser mosquito killing cleaning robot provided by an embodiment of the invention comprises a main body, a mosquito attracting device, a laser assembly and a mosquito detecting device, wherein the mosquito attracting device, the laser assembly and the mosquito detecting device are installed on the main body. The mosquito attracting device is used for attracting mosquitoes into a preset area, so that the mosquitoes are gathered in the preset area. The mosquito detecting device is used for acquiring the number and positions of the mosquitoes in the preset area and determining boundary characteristics of mosquito groups. A laser emitting assembly is arranged toadjust the angle and range of output laser according to the positions and boundary characteristics of the mosquito groups, so that the range defined by output laser beams is matched with the boundaries of the mosquito groups. Therefore, the laser emitted by the laser beam emitting assembly can fully cover the range of the mosquito groups, and the mosquito groups are killed collectively. The mosquitoes in the preset range are actively killed, moreover, the mosquito killing efficiency is high, and no pollution is caused to the environment.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

Multi-focal-plane display system and device

ActiveCN109633905ARealize a minimalist architectureEasy to manufactureColor television detailsOptical elementsLight beamOptoelectronics

The invention provides a multi-focal plane display system and device. The system comprises a laser projection light engine and a holographic reflected light fusion device. The laser projection light engine generates and modulates at least two laser light beam groups, and transmits the laser light beam groups to the holographic reflected light fusion device; each laser light beam group correspondsto one display image; the holographic reflected light fusion device reflects the at least two laser beam groups; the pupil exiting positions of the laser beam groups are the same, and a display imagewith at least two focal planes is obtained after that imaging by the human eyes of the laser beam groups. The multi-focal plane display system is simple in structure and easy to realize.

Owner:HUAWEI TECH CO LTD

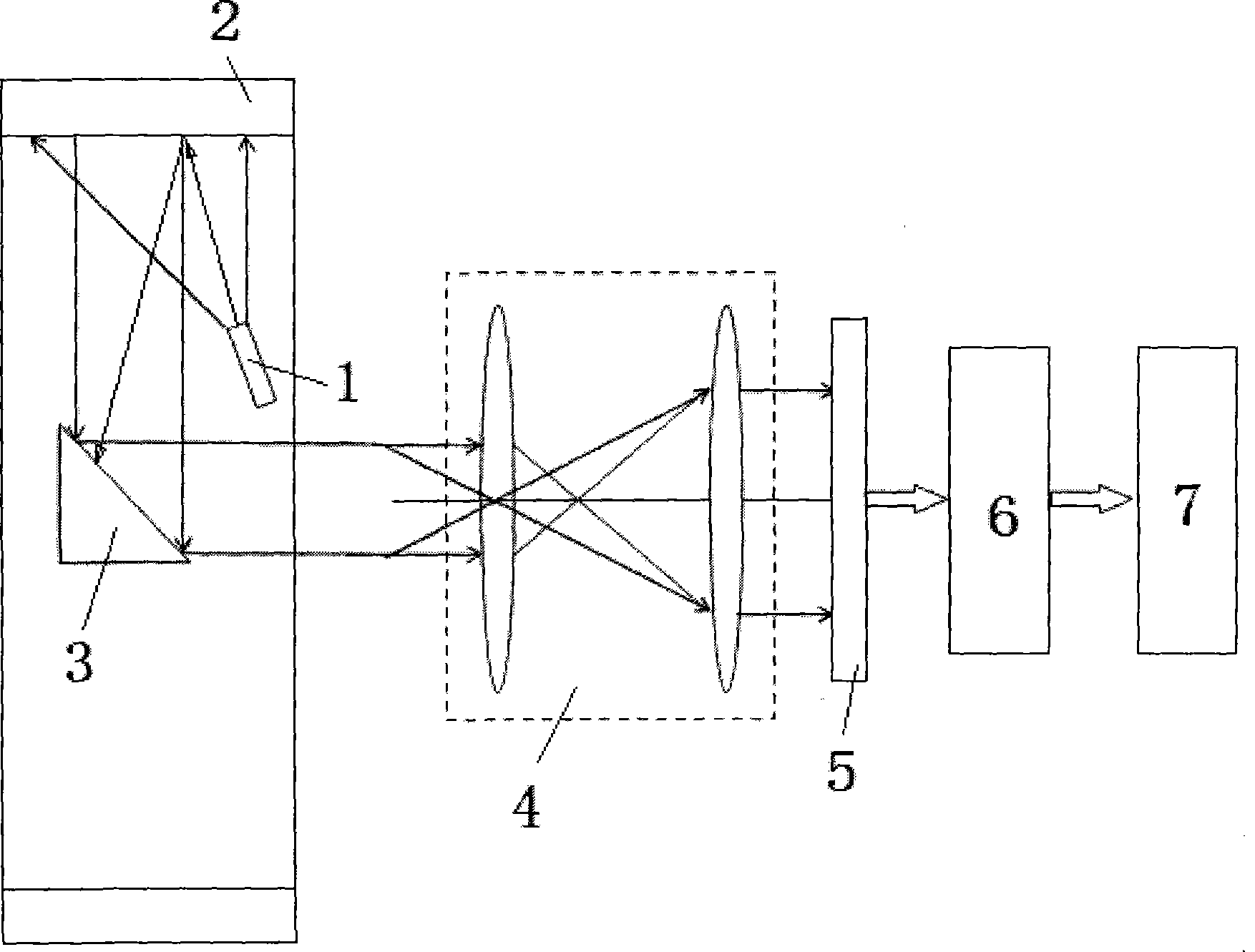

Device and method for detecting optical detector working point of particle detector

InactiveCN101852712AHigh measurement accuracySimple structural designParticle size analysisSignal onComputational physics

Owner:BEIJING JIAOTONG UNIV

Laser powered automobile window cleaning system and method

InactiveUS7946301B1Easy to disassembleWork treatment devicesElectrostatic cleaningEngineeringLaser beams

A laser powered cleaning system for cleaning pollutants and debris from both sides of automobile windshields and windows. The system includes an electromagnetic interior block having a top surface having a plurality of focused laser beams, and a magnetic exterior block having a top surface including a reflective surface. The windshield or window is situated between the interior and exterior blocks which pass over the window for cleaning. A power cord connected to an adapter plugs into an automobile power outlet for supplying power. A safety sensor is integrally coupled to the interior block for actuating the system when safe. The system is fixable onto a windshield or window within a door of an automobile. An on-off switch actuates the fixed system.

Owner:WALSH JOHN

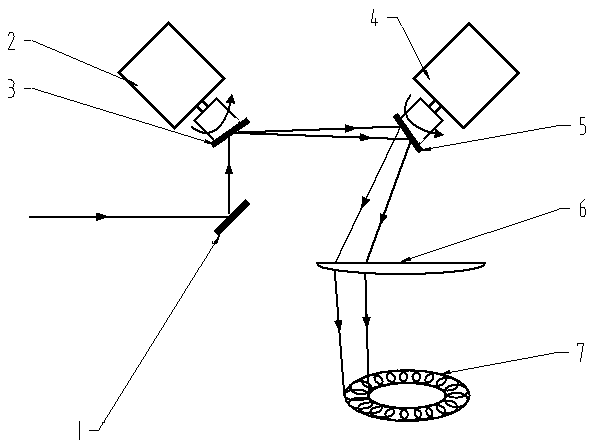

Two unidirectional rotating mirrors based method and device for realizing uniform laser cleaning

InactiveCN110262037AScan evenlyAvoid damageCleaning processes and apparatusOptical elementsSurface cleaningLight beam

Owner:WEIFANG UNIVERSITY

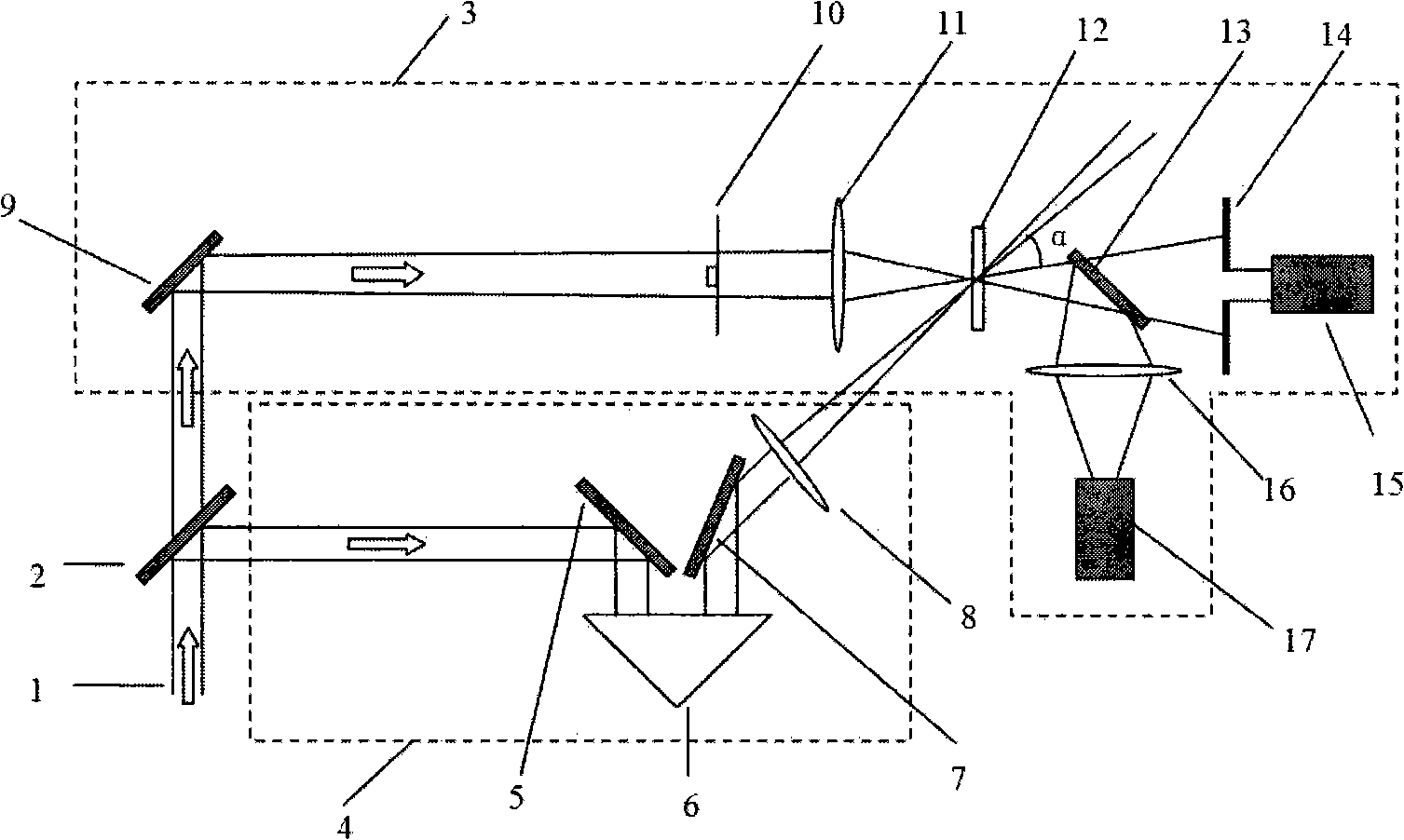

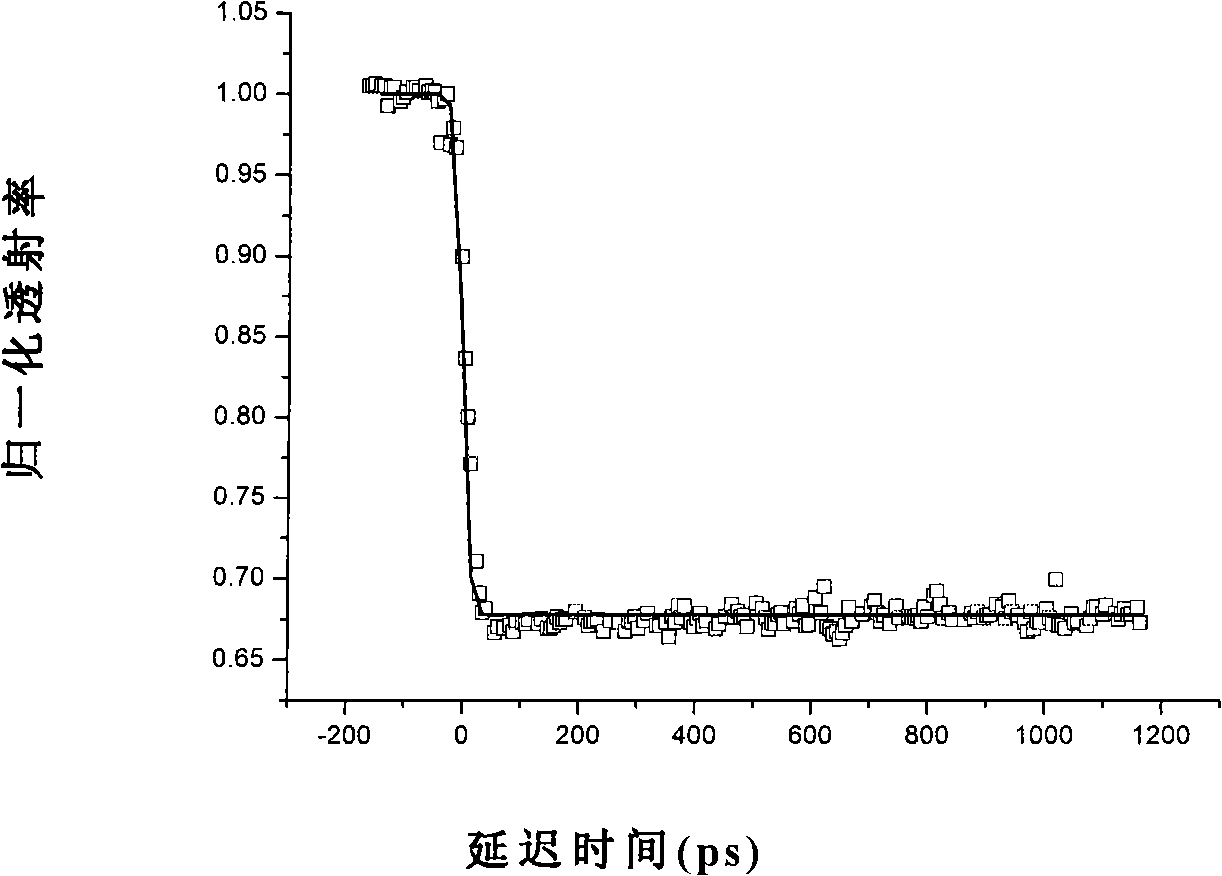

Pumping detection method based on Z scan

InactiveCN101324503ADetermine absorbencyDetermining lifeMaterial analysis by optical meansDelayed timePump probe

Owner:SUZHOU UNIV

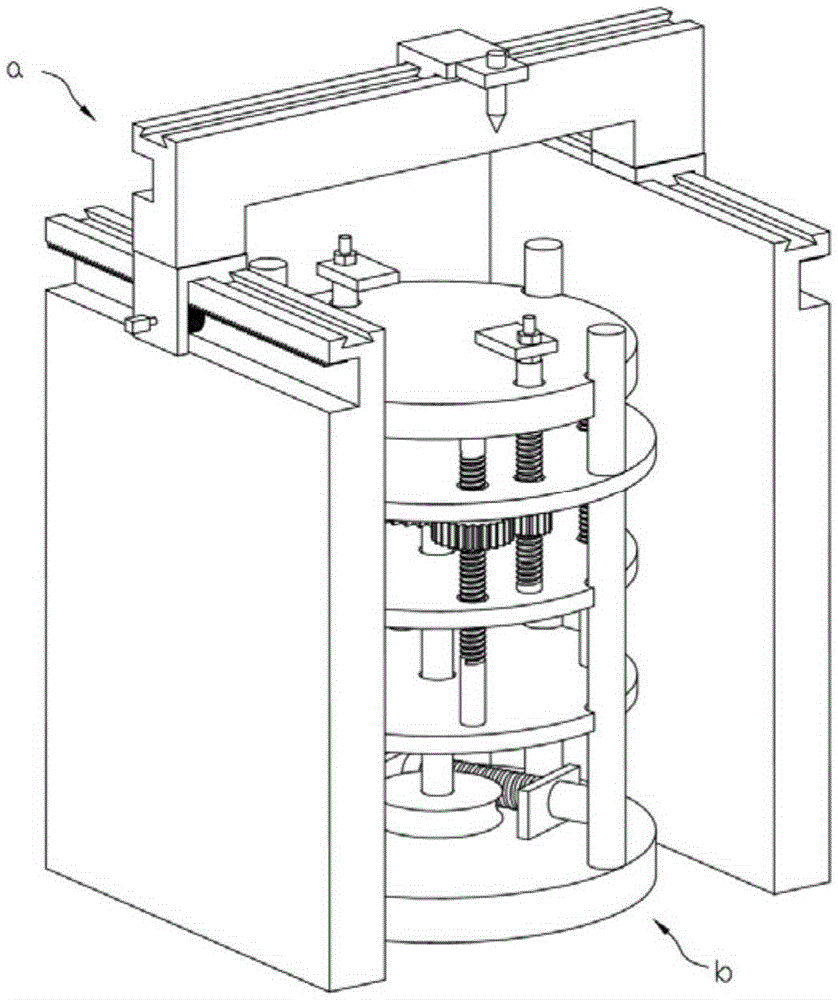

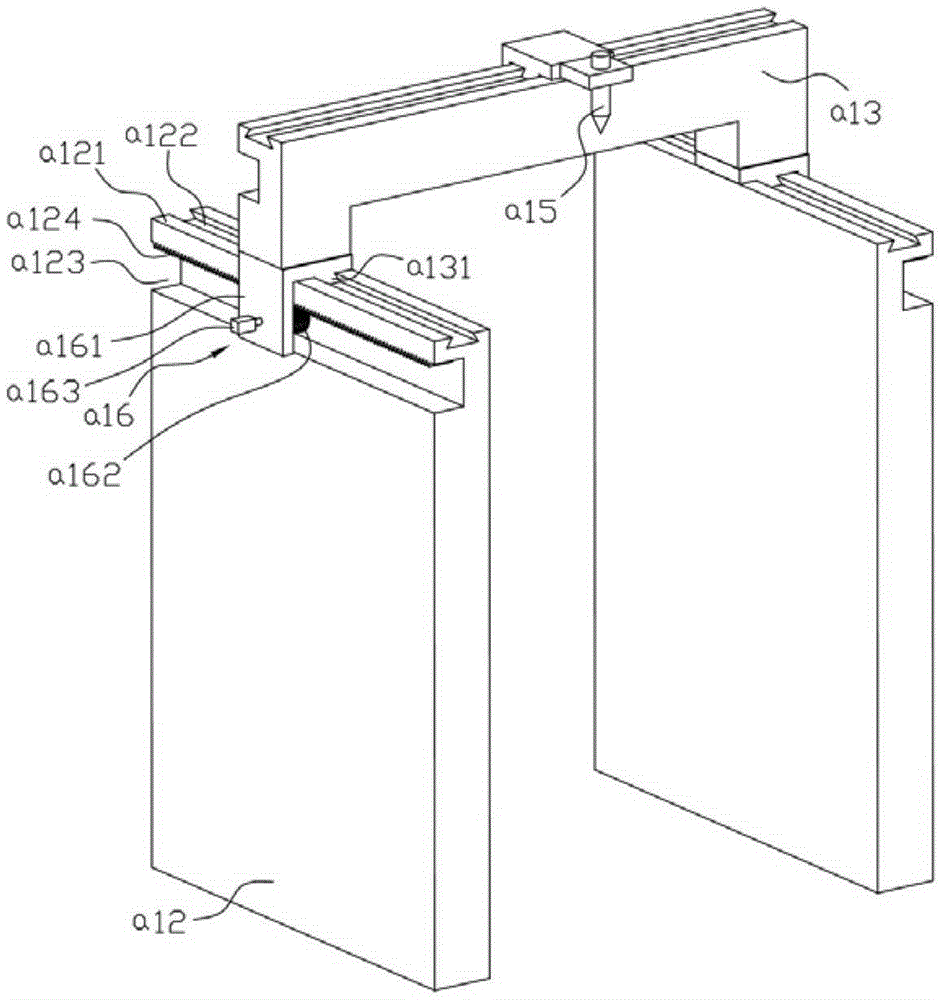

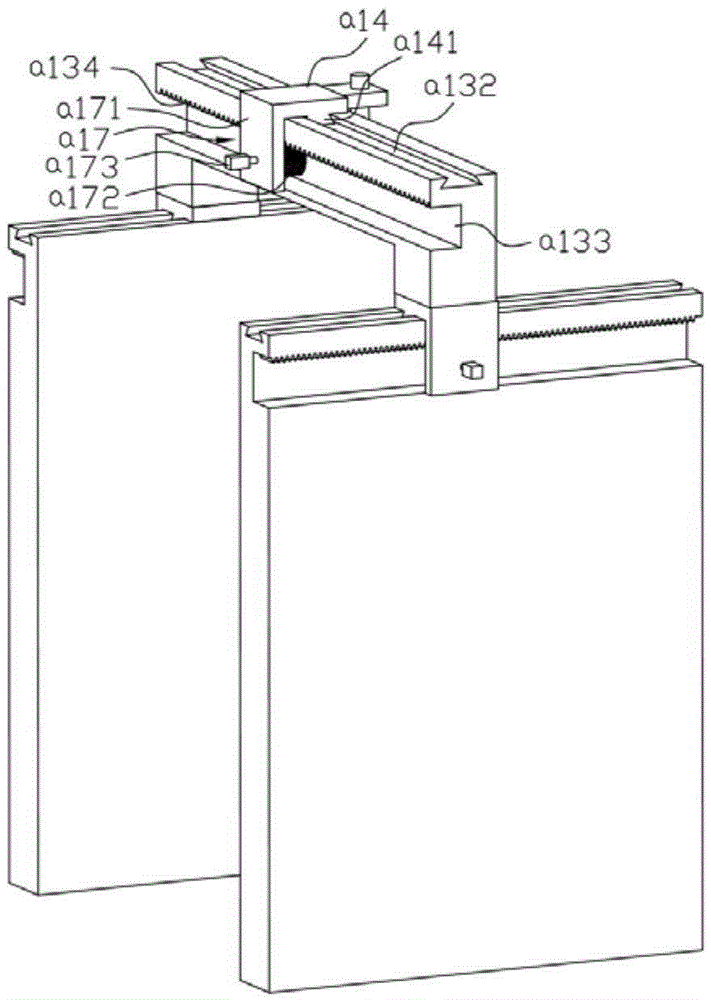

Template laser cutting equipment provided with template fixture

InactiveCN105414750AWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingLaser beams

Owner:DONGGUAN QINZHI IND DESIGN CO LTD

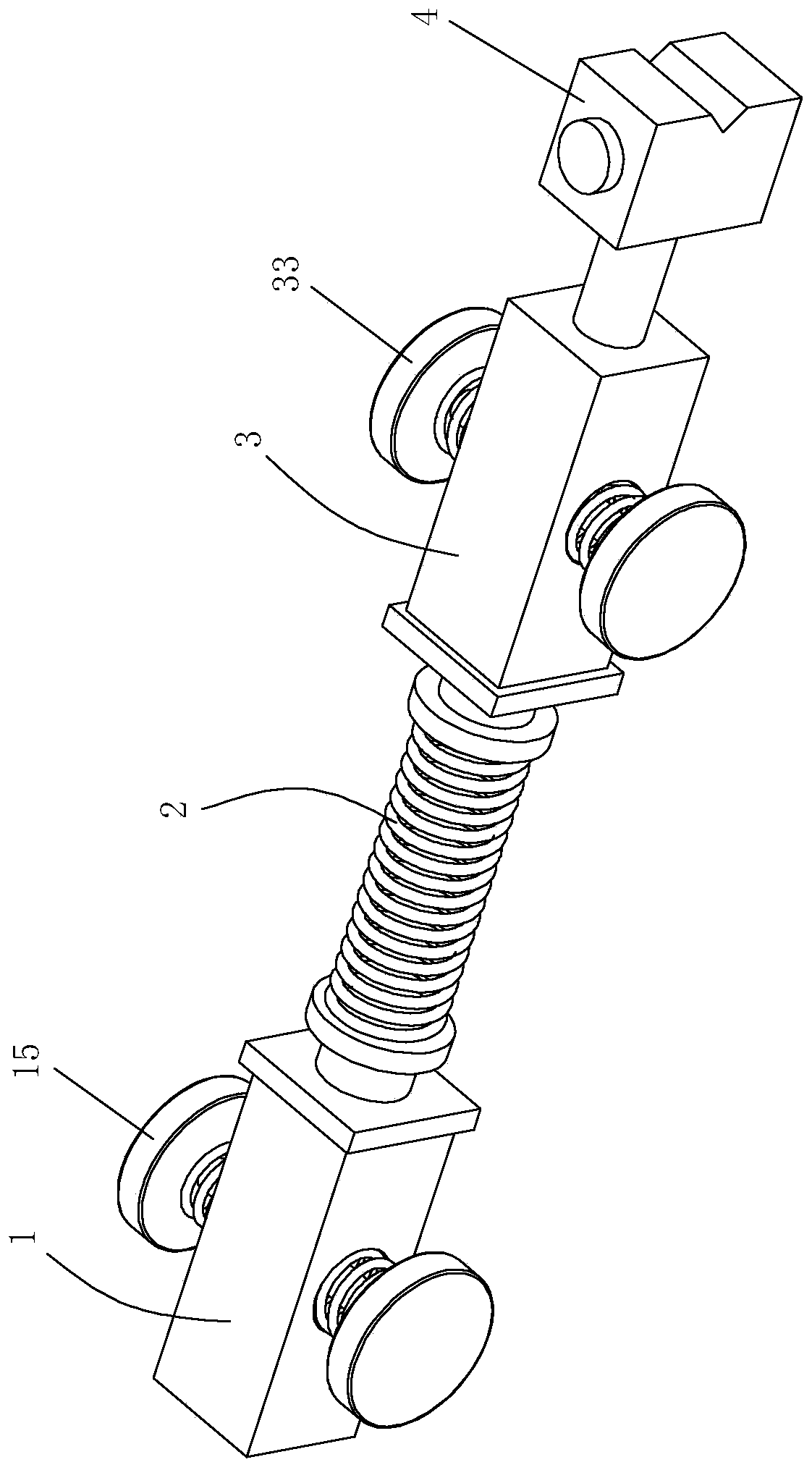

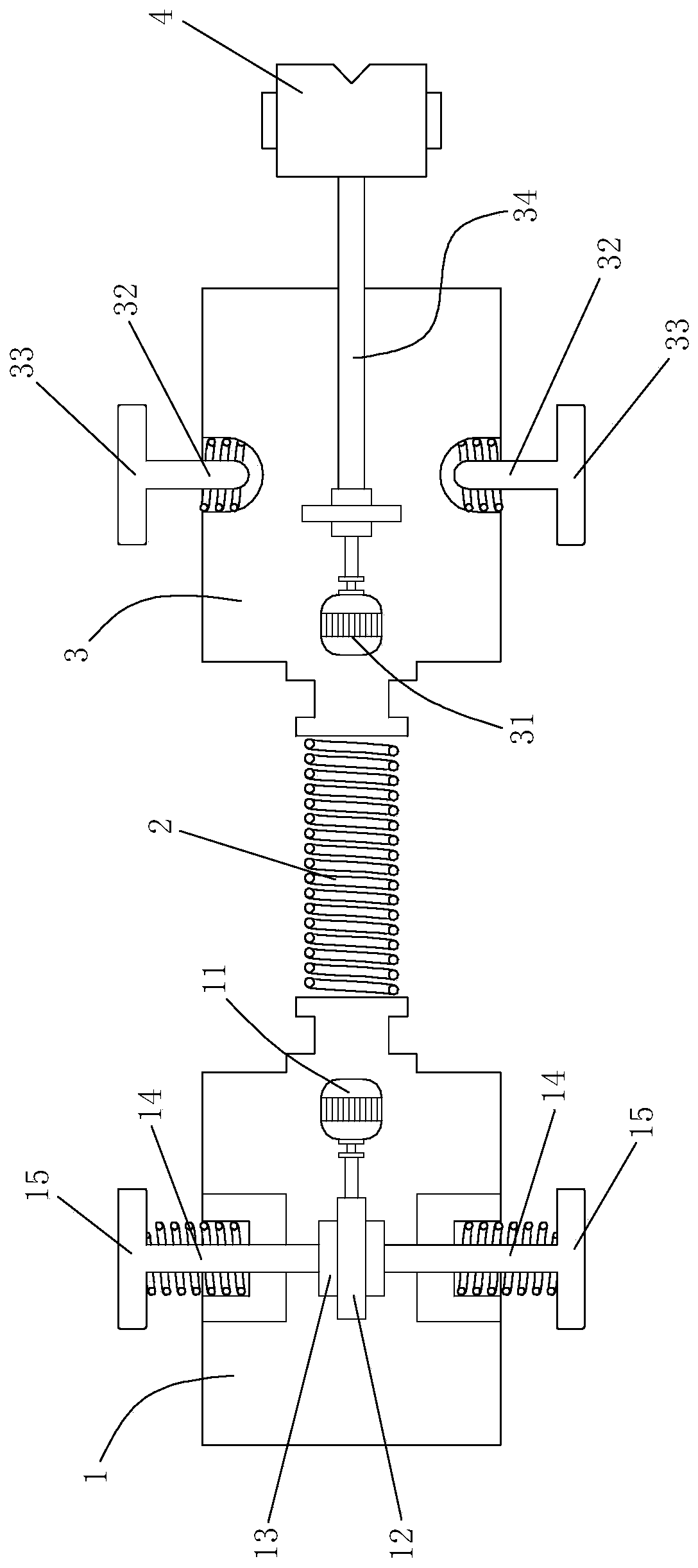

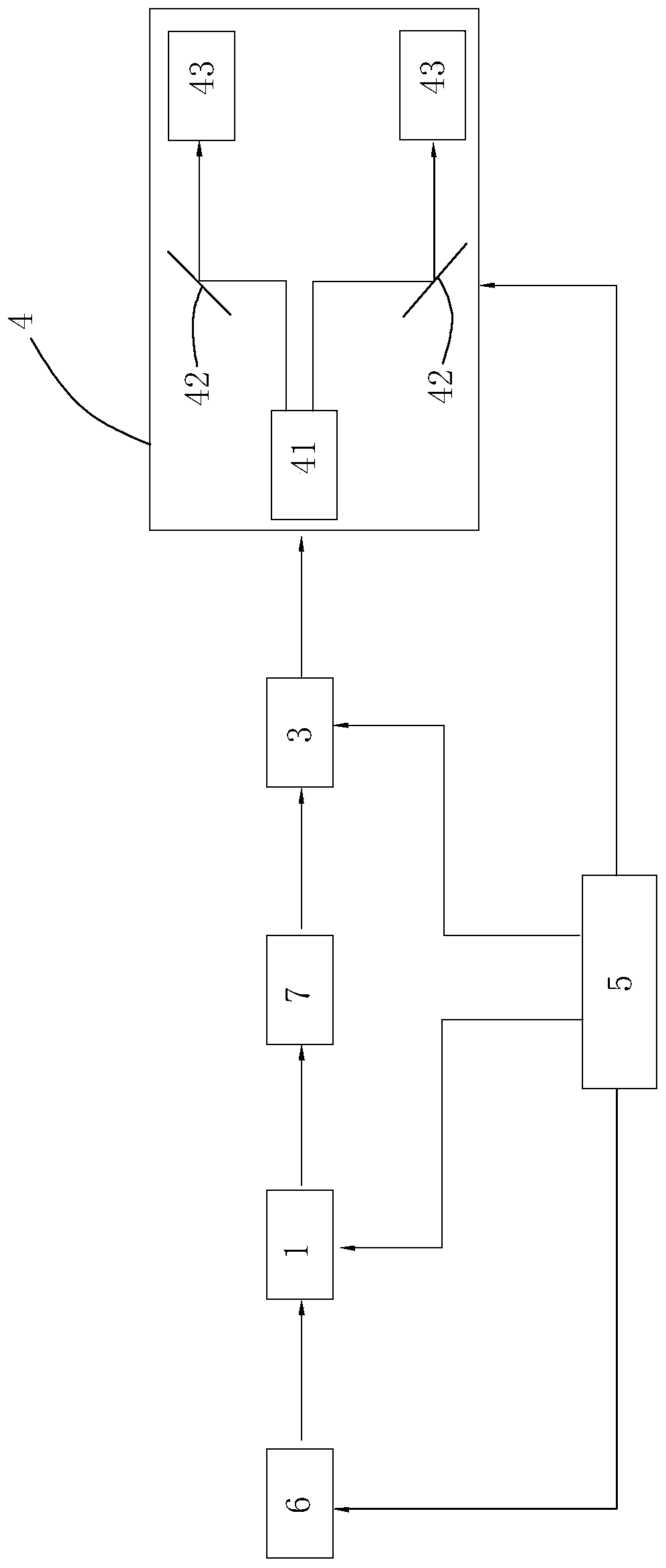

Simple pendulum

InactiveCN101650889AAccurate measurementAchieve regulationMechanical unknown time interval measurementEducational modelsProtractorControl signal

The invention provides a simple pendulum comprising a simple pendulum support, a pendulum rope and a pendulum ball. The simple pendulum also comprises a laser pointer and an electronic stopwatch. Thelaser beams sent out by the laser pointer are used as control signals. The case of the electronic stopwatch is provided with light receiving holes and the electronic stopwatch is provided with a photoelectric gate circuit capable of controlling stopwatch timing. The laser pointer is fixed at one end of a U-shaped support and the electronic stopwatch over against the laser beams sent out by the laser pointer is fixed at the other end of the U-shaped support. A device capable of generating the magnetic field is arranged below the equilibrium position of the simple pendulum. At the fixed point ofthe pendulum rope on the simple pendulum support, a protractor is arranged on a plane parallel with the plane of motion of the pendulum ball. The zero graduation line of the protractor and the plumbline coincide, and then the graduation lines of 1-90 degrees are marked symmetrically at the left and right sides of the protractor.

Owner:屈社文

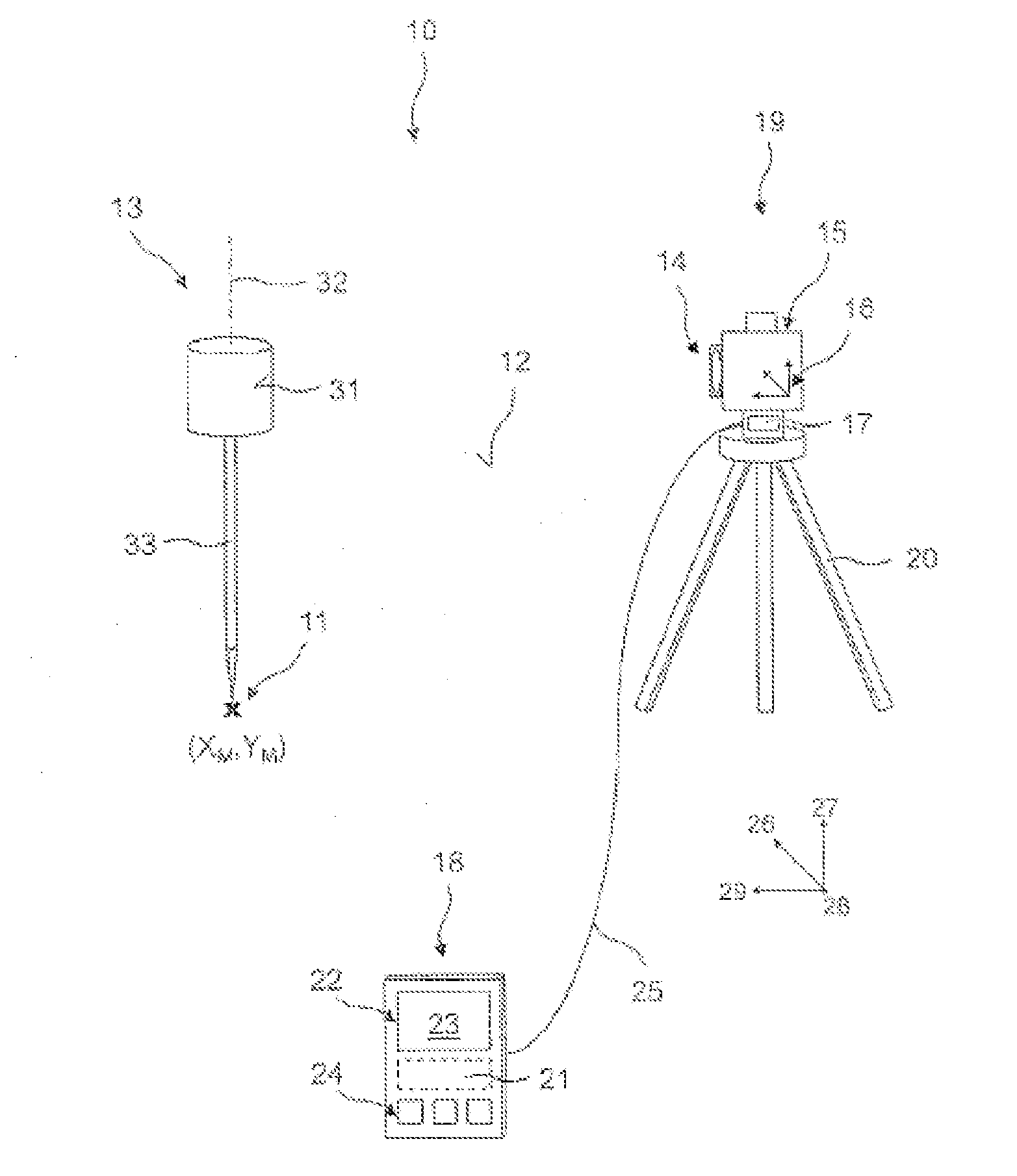

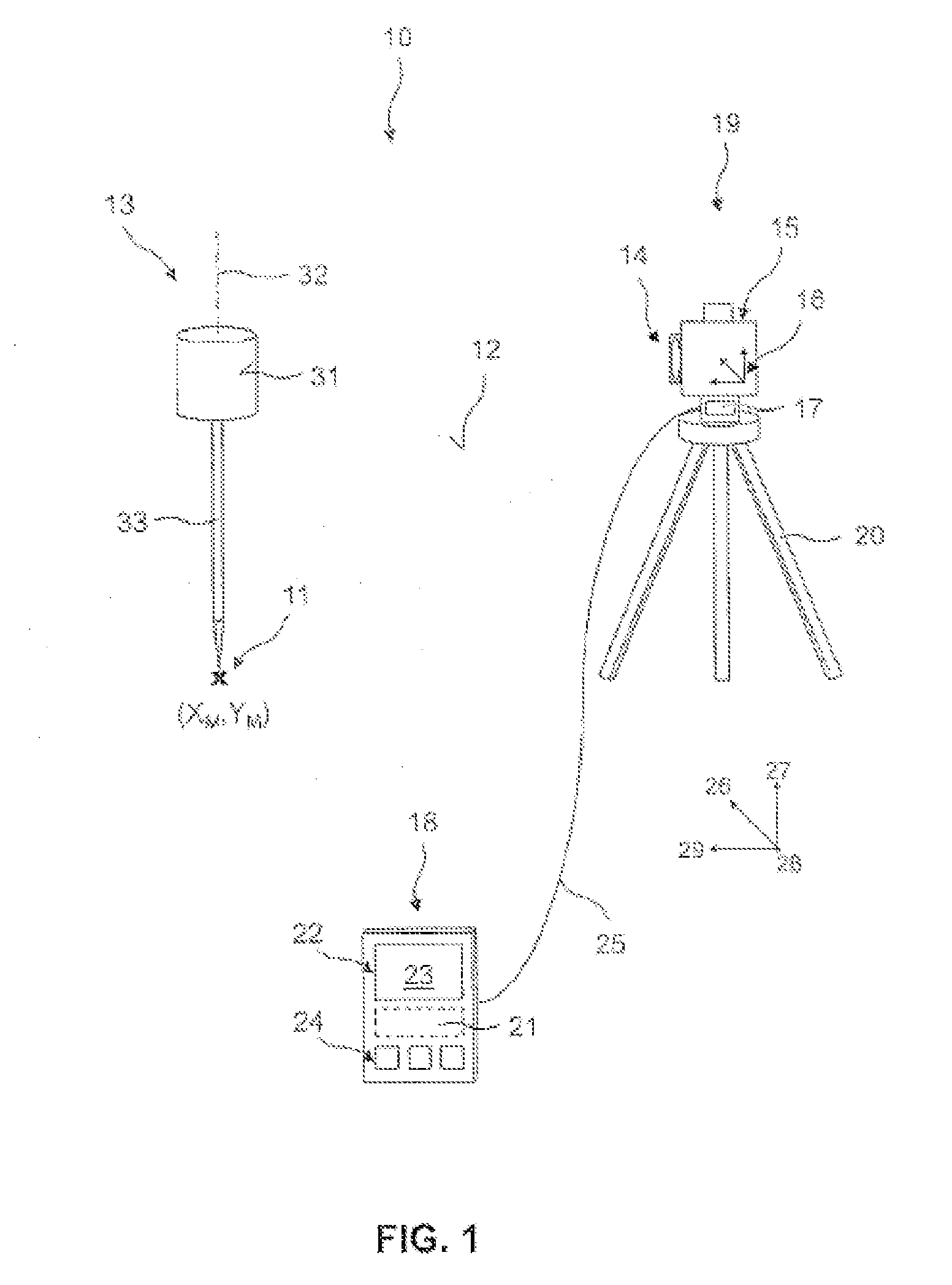

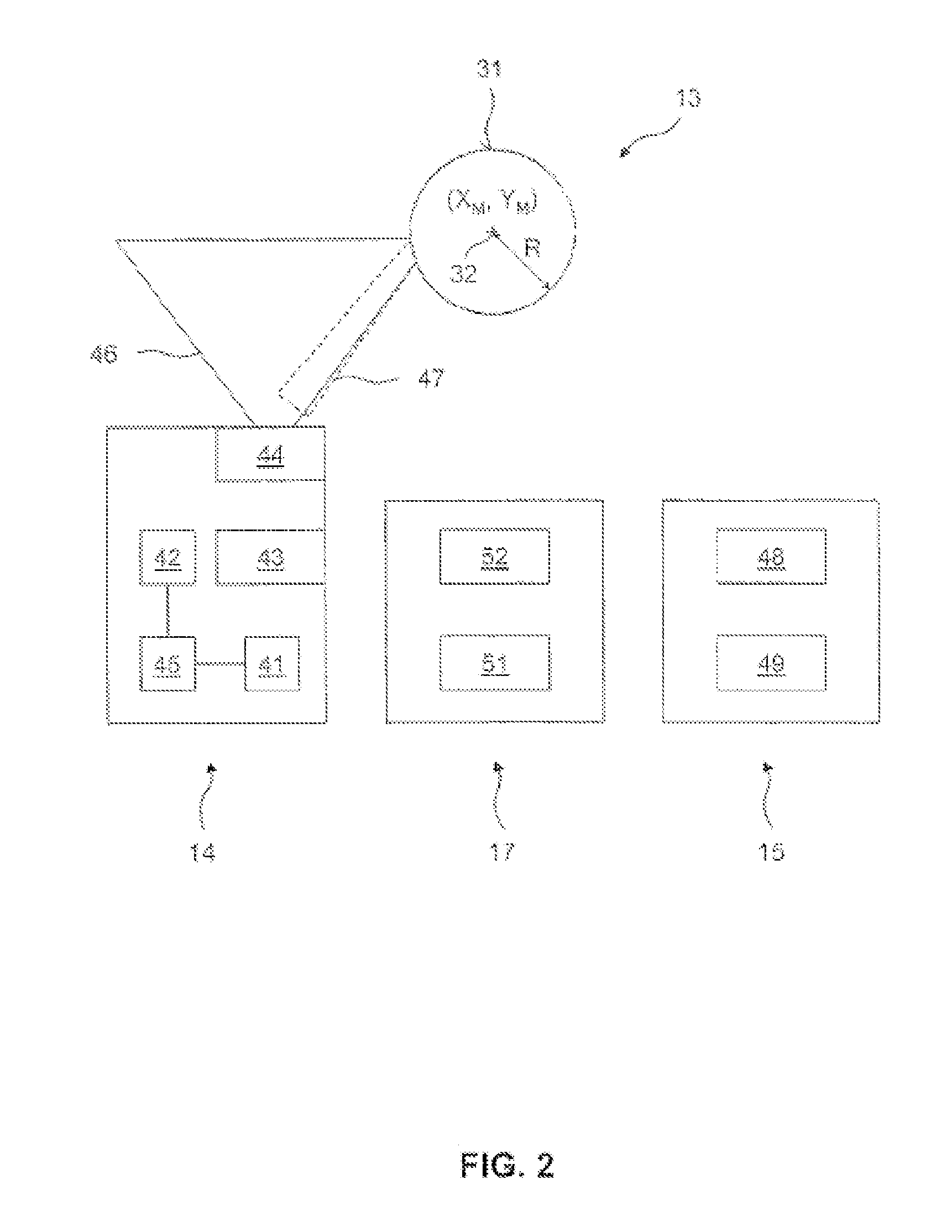

Method and Device for Determining the Position Coordinates of a Target Object

ActiveUS20150346341A1Improve accuracyLimited equipment expenseOptical rangefindersActive open surveying meansMeasurement deviceLight beam

Owner:HILTI AG

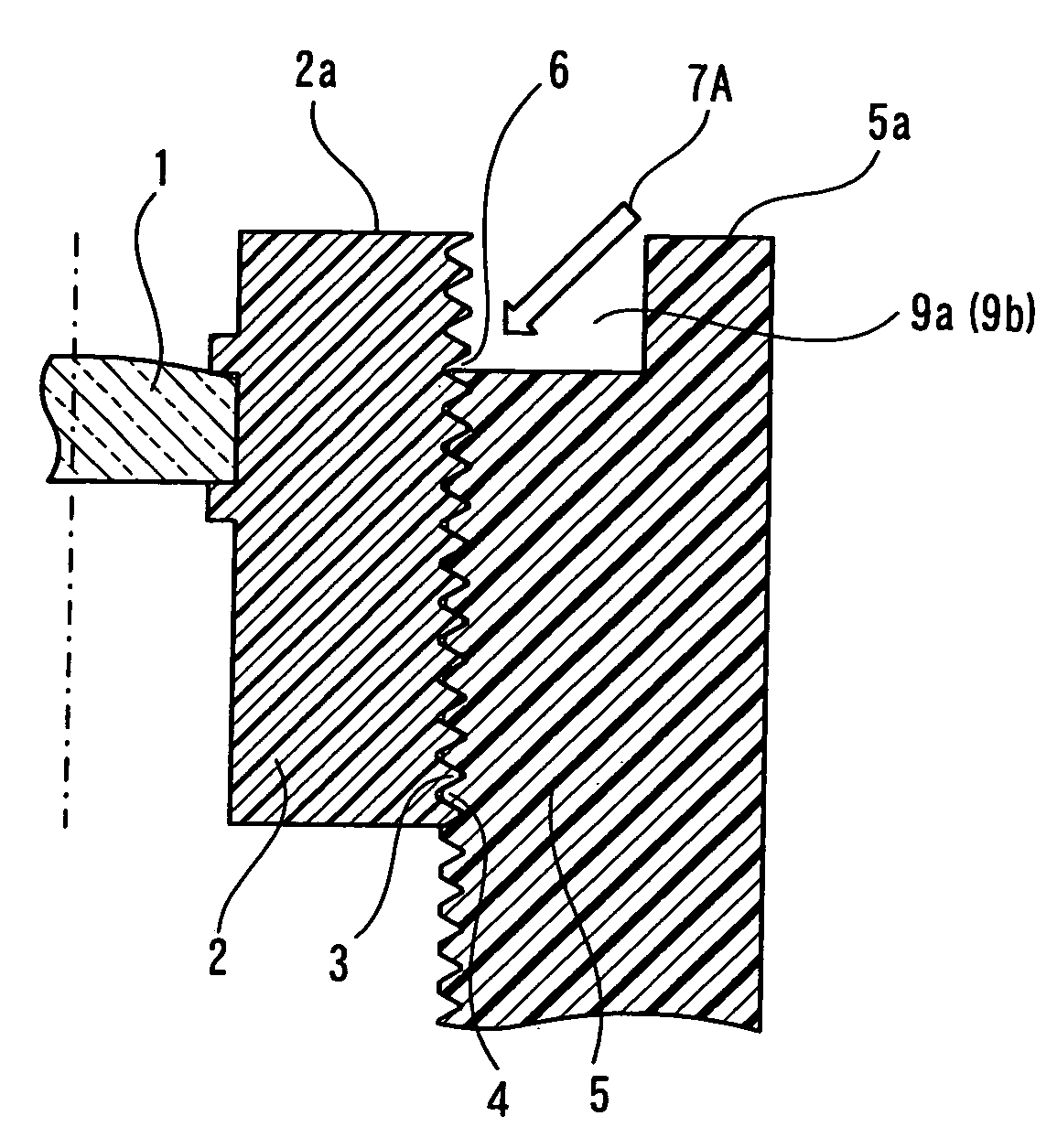

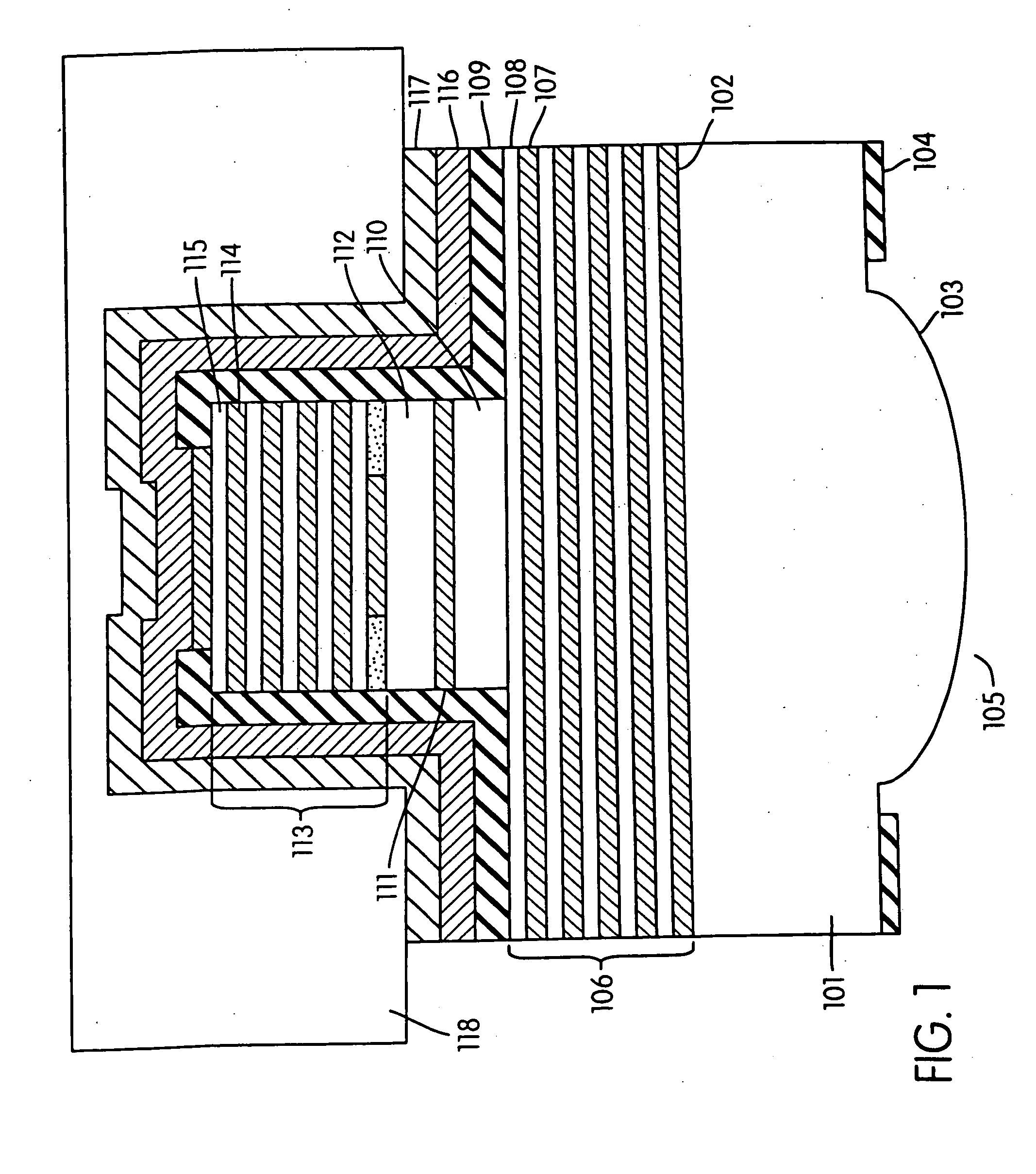

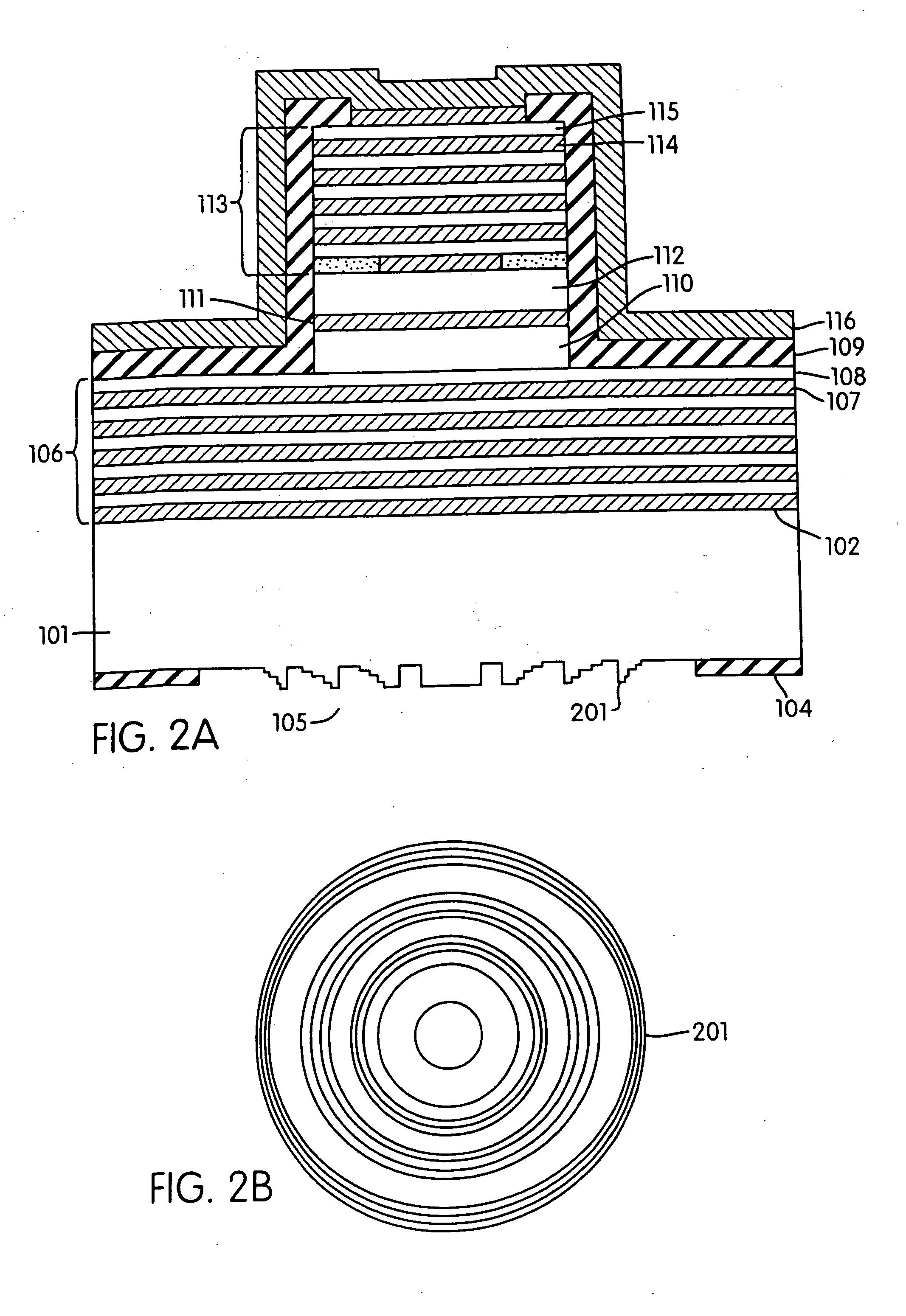

Process for produicng stamper for direct mastering, and stamper produced by such process and optical disc

InactiveUS20060290018A1Increased durabilityWeaken energyOptical articlesRecord information storageEngineeringInjection molding machine

In producing a stamper for molding an optical disc, a master disc which can be obtained from the steps of forming a thermosensitive material layer capable of acting as a negative type by a laser beam on a substrate, irradiating a laser beam to predetermined areas of the thermosensitive material layer so as to partially perform exposure and wet-etching the partially exposed thermosensitive material layer so as to form a fine pits-and-bumps pattern is used as a stamper for injection molding machine. Therefore, minute pits each having a size smaller than the spot of the laser beam of optical limit are formed, thereby providing a stamper with the small number of deficiencies.

Owner:PANASONIC CORP

Laser welding apparatus and method of laser welding

ActiveCN102196879AAvoid meltingInhibitionWelding/cutting auxillary devicesAuxillary welding devicesThick wallLaser beams

Owner:MITSUBISHI SHIPBUILDING CO LTD

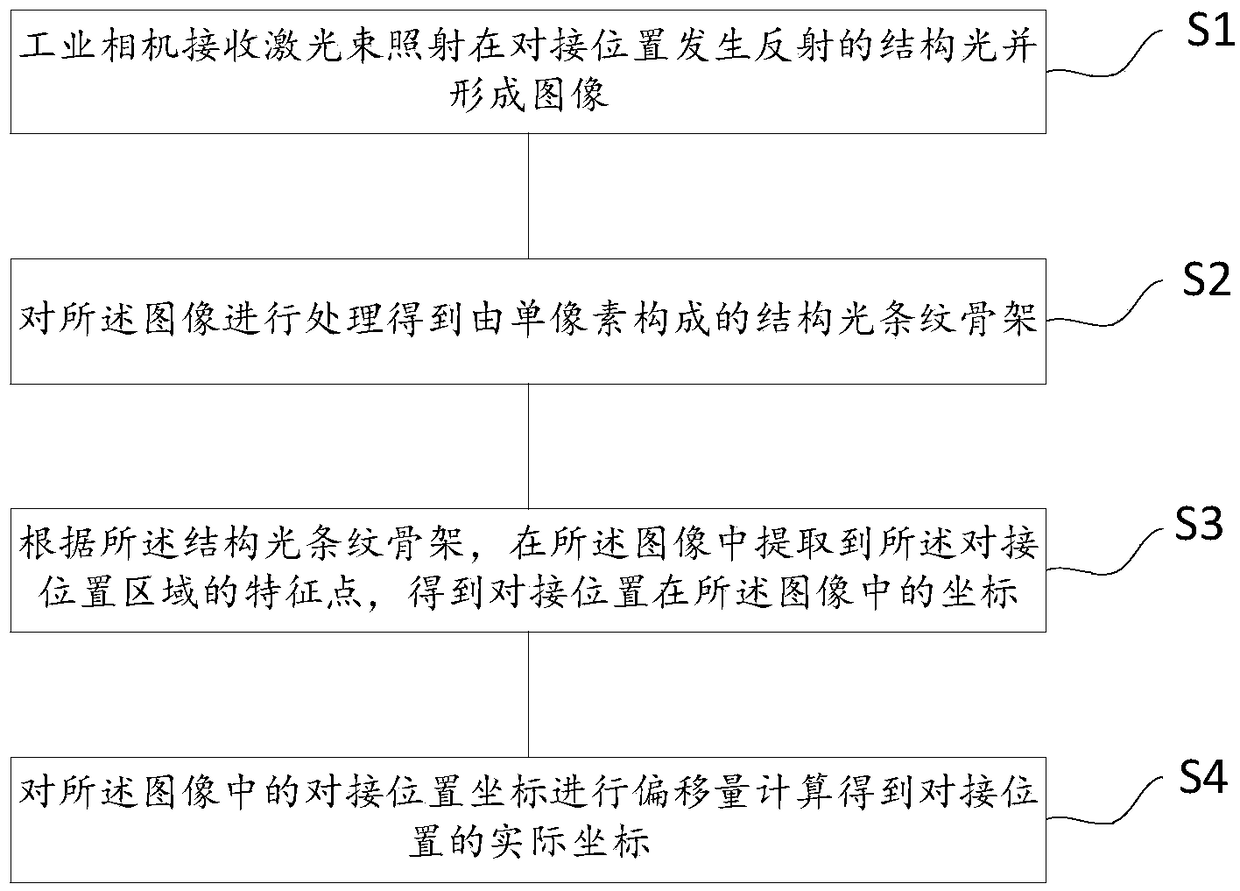

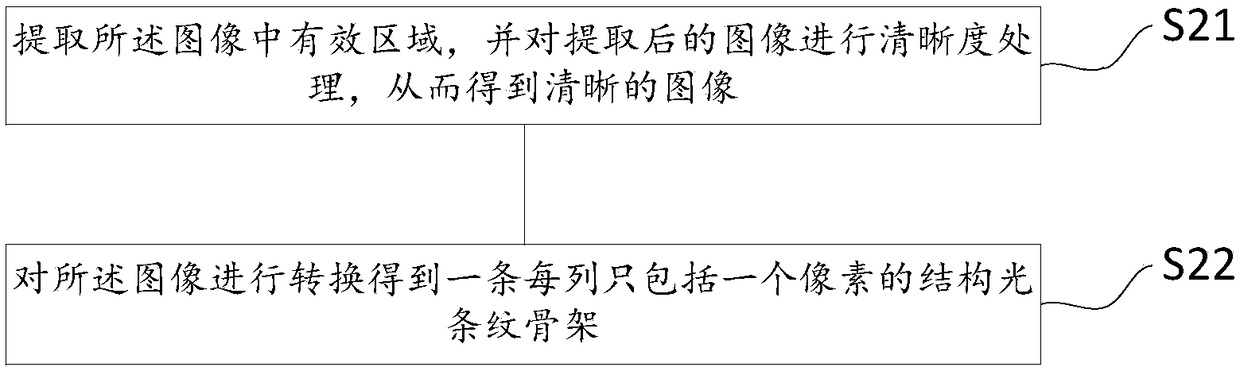

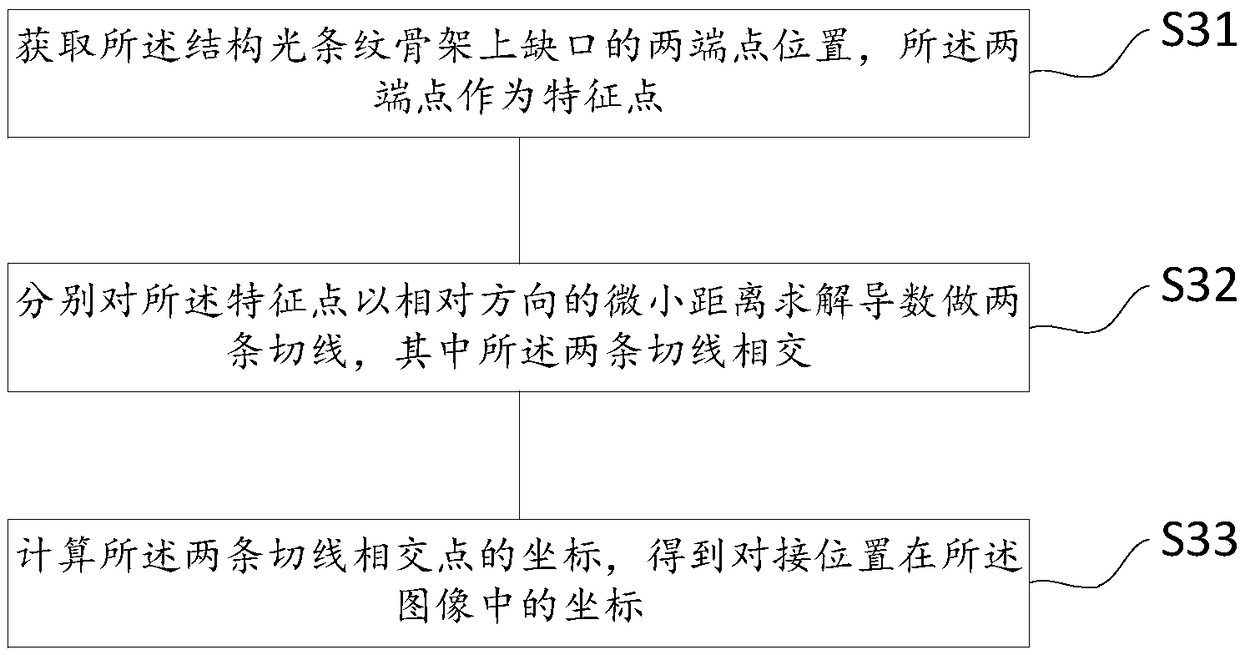

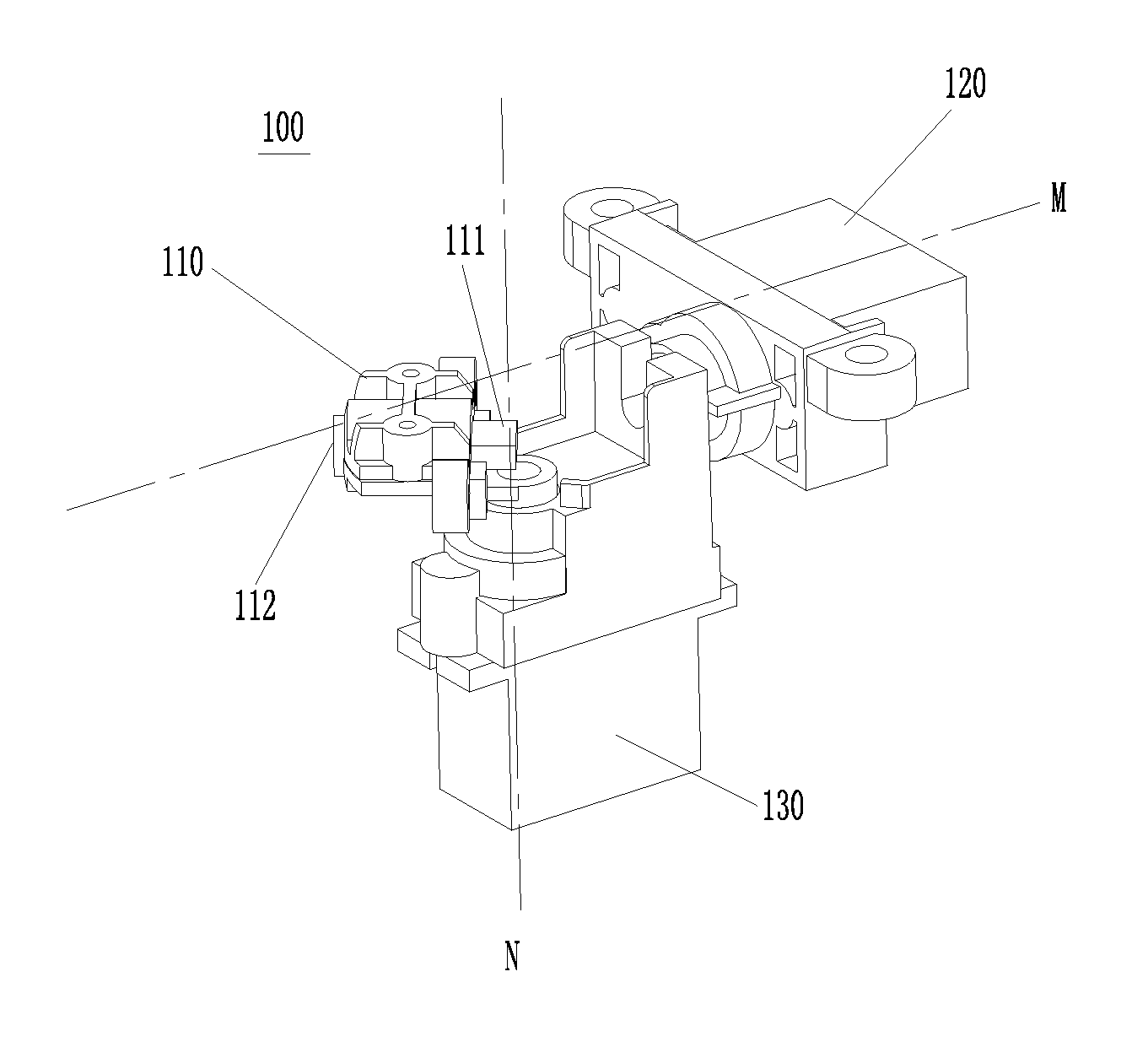

Welding line positioning method and system applied to welding line positioning

InactiveCN109202284AFix inaccurate positioningHigh positioning accuracyLaser beam welding apparatusButt jointEngineering

Owner:HANS LASER TECH IND GRP CO LTD +1

Light spot indication robot and light spot indication method thereof

ActiveUS20160368143A1Programme controlInput/output for user-computer interactionLaser beamsLight beam

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

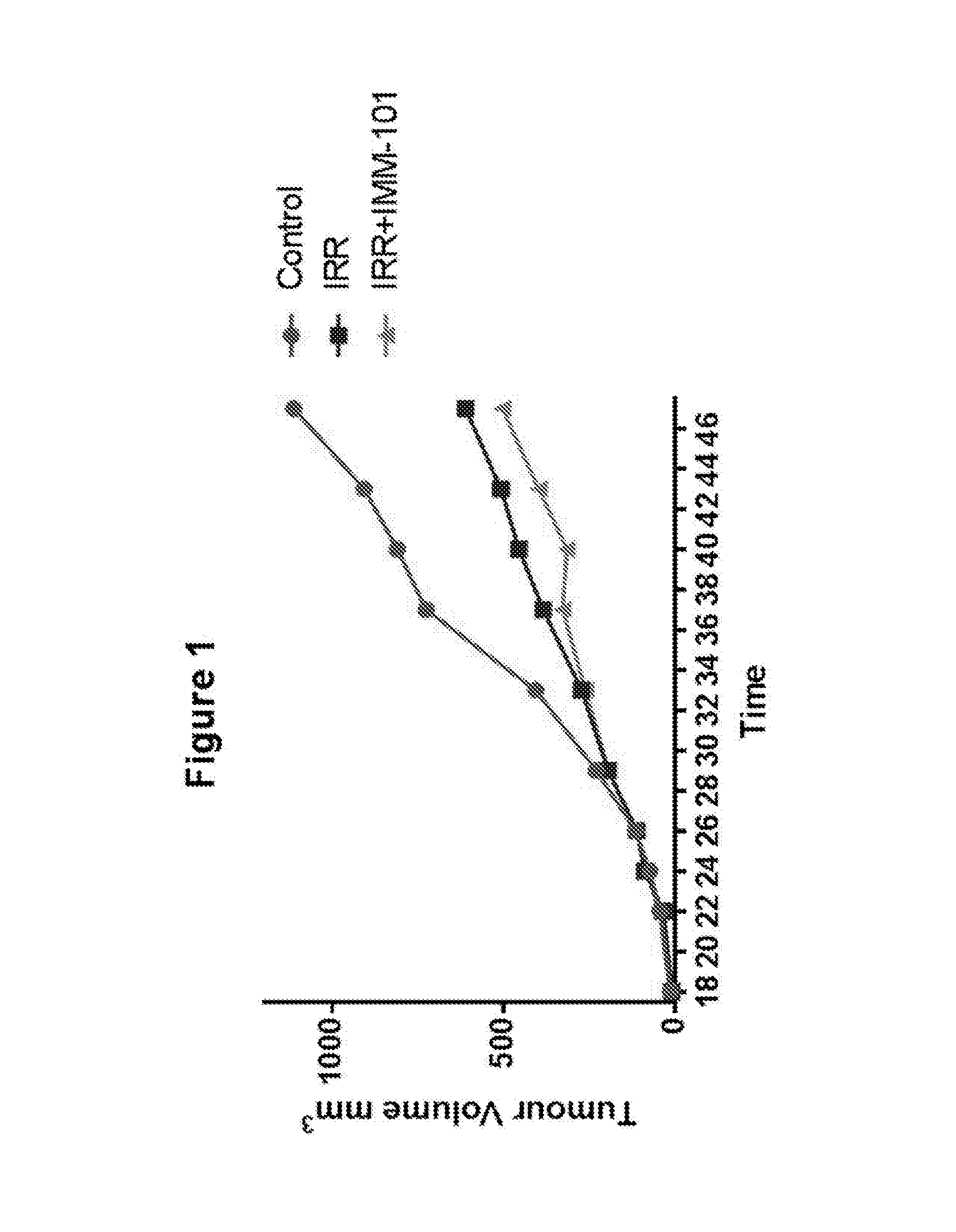

Immunogenic Treatment Of Cancer

InactiveUS20140356397A1Bacterial antigen ingredientsElectrotherapyRadiofrequency ablationRadiation exposure

Owner:IMMODULON THERAPEUTICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap