Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Laser line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

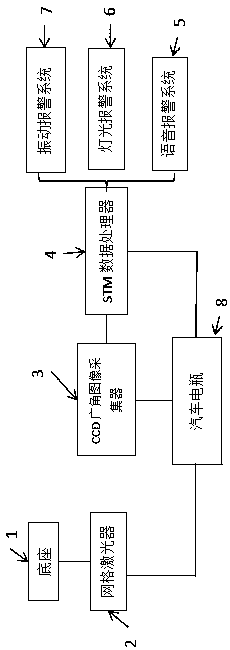

Method and device for measuring position and line width of laser beam by using line array CCD (Charge Coupled Device)

The invention relates to a method and device for measuring position and line width of a laser beam by using a line array CCD (Charge Coupled Device). The method comprises the following steps of: 1, obtaining a Gaussian curve of an incident laser line beam; and 2, detecting the position and the line width of the laser beam according to the Gaussian curve. The method and the device can be used for detecting the absolute and the relative positions of the laser line beam and detecting the line width of the line beam, and can be converted into a mode of measuring displacement, length, angle displacement and the like; and by using the method, the deformation and the amplitude of a platform are detected, the line linearity of the straight line laser is measured, and a laser instrument is comprehensively detected.

Owner:XIAN HUANIC OPTOELECTRONICS CORP

Plate leveling method for plate jointing operation in shipbuilding plane section assembly line

The invention provides a plate leveling method for plate jointing operation in a shipbuilding plane section assembly line. The plate leveling method comprises the following steps of: adopting a linear laser in the plate jointing operation; transmitting laser lines at an angle of 40-45 degrees formed by the linear laser and the horizontal direction for simultaneously projecting plate surfaces with different heights, wherein if the heights of the plate surfaces are different, intersection points of the laser lines reaching the plate surface are different, and if the heights of the plate surfaces are identical, intersection points of the laser lines reaching the plate surfaces are identical; and adjusting the levelness of the joined plate according to information of the intersection points. According to the plate leveling method disclosed by the invention, the problems of lower work efficiency and longer consumed time in the plate jointing work in the prior art can be solved; information judgment of operators is visual, so that the accuracy of the operation position of the plate can be achieved quickly and effectively; and the time consumed by assembling and positioning operation quantity of same weld joints is shortened by 50 percent compared with the prior time, and thus the work efficiency of jointing plate is greatly increased.

Owner:QINGDAO YANGFAN SHIPBUILDING CO LTD

Microminiature laser linear module

PendingCN112448264AThe volume can be miniaturizedLaser detailsSemiconductor lasersFixed frameEngineering

The invention relates to a miniature laser linear module, and the module comprises a heat dissipation seat, wherein a fixed frame is formed above the heat dissipation seat, and a plurality of pins arearranged below the heat dissipation seat; a laser diode crystal grain which is arranged on the fixed frame; a sealing cover which seals the heat dissipation base, wherein a containing groove is formed in the sealing cover, a light outlet window is formed in the sealing cover, the light outlet window is located in front of the containing groove, the containing groove is communicated with the lightoutlet window, and the positions of the laser diode crystal grains correspond to the positions of the containing groove and the light outlet window; a cylindrical lens which is arranged in the accommodating groove and is provided with a first surface and a second surface on the opposite side, so that the first surface faces the laser diode crystal grain at a first micro distance, and the second surface faces the light emitting window at a second micro distance; therefore, the laser diode crystal grain excites a laser light source to the cylindrical lens, the laser light source is in an elliptical cone shape to form a light source angle, and the light source angle is gradually collimated after passing through the first surface of the cylindrical lens to the second surface of the cylindrical lens, so that the laser light source can be converted into a linear light source.

Owner:ARIMA LASERS CORP

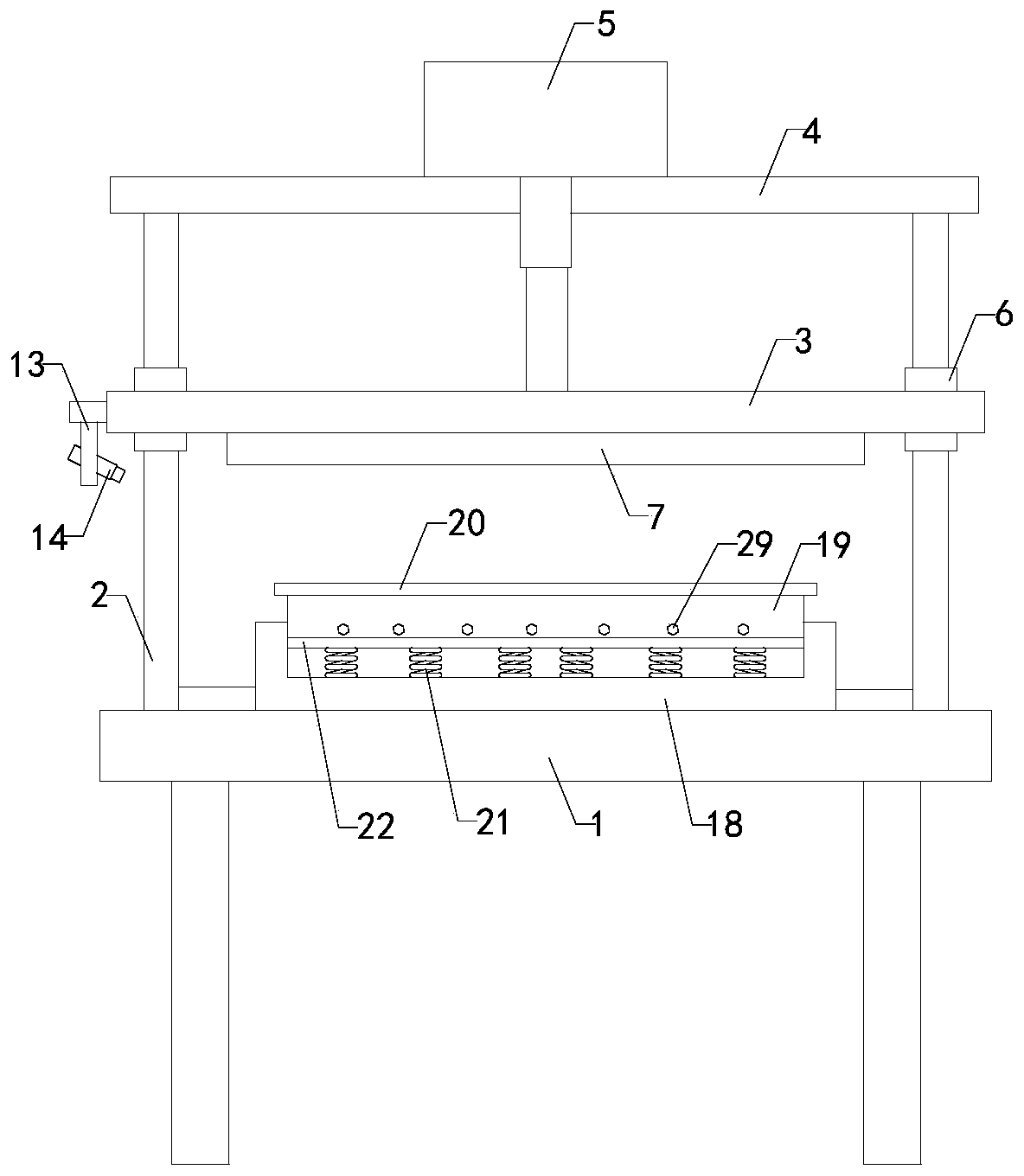

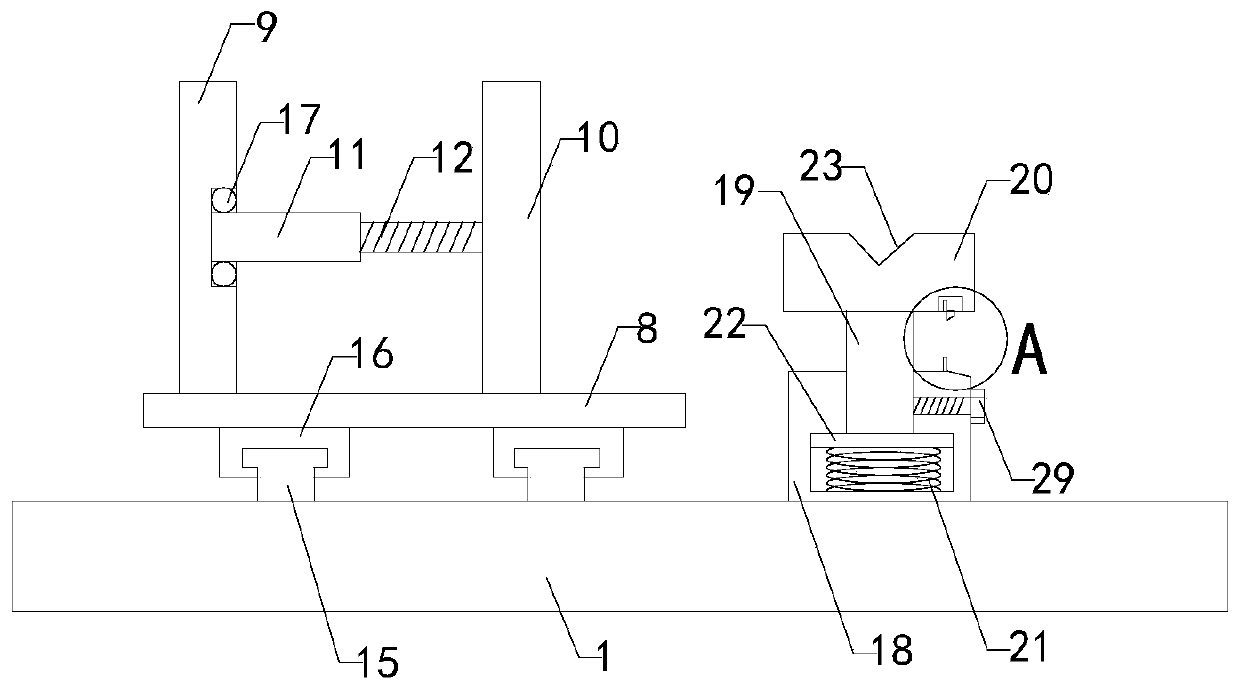

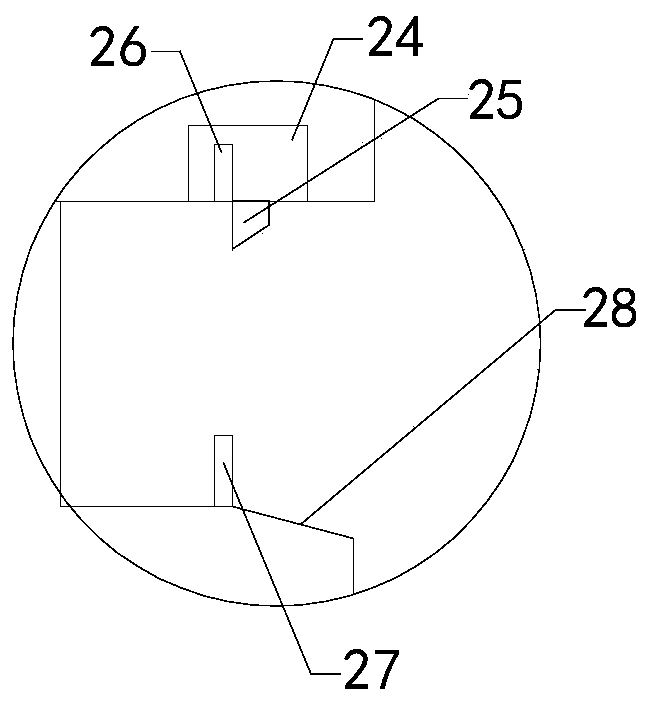

Automobile edging mechanism

InactiveCN111069380APrecise positioningImprove use reliabilityMetal-working feeding devicesVehicle componentsLaser transmitterHydraulic cylinder

Owner:江苏固诺自动化装备有限公司

Night driving road surface monitoring device

PendingCN108116311ASimple structureOperational securitySignalling/lighting devicesElectricityNight driving

Owner:肖雄飞

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap