Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about "Vehicle components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gripping mechanism for gripping portable object

Owner:ACCO BRANDS USA LLC

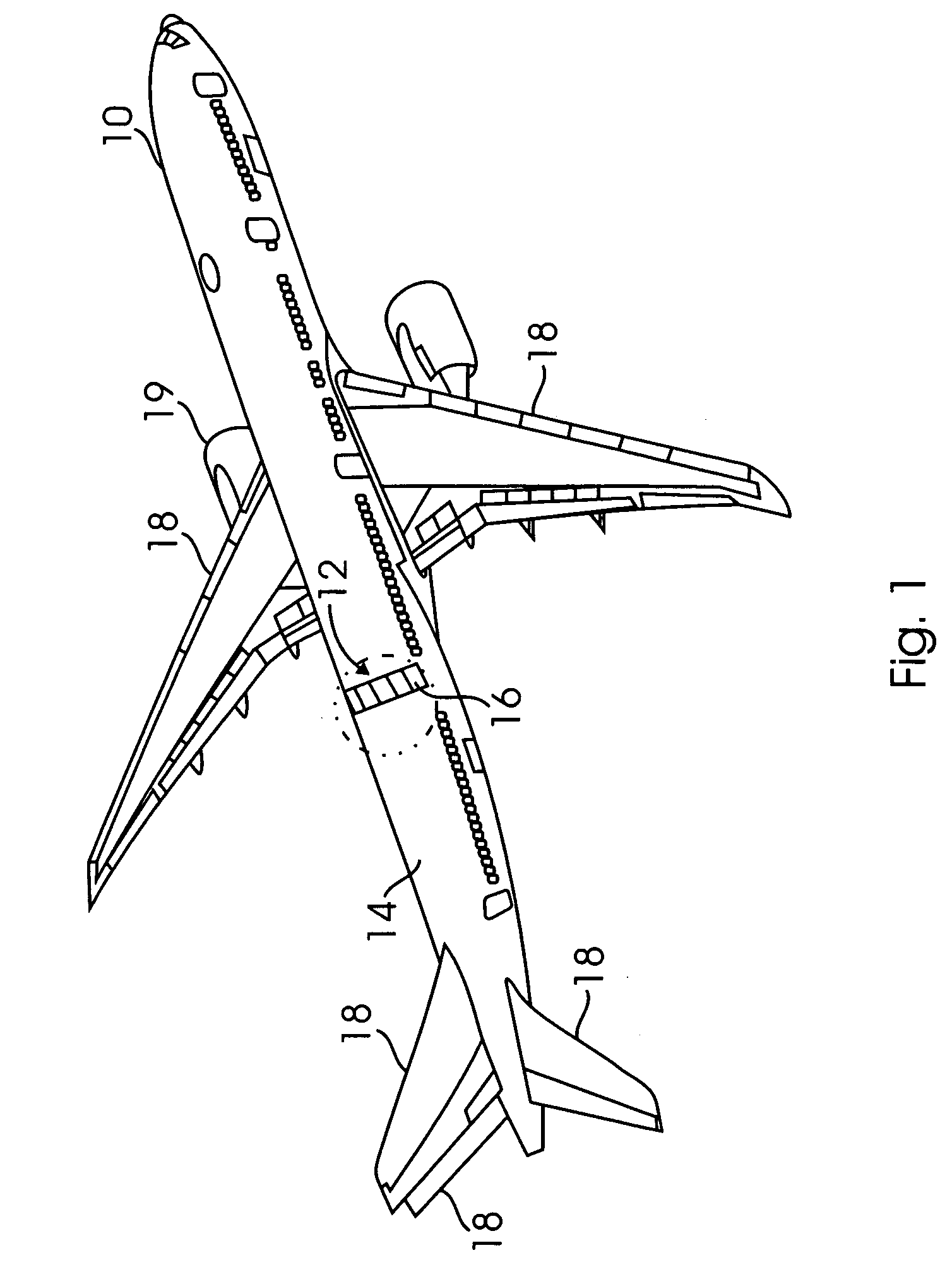

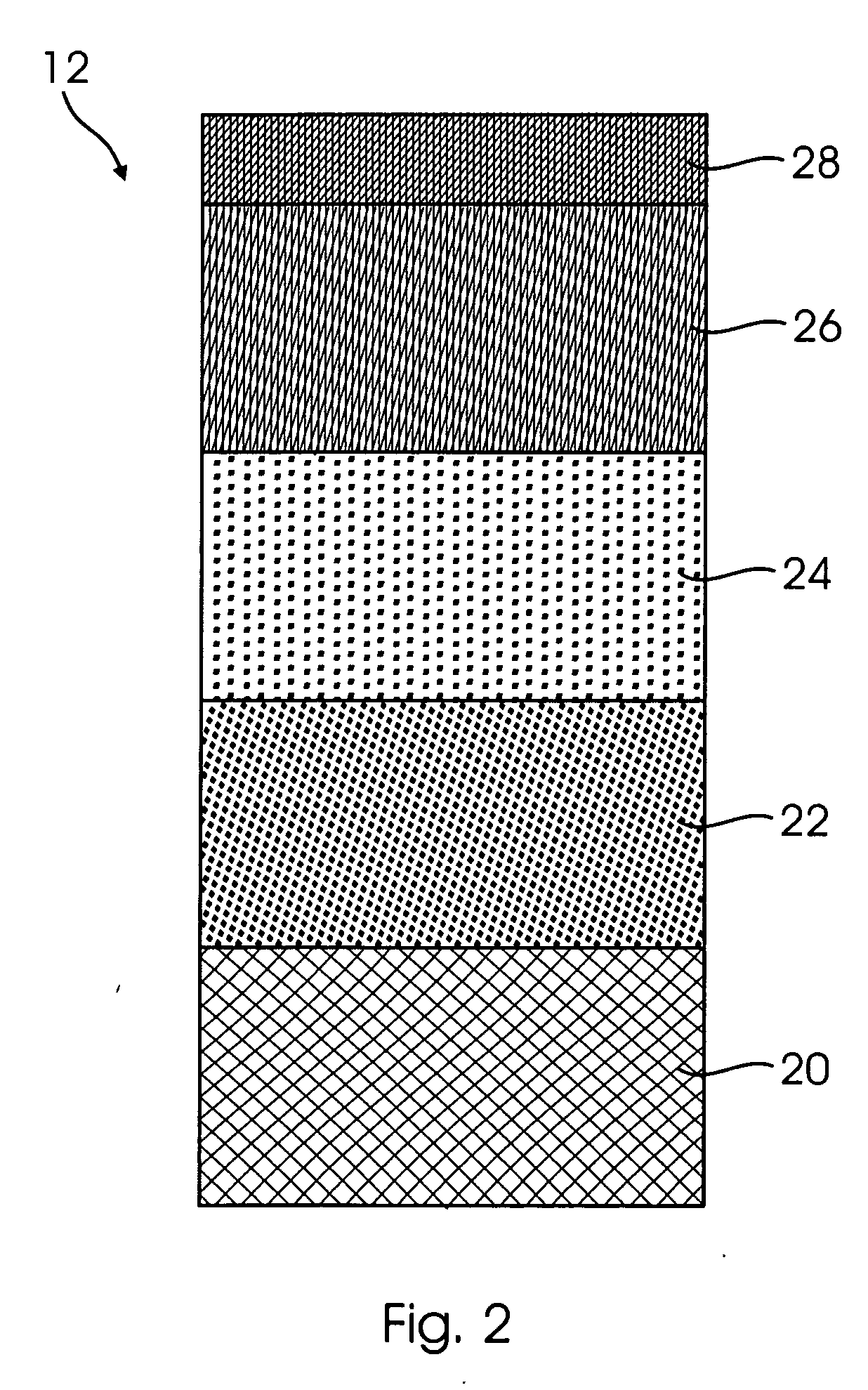

Method and system for exterior protection of an aircraft

InactiveUS20070141927A1Improve structural durabilityReduce weightAircraft lighting protectorsSynthetic resin layered productsEngineeringMetal

Owner:THE BOEING CO

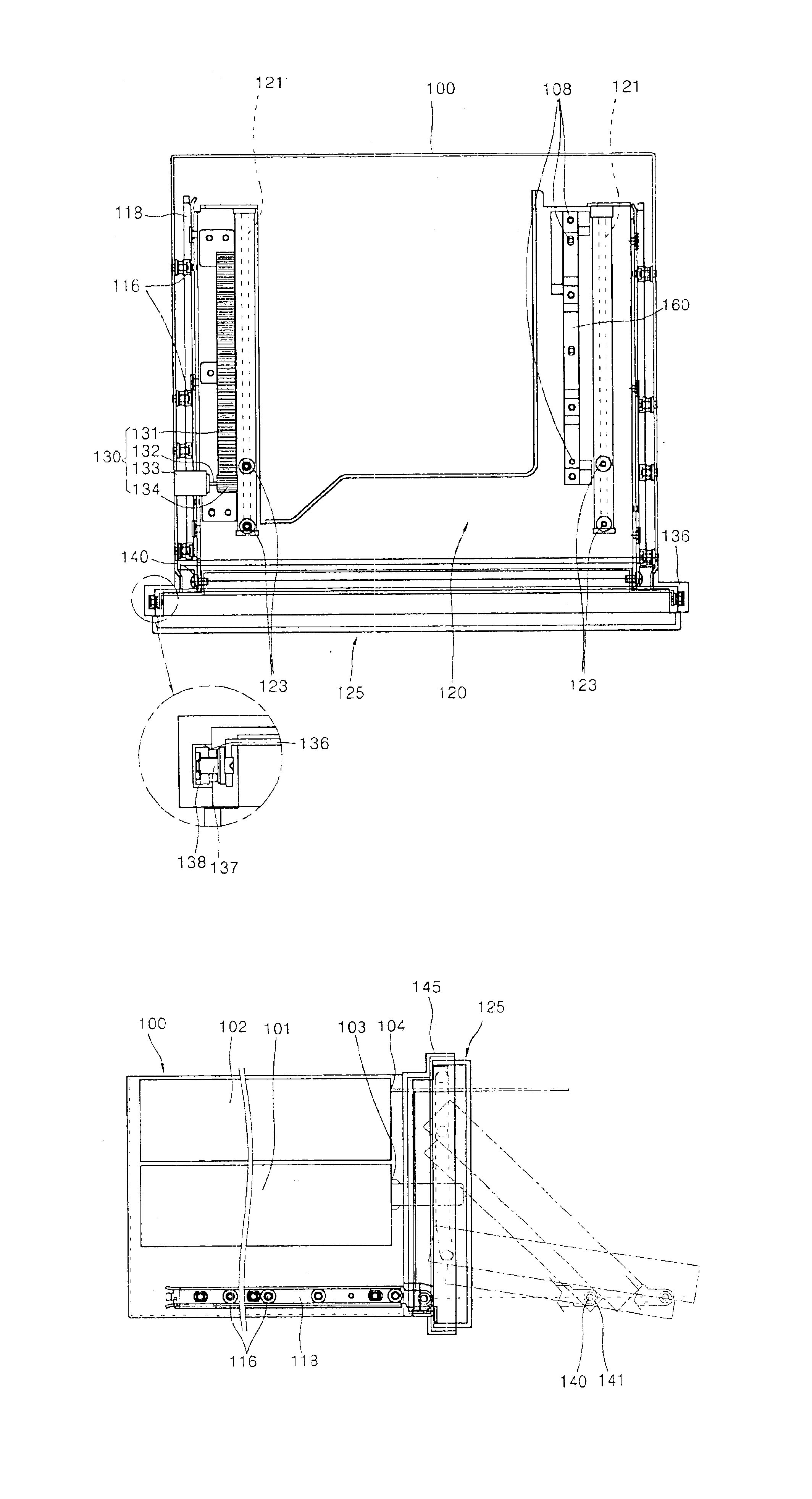

Mechanical and automatic liquid crystal display device

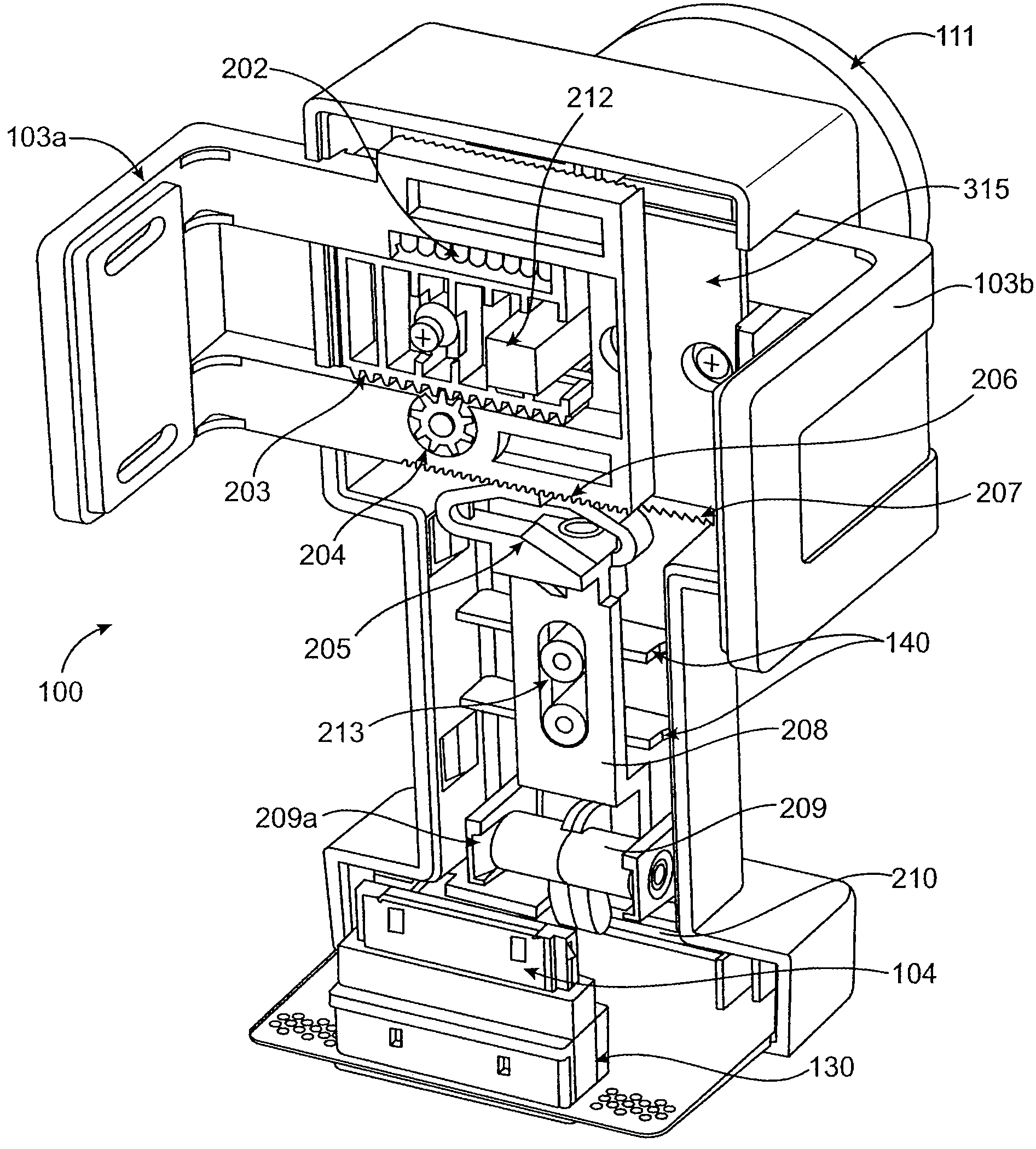

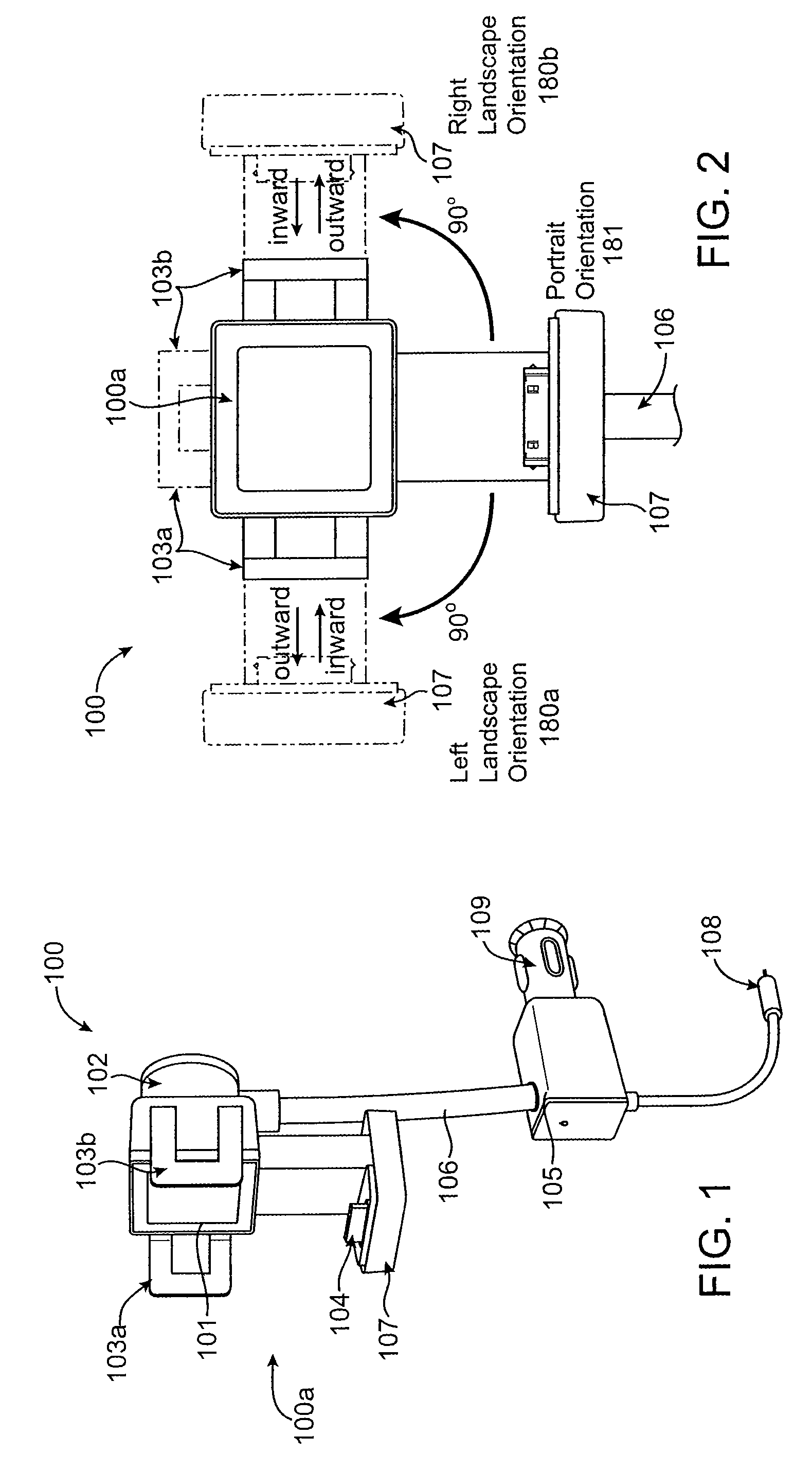

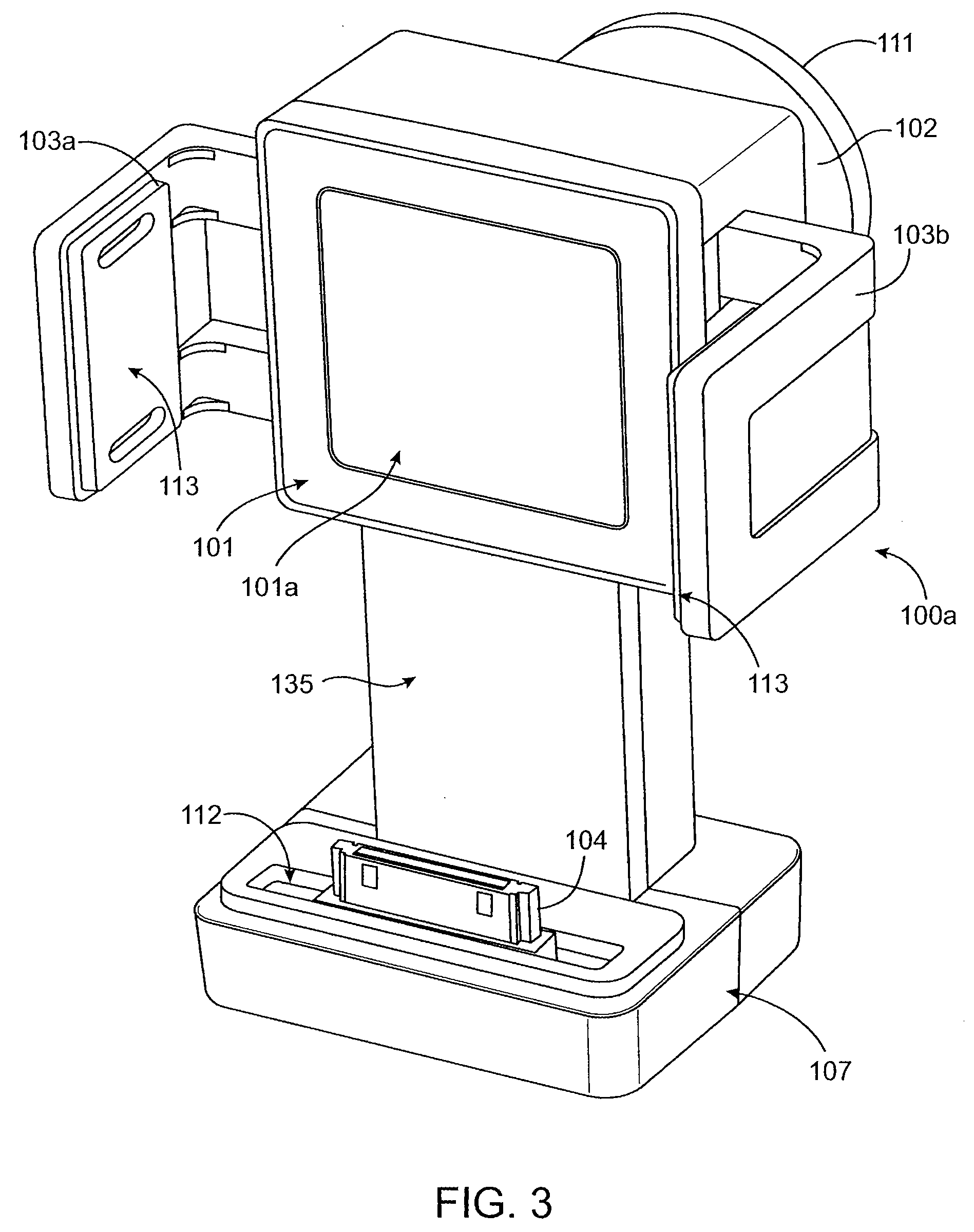

InactiveUS20050174724A1Adjustable viewing angleDigital data processing detailsFurniture partsLiquid-crystal displayEngineering

A mechanical and automatic liquid crystal display (LCD) device and particularly to a mechanical and automatic LCD device for automatically and rapidly unloading and storing the LCD panel that is especially suitable for a LCD device which has a display panel foldable upwards for storing includes a case for housing an extendable deck, a coupling mechanism, a display panel holding mechanism and an upward folding actuation means. The structure thus formed can replace the expensive electronic circuit control to enable users to automatically and rapidly unload or retract and store the display panel, and also adjust and remember the viewing angle of the display panel to meet user's requirements.

Owner:E LEAD ELECTRONICS CO LTD

Novel process for precision forging of disc steering knuckle

InactiveCN102319866AAdvanced precision forging technologyIncrease productivityRailway componentsVehicle componentsNational standardForge

Owner:桂林福达重工锻造有限公司

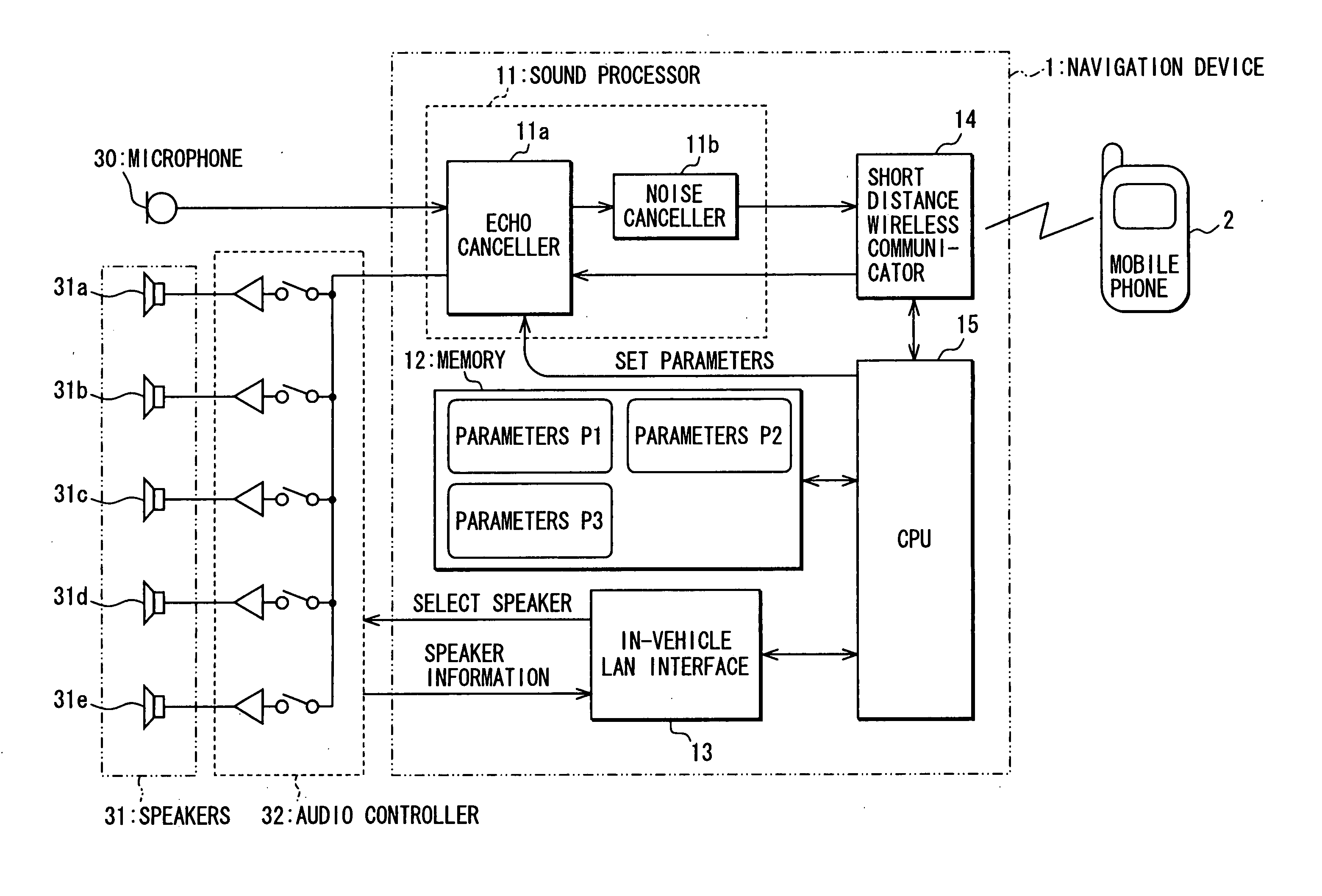

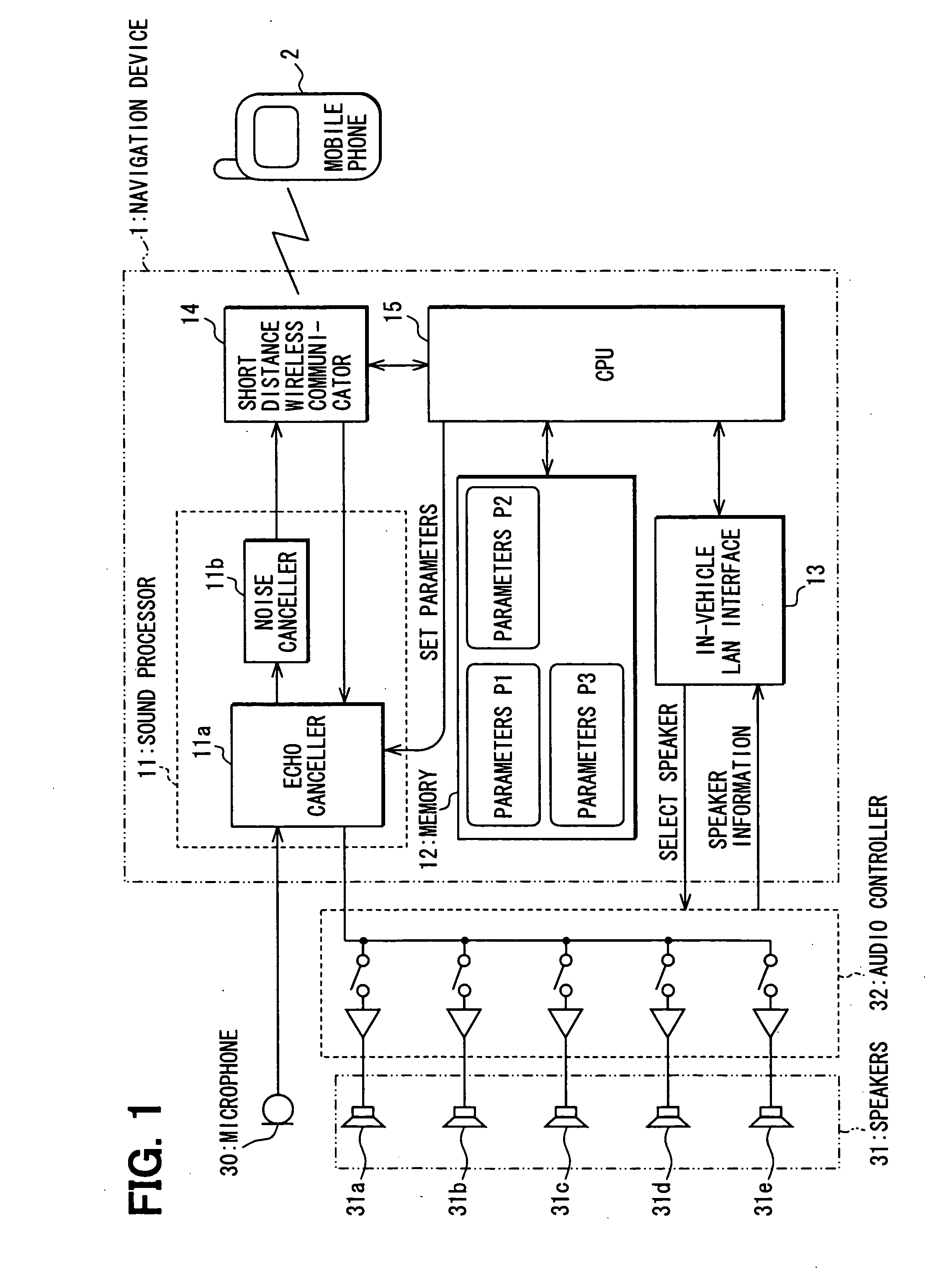

Hands-free communication system for use in automotive vehicle

InactiveUS20070037607A1Lessen awkward feelingInterconnection arrangementsSubstation speech amplifiersDriver/operatorCommunications system

Owner:DENSO CORP

Front panel operating apparatus and method

InactiveUS6883759B2Instruments for road network navigationNavigation by speed/acceleration measurementsDisplay deviceFace sheet

Owner:LG ELECTRONICS INC

Avoiding hot cracks during laser welding of a workpiece stack-up assembly of aluminum alloy workpieces

ActiveUS20180243861A1Vehicle componentsWelding/soldering/cutting articlesIntermediate stageOptoelectronics

A method of laser welding a workpiece stack-up that includes two or more overlapping aluminum alloy workpieces is disclosed. The method involves controlling the power level of the laser beam during at least one of an initial stage or a final stage of advancing the laser beam along a weld path so as to limit a line energy of the laser beam during such stage or stages to being no greater than 10% above a line energy of the laser beam during an intermediate stage of laser beam advancement that is performed between the initial and final stages. By limiting the line energy during the initial and / or final stages of laser beam advancement along the weld path, excessive fusion of the workpiece stack-up assembly can be avoided in those locations to help protect against hot-cracking in the resultant laser weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of resistance spot welding aluminum alloy workpieces

ActiveUS20140076859A1Easy to moveEliminate contaminationVehicle componentsWelding/cutting media/materialsSurface roughnessSpot welding

A method of resistance spot welding aluminum alloy workpieces together includes several steps. In one step a welding electrode is provided. The welding electrode has a weld face. In another step, the weld face of the welding electrode is shaped to have a desired radius of curvature. The shaped weld face is then textured to a desired surface roughness, and resistance spot welding using the welding electrode is performed to the aluminum alloy workpieces. In yet another step, the weld face is dressed to an extent sufficient to remove contamination build-up that may have accumulated on the weld face from the aluminum alloy workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

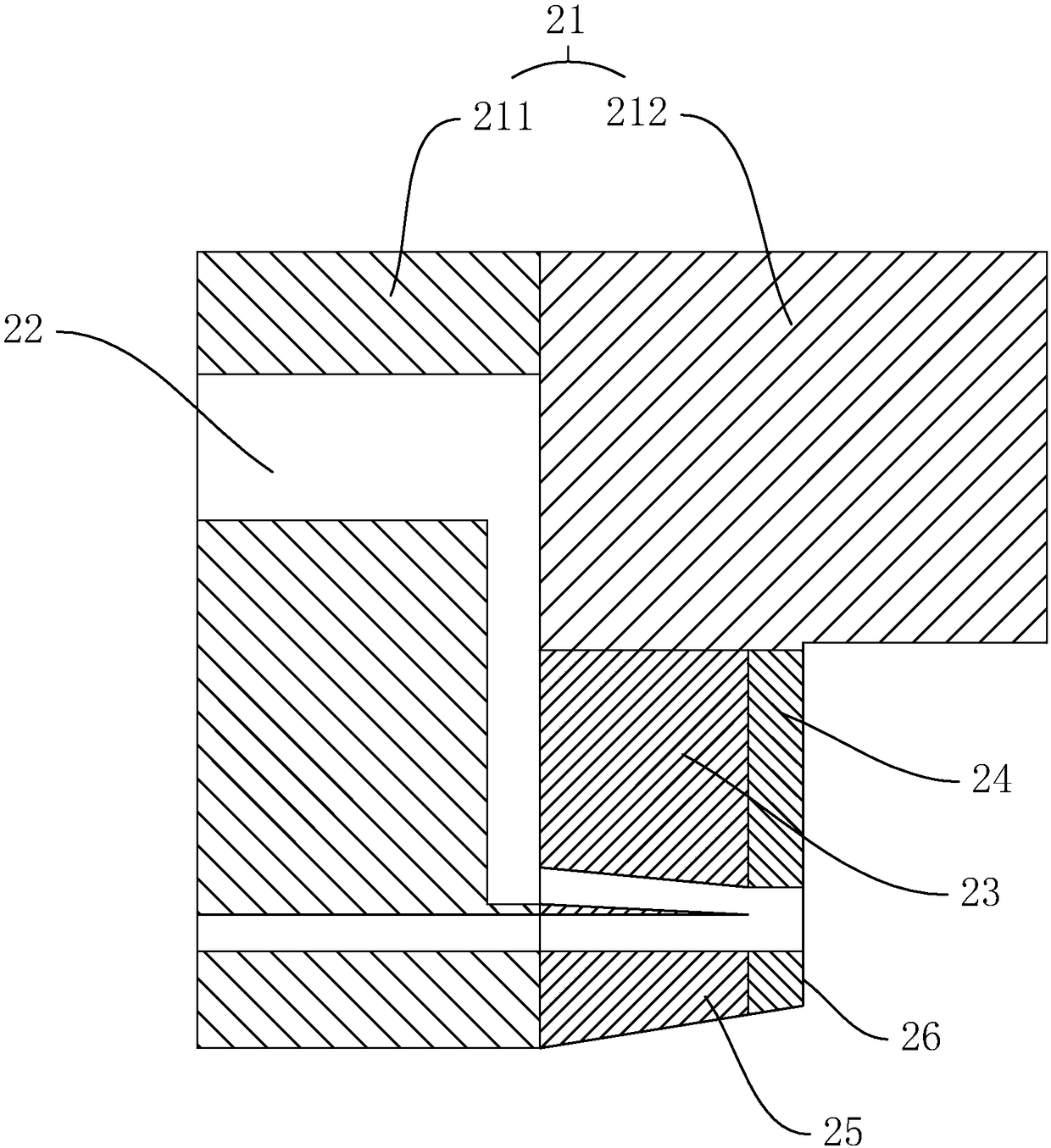

Laminated plate and end treatment method of the laminated plate

ActiveUS20100021675A1Welding/cutting auxillary devicesHollow wall articlesEngineeringMechanical engineering

A manufacturing method of a laminated plate (19) includes: a first step of supporting, by a support member (9), a thermoplastic resin-made laminated material (1) in which a pair of plate-like members (3, 4) are laminated to each other while interposing a longitudinal wall portion (2b) so that a peripheral edge portion (1a) of the laminated material (1) can be exposed, and heating and softening the peripheral edge portion (1a) by blowing a hot air to the peripheral edge portion (1a); and a second step of pressing the plate-like member (4) as one of the pair of plate-like members (3, 4) against other plate-like member (3) by thrusting a cutting blade (17a) of a cutting die (17) against the heated and softened peripheral edge portion (1a), thereby bringing the pair of plate-like members (3, 4) into contact with each other and welding the plate-like members (3, 4) to each other, and then cutting the laminated plate (19) out of the laminated material (1).

Owner:MEIWA IND CO LTD

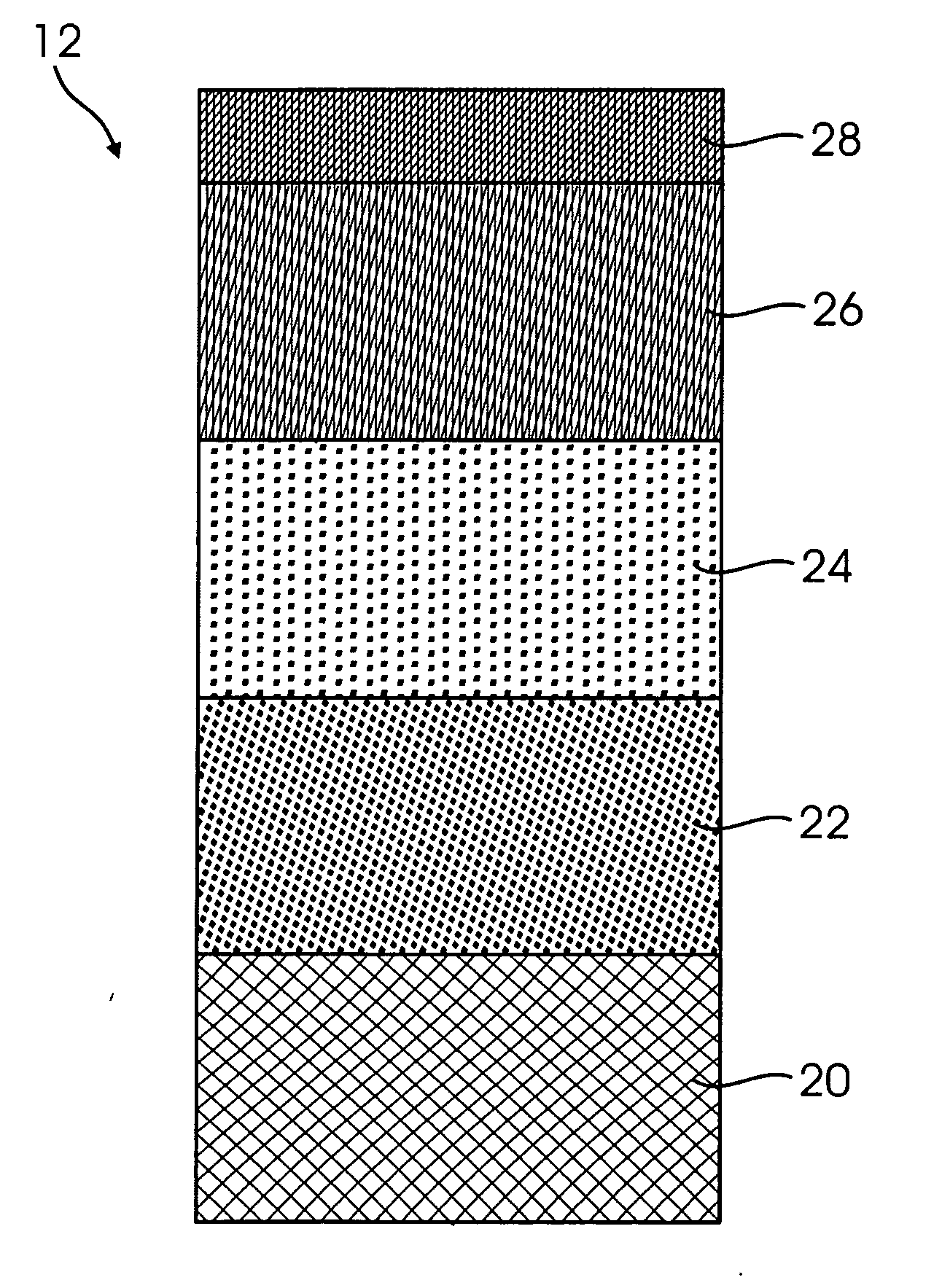

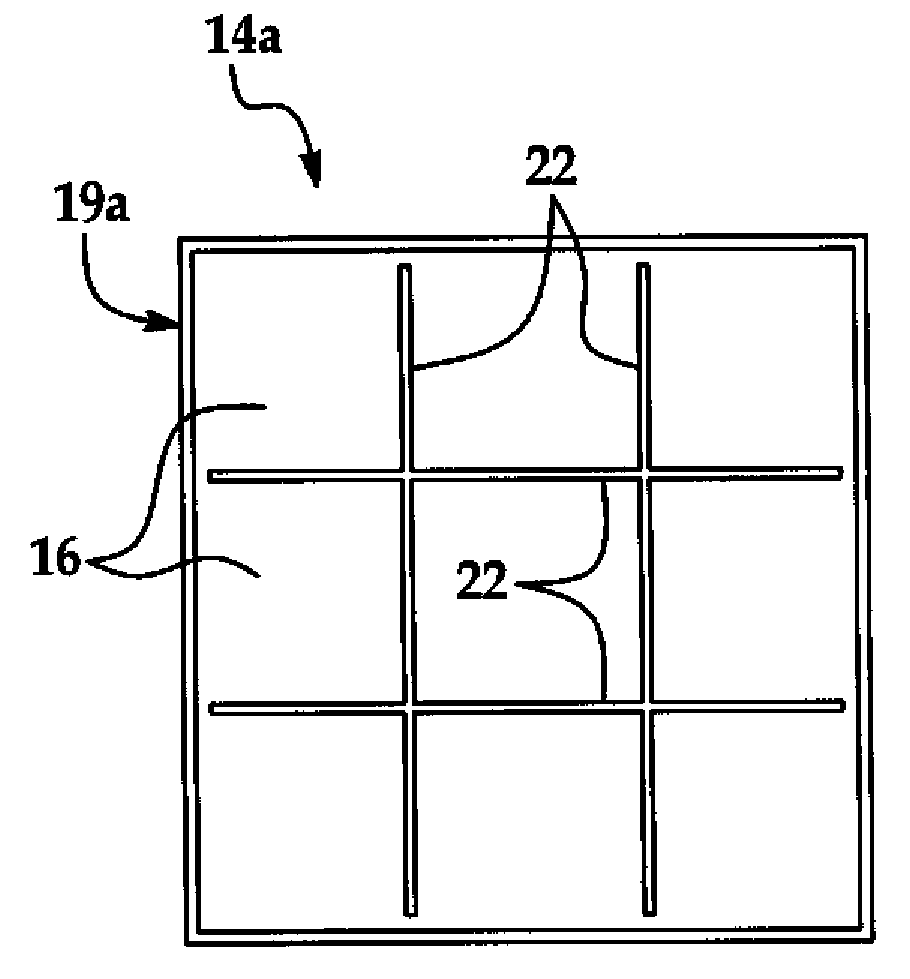

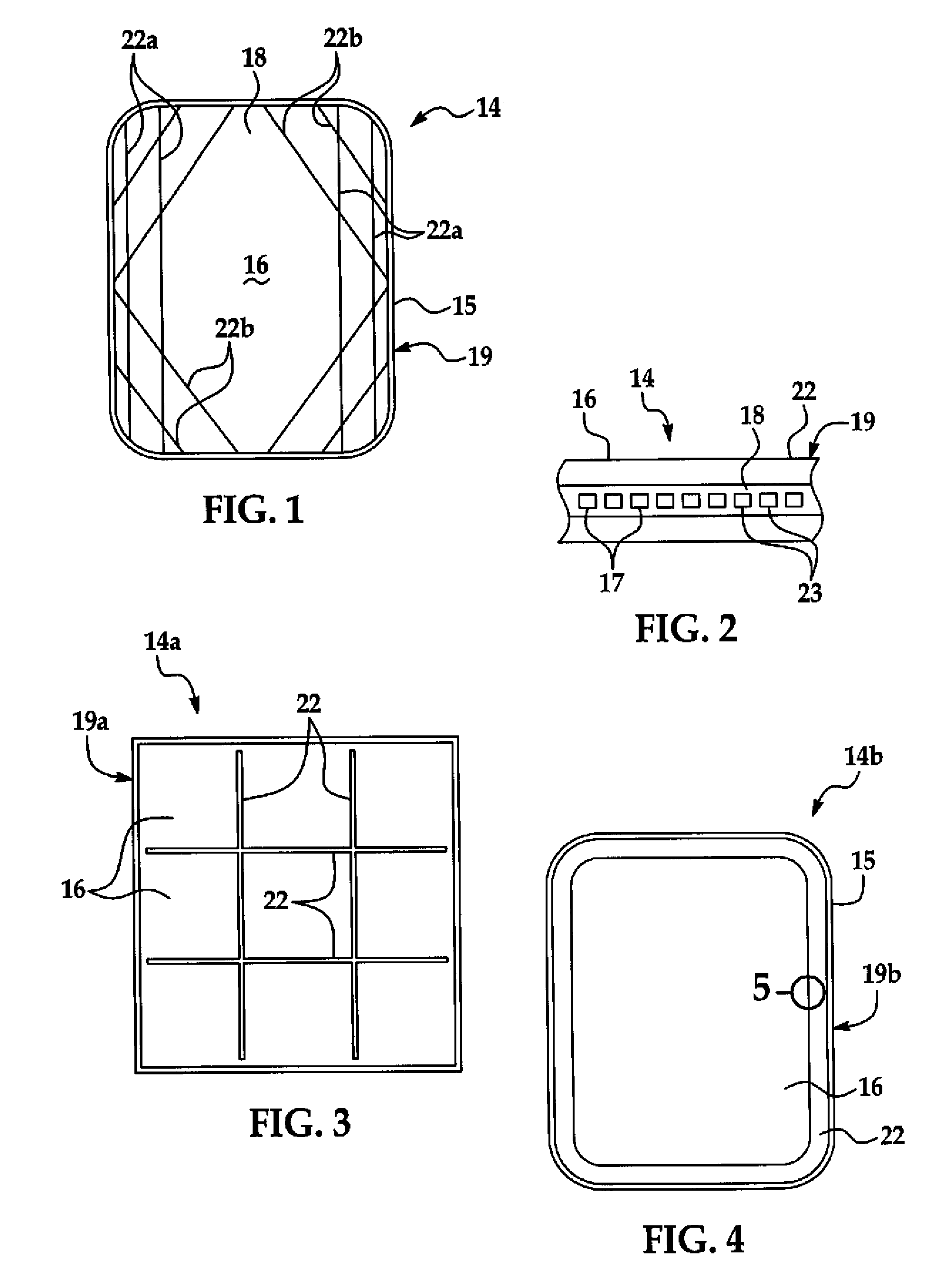

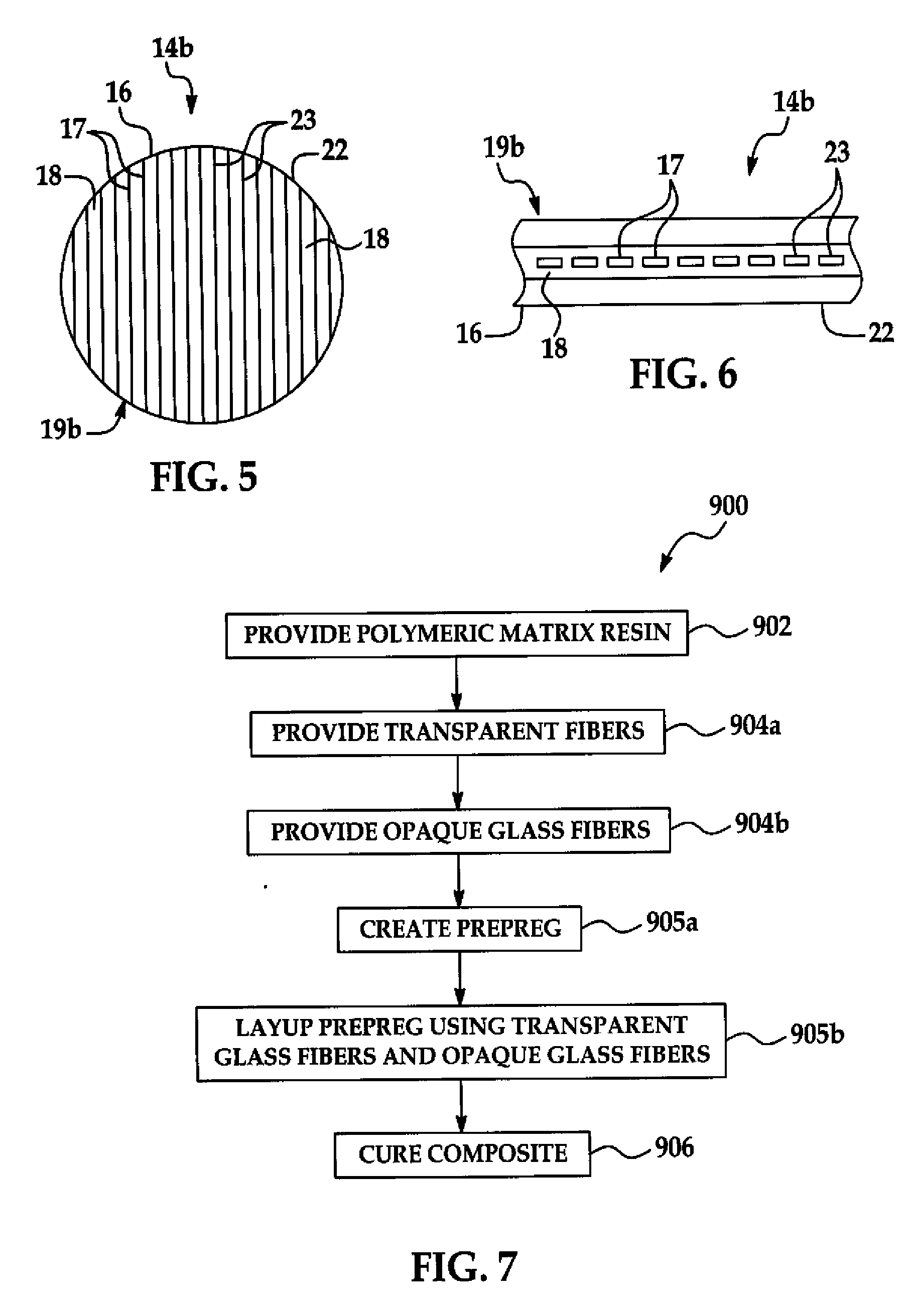

Opaque fiber reinforcement of composites

ActiveUS20100011702A1Synthetic resin layered productsEfficient propulsion technologiesFiber reinforcementPolymeric matrix

Owner:THE BOEING CO

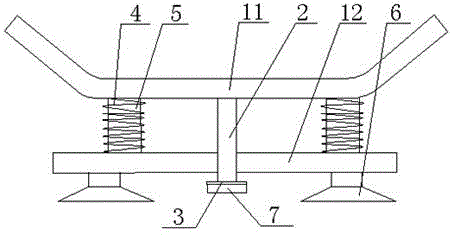

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce impactAvoid crackingElectric heatingWelding/cutting auxillary devicesFuel tankThermal deformation

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

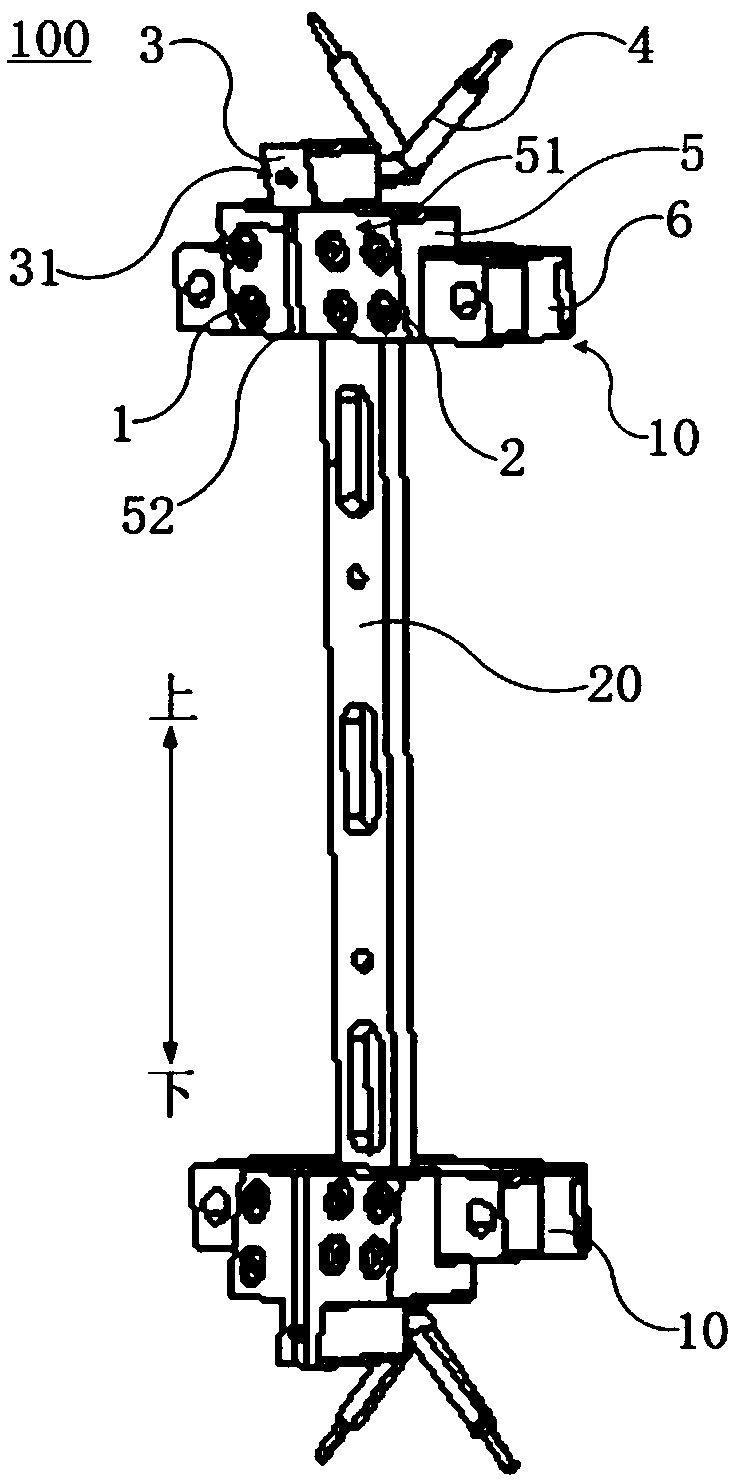

Vehicle locating device with high stability

Owner:CHENGDU RUIYI INFORMATION TECH

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

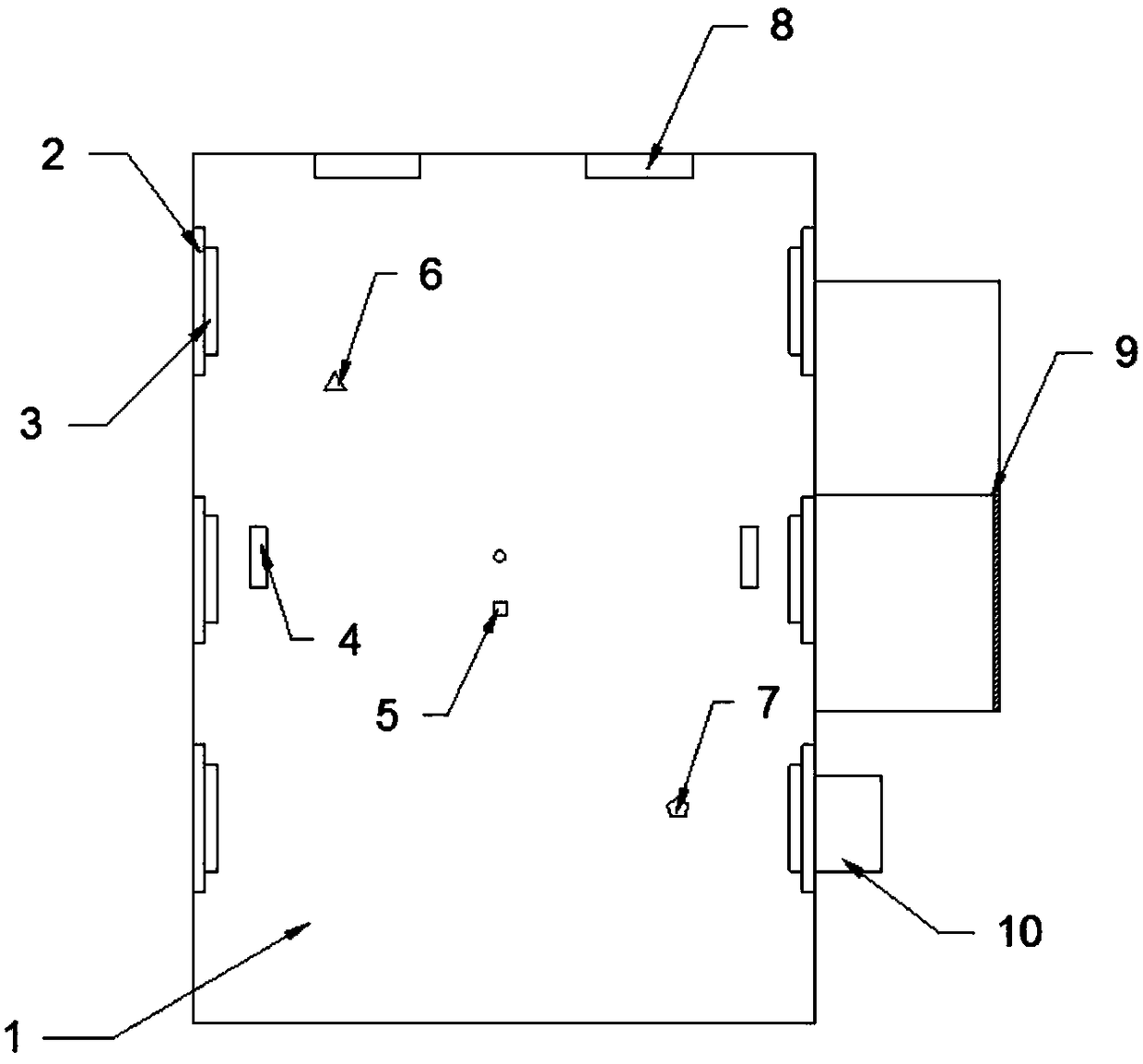

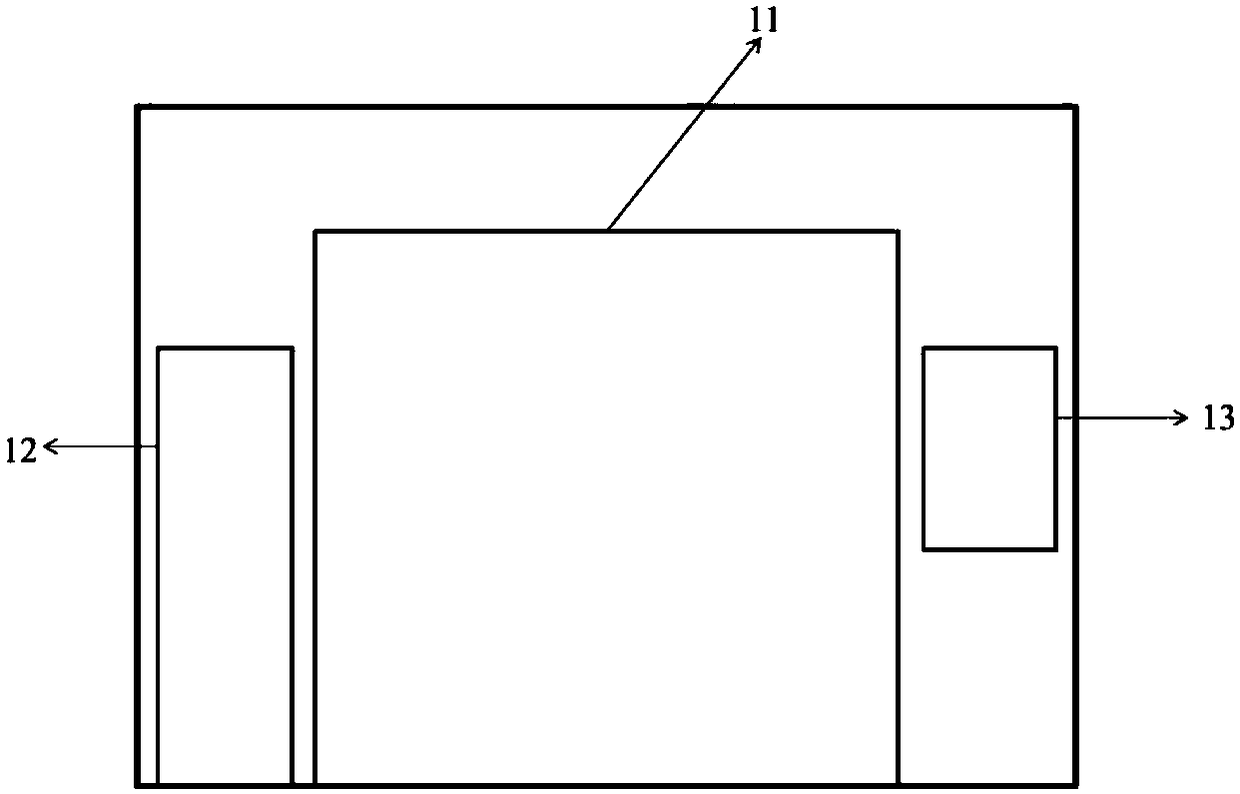

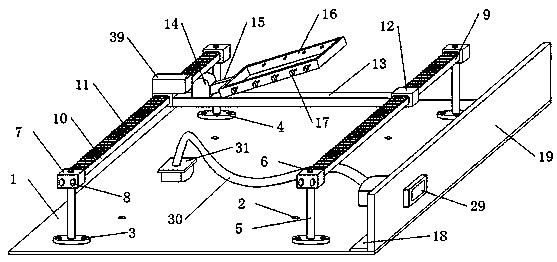

Vehicle-mounted theodolite supporting platform

ActiveCN108482263AImprove bearing efficiencyImprove dynamic characteristicsGeometric CADDesign optimisation/simulationTheodoliteCable stayed

The invention discloses a vehicle-mounted theodolite supporting platform. The vehicle-mounted theodolite supporting platform comprises a platform supporting frame, a platform skin, a device installingboss, a platform supporting leg transferring member and a platform supporting leg assembly. The platform skin covers the platform supporting frame, the device installing boss is arranged on the platform supporting frame, the platform supporting frame is a rectangular frame welded by metal pipes, and cable-stayed rods are arranged in the rectangular frame according to the transfer path of force based on results of topological optimization. The platform supporting leg assembly is arranged below the four top corners of the platform supporting frame, and the platform supporting leg transferring member is arranged at the joint of the four top corners of the platform supporting frame and the platform supporting leg assembly. The vehicle-mounted theodolite supporting platform can guarantee the supporting stiffness of the vehicle-mounted platform and realizes the lightweight of the vehicle-mounted platform on the premise of fundamental vibrational frequency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

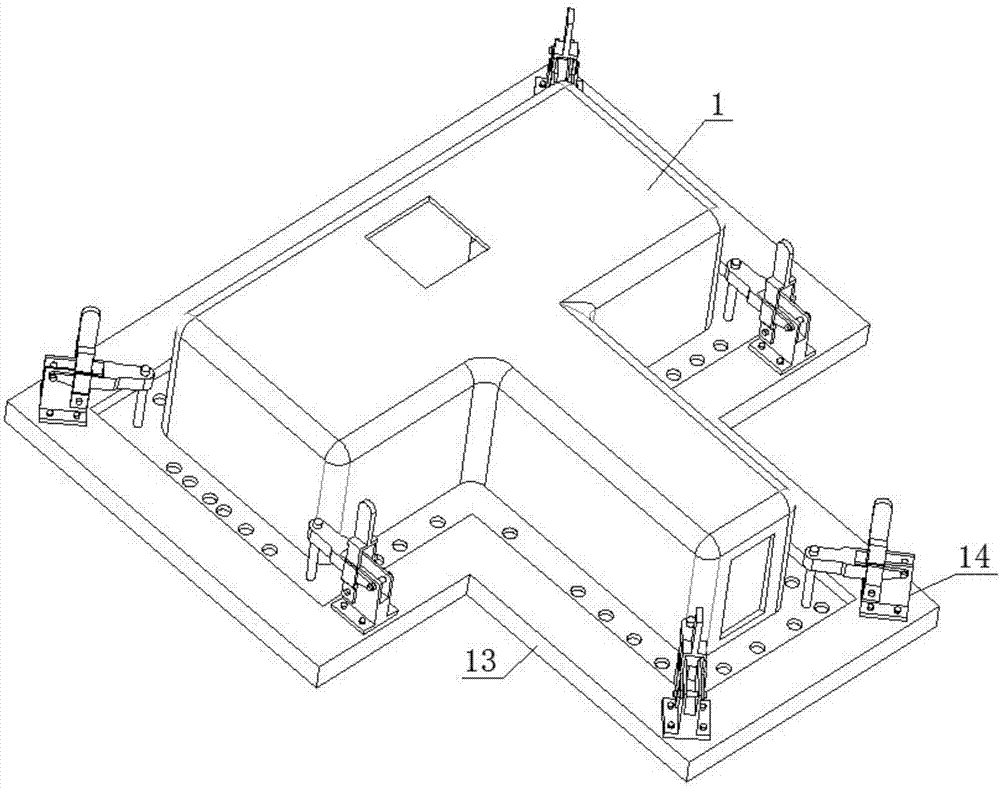

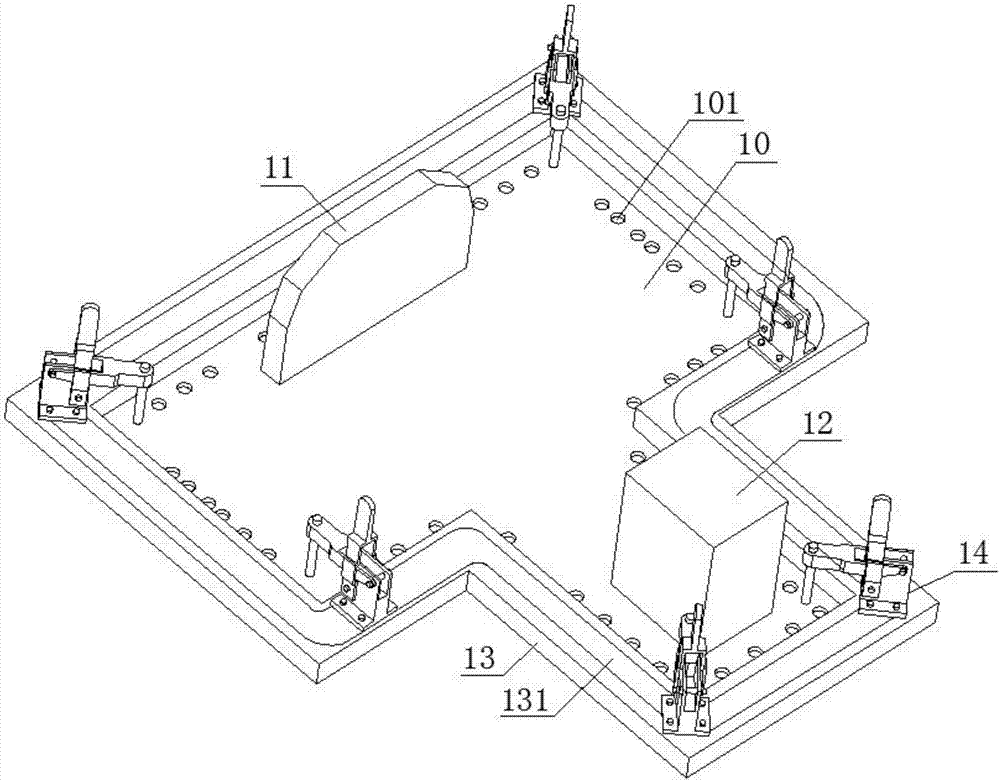

Automotive chassis support positioning mechanism and offline detection platform

ActiveCN106078051ASimple structureSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesElectrical and Electronics engineeringRolling chassis

Owner:SHANGHAI SINYLON AUTO EQUIPMENT MANUFACTURE CO LTD

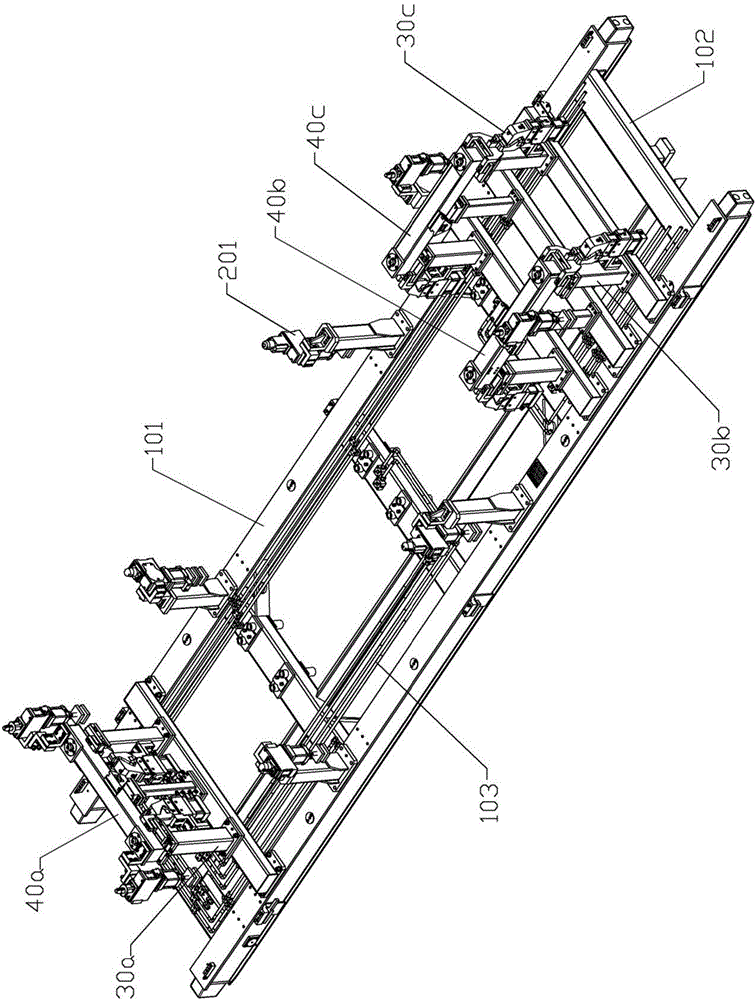

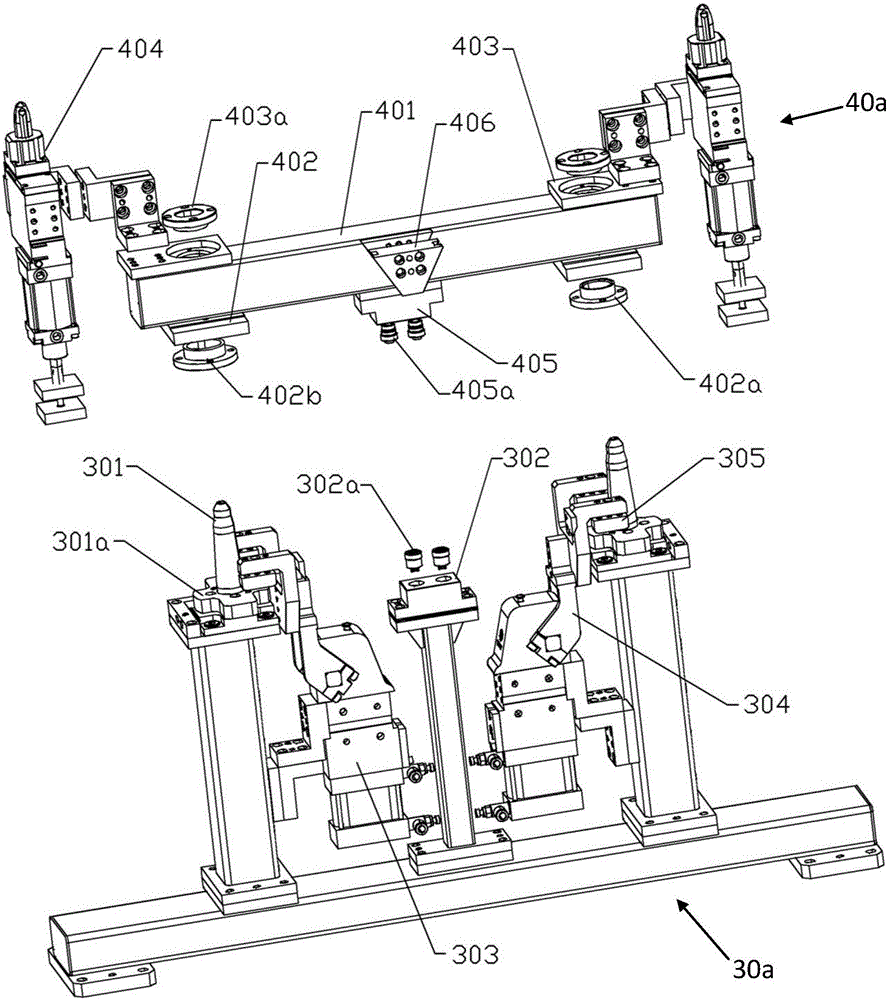

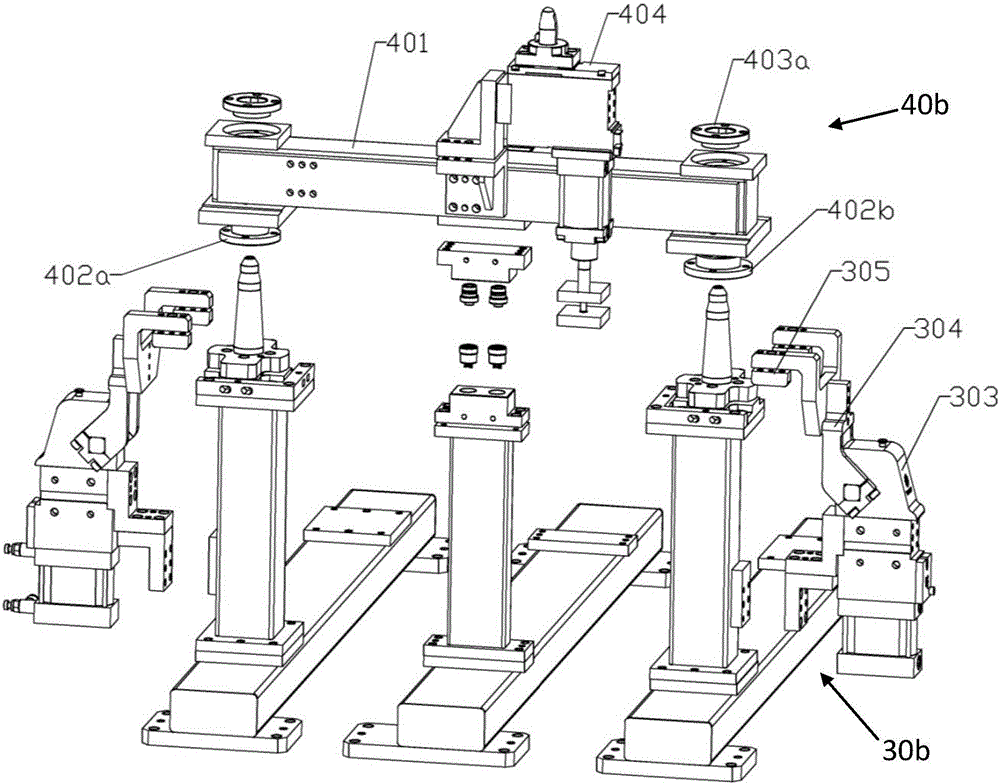

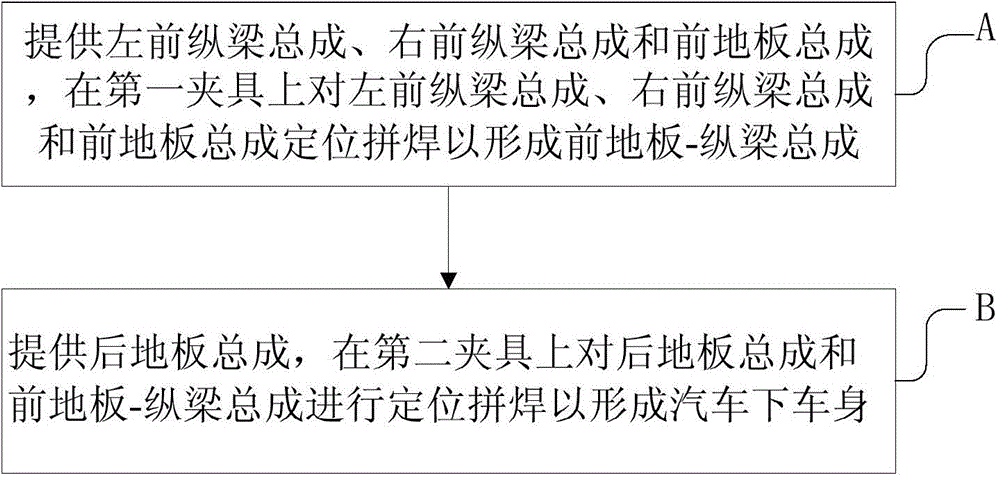

Welding method of lower vehicle body

The invention discloses a welding method of a lower vehicle body. The welding method comprises the following steps: (A) a left front longitudinal beam assembly, a right front longitudinal beam assembly and a front floor assembly are provided; and the positioned welding is performed for the left front longitudinal beam assembly, the right front longitudinal beam assembly and the front floor assembly on a first fixture to form a front floor-longitudinal beam assembly; and (B) a back floor assembly is provided; and the positioned welding is performed for the back floor assembly and the front floor-longitudinal beam assembly on a second fixture to form the lower vehicle body. According to the welding method of the lower vehicle body, through the two-fixture positioned welding mode, the complexity of the fixtures for collinear production of multiple vehicle types is effectively reduced, the process and equipment complexity is reduced, and a certain effect on the vehicle body product quality is achieved.

Owner:BEIQI FOTON MOTOR CO LTD

Window member and display device including the same

ActiveCN109801561ACasings with display/control unitsCasings/cabinets/drawers detailsDisplay deviceEngineering

The present invention relates to a window member and a display device including the same. The window member comprises: a first base member having a first thickness, a first impact absorbing layer disposed on one surface of the first base member and having a storage modulus less than that of the first base member and a second thickness, a first hard coating layer disposed on the first impact absorbing layer, and a second hard coating layer disposed on the other surface that is opposite to the one surface of the first base member. Here, a ratio of the second thickness to the first thickness is equal to or greater than about 1.0 and equal to or less than about 1.67. The first base member is bent with respect to a bending axis extending in one direction.

Owner:SAMSUNG DISPLAY CO LTD

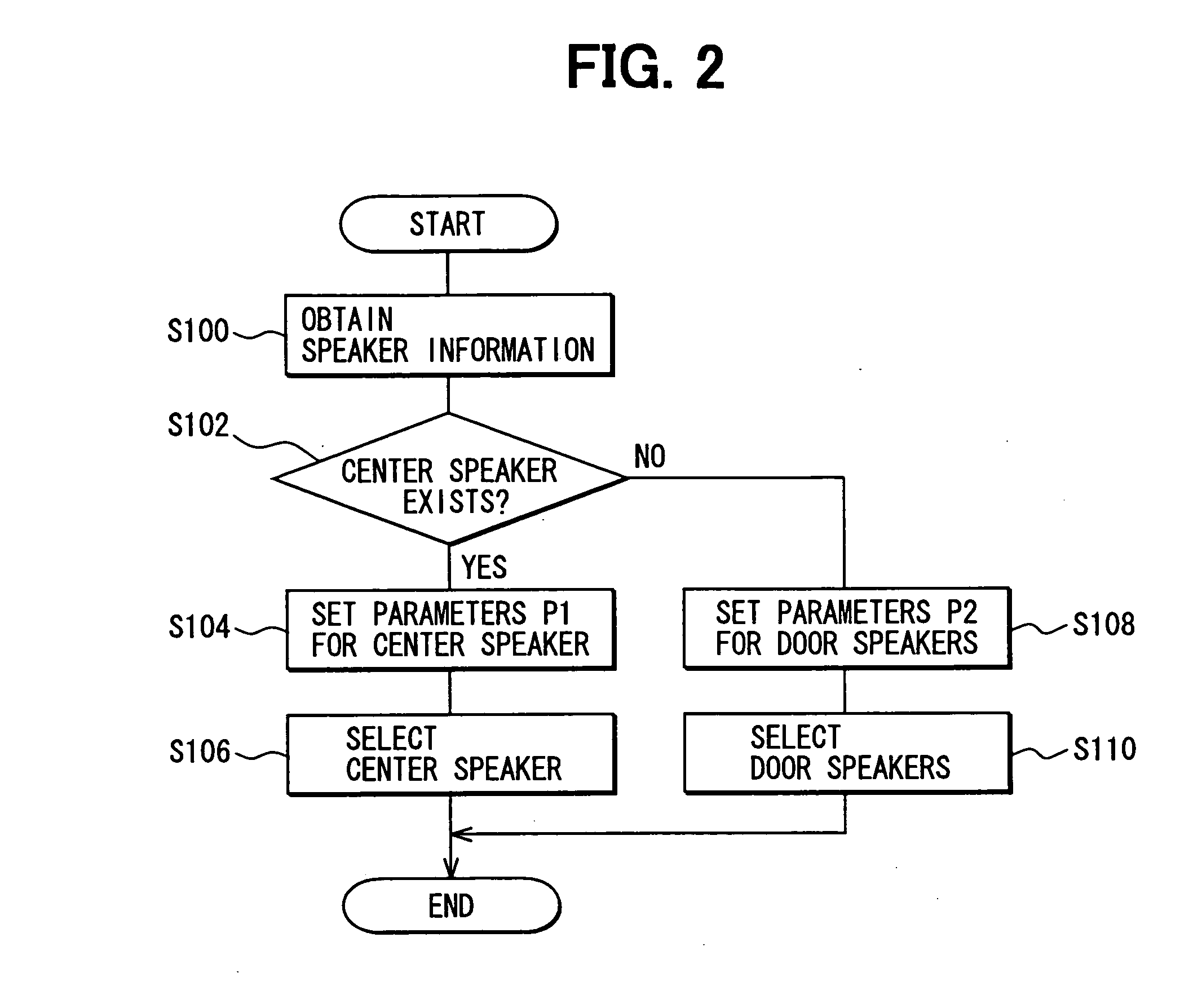

In-vehicle audio apparatus

InactiveCN102693743AKeep status ensuredUndesired vibrations/sounds insulation/absorptionVehicle componentsIn vehicleEngineering

Owner:SONY CORP

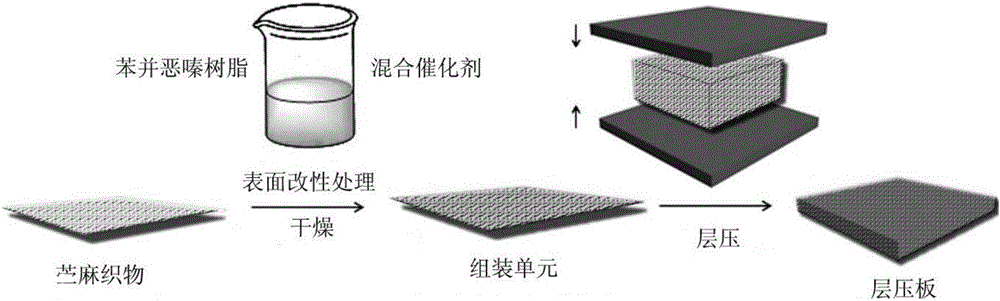

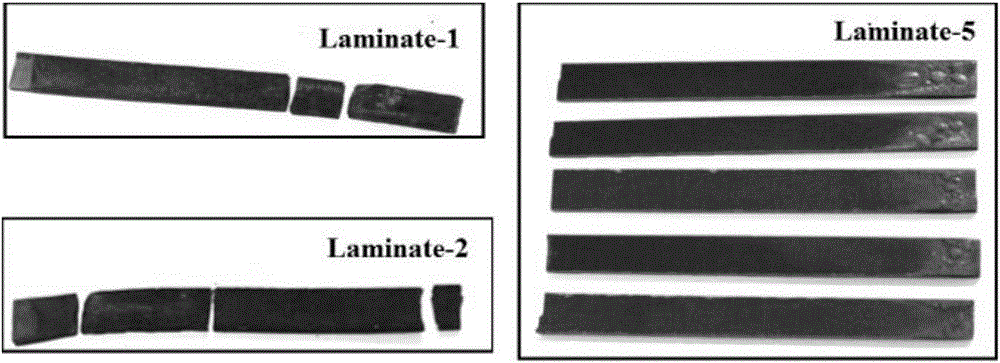

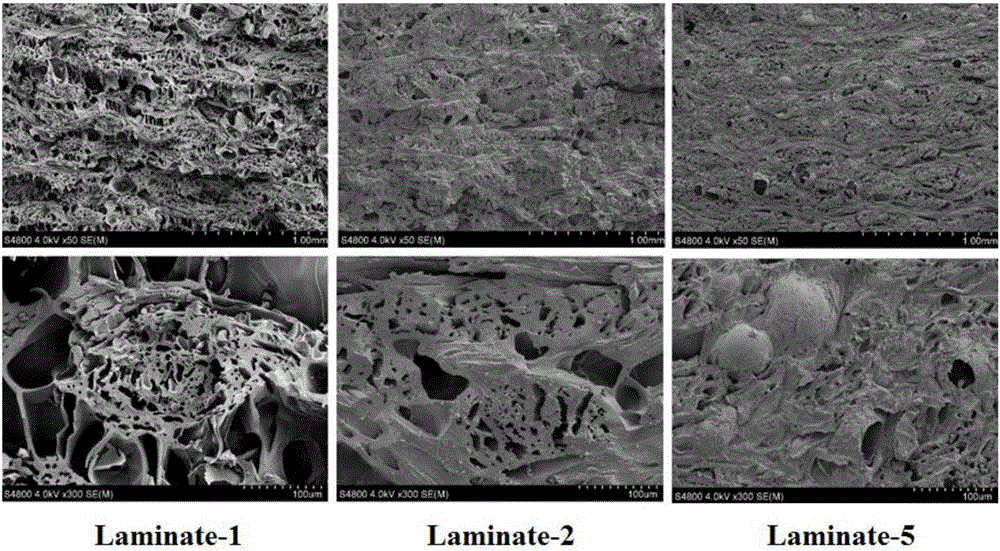

Flame-retardant modified ramie fabric/benzoxazine resin laminated board and preparation method thereof

ActiveCN106079723AImprove flame retardant performanceImprove performanceLamination ancillary operationsLayered product treatmentEngineeringFire retardant

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

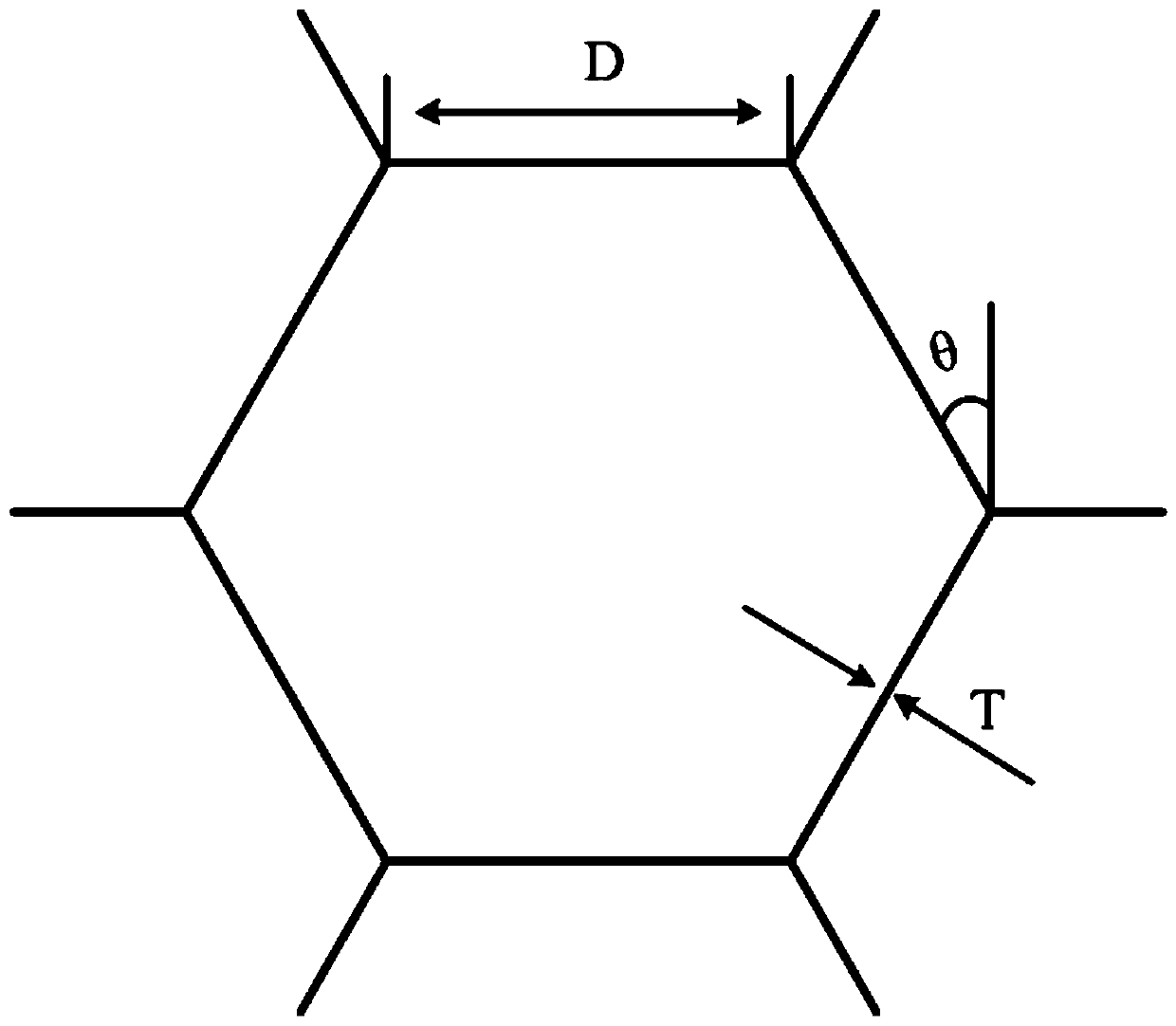

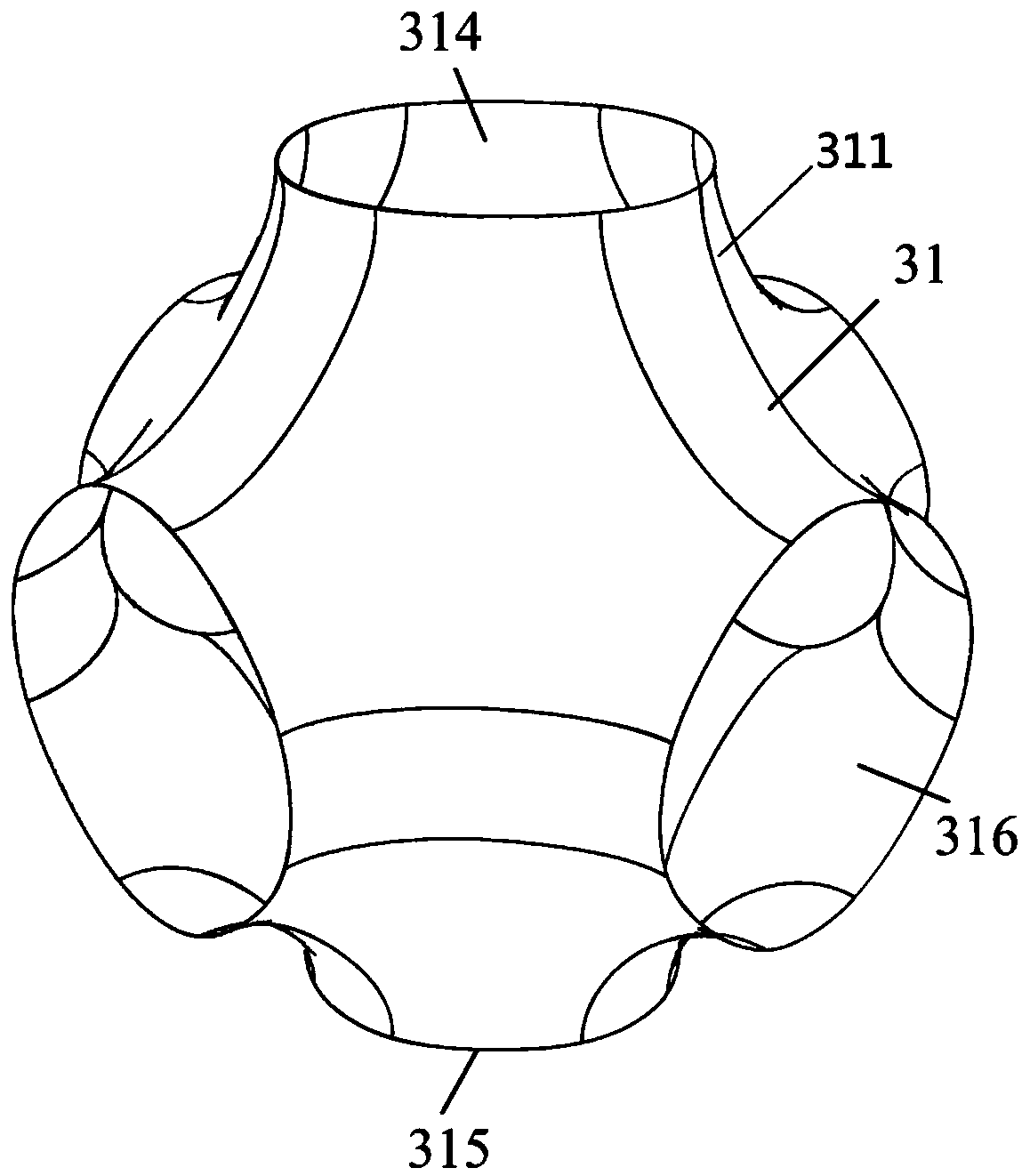

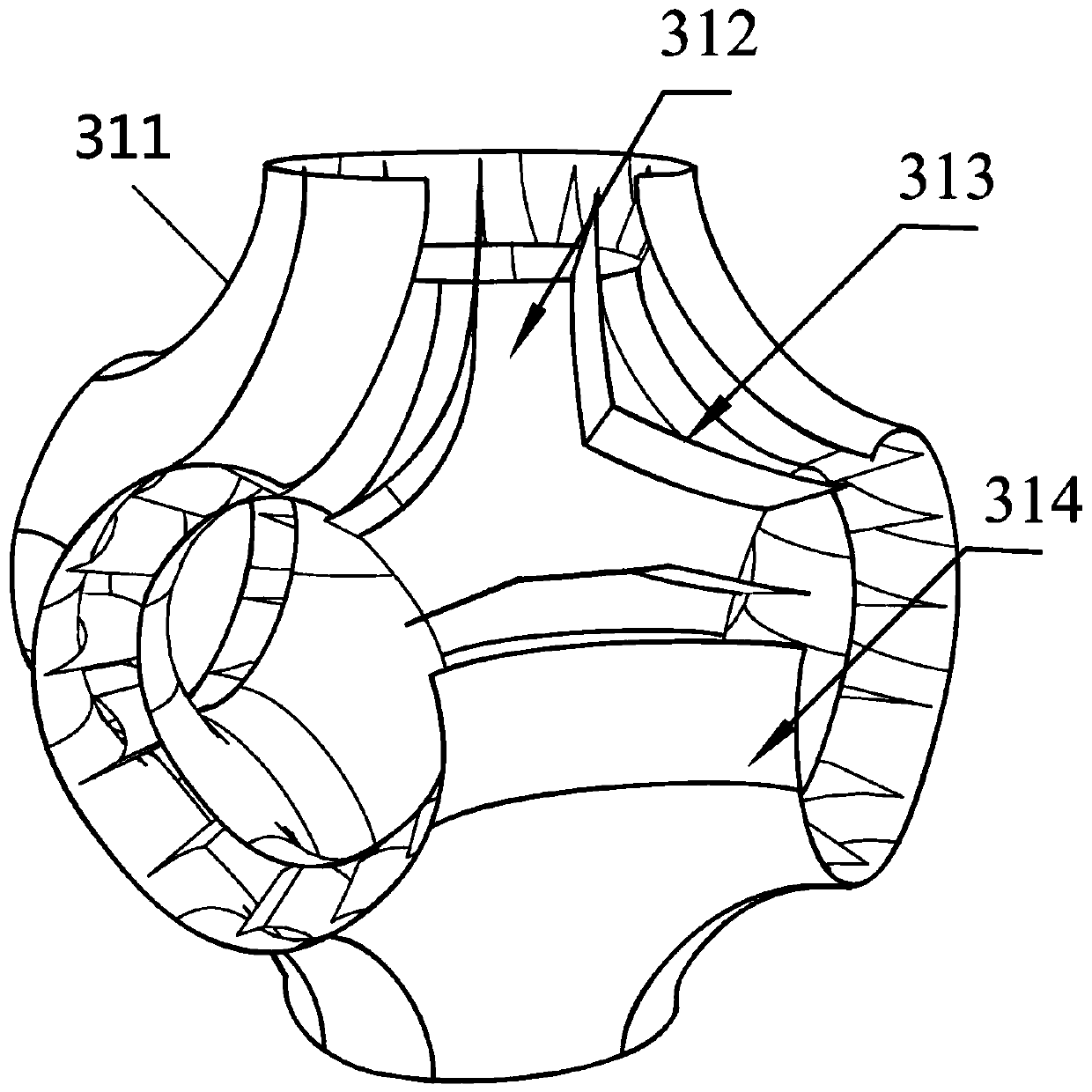

Core cell structure, core with porous structure and sandwich energy absorption structure

Owner:HUNAN UNIV

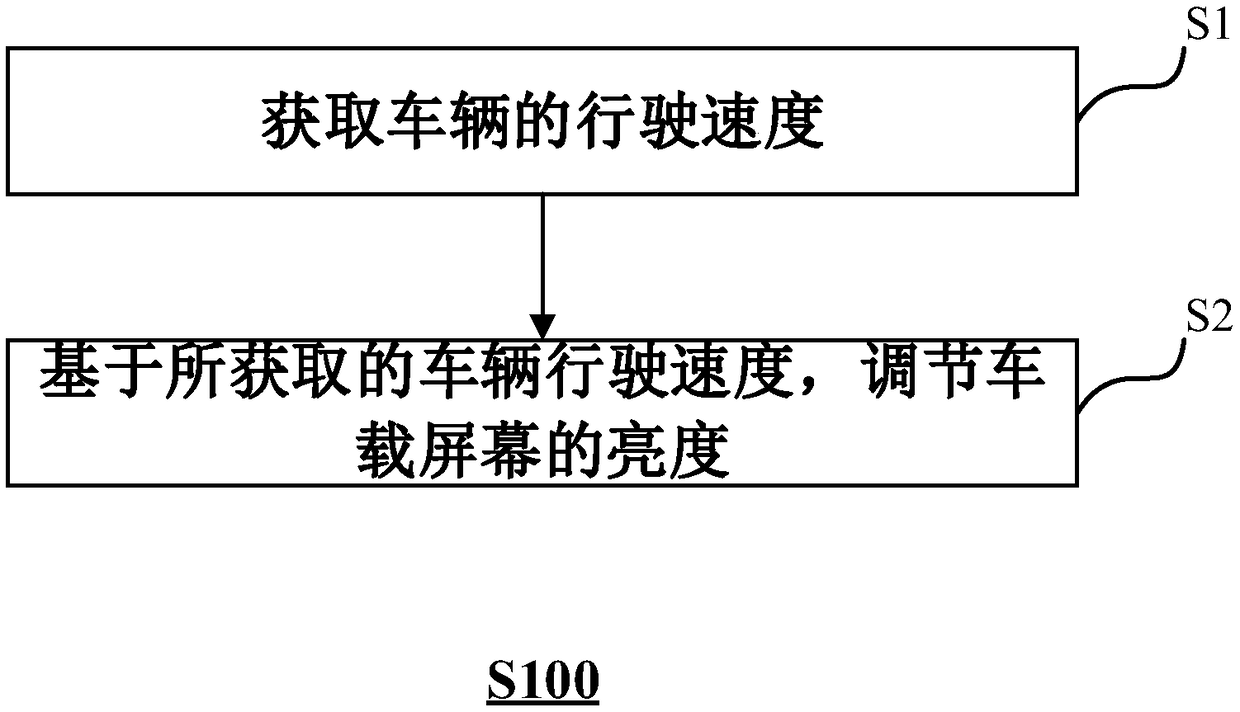

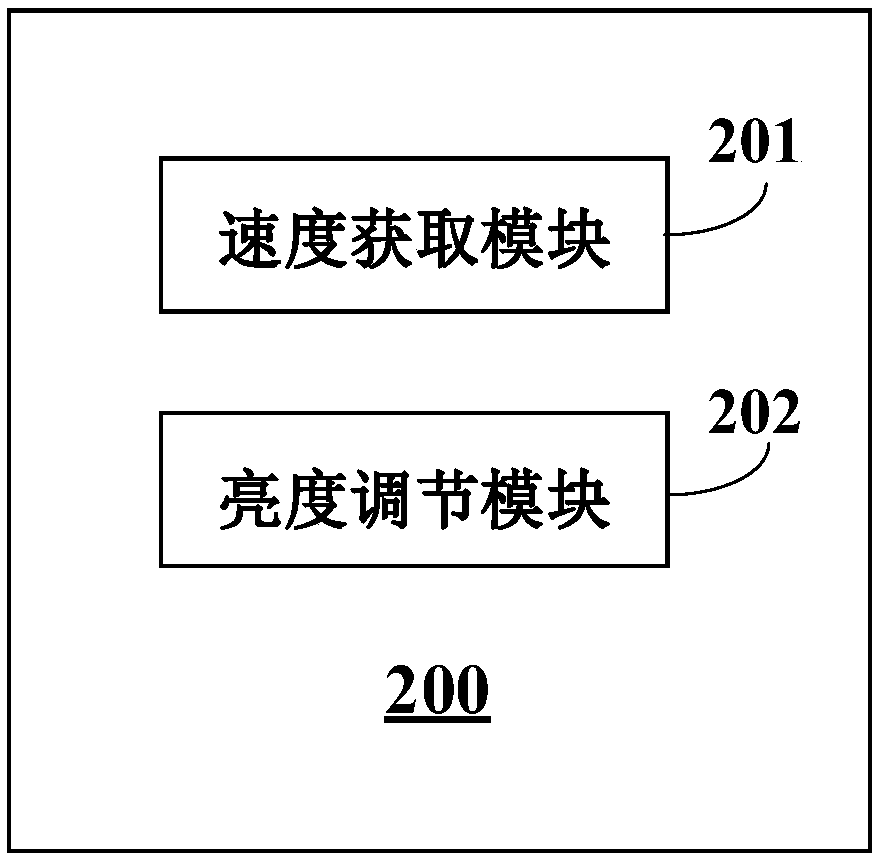

Method and device for adjusting brightness of on-board screen, controller and recording medium

InactiveCN108962188AEasy to operateImprove securityCathode-ray tube indicatorsVehicle componentsOn boardBrightness perception

Owner:NIO NEXTEV LTD

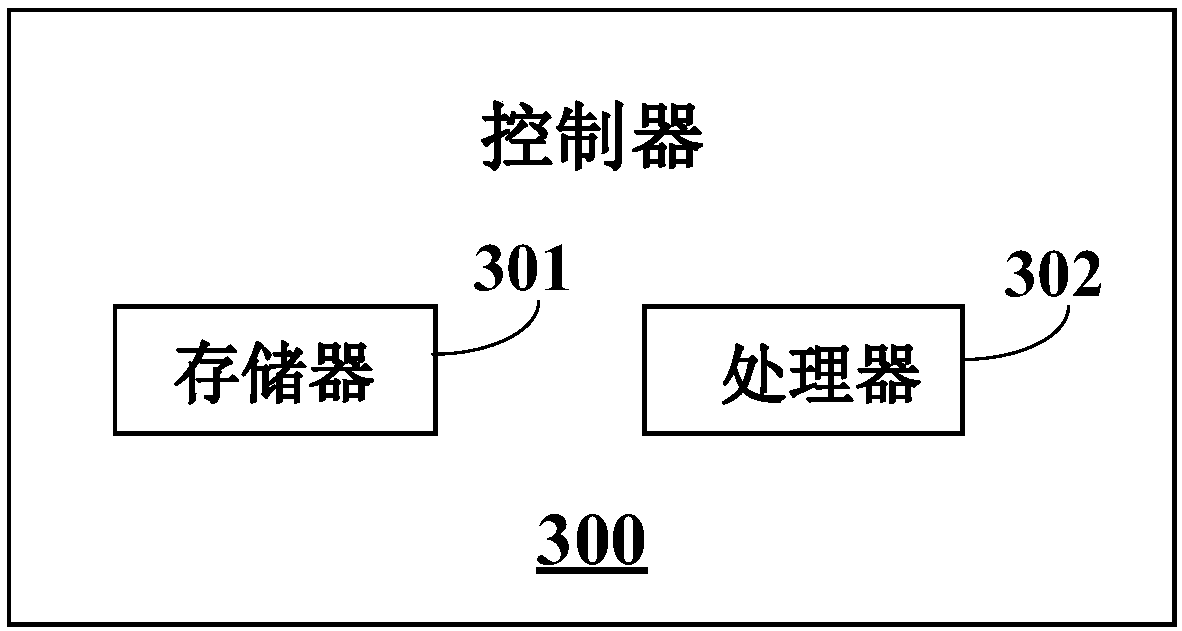

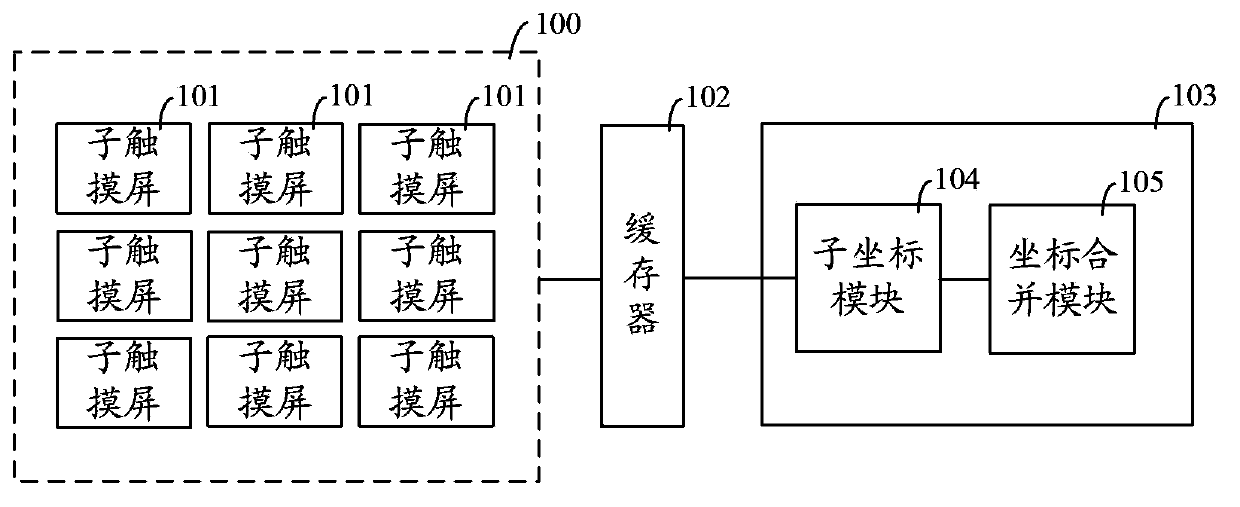

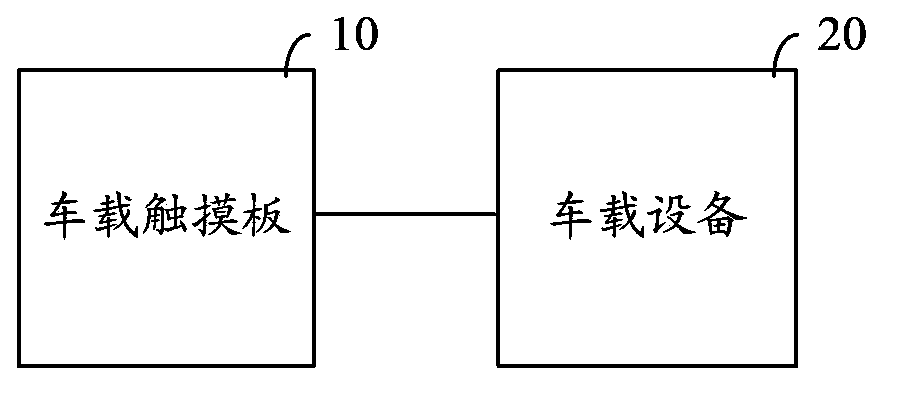

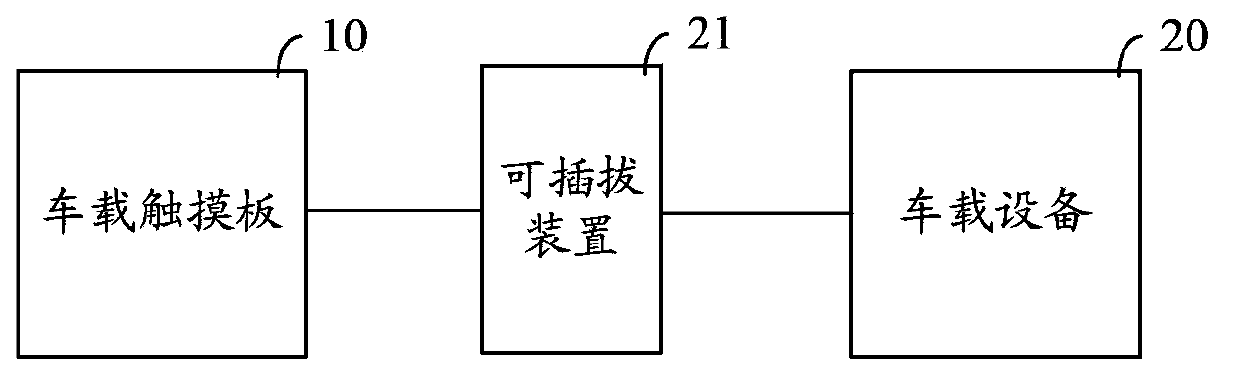

Vehicle-mounted touchpad, vehicle-mounted system and automobile

InactiveCN103631420AVehicle componentsInput/output processes for data processingReal-time computingTouchpad

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

Automobile external glazing tape manufacturing technique and correction tool applied to technique

PendingCN108723143AIncrease productivityAvoid destructionShaping toolsVehicle componentsCross-linkMetal framework

Owner:上海敏孚汽车饰件有限公司

Vehicle body gap surface difference adjustment auxiliary tool

Owner:BEIJING ELECTRIC VEHICLE

Electric automobile battery box upper cover bushing assembling tool

InactiveCN107322266AGood technical effectVehicle componentsMetal working apparatusAutomotive batteryEngineering

Owner:HANGZHOU DAYBREAK NEW MATERIAL SCI & TECH CO LTD

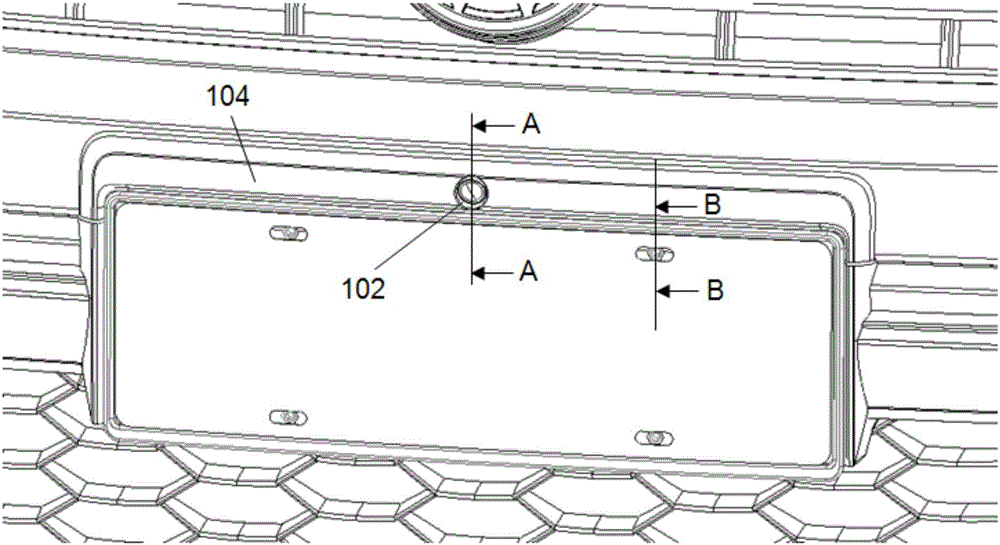

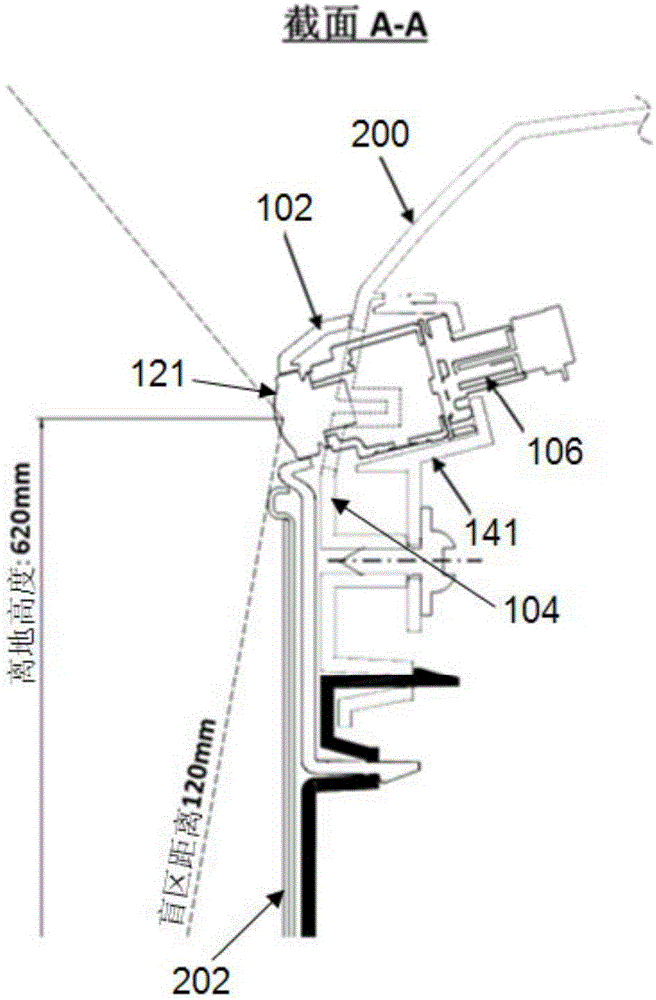

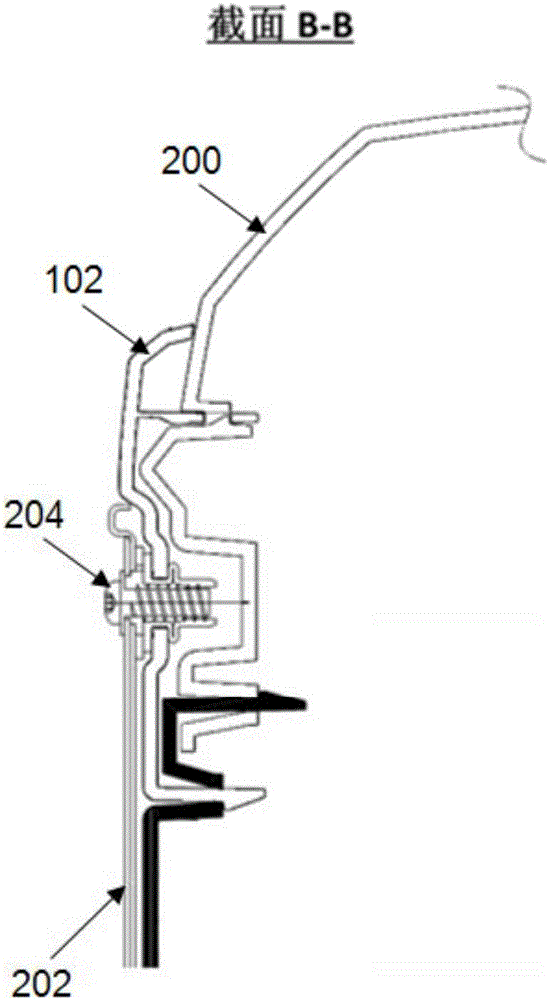

License plate frame support

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Vehicle-mounted monitor driving device

ActiveCN103085728AImprove noiseIncrease jitterNon-rotating vibration suppressionVehicle componentsElectric machineEngineering

The invention provides a vehicle-mounted monitor driving device. The vehicle-mounted monitor driving device comprises a direct current (DC) motor mechanically combined with a monitor, a transmission module, a spring assisting driving force of the DC motor and a shock absorber for reducing elasticity and bounce of the spring, wherein the transmission module is mechanically combined on the monitor together with the DC motor and used for converting rotating force of the DC motor into vertical motion force.

Owner:HYUNDAI MOBIS CO LTD

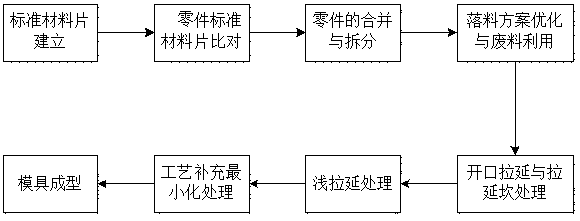

Intelligent forming method for automobile covering part mold

ActiveCN110929337AHigh material utilizationLow costGeometric CADDesign optimisation/simulationWaste materialCost savings

Owner:HEBI TIANQI MOTOR DIES

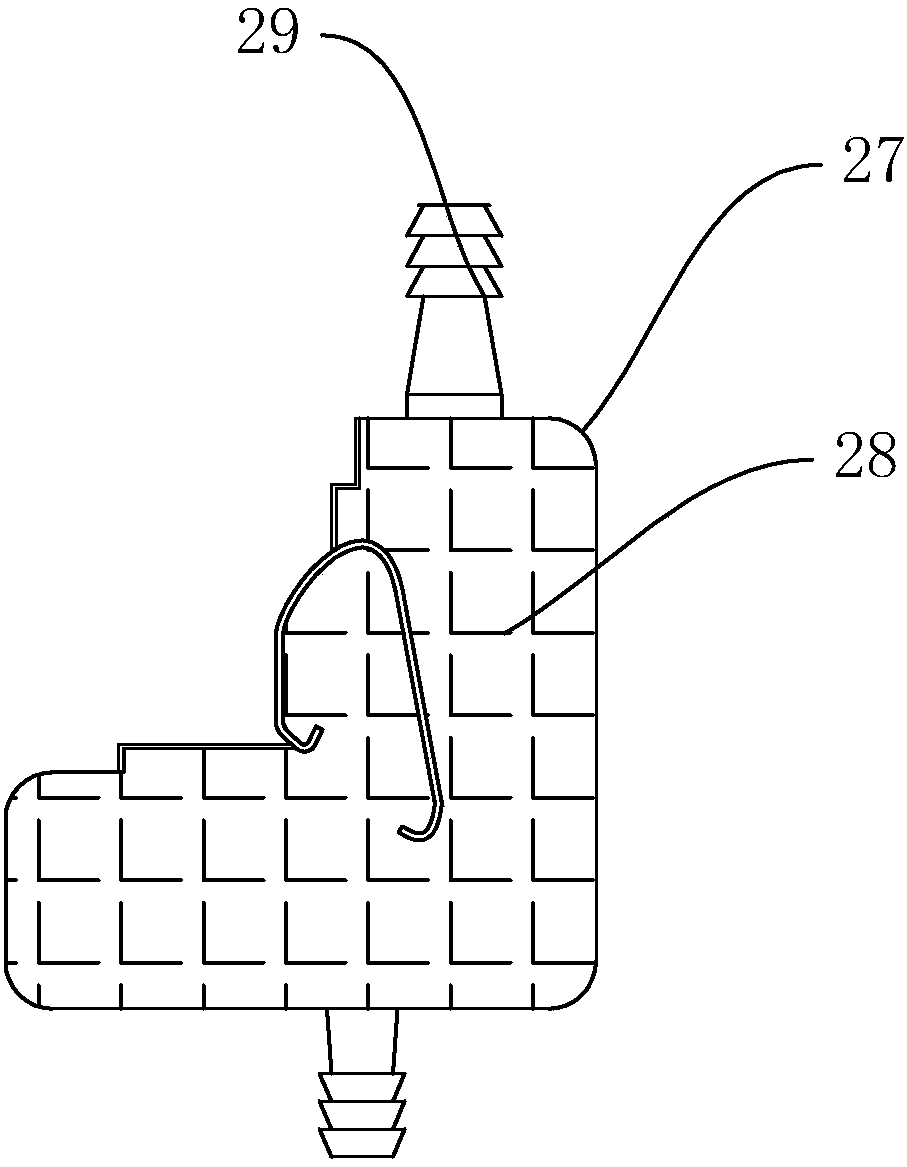

Purification treatment device

PendingCN108081851AFast releasePrevent biological contaminationCovering/liningsPretreated surfacesEngineeringAir pollution

Owner:UNIV OF SCI & TECH BEIJING

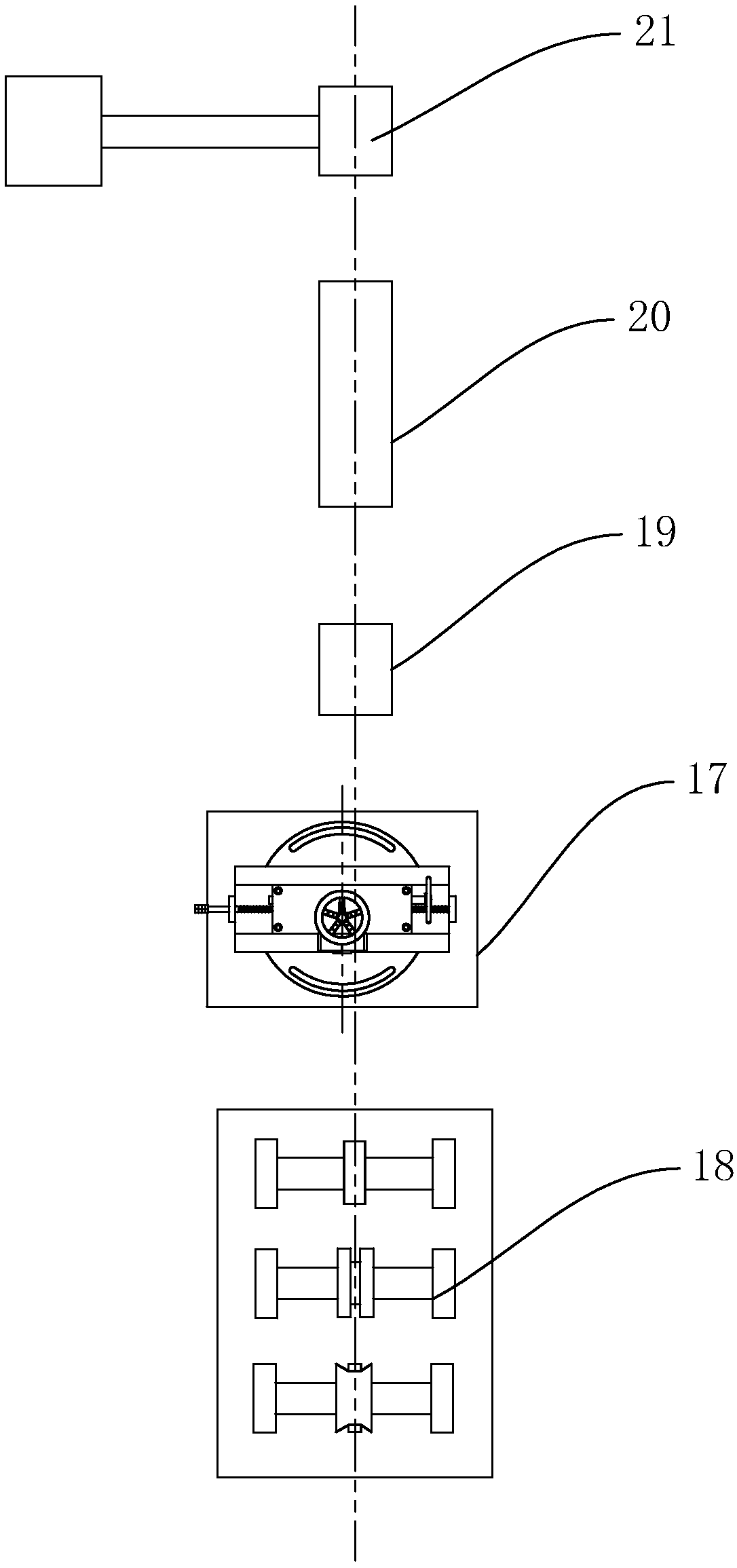

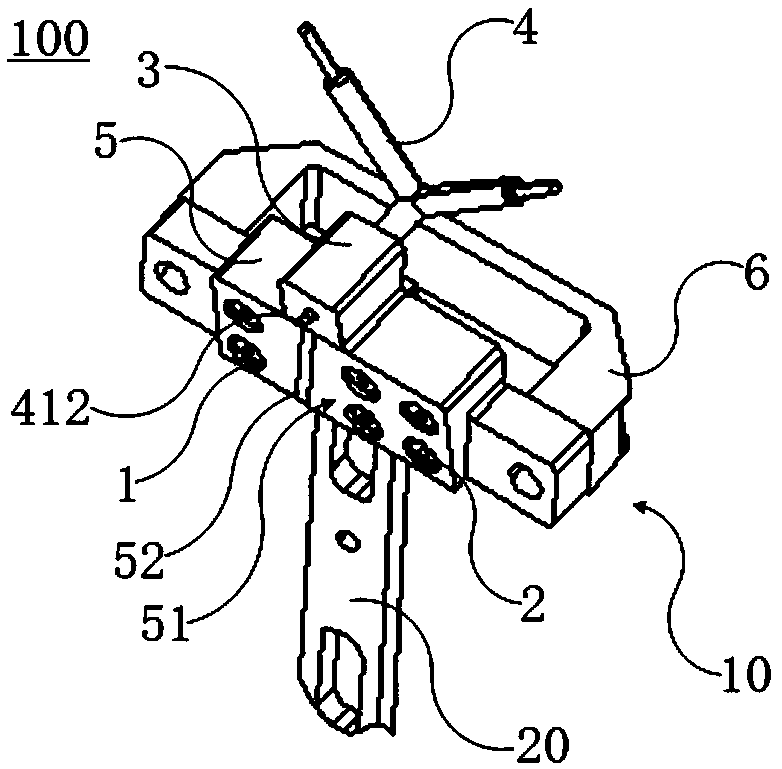

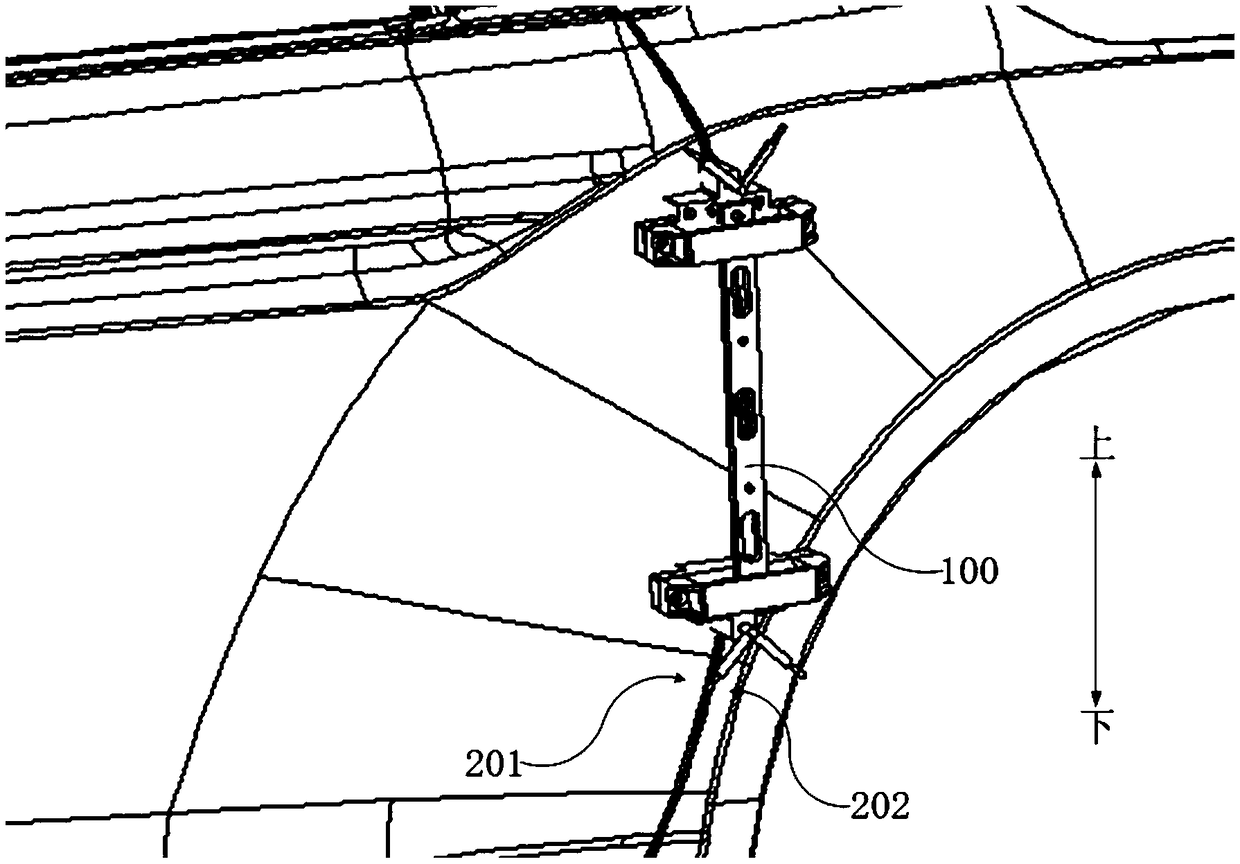

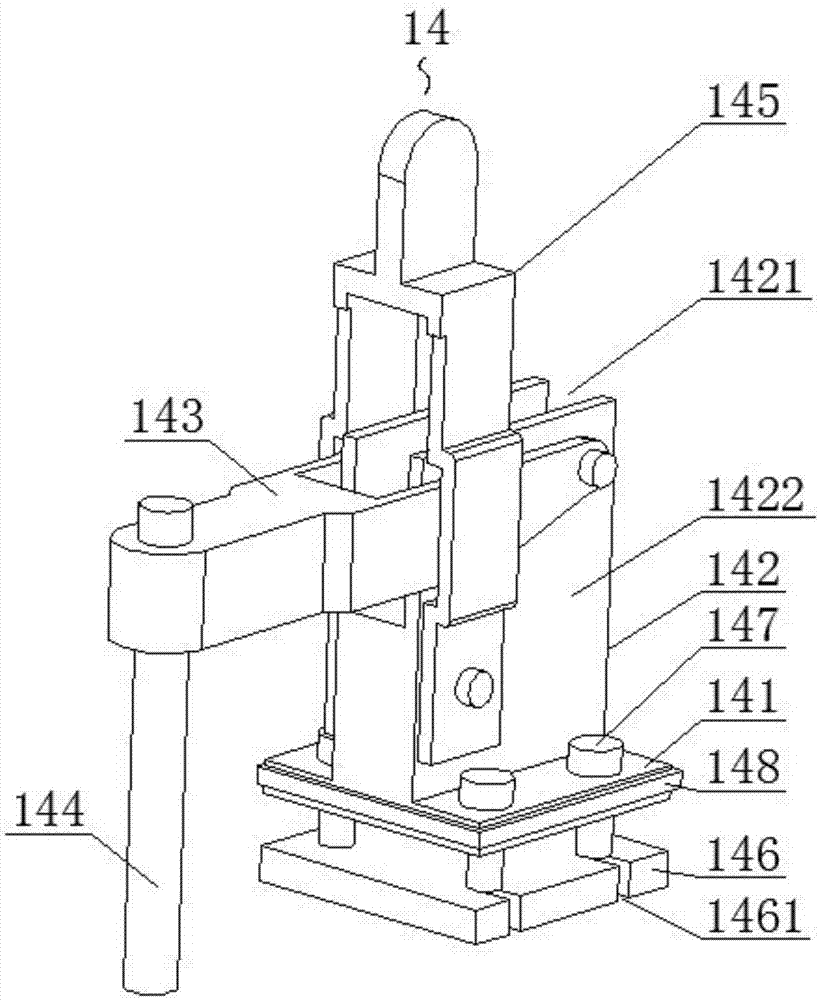

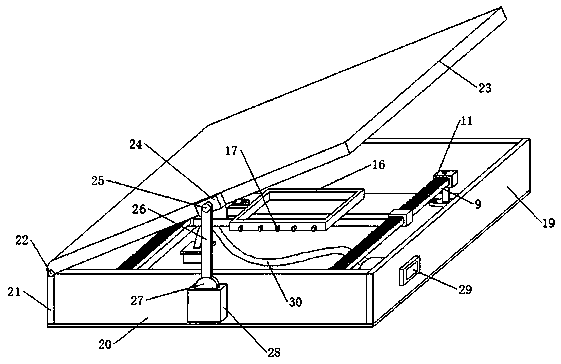

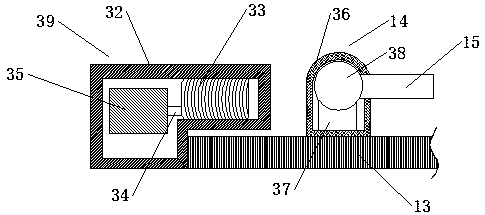

Translation turnover device for vehicle-mounted GPS positioner

ActiveCN108382798AReduce difficultyIncrease activity spaceSatellite radio beaconingVehicle componentsFixed frameEngineering

Owner:梁山鸿福交通设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap