Automobile external glazing tape manufacturing technique and correction tool applied to technique

A production process, external water cutting technology, applied in applications, household components, molding tools, etc., can solve the problems of low material utilization, low bending efficiency, poor quality stability, etc., to reduce production costs, improve production efficiency, and increase market share. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

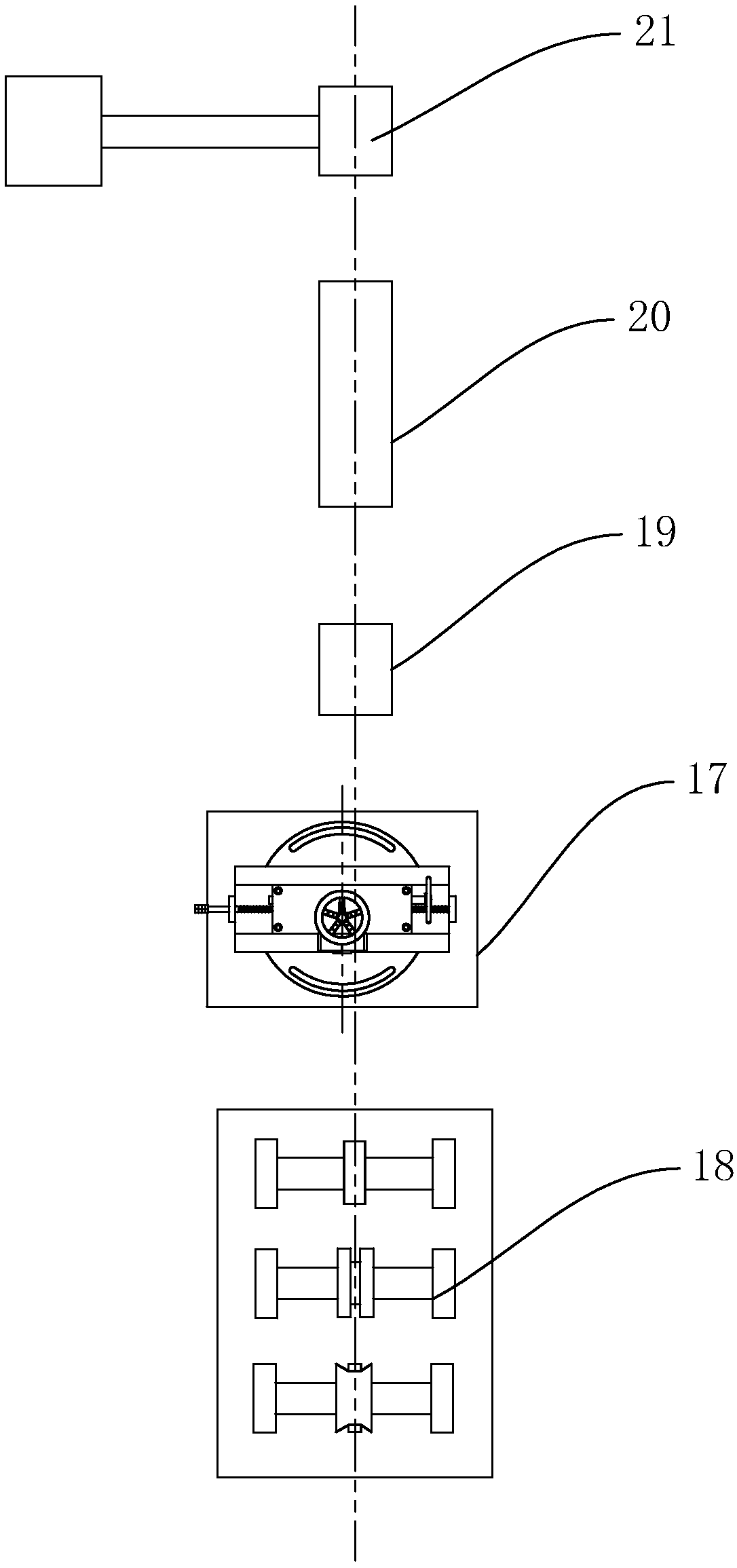

[0035] A water-cutting production process for automobiles, comprising step A, using an uncoiler to uncoil metal coils and conveying them in a sheet shape; step B, using a rougher to grind the sheet metal that is conveyed from the uncoiler Grinding and wiping oil stains on the surface of the material; step C, using two rotating rollers arranged up and down and in parallel to level the surface of the metal sheet passing therethrough; step D, combining figure 1 As shown, multiple sets of rolling dies 18 are used to continuously roll the metal sheet and make its cross-section U-shaped. Multiple sets of rolling dies 18 are on the same straight line, and each set of rolling dies 18 extrudes the metal sheet All utilize water outlet pipe to cool it in the material process, each group of rolling mold 18 all comprises the patrix and the lower die that are arranged up and down, the shape of the patrix and the lower die is designed according to the shape that metal skeleton needs to form; E.

Embodiment 2

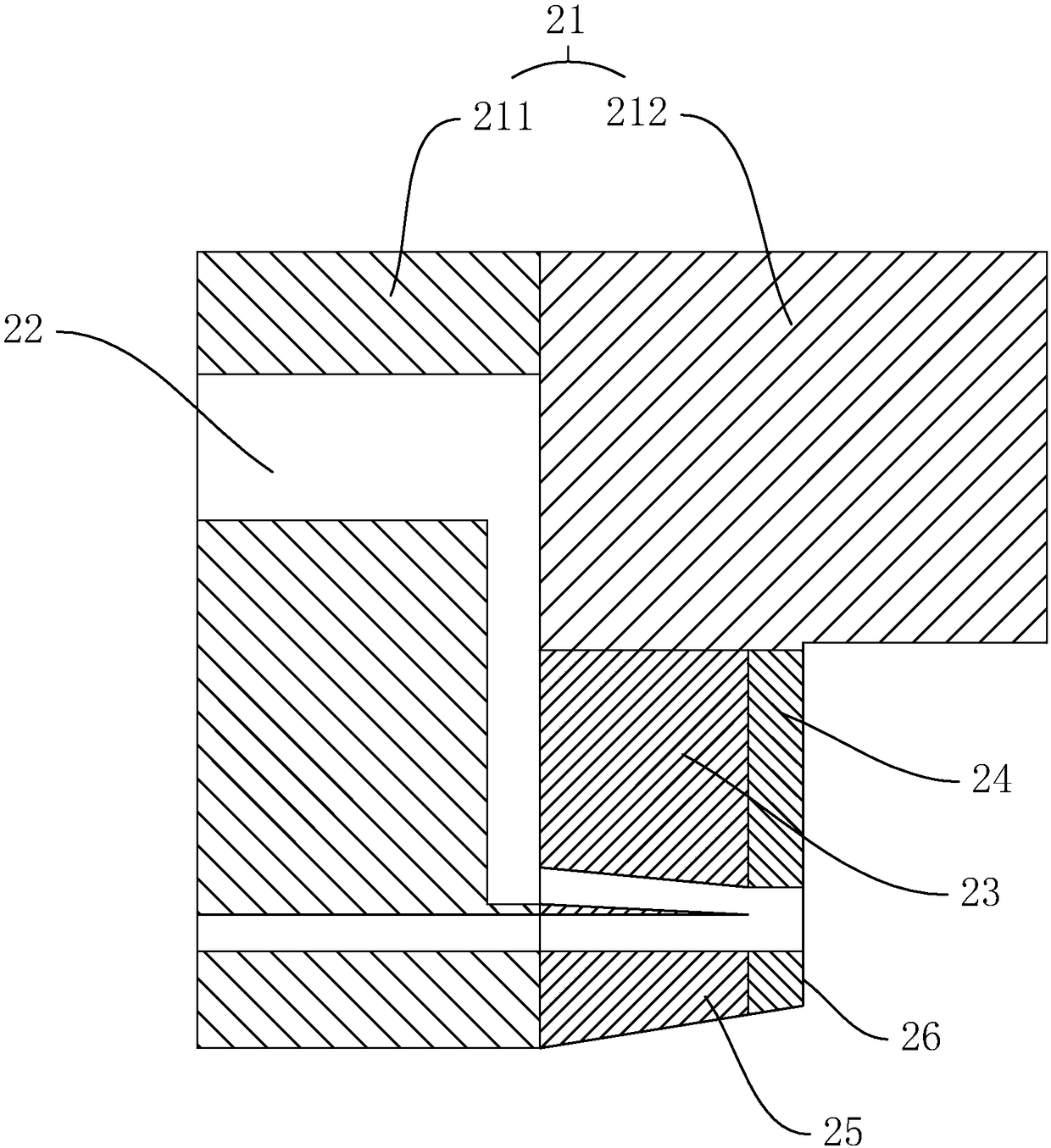

[0037] A calibration tool, combined with Figure 4-5 As shown, it includes a cuboid base 1 that can be fixed on the frame body, and a slide rail 4 is arranged on the cuboid base 1. The length direction of the slide rail 4 is perpendicular to the conveying direction of the outer water cut; the center position of the slide rail 4 is in line with the base 1. It is rotationally fitted in the horizontal plane; a fixed plate 12 is uniformly formed on the side walls on both sides of the width direction of the slide rail 4, and an arc-shaped adjustment groove 13 concentric with the rotating shaft is opened on the fixed plate 12. When adjusting The groove 13 is perforated with a fixing bolt 11 that is threadedly connected to the base 1, and the fixing bolt 11 can press the fixing plate 12 against the base 1; on the slide rail 4, there is an inverted T-shaped and parallel to the length direction. The chute 14 is embedded in the chute 14 and is slidably connected with a glyph-shaped and ver

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap