Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about "Shaping tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

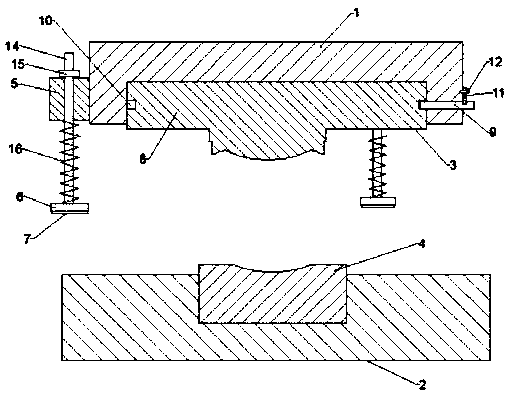

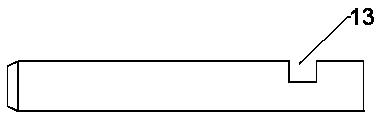

Method for drawing and forming parabola revolution body

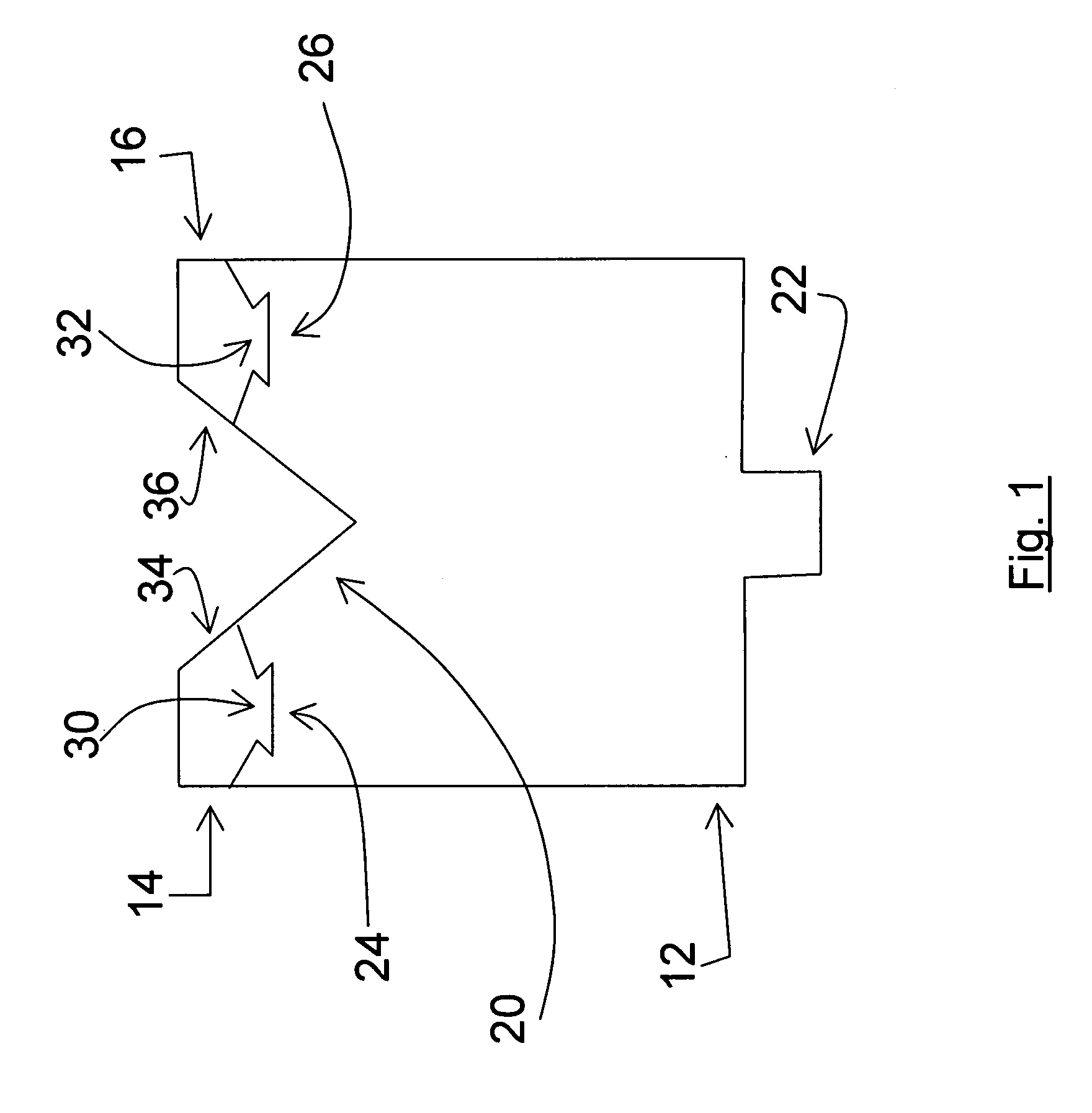

The invention relates to a method for drawing shaped parabola revolving body, belonging to the technical field of the plastic forming of material processing engineering. The method comprises the following steps: (1) a set of mould is designed according to the final shape of revolving body parts; (2) the first drawing: when being drawn, a movable soft punch cushion block is arranged on a mould punch; the inner shape of the movable soft punch cushion block is similar to the shape of the punch; a movable rigidity limit cushion block is arranged below a blank holder with a belt drawbead; (3) the annealing heat treatment, the annealing heat treatment is carried out on the parts after the first drawing is carried out on the parts; (4) the second drawing, the same set of module is used; when in drawing, the movable soft punch cushion block and the movable rigidity limit cushion block are removed. In the invention, the movable soft punch cushion block is added on a drawing mould rigidity punch for enlarging the plastic forming of the materials in the first drawing; only one set of drawing module is used on an ordinary hydraulic press, therefore, the parahola revolving body parts which are usually formed with 3-4 sets of moulds by the common drawing processing are successfully formed by twice drawing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

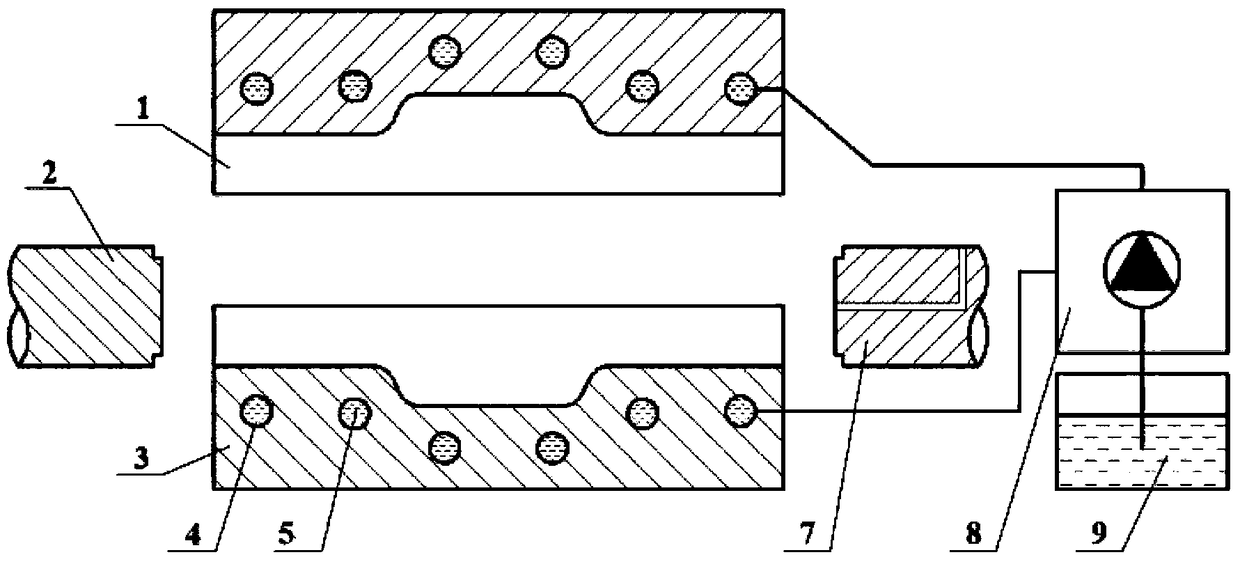

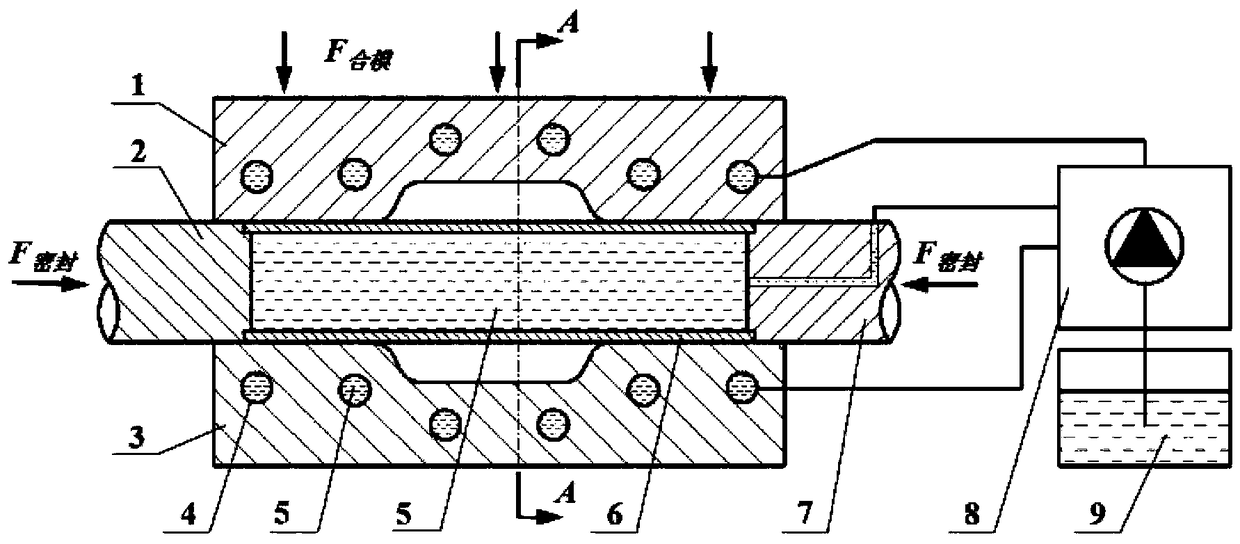

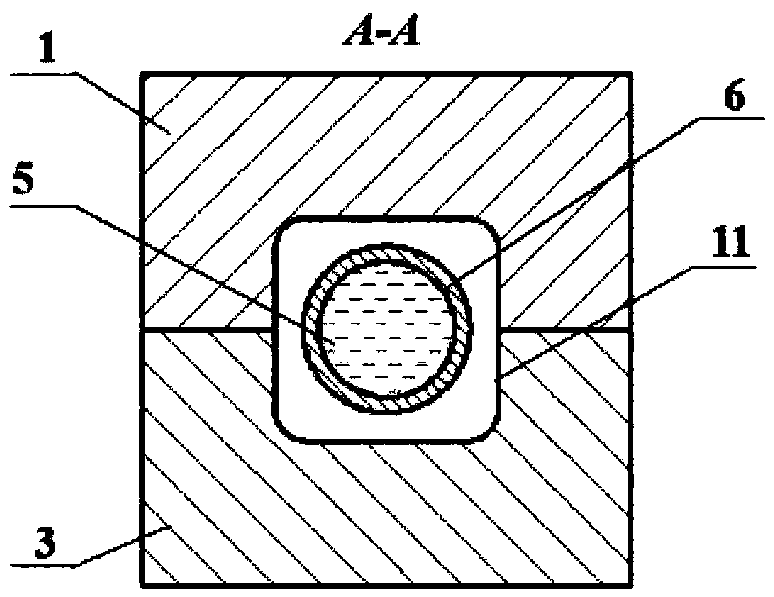

Aluminum alloy special-shaped pipe ultralow temperature medium pressure forming method

ActiveCN109500195AAvoid cracking problemsAchieving flexible loadingShaping toolsWeld seamAbnormal shaped

Owner:DALIAN UNIV OF TECH

Upper die clamp-type hydraulic clamping device of bending machine

Owner:HUANGSHI HUAXIN MACHINERY EQUIP

Magnetic collector for magnetic pulse forming

Owner:HARBIN INST OF TECH

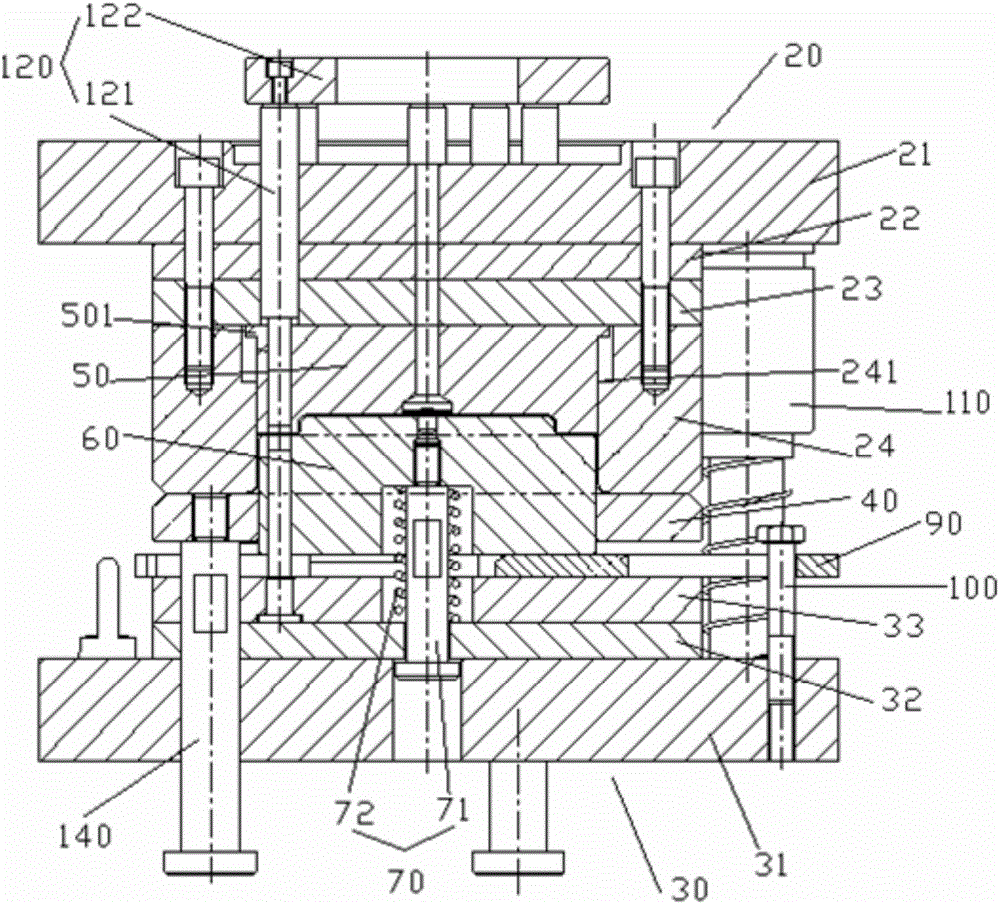

Metal plate forming mold and forming method thereof

Owner:浙江鑫正工贸有限公司

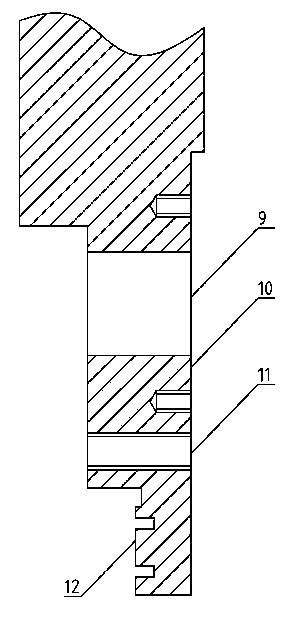

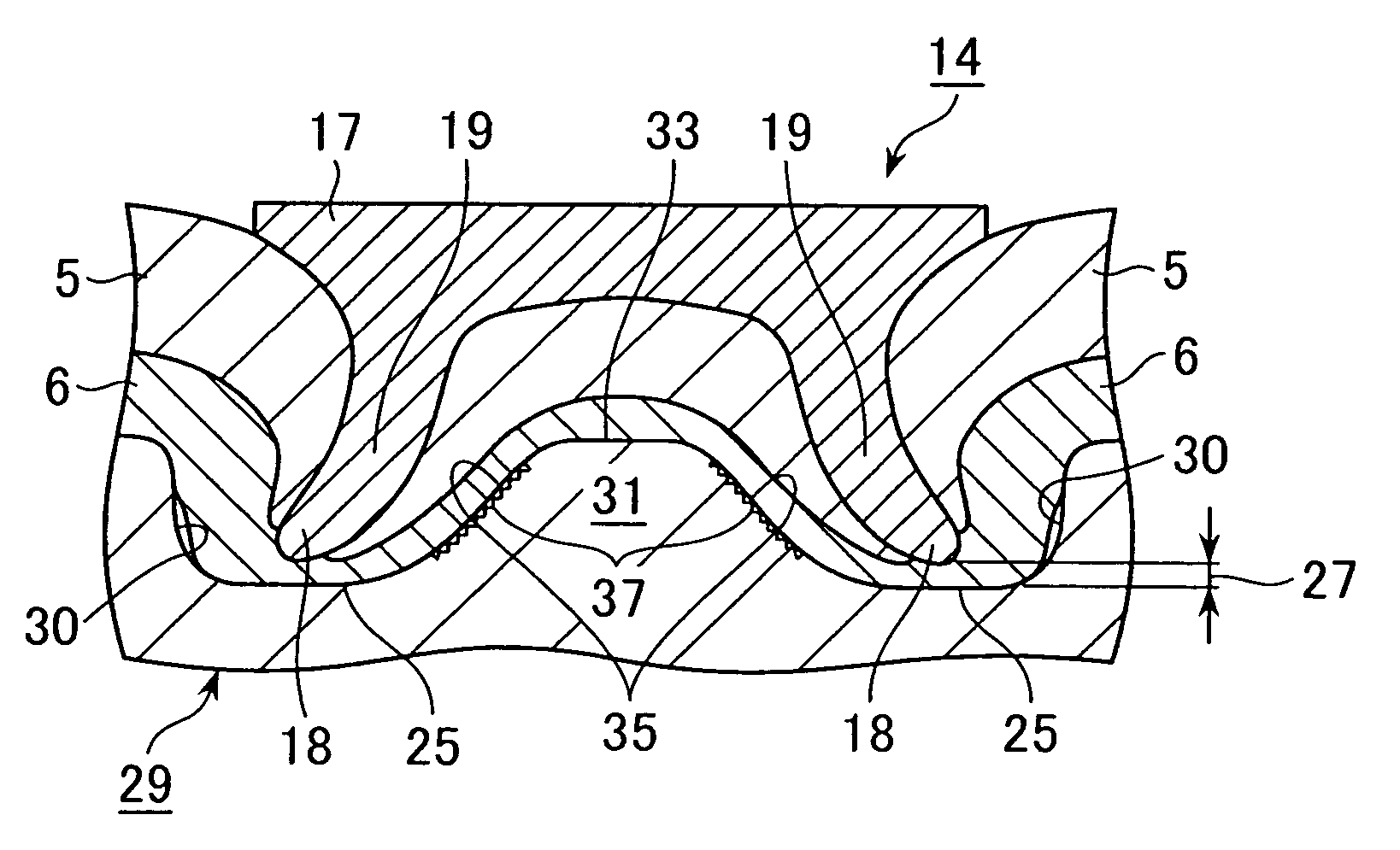

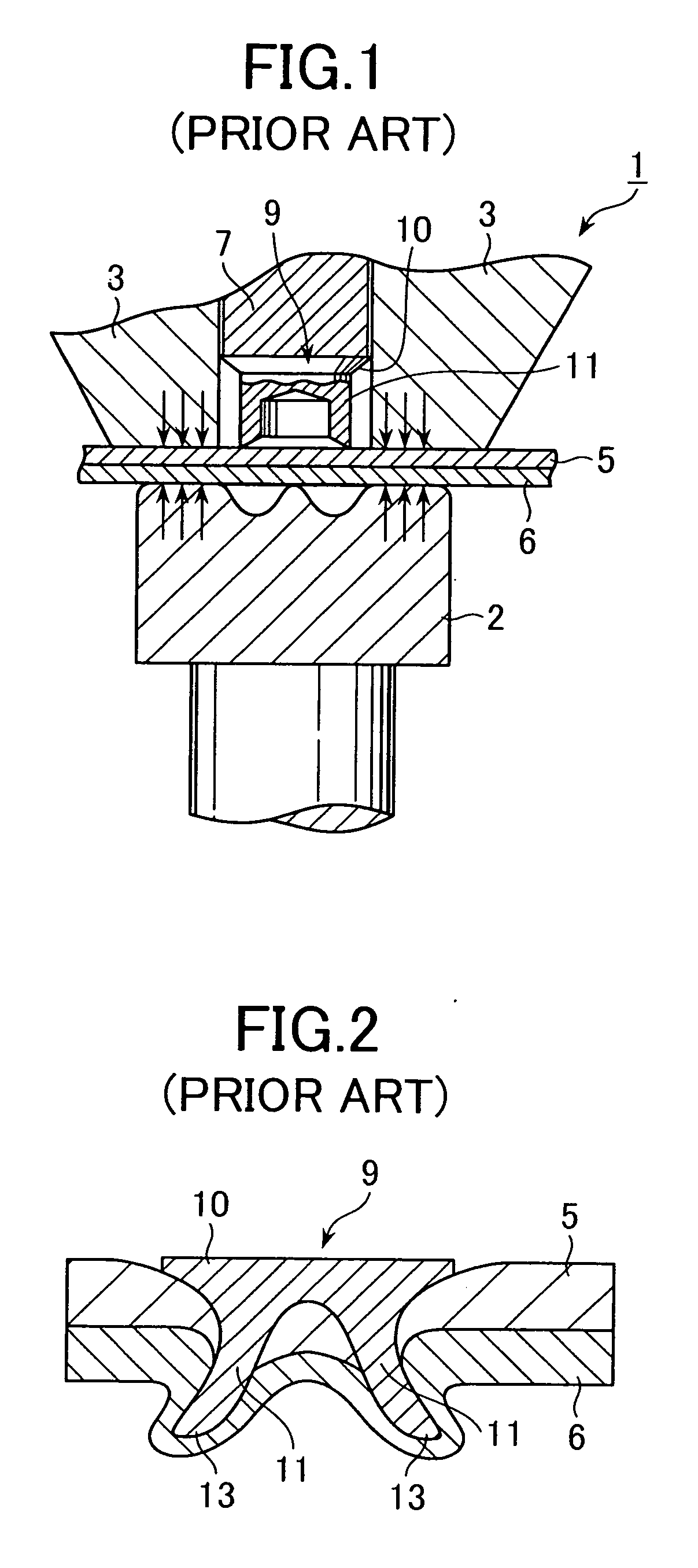

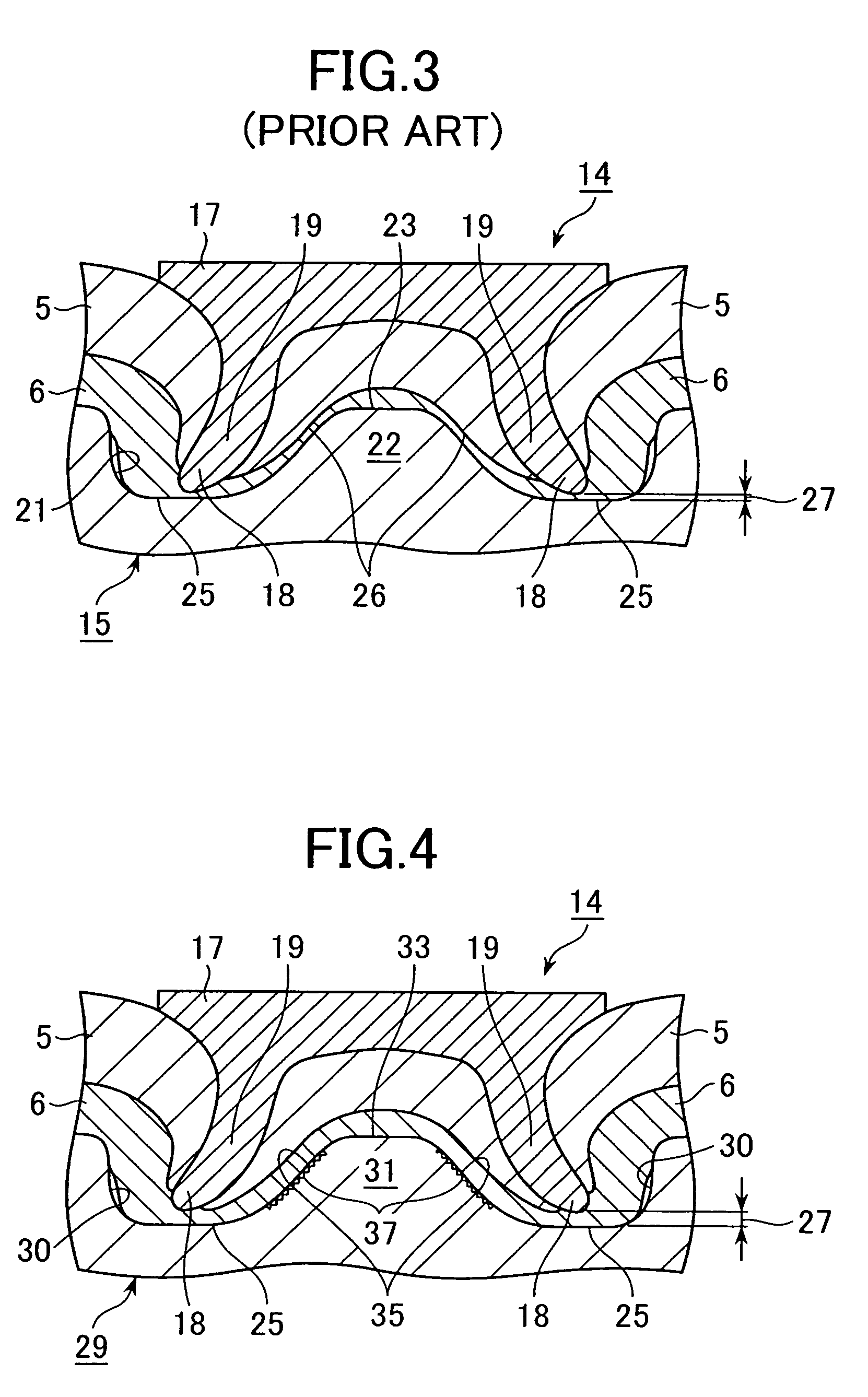

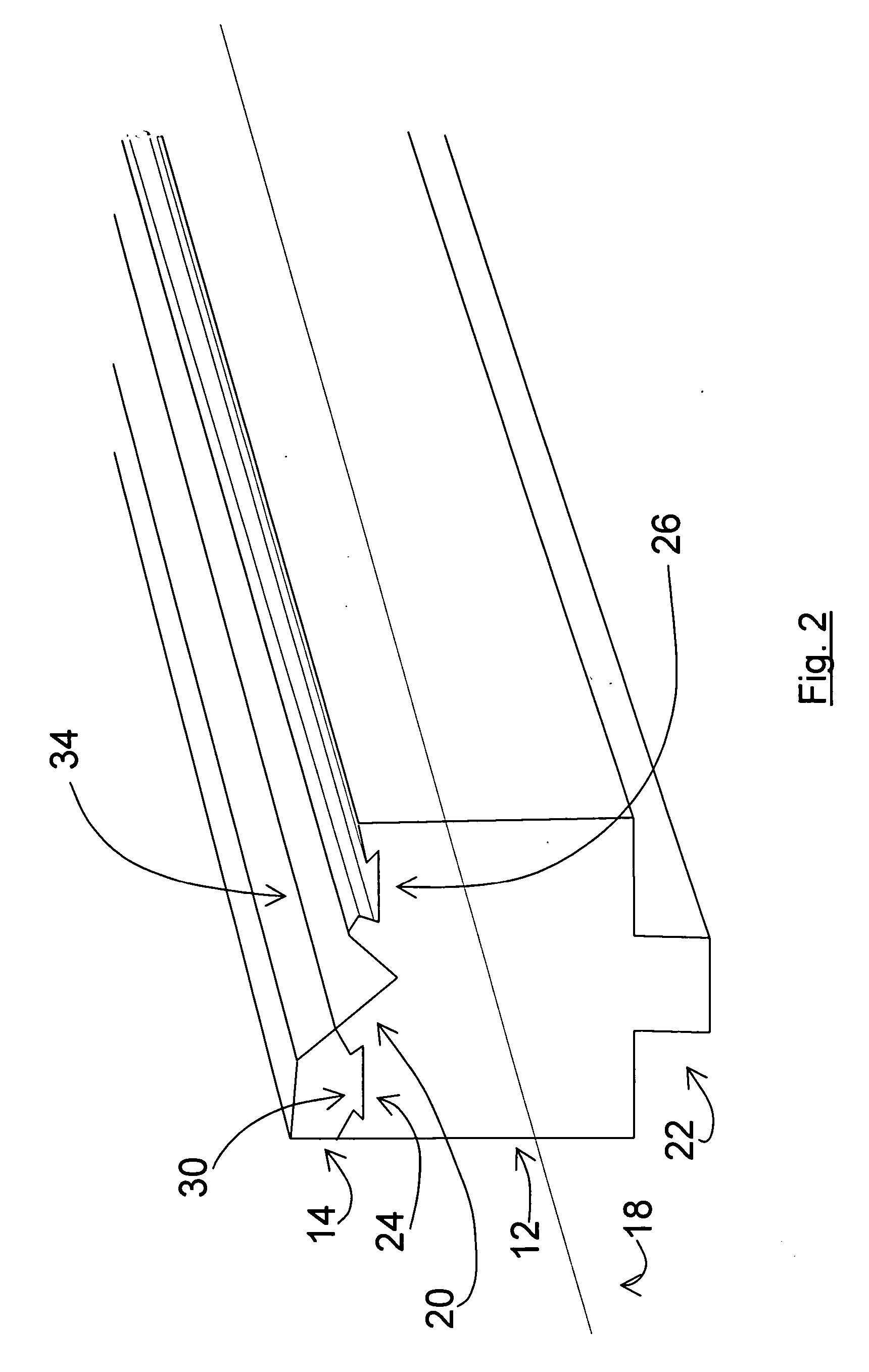

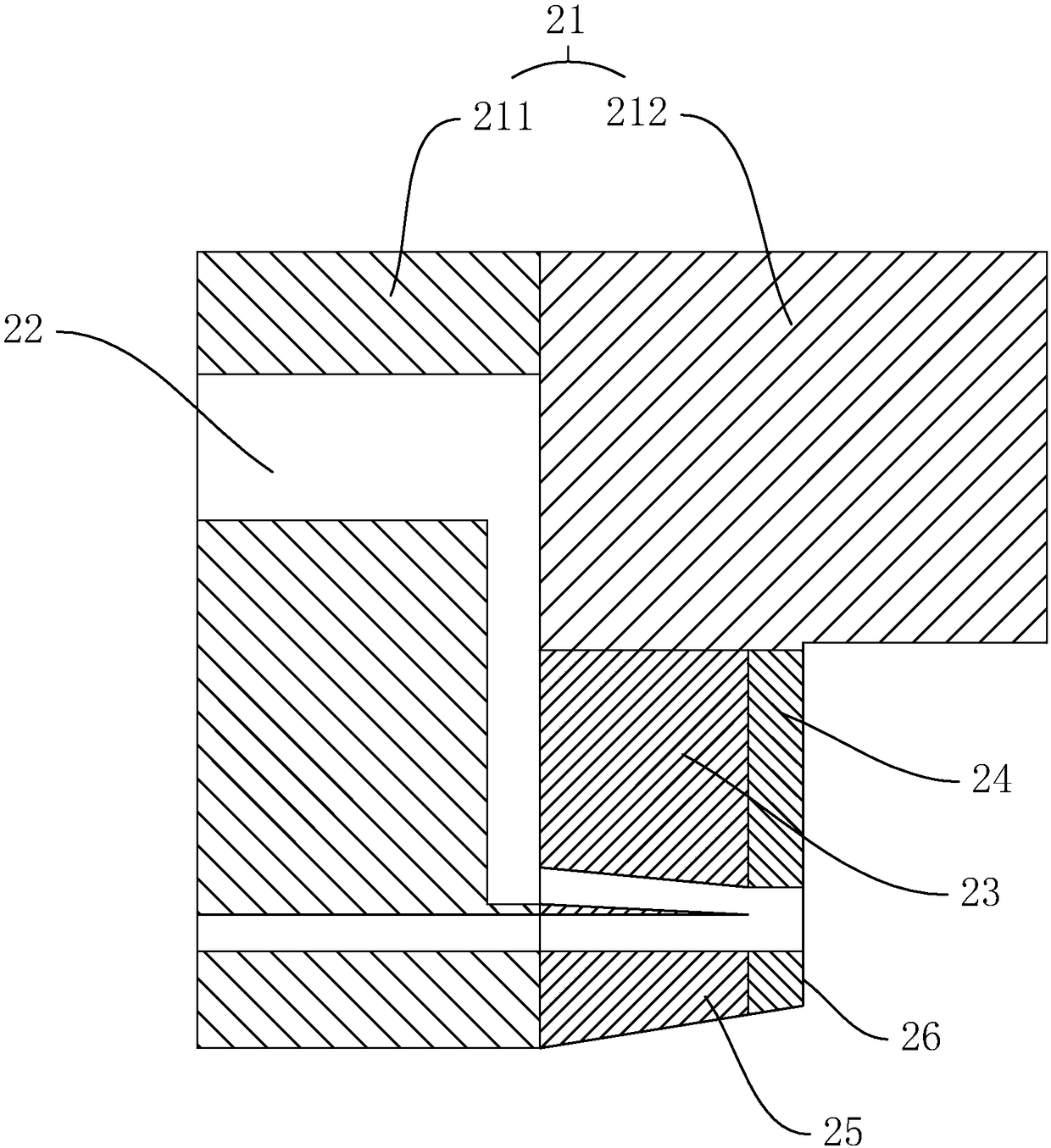

Self-piercing rivet fastening device with improved die

InactiveUS20060016056A1Improve gripPrevent materialShaping toolsForging/hammering/pressing machinesEngineeringRivet

A self-piercing rivet fastening device has a punch that drives legs of the rivet into portions of workpieces that are forced into a die cavity, in order to join the workpieces. Particular surfaces of the die cavity are modified to increase the coefficient of friction in order to prevent tips of the legs of the rivet from breaking through a workpiece adjacent to the die and forming holes.

Owner:NEWFREY

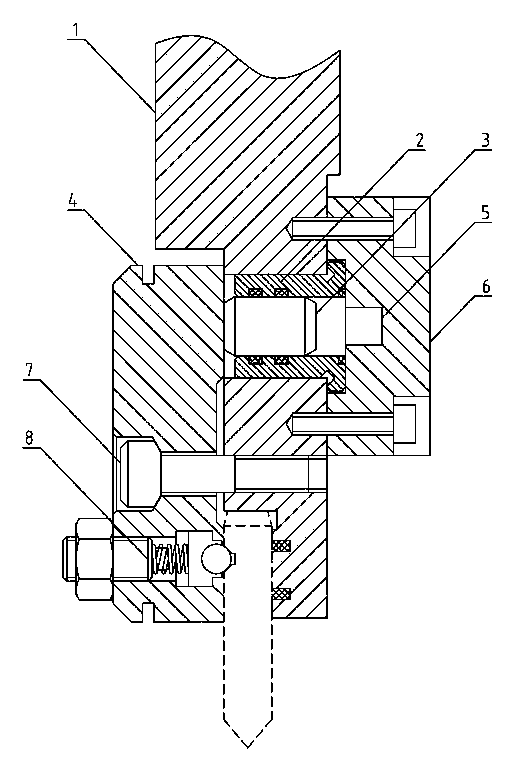

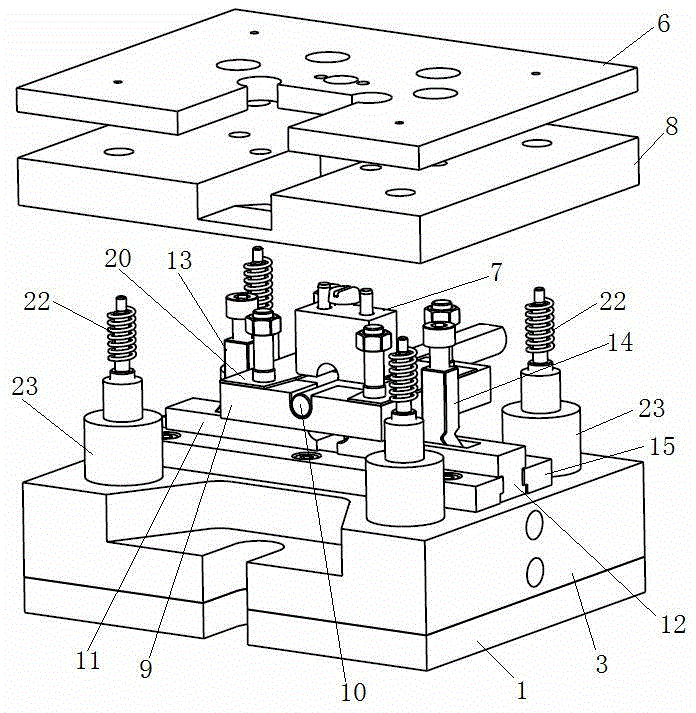

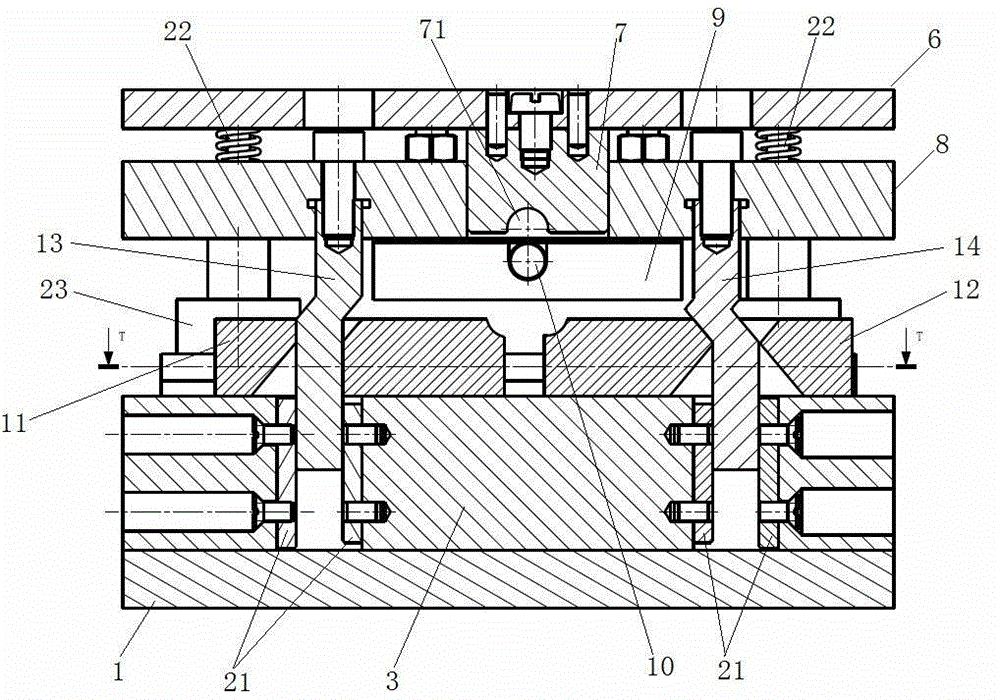

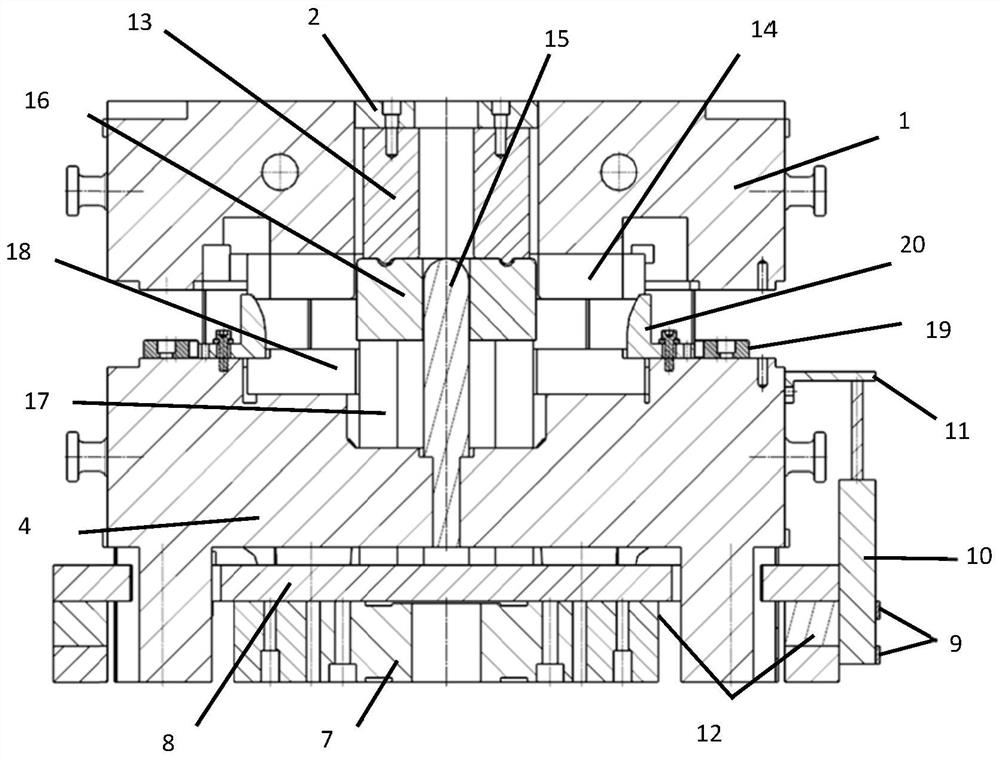

Special die having movable force plug for the hydraulic forming of outer housing

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

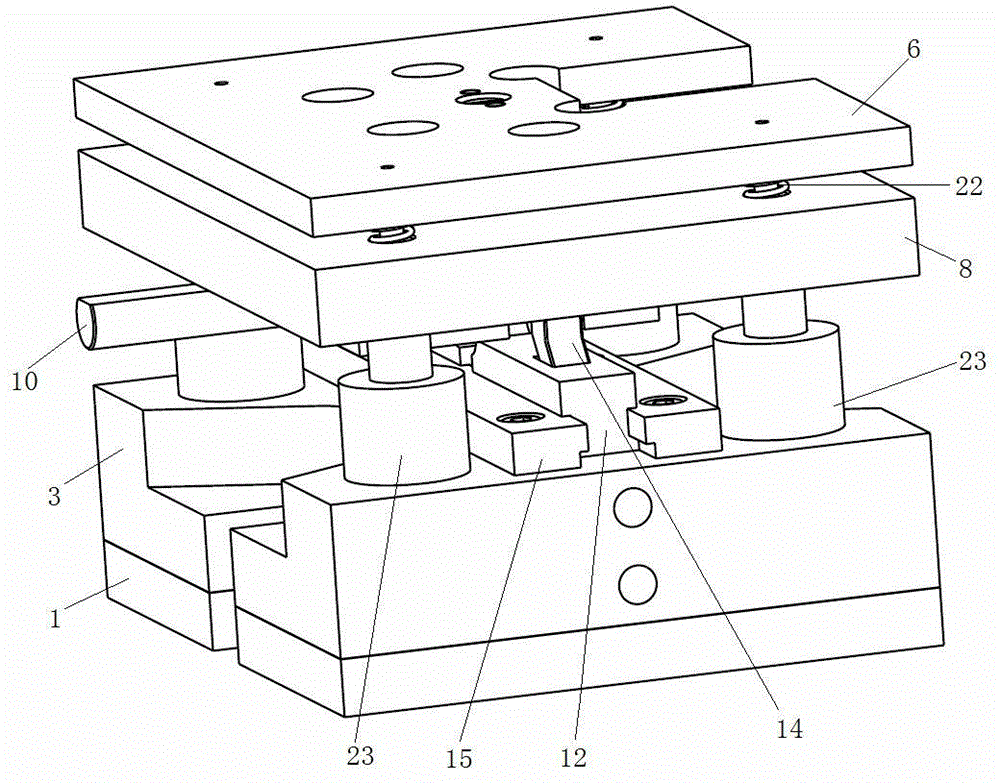

Processing technique of liquid crystal television metal frame

ActiveCN101332483ASmall Bend Edge Fillet RadiusReduce shockShaping toolsEngineeringMachining process

The invention discloses a processing technology of a metal face frame of a liquid crystal television, and the processing technology comprises a processing procedure of folding edges and a processing procedure of ambient round angles. The processing technology is characterized in that an aluminum sheet with a cut in the middle is fixed between a concave pattern plate and a fixing plate in the processing procedure of folding edges, wherein the edge of a concave pattern cavity of the concave pattern plate is added with a ring of pressed rib pressed into the aluminum sheet, and the inner edge of the aluminum sheet is pressed by a convex pattern plate to form the folding edge; in the processing procedure of ambient round angles, three pairs of concave-convex pattern insert block components are adopted to bend, punch and shape the four round angles at the connecting places of the four straight edges on the folding edges in three steps, and the radiuses of the arc surfaces on the three convex pattern insert blocks of the concave-convex pattern insert block components are decreased sequentially. The processing technology of the invention can press the folding edges with smaller round angle radius and the four round angles at the connecting places of the four straight edges on the folding edges, and effectively prevent rupture at the four round angles in the processing course, which improves the product quality greatly.

Owner:SUZHOU VICTORY PRECISION MFG

Fixture for forming U-shaped clip of steel plate spring

Owner:诸城市恒信基汽车部件有限公司

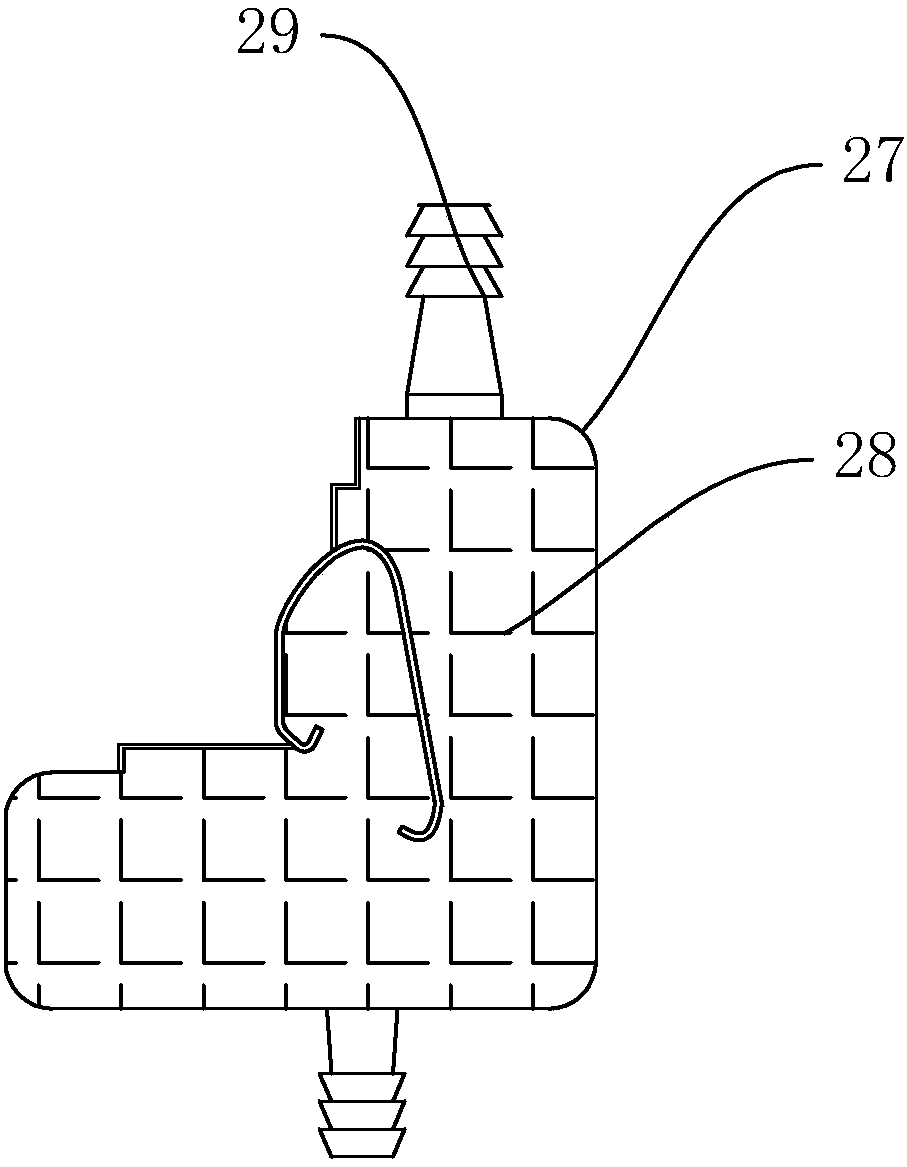

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

Brake punch inserts

Owner:LELAND DAVID

Drawing punching compound die

Owner:CHINA HANGFA SOUTH IND CO LTD

Stamping die capable of keeping pressing leftover material parts of plates

Owner:天津市武清区环球锌业有限公司

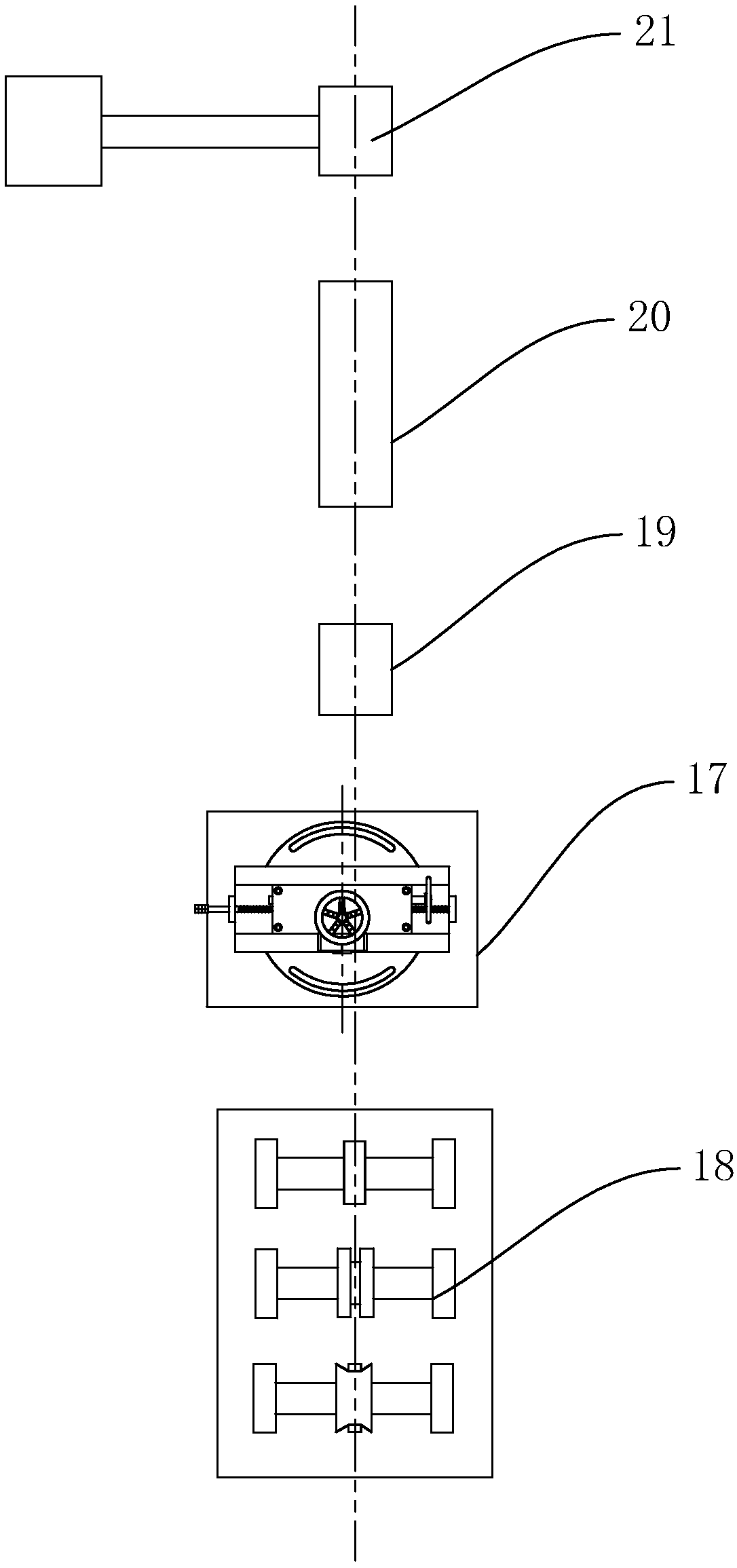

Multi-station bending device

InactiveCN105251837AImprove bending qualityImprove bending efficiencyShaping toolsEngineeringElectronic component

Owner:SUZHOU FINTESTS MEASUREMENT & CONTROL TECH CO LTD

Stamping die for automobile interior plates

Owner:TIANJIN BINHAI HIGH NEW DISTRICT WANGYUE TECH DEV CO LTD

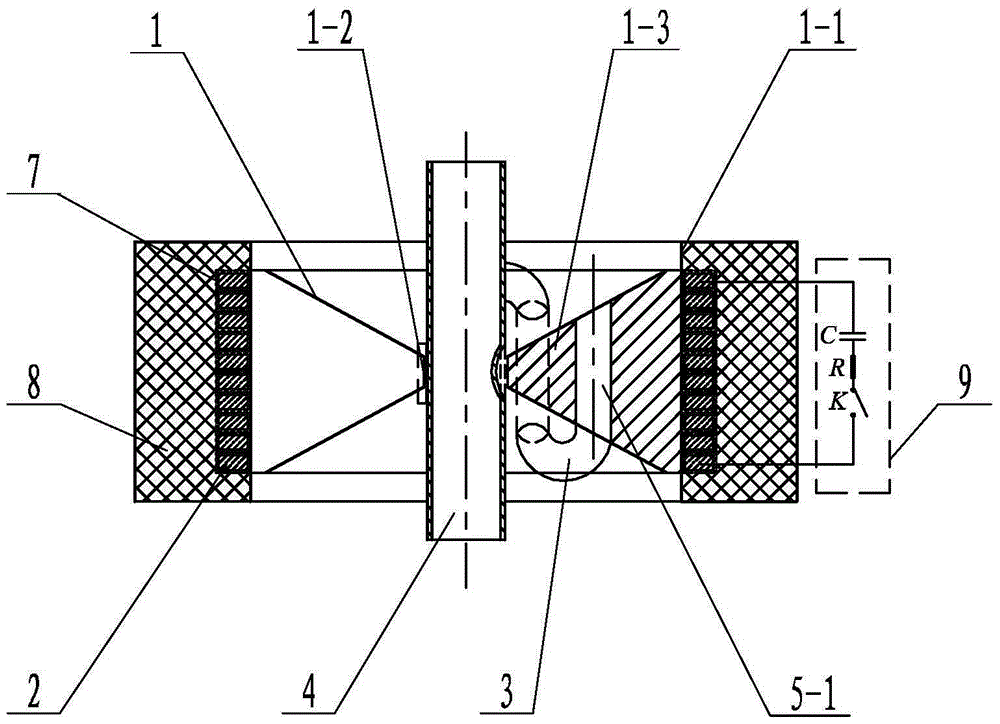

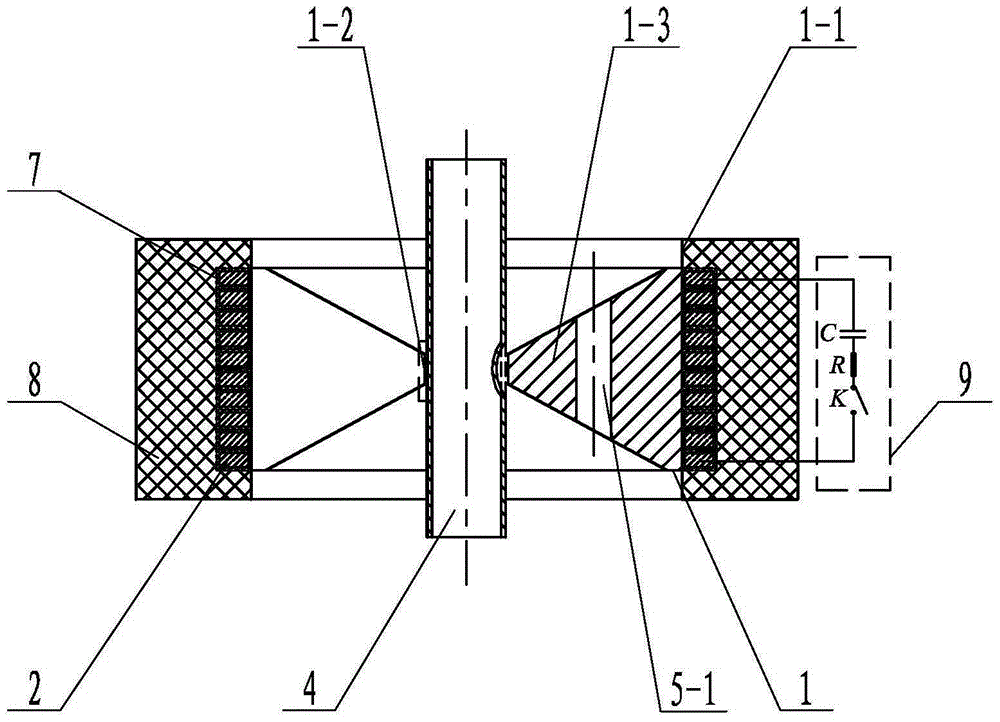

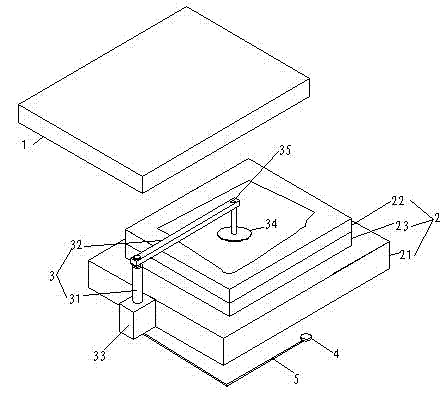

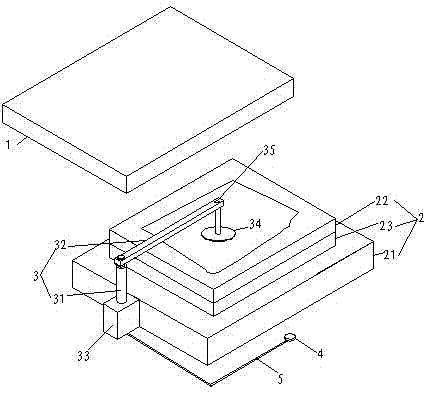

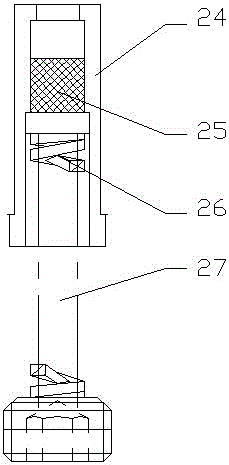

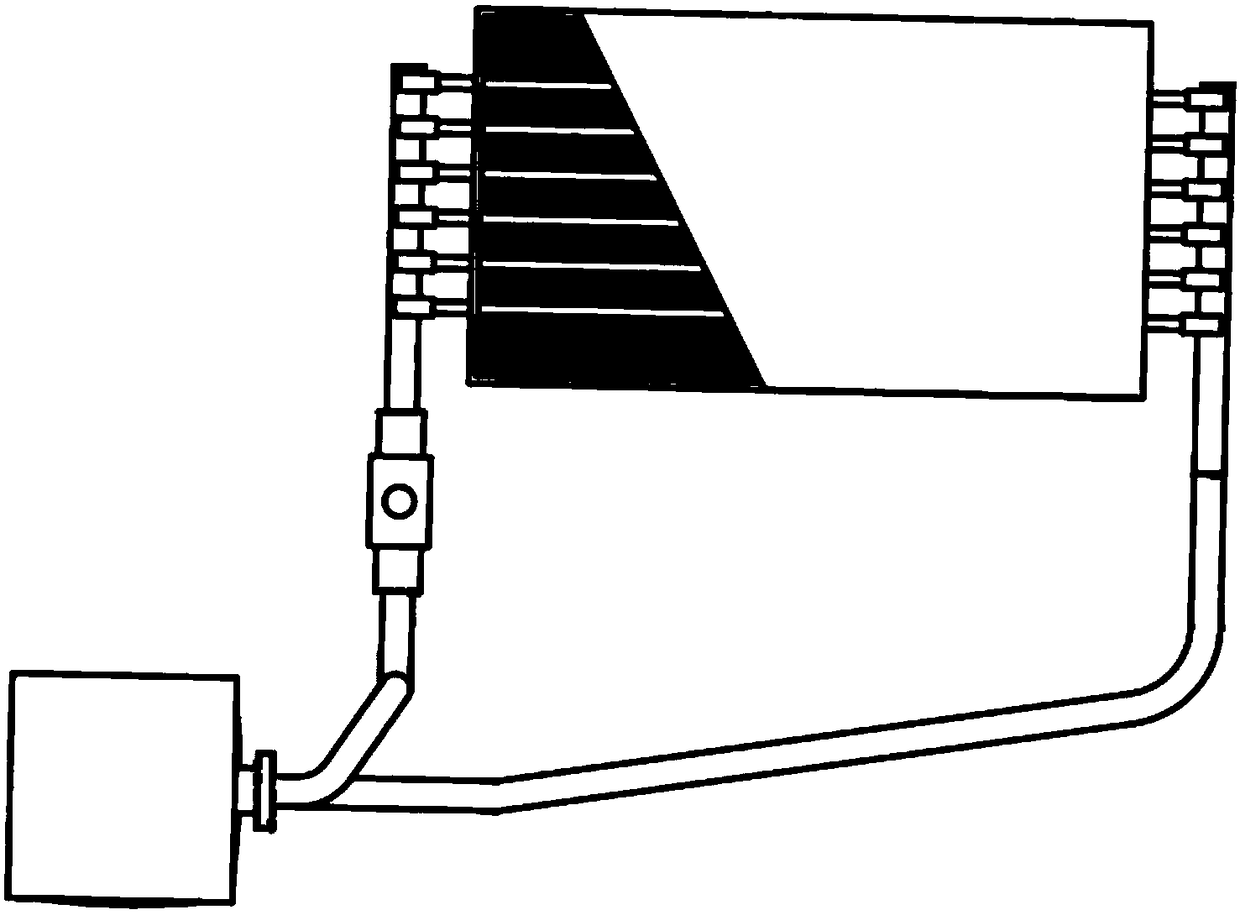

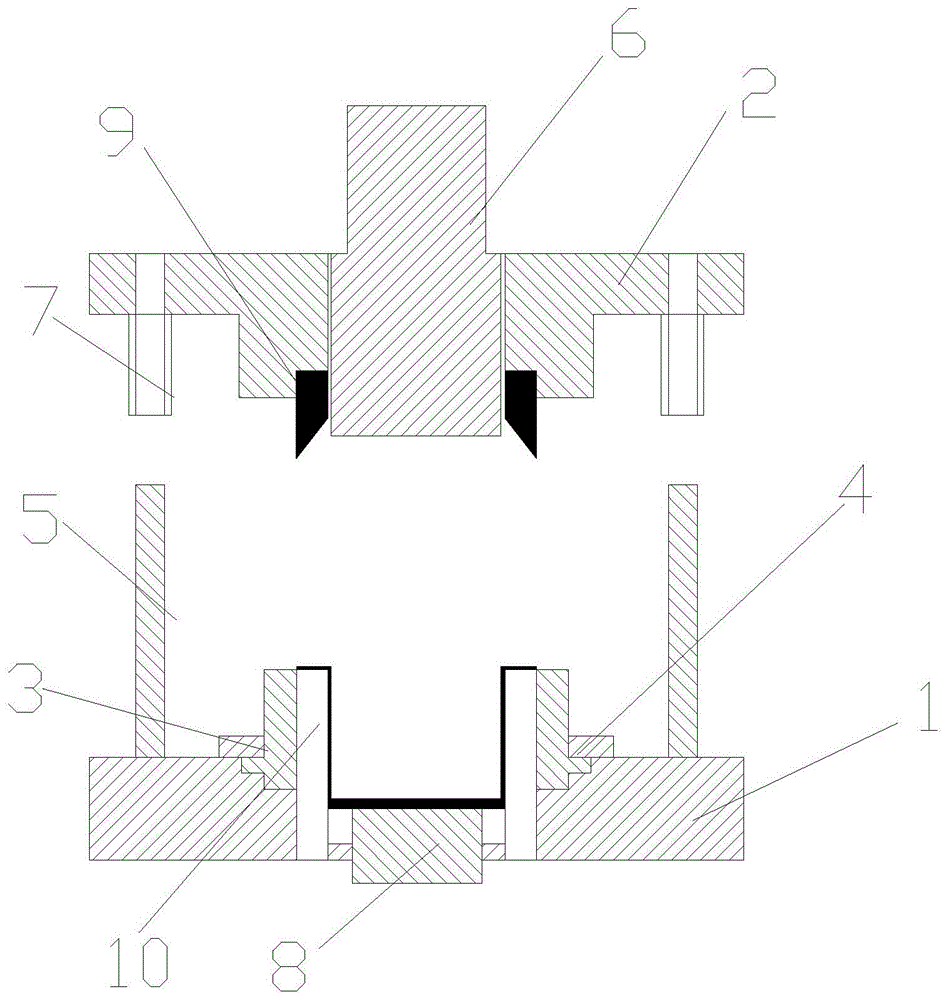

Angle iron rolling machine

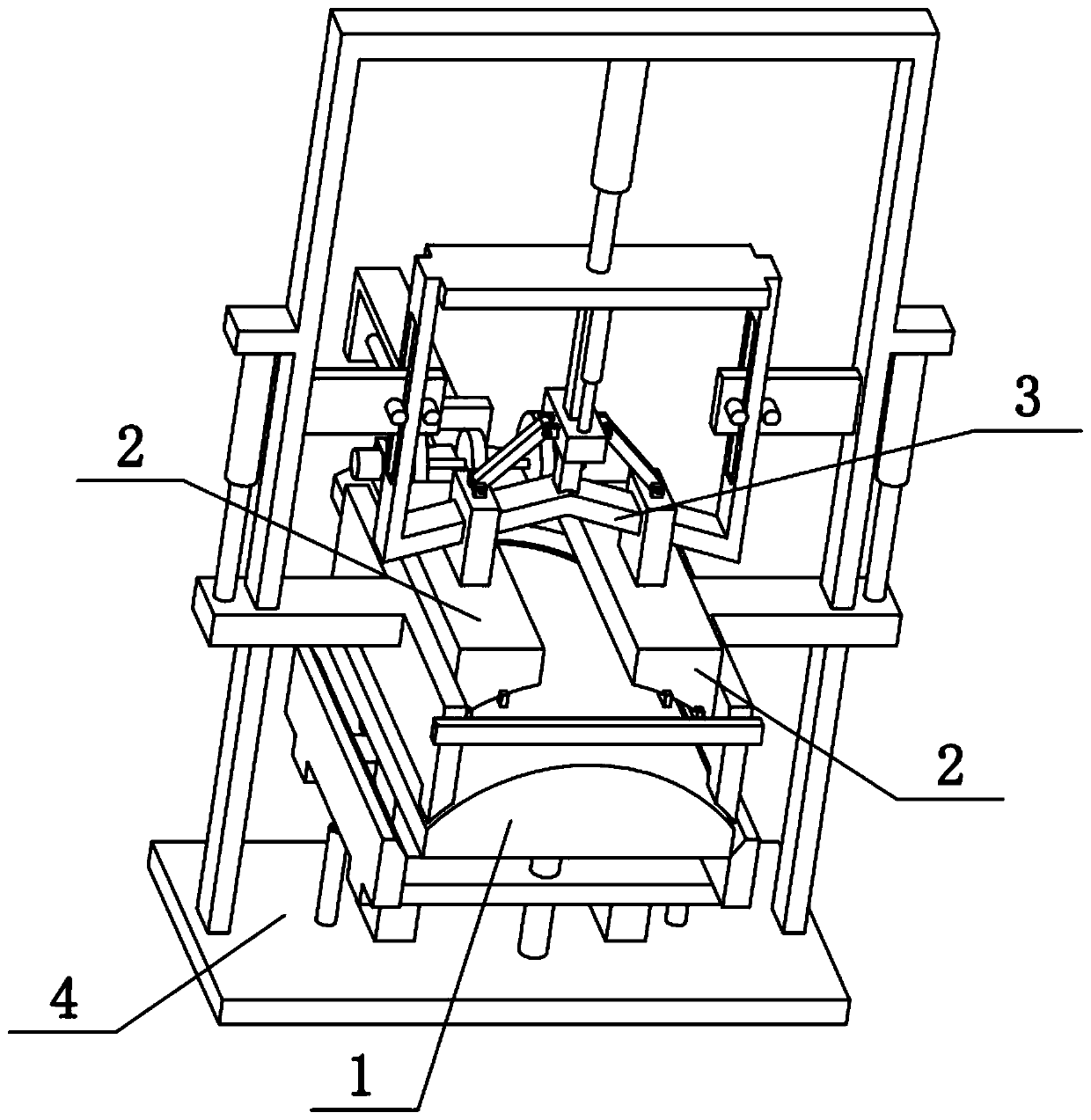

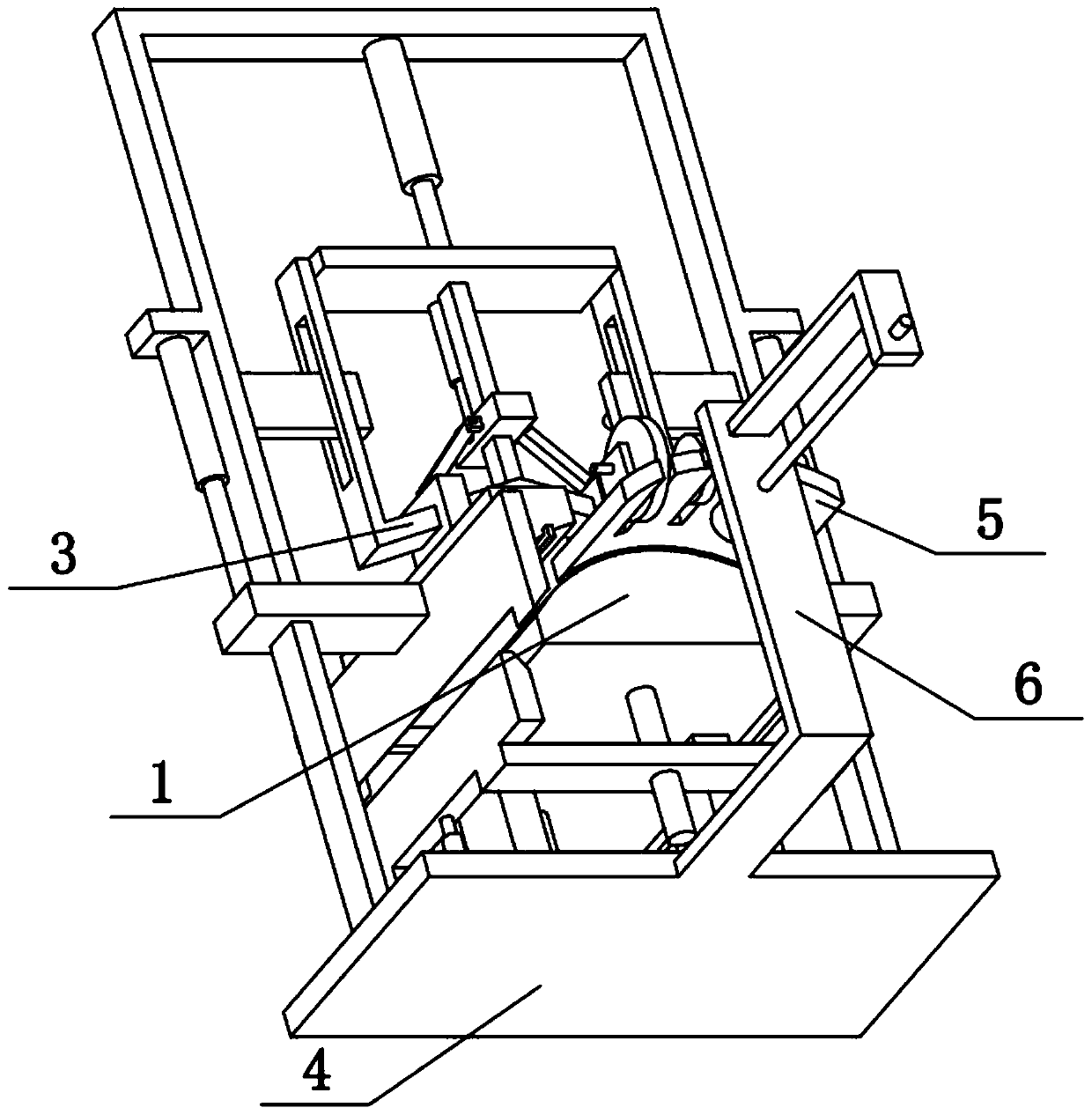

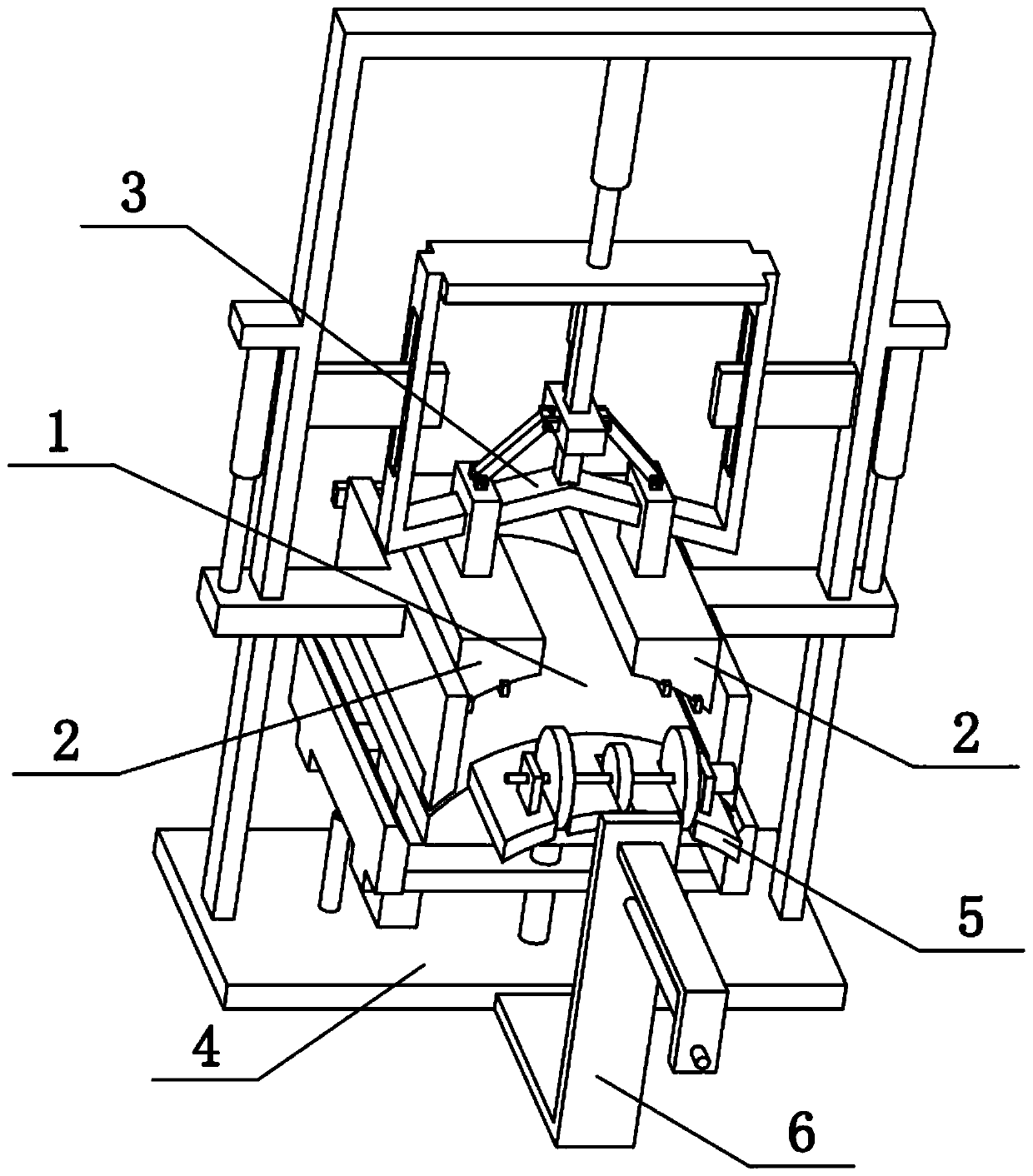

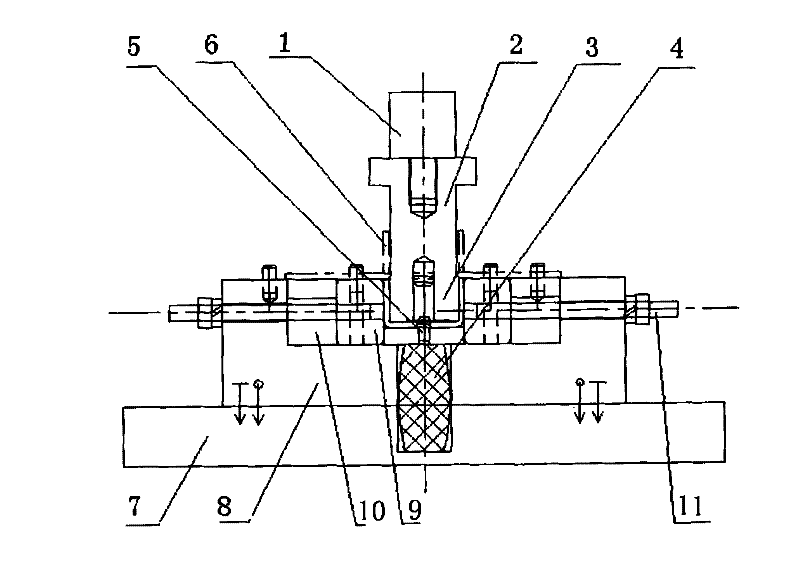

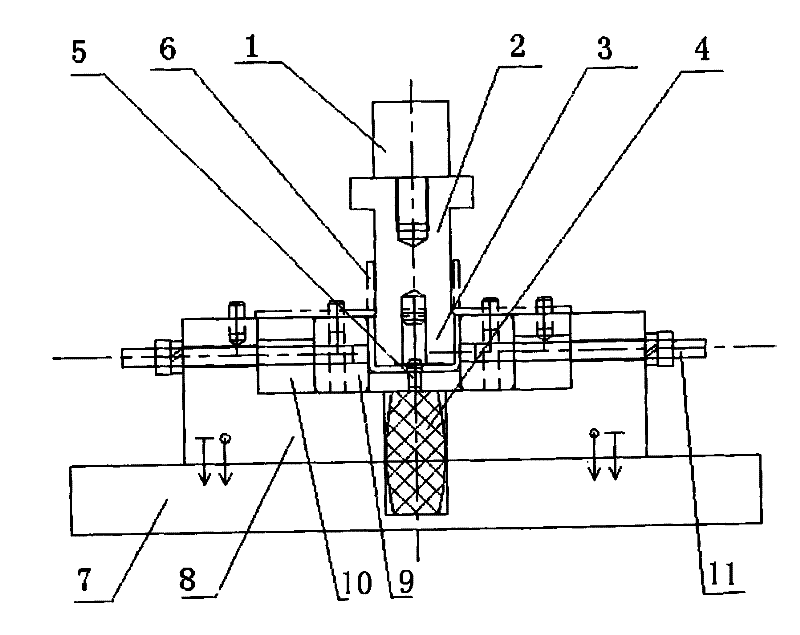

The invention discloses an angle iron rolling machine. The angle iron rolling machine is formed by refitting an original three-roller plate rolling machine. The angle iron rolling machine is composed of a plate rolling machine (1), an upper bending mold (2), angle iron (3), lower bending molds (4), shaft end baffles (5), fixing screws (6) and spring washers (7). A reserved connection interface is arranged at the outer end of a working roller of the plate rolling machine. The upper bending mold (2) and the lower bending molds (4) corresponding to the angle iron (3) are adopted, and the purpose that the angle iron (3) is rolled is achieved. In the working process, the angle iron(3) needing to be bent is put on the lower bending molds (4); the plate rolling machine (1) is started to drive the lower bending molds (4) to rotate; the upper bending mold (2) is pressed downwards through a downward-pressing oil cylinder of the plate rolling machine; and the angle iron (3) is gradually changed to be in the arc shape till the required dimensions are achieved. The angle iron rolling machine has the beneficial effects of being simple in structure, low in investment, quick in economic benefit production and high in production efficiency.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

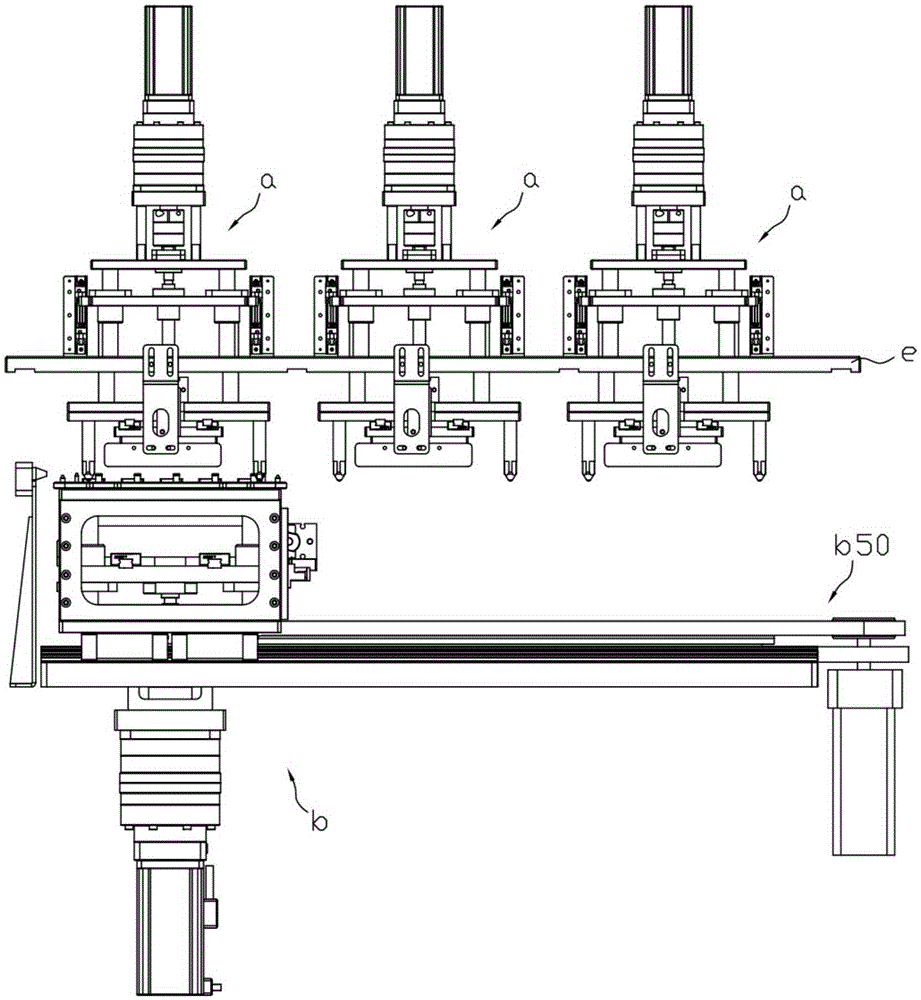

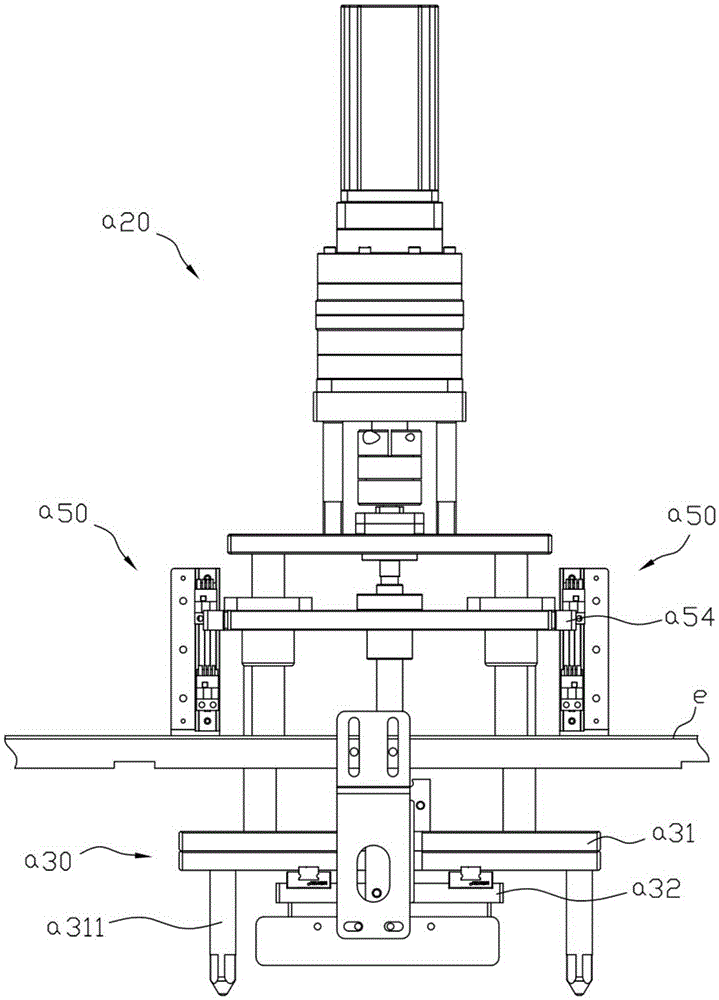

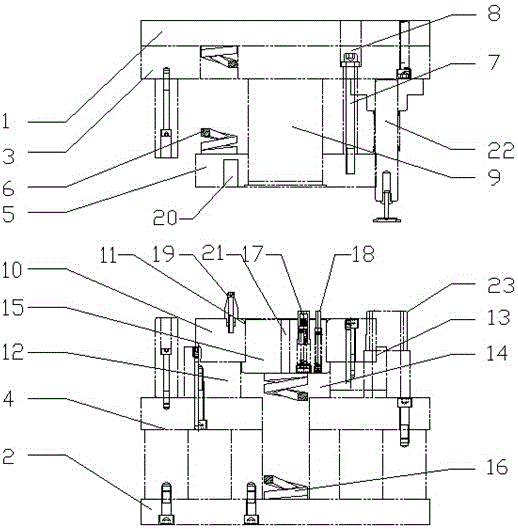

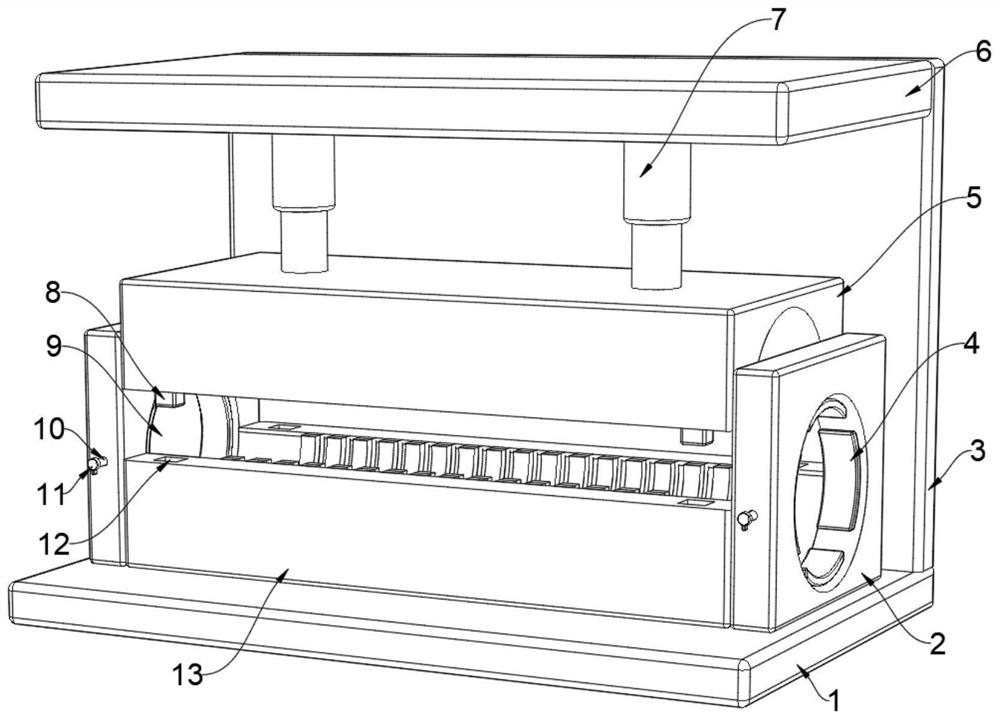

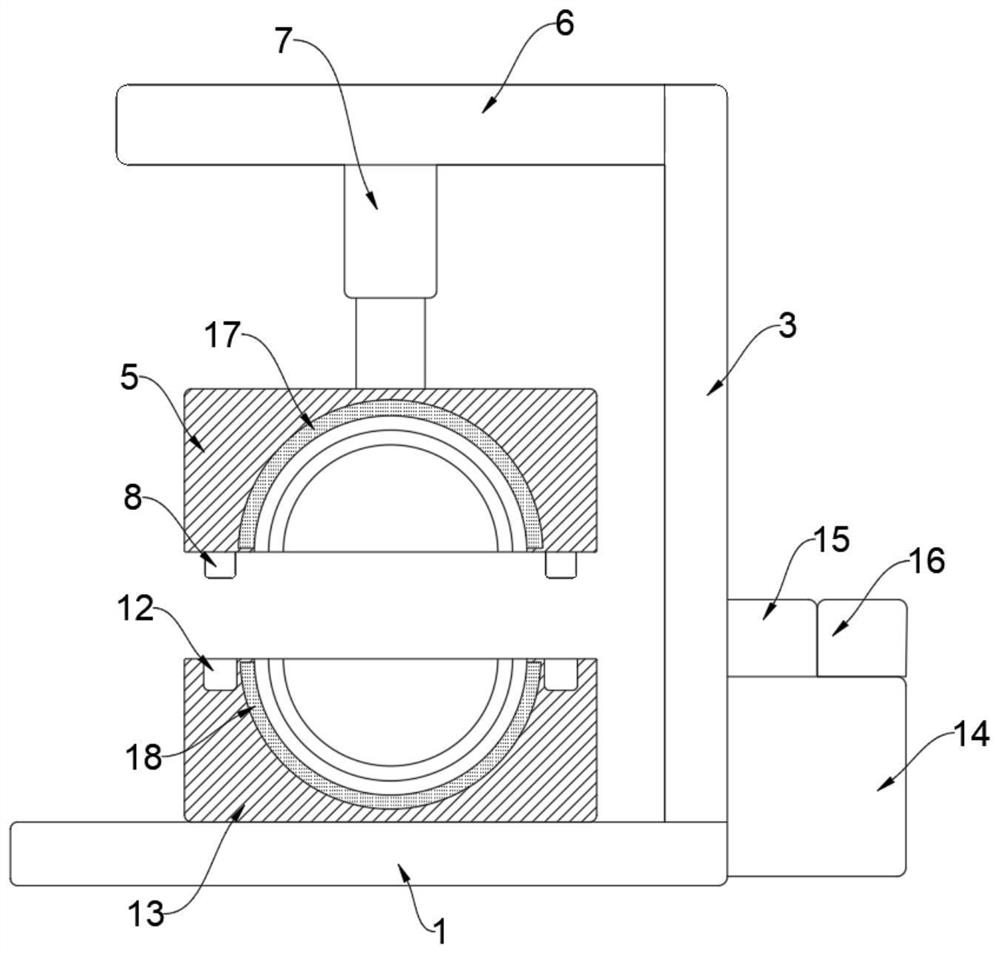

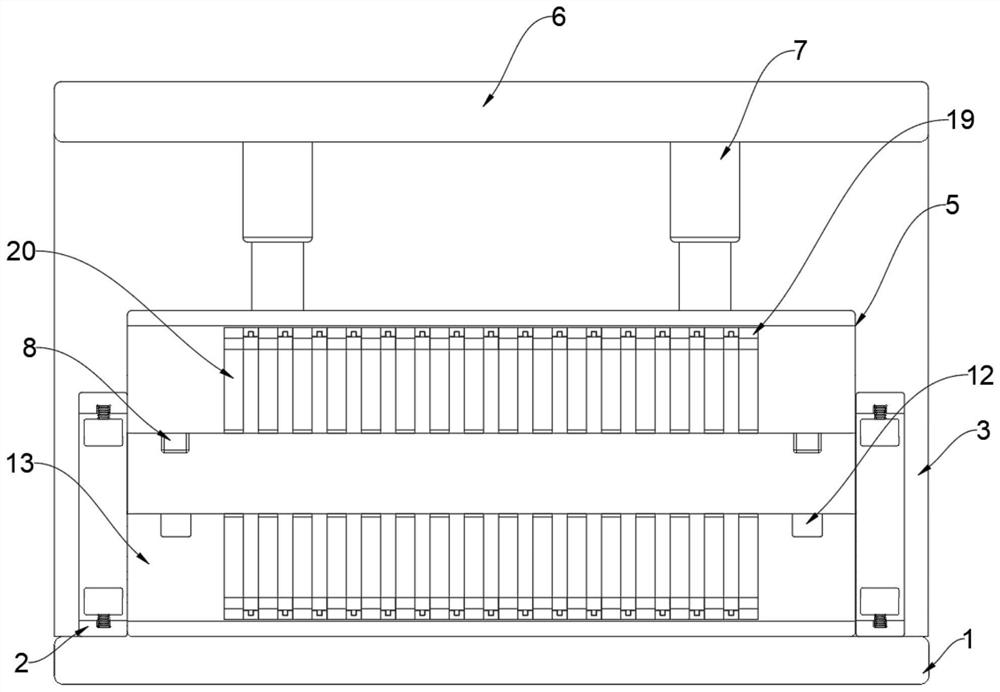

Novel equipment for processing box-shaped electronic elements

InactiveCN104128417AReduce laborIncrease productivityShaping toolsPressesEngineeringElectronic component

Owner:成都丽元电器有限公司

Automobile external glazing tape manufacturing technique and correction tool applied to technique

PendingCN108723143AIncrease productivityAvoid destructionShaping toolsVehicle componentsCross-linkMetal framework

Owner:上海敏孚汽车饰件有限公司

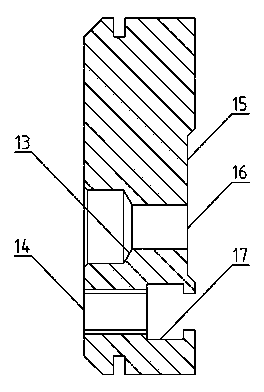

Slotting bush forming manufacturing mechanism

ActiveCN104907406AMolding and manufacturing realizationSolve manufacturing problemsShaping toolsStripping-off devicesEngineeringMechanical engineering

Owner:LANDING GEAR ADVANCED MFG

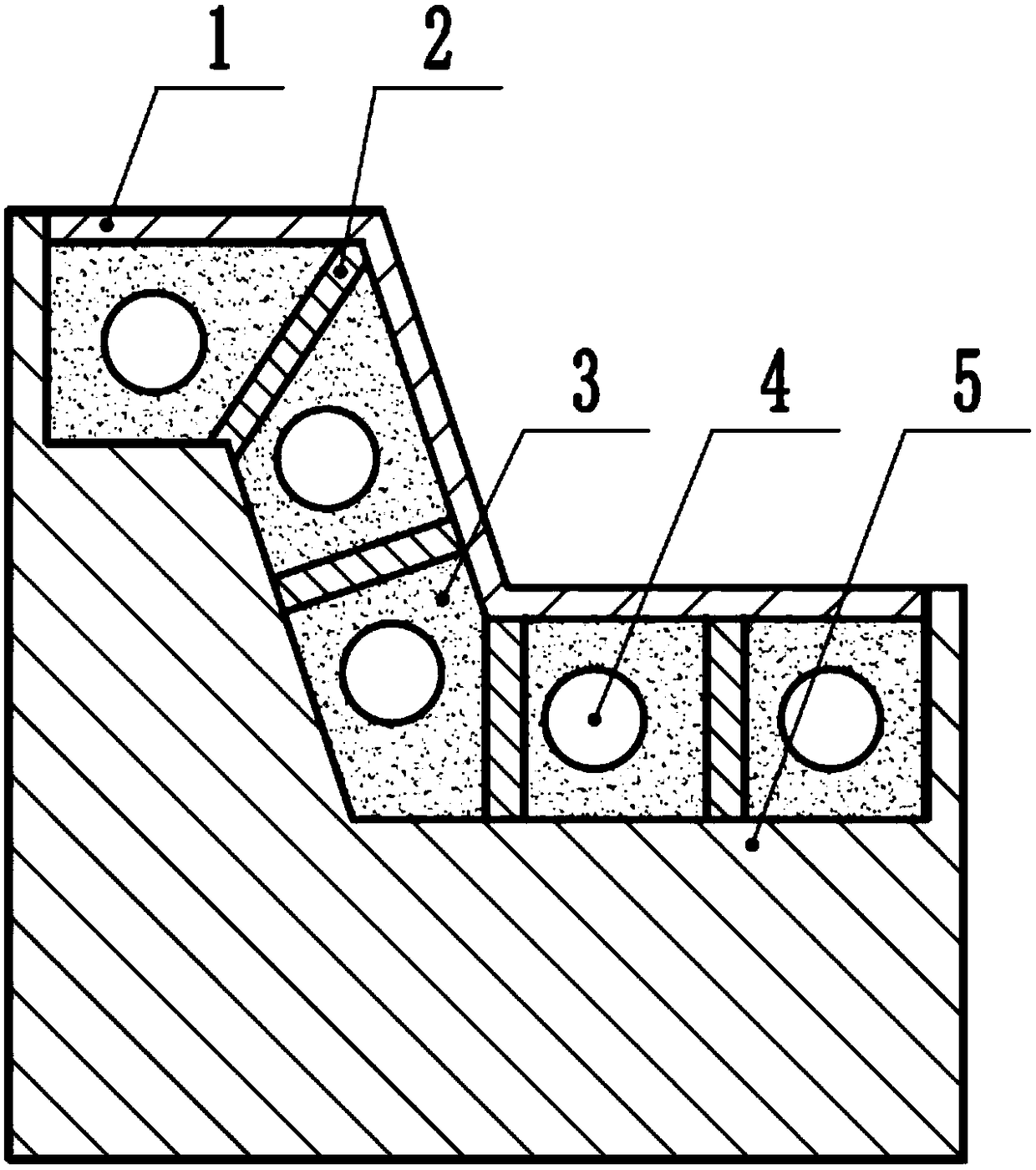

Pipe bulging method and die based on volume expansion force

The invention relates to a pipe bulging method and die based on volume expansion force and belongs to the technical field of the production technology of auto spare parts. The pipe bulging method comprises the following steps: filling water in a sealed pipe, cooling to freeze the water, and expanding the pipe into a demanded shape under the guidance of the cavity of the die. With adoption of the pipe bulging method, the sealing requirement of equipment and the requirement of a high pressure liquid source to pipe expansion are lowered, the trial-manufacture period is shortened and the development cost is lowered.

Owner:DONGFENG MOTOR CORP HUBEI

Automatic mold material taking device

InactiveCN102554034AReduce disconnectionReduce damage and other issuesShaping toolsStripping-off devicesBiochemical engineeringElectric cables

Owner:SUZHOU KABUL MOLD TECH

Metal lithium strip die cutting device

ActiveCN111360136AExtended service lifeHigh precisionShaping toolsCell electrodesMetallic lithiumReciprocating motion

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Drawing die for sheet metal part of automobile shock absorber

InactiveCN106001276AQuality assuranceAchieve drawing formingShaping toolsMetal-working feeding devicesWrinkle skinEngineering

Owner:SHAZHOU PROFESSIONAL INST OF TECH

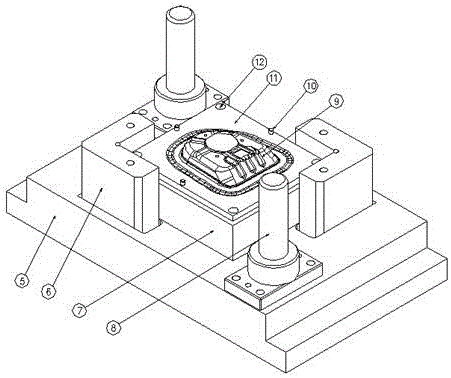

Deep drawing die for compressor rack

Owner:WUHU ZHUOYUE AIR CONDITIONING PARTS CO LTD

Thermoforming soft mold structure and manufacturing method

Owner:上海博汇模具有限公司

Press machine device for bending deformed steel bar in shape of Chinese character 'ji'

The invention relates to a press machine device for bending a deformed steel bar in a shape of a Chinese character 'ji'. The device comprises a first machining die and a second machining die, the first machining die comprises a first upper die and a first lower die, and the second machining die comprises a second upper die and a second lower die. The press machine device uses a press machine to press the deformed steel bar into a shape of the Chinese character 'ji', and is good in molding, high in accuracy, wide in applicable scope, simple in operation and high in work efficiency.

Owner:JIANGSU HUNING STEEL MECHANISM

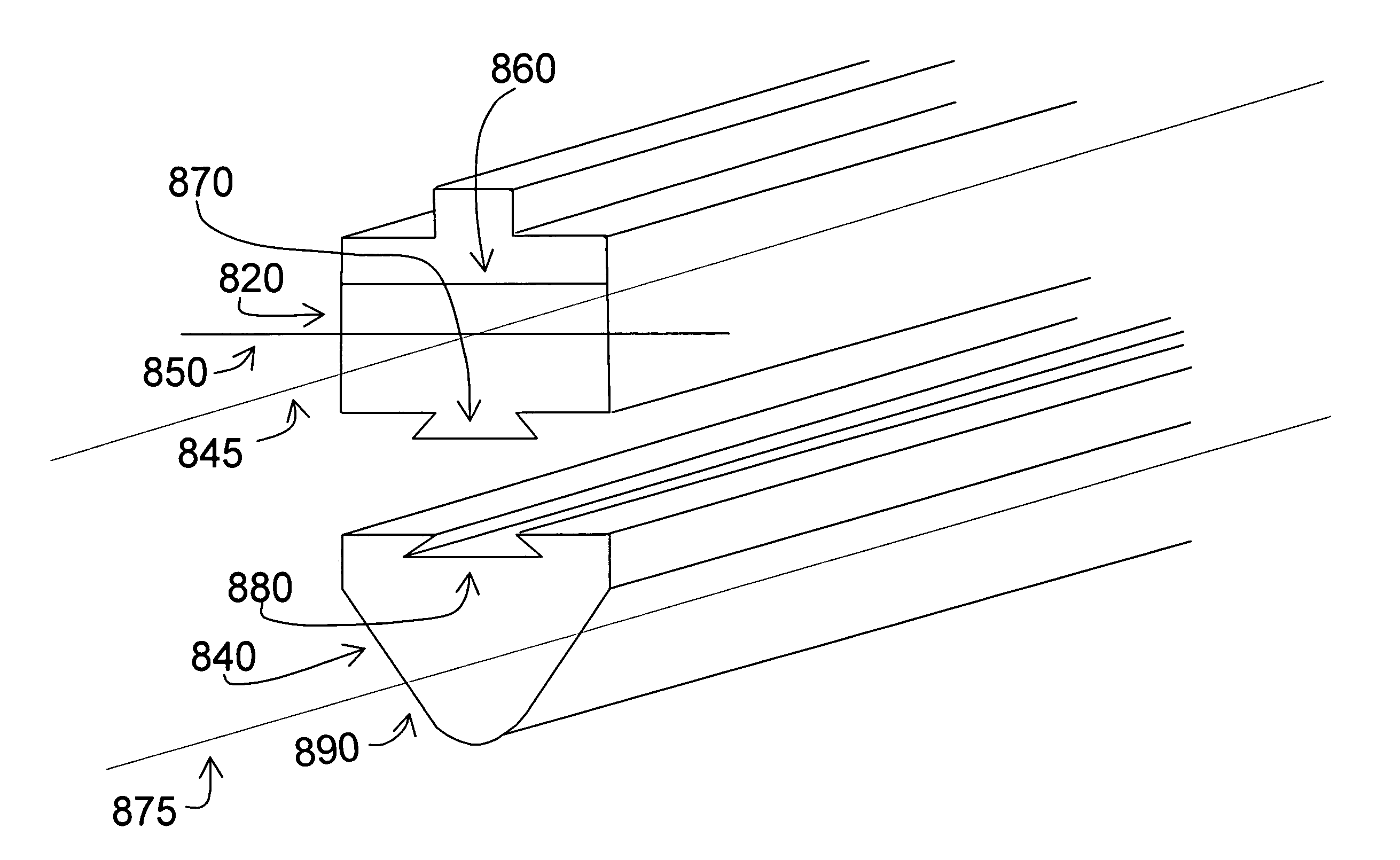

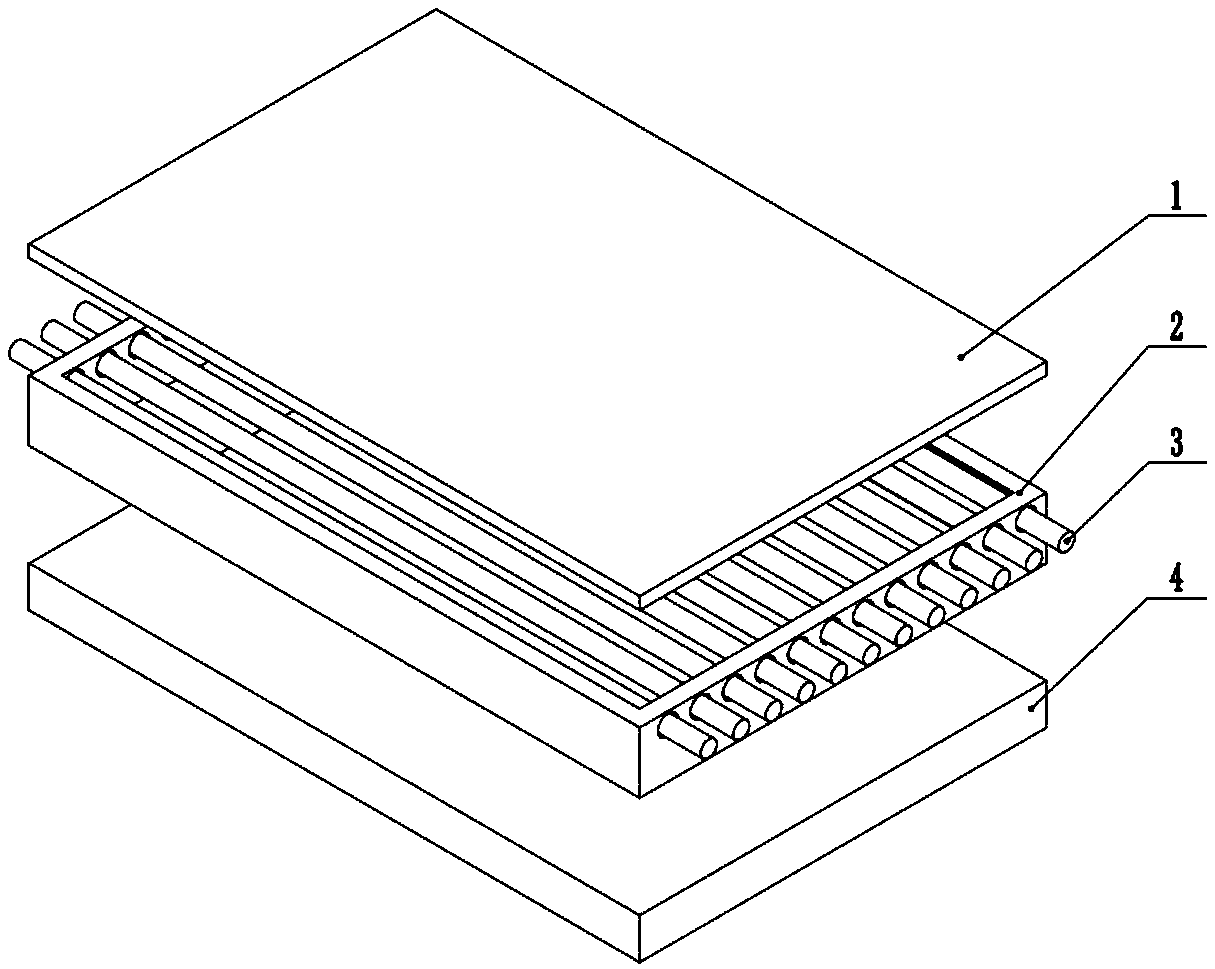

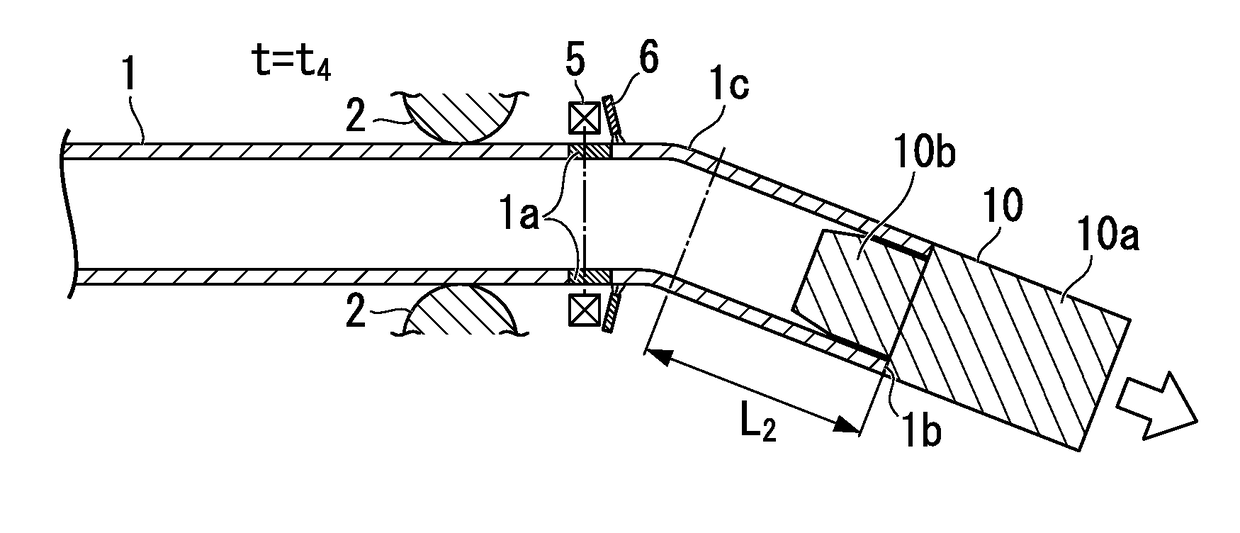

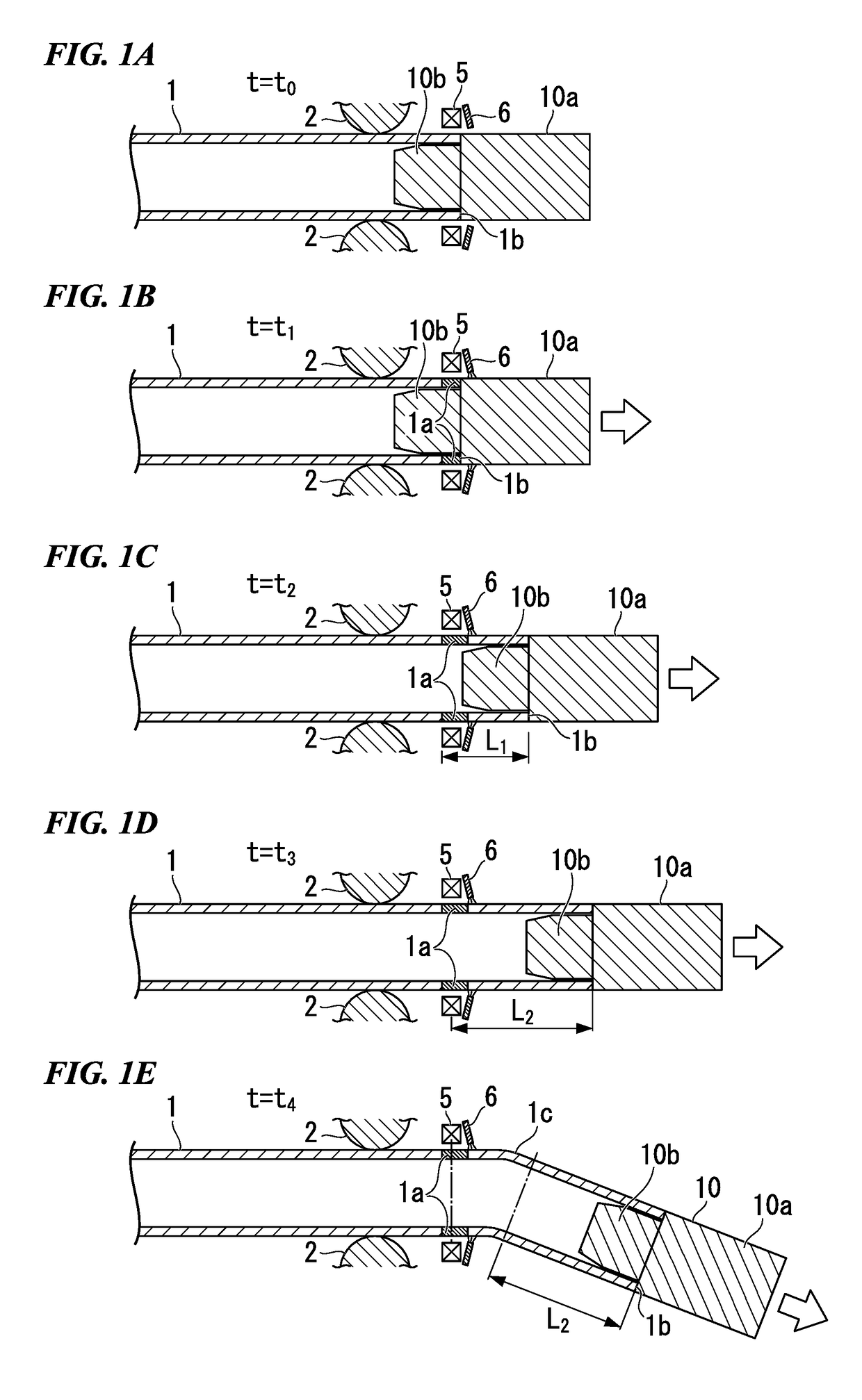

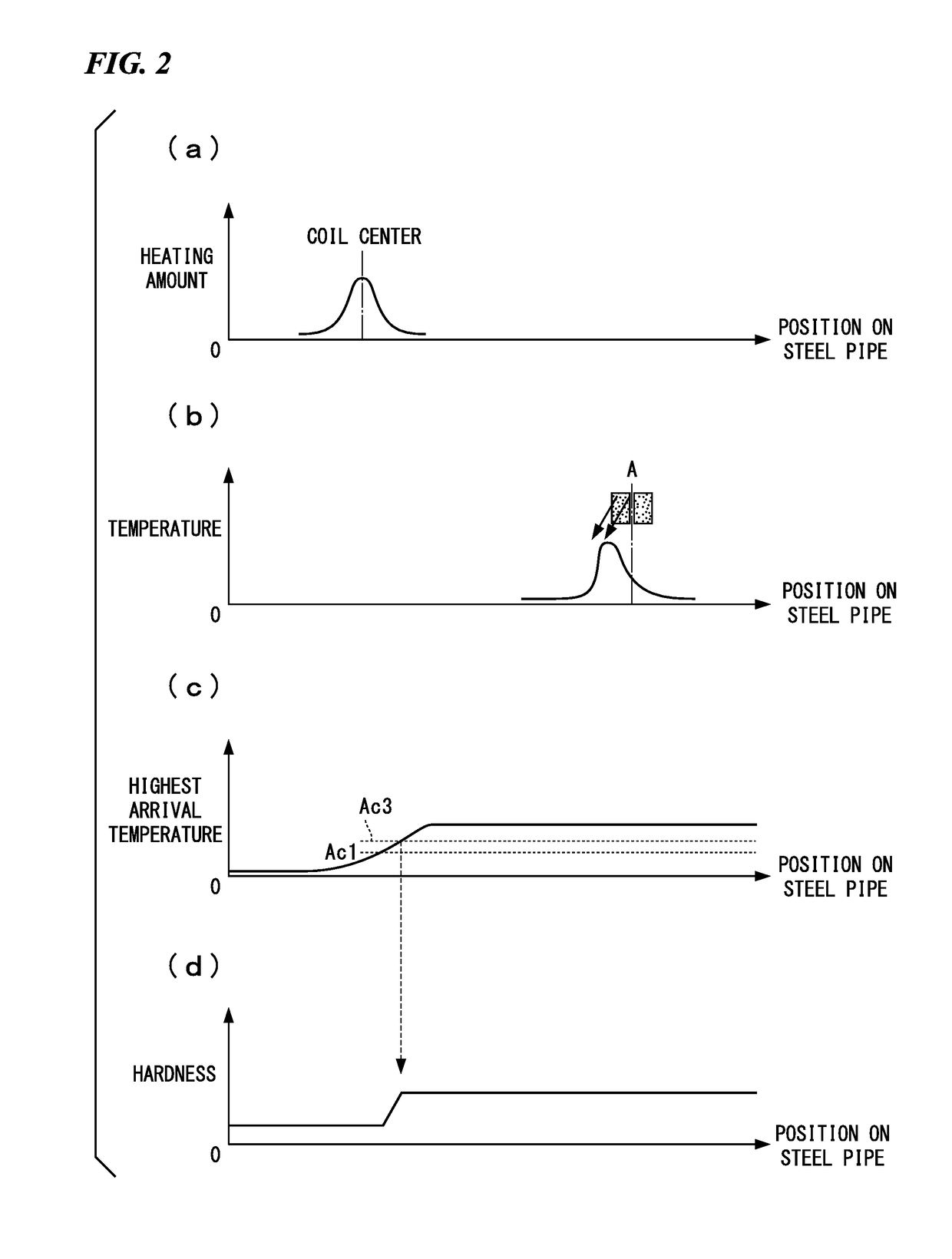

Manufacturing method for bent member and hot-bending apparatus for steel material

ActiveUS20170197237A1Avoid fatigue fractureIncrease productivityShaping toolsBending momentEngineering

Owner:NIPPON STEEL CORP

Corrugated pipe forming device

ActiveCN112958671AEasy to holdStable clampingShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

Owner:江苏新汇烽塑胶有限公司

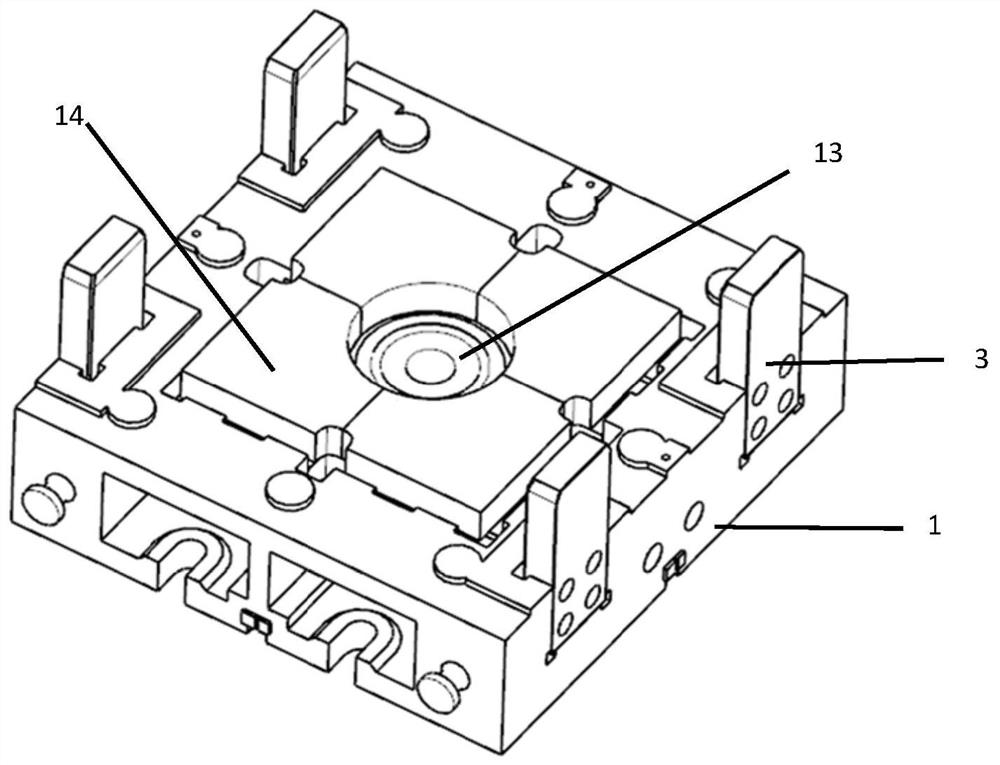

Die structure for plate drawing and bulging performance experiments

ActiveCN112045052AAvoid wastingGuaranteed accuracyShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

Owner:HUNAN UNIV +1

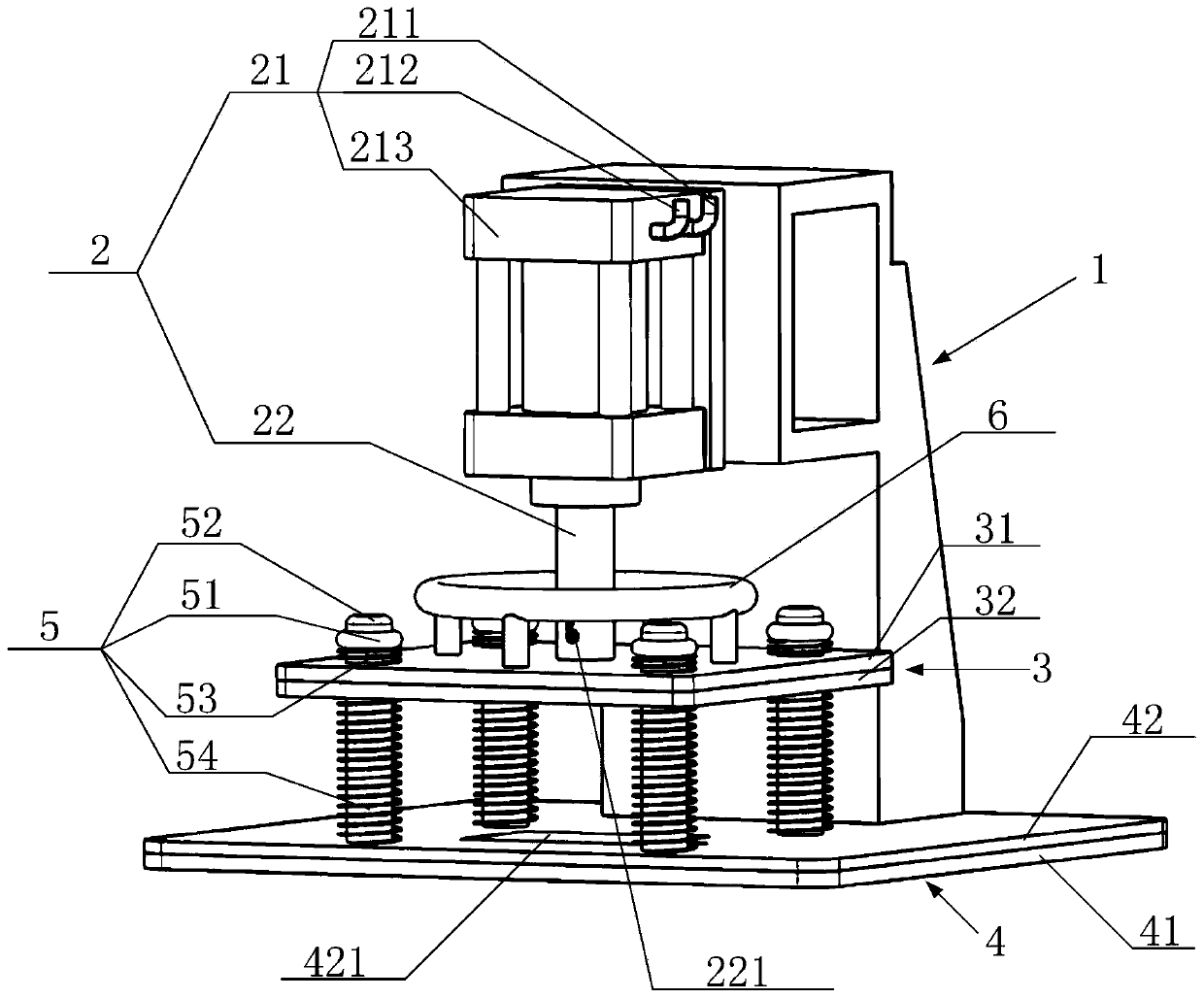

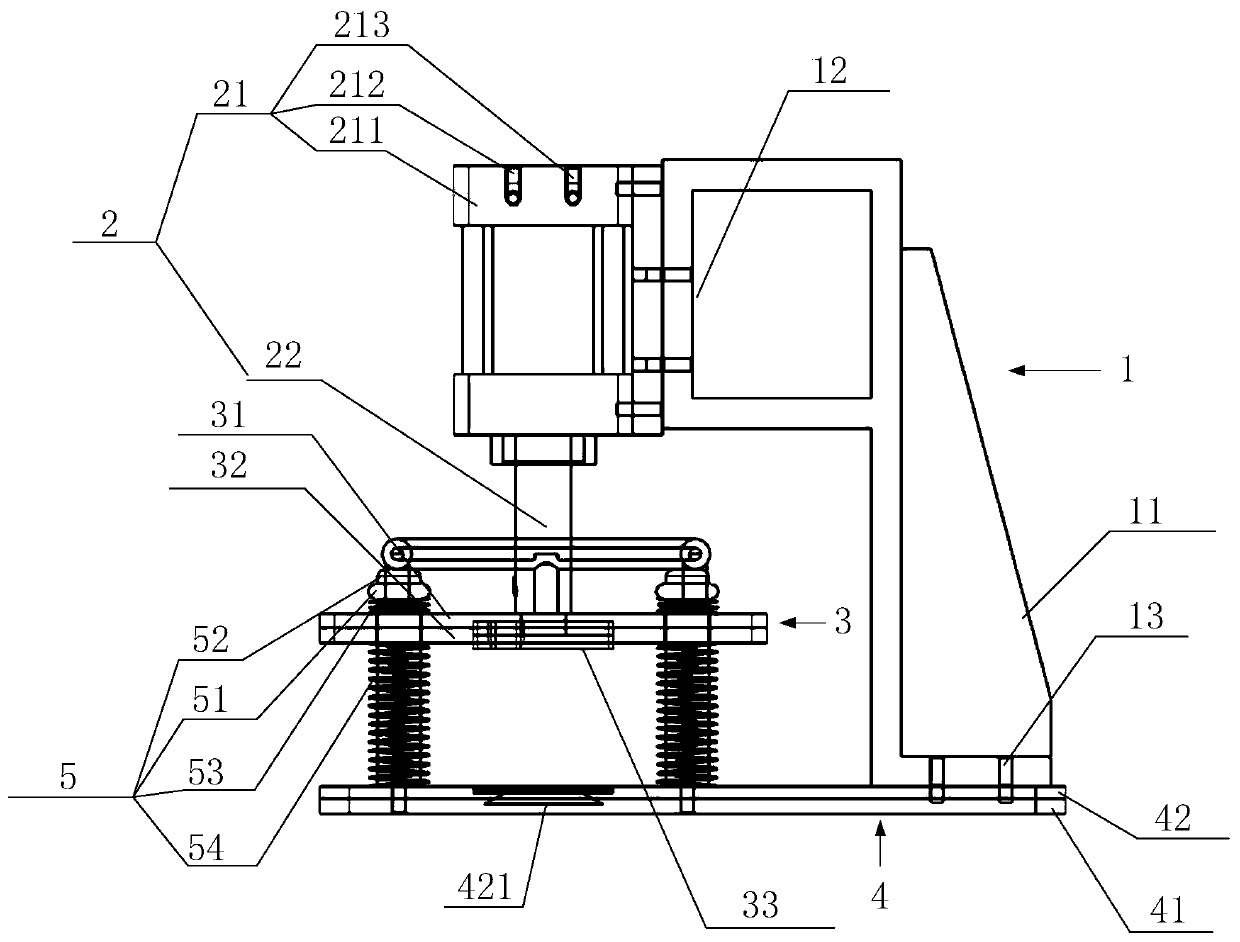

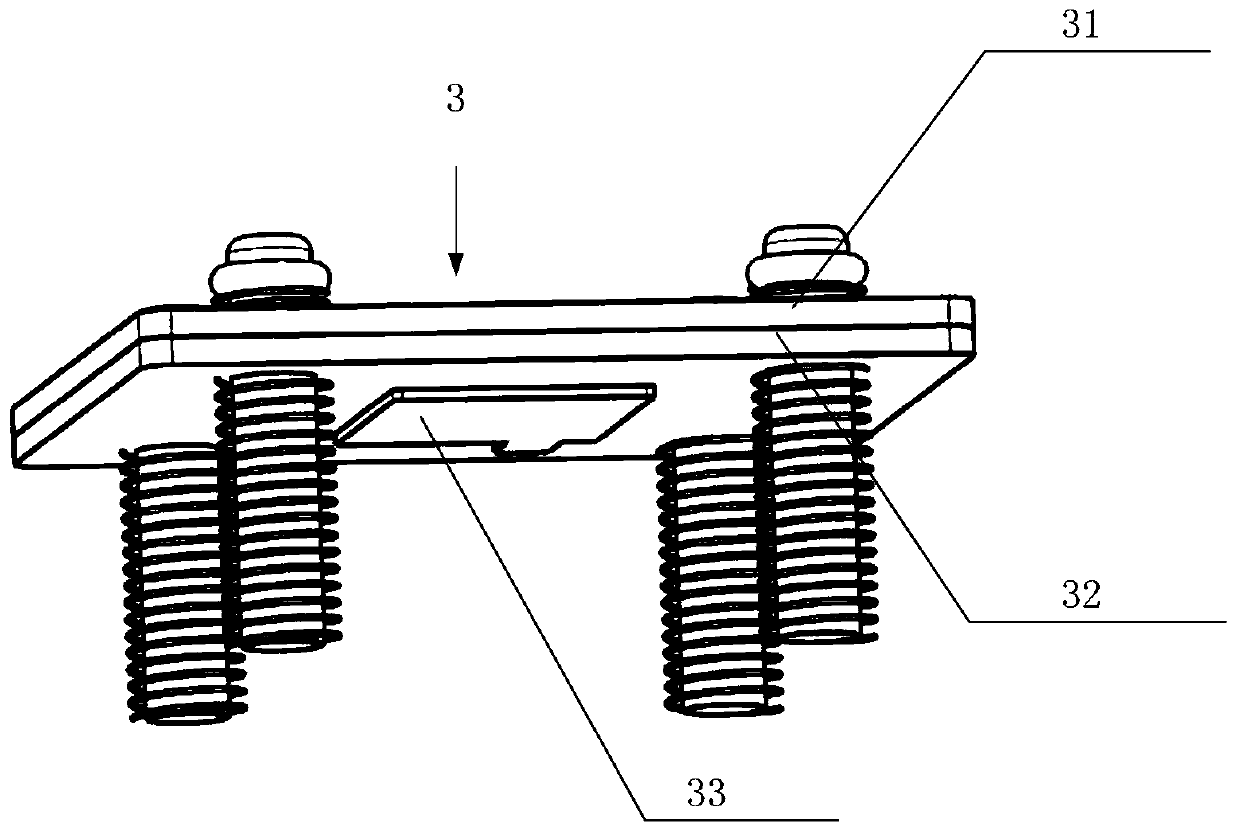

Punching forming clamp

InactiveCN104438879AGuaranteed stabilityImprove pass rateShaping toolsMetal-working feeding devicesPunchingEngineering

Owner:SUZHOU SONGSHUN HARDWARE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap