Multi-station bending device

A multi-station and equipment technology, applied in metal processing equipment, forming tools, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

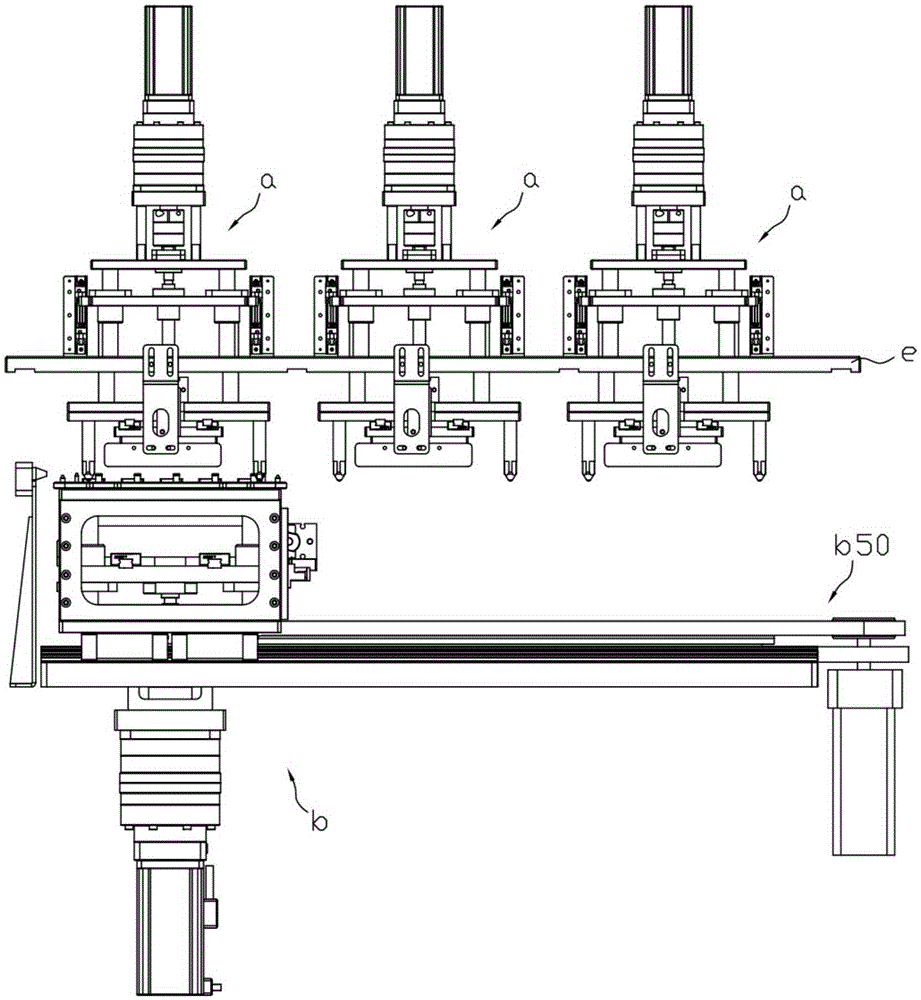

[0049] Such as figure 1 , a multi-station bending equipment, including a plurality of upper die mechanisms a and a lower die mechanism b; a plurality of upper die mechanisms are installed on a connecting plate e, and a lower die mechanism is installed on a forward and backward moving mechanism b50; Two upper mold mechanisms are arranged side by side laterally, and the front and rear moving mechanism drives the upper mold mechanism to move laterally.

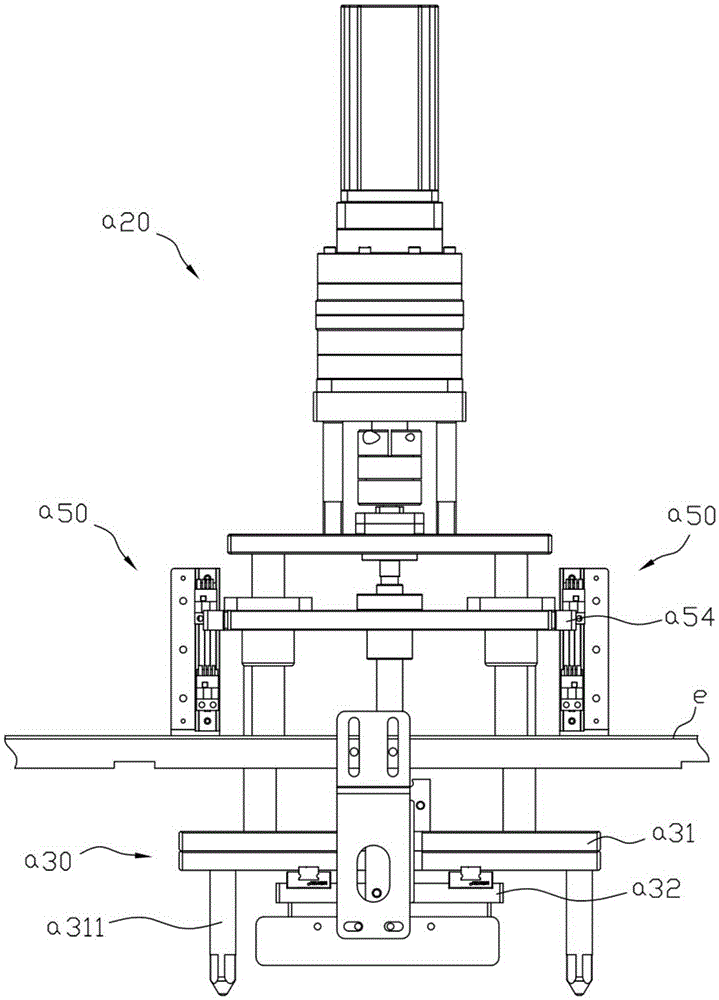

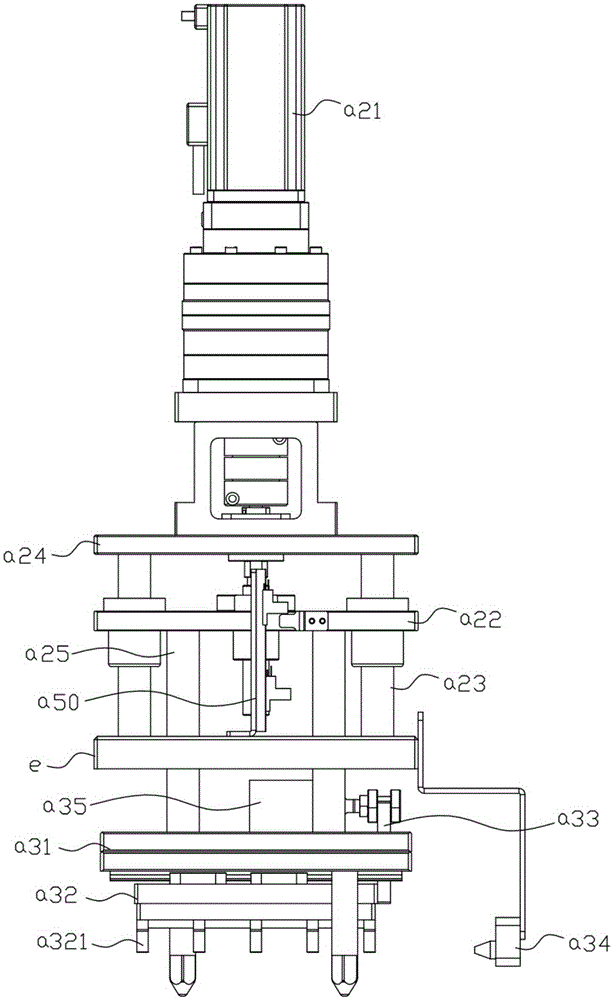

[0050] combine Figure 2 to Figure 4 Any upper mold mechanism in the above-mentioned multi-station bending equipment includes a lifting drive mechanism a20 installed on the connecting plate, a bending module a30 located below the connecting plate and connected to the lifting driving mechanism; the bending module includes The upper composite plate a31 and the bending module a32, the bottom of the upper composite plate is provided with a slide rail, the top of the bending module is provided with a chute matched with the slide rail, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap