Equipment for machining elbow through explorator extruding

A technology of die-cutting and pipe bending, which is applied to the field of equipment to complete pipe bending, can solve problems such as difficulty in ensuring thinning rate and roundness rate, and achieve the effect of improving bending quality and technical indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

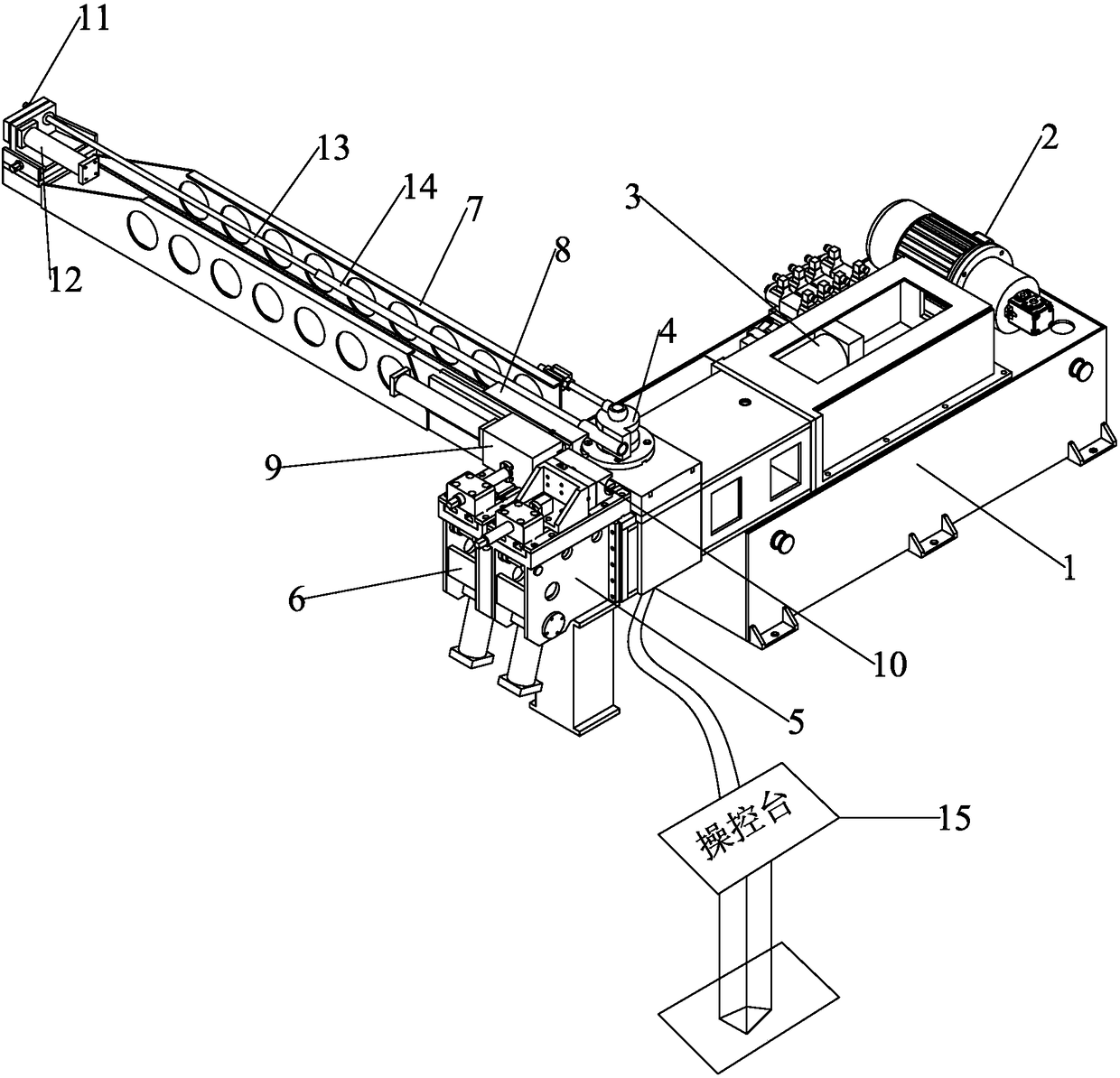

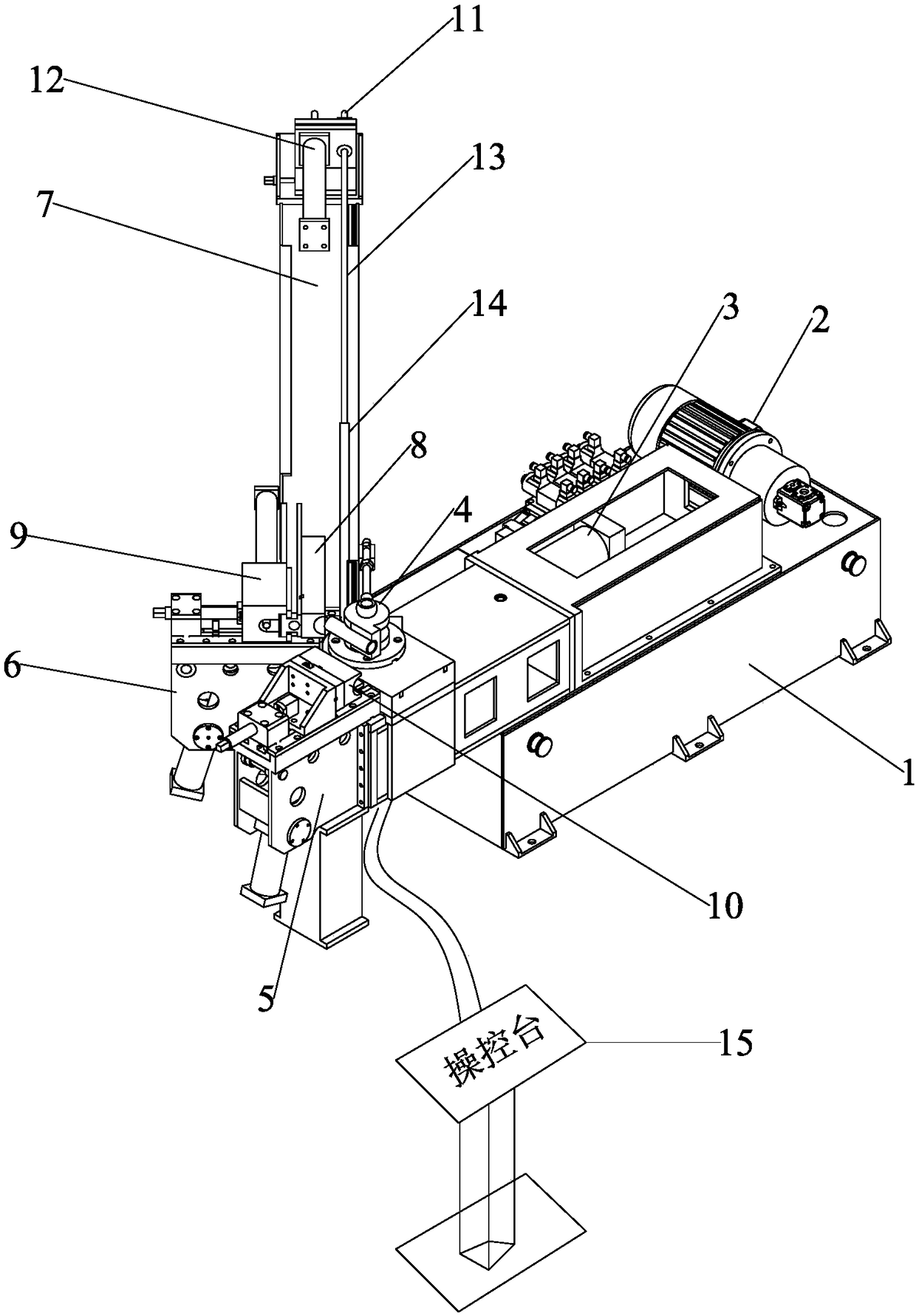

[0017] The equipment of the present invention for processing bending pipes by extruding a master includes a pipe bending equipment bed 1, a driving device composed of a motor 2 fixed on the bed and a main power hydraulic pump 3, a bending tire mold 4 fixed on the bed, and a fixed Arm 5 and hydraulic clamping device, integrated rotating arm 6 and bracket 7, hydraulic profiling device 9, profiling guide plate 8 and sliding block, clamp 10, core rods with different sizes of locking cores provided inside the rotating arm The rod locking device 11, the hydraulic core pulling device 12, the core rod 13 and the core rod 14 connected by threads, and the control console 15.

[0018] Specific steps:

[0019] The equipment bed is constructed of steel, which mainly fixes the various components of the bending equipment on the bed 1, and then the equipment bed 1 is fixed on the ground to prevent the equipment from vibrating during the working process and affecting the bending accuracy.

[0020] The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap