Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

736results about "Semiconductor/solid-state device manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

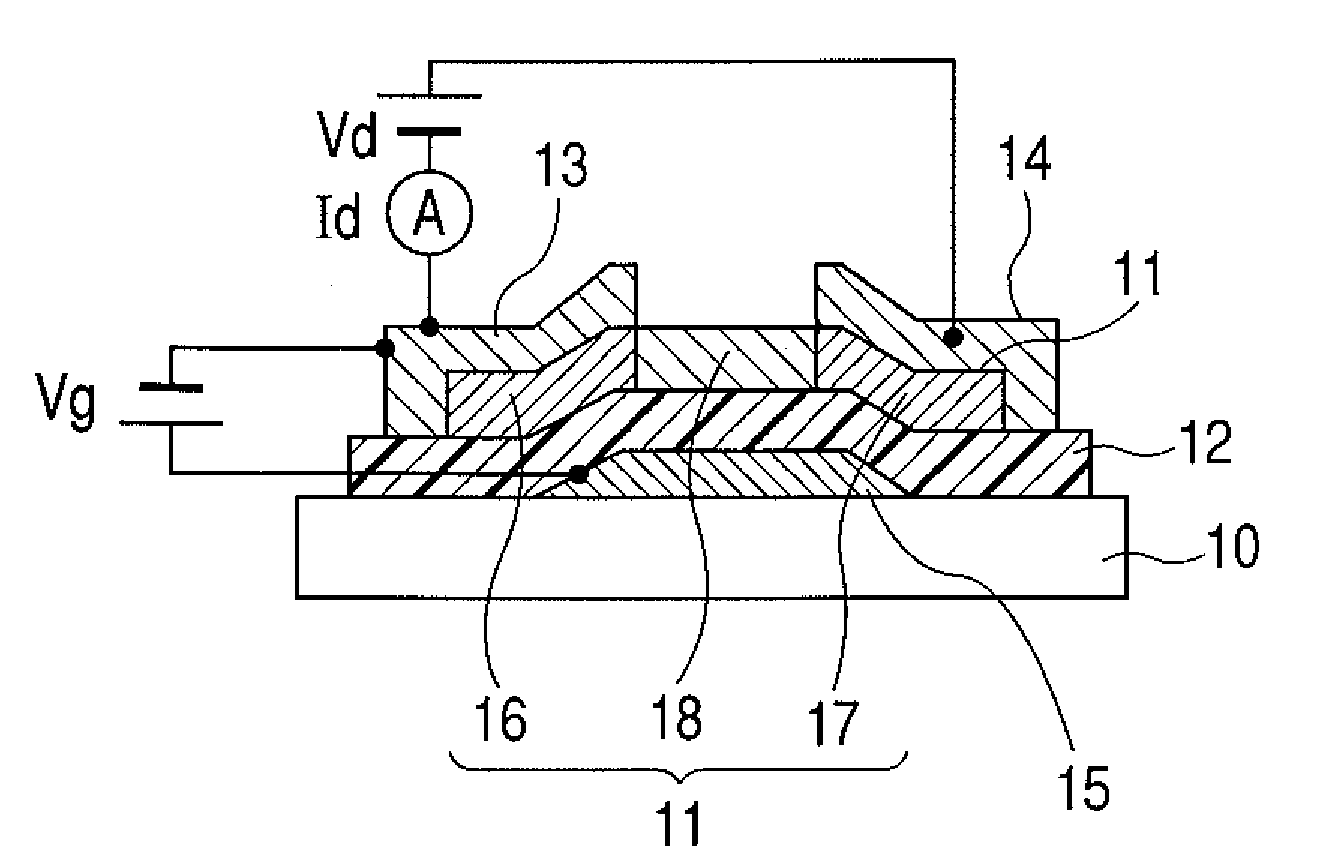

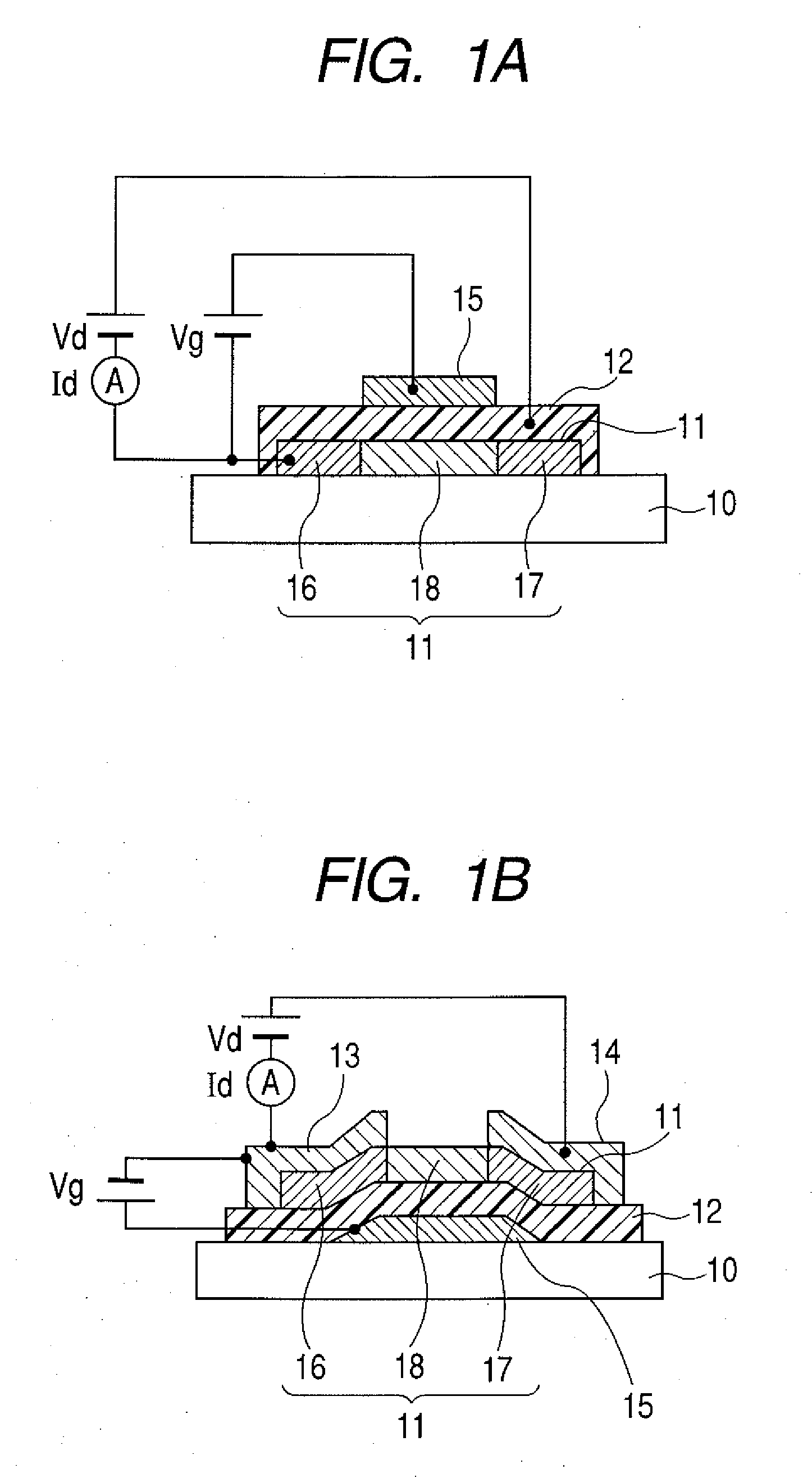

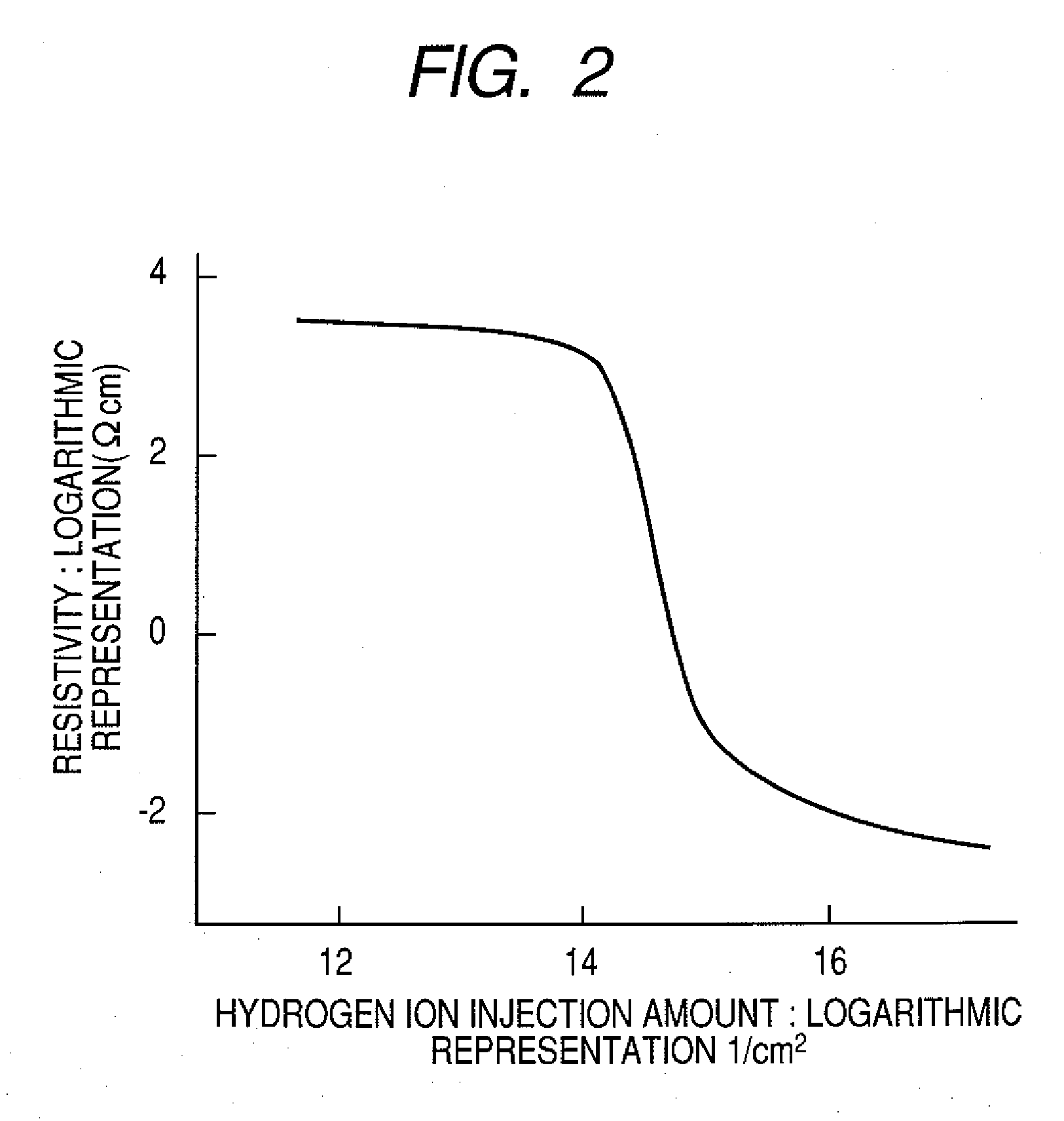

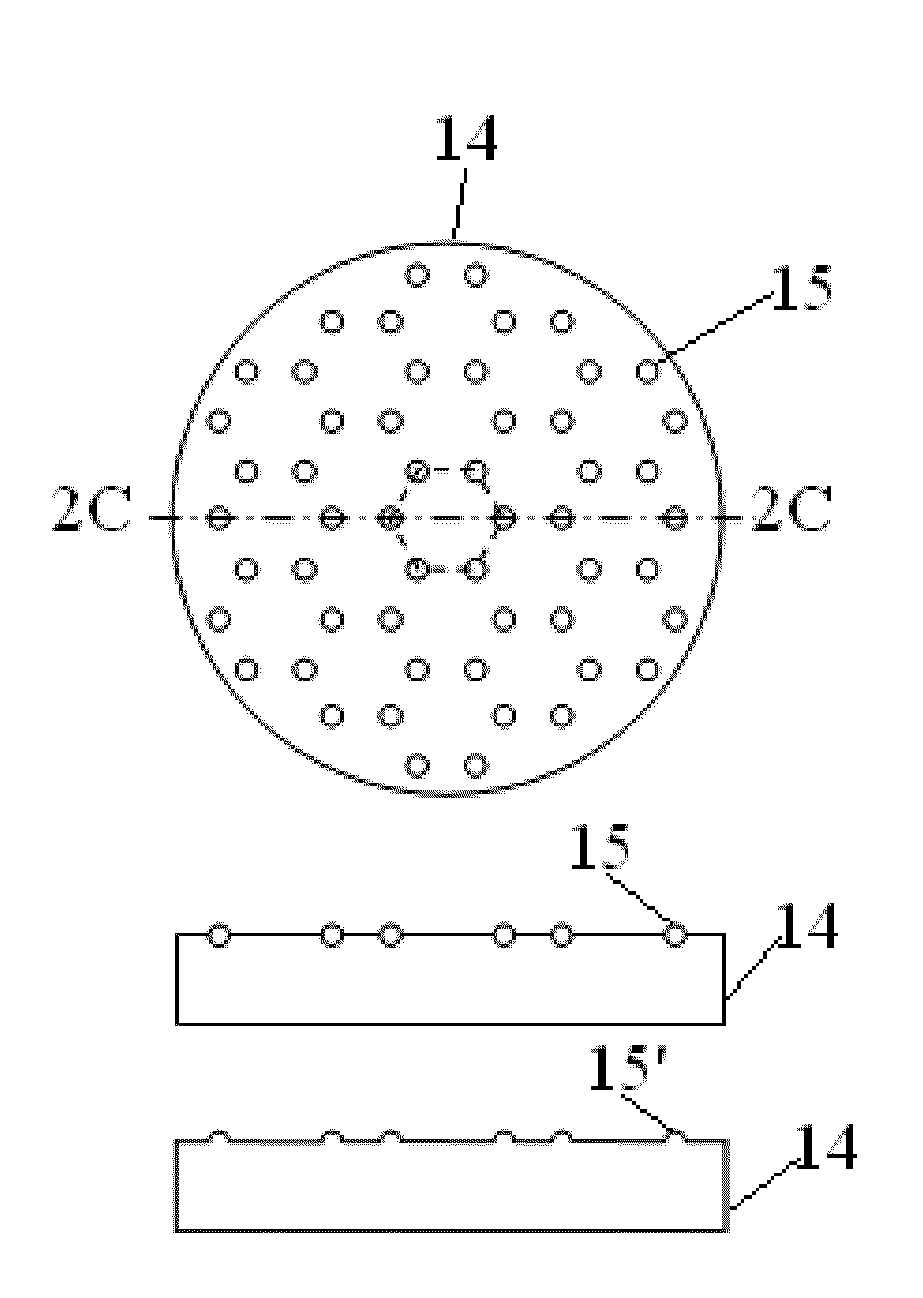

Field effect transistor using oxide film for channel and method of manufacturing the same

ActiveUS20090065771A1Reduce variationImprove accuracyTransistorSemiconductor/solid-state device manufacturingHydrogenField-effect transistor

Owner:CANON KK

Wafer-Supporting Device and Method for Producing Same

ActiveUS20130014896A1Semiconductor/solid-state device manufacturingSpecial surfacesEngineeringSemiconductor

Owner:ASM JAPAN

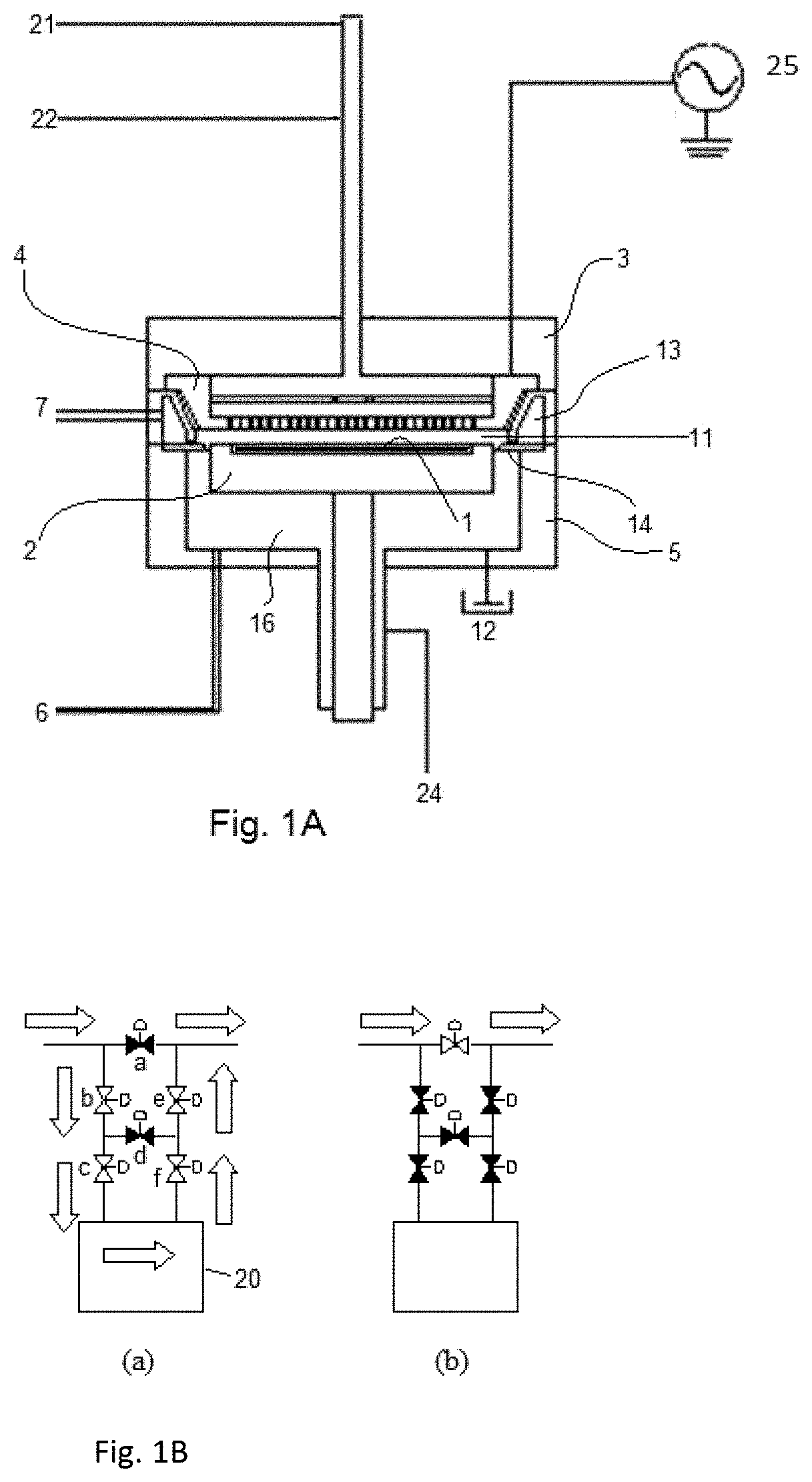

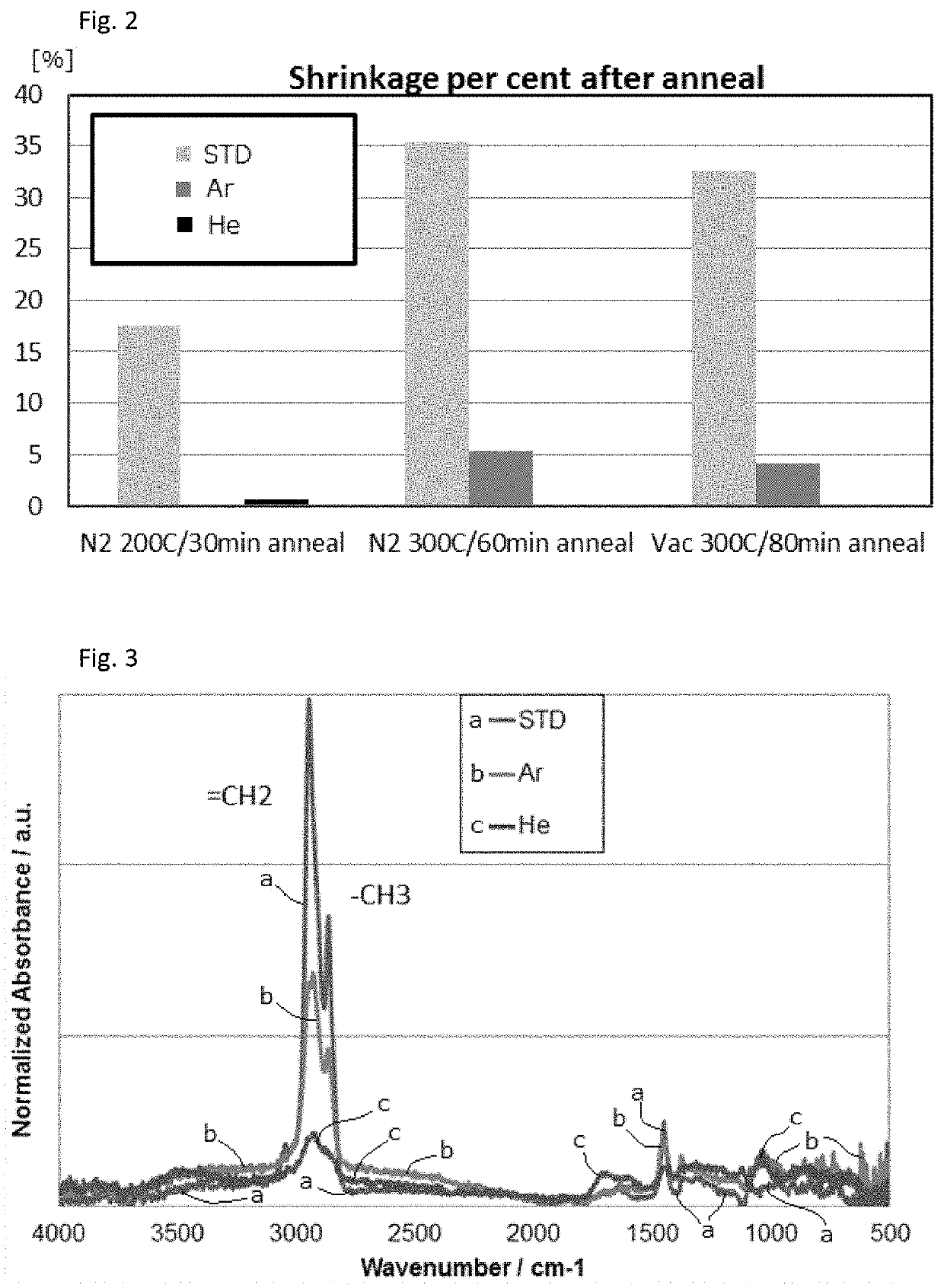

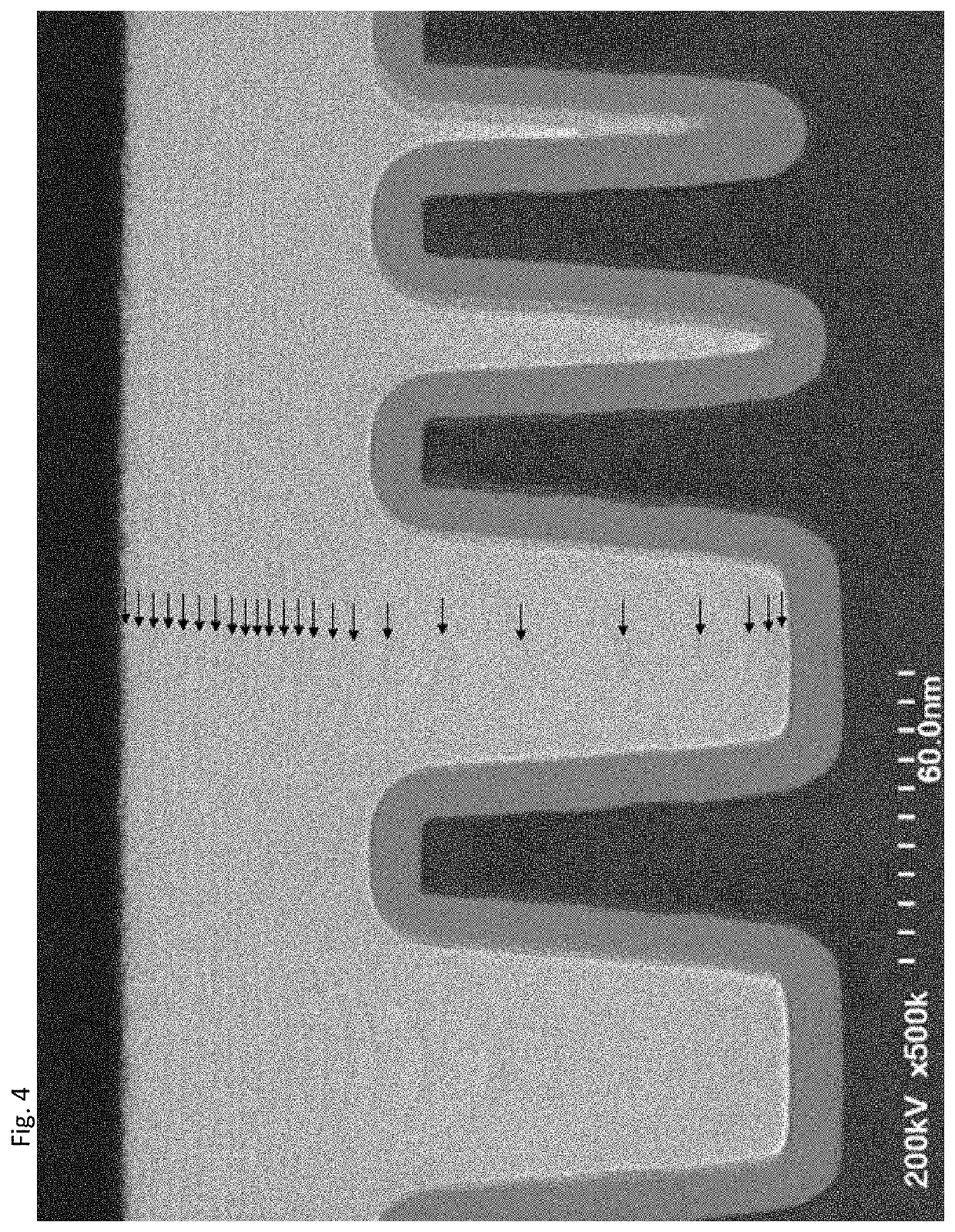

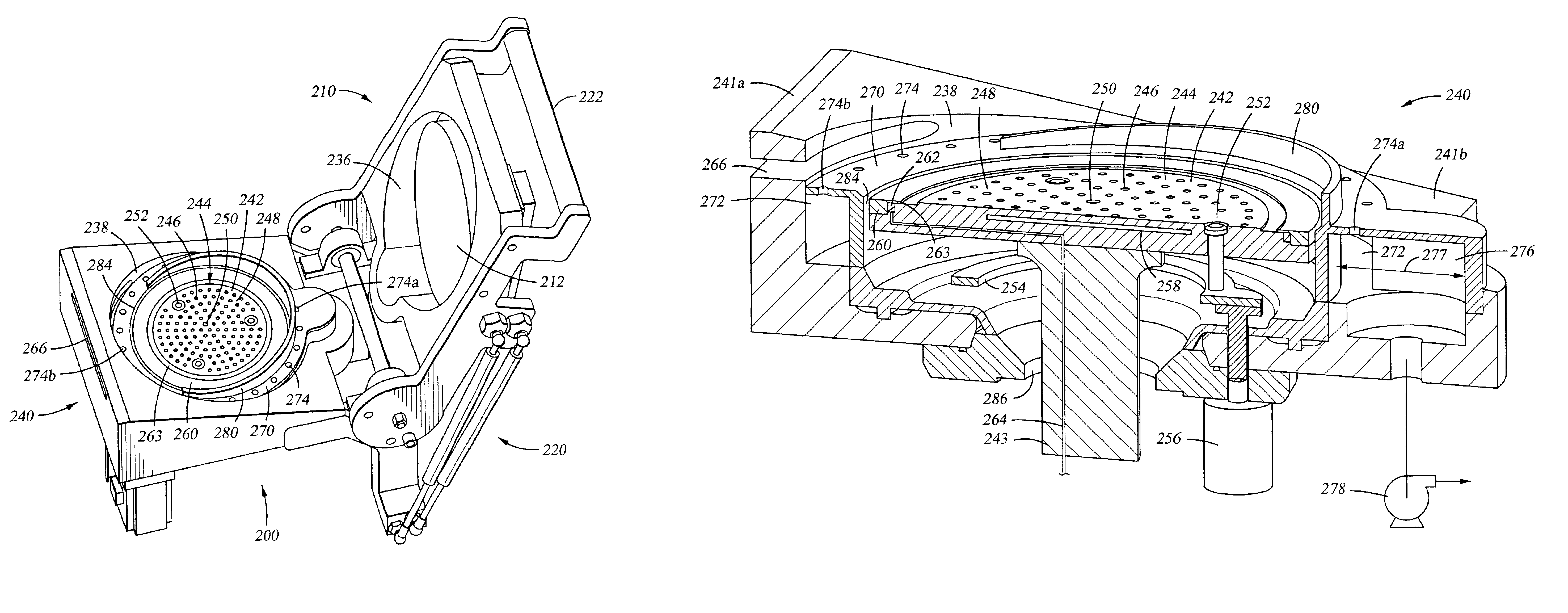

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013612A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

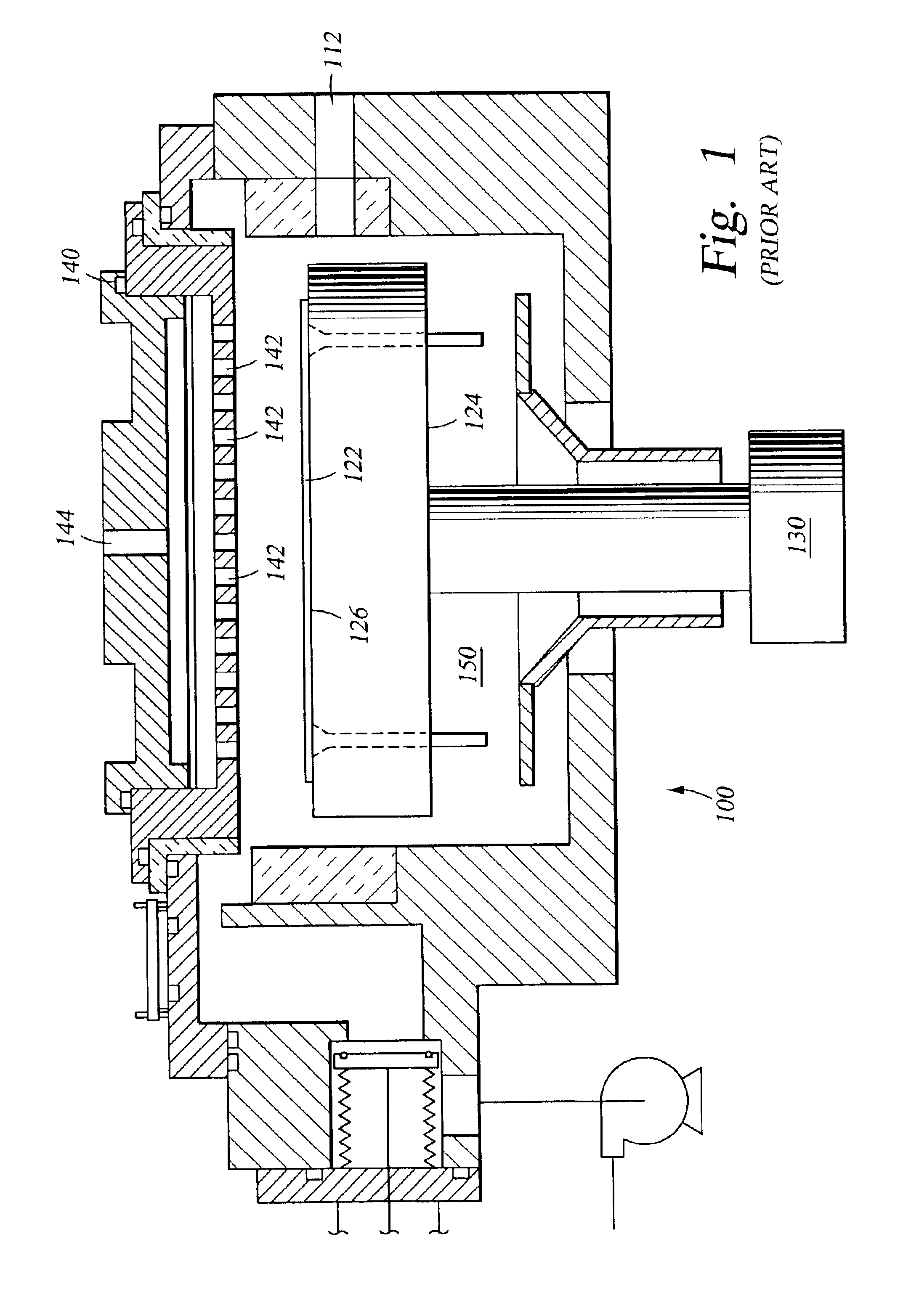

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

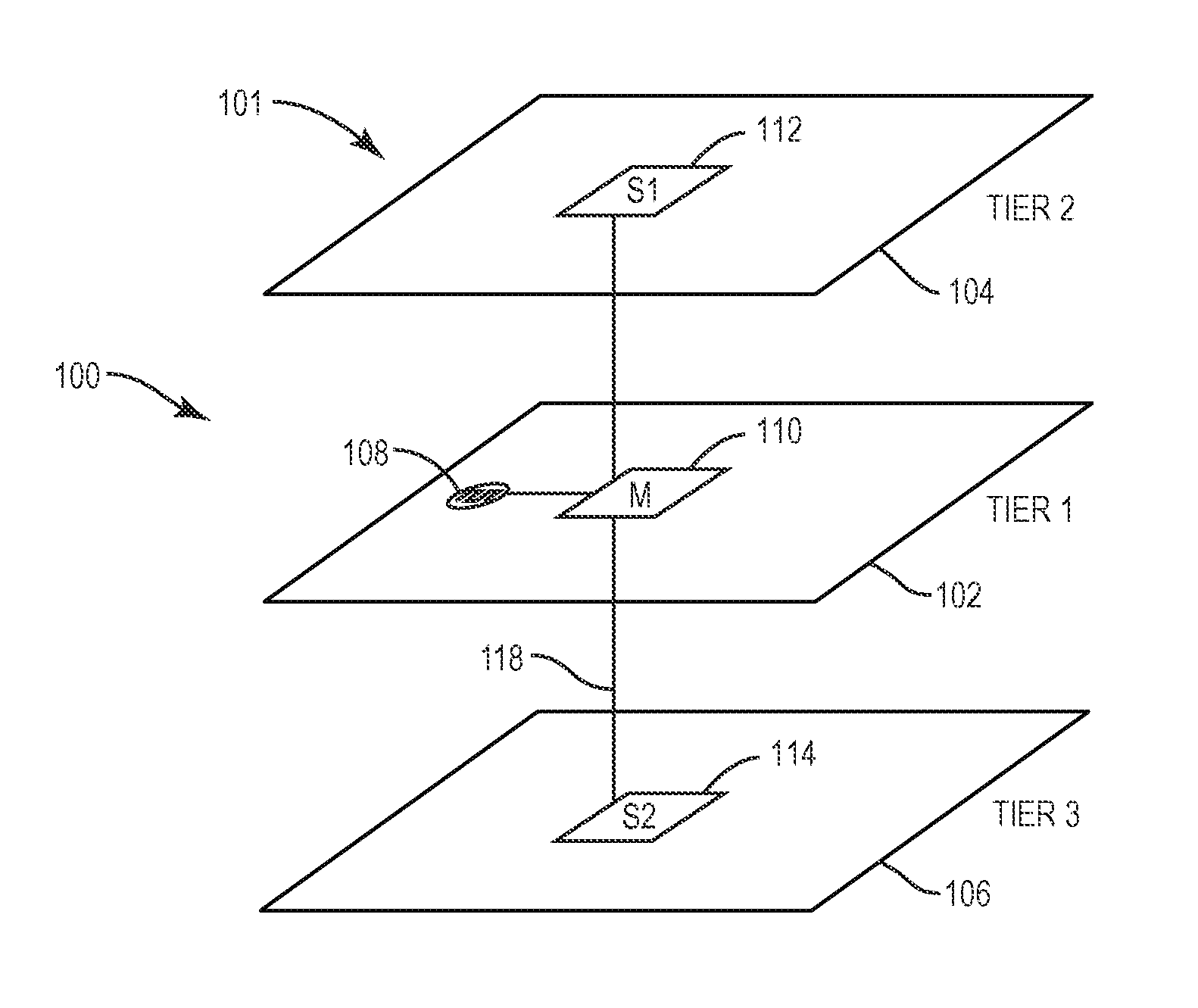

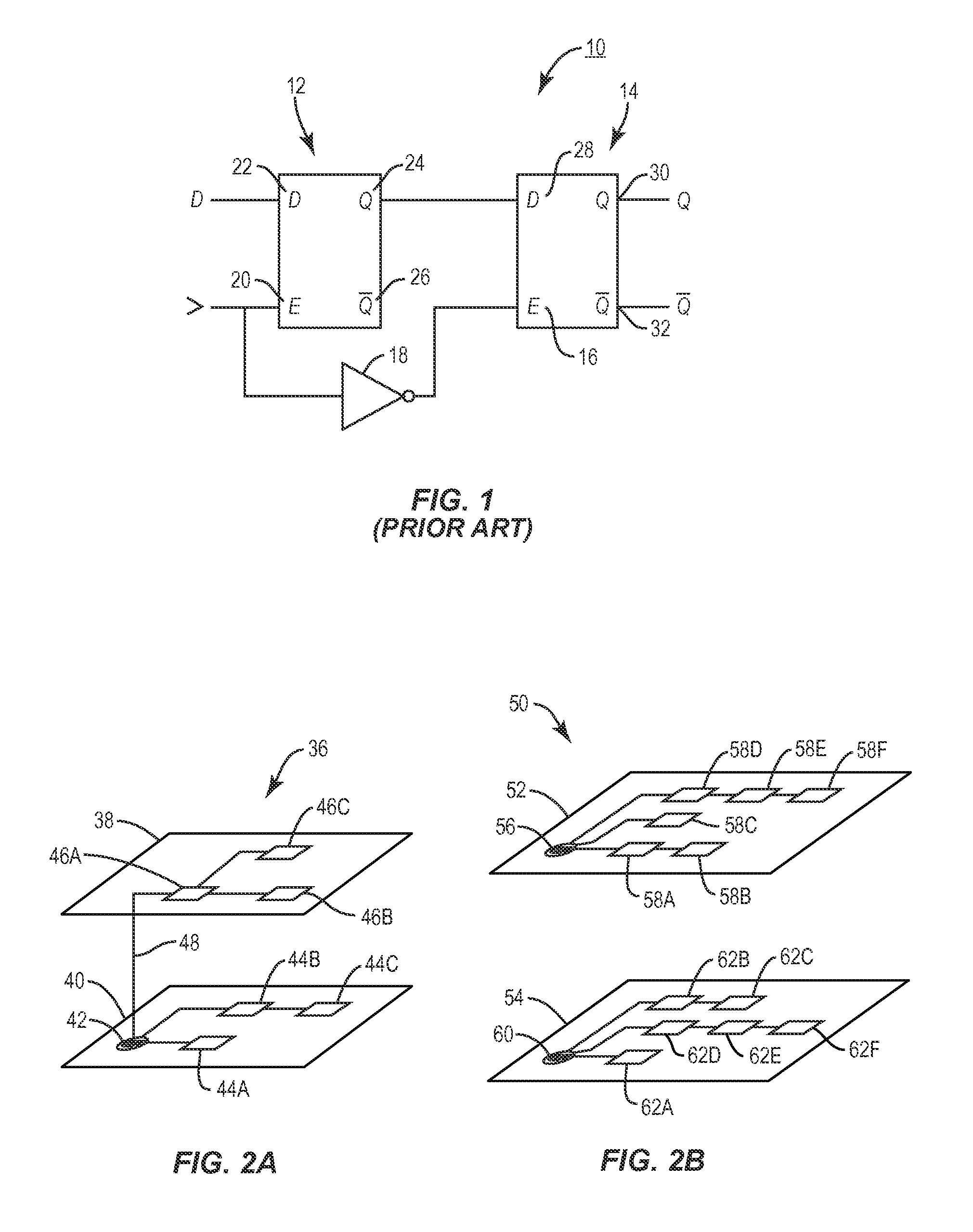

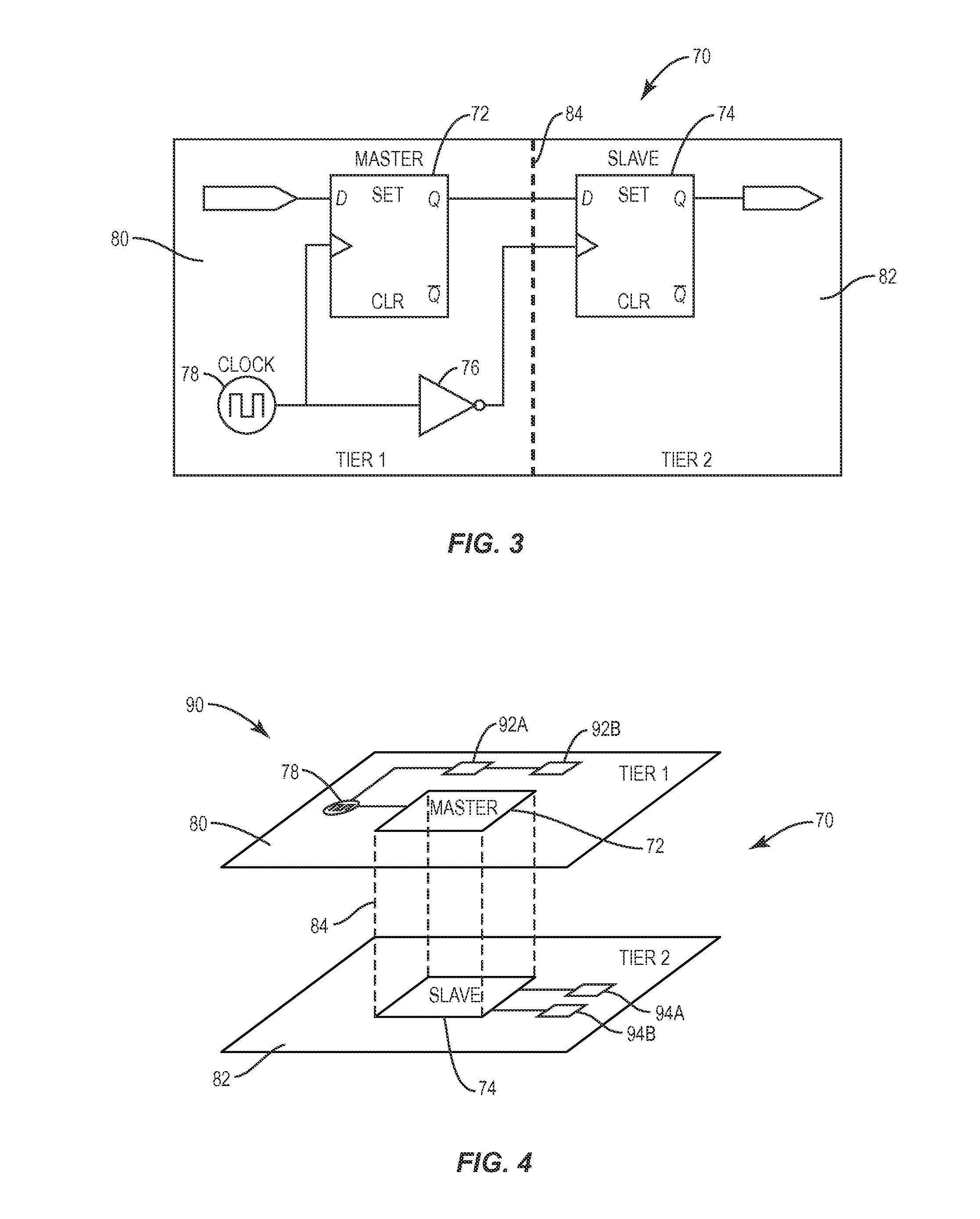

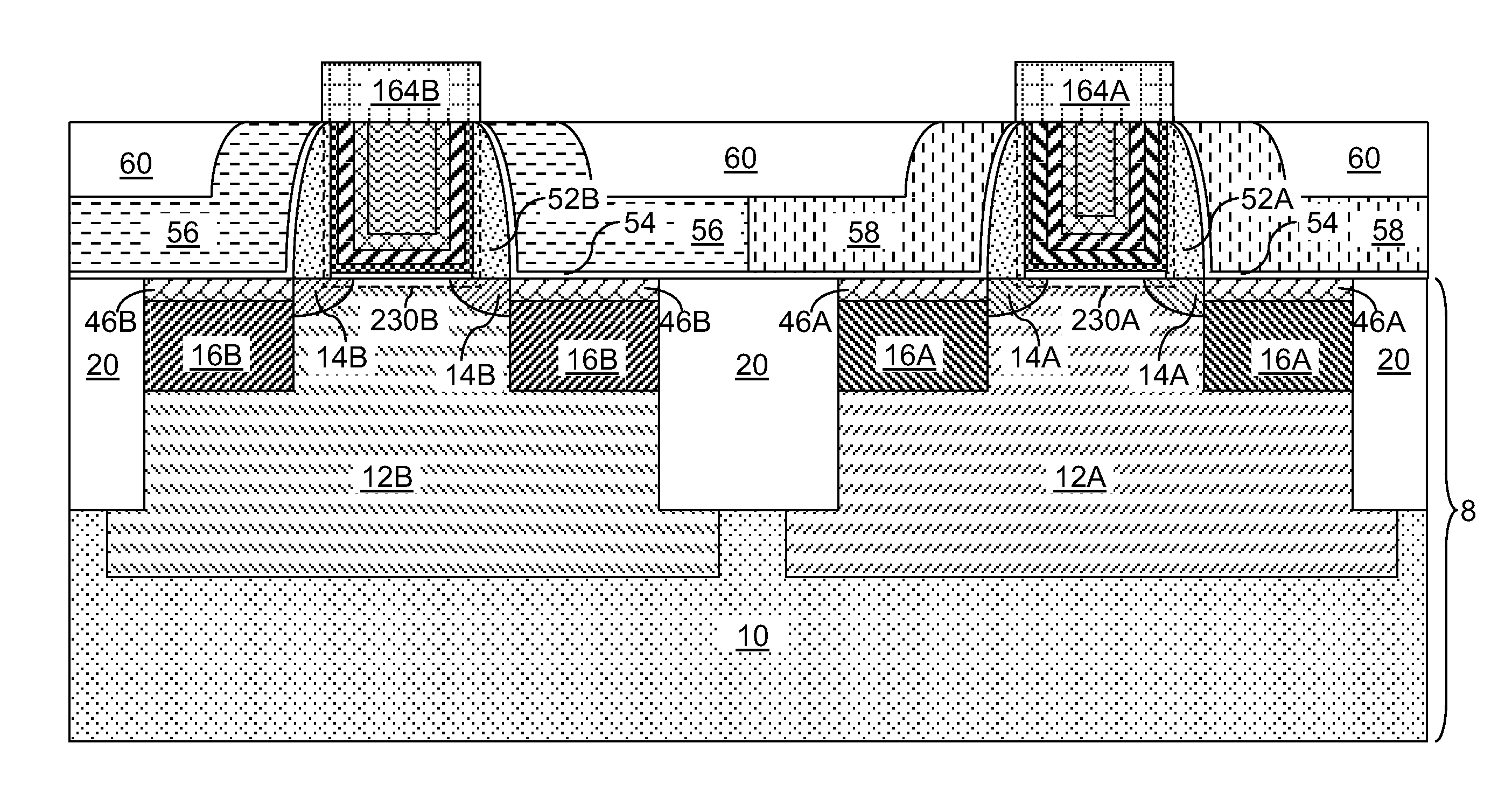

Flip-flops in a monolithic three-dimensional (3D) integrated circuit (IC) (3DIC) and related methods

ActiveUS20140253196A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringIntegrated circuit

Owner:QUALCOMM INC

Method for reforming amorphous carbon polymer film

ActiveUS20210043444A1Improve thermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon filmThin membrane

Owner:ASM IP HLDG BV

Electronics module having high density interconnect structures incorporating an improved dielectric lamination adhesive

InactiveUS6294741B1Improve electrical performanceAdequate processing propertyInsulating substrate metal adhesion improvementPrinted electric component incorporationComposite filmHigh density

A multi-chip electronics module is provided which utilizes benzocyclobutene as a laminate adhesive for bonding the upper dielectric films in a high density interconnect structure. The benzocyclobutene thermosetting polymer is spin coated on a polyimide film, and baked at low temperature to remove any solvent to leave a B-staged coating on the polyimide film. The composite film can be laminated to an underlying electrical structure using a vacuum laminator and heat. As the heat is applied, the BCB layer softens, flows and then cures to bond the polyimide film to the underlying electrical structure.

Owner:LOCKHEED MARTIN CORP

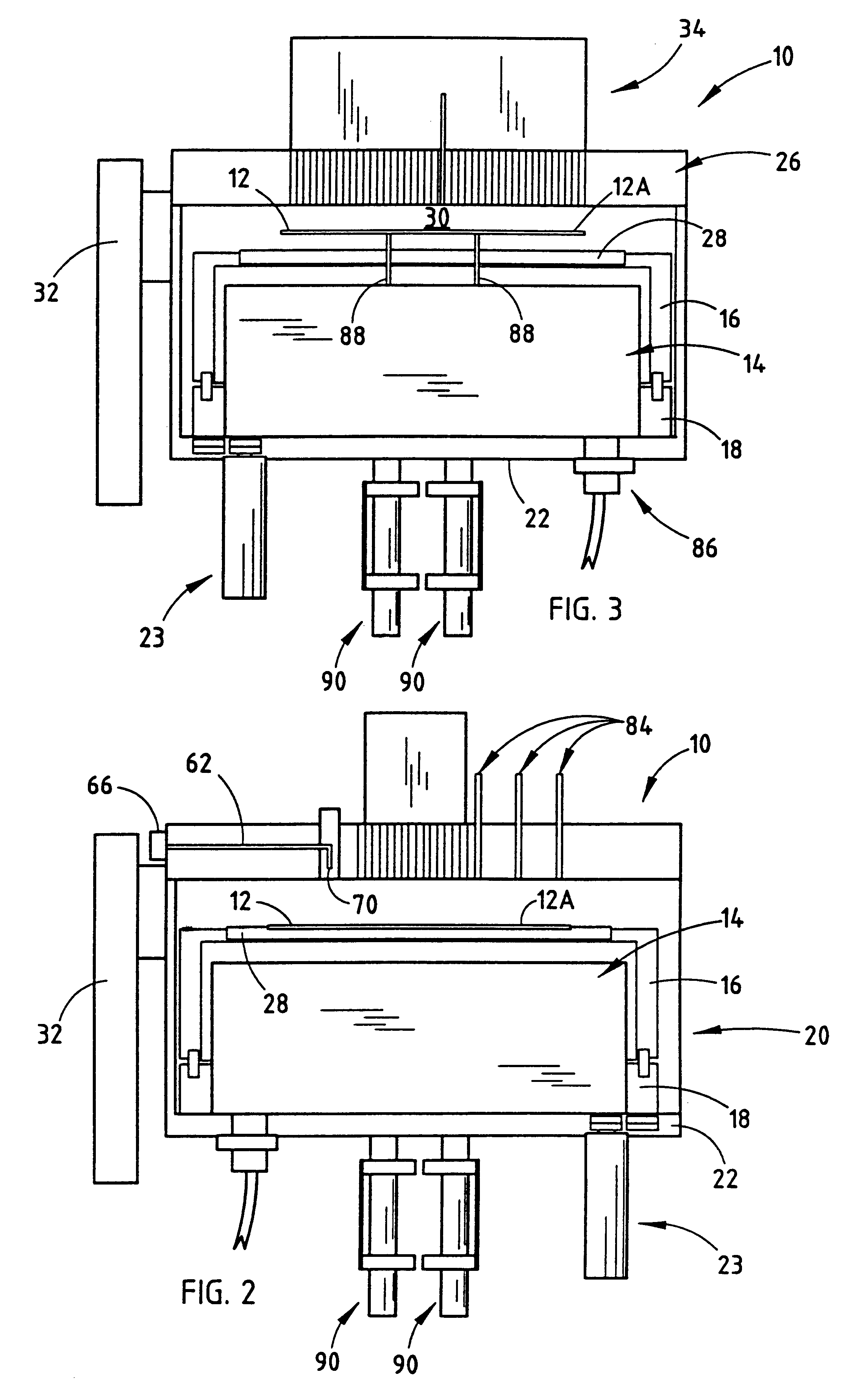

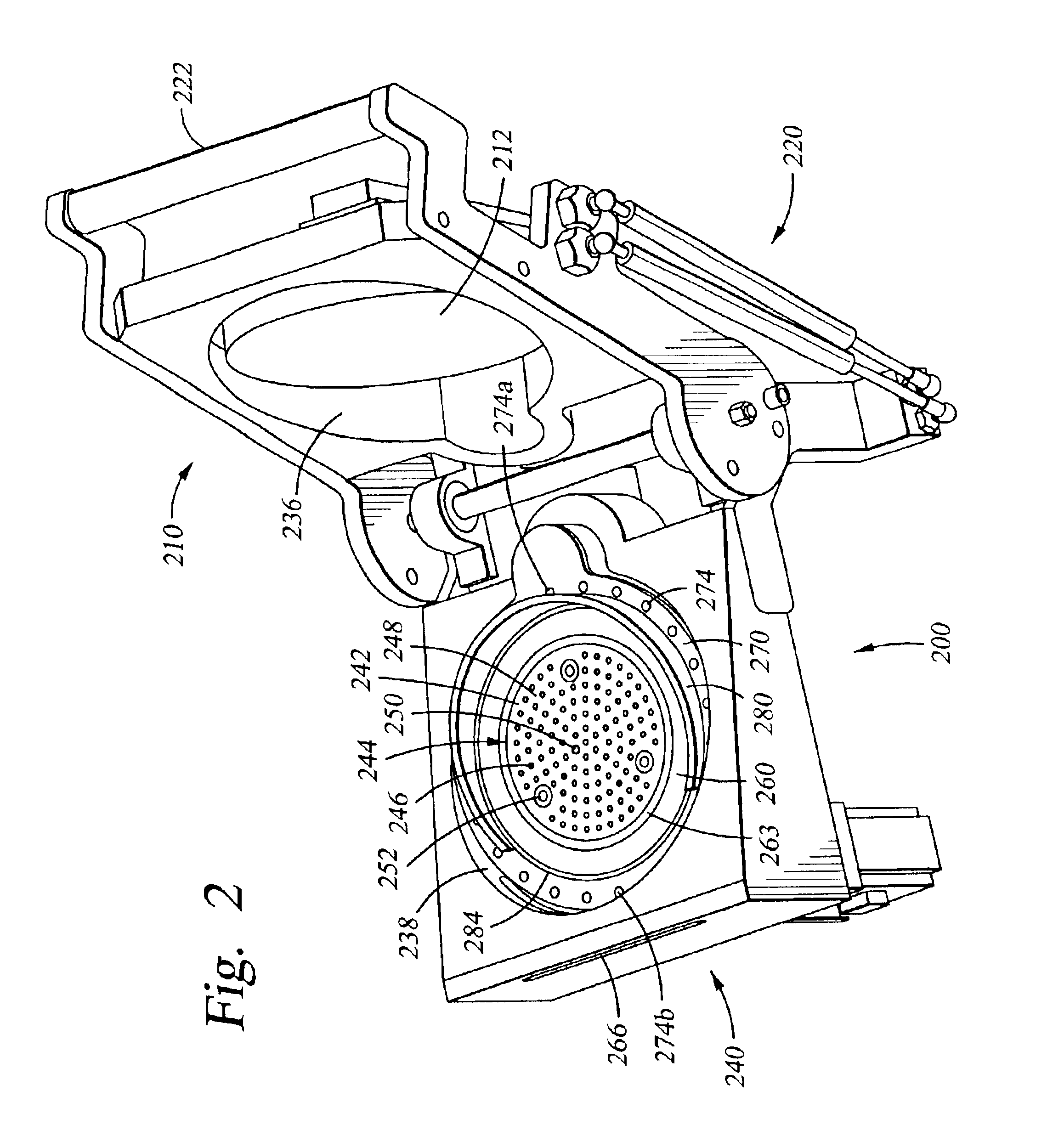

Clamshell and small volume chamber with fixed substrate support

InactiveUS6866746B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHinge angleEngineering

Owner:APPLIED MATERIALS INC

Electronic Devices With Retractable Displays

ActiveUS20170060183A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An electronic device may have a pair of elongated housings. A flexible display may be placed in a first position in which the display is retracted within one of the housings and a second position in which the flexible display is deployed and extends between the housings in a planar shape for viewing by a user. Support structures such as rigid slats that run parallel to the housings and bistable slats that run perpendicular to the rigid slats may be used to support the flexible display. Speakers, microphones, cameras, and other components can be mounted in the housings. The housings may be held together using magnets and may contain electrical components such as integrated circuits, batteries, and other devices. The components may be mounted on printed circuit boards that rotate within a rotating roller around which the display is wrapped when retracted.

Owner:APPLE INC

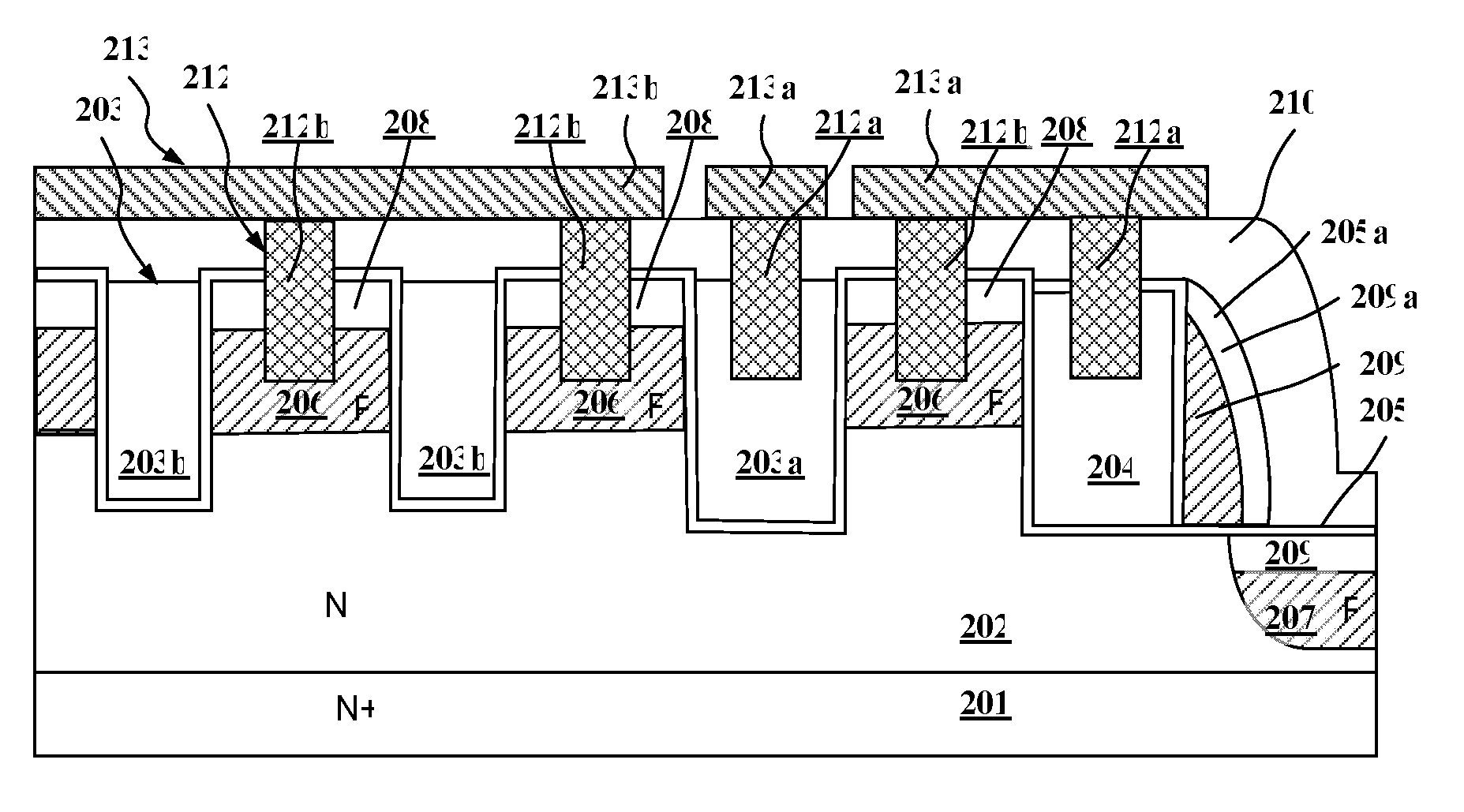

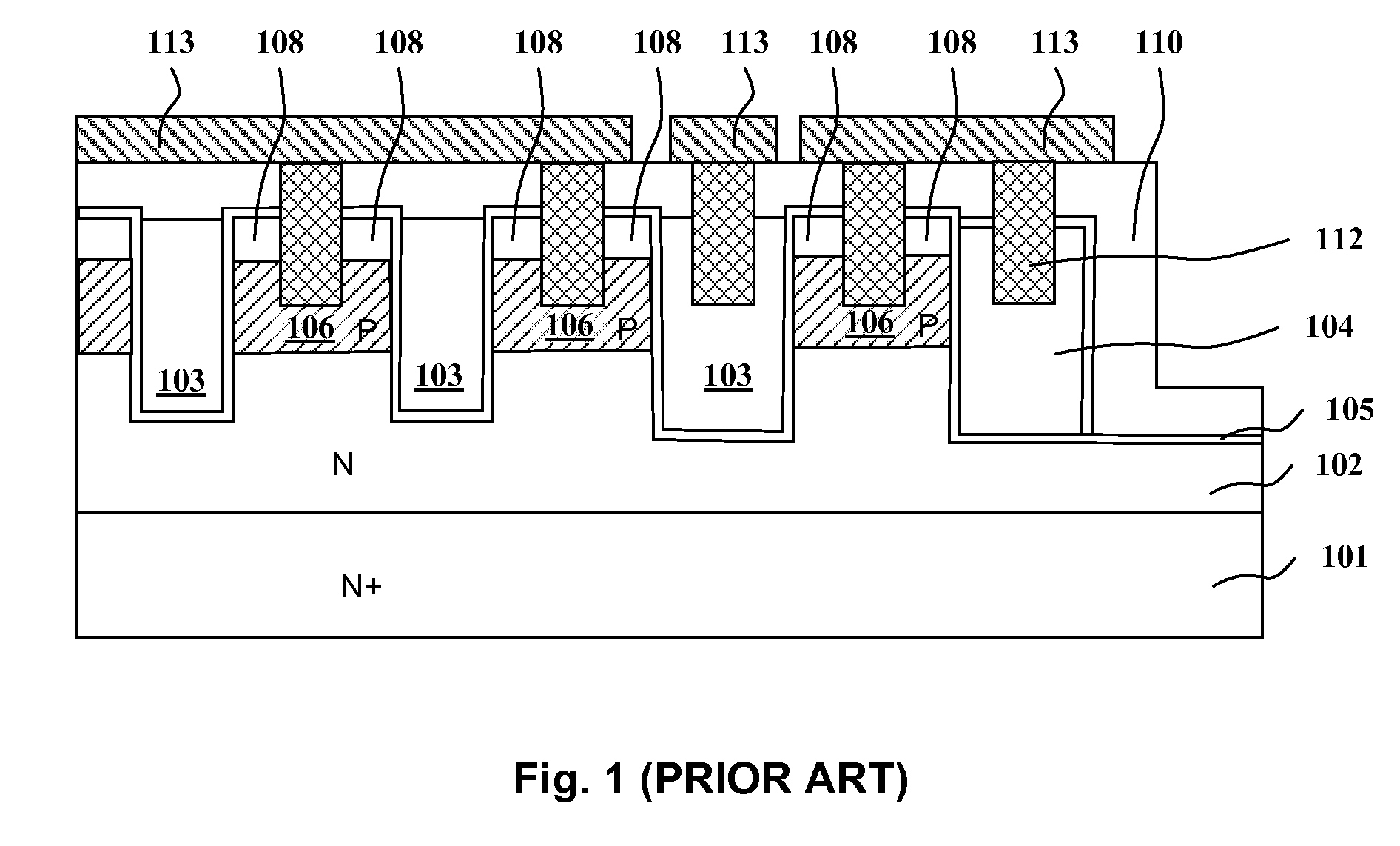

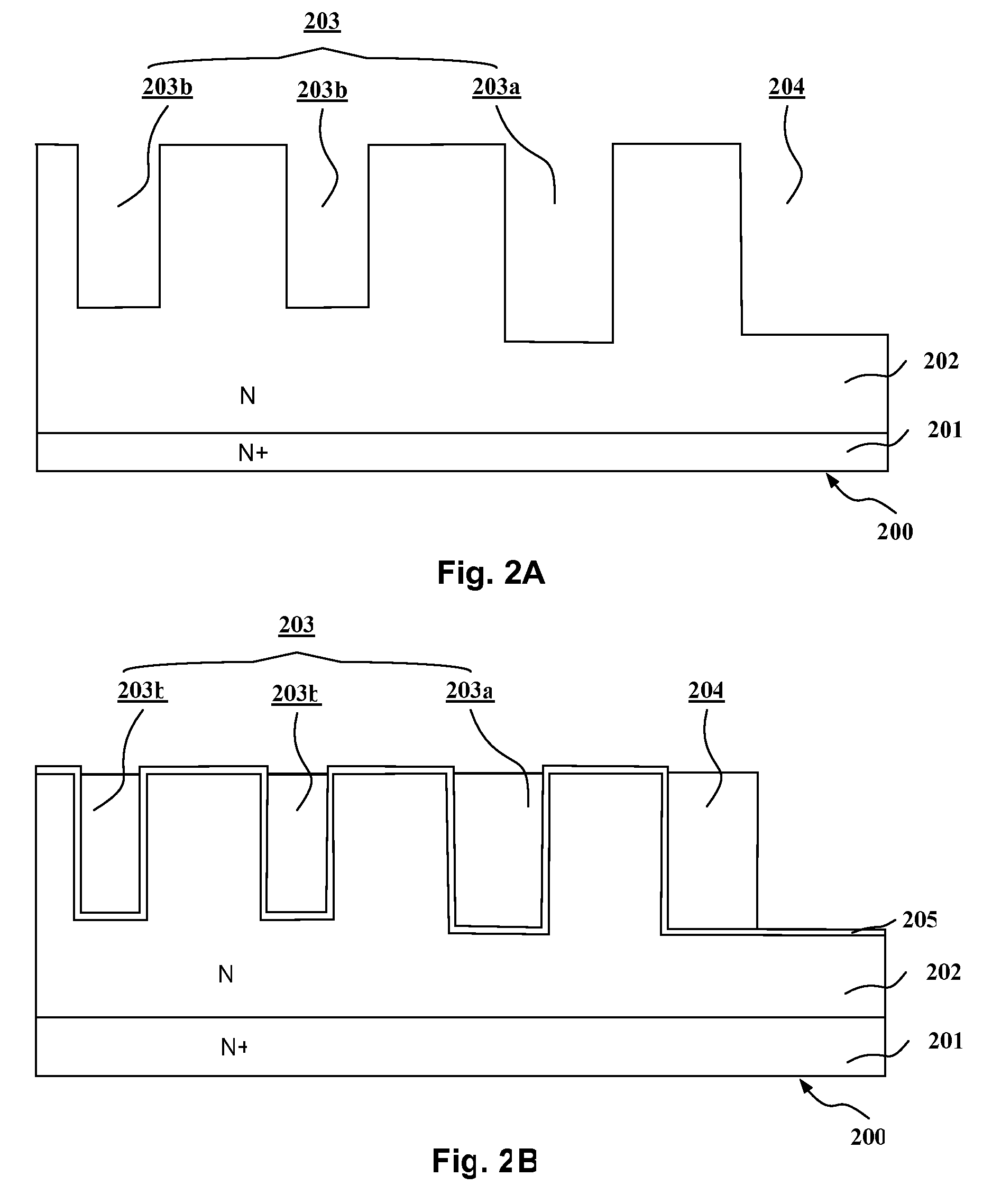

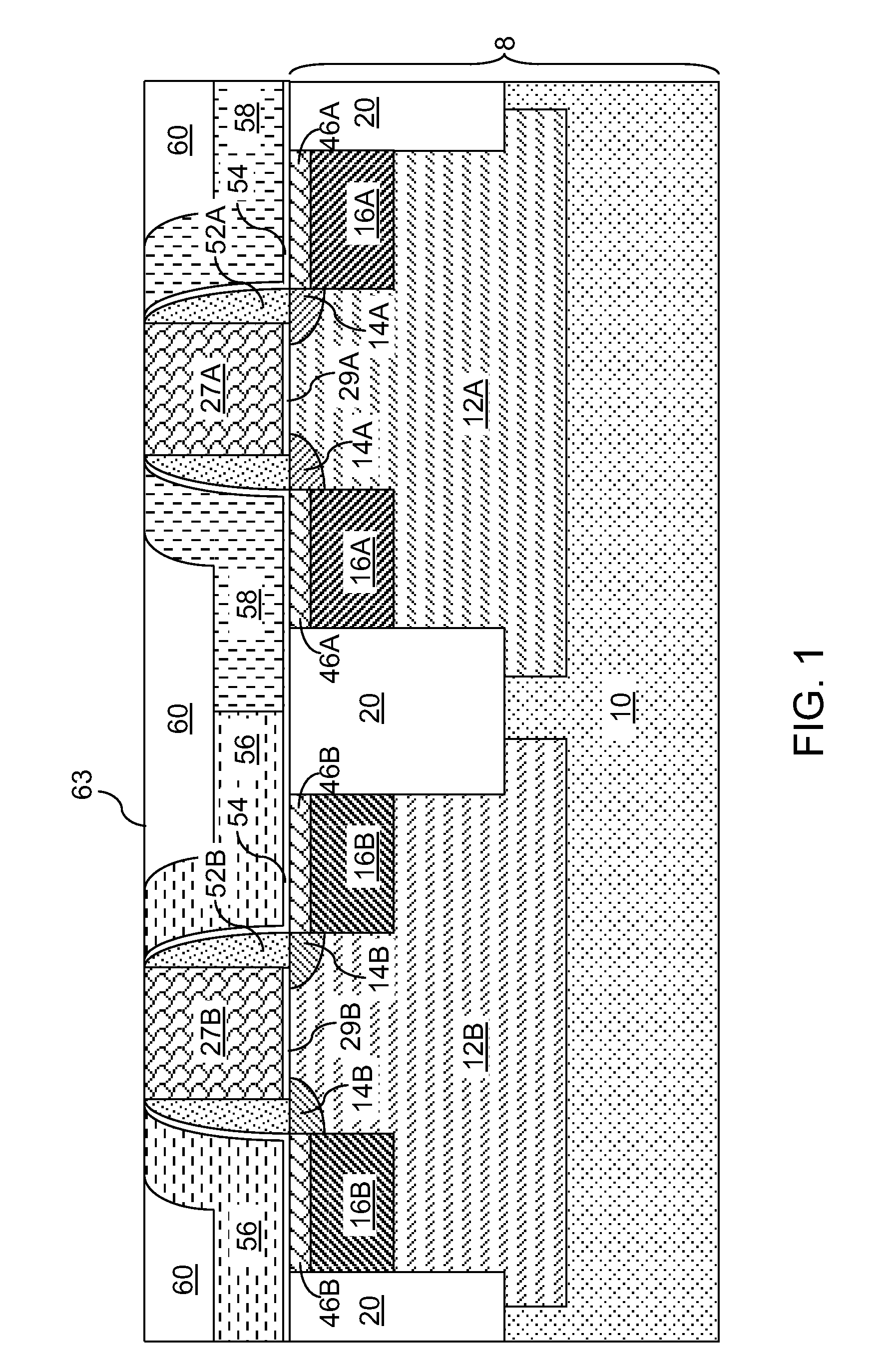

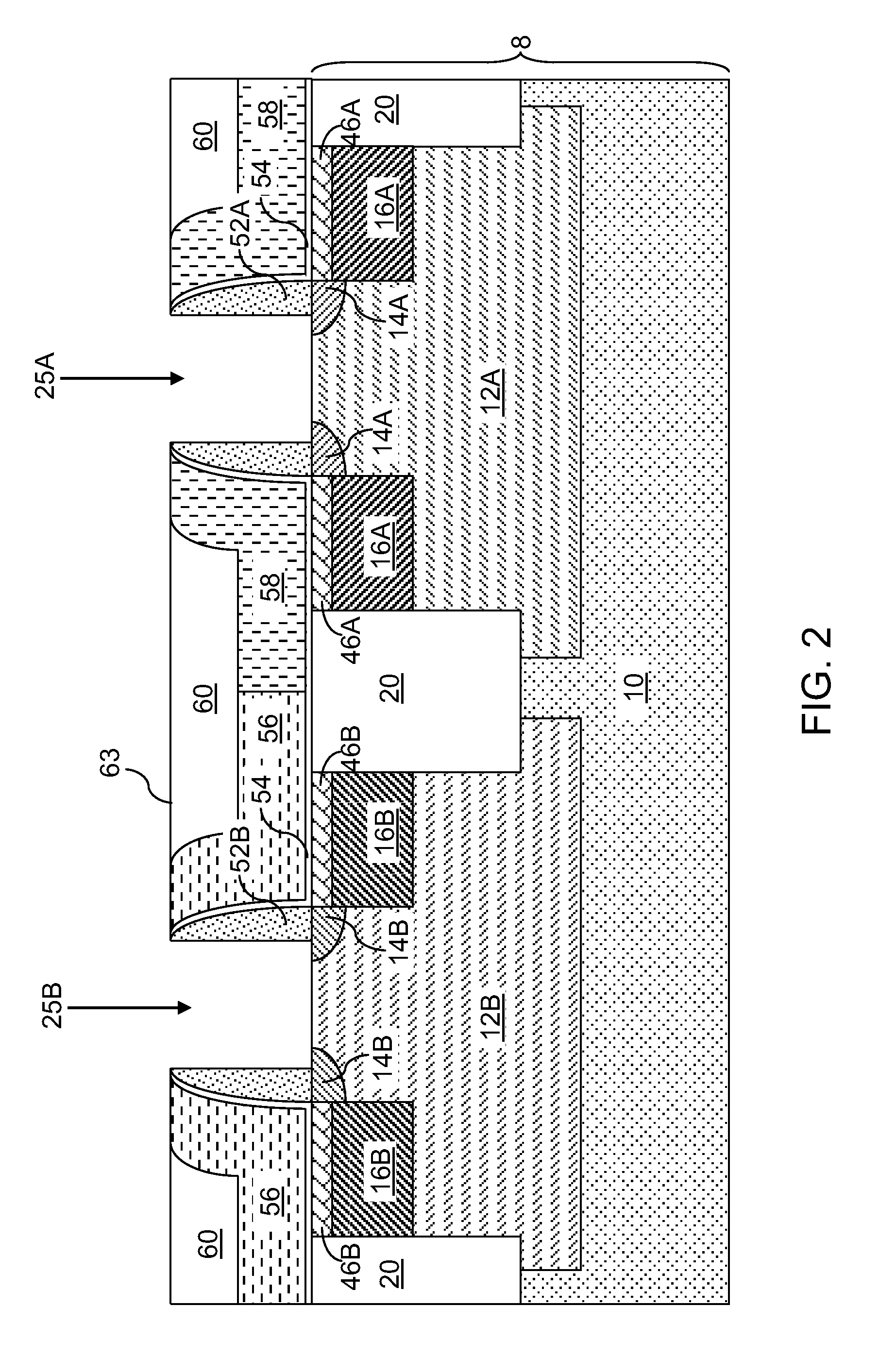

Trench MOSFET with Trench Termination and manufacture thereof

InactiveUS20090057756A1Lower on-resistanceImprove device ruggednessSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorBody region

A trench MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) with a trench termination, including a substrate including a drain region which is strongly doped and a doping epi layer region, which is weekly doped the same type as the drain region, on the drain region; a plurality of source and body regions formed in the epi layer; a metal layer including a plurality of metal layer regions which are connected to respective source and body, and gate regions forming metal connections of the MOSFET; a plurality of metal contact plugs connected to respective metal layer regions; a plurality of gate trenches filled with polysilicon to form a plurality of trenched gates on top of epi layer; an insulating layer deposited on the epi layer formed underneath the metal layer with a plurality of metal contact holes therein for contacting respective source and body regions; a margin terminating gate trench which is around the gate trenches; and a margin terminating active region which is formed underneath the margin terminating gate trench.

Owner:FORCE MOS TECH CO LTD

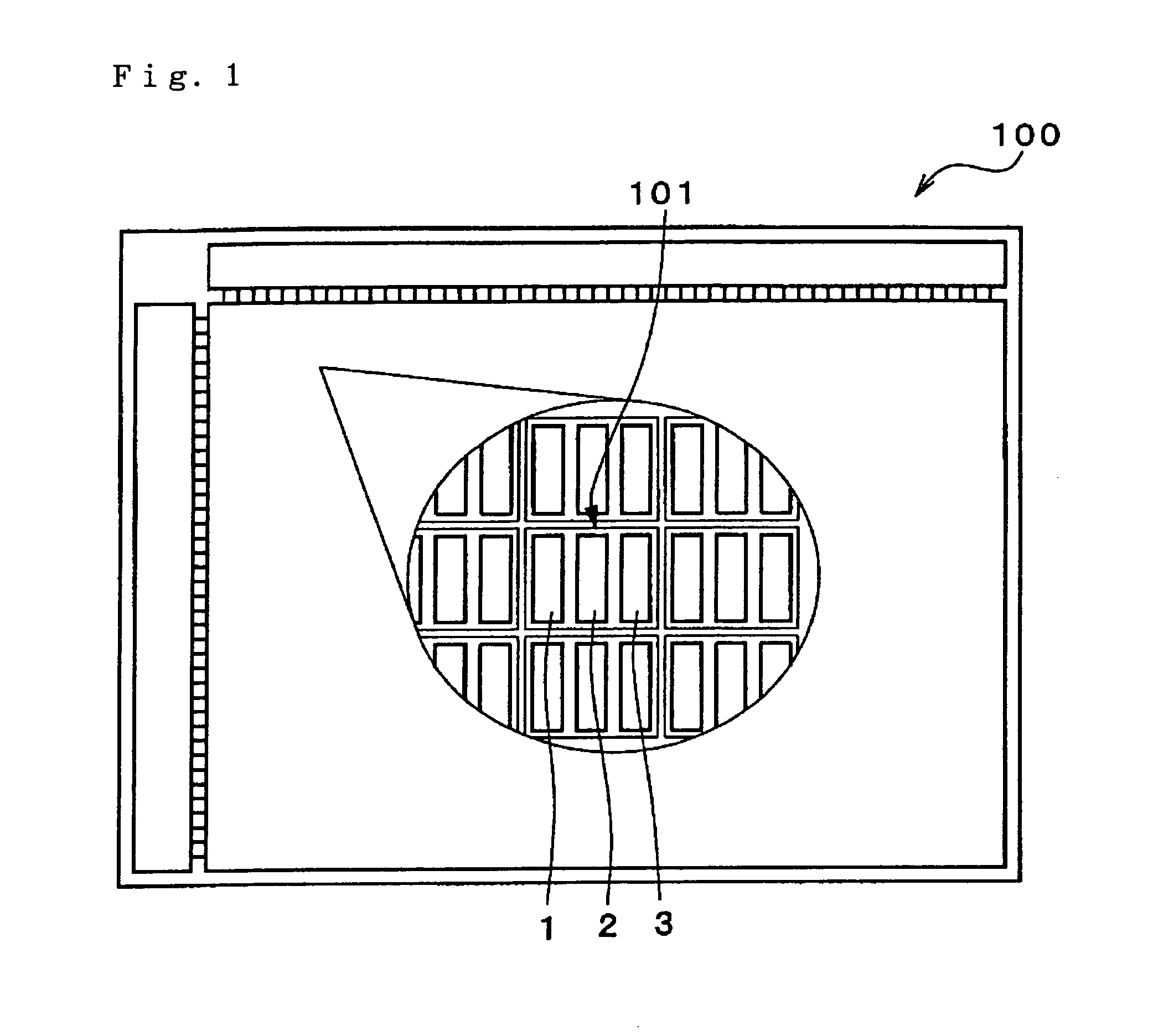

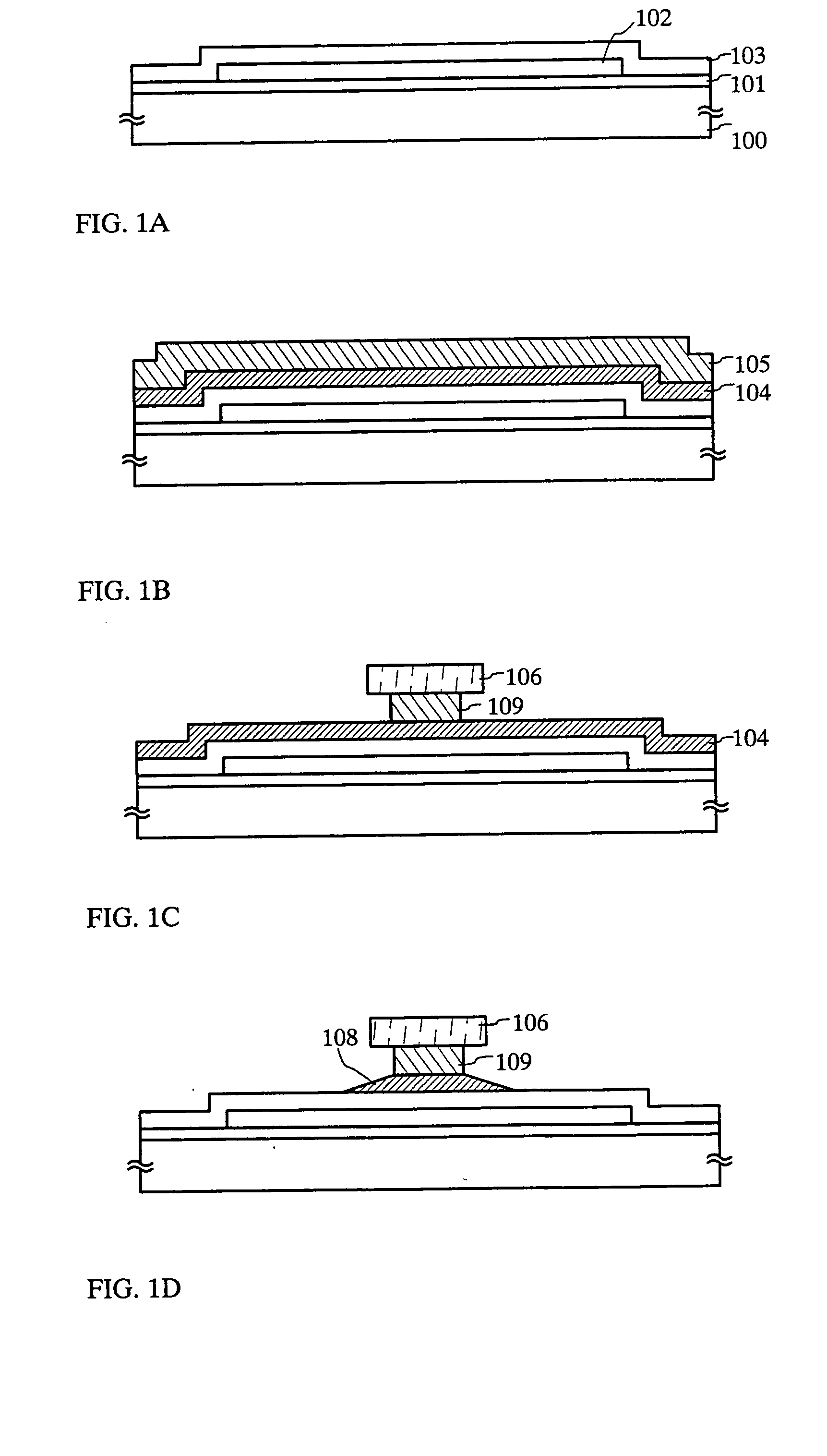

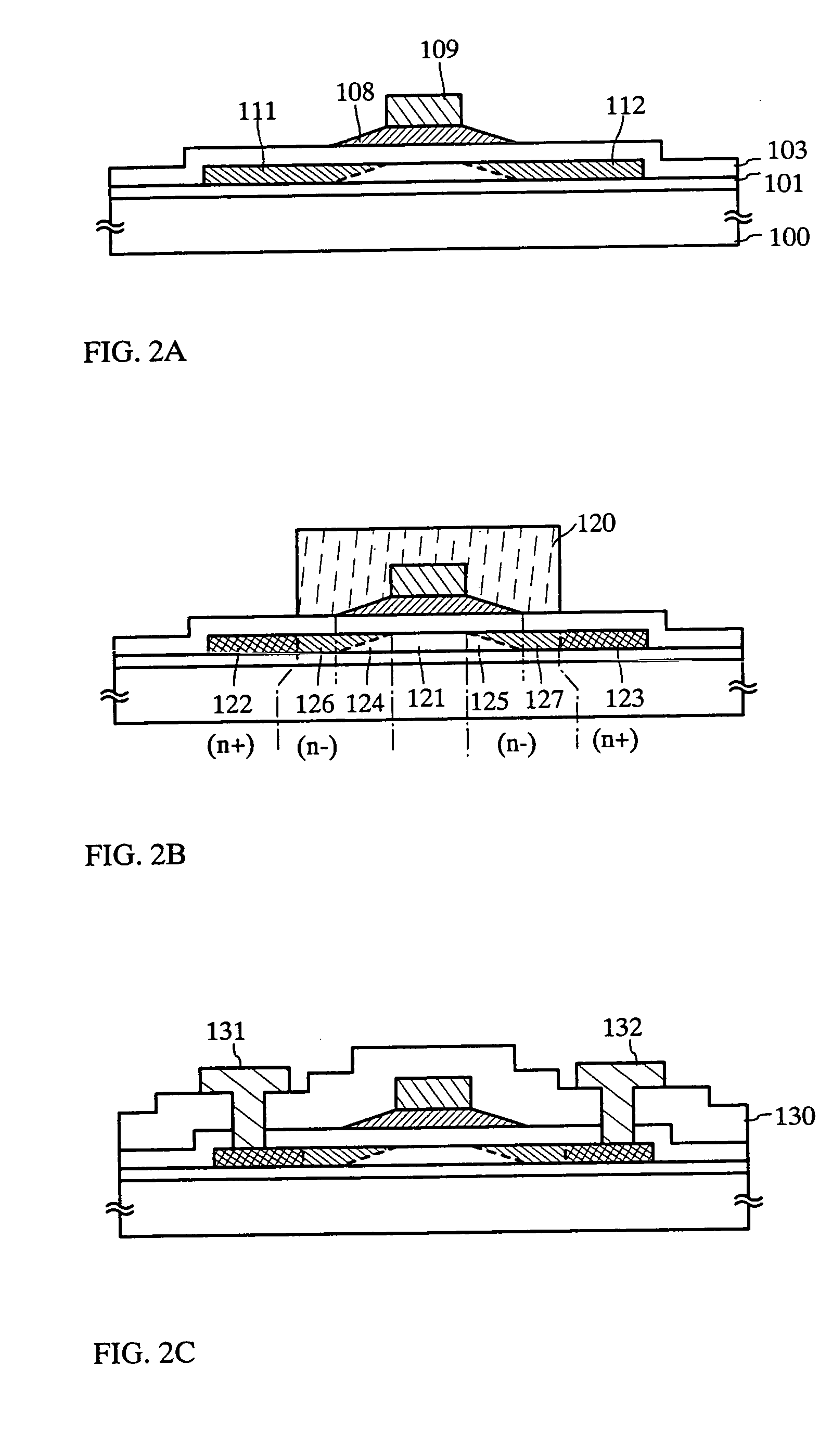

Semiconductor device and method of manufacturing the same

InactiveUS7091070B2Improve substrate adhesionReduce adhesiveness of substrateTransistorSolid-state devicesEngineeringIntegrated circuit

To provide a method for manufacturing a semiconductor device including a transfer step that is capable of controlling the adhesiveness of a substrate and an element-formed layer in the case of separating the element-formed layer including a semiconductor element or an integrated circuit formed over the substrate from the substrate and bonding it to another substrate. An adhesive agent made of a good adhesiveness material is formed between the semiconductor element or the integrated circuit comprising plural semiconductor elements formed over the substrate (a first substrate) and the substrate, and thus it is possible to prevent a semiconductor element from peeling off a substrate in manufacturing the semiconductor element, and further, to make it easier to separate the semiconductor element from the substrate by removing the adhesive agent after forming the semiconductor element.

Owner:SEMICON ENERGY LAB CO LTD

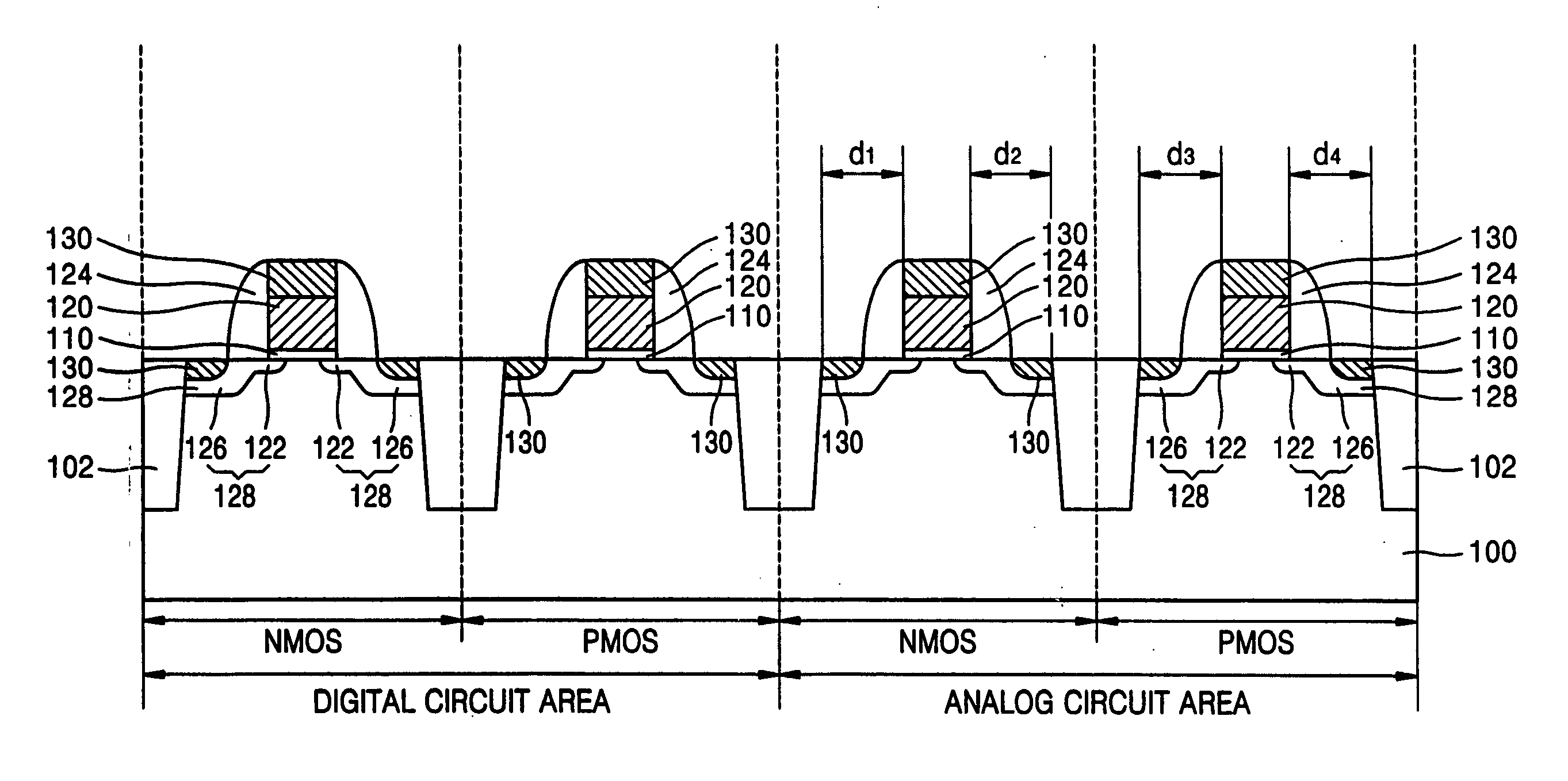

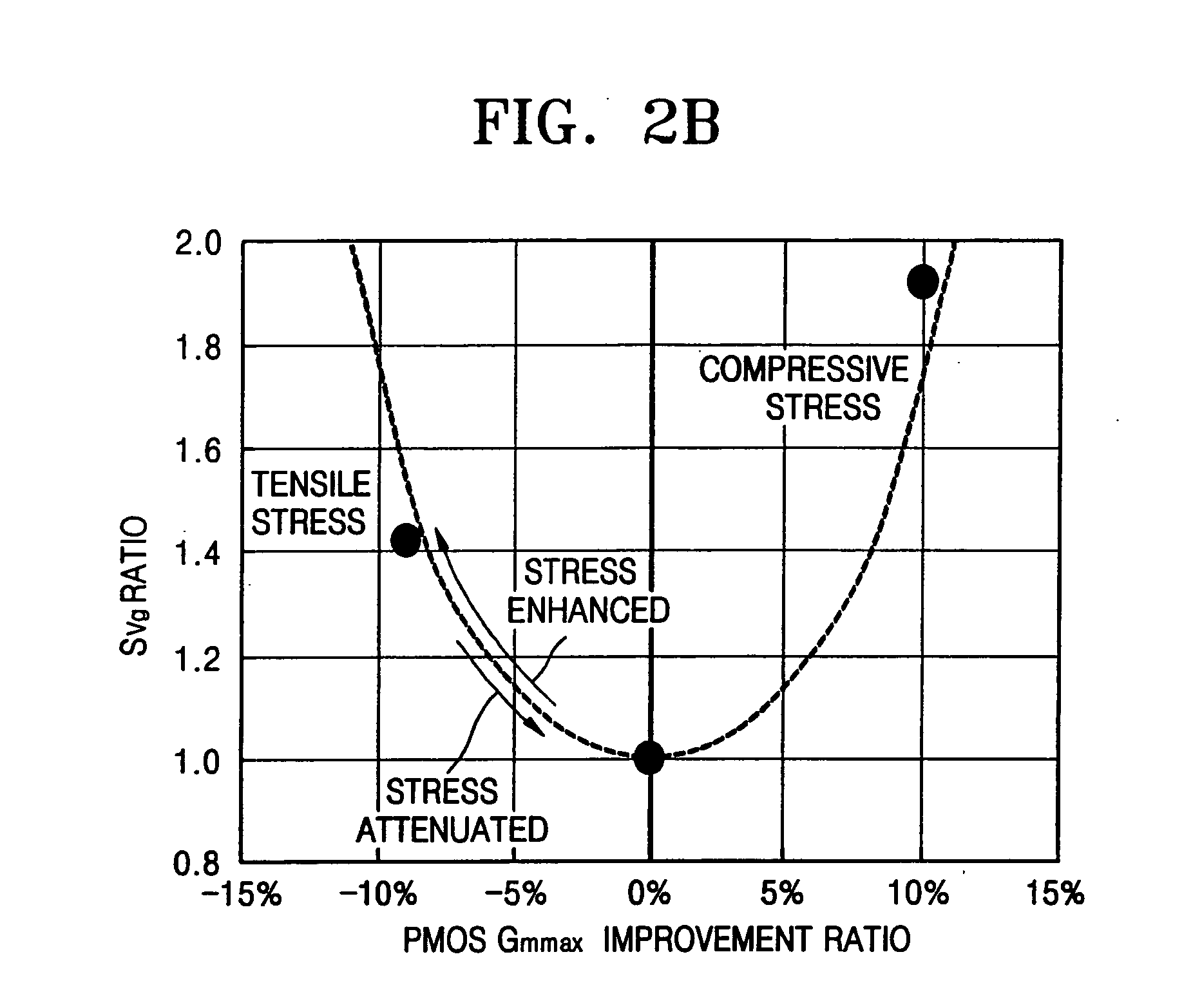

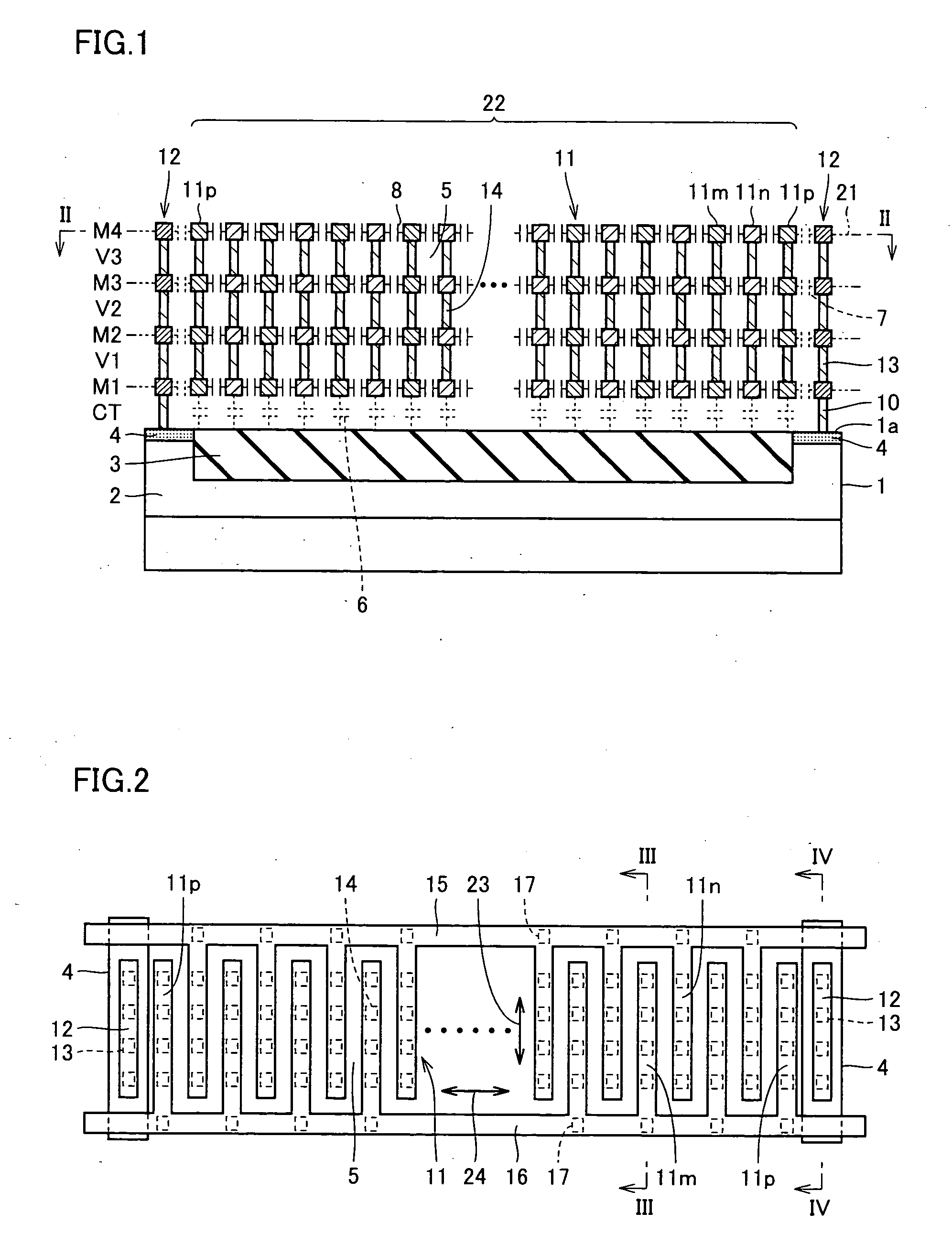

Low noise and high performance LSI device, layout and manufacturing method

ActiveUS20050218455A1Improve device performanceReduce the impactTransistorSolid-state devicesLow noiseLow speed

Owner:SAMSUNG ELECTRONICS CO LTD

Technique for perfecting the active regions of wide bandgap semiconductor nitride devices

InactiveUS20050164475A1Lower average currentHigh densityPolycrystalline material growthFrom solid stateEngineeringNitride

This invention pertains to e lectronic / optoelectronic devices with reduced extended defects and to a method for making it. The method includes the steps of depositing a dielectric thin film mask material on a semiconductor substrate surface; patterning the mask material to form openings therein extending to the substrate surface; growing active material in the openings; removing the mask material to form the device with reduced extended defect density; and depositing electrical contacts on the device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Semiconductor device

ActiveUS20050145987A1Reduce distractionsDesired characteristicTransistorSemiconductor/solid-state device detailsCapacitanceDevice material

Owner:RENESAS ELECTRONICS CORP +1

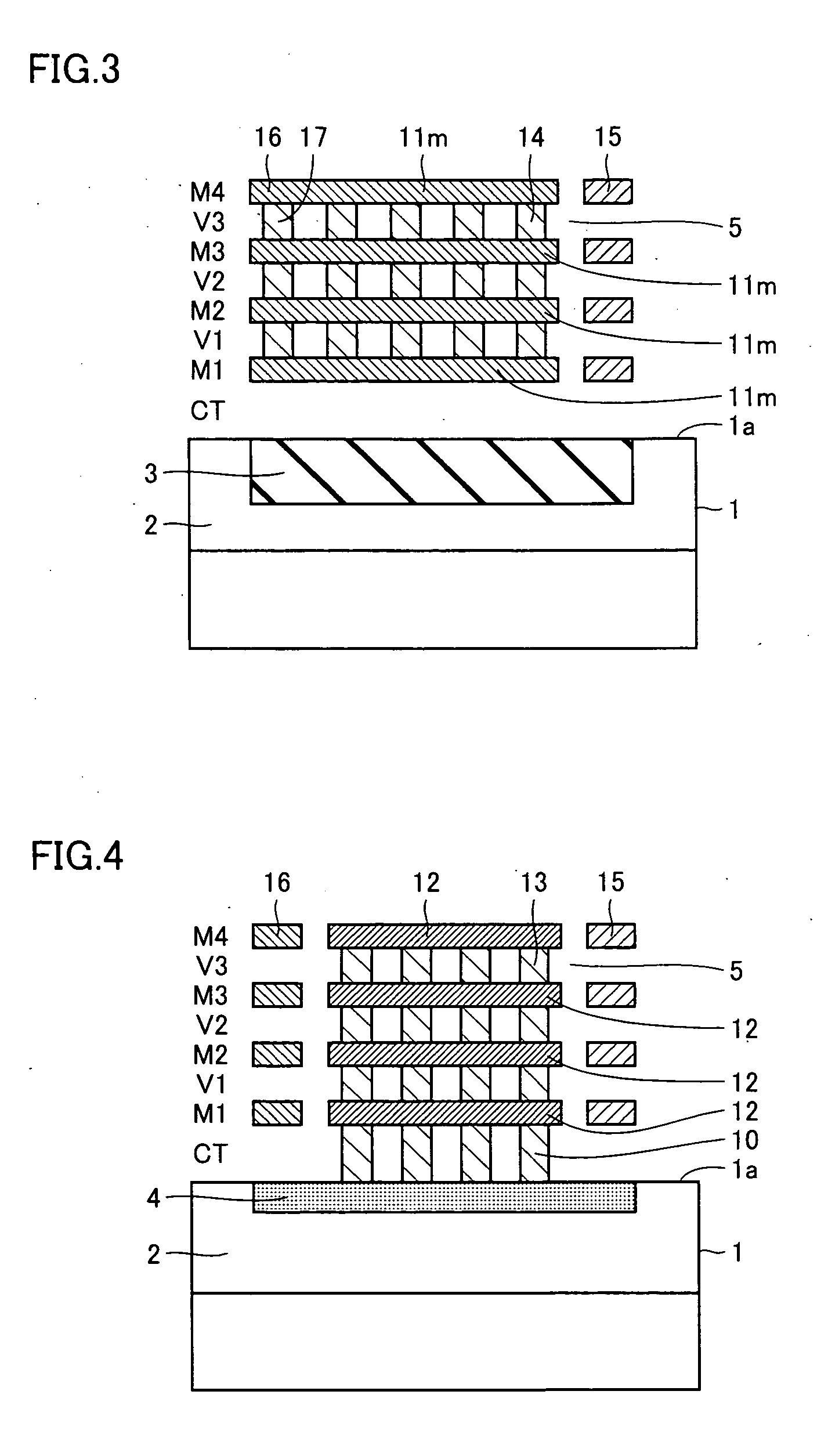

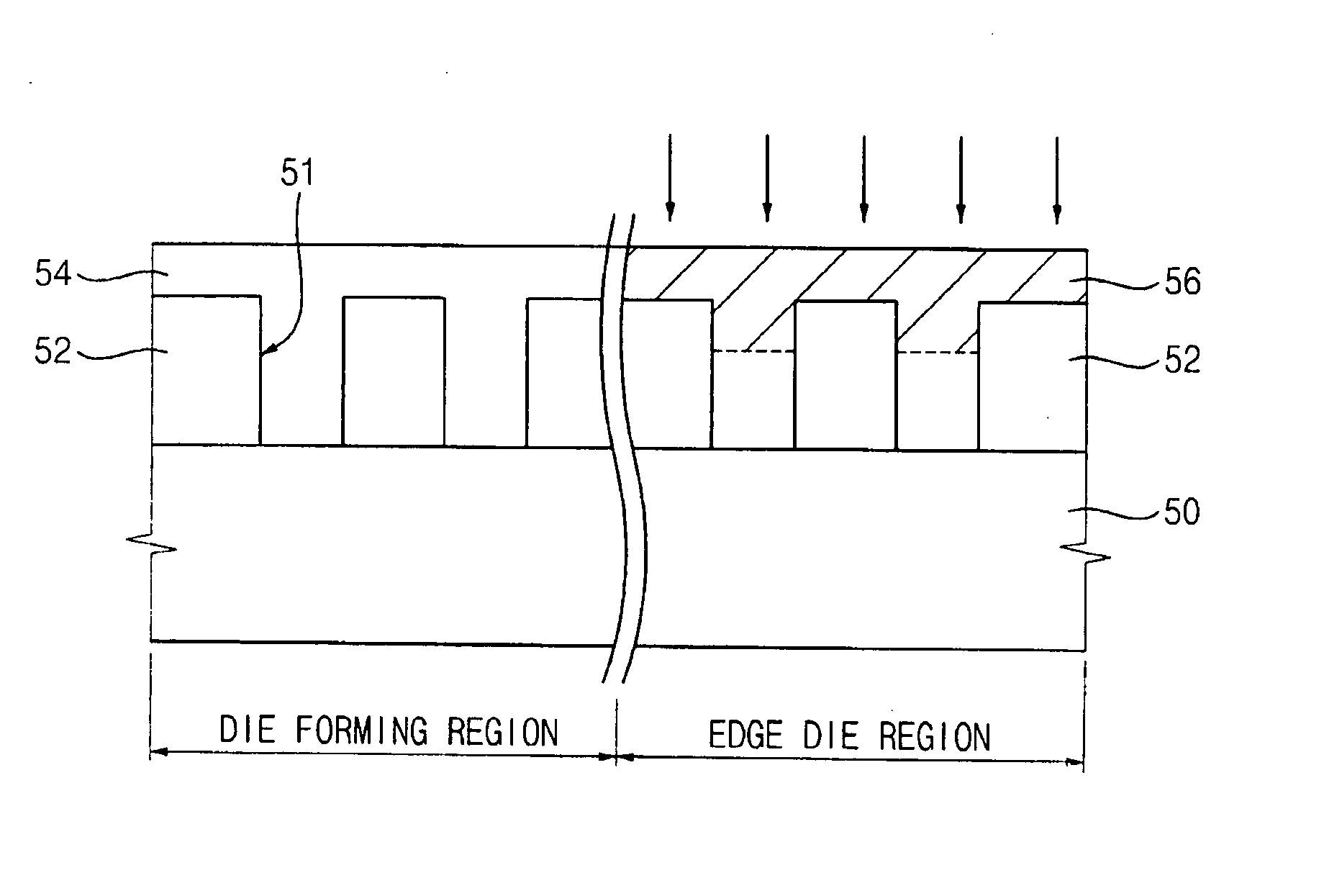

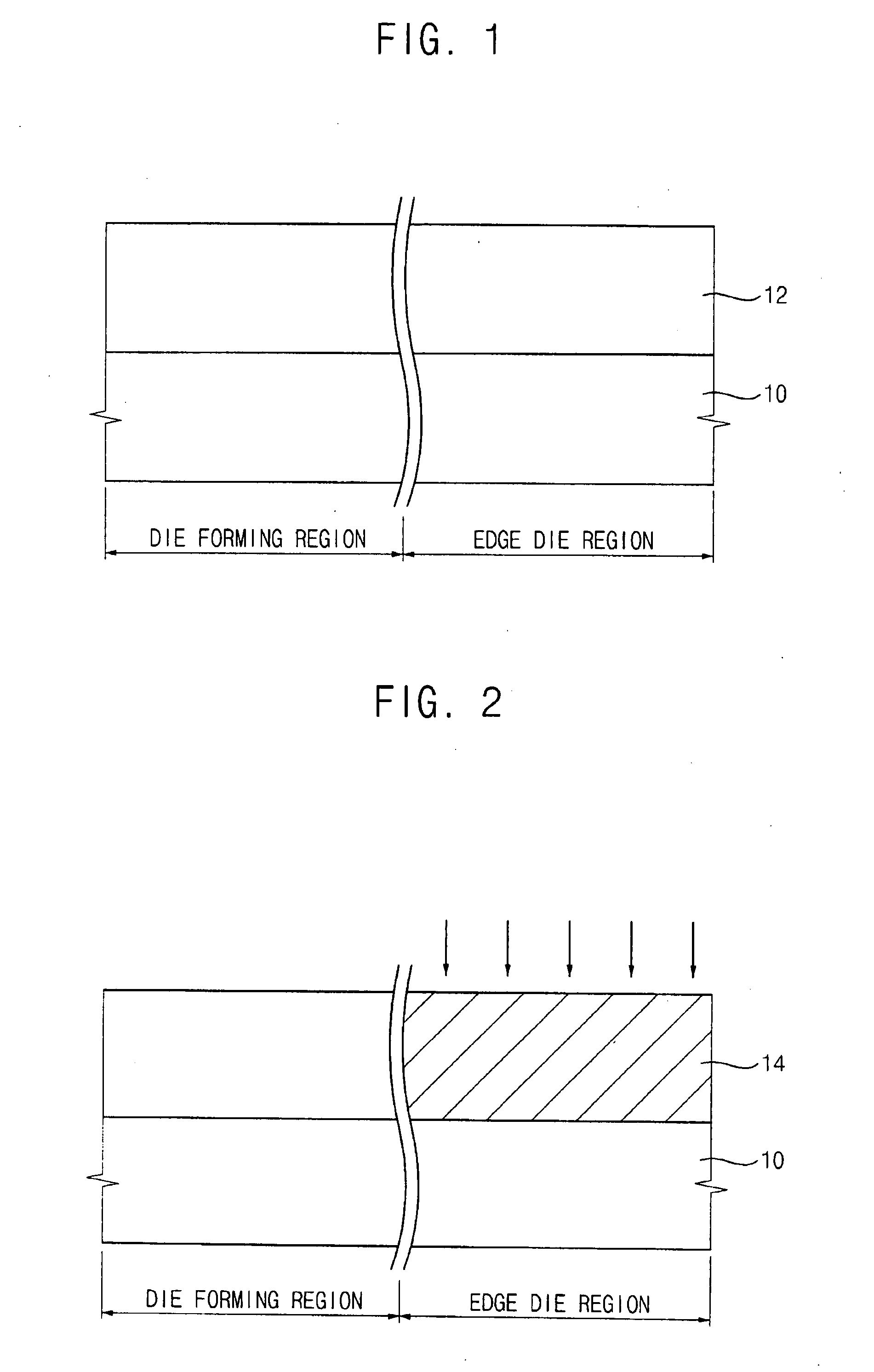

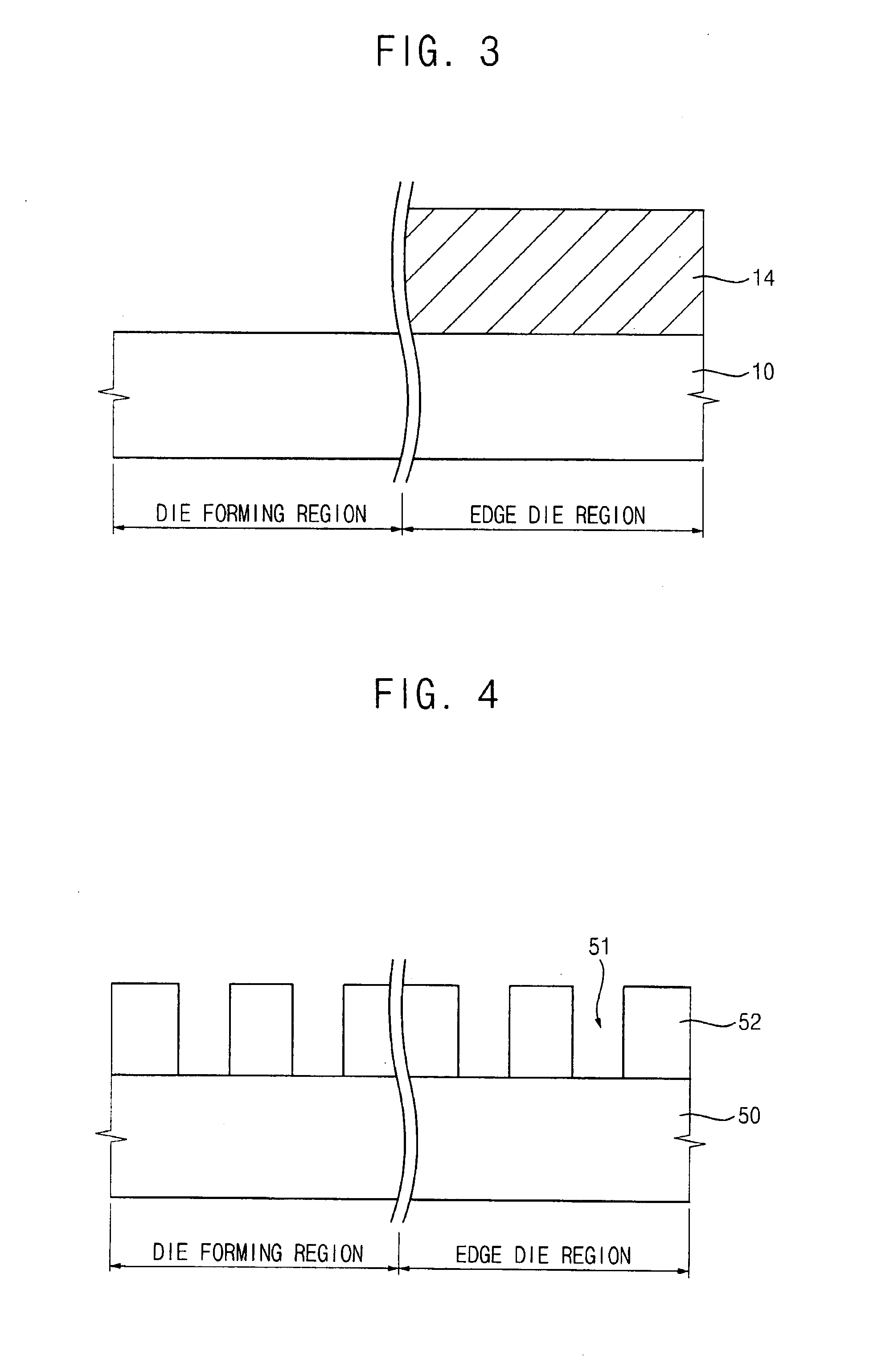

Method of manufacturing electro-optical device, electro-optical device, transferred chip, transfer origin substrate

InactiveUS7169652B2Low costProduct yield is lowTransistorSolid-state devicesDisplay deviceEngineering

Owner:SEIKO EPSON CORP

Apparatus for producing semiconductors and other devices and cleaning apparatus

InactiveUS6035871AWater/sewage treatment by electrochemical methodsSemiconductor/solid-state device manufacturingSemiconductorBiomedical engineering

Provided is an apparatus for producing semiconductor and other devices, which can improve the quality of deposited films and increase the yield of produced devices in comparison with the conventional apparatus. The apparatus of the invention comprises a plurality of dry treatment chambers (7a, 7b, 7c, 7d, 7e), a transfer room (6) interconnecting the dry treatment chambers (7a, 7b, 7c, 7d, 7e), loading / unloading chambers (8a, 8b, 8c, 8d), and a cleaning apparatus (13). The transfer room (6) and the cleaning apparatus (13) are directly or indirectly connected to each other.

Owner:ALPS ALPINE CO LTD

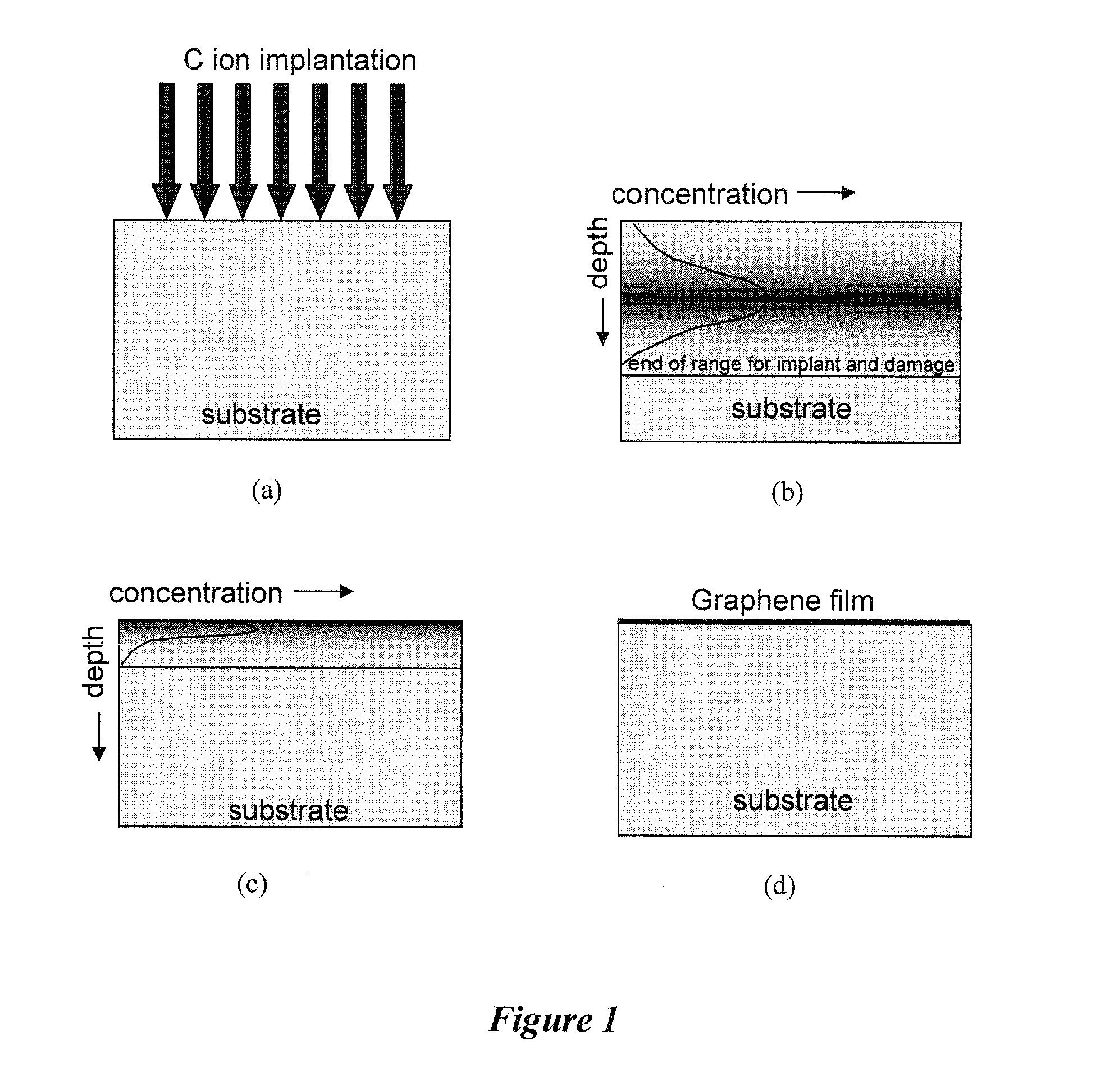

Fabrication of graphene nanoelectronic devices on SOI structures

ActiveUS20110114918A1Eliminates thermal budget limitationGood substrateSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureGraphene

A semiconductor-on-insulator structure and a method of forming the silicon-on-insulator structure including an integrated graphene layer are disclosed. In an embodiment, the method comprises processing a silicon material to form a buried oxide layer within the silicon material, a silicon substrate below the buried oxide, and a silicon-on-insulator layer on the buried oxide. A graphene layer is transferred onto the silicon-on-insulator layer. Source and drain regions are formed in the silicon-on-insulator layer, and a gate is formed above the graphene. In one embodiment, the processing includes growing a respective oxide layer on each of first and second silicon sections, and joining these silicon sections together via the oxide layers to form the silicon material. The processing, in an embodiment, further includes removing a portion of the first silicon section, leaving a residual silicon layer on the bonded oxide, and the graphene layer is positioned on this residual silicon layer.

Owner:GLOBALFOUNDRIES U S INC

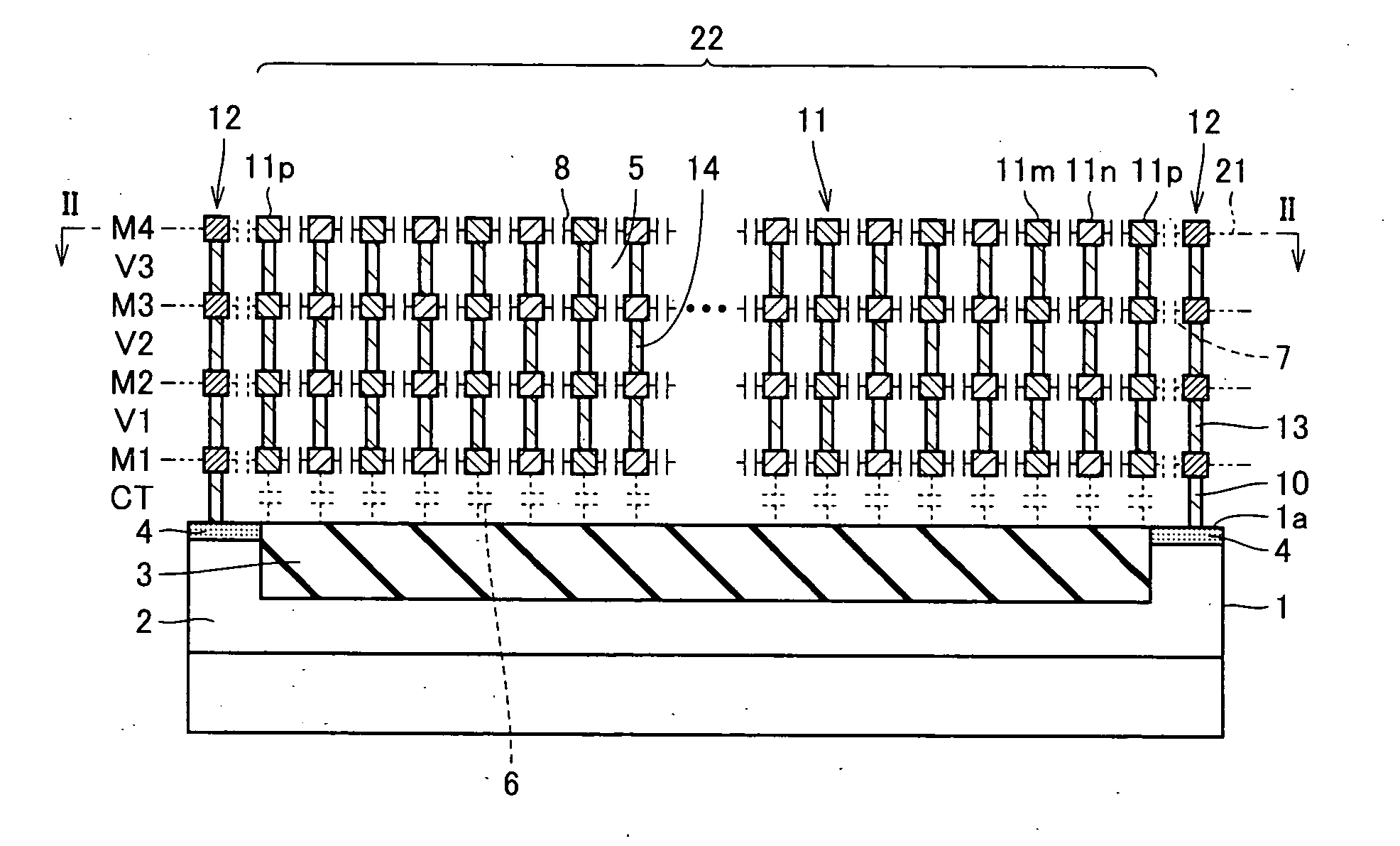

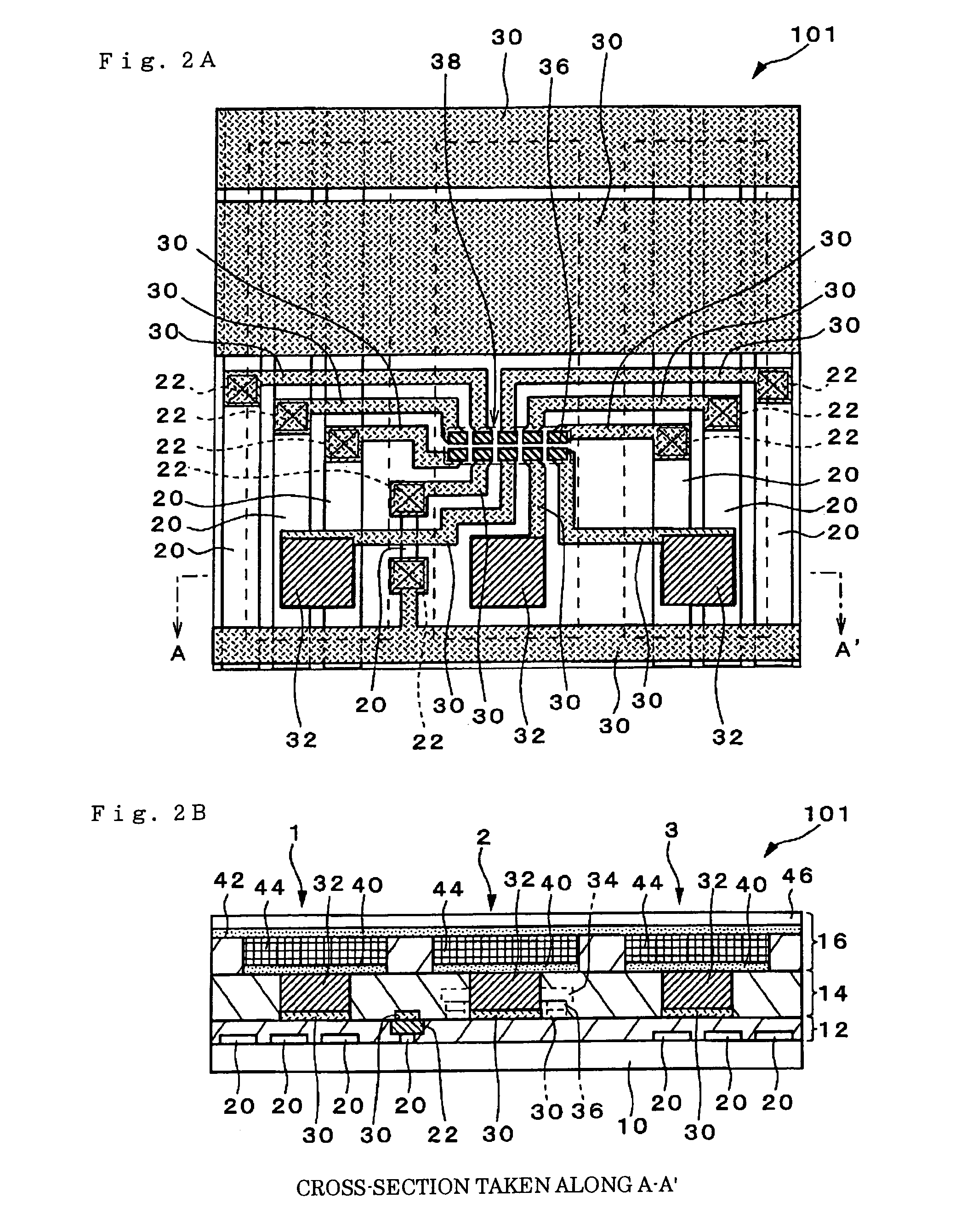

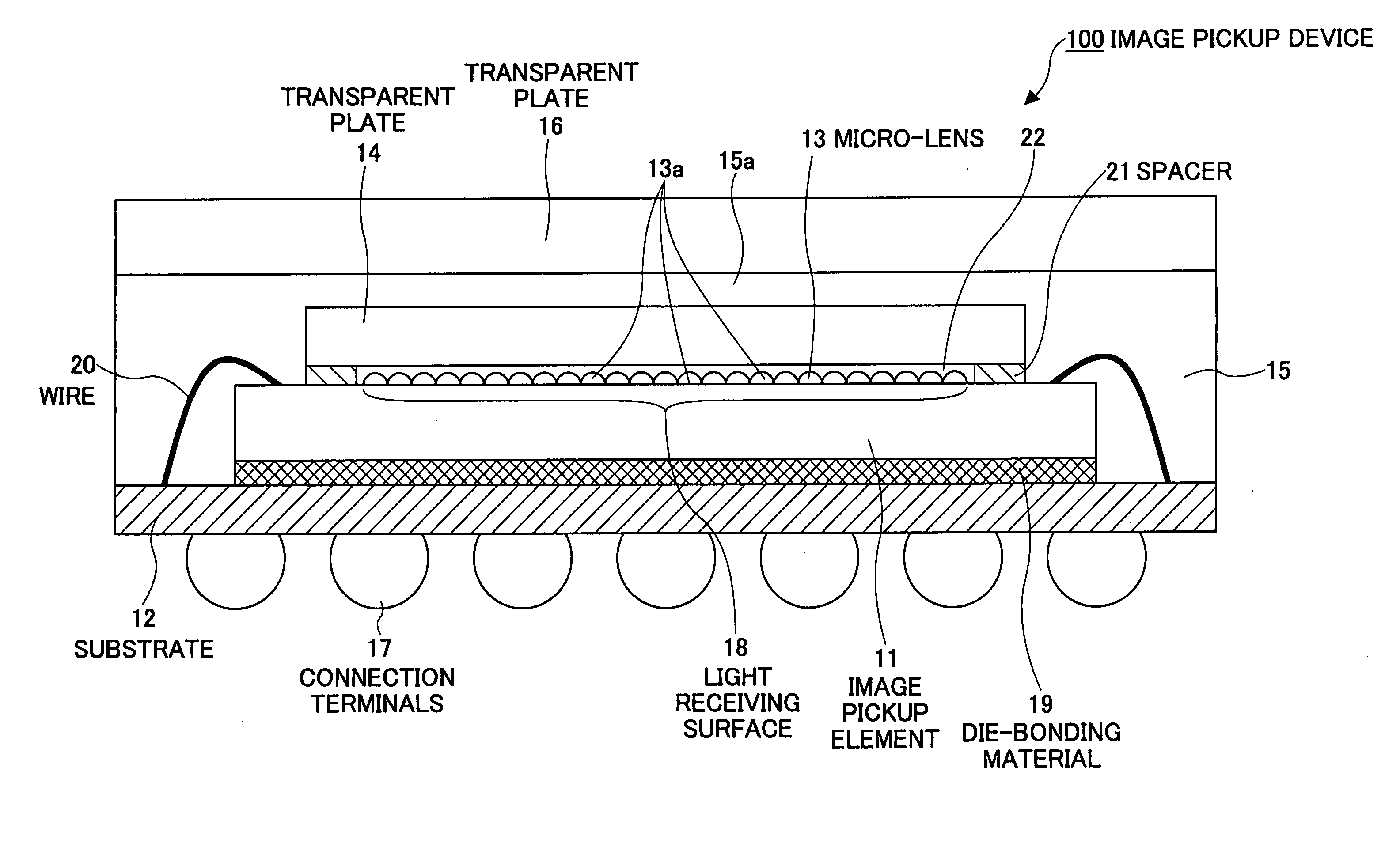

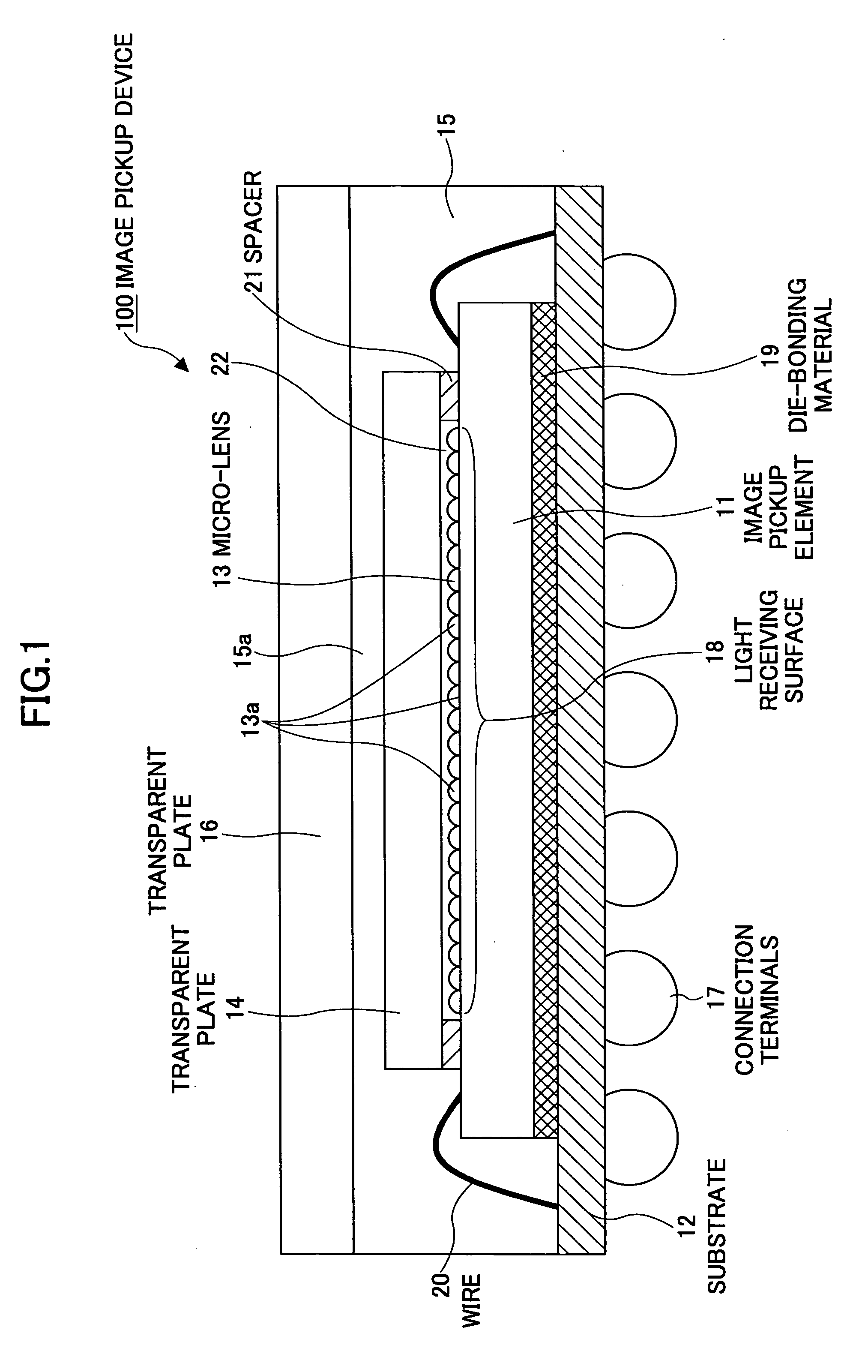

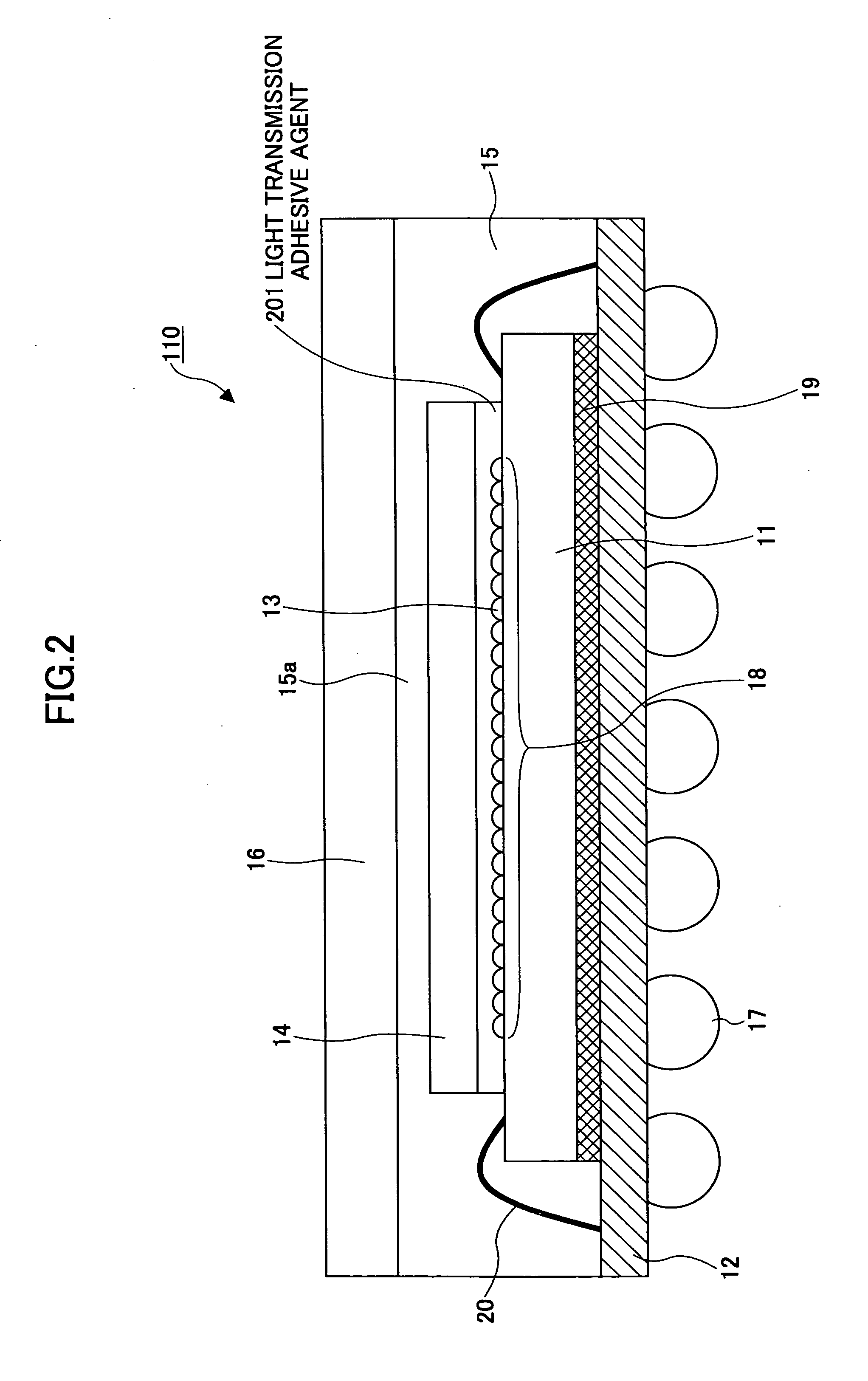

Image pickup device and production method thereof

InactiveUS20050275741A1Good lighting performanceSmall overall deformationTelevision system detailsSemiconductor/solid-state device detailsThermal expansionComputer science

Owner:SOCIONEXT INC

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor device and method of manufacturing the same, circuit board and electronic instrument

InactiveUS6841849B2Not easily oxidizedSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A depression is formed from a first surface of a semiconductor substrate on which is formed an integrated circuit. An insulating layer is provided on the inner surface of the depression. A first conductive portion is provided on the inside of the insulating layer. A second conductive portion is formed on the inside of the insulating layer and over the first conductive portion, of a different material from the first conductive portion. The first conductive portion is exposed from a second surface of the semiconductor substrate opposite to the first surface.

Owner:ADVANCED INTERCONNECT SYST LTD

Method of fabricating a semiconductor device

Owner:SEMICON ENERGY LAB CO LTD

Extreme ultraviolet light source

InactiveUS20050230645A1Improve efficiencyImprove performanceNanoinformaticsSemiconductor/solid-state device manufacturingAtomic elementLight energy

The present invention provides a reliable, high-repetition rate, production line compatible high energy photon source. A very hot plasma containing an active material is produced in vacuum chamber. The active material is an atomic element having an emission line within a desired extreme ultraviolet (EUV) range. A pulse power source comprising a charging capacitor and a magnetic compression circuit comprising a pulse transformer, provides electrical pulses having sufficient energy and electrical potential sufficient to produce the EUV light at an intermediate focus at rates in excess of 5 Watts. In preferred embodiments designed by Applicants in-band, EUV light energy at the intermediate focus is 45 Watts extendable to 105.8 Watts.

Owner:CYMER INC

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

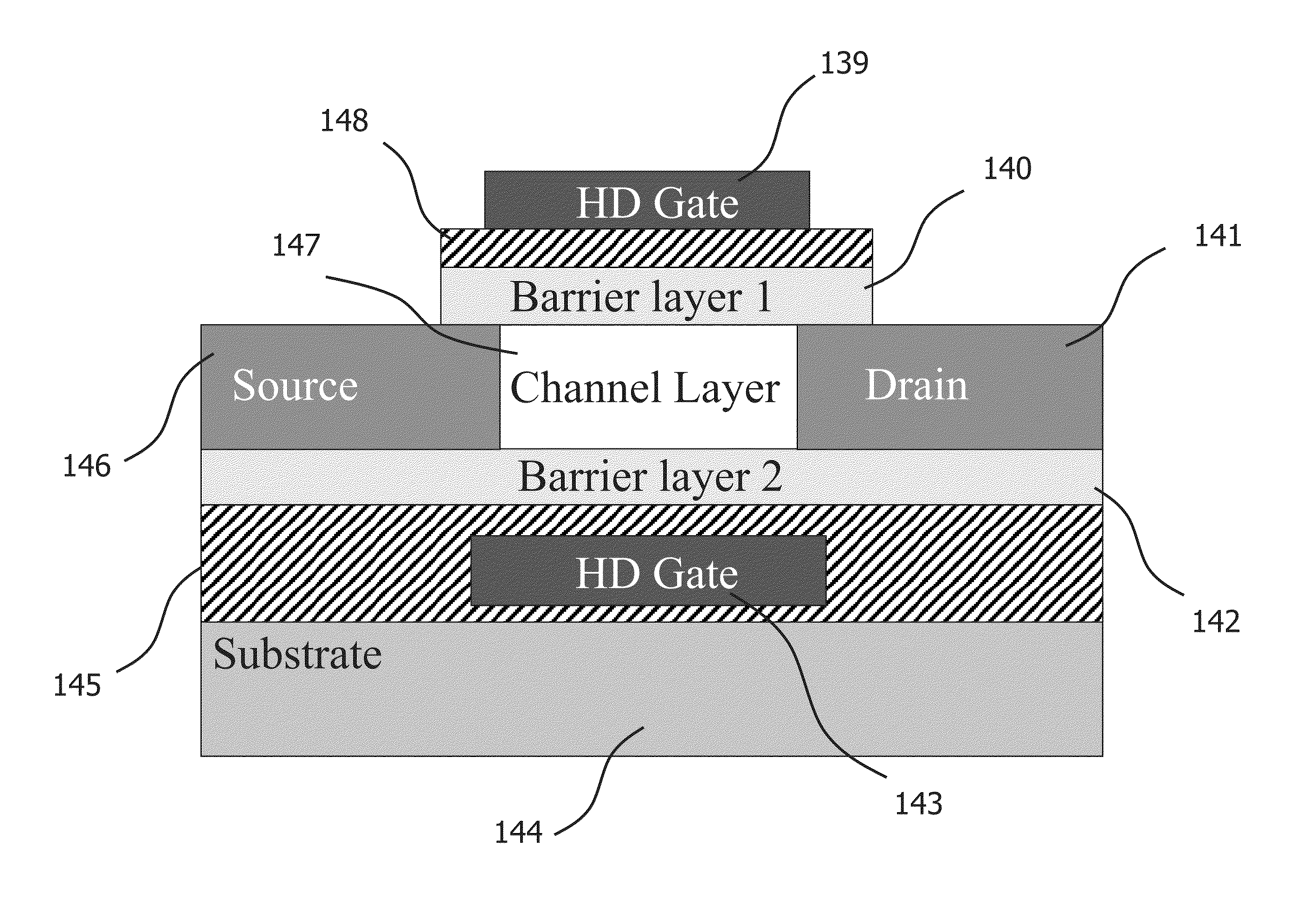

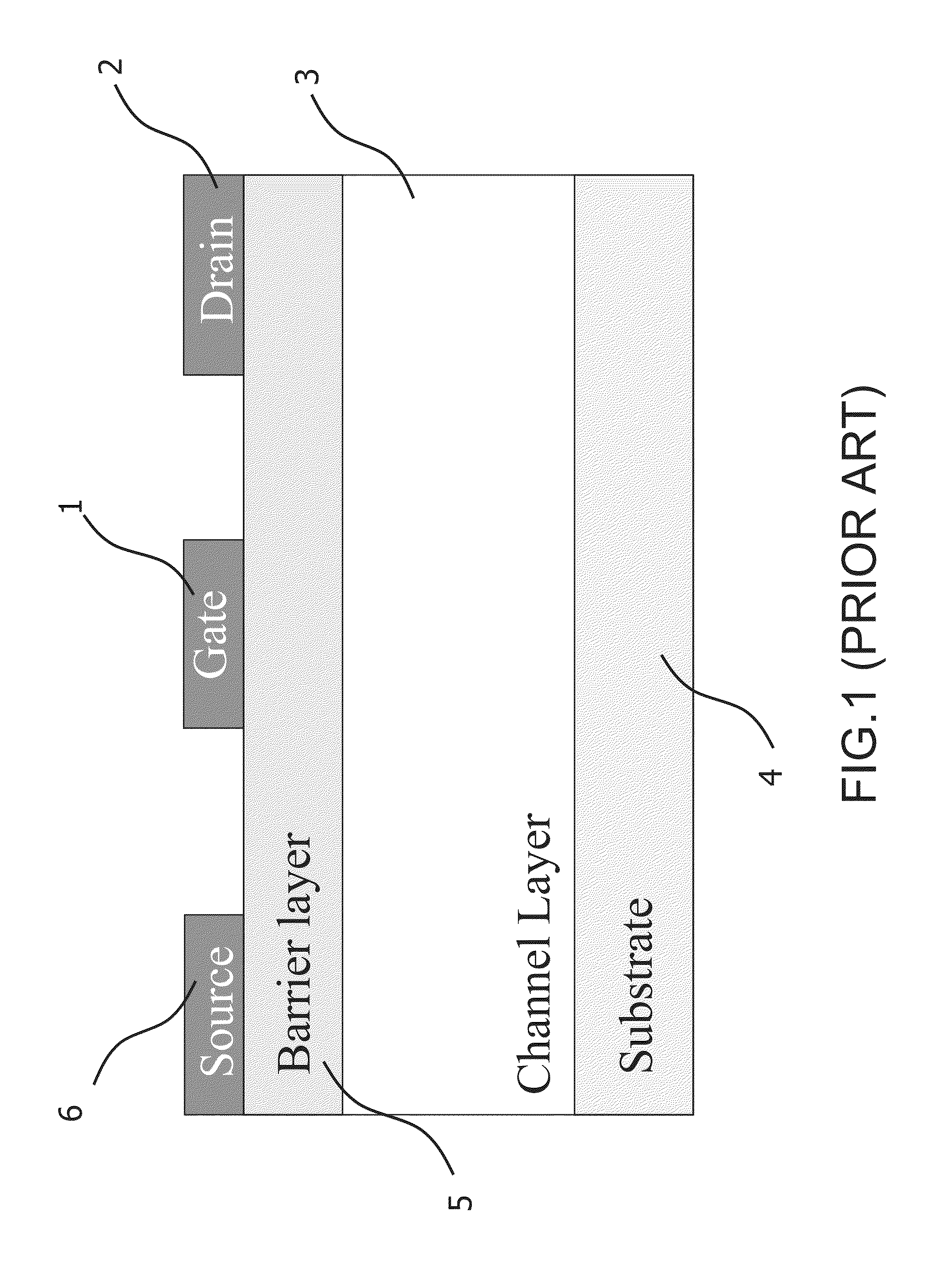

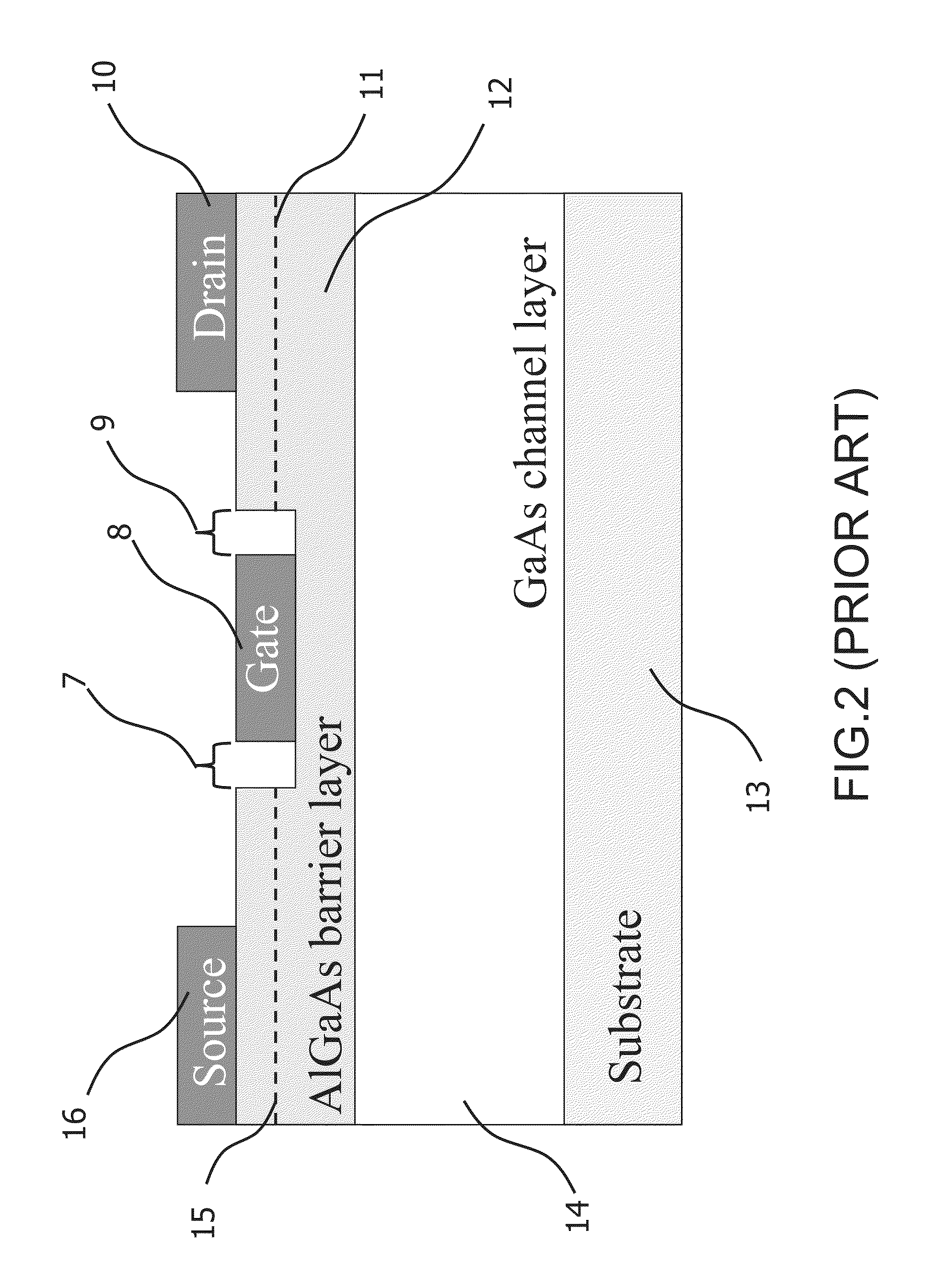

E-mode hfet device

ActiveUS20130161698A1Reduce gate leakage currentEasy to operateTransistorSemiconductor/solid-state device manufacturingGate currentShort-channel effect

Owner:QUALCOMM INC

Borderless contact for replacement gate employing selective deposition

ActiveUS20120126295A1TransistorSemiconductor/solid-state device manufacturingElectrical ShortingOxide

Owner:AURIGA INNOVATIONS INC

Method of manufacturing a cover of a backlit display using fluorescing materials

InactiveUS6905901B1Avoid passingAvoid choiceAircraft componentsInstrument arrangements/adaptationsFluorescenceDisplay device

A backlit display allowing one or more colors to be properly illuminated. Included in the backlit display is a light source that emits light upon a backside of a substrate. A selectively applied opaque layer prevents light from a light source from passing through at least one selected portion of said substrate. Incorporated into the substrate is one or more fluorescing materials to diffuse the light and / or change the color of the light emitted from the light source.

Owner:APTIV TECH LTD

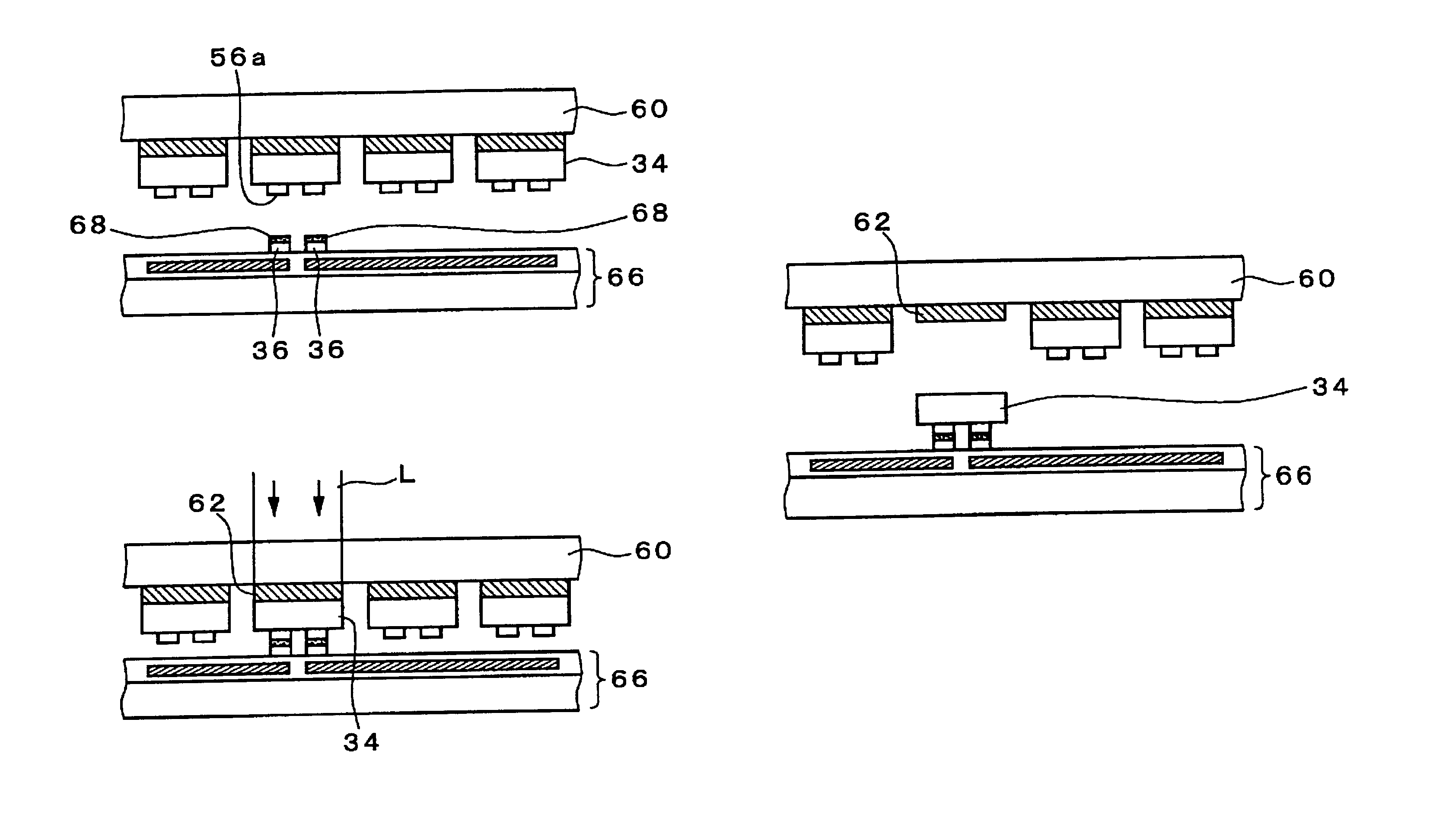

Organic light emitting display panel and manufacturing method

ActiveCN106449702APrevent peelingImprove adhesionFinal product manufactureSolid-state devicesOptoelectronicsSurface plate

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

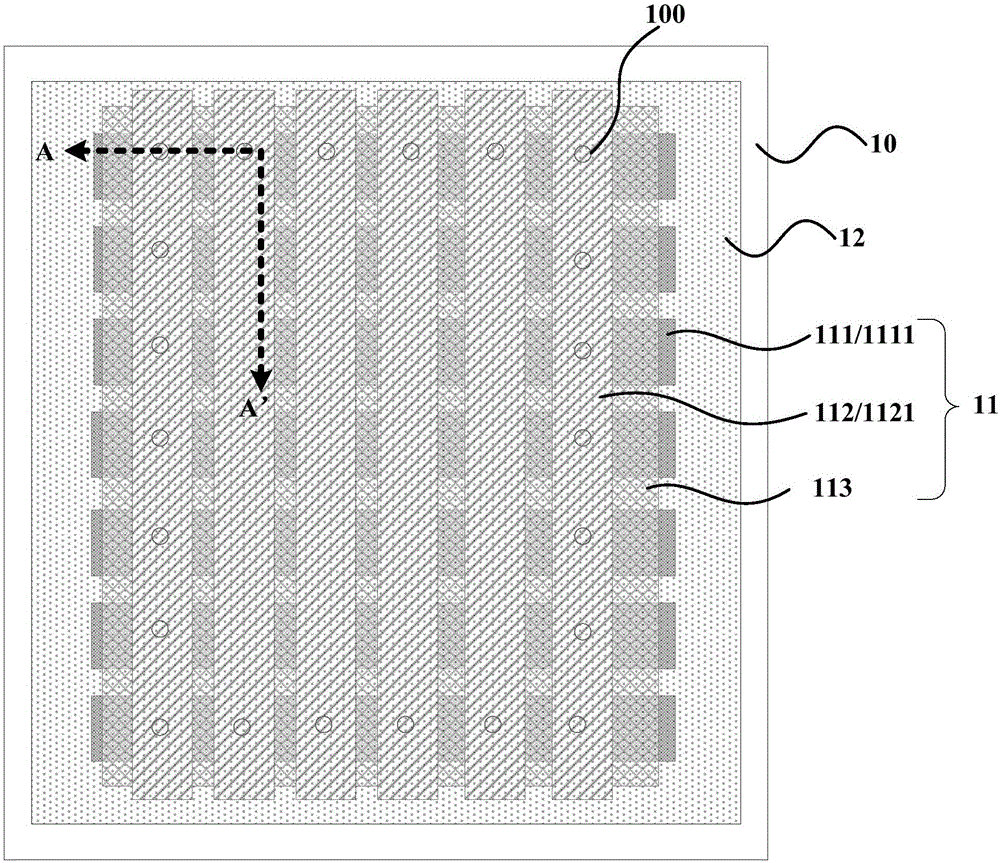

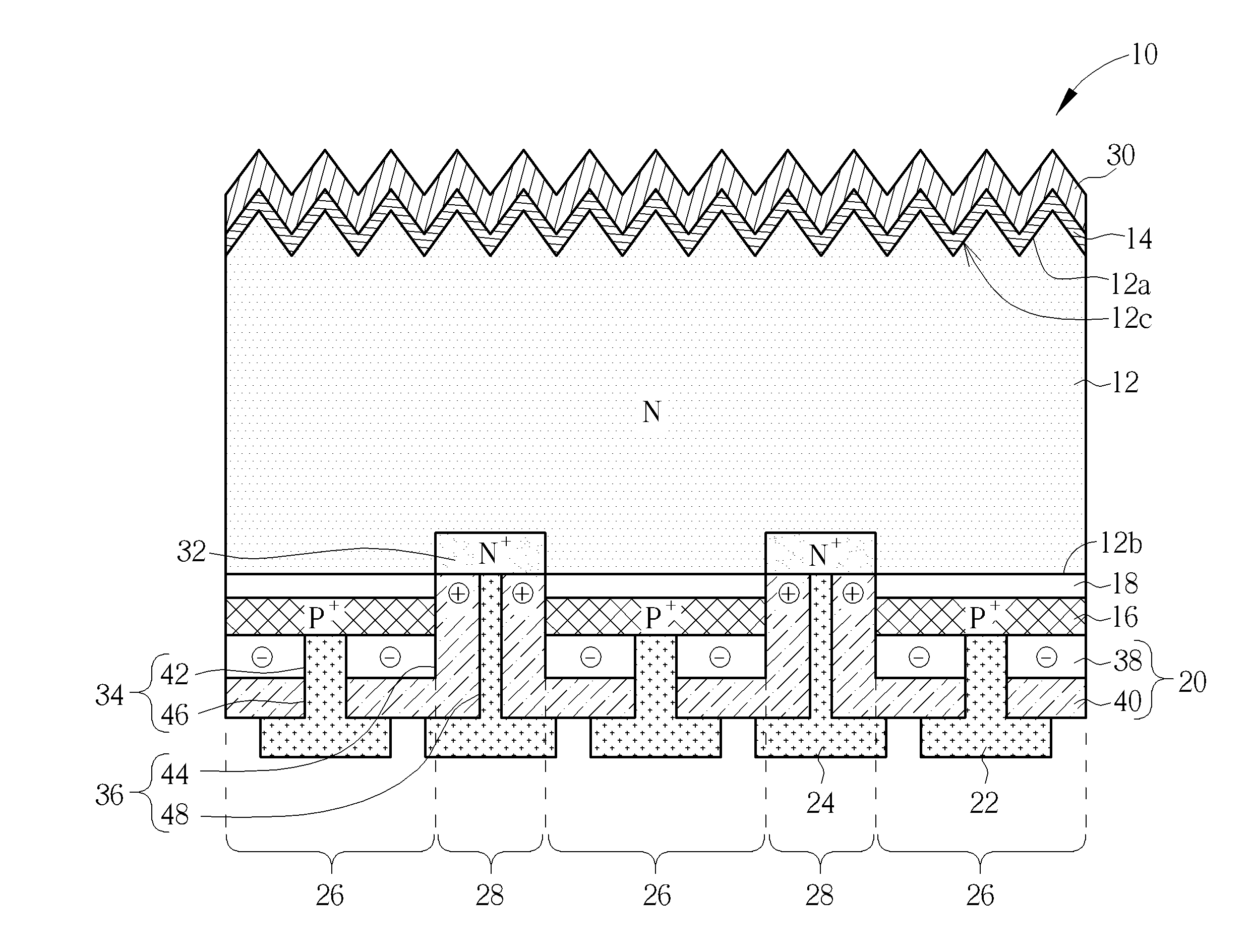

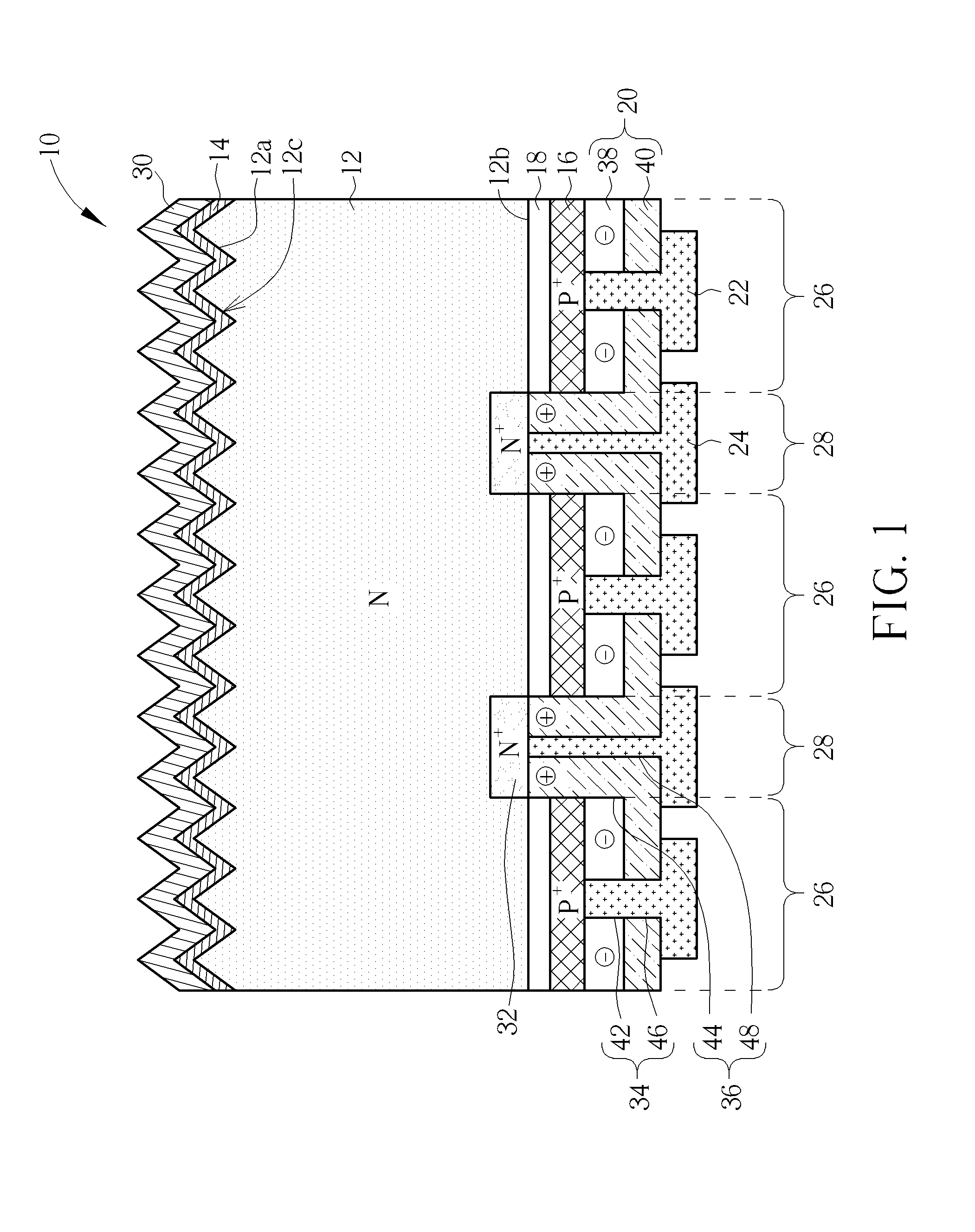

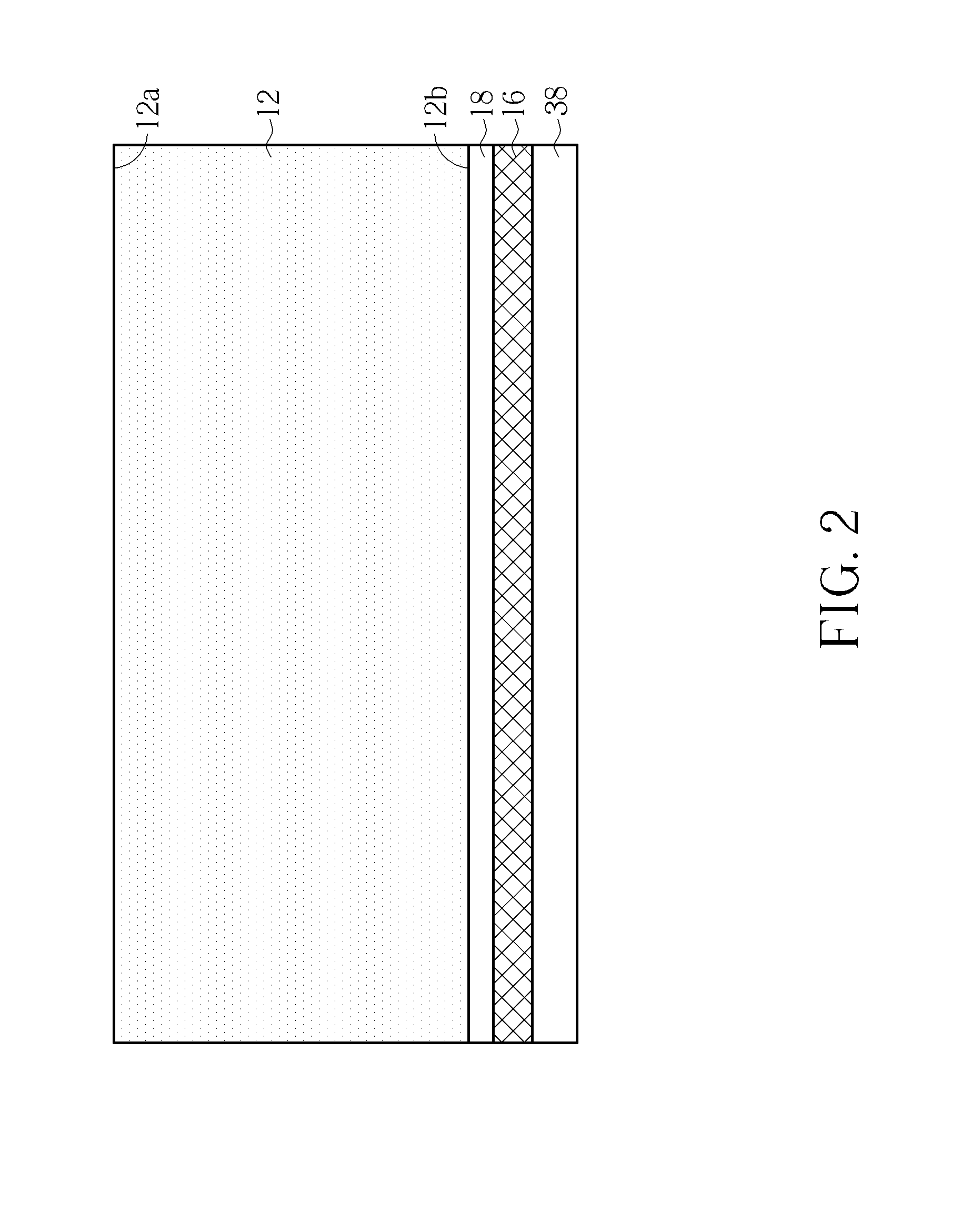

Solar cell and method for making thereof

ActiveUS20140096821A1Reduce generationImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSemiconductor

Owner:AU OPTRONICS CORP

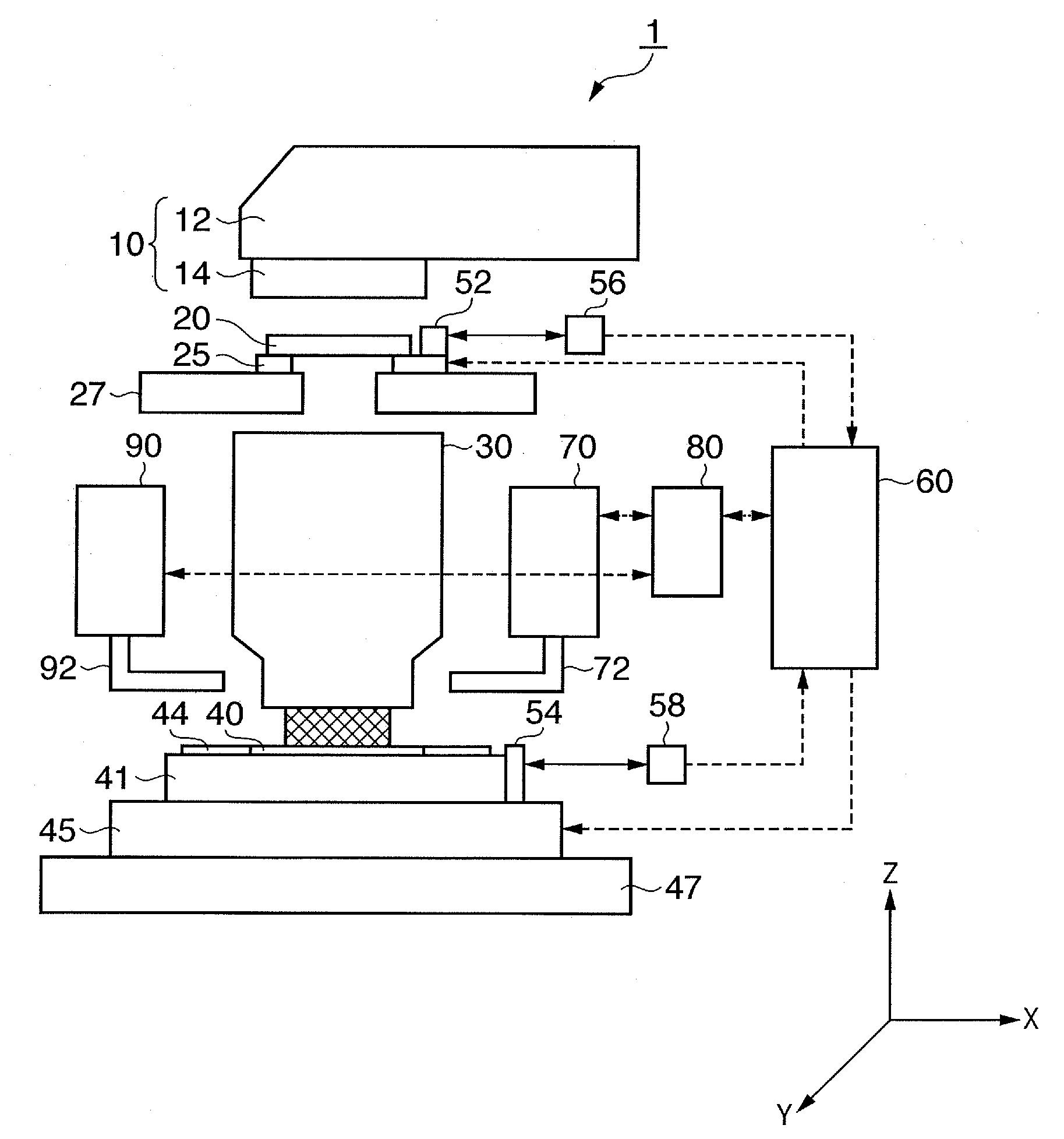

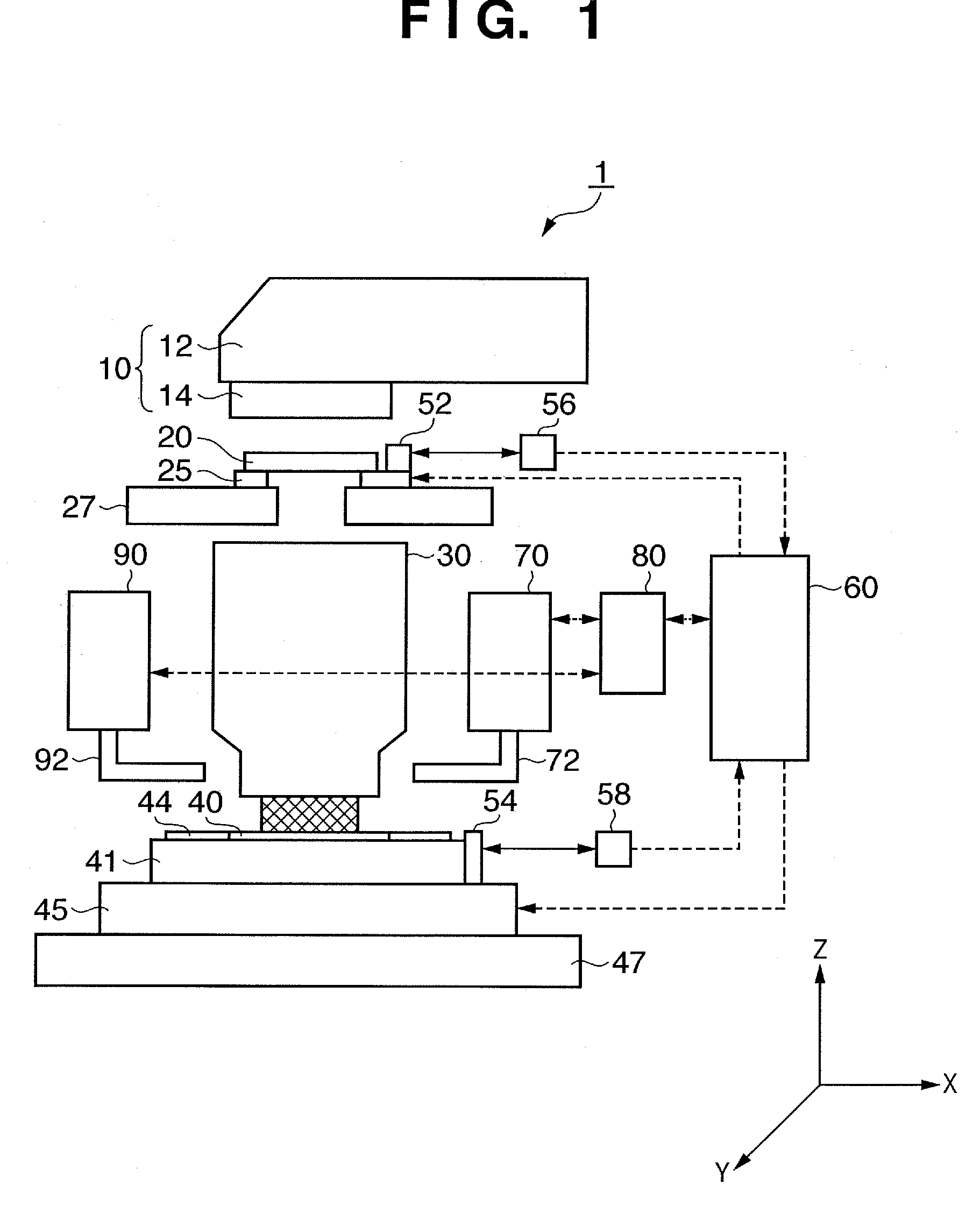

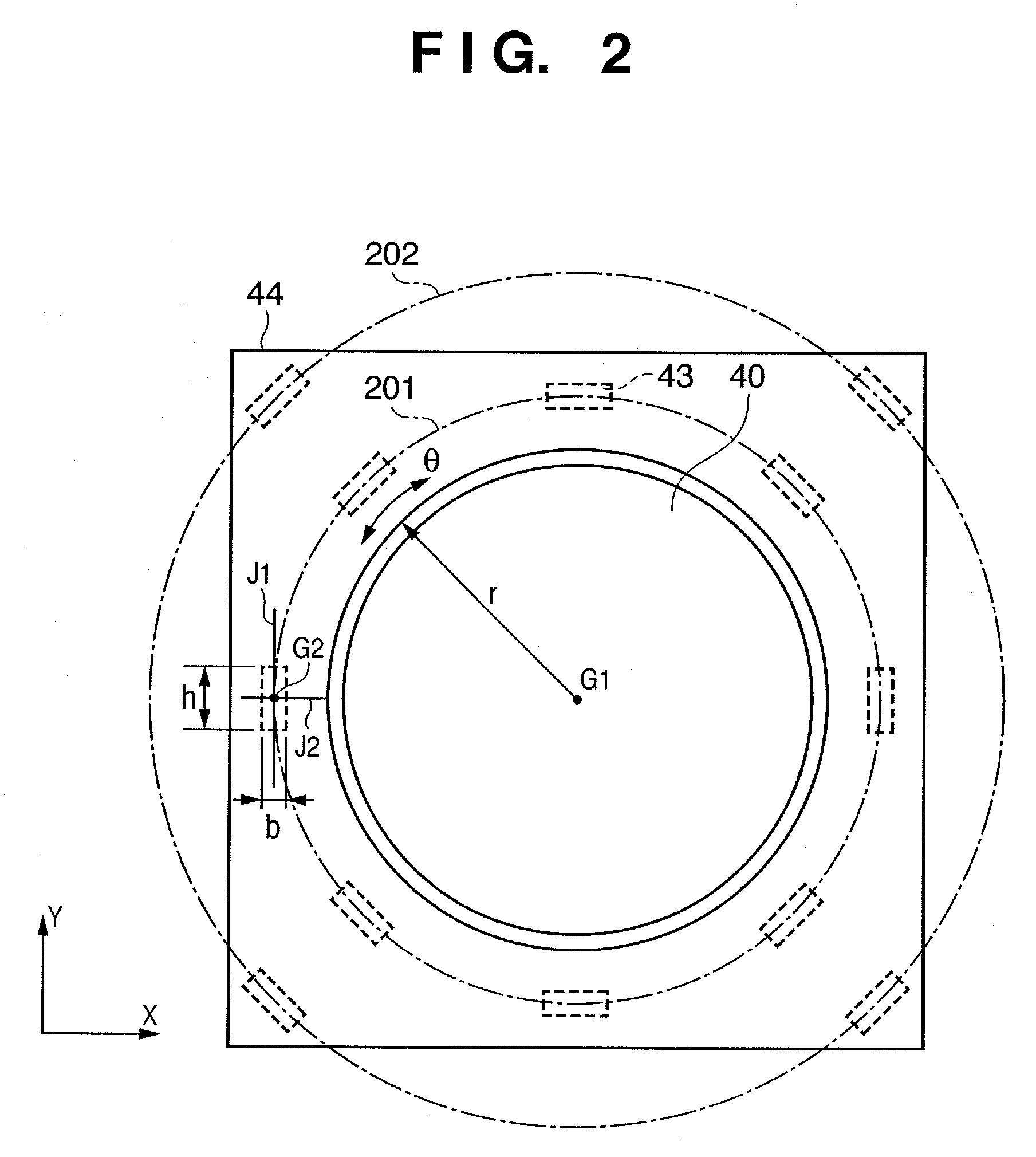

Exposure apparatus

InactiveUS20070229787A1Reduce distortionInfluence of thermal deformationLiquid processingPhotomechanical apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

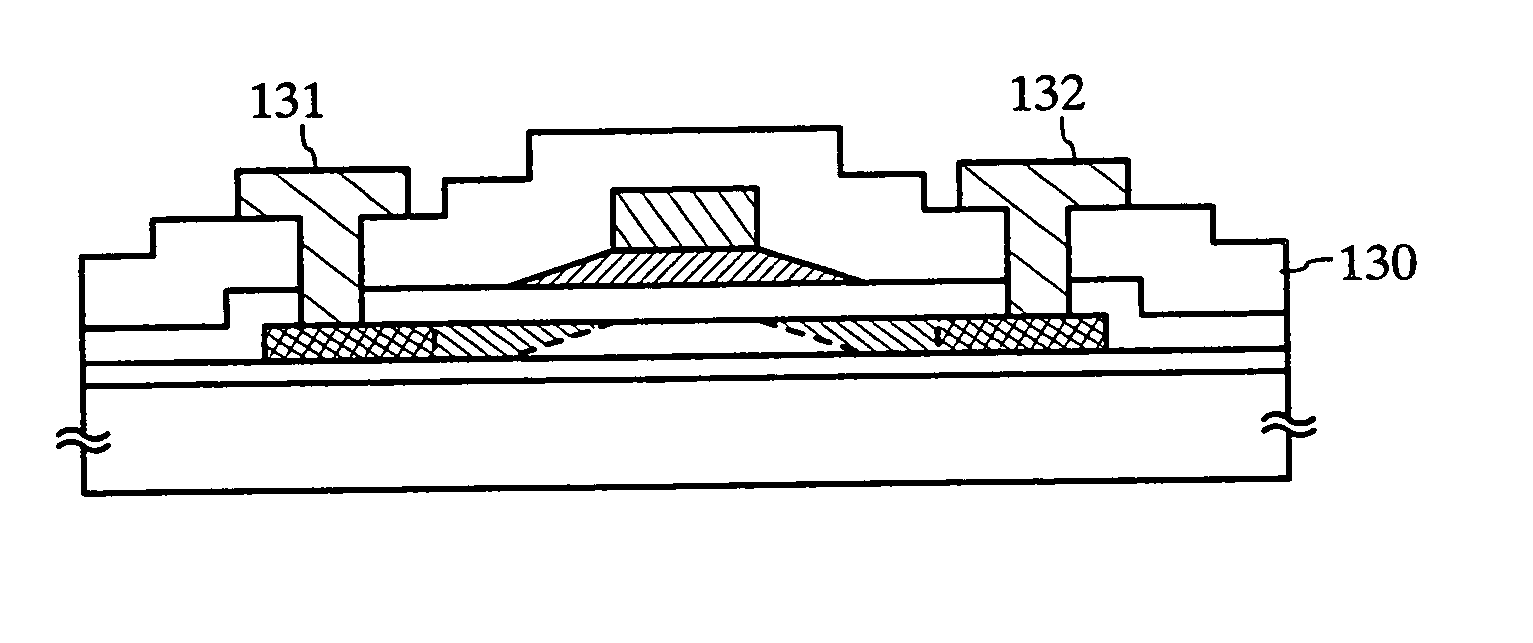

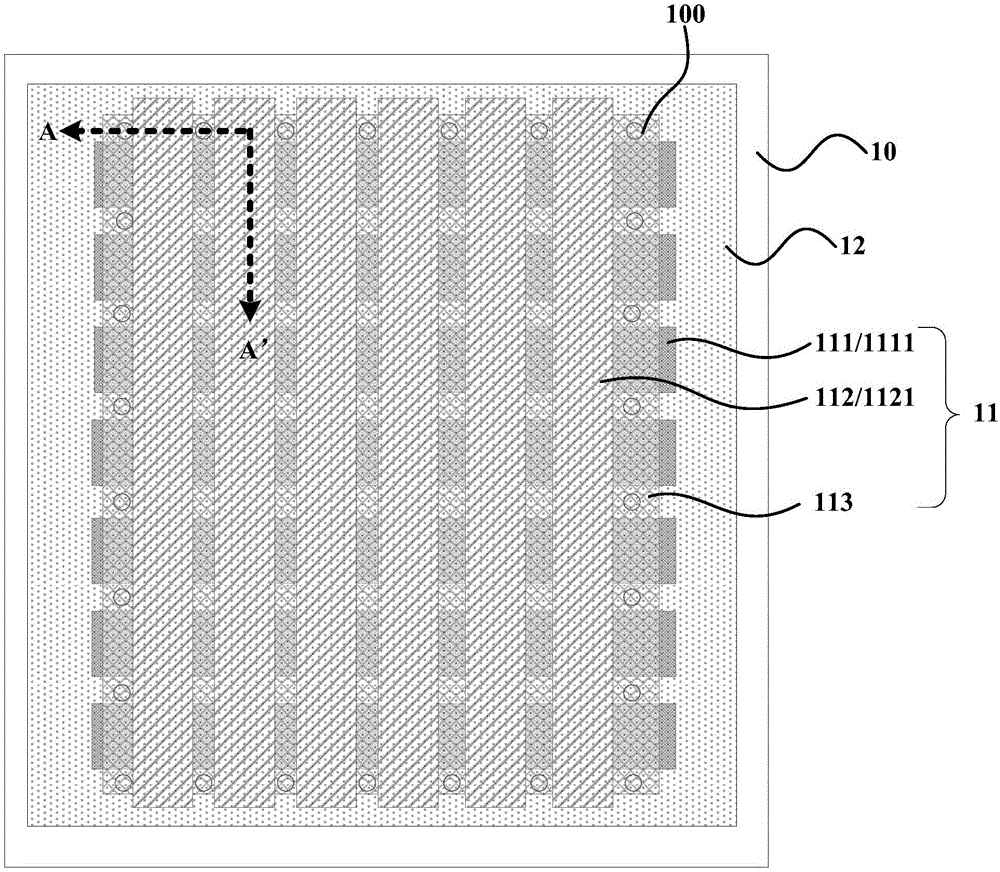

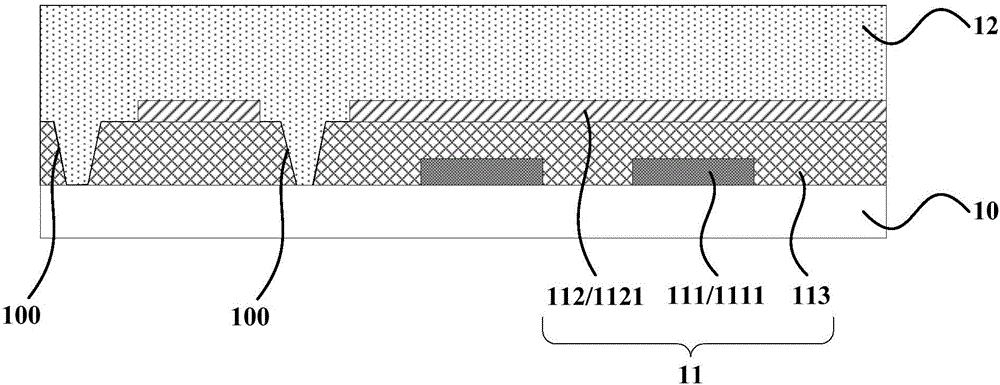

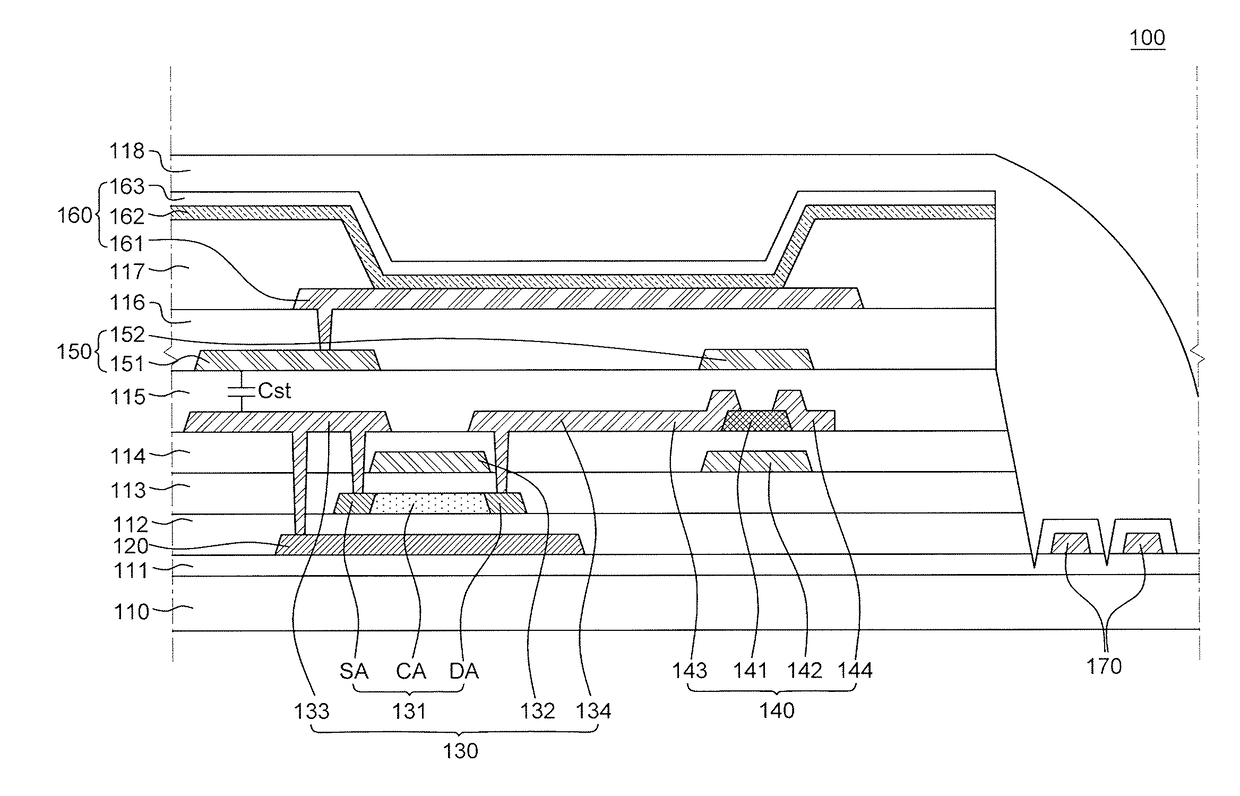

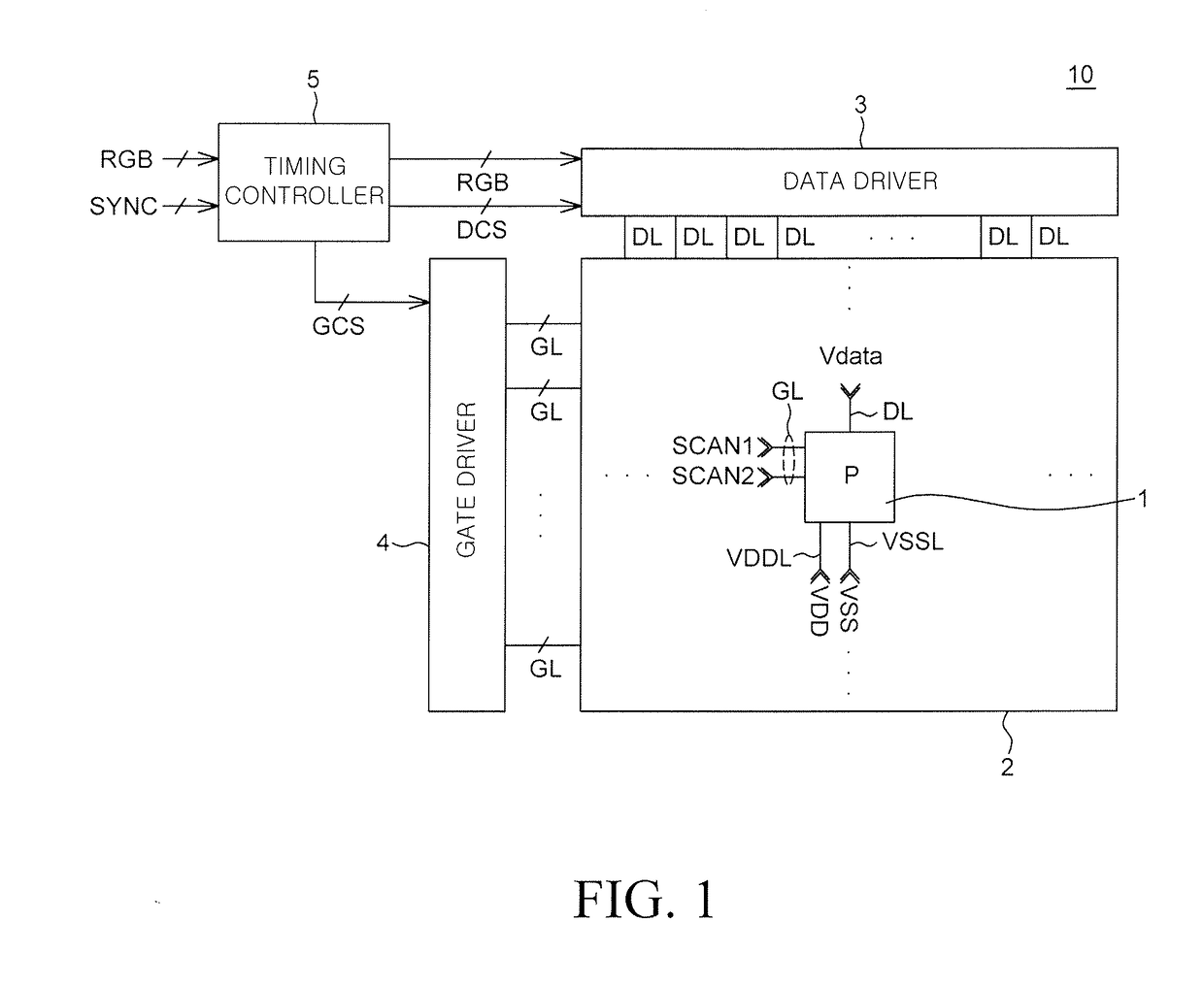

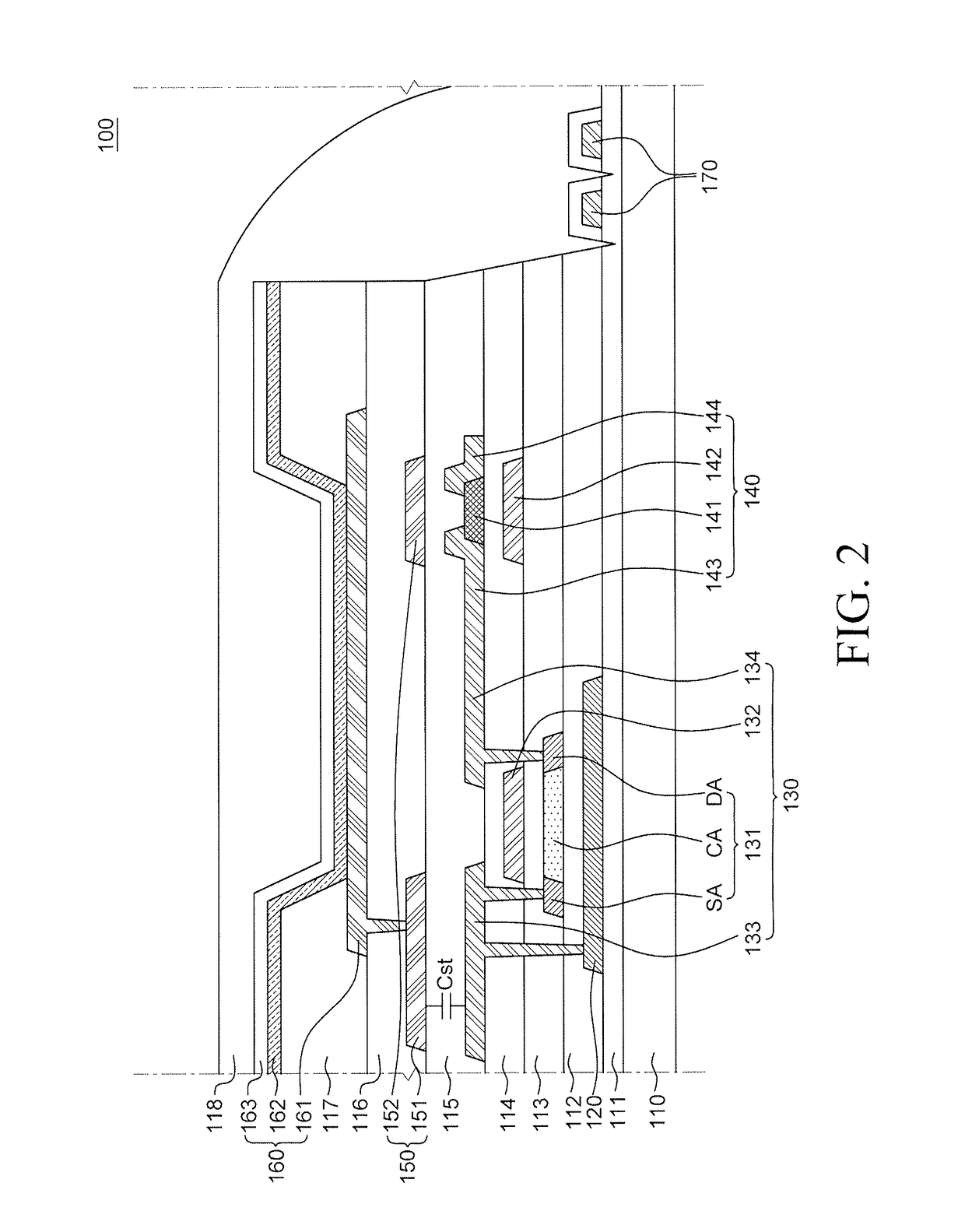

Hybrid thin film transistor and organic light emitting display device using the same

ActiveUS20180033849A1Reduce power consumptionImprove bias temperature stressSolid-state devicesSemiconductor/solid-state device manufacturingPolycrystalline siliconOptoelectronics

Owner:LG DISPLAY CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap