Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Single crystal growth details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for perfecting the active regions of wide bandgap semiconductor nitride devices

InactiveUS20050164475A1Lower average currentHigh densityPolycrystalline material growthFrom solid stateEngineeringNitride

This invention pertains to e lectronic / optoelectronic devices with reduced extended defects and to a method for making it. The method includes the steps of depositing a dielectric thin film mask material on a semiconductor substrate surface; patterning the mask material to form openings therein extending to the substrate surface; growing active material in the openings; removing the mask material to form the device with reduced extended defect density; and depositing electrical contacts on the device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

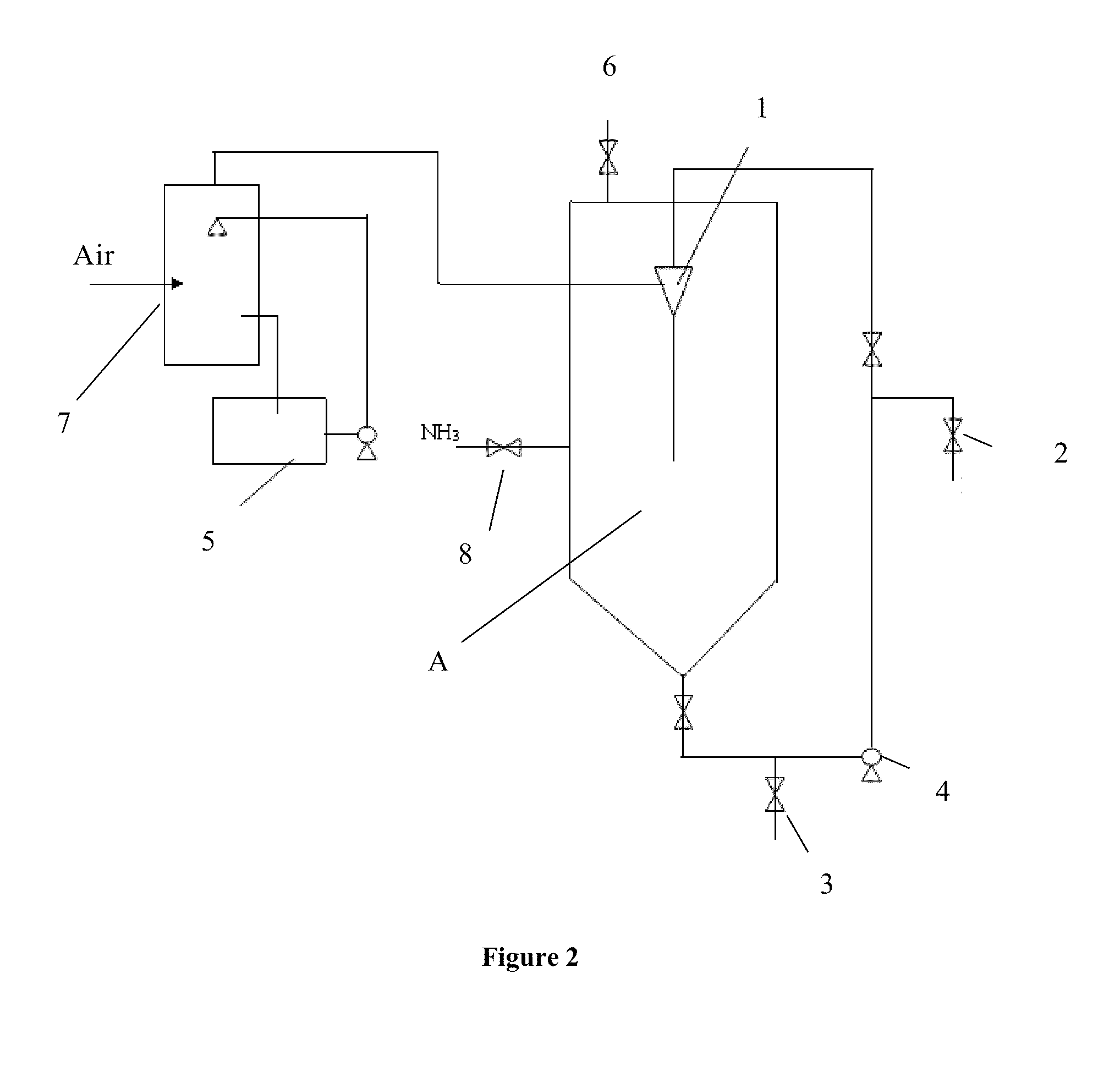

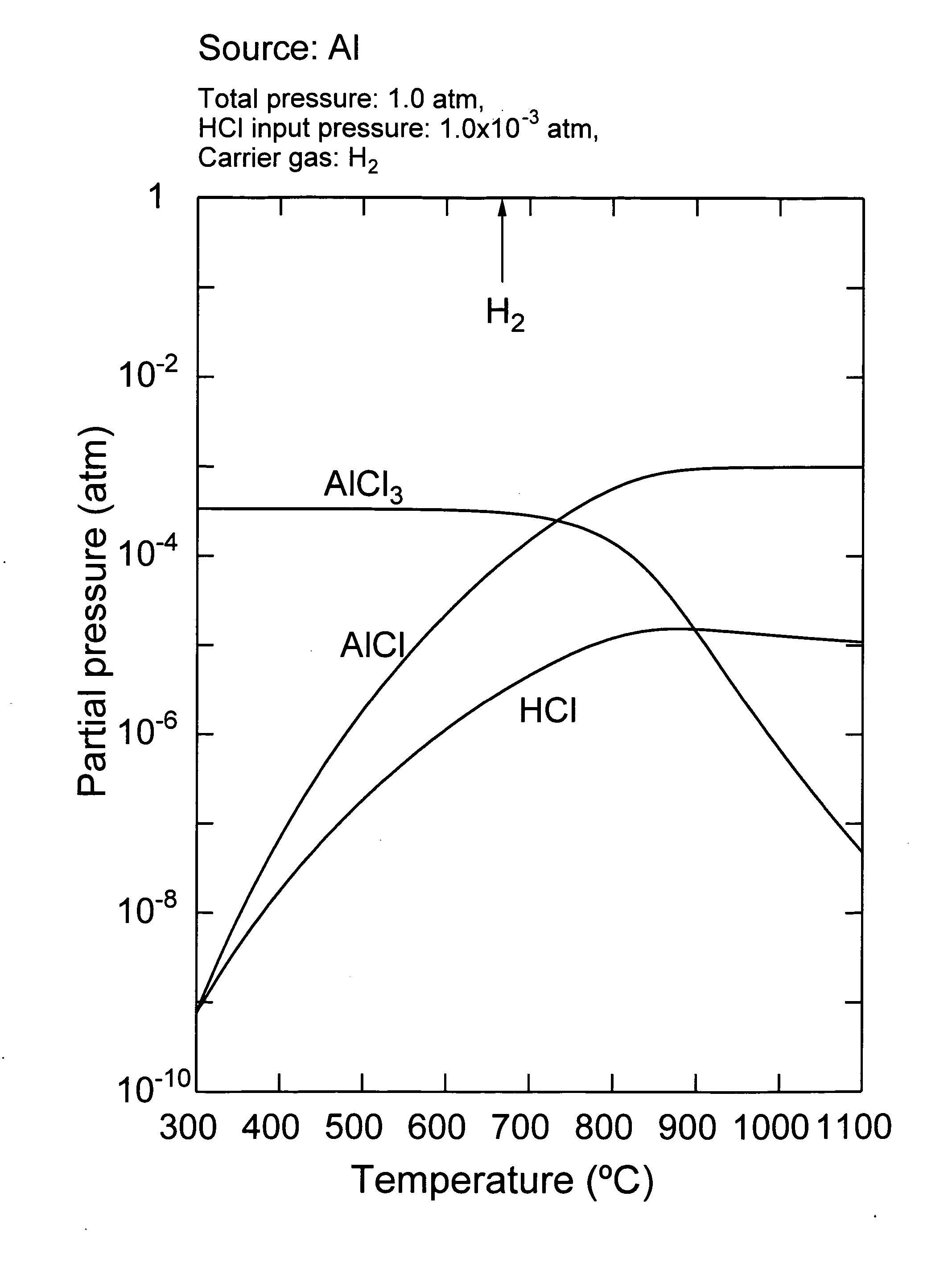

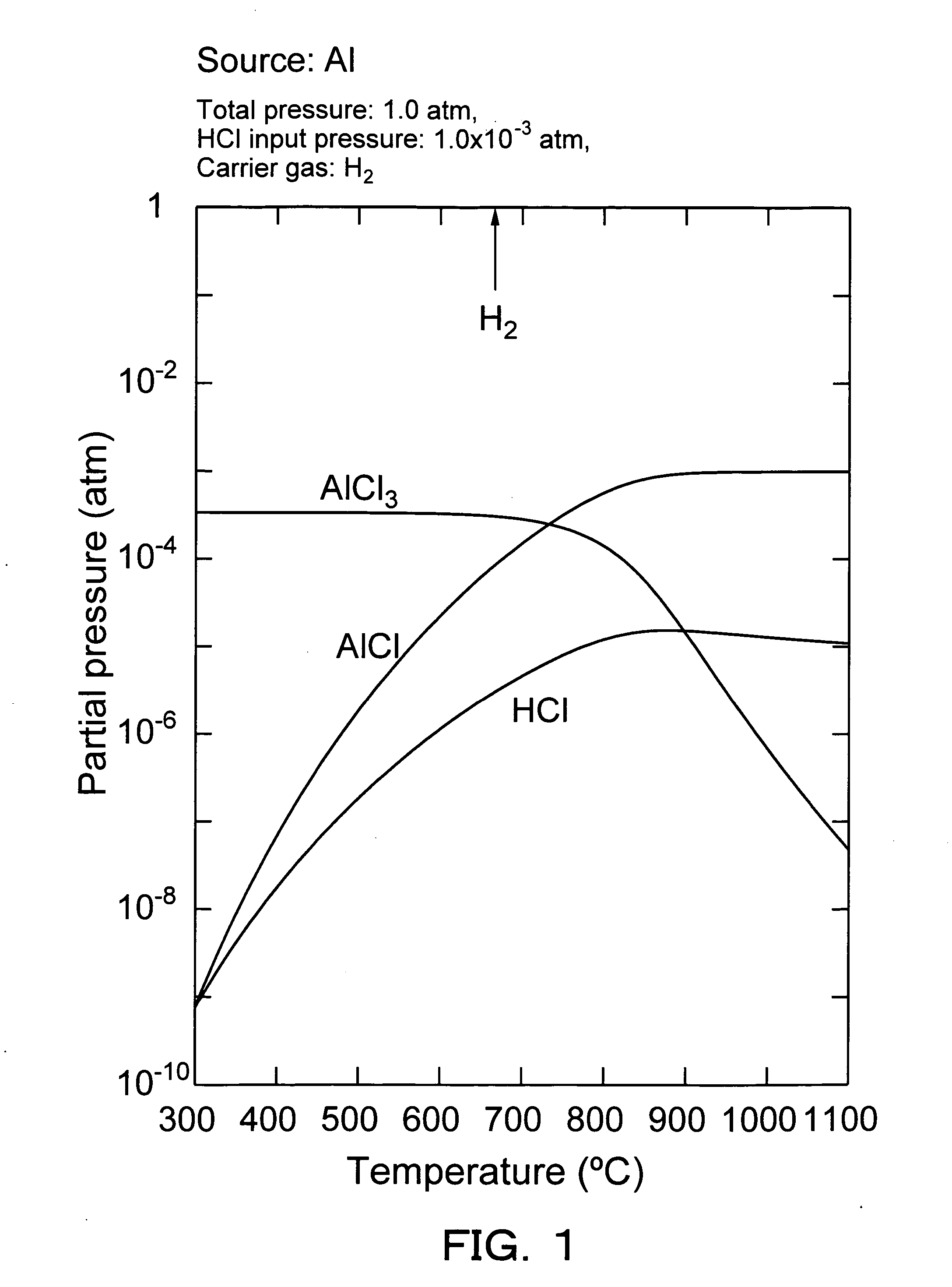

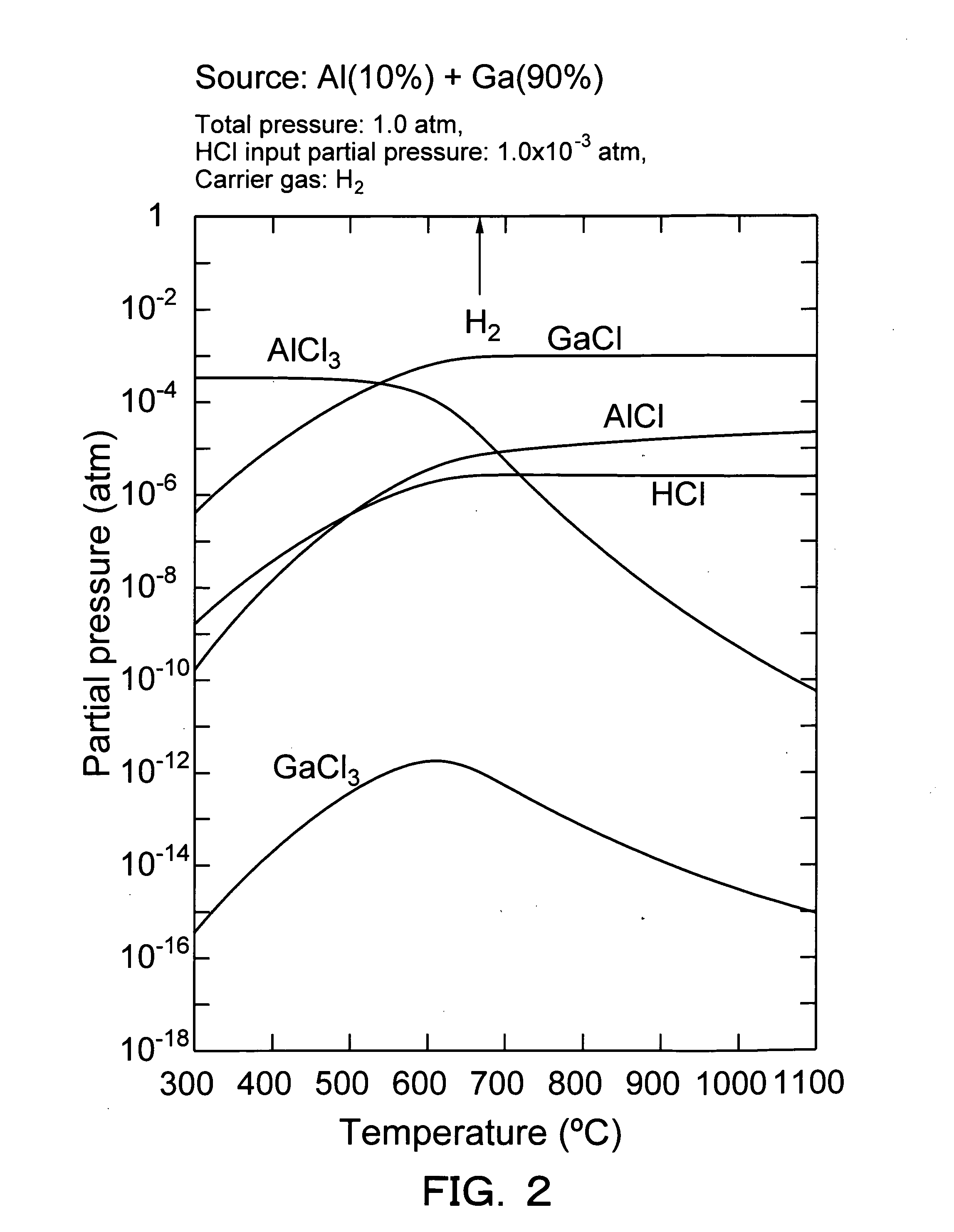

Vapor phase growth method for al-containing III-V group compound semiconductor, and method and device for producing al-containing IIl-V group compound semiconductor

InactiveUS20050166835A1Inhibits the formation of cracksAfter-treatment apparatusPolycrystalline material growthHydrogen halideGas phase

Owner:NOKODAI TLO KK

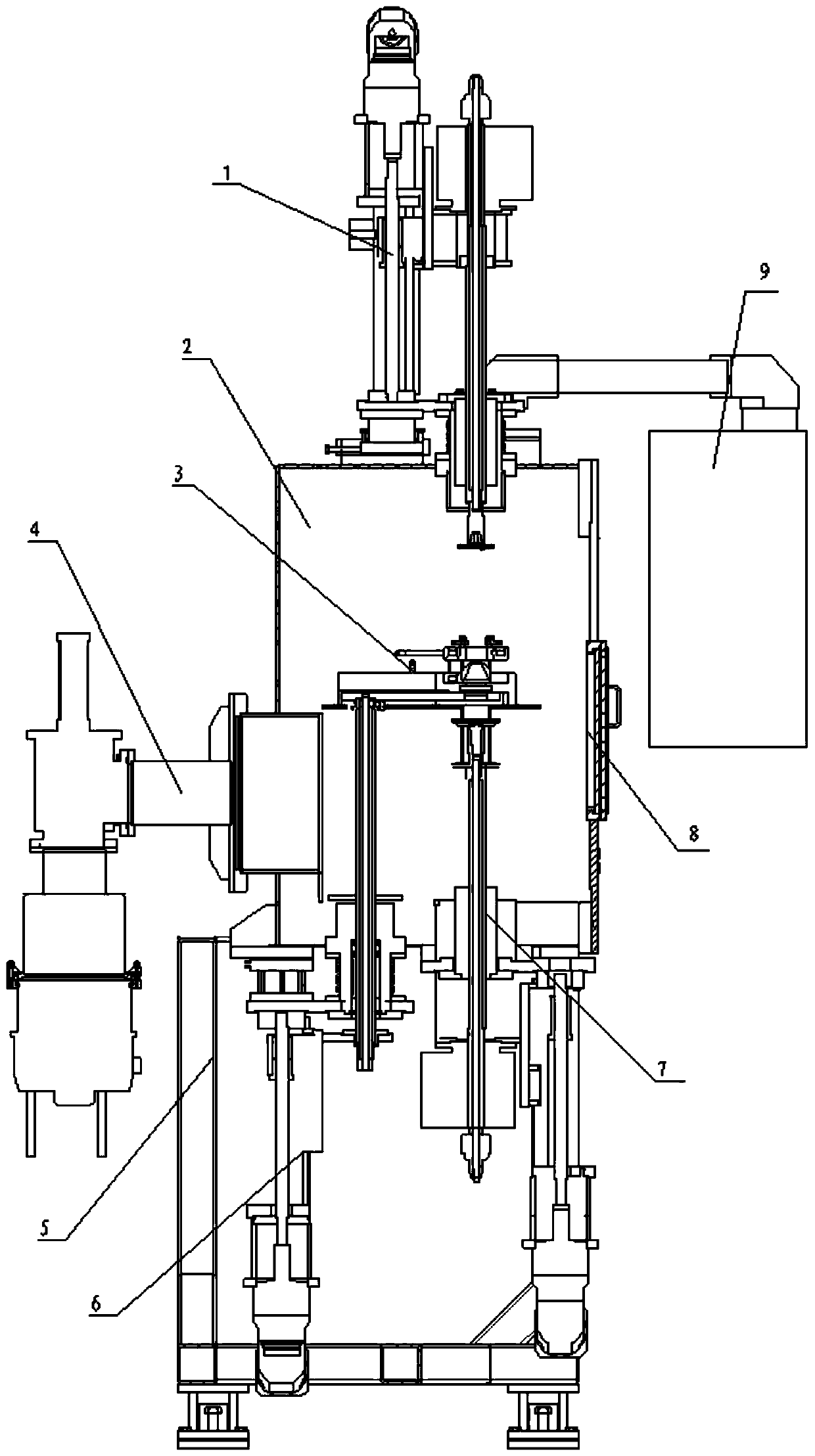

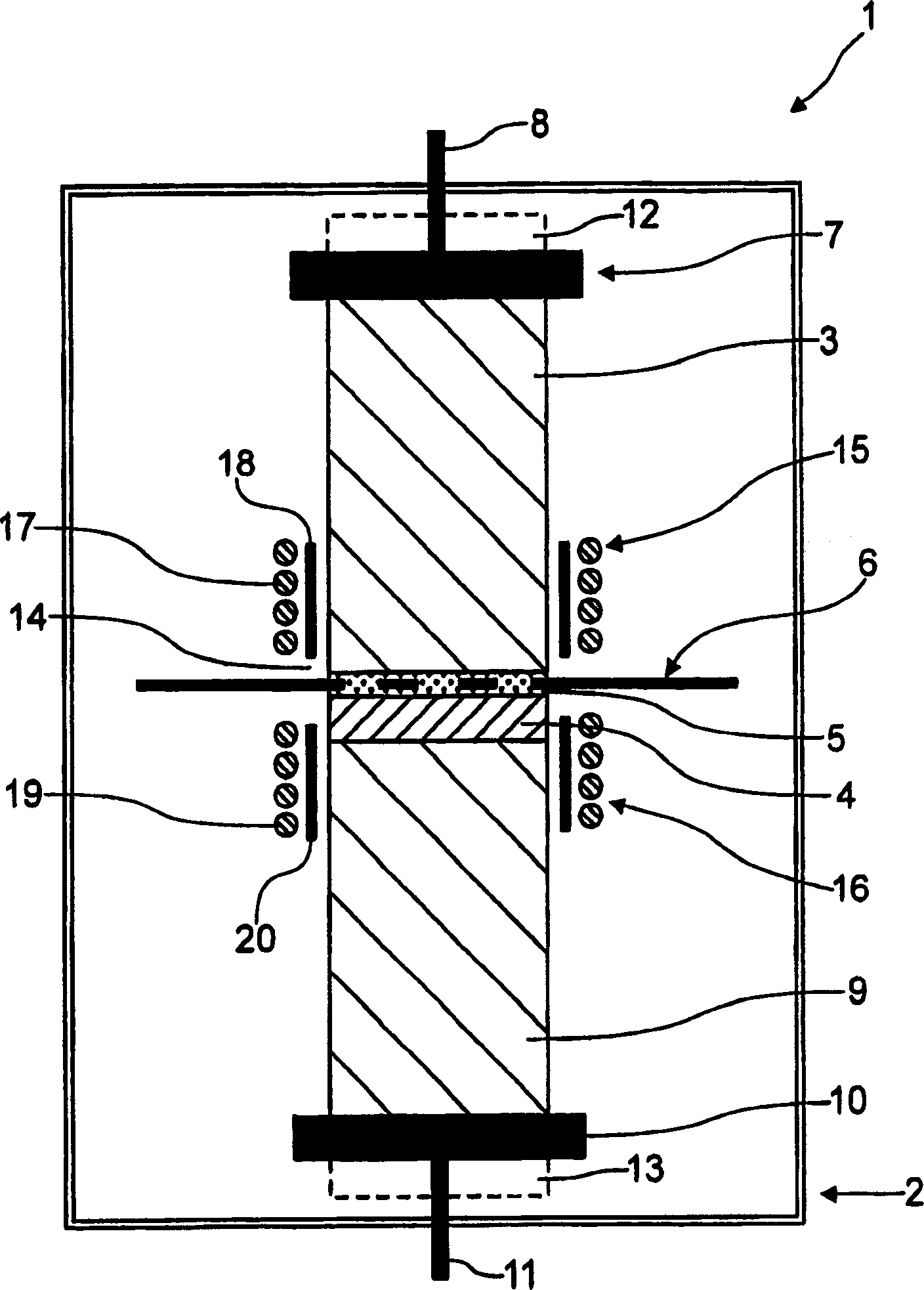

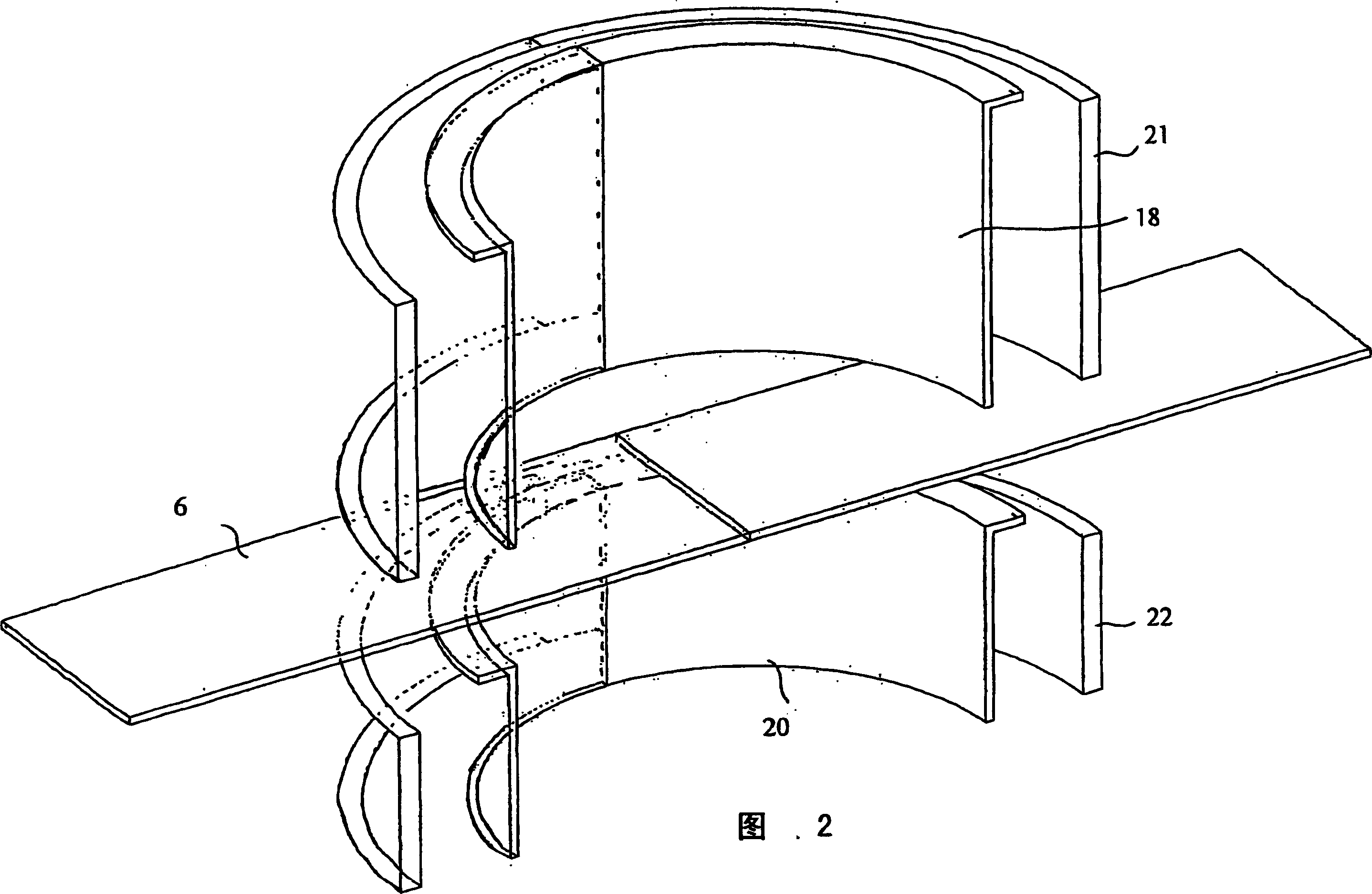

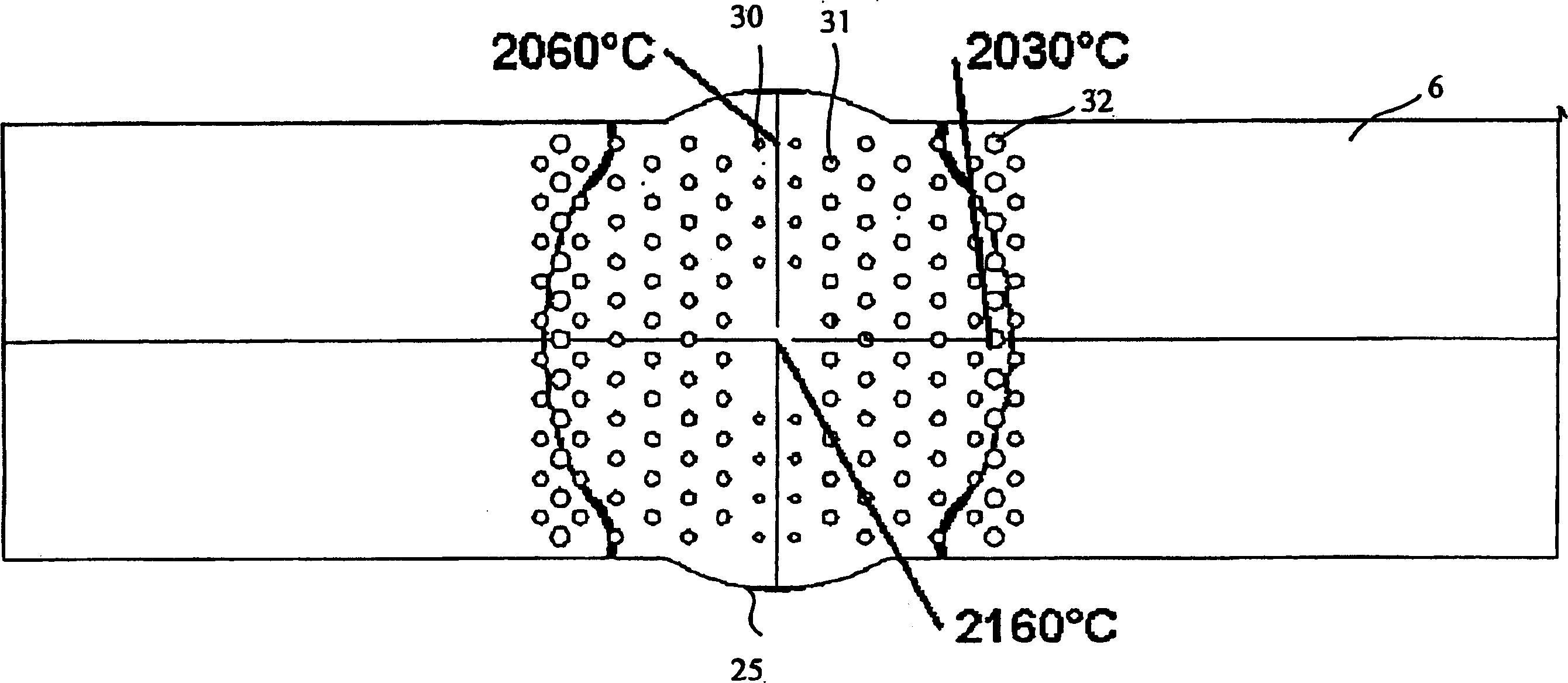

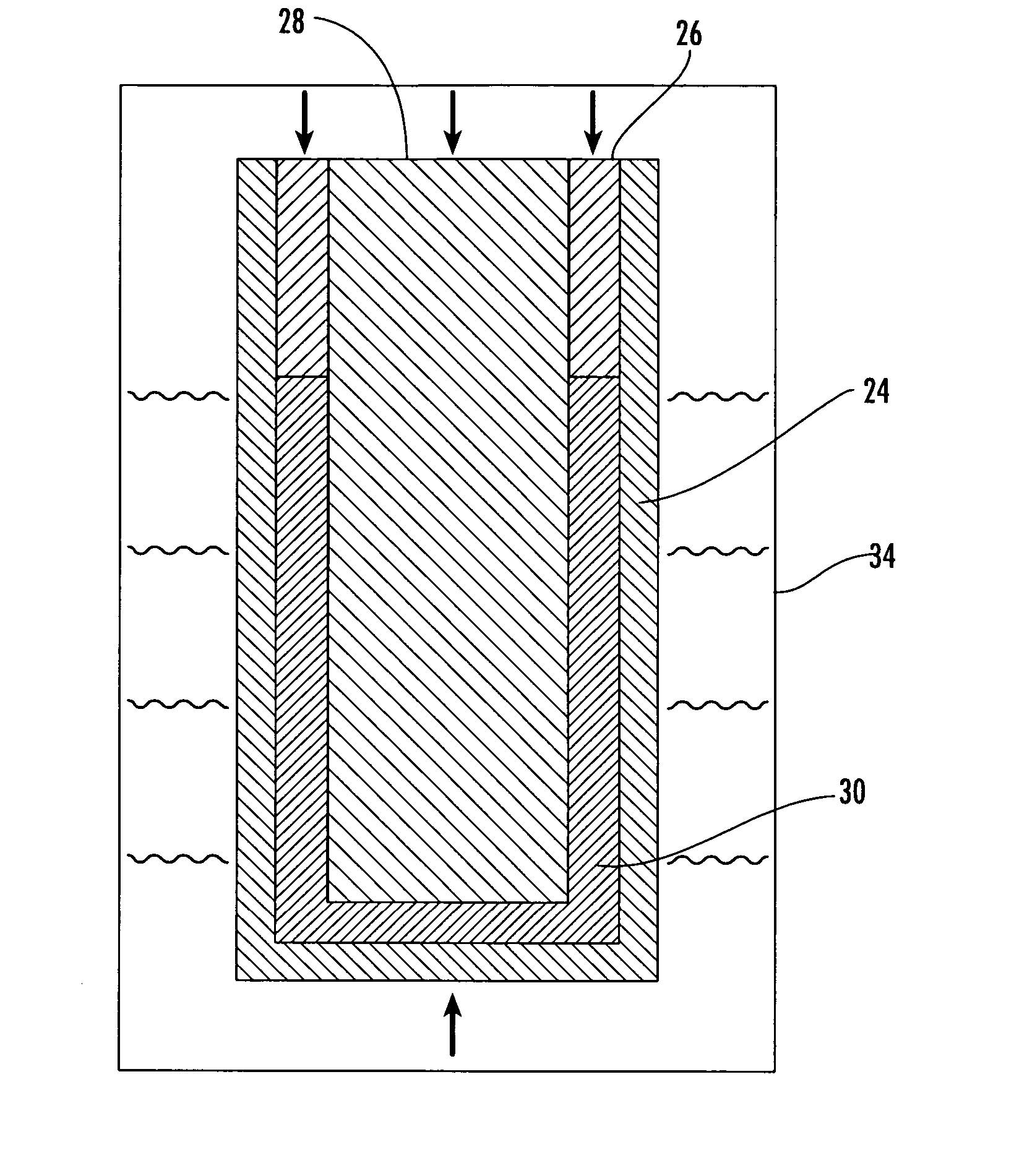

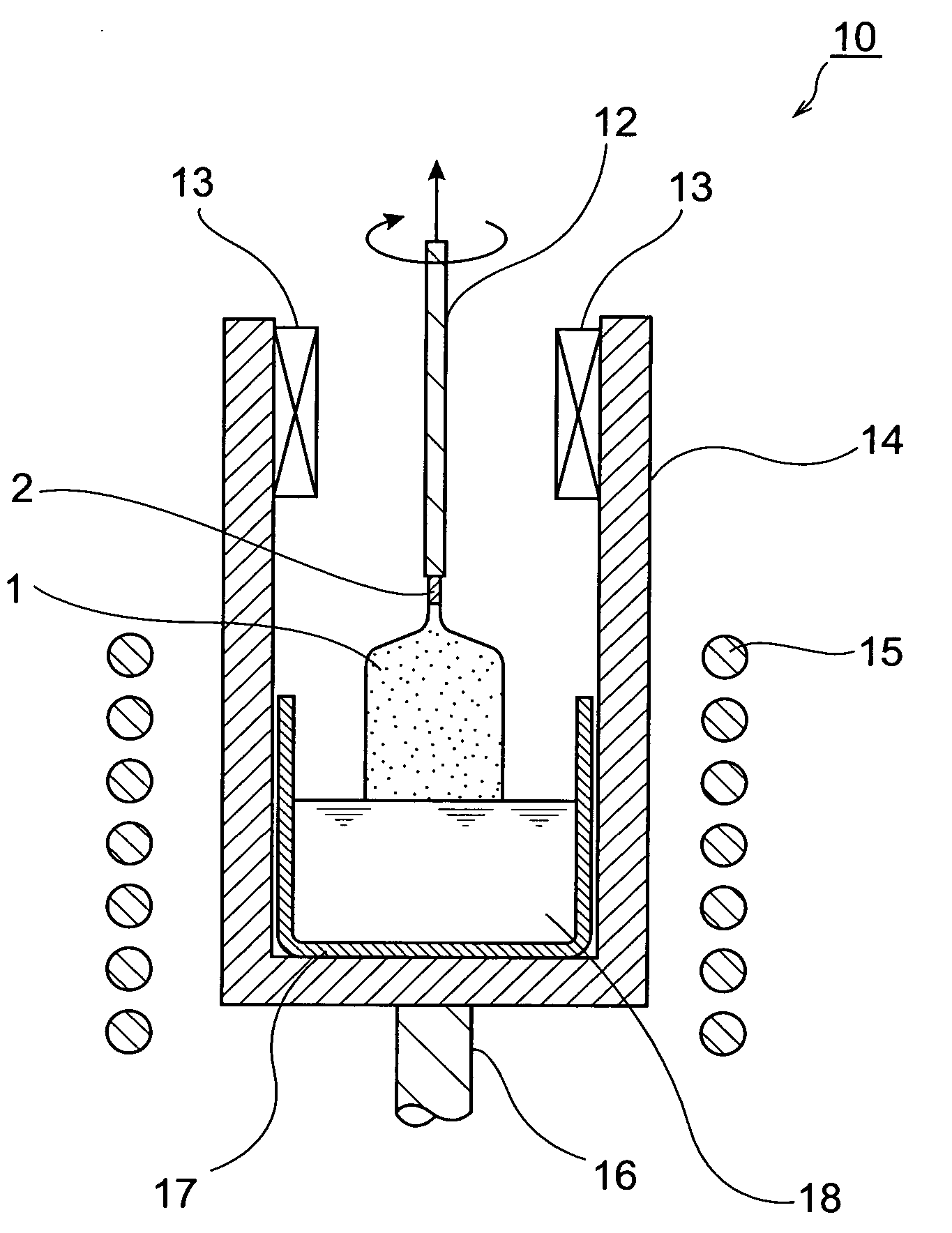

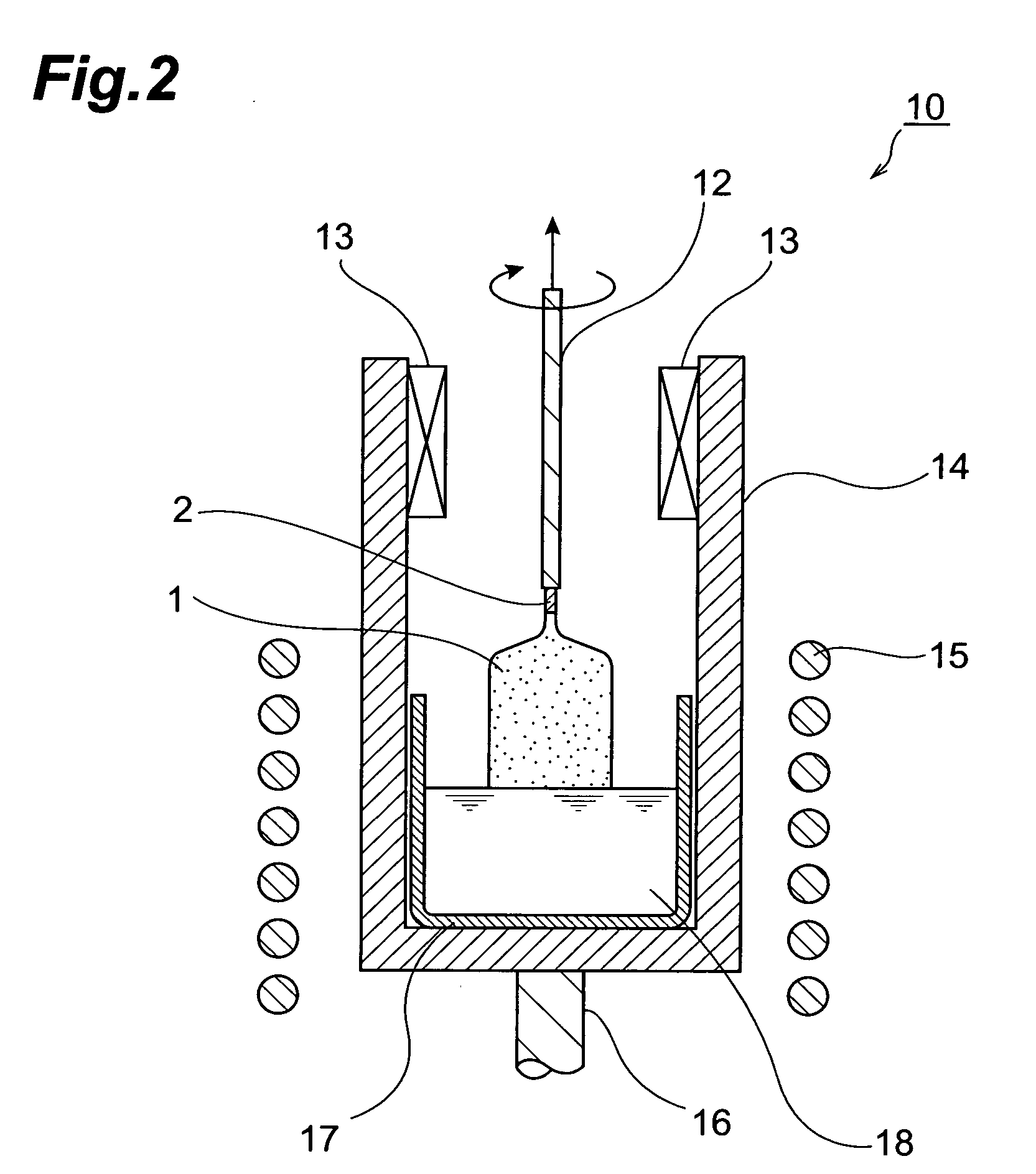

Method and apparatus for preparing major diameter single crystal

InactiveCN1847468AMake up for heat lossHigh Inductive Heat InputPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

Owner:SCHOTT AG

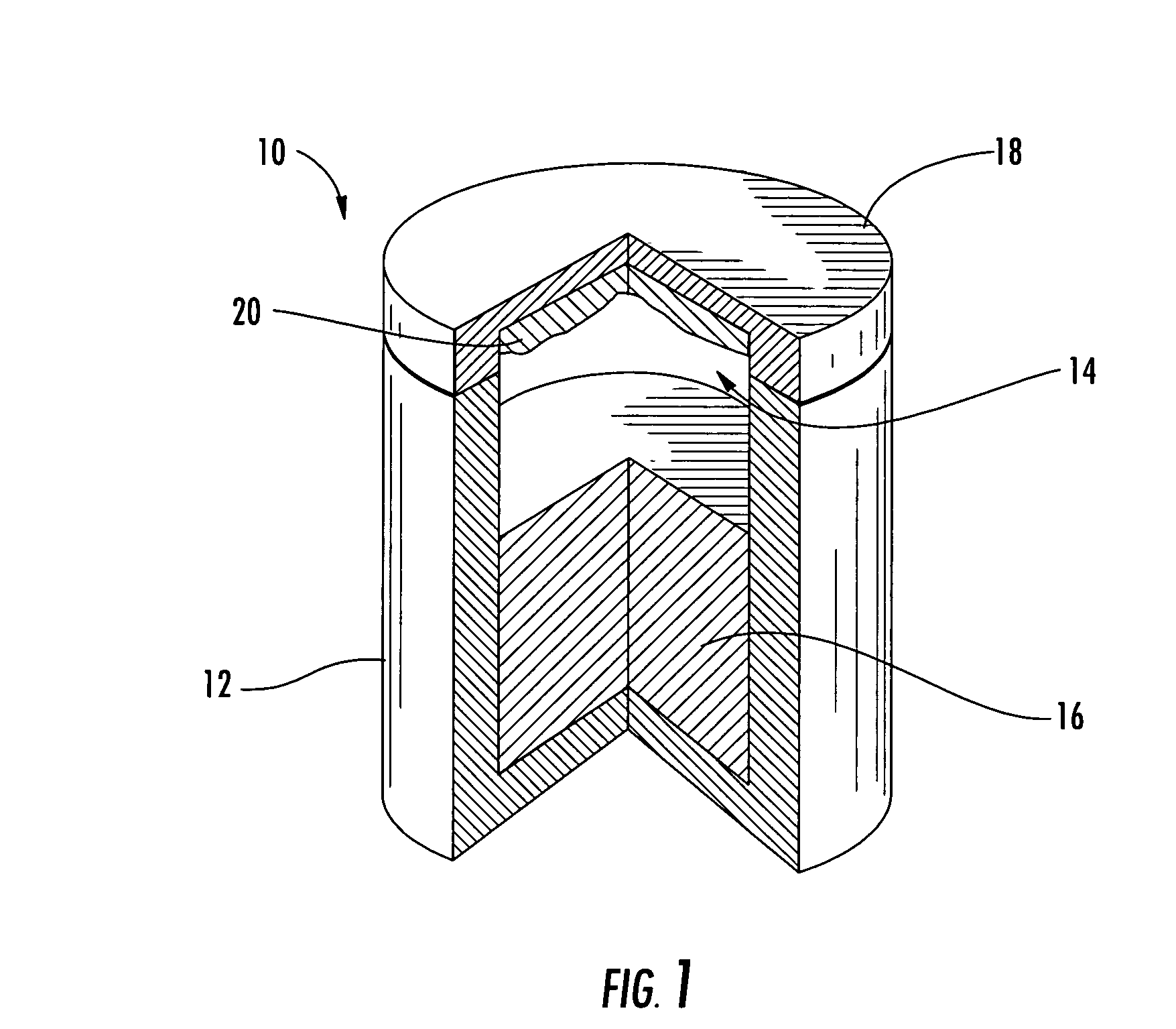

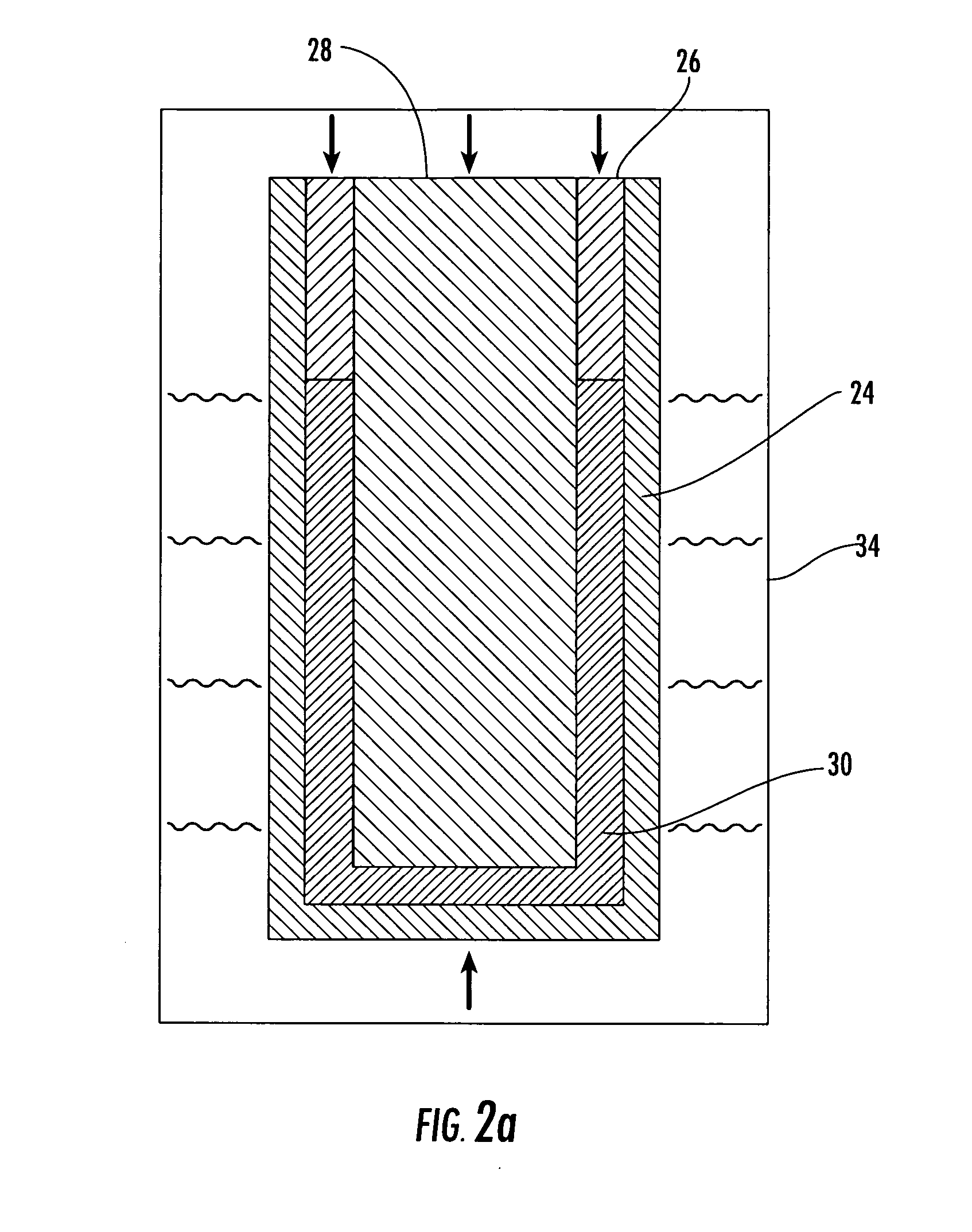

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

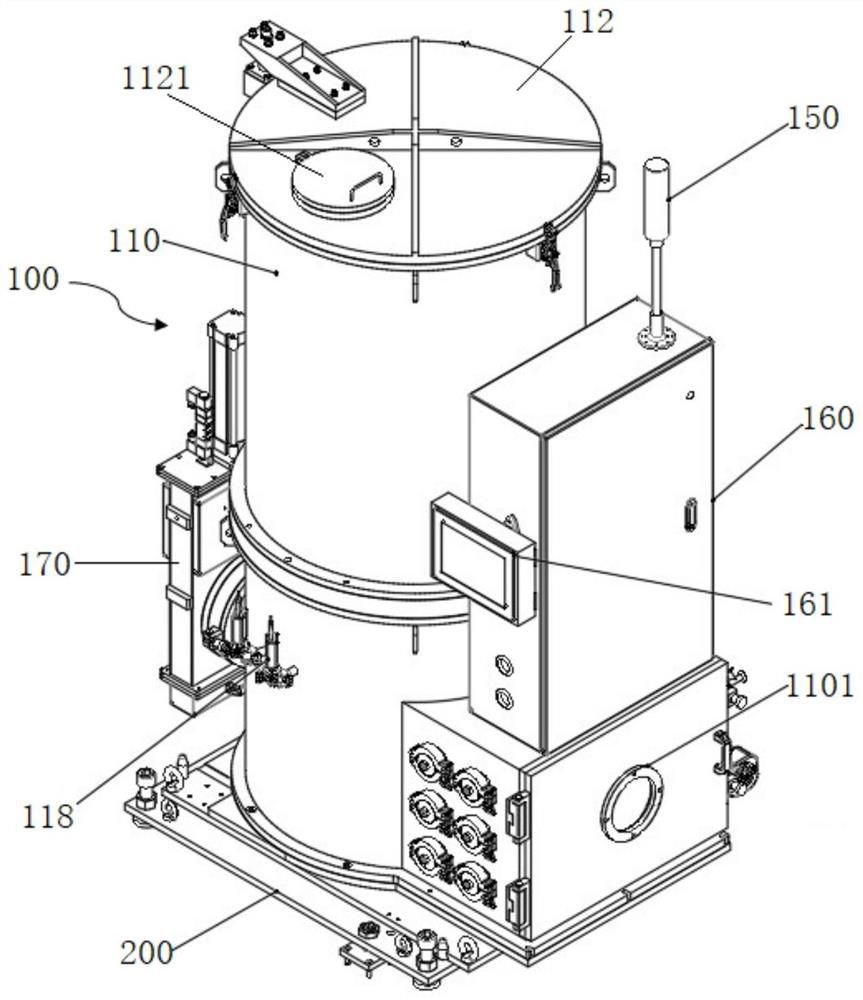

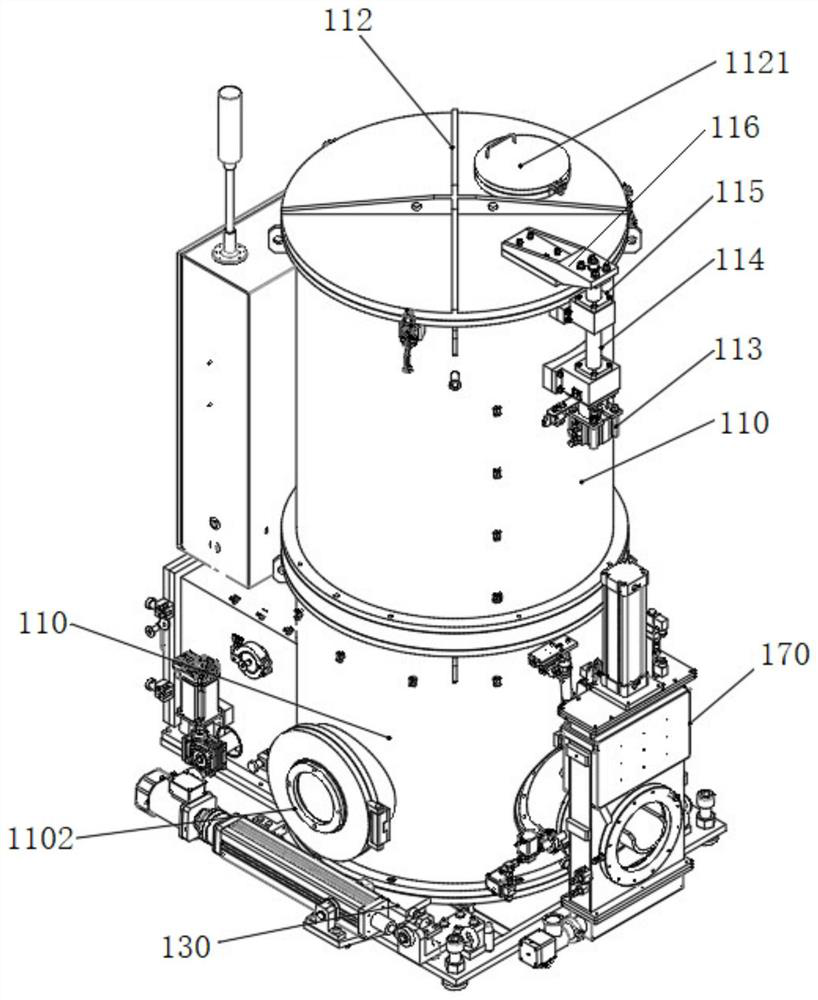

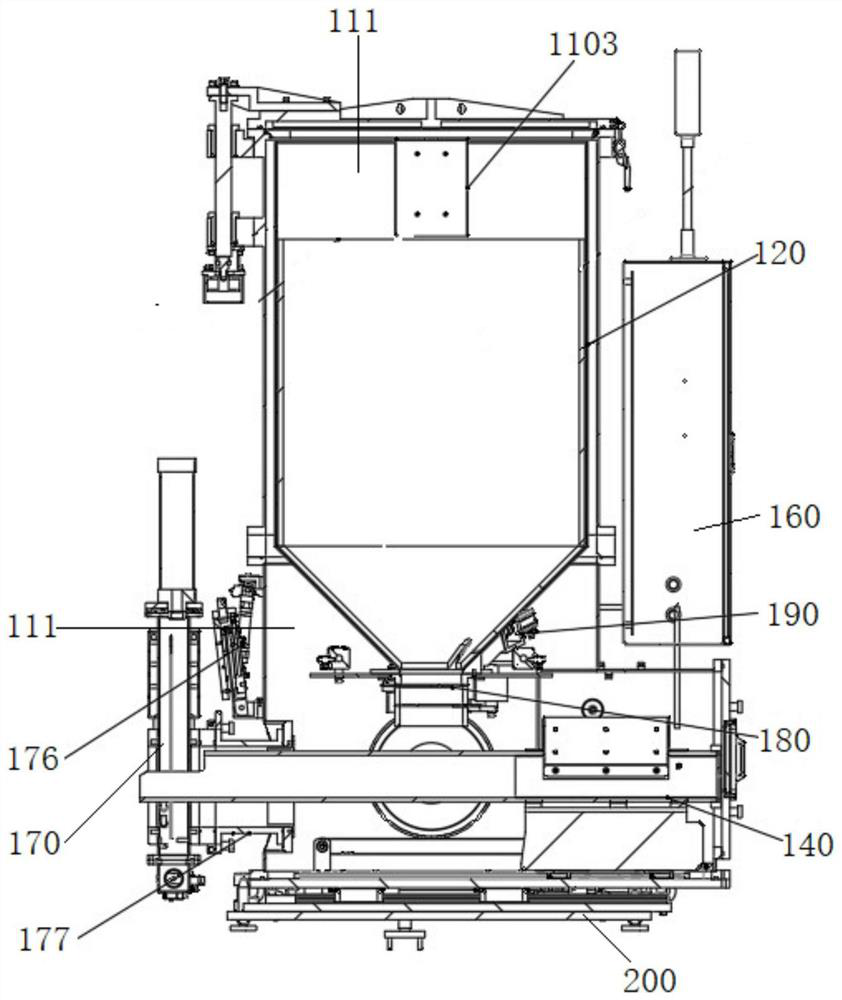

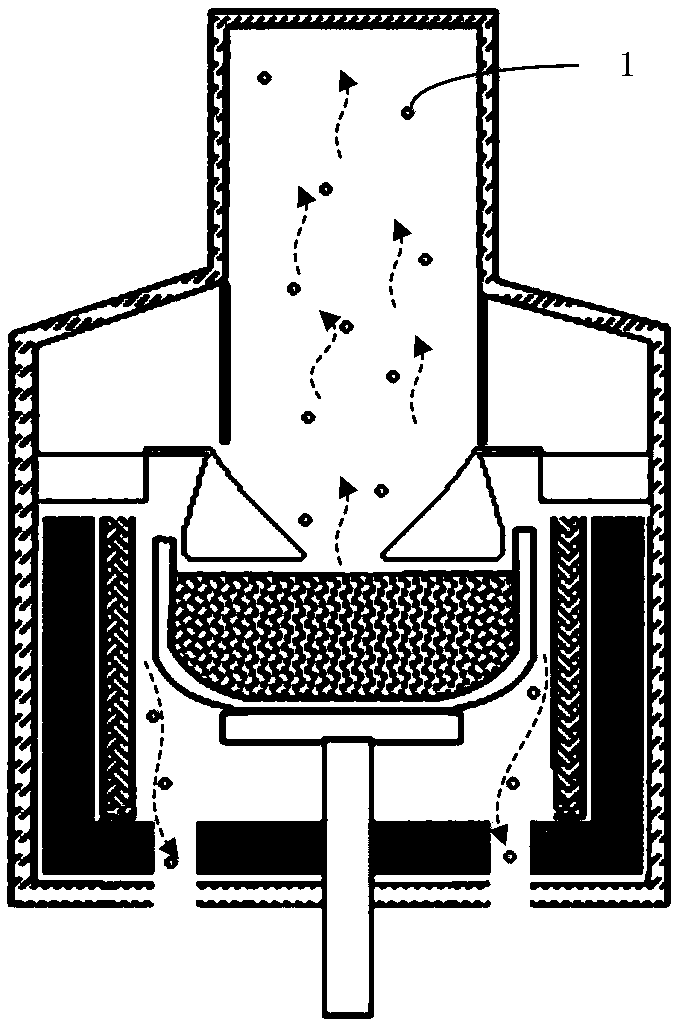

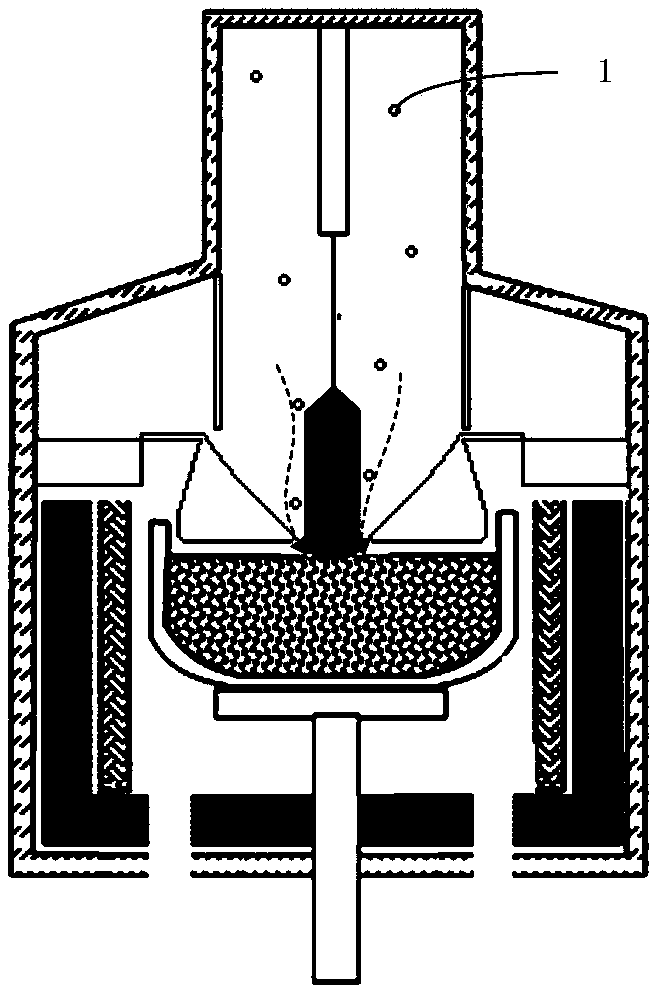

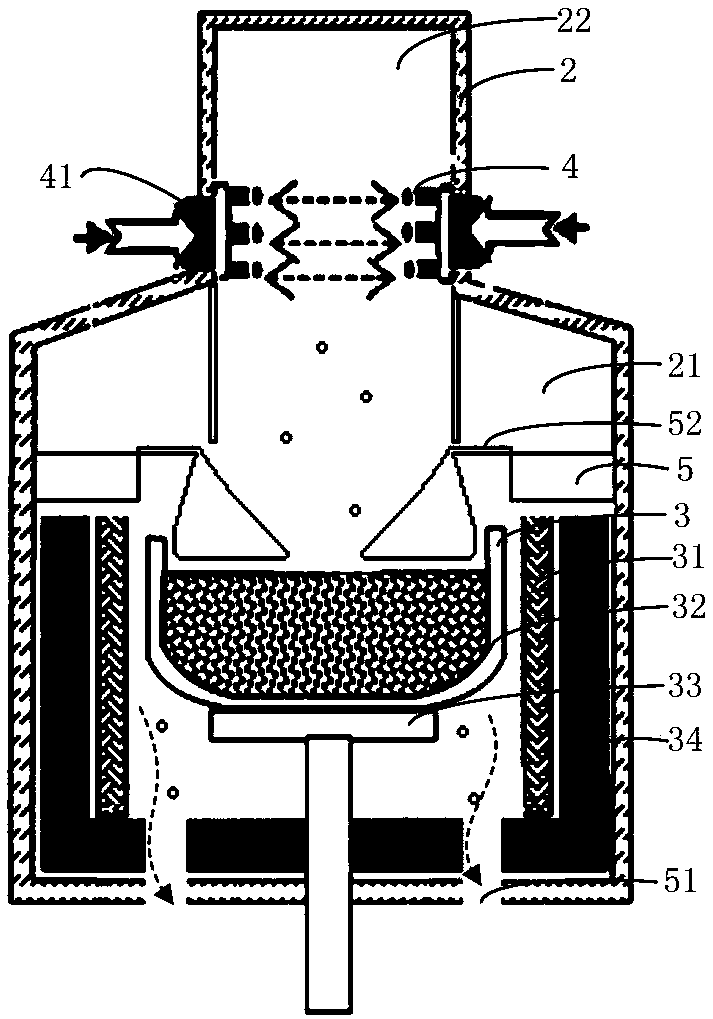

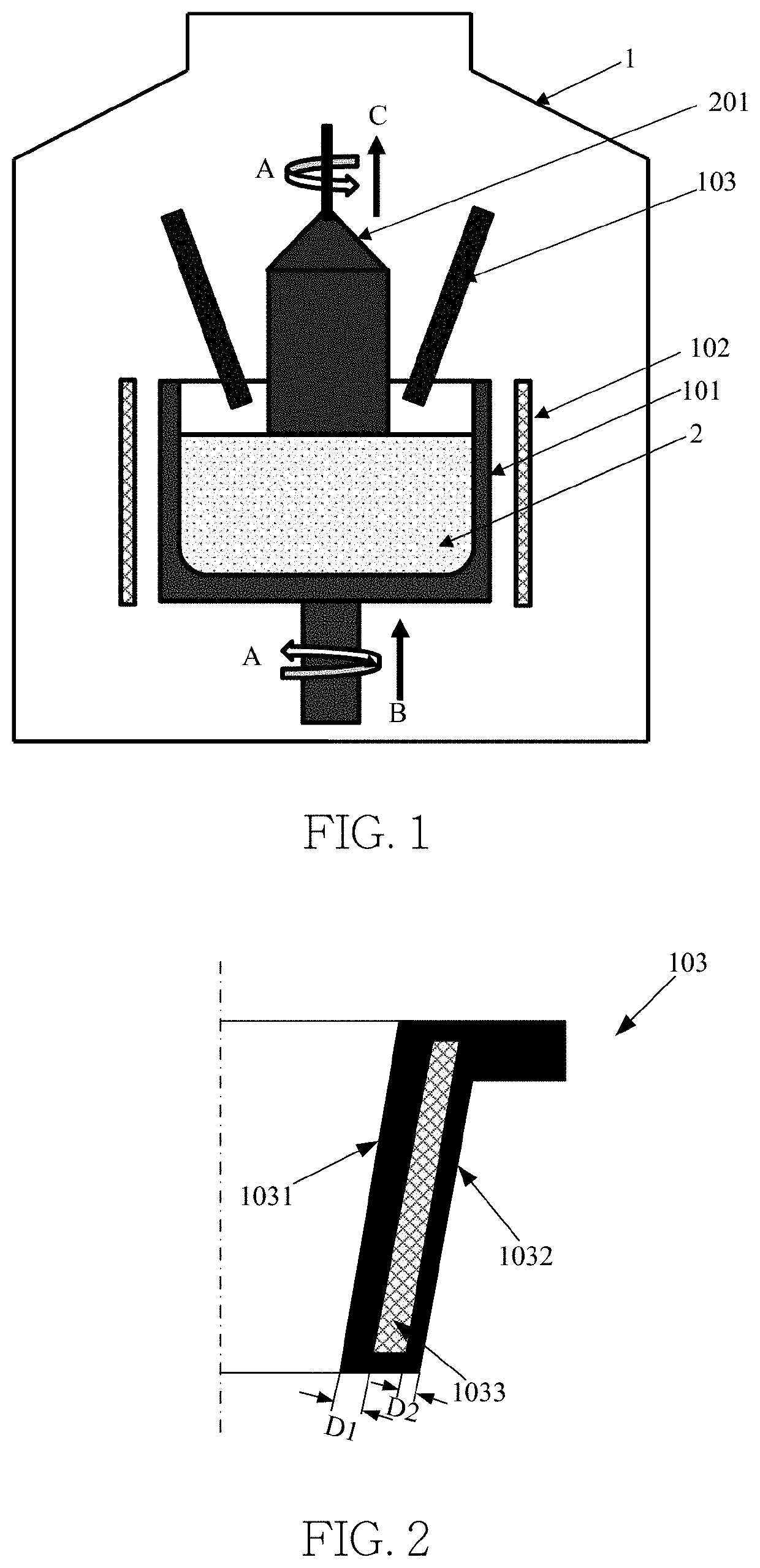

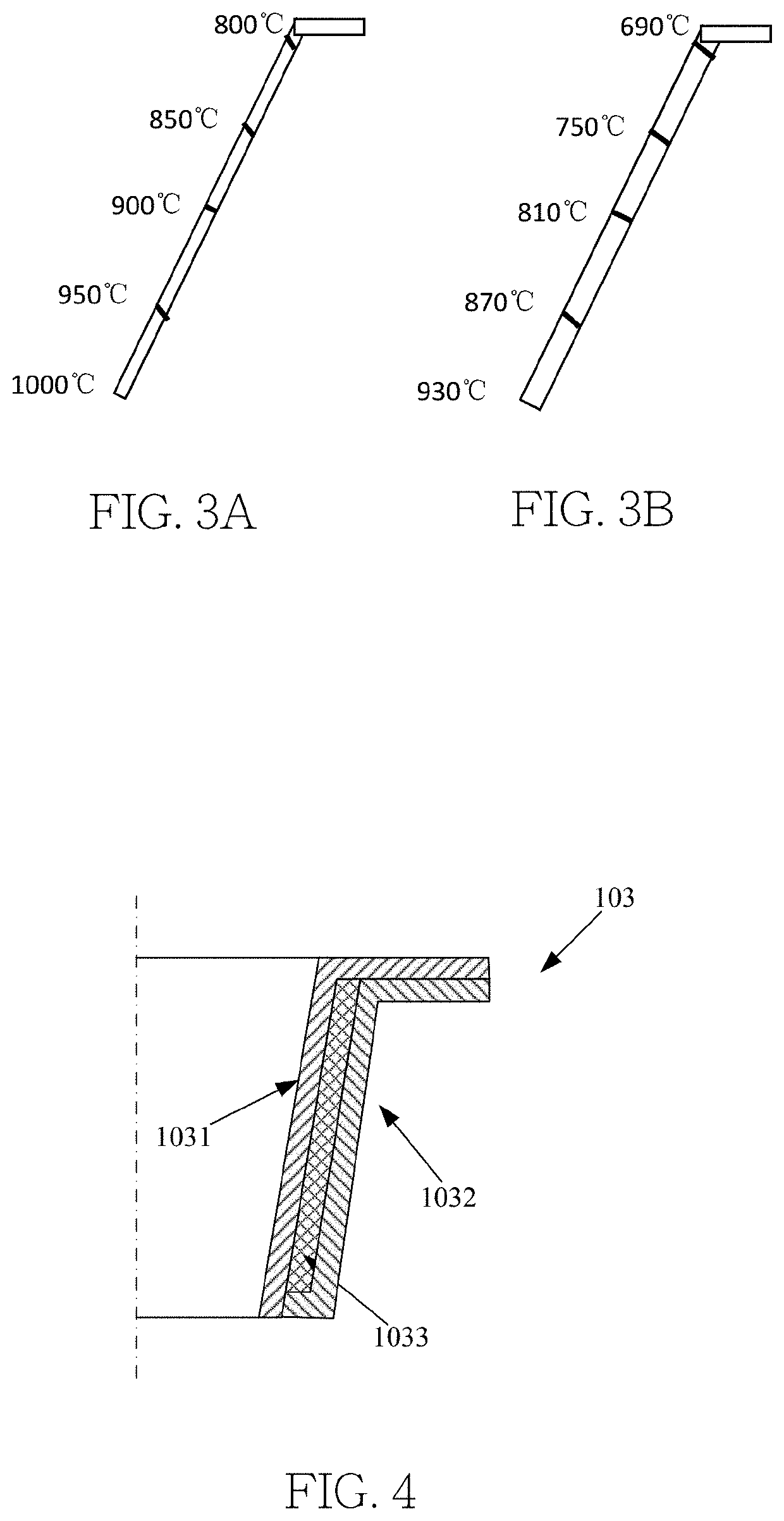

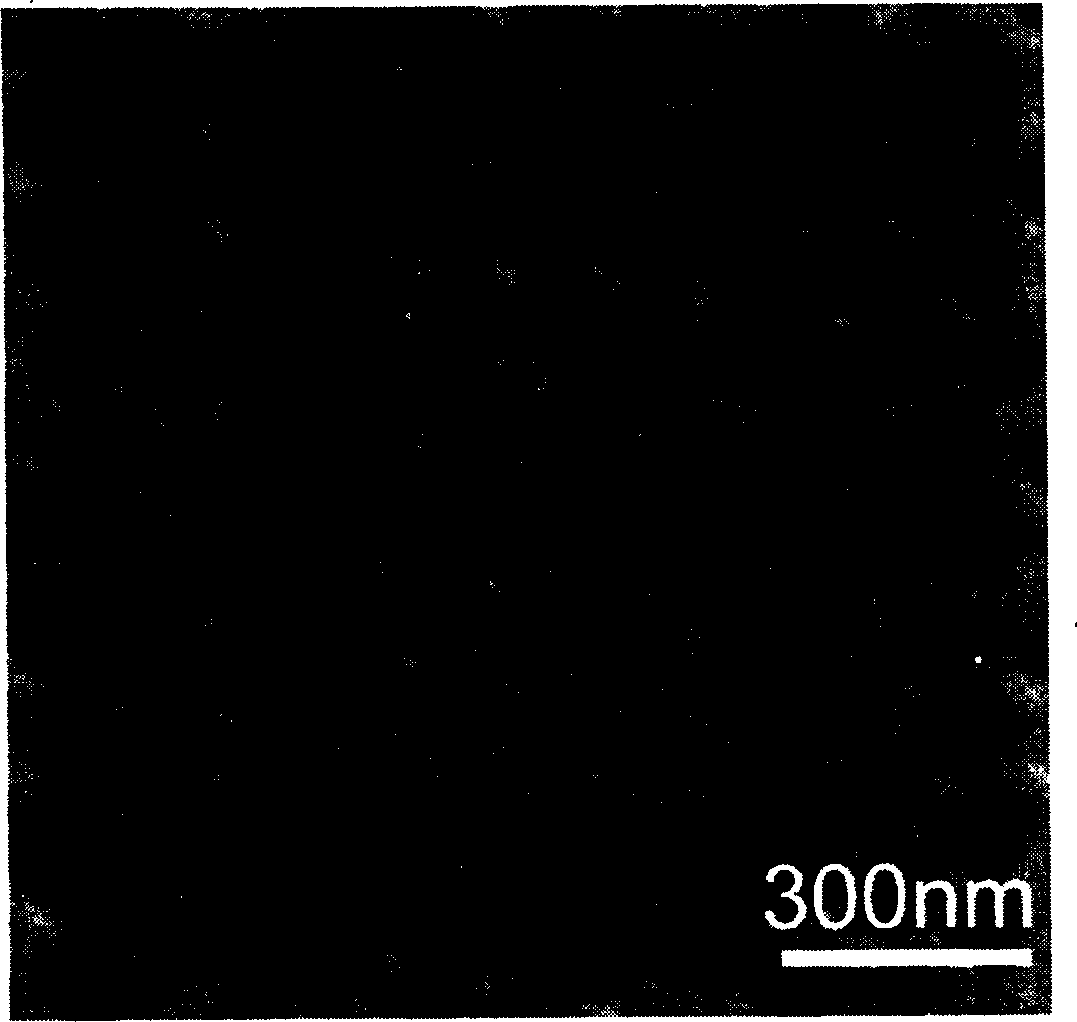

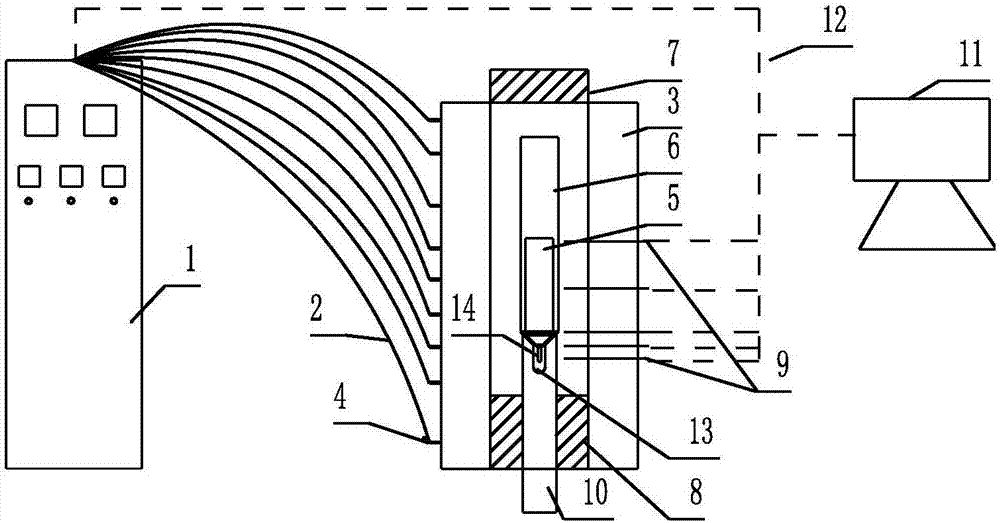

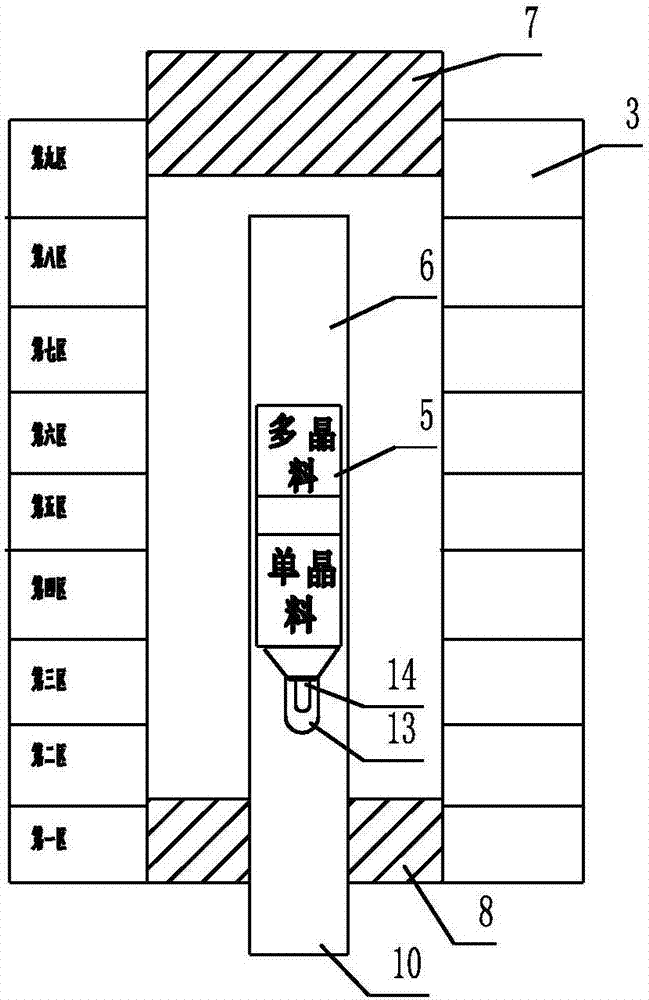

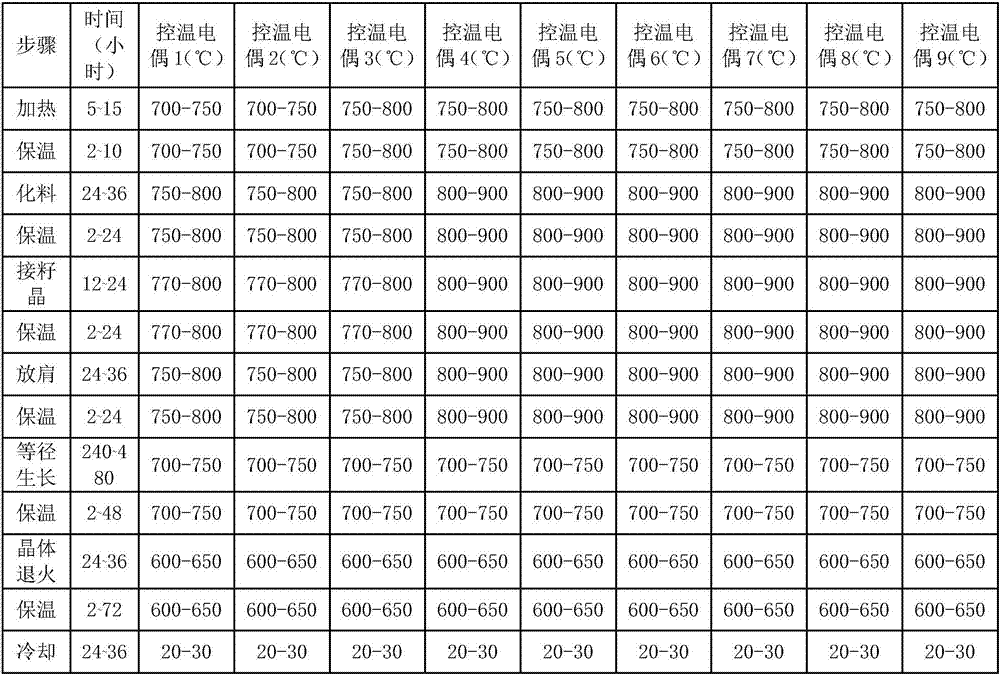

Novel single-crystal furnace for zinc cadmium telluride single crystal and growth process

PendingCN107059132AAchieve growthImprove the growing environmentPolycrystalline material growthFrom frozen solutionsTemperature controlCrucible

Owner:磐石创新(江苏)电子装备有限公司

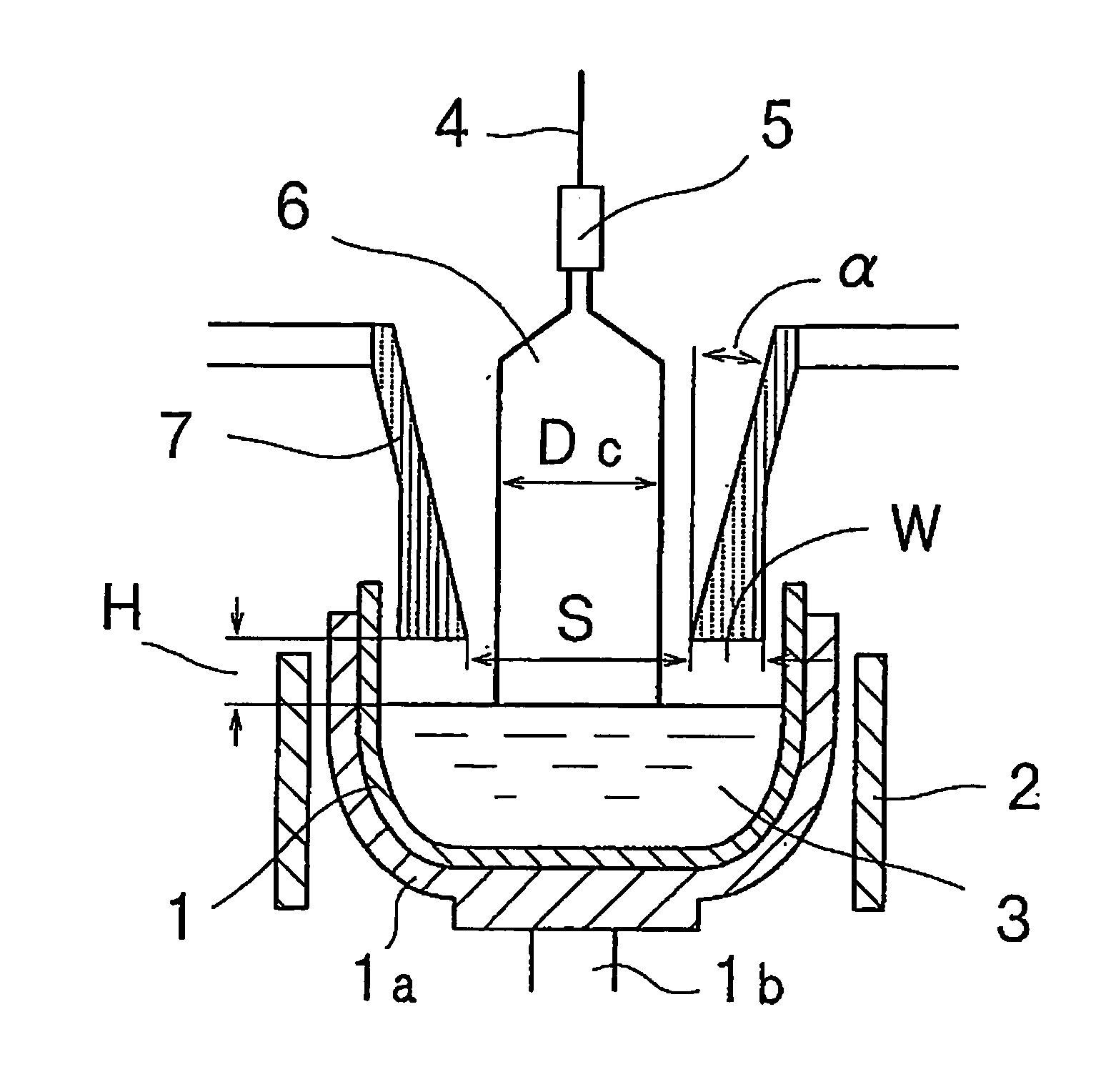

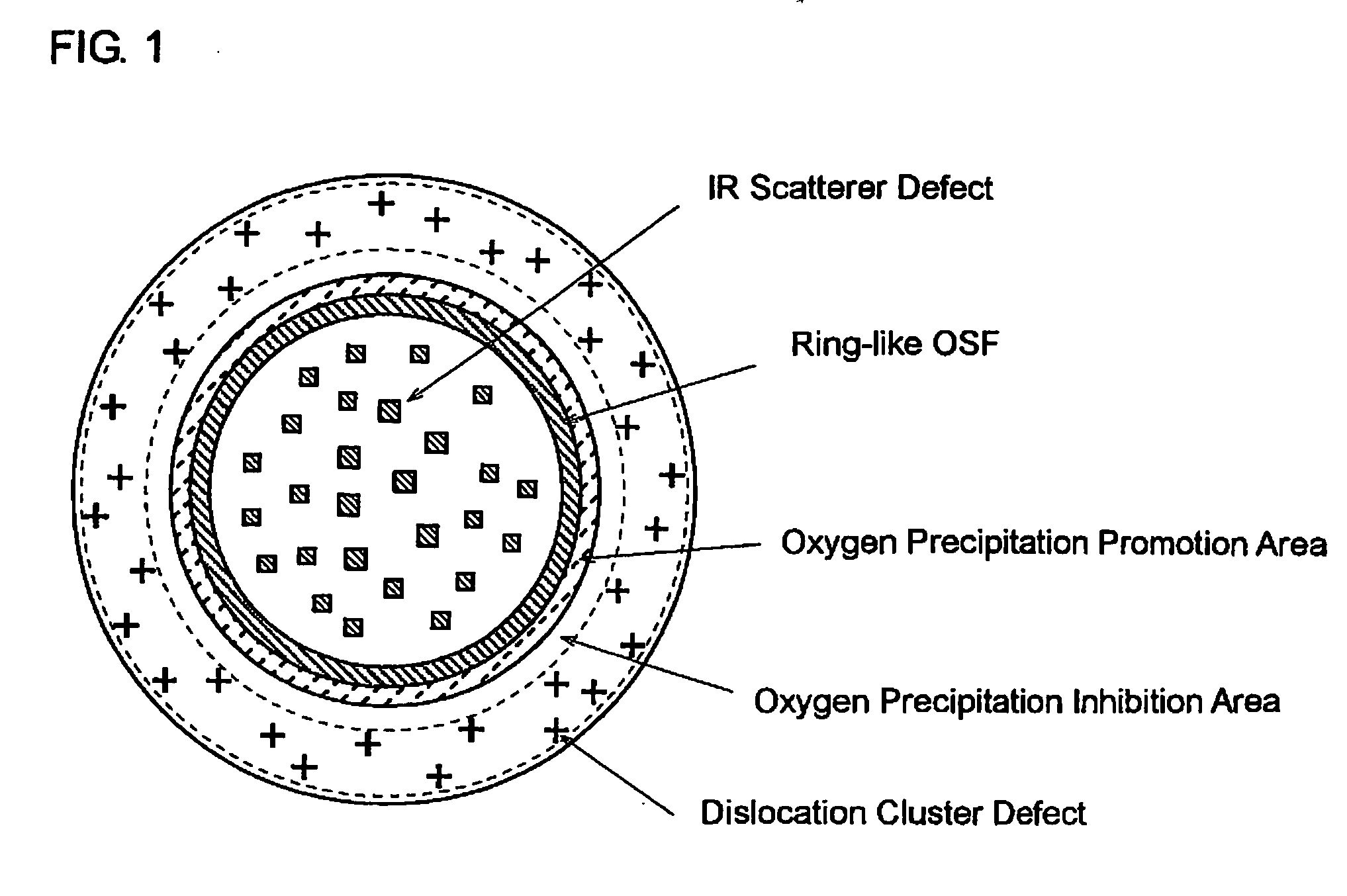

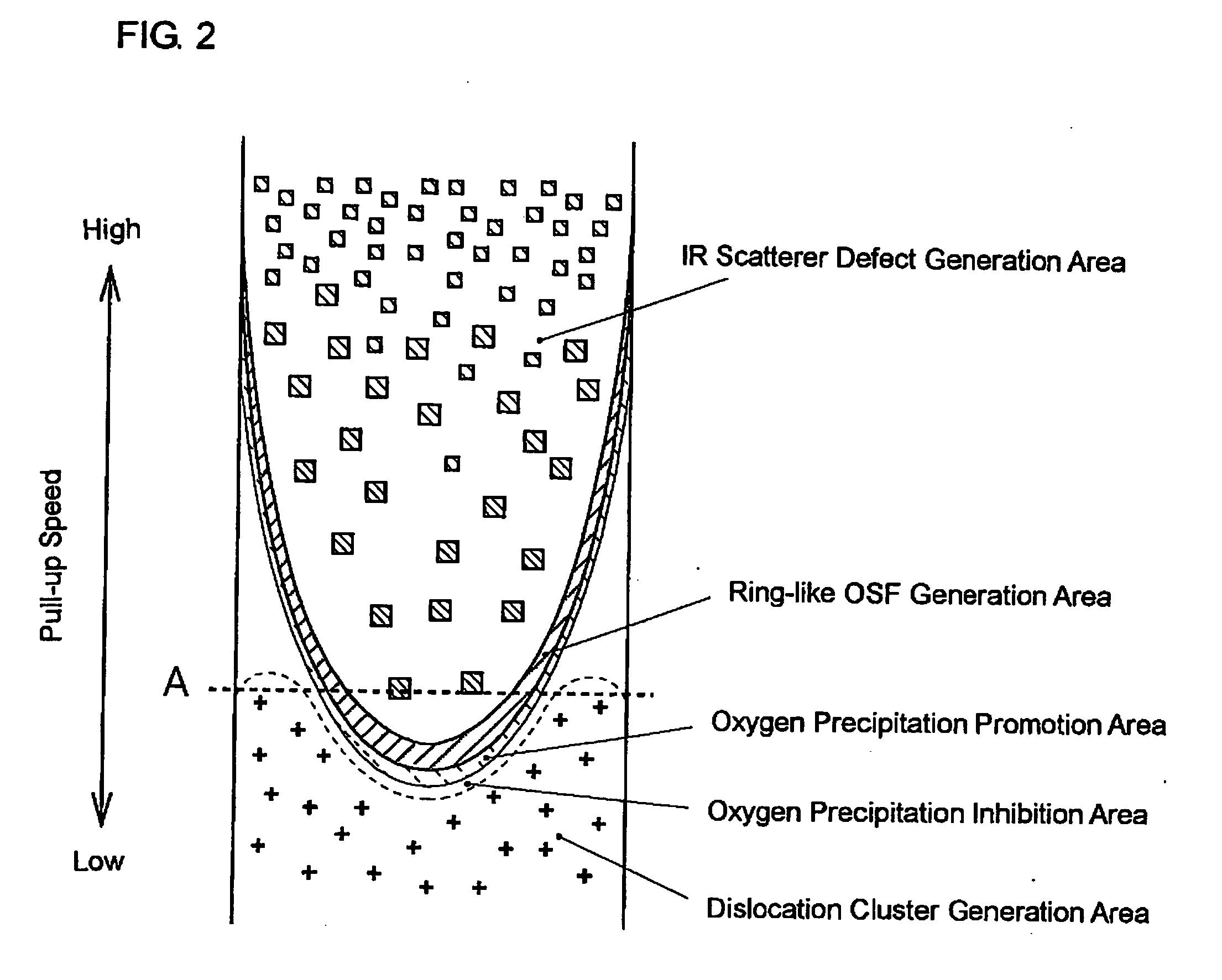

Method for growing silicon single crystal, and silicon wafer

InactiveUS20060225639A1Stable productionEasy to adaptPolycrystalline material growthBy pulling from meltHigh densityMiniaturization

Owner:SUMCO CORP

Seeding mold for growing silicon crystals by using orientated solidification method and crystal growing method

InactiveCN102146580AFix placement issuesEliminate dislocationsPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationDislocation

Owner:GREENERGY CRYSTAL TECH

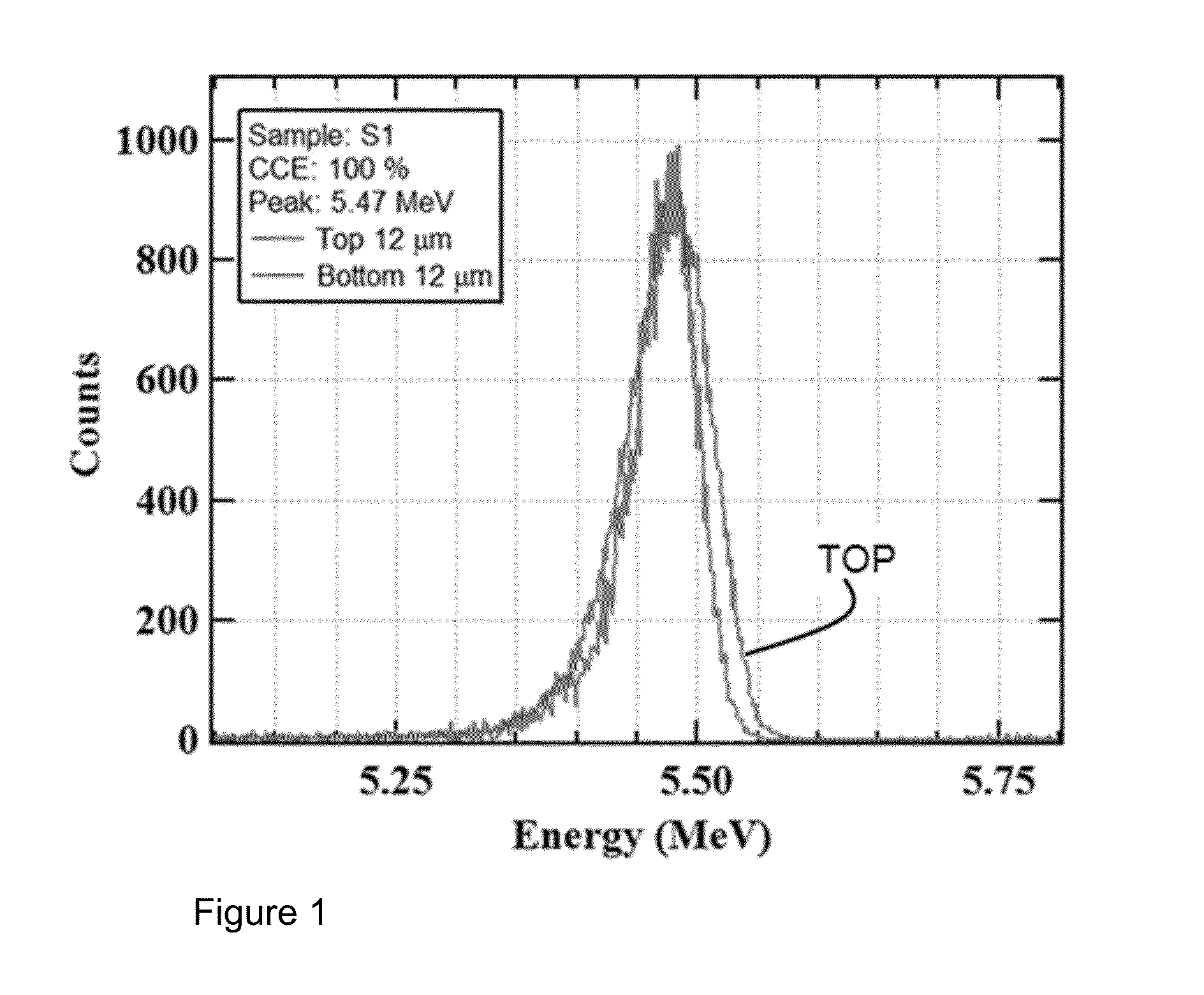

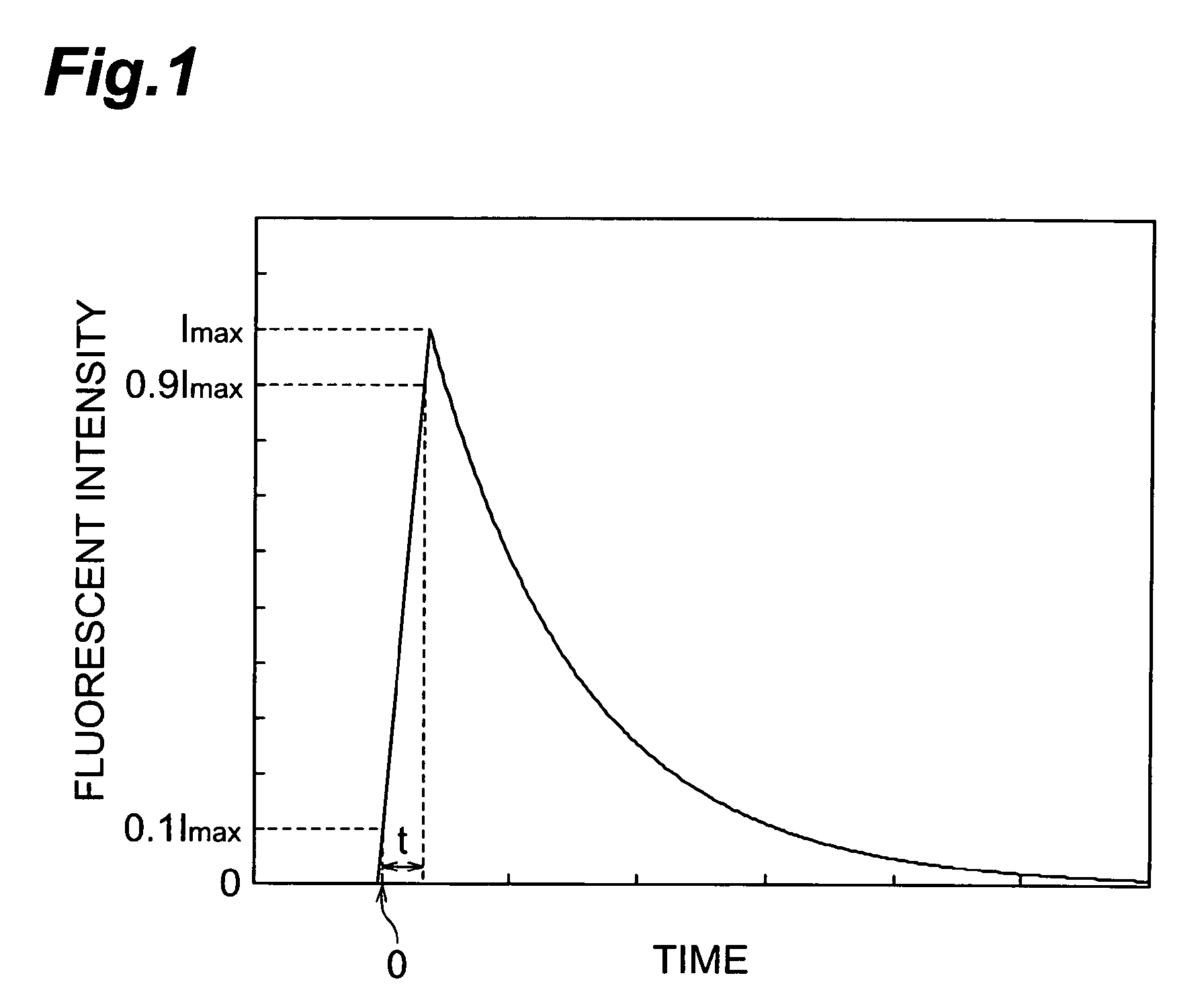

Electronic device grade single crystal diamonds and method of producing the same

ActiveUS20160201221A1Reduce crystal defect densityPolycrystalline material growthUltra-high pressure processesMicrowaveSingle crystal

Owner:IIA TECH

Nanostructuring process for ingot surface, wafer manufacturing method, and wafer using the same

InactiveUS20120193764A1Improve surface strengthReduce generationMaterial nanotechnologyPolycrystalline material growthWaferingMetallurgy

The instant disclosure relates to a nanostructuring process for an ingot surface prior to the slicing operation. A surface treatment step is performed for at least one surface of the ingot in forming a nanostructure layer thereon. The nanostructure layer is capable of enhancing the mechanical strength of the ingot surface to reduce the chipping ratio of the wafer during slicing.

Owner:SINO AMERICAN SILICON PROD

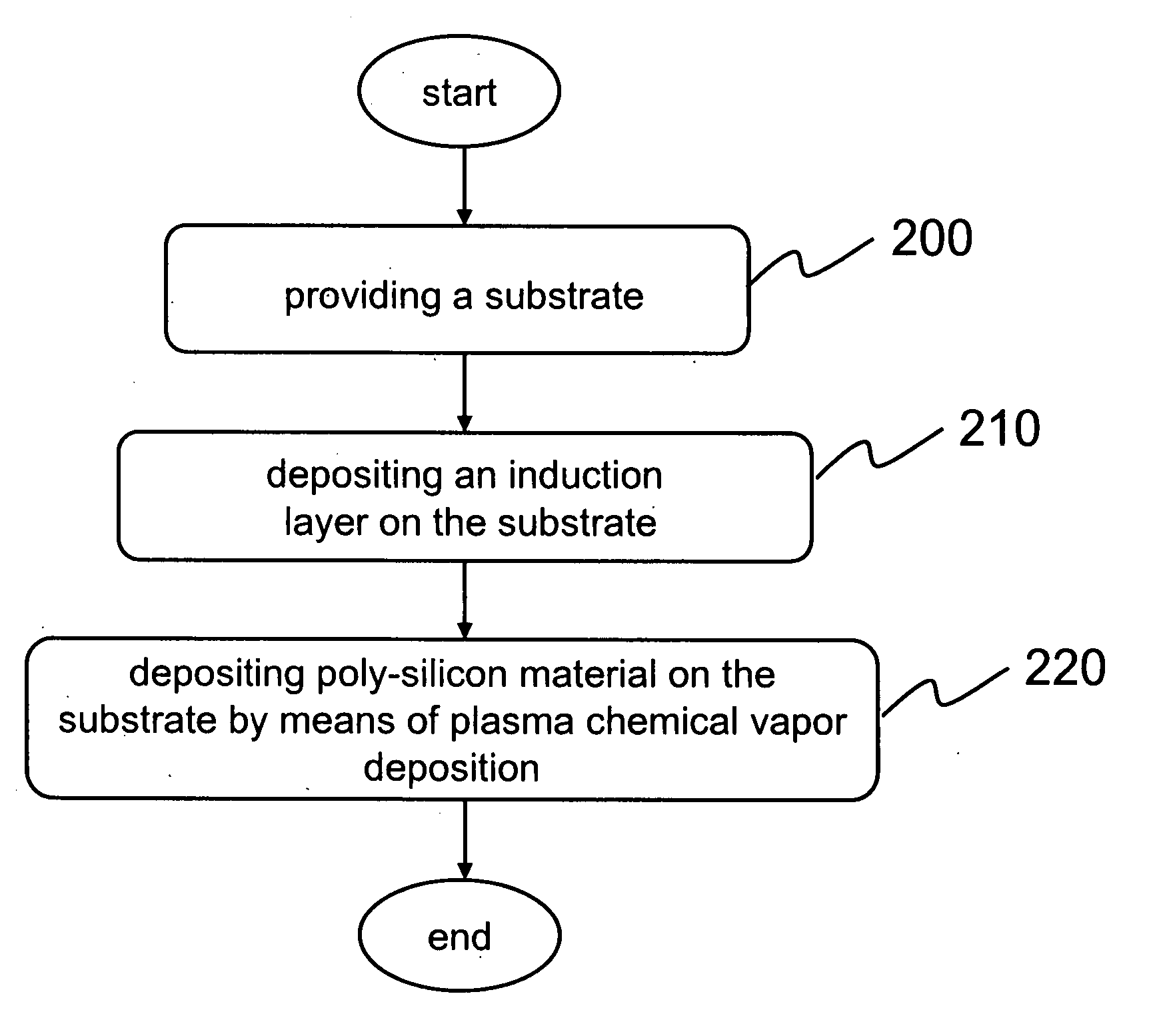

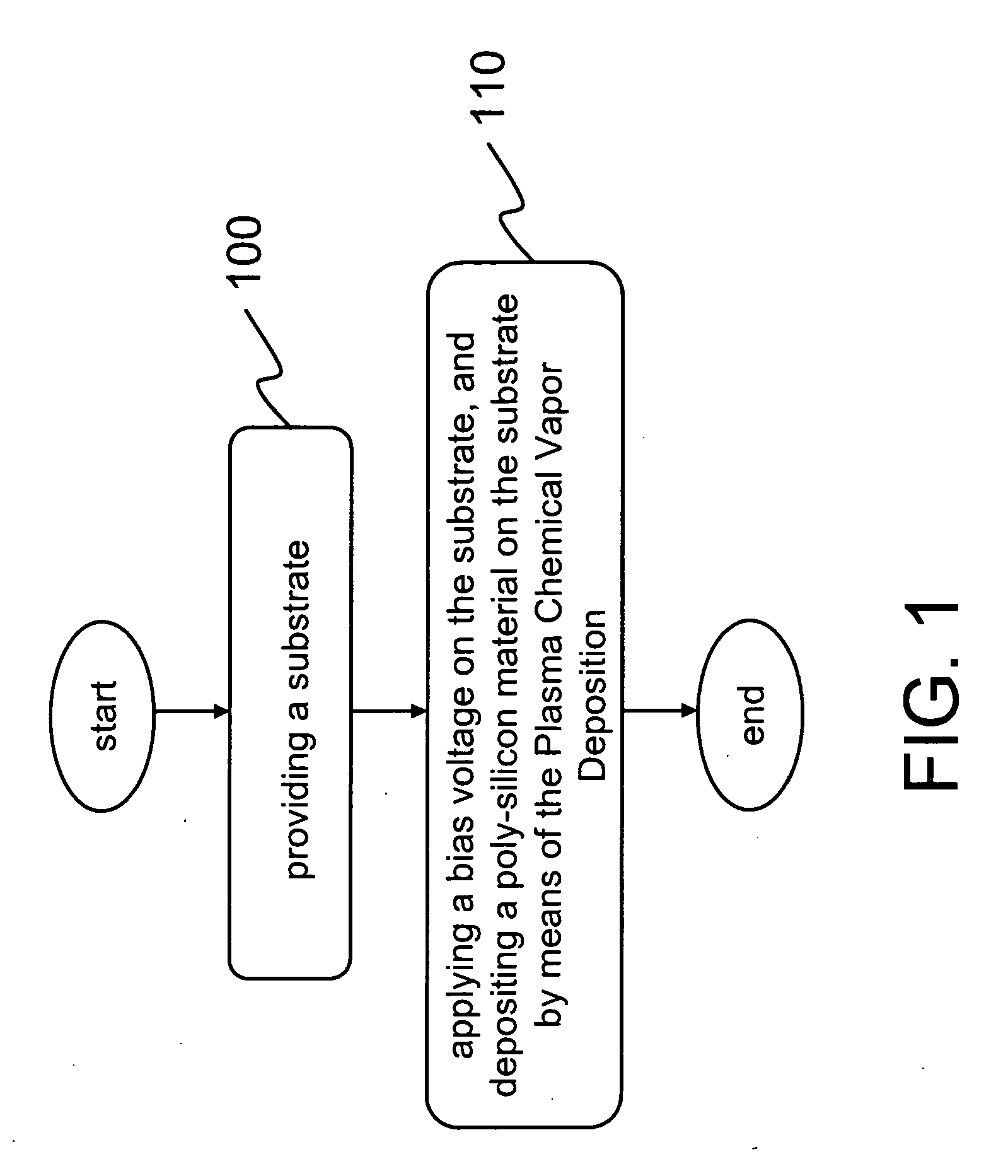

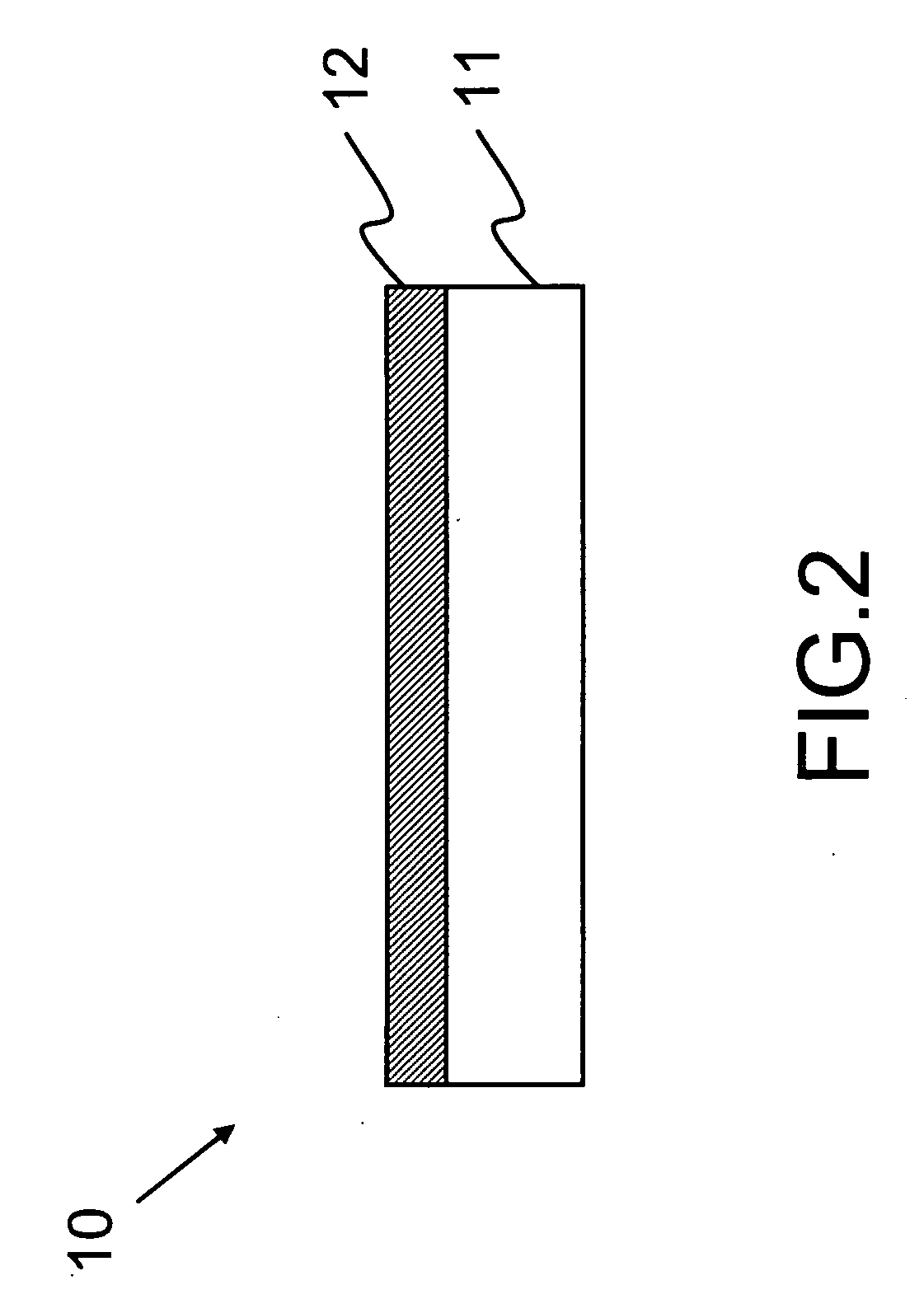

Element of low temperature poly-silicon thin film and method of making poly-silicon thin film by direct deposition at low temperature and inductively-coupled plasma chemical vapor deposition equipment therefor

InactiveUS20070077735A1Quality improvementReduce thicknessPolycrystalline material growthSolid-state devicesInductively coupled plasmaSilicon thin film

Owner:IND TECH RES INST

Method for preparing polysilicon

InactiveCN1727525AReduce the temperatureLower threshold voltagePolycrystalline material growthSemiconductor/solid-state device manufacturingFine lineSemiconductor materials

A process for preparing polycrystal silicon includes preparing non-crystal silicon film on glass substrate, preparing a thin Ni layer, photoetching the Ni layer to become fine lines, laser annealing, removing excessive Ni, and laser annealing again for crystallizing the silicon film. Its advantages are short time and low substrate temp.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Manufacturing method of semiconductor device

InactiveCN102468153AEfficient reorganizationIncrease etch ratePolycrystalline material growthAfter-treatment detailsPulsed laser beamCrystalline silicon

In a manufacturing method of a semiconductor device, a substrate including single crystalline silicon is prepared, a reformed layer that continuously extends is formed in the substrate, and the reformed layer is removed by etching. The forming the reformed layer includes polycrystallizing a portion of the single crystalline silicon by irradiating the substrate with a pulsed laser beam while moving a focal point of the laser beam in the substrate.

Owner:DENSO CORP

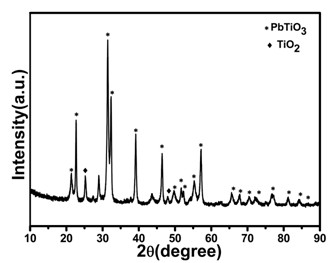

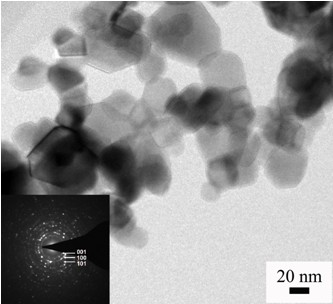

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

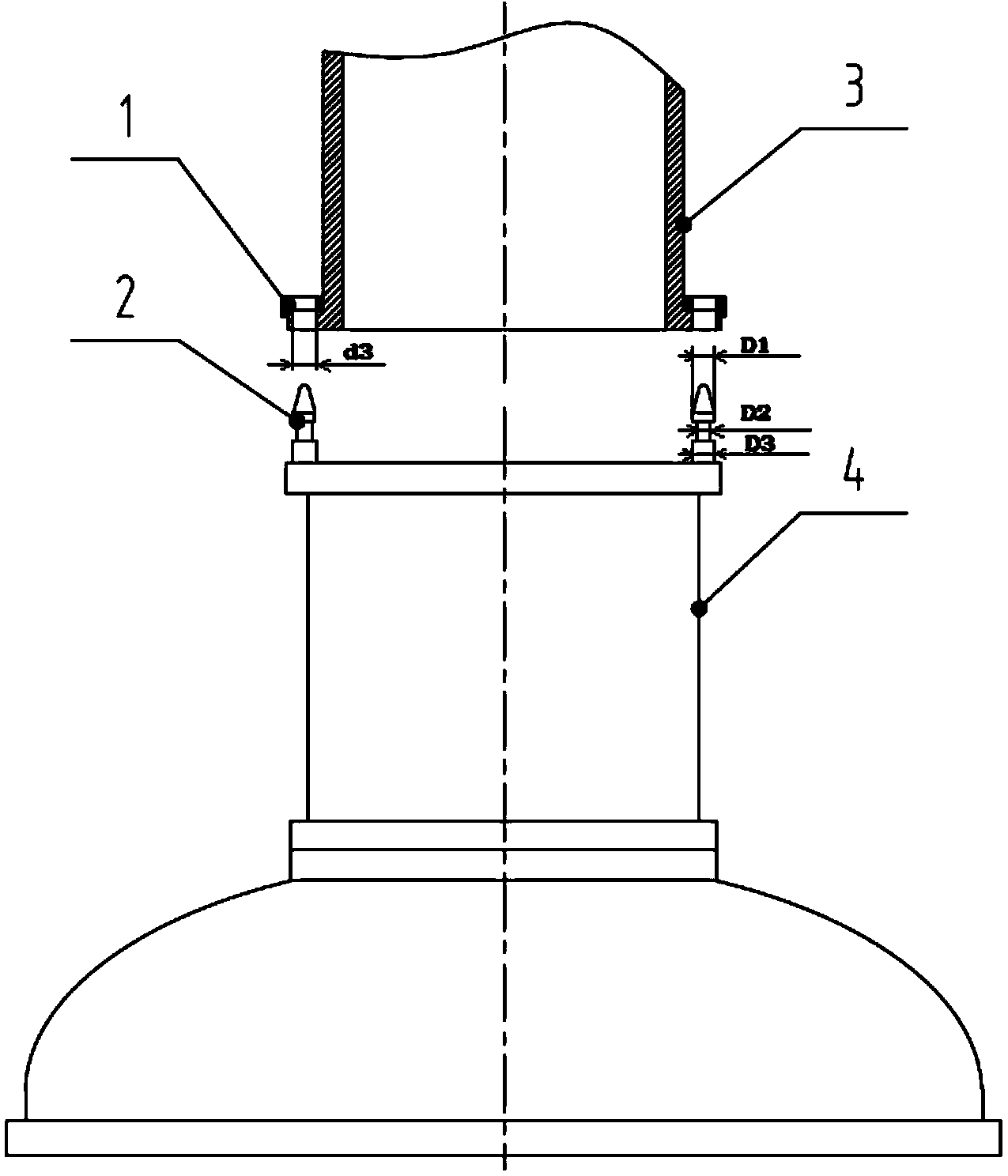

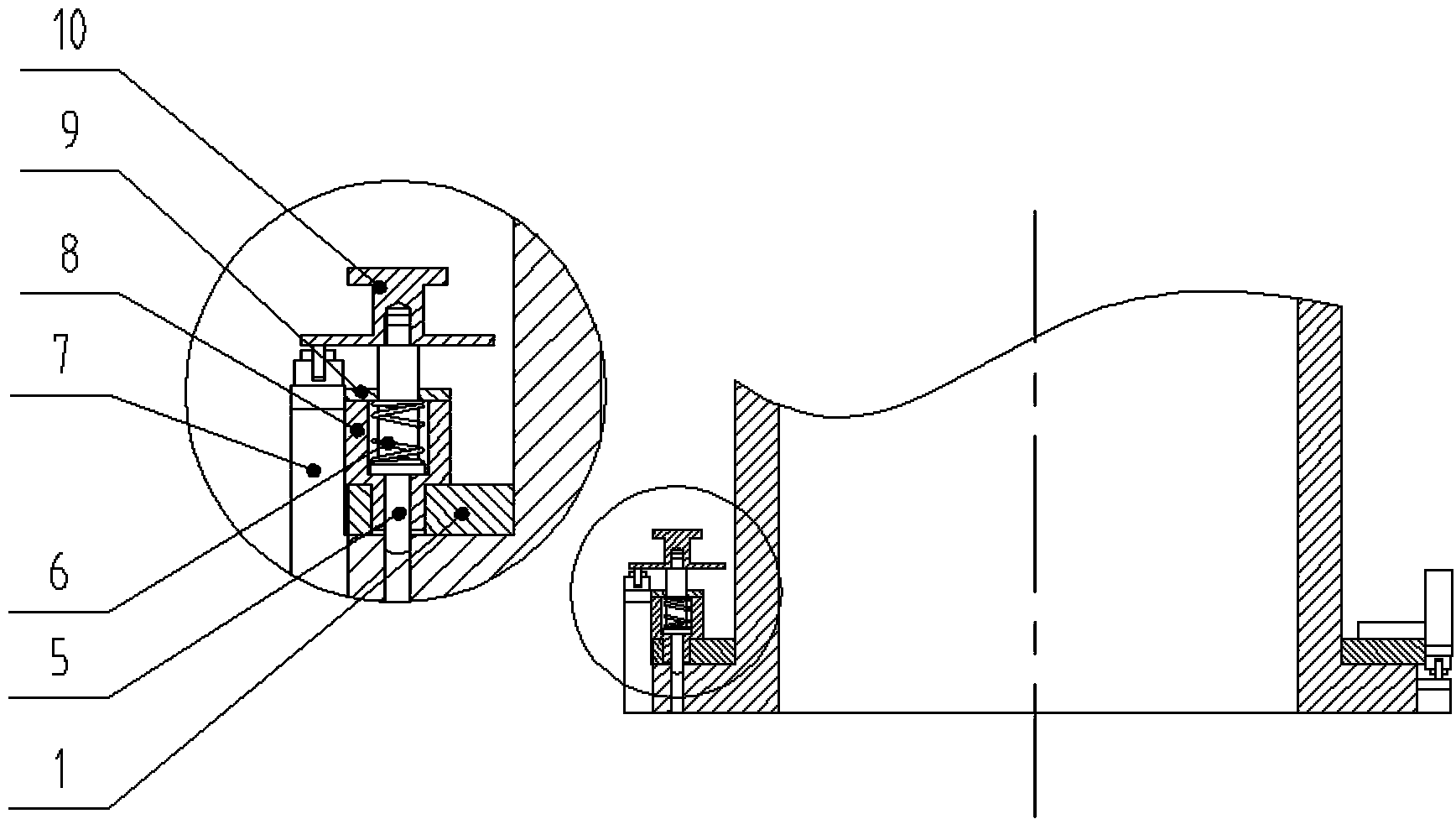

Mounting plate assembly for monocrystalline silicon growth furnace

ActiveCN104213190AConvenient and safe crystal extractionShorten the timePolycrystalline material growthBy pulling from meltEngineeringCooling time

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

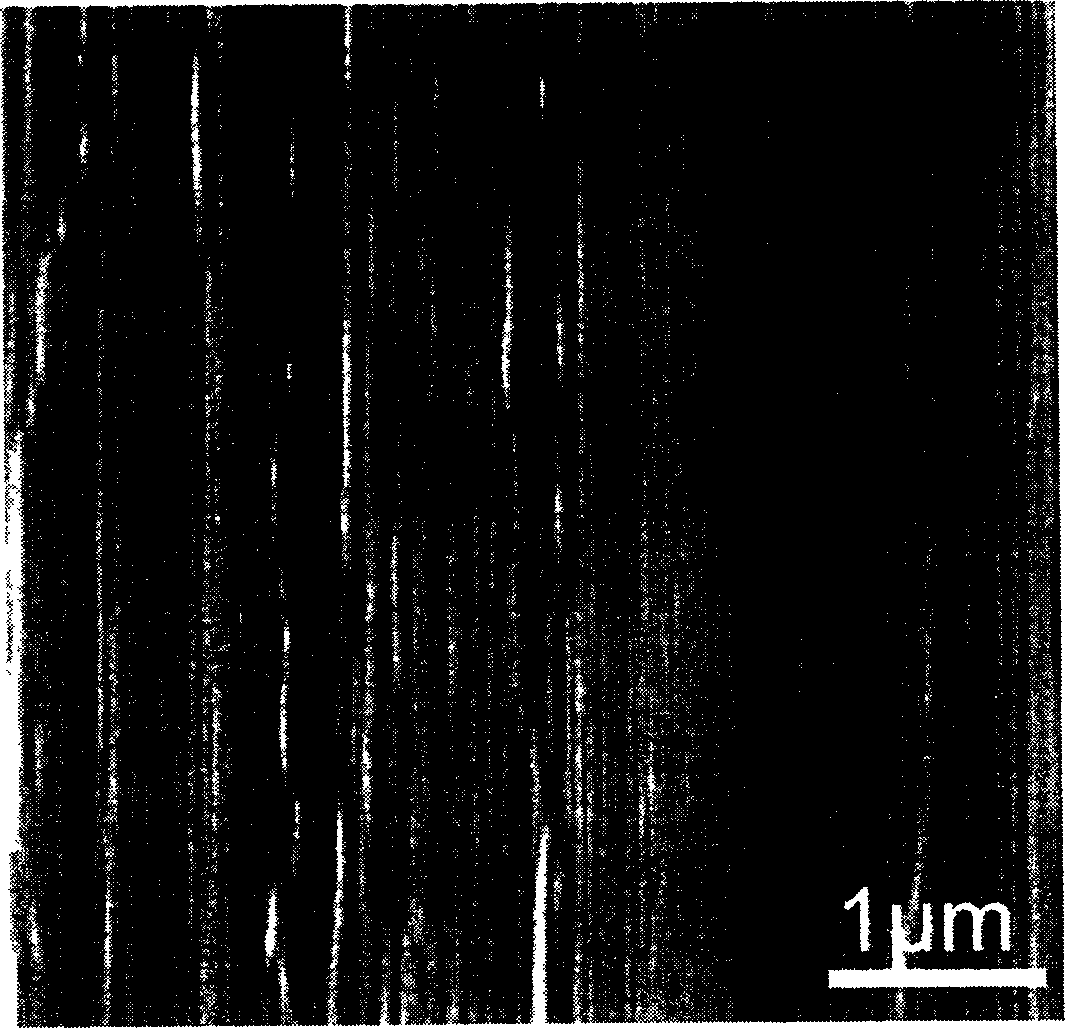

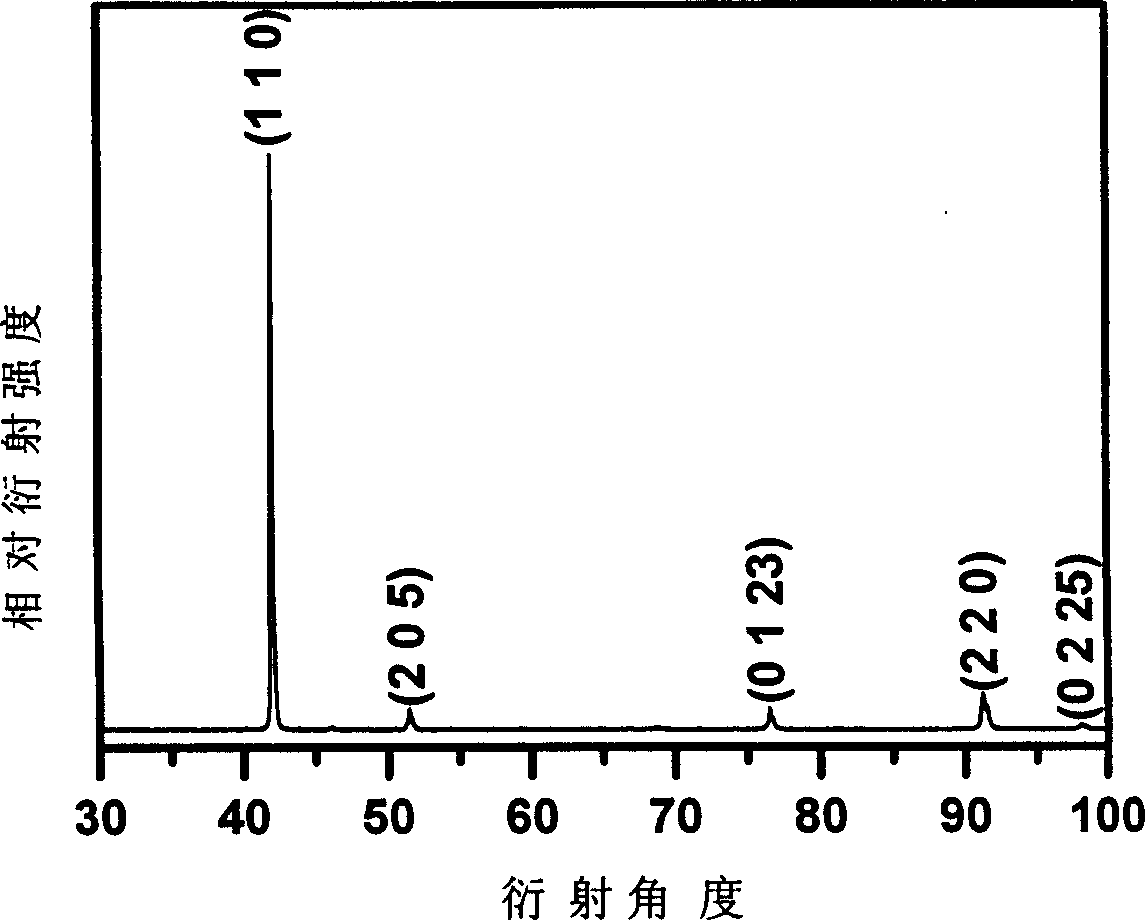

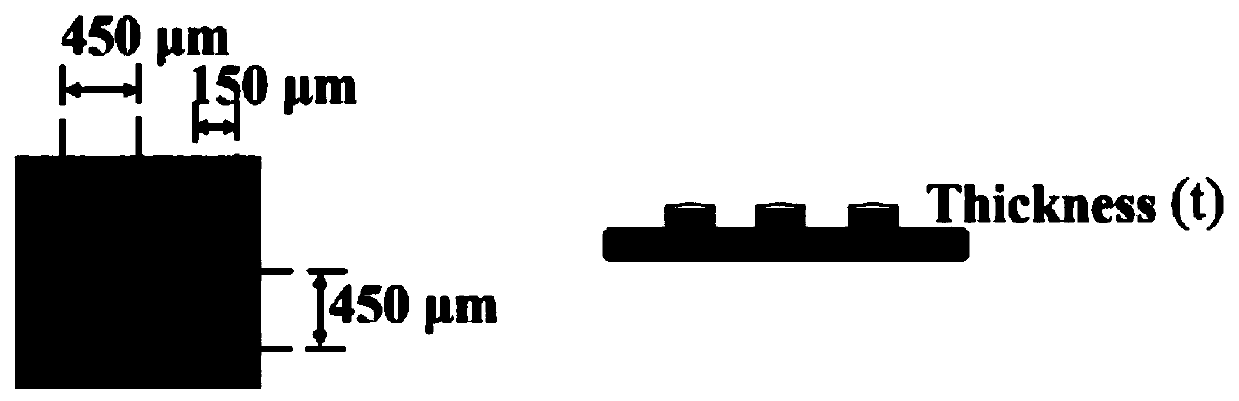

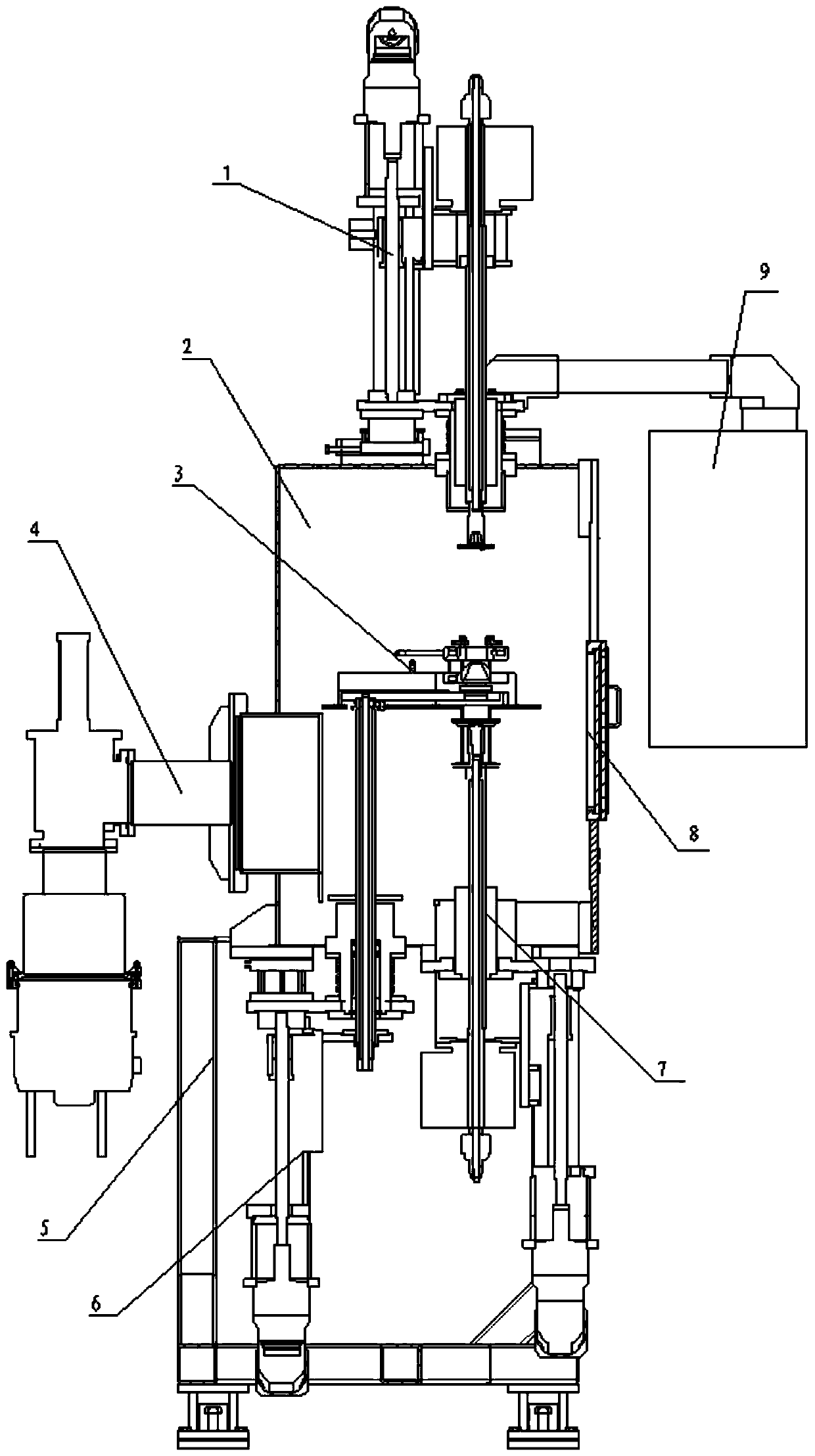

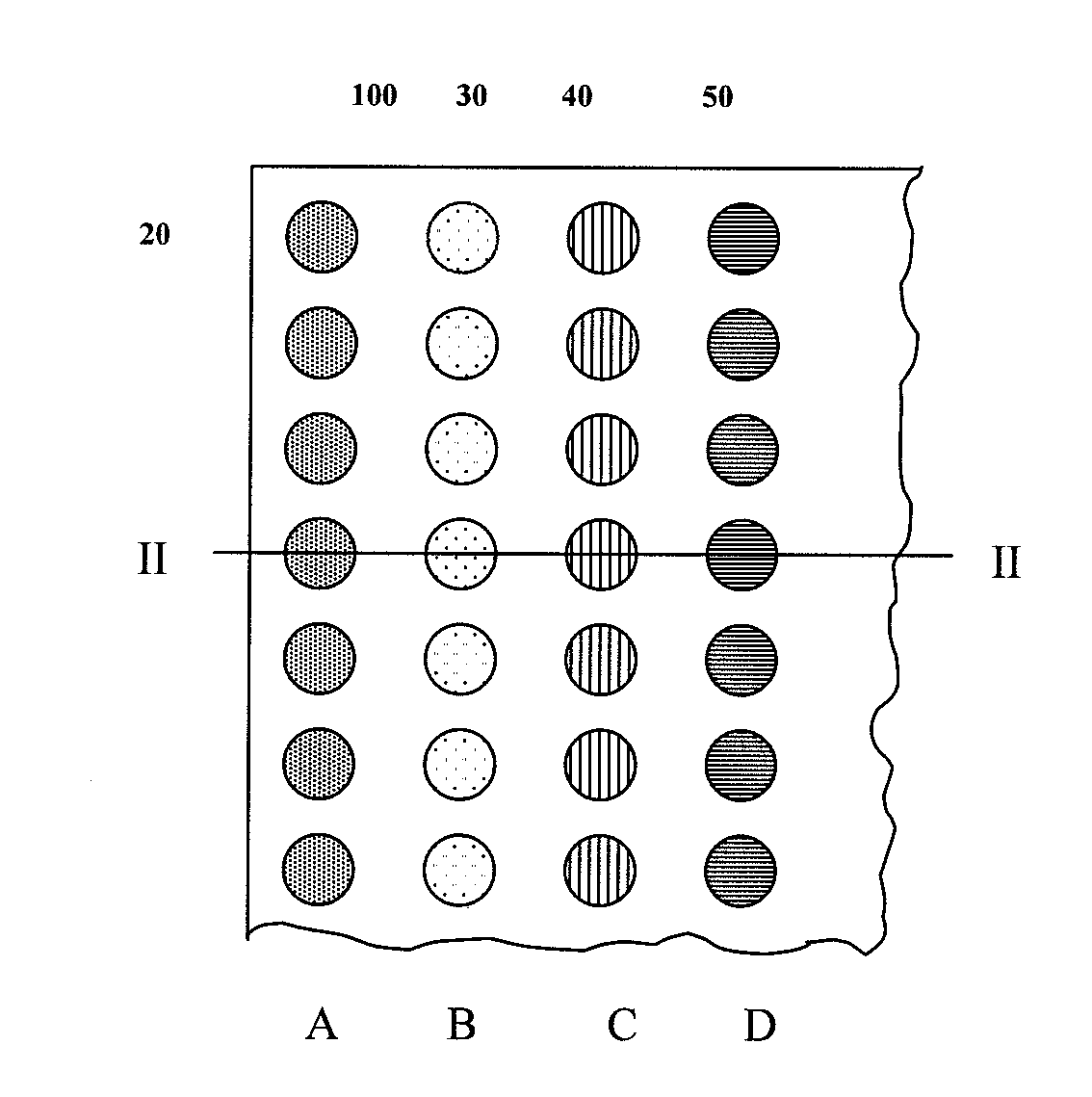

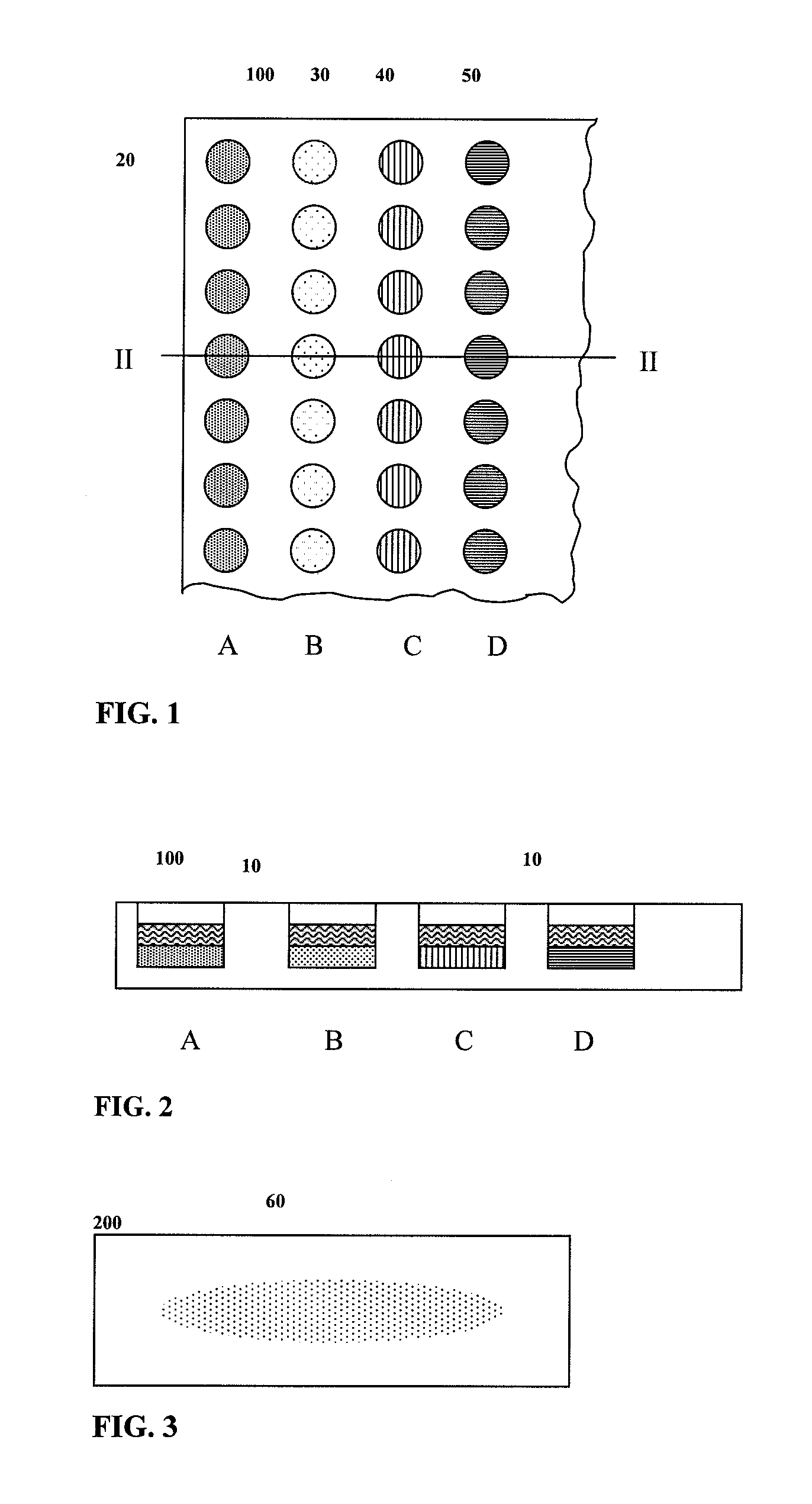

Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method

InactiveCN104862702ADislocation display validEtching is effective for dislocation displayPolycrystalline material growthAfter-treatment detailsWater bathsWafering

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Feeding device for single crystal furnace

PendingCN114395795ASmall footprintAvoid damagePolycrystalline material growthBy pulling from meltElectrical connectionSingle crystal

Owner:晶澳(无锡)光伏科技有限公司

Single crystal pulling device, preparation method of single crystal silicon and single crystal silicon

InactiveCN109554756APrevent inflowReduce dislocationPolycrystalline material growthUnder a protective fluidSingle crystalEngineering

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

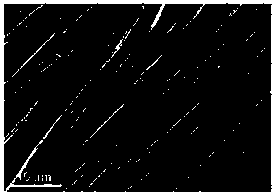

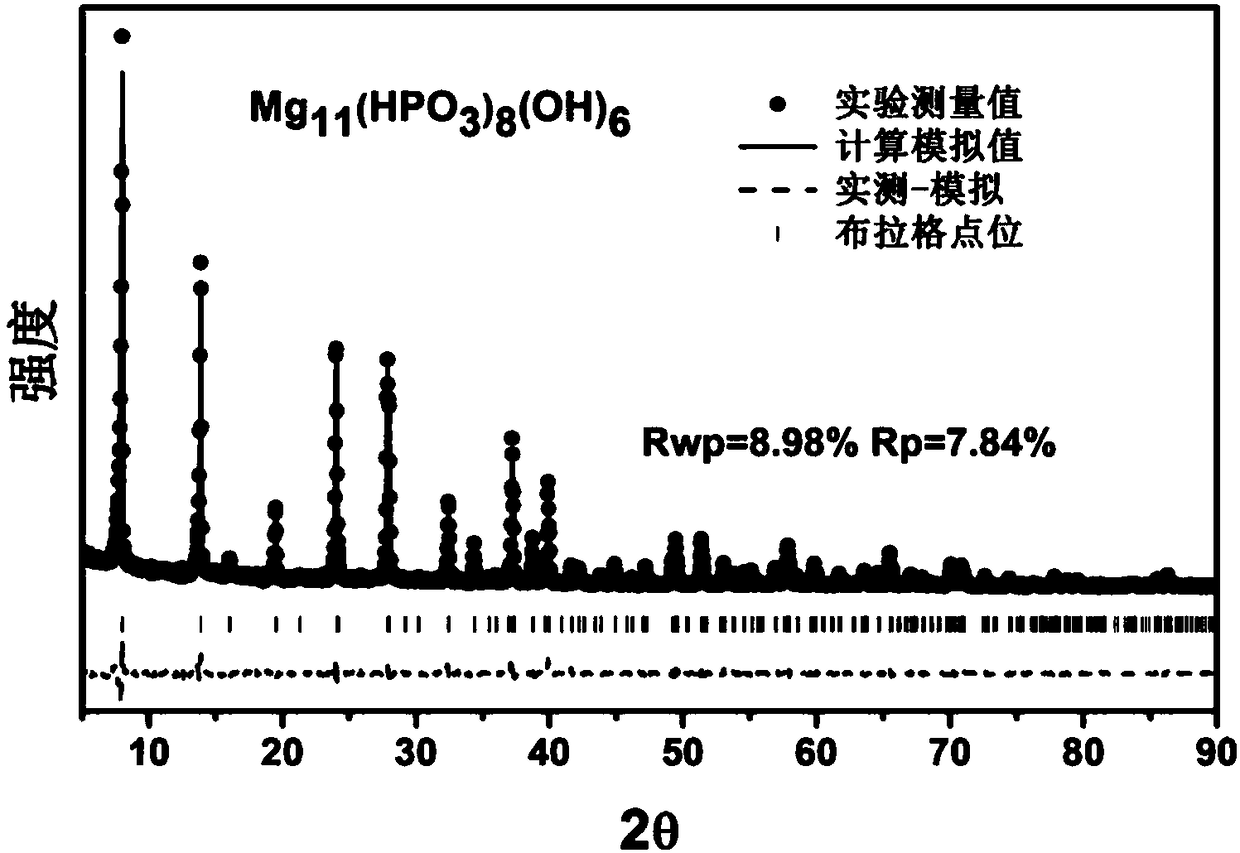

Crystal material, and preparation method and application thereof

ActiveCN108193268AHigh UV-Vis-NIR high reflectivityImprove performancePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidMagnesium Acetate Tetrahydrate

Owner:SOUTH CHINA UNIV OF TECH

Draft tube of crystal growing furnace and the crystal growing furnace

InactiveUS20200255970A1Well formedPolycrystalline material growthBy pulling from meltEngineeringIngot

Owner:ZING SEMICON CORP

Sb2Te3 monocrystalline nanometer line ordered array and its preparation method

InactiveCN1769539ASolve easy hydrolysisAddress effectivenessPolycrystalline material growthElectrolytic organic material coatingNanowireAuxiliary electrode

Owner:UNIV OF SCI & TECH OF CHINA

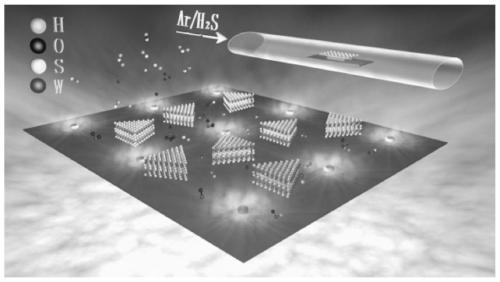

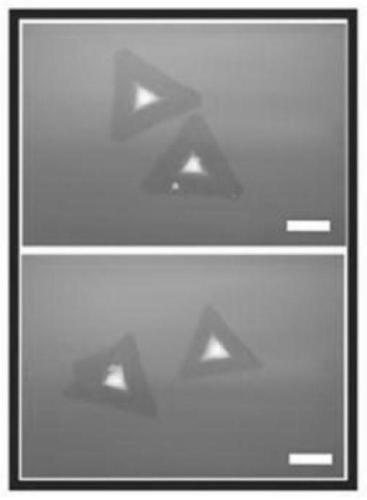

Preparation method of tungsten disulfide single crystal with controllable layer number

ActiveCN111472049AIncrease profitHigh repetition ratePolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

Owner:WENZHOU UNIVERSITY

Method for reducing content of carbon in single crystal bar

ActiveCN109097822APrevent fallingAvoid enteringPolycrystalline material growthBy pulling from meltLower limitCrucible

The invention discloses a method for reducing content of carbon in a single crystal bar. The method specifically comprises steps as follows: (1) a thermal field below a liquid level is mounted at thelower end of a furnace tube; (2) a material block is put in a crucible by means of a hoisting procedure, material protecting cloth is uniformly spread, wherein traction wires are uniformly arranged onone surface of the material protecting cloth, all the traction wires are connected together through a traction wire guide block, the traction wire guide block is arranged in the center of the material protecting cloth, the surface without traction wires completely covers the material blocks put in the crucible, and the crucible is descended to the lower limit position in the furnace tube and located at the upper end of the thermal field below the liquid level; (3) a thermal field above the liquid level is mounted, and the furnace tube is started to be closed after mounting; (4) after the furnace tube is closed, the traction wire guide block is lifted upwards, the material protecting cloth is directly taken out, and the furnace is continuously closed; (5) after the tube is closed, the material protecting cloth is turned over in the designated position of a workshop, so that lifted graphite powder and other impurities are lifted, then, the material protecting cloth is blown clean on thewhole with a blower, and the material protecting cloth and a sucker are transported to a charging chamber.

Owner:BAOTOU MEIKE SILICON ENERGY CO LTD

Preparation method of silicon carbide microcrystalline homogenized in dimension and shaped in polyhedron form

ActiveCN103643294AUniform nucleationUniform growth orientationPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

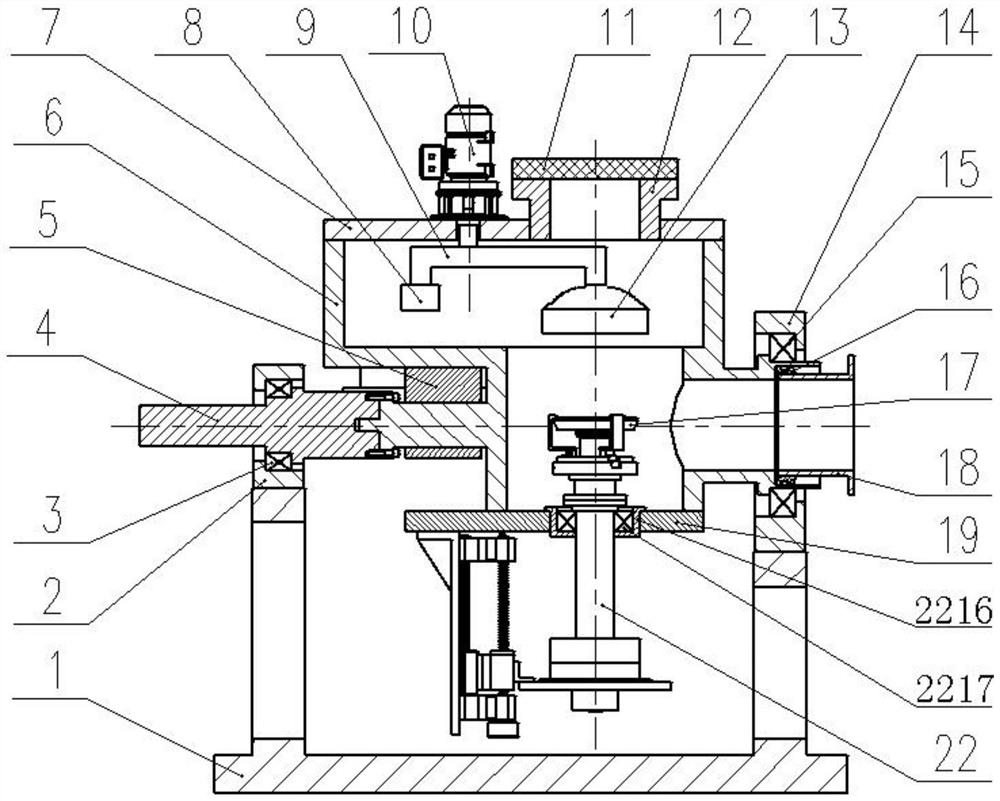

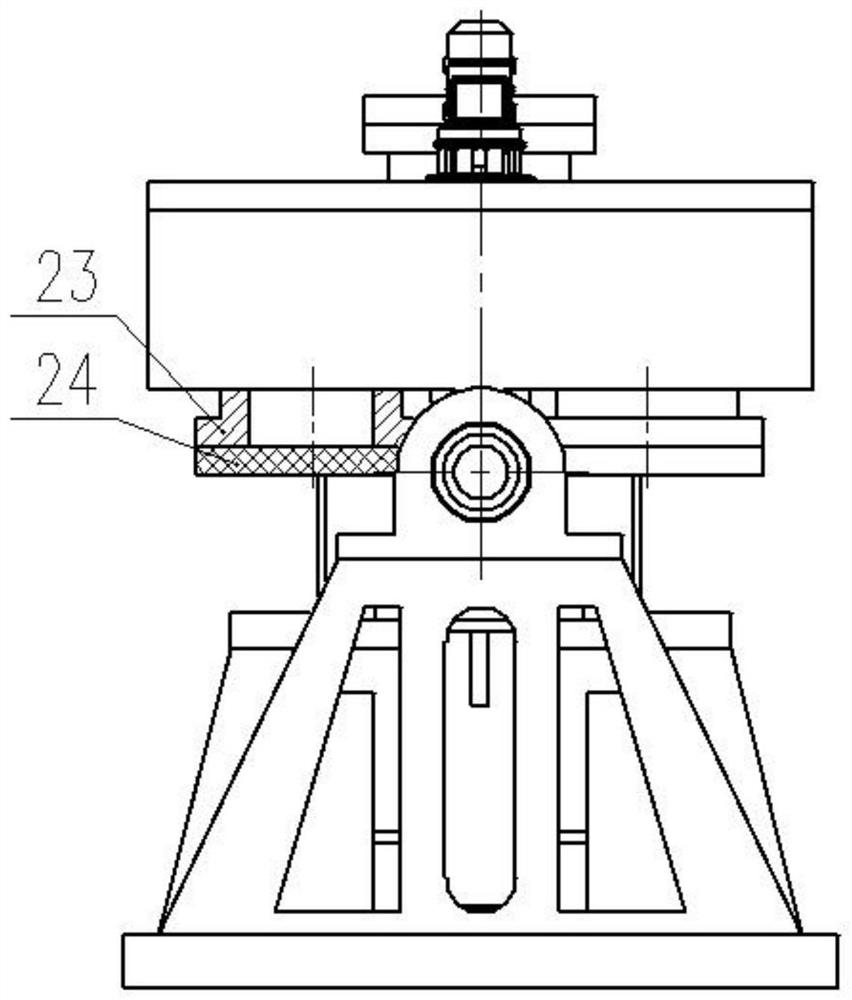

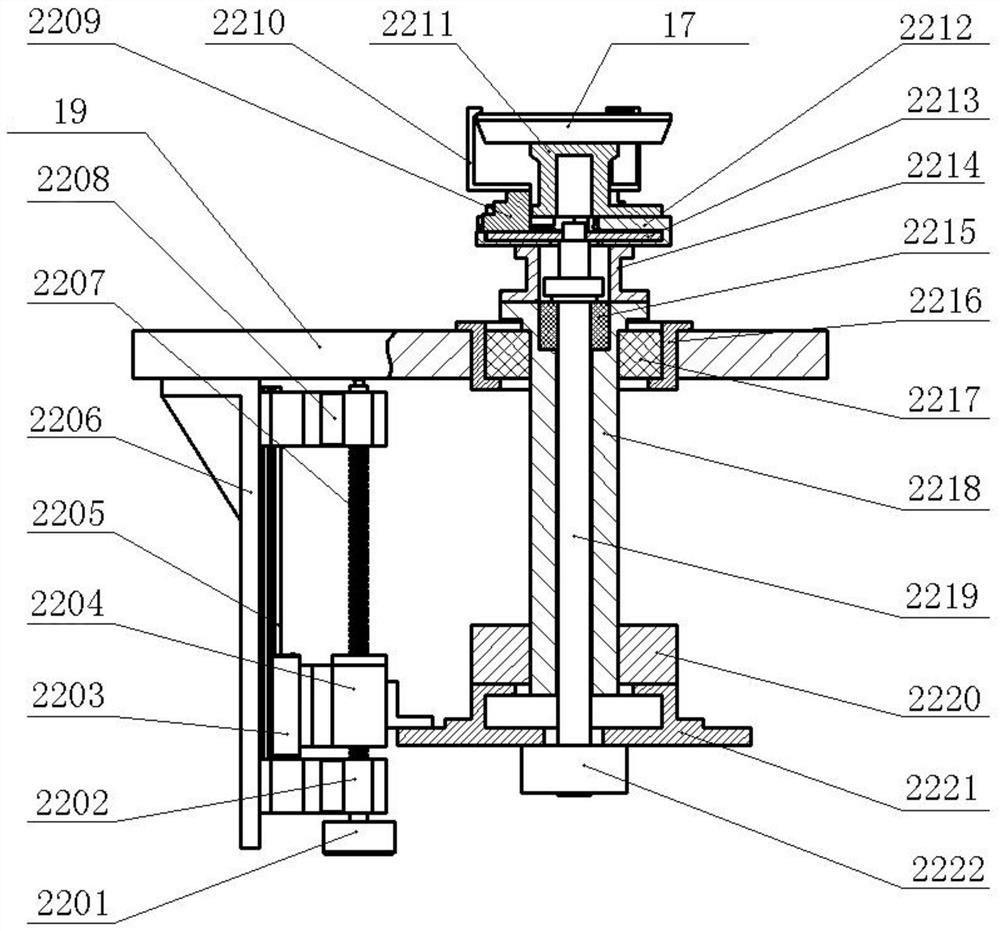

Multifunctional electron beam zone melting furnace

PendingCN111118596AMeet the smelting methodSynchronized Coordinated MovementsPolycrystalline material growthBy zone-melting liquidsAutomatic controlZone melting

Owner:GRIMAT ENG INST CO LTD

Controlled surface topography for enhanced protein crystallization rates

InactiveUS20080119642A1Prevent uncontrolled evaporationPolycrystalline material growthFrom normal temperature solutionsProtein solutionTopography

Owner:ALFRED UNIVERSITY

Preparation method of lithium niobate single crystal

ActiveCN105839178AHigh purityUniform compositionPolycrystalline material growthBy pulling from meltMass ratioLithium carbonate

Owner:YANCHENG GENION ELECTRONICS MATERIALS FACTORY

Method for improving epitaxial growth rate of silicon

ActiveCN113737276AIncrease productivityAvoid time costPolycrystalline material growthSemiconductor/solid-state device manufacturingPhysical chemistryMaterials science

A method for improving the epitaxial growth rate of silicon comprises the following steps: heating a reaction cavity base; introducing gaseous trichlorosilane carried by hydrogen as a growth raw material; removing reaction byproducts by using hydrogen; mounting a silicon substrate slice on the reaction cavity base, and heating the base; removing various impurities volatilized from the silicon substrate slice and the base by using hydrogen; taking gaseous trichlorosilane carried by hydrogen as a growth raw material, and growing a silicon epitaxial layer on the surface of the silicon substrate slice; removing the reaction byproducts in the growth process out of the reaction cavity by using hydrogen; and taking out after the temperature of the silicon epitaxial wafer is reached. The production efficiency of the silicon epitaxial wafer with the thickness of 150-200 mm is greatly improved, the process time and the maintenance cost are remarkably reduced, the process is simple, the operability is high, and the method is a large-scale industrial production technology suitable for the extremely-thick silicon epitaxial wafer with the silicon epitaxial layer thickness higher than 150 [mu]m and can be applied to the field of high-voltage power devices.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST +1

Graphite disc turnover type GaN single crystal substrate laser pre-stripping integrated cavity

PendingCN111778559AAchieve heat preservationReduced growth quality issuesPolycrystalline material growthFrom chemically reactive gasesSingle crystal substrateSingle crystal

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

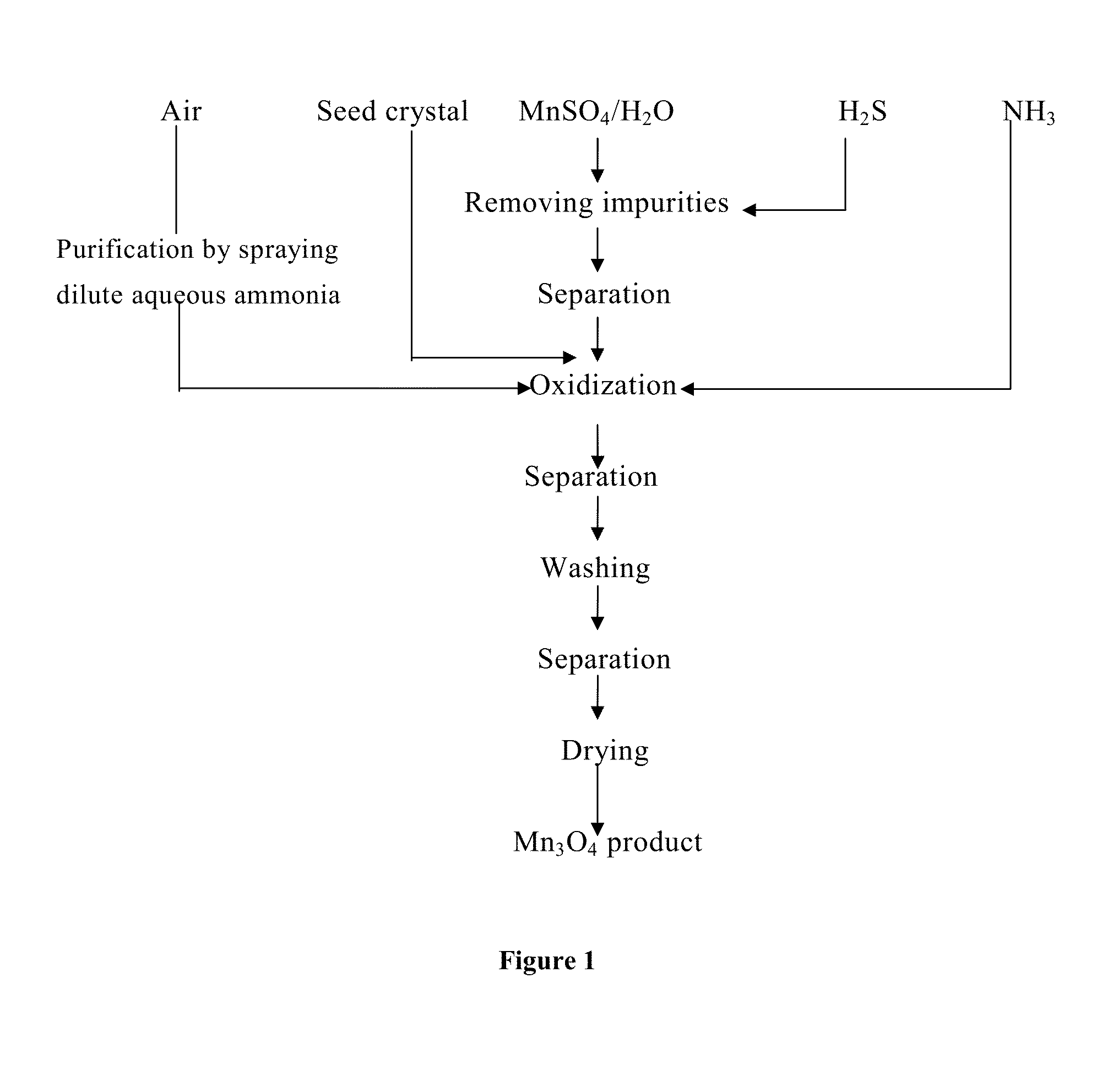

Methods for preparing trimanganese tetroxide with low bet specific surface area, methods for controlling particle size of trimanganese tetroxide and trimanganese tetroxide product

InactiveUS20130344333A1Improve battery cycle performanceReduce the presence of impuritiesFrom normal temperature solutionsManganese oxides/hydroxidesManganese(II,III) oxideChemistry

Owner:GUIZHOU REDSTAR DEVING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap

![Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method](https://images-eureka.patsnap.com/patent_img_release/38585591-87d6-4f06-8e07-ed0eac7d2896/HDA0000721352810000011.PNG)

![Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method](https://images-eureka.patsnap.com/patent_img_release/38585591-87d6-4f06-8e07-ed0eac7d2896/HDA0000721352810000021.PNG)

![Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method Etching solution for dislocation display of monocrystal germanium wafer deflecting to crystal orientation [111] and etching method](https://images-eureka.patsnap.com/patent_img_release/38585591-87d6-4f06-8e07-ed0eac7d2896/HDA0000721352810000022.PNG)