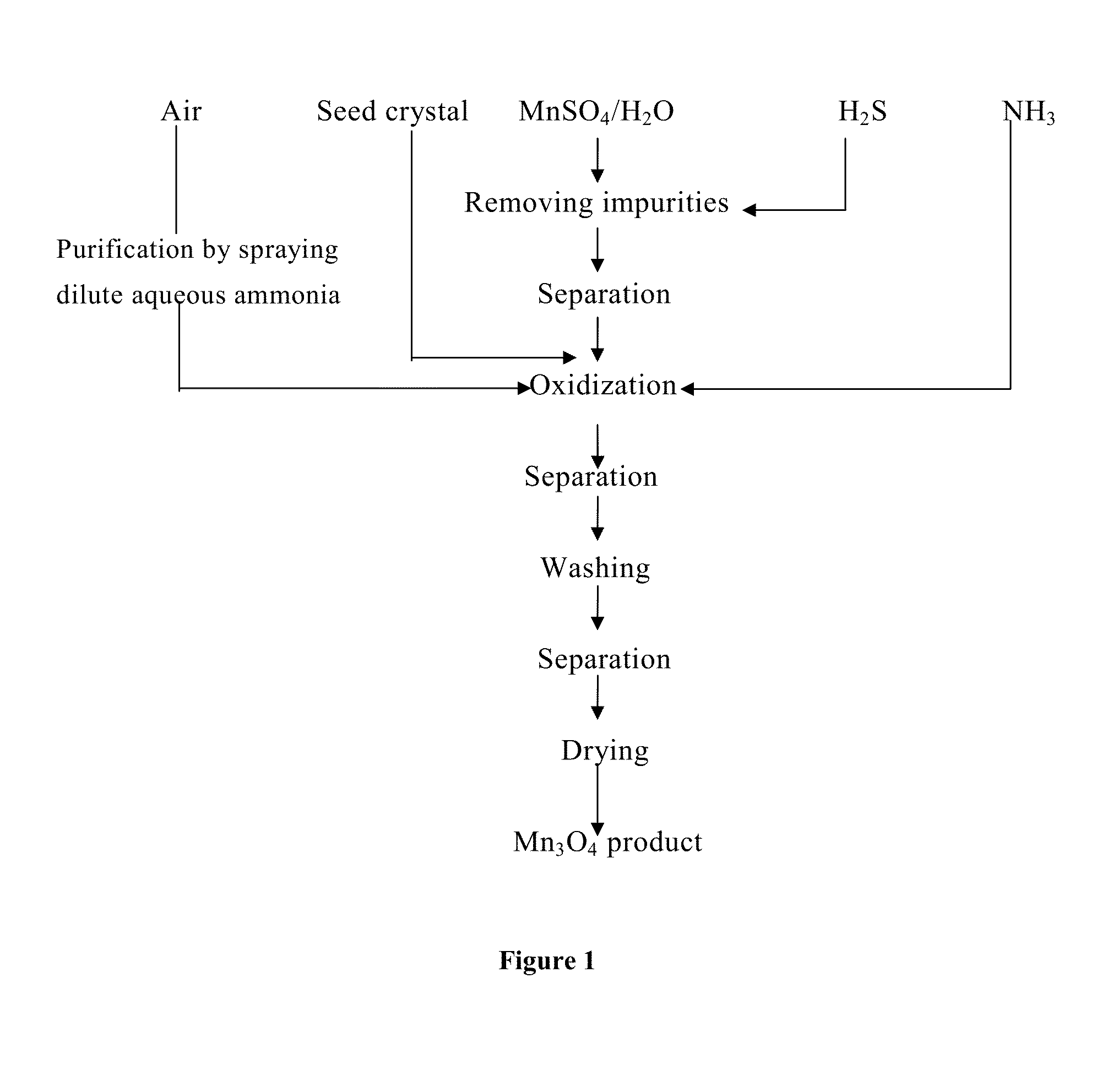

Methods for preparing trimanganese tetroxide with low bet specific surface area, methods for controlling particle size of trimanganese tetroxide and trimanganese tetroxide product

a technology of trimanganese tetroxide and specific surface area, which is applied in the field of secondary batteries, can solve the problems of not being able to ensure the purity of mn3o4 obtained, the inability to prepare lithium manganate materials, and the gap between the properties of the product and the requirements of international mainstream clients, so as to improve the circulation property of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Purifying Air

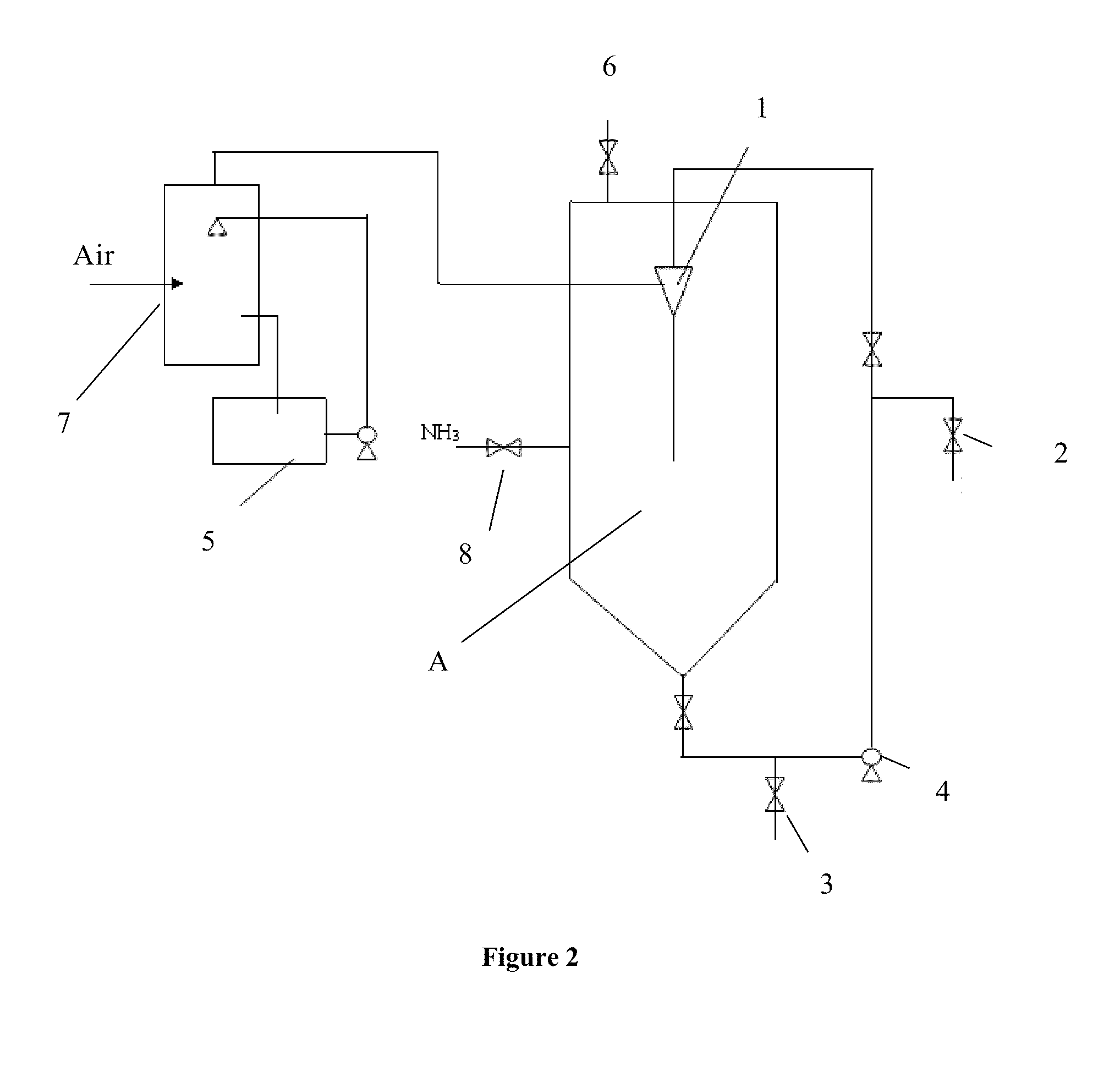

[0099]As shown in FIG. 2, the air is purified in the air purification tower 7 which is shown in FIG. 2 by spraying dilute aqueous ammonia with a concentration of 0.5 mol / L according to the proportion of 8 L of the dilute aqueous ammonia per cubic meter of air.

(2) Pretreatment of MnSO4 / H2O

[0100]The concentration of the MnSO4 solution obtained from product prepared by absorption of SO2 fume with manganese dioxide ore is adjusted to 150 g / L (in a container which is not shown in FIG. 2). NH4OH solution with a concentration of 10 mol / L is added so as to adjust pH value of the solution to 5.5. H2S gas is introduced into the MnSO4 solution until pH value reaches 2.5, and then the mixture is separated by pressure-filtration separation to obtain filtrate and solid. The filter residue is discarded. H2O2 solution is added to the filtrate according to the proportion of 2.5 L H2O2 with weight content of 27.5 wt % per cubic meter of the filtrate and the mixture is heated to

example 2

(1) Purifying Air

[0103]As shown in FIG. 2, the air is purified in the air purification tower 7 which is shown in FIG. 2 by spraying dilute aqueous ammonia with a concentration of 0.8 mol / L according to the proportion of 9 L of the dilute aqueous ammonia per cubic meter of air.

(2) Pretreatment of MnSO4 / H2O

[0104]The concentration of the MnSO4 solution obtained from product prepared by absorption of SO2 fume with manganese dioxide ore is adjusted to 150 g / L (in a container which is not shown in FIG. 2). NH4OH solution with a concentration of 10 mol / L is added so as to adjust pH value of the solution to 5.8. H2S gas is introduced into the MnSO4 solution until pH value reaches 2.8, and then the mixture is separated by pressure-filtration separation to obtain filtrate and solid. The obtained filter residue is discarded. H2O2 solution is added to the filtrate according to the proportion of 2.5 L H2O2 with weight content of 27.5 wt % per cubic meter of the filtrate and the mixture is h

example 3

(1) Purifying Air

[0107]As shown in FIG. 2, the air is purified in the air purification tower 7 which is shown in FIG. 2 by spraying dilute aqueous ammonia with a concentration of 1.0 mol / L according to the proportion of 10 L of the dilute aqueous ammonia per cubic meter of air.

(2) Pretreatment of MnSO4 / H2O

[0108]The concentration of the MnSO4 solution obtained from product prepared by absorption of SO2 fume with manganese dioxide ore is adjusted to 200 g / L (in a container which is not shown in FIG. 2). NH4OH solution with a concentration of 10 mol / L is added so as to adjust pH value of the solution to 6.0. H2S gas is introduced into the MnSO4 solution until pH value reaches 3.0, and then the mixture is separated by pressure-filtration separation to obtain filtrate and solid. The filter residue is discarded. H2O2 solution is added to the filtrate according to the proportion of 2.5 L H2O2 with weight content of 27.5 wt % per cubic meter of the filtrate and the mixture is heated to

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap