Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about "Biofuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

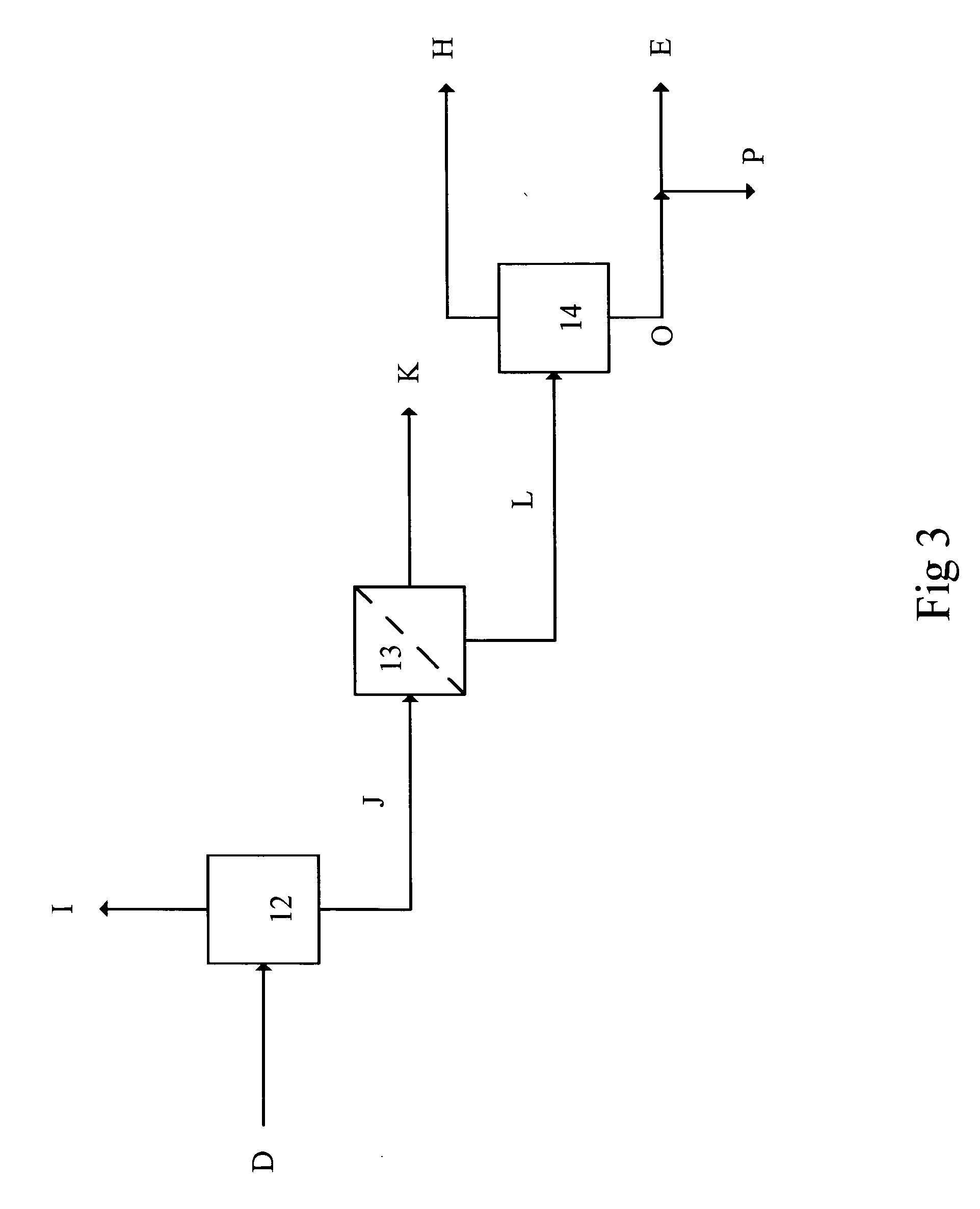

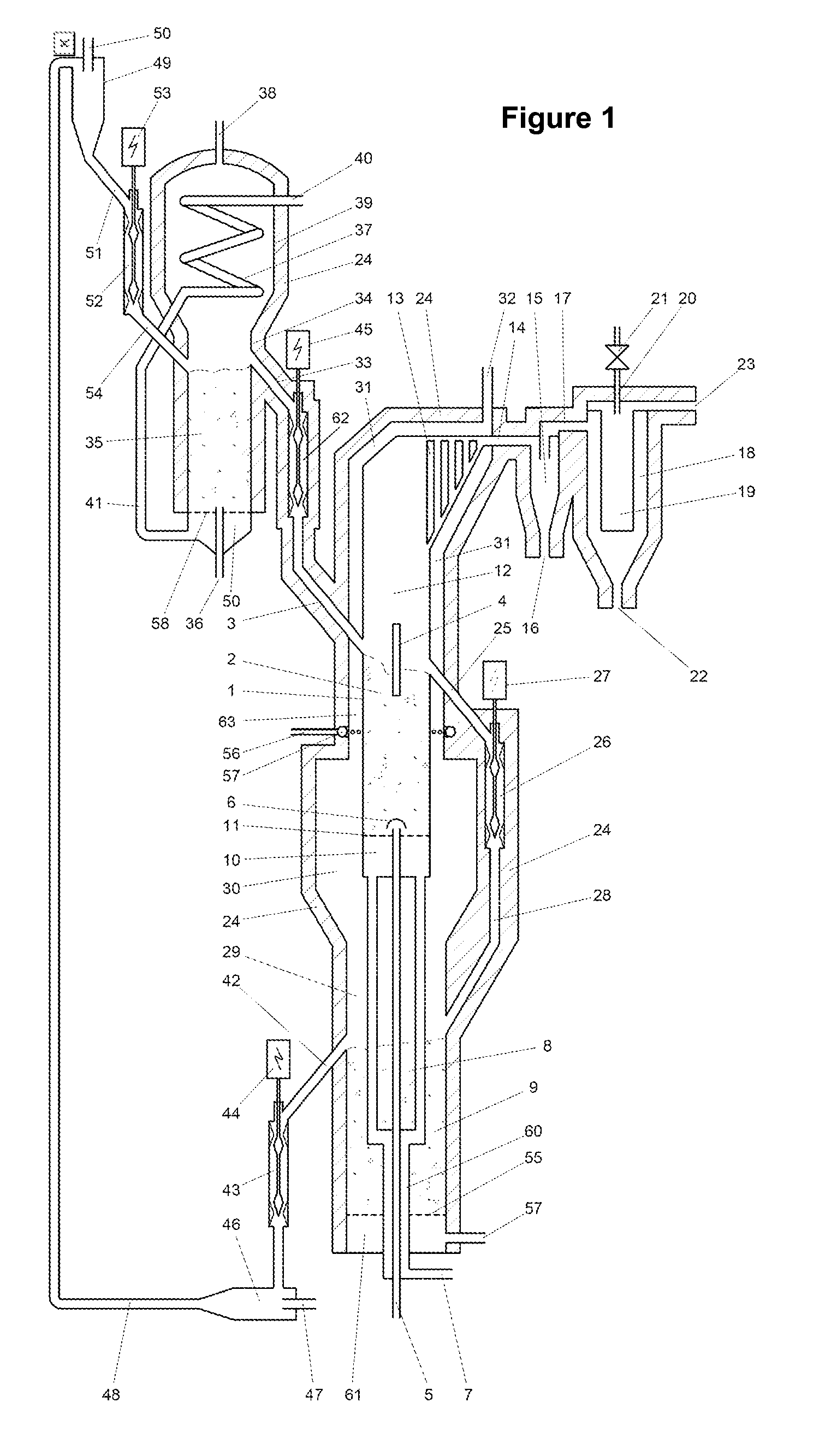

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

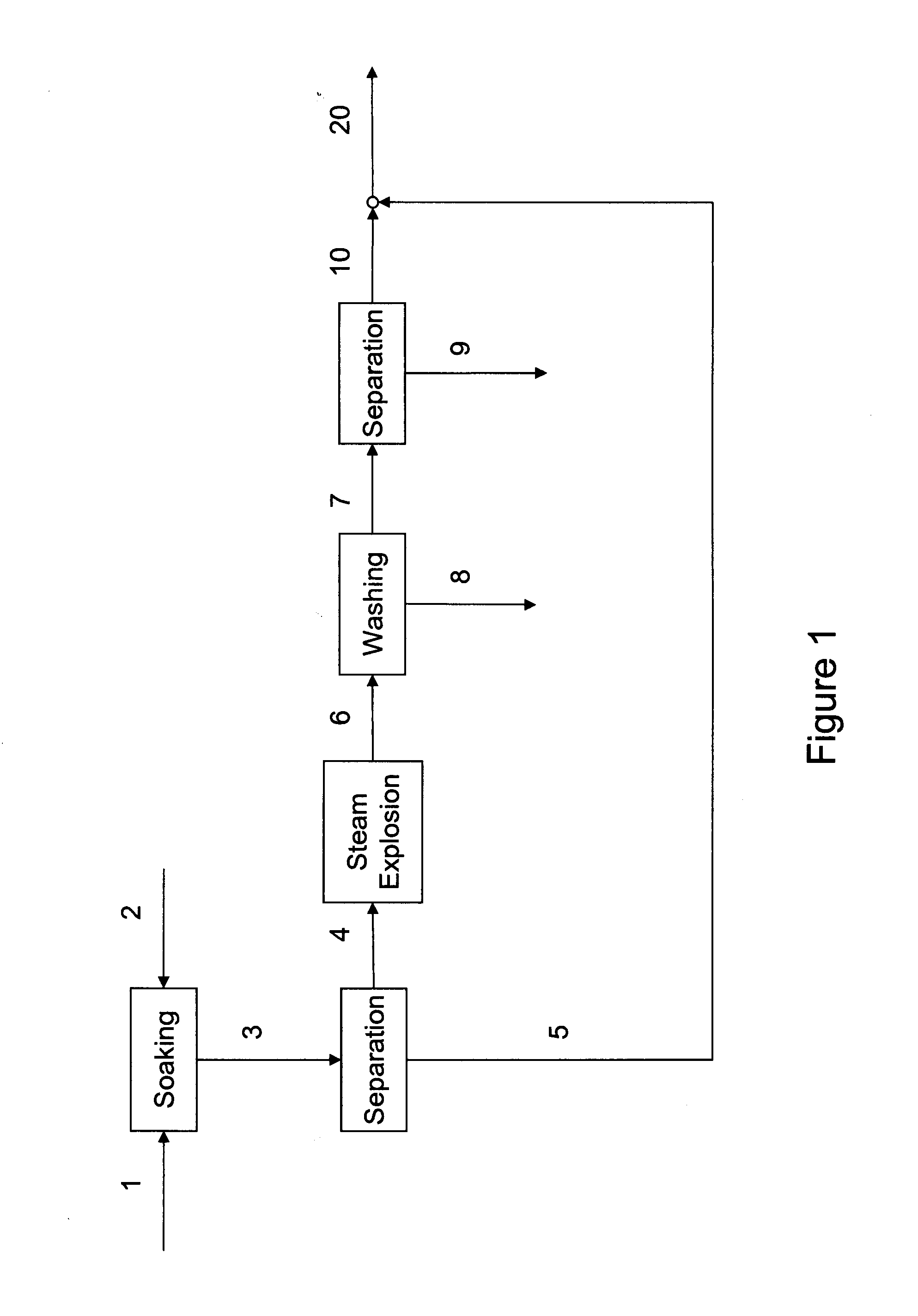

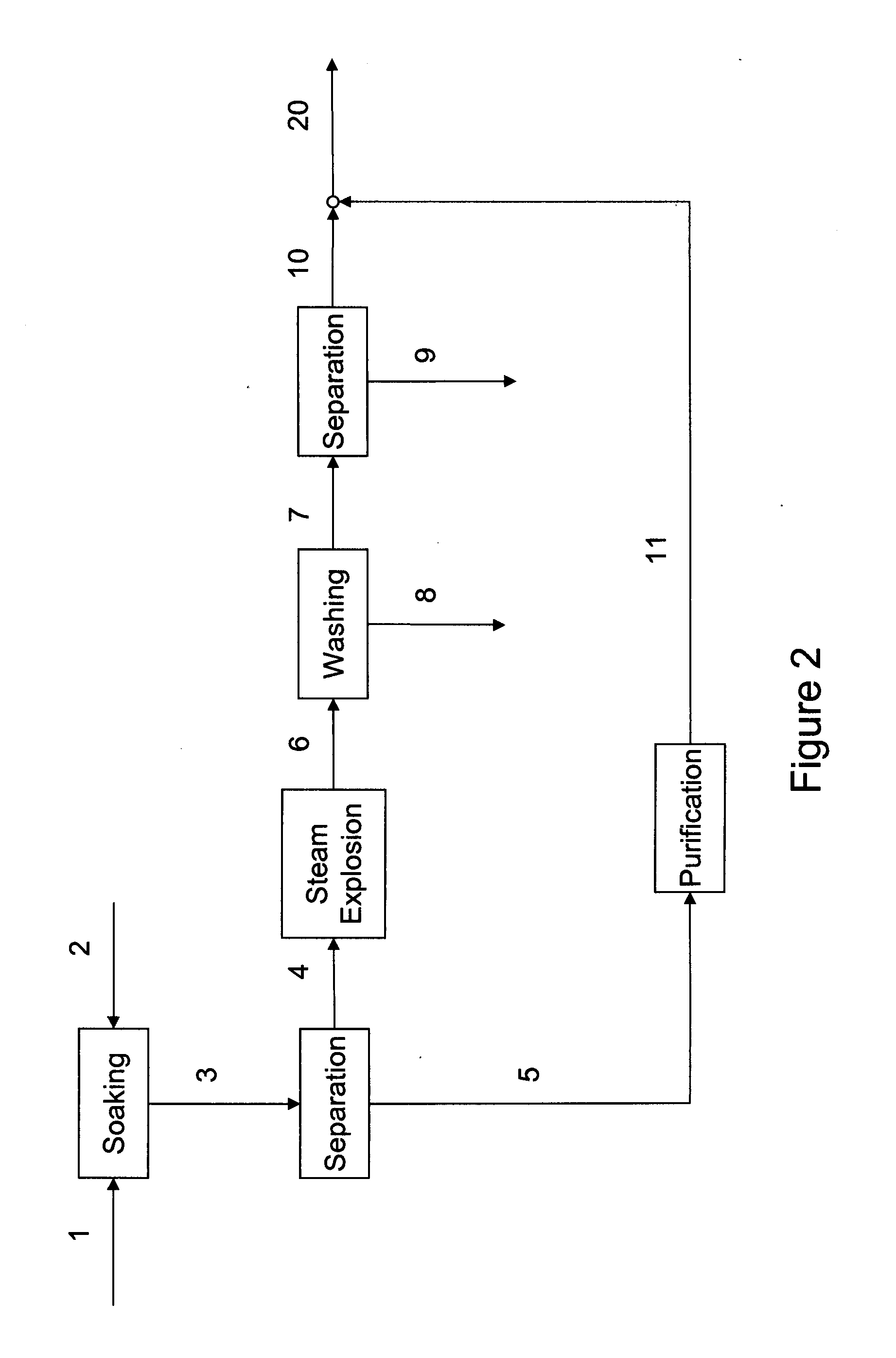

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

Method for preparing biodiesel by lowering value of high acid palm oil

InactiveCN101230309ALow acid valueHigh catalytic activityFatty acid esterificationBiofuelsAlcoholBiodiesel

The invention provides a method which uses palm oil to prepare biologic diesel oil and can lower the high acid value. The method uses solid super acids of SO>4<2- > / ZrO2, SO4< 2- > / TiO2, and SO4< 2- > / xZrO<2- yTiO2 as catalyst, and uses low-carbon alcohol as esterifying agent to pre-treat the high acid value palm oil, can effectively lower the acid value of the oil, and can ensure the acid vale of the obtained biologic diesel oil to easily meet the standard (less than 0.8mgKOH / g, ASTM). The catalyst used by the invention has high catalytic activity, and is reusable. The process flow is simple, the production cost is decreased, and the environmental pollution is reduced greatly.

Owner:SICHUAN UNIV

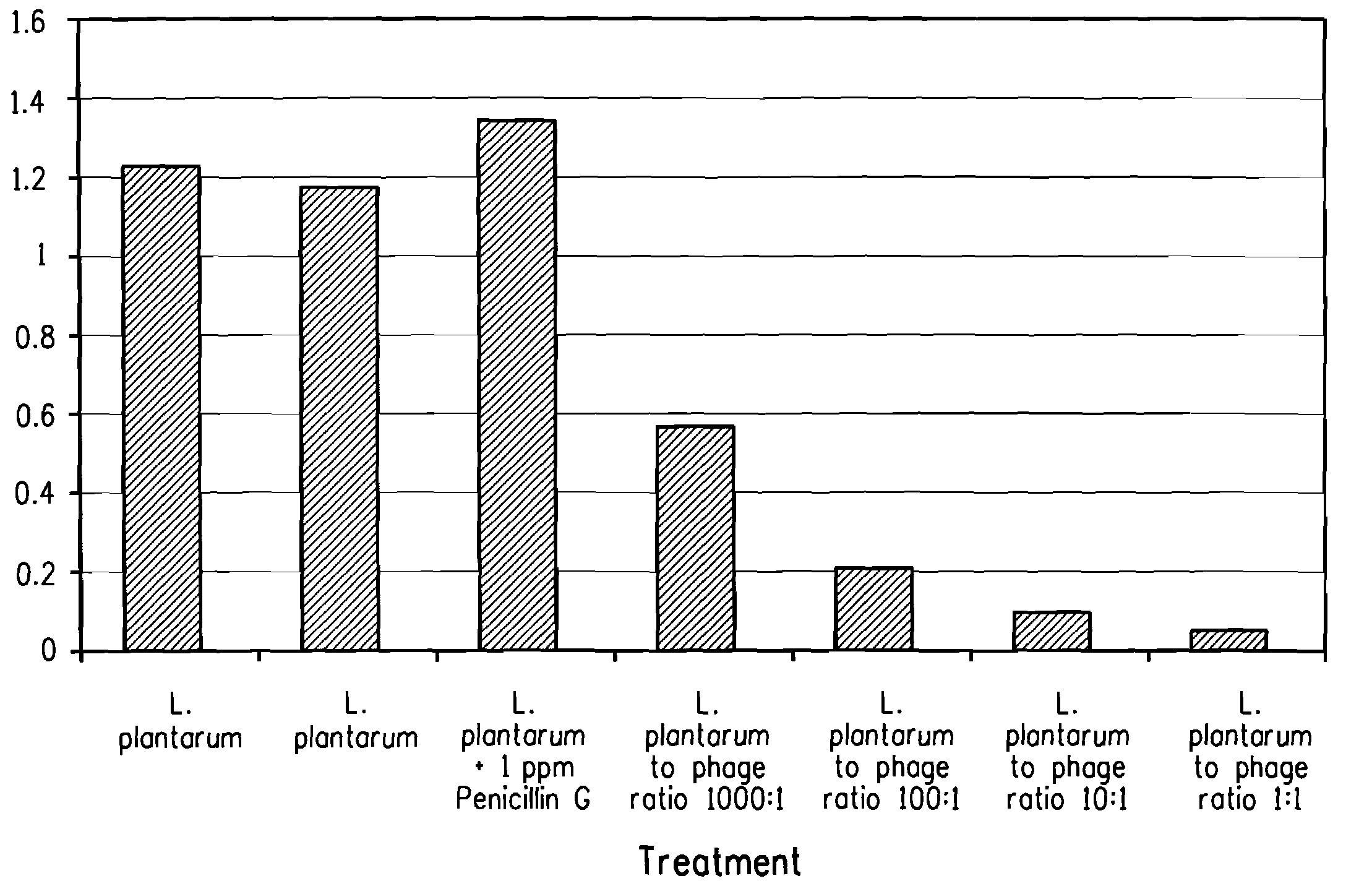

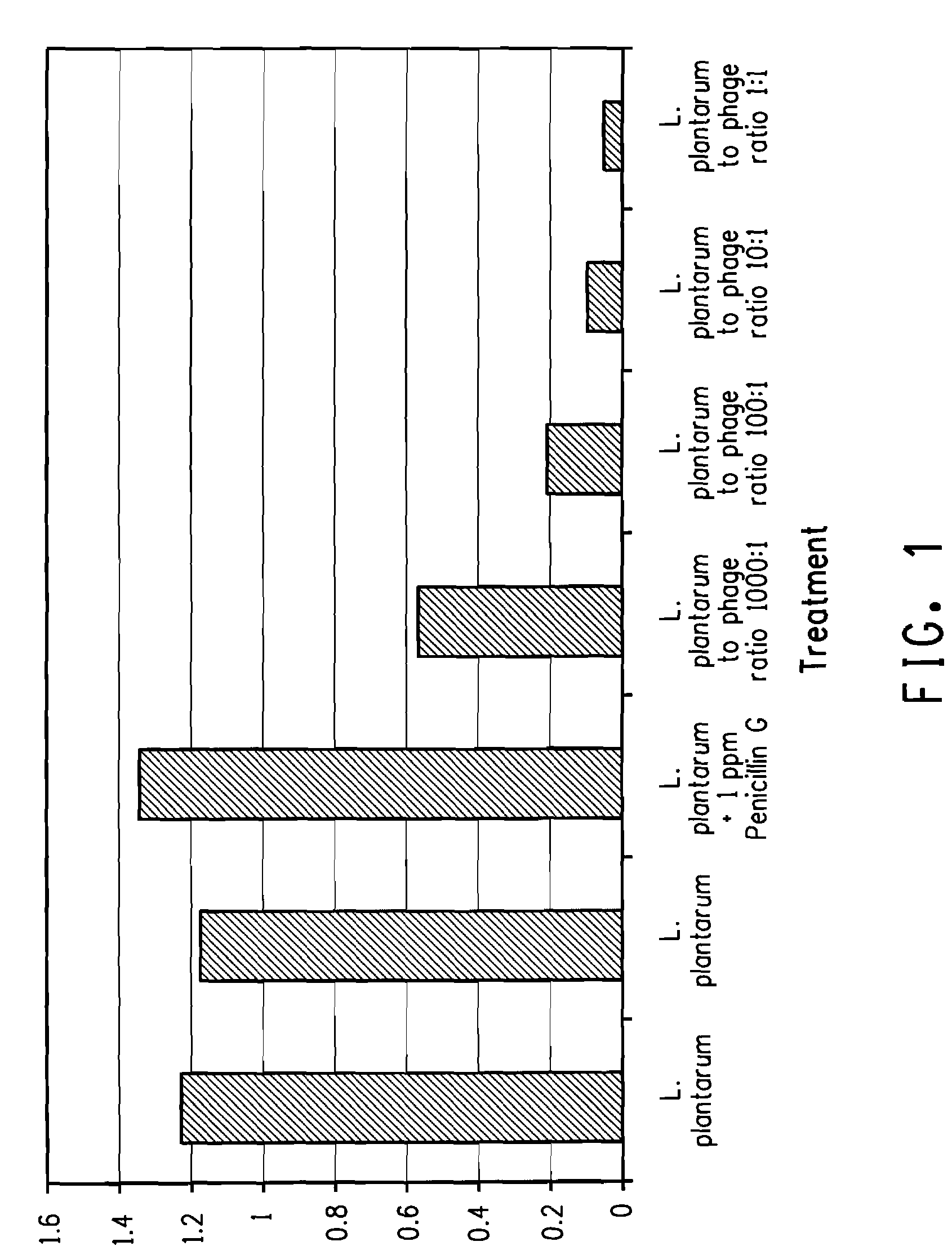

Utilization of bacteriophage to control bacterial contamination in fermentation processes

Owner:EI DU PONT DE NEMOURS & CO

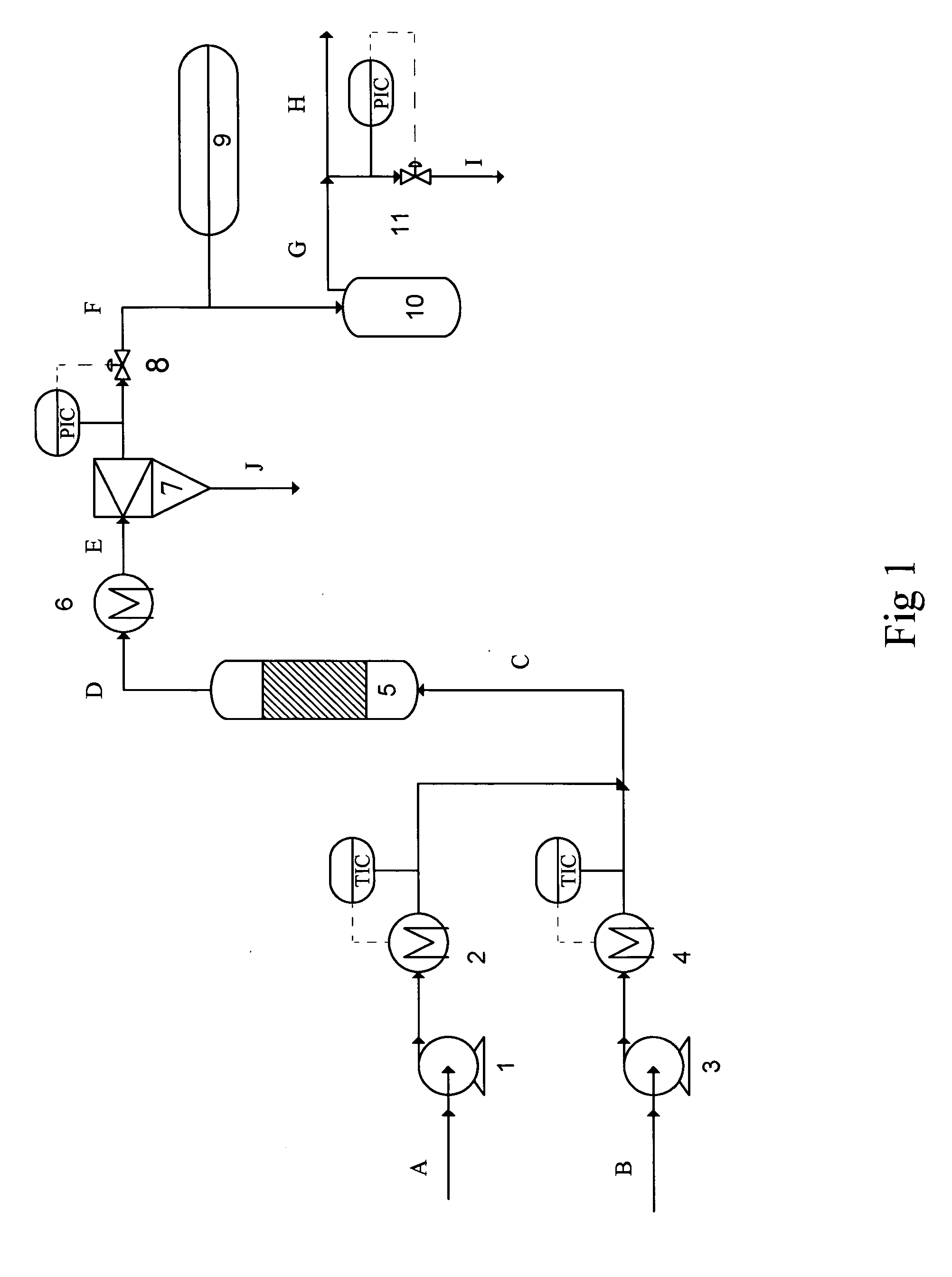

Method for producing ethanol from crop straw

ActiveCN101186943AEasy to separateTake advantage ofBiofuelsMicroorganism based processesSolid componentFiltration

The invention provides a process for producing ethanol with raw materials of straws. The process comprises preliminary treatment to crops straws, solid-liquid separation, hydrolyzed solid components and fermentation with yeasts after hyperfiltration and filtration enrichment by RO combination. The invention can simultaneously conduct evaporating concentration to liquid components, and produce corresponding by-product of lignosulfonate by adding sulfonating agent. The ethanol producing process of the invention greatly decreases the cost of industrial production which ferments straws to produce ethanol, and efficiently utilizes all the ingredients of crops straws.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

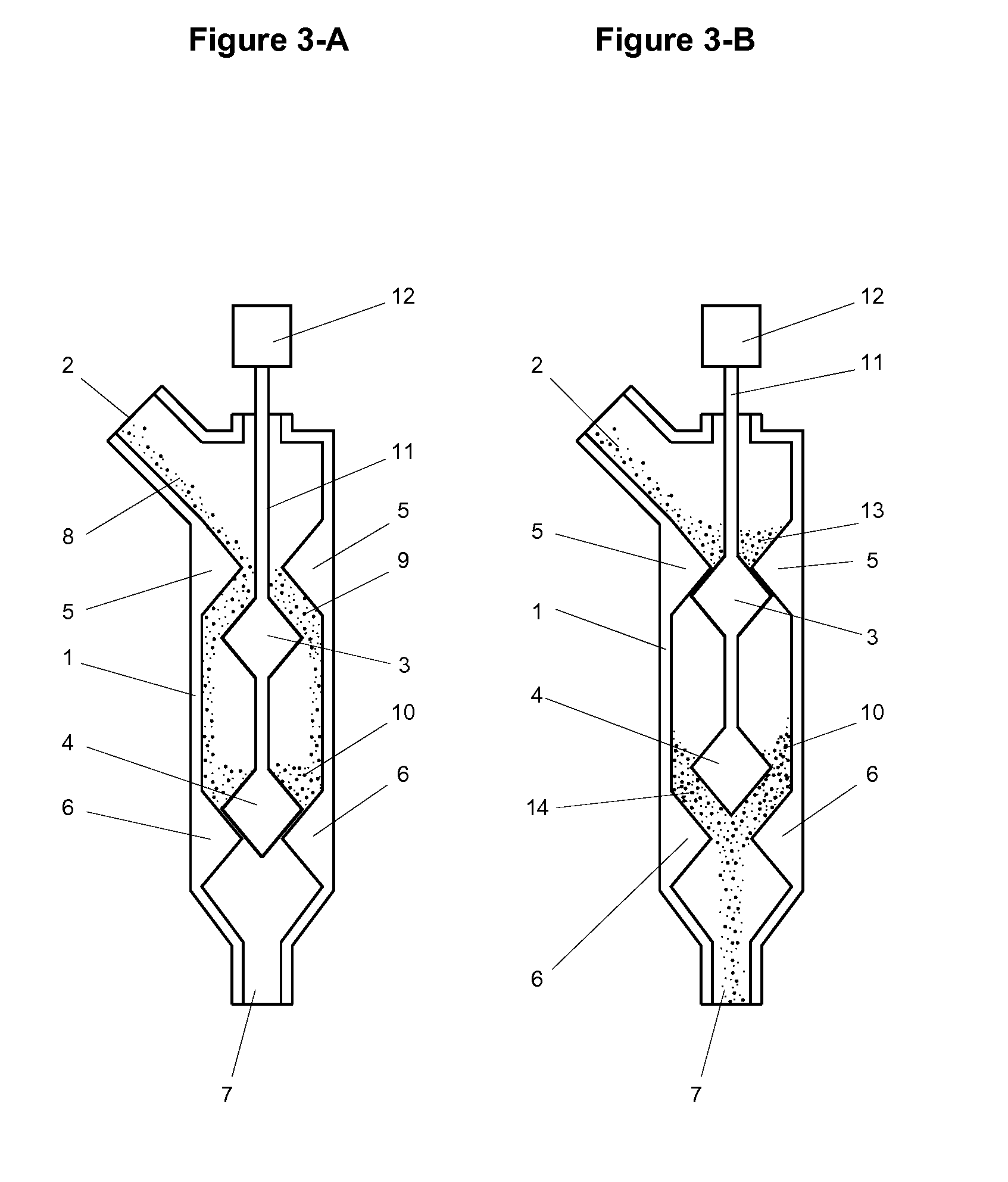

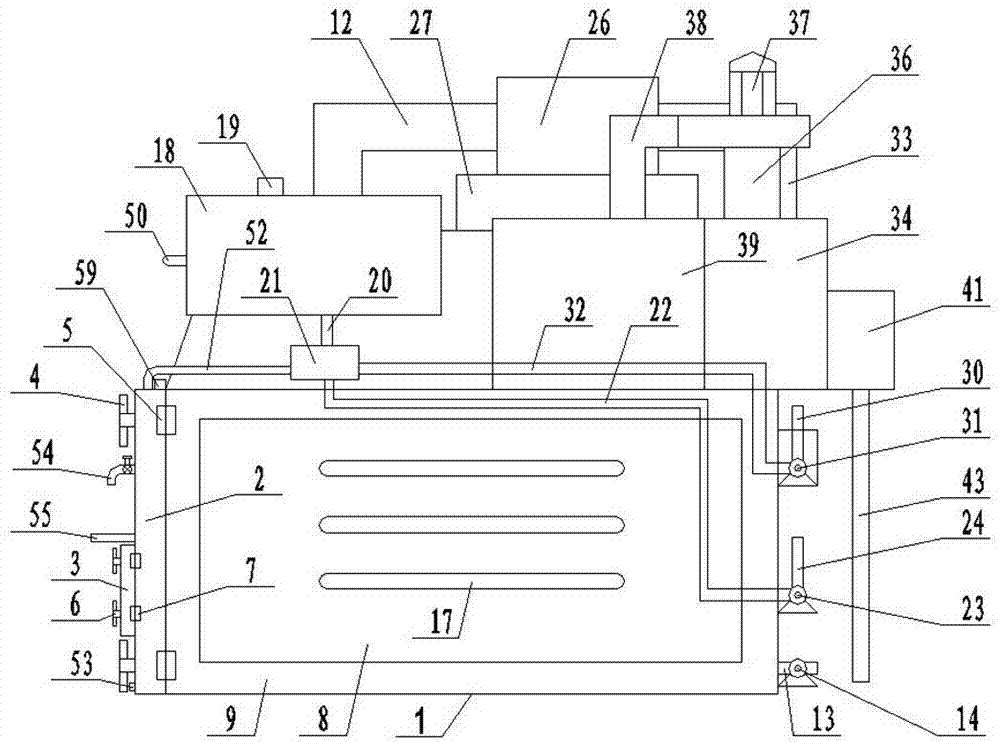

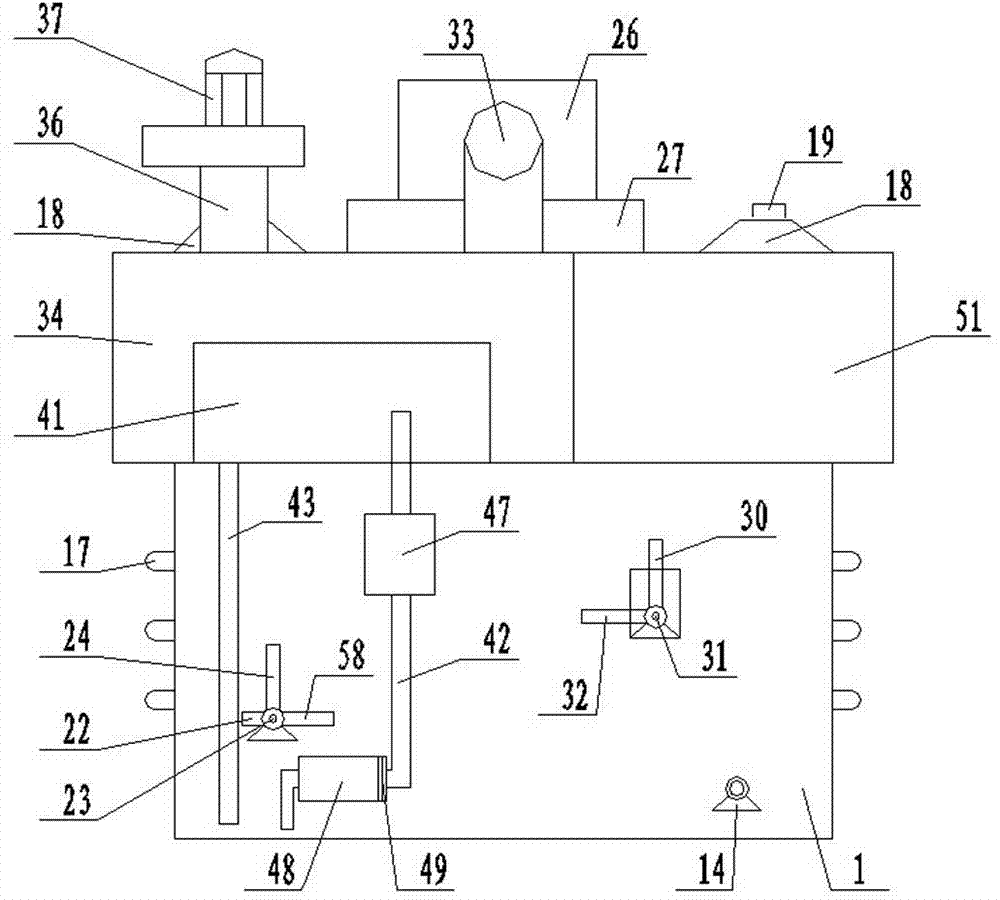

Regulation and control testing device for preparation of bio-oil through quick thermal cracking of biomass

Owner:BEIJING FORESTRY UNIVERSITY

Alcohol crossed circle manufacturing technique with potatoes as the main materials

The invention relates to an alcohol dual manufacturing technique with tuber as the main material in the alcohol fermentation industry technique, which comprises the following steps: mixing starch and the last anaerobic fermentation digestive liquid; heating, liquefying and reducing the temperature by adding maxilase and mixing homogeneously; adding the last distillery slop; saccharifying by adding glucoamylase; reducing the temperature; inoculating the extended culture distillery yeast; culturing in the constant temperature; acquiring the product alcohol by distilling; using distillery slop as the water for the next saccharifying and adjusting acid; cooling the rest slop and inoculating the last activated sludge in order to produce methane with anaerobic fermentation; recovering the activated sludge and digestive liquid by separating anaerobic fermentation liquid; making the digestive liquid back to the proportioning procedure as the technology water; circulating sequentially. The invention only needs a step anaerobic fermentation of distillery slop, which reduces investment of accommodation area and capital assets, can circulate anaerobic fermentation digestive liquid, achieves zero discharge of the wastewater from fermentation, achieves the circulation of the water resource and reduces the cost of alcohol.

Owner:JIANGNAN UNIV

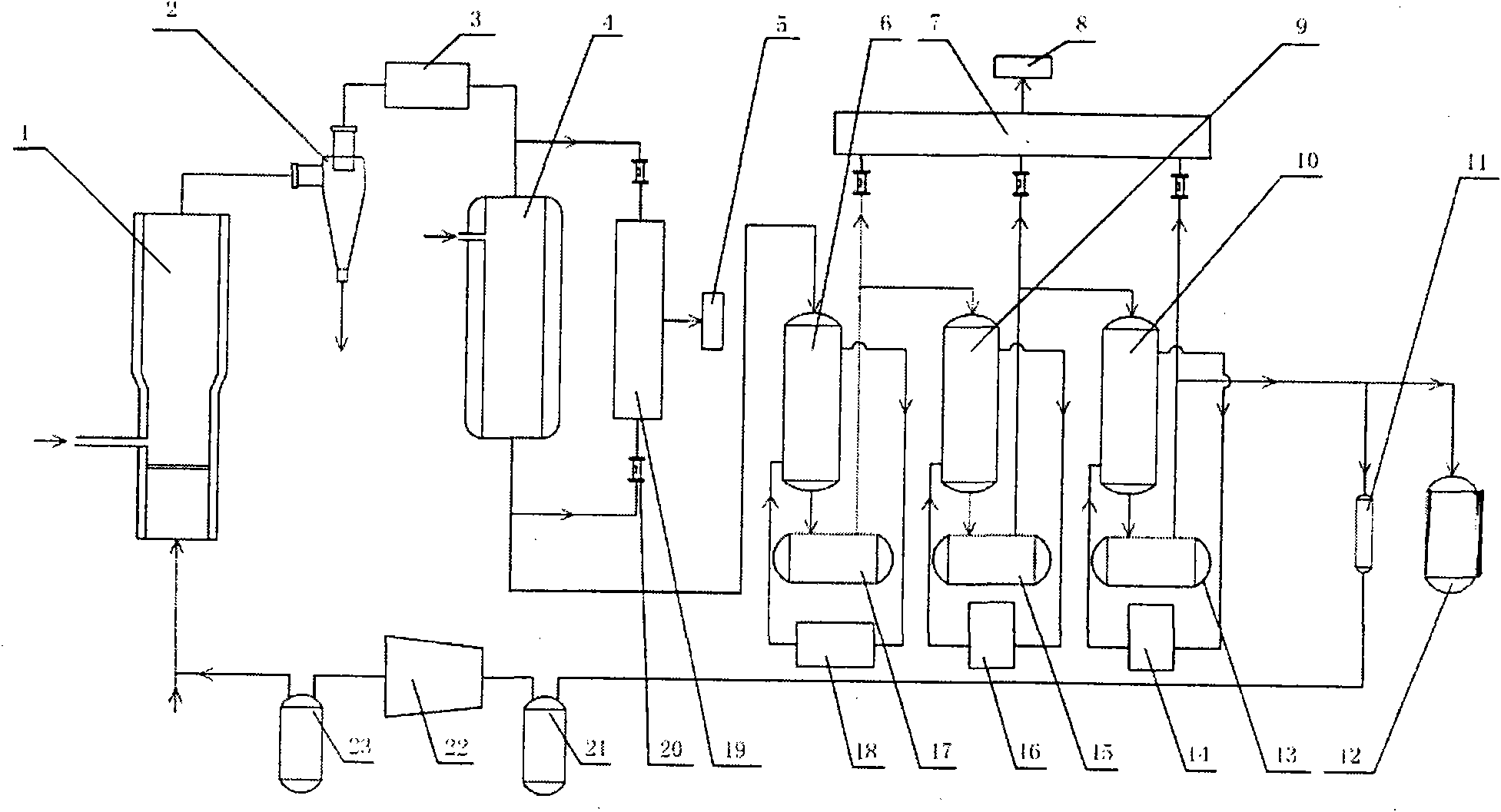

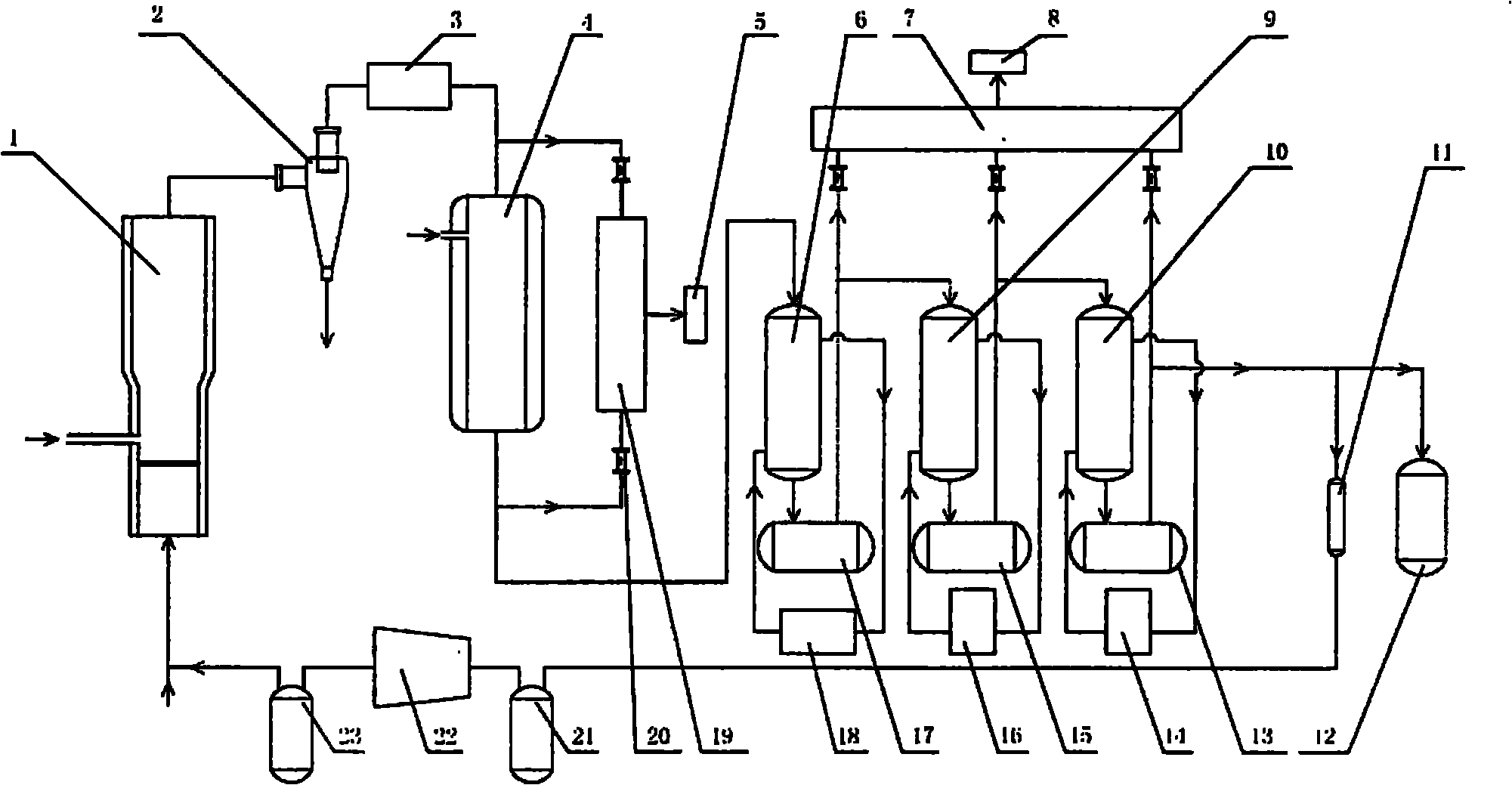

Equipment and a method for generating biofuel based on rapid pyrolysis of biomass

Owner:UNIV DE CONCEPCION

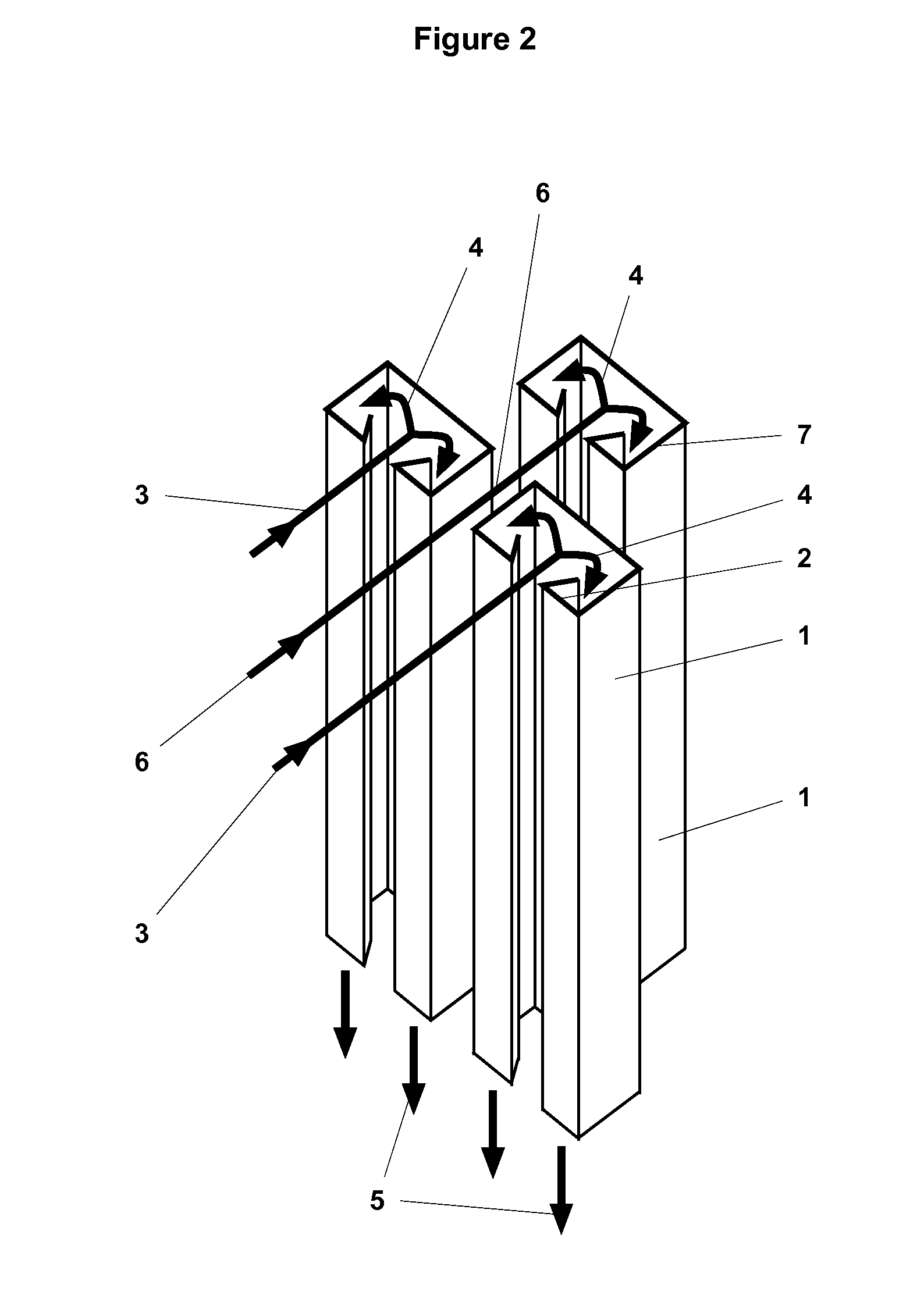

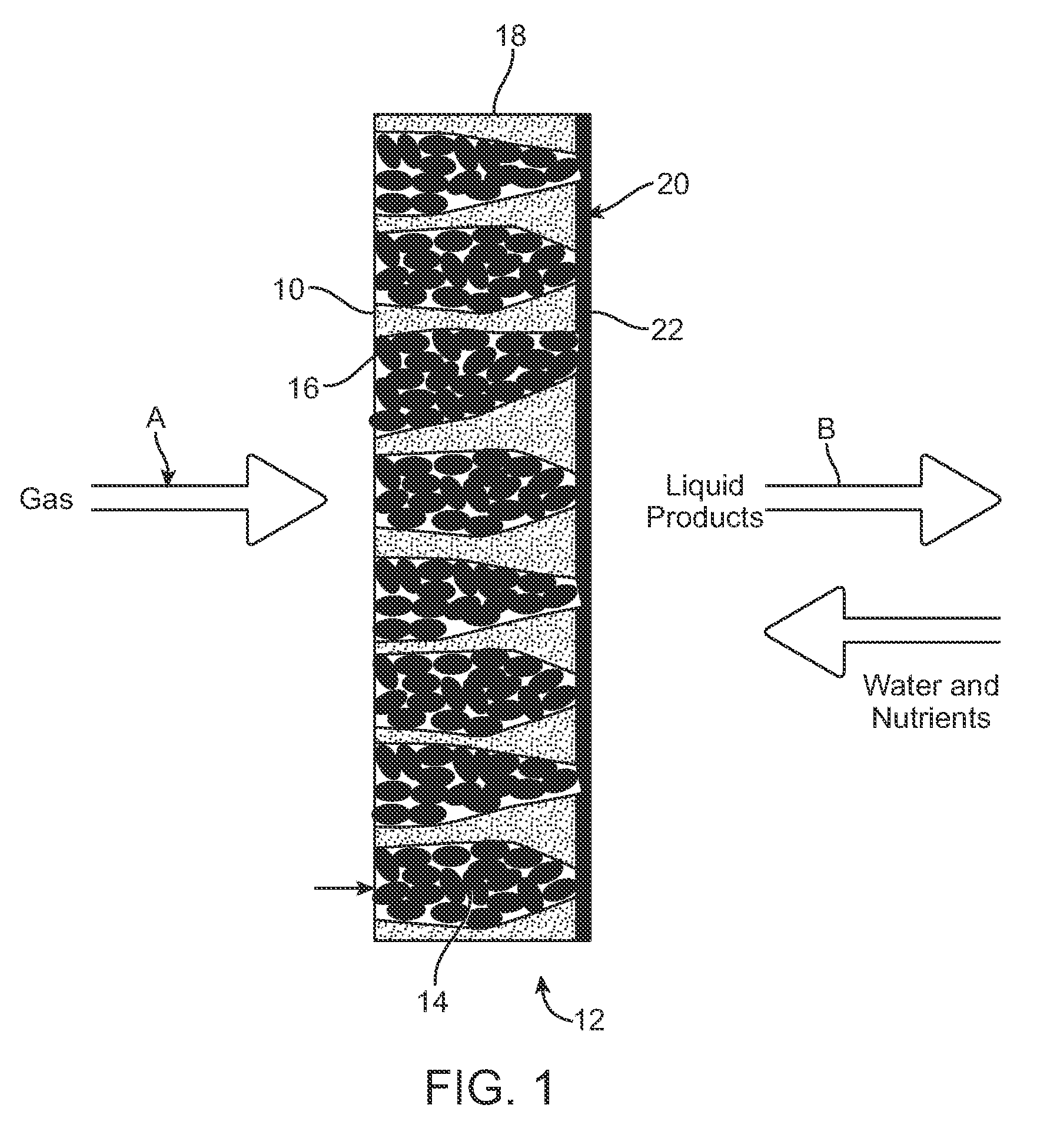

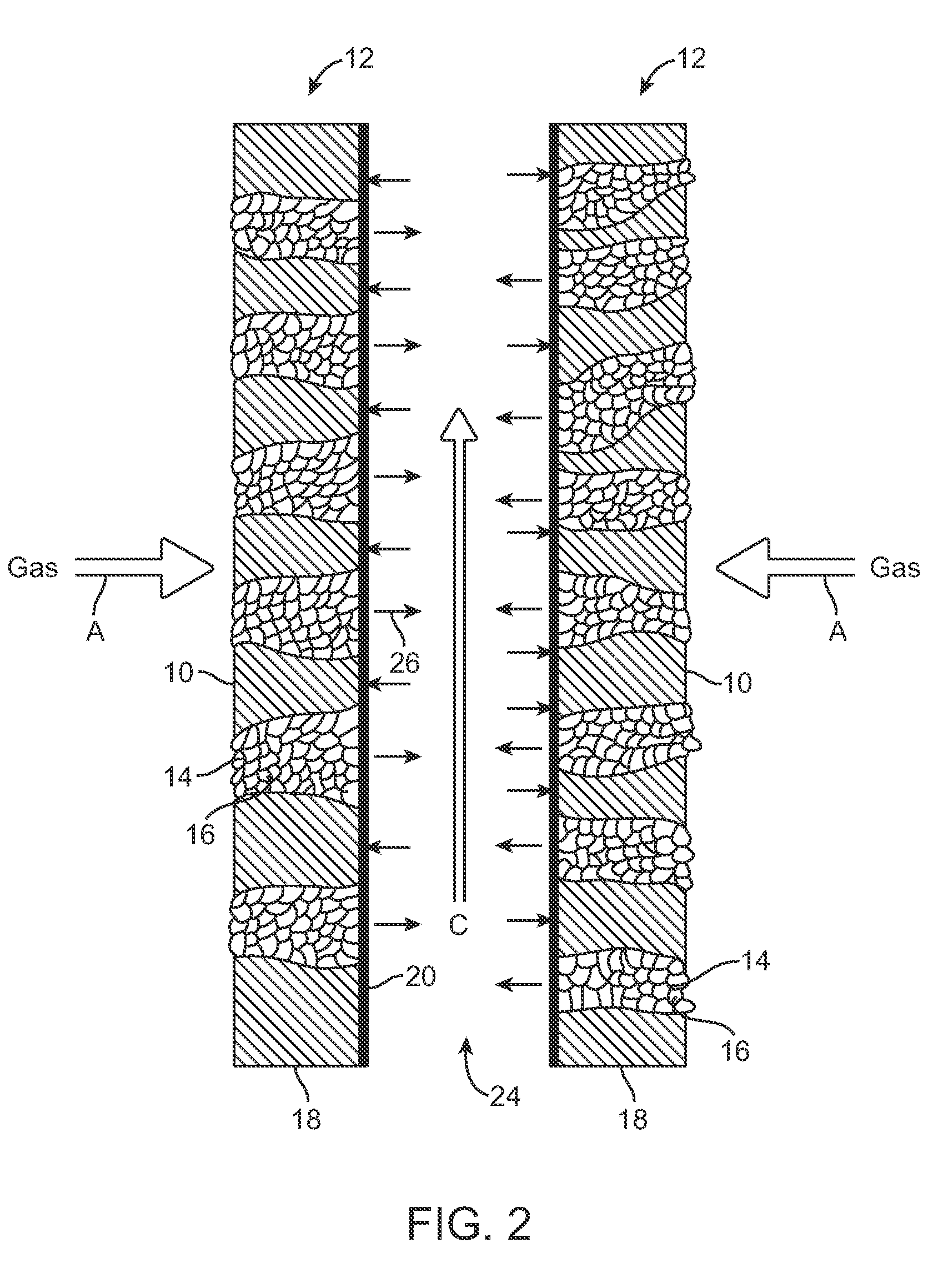

Stacked Array Bioreactor for Conversion of Syngas Components to Liquid Products

InactiveUS20090215153A1Promote and controlLess permeabilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productFiber

Owner:SYNATA BIO INC

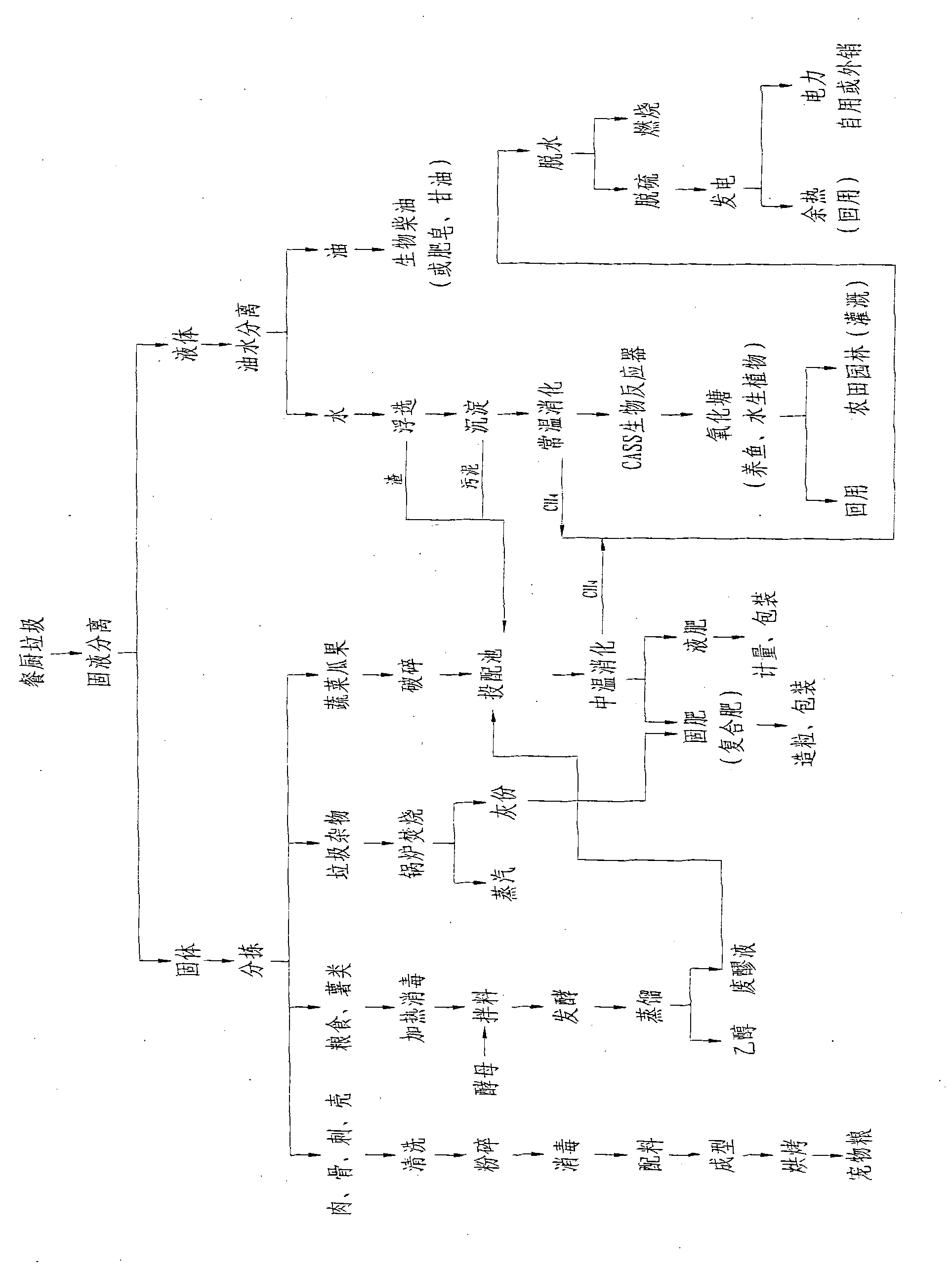

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

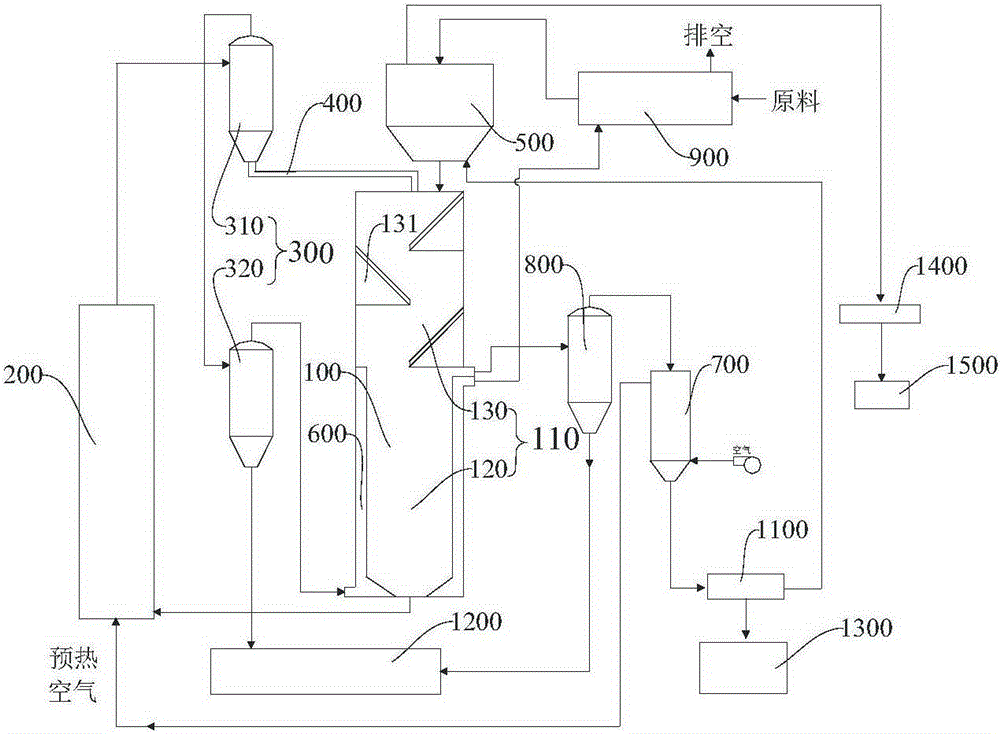

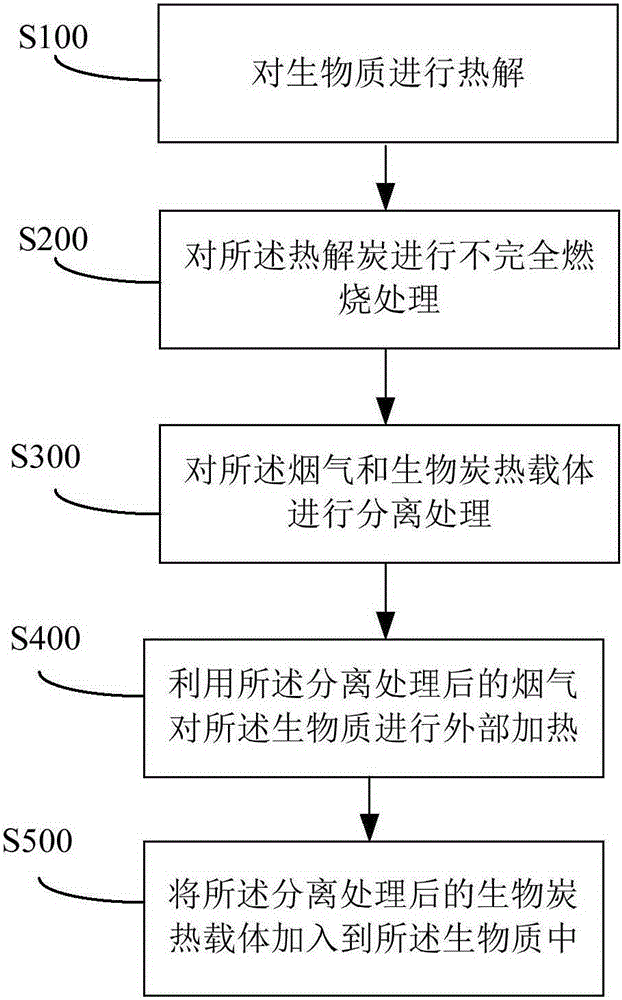

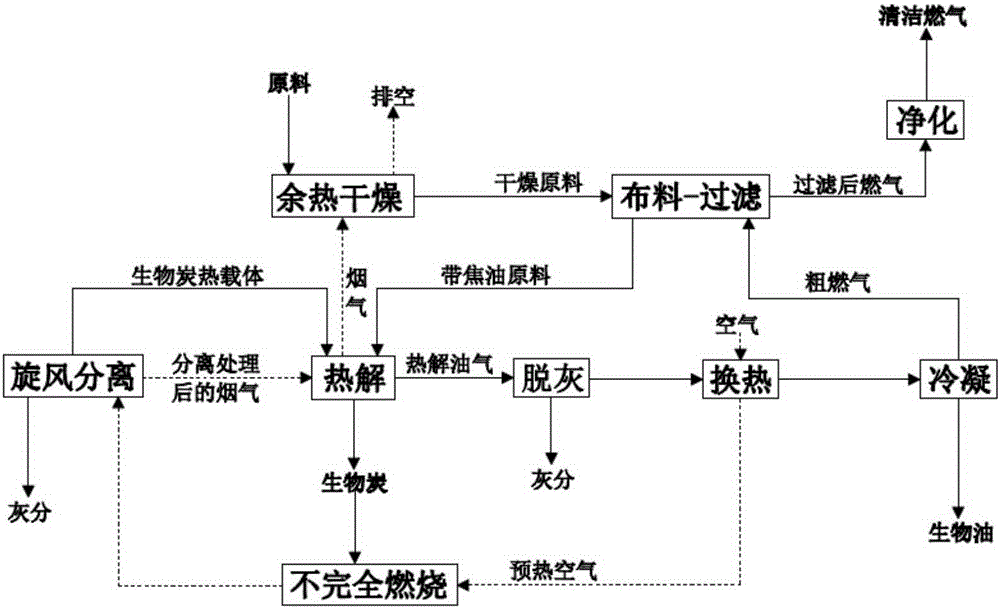

Biomass pyrolysis system and biomass pyrolysis method

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

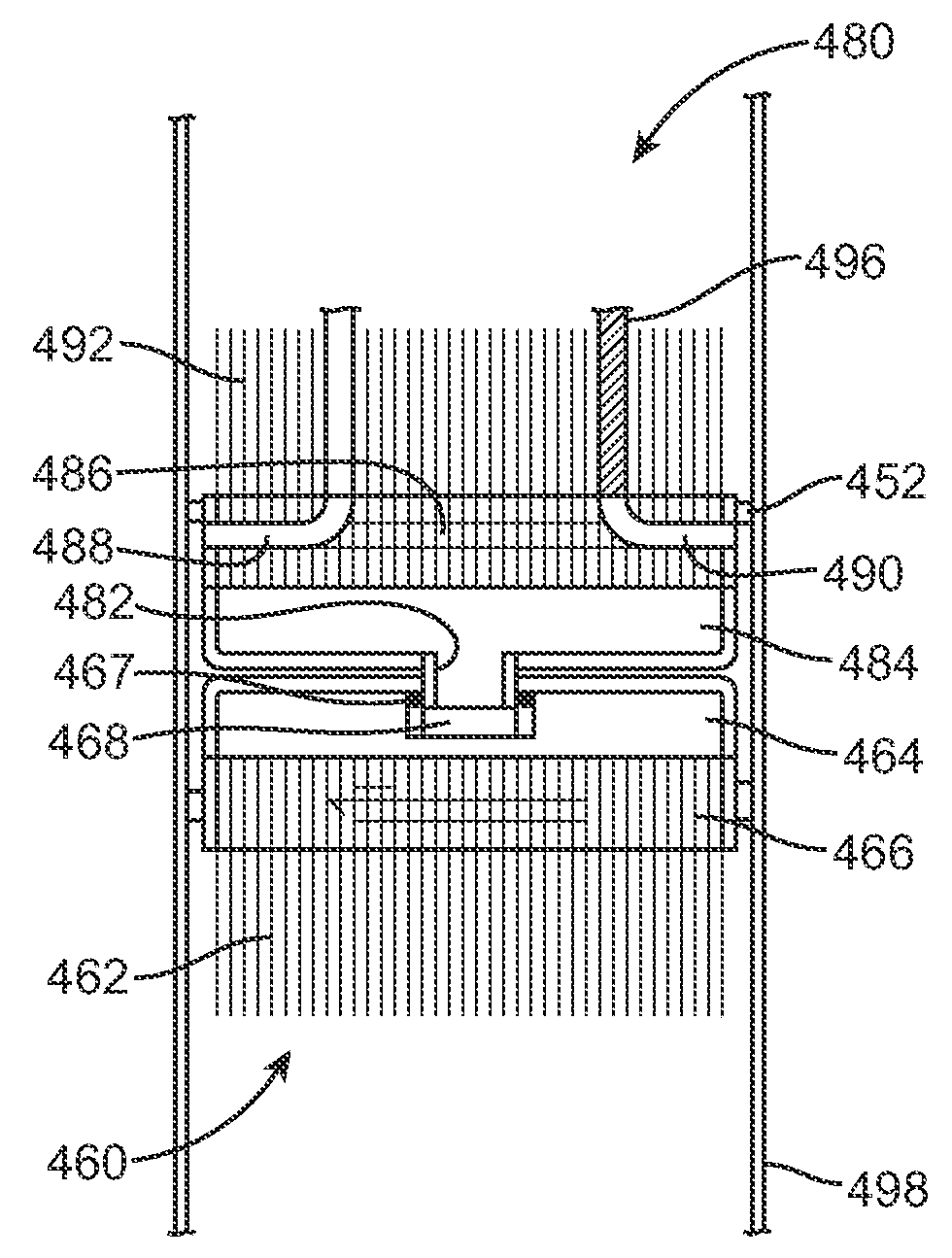

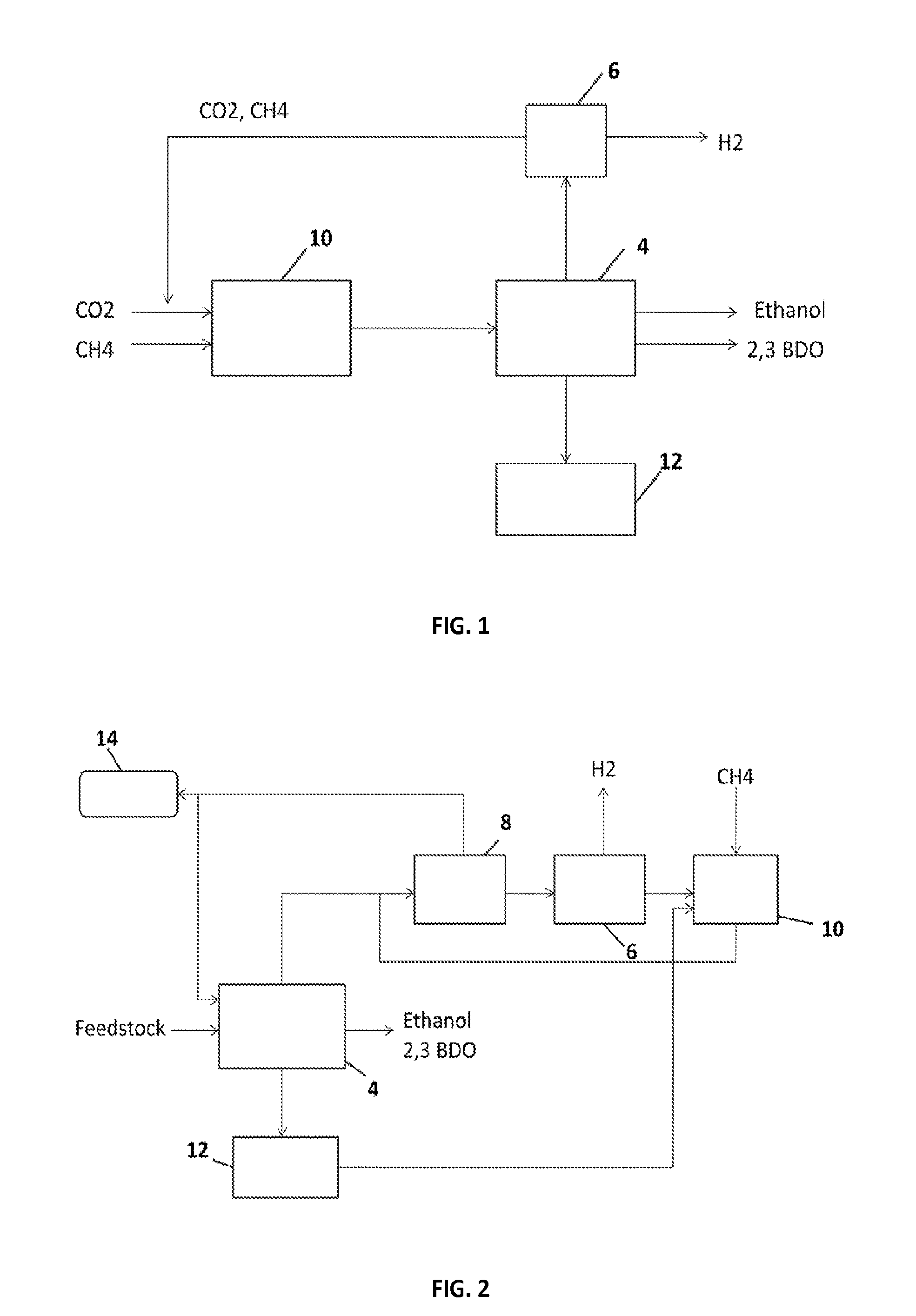

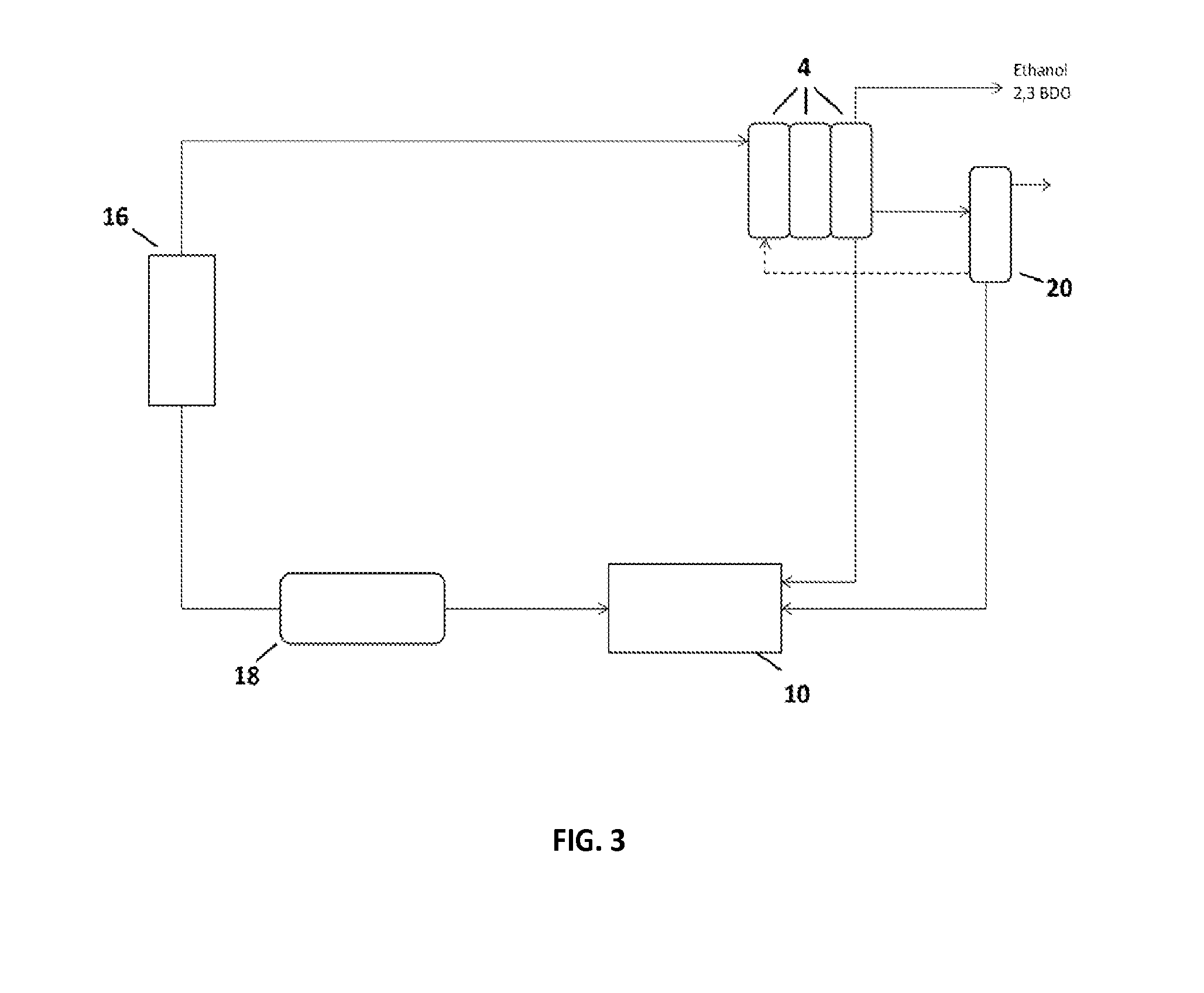

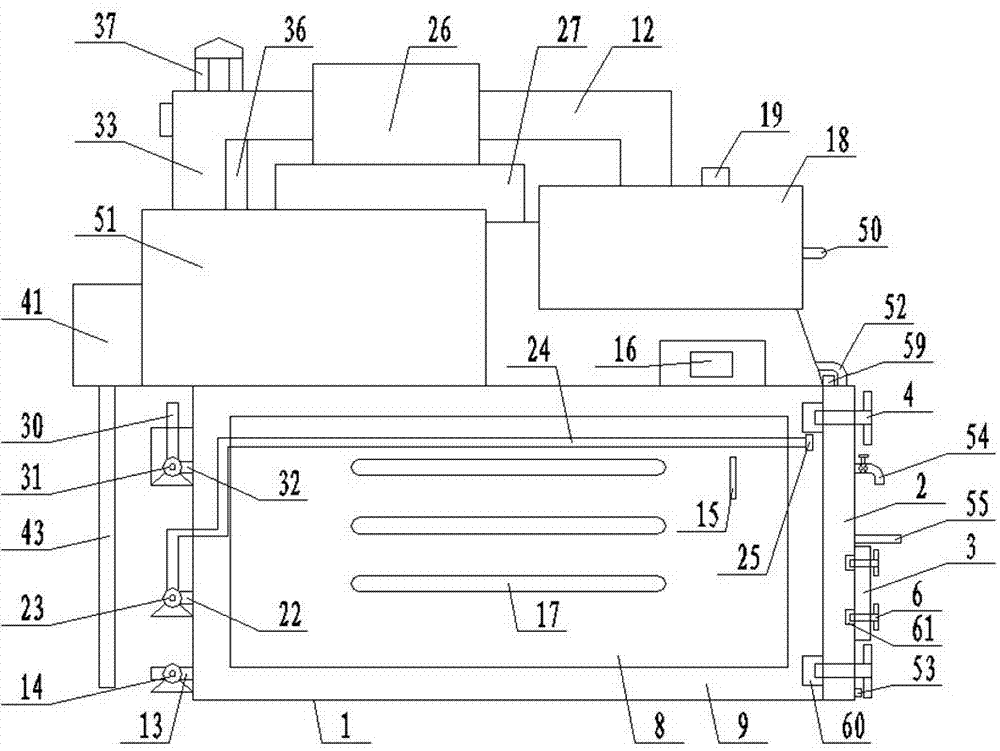

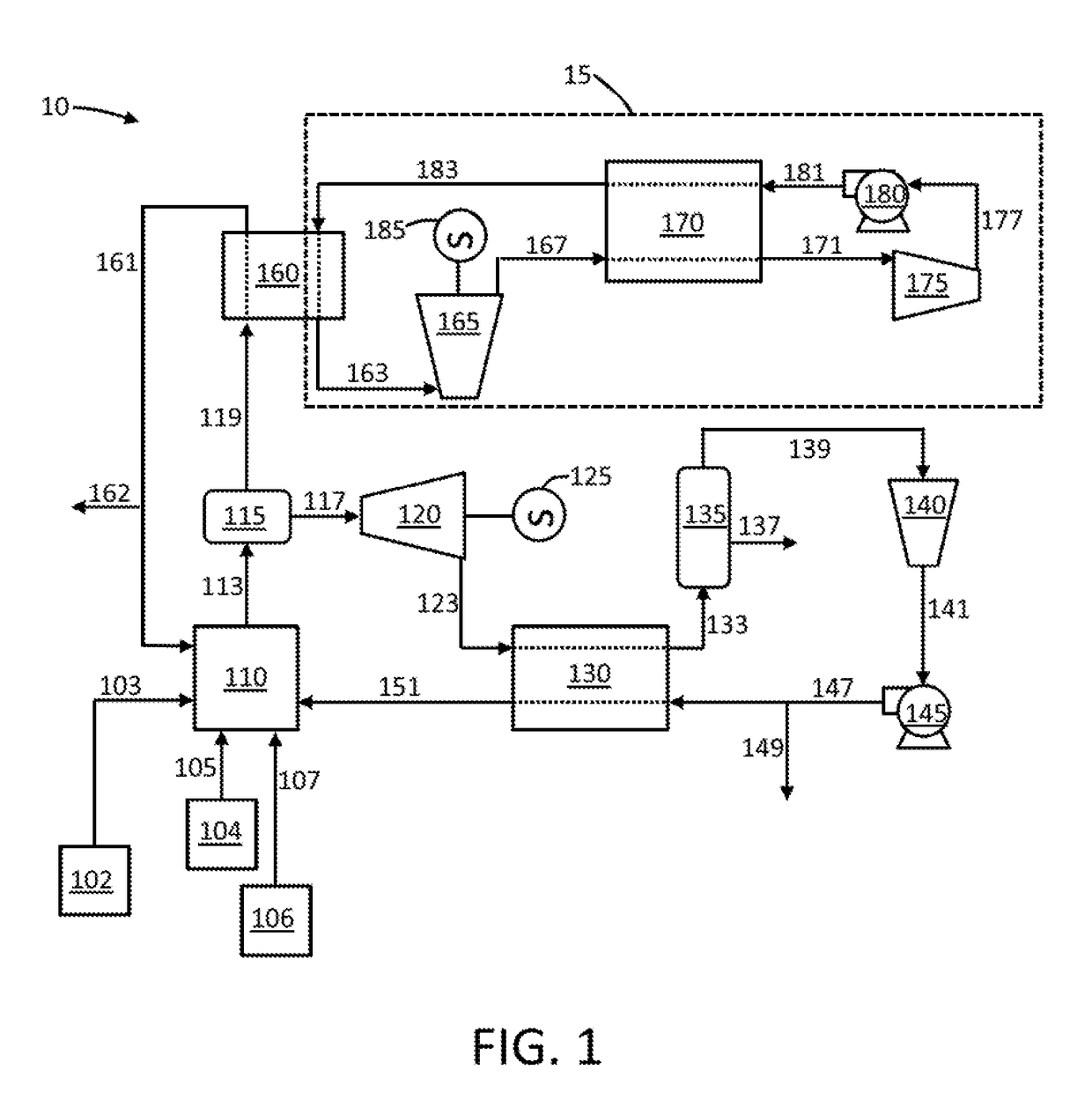

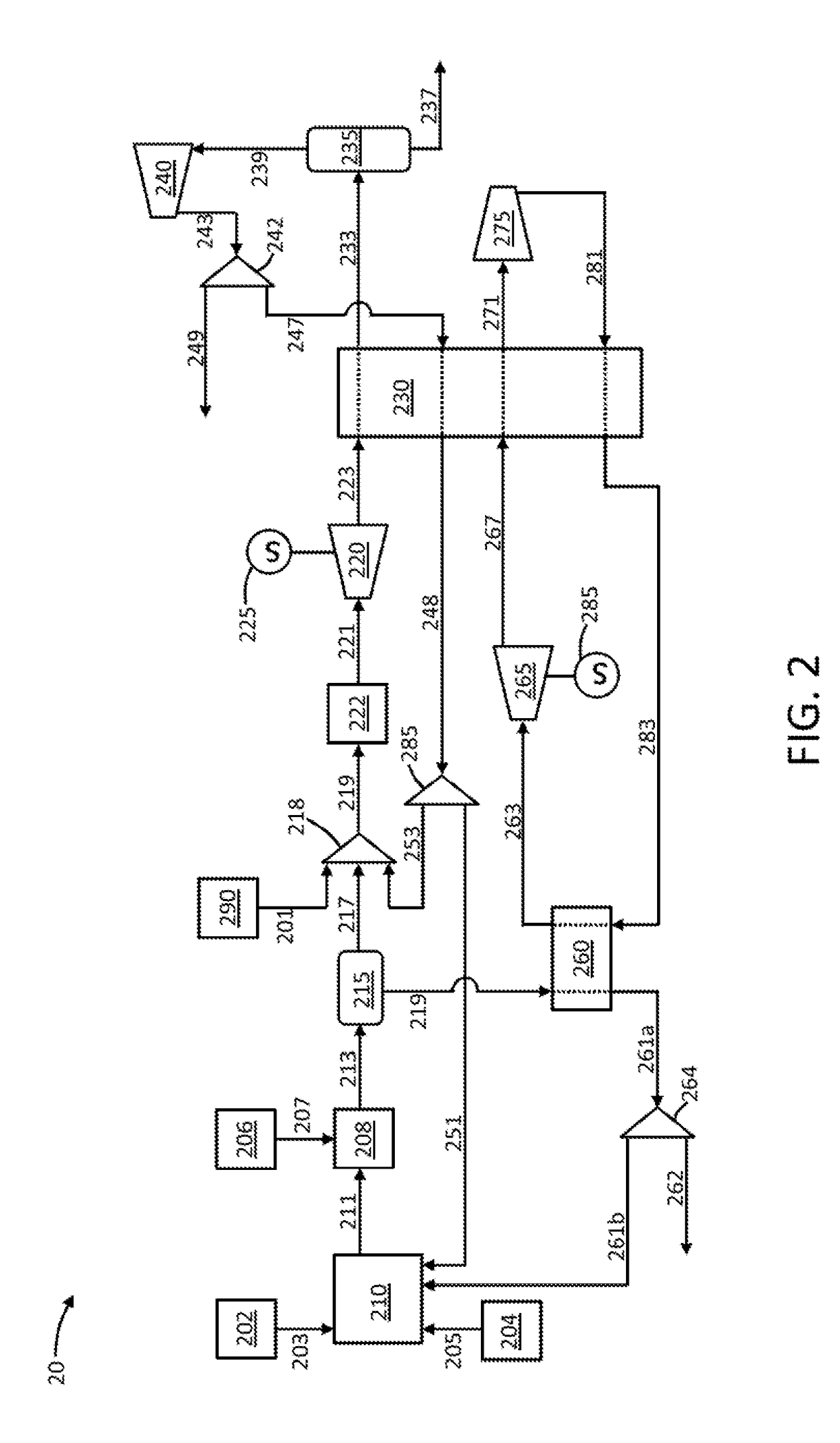

Methods and Systems for the Production of Hydrocarbon Products

InactiveUS20130203143A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorHydrocarbon

Owner:LANZATECH NZ INC

Chinese chestnut bract shell solid shape carbon and its manufacturing method

Owner:HUBEI FORESTRY SCI INST

Method for producing microbial grease by fermenting inulin serving as raw material

InactiveCN102417915AExpand sourceLow costBiofuelsMicroorganism based processesBiodiesel feedstockBiodiesel

Owner:HENAN UNIV OF SCI & TECH

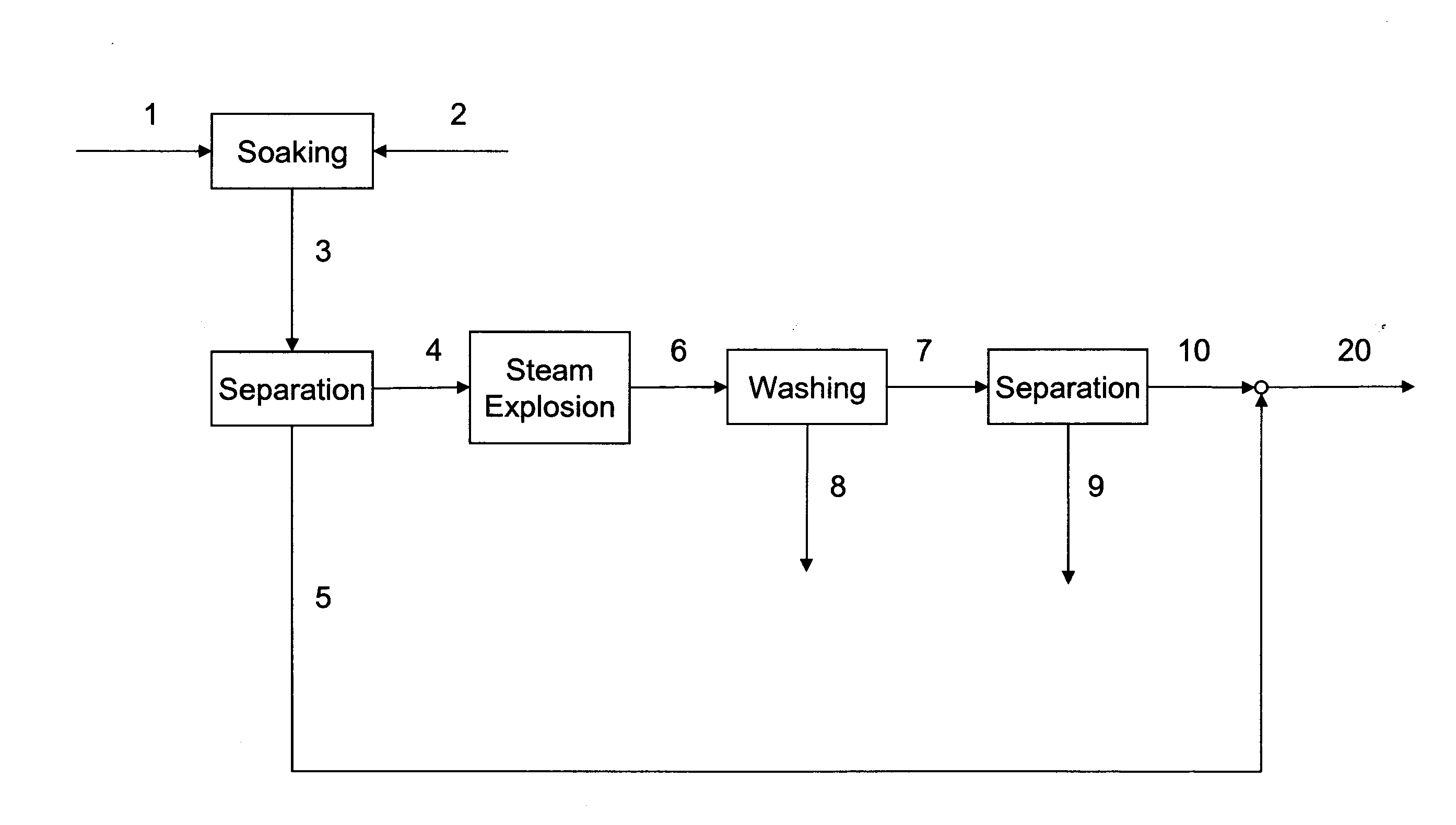

Methods for producing fuel ethanol by using cellulosic waste plants

InactiveCN101613723AReduce removalEliminate omissionBiofuelsMicroorganism based processesChemistryEthanol fuel

The invention provides methods for producing fuel ethanol by using cellulosic waste plants. One method comprises the following steps of: cleaning and grinding the waste plants, adding dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, adding lime in filtrate, and removing precipitation; and carrying out delignification treatment on residue, adding sulfuric acid, heating to lead cellulose to be hydrolyzed, diluting till the weight percentage concentration of the sulfuric acid is 30-40%, recycling the sulfuric acid, heating acidiferous sugar liquor again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate. The other method comprises the following steps of: cleaning and grinding the waste plants, adding waste dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, then adding lime in filtrate, and removing precipitation; adding waste concentrated sulfuric acid in residue, heating, cooling, diluting, heating again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate; and adding yeast in the product obtained by the method for fermentation, distilling, and dehydrating to obtain the finished product of the fuel ethanol. The methods greatly reduce the cost, have simple process, and are convenient for wide range of generalization and application.

Owner:张羡信

Method for producing biodiesel by waste oil ester biological process

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

Straw carbonization furnace

InactiveCN103497773AAchieve recyclingHigh heat conversion efficiencyBiofuelsEnergy inputCombustion chamberCarbonization

Owner:YANCHENG CHENGXIN MACHINERY MFG

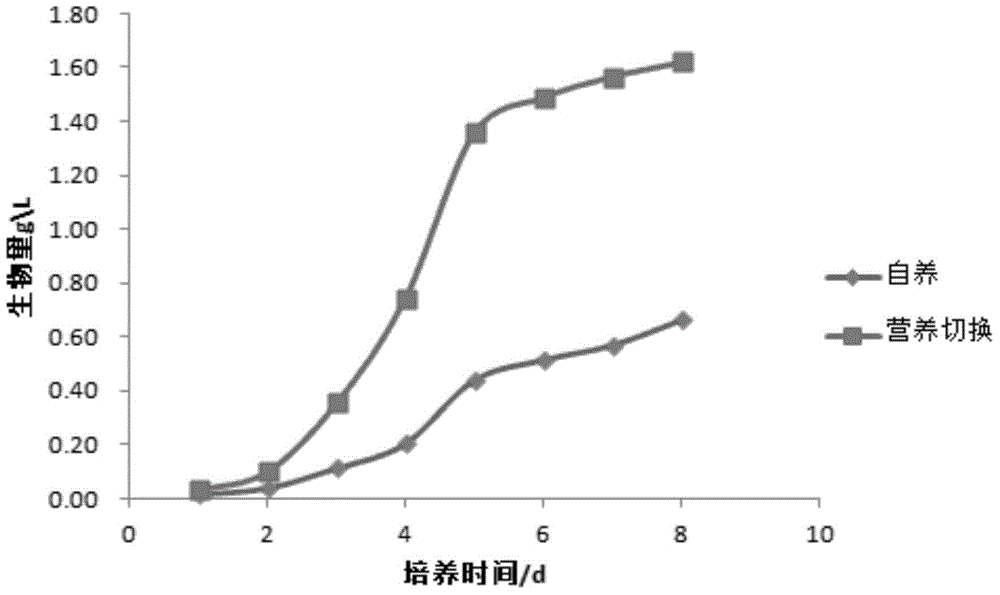

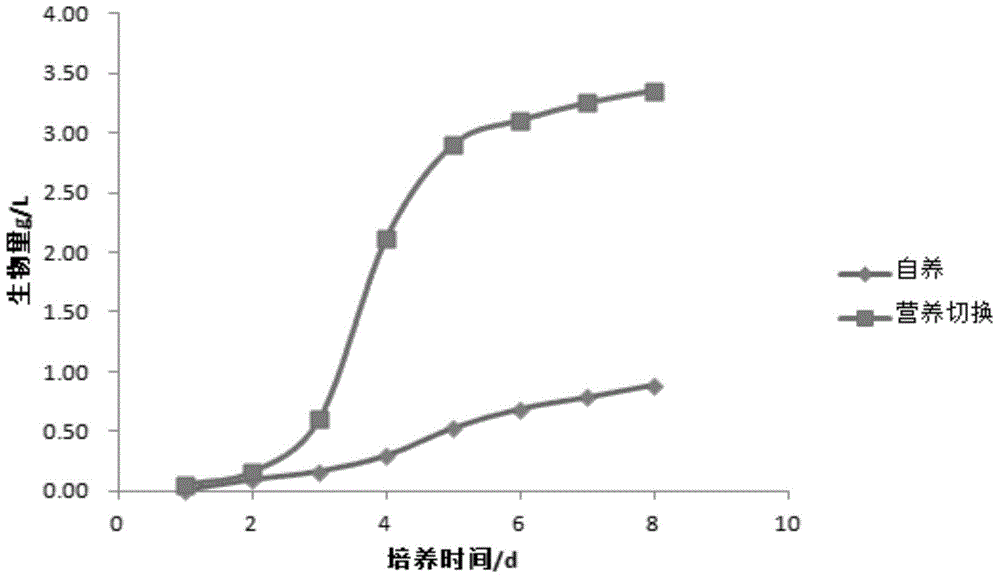

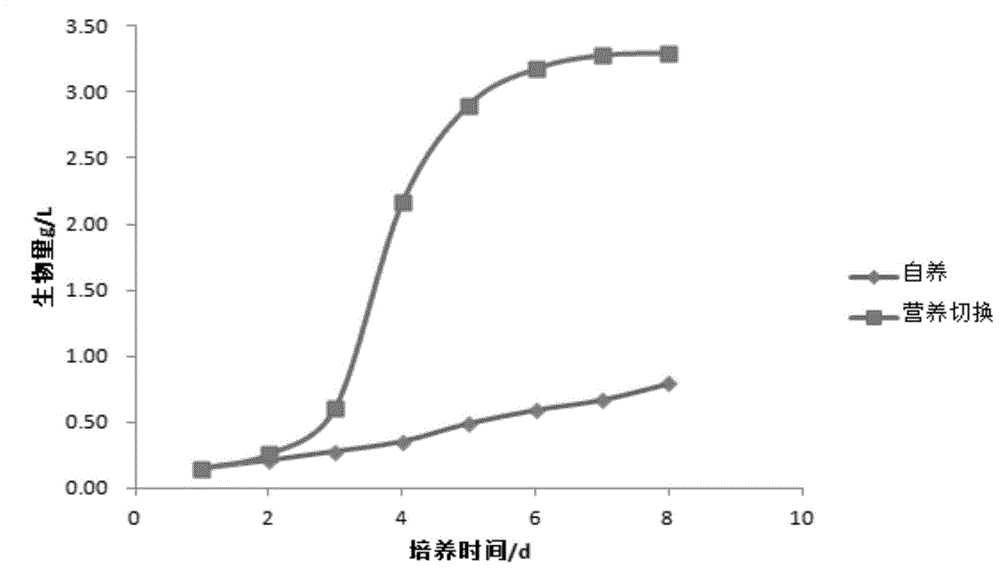

Nutrient switching method for culturing oleaginous microalgae

InactiveCN104830693AHigh biomassIncrease productionUnicellular algaeBiofuelsIrradiationCulture mediums

Owner:SHANGHAI JIAO TONG UNIV

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

Renewable energy source system for environmental-friendly treatment of domestic garbage and technology

ActiveCN109092868ASolve the accumulationReduce pollutionWaste processingSolid waste disposalLitterPollution

The invention discloses a renewable energy source system for environmental-friendly treatment of domestic garbage and a technology. The renewable energy source system comprises a vibrating feeder, a shredder, a screening machine, a first shearer, a second shearer, a baking oven, a baking main drum airflow pipeline, a draught fan, a cyclone dust collector, a pelleting machine, a material bin and awater curtain dust collector, wherein the vibrating feeder is arranged on one side of the shredder, and a discharge opening of the vibrating feeder is arranged above a feed hopper of the shredder; thescreening machine is arranged on one side, away from the vibrating feeder, of the shredder; the shredder and the screening machine are connected through a first belt conveyor; the screening machine and the first shearer are connected through a second belt conveyor; and the first shearer and the second shearer are connected through a third belt conveyor. Through the adoption of the renewable energy source system disclosed by the invention, the domestic garbage is made into flammable renewable energy sources through technologies of shredding, screening, shearing, crushing, baking, pelleting andthe like, and waste is turned into wealth, so that the problem of massive accumulation of the domestic garbage is solved to a great extent, and environment pollution caused by the domestic garbage isreduced.

Owner:JIANGXI TINGFA RENEWABLE ENERGY CO LTD

Continuous single vessel butanol synthesis by fermentation

The present invention describes a method for producing butanol by fermentation of carbohydrates using mixed populations of acidogenic-phase cells and solventogenic-phase cells of Clostridium in a solitary vessel. The present system as described does not require intermittent adjustment of pH or venting of headspace gases. The method provides a process for removal of the butanol product which does not irreversibly harm the cells and conditions are described where such cells may resume butanol synthesis in the same solitary vessel. The invention also describes compositions and biologically pure cultures which comprise the Clostridium cells as disclosed.

Owner:尤金 T 巴特勒三世

System and method for power production with solid fuel combustion and carbon capture

Owner:8 RIVERS CAPTTAL LLC

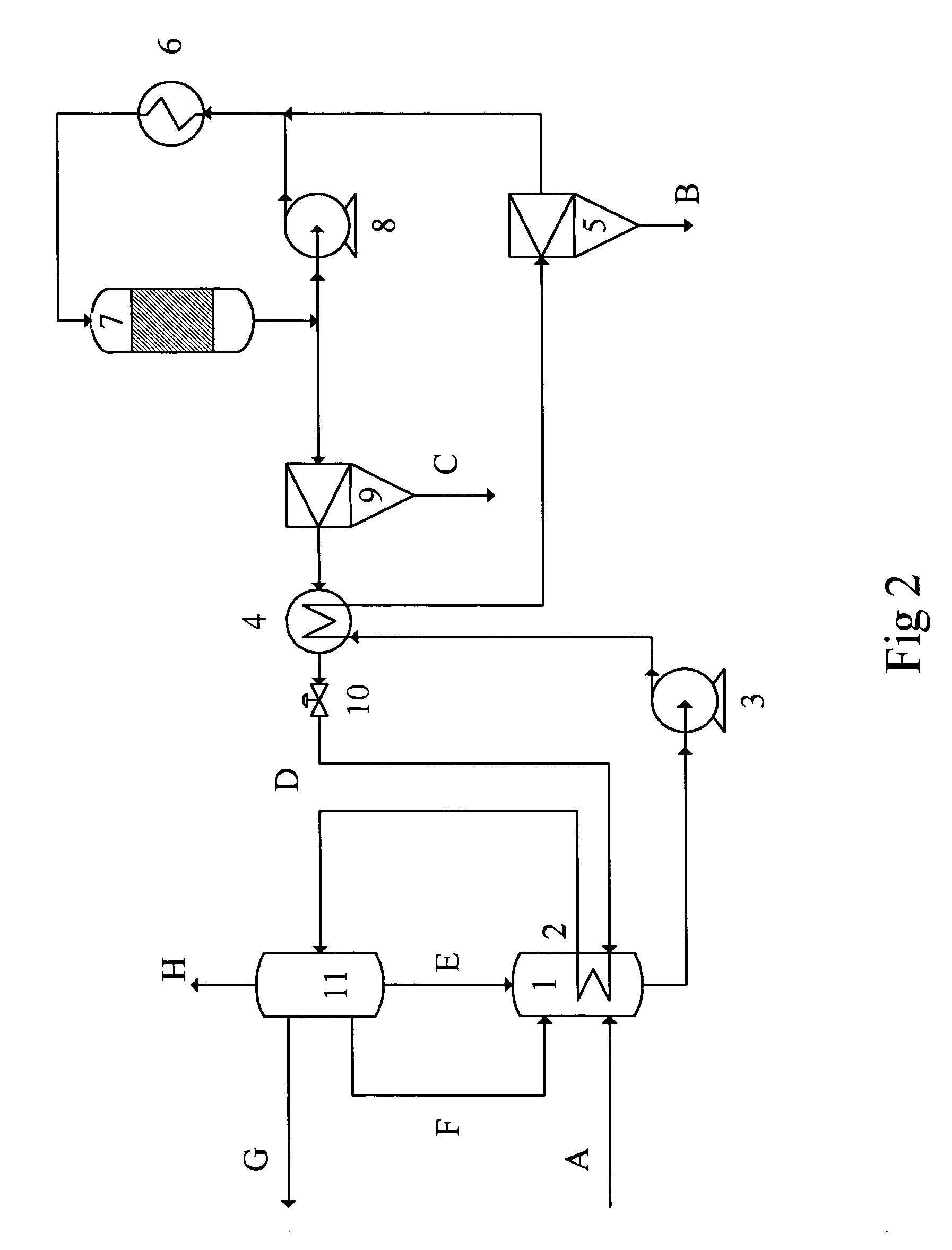

Method for the simultaneous production of ethanol and a fermented, solid product

The invention relates to a method for the simultaneous production of a fermented, solid product and ethanol comprising the following steps: 1) providing a mixture of milled or flaked or otherwise disintegrated biomass, comprising oligosaccharides and / or polysaccharides and live yeast in a dry matter ratio of from 2:1 to 100:1, and water; 2) fermenting the mixture resulting from step (1) under conditions where the water content in the initial mixture does not exceed 65% by weight, for 1-36 hours at a temperature of about 25-60° C. under anaerobic conditions; 3) incubating the fermented mixture resulting from step (2) for 0.5-240 minutes at a temperature of about 70-150° C.; and 4) separating wet fermented, solid product from the fermented mixture resulting from step (3); further comprising either a) that the fermentation in step (2) is performed in one or more interconnected paddle worm or continuous worm conveyers with inlet means for the fermentation mixture and additives and outlet means for the ferment as well as control means for rotation speed, temperature and pH, or b) that one or more processing aids are added in any of steps (1), (2) and (3) and further comprising a step of 5) separating crude ethanol from the fermented mixture in step (2) by vacuum and / or in step (3) by vacuum or by injection of steam and condensing the surplus stripping steam. The invention further relates to the products of this method as well as uses thereof.

Owner:HAMLET PROTEIN AS

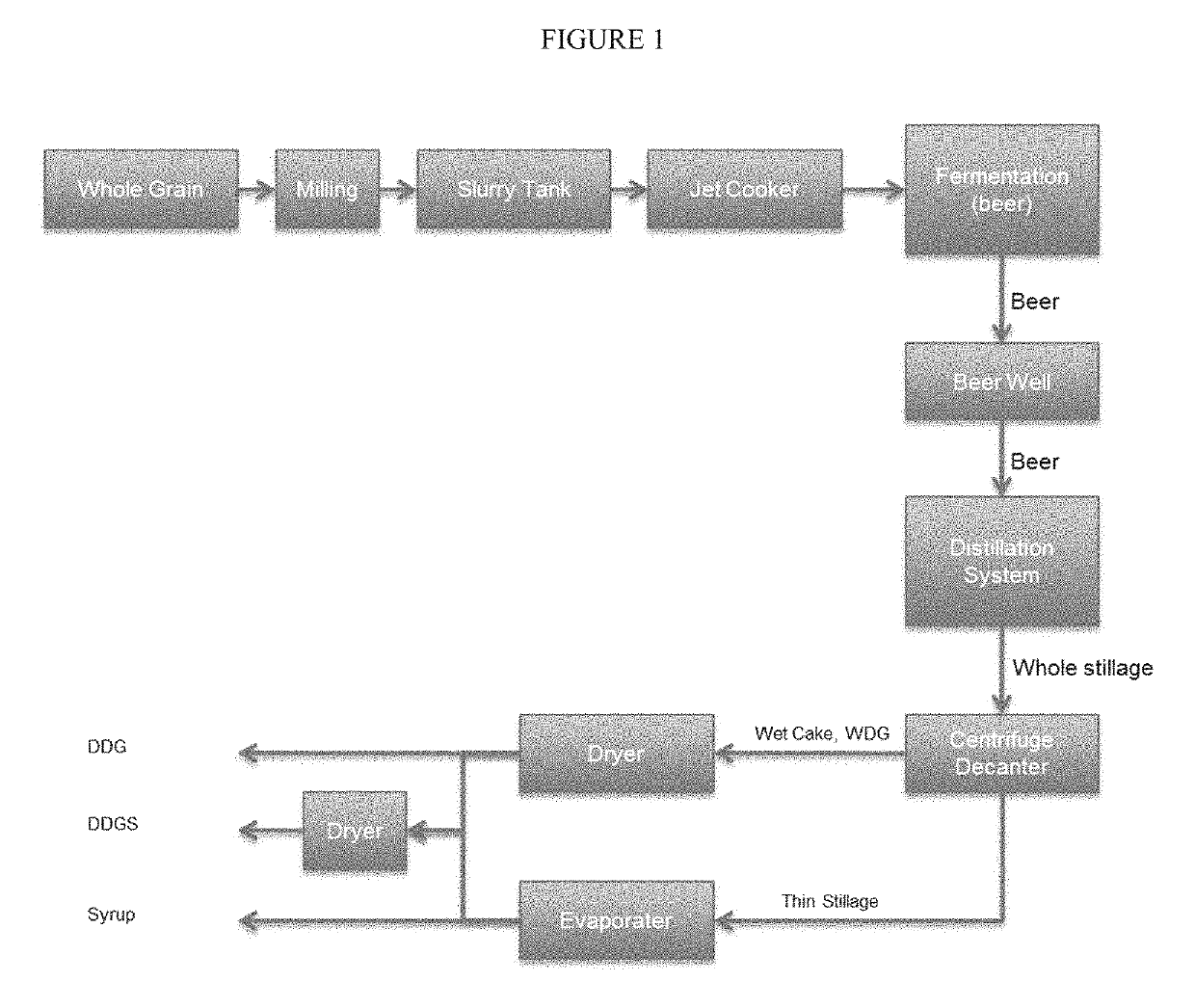

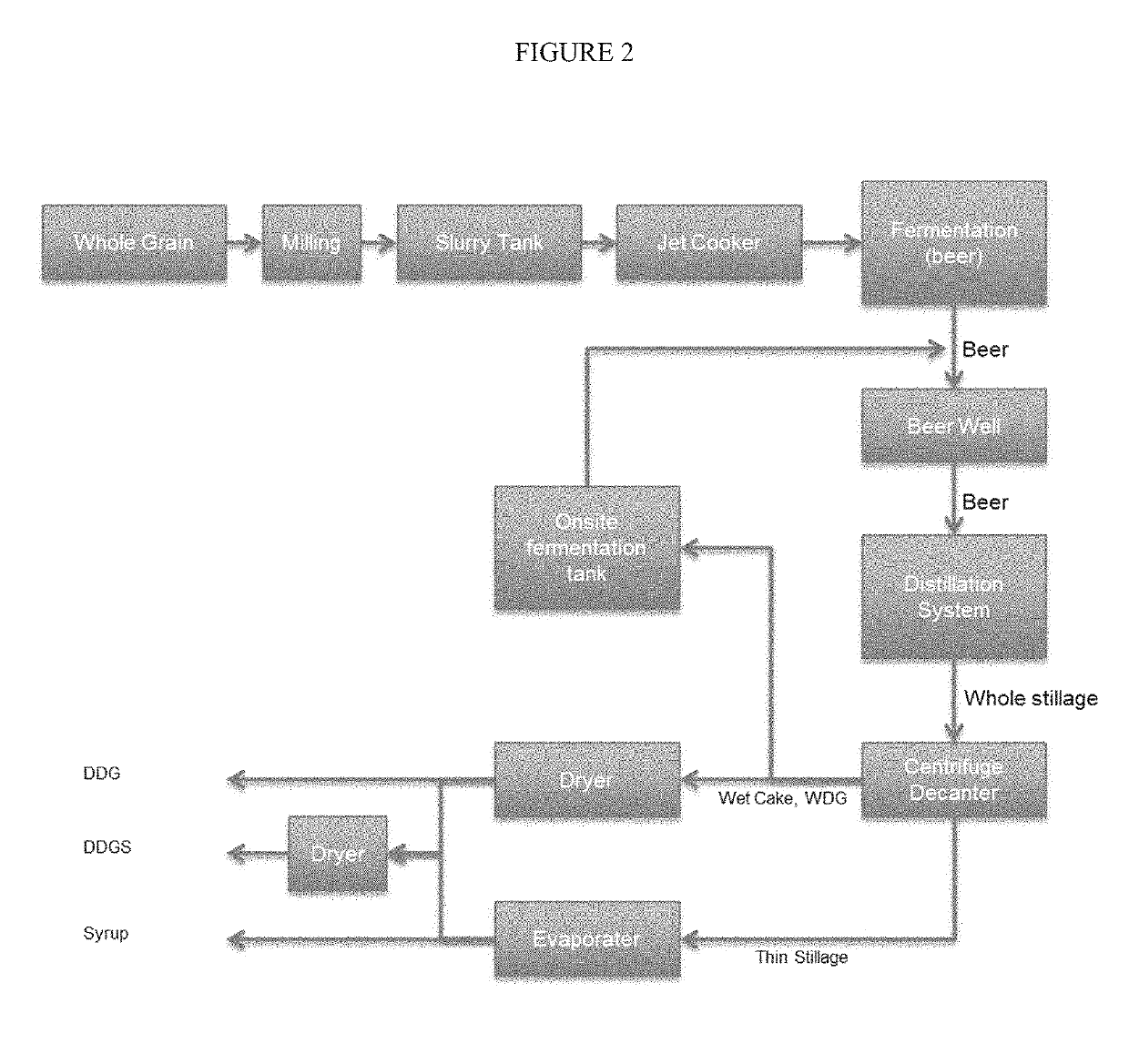

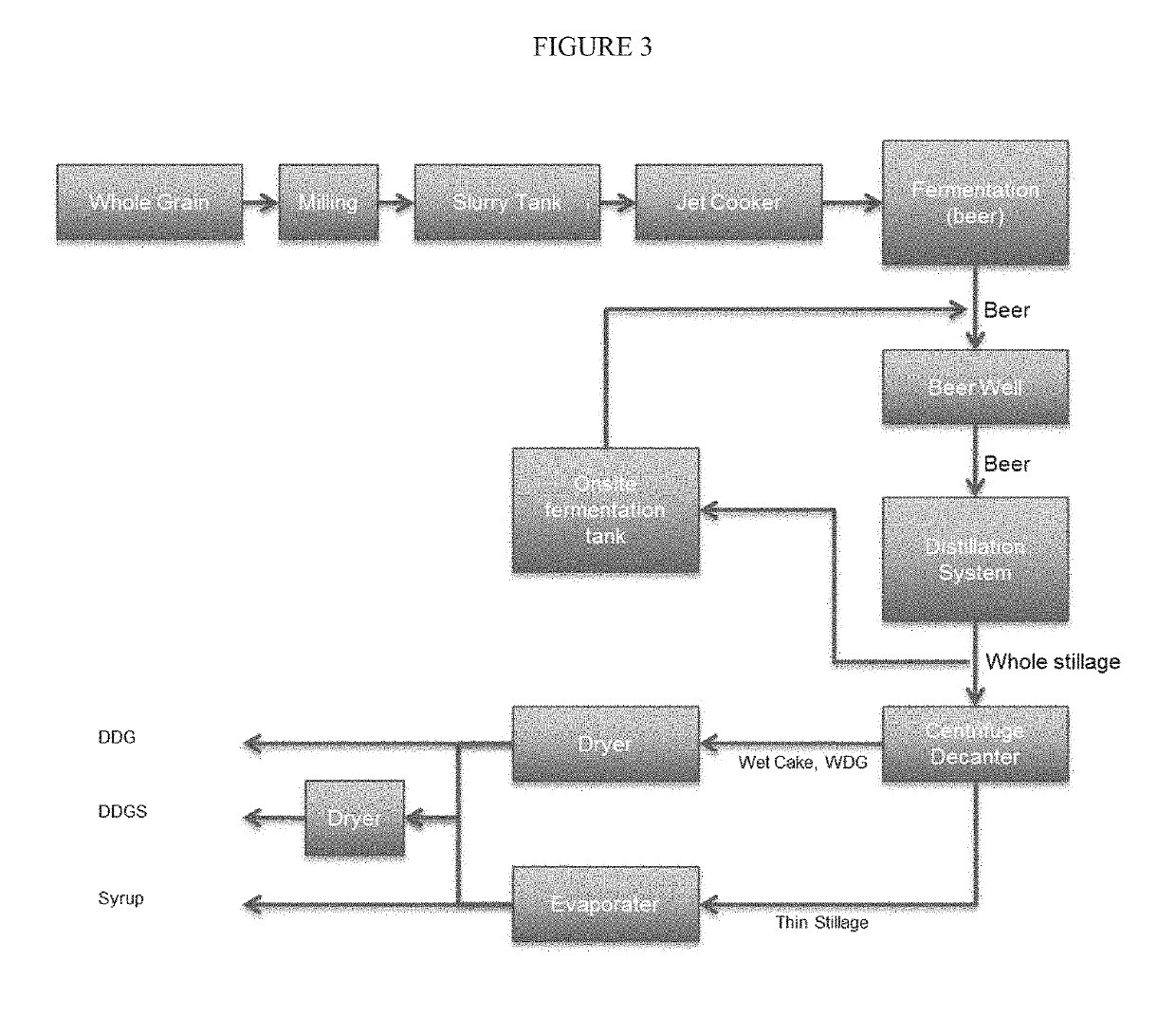

Producing recoverable oil from fermentation processes

InactiveUS20190211291A1Less oilBy-product recoveryWort preparationPectinaseAlpha-amylase

Owner:BASF ENZYMES

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

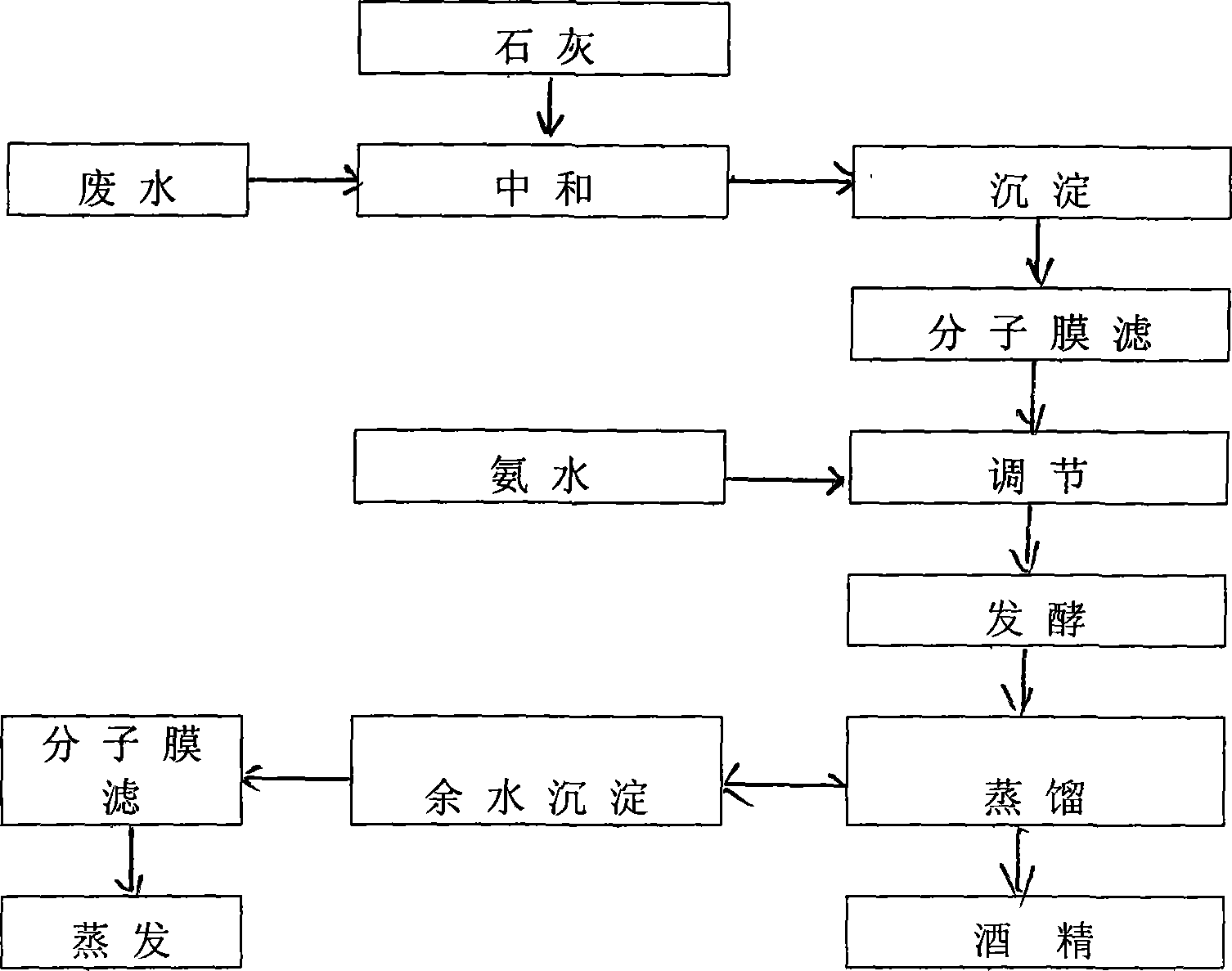

Method for producing ethanol by recycling anaerobic digestion effluent and vinasse clear liquid

ActiveCN108841873AIncrease the reuse ratioEmission reductionBiofuelsFermentationFiltrationWater treatment

The invention discloses a method for producing ethanol by recycling anaerobic digestion effluent and vinasse clear liquid and belongs to the technical fields of waste water treatment and ethanol fermentation industry. The method comprises the following steps: mixing and blending membrane filtrate obtained after membrane filtration of anaerobic digestion effluent, part of vinasse clear liquid, other material mixing water and crushed cereal raw materials, and performing processes of liquefying, saccharifying, fermenting and distilling to obtain ethanol, wherein the membrane filtrate accounts for30 to 90 percent of the total weight of the blending water, the vinasse clear liquid accounts for 10 to 40 percent of the total weight of the blending water, and the rest is other material mixing water; and the concentration of volatile acid of the blending water is controlled to be 100 to 1200 mg / L (based on acetic acid) by adjusting the proportion of the membrane filtrate, the vinasse clear liquid and other material mixing water or adding the acetic acid. By the method, discharge of ethanol production waste water is greatly reduced and water resources are saved; meanwhile, the problem thatthe ethanol is fermented to generate acid is effectively avoided, the alcohol yield is significantly increased, the utilization rate of the raw materials is increased by 1 to 5 percent, and the production energy consumption and cost of the ethanol are reduced.

Owner:JIANGNAN UNIV

Method for preparing biomass fuel by catalyzing rice straw

InactiveCN108913176ASmall particle sizeIncreases chances of effective chemical reaction collisionsPhysical/chemical process catalystsBiofuelsCelluloseChemical reaction

The invention discloses a method for preparing biomass fuel by catalyzing rice straw. The method comprises the following steps that the rice straw serves as a main raw material, primary pretreatment is carried out on the rice straw so as to obtain straw powder, then secondary pretreatment is carried out on the straw powder so as to obtain a straw suspension II. According to the method, the structure of cellulose is changed through the pre-treatment process, the size of particles of the cellulose is decreased, the probability of effective chemical reaction collision between cellulose moleculesand a solvent is improved, and the yield of a final target product is increased; and a catalyst carrier is used for adsorbing a catalyst, then the carrier is taken as a unit, a target substrate is catalyzed, and therefore a good effect is achieved.

Owner:ANHUI SHENGBAO NEW ENERGY TECH CO LTD

Production method for microwave catalytic pyrolysis of Eupatorium adenophorum

Owner:KUNMING UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap