Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Biomass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass is plant or animal material used for energy production (electricity or heat), or in various industrial processes as raw material for a range of products. It can be purposely grown energy crops (e.g. miscanthus, switchgrass), wood or forest residues, waste from food crops (wheat straw, bagasse), horticulture (yard waste), food processing (corn cobs), animal farming (manure, rich in nitrogen and phosphorus), or human waste from sewage plants.

Device for Treating Wastewater Comprising Nitrogen and Phosphorus and a Method for the Same

InactiveUS20110247977A1Low costEasy maintenanceMembranesWater contaminantsHigh concentrationNitrogen

Disclosed are a device for treating nitrogen and phosphorus from wastewater, including: an algal culture tank for culturing microalgae capable of treating nitrogen and phosphorus from wastewater; and a separation membrane for separating thus treated water from the microalgae, and a method for the same.According to the disclosed device and method, microalgae are cultured at high concentrations using wastewater, instead of an artificial culture medium, as a culture medium. As a result, nitrogen and phosphorus can be effectively treated from the wastewater, and the microalgae, which are useful as a biomass, may be cultured and recovered stably.

Owner:KOREA INST OF SCI & TECH

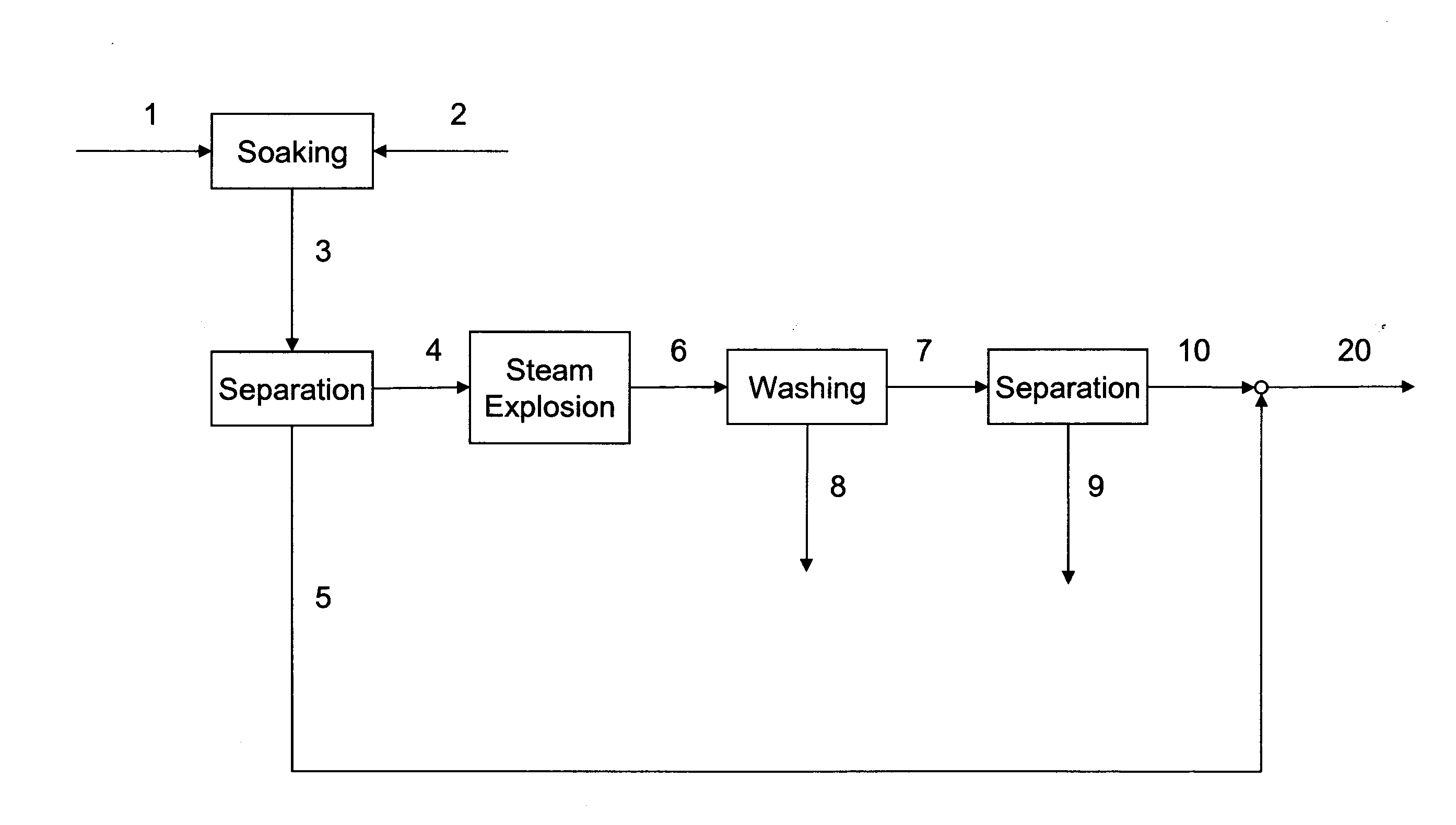

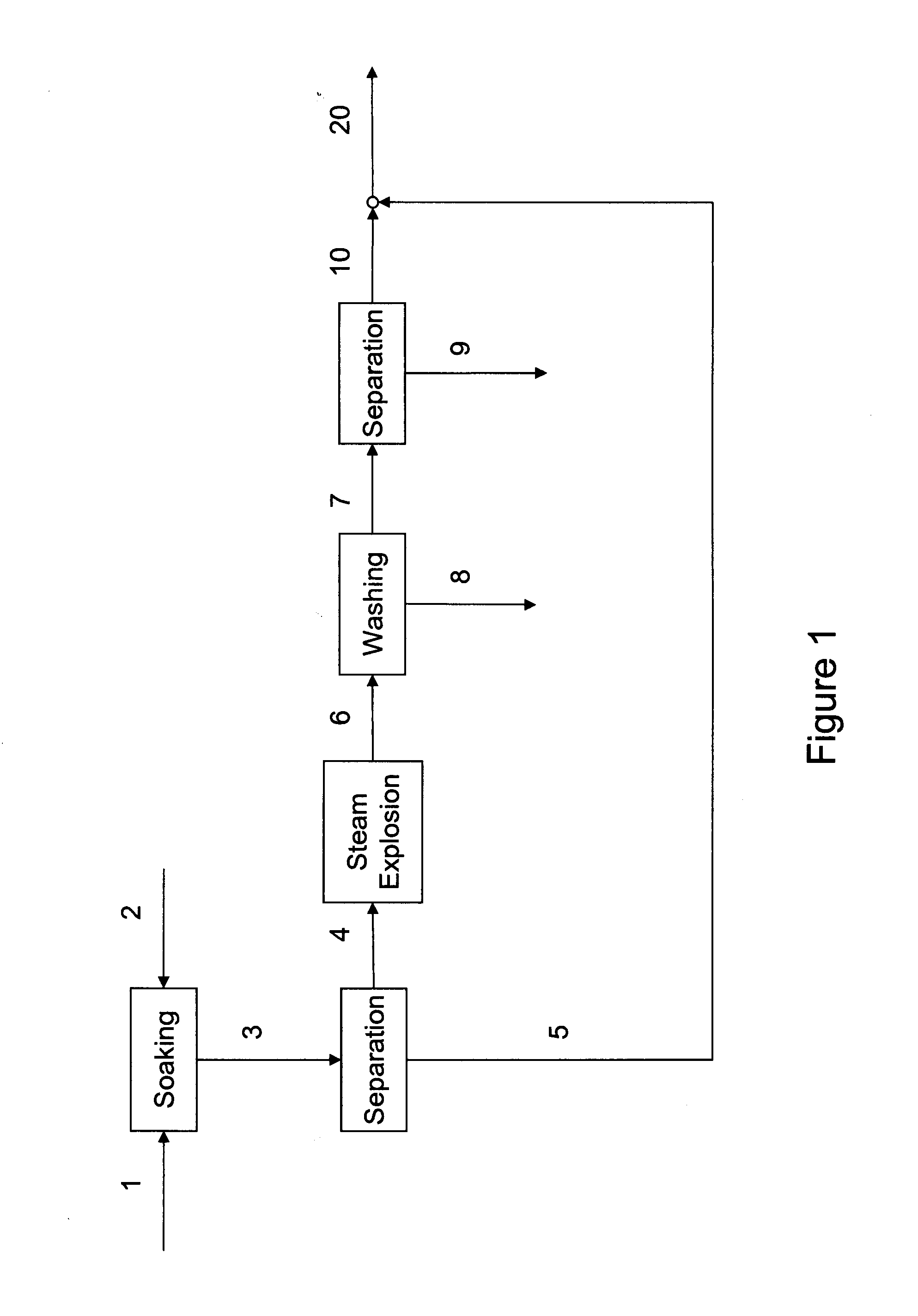

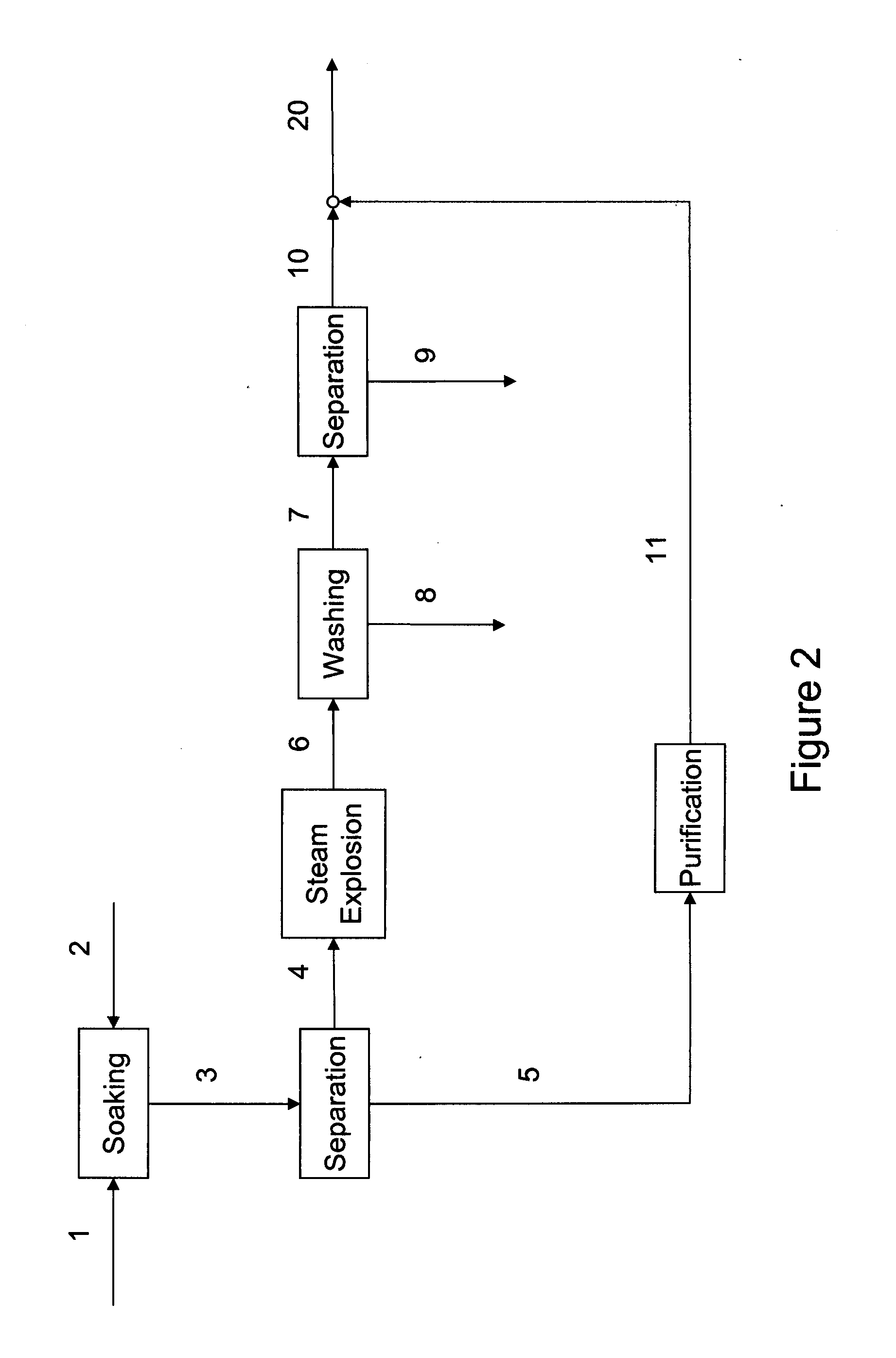

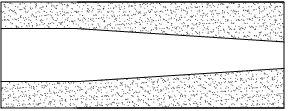

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

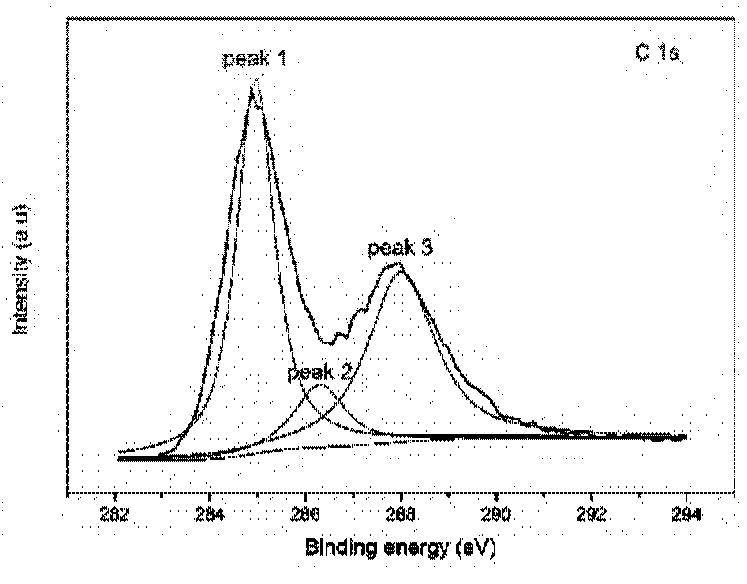

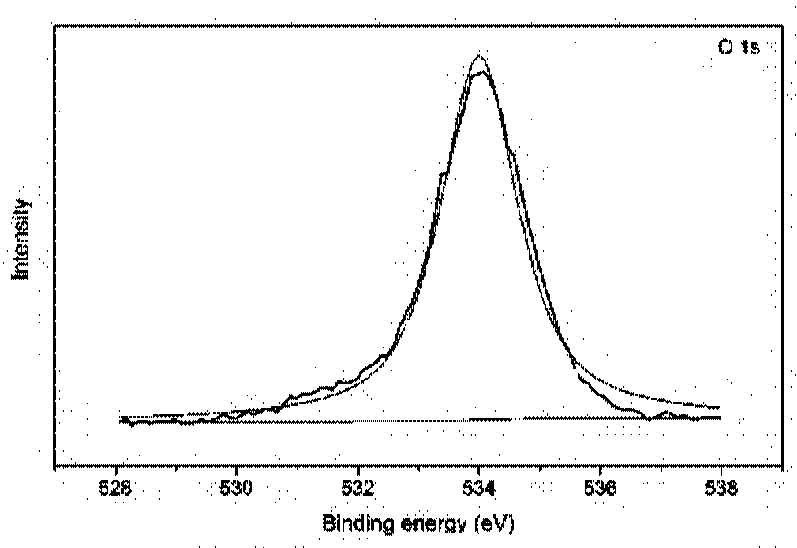

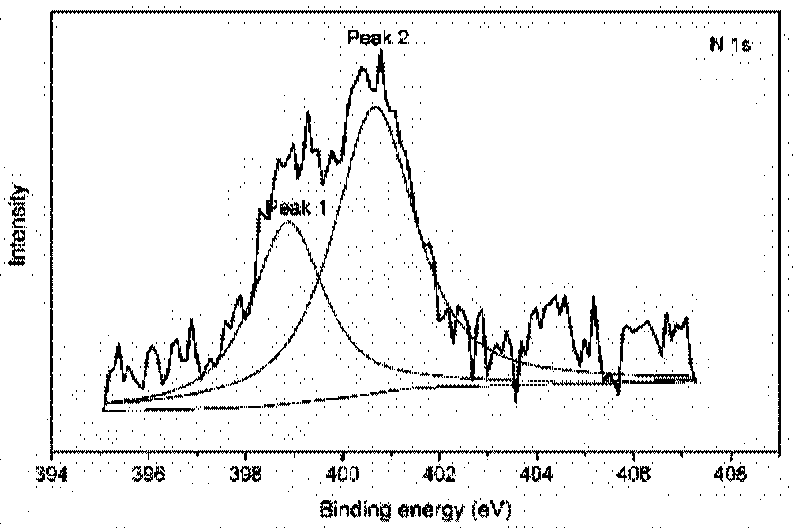

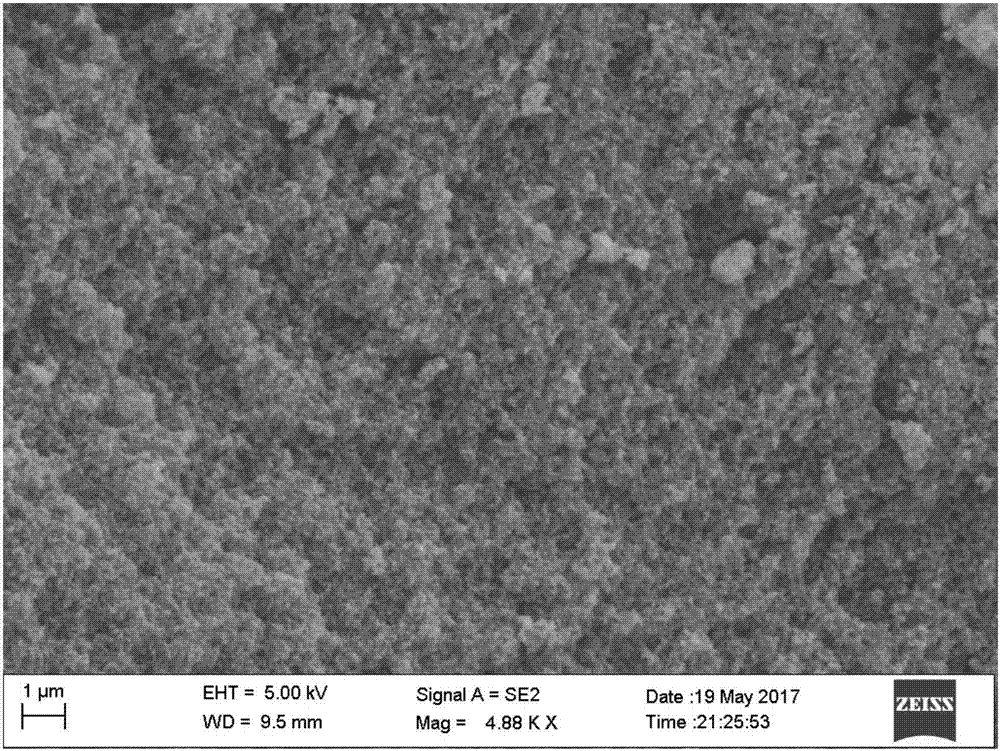

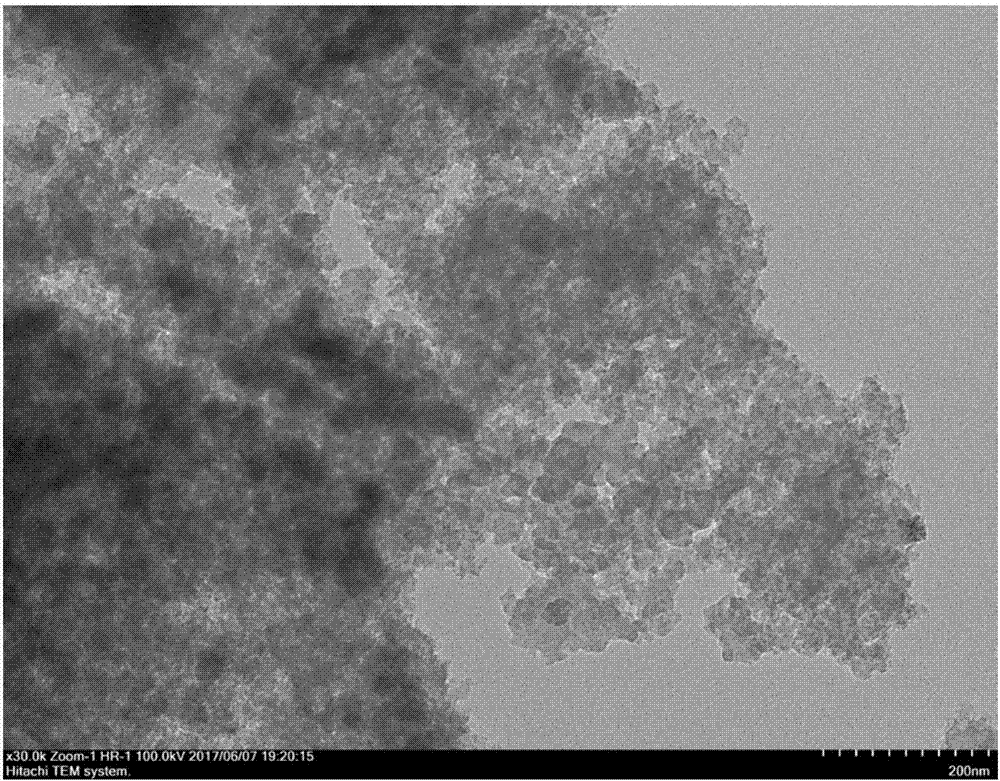

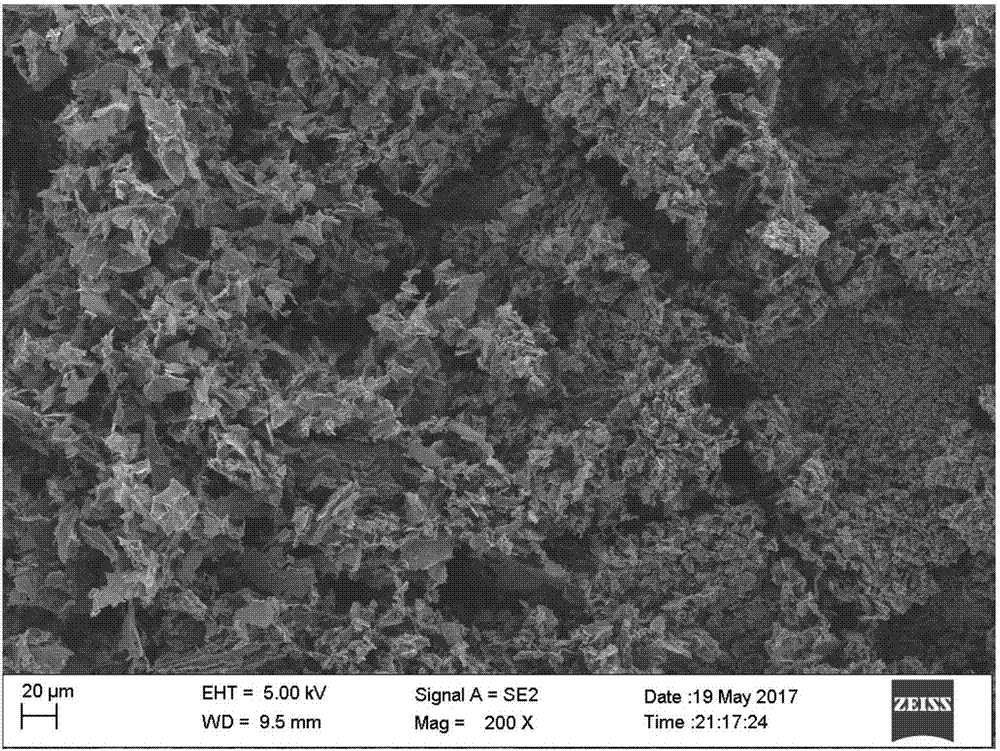

Method for preparing hetero-atom doped porous carbon material through carbonation of biomass under assistance of molten salt

The invention provides a method for preparing a hetero-atom doped porous carbon material through carbonation of biomass under the assistance of molten salt. The method comprises the following steps: uniformly mixing biomass powder, the molten salt and a hetero-atom doped compound to obtain a product A, wherein the molten salt contains LiCl and KCl, the mass of LiCl accounts for 59 percent of that of the molten salt, and the mass of KCl accounts for 59 percent of that of the molten salt; putting the product A in a pipe furnace; carrying out high-temperature calcination; cleaning with distilled water to remove the molten salt and obtain the final product, namely the hetero-atom doped porous carbon material. The method has the advantages that the biomass is taken as a raw material, and the molten salt containing hetero-atoms is taken as a carbonization medium, so that the hetero-atoms can be introduced into the skeleton of the carbon material during the pyrolysis and carbonization process of the biomass synchronously and controllably, and the hetero-atom in-situ doped porous carbon material is obtained finally. Compared with the conventional doping method, the method provided by the invention have the advantages that the steps are simple; the cost is low; the operation is easy; the reactant purity is high; the application prospect is relatively good.

Owner:HARBIN ENG UNIV

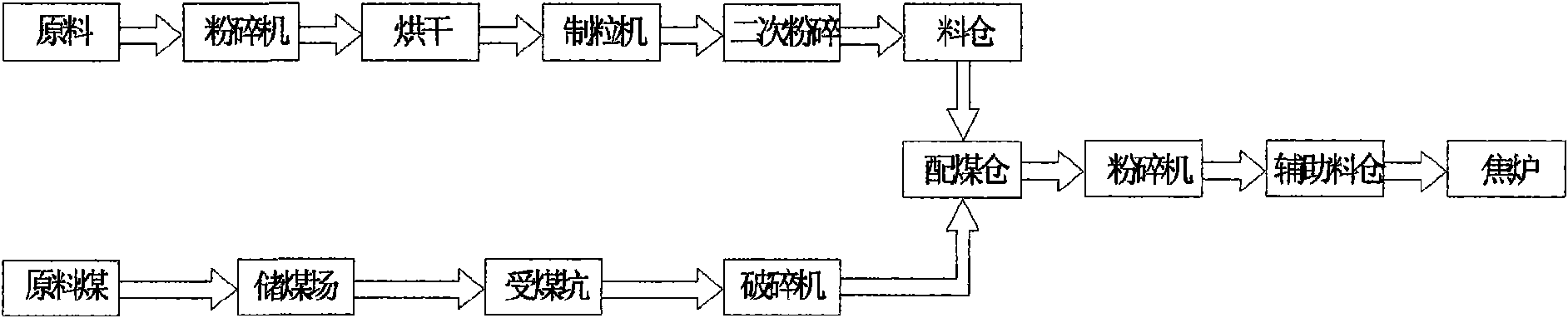

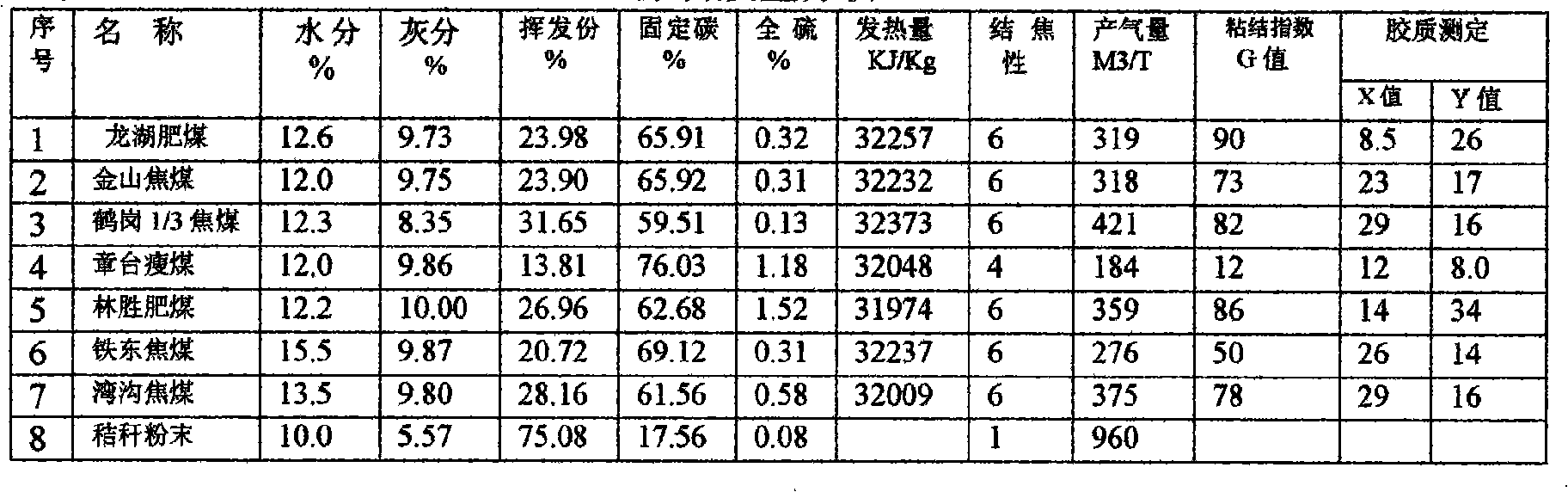

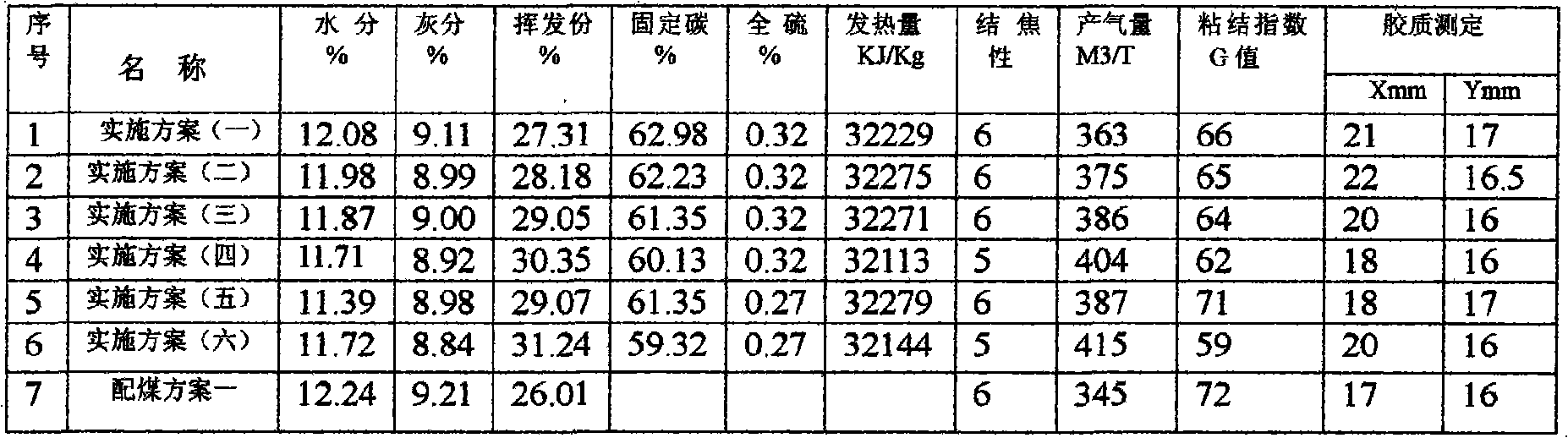

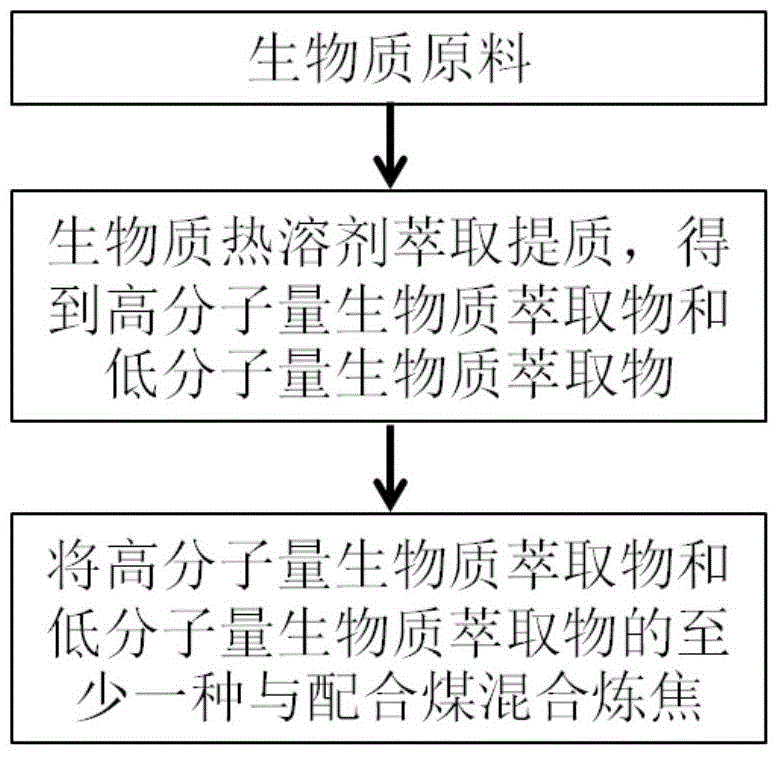

Coke making method by adding biomass energy to mixed coal

The invention relates to a coke making method by adding biomass energy to mixed coal, which is a technical proposal by mixing biomass fuel and mixed coal for making coke in a certain proportion. The method aims to replace coal for making coke with renewable energy sources, expand the resources of coal for making coke, reduce the independence on high-quality coal in the coke-making process and realize the optimal coke-making coal blending technology by using renewable energy sources instead of fossil energy sources. Compared with the prior traditional coal blending technique, the method has the advantages of simple technique and low equipment cost, and does not require repetitive constructions and remodifications on technical equipment; therefore, the method can greatly reduce the coke-making cost, save large quantities of high-quality coal resources, propel the utilization of renewable energy sources to realize energy saving and emission reduction, and reduce the secondary pollution of the biomass energy sources to the environment. The realization of the project has obvious economic and social benefits.

Owner:韩大海

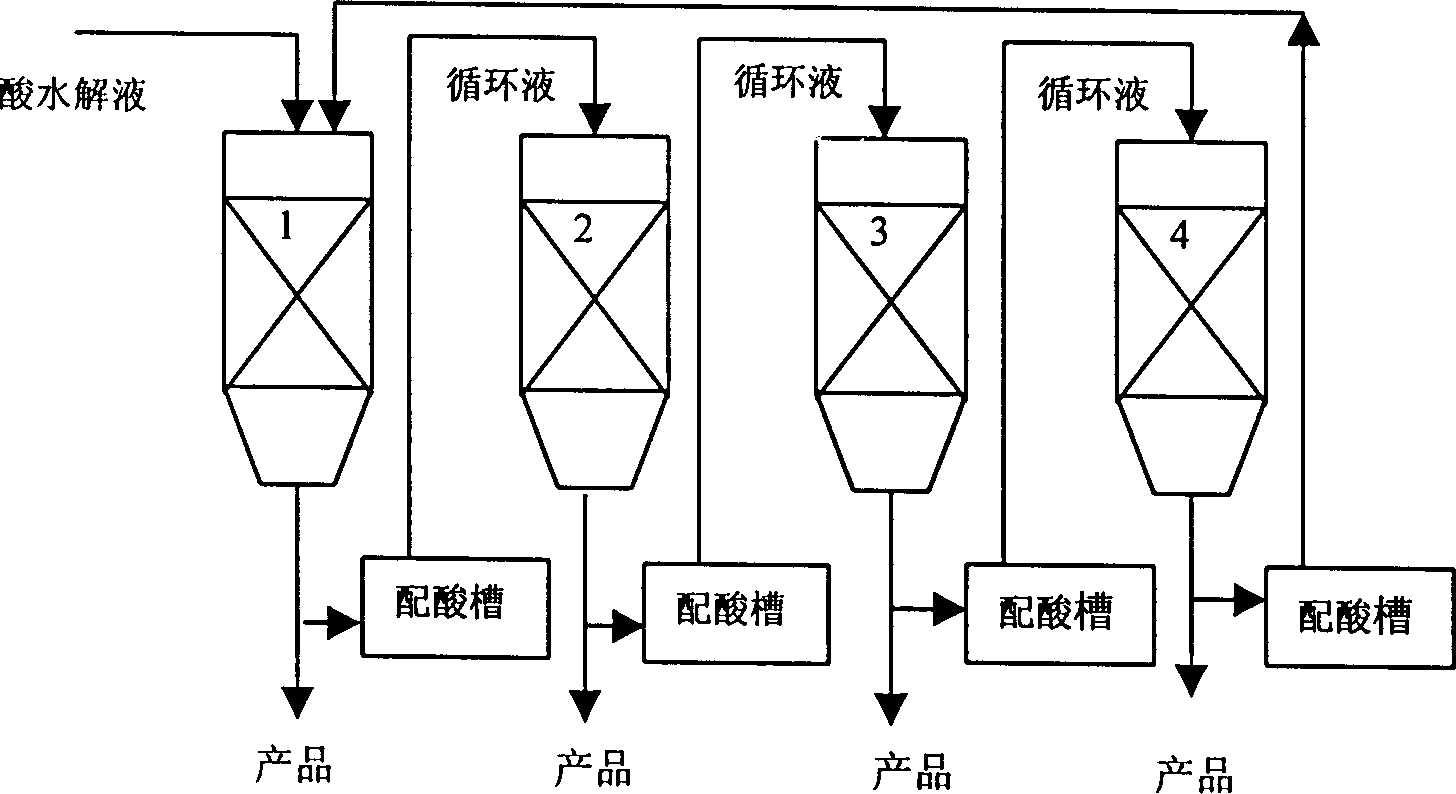

Biomass hydrolyzing process of preparing reductive monosaccharide

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing nitrogen/carbon-containing material by biomass pyrolysis and carbonization

Owner:UNIV OF SCI & TECH OF CHINA

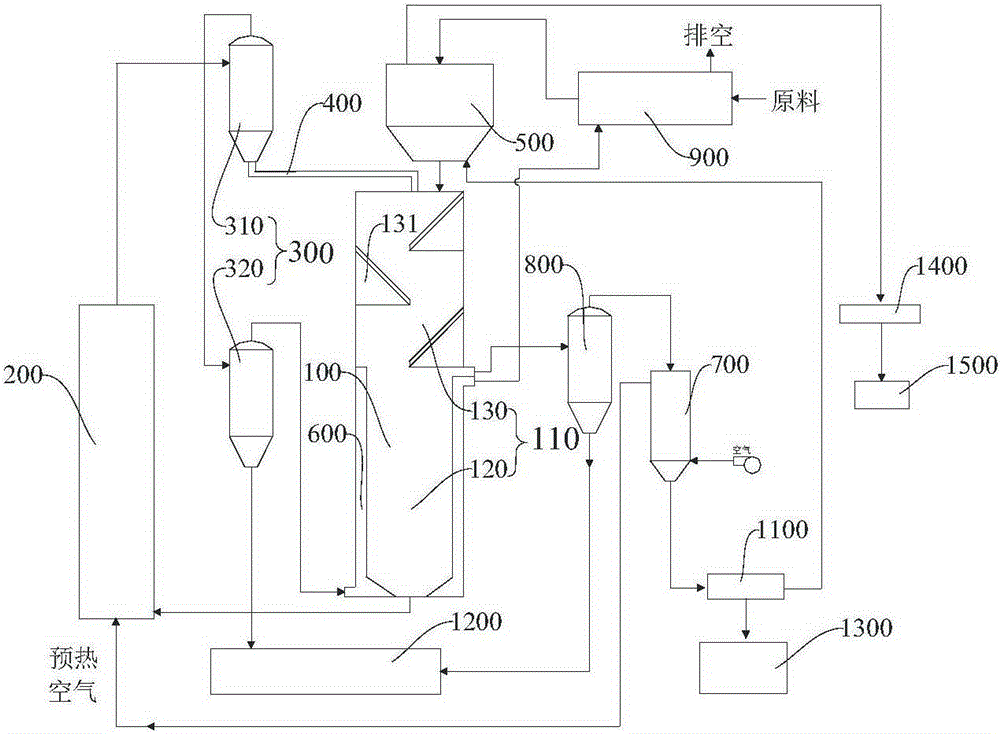

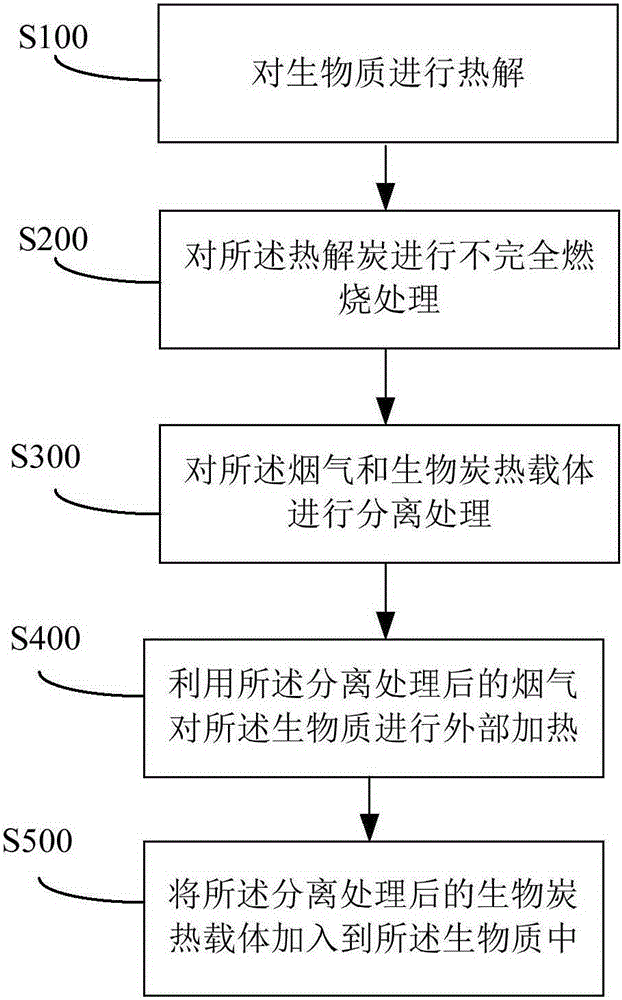

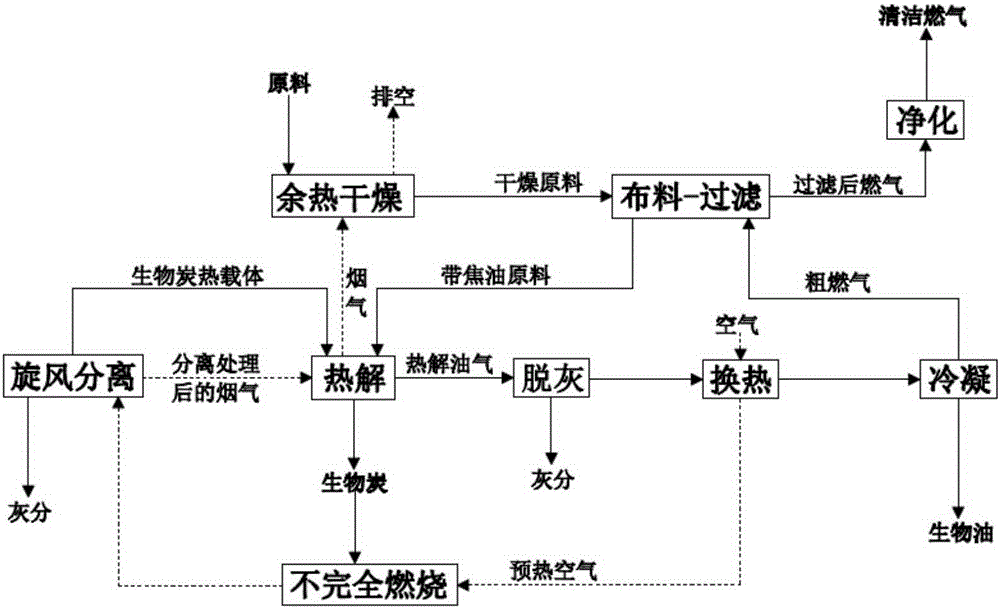

Biomass pyrolysis system and biomass pyrolysis method

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

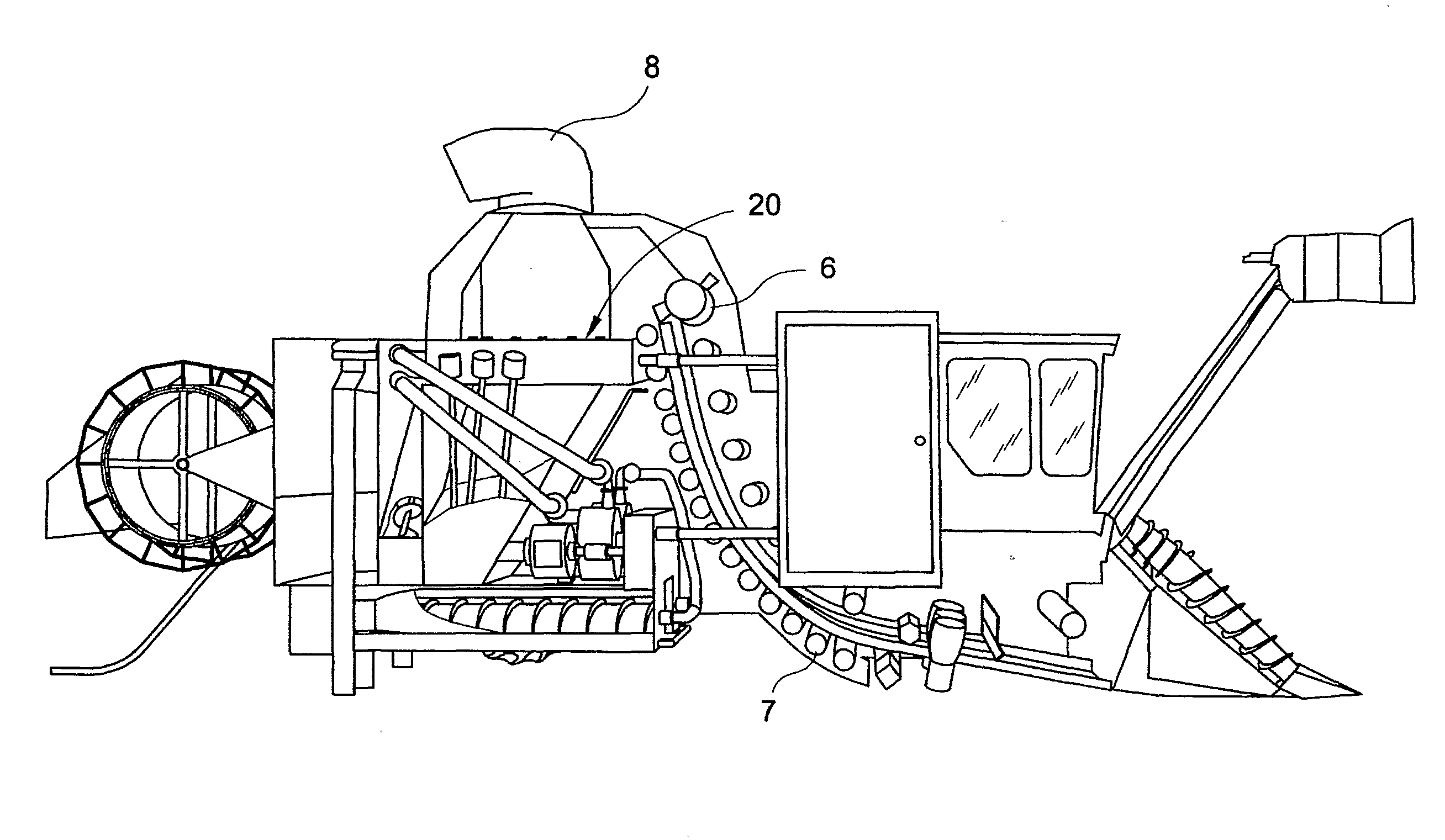

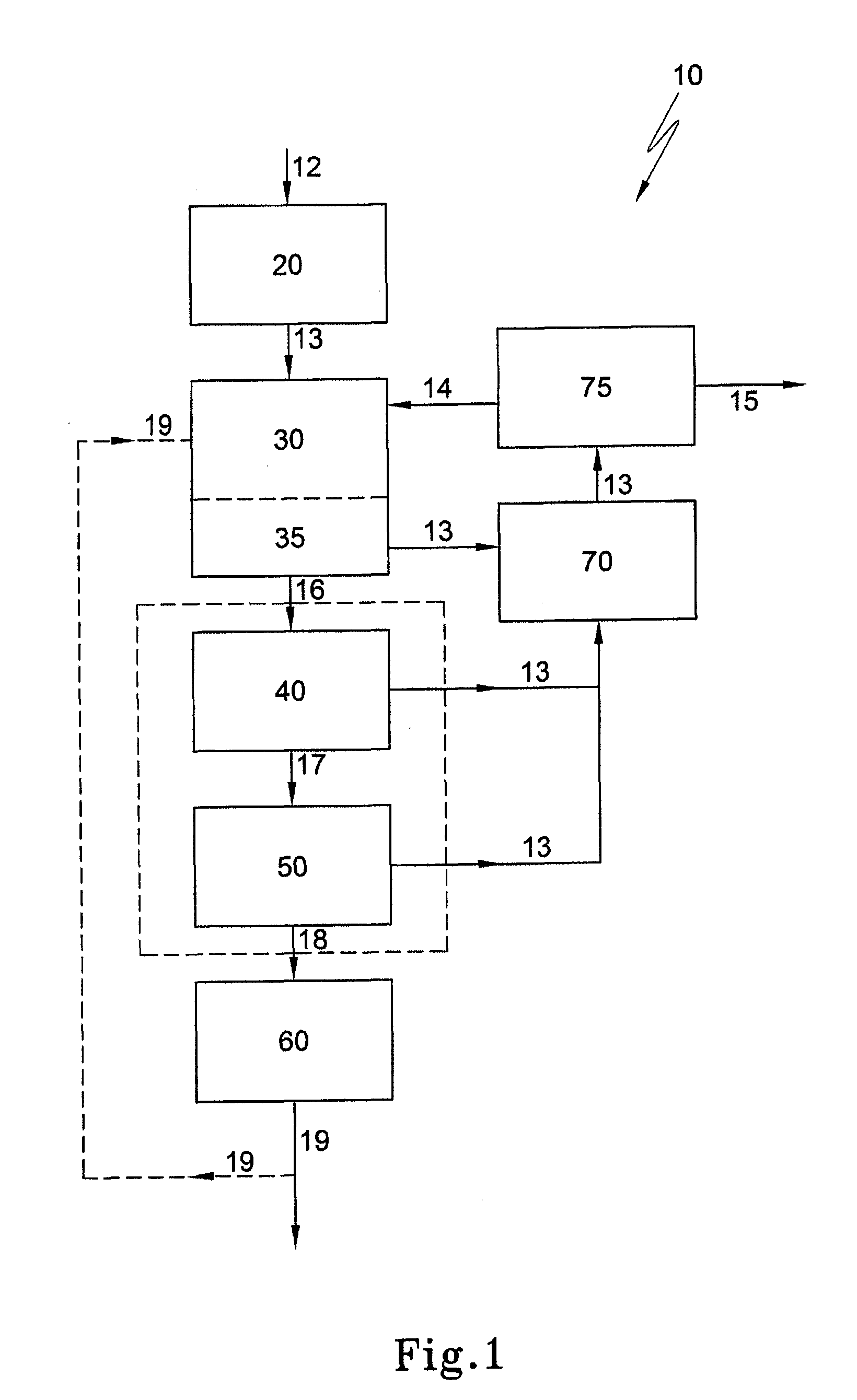

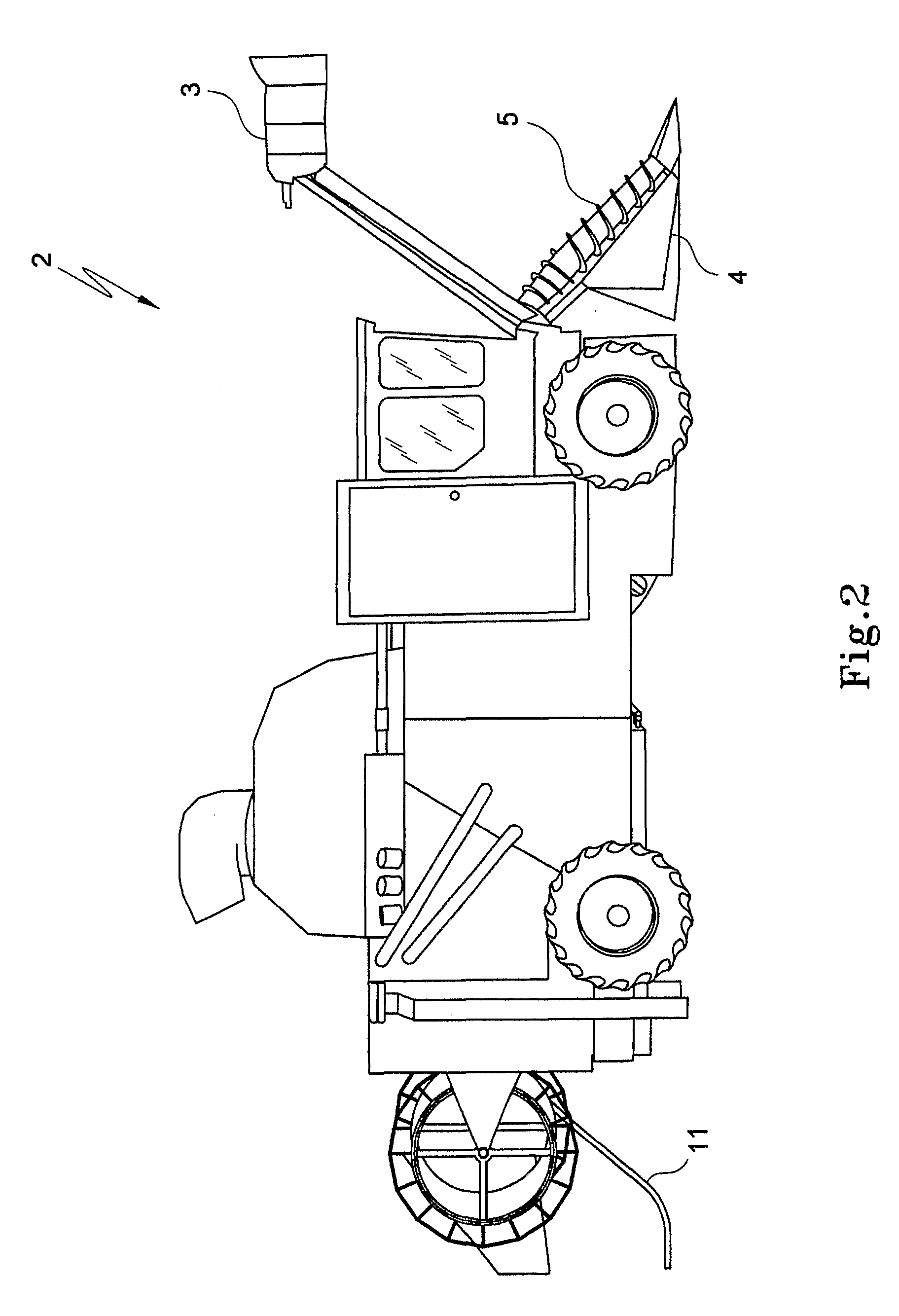

Biomass Processor

ActiveUS20090241944A1Facilitated releaseIncrease shear forcePressurized chemical processSugarcane cuttingFiberBiomedical engineering

Owner:BIOMASS TECH PTY LTD

Method for applying biomass extract product to coal blending for coking as additive

ActiveCN104673346AImprove performanceImprove qualityCoke ovensOrganic solventUltimate tensile strength

Owner:HUAZHONG UNIV OF SCI & TECH +1

Shale-sintered hollow ganged brick

Owner:陈振杰

Method for preparing active carbon from biomass, and prepared active carbon

InactiveCN107337206AReduce pollutionRecycling reducesZinc halidesCarbon compoundsActivated carbonAcid washing

Owner:HEFEI UNIV OF TECH

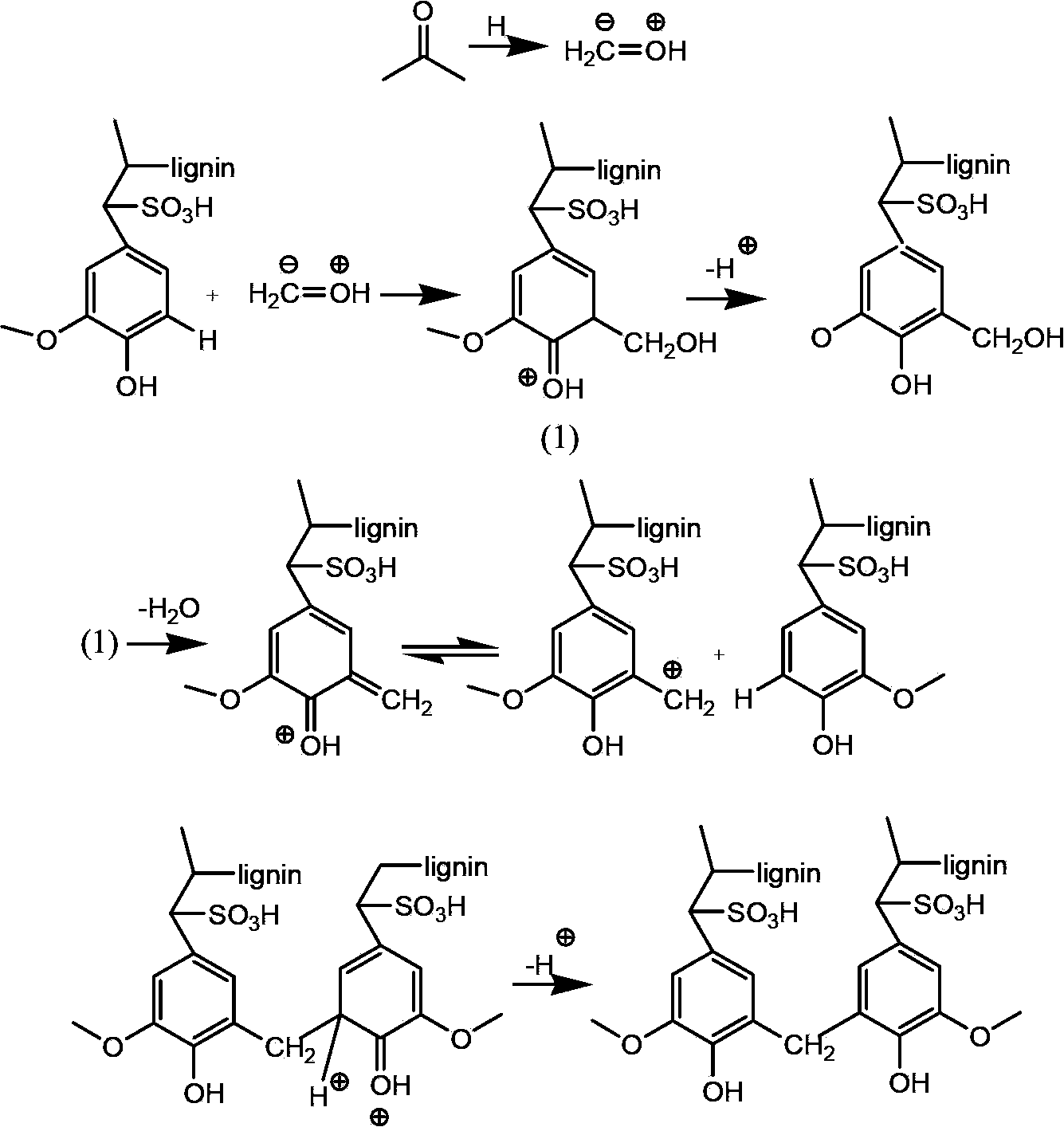

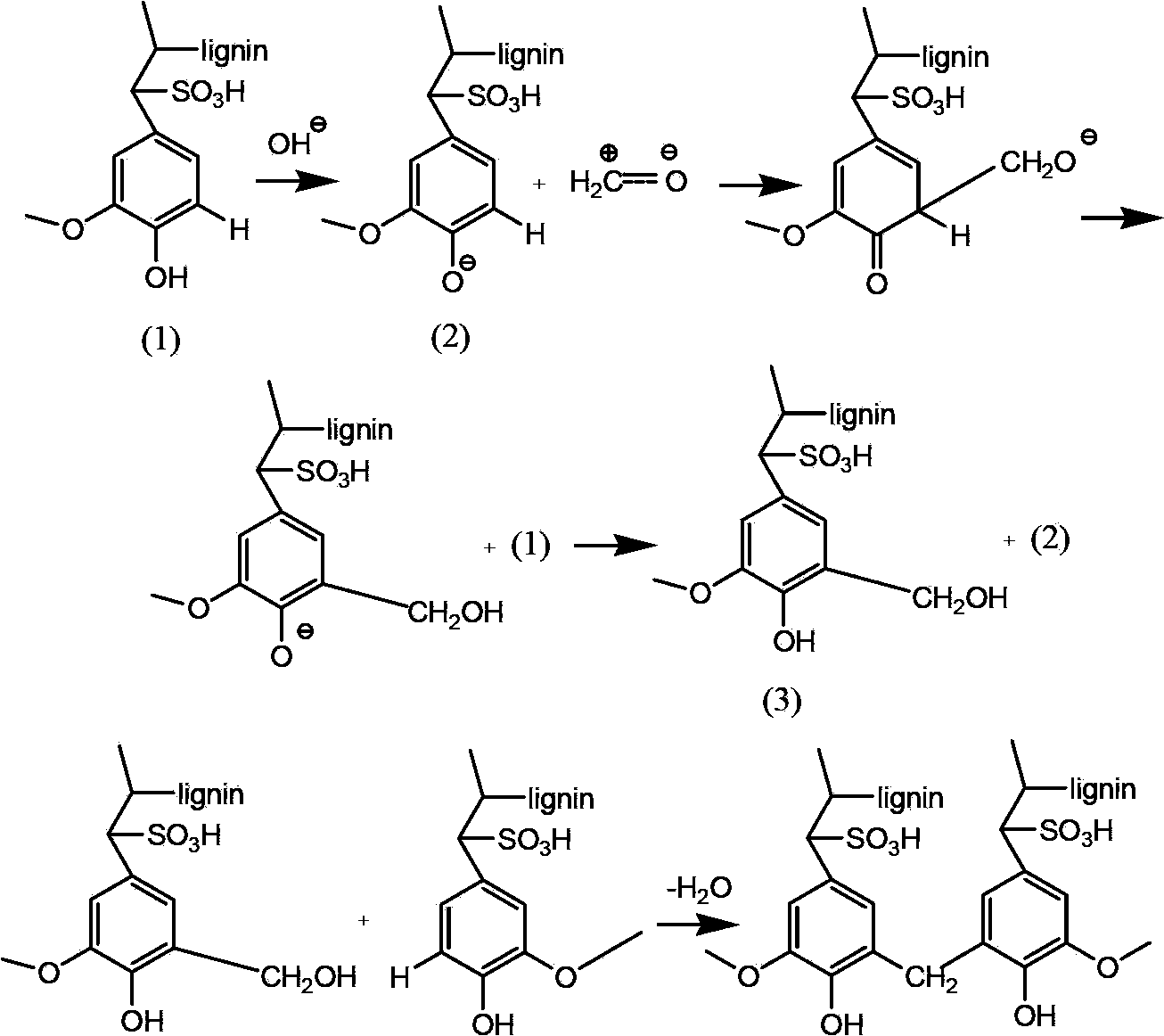

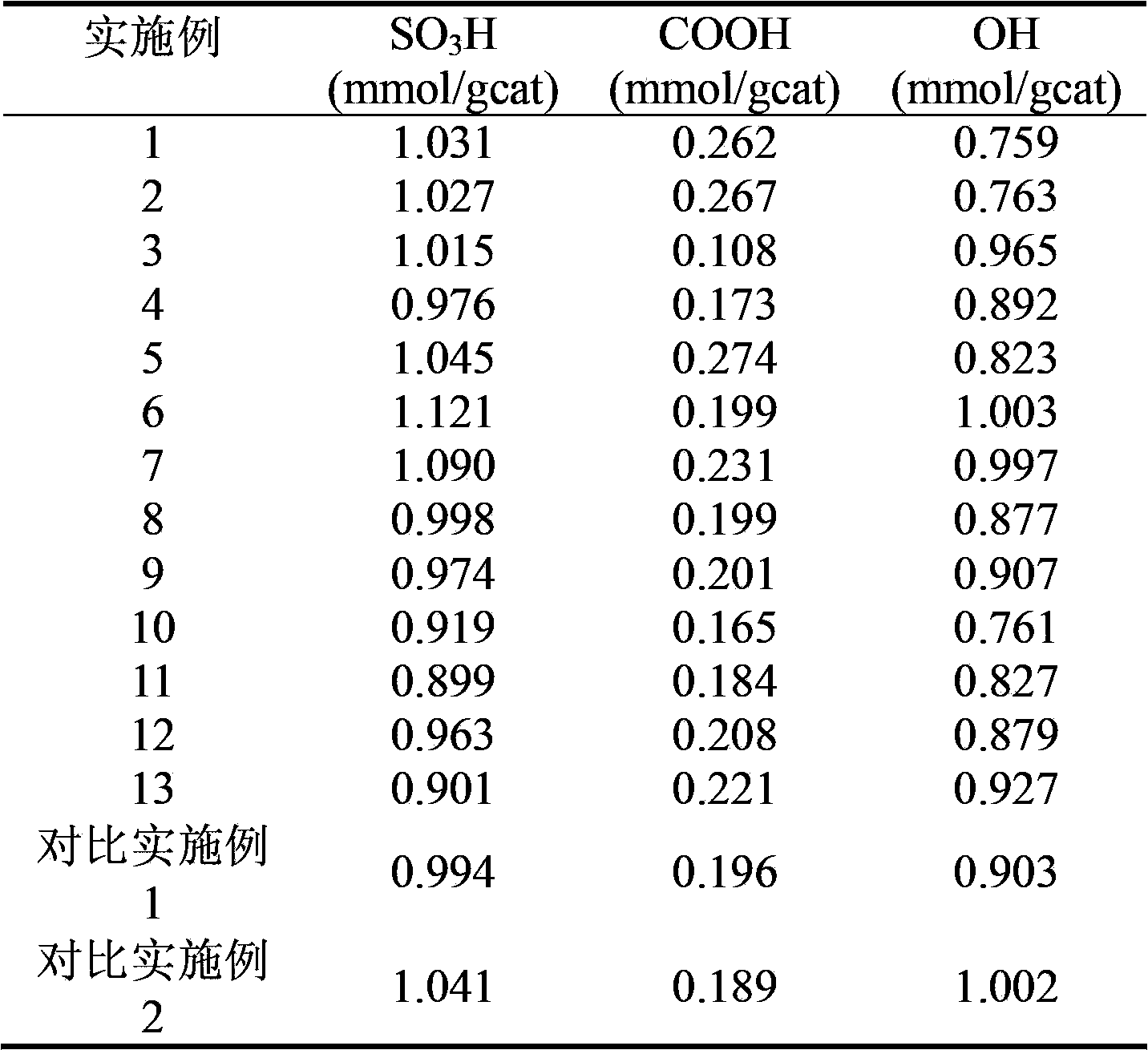

Porous biomass acidic solid material, and preparation and application thereof

InactiveCN103509194ARich sourcesLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLignosulfonatesEsterification reaction

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

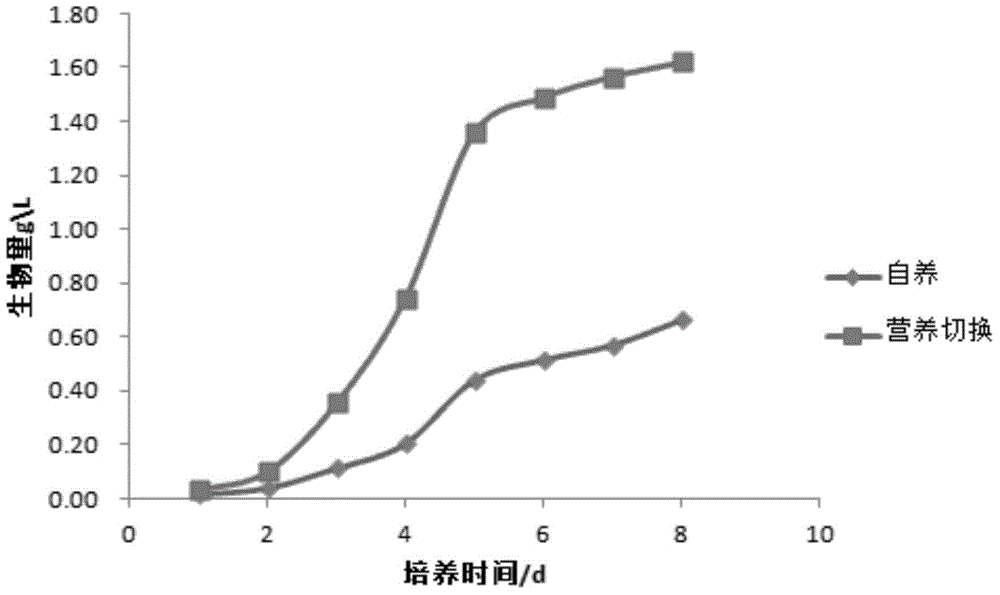

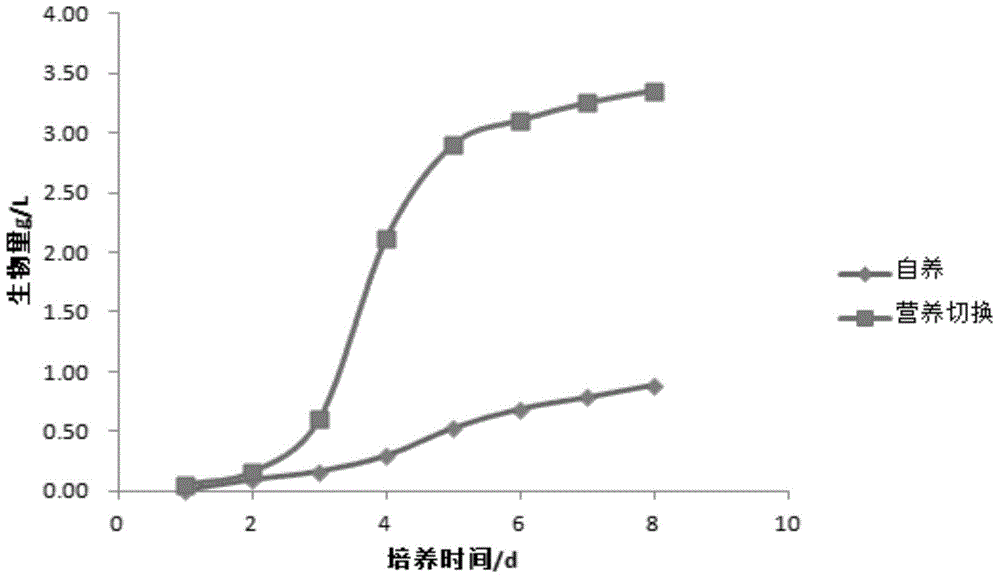

Nutrient switching method for culturing oleaginous microalgae

InactiveCN104830693AHigh biomassIncrease productionUnicellular algaeBiofuelsIrradiationCulture mediums

Owner:SHANGHAI JIAO TONG UNIV

Self-repairing ecological cement road material and preparation method

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for the simultaneous production of ethanol and a fermented, solid product

The invention relates to a method for the simultaneous production of a fermented, solid product and ethanol comprising the following steps: 1) providing a mixture of milled or flaked or otherwise disintegrated biomass, comprising oligosaccharides and / or polysaccharides and live yeast in a dry matter ratio of from 2:1 to 100:1, and water; 2) fermenting the mixture resulting from step (1) under conditions where the water content in the initial mixture does not exceed 65% by weight, for 1-36 hours at a temperature of about 25-60° C. under anaerobic conditions; 3) incubating the fermented mixture resulting from step (2) for 0.5-240 minutes at a temperature of about 70-150° C.; and 4) separating wet fermented, solid product from the fermented mixture resulting from step (3); further comprising either a) that the fermentation in step (2) is performed in one or more interconnected paddle worm or continuous worm conveyers with inlet means for the fermentation mixture and additives and outlet means for the ferment as well as control means for rotation speed, temperature and pH, or b) that one or more processing aids are added in any of steps (1), (2) and (3) and further comprising a step of 5) separating crude ethanol from the fermented mixture in step (2) by vacuum and / or in step (3) by vacuum or by injection of steam and condensing the surplus stripping steam. The invention further relates to the products of this method as well as uses thereof.

Owner:HAMLET PROTEIN AS

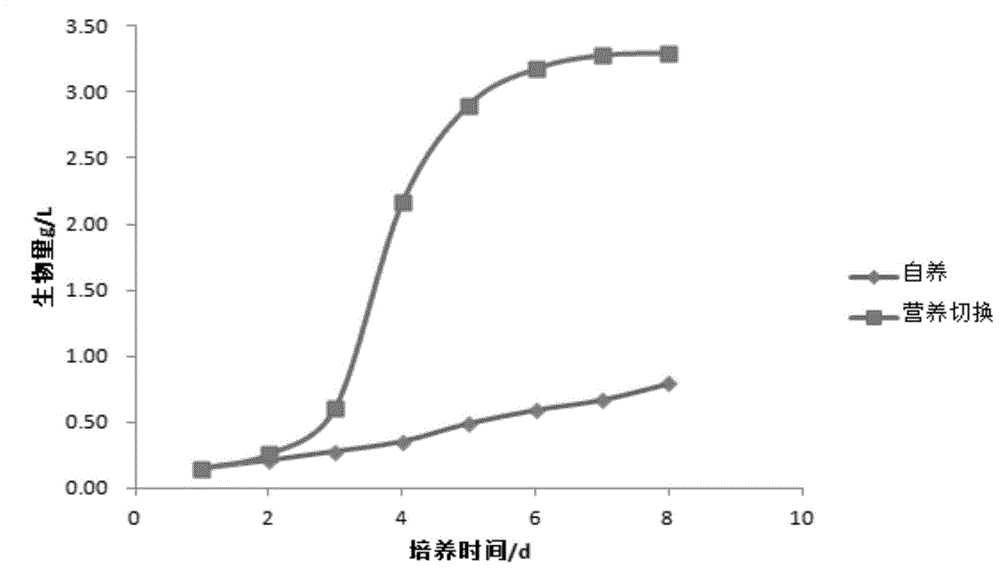

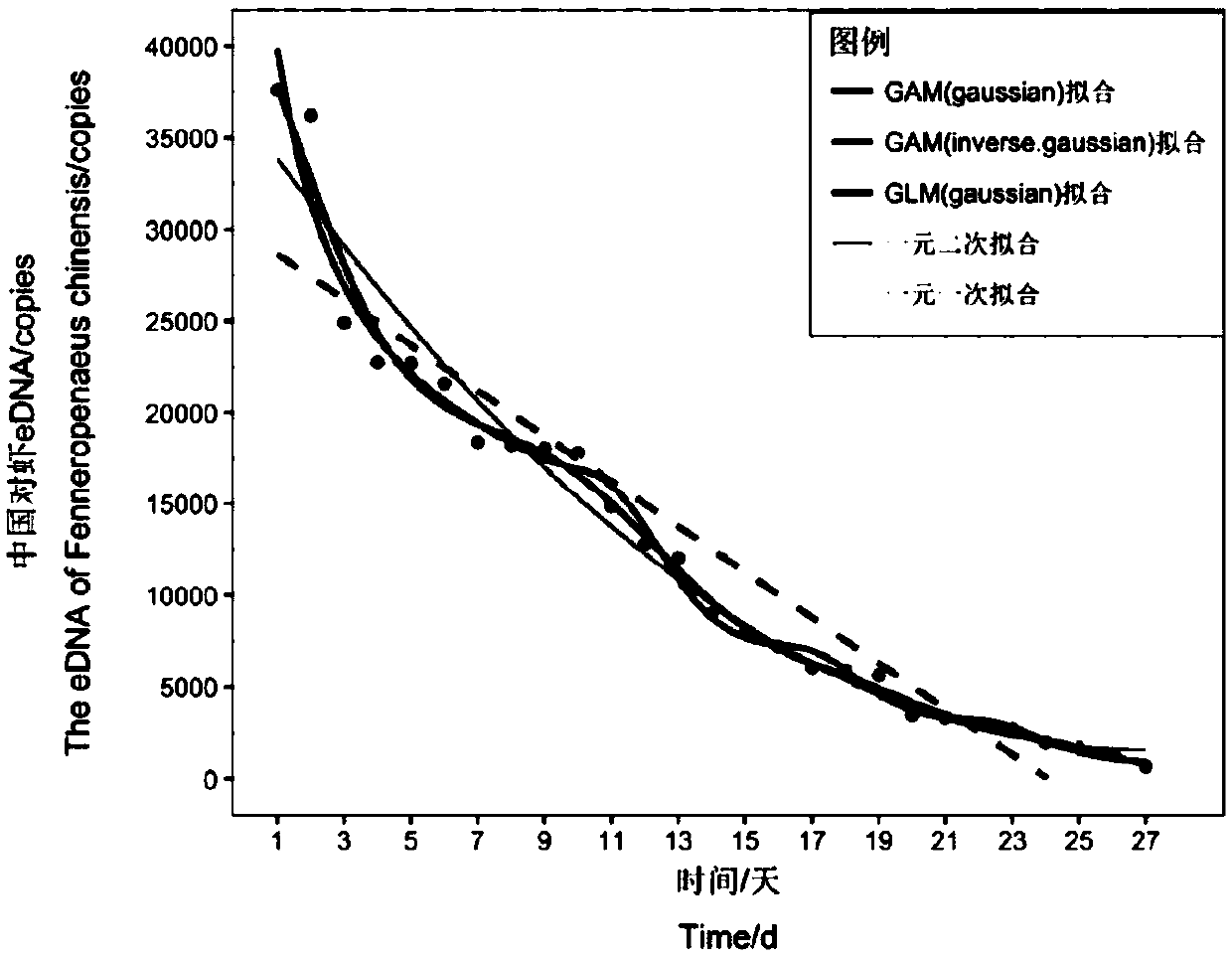

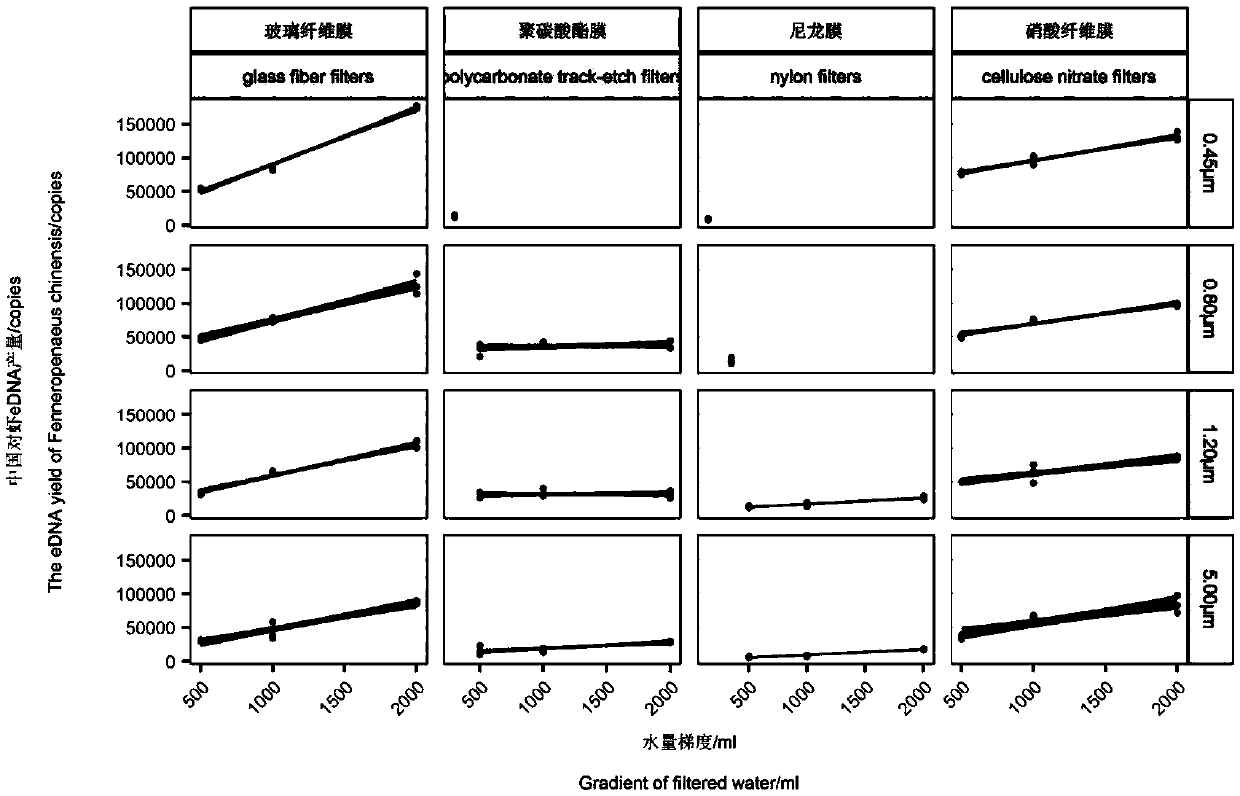

Investigation method of released Chinese prawns

InactiveCN109628608ARealize accurate detectionReduce distractionsMicrobiological testing/measurementInvestigation methodsDynamic population

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Tomato fertilizer containing rich nucleic acid and preparation method of tomato fertilizer

InactiveCN106007932AImprove water holding capacityImprove stabilityCalcareous fertilisersAlkali orthophosphate fertiliserHeavy metal chelationPolyvinyl alcohol

The invention discloses a tomato fertilizer containing rich nucleic acid. The tomato fertilizer is prepared from raw materials in parts by weight as follows: 200-210 parts of rice straw, 20-21 parts of kaoline, 10-11 parts of urea, 10-11 parts of furnace dust, 5-6 parts of hawthorn seeds, 7-8 parts of nucleic acid wastewater, 0.3-0.4 parts of ammonium polyphosphate, 0.1-0.2 parts of a urease inhibitor, 1-2 parts of gypsum powder, 1-2 parts of amino acid powder, 15-16 parts of polyvinyl alcohol, 1-1.1 parts of tea polyphenol, 1-1.1 parts of carbon nanotubes, 1.2-1.3 parts of beta-cyclodextrine and 800-810 parts of 28% ammonia water. Amino groups are introduced to biomass charcoal prepared from the rice straw and can be chelated with heavy metal, the heavy metal adsorption capability is improved, and the pollution influence of the heavy metal on soil and the environment is reduced. The carbon nanotubes are added to a film coating liquid, the mechanical strength of a film can be improved, and added tea polyphenol can improve the slow-release property of the film; besides, the tomato fertilizer contains rich nucleic acid, the activity of tomatoes can be enhanced, decaying of the tomatoes is delayed, and the yield is increased.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

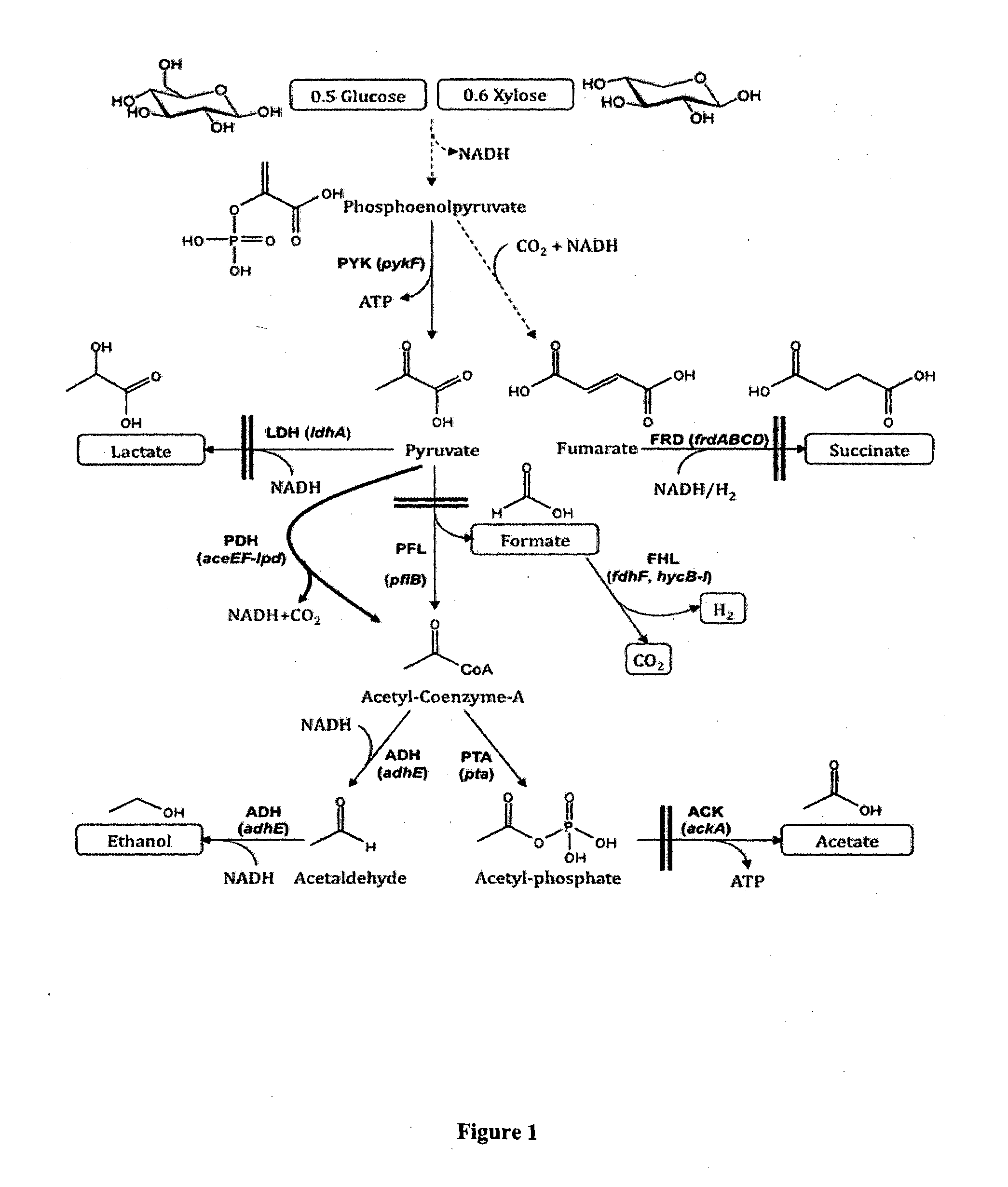

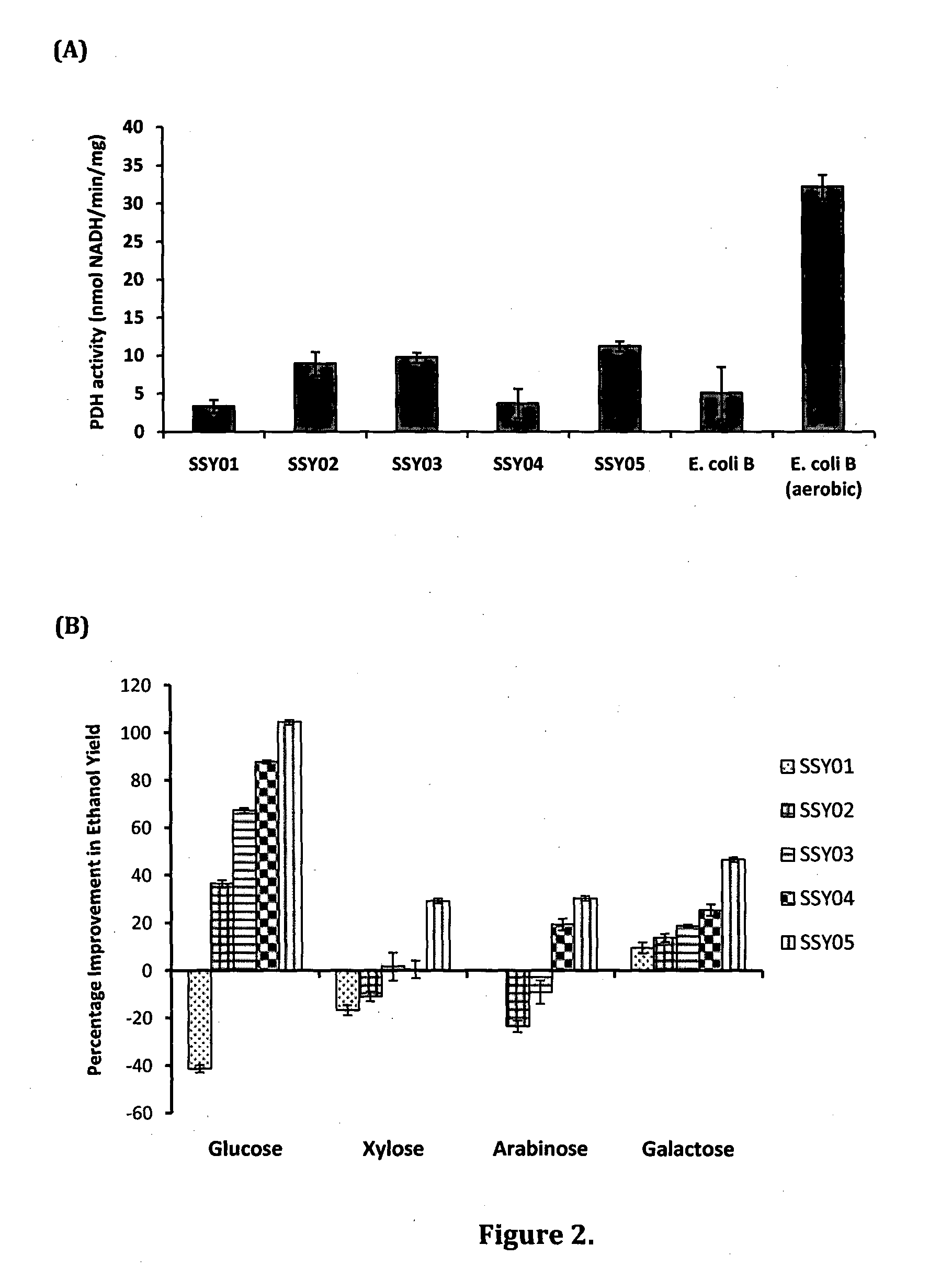

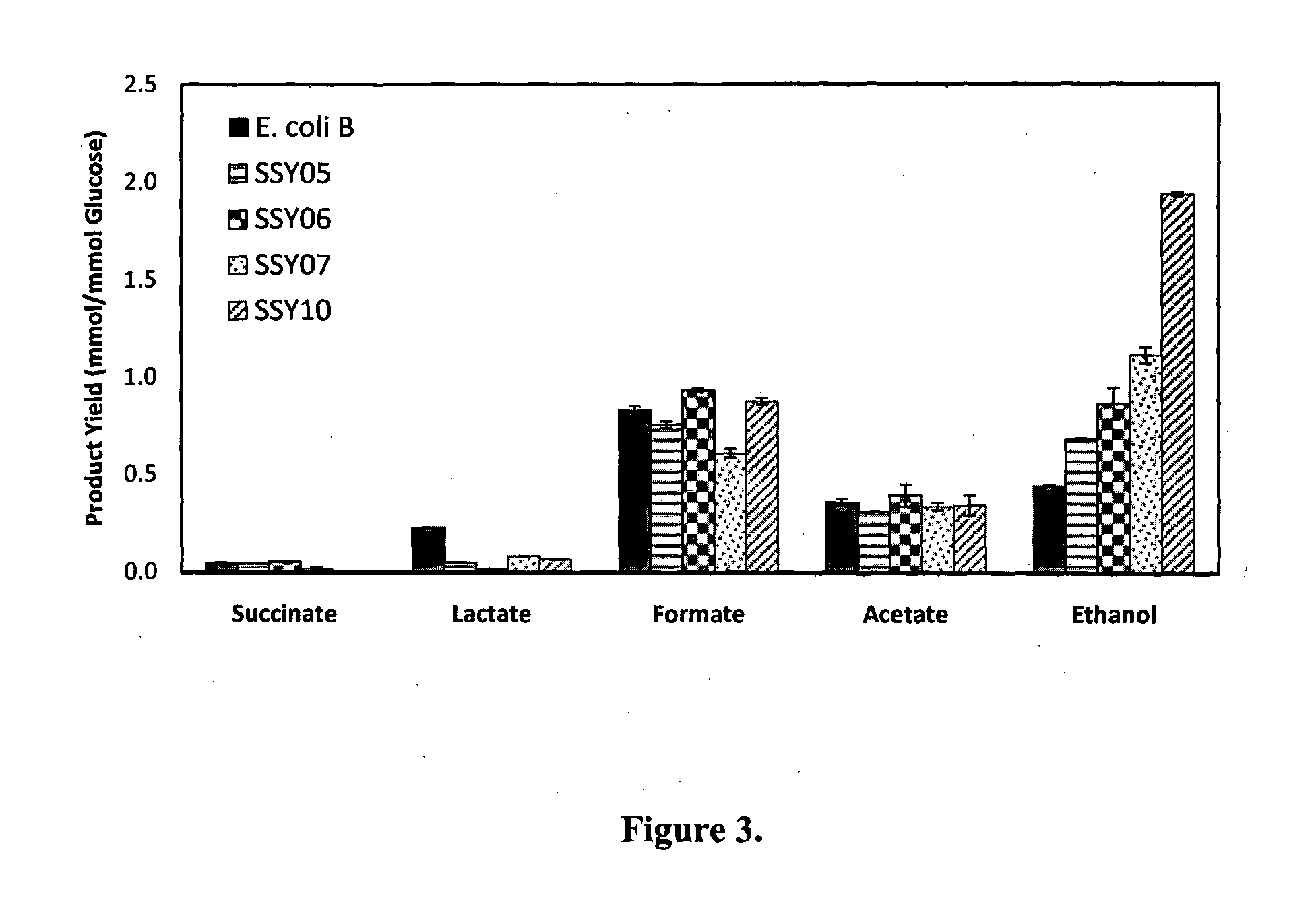

Modified bacteria for the production of bioalcohol

Owner:DEPT OF BIOTECHNOLOGY MINIST OF SCI & TECH GOVERNMENT OF INDIA +1

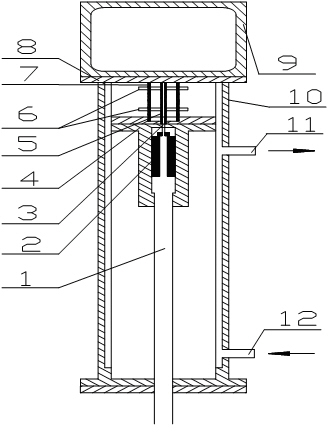

Epithermal injection biomass pyrolytic system

InactiveCN102071034AAvoid secondary pyrolysis reactionsRapid coolingElectrical coke oven heatingDirect heating destructive distillationGraphite electrodeRadiation resistant

Owner:CHONGQING UNIV

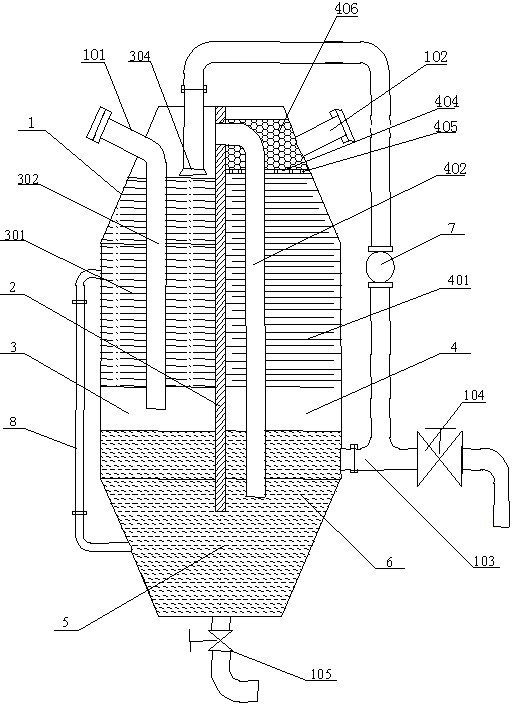

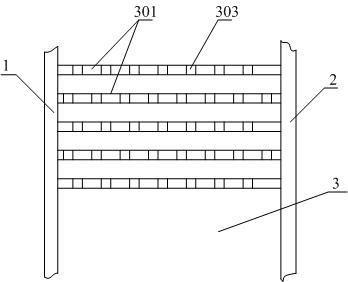

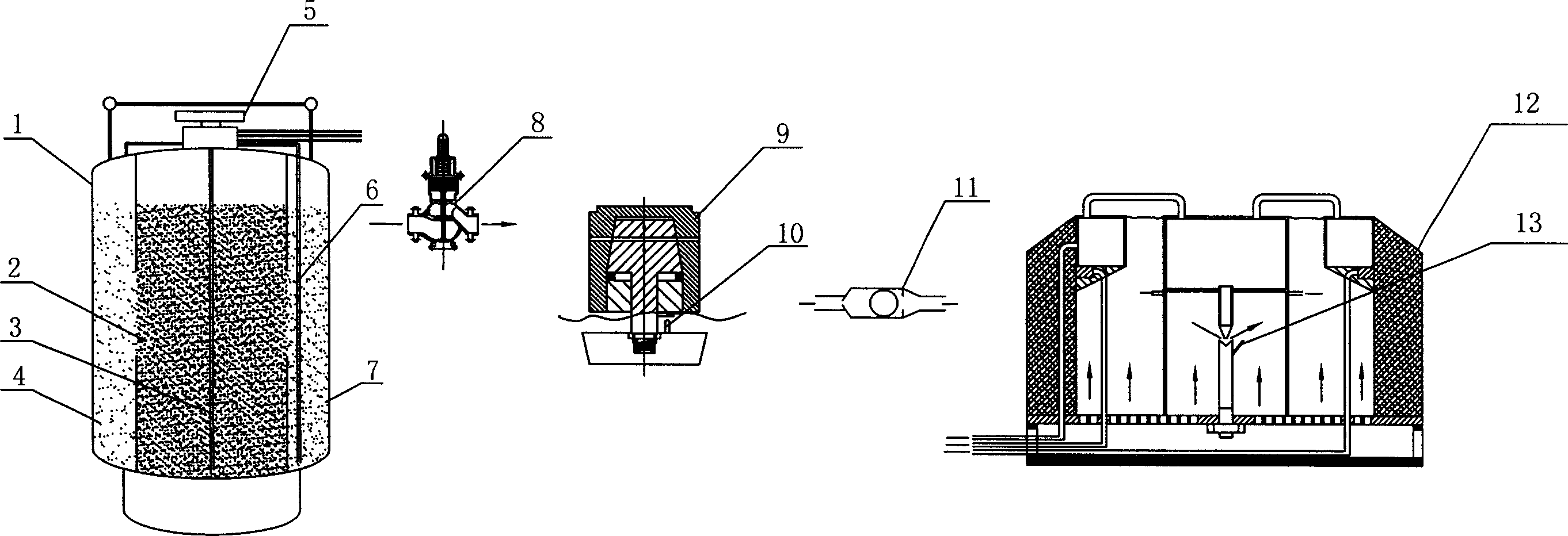

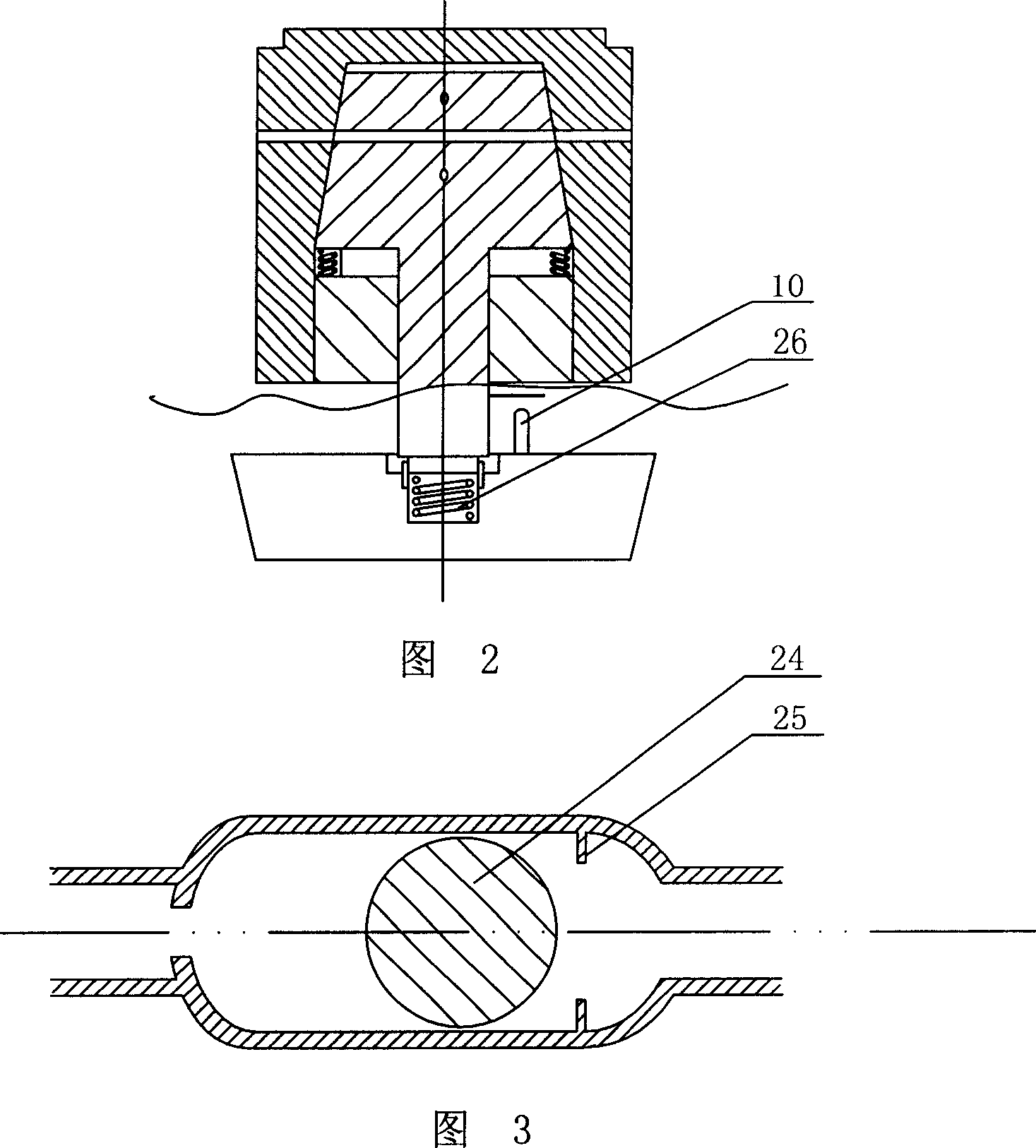

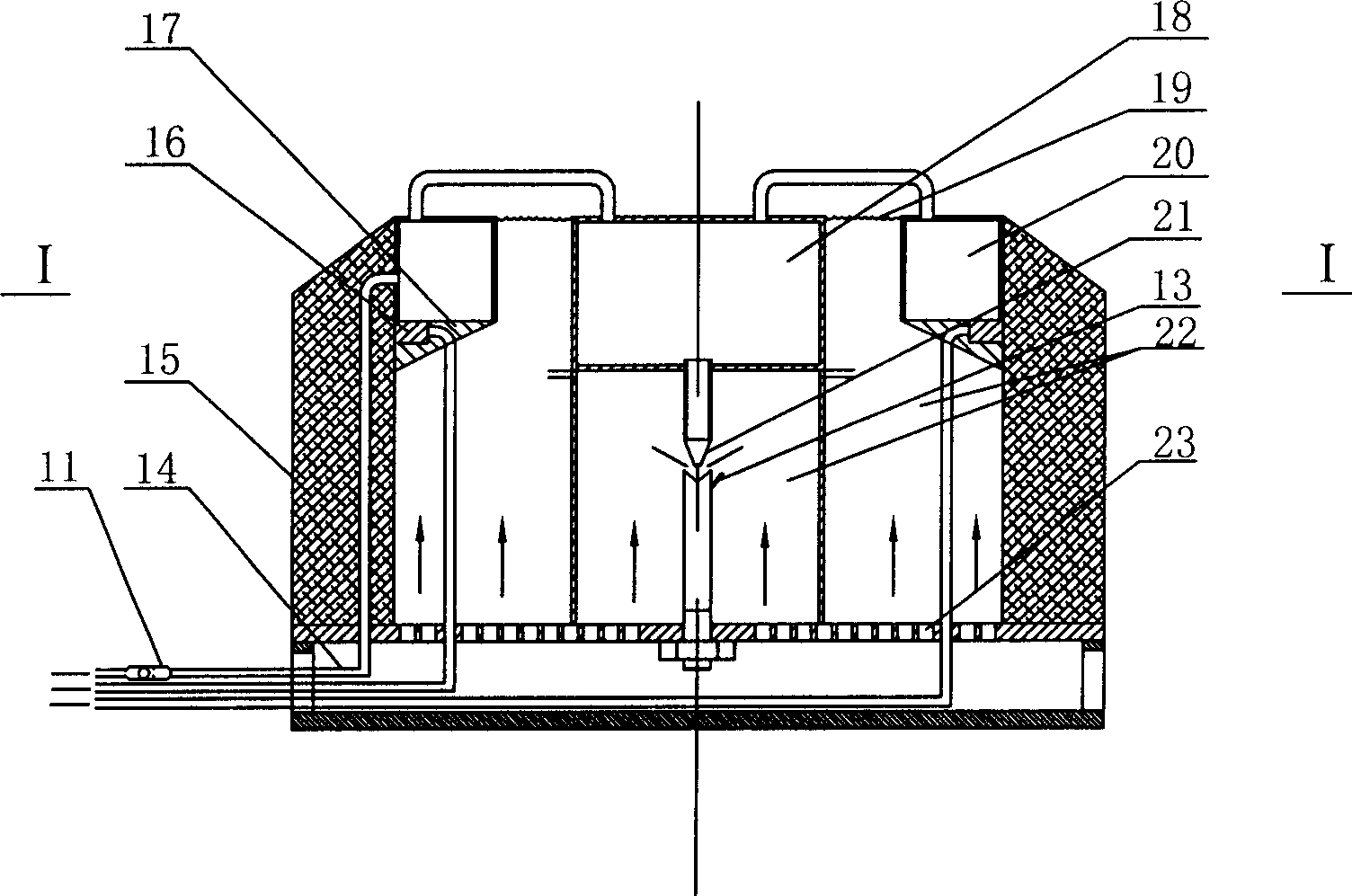

Purification device in waste biomass resource pyrolysis and gasification system

InactiveCN102504884ACompact structureSmall footprintGas purification by liquid washingSolventBiomass

Owner:LUOYANG JUNTENG ENERGY TECH +1

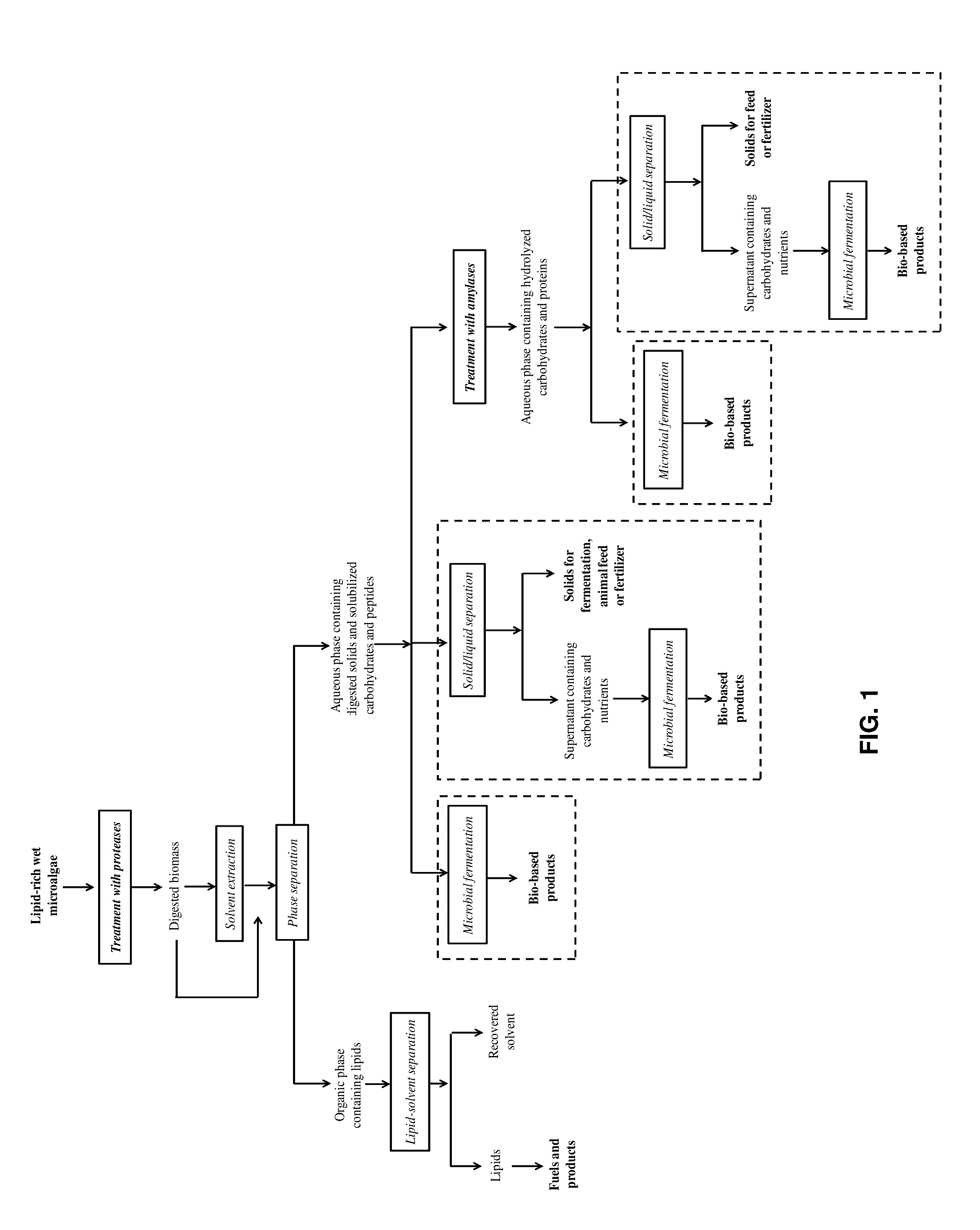

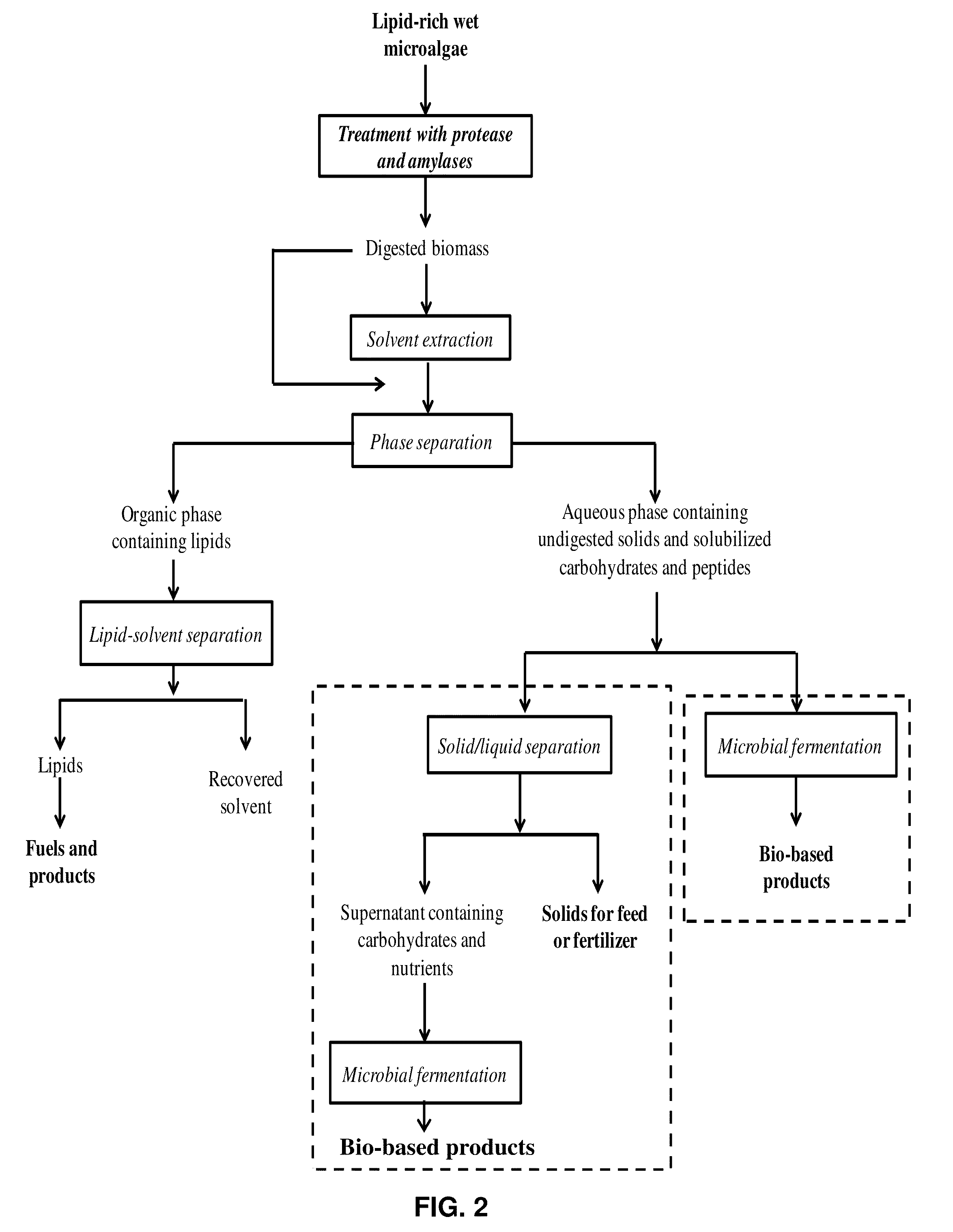

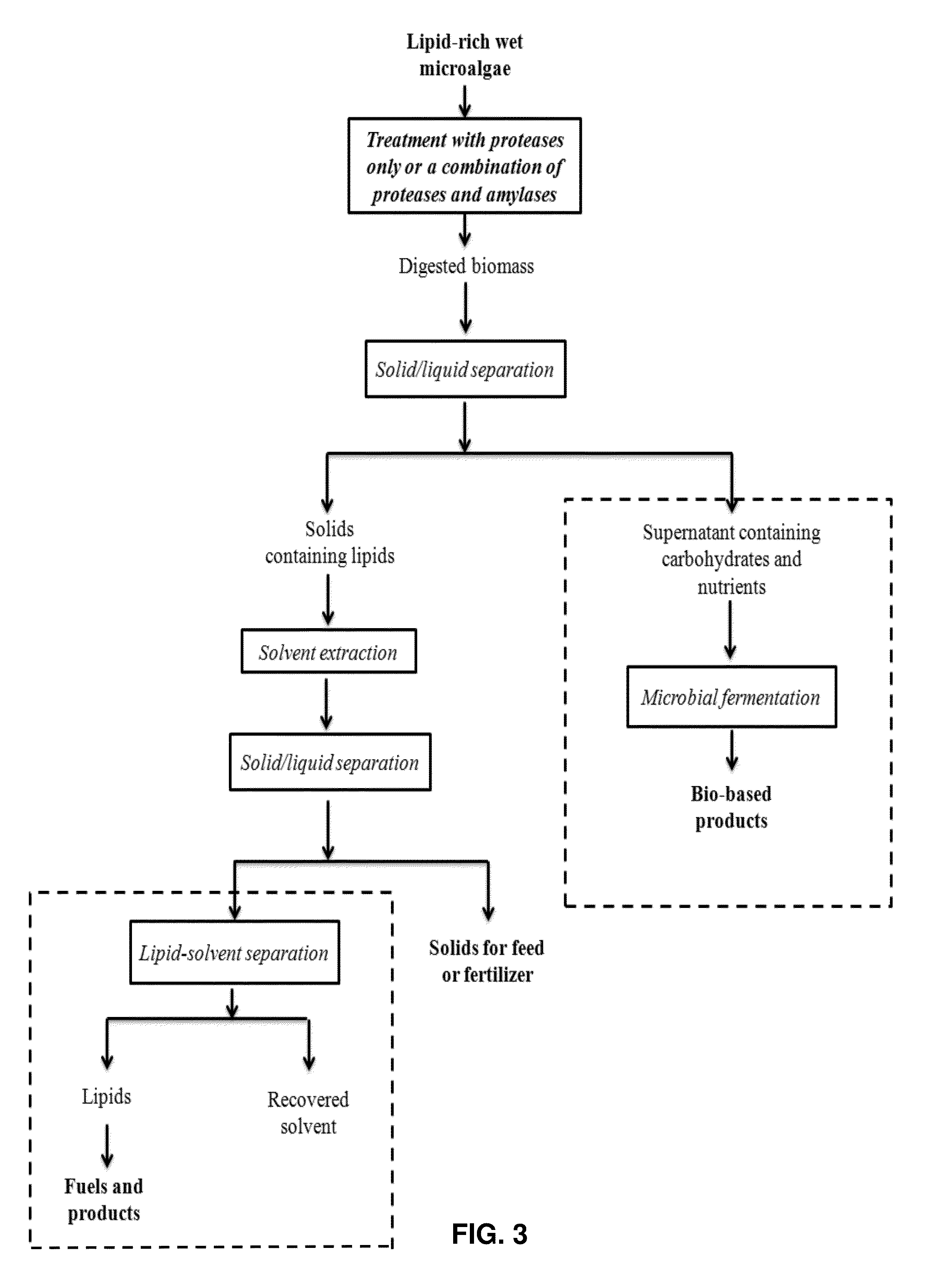

Enzymatic Digestion of Microalgal Biomass for Lipid, Sugar, and Protein Recovery

Owner:UNIVERSITY OF TOLEDO

Reduction or elimination of microbial growth and biofouling of salted wet biomass byproducts

InactiveUS20070110909A1Negligibly corrosiveAvoid small quantitiesBiocideAntifouling/underwater paintsSimple Organic CompoundsSaline water

The invention describes a method, composition, and system of treating soluble organic compounds in combination with salts or brine used primarily for freezing point depression liquids, capable of aerobic and anaerobic microorganism growth such that by applying sufficient caustic in a caustic wash to an inside surface of any liquid media transport device for these freezing point depression liquids a caustic residue or caustic concentration associated with the caustic wash is created that results in mitigating or eliminating microorganism growth.

Owner:ISAKOFF LOUIS A +1

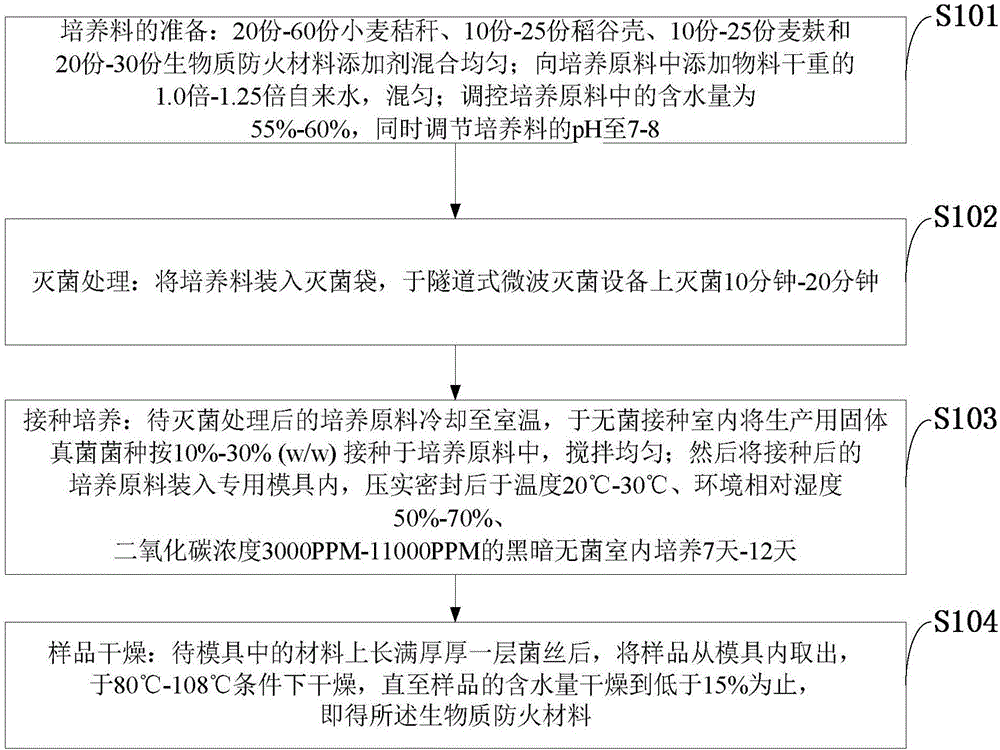

Fungus-based biomass fireproof material with wheat straw as main material and preparation method thereof

Owner:SHENZHEN ZEQINGYUAN TECH DEV SERVICE CO LTD

Range with biomass oil as fuel

InactiveCN1844754ASolve black smokeSolve the problem of coking and blocking oil passageLiquid fuel feeder/distributionDomestic stoves or rangesCombustion chamberEngineering

Owner:何仁

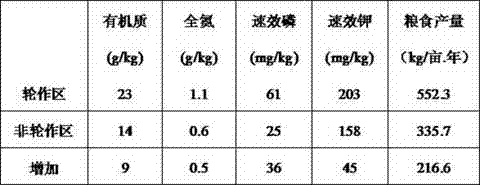

Method for increasing volume of low-yield land by crop rotation of wheat straw hoods

Owner:NANYANG NORMAL UNIV

Preparation method of biomass derived carbon material

Owner:ZHEJIANG FORESTRY UNIVERSITY

Composition for remediating arsenic-phenanthrene complex contaminated soil and application thereof

ActiveCN109385282APromote repairLarge biomassContaminated soil reclamationProcess efficiency improvementMicrobial agentBiology

The invention belongs to the field of environmental remediation engineering, and relates to a composition for soil remediation and application thereof. The composition comprises pteris vittata, a microbial agent and glutathione. According to the invention, remediation treatment is performed on organic-inorganic substances contaminated soil through a plant-microorganism system, and pteris vittata,the microbial agent and glutathione are used in combination for achieving a synergistic effect, wherein the microbial agent can effectively promote the increment of pteris vittata biomass, thereby improving the accumulation of arsenic; pteris vittata provides attachment carriers for microorganisms, thereby promoting the degradation of phenanthrene by microorganisms; and glutathione can effectivelyeliminate the inhibition action of arsenic-phenanthrene on pteris vittata and the microorganisms, thereby obviously improving the handling capacity of pteris vittata and the microorganisms on pollutants and promoting the soil remediation.

Owner:中国地质环境监测院(自然资源部地质灾害技术指导中心) +1

High-temperature-resistant special water-retaining admixture for concrete as well as preparation process and application of admixture

ActiveCN109867486AImprove water retentionGood and lasting water-locking effectCarboxylic acidTartrate

The invention discloses a high-temperature-resistant special water-retaining admixture for concrete as well as a preparation process and application of the admixture. The admixture comprises the following components: 1-5 parts of a sustained-release polycarboxylic acid, 5-20 parts of a comprehensive polycarboxylic acid, 1-10 parts of a retarder, 0.1-2 parts of a biomass glue, 0.1-5 parts of an airentraining agent, 0.1-5 parts of a defoaming agent, and 63.8-92.97 parts of water, wherein the sustained-release polycarboxylic acid is composed of isopentenyl polyoxyethylene ether, water, acrylic acid, hydroxyethyl acrylate, sodium methallyl sulfonate and ammonium persulfate, and the comprehensive polycarboxylic acid is composed of isobutylene polyoxyethylene ether, water, acrylic acid, tartrate acrylate, ascorbic acid and mercaptopropionic acid. The water-retaining admixture provided by the invention has a better water-retaining effect, and the preparation process provided by the inventionmakes the obtained admixture less prone to overpolymerization; and according to the application of the water-retaining admixture, the concrete can maintain a better water lock effect for a long timein a high-temperature environment in summer, so that the phenomenon of blocking of a pumping pipe when the concrete is pumped is not easy to cause.

Owner:HANGZHOU JIANSHE NEW MATERIALS CO LTD

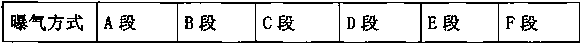

Method for biologically drying sludge by using rice hull as additive

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

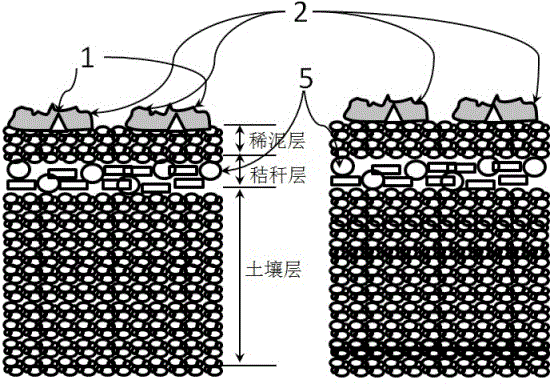

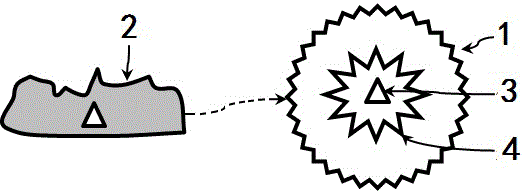

Semi-solid-state complex no-tillage dry direct seeding method for crop seeds

InactiveCN104663207AAddressing supply shortagesGuaranteed supplySowingFertilising methodsFertilizerBiomass

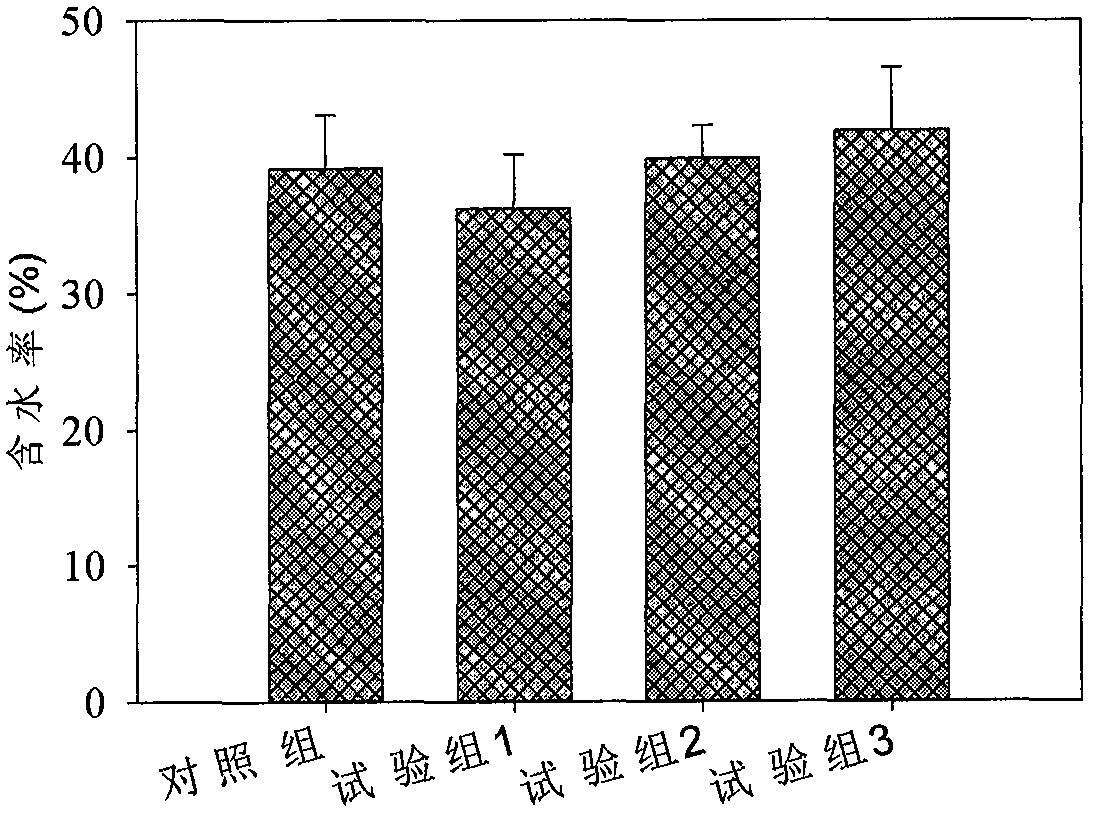

The invention discloses a semi-solid-state complex no-tillage dry direct seeding method for crop seeds. The no-tillage dry direct seeding method comprises the following steps: S1, keeping a water layer of 1cm-5cm in a ditch, and paving straws obtained by harvesting preceding crops on a ditch surface; S2, applying a base fertilizer on the ditch surface paved with the straws and cleaning the ditch; S3, seeding the crop seeds on the ditch surface, and mixing the crop seeds with semi-solid-state biomass materials, a compound fertilizer and a biopesticide before seeding before seeding seeds, wherein the mixing mass ratio is that the crop seeds to the semi-solid-state biomass materials to the biopesticide is (1-10) to (70-800) to (1-3), and the moisture content of the semi-solid-state biomass materials is 40%-80%; and S4, after seeding the seeds, keeping the ditch surface at a dry state for 3-7 days. According to the semi-solid-state complex no-tillage dry direct seeding method, tillage and combustion of winter crop straws are not carried out, a whole land of field immersing water is not used for irrigation and the water immerses after the seeding, and the biological benefits are obvious; the working energy consumption is reduced, stubbles are not killed by pesticides, haze is reduced and the irrigation water is reduced.

Owner:HUNAN AGRICULTURAL UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap