Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Calcination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The IUPAC defines calcination as "heating to high temperatures in air or oxygen". However, calcination is also used to mean a thermal treatment process in the absence or limited supply of air or oxygen applied to ores and other solid materials to bring about a thermal decomposition. A calciner is a steel cylinder that rotates inside a heated furnace and performs indirect high-temperature processing (550–1150 °C, or 1000–2100 °F) within a controlled atmosphere.

Prepn of nano-cobaltosic oxide powder

InactiveCN1344682ASuitable for large-scale industrial productionEasy to operateCobalt oxides/hydroxidesCobalt carbonatesCobalt(II,III) oxideCobalt salt

The present invention relates to chemical industry technology. The preparation of nanometer cobaltosic oxide powder includes purifying material, cobalt salt deposition, solid-liquid separation and solid calcination. Cobalt sheet is dissolved in nitric acid while being heated and high purity water is added to regulate solution density and pH value so as to obtain cobalt nitrate solution of 1.5-1.65 g / cu cm density and pH 4-5; ammonium bicarbonate suspension in 14-30 wt% is prepared with ammonium bicarbonate and water; cobalt nitrate solution is added into the suspension slowly to result in weight ratio of carbonate radical to cobalt ion being 2.4-2.6; and the wet cobalt carbonate material is heated to 300-450 deg.c for 3-6 hr to obtain black Co3O4 powder.

Owner:SHANDONG UNIV +1

Method for preparing hetero-atom doped porous carbon material through carbonation of biomass under assistance of molten salt

The invention provides a method for preparing a hetero-atom doped porous carbon material through carbonation of biomass under the assistance of molten salt. The method comprises the following steps: uniformly mixing biomass powder, the molten salt and a hetero-atom doped compound to obtain a product A, wherein the molten salt contains LiCl and KCl, the mass of LiCl accounts for 59 percent of that of the molten salt, and the mass of KCl accounts for 59 percent of that of the molten salt; putting the product A in a pipe furnace; carrying out high-temperature calcination; cleaning with distilled water to remove the molten salt and obtain the final product, namely the hetero-atom doped porous carbon material. The method has the advantages that the biomass is taken as a raw material, and the molten salt containing hetero-atoms is taken as a carbonization medium, so that the hetero-atoms can be introduced into the skeleton of the carbon material during the pyrolysis and carbonization process of the biomass synchronously and controllably, and the hetero-atom in-situ doped porous carbon material is obtained finally. Compared with the conventional doping method, the method provided by the invention have the advantages that the steps are simple; the cost is low; the operation is easy; the reactant purity is high; the application prospect is relatively good.

Owner:HARBIN ENG UNIV

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

Ferrierite molecular sieve, preparation method thereof and application

ActiveCN107010636AGood choiceImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationCrystallinity

The invention provides a ferrierite molecular sieve, a preparation method thereof and an application. The preparation method includes the steps: mixing silicon sources, alkalinity conditioning agents, aluminum sources, template agents and water to form uniform sol; controlling the molar ratio of SiO2, Al2O3, R, Na2O to H2O to be 1.0:(0.005-0.10):(0.05-1.2):(0.03-0.50):(5.0-100.0), and enabling a pH (potential of hydrogen) value to be lower than 12.8; performing pre-crystallization, crystallization, drying and calcination to obtain molecular sieve raw powder; performing acid treatment on the obtained molecular sieve raw powder; mixing the molecular sieve raw powder, the template agents and the water or further mixing the molecular sieve raw powder, the template agents, the water and the silicon sources to form water solution; performing water-heat treatment, drying and calcination to obtain the ferrierite molecular sieve. R is the template agents. The prepared ferrierite molecular sieve is high in relative crystallinity and silica alumina ratio, large in specific surface area and crystal particle and adjustable in acidity and has excellent selectivity and stability when being applied to linear-chain olefin skeletal isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for high-purity rhenium powder

Owner:湖南元极新材料有限公司

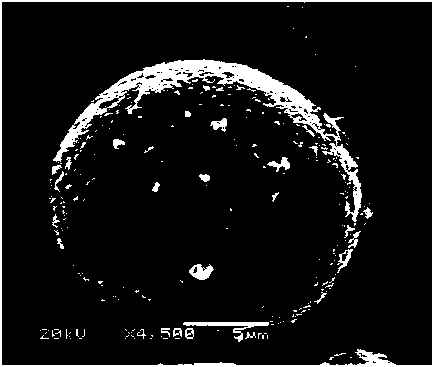

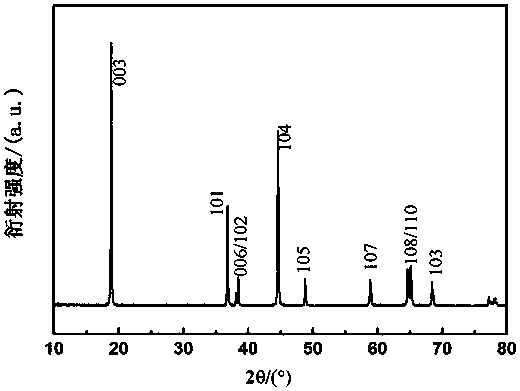

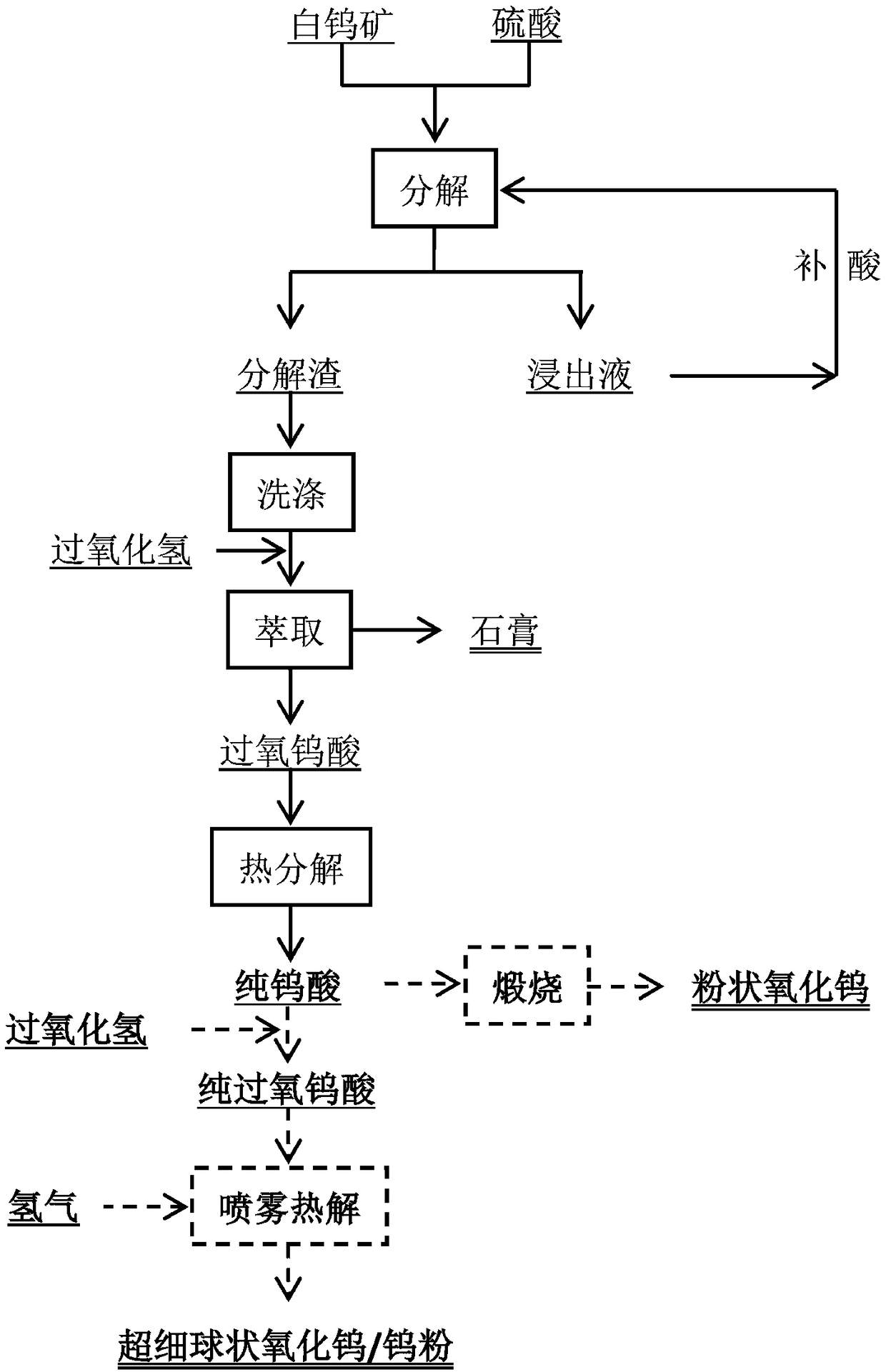

Method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementDecompositionCalcination

Owner:CENT SOUTH UNIV

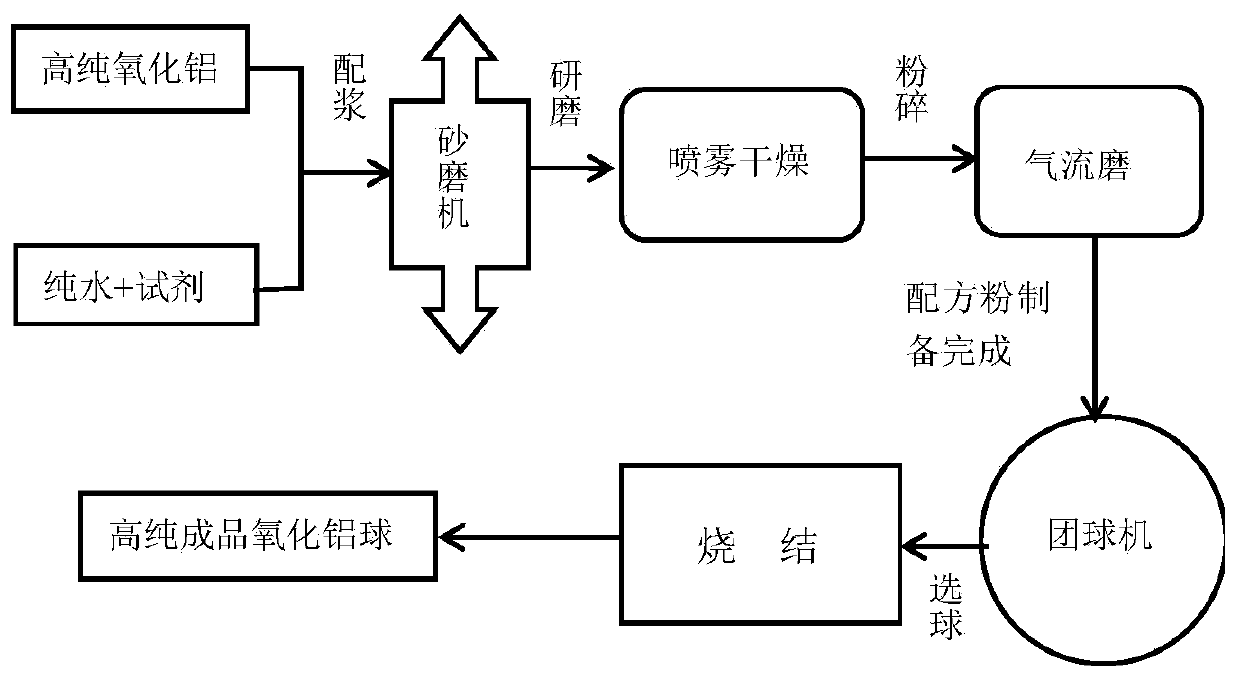

Alumina grinding ball preparation method

Owner:青海万加环保新材料有限公司

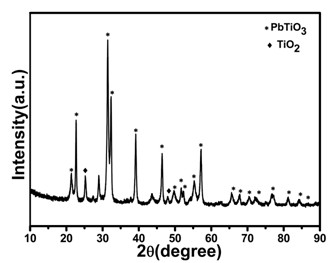

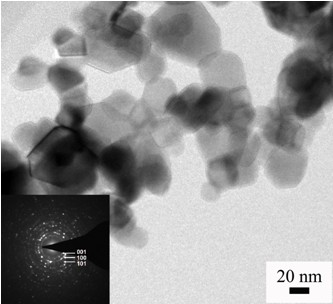

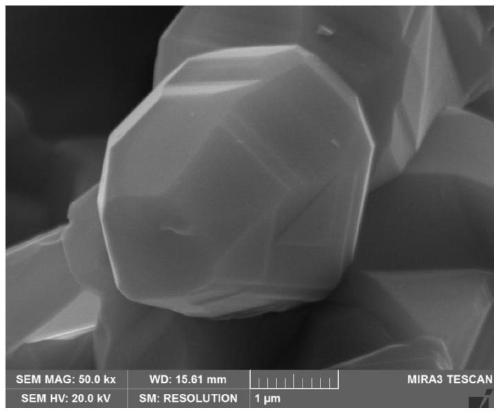

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

Method for preparing lithium manganate by wet-doping method

InactiveCN103337619AIncrease the average oxidation stateSuppress purityCell electrodesManganates/permanganatesOxidation stateManganate

Owner:HUNAN DAHUA NEW ENERGY

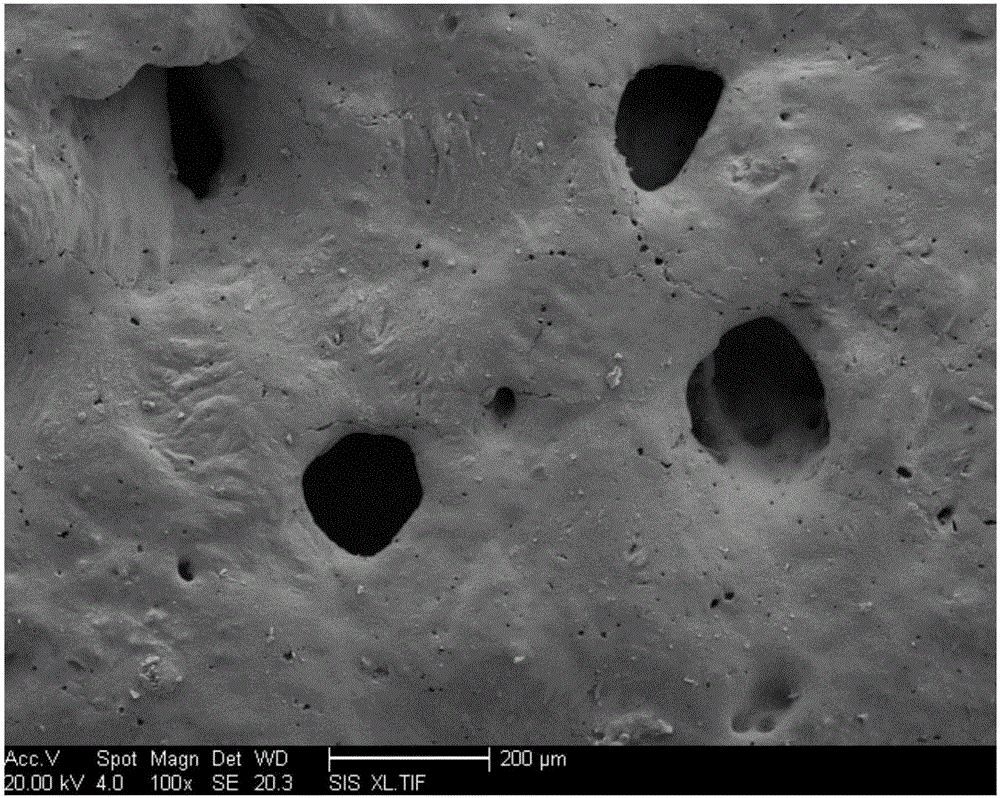

Preparation method of residual-sludge-based particle electrode carrier

InactiveCN105218073AImprove processing efficiencyReduce processing energy consumptionWater/sewage treatmentCeramic materials productionSludgeDyeing wastewater

Owner:HARBIN UNIV OF SCI & TECH

Method for rapidly synthesizing mesoporous Silicalite-1 molecular sieve by taking silica gel as silicon source

ActiveCN105668579ALow priceShort reaction timeCrystalline aluminosilicate zeolitesMolecular sieveCentrifugation

The invention relates to the field of preparation of a zeolite molecular sieve Silicalite-1 and particularly relates to a method for rapidly synthesizing mesoporous Silicalite-1 molecular sieve by taking silica gel as a silicon source. The method comprises the steps of with a small amount of tetrapropylammonium bromide as a microhole template agent, a cheap KF as a mesoporous template agent, silicon sol as the silicon source as well as deionized water as a solvent, adding a trace amount of seed crystals, heating in a reaction kettle, carrying out crystallization to obtain a crystallization solution, and carrying out centrifugation, washing, drying and calcination, so as to obtain the Silicalite-1 molecular sieve. The preparation method has the beneficial effects that the selected raw materials are economic, the reaction time is short, and data is full and accurate.

Owner:TAIYUAN UNIV OF TECH

Municipal waste harmless recycling method with sewage cyclic utilization

InactiveCN109500049AHarmlessRealize resource processingGeneral water supply conservationSolid waste disposalRefuse-derived fuelChemical reaction

The invention relates to a municipal waste harmless recycling method with sewage cyclic utilization. Municipal waste is sorted into waste raw materials and preparation raw materials of waste derived fuel in manual sorting, magnetic sorting and mechanical sorting modes, then the preparation raw materials of the waste derived fuel obtained in the previous process are prepared into the waste derivedfuel, additionally, the raw materials are mixed with clay, limestone and iron powder and are crushed so as to be calcined in a rotary kiln to prepare raw materials for building materials, fly ash andsmoke which are generated by calcination of the rotary kiln are treated in dedusting and chemical reaction modes, and finally, denitrification, nitrification, ultrafiltration and reverse osmosis treatment are performed on sewage, so that the waste cleaning water is purified. The municipal waste is converted into the raw materials for the building materials, the municipal waste can be recycled, sothat the use rate of the municipal waste is greatly increased, and the sewage generated in a waste treatment process can be purified and reused, so that water resources are saved.

Owner:DONGGUAN UNIV OF TECH

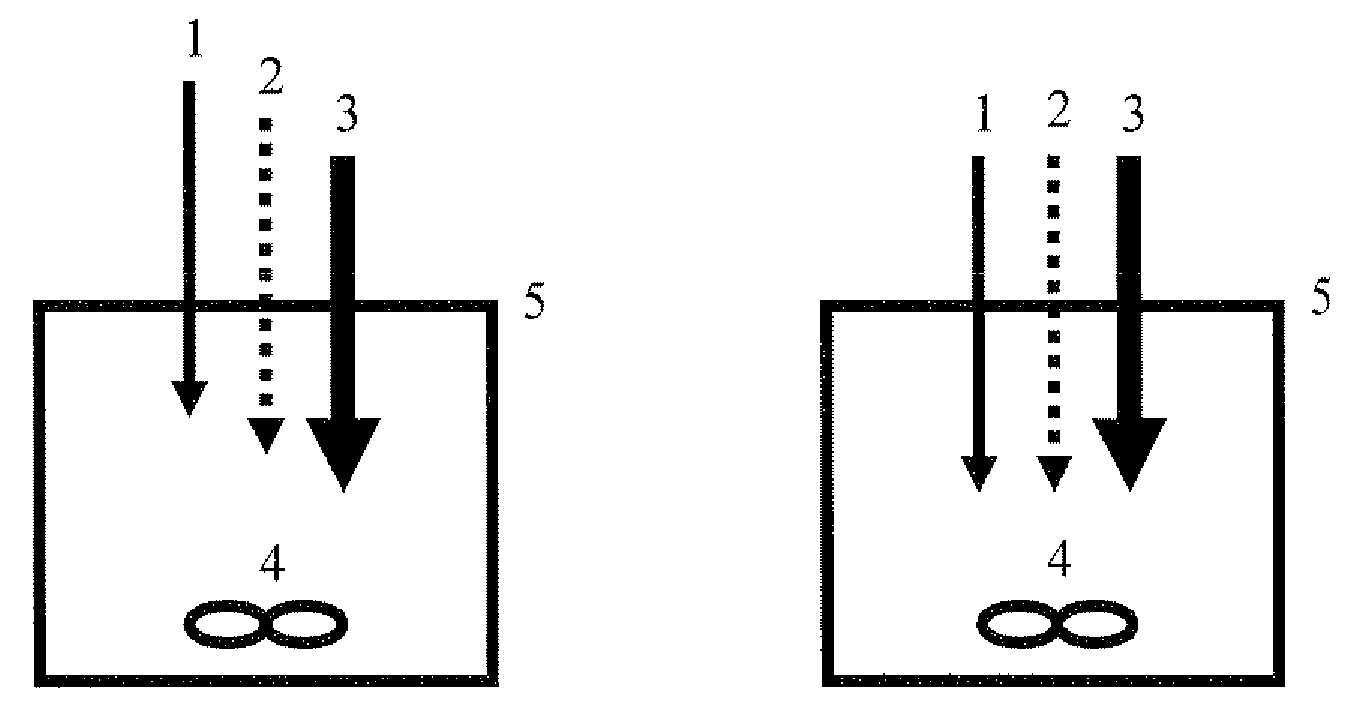

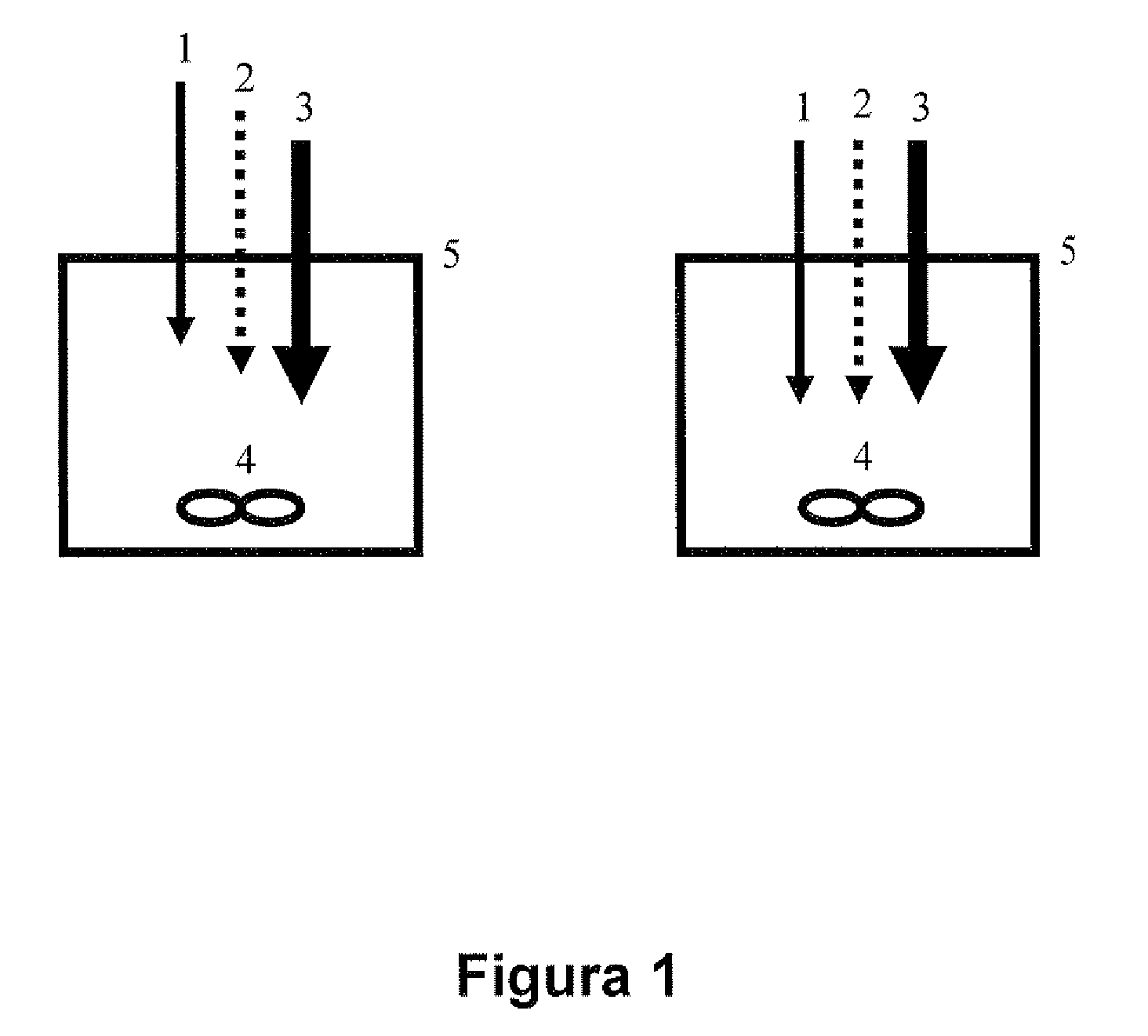

Additive for maximizing light olefins in fcc and process for preparation thereof

InactiveUS20090099006A1Improve performanceCatalytic crackingMolecular sieve catalystsAlkaline earth metalPhosphate

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

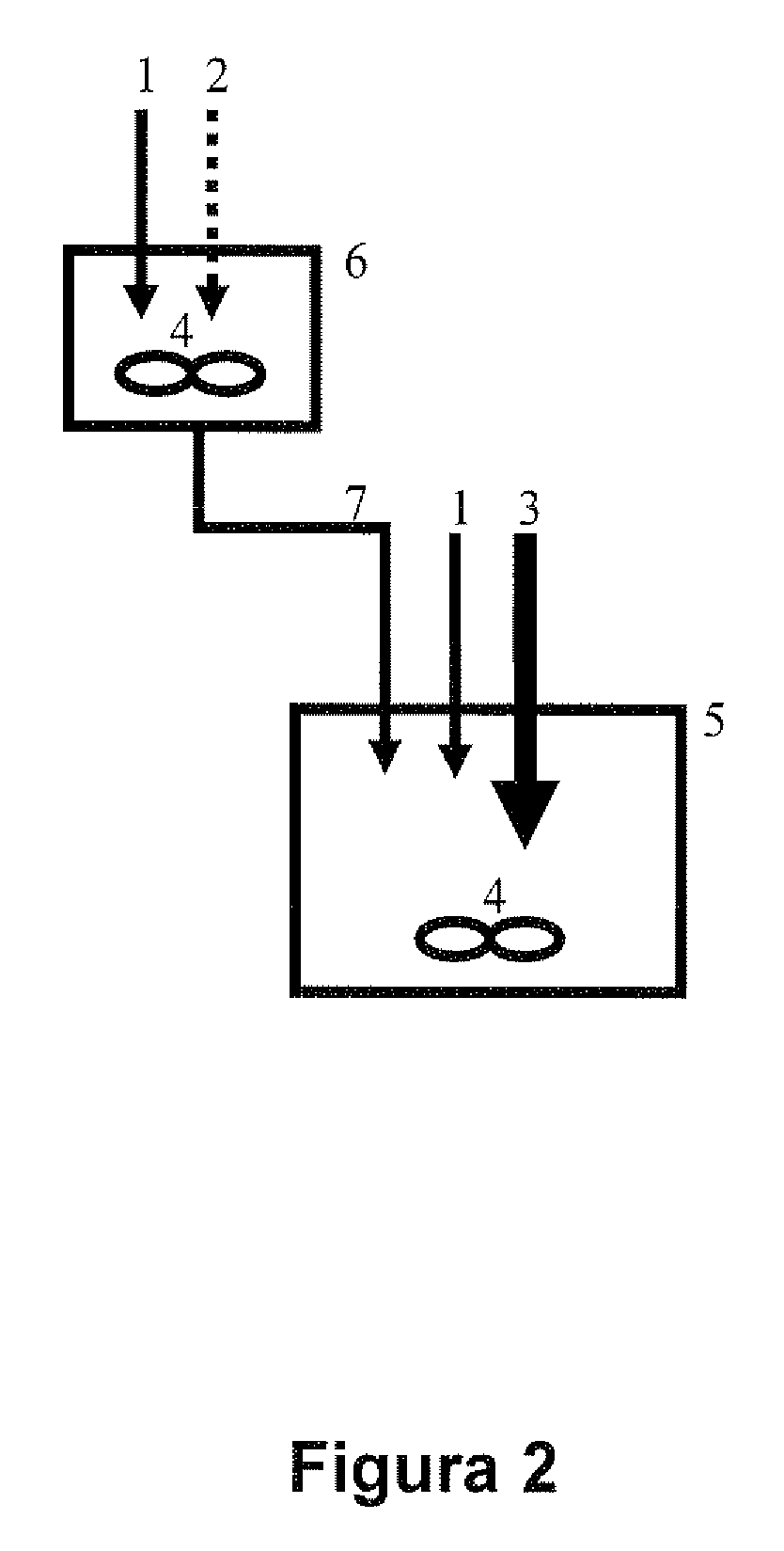

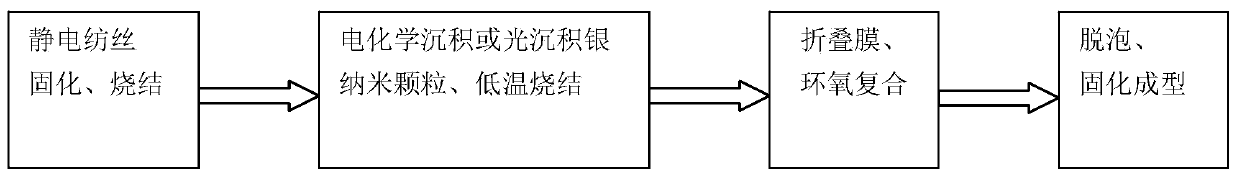

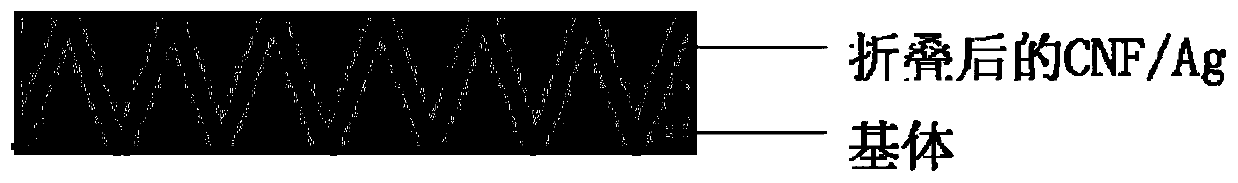

Composite heat-conductive material and preparation method thereof

ActiveCN110452494AGood general applicabilityThe experimental operation method is simpleCarbon fibresElectrospinningWave shape

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Copper oxide/carboxymethyl cellulose gel modified composite film, and making method and use thereof

InactiveCN106943883AEfficient separationSimple construction methodSemi-permeable membranesNon-miscible liquid separationCarboxymethyl celluloseComposite film

Owner:JIANGSU UNIV

Novel method for preparing recyclable graphene composite titanium dioxide nano material

InactiveCN111821979AEasy to operateReaction conditions are easy to controlHeterogenous catalyst chemical elementsCatalyst activation/preparationPhoto catalysisCalcination

Owner:江苏康德龙环保有限公司

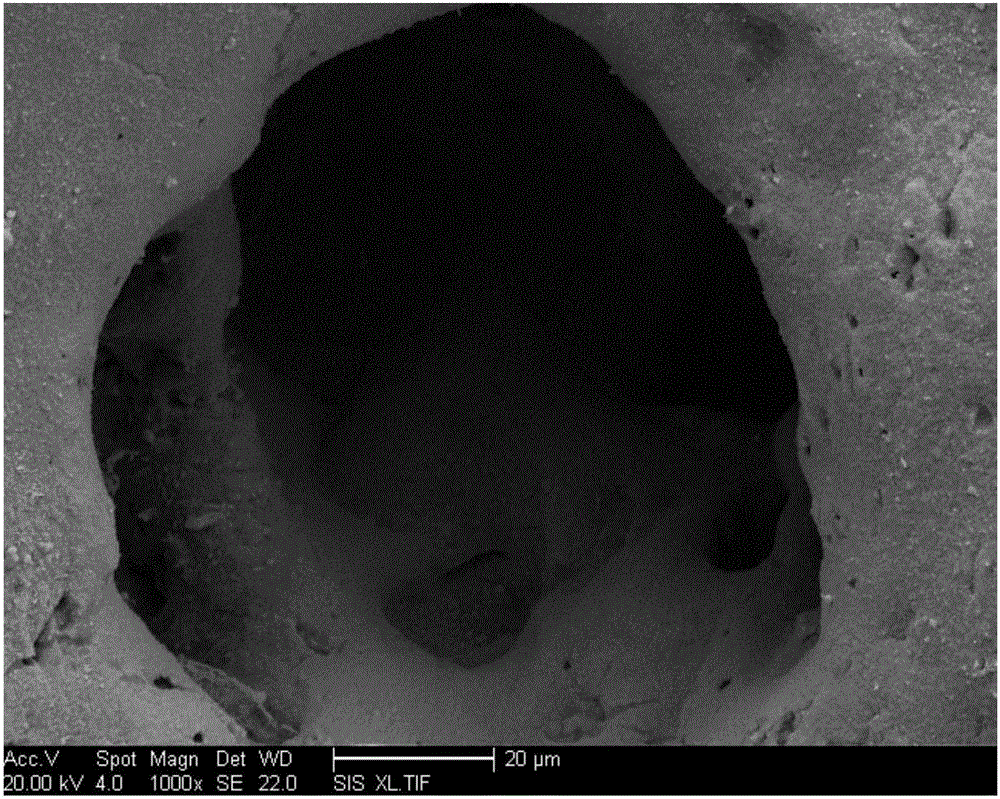

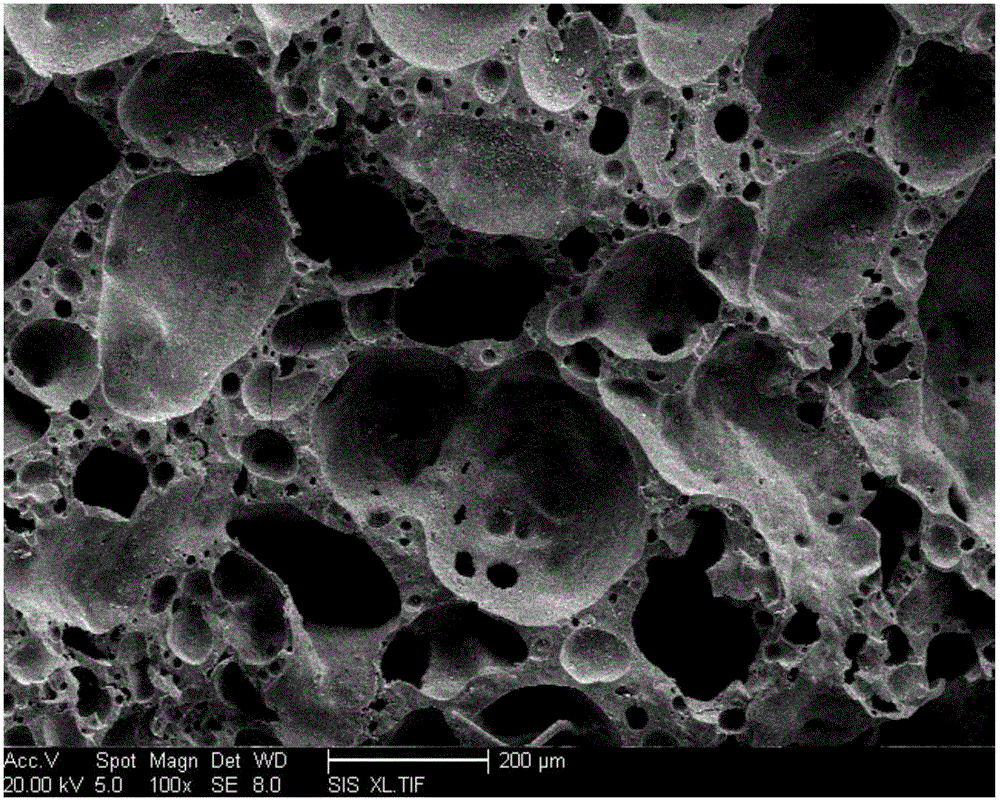

Fish roe based porous carbon material preparation and application

InactiveCN108793158ASimple design processLow activation temperatureCarbon compoundsMaterials preparationCapacitance

Owner:GUILIN UNIV OF ELECTRONIC TECH

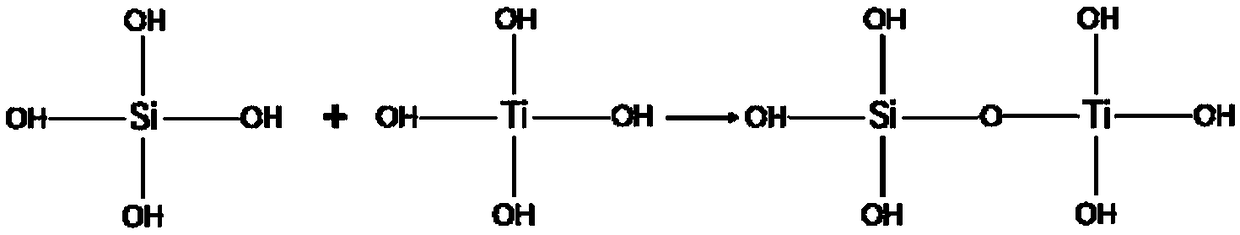

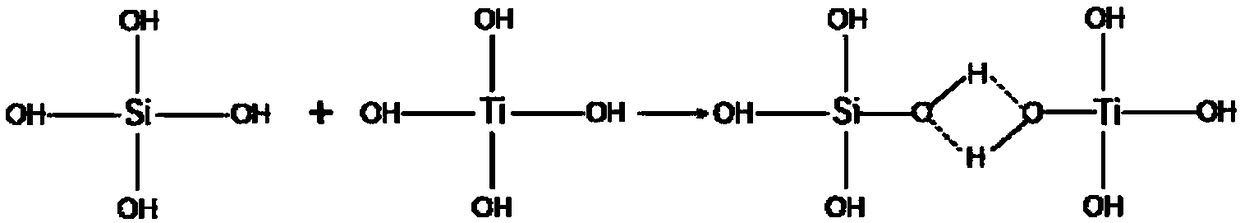

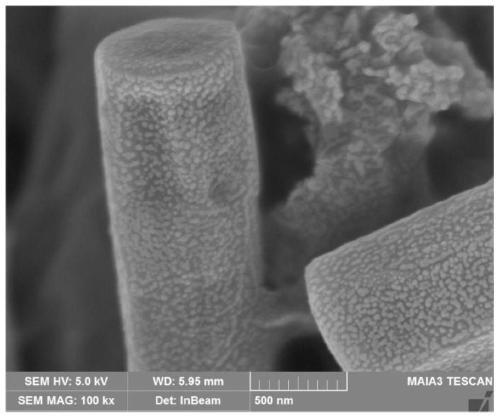

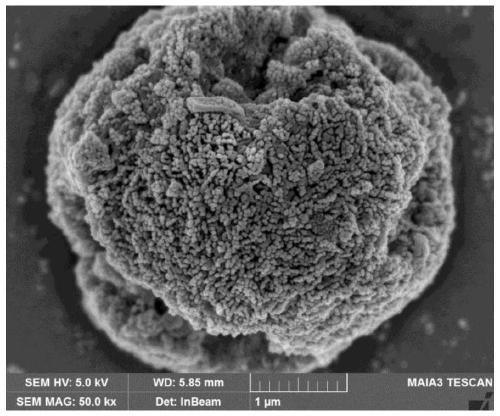

Method for preparing silicon and titanium composite powder

Owner:泉州特斯拉高分子科技有限公司

Preparation method of special-morphology micro nano structural lithium-rich manganese-based cathode material

ActiveCN110143619AAchieving controllable equipmentRealize controllable preparation of special morphologyMaterial nanotechnologyPositive electrodesNickel saltHigh energy

Owner:JISHOU UNIVERSITY

Efficient bleaching process of white cement clinkers

InactiveCN109206031AHigh whitenessIncrease the rate of temperature dropLiquid nitrogenCalcination

The invention discloses an efficient bleaching process of white cement clinkers. The efficient bleaching process of the white cement clinkers comprises the following steps of performing high-temperature firing on the white cement clinkers by a rotary kiln; discharging the white cement clinkers into a grate cooler from the discharging end of the rotary kiln for cooling; after the high-temperature cement clinkers enter the grate cooler, falling the high-temperature cement clinkers onto a first grate bed for cooling; performing sharp cooling on the cement clinkers in the first grate bed through providing mixed liquid nitrogen and air; cooling the cement clinkers to 600 to 800 DEG C; then, falling the cement clinkers onto a second grate bed to be cooled; performing air cooling in the second grate bed completely through the air; cooling the cement clinkers to 80 to 100 DEG C; discharging the cement clinkers out of the grate cooler. The invention aims at providing the efficient bleaching process of the white cement clinkers so as to solve the problems of whiteness improvement limitation and more heat consumption requirement during white cement clinker calcination.

Owner:JIANGXI YINSHAN WHITE CEMENT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap