Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Sieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mesh strainer, also known as sift, commonly known as sieve, is a device for separating wanted elements from unwanted material or for characterizing the particle size distribution of a sample, typically using a woven screen such as a mesh or net or metal. The word "sift" derives from "sieve". In cooking, a sifter is used to separate and break up clumps in dry ingredients such as flour, as well as to aerate and combine them. A strainer is a form of sieve used to separate solids from liquid.

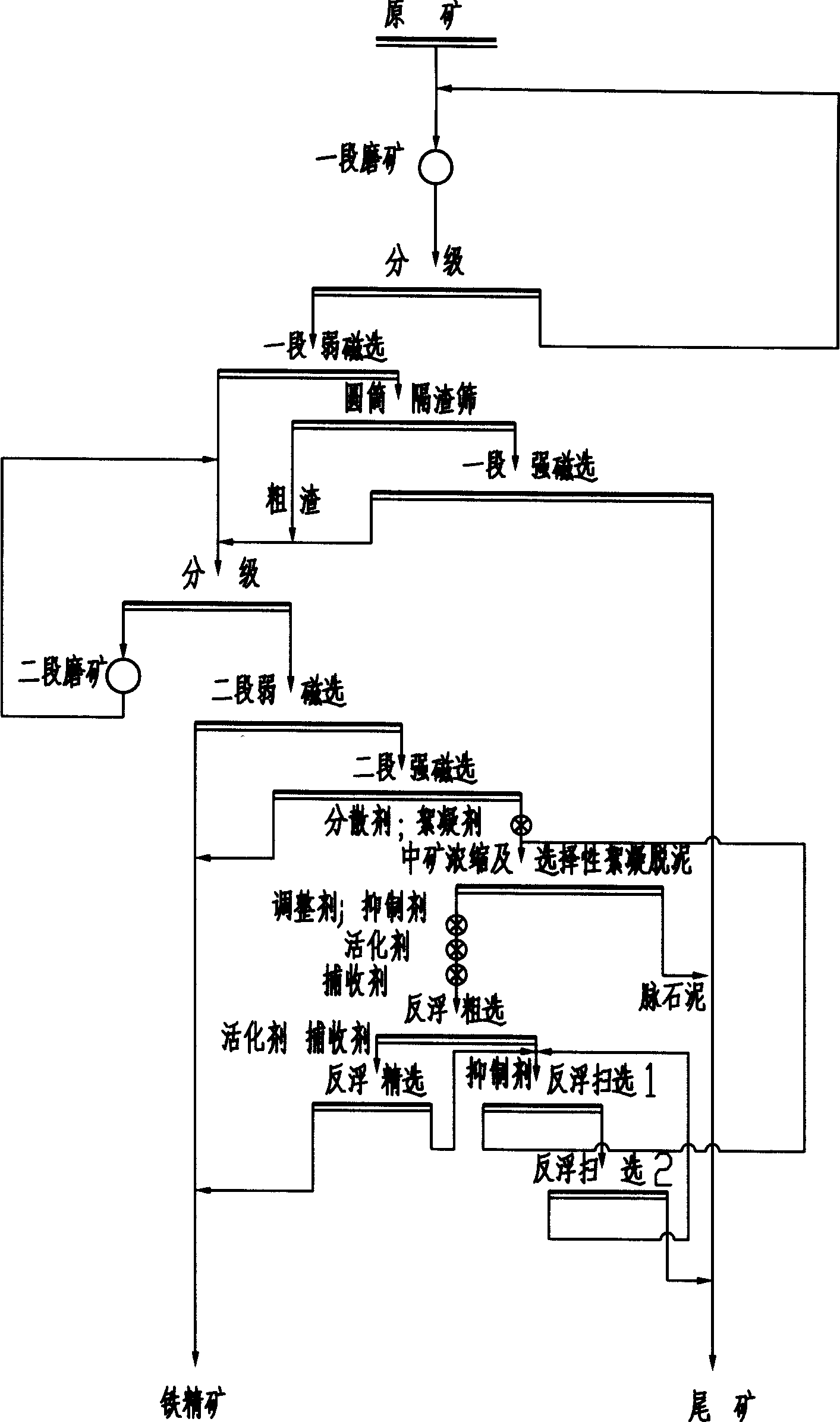

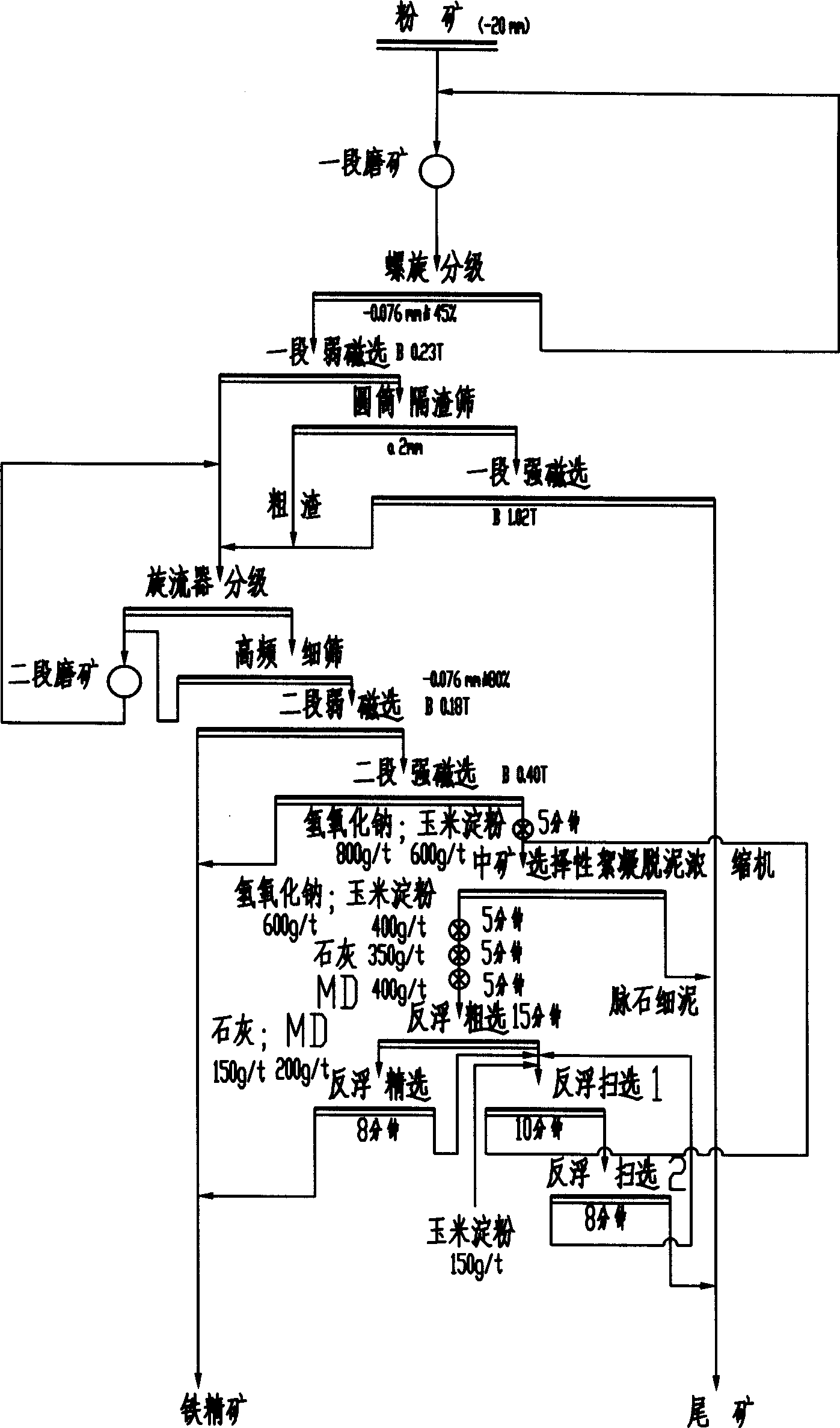

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Sand screening device for bridge construction

Owner:赣州市兴顺辉科技有限公司

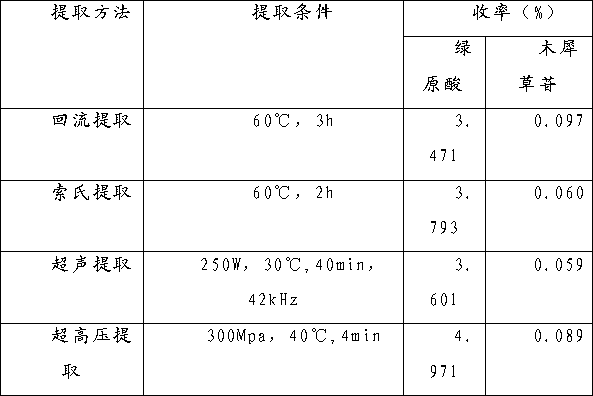

Chlorogenic acid and galuteolin in honeysuckle flower superhigh pressure extraction method and HPLC quantitative analysis method

Owner:SUZHOU UNIV

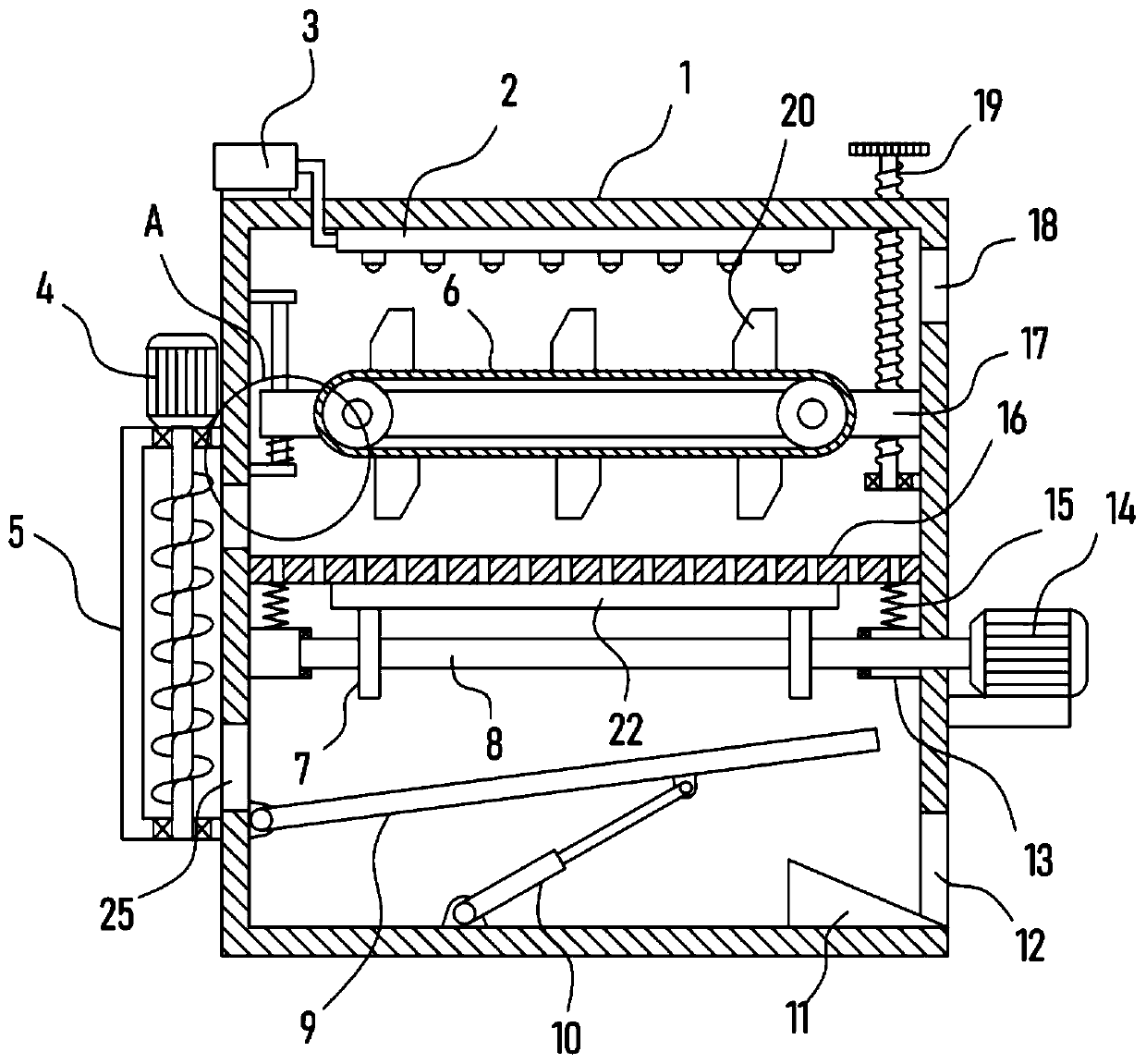

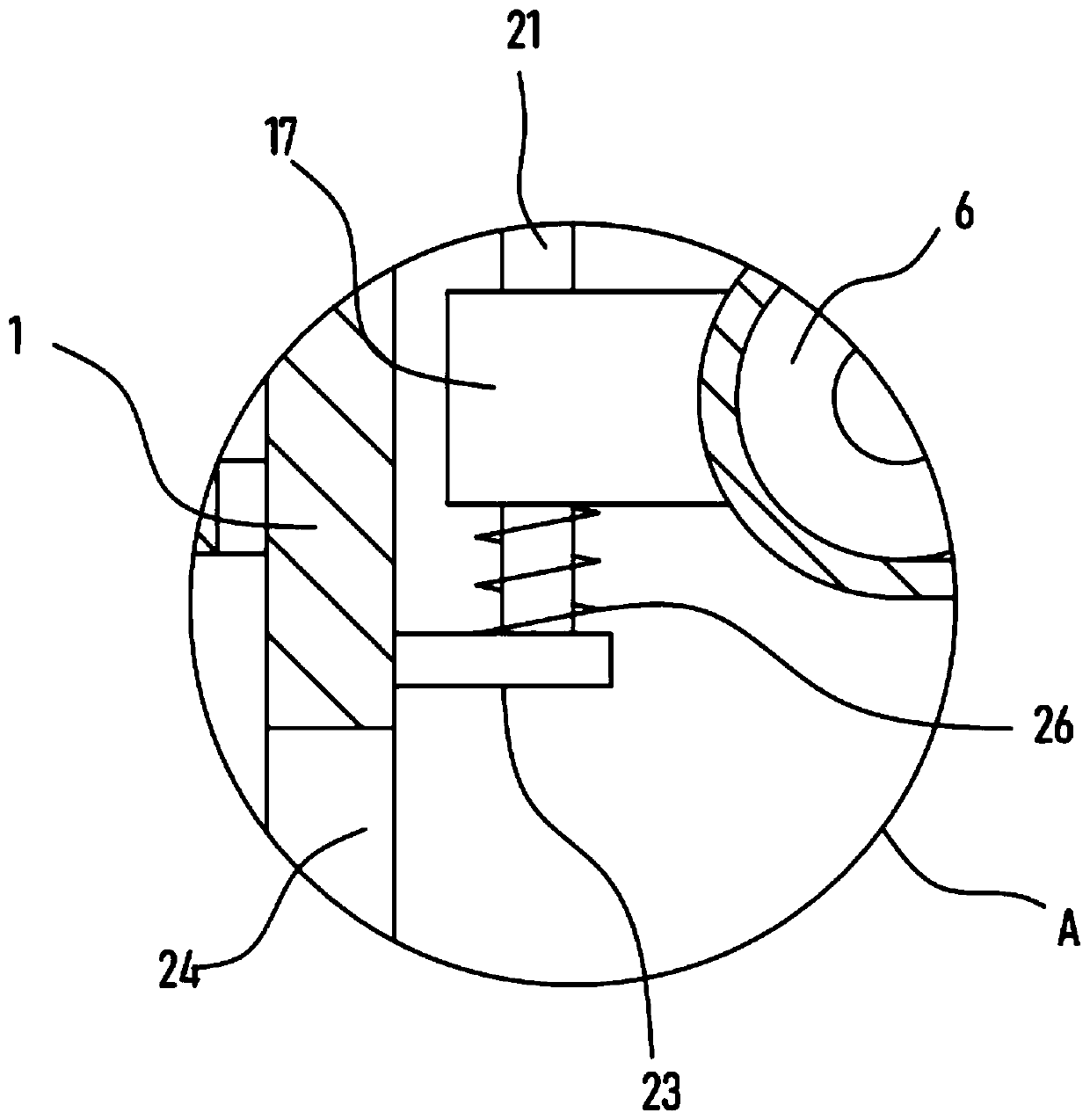

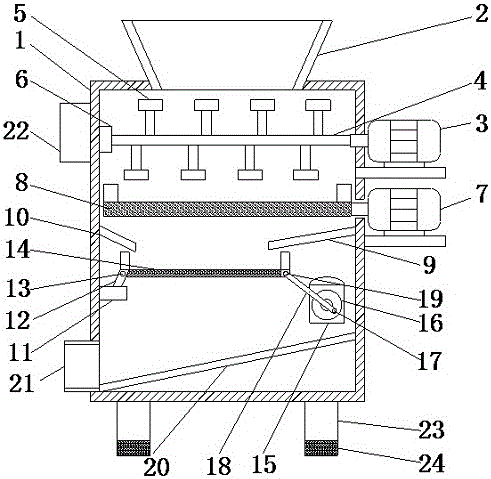

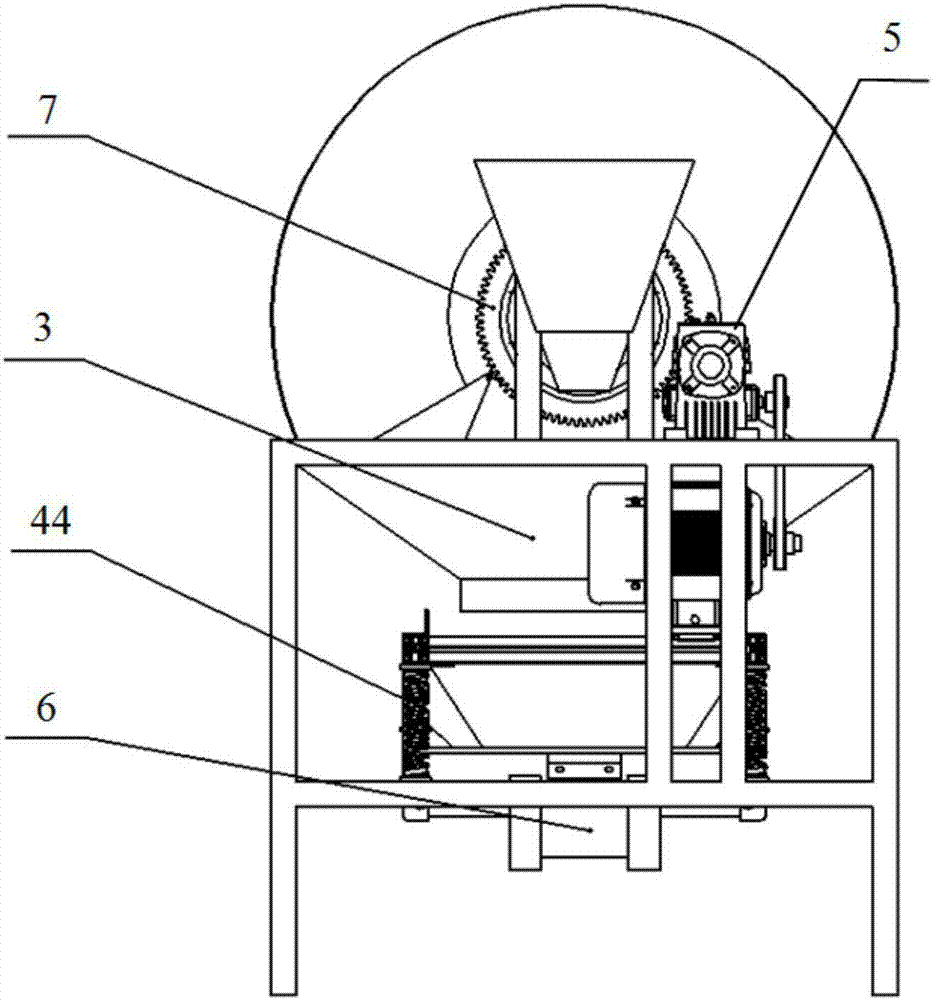

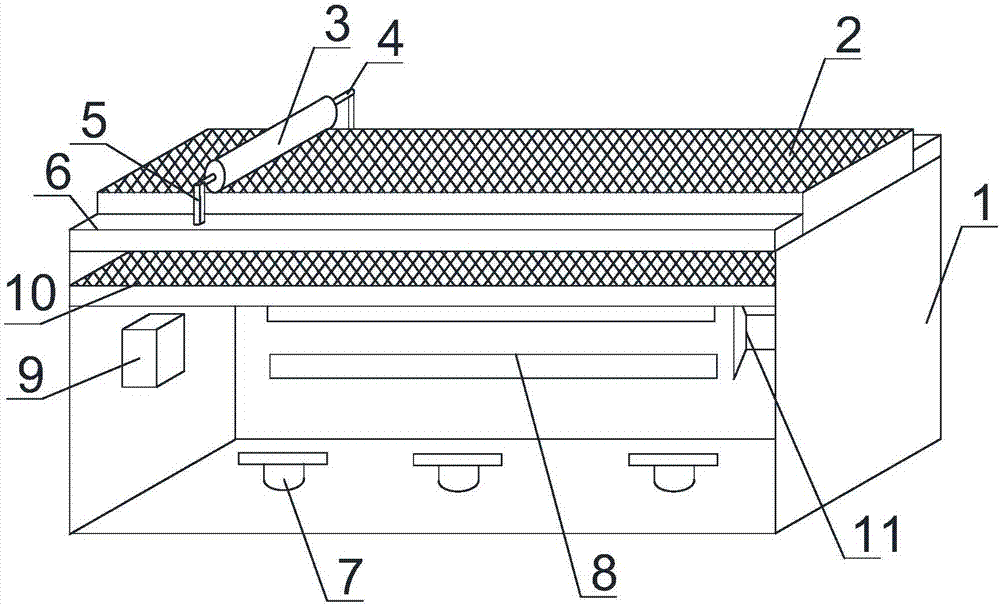

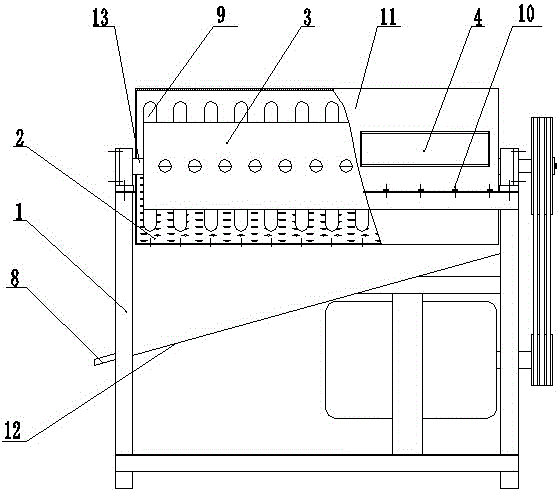

Construction sand screening machine

InactiveCN106540782ASolve the inefficiency of screeningPrevent leakageGrain treatmentsSieveScreening effect

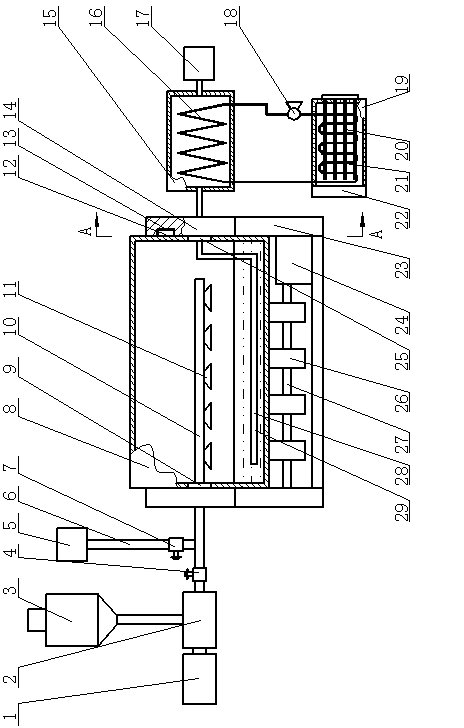

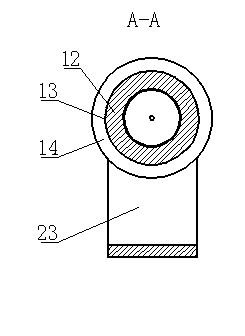

The invention discloses a construction sand screening machine which comprises a machine body. The top of the machine body communicates with a feed hopper. A first motor is fixedly mounted at the top of the right side of the machine body. The output end of the first motor penetrates through the machine body and extends into the machine body to be fixedly connected with a rotary shaft. Stirring rods are fixedly mounted on the surface of the rotary shaft. A bearing is movably connected with the left side of the rotary shaft. The left side of the bearing is fixedly connected with the left side of the inner wall of the machine body. A second motor is fixedly mounted on the portion, under the first motor, of the right side of the machine body. According to the construction sand screening machine, the leakage problem when sand falls to a secondary sieve from a primary sieve can be effectively avoided through a first baffle and a second baffle, screening can be effectively conducted through cooperation of the secondary sieve, a disc and a third motor, the screening effect of the coarse sand and the fine sand can be better through arrangement of the primary sieve and the secondary sieve, and therefore the problem of low screening efficiency is solved.

Owner:林志城

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production method for sintered valve guide

Owner:HITACHI POWDERED METALS COMPANY

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

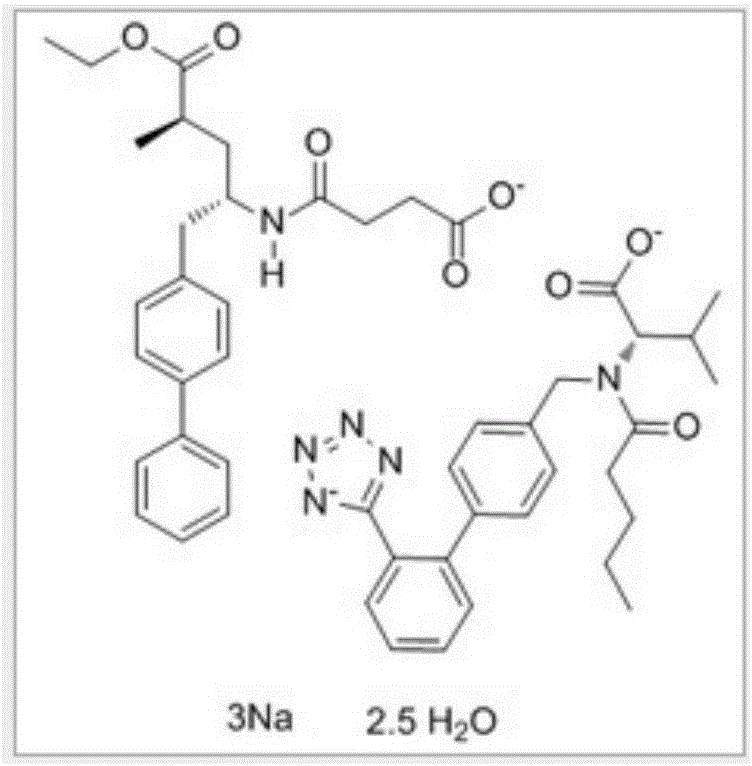

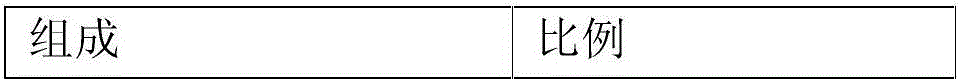

Preparation method of LCZ696 sustained release matrix tablet for treatment of heart failure

ActiveCN105748420AReduce releaseStable blood concentrationPill deliveryPharmaceutical non-active ingredientsSustained Release TabletSide effect

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

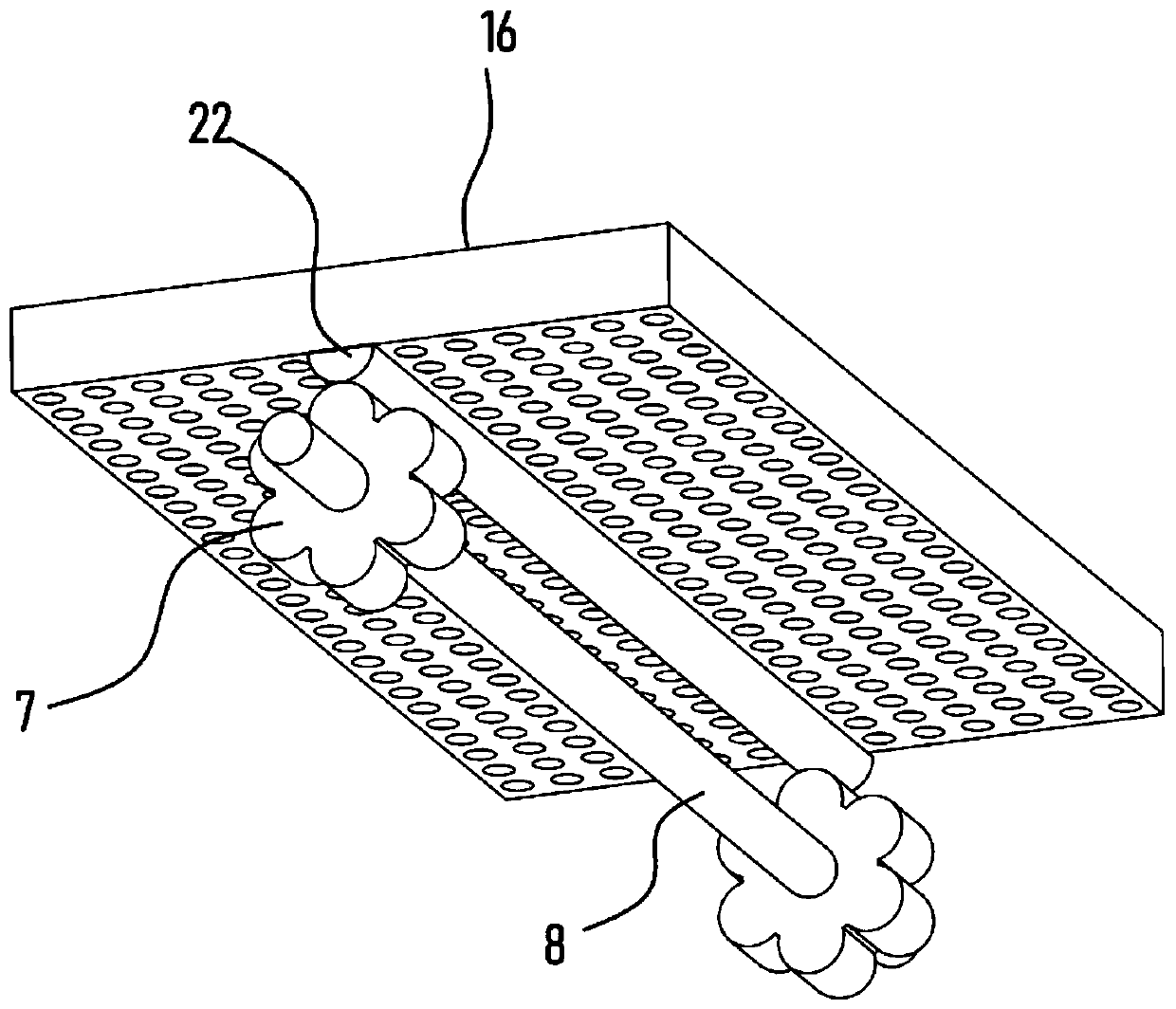

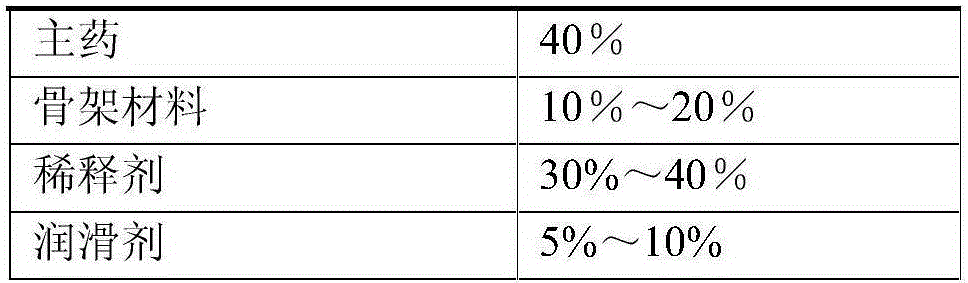

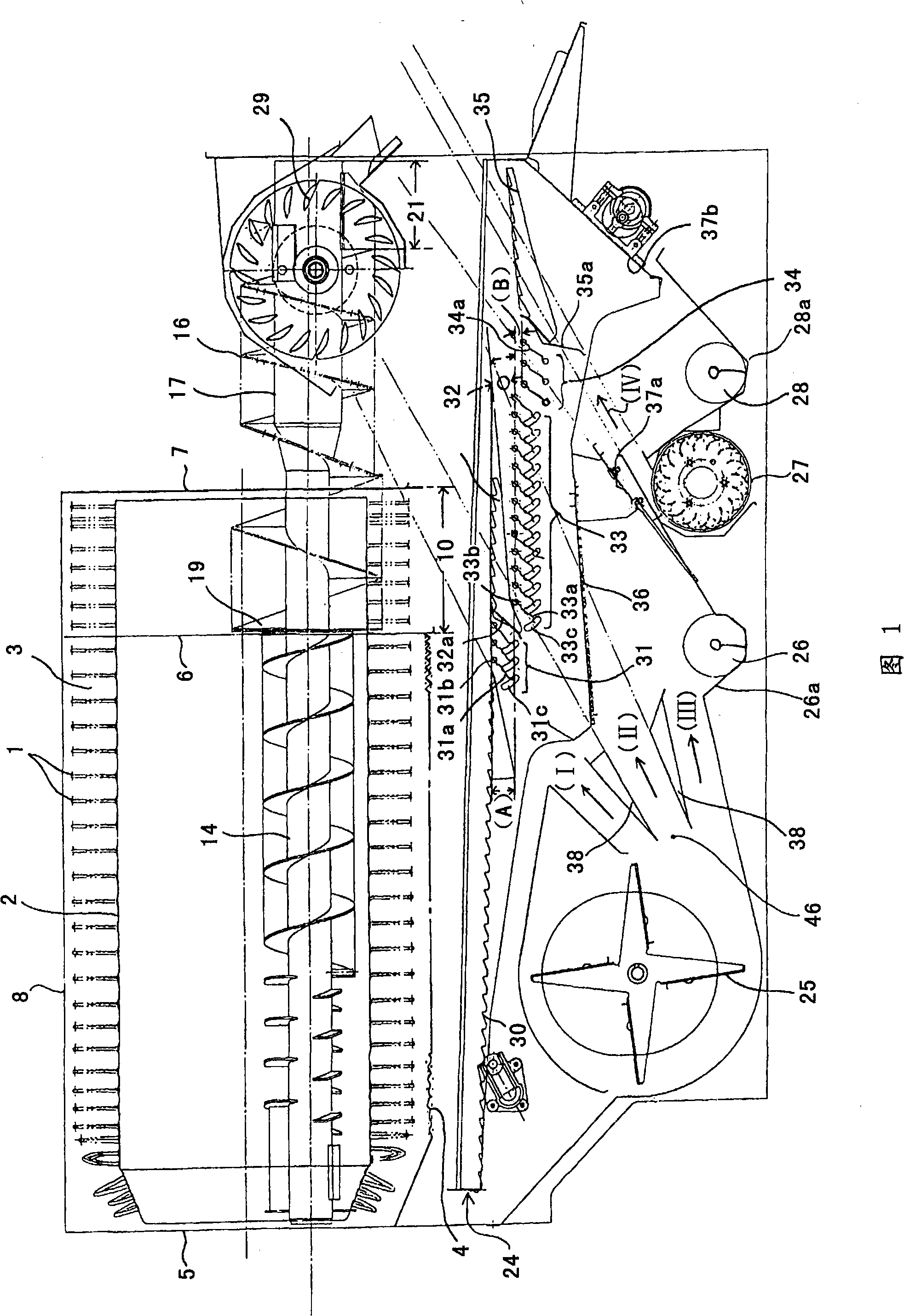

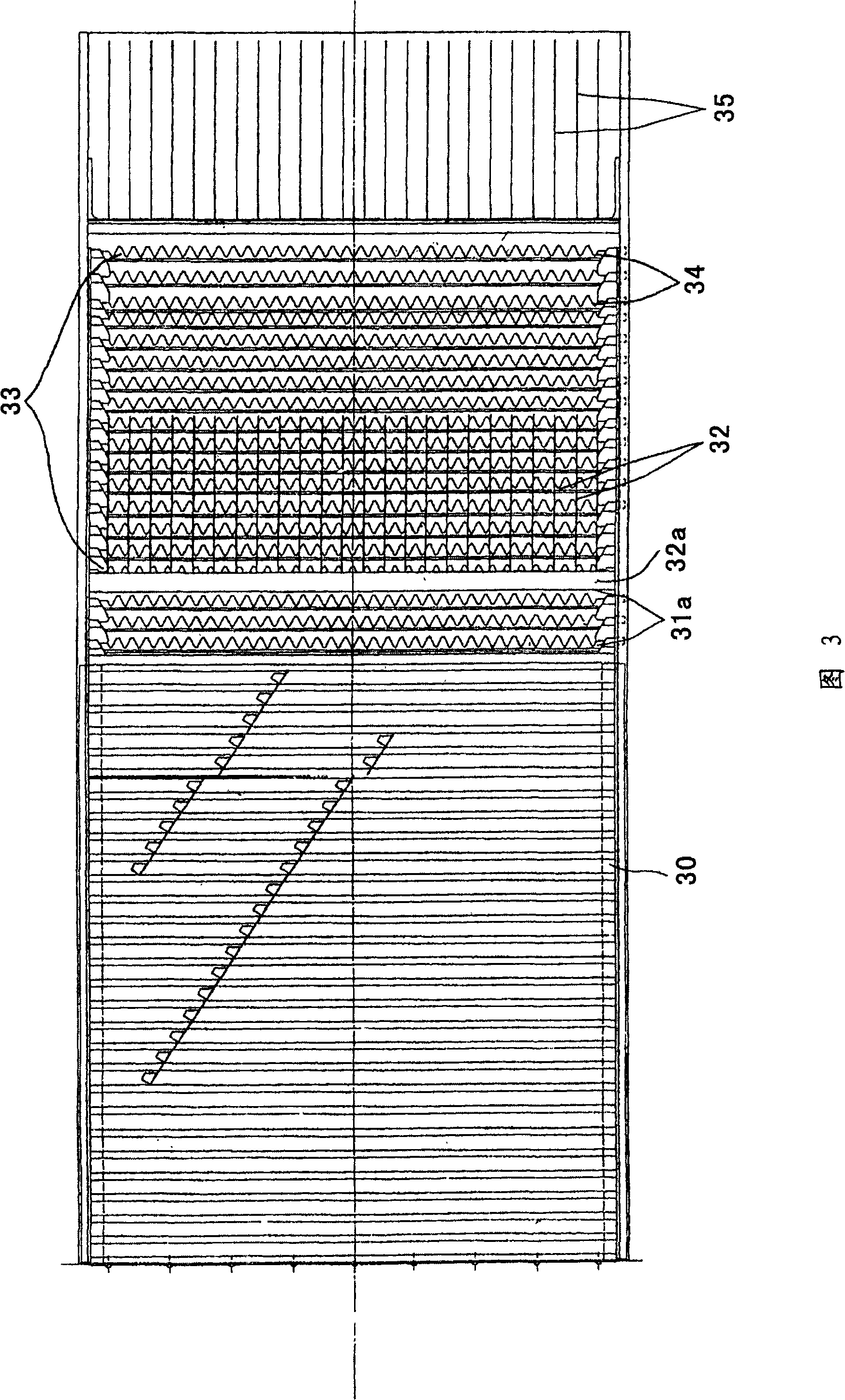

Threshing apparatus

ActiveCN101253833AEfficient separationAccurate separation and sortingThreshersEngineeringMechanical engineering

Owner:ISEKI & CO LTD

Preparation method of traditional Chinese medicine composition for purifying mandarin fish ponds

ActiveCN105394109AGood antivirus effectEfficient in situ bioremediationBiocideDisinfectantsMicrocrystalline waxBaical Skullcap Root

Owner:全椒县鮰鱼养殖专业合作社

Ganoderma powder preparation method

ActiveCN109010385ATo achieve the effect of breaking the wallImprove securityPlant ingredientsQuick FreezeTemperature difference

The invention relates to the technical field of ganoderma processing and specifically relates to a ganoderma powder preparation method. The ganoderma powder preparation method comprises the steps: S1,cleaning, slicing and drying ganoderma solid to obtain ganoderma slices for standby application; S2, smashing the ganoderma slices and sieving by a 60-mesh sieve to obtain ganoderma coarse powder; S3, jet wetting the ganoderma coarse powder, putting into a constant-temperature and constant-humidity culture box to be cultured for 6 hours to obtain wet ganoderma coarse powder, wherein the temperature of the constant-temperature and constant-humidity culture box is set as 20 to 35 DEG C, and the humidity of the constant-temperature and constant-humidity culture box is set as 85% to 95%; S4, performing ultralow-temperature quick freeze and vacuum quick dry on the wet ganoderma coarse powder; S5, then performing air jet pulverization to obtain ganoderma superfine powder; S6, packaging in vacuum and light shielding modes. The ganoderma coarse powder is treated by jet wetting, culturing, ultralow-temperature quick freeze and vacuum quick dry, cell walls are damaged by larger temperature difference and ice sublimation, and then a supersonic-speed air-flow smashing technology is utilized to further smash the cell walls. The cell walls of the prepared ganoderma powder are completely broken,the technology can greatly reduce the heavy metal introducing amount, and product safety is improved.

Owner:HANGZHOU KANGLI HEALTH PROD CO LTD

Adsorption device

InactiveCN105498441AReduce gas distribution spaceIncrease profitGas treatmentDispersed particle separationEngineeringAirflow

Owner:王晓晓

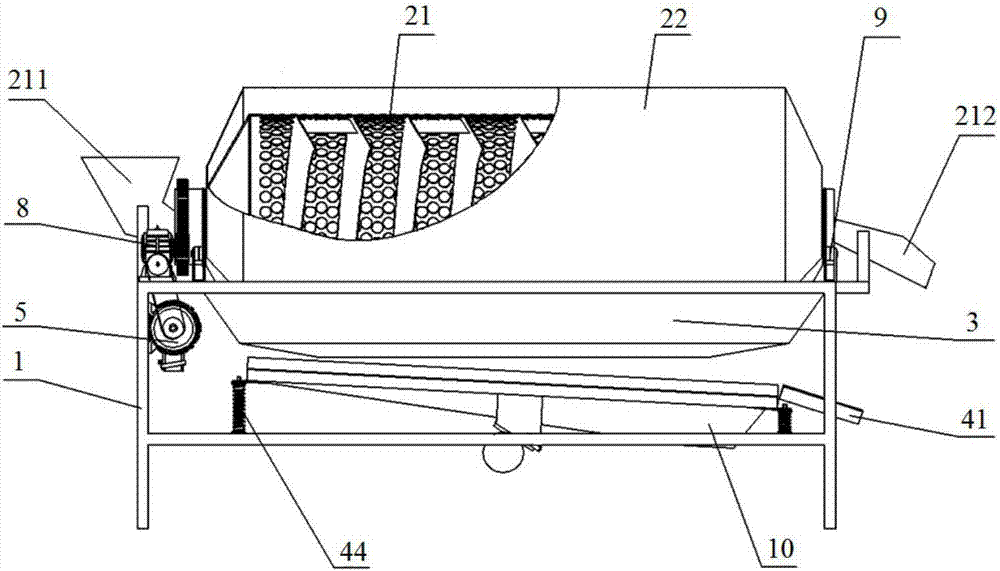

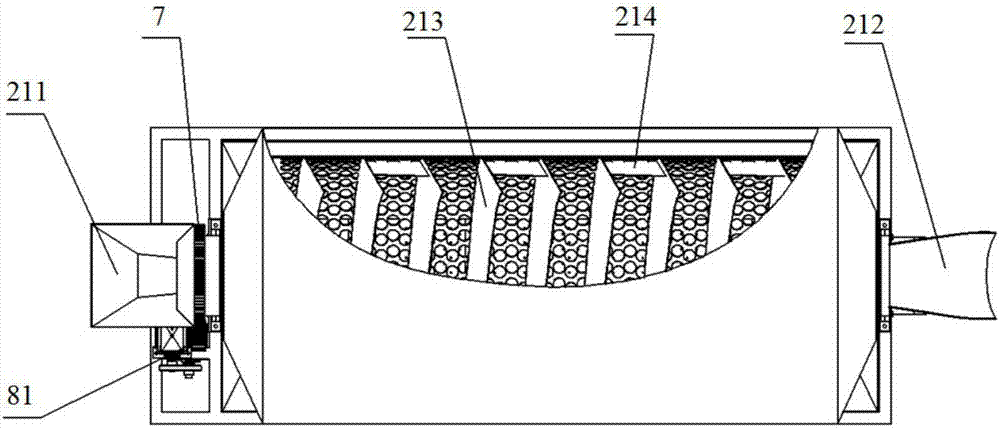

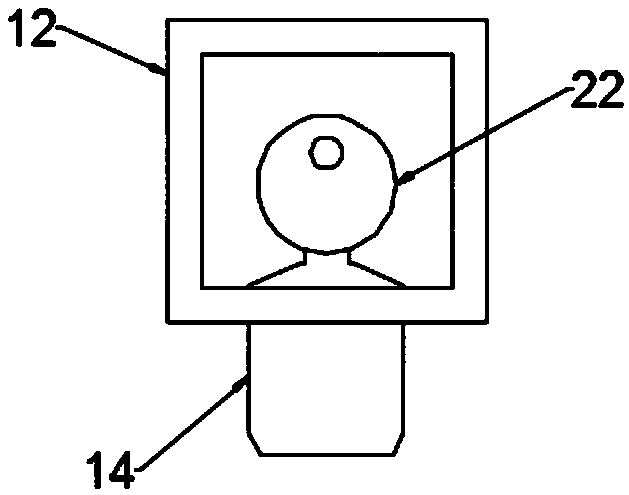

Multifunctional lotus nut screening machine

InactiveCN107051882AImprove qualityImprove separation rateSievingGas current separationVibration controlHusk

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

Steamed total millet flour cone-shaped bread and producing method thereof

Owner:CHINA AGRI UNIV

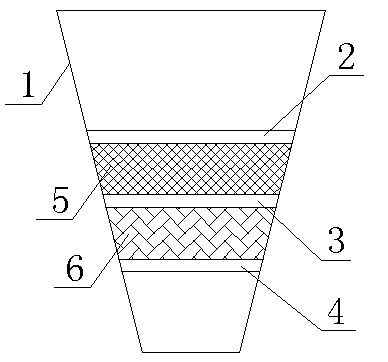

A purifying column

Owner:SUZHOU NEW DISTRICT FENGQIAO PURIFICATION EQUIP FACTORY

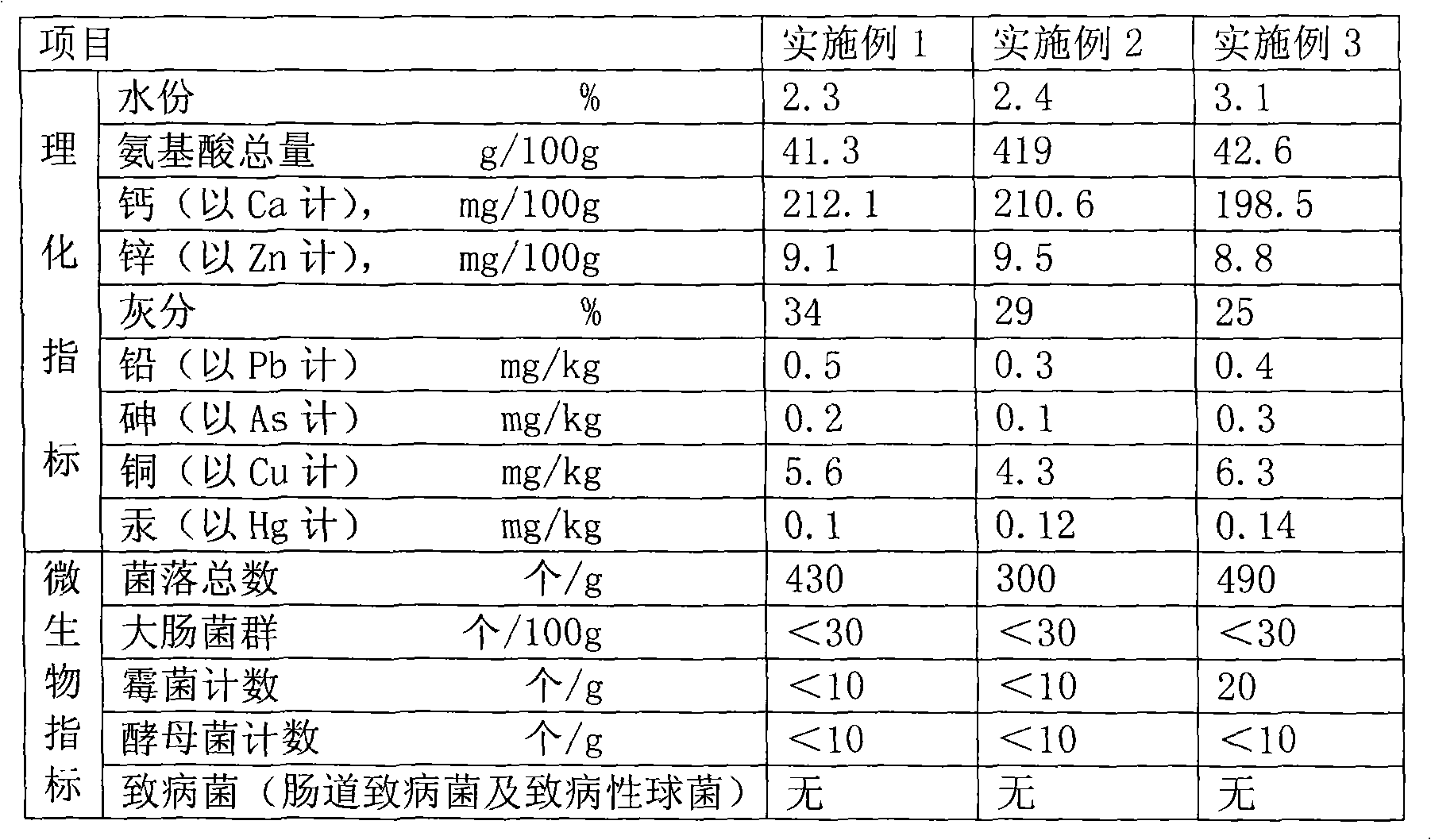

Active pure snake powder capsule and preparation technique thereof

ActiveCN101647820AGood for healthExpelling wind and dampness is beneficialMetabolism disorderAntinoxious agentsMedicineFreeze-drying

Owner:BENXI LONGBAO GROUP GINSENG & VELVET

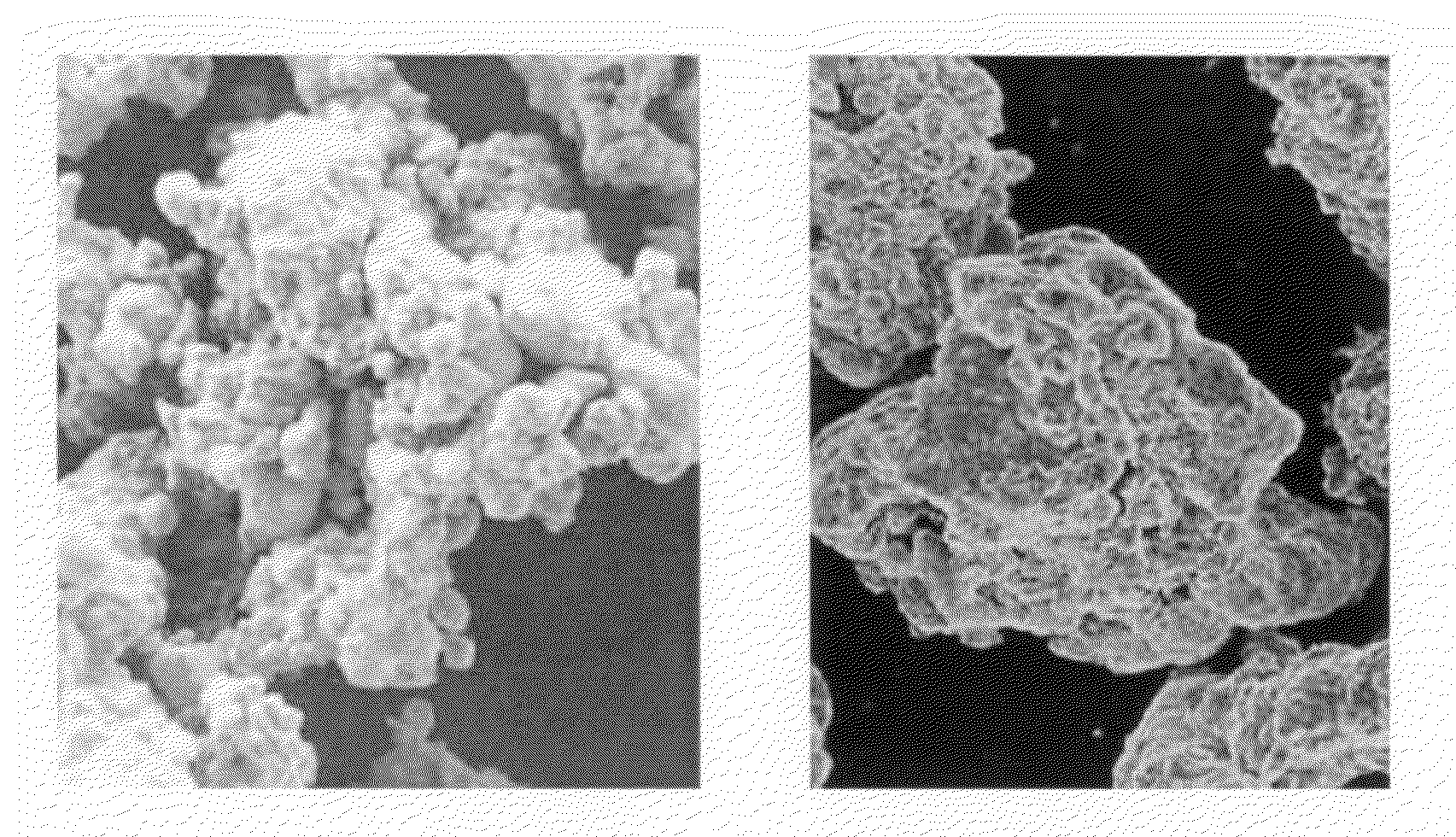

Efficient preparation method of ultra-precision cutting abrasive sand

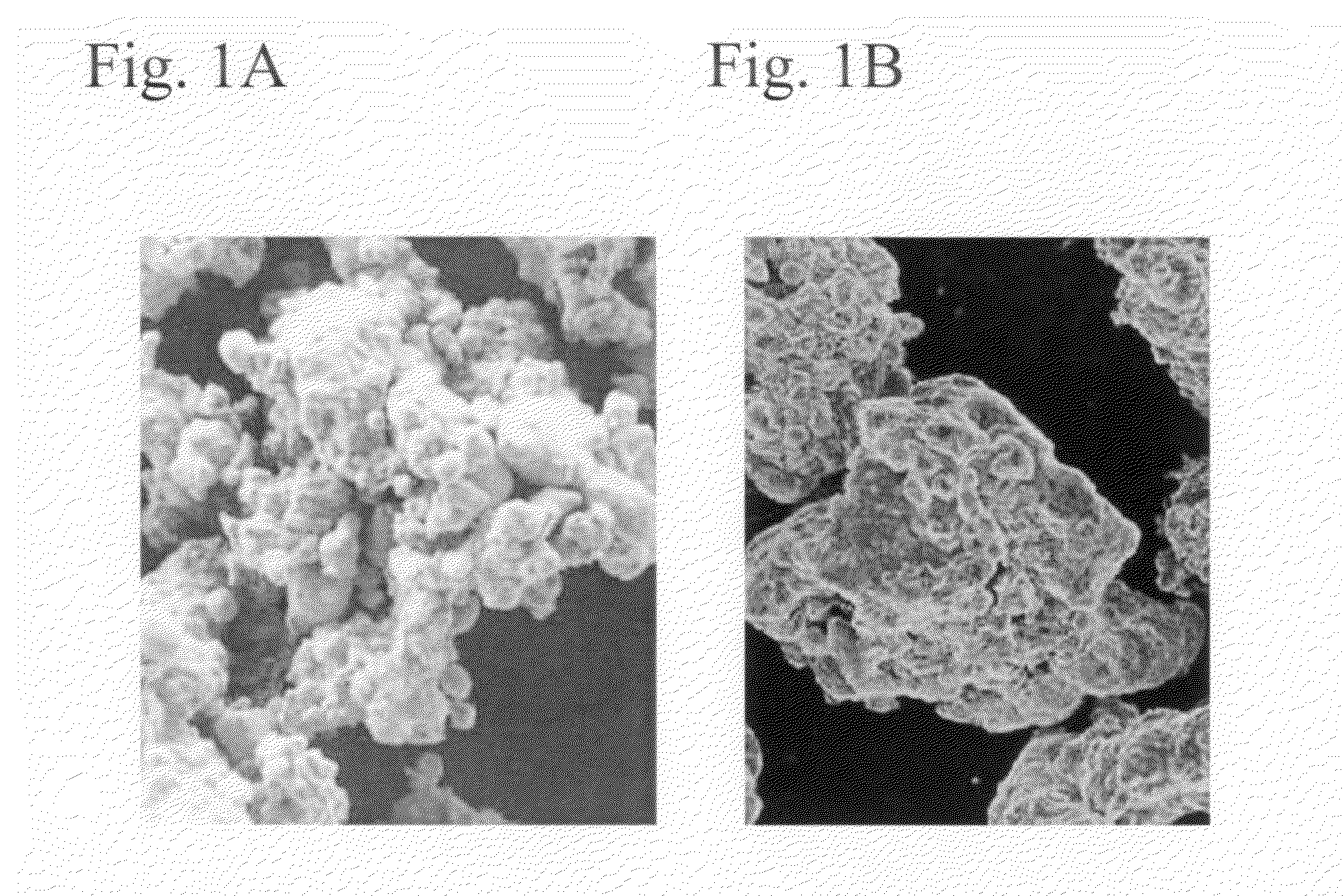

ActiveCN103937451AFine and uniform particle sizeCause gagOther chemical processesEngineeringParticle-size distribution

Owner:LIANYUNGANG LONGHE GARNET

Sandy soil screening device for building construction

ActiveCN108636784AImprove screening efficiencyImprove work efficiencySievingScreeningPore diameterEngineering

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

Green ecological foam glass and production method thereof

InactiveCN105384341AImprove adsorption capacityLow thermal conductivityGlass shaping apparatusRenewable resourceBottle

The invention provides green ecological foam glass prepared from the following raw materials in parts by weight: 75-80 parts of waste glass powder, 15-20 parts of shell powder and 0-5 parts of coal ash. The green ecological foam glass is produced by using a production method comprising the steps of 1, respectively crushing and grinding waste beer bottles and shells, and controlling the fineness, namely the screen residue of a 0.08mm square hole sieve, to be lower than 10%; 2, uniformly mixing the waste glass powder, the shell powder and the coal ash, placing the mixture into a mould in which alundum powder serving as a separant, calcining at 800-850 DEG C in a high-temperature furnace, preserving the heat for 0.8-1.2 hours, and annealing at the temperature of 500-600 DEG C; and 3, cooling the high-temperature furnace to 180-220 DEG C, taking out the mould, and demolding to obtain the green ecological foam glass. The foam glass produced by using the waste glass, shells serving as renewable resources and the coal ash has the advantages of high adsorptivity, bacterium inhibition, nontoxicity, no combustibility, small heat conductivity coefficient and energy saving so as to be a novel green ecological heat insulation material.

Owner:YANTAI UNIV

Screening device for organic fertilizer production

InactiveCN107879779AImprove uniformityImprove fertilizer efficiencyBio-organic fraction processingGrain treatmentsOrganic manureEngineering

Owner:SICHUAN WO DA BIOLOGICAL TECH

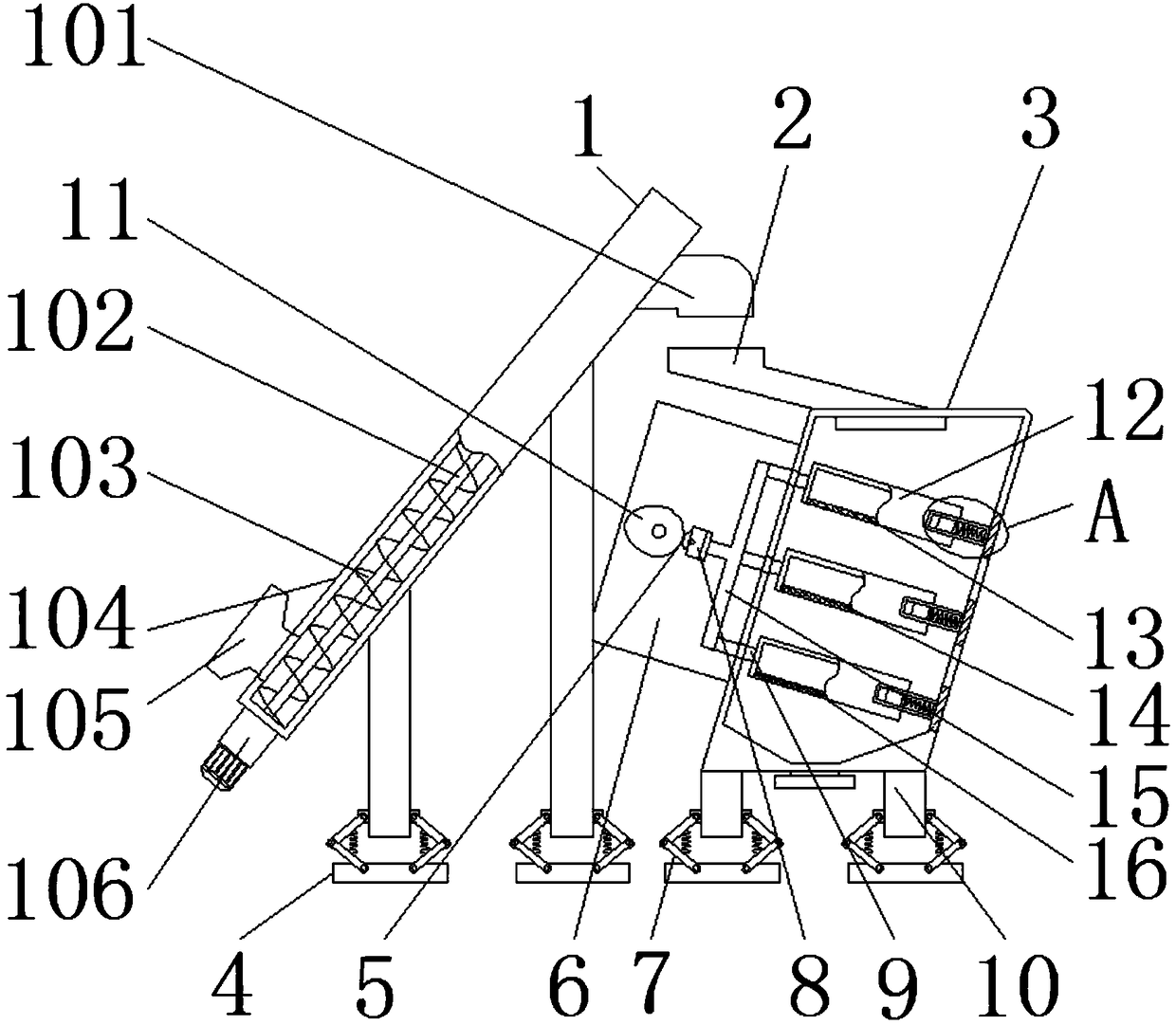

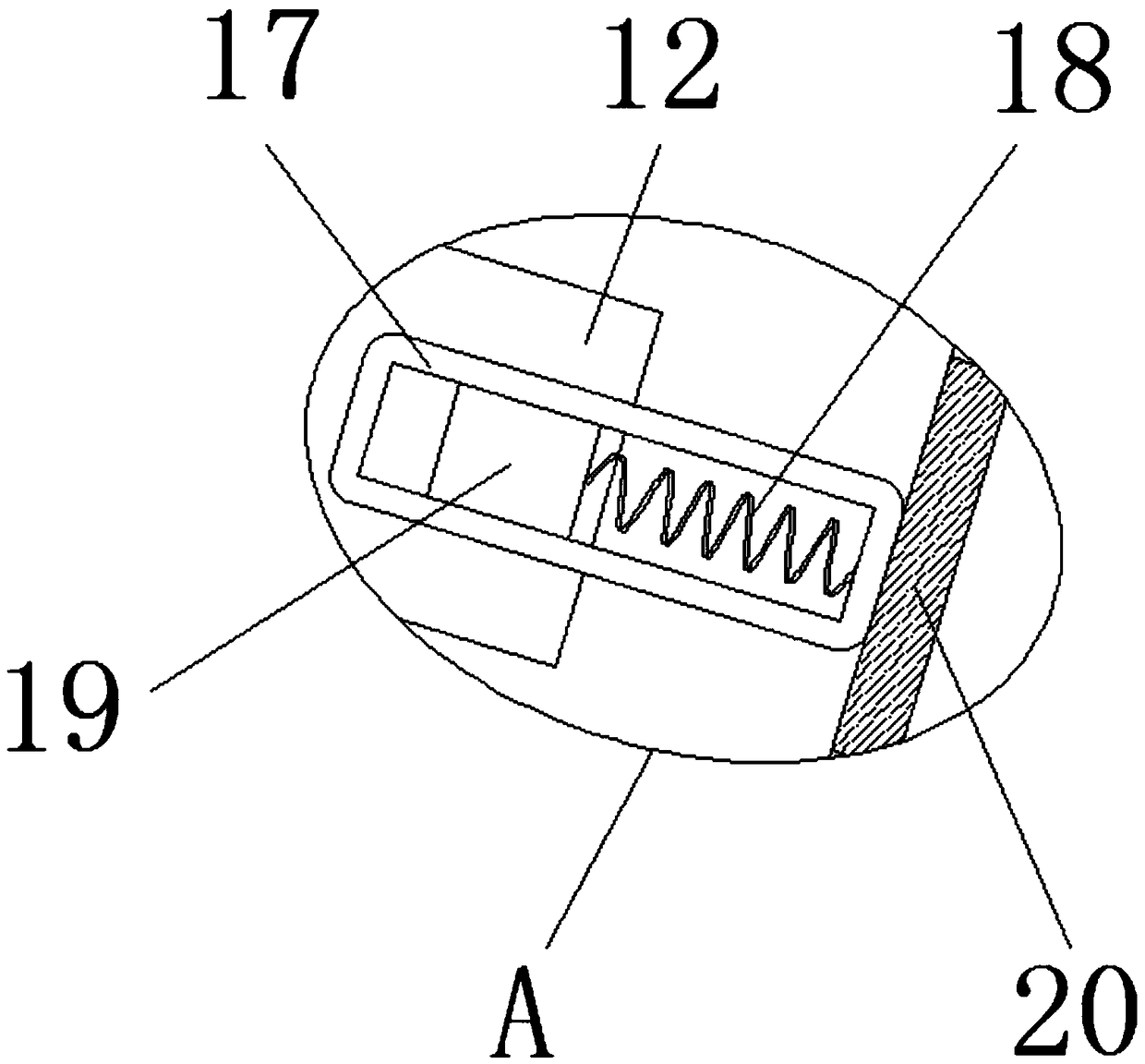

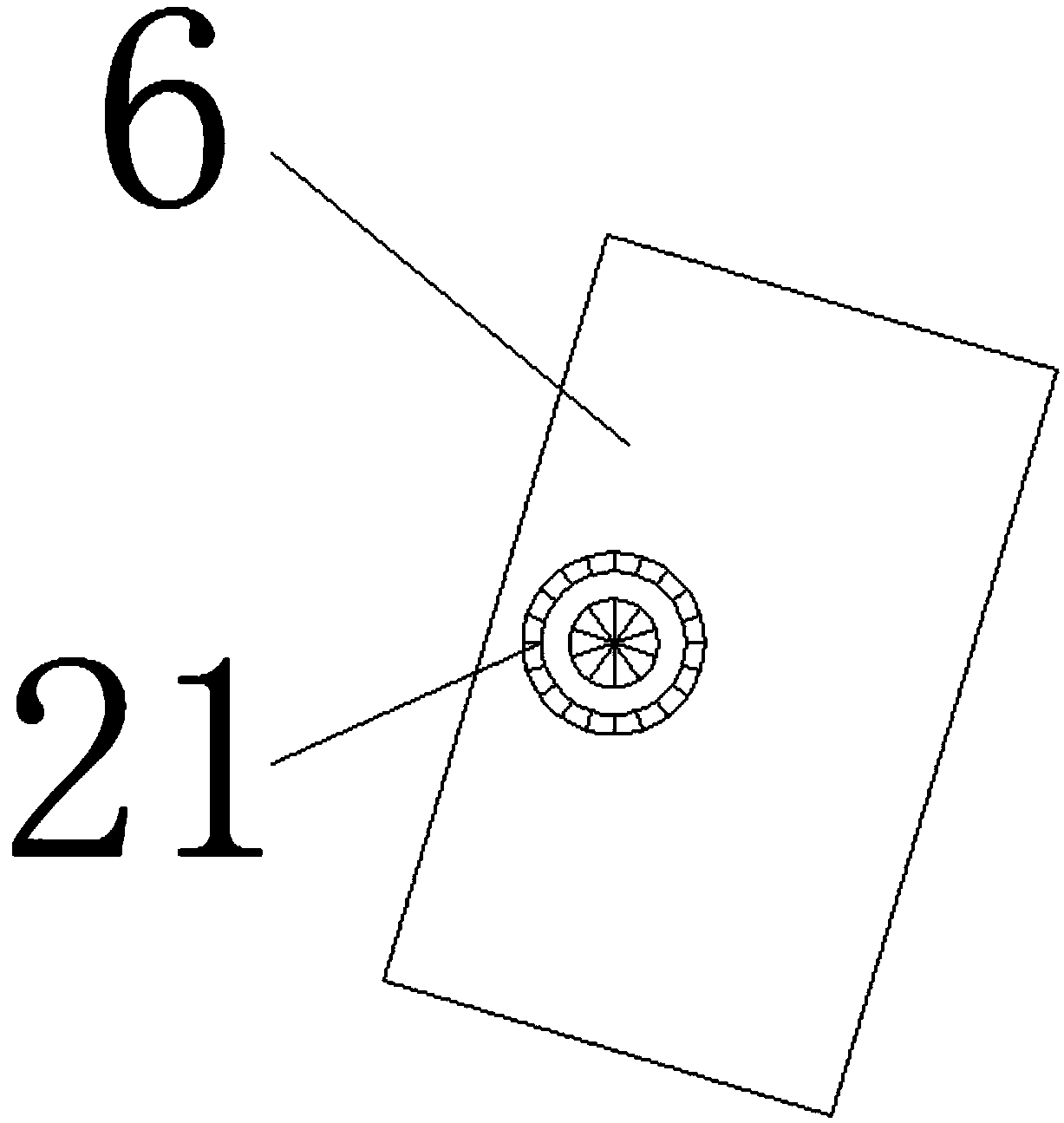

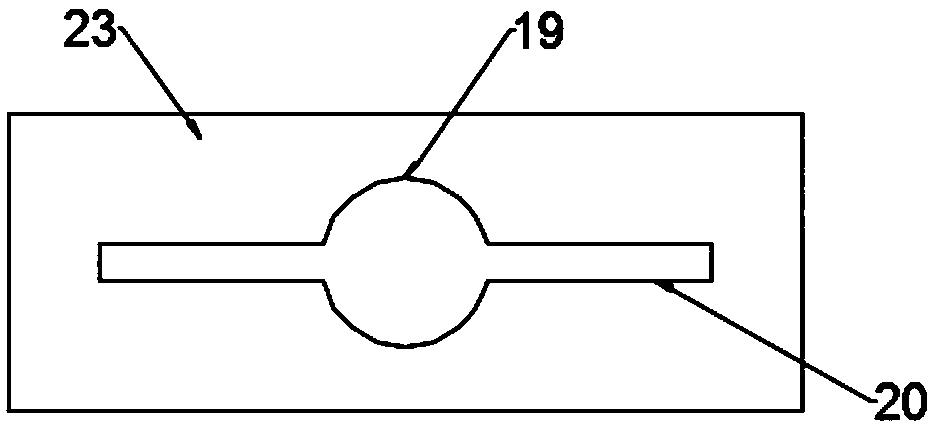

Intermittent feeding type sand sieving device for building

ActiveCN108906576AImprove screening efficiencyAvoid affecting the screening effectSievingScreeningCircular cavitySieve

The invention discloses an intermittent feeding type sand sieving device for building. The intermittent feeding type sand sieving device comprises a storage cavity and a sieving cavity and is characterized in that the storage cavity is arranged at the upper end of the left side of the sieving cavity and communicated with the sieving cavity through a discharge outlet, a transverse plate is fixedlymounted in the sieving cavity, the inner side of the transverse plate is provided with a circular cavity, a first eccentric wheel is arranged on the inner side of the circular cavity, push rods are symmetrically arranged at the left end and the right end of the first eccentric wheel, fixing parts are mounted at the lower ends of the push rods, the lower ends of the fixing parts are hinged to one ends of the connecting rods, and the other ends of the connecting rods are hinged to the upper end of a sieve plate. The intermittent feeding type sand sieving device has the advantages that the deviceis novel in design, a second eccentric wheel rotates to drive a retaining plate to move vertically in a reciprocating manner to intermittently open the discharge outlet so as to achieve intermittentfeeding, and accordingly the sieving effect can be effectively prevented from being affected by the fact that excessive sand enters the sieving cavity at the same time; the push rods move leftwards and rightwards to drive the sieve plate to swing in a reciprocating manner through the connecting rods, and accordingly the sieving efficiency of the sieve plate is increased, and high practicality is achieved.

Owner:安徽谦源项目管理有限公司

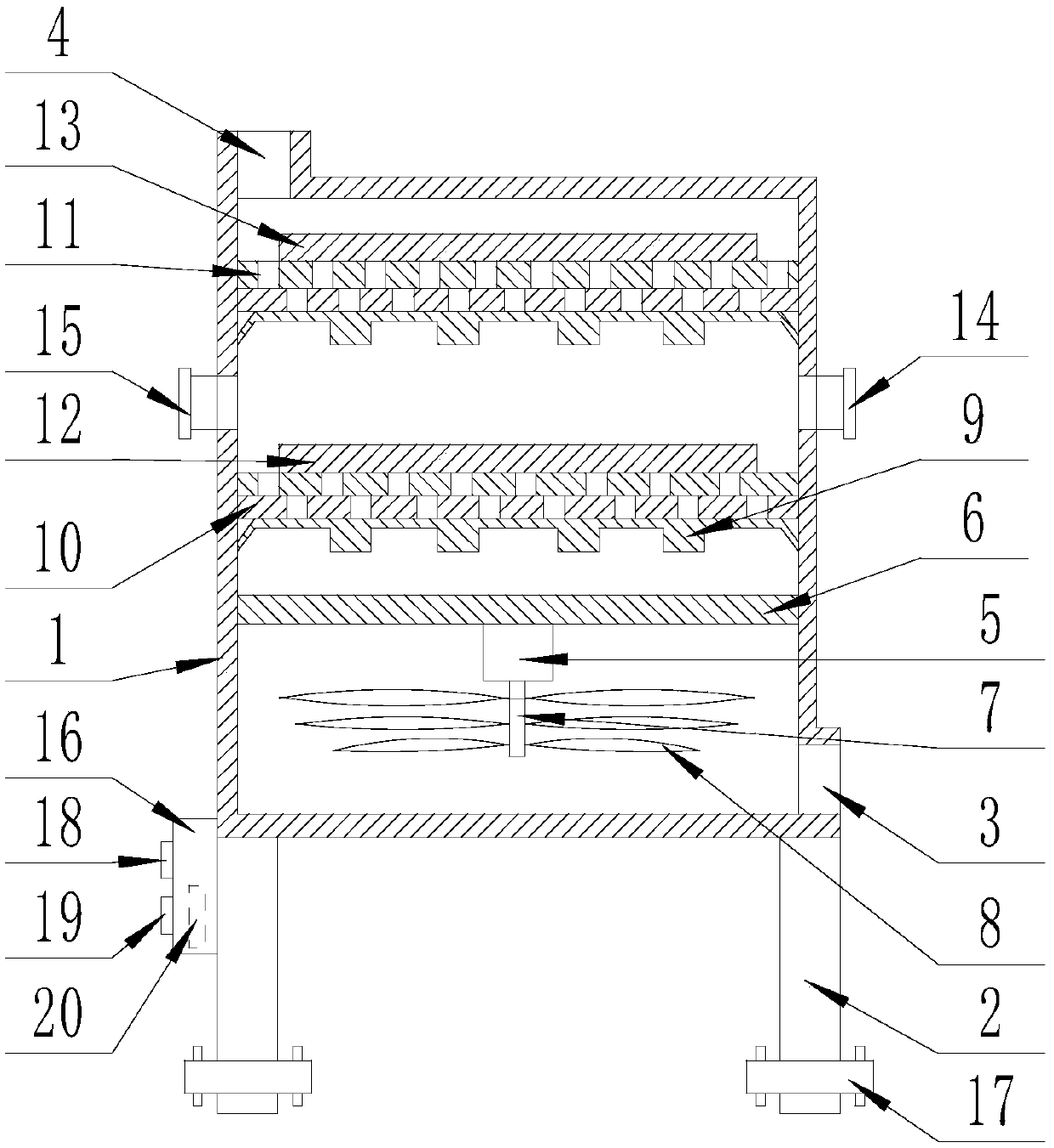

Small soy sauce fermentation tank

InactiveCN111876322AImprove accuracyFacilitate conductionBioreactor/fermenter combinationsBiological substance pretreatmentsStructural engineeringMechanical engineering

The invention discloses a small soy sauce fermentation tank. The small soy sauce fermentation tank comprises a tank body, wherein a top cover is arranged at the top of the tank body, a sieve plate isarranged at the bottom of the circumferential inner wall of the tank body, a distributor is arranged at the bottom of the sieve plate, an air inlet pipe is arranged at the bottom of the distributor, and a residue outlet is inserted into the outer wall of one side of the tank body; a feeding opening is formed in one side of the outer wall of the top of the top cover, an air outlet pipe is insertedinto the outer wall of the top of the top cover, and two fixing rods are arranged on the inner wall of the top of the top cover. The height of a temperature sensor is adjusted by pulling an extensionrod to measure the temperature of materials at different horizontal positions, and when the extension rod is pulled, the circumferential inner wall of a material scraping ring makes contact with the extension rod and the circumference of the temperature sensor to conduct scraping. Therefore, inaccurate temperature detection caused by the fact that a large number of materials at original positionsare adhered to the outer wall of the temperature sensor and move to a to-be-detected position when the temperature sensor moves is avoided, and temperature detection accuracy is improved.

Owner:冯步迎

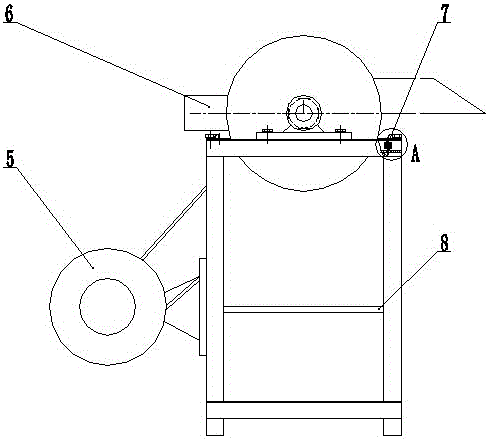

Low-breakage sunflower threshing machine capable of automatically adjusting de-seeding gaps

Owner:HENAN UNIV OF SCI & TECH

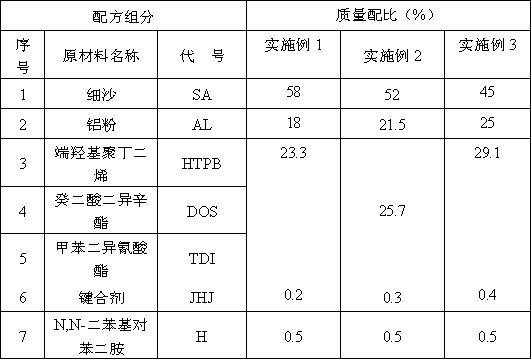

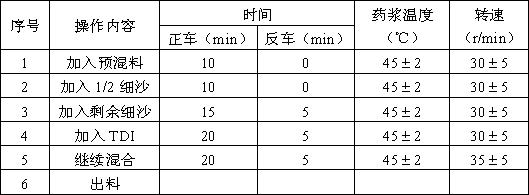

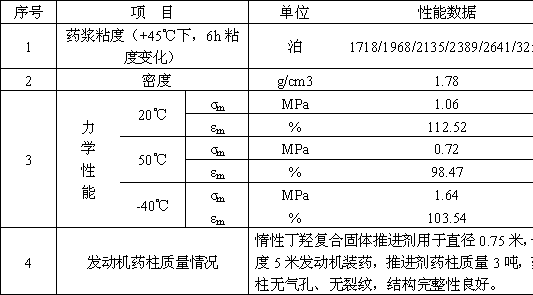

Low-cost inert hydroxyl terminated polybutadiene (HTPB) composite solid propellant and preparation method thereof

InactiveCN110204408AAdjust mechanical propertiesNot easy to absorb moisturePressure gas generationCross-linkSlurry

Owner:江西航天经纬化工有限公司

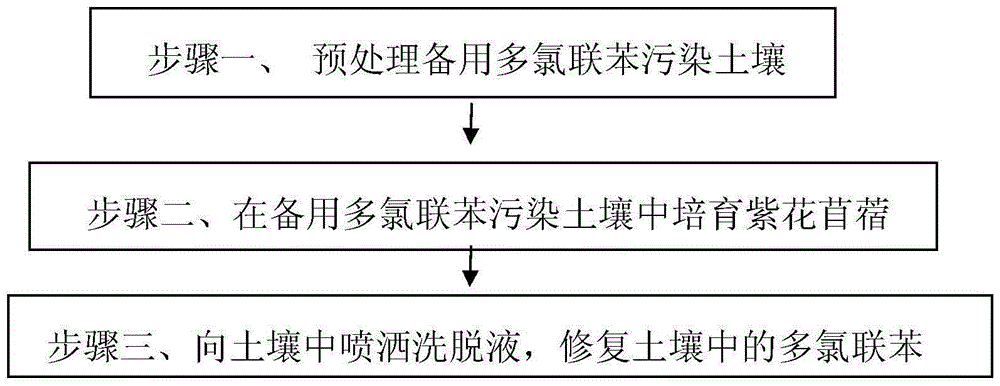

Method for remediating polychlorinated biphenyl polluted soil through combination of chemical elution and plants

ActiveCN105170624AEasy to operateEasy to handleContaminated soil reclamationTreatment effectPolychlorinated biphenyl

Owner:STATE GRID CORP OF CHINA +1

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

Method for detoxifying cottonseed meal

InactiveCN104905003AEasy to operateShorten detox timeFood processingAnimal feeding stuffPulsed magnetCottonseed oil

Owner:JIANGSU UNIV

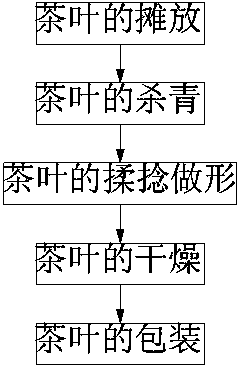

Processing procedure of green tea having excellent taste

InactiveCN108835301AShorten stir frying timeGreat tastePre-extraction tea treatmentClimate change adaptationGreen teaPolyphenol

Owner:屏山县水中韵茶业有限责任公司

Bottom suction type dust collection mechanism

InactiveCN111053495AImprove vacuumingIt is not easy to fly out againSuction filtersElectric machineEnvironmental engineering

The invention belongs to the technical field of dust collection, and particularly relates to a bottom suction type dust collection mechanism. The bottom suction type dust collection mechanism comprises a bottom plate, roller assemblies are connected to four corners on the lower surface of the bottom plate correspondingly, a gyrotron is mounted at the left side on the upper surface of the bottom plate, the bottom of the gyrotron is open, the left side of the bottom plate body is provided with a dust collection groove corresponding to the opening position at the bottom of the gyrotron, a dust discharging pipe is arranged at the right side o the upper surface of the gyrotron, a driving motor is fixedly connected to the middle on the upper surface of the gyrotron through a bolt, dust can be adsorbed through corresponding arrangement of the dust collection groove and the gyrotron, then the gyrotron can be close to the ground, therefore the effect of improving the dust suction strength is achieved; dust is output into a dust collecting tank through a dust discharging pipe and is collected through water in the dust collecting tank, and the situation that the dust flies out again is not prone to occurring; and through the arrangement of a filtering sieve plate, the effect that dust entering the dust collecting tank cannot float upwards can be further controlled.

Owner:SUZHOU HOUZHEN ELECTROMECHANICAL EQUIP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap