A purifying column

A purification column and sieve plate technology, which is applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems that affect the analysis effect, impurities are not removed, and raw materials stick to the inner wall of the shell, etc., to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

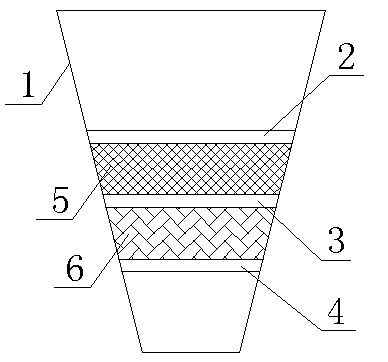

[0011] see figure 1 , the embodiment of the present invention includes:

[0012] A purification column, which consists of a shell 1, a sieve plate and an adsorption packing 6 arranged in the shell 1, and the sieve plate is a first sieve plate 2, a second sieve plate 3 and a third sieve plate from top to bottom 4. A filter layer 5 is provided between the first sieve plate 2 and the second sieve plate 3 , and an adsorption filler 6 is provided between the second sieve plate 3 and the third sieve plate 4 .

[0013] The shape of the shell 1 is inverted conical, and the side wall has a slope, which is beneficial for all raw materials to flow into the fi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap